Lubricating oil composition for shock absorber and friction reduction method for shock absorber

A lubricating oil composition and buffer technology, applied in lubricating compositions, petroleum industry, base materials, etc., can solve the problems of poor thermal stability of additives, easy oxidation of lubricating oil compositions, great importance of thermal stability, etc. , to achieve excellent thermal stability, excellent effect, and the effect of reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

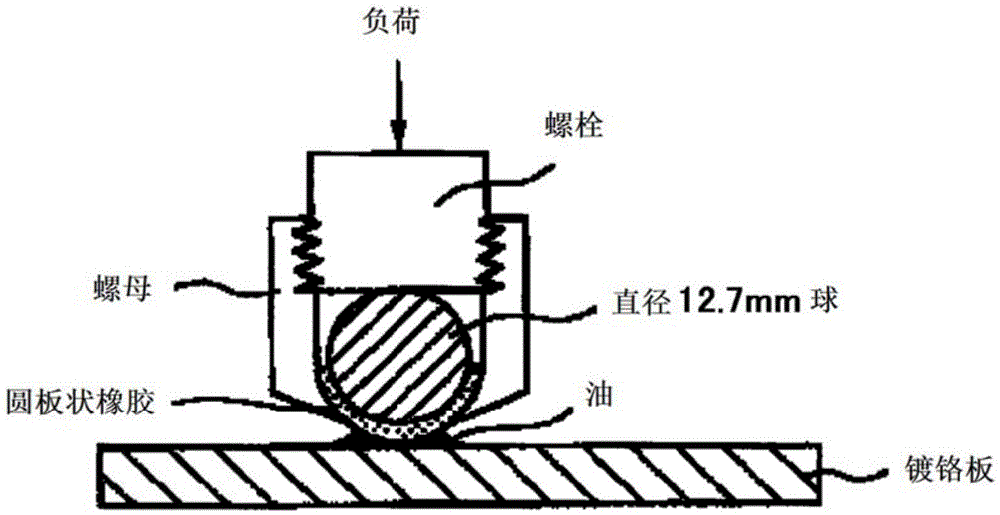

Image

Examples

Embodiment 1~2 and comparative example 1~5

[0118] A lubricating oil composition for a shock absorber containing each component shown in Table 1 was prepared, and a friction coefficient measurement and a thermal stability test were performed. The results are shown in Table 1. In addition, the amount of phosphorus not bonded to sulfur atoms in the lubricating oil compositions for shock absorbers of Examples 1 and 2 was 0.1% by mass or less with respect to the total amount of the lubricating oil compositions.

[0119] [Table 1]

[0120] Table 1

[0121]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com