Diesel engine lubricating oil composition, preparation method, and application thereof

A technology of lubricating oil composition and diesel engine, applied in lubricating composition, petroleum industry, organic chemistry, etc., can solve problems such as low emission, blocked oil filter, cylinder liner piston ring, friction pair wear of valve group, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

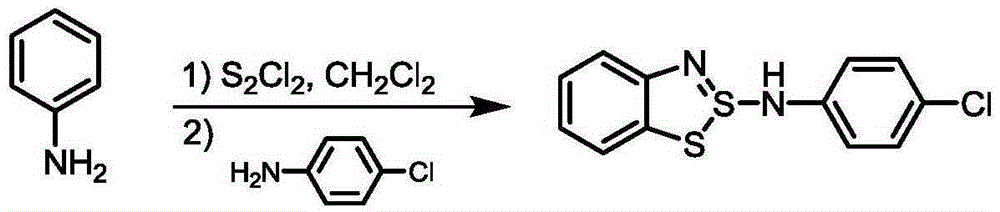

[0086] Fill a 500ml flask with an electromagnetic stirrer (stirring speed is 300rpm) with nitrogen protection, add 150ml of dichloromethane, then add 0.2mol of sulfur chloride, fully cool in an ice-water bath, add 0.2mol of aniline . Remove the ice-water bath after monitoring until the reaction is complete, and place it at room temperature of 25°C. After the reaction system gradually rises to 25°C, add 4-chloroaniline in 3 times for reaction. The amount added each time is the same, and 4-chloroaniline is added in total 0.15mol. After the reaction was continued for 2 hours, 30ml of saturated brine was added to quench the reaction, and then the reaction system was transferred to a separatory funnel, washed with 50ml of distilled water and 50ml of saturated brine, and dried by adding 10g of anhydrous sodium sulfate at 25°C for 20min. The filtered filtrate was evaporated to remove the solvent at 40° C. and 0.05 MPa to obtain intermediate M1.

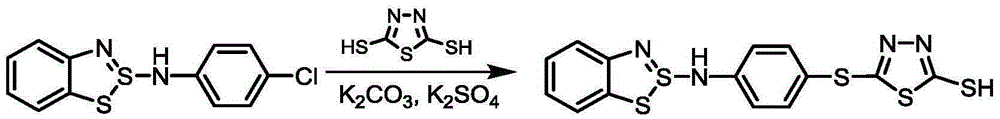

[0087]Fill a 500ml flask with an el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com