Processing method of prefabricated loach dish

A processing method and technology of loach, which are applied in heating preservation of meat/fish, food science, etc., can solve the problems of bad taste of loach and cannot be preserved for a long time, and achieve the effects of rich taste, improved sensory quality and nourishing body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

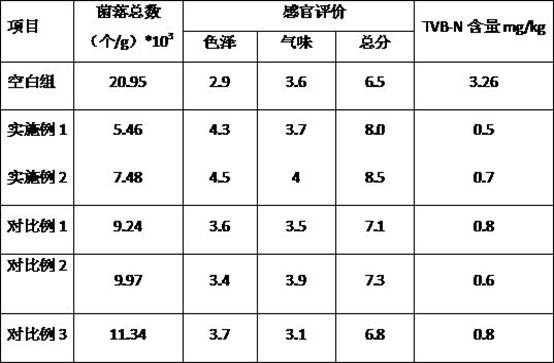

Examples

Embodiment 1

[0028] A processing method for prefabricated loach dishes, which is completed by thawing, cleaning, deodorizing, frying, pickling, vacuum packaging and microwave sterilization, and is composed of the following raw and auxiliary materials, including large loach, salt, onion, ginger, Black pepper powder, cooking wine, white wine, garlic, chili, soybean oil, salad oil, lard, monosodium glutamate, sugar, vinegar, soy sauce, green and red pepper, onion, soybean paste, hot sauce, garlic sauce, grass fruit, star anise, Cinnamon bark, bay leaves, nutmeg, chives, water, frangipani extract, camellia camellia extract, rosemary extract and lysozyme;

[0029] The raw and auxiliary materials are composed of 250 parts of big loach, 460 parts of salt, 62.5 parts of green onion, 43 parts of ginger, 10 parts of black pepper, 10 parts of cooking wine, 2.5 parts of white wine, 1.5 parts of garlic, 1 part of pepper, soybean oil 15 parts, 550 parts of salad oil, 10 parts of lard, 4 parts of monosod...

Embodiment 2

[0046] A processing method for prefabricated loach dishes, which is completed by thawing, cleaning, deodorizing, frying, pickling, vacuum packaging and microwave sterilization, and is composed of the following raw and auxiliary materials, including large loach, salt, onion, ginger, Black pepper powder, cooking wine, white wine, garlic, chili, soybean oil, salad oil, lard, monosodium glutamate, sugar, vinegar, soy sauce, green and red pepper, onion, soybean paste, hot sauce, garlic sauce, grass fruit, star anise, Cinnamon bark, bay leaves, nutmeg, chives, water, frangipani extract, camellia camellia extract, rosemary extract and lysozyme;

[0047] The raw and auxiliary materials are composed of 200 parts of large loach, 48 parts of salt, 50 parts of green onion, 34.4 parts of ginger, 8 parts of black pepper, 8 parts of cooking wine, 2 parts of white wine, 1.2 parts of garlic, 0.8 parts of pepper, soybean oil 12 parts, 440 parts of salad oil, 8 parts of lard, 3.2 parts of monoso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com