High-strength and high-toughness TaxHf1-xC-based composite material and preparation method thereof

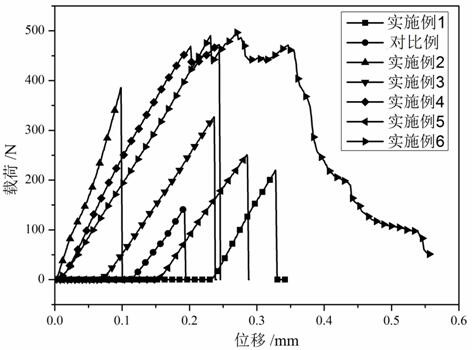

A taxhf1-xc, composite material technology, which is applied in the field of ultra-high temperature resistant materials, can solve the problems of poor toughness of C-based composite materials, cannot meet urgent needs, etc., to ensure service life and reliability, anti-oxidation performance and anti-ablation. Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also proposes a high-strength and high-toughness Ta x f 1-x The preparation method of C-based composite material, comprising:

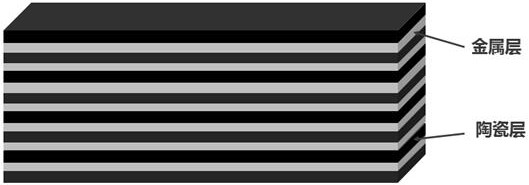

[0047] S1: Design Ta x f 1-x Layered structure of C-based composite material, said layered structure comprising Ta x f 1-x The C ceramic layer and the metal Ta layer are alternately stacked, and the Ta x f 1-x The upper and lower surfaces of C-based composites are Ta x f 1-x C ceramic layer, and Ta x f 1-x The number of layers and layer thickness ratio of C ceramic layer and metal Ta layer;

[0048] Preferably, the number of layers of the metal Ta layer ≥ 1, the metal Ta layer and Ta x f 1-x The layer thickness ratio of the C ceramic layer is 0.1~1.

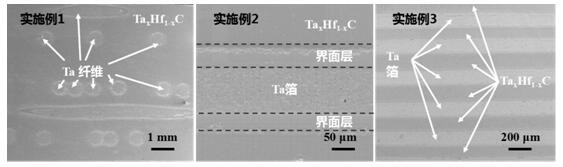

[0049] The shape of the metal Ta is at least one of continuous fiber, continuous fiber two-dimensional fabric, ribbon and foil.

[0050] The continuous fiber diameter is 0.3 ~ 0.8 mm;

[0051] The continuous fiber two-dimensional fabric is woven with continuous...

Embodiment 1

[0068] This embodiment provides a high-strength and high-toughness Ta x f 1-x C-based composites, the Ta x f 1-x C-based composites with Ta x f 1-x C ceramics as the substrate, metal Ta as the toughening phase;

[0069] The Ta x f 1-x The C-based composite material is a layered structure, Ta x f 1-x The C ceramic layer and the metal Ta layer are arranged in layers, and the Ta x f 1-x Both the upper and lower surfaces of the C-based composite are Ta x f 1-x C ceramic phase.

[0070] This embodiment also provides a kind of above-mentioned Ta x f 1-x A preparation method for a C-based composite material, comprising the steps of:

[0071] S1: Design Ta x f 1-x The layered structure of C-based composites, including Ta x f 1-x C The ceramic layer and the metal Ta layer are arranged in layers, and the upper surface and the lower surface are both Ta x f 1-x C ceramic phase, Ta x f 1-x C ceramic layer 7 layers and metal Ta layer 6 layers;

[0072] S2: Weigh the ...

Embodiment 2

[0081] This embodiment provides a high-strength and high-toughness Ta x f 1-x C-based composites, the Ta x f 1-x C-based composites with Ta x f 1-x C ceramics as the substrate, metal Ta as the toughening phase;

[0082] The Ta x f 1-x The C-based composite material is a layered structure, Ta x f 1-x The C ceramic layer and the metal Ta layer are arranged in layers, and the Ta x f 1-x Both the upper and lower surfaces of the C-based composite are Ta x f 1-x C ceramic phase.

[0083] This embodiment also provides a kind of above-mentioned Ta x f 1-x A preparation method for a C-based composite material, comprising the steps of:

[0084] S1: Design Ta x f 1-x The layered structure of C-based composites, including Ta x f 1-x C The ceramic layer and the metal Ta layer are arranged in layers, and the upper surface and the lower surface are both Ta x f 1-x C ceramic phase, Ta x f 1-x C ceramic layer 2 layers and metal Ta layer 1 layer;

[0085] S2: Weigh the T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com