Patents

Literature

70 results about "Extreme heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

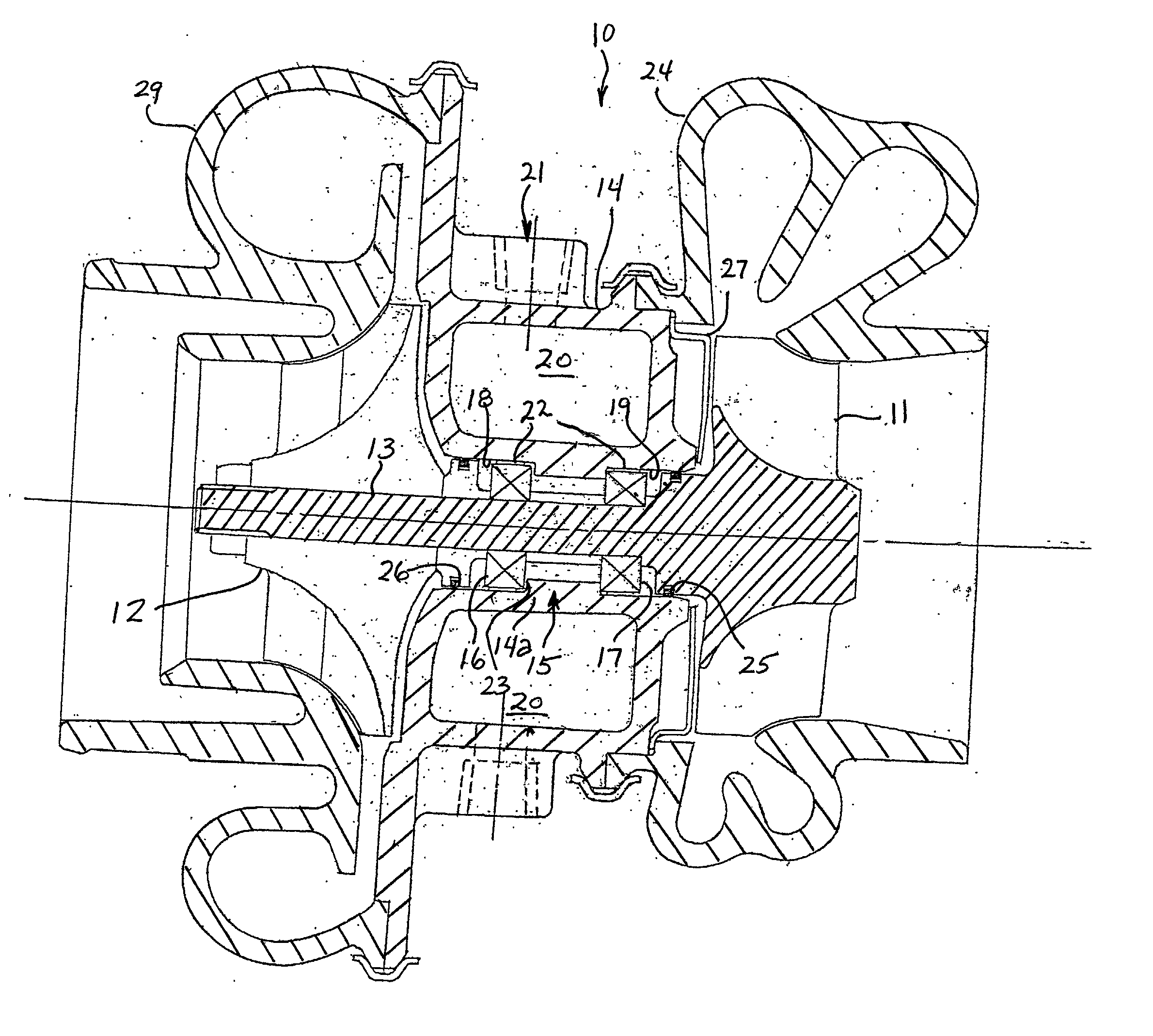

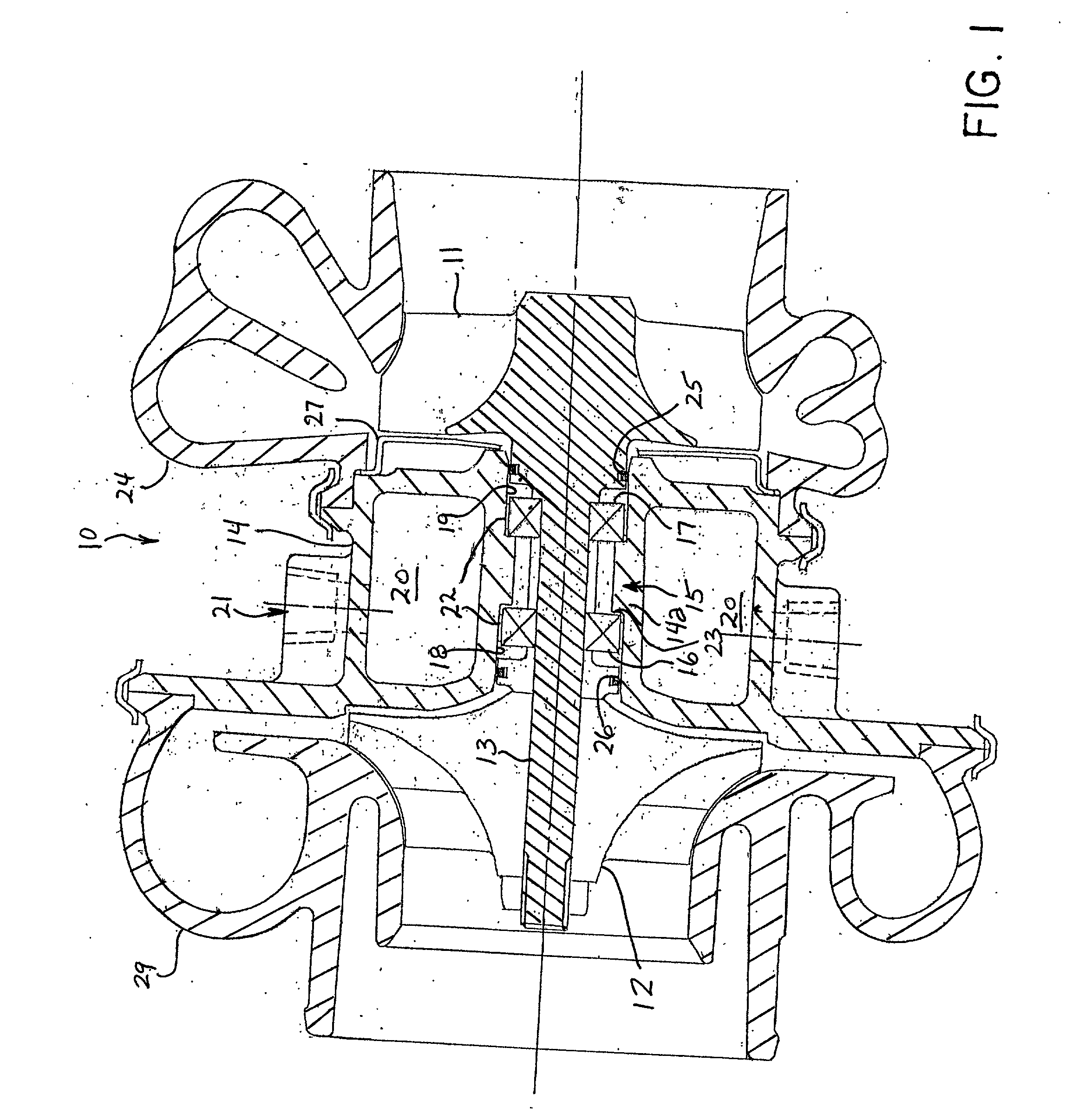

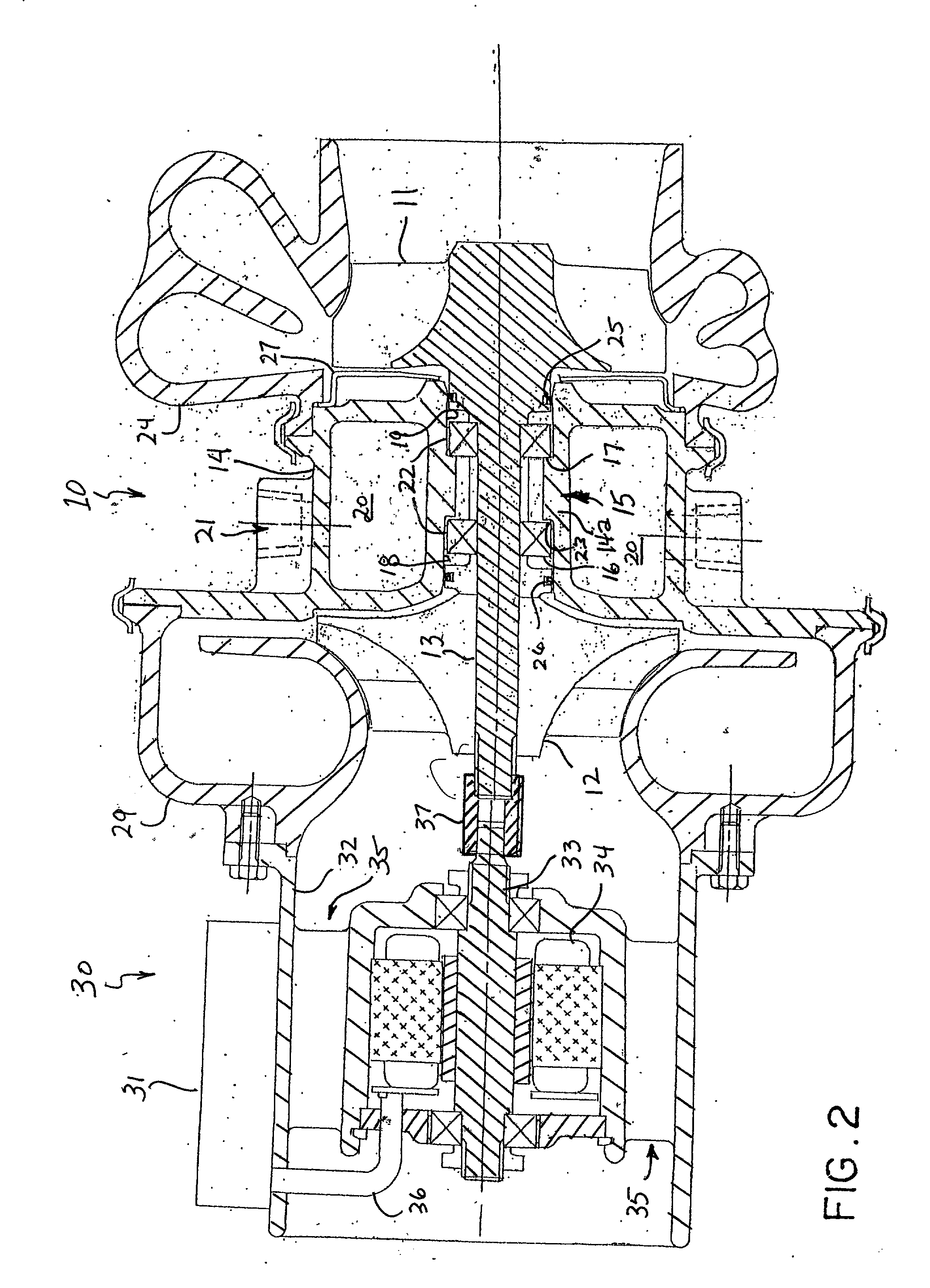

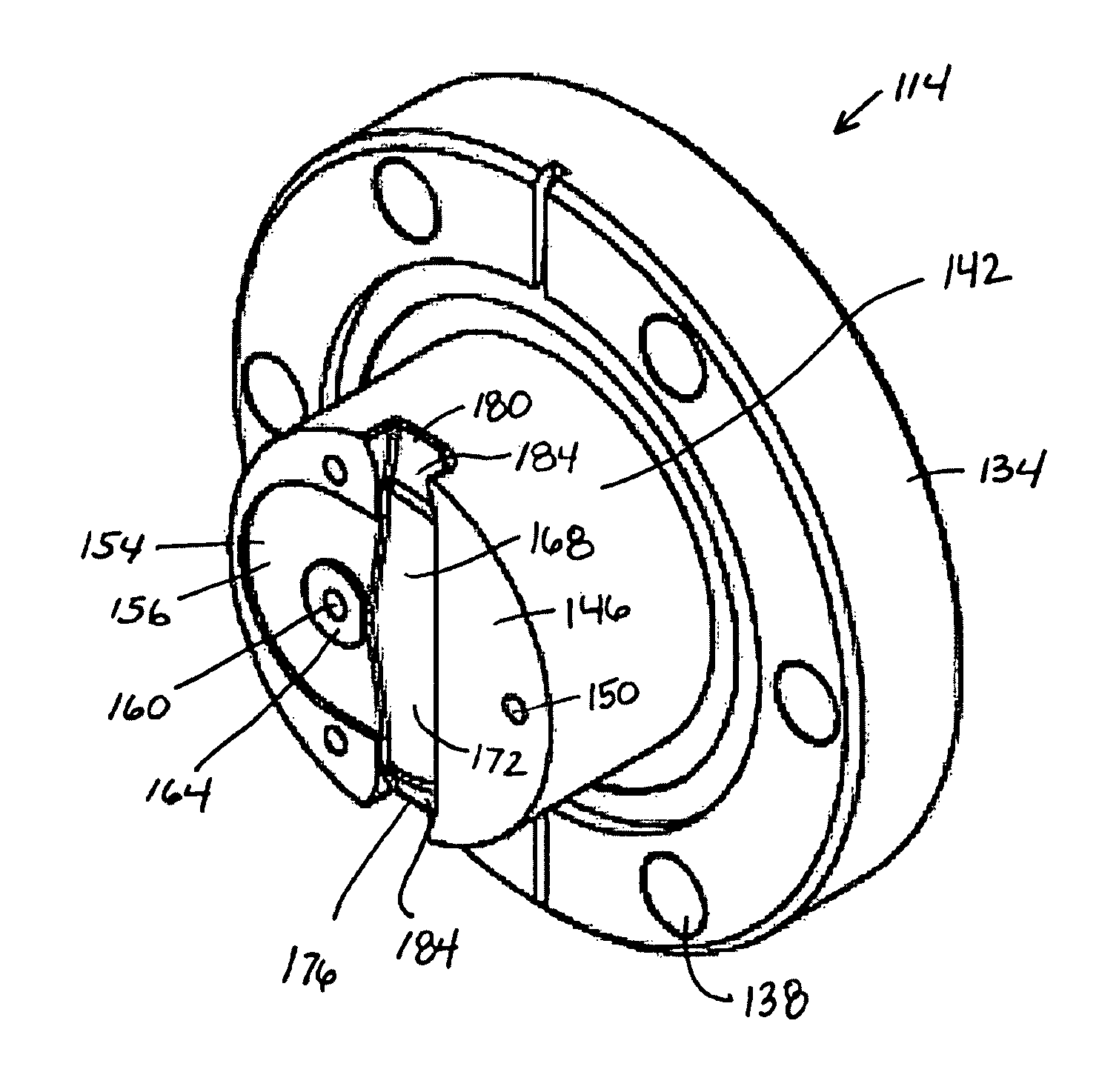

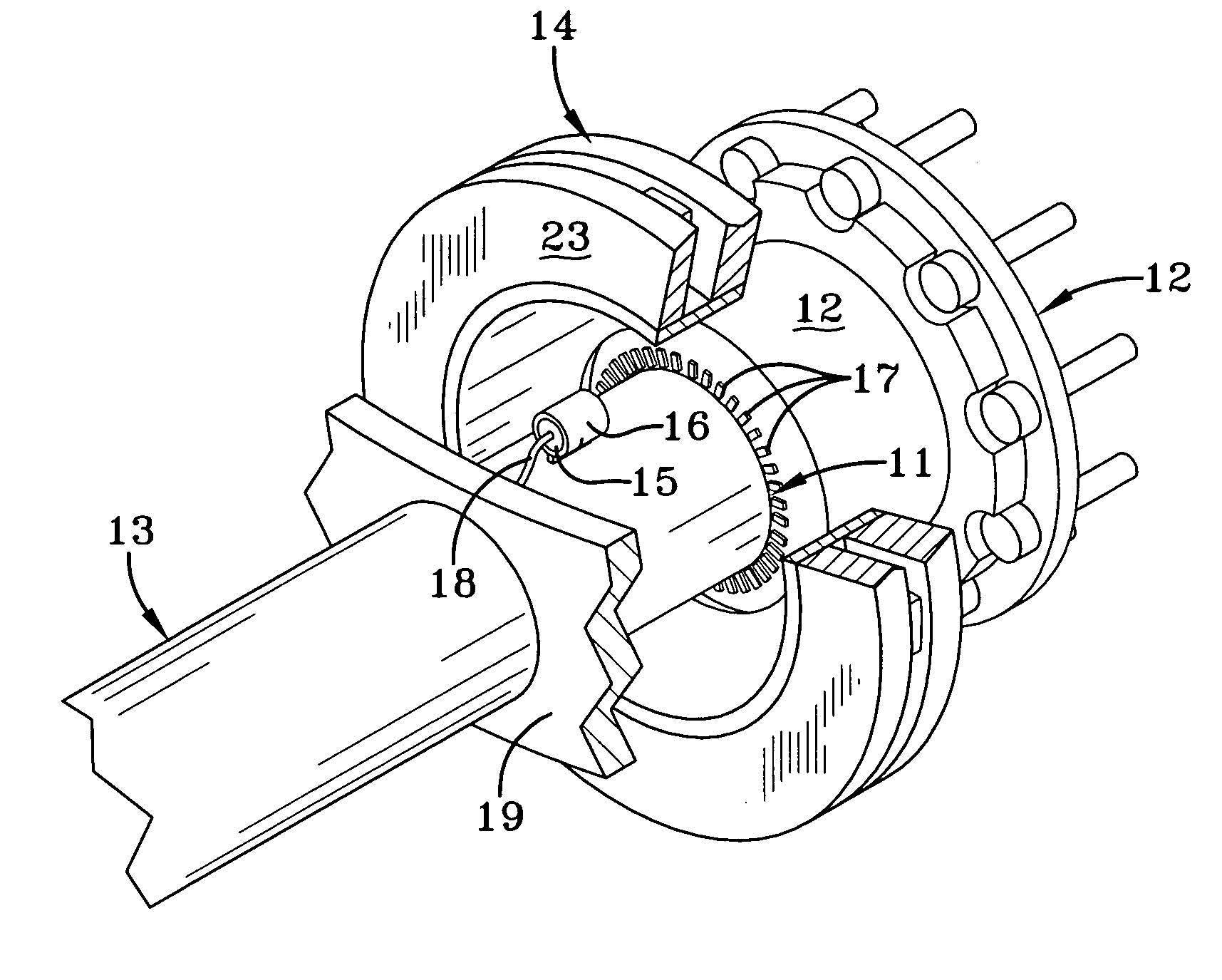

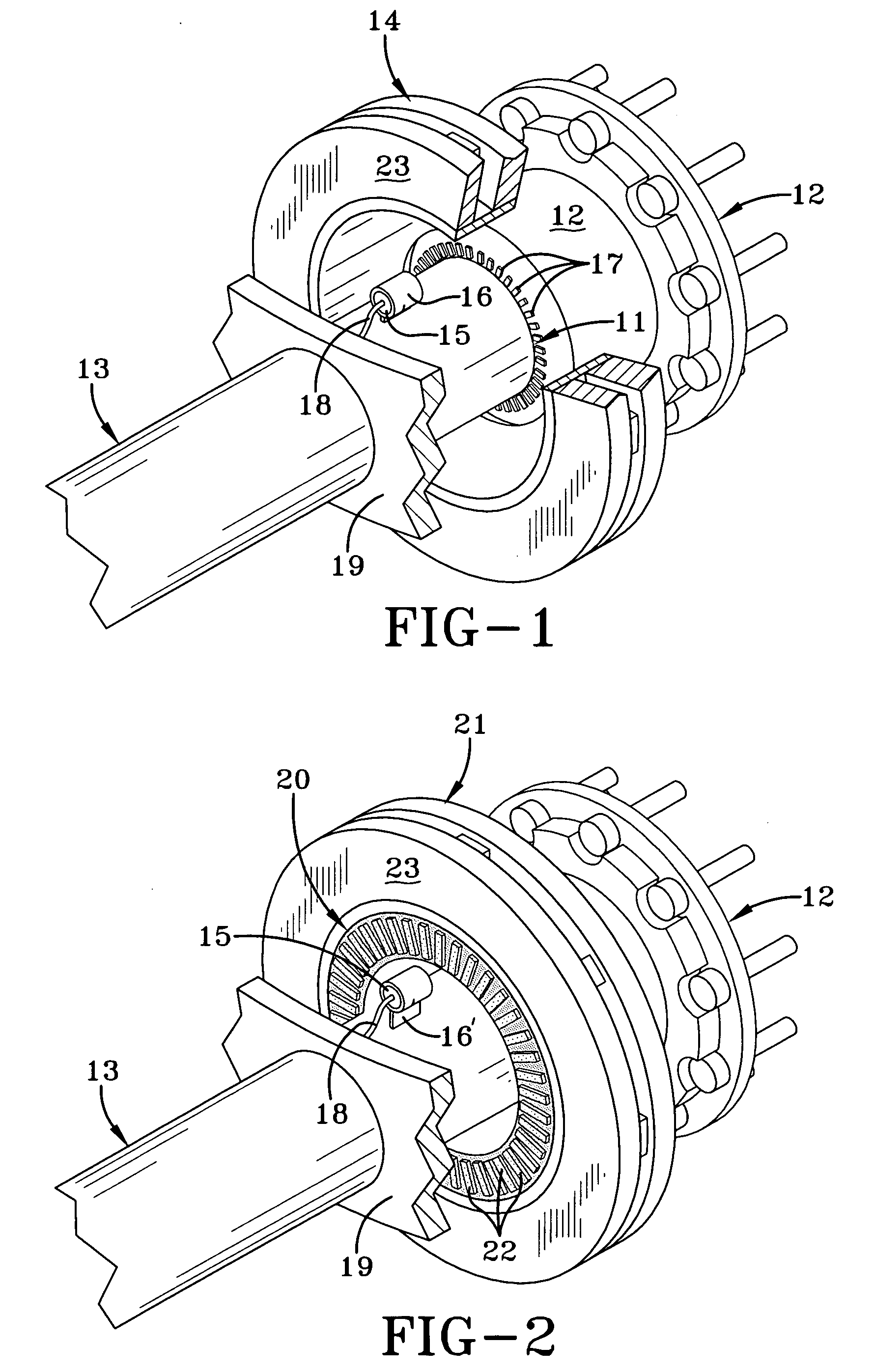

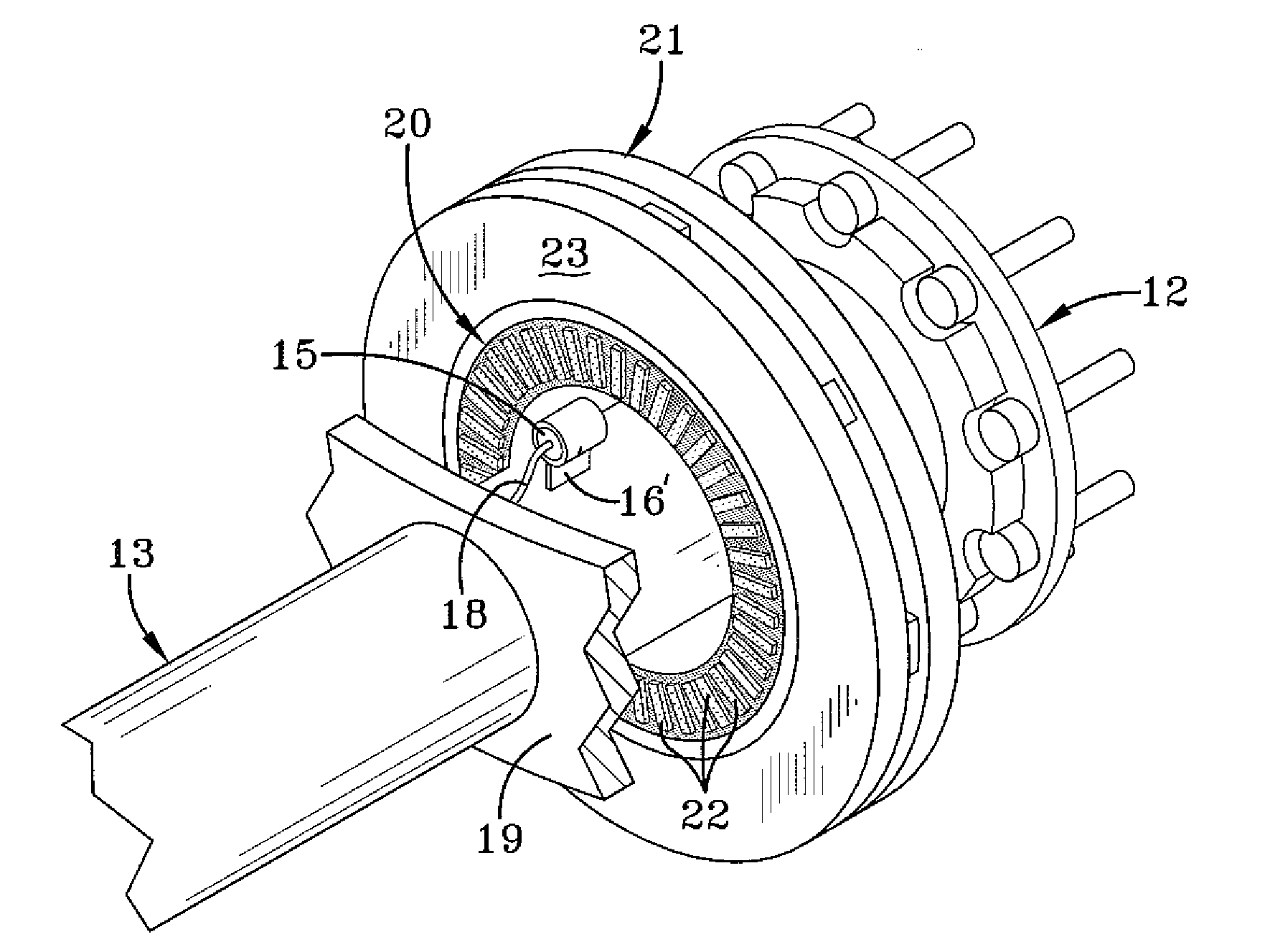

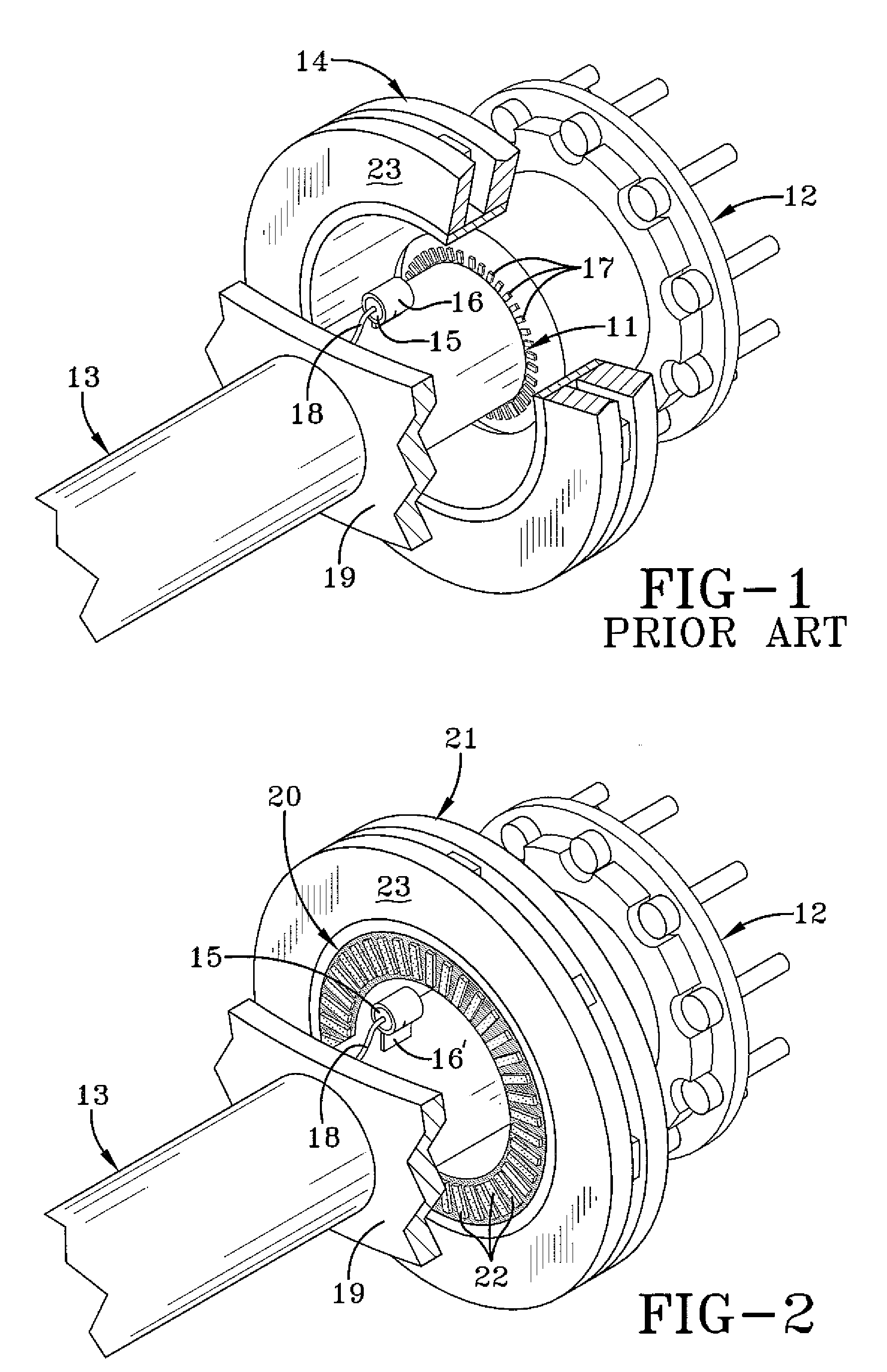

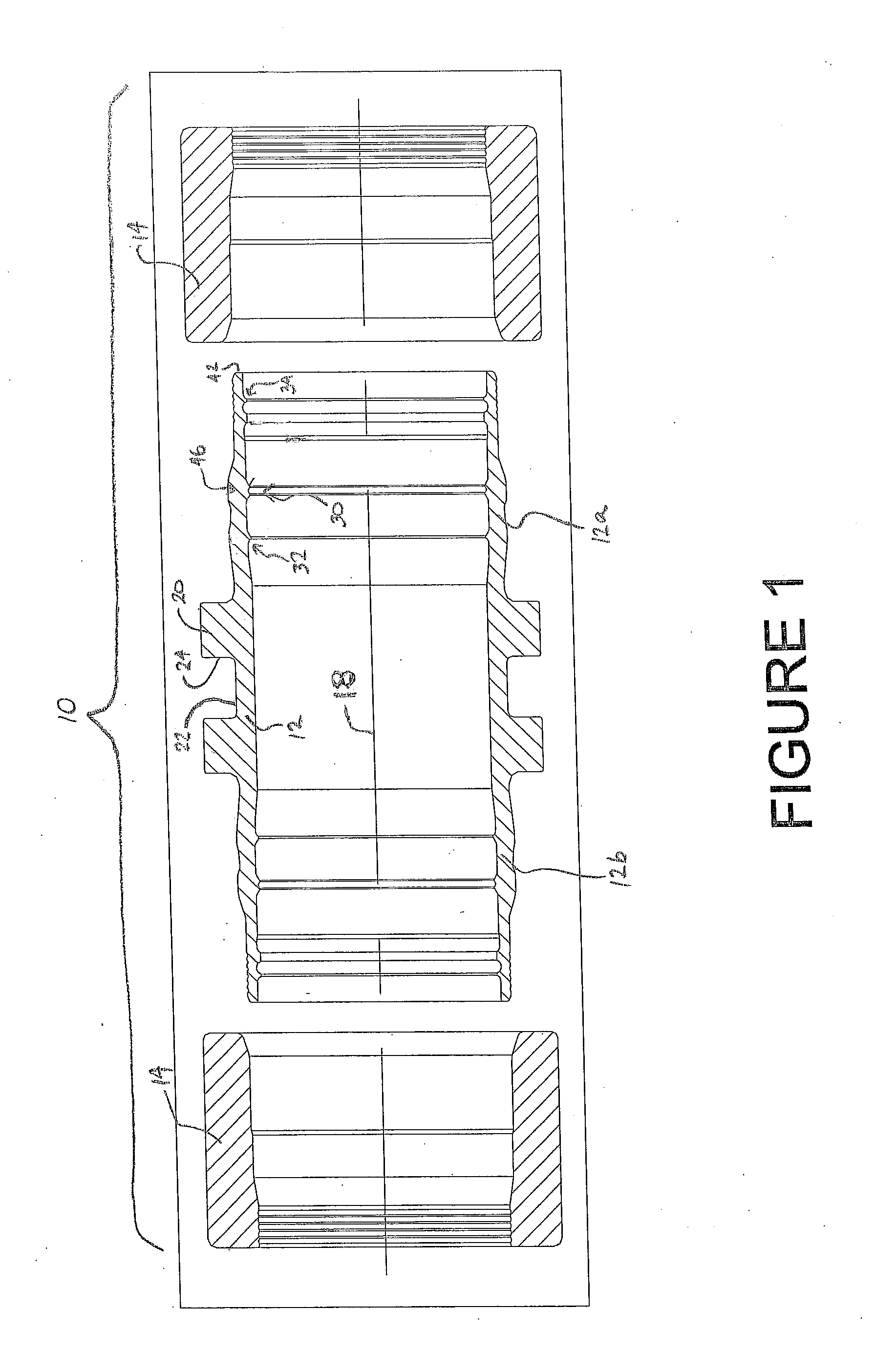

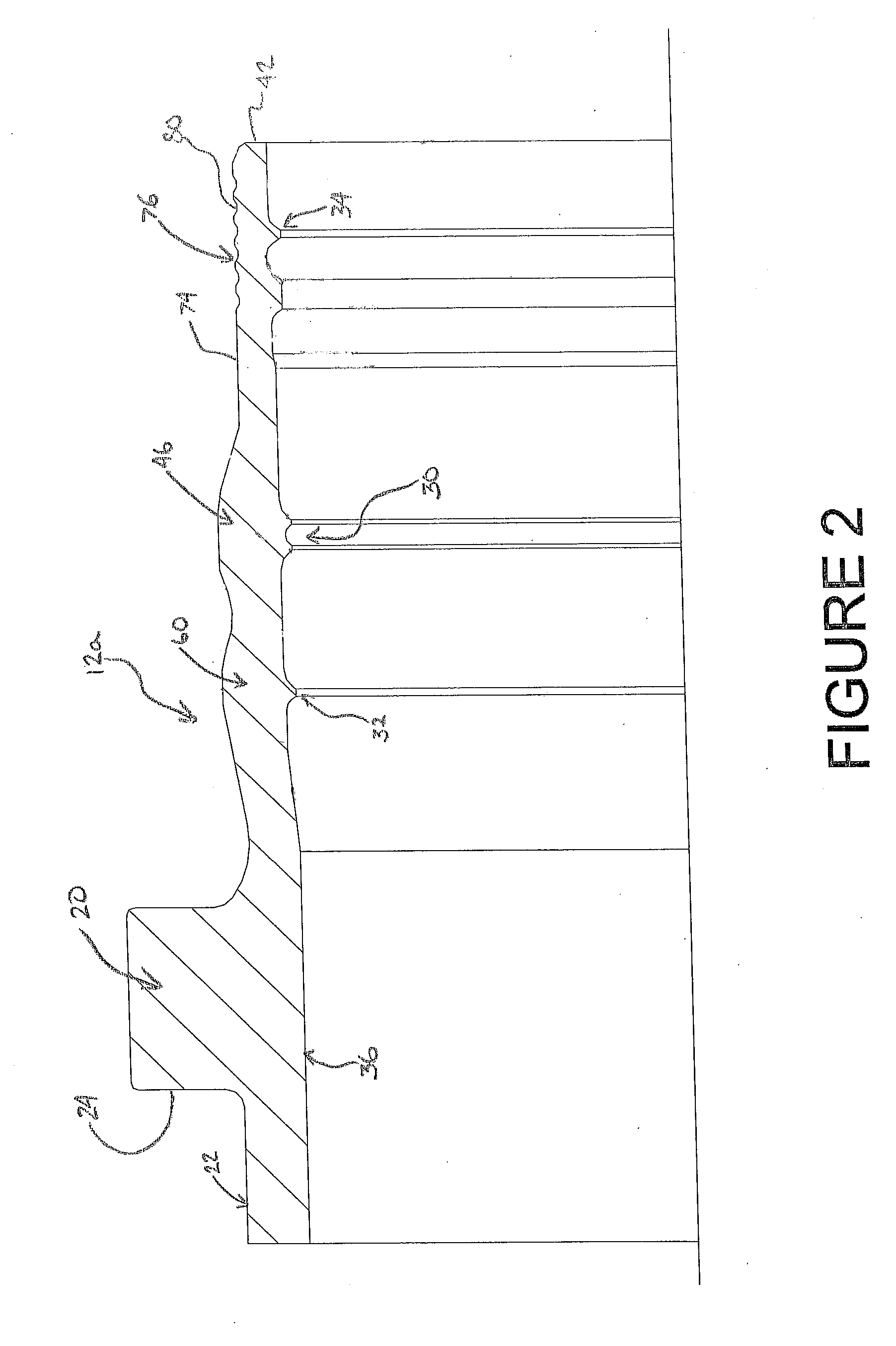

Compact turbocharger

InactiveUS20030223892A1Minimal lengthLow thermal expansionInternal combustion piston enginesPump componentsClose couplingBall bearing

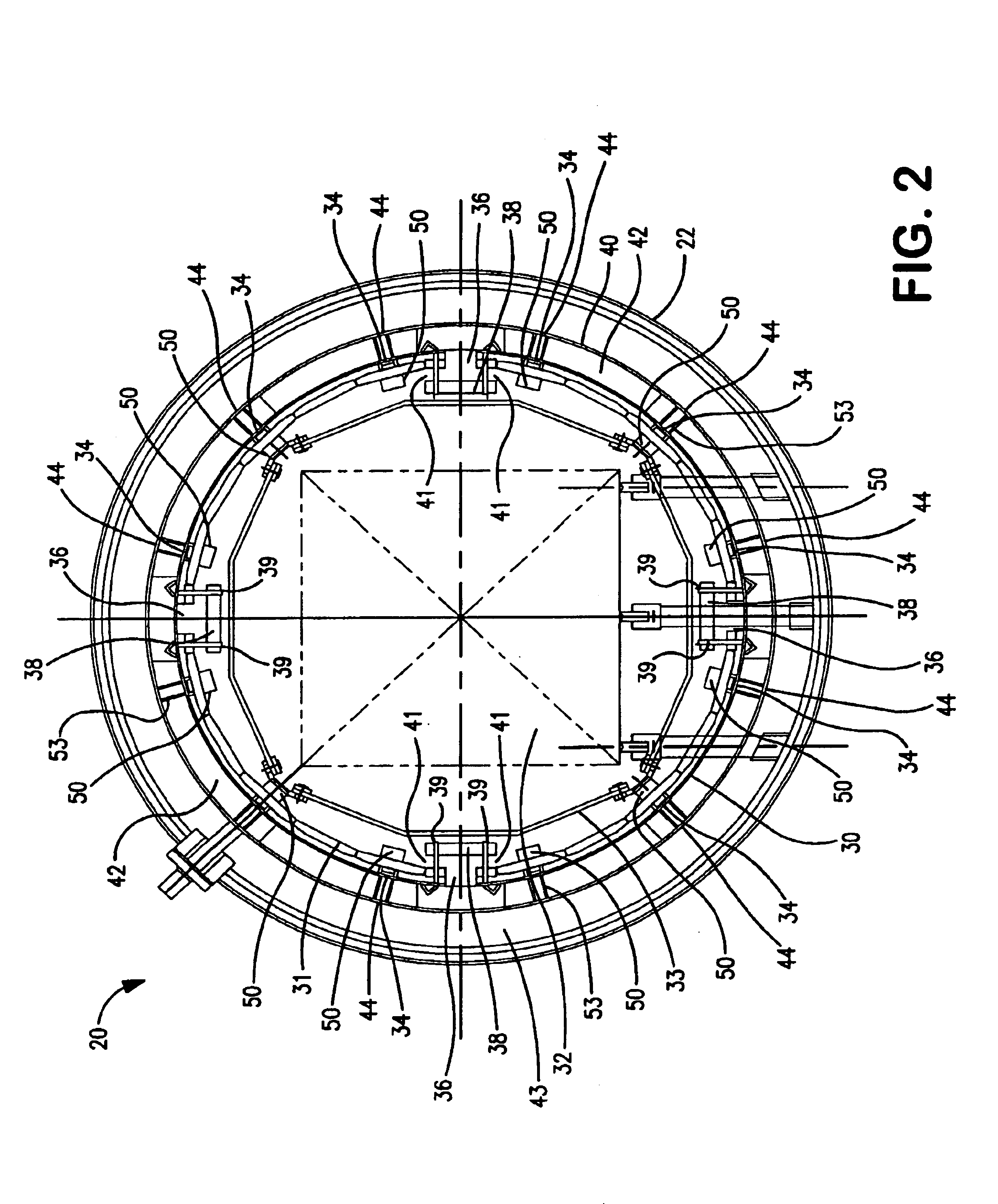

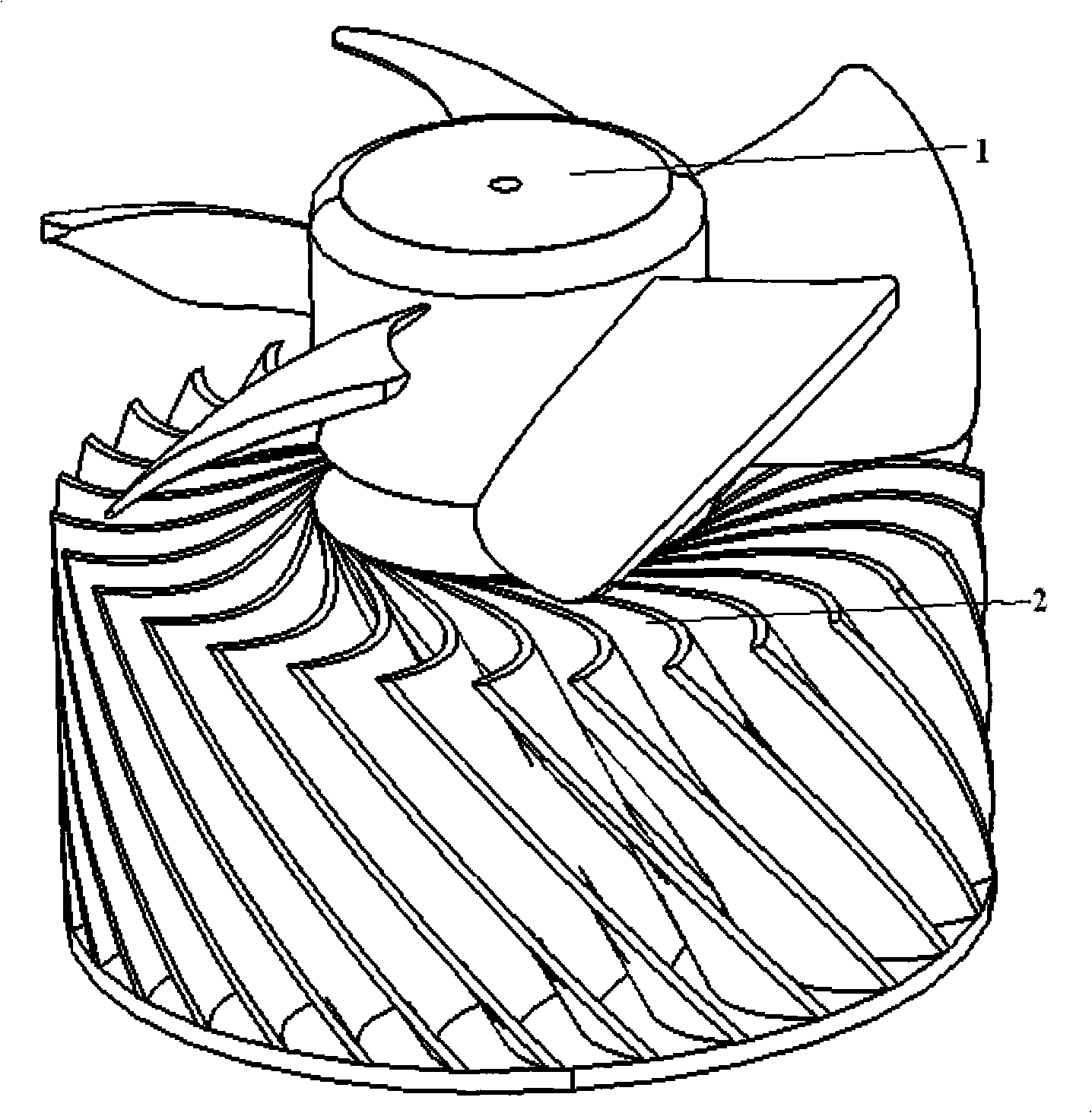

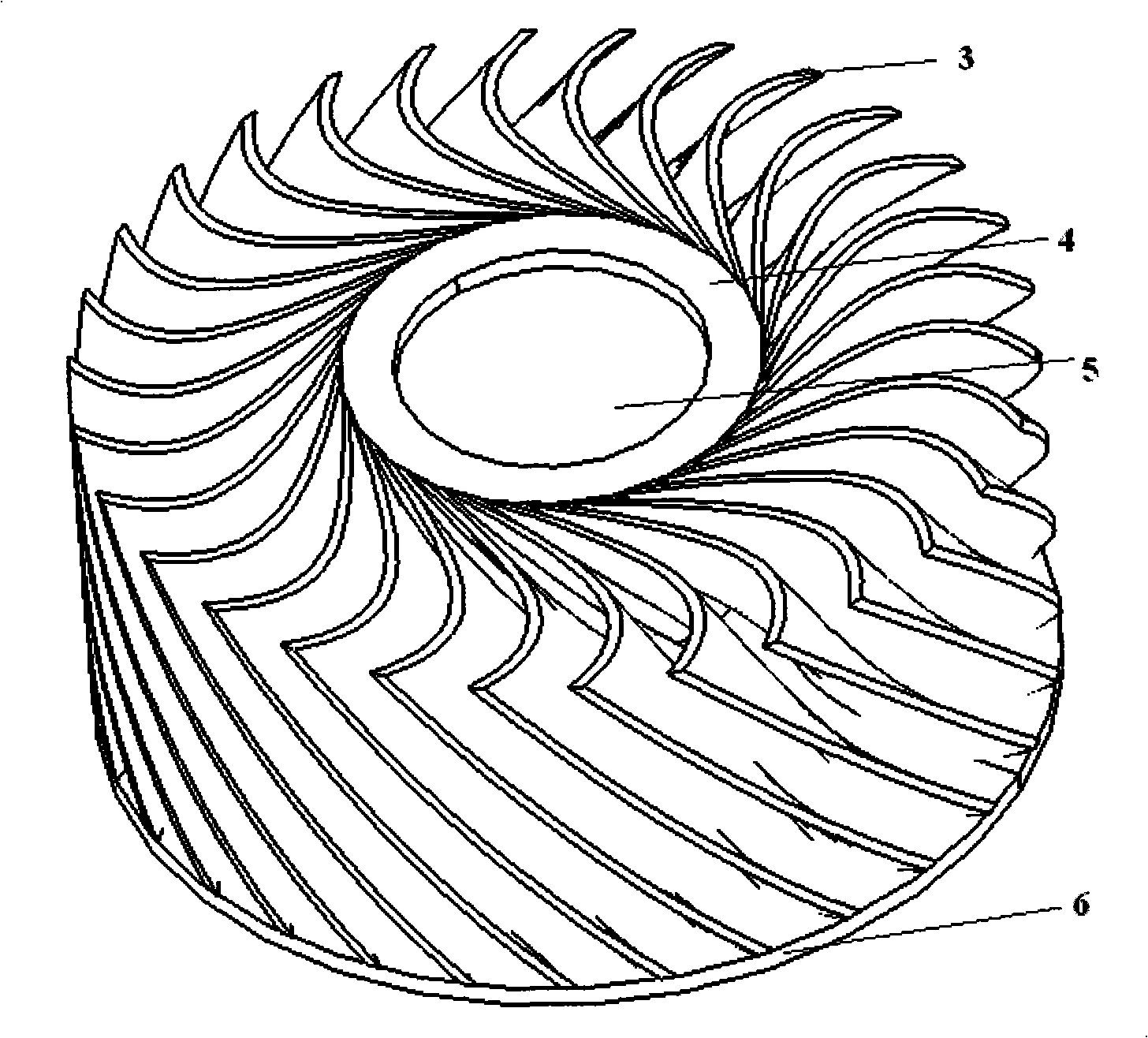

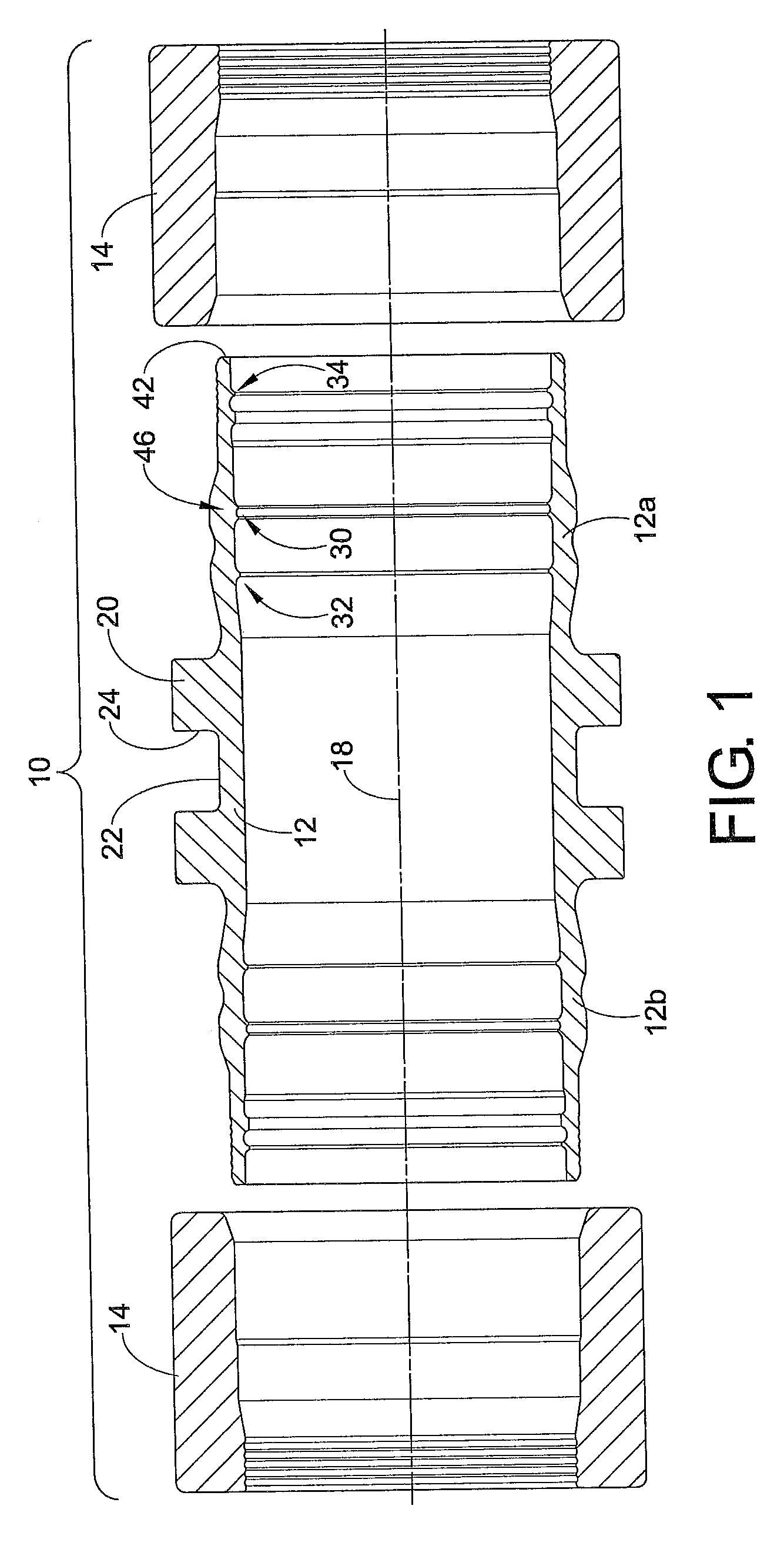

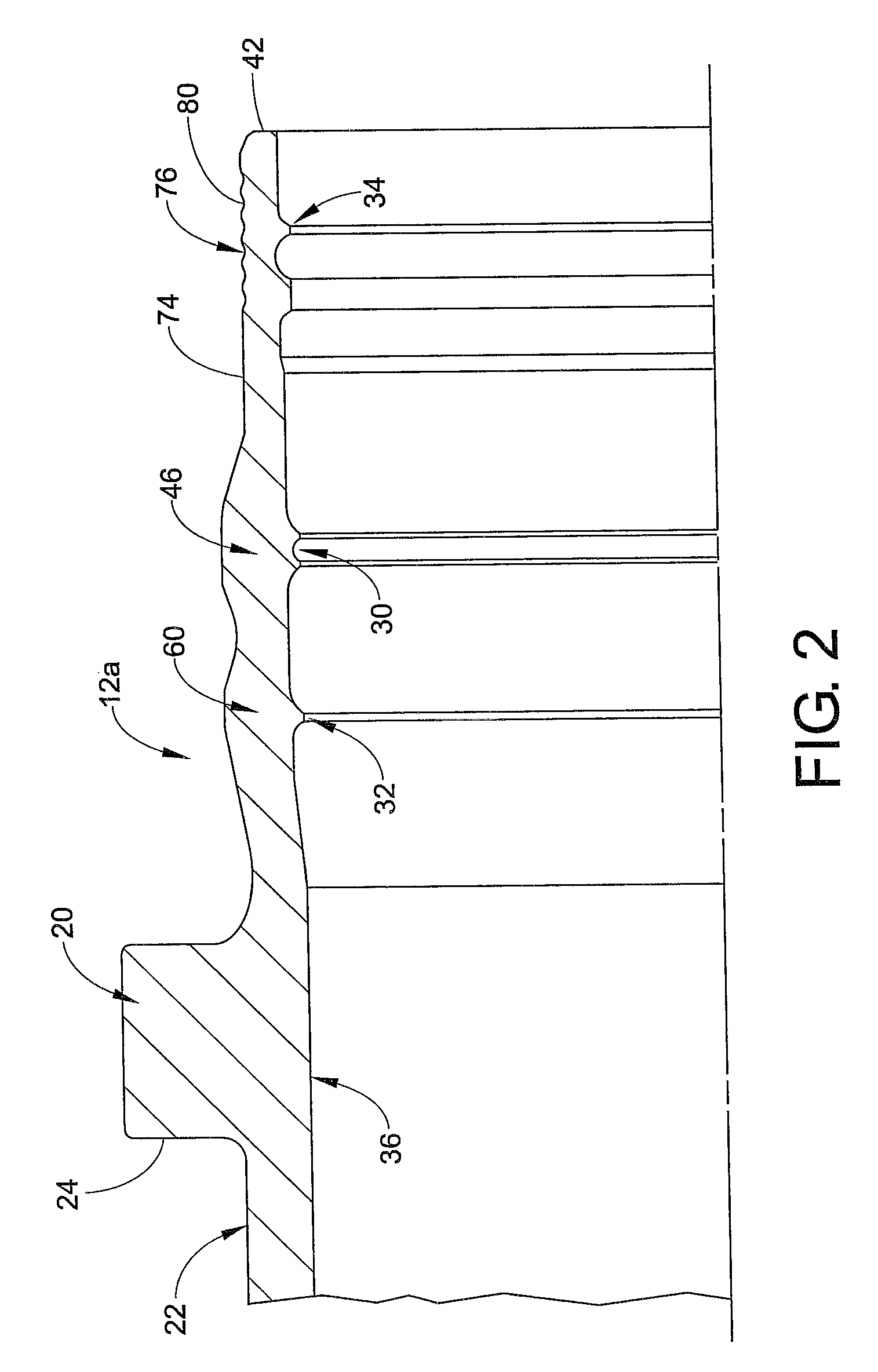

The use of anti-friction ball bearings in a unique arrangement does not require the use of lubricating oil from the internal combustion engine lubricating system and permits close coupling of the bearings and a compact turbocharger. A turbocharger bearing housing forms a coolant jacket with an inner bearing engaging portion that has two bearing engagement surfaces engaged with the outer races of two anti-friction bearings whose inner races carry rotating shaft, turbine and compressor of the turbocharger. The anti-friction bearings are, preferably, angular contact ball bearings, and the two bearing engagement surfaces of the bearing housing are closely spaced, providing a turbocharger shaft of minimal length and substantially reducing the thermal expansion of the shaft. The coolant jacket protects the anti-friction bearings from exposure to the extreme heat of the exhaust gas driven turbine, notwithstanding their increased proximity due to the shortened turbocharger shaft. In addition, an external motor-generator may be carried by the compact turbocharger, and its motor may be connected to the turbocharger rotor assembly by a permanent, solid connector and stay connected throughout the entire operating range of the turbocharger. In such assembly, the electronic motor-generator control is mounted on the motor housing and energizes the motor from battery power during the engine acceleration period up to approximately the torque peak speed; thereafter, the control changes to a generator mode when excess energy is available in the engine exhaust gas.

Owner:WOOLLENWEBER WILLIAM E

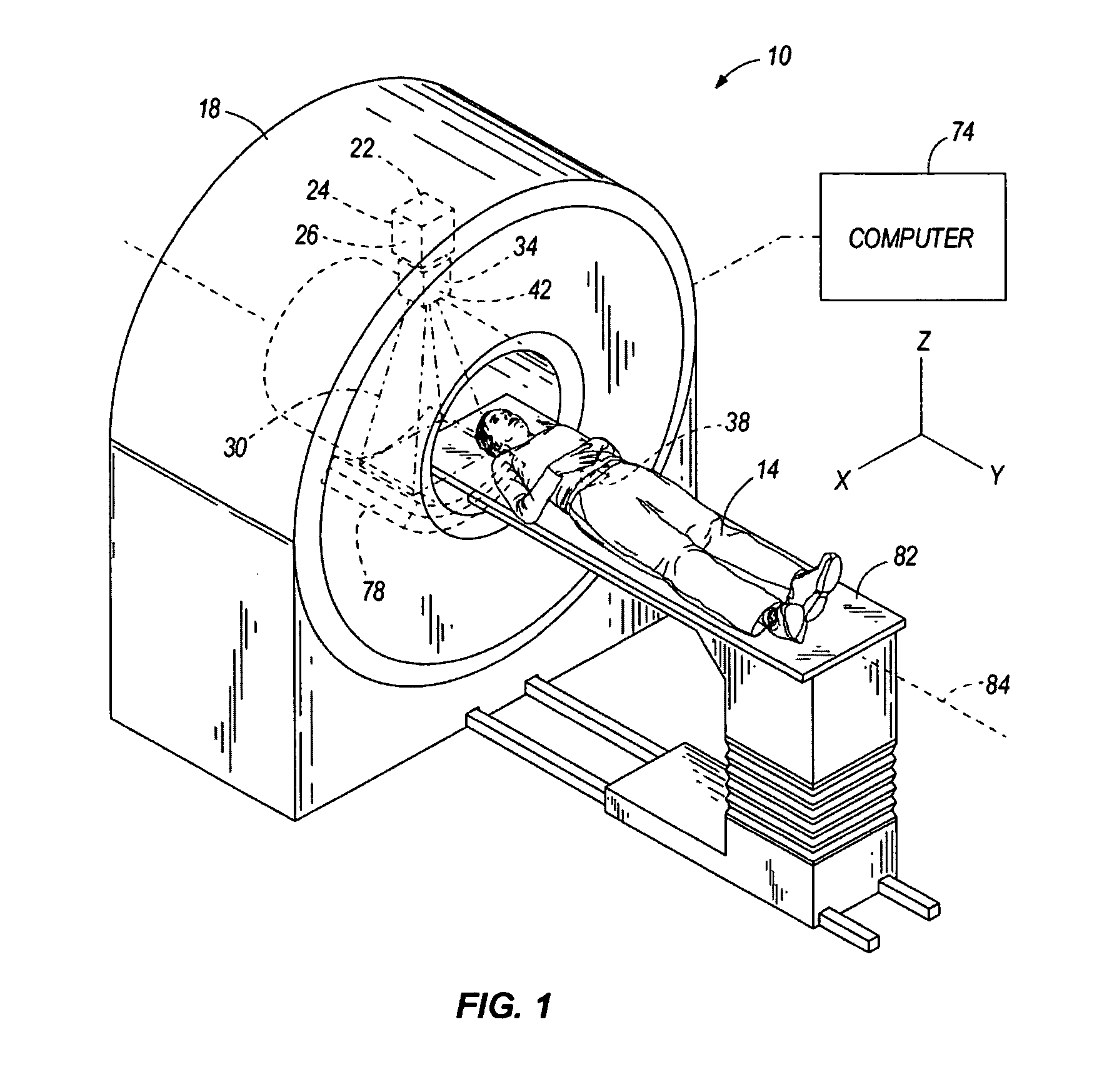

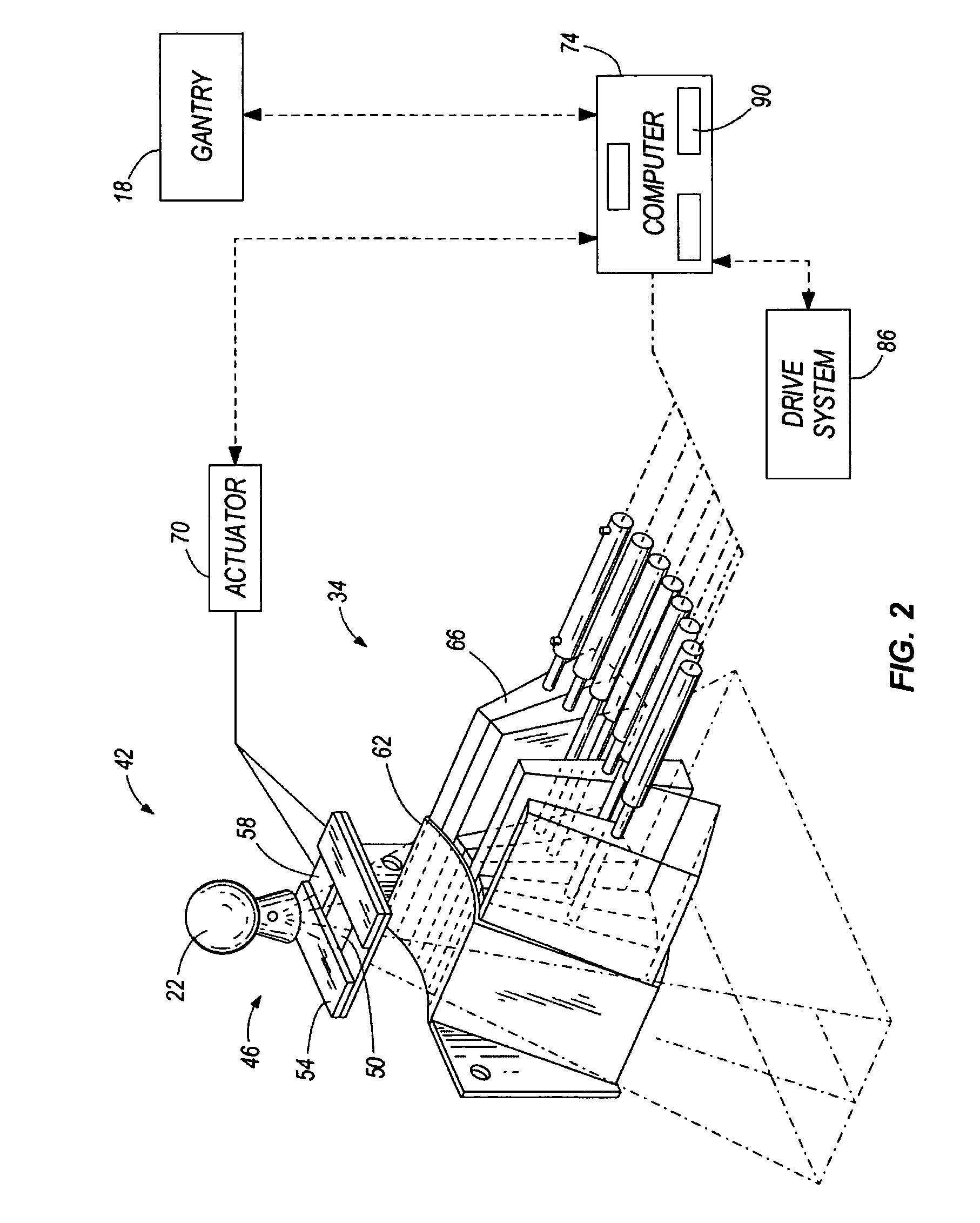

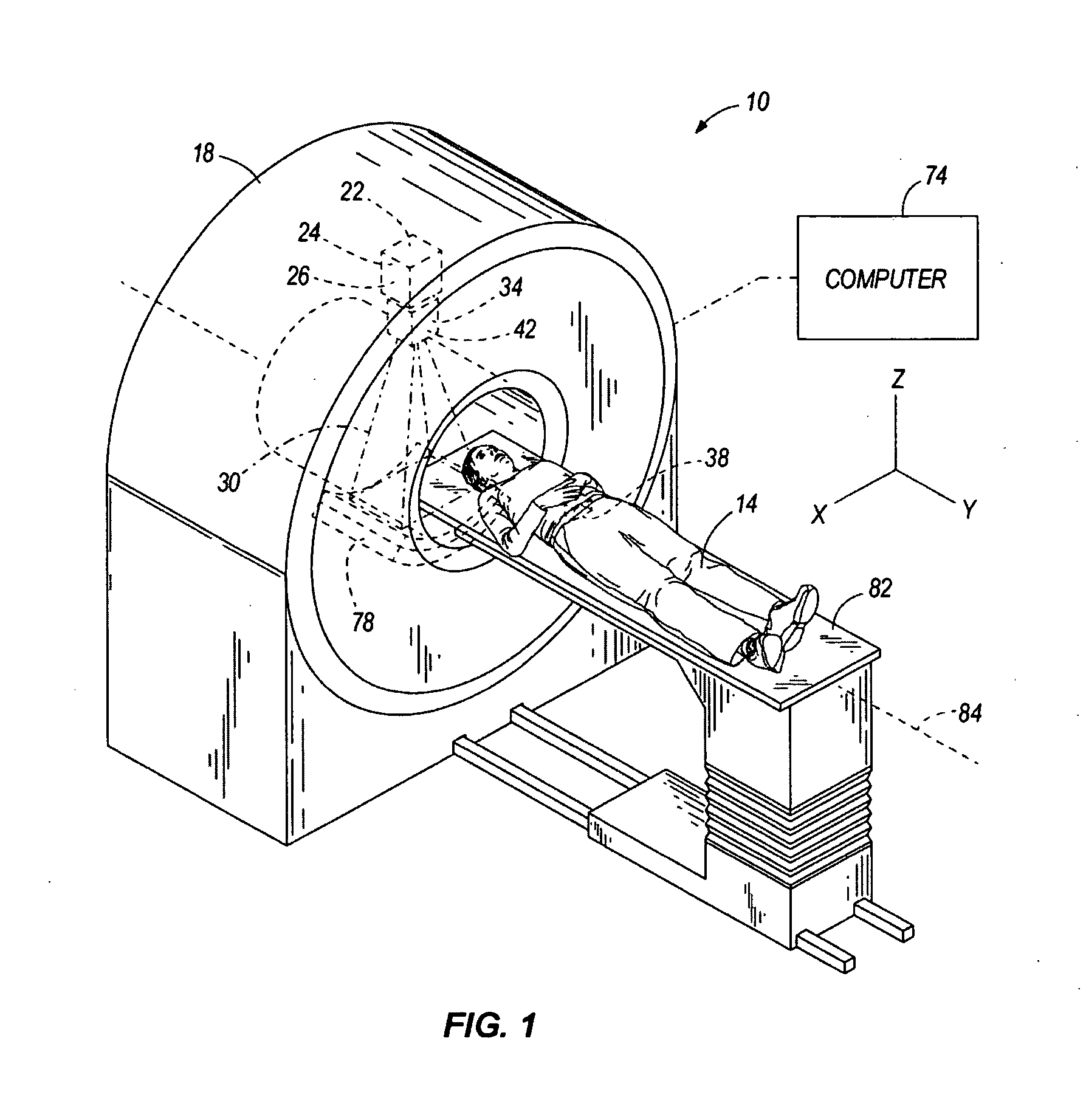

Target pedestal assembly and method of preserving the target

ActiveUS7835502B2Prolong lifeHeat dissipationX-ray tube anode coolingX-ray tube electrodesSoft x rayChemical reaction

An x-ray target pedestal assembly and a method of protecting the x-ray target from breaking down as a result of the extreme heat that is produced when an electron beam is aimed at the target to produce x-rays. The target is submerged in cooling fluid and is rotated by a constant flow of the cooling fluid over and around the target in order to dissipate heat. The fluid is guided by integrated flow diverters in the target cover. The target may also be protectively coated either in its entirety or along the electron beam path in order to further protect it from the heat of the electron beam impact or from breakdown as a result of attack of free radicals or other chemically reactive components of the cooling fluid which are produced in the extreme target environment.

Owner:TOMOTHERAPY INC

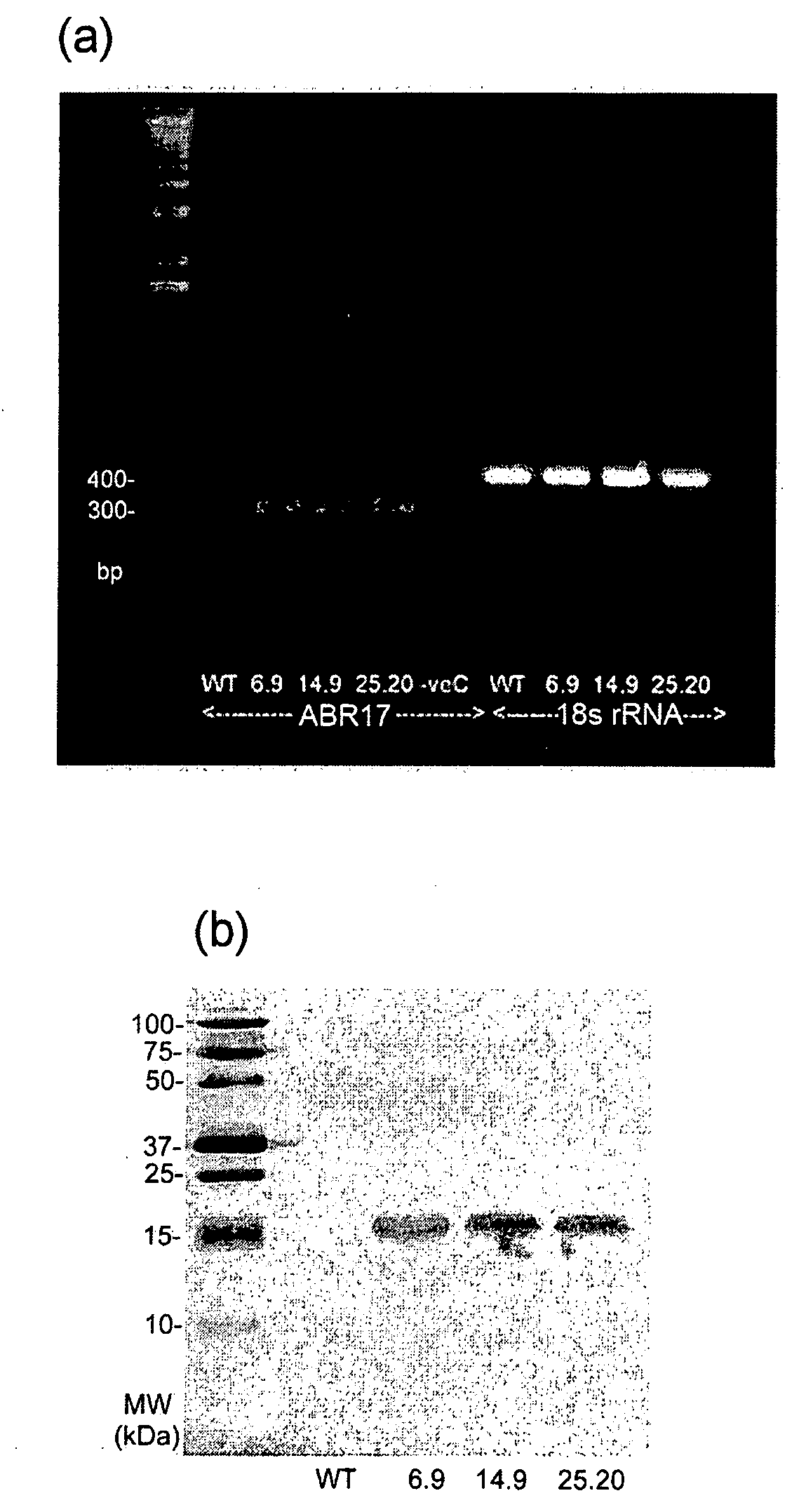

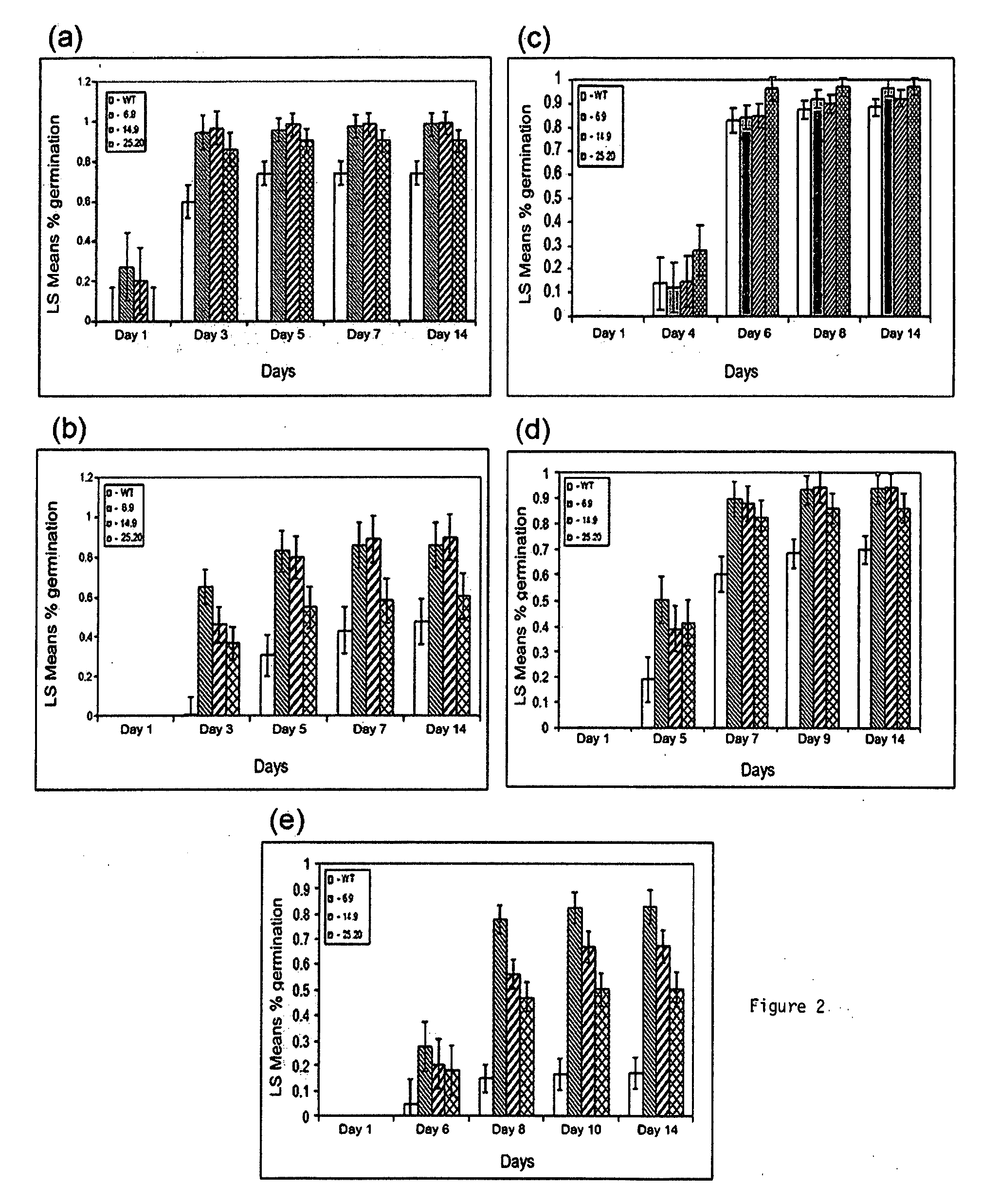

Method of conferring multiple stress tolerance and early flowering in plants

InactiveUS20080005810A1Improve germination rateImprove toleranceOther foreign material introduction processesFermentationAbscisic acidNannochloropsis

Transgenic plants are more tolerant to environmental stresses than untransformed plants. The pea ABR17 (Abscisic acid responsive 17) is used to enhance germination of plants such as Arabidopsis sp. and Brassica sp. while under multiple abiotic stresses, and to enhance the tolerance of these plants to these stresses. Three independently derived Arabidopsis transgenic lines, containing ABR17, germinated better in the presence of salt, cold temperature or both. The transgenic plants also exhibited enhanced tolerance to freezing temperature or extreme heat. Furthermore, the transgenic plants demonstrated early flowering even under normal, non-stressed conditions.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA

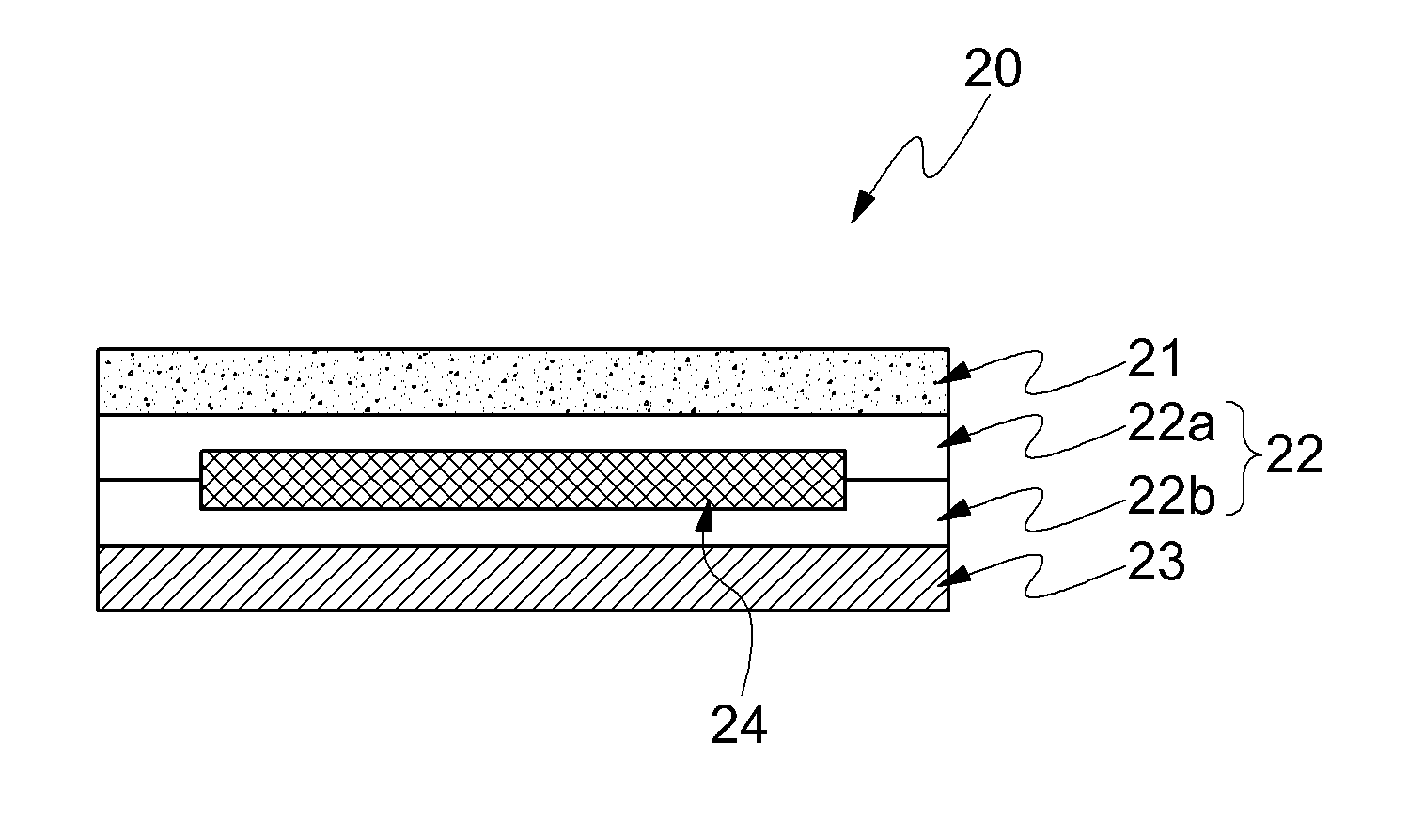

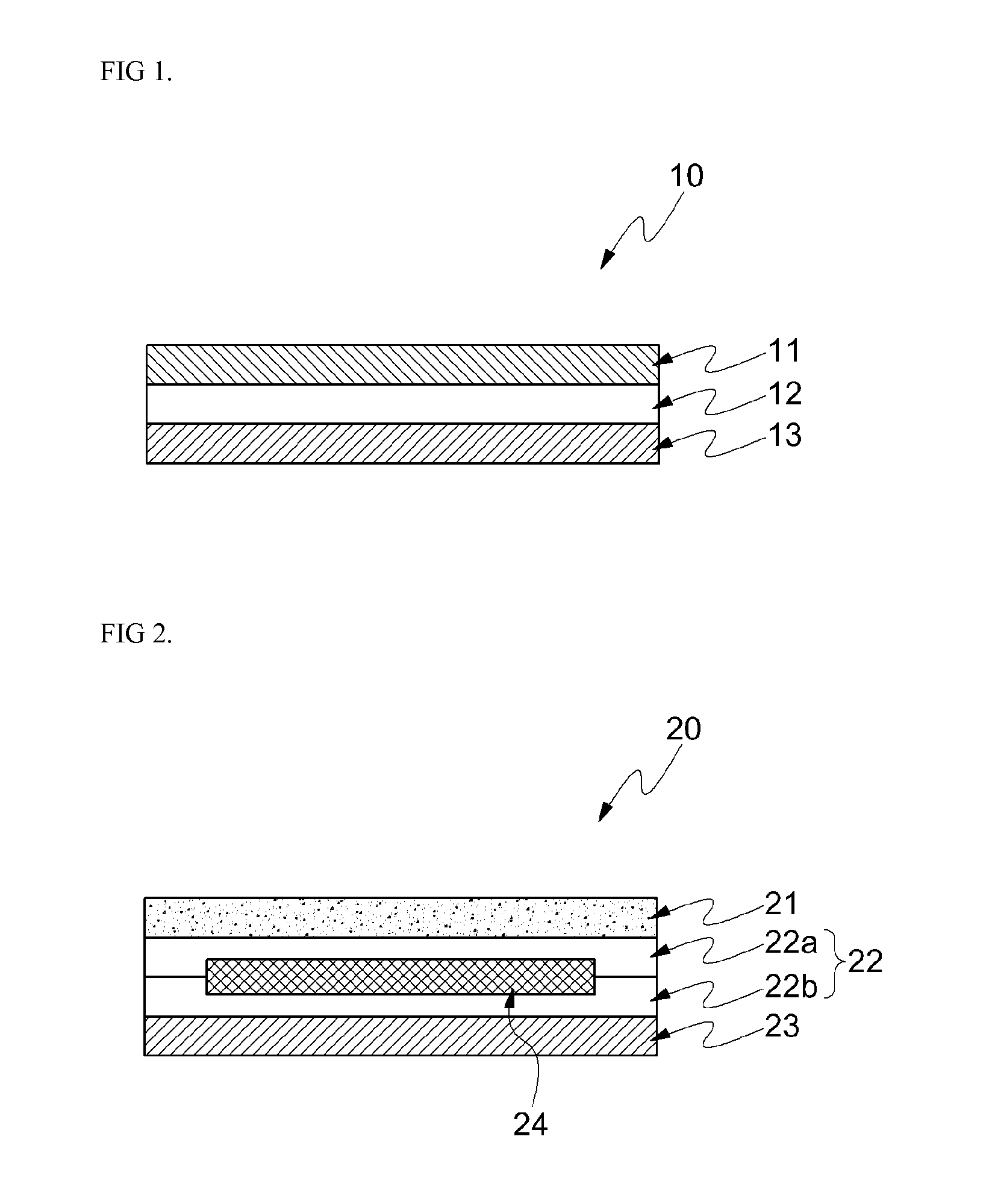

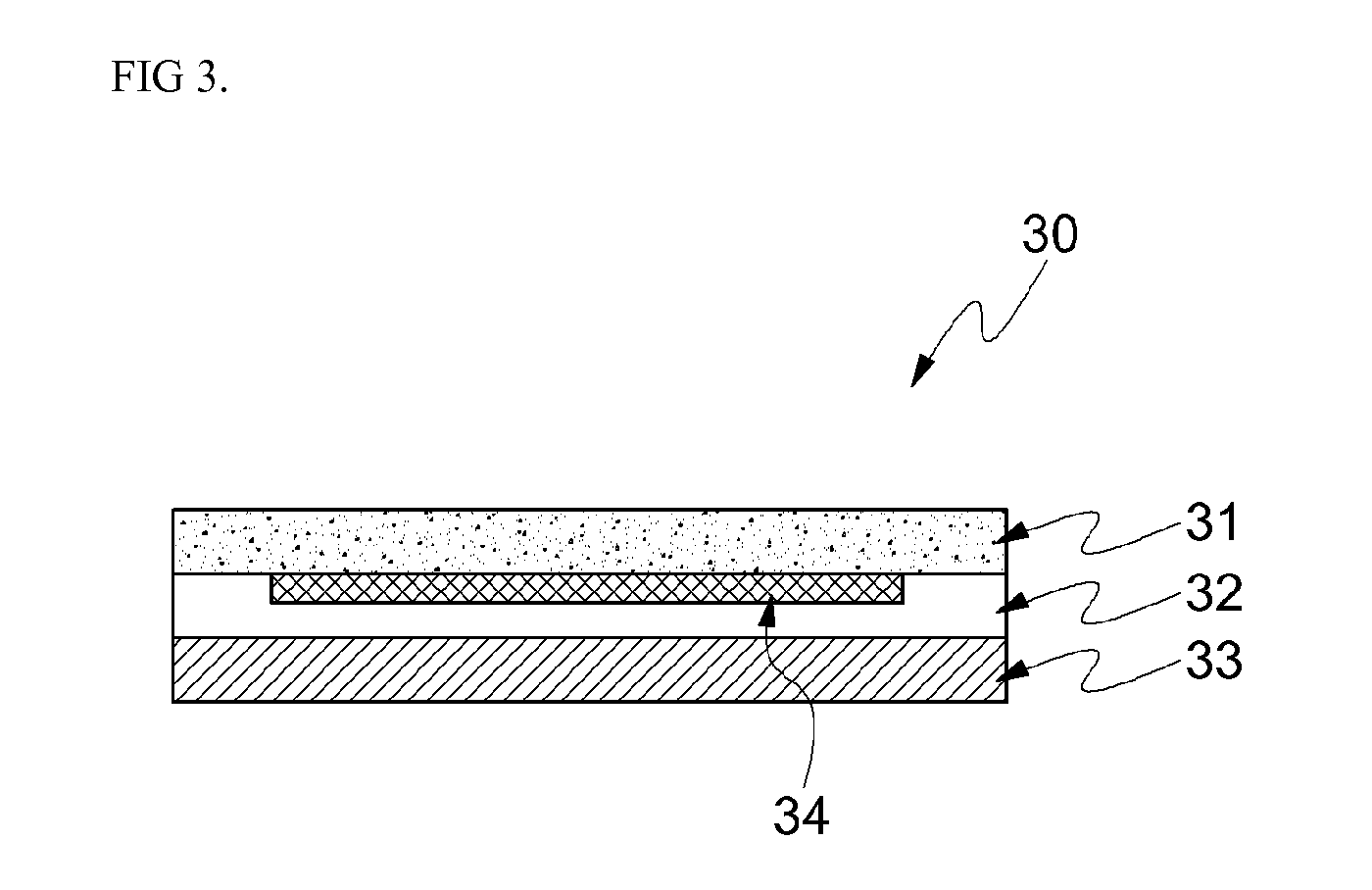

Backsheet

InactiveUS20150303338A1Improve reliabilityImprove adhesion strengthFilm/foil adhesivesPolyureas/polyurethane adhesivesEngineeringUltimate tensile strength

There are provided a backsheet, a method of manufacturing the same, and a photovoltaic module including the same. In the present application, there is provided a backsheet, which exhibits excellent reliability and adhesive strength under extreme heat and / or humidity conditions, thereby improving weatherability and durability. Such a backsheet can be applied for a photovoltaic module, for example.

Owner:LG CHEM LTD

Corrosion-resistant ABS tone ring

ActiveUS20060124411A1Effective characterizationBraking element arrangementsBraking action transmissionMulti materialNonferrous metal

A tone ring of a vehicle anti-lock braking system of the type that is integrated into a disc brake rotor. The tone ring has a protective layer which enables it to withstand the combination of extreme heat and harsh environmental conditions to which it is exposed during operation of the vehicle. The protective layer is applied by thermally spraying a selected one of a plurality of materials, such as a nickel-based alloy, a high-chrome stainless steel, or non-ferrous materials such as an aluminum, copper-based alloys or a ceramic, on teeth of the tone ring, and without causing the protective layer to be deposited on the rotor braking surfaces. The protective layer generally prevents the formation of oxidation and corrosion byproduct layers on the teeth, to thereby maintain sensitivity for detection of teeth movement by the anti-lock braking system sensor during operation of the system.

Owner:HENDRICKSON USA L L C

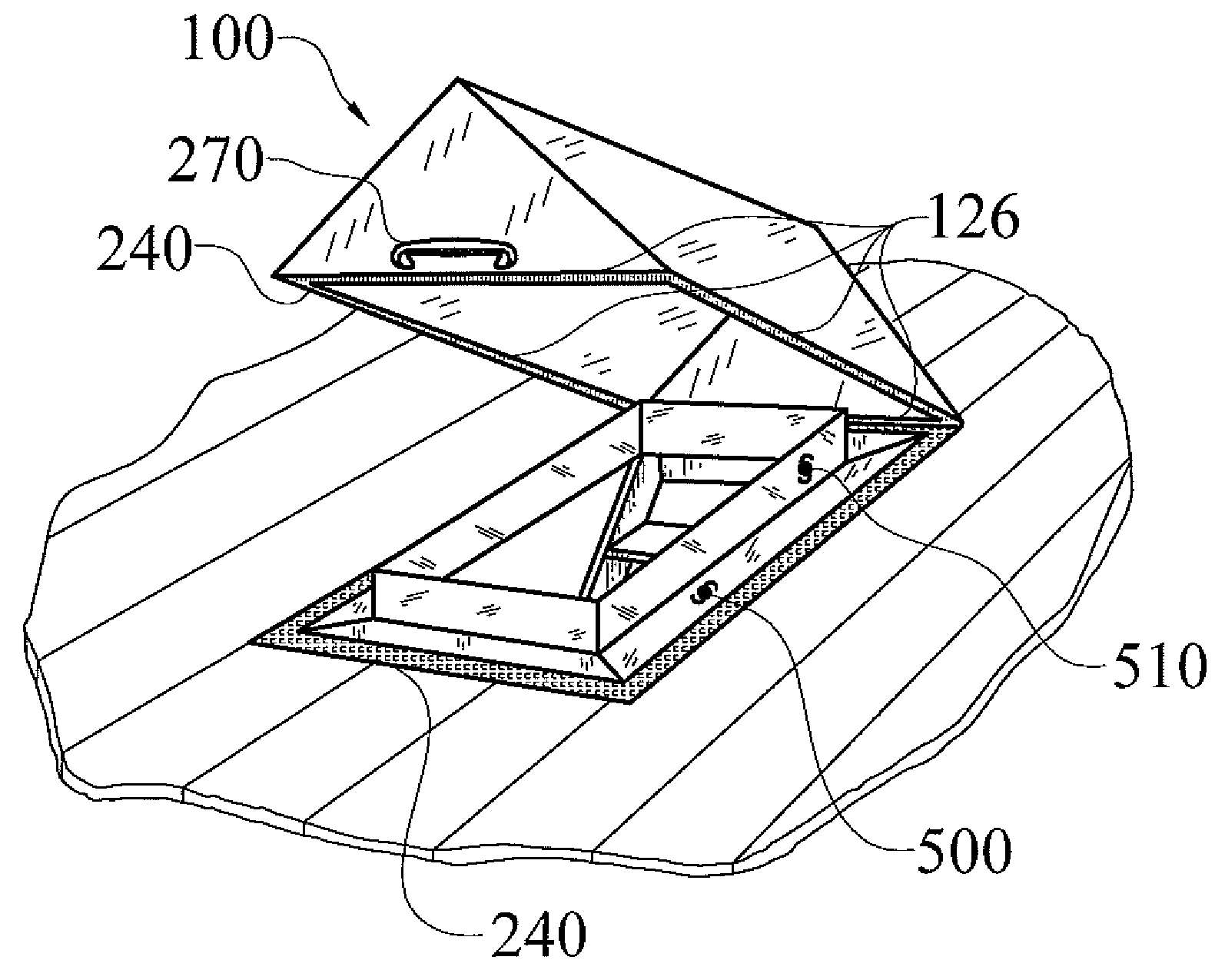

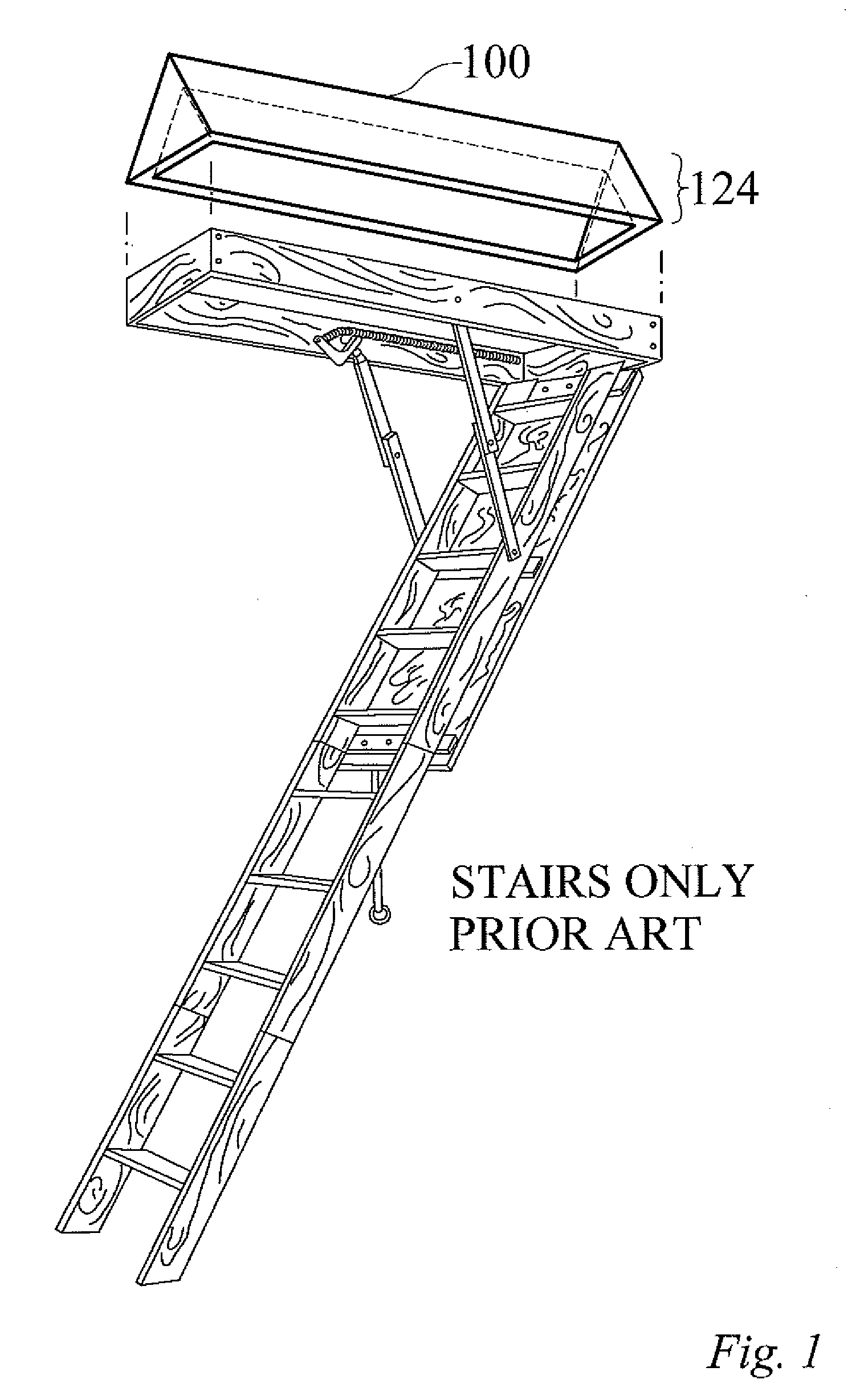

Flexible Fire-Resistant Thermally Insulated Composite Structures

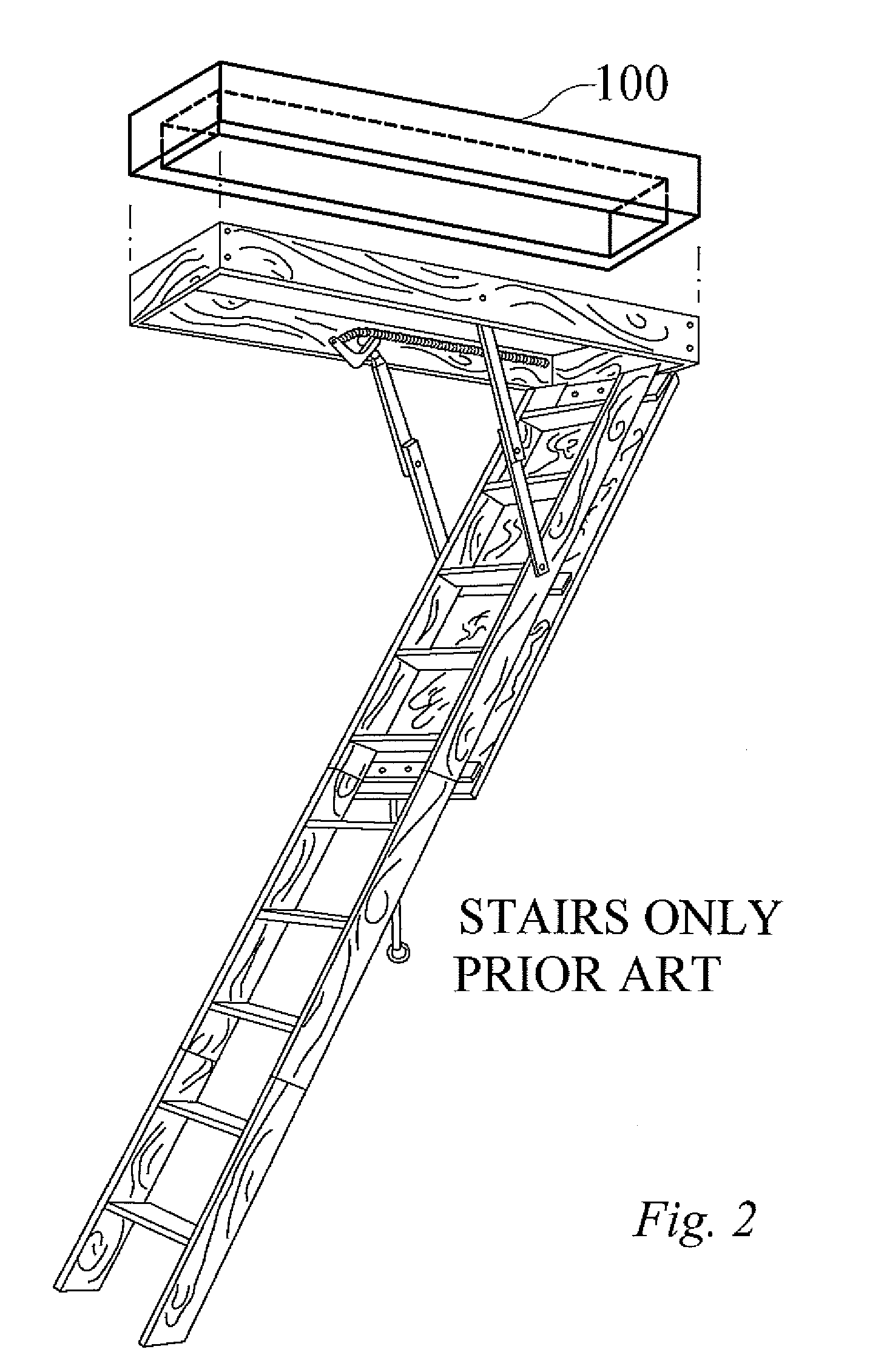

InactiveUS20090094908A1Decrease natural tendencyIncreased durabilityRoof coveringHeat proofingEmbodiment designMechanical engineering

The instant invention includes a flexible fire-resistant thermally insulated composite structure designed in some embodiments to pass through an opening. The structure may be self-supporting due to the stiffness of various layers, and battens may contribute to the self-supporting capacity of the structure.The flexible composite structure may have a collapsed transit configuration, allowing the structure to be compressed to more easily pass it through an opening, a rotable attachment to allow the structure to rotate away from the opening, and a releasable attachment for attaching the structure around an opening periphery. In another embodiment, the structure may also include a bottom and such a structure could provide shelter in conditions ranging from ambient environmental conditions to the extreme heat of certain fires.The insulative structures of the instant invention are not limited to embodiments designed to rest on generally horizontal surfaces. For example, it may be desirable to utilize such a structure to block an attic fan, or other roof penetration, during certain seasons of the year. Such an embodiment may also include a releasable attachment configured for releasably attaching the installation periphery to a surface inclined from the horizontal.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

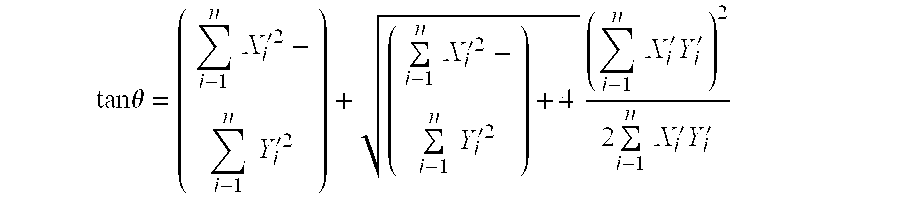

Method of modeling the socio-spatial dynamics of extreme urban heat events

InactiveUS20100305913A1ForecastingComputation using non-denominational number representationHealth professionalsPublic health

A method of coupling surface urban heat island measures with socio-economic indicators of vulnerability to create improved spatially specific models to assist public health professionals in predicting extreme heat events mortality in urban environments. The method includes utilizing landsat TM imagery for the measuring of the urban heat island intensity levels and a spatial analysis of the variables in question.

Owner:INDIANA UNIV RES & TECH CORP

Corrosion-resistant ABS tone ring

ActiveUS7306293B2Effective characterizationBraking action transmissionApplication and release valvesAlloyProtection layer

A tone ring of a vehicle anti-lock braking system of the type that is integrated into a disc brake rotor. The tone ring has a protective layer which enables it to withstand the combination of extreme heat and harsh environmental conditions to which it is exposed during operation of the vehicle. The protective layer is applied by thermally spraying a selected one of a plurality of materials, such as a nickel-based alloy, a high-chrome stainless steel, or non-ferrous materials such as an aluminum, copper-based alloys or a ceramic, on teeth of the tone ring, and without causing the protective layer to be deposited on the rotor braking surfaces. The protective layer generally prevents the formation of oxidation and corrosion byproduct layers on the teeth, to thereby maintain sensitivity for detection of teeth movement by the anti-lock braking system sensor during operation of the system.

Owner:HENDRICKSON USA L L C

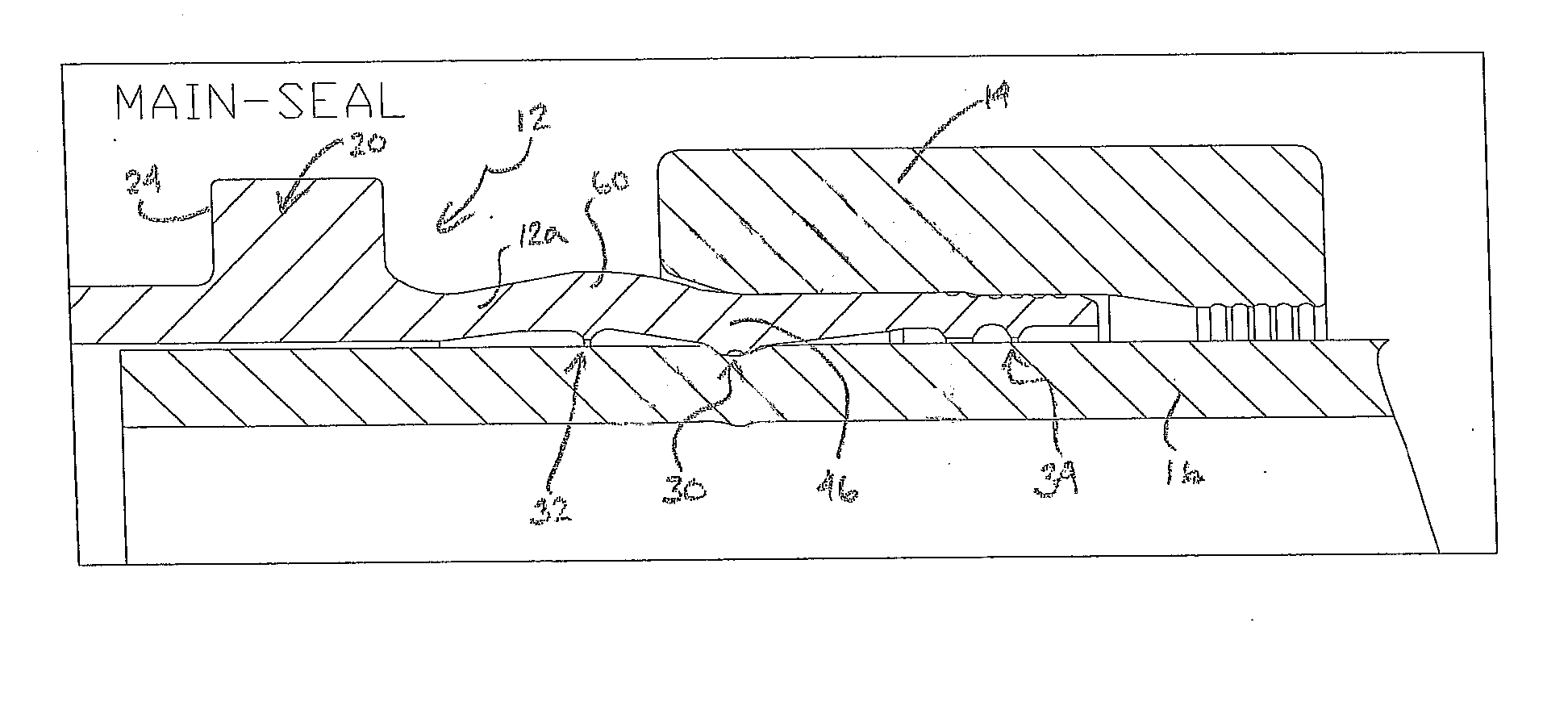

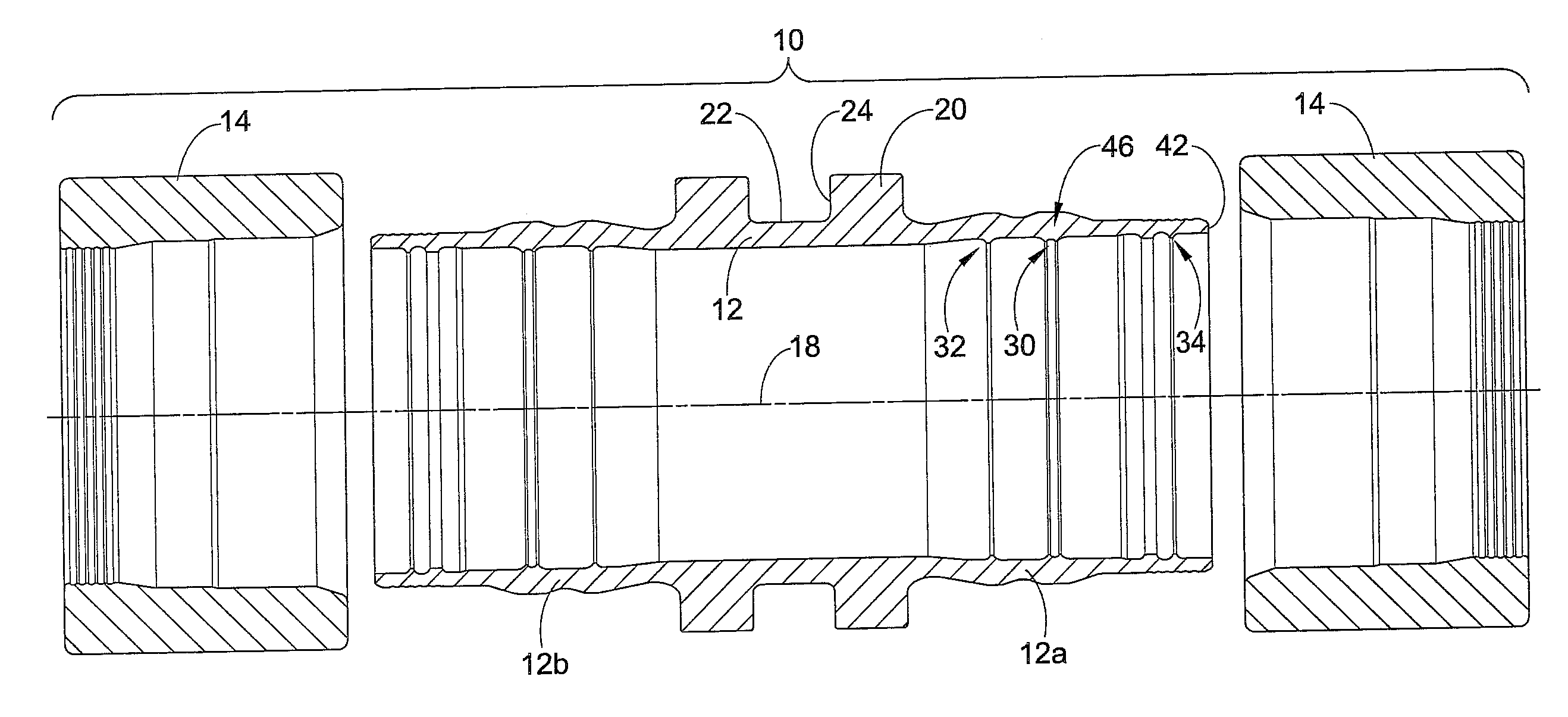

Fitting with complementary fitting materials

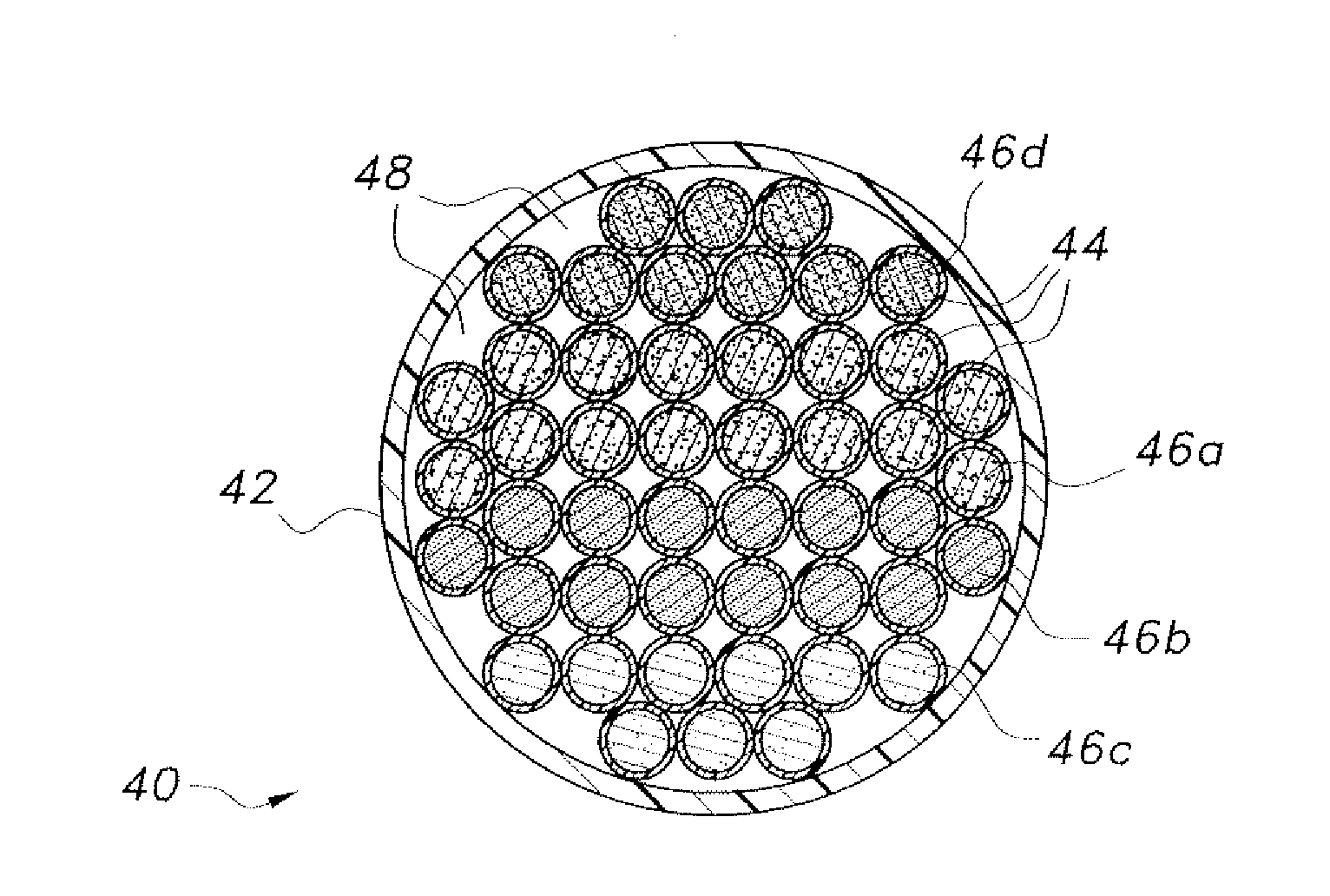

ActiveUS20070108760A1Restoring compressive stressRestoring tensile stressSleeve/socket jointsHose connectionsEngineeringThermal expansion

The present disclosure relates to a fitting assembly for maintaining a leak free seal connection with an associated fluid conduit during and after exposure to extreme heat. The fitting assembly comprises a coupling body including an inside surface defining a bore for receiving the associated fluid conduit. The inside surface engages an outside surface of the associated fluid conduit. At least one seal is formed on the inside surface of the coupling body. At least one ring is annularly disposed on the coupling body urging the at least one seal into the associated fluid conduit to seal and mechanically connect the coupling body to the associated fluid conduit. The coupling body is made of a first corrosion resistant material having a first coefficient of thermal expansion. The at least one ring is made of a complementary second corrosion resistant material having a second larger coefficient of thermal expansion such that the second material will expand at a greater rate than the first material during heating to a first temperature generally exceeding annealing temperatures of both the first material and the second material. The second material contracts at a greater rate than the first material during subsequent cooling to a second temperature below the annealing temperatures thereby restoring compressive and tensile stresses in the associated fluid conduit and the fitting assembly for ensuring that the fitting assembly maintains a leak free seal connection with the associated fluid conduit.

Owner:LOKRING TECHNOLOGY

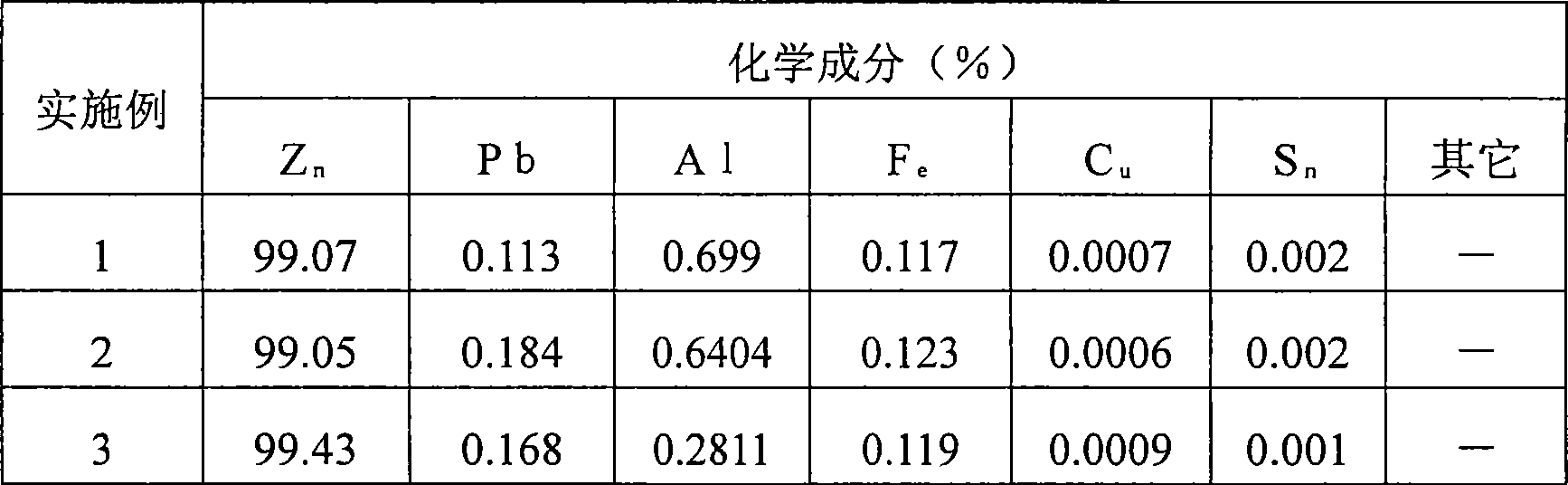

Method and apparatus for purifying zincilate

InactiveCN101469372AReduce consumptionAvoid extreme cold and heatRetort furnacesPurification methodsSlag

The invention provides a zinc slag purification method and a zinc slag purification device. The zinc slag purification method comprises the following steps: zinc slag is melted through a melting furnace and then is sent into a rectification column for distillation through a feeder, evaporated zinc steam is condensed into a pure zinc liquid through a condenser, and the pure zinc liquid flows into a zinc storage tank and is cast into a zinc ingot of No. 0 zinc through a casting mold; and an unevaporated zinc liquid flows into a liquating furnace, zinc slag ash produced through the treatment of the liquating furnace is discharged from a slag hole, and No. B zinc is transported back to the melting furnace for next cycle. The melting furnace, the rectification column and the liquating furnace are all heated by adopting mixed coal gas of a coke oven and a blast furnace. The method has the advantages of simple equipment structure, reasonable process, and low production cost, reduces energy consumption of furnace ignition by adopting continuous production, avoids the extreme cold and extreme heat of furnace bodies, prolongs the service life of the furnace bodies, and can extract high-quality No. zinc by adopting the distillation of the rectification column.

Owner:鞍钢实业集团有限公司

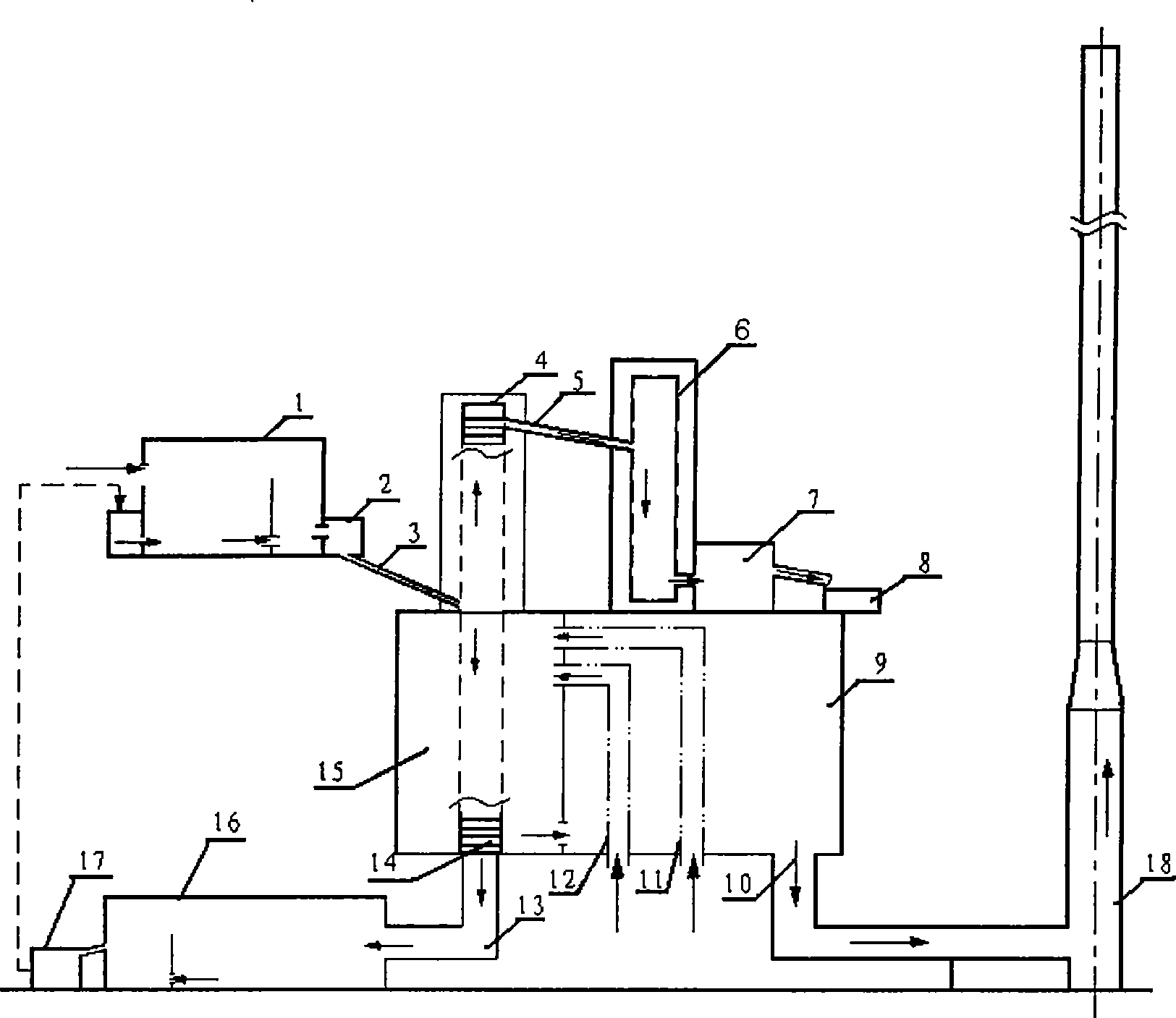

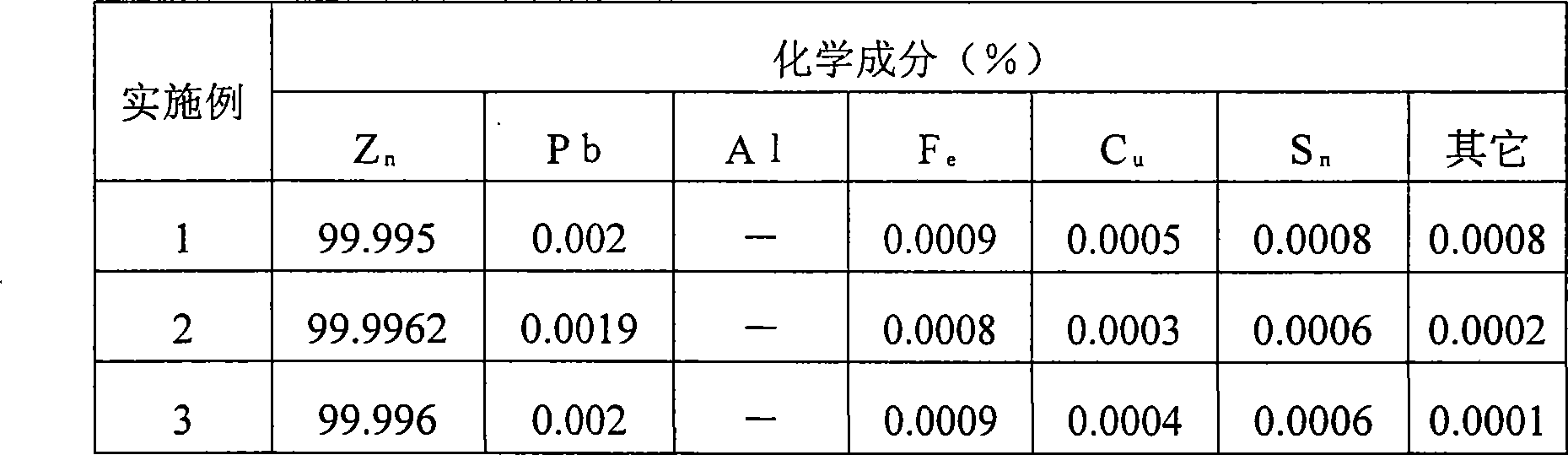

Directional cooling system for vacuum heat treating furnace

InactiveUS6903306B2Overcome problemsDrying solid materials with heatMuffle furnacesHot zoneProduct gas

A furnace for heat treating of metal parts includes a hot zone enclosure defining a hot zone therein. The hot zone enclosure has a side wall, a first end wall, and a second end wall. The side wall has slots formed therethrough and along the length thereof. The heat treating furnace also includes a system for injecting a cooling gas into the hot zone through the hot zone enclosure. The heat treating furnace further includes a damper arrangement for directing the cooling gas over a selected portion or portions of the workpiece load and through one or more of the slots. In one embodiment of the invention, all actuated components in the furnace are located outside of the hot zone to minimize damage to moving parts that are caused by exposure to extreme heat.

Owner:IPSEN INT

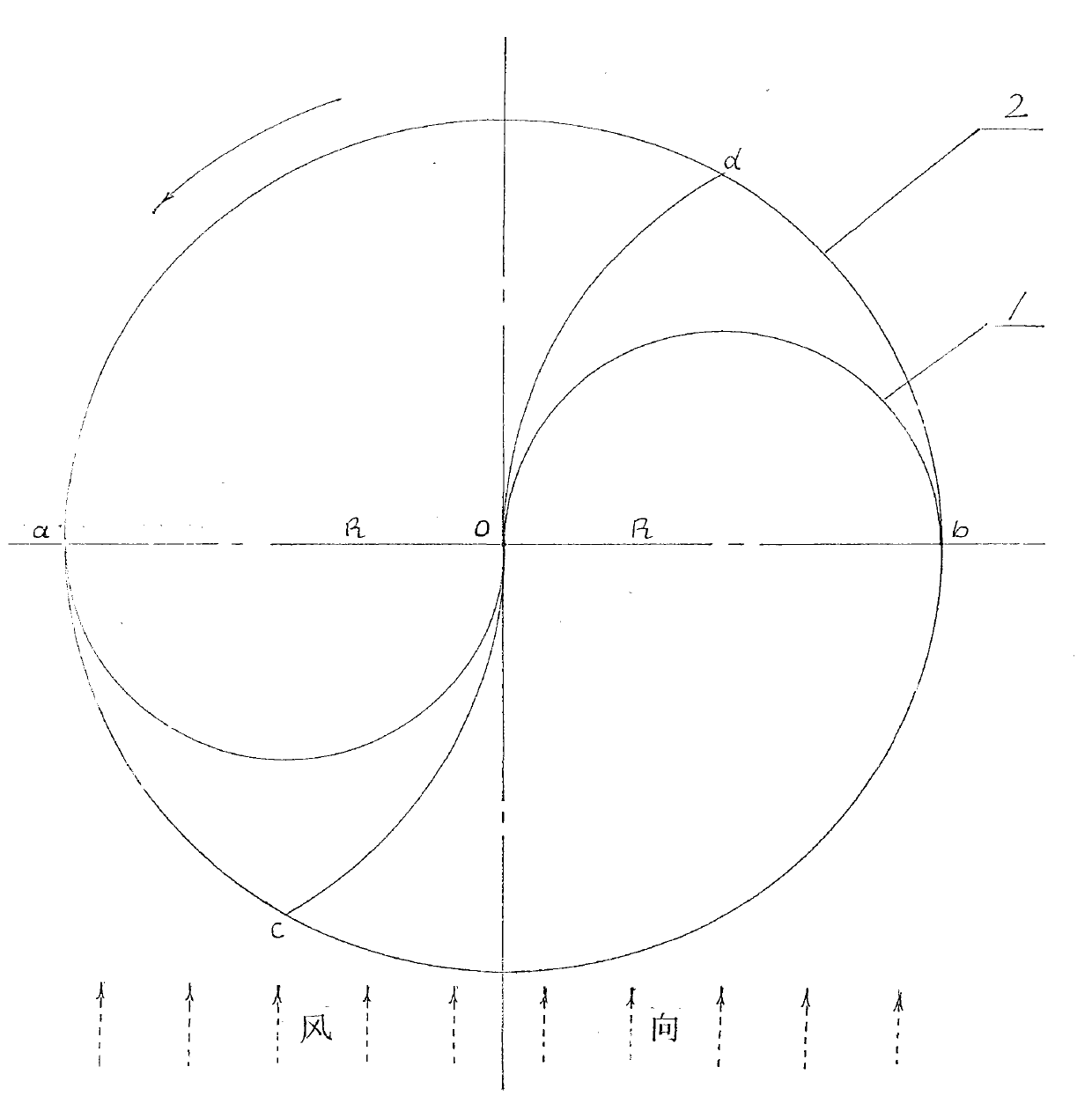

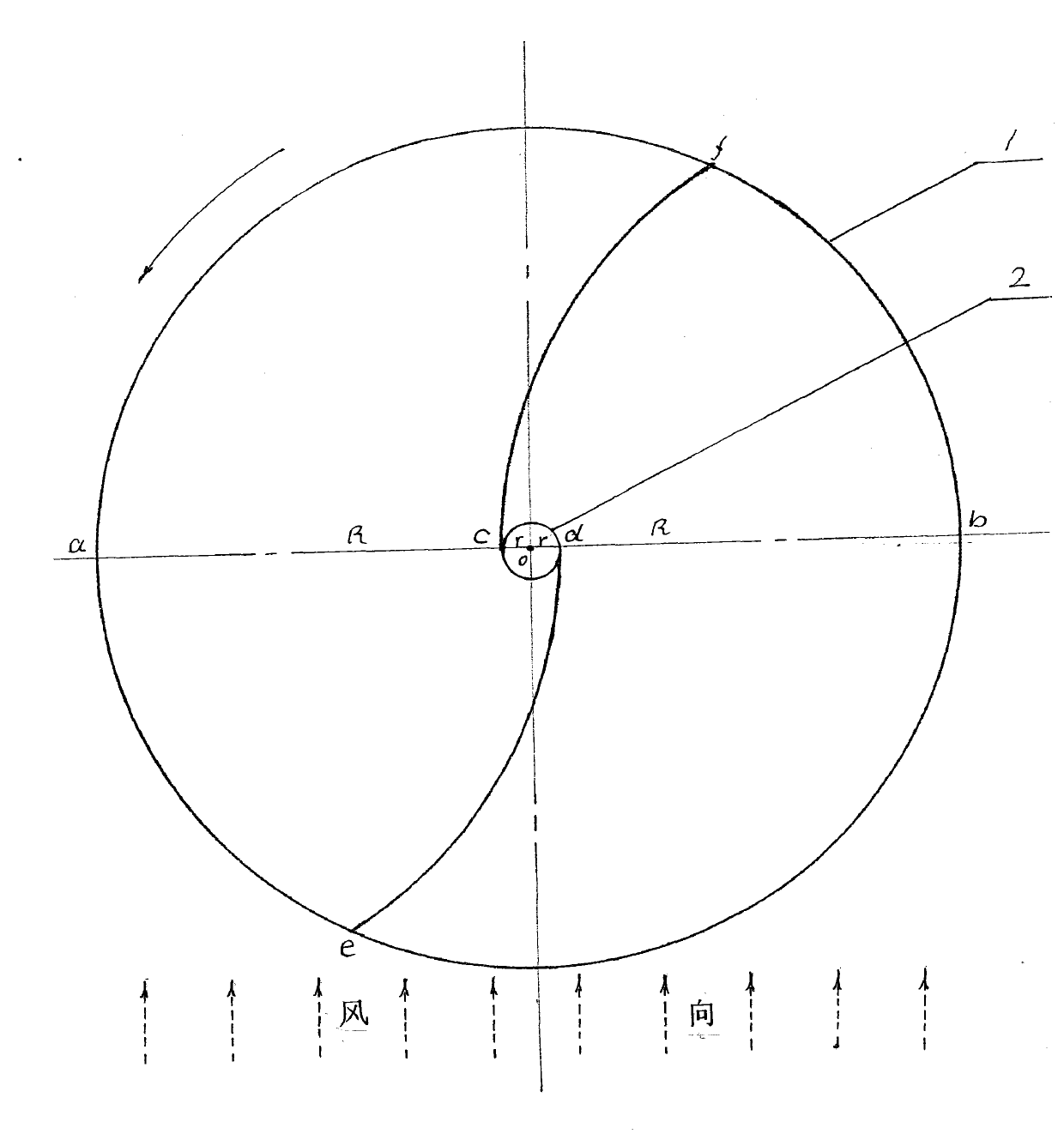

Streamline shaped heat radiator for electronic equipment

InactiveCN101340799AReduced entropy productionImprove useful work lossDigital data processing detailsSemiconductor/solid-state device detailsHeat flowEngineering

The invention belongs to a streamline electronic equipment radiator, which relates to the technical field of electronic equipment heat dissipation. The streamline electronic equipment radiator comprises a streamline rib and a heat sink block. In order to solve the extreme heat dissipation problem of large power and high thermal-flow density, an integral design concept of fan and radiator is adopted, and the streamline radiator which is consistent to the wind direction of the fan outlet is designed according to the characteristics of the fan; the streamline electronic equipment radiator is characterized in that the surface of the streamline rib is tangent to the fan out-flow speed field vector, conforms the wind direction of the fan outlet, and reduces the flow resistance; the distortion surface effectively enlarges the heat dissipation area, thus improving the convection heat exchange capability; meanwhile, the streamline radiator has the effect of fan static vane guiding and reduces the whole noise.

Owner:BEIHANG UNIV

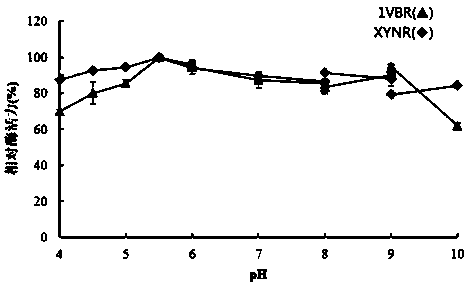

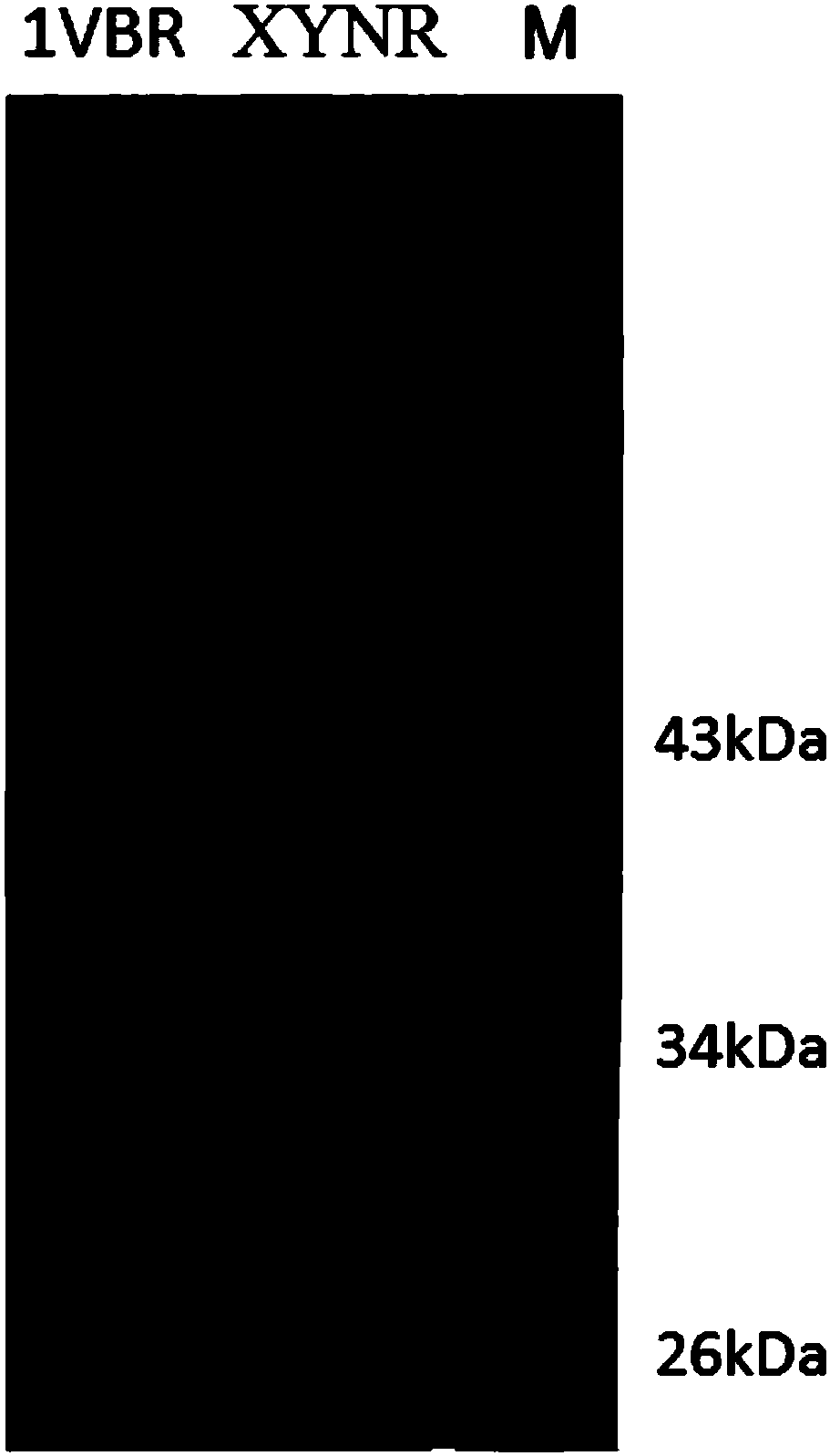

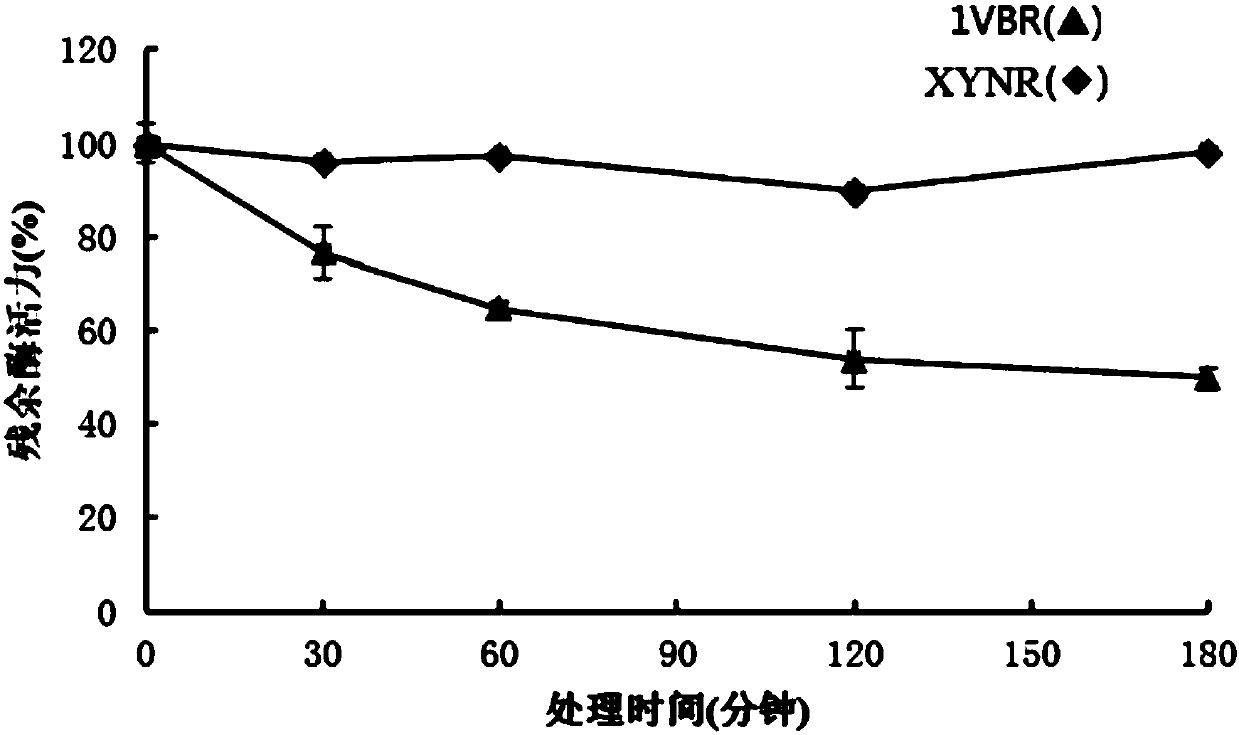

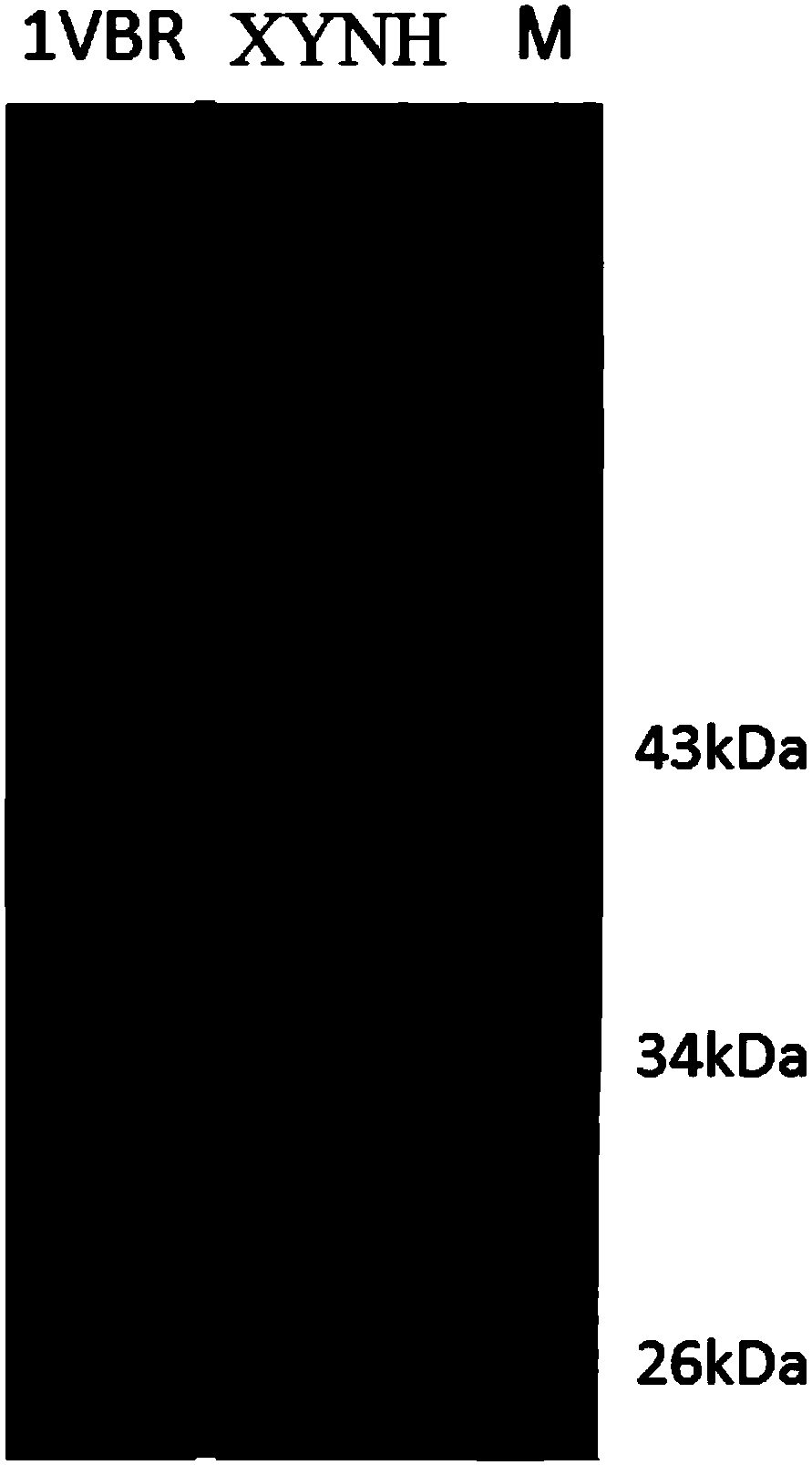

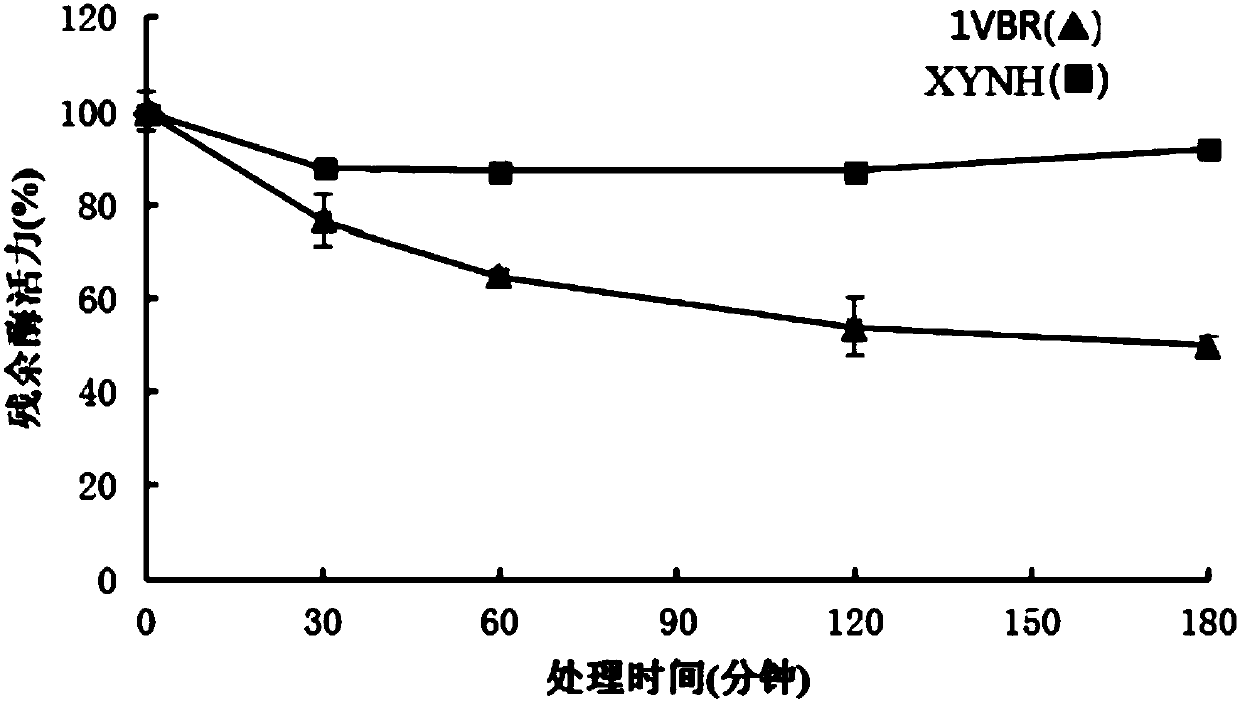

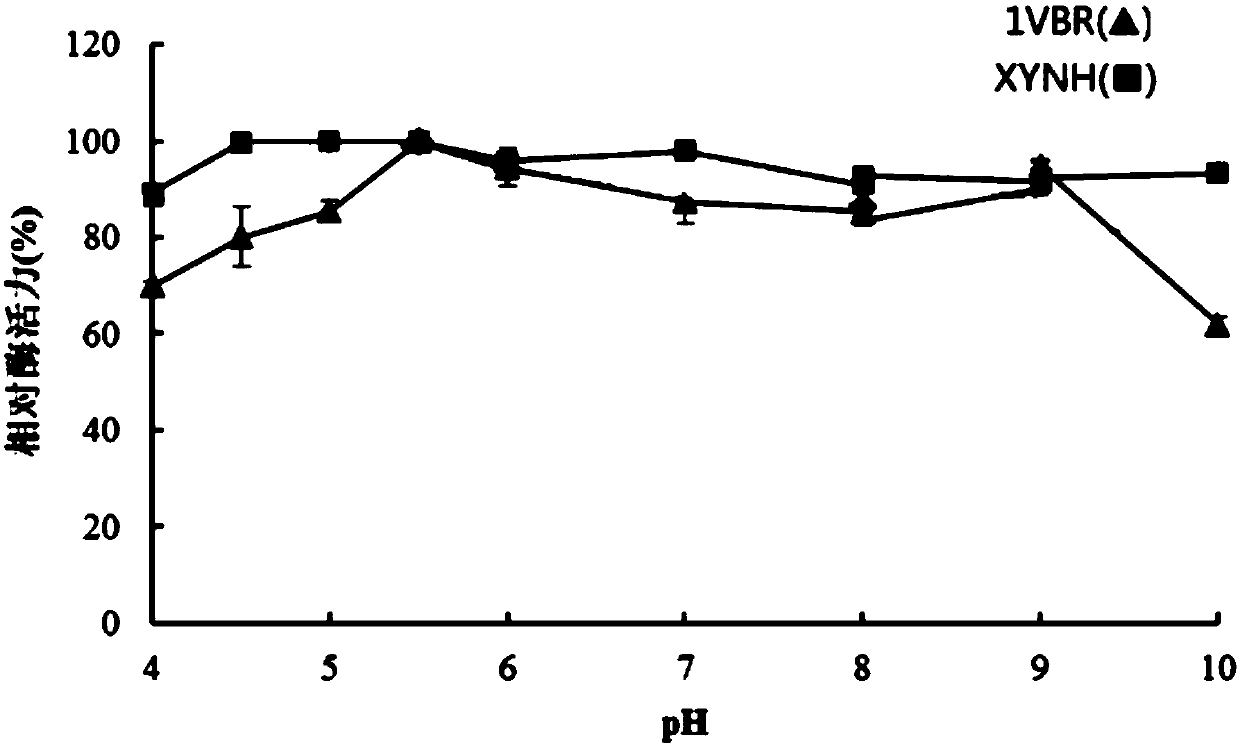

Mutant XYNR of extreme heat-resistant xylanase 1VBR and use thereof

The invention provides a mutant XYNR of an extreme heat-resistant xylanase 1VBR. The mutant XYNR is prepared through mutation of phenylalanine at the 290th of an amino acid sequence of the xylanase 1VBR into valine and has an amino acid sequence shown in the formula of SEQ ID NO.1. The invention also provides a gene for encoding the mutant XYNR. The gene has a nucleotide sequence shown in the formula of SEQ ID NO.2. The invention also provides a recombinant expression vector pPIC9K-XYNR with the gene for encoding the mutant XYNR and a recombinant strain with the recombinant expression vector.After the amino acid sequence of the xylanase 1VBR is subjected to site-directed mutagenesis, the high heat-resistant mutant XYNR is obtained, is highly expressed in a pichia pastoris expression system and has a wide application prospect in the fields of feed additives, health foods, papermaking, washing, brewing, textiles and pharmacy.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

Target pedestal assembly and method of preserving the target

ActiveUS20100202593A1Prolong target lifeHeat dissipationX-ray tube anode coolingX-ray tube electrodesSoft x rayChemical reaction

An x-ray target pedestal assembly and a method of protecting the x-ray target from breaking down as a result of the extreme heat that is produced when an electron beam is aimed at the target to produce x-rays. The target is submerged in cooling fluid and is rotated by a constant flow of the cooling fluid over and around the target in order to dissipate heat. The fluid is guided by integrated flow diverters in the target cover. The target may also be protectively coated either in its entirety or along the electron beam path in order to further protect it from the heat of the electron beam impact or from breakdown as a result of attack of free radicals or other chemically reactive components of the cooling fluid which are produced in the extreme target environment.

Owner:TOMOTHERAPY INC

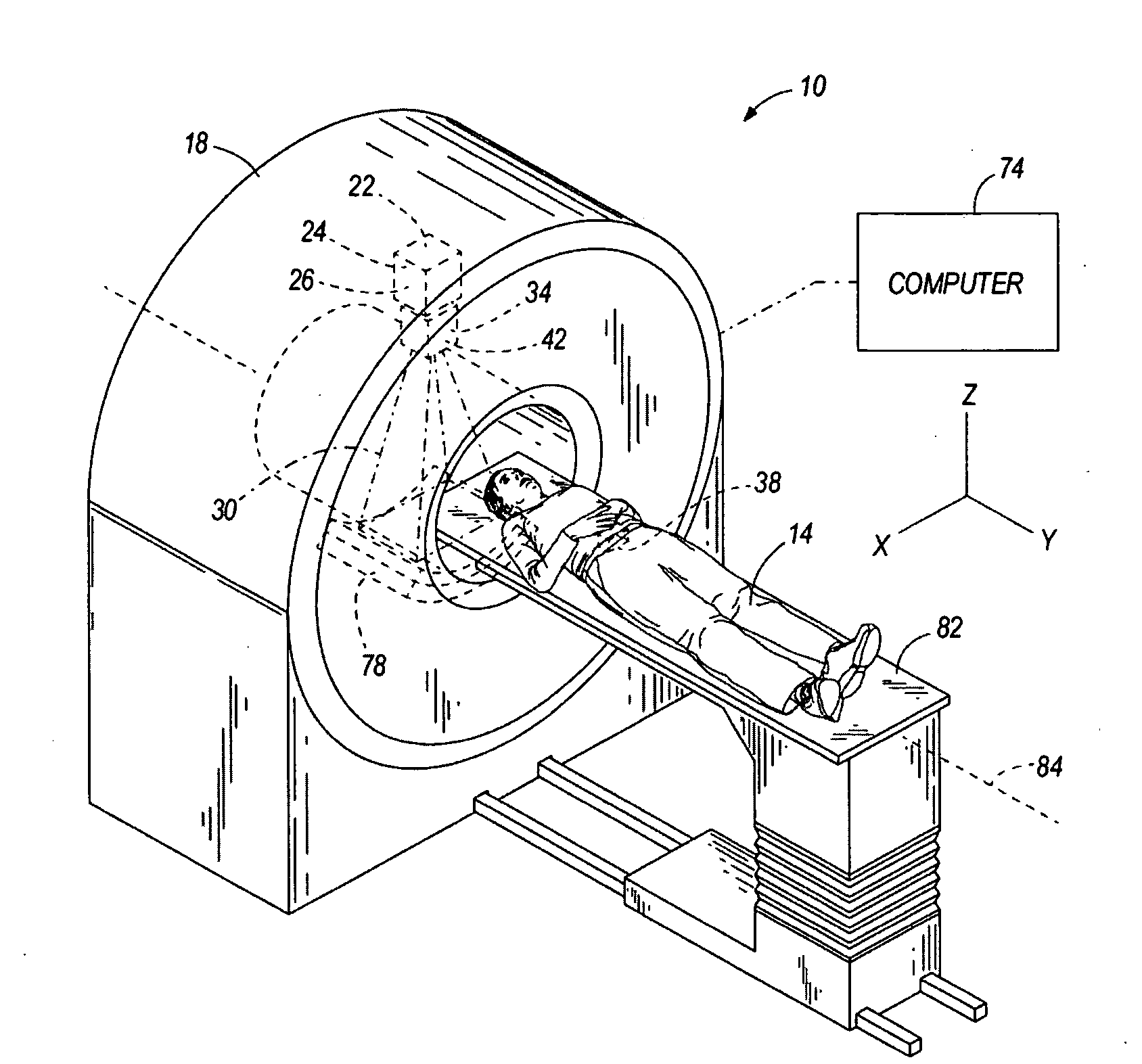

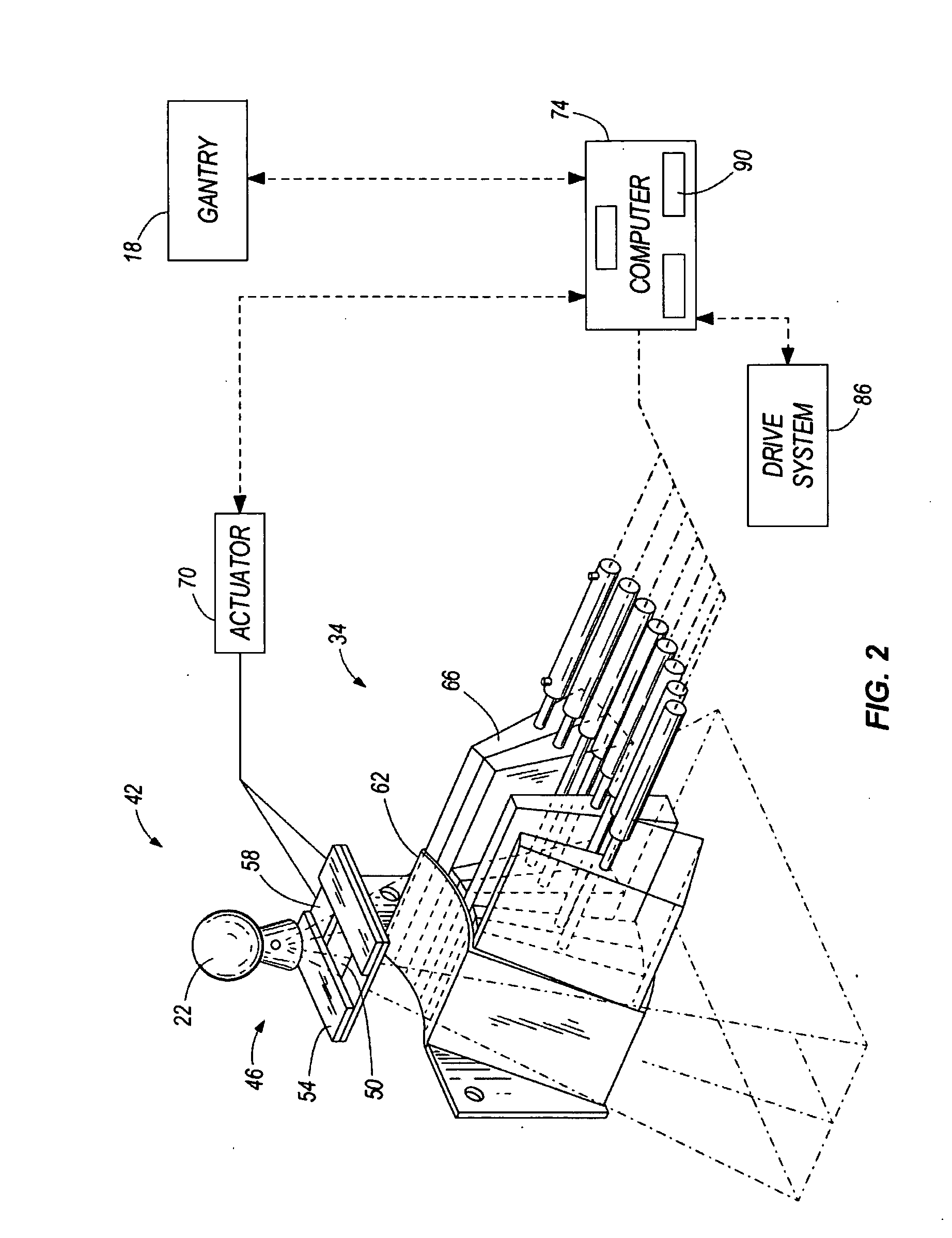

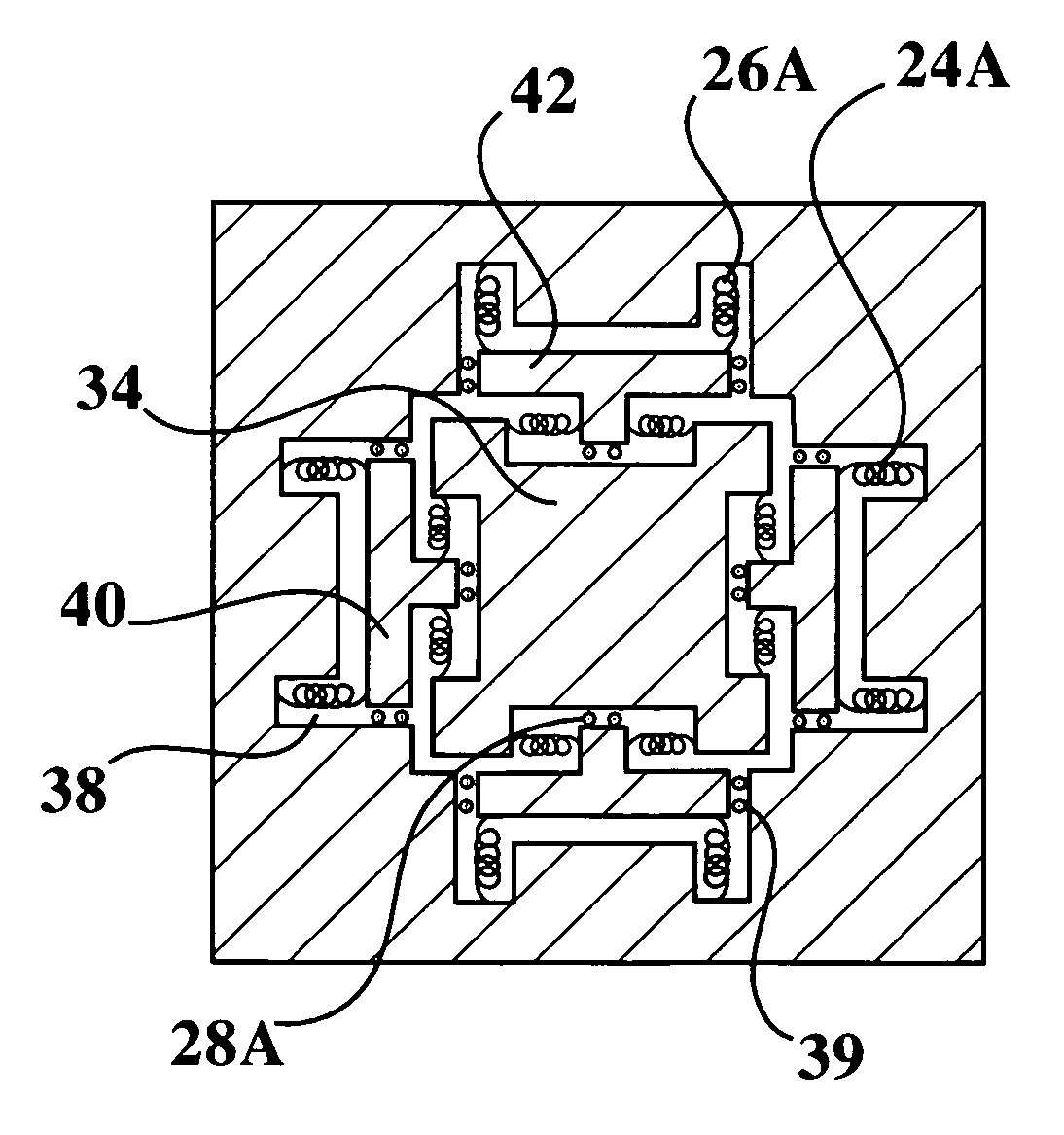

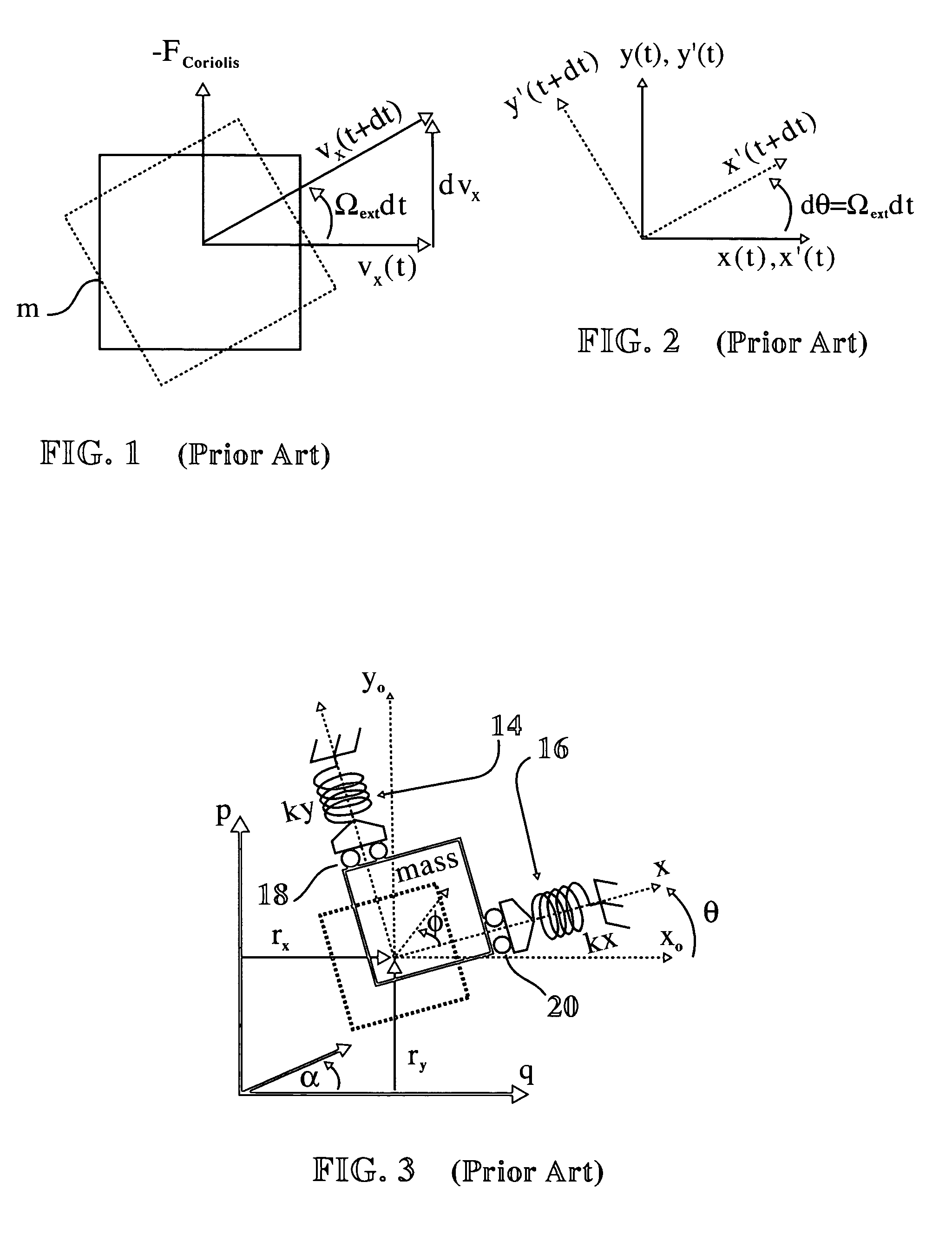

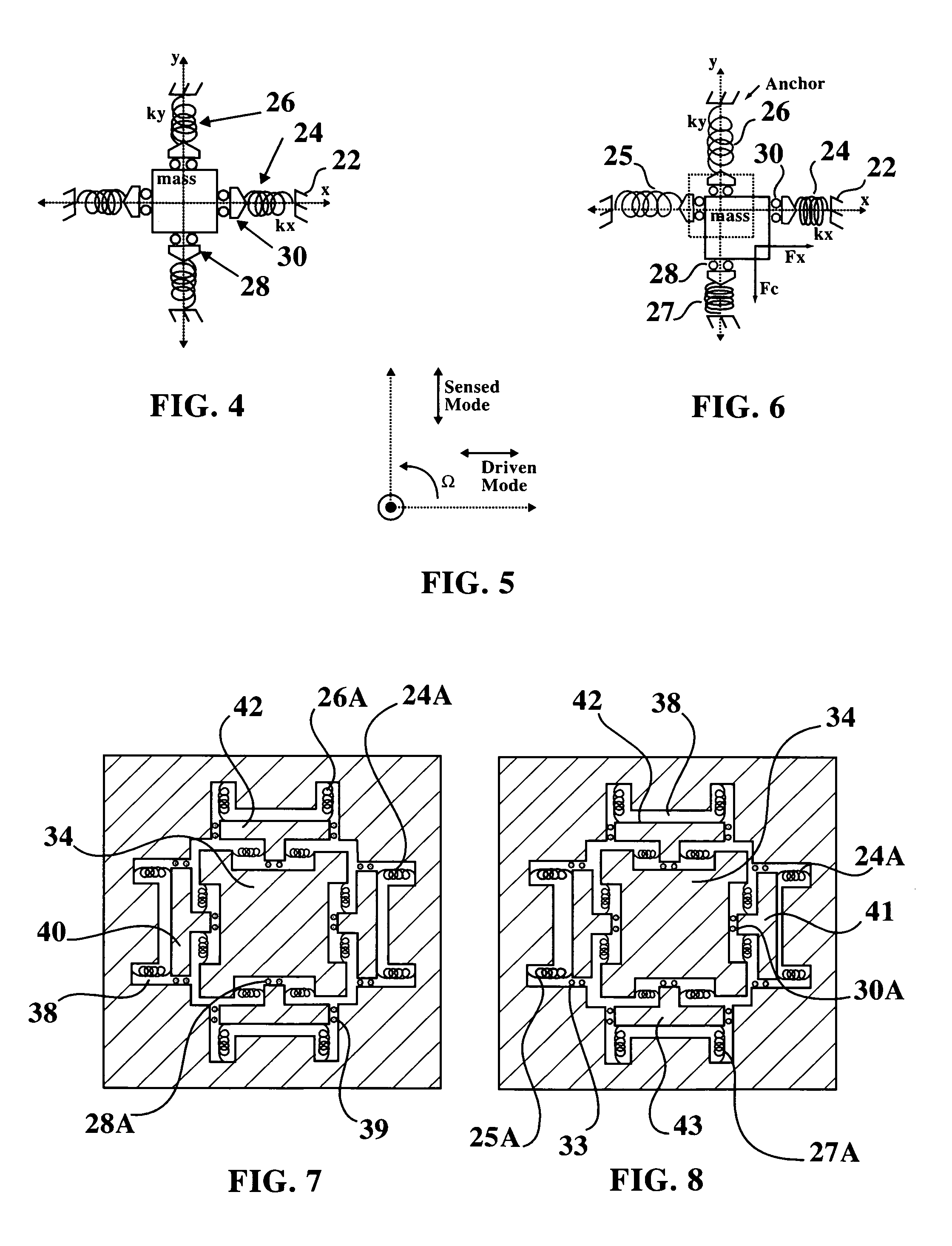

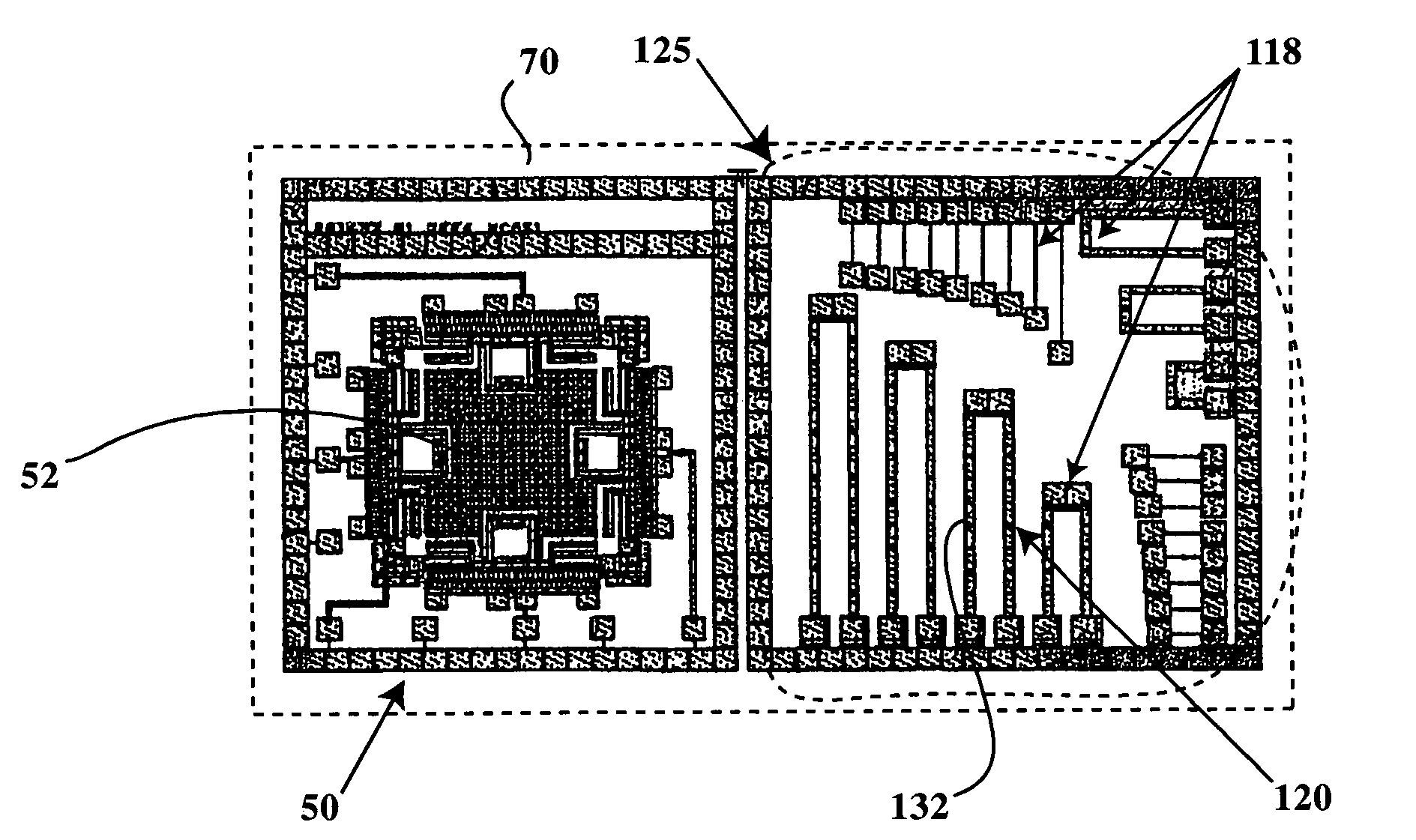

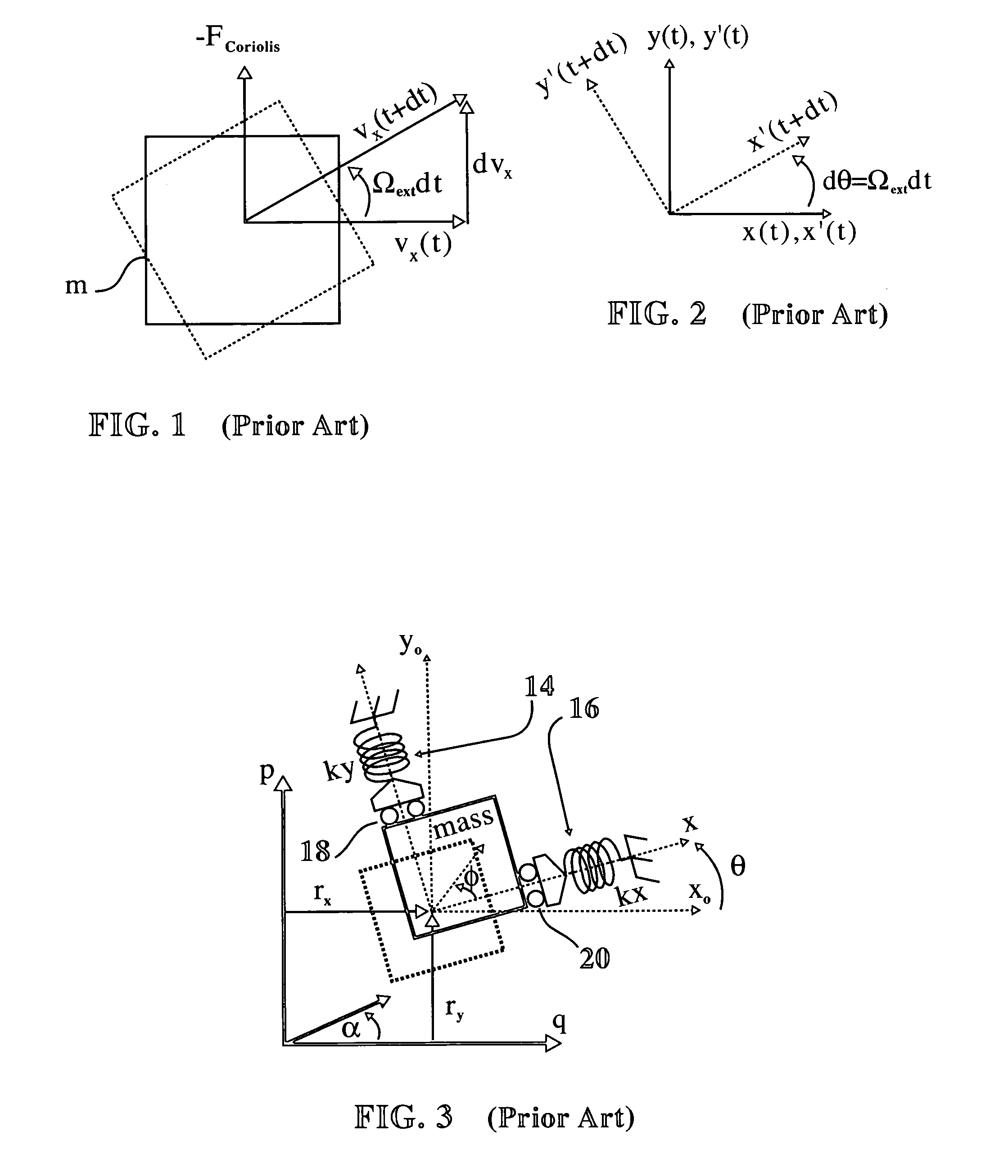

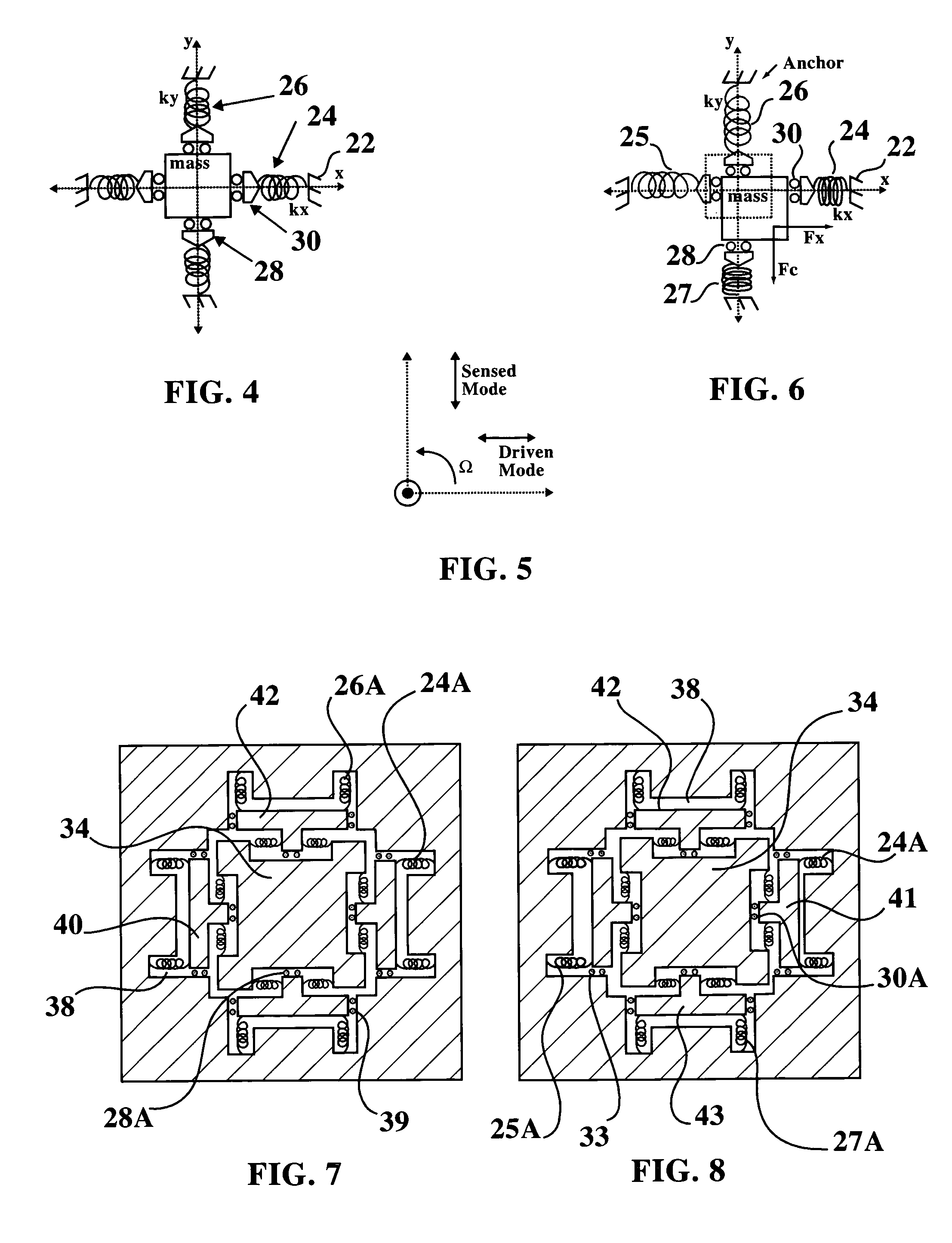

Integrated gyroscope and temperature sensor

InactiveUS20060196266A1Maximize dynamic rangeHigh sensitivityAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsExtreme heatControl system

A gyroscope and temperature sensor are formed on a single chip using SOI-MEMS technology. The temperature sensor has an array of resistors to accurately detect the temperature of the gyroscope in temperatures and conditions that can range from extreme heat to extreme cold. The positioning of the gyroscope and temperature sensor on the same chip allow for extremely accurate real-time feedback of the gyroscope's temperature for utilization by a control system.

Owner:ARMY US SEC THE

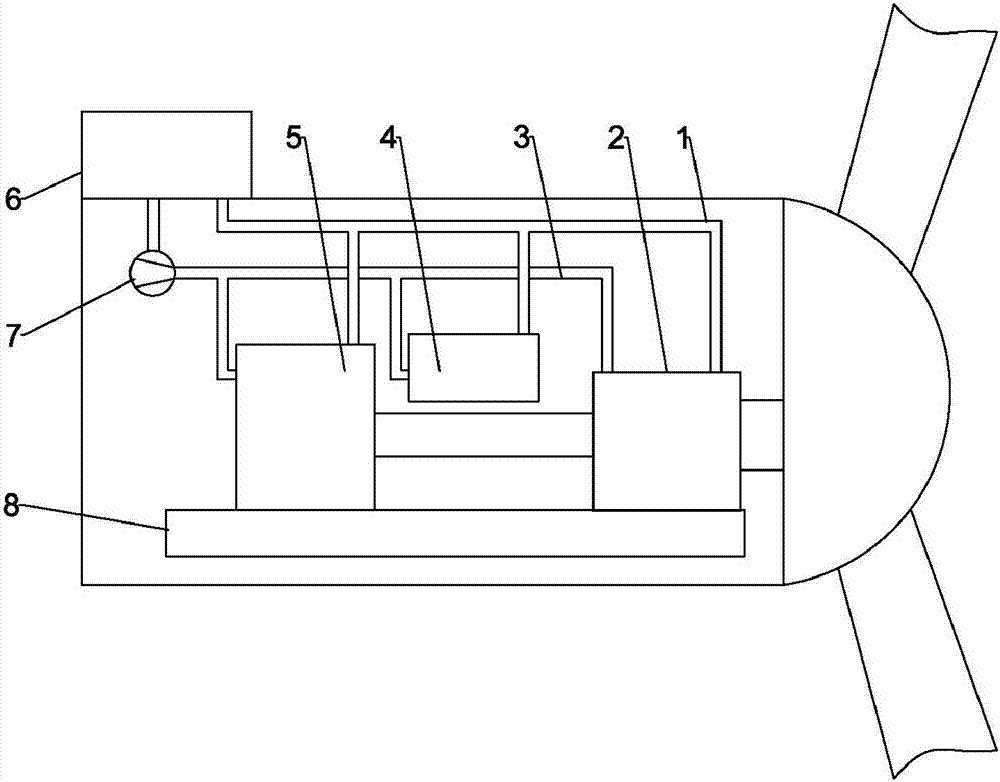

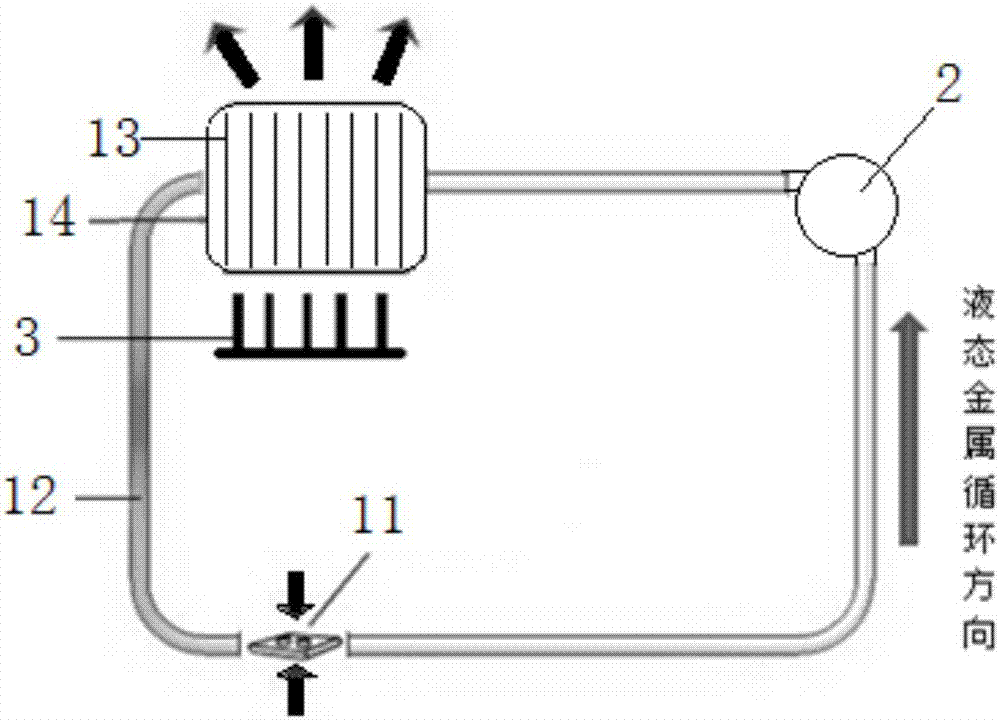

Cooling device for wind power generating unit and wind power generating unit

InactiveCN107542629AGuaranteed uptimeGuaranteed safe operationFinal product manufactureMachines/enginesEngineeringLiquid metal

The invention relates to the technical field of wind power generator cooling equipment, in particular to a cooling device for a wind power generating unit and the wind power generating unit. The cooling device for the wind power generating unit is provided and comprises an outer radiator, a drive mechanism and at least one heat exchange element, the heat exchange element and the outer radiator arein communication through a pipeline to form a cooling loop, the cooling loop is internally provided with liquid metal, and the drive mechanism drives the liquid metal to circularly move in the cooling loop. According to the cooling device for the wind power generating unit and the wind power generating unit, the liquid metal is introduced for the first time to serve as a cooling medium of the wind power generating unit, and due to the fact that the liquid metal combines high heat conductivity of the metal medium and fluidity of fluid, efficient heat transportation and extreme heat dissipationcapability is achieved, and the cooling efficiency is improved. Meanwhile, the liquid metal is stable in physical and chemical property and easy to recycle, and safe and efficient running of the cooling device can be guaranteed. In addition, the provided cooling device is simple in structure, low in manufacturing cost and high in practicability.

Owner:YUNNAN KEWEI LIQUID METAL VALLEY R & D CO LTD

Gun oil composition

InactiveUS20150252284A1Improve the lubrication effectEnhanced gun performanceLiquid carbonaceous fuelsAdditivesEngineeringBase oil

A gun oil composition adapted specifically for the needs and requirements of modern firearms. The gun oil composition improves lubricity and gun performance under normal and extreme heat and pressure, minimizes and largely prevents the build-up of carbon and debris fouling on metal and non-metal components of the firearm, and substantially reduces cleaning time, while providing increased protection against environmental components such as dust, dirt and rust. The gun oil composition can include a high viscosity base oil, a medium viscosity oil with detergent additive, and a low viscosity penetrating oil.

Owner:MONGOOSE LUBRICANTS

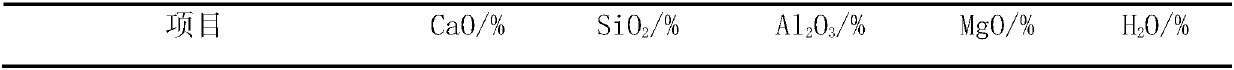

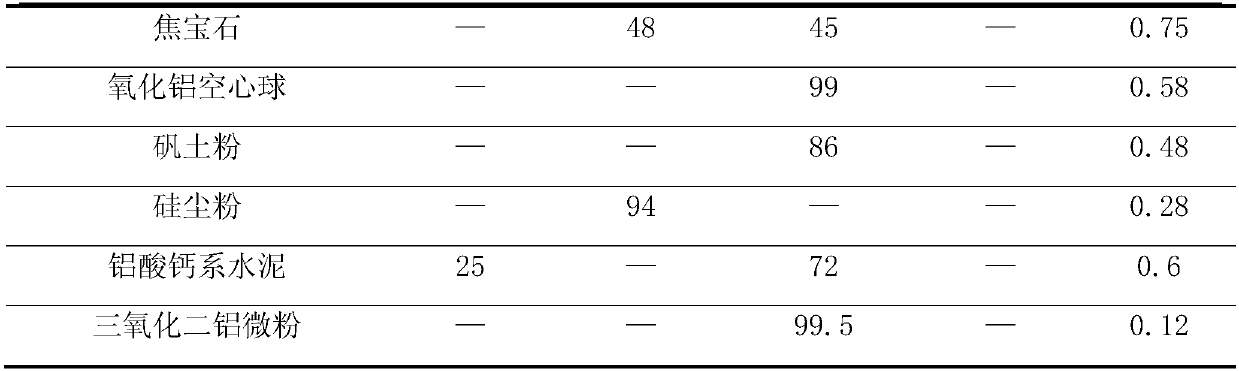

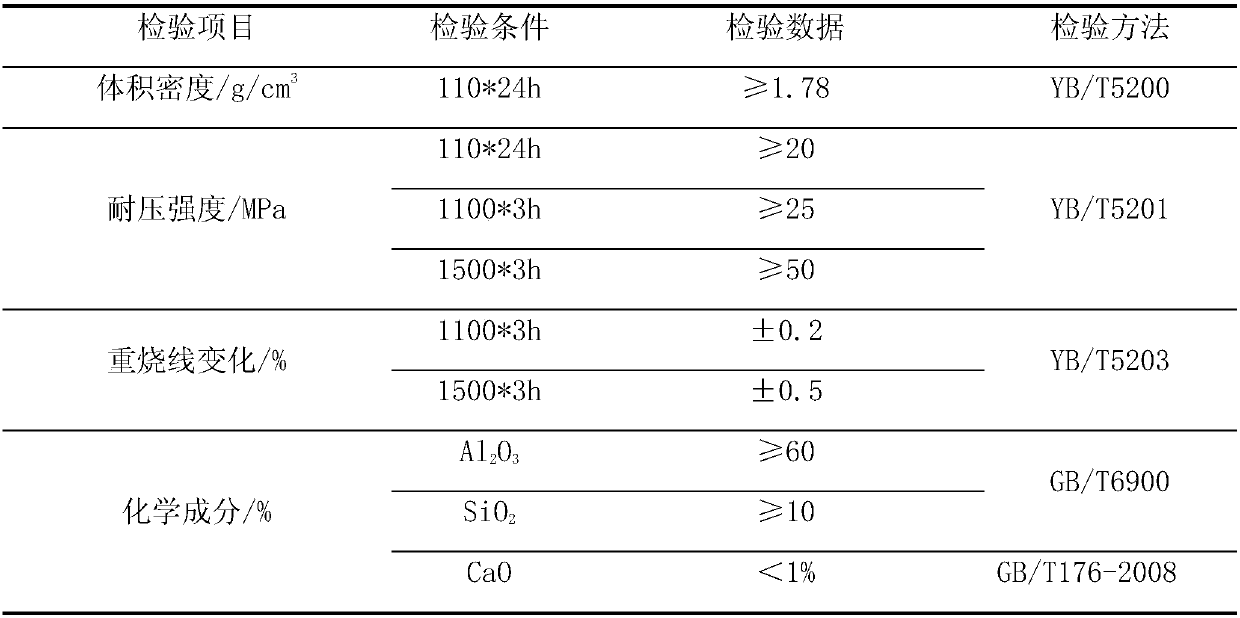

Semi-steel can permanent layer castable

InactiveCN109534831AImprove heat storage capacityImprove thermal performanceClaywaresExtreme ColdUltimate tensile strength

The invention relates to a semi-steel can permanent layer castable. The semi-steel can permanent layer castable comprises, in percentage by weight, greater than or equal to 60% of Al2O3, greater thanor equal to 10% of SiO2, less than or equal to 1% of CaO and less than or equal to 1% of water. By means of the iron-making blast furnace main iron runner fire-resistant castable which is superior inperformance, high in heat storage capacity, stable in thermodynamic performance and long in service life, the problems of temperature reduction and low castable strength which are caused in a semi-steel can online transportation process, and increase and enlargement of cracks after an overhaul can be effectively solved. According to the semi-steel can permanent layer castable, flint clay and alumina hollow balls are used as main aggregate, high-purity aluminum, silicon and fire-resistant cement are used as binding agents, sodium hexametaphosphate is used as a dispersion agent, thus the semi-steel can permanent layer castable is produced, the heat storage capability and the thermal performance of a semi-steel can permanent layer can be effectively improved, the phenomenon of cracking causedby extreme cold and extreme heat can be effectively avoided, and the service cycle is obviously prolonged, so that the semi-steel can permanent layer castable has good application prospects.

Owner:GANGCHENG GRP LIANGSHAN RUIHAI IND

Gun oil composition

ActiveUS9637705B1Improve the lubrication effectEnhanced gun performanceWeapon cleaningBase-materialsViscosity indexBase oil

A gun oil composition adapted specifically for the needs and requirements of modern firearms. The gun oil composition improves lubricity and gun performance under normal and extreme heat and pressure, minimizes and largely prevents the build-up of carbon and debris fouling on metal and non-metal components of the firearm, and substantially reduces cleaning time, while providing increased protection against environmental components such as dust, dirt and rust. The gun oil composition can include a base oil having at least a high viscosity index, an oil having at least a medium viscosity index with a detergent additive, a low viscosity penetrating oil, and a sulfurized ester.

Owner:MONGOOSE LUBRICANTS

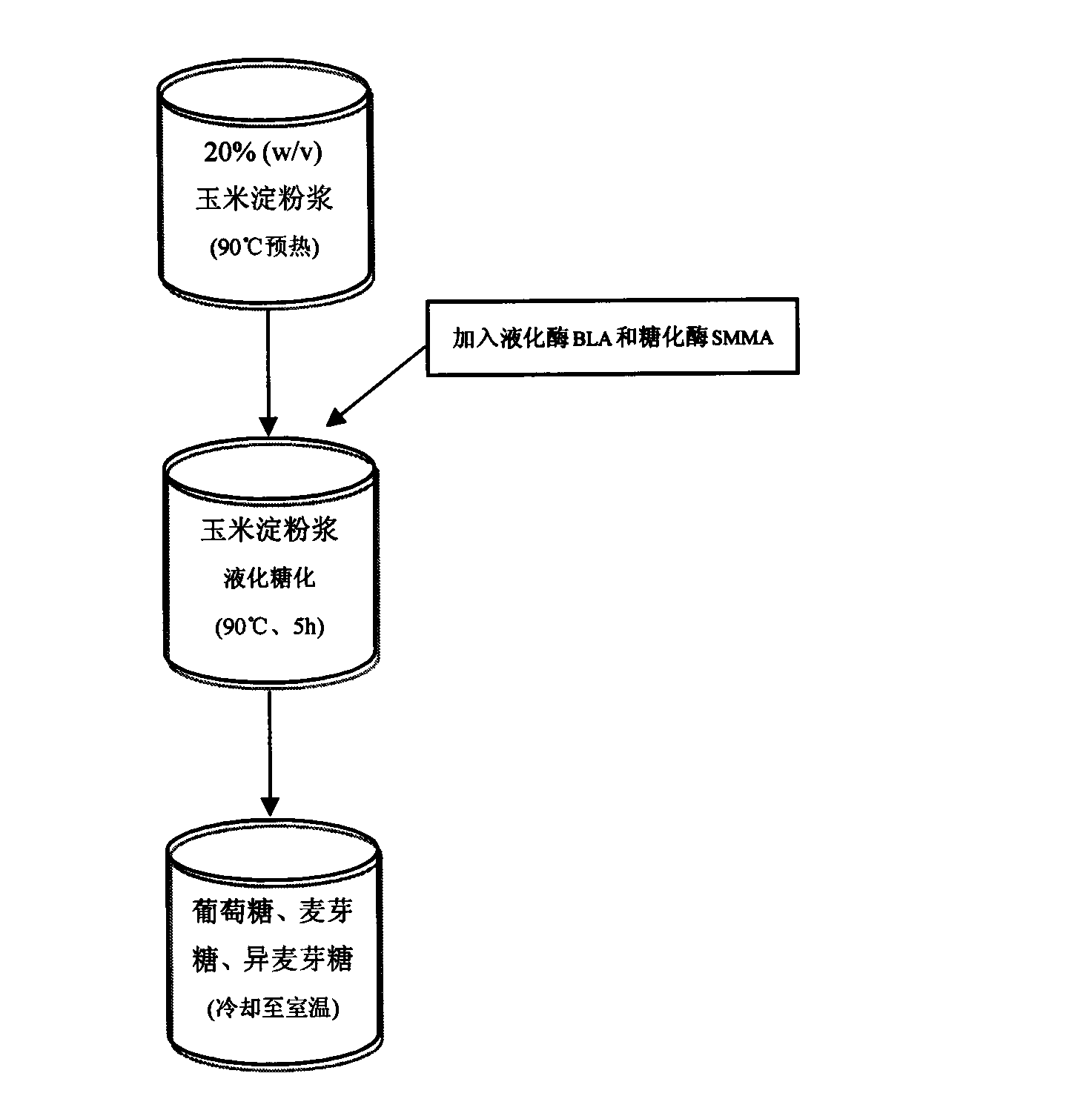

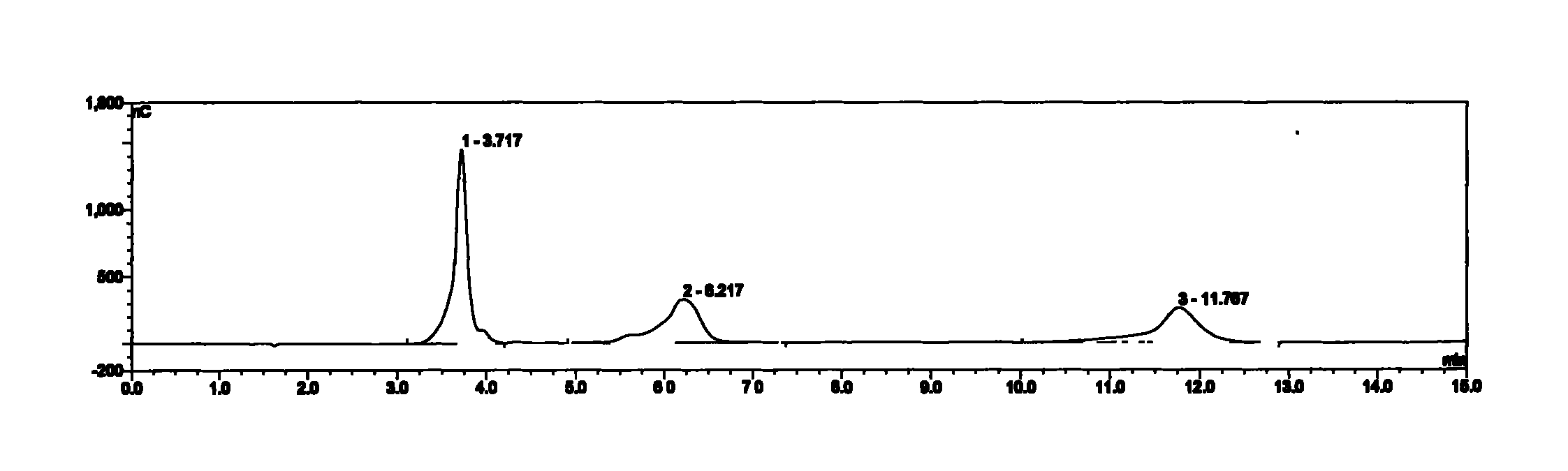

Method of simultaneously liquefying and saccharifying cirn starch

The invention relates to a method of simultaneously liquefying and saccharifying cirn starch. The method uses an extreme heat-stable amylase maltose with an optimum catalytic reaction temperature of 90-100 DEG C to substitute an Aspergillus niger glucoamylase with an optimum catalytic reaction temperature of 55-65 DEG C. Because the extreme heat-stable amylase maltose has similar optimum catalytic reaction temperature and optimum catalytic reaction pH with a Bacillus licheniformis alpha-amylase, the extreme heat-stable amylase maltose, together with Bacillus licheniformis alpha-amylase, can be added into a corn starch slurry preheated to 90-100 DEG C and with a concentration of 10-30 % (w / v), and then kept warm for a while at a same temperature to obtain the corn starch syrup with a total yield of glucose, maltose and isomaltose being more than 110 % (w / w). The method overcomes a problem that in traditional production technology of corn starch syrup, the Bacillus licheniformis alpha-amylase is firstly used to liquefy the corn starch under 90-100 DEG C and a pH of 5.0-6.0, and then the Aspergillus niger glucoamylase is used to saccharify the corn starch under 55-65 DEG C and a pH of 4.2-4.5, and operation steps of adjusting temperature and pH are thus needed, thereby improving production speed of the starch sugar.

Owner:CHANGCHUN UNIV +2

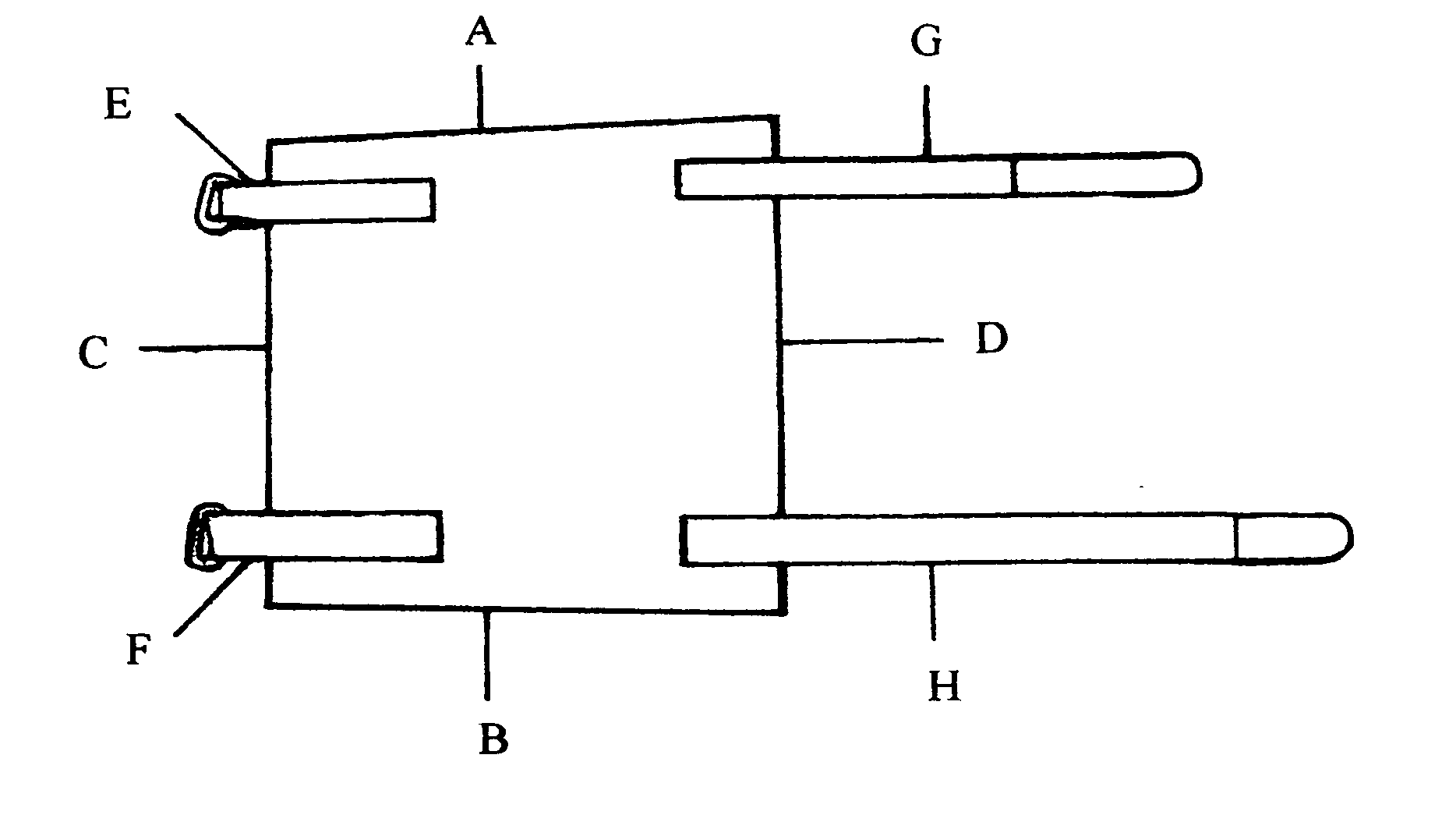

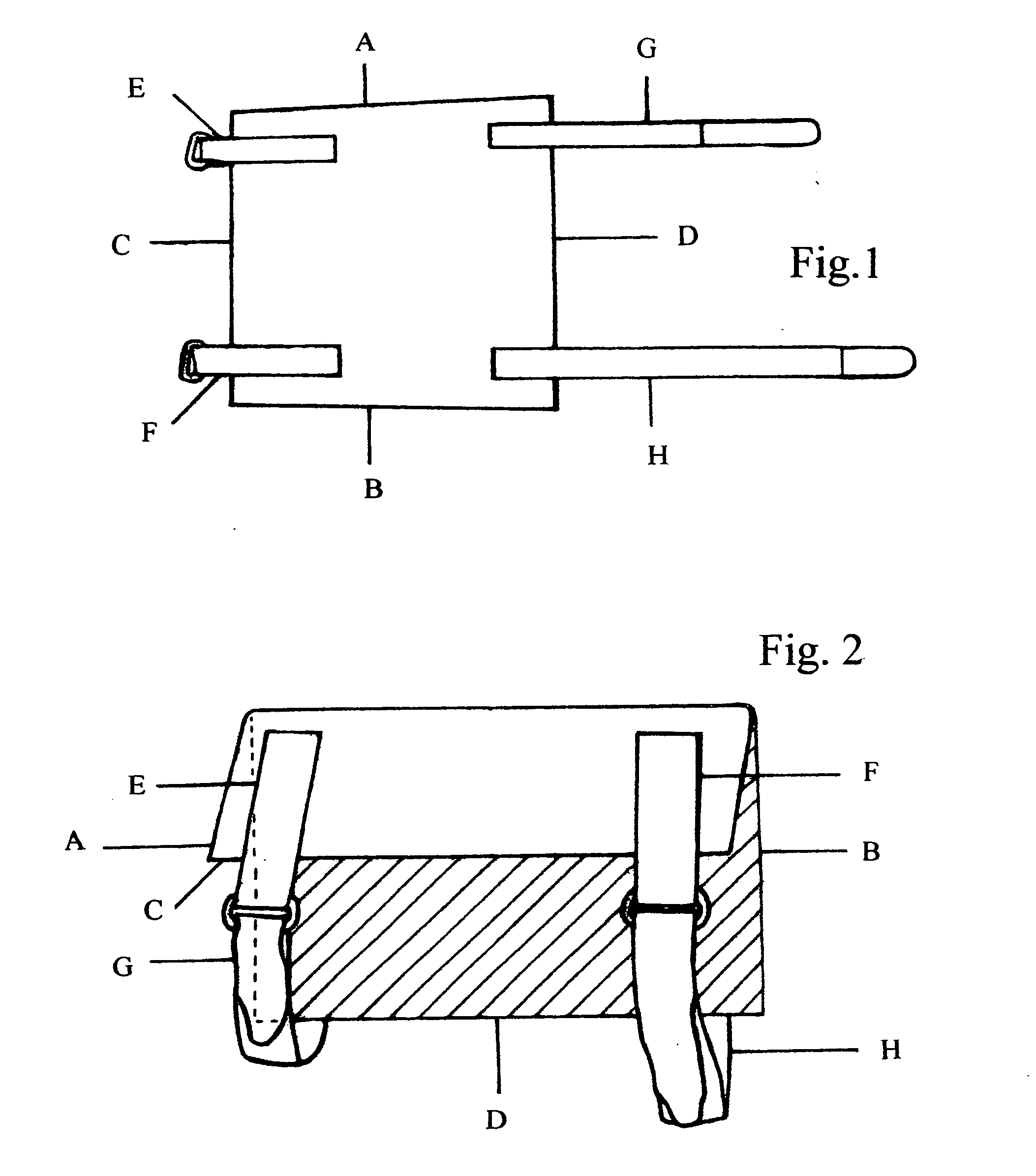

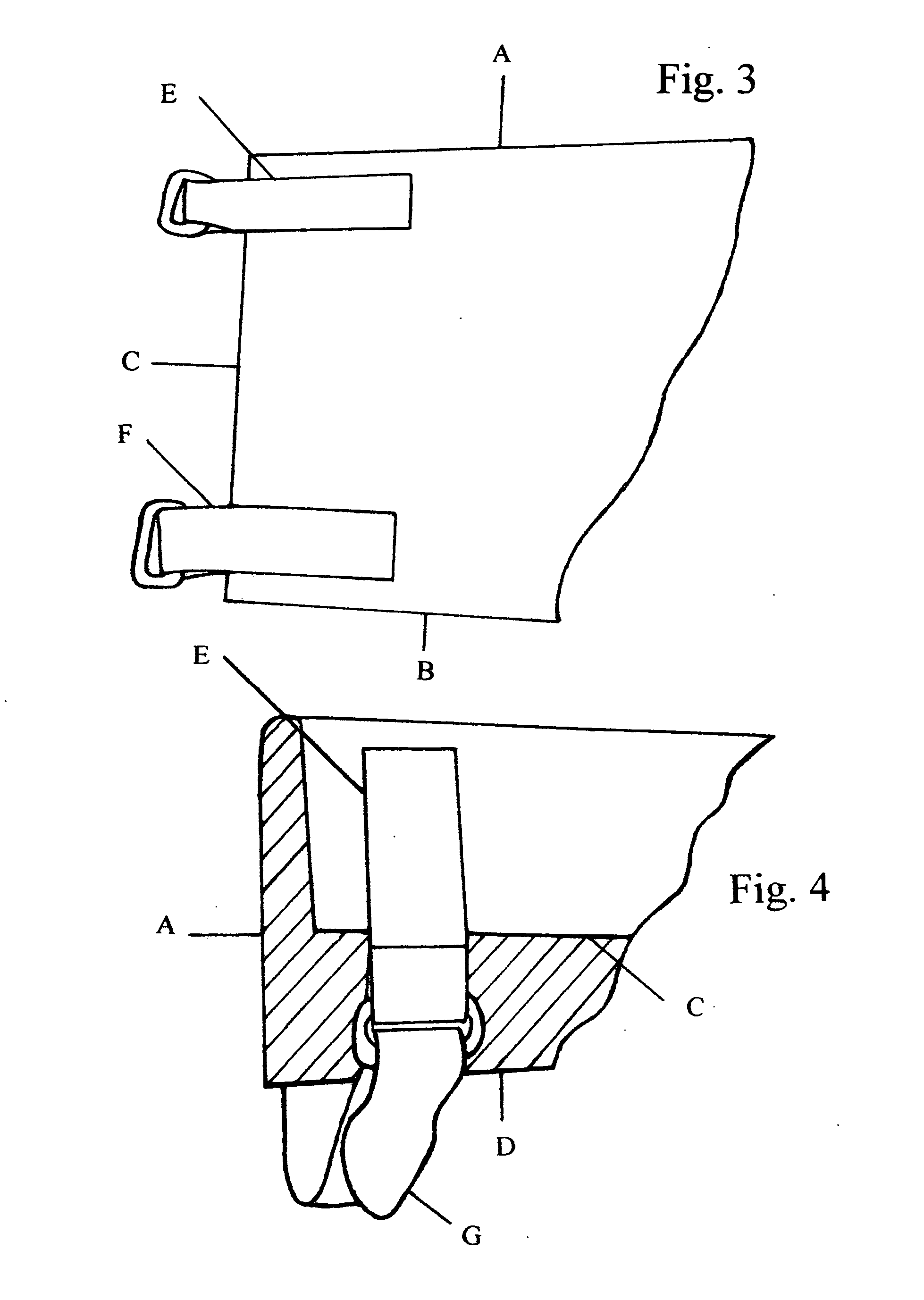

Thigh heat guard for motorcycle riders

An improved way to protect the thigh of motorcycle riders from heat of a motorcycle engine and the hot pavement of the road. The rider's body is leveraged over the engine of the bike, and the need arises to protect the thigh of the rider from extreme heat. Intense heat often causes blisters on the rider's thighs after a long ride. To protect themselves, motorcyclist have used different items, from chaps to mounting a shield apparatus directly on the motorcycle. The Thigh Heat Guard prevents blisters by covering the rider's thigh with a flexible material in a predetermined shape. Further including straps to secure said invention to the human thigh. Allows for easy adjustment and a custom fit for each rider. Lightweight for freedom of movement and easily removed when not needed. Thigh Heat Guard requires no modification to the motorcycle, and is inexpensive.

Owner:BODNAR MARLIS C

Integrated gyroscope and temperature sensor

InactiveUS7308827B2Accurately conveysAvoid failureAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsThermodynamicsExtreme Cold

A gyroscope and temperature sensor are formed on a single chip using SOI-MEMS technology. The temperature sensor has an array of resistors to accurately detect the temperature of the gyroscope in temperatures and conditions that can range from extreme heat to extreme cold. The positioning of the gyroscope and temperature sensor on the same chip allow for extremely accurate real-time feedback of the gyroscope's temperature for utilization by a control system.

Owner:ARMY US SEC THE

Mutant XYNH of extreme heat-resistant xylanase 1VBR and use thereof

The invention provides a mutant XYNH of an extreme heat-resistant xylanase 1VBR. The mutant XYNH is prepared through mutation of phenylalanine at the 290th of an amino acid sequence of the xylanase 1VBR into histidine and has an amino acid sequence shown in the formula of SEQ ID NO.1. The invention also provides a gene for encoding the mutant XYNH. The gene has a nucleotide sequence shown in the formula of SEQ ID NO.2. The invention also provides a recombinant expression vector pPIC9K-XYNH with the gene for encoding the mutant XYNH and a recombinant strain with the recombinant expression vector. After the amino acid sequence of the xylanase 1VBR is subjected to site-directed mutagenesis, the high heat-resistant mutant XYNH is obtained, is highly expressed in a pichia pastoris expression system and has a wide application prospect in the fields of feed additives, health foods, papermaking, washing, brewing, textiles and pharmacy.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

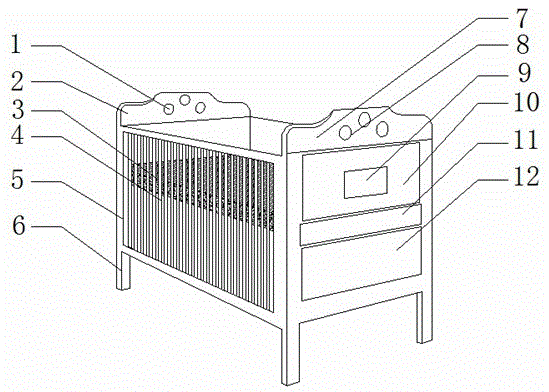

Baby crib

InactiveCN105534172AScientific and reasonable structureEasy to useMechanical apparatusSpace heating and ventilation safety systemsUltravioletEngineering

The invention discloses a baby crib which comprises an ultraviolet generator, a left end plate, a human induction mattress, protective barriers, a protective bed body, safety supporting legs, a right end plate, a control box and a peculiar smell detection device. The left end plate is arranged at the left end of the upper surface of the protective bed body. The ultrasonic generator is arranged on the left end plate. The human induction mattress is installed inside the protective bed body. The right end plate is arranged at the right end of the upper surface of the protective bed body. An ultraviolet signal receiving device is arranged on the right end plate. The control box is installed below the ultraviolet signal receiving device. The peculiar smell detection device is installed below the control box. A PM2.5 detection device is arranged below the peculiar smell detection device. The baby crib can effectively solve the problem that a guardian of a baby cannot be effectively promoted to protect the baby in uncomfortable environments such as air pollution, optical radiation pollution, electromagnetic radiation pollution, extreme coldness, extreme heat and the like.

Owner:陈建荣

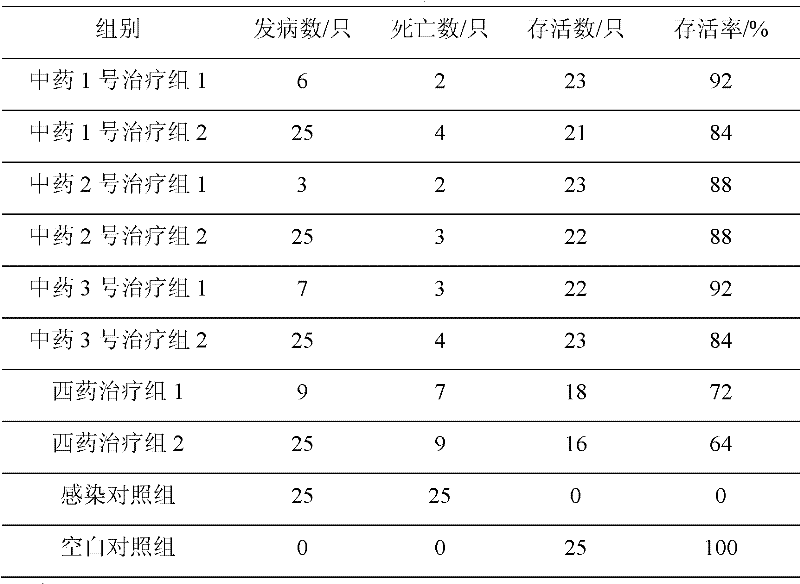

Veterinary drug for treatment of duck virus hepatitis and preparation method thereof

The invention discloses a veterinary drug for treatment of duck virus hepatitis, which consists of components in part by weight: 15-45 parts of radix isatidis, 9-15 parts of scutellaria root, 30-90 parts of oriental wormwood, 9-15 parts of rheum officinale, 15-30 parts of cape jasmine, 6-15 parts of caulis clematidis armandii, 9-24 parts of semen plantaginis and 9-21 parts of felwort. The veterinary drug for treatment of duck virus hepatitis is prepared based on the traditional Chinese veterinary theory. According to the traditional Chinese veterinary theory, duck virus hepatitis refers to dampness-heat of the liver and gallbladder caused by exogenous viruses and gallbladder and diarrhea resulting from damp heat. Wind can be caused by extreme heat, thereby resulting wind agitation in the liver, i.e. coma, spasms, convulsions, diarrhea and other symptoms in clinical manifestations. When the drug is applied in treatment, heat can be cleared away, toxicity can be removed, the liver can be soothed, depression can be relieved, wind and spasms can be avoided, and the stagnation can be relieved.

Owner:ZHENGZHOU HOUYI PHARMA

Fitting with complementary fitting materials

ActiveUS9194514B2Restoring compressive and tensile stressSleeve/socket jointsHose connectionsThermal expansionEngineering

A fitting assembly for maintaining a leak free seal connection with an associated fluid conduit during and after exposure to extreme heat is provided. The fitting assembly includes a coupling body including an inside surface defining a bore for receiving the associated fluid conduit. The coupling body is made of a first corrosion resistant material having a first coefficient of thermal expansion. The at least one ring is made of a complementary second corrosion resistant material having a second larger coefficient of thermal expansion such that the second material will expand at a greater rate that the first material during heating to a first temperature generally exceeding annealing temperatures of both the first material and the second material. The second material contracts at a greater rate that the first material during subsequent cooling to a second temperature below the annealing temperatures thereby restoring compressive and tensile stresses in the associated fluid conduit and the fitting assembly for ensuring that the fitting assembly maintains a leak free seal connection with the associated fluid conduit.

Owner:LOKRING TECHNOLOGY

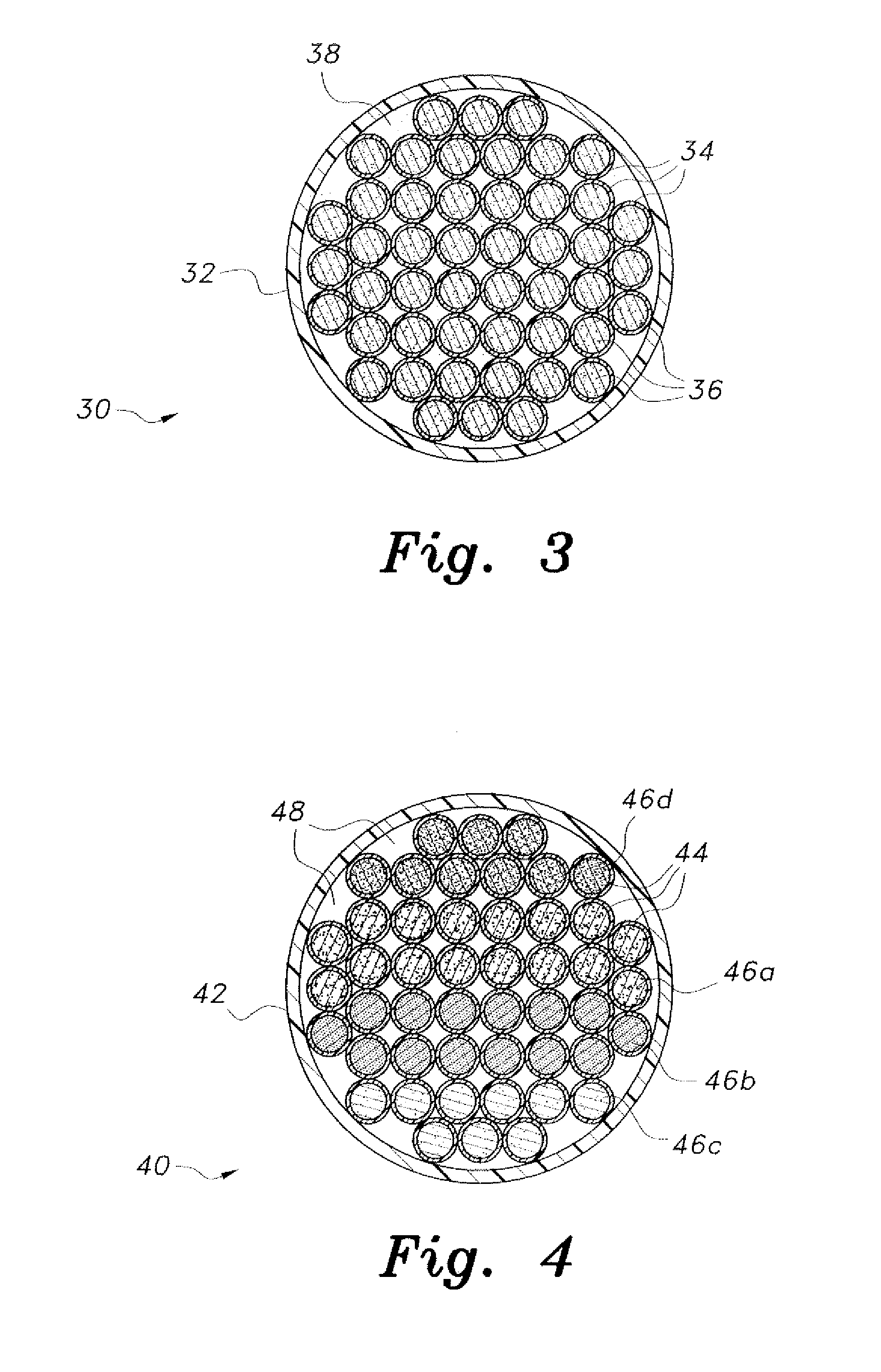

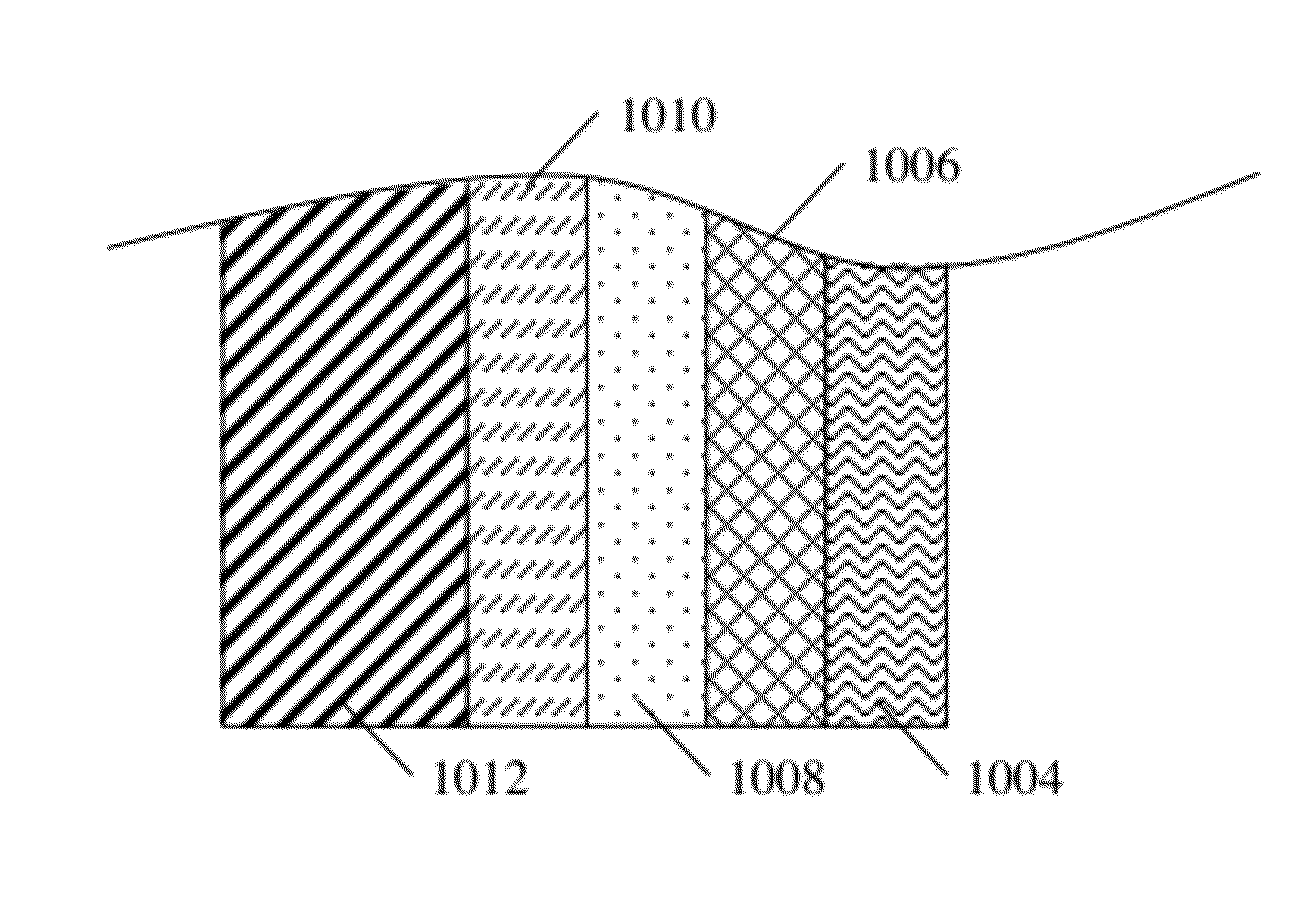

Encapsulated fire extinguishing agents

The encapsulated fire extinguishing agents include a sealed outer shell containing at least one fire extinguishing agent therein. The shell is formed of material that melts when exposed to extreme heat, as in a fire. One embodiment has a single outer shell with a single fire retardant agent therein. Other embodiments may have a second shell within the outer shell, each shell defining an interior volume containing a separate fire extinguishing agent. The agents may combine to form a more effective fire extinguishing agent when the two shells melt. The shells may be formed to melt at different temperatures. Another embodiment includes an outer shell filled with a large number of smaller capsules, each of the smaller capsules filled with a fire extinguishing agent. The smaller capsules may each contain identical agents, or two or more different agents from one another.

Owner:ANZI BADER SHAFAQA

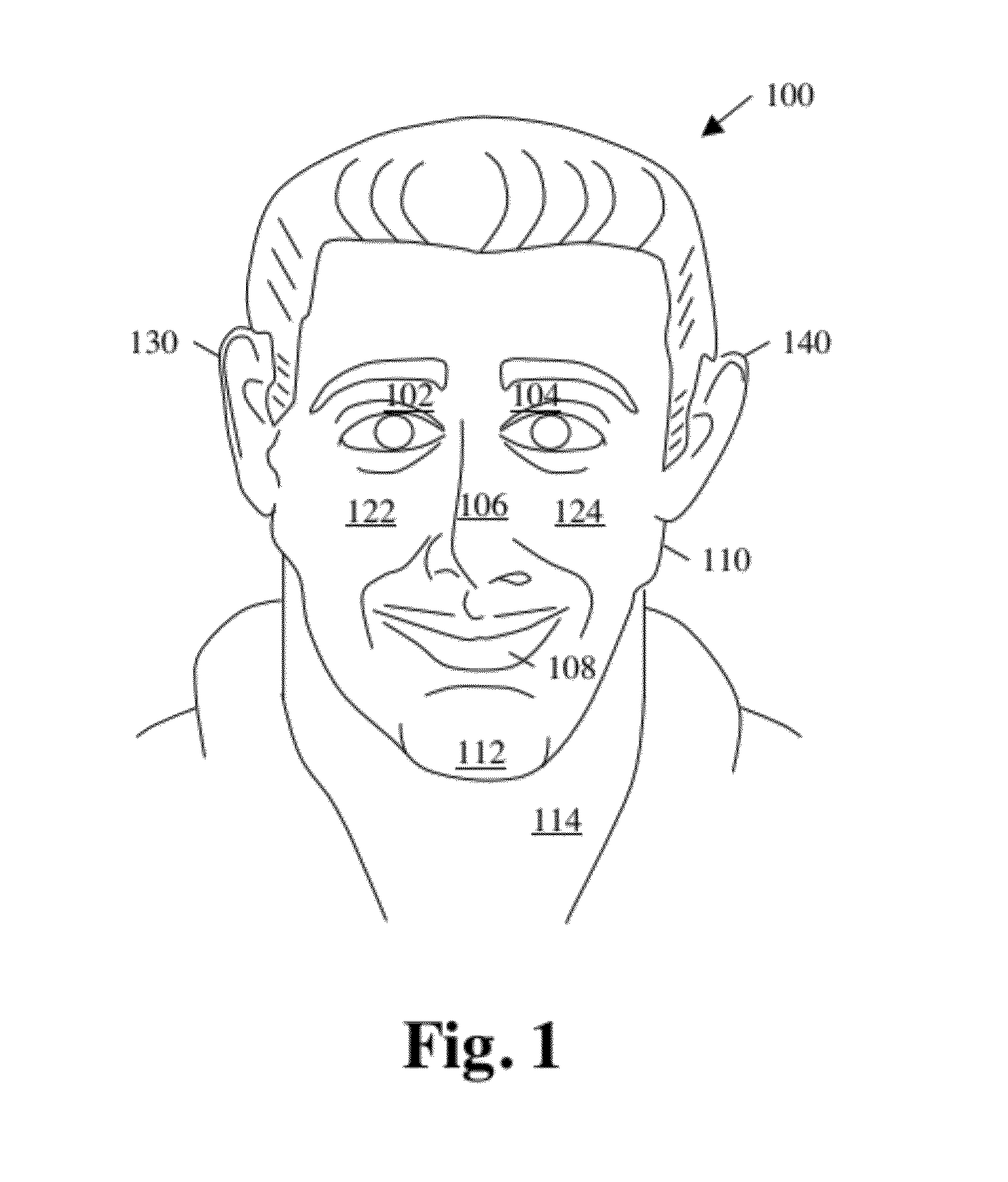

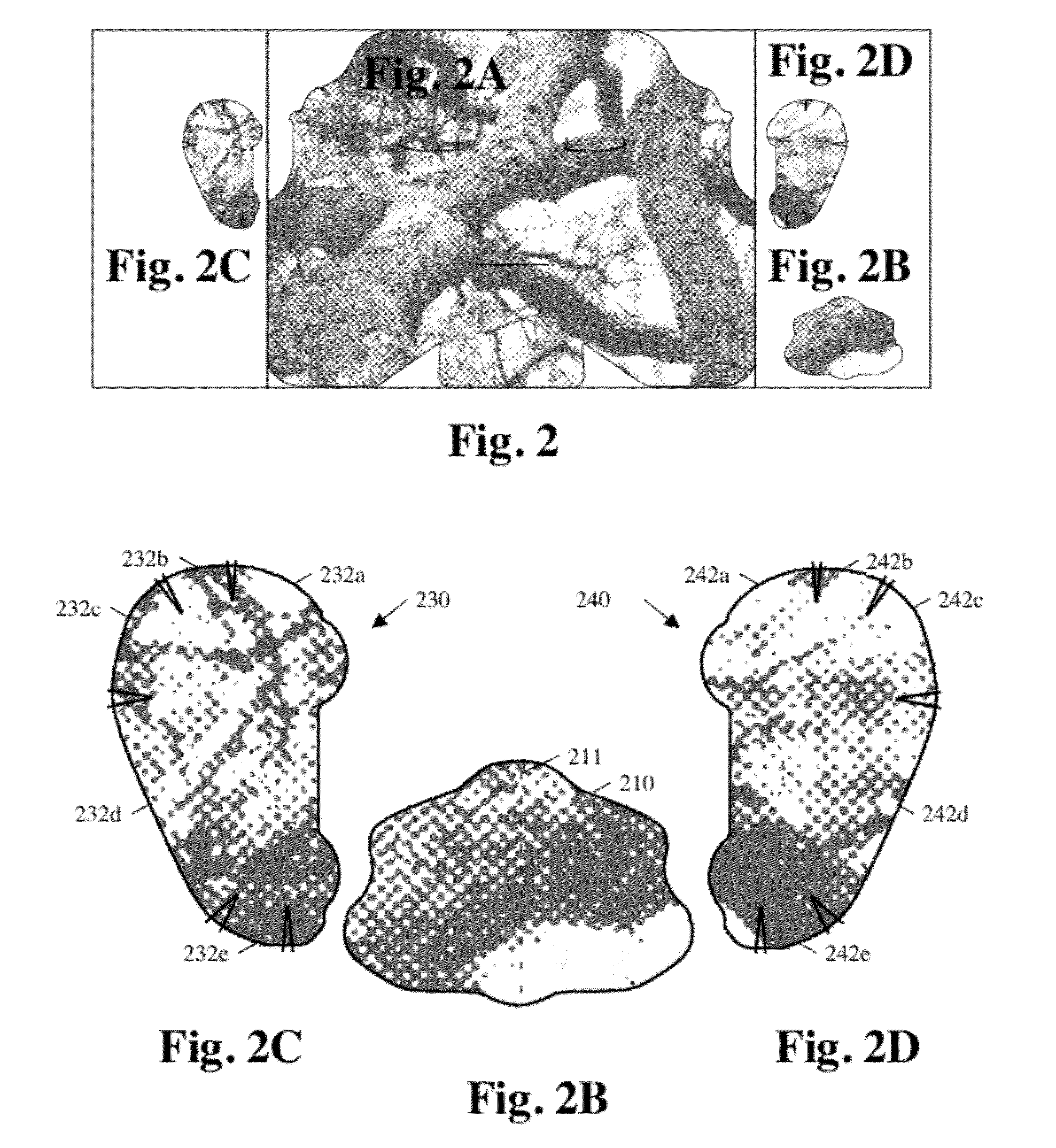

Extreme Heat Protection Applied Directly To Skin

Applicators provide heat shields for uncovered skin, in particular the face, hands, and other body parts that may not be clothed such as arms, legs, or torso. In one embodiment, a continuous heat shield is applied the entire face and ears. In another embodiment, a heat shield is applied to portions of the face and neck. In yet another embodiment, a heat shield is applied by multiple applicators. Sets of applicators apply a portions of a contiguous heat shield. Books contain multiple sets of applicators. Camouflage is used for military concealment. Other uses include firefighting, iron working, glass blowing and cooking. Entrained ceramic particles provide heat reflection and insulation.

Owner:EVRIO

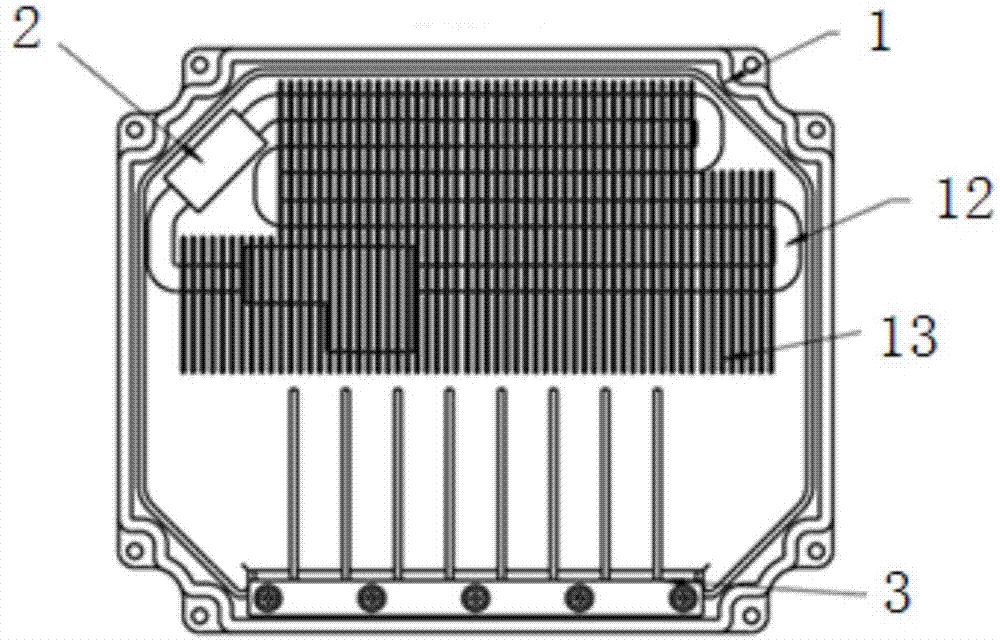

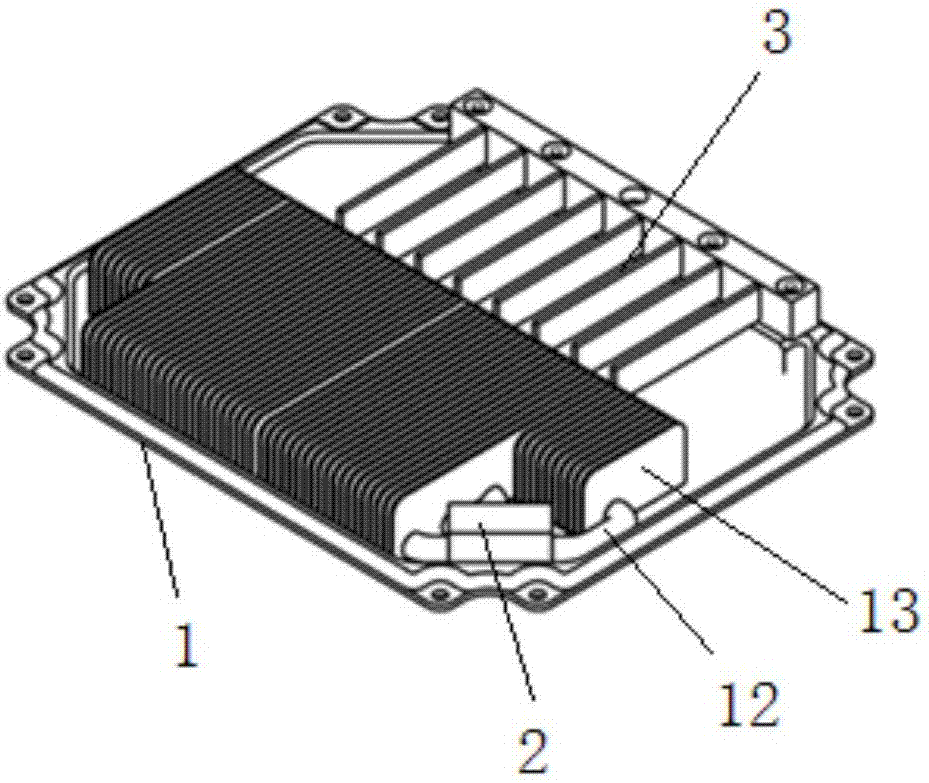

High-efficiency heat radiator for closed-structure high-heat flux device

ActiveCN107887356AReduce thermal resistanceImprove thermal efficiencySemiconductor/solid-state device detailsSolid-state devicesLiquid metalCold plate

The invention provides a high-efficiency heat radiator for a closed-structure high-heat flux device, which comprises a liquid metal pipeline and heat radiation fins, wherein the liquid metal pipelinepasses through the heat radiation fins; and the liquid metal pipeline is filled with liquid metal capable of flowing. A driving pump is also included, and the driving pump is arranged on the liquid metal pipeline for driving the liquid metal in the liquid metal pipeline to flow. A liquid metal self-circulating cold plate is made by adopting a processing mode such as overall casting or welding, a heat absorption device, a heat radiation plate, the heat radiation fins and the liquid metal pipeline are integrated, the heat resistance of the system is reduced to the most extent, and the heat conduction efficiency is high; and the heat conductivity of the liquid metal is much higher than that of water, air and multiple non-metallic media, and thus, the liquid metal heat radiator can achieve more efficient heat transport and extreme heat radiation ability than traditional water cooling.

Owner:SICHUAN JIUZHOU ELECTRIC GROUP

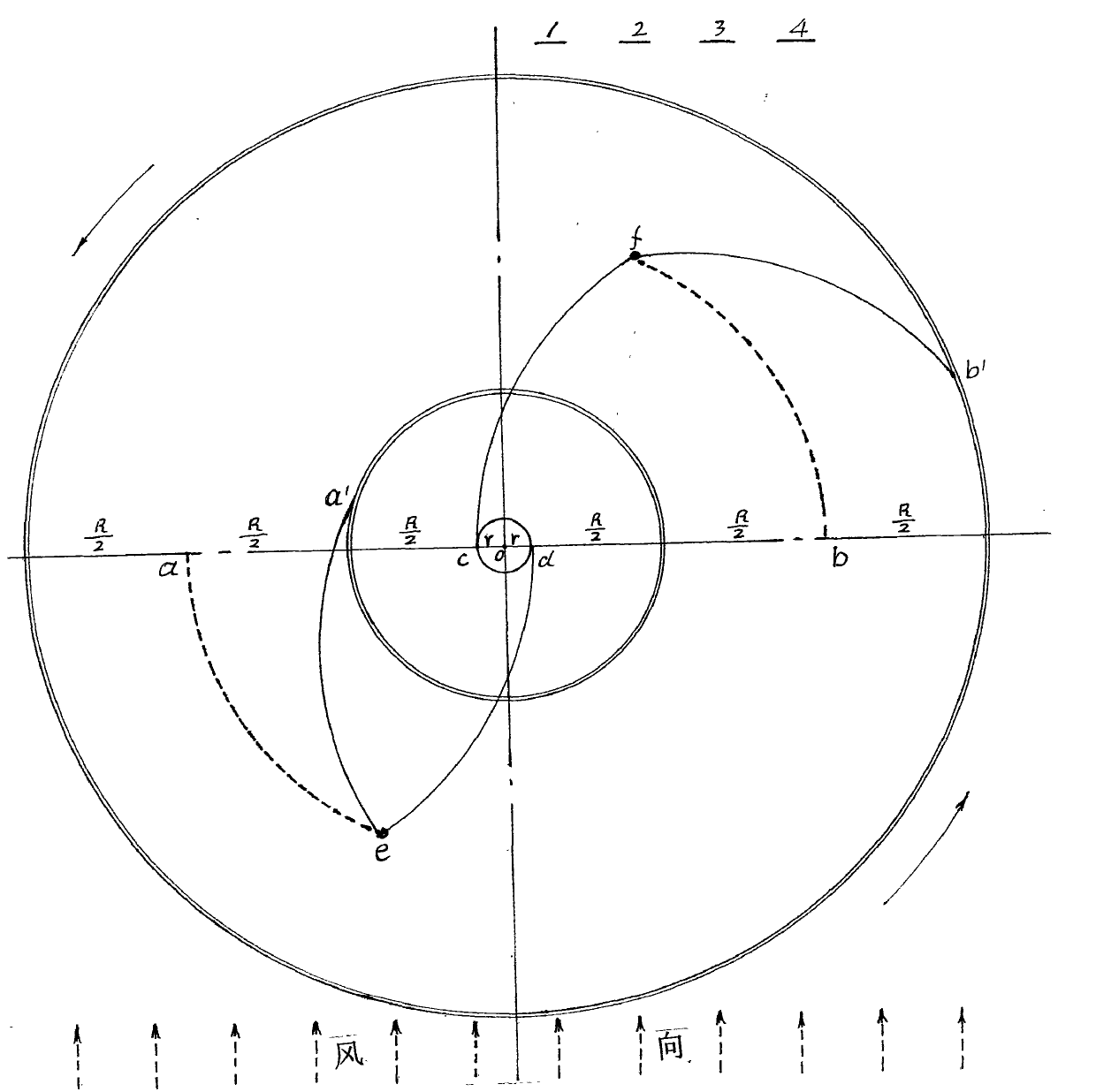

Resistance difference type synchronous linkage integrated wind wave and light heat electromechanical energy conversion system

InactiveCN102168655AImprove efficiencyChange performanceGeneral water supply conservationFinal product manufactureExtreme ColdEngineering

The invention discloses a resistance difference type synchronous linkage integrated wind wave and light heat electromechanical energy conversion system and aims to combine the Marxist dialectical materialism with energy science and technology to provide a simple and efficient device for utilizing wind energy and ocean energy, and lead the economic society out of the plights of energy crisis and climate warming, and open up a sustainable novel industrialization road to the future society with Chinese characteristics in a way of driving the overall situation by a breakthrough. The technical problem is that there are a large quantity of energy sources in the natural world, however, the energy developed and utilized technically cannot meet the social demand, and in order to solve the contradiction, the energy technology development is returned to a resistance difference type engine in a negative negative way; rotating wheels are closely and repeatedly arrayed by a method that change in quantity leads to change in quality, so the energy conversion efficiency is improved to 80 percent. Furthermore, the methods that change in quality leads to change in quantity, extreme cold generates heat and extreme heat generates cold are used, and the restrictions of typhoon, thunderstorm and low temperature are released, so the available energy is greatly increased, and the wind energy and the ocean energy become the main energy sources for social production.

Owner:石运达

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com