High-efficiency heat radiator for closed-structure high-heat flux device

A technology with high heat flux density and heat sink, applied in electric solid devices, semiconductor devices, semiconductor/solid state device components, etc., can solve problems such as inability to meet thermal design indicators, pipeline connection, increased energy consumption, etc., and reach the limit of high efficiency High heat dissipation capacity, high thermal conductivity, and not easy to leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

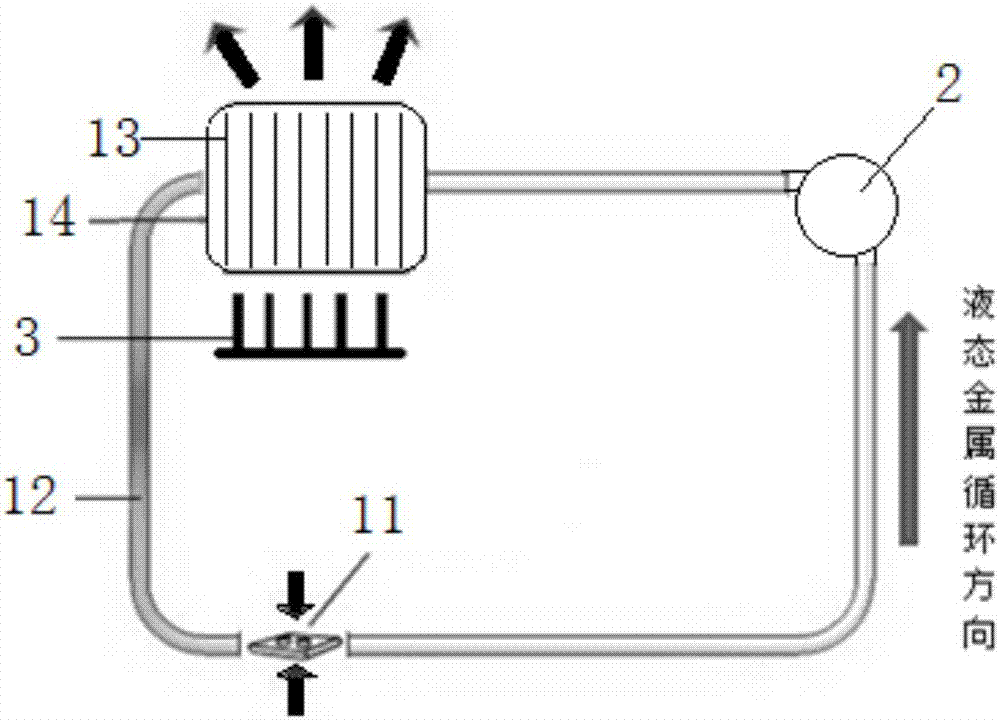

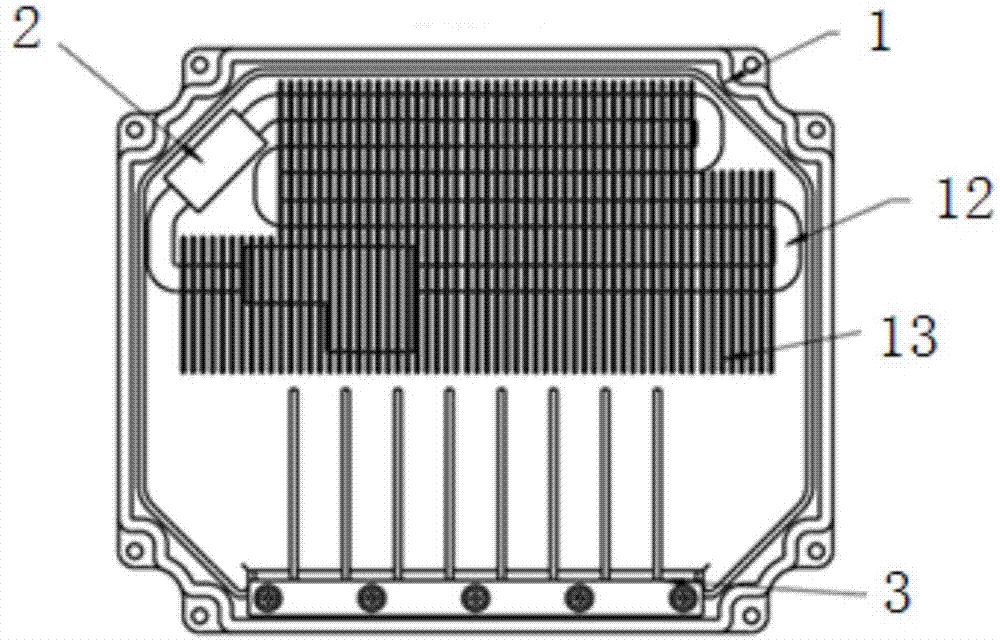

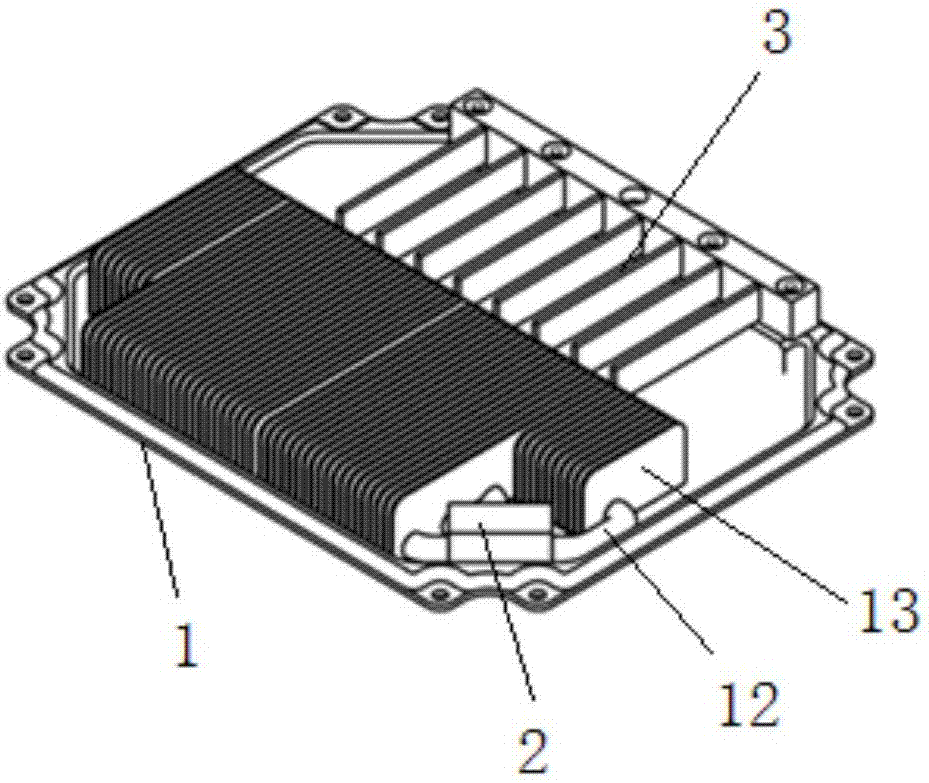

[0029] First, if figure 1 As shown, it provides a working principle diagram of a high-efficiency radiator for devices with a closed structure and high heat flux density in the present invention. The working principle of the present invention is: the liquid metal pipe 12 forms a circuit and is filled with liquid metal, and the liquid metal pipe 12 is provided with a heat absorbing device 11 for absorbing the heat of the heat generating device inside the closed structure, for driving the liquid metal to flow The drive pump 2 and the cooling fins 13 and cooling plates 14 for cooling the liquid metal. When the liquid metal in the liquid metal pipeline 12 absorbs heat from the heat absorbing device 11 , the cooling fins 13 and the cooling plate 14 jointly dissipate heat from the liquid metal. In addition, one side of the heat dissipation fins 13 and the heat dissipation plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com