Patents

Literature

33results about How to "Increase control pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

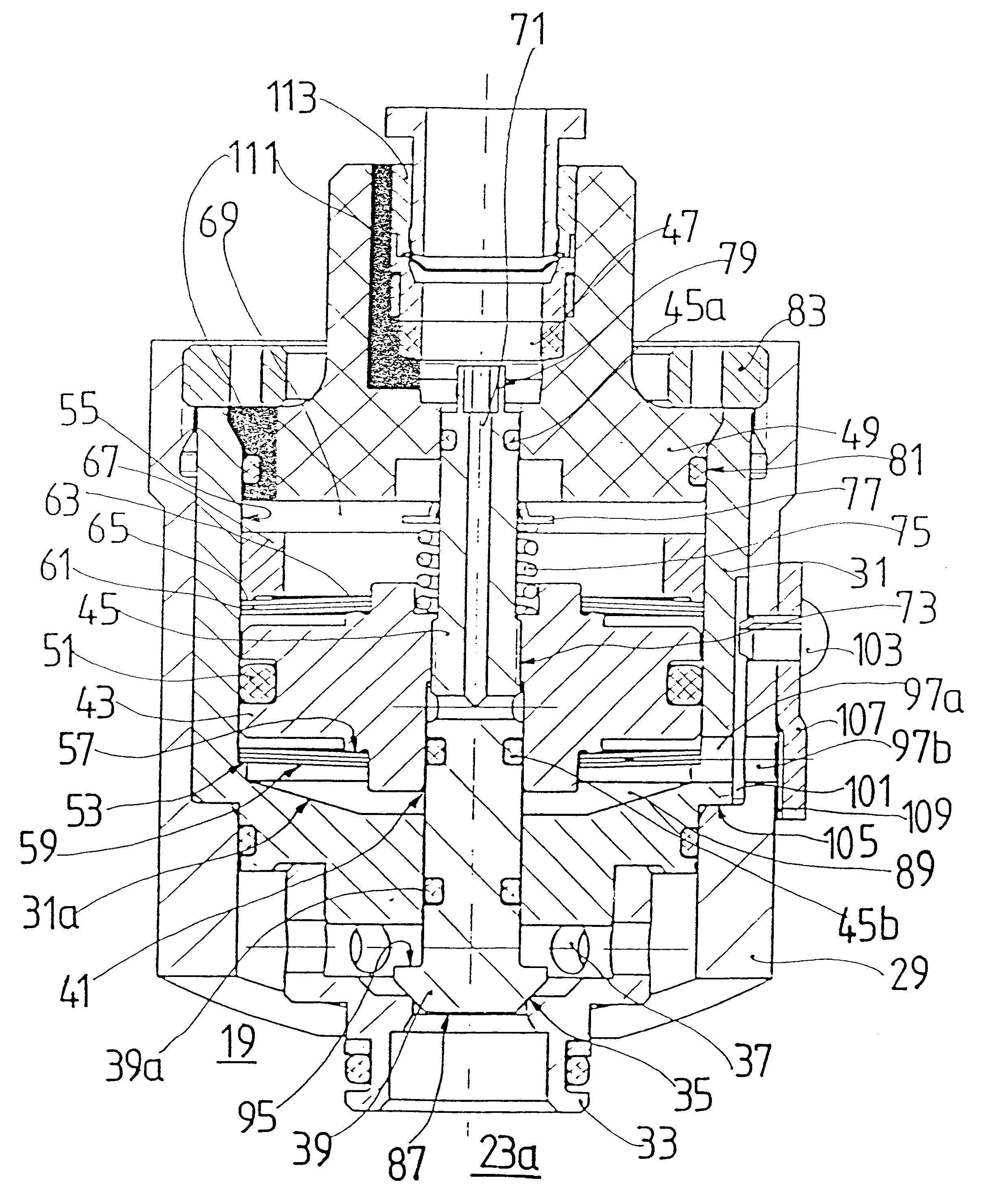

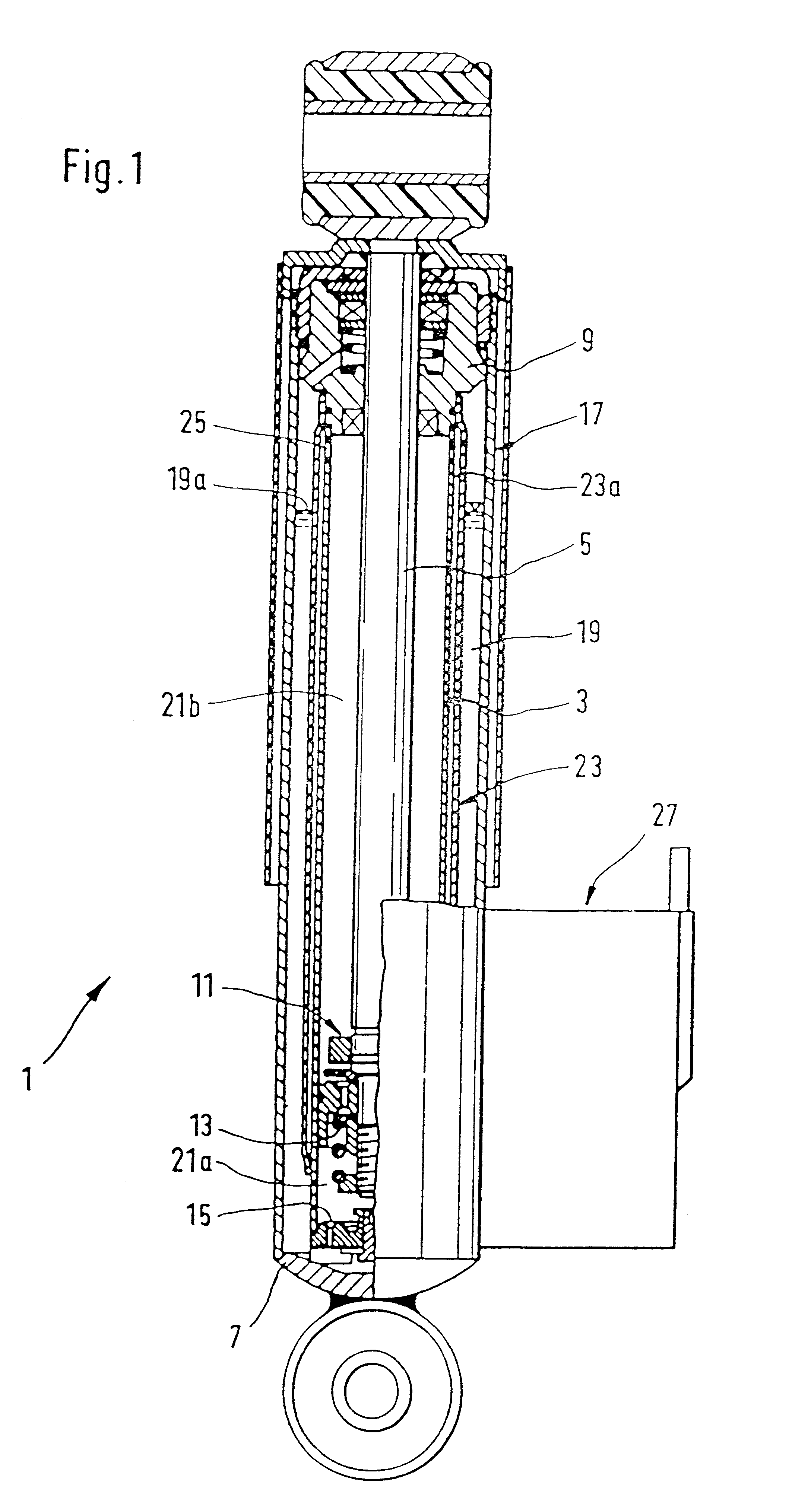

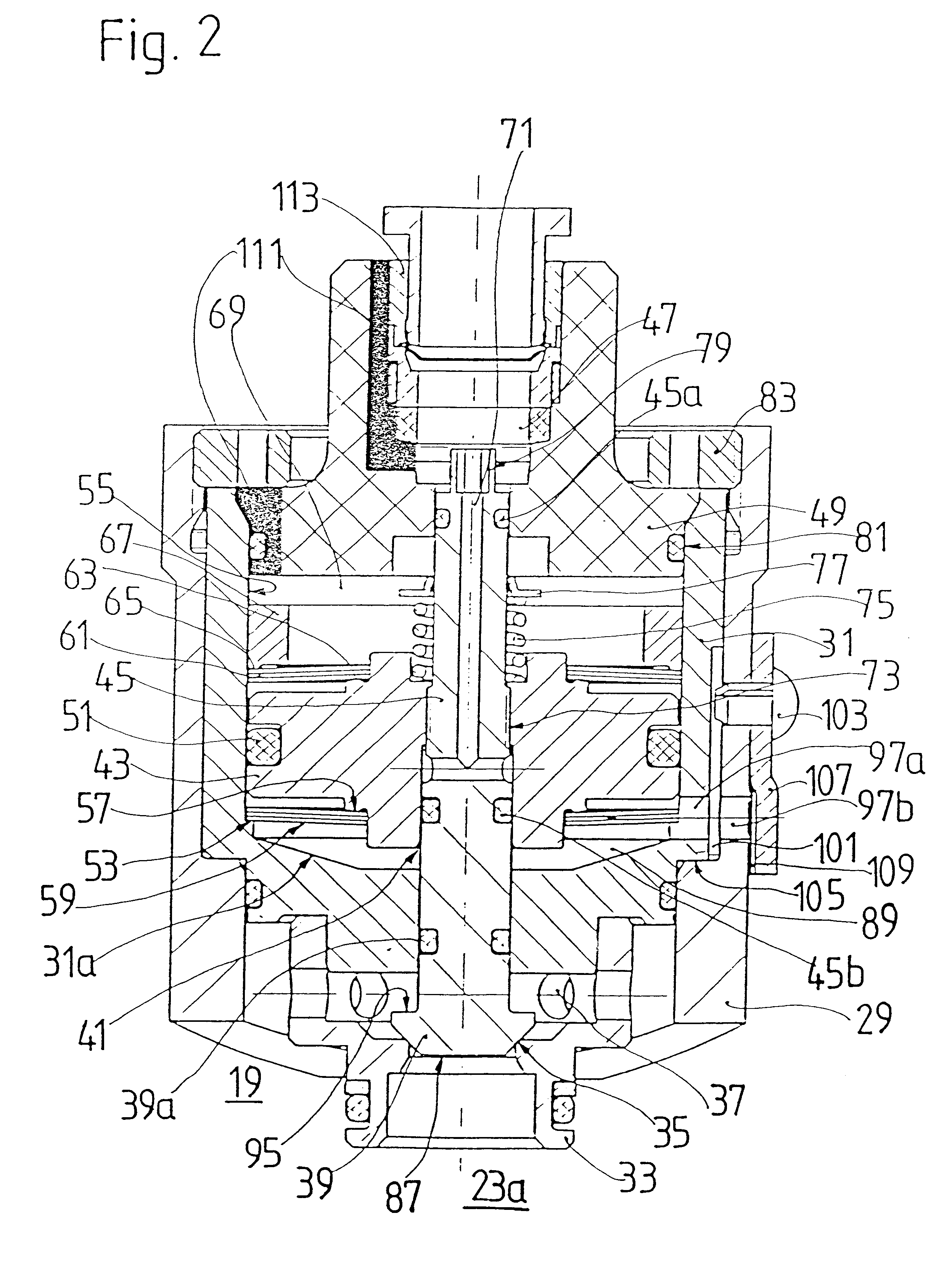

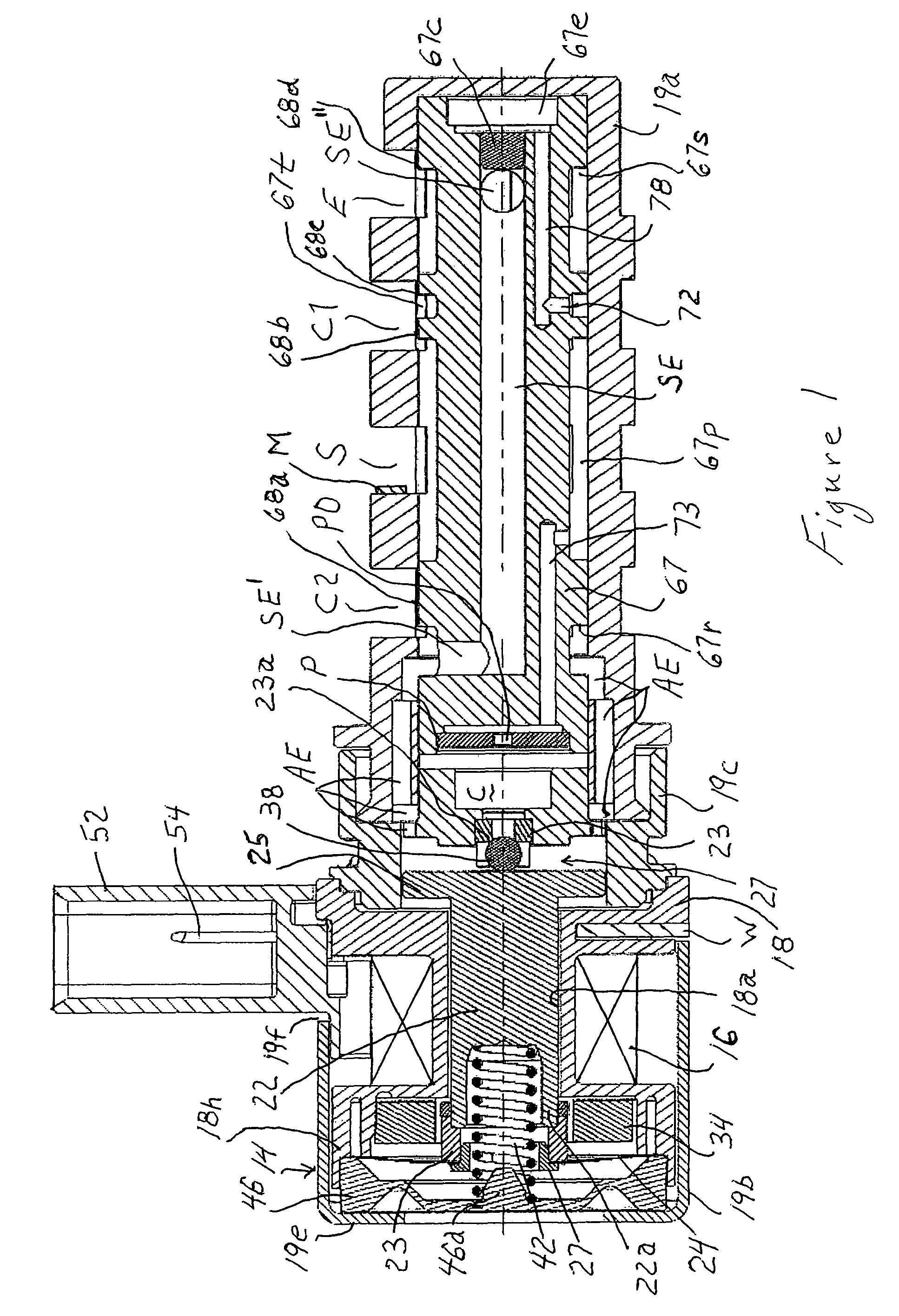

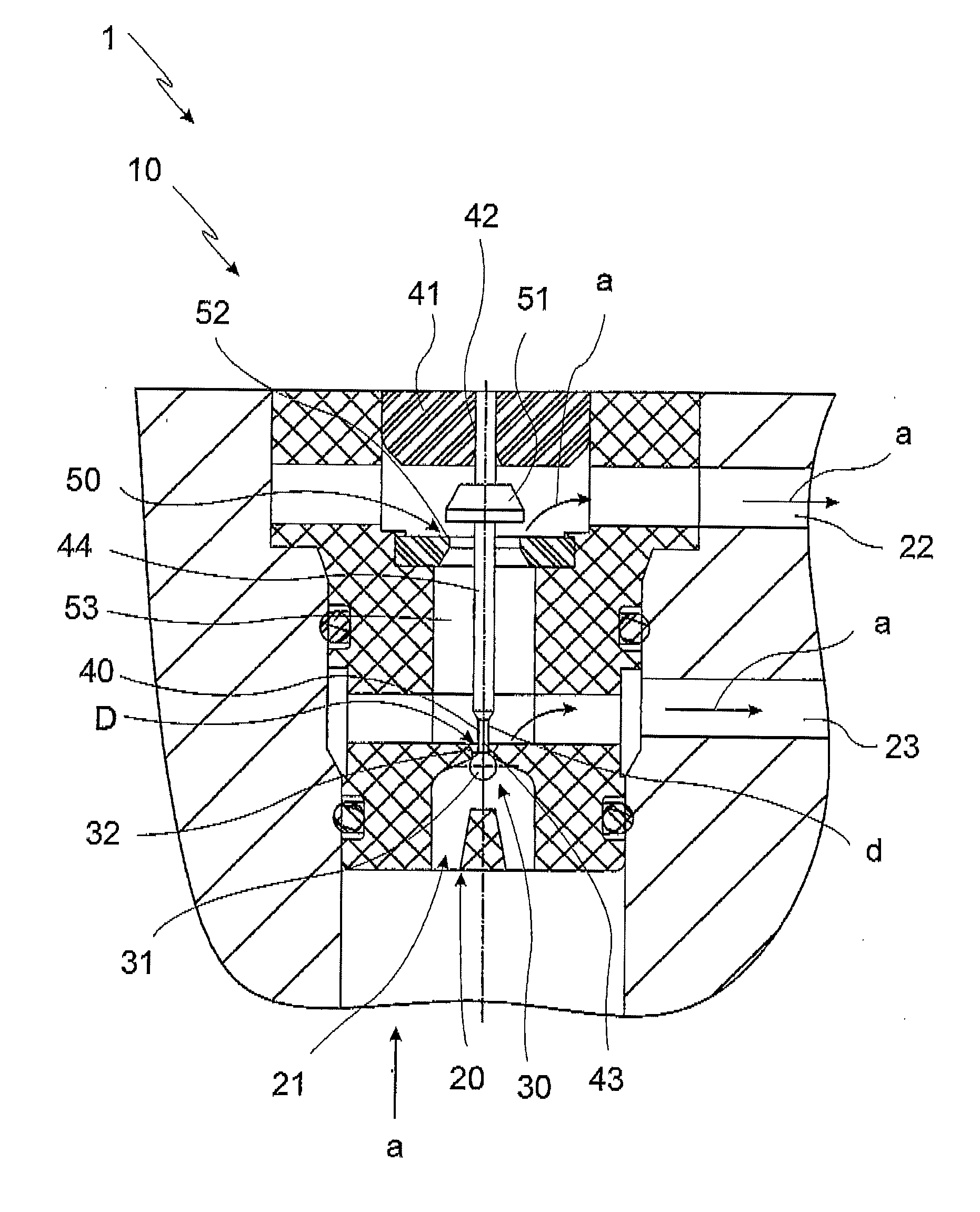

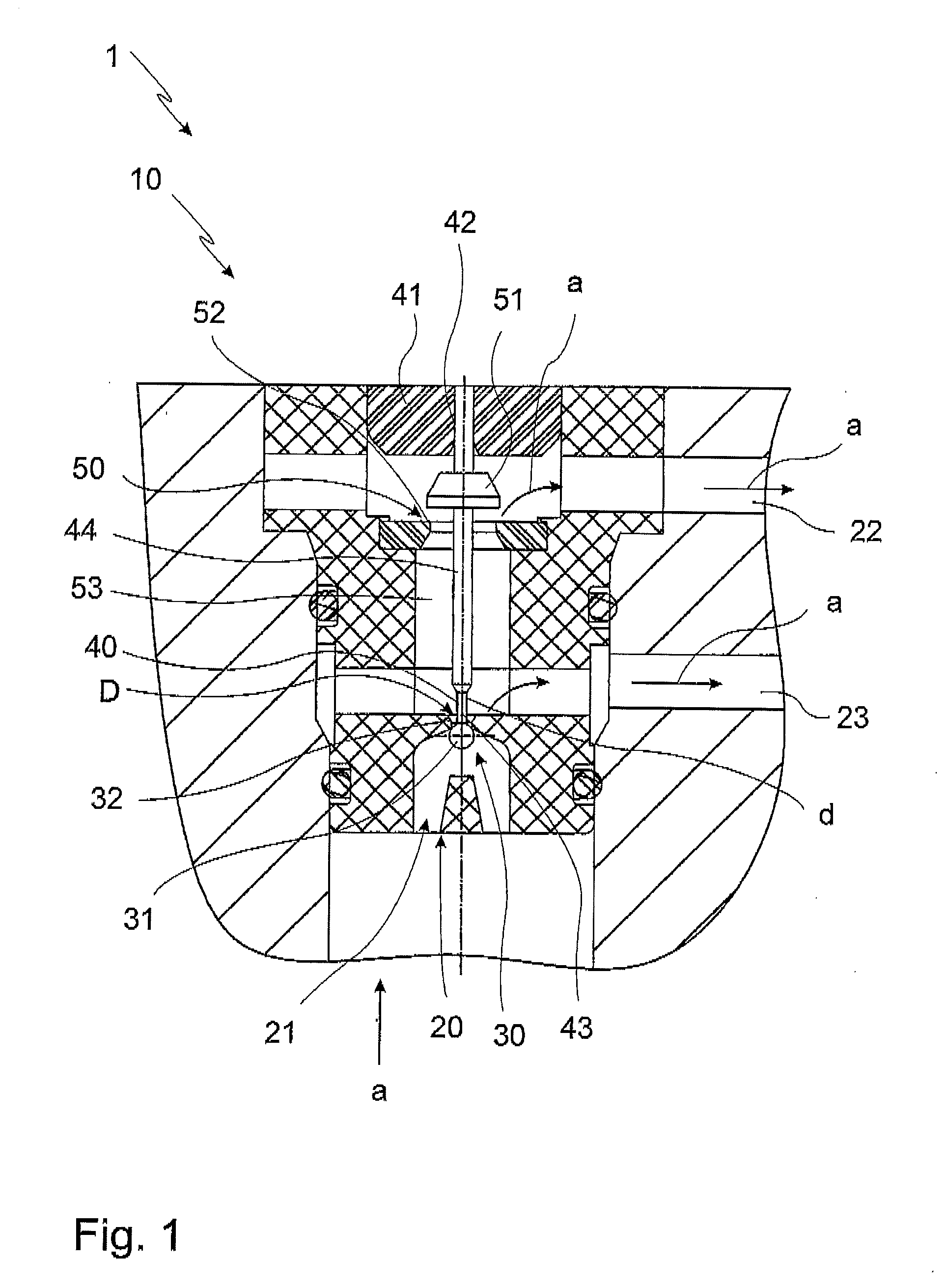

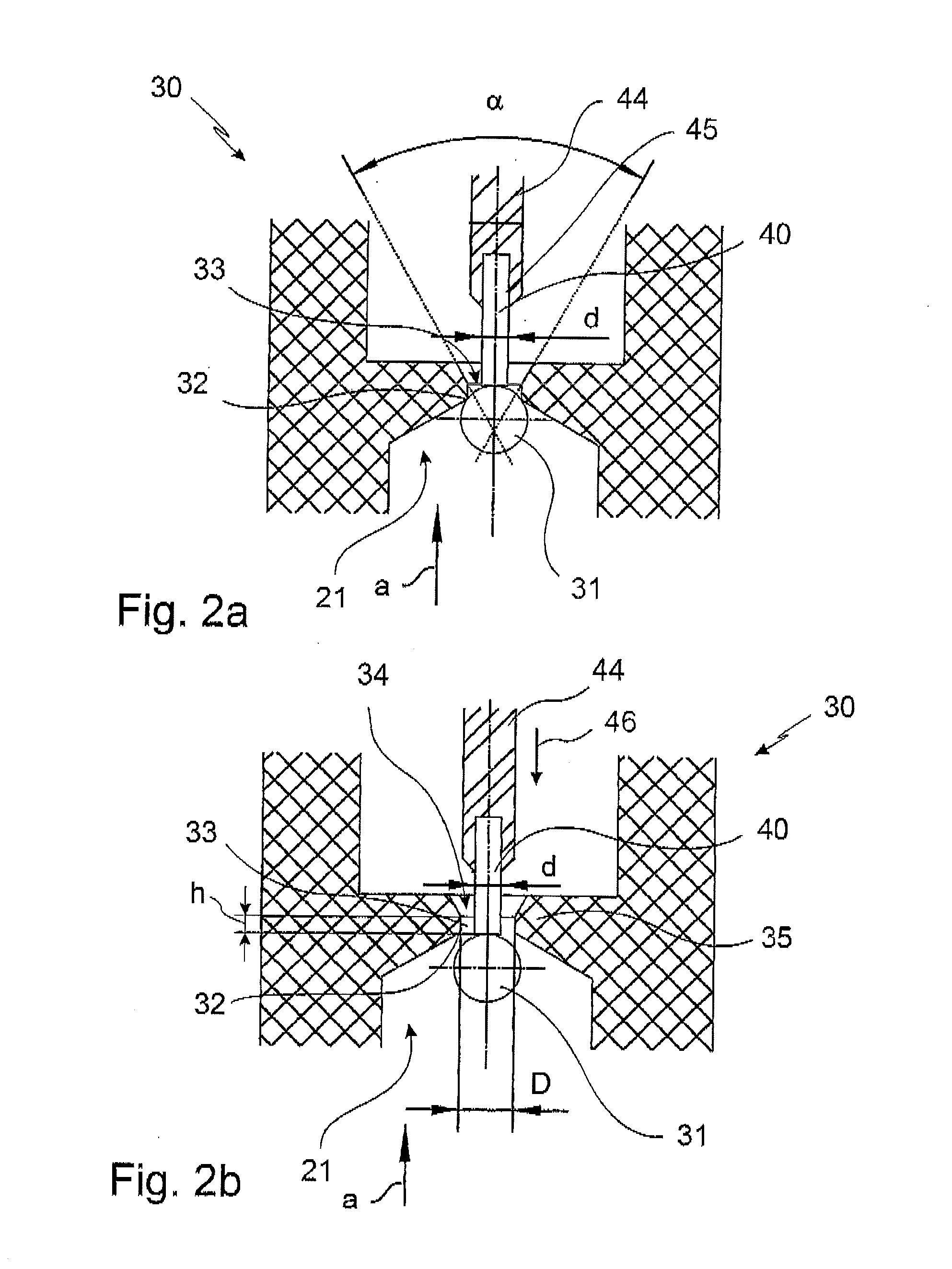

Valve which reacts as a function of pressure, especially for a vibration damper

InactiveUS6305512B1Reduce thermal resistanceIncrease control pressureSpringsSprings/dampers design characteristicsMechanical engineeringVibration damper

A pressure operated valve is provided including an adjusting device, a spring and a vent connection. The adjusting device is axially movably arranged in a pressure chamber defined in the valve and comprises a valve body and a pressure intensifier. A space between the valve body and valve face defines a valve passage cross section. The spring is operatively arranged for holding the pressure intensifier in a floating arrangement in the pressure chamber. The pressure intensifier has a first side exposed to a pressure in the pressure connection opening and a second side facing away from the pressure connection opening. The second side of the pressure intensifier and the adjusting device define a low pressure chamber within the pressure chamber. The vent connection is an inflow restrictor arranged between the lower pressure chamber and a space having a lower pressure than the low pressure chamber.

Owner:ZF FRIEDRICHSHAFEN AG

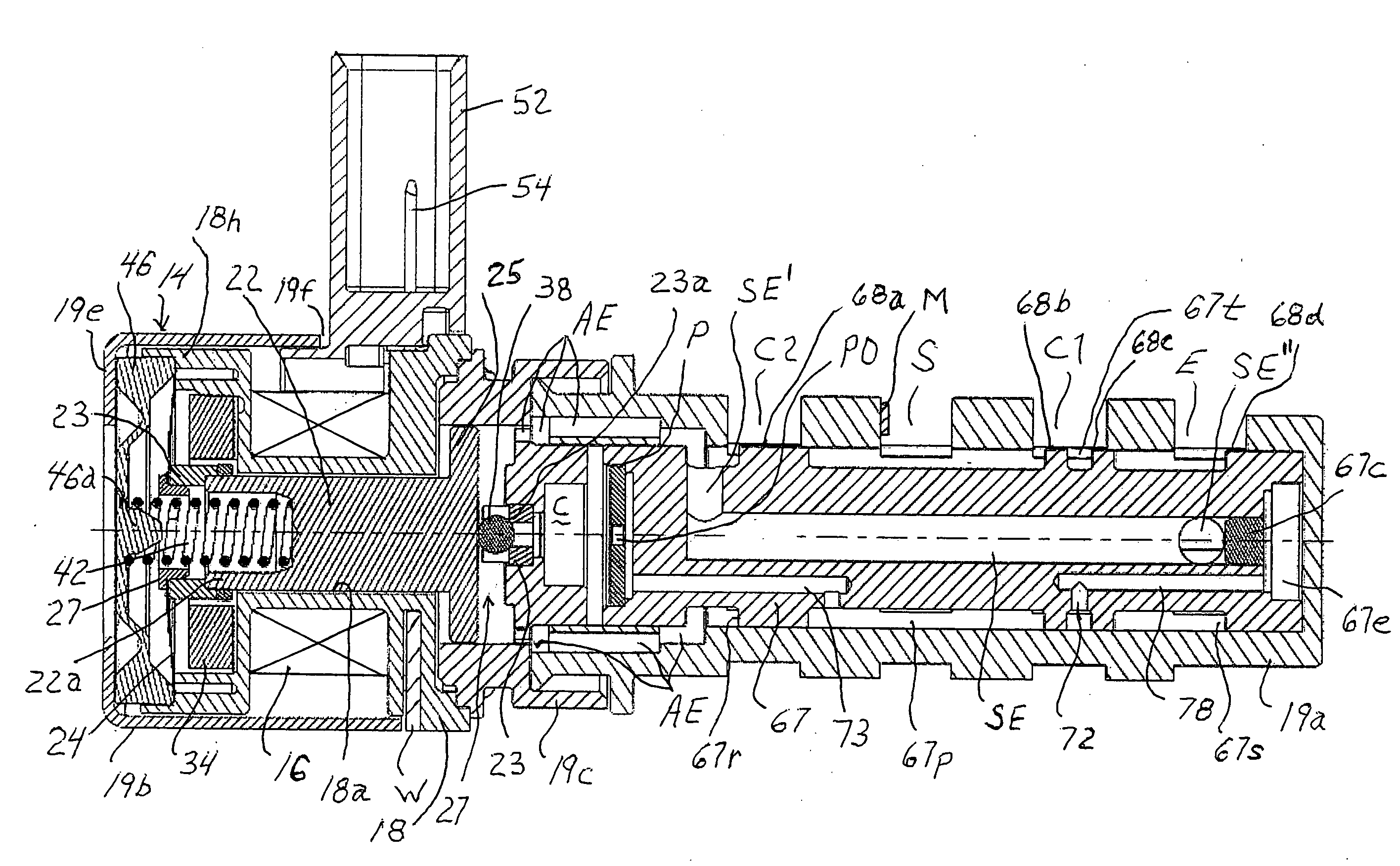

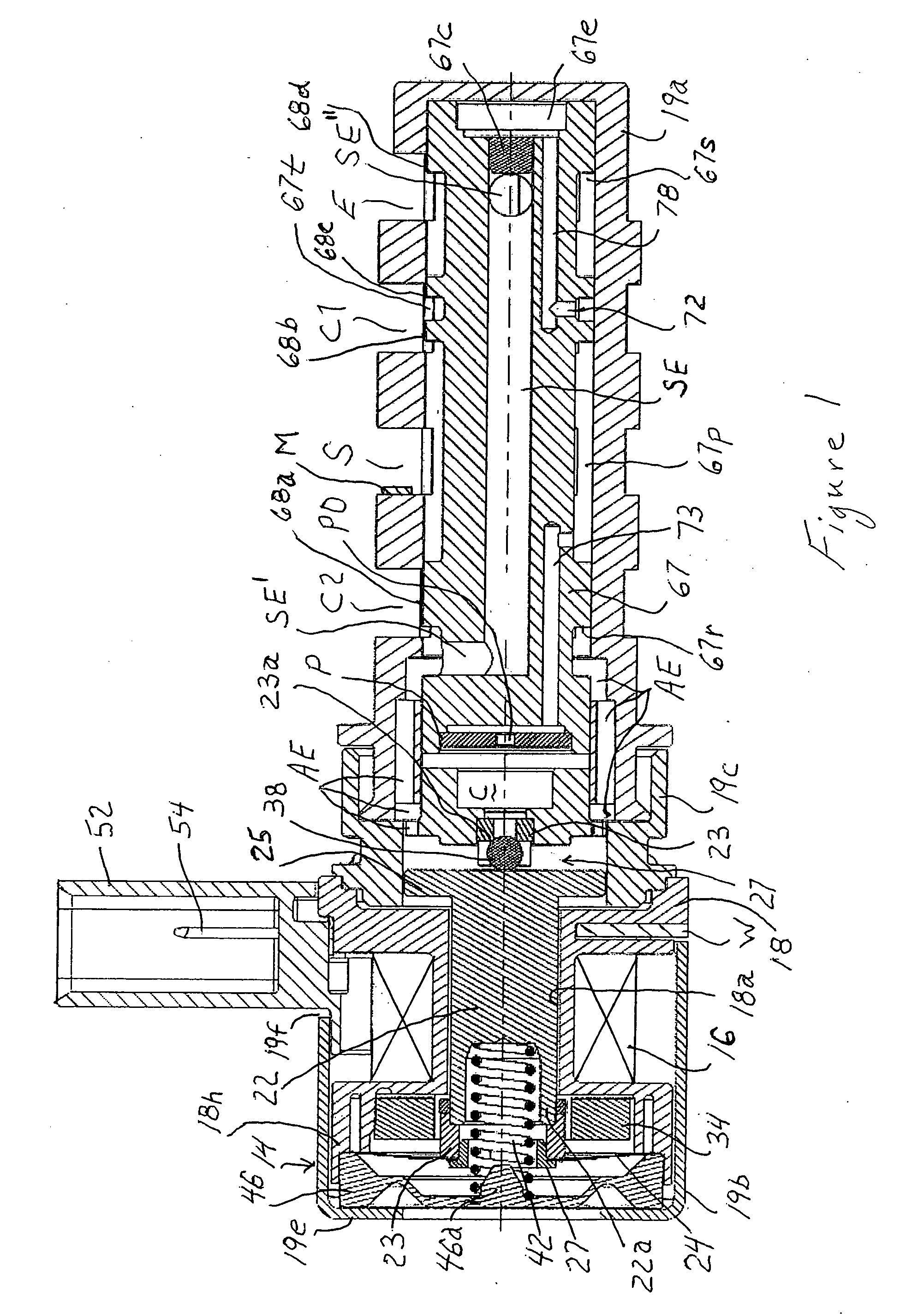

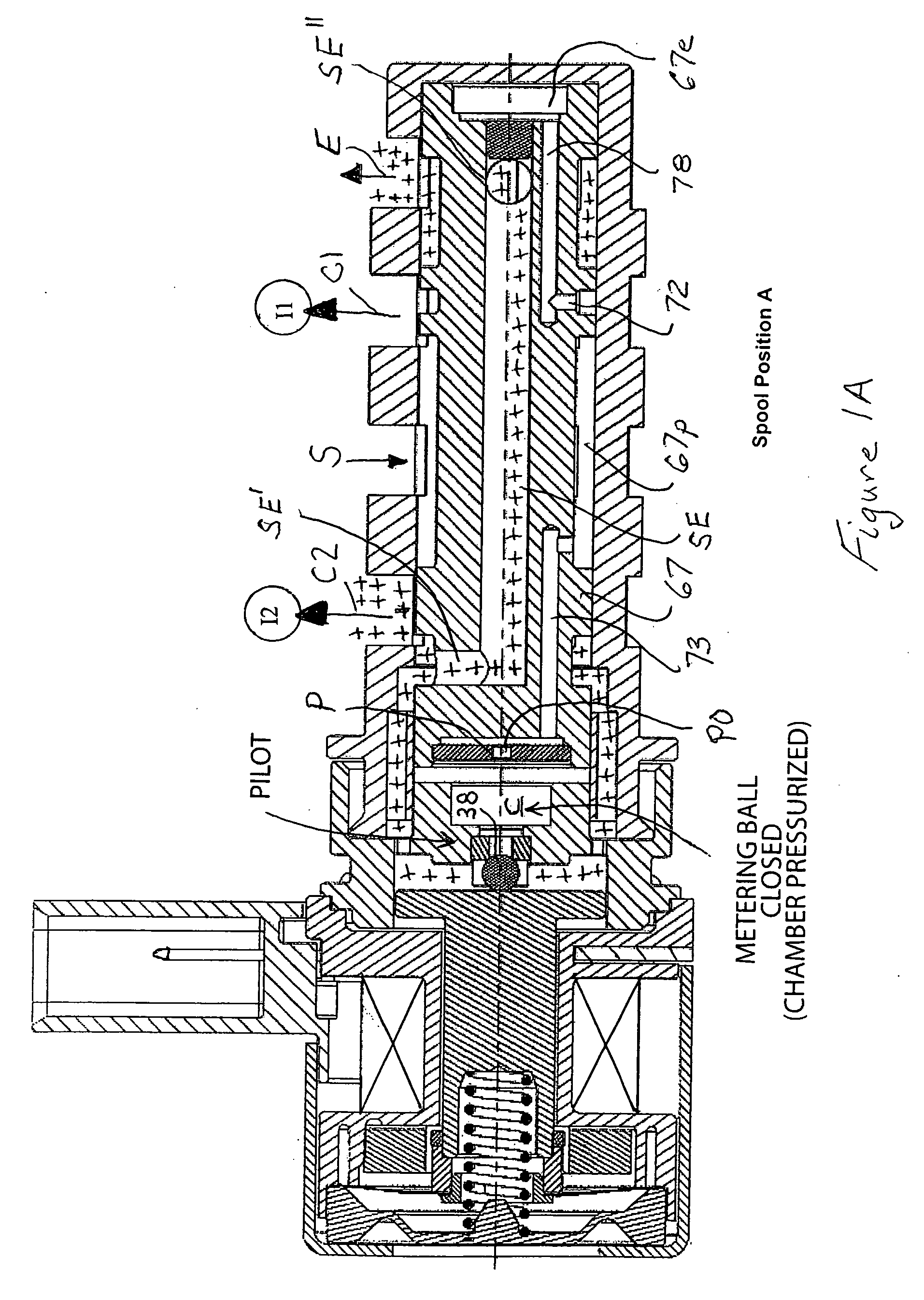

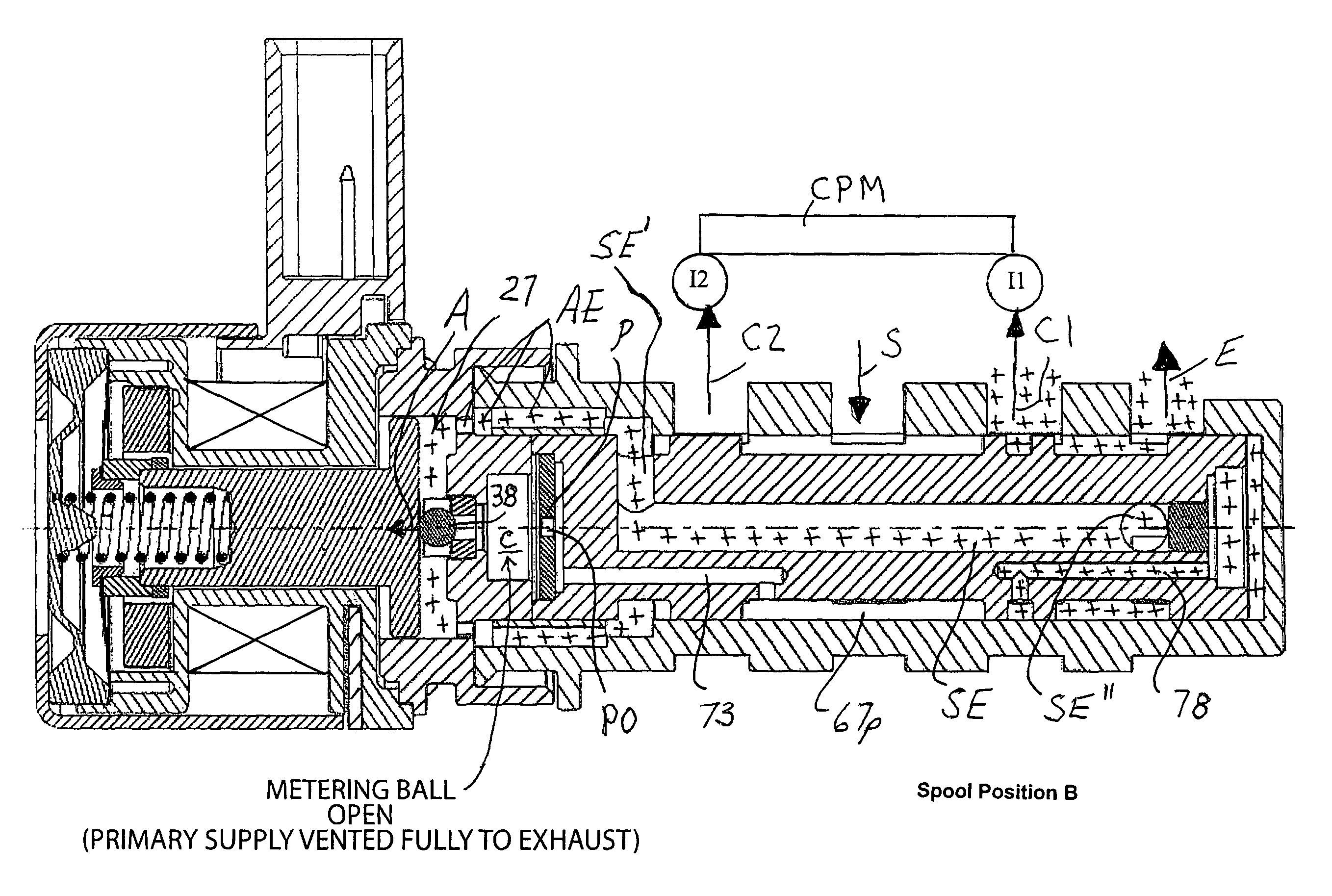

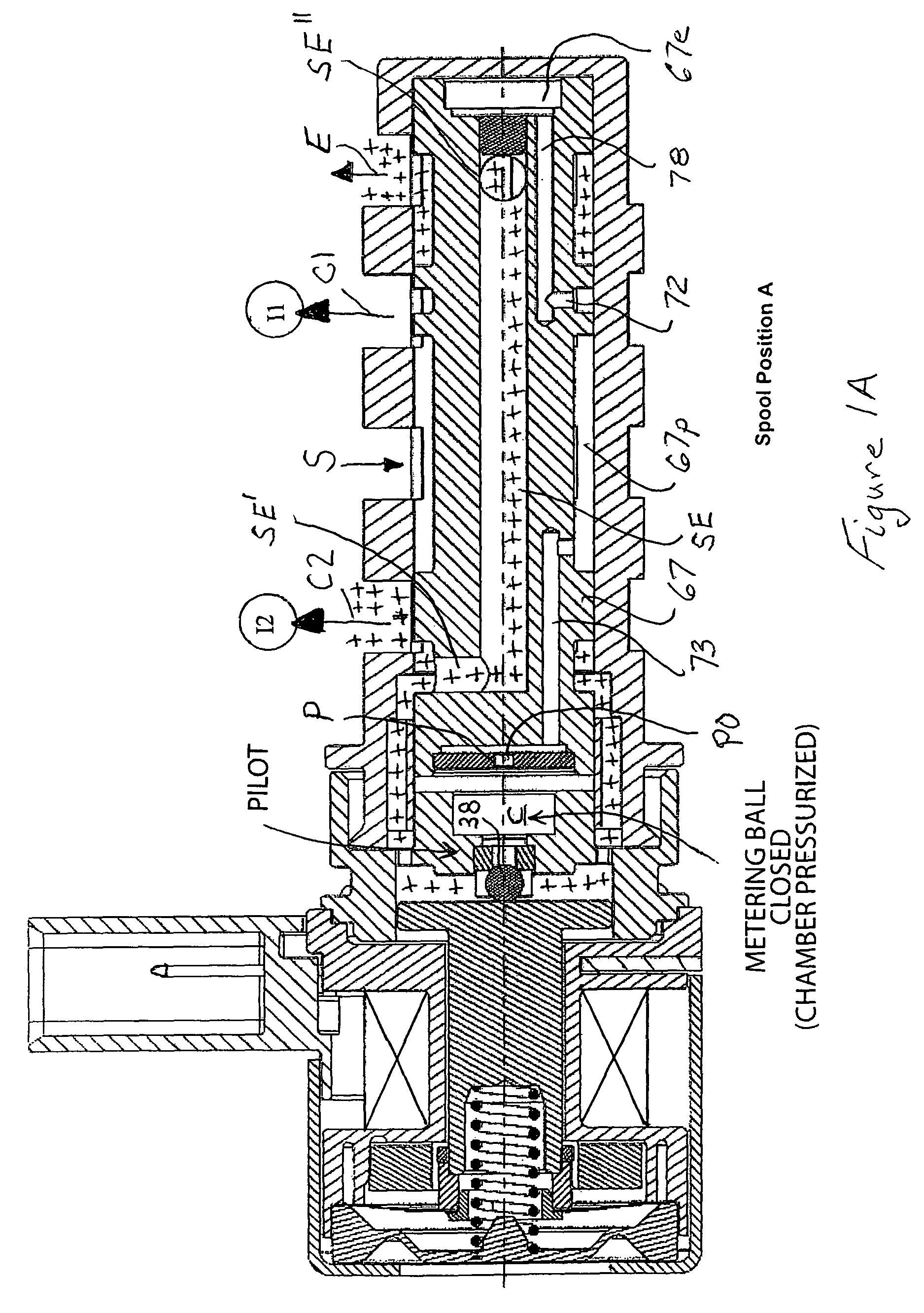

Solenoid operated fluid control valve

ActiveUS20080258090A1Improve liquidityIncrease control pressureOperating means/releasing devices for valvesServomotor componentsSpool valveFluid control

Solenoid operated fluid control valve for a cam phasing mechanism of an internal combustion engine includes first and second control ports, a 2-stage hydraulically pilot-actuated, pressure balanced spool having an integral control feedback passage and a linear force solenoid actuator operably coupled to a pilot valve of a pilot stage. The spool valve includes an exhaust path common to pilot and spool exhaust passages.

Owner:FLEXTRONICS AUTOMOTIVE USA

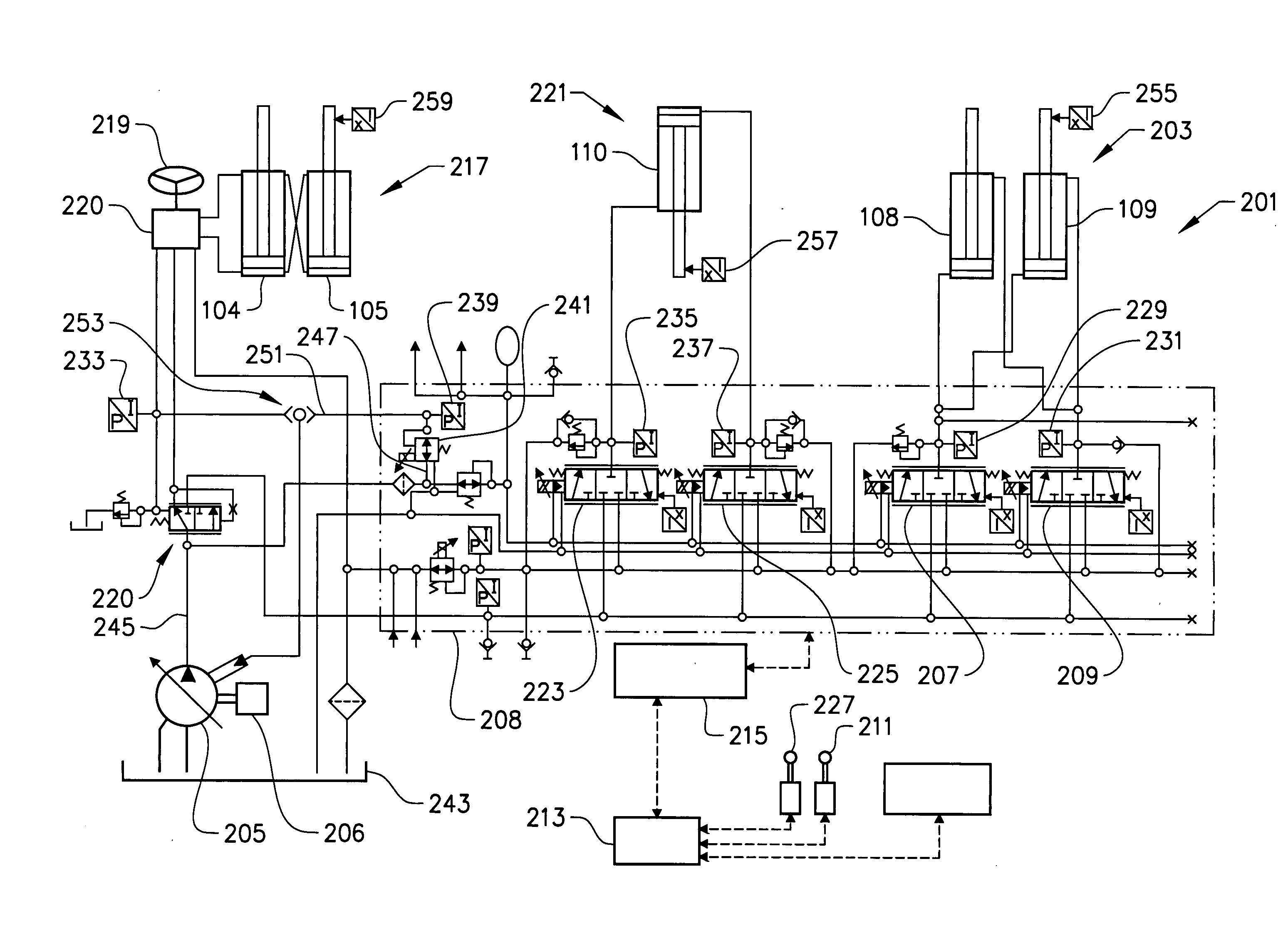

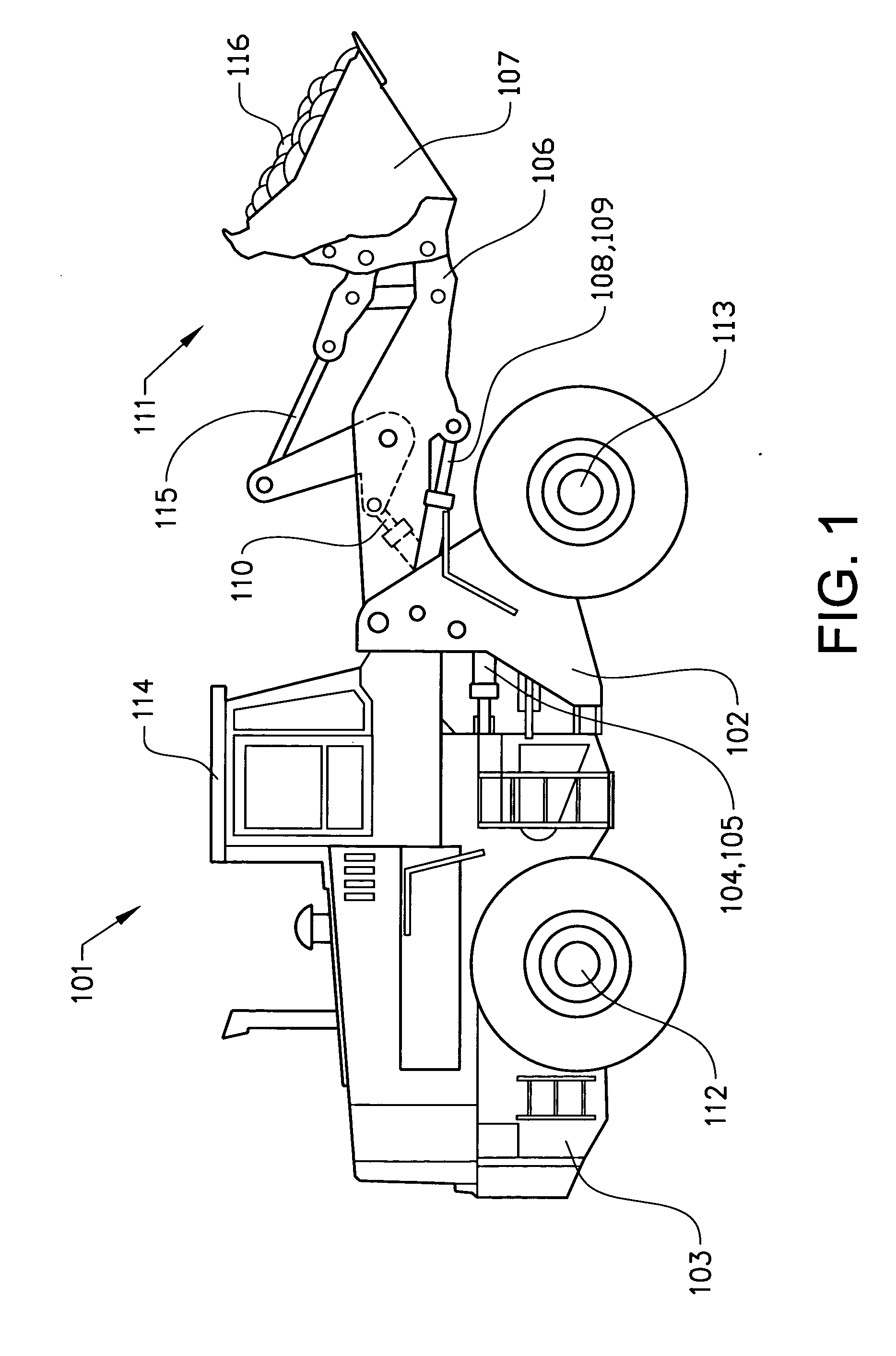

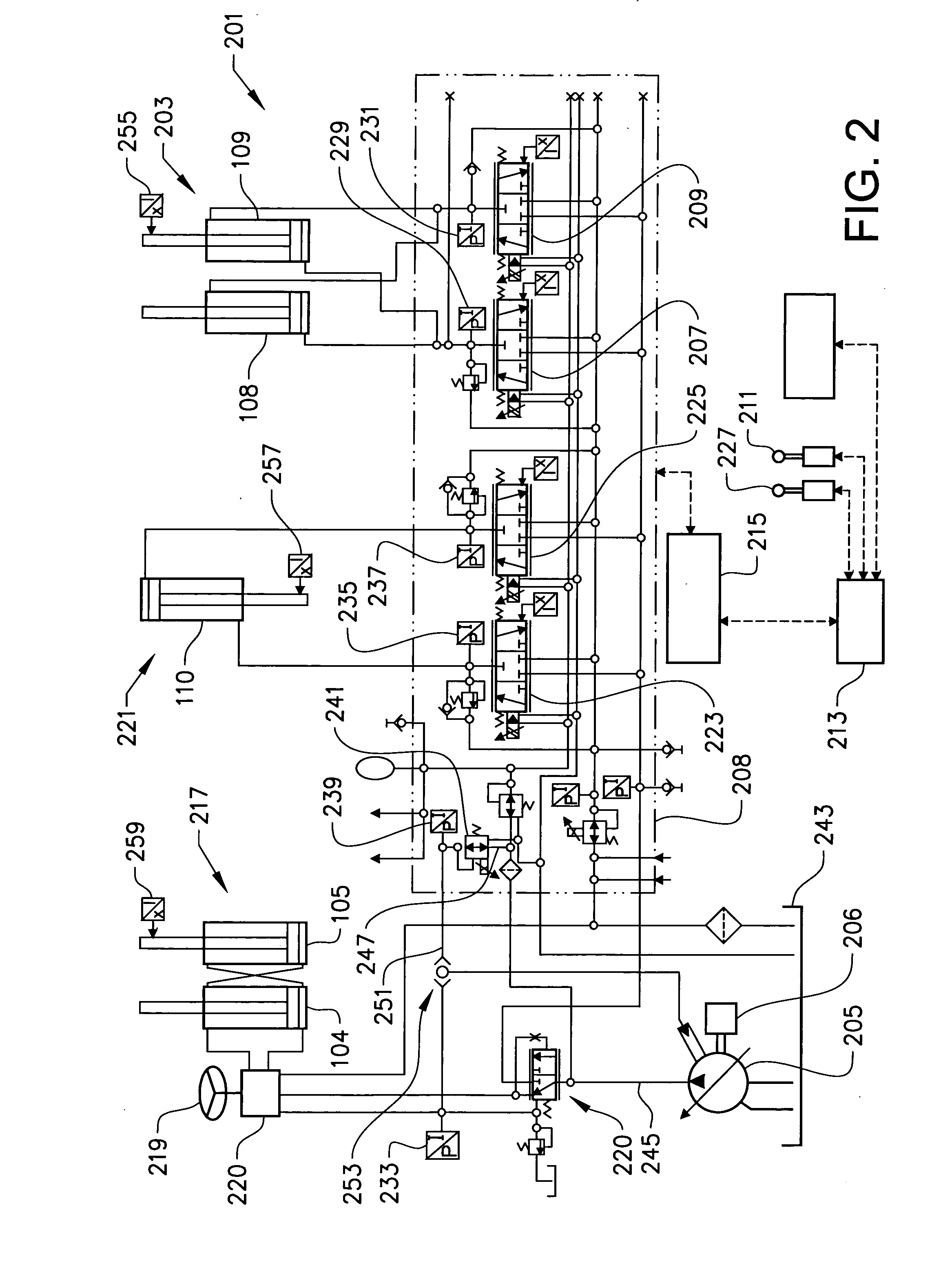

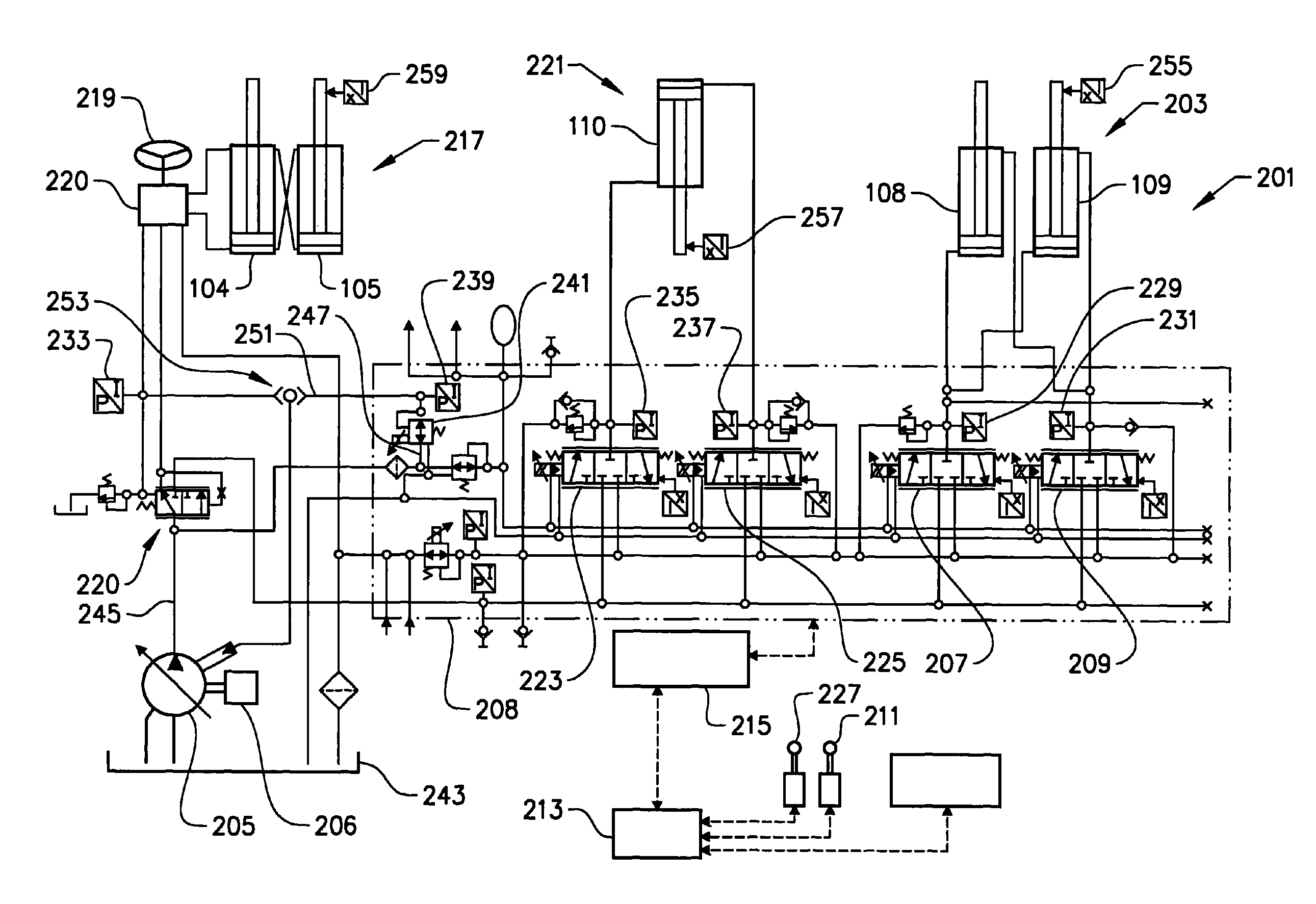

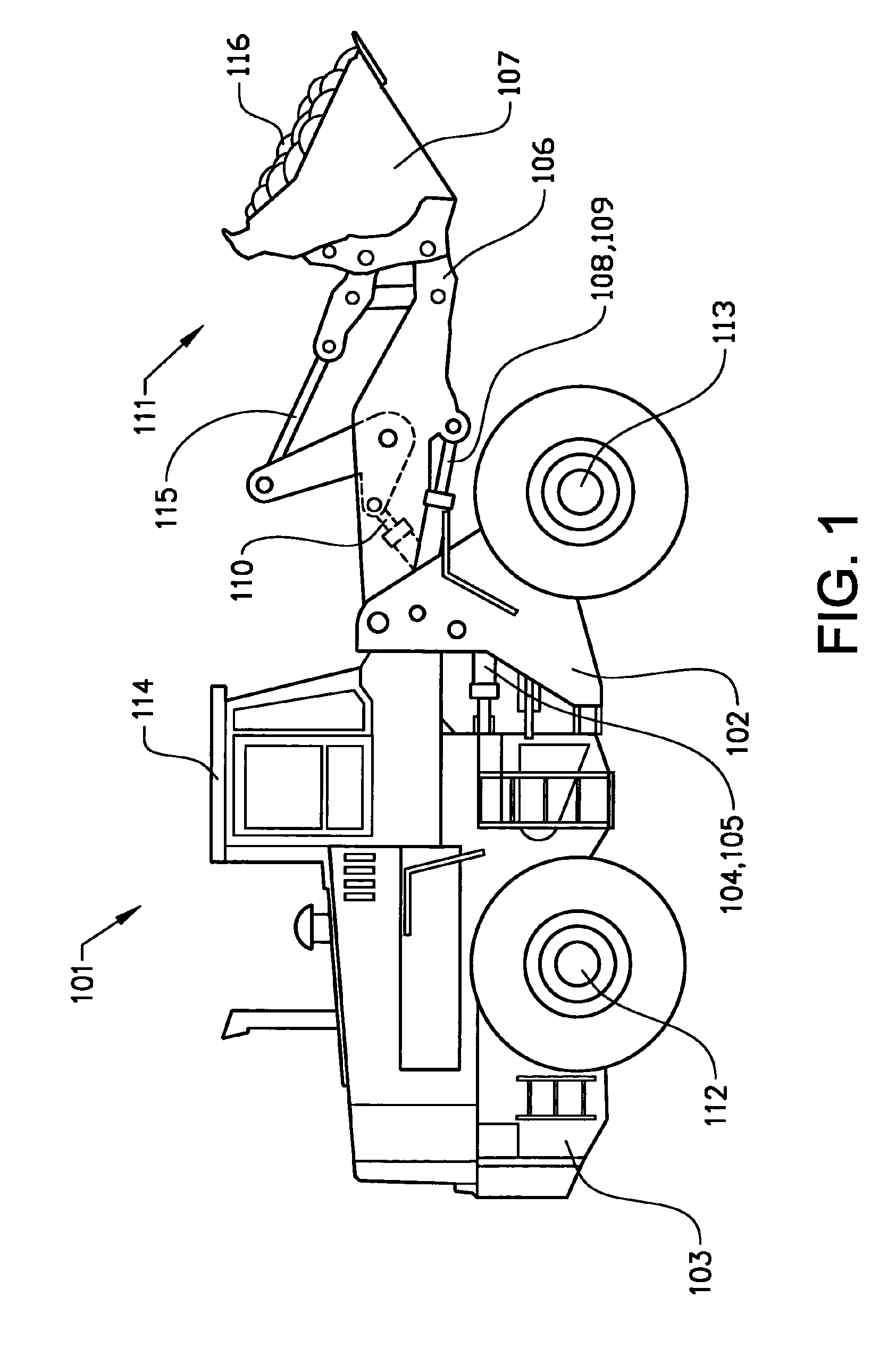

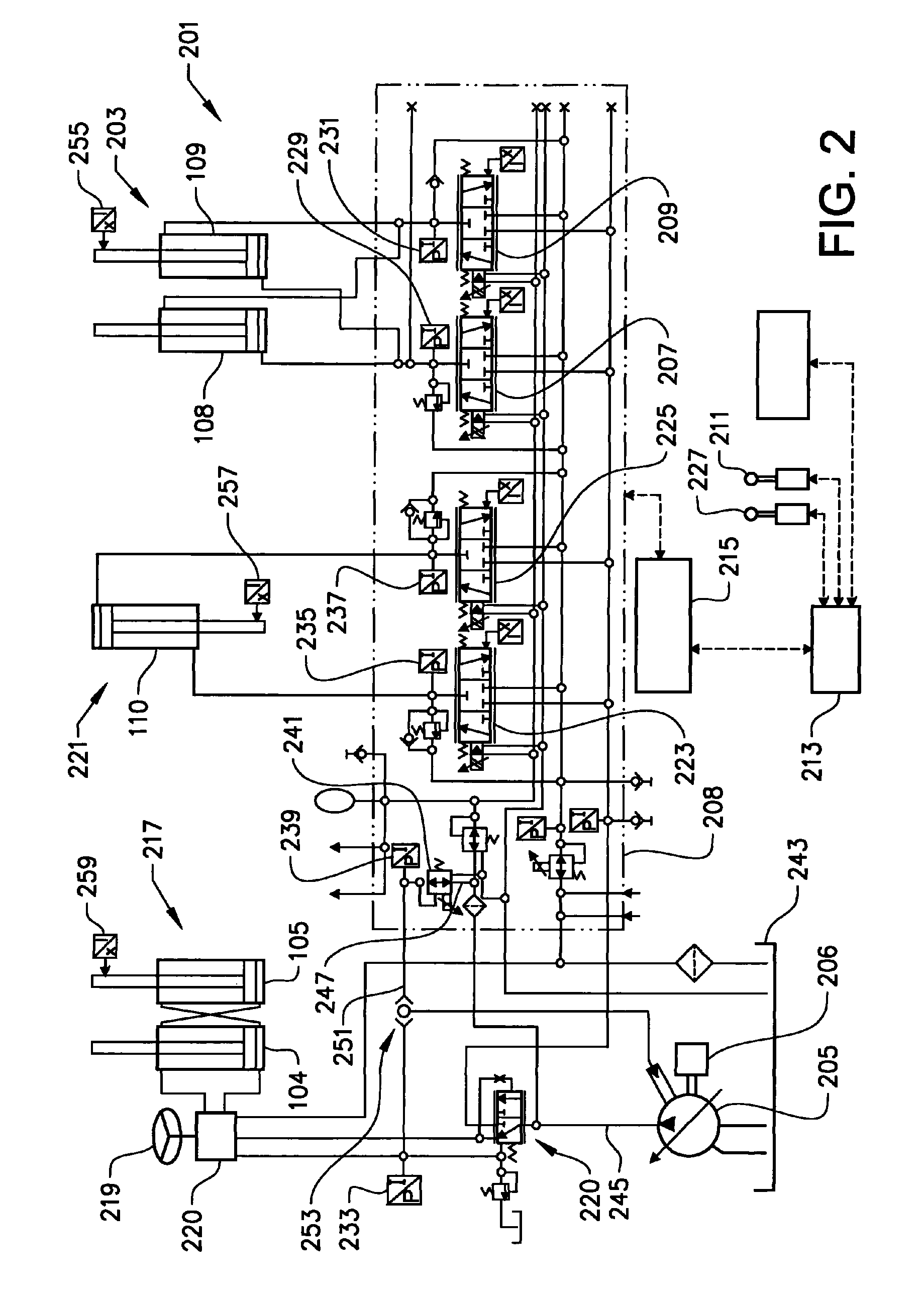

Load sensing system, working machine comprising the system, and method for controlling a hydraulic function

ActiveUS20100242464A1Reduce probabilitySignificant rateServomotor componentsRotary clutchesControl signalLoad sensing

A load sensing system includes a first assembly of actuators for controlling a first hydraulic function, a pump adapted to supply the actuators with pressurized hydraulic fluid, an electrically controlled valve adapted to control the output pressure of the pump via a hydraulic signal, a first pressure sensor for detecting a load pressure of the first actuator assembly, and a control unit adapted to receive a signal with information about the load pressure detected by the first pressure sensor and to generate a control signal, corresponding to the detected load pressure, to the electrically controlled valve.

Owner:VOLVO CONSTR EQUIP

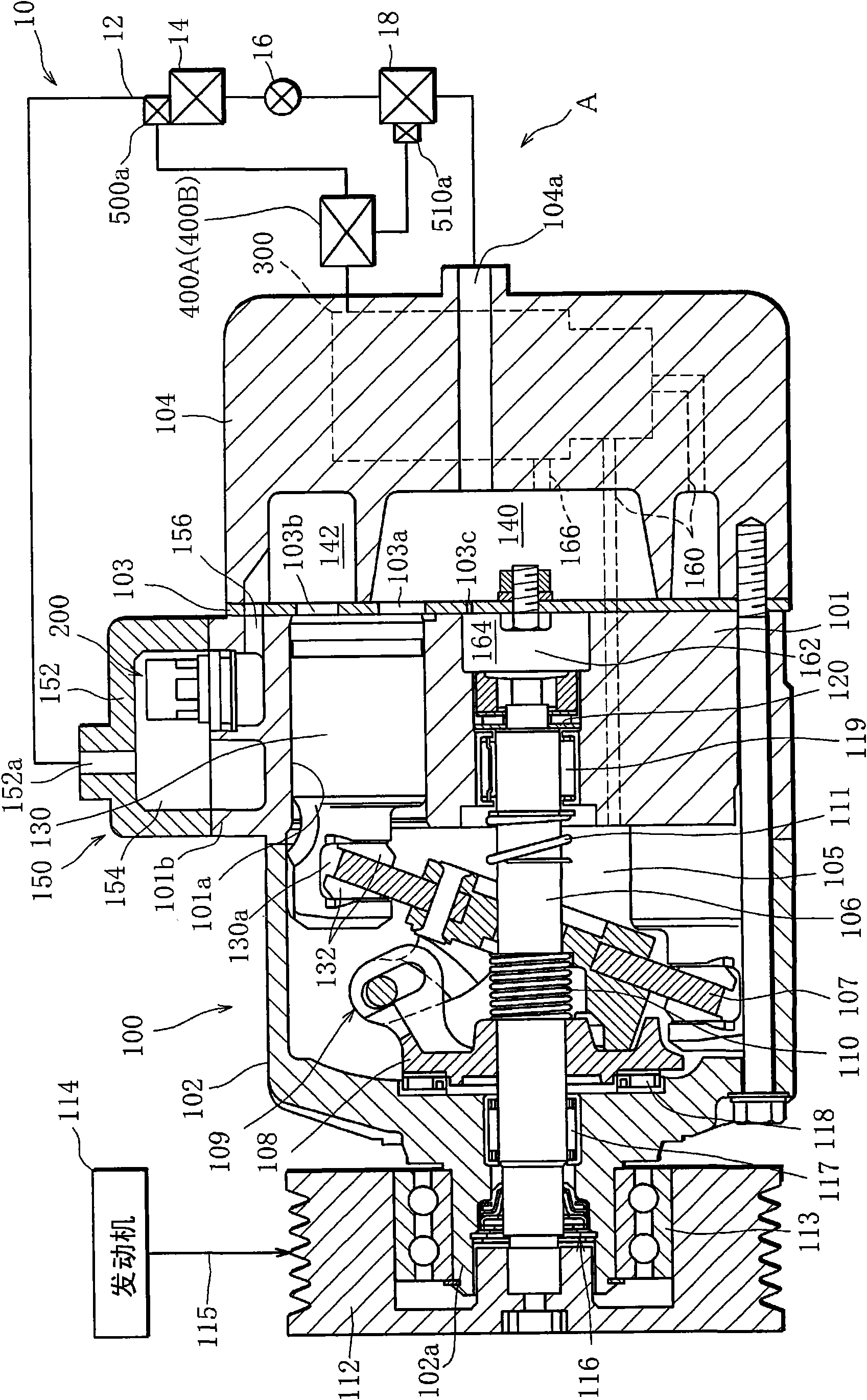

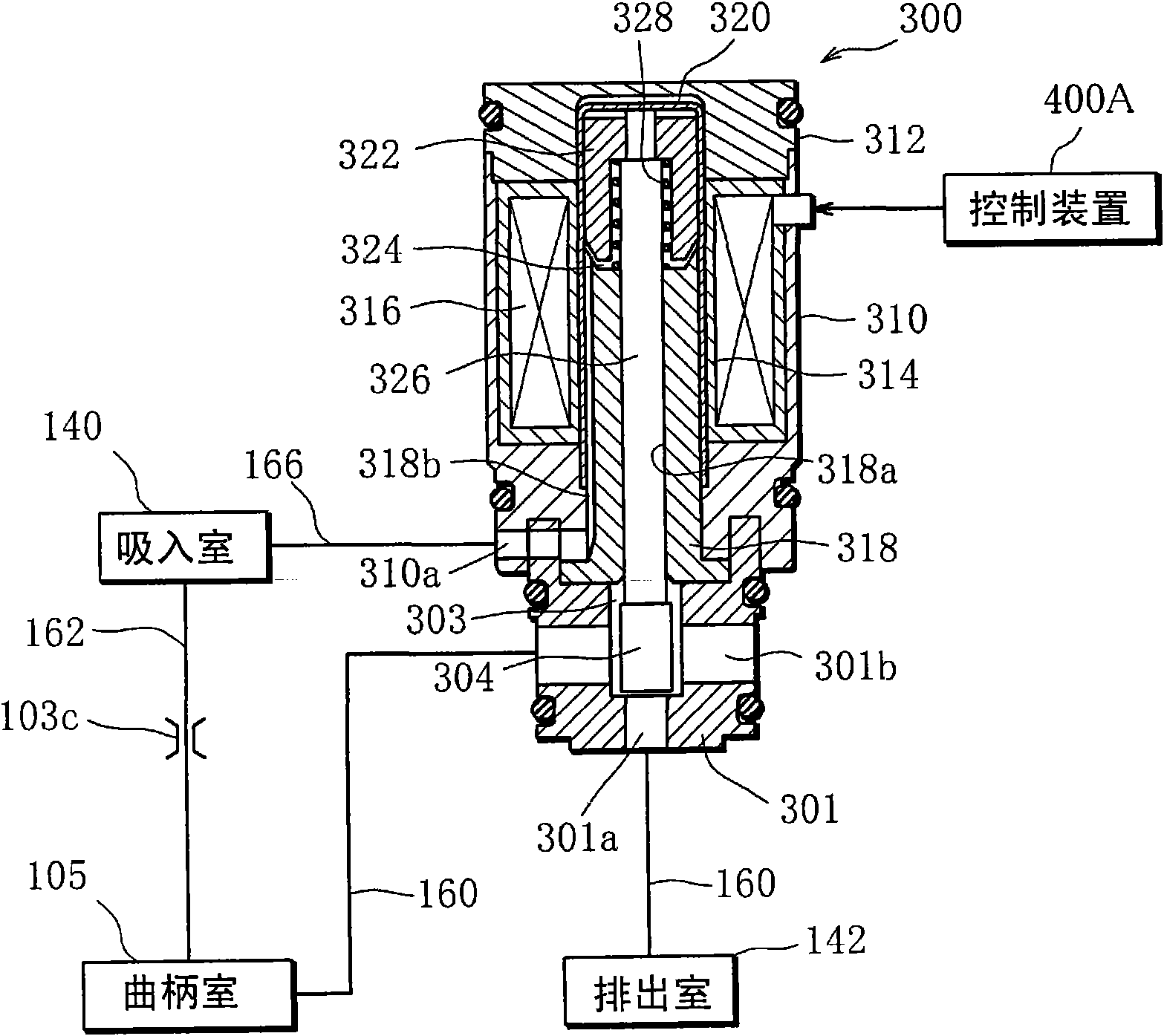

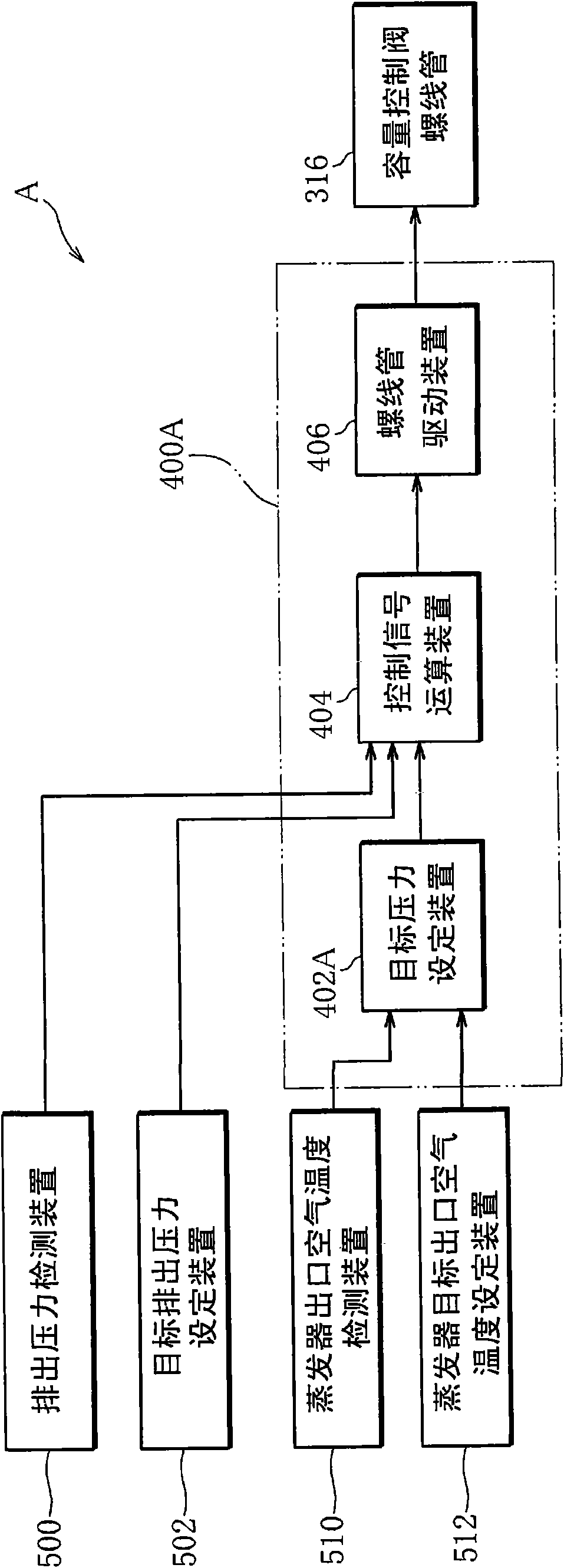

Displacement control system for variable displacement compressor

ActiveCN101605990AComfort adjustment stateOptimum Discharge Capacity ControlAir-treating devicesCompression machines with non-reversible cycleControl systemEngineering

A discharge displacement control system (A) of a variable displacement compressor has target pressure setting means (402A), discharge pressure detection means (500), and electric current regulation means (404, 406). The target pressure setting means (402A) sets a target of either the pressure in a suction chamber or the pressure in a crank chamber based on a target air temperature at the evaporator exit detected by means (510) for detecting the air temperature at the evaporator exit and on a target air temperature at the evaporator exit set by means (512) for setting a target air temperature at the evaporator exit. The discharge pressure detection means (500) detects the pressure of refrigerant in a high-pressure region. The electric current regulation means (404, 406) regulate, based on both the pressure of the refrigerant in the high-pressure region detected by the discharge pressure detection means (500) and the target pressure set by the target pressure setting means (402A), electric current supplied to a solenoid (316) of a displacement control valve.

Owner:SANDEN CO LTD

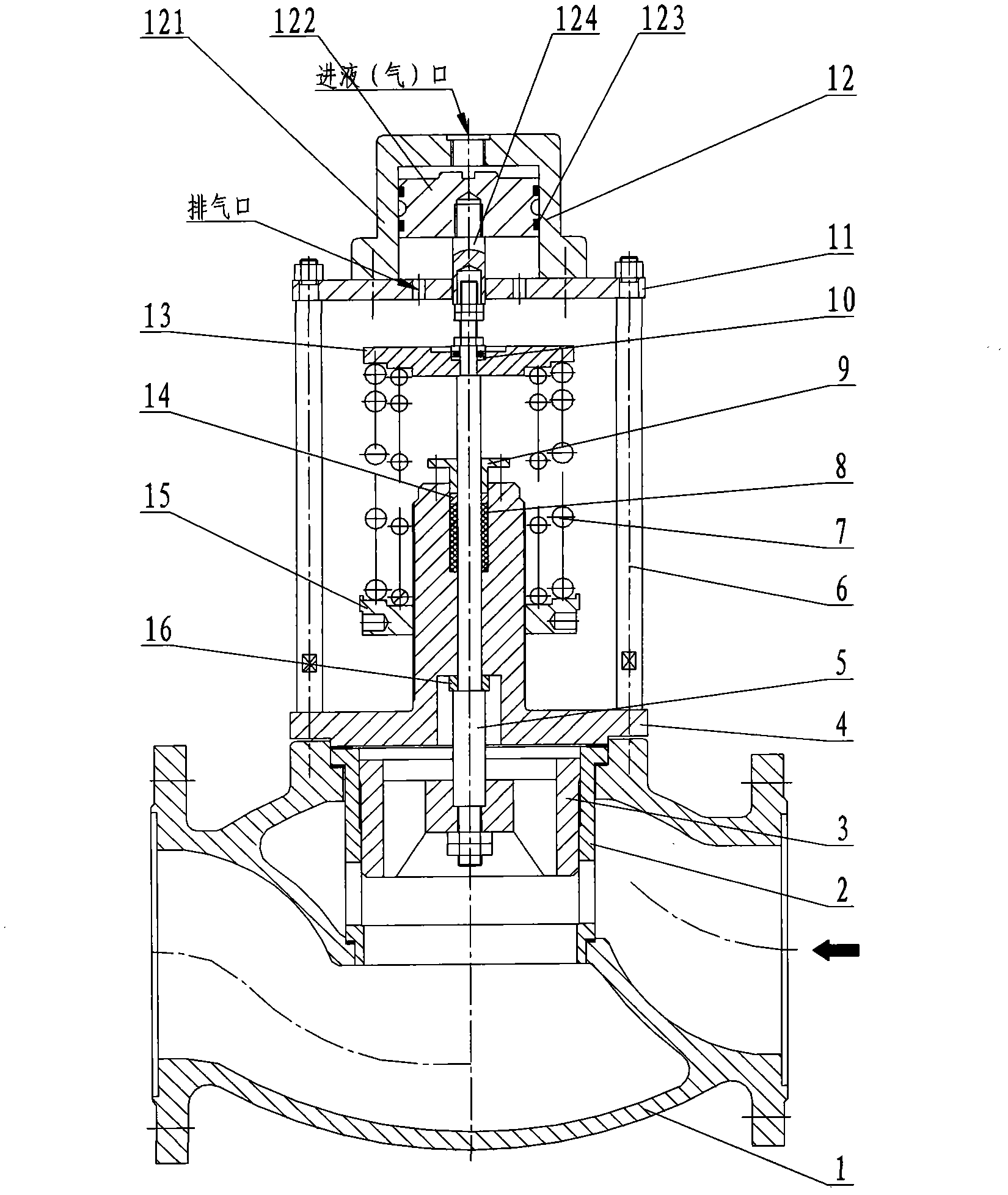

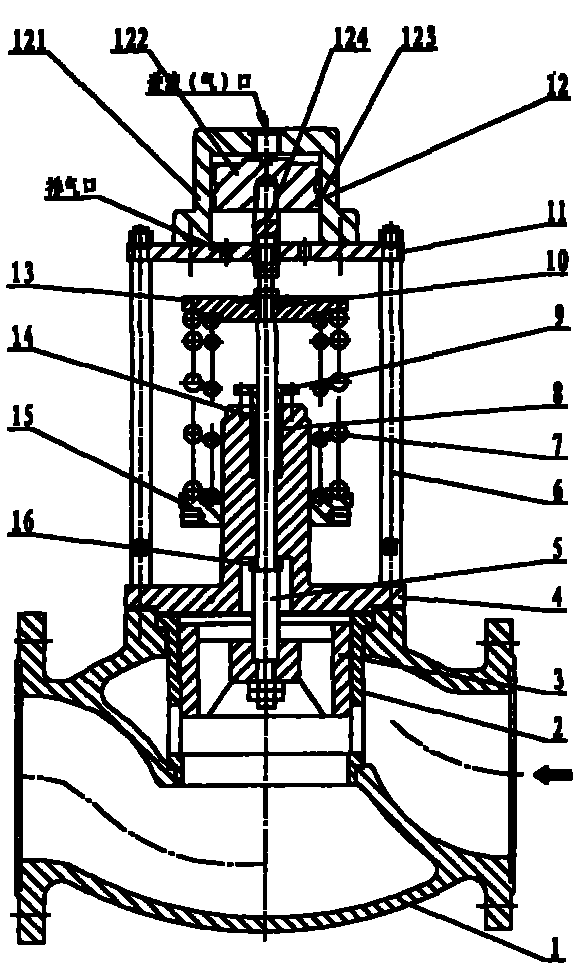

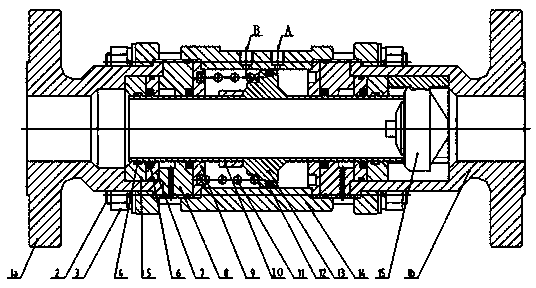

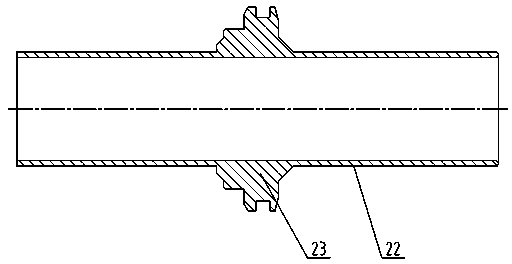

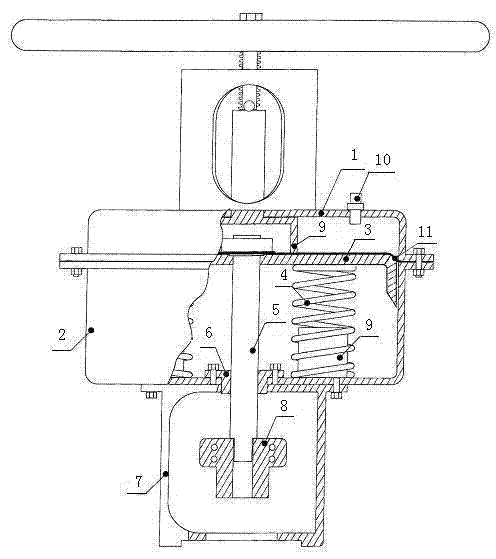

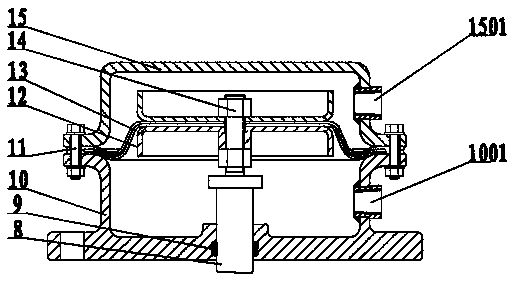

Self-operated sleeve regulating valve

InactiveCN102563104ACompact structureIncrease control pressureOperating means/releasing devices for valvesSlide valveAuto regulationBall bearing

The invention discloses a self-operated sleeve regulating valve, which comprises a valve body, a sleeve, a valve spool, a valve cover, a valve rod, a vertical column, a regulating spring, sealing packing, a packing gland, a thrust ball bearing, an upper pressing plate, an actuator, a spring seat, a packing gasket, a regulating disk, a regulating pad and a connector. A valve cavity is arranged in the valve body, the sleeve and the valve spool matched with the sleeve are mounted in the valve cavity, the valve spool is fixed to the lower end of the valve rod and is capable of vertically moving in the sleeve, the valve cavity is divided into an upper cavity and a lower cavity when the valve spool and the sleeve are sealed, the upper end of the valve rod penetrates through the upper pressing plate and is connected with a push rod of the actuator, and the pressure of the upper valve cavity and the lower valve cavity is balanced under the combined action of the sleeve, the valve spool and the actuator. The self-operated sleeve regulating valve has the advantages of simple and compact structure, high adjustable and controllable pressure, capability of setting online non-interference regulation and the like, and is applicable to automatic regulation and control for the pressure of process pipelines with gas, liquid, steam and the like with pressure needing to be regulated to be higher than or equal to 0.5Mpa.

Owner:ZHEJIANG KEHAI INSTR

Load sensing system, working machine comprising the system, and method for controlling a hydraulic function

ActiveUS8869520B2Lower drag lossesIncrease control pressureRotary clutchesServomotorsControl signalLoad sensing

A load sensing system includes a first assembly of actuators for controlling a first hydraulic function, a pump adapted to supply the actuators with pressurized hydraulic fluid, an electrically controlled valve adapted to control the output pressure of the pump via a hydraulic signal, a first pressure sensor for detecting a load pressure of the first actuator assembly, and a control unit adapted to receive a signal with information about the load pressure detected by the first pressure sensor and to generate a control signal, corresponding to the detected load pressure, to the electrically controlled valve.

Owner:VOLVO CONSTR EQUIP AB

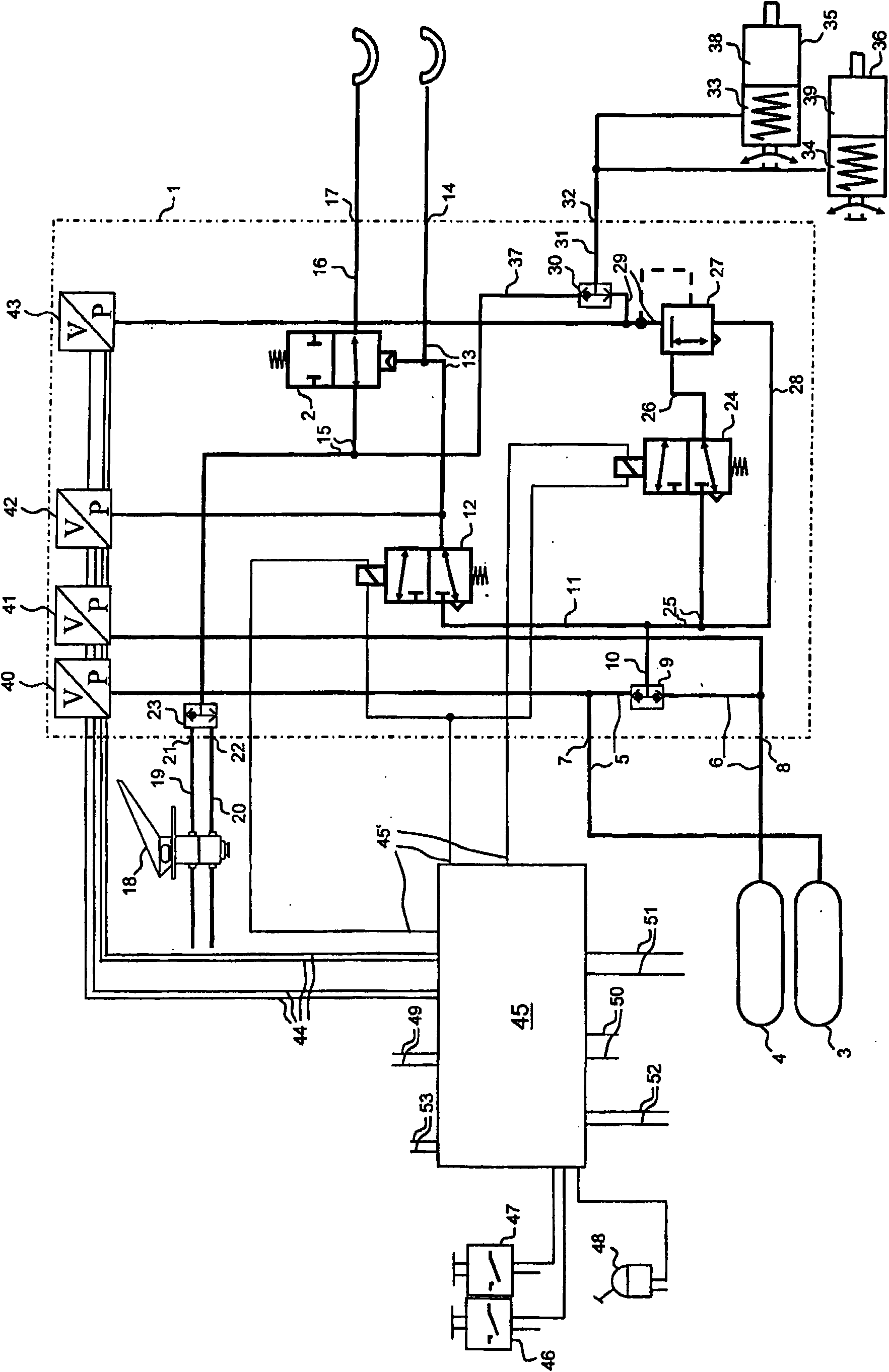

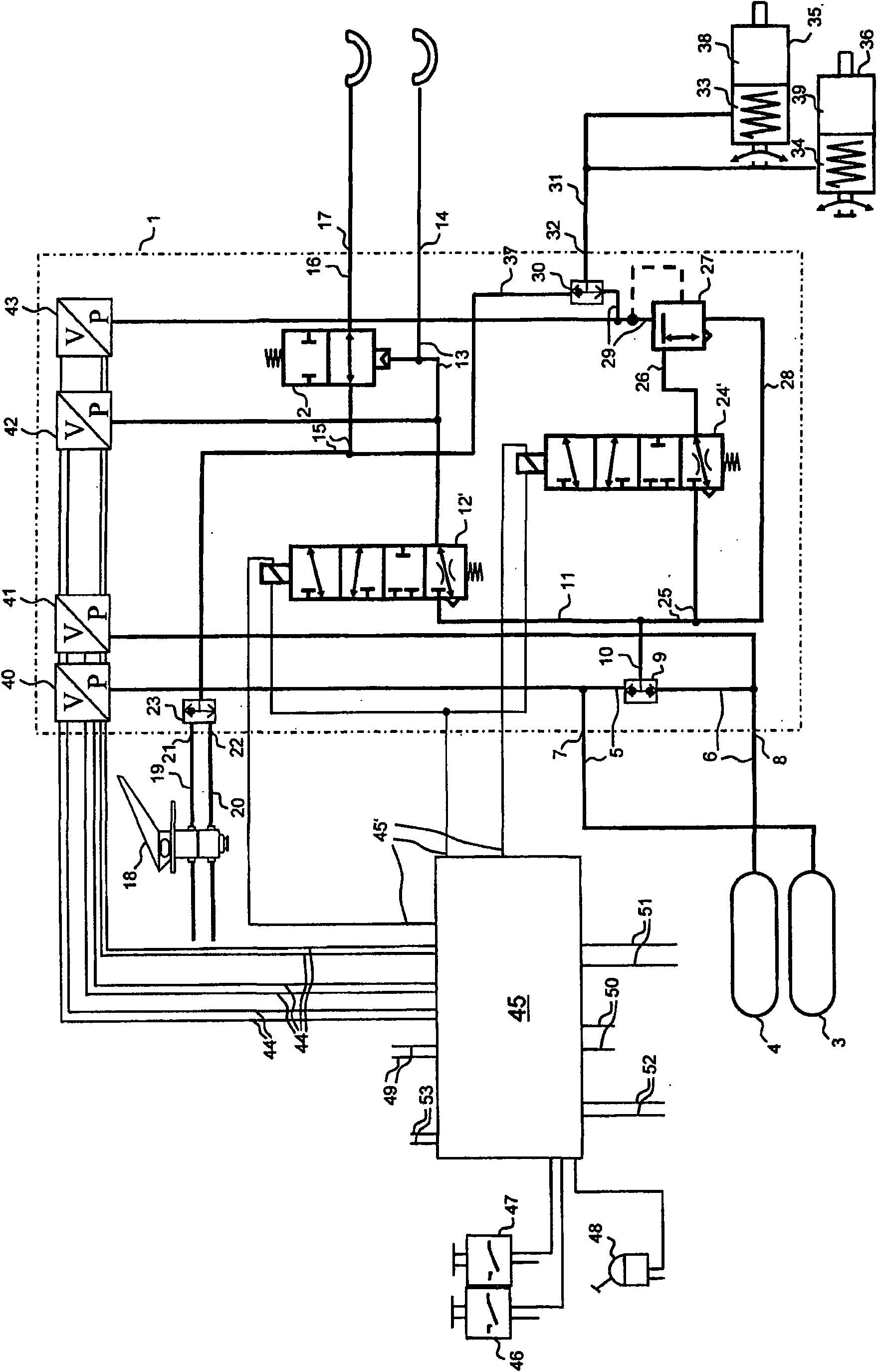

Electropneumatic parking brake modulator for a trailer in a vehicle/trailer combination

ActiveCN101801747ALow costAvoid pressure lossBraking action transmissionAutomatic initiationsCost effectivenessParking brake

The invention relates to an electropneumatic parking brake modulator for controlling a parking brake mode of brakes of at least one trailer in a vehicle / trailer combination that consists of a towing vehicle and the trailer. The parking brake modulator (1) comprises a valve element (12) for airing and bleeding the spring brake cylinders of the brakes of the trailer. The parking brake modulator (1) further comprises at least one compressed air reservoir inlet (7, 8) for airing at least one compressed air line (10) in the parking brake modulator (1) with compressed air from a compressed air reservoir (3, 4) of the towing vehicle and at least one compressed air reservoir outlet (14) at which a reservoir pressure can be made available for the brakes of the trailer. The parking brake modulator (1) finally comprises at least one compressed air control outlet (17) at which a control pressure can be made available for the brakes of the trailer. In order to increase the cost-effectiveness of such a device, a towing vehicle protection valve (2) is integrated into the parking brake modulator (1), a compressed air line (16) to the at least one compressed air control outlet (17) being automatically blockable in the case of a pressure drop of the reservoir pressure made available for the trailer below a predetermined threshold value.

Owner:ZF CV SYST EURO BV

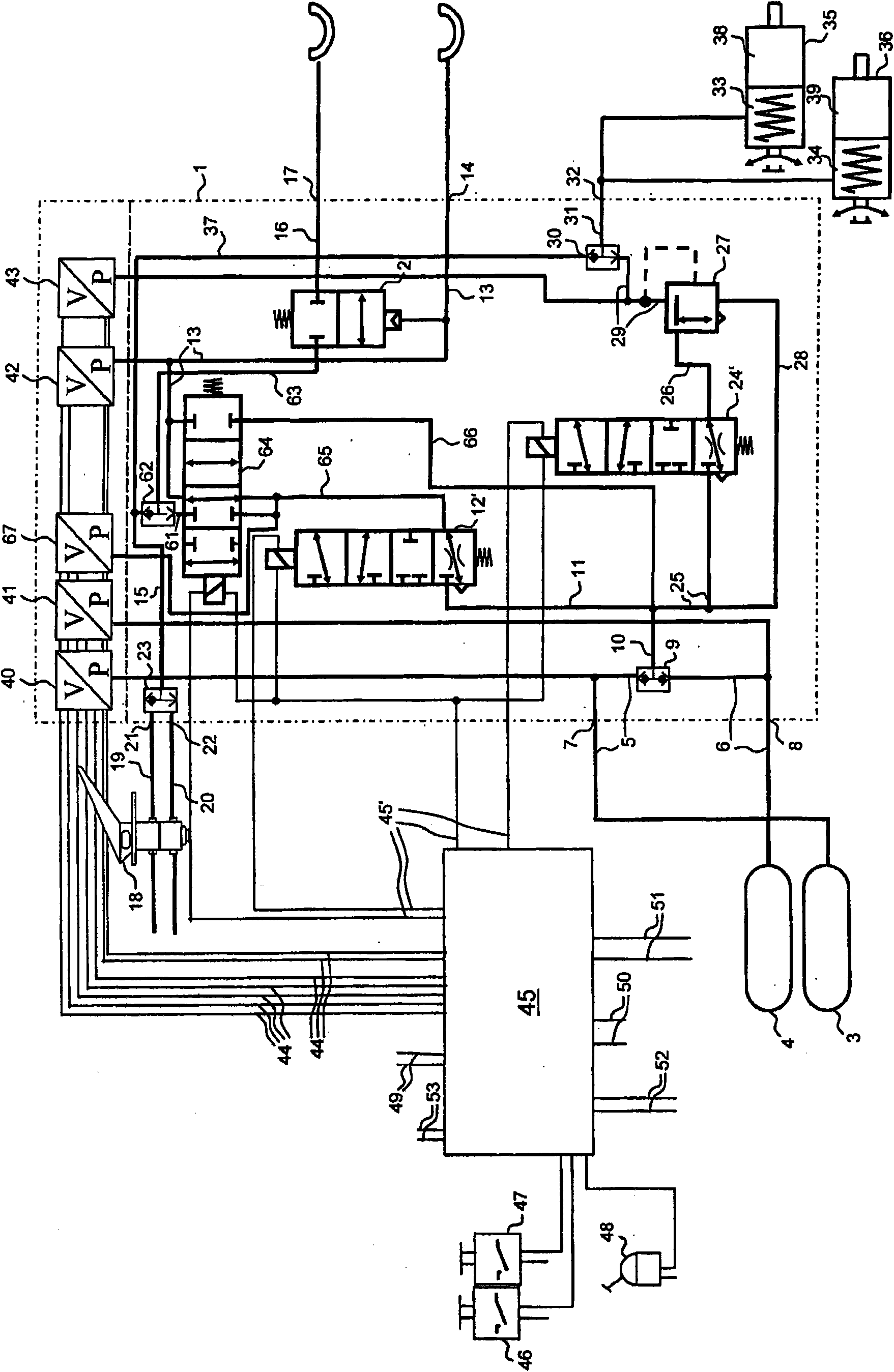

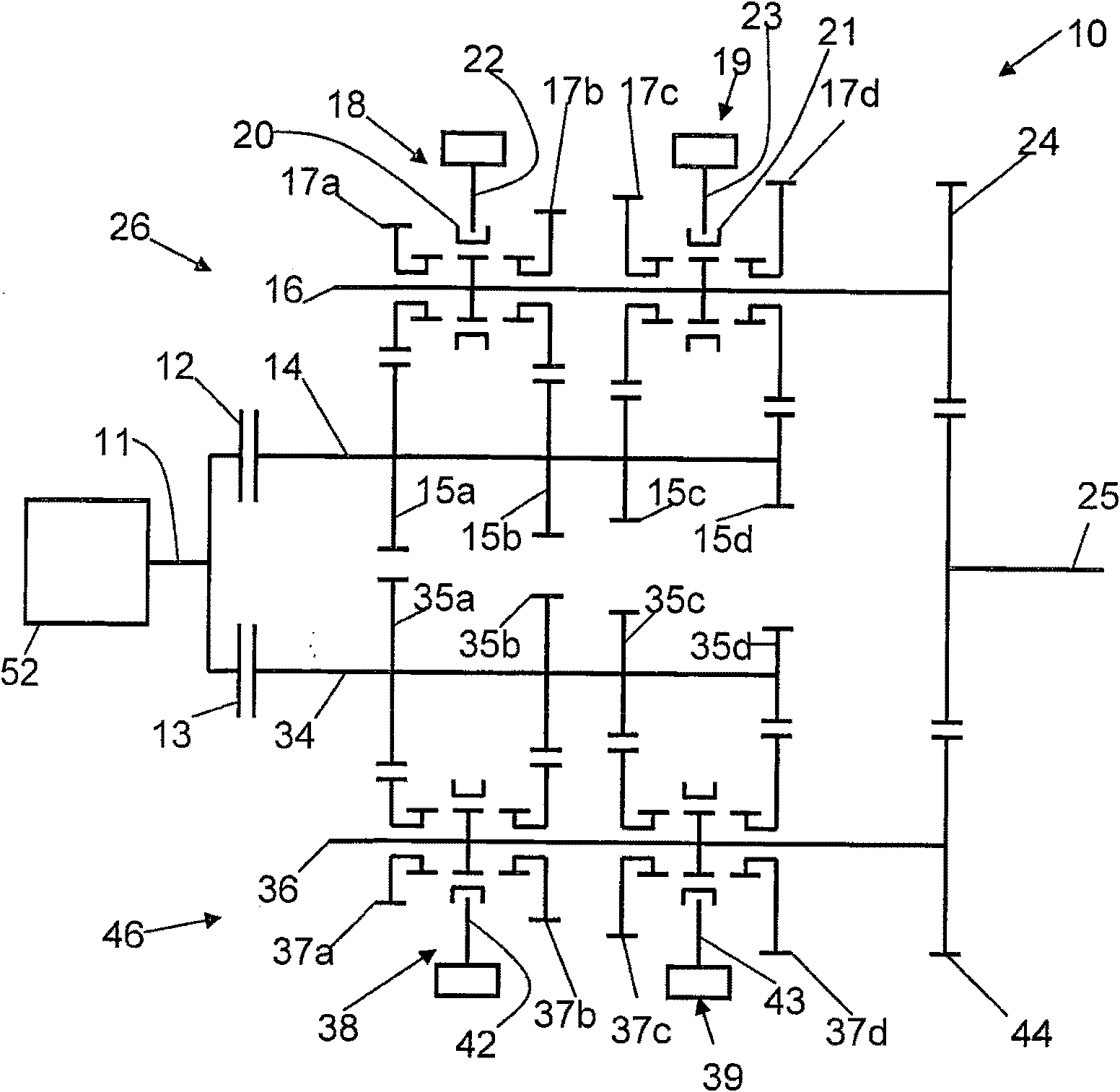

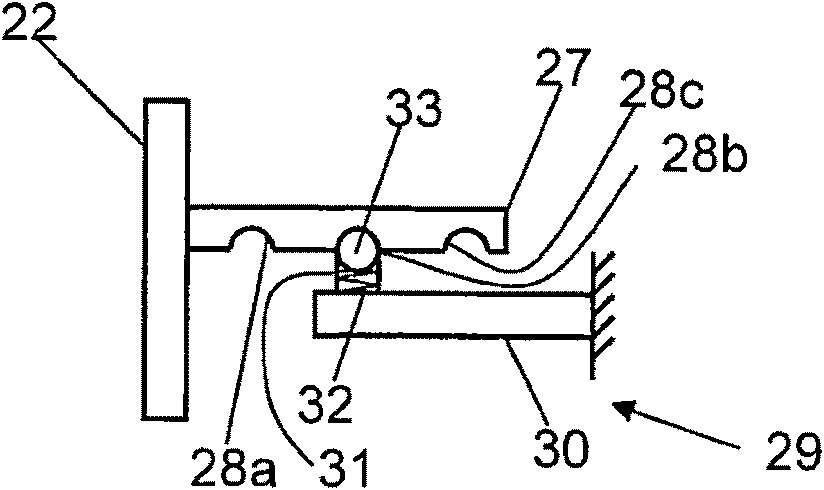

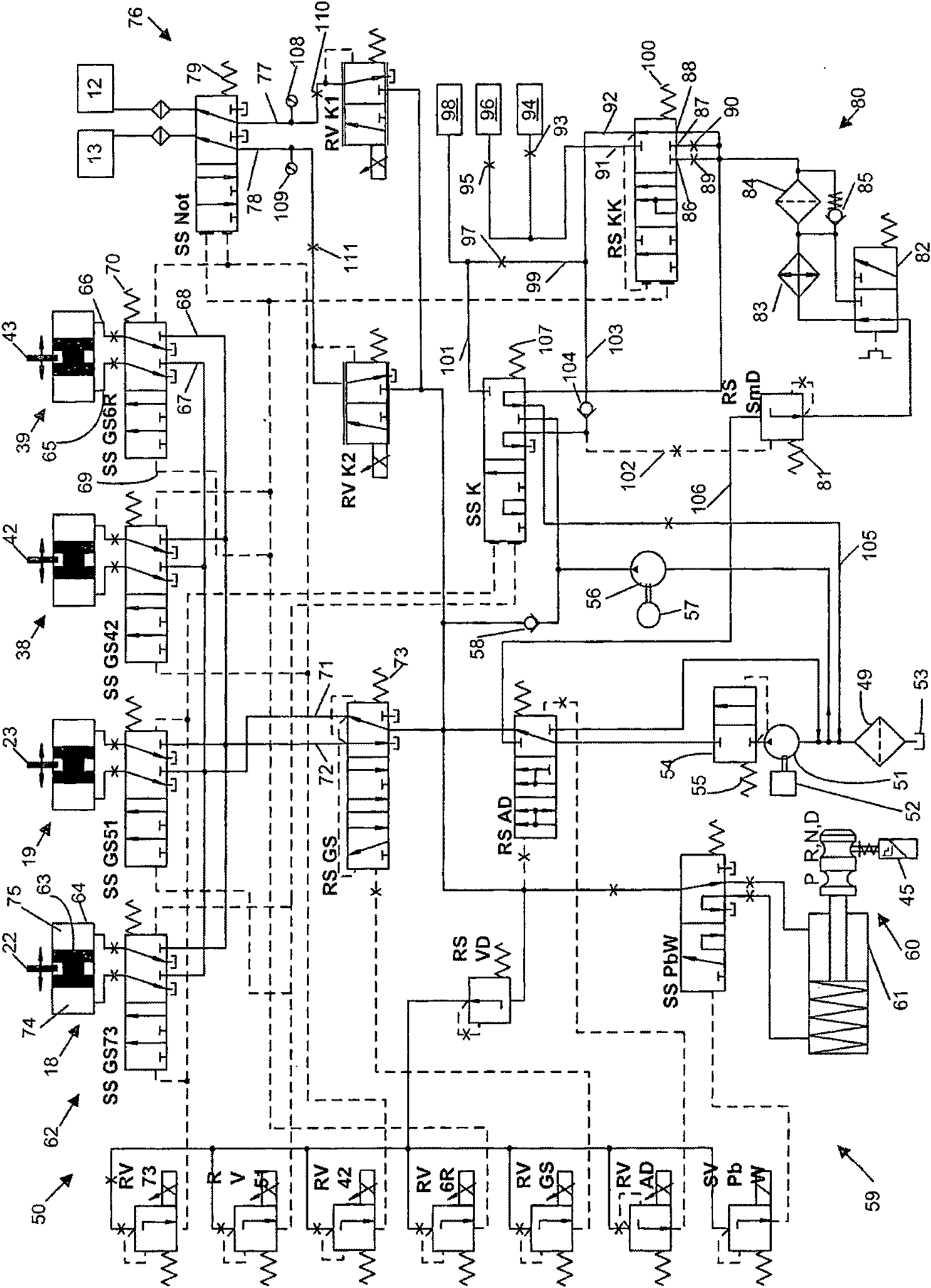

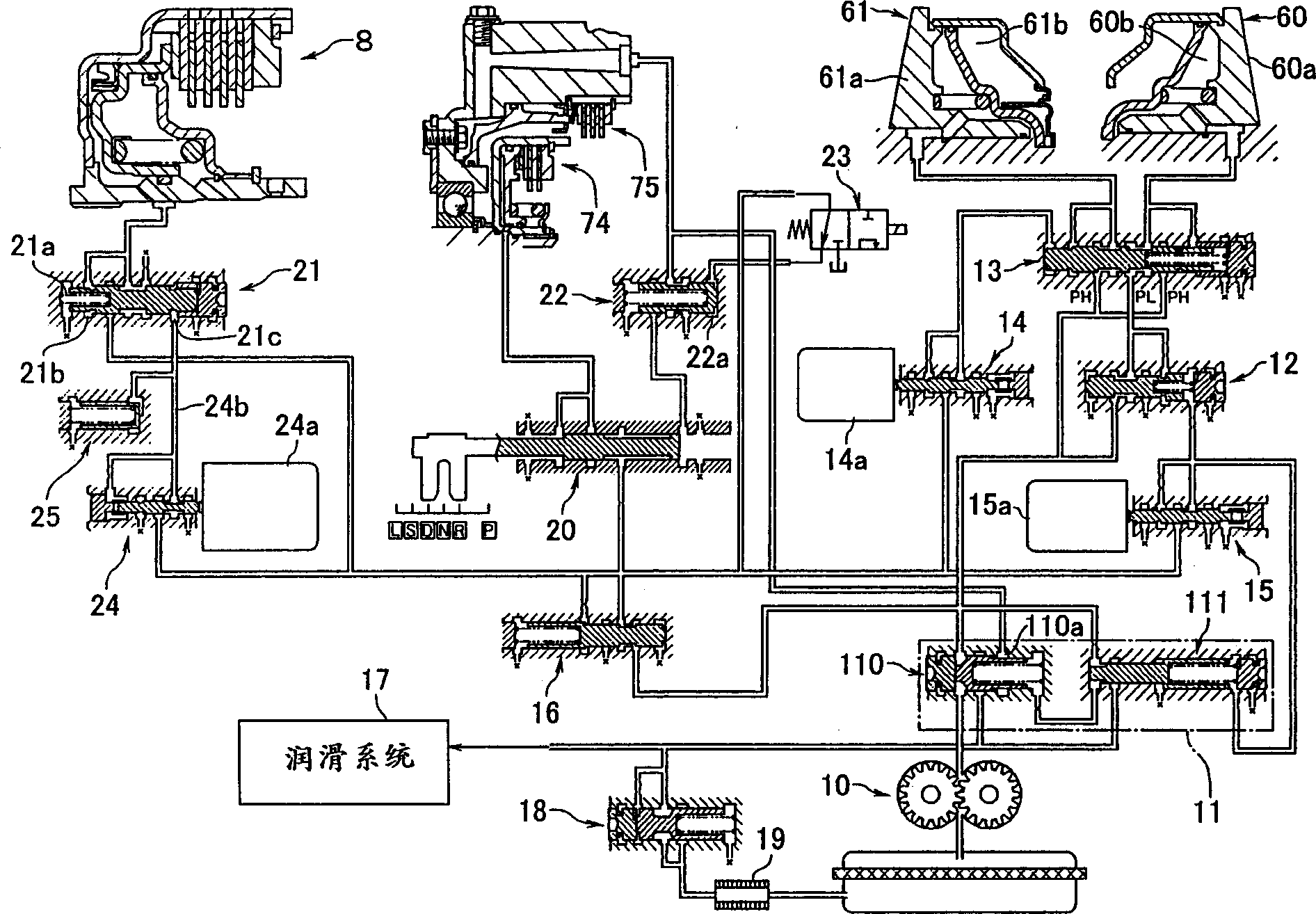

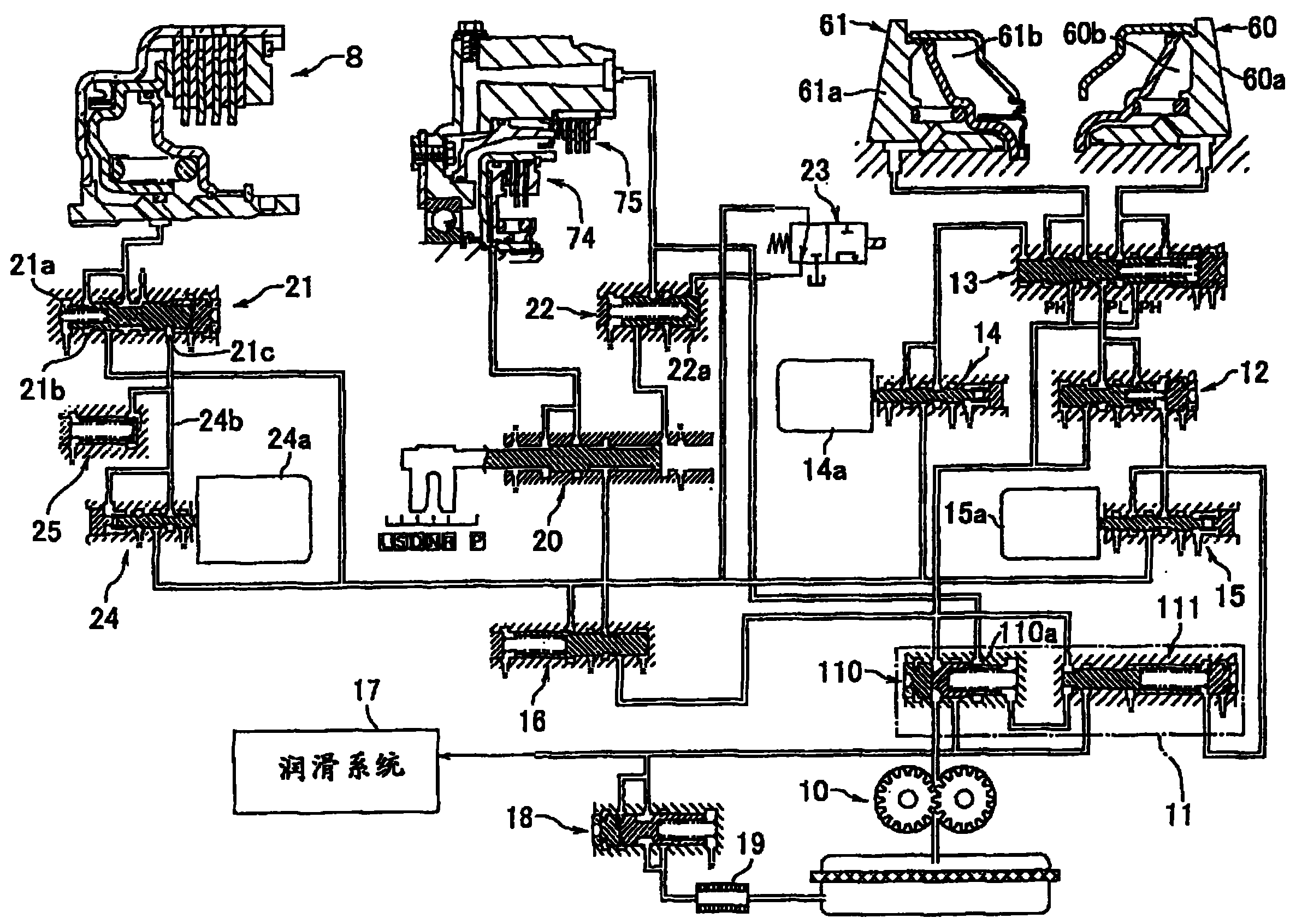

Control device for automatic gear transmission

InactiveCN102292574AReliable lockingIncrease control pressureGearing controlAutomatic transmissionEngineering

The invention relates to a control device for an automated geared transmission, in particular a dual clutch transmission. In such transmissions, two gears of a partial transmission must not be simultaneously engaged because the transmission would be blocked such that the motor vehicle could no longer be kept under control while driving, and the transmission would be damaged. The aim of the invention is to design a control device for an automated geared transmission in which two gears of a partial transmission are prevented in a simple manner from being simultaneously engaged. Said aim is achieved by providing the gear actuation system (62) with a first and a second gear slide (SS GS73, SS GS51) which allow a shifting mechanism (18, 19) to be selected. A second gear control pressure of the second gear slide (SS GS51) counteracts the first gear control pressure on the first gear slide (SS GS73) such that the first gear slide (SS GS73) can be blocked using the second control pressure.

Owner:DAIMLER AG

Solenoid operated fluid control valve

ActiveUS8387644B2Improve liquidityIncrease control pressureOperating means/releasing devices for valvesServomotor componentsSpool valveFluid control

Owner:FLEXTRONICS AUTOMOTIVE USA

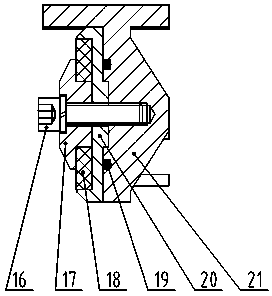

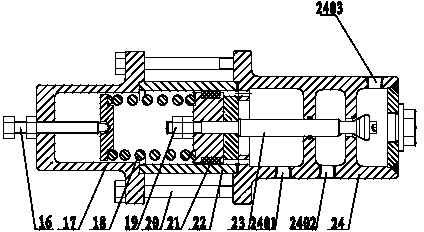

Axial-flow-type switch valve

InactiveCN103968092ASimple structureReasonable designOperating means/releasing devices for valvesLift valveEngineeringElastic matching

The invention discloses an axial-flow-type switch valve, and belongs to the technical field of valves. The axial-flow-type switch valve comprises a first flange connecting sleeve, an executing mechanism piston cylinder and a second flange connecting sleeve which are mutually connected. A piston-type driving mechanism is arranged in the executing mechanism piston cylinder, the piston-type driving mechanism comprises a valve element of a cylindrical structure and a piston connected with the outer side of the valve element in a sleeved mode, a piston is in elastic matching with a spring pad arranged in the executing mechanism piston cylinder, one end of the valve element is in sealing matching with the first flange connecting sleeve, and the other end of the valve element is matched with a valve seat arranged in the second flange connecting sleeve. According to the axial-flow-type switch valve, the mode that an executing mechanism, the piston, the valve element, the valve seat and the flange connecting sleeves are coaxially combined is adopted, the valve structure design concept that in the prior art, an executing mechanism can only be arranged outside a valve body is broken through, and the defects that an existing piston-type executing mechanism is large in friction force, low in response speed, low in adjusting precision and large in leakage rate are overcome.

Owner:HANGZHOU LIANGGONG VALVES

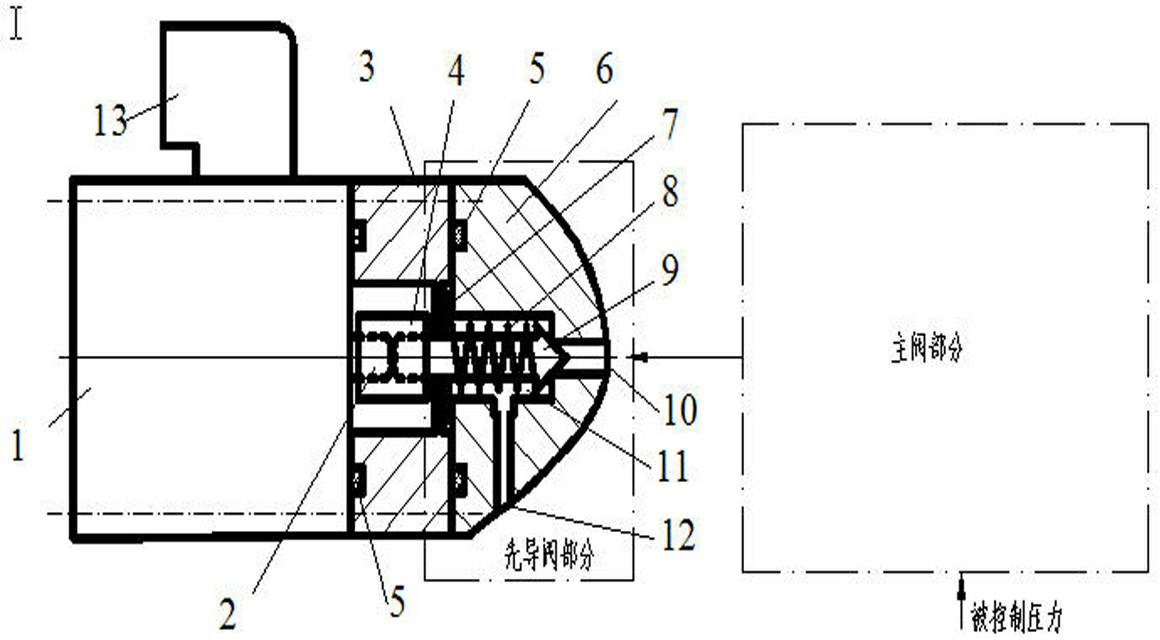

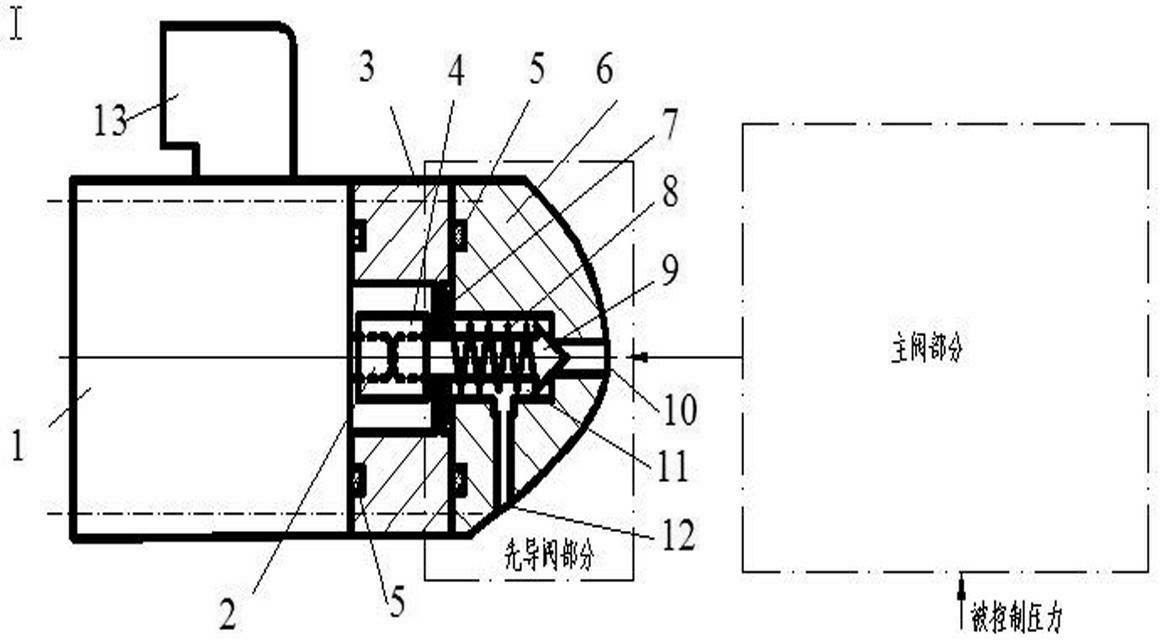

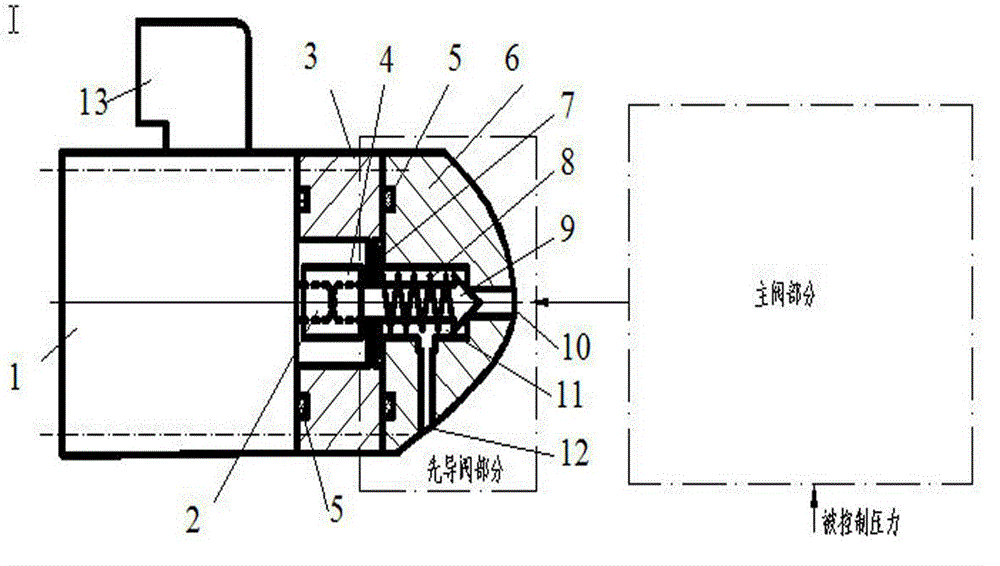

Electro-hydraulic proportional relief valve

InactiveCN102588372AThrust offsetReduce minimum control pressureServomotor componentsElectro hydraulicEngineering

An electro-hydraulic proportional relief valve is provided with a bidirectional proportional electromagnet. An output rod of the proportional electromagnet is axially rigidly connected with a pilot valve spool through a connector so as to drive the pilot valve spool bidirectionally. A spring of the electro-hydraulic proportional relief valve is compressed when no current is led into a coil of the bidirectional proportional electromagnet, the sum of the pretension force generated from the spring and the maximum output force of the proportional electromagnet in the same direction corresponds to the maximum control pressure controlled by the electro-hydraulic proportional relief valve, and the maximum control pressure is higher than control pressure generated when only thrust of the bidirectional proportional electromagnet acts individually. Accordingly, the maximum control pressure of the electro-hydraulic proportional relief valve is increased.

Owner:TAIYUAN UNIV OF TECH

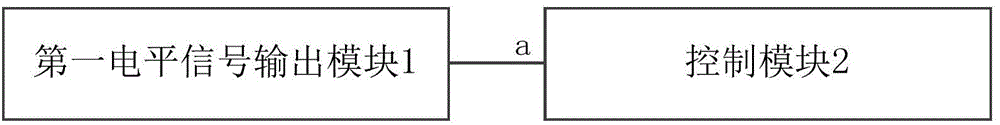

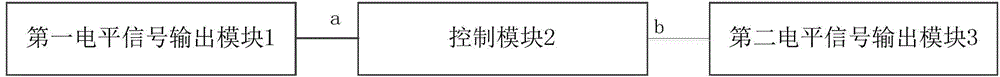

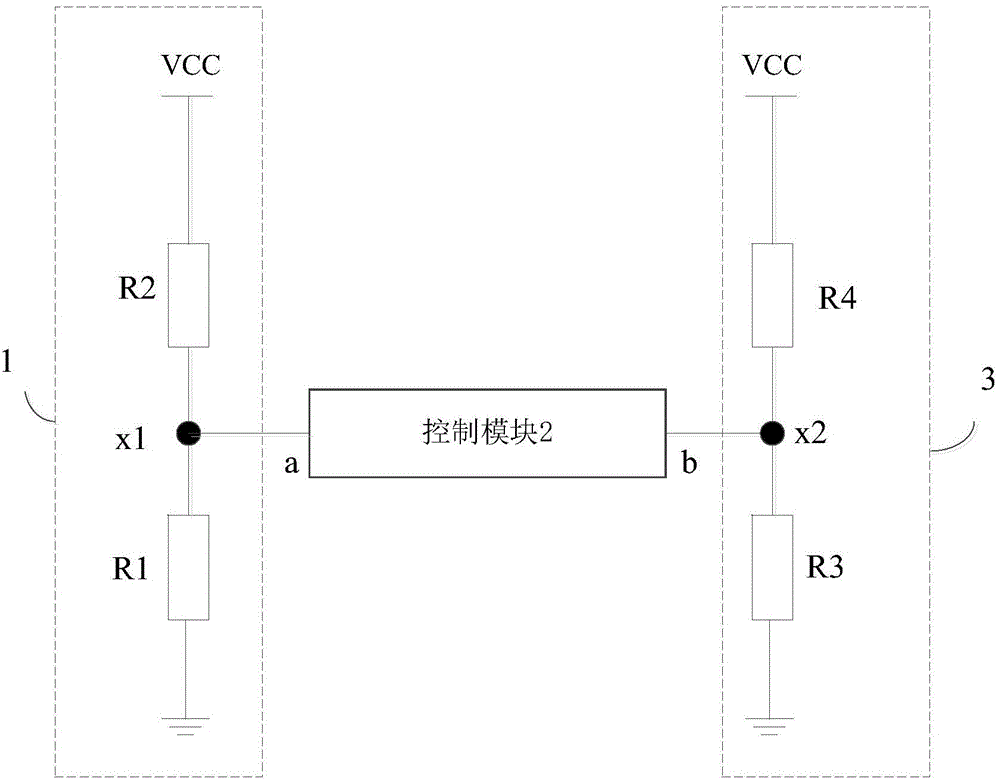

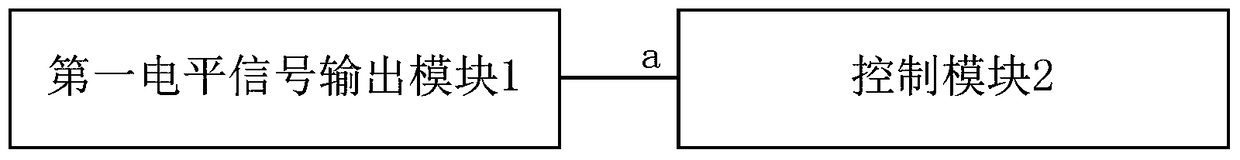

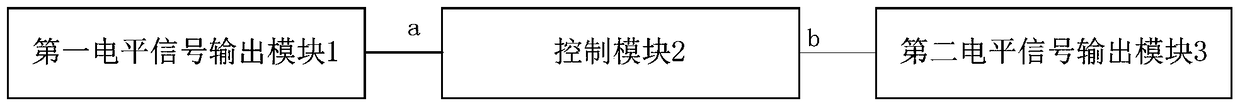

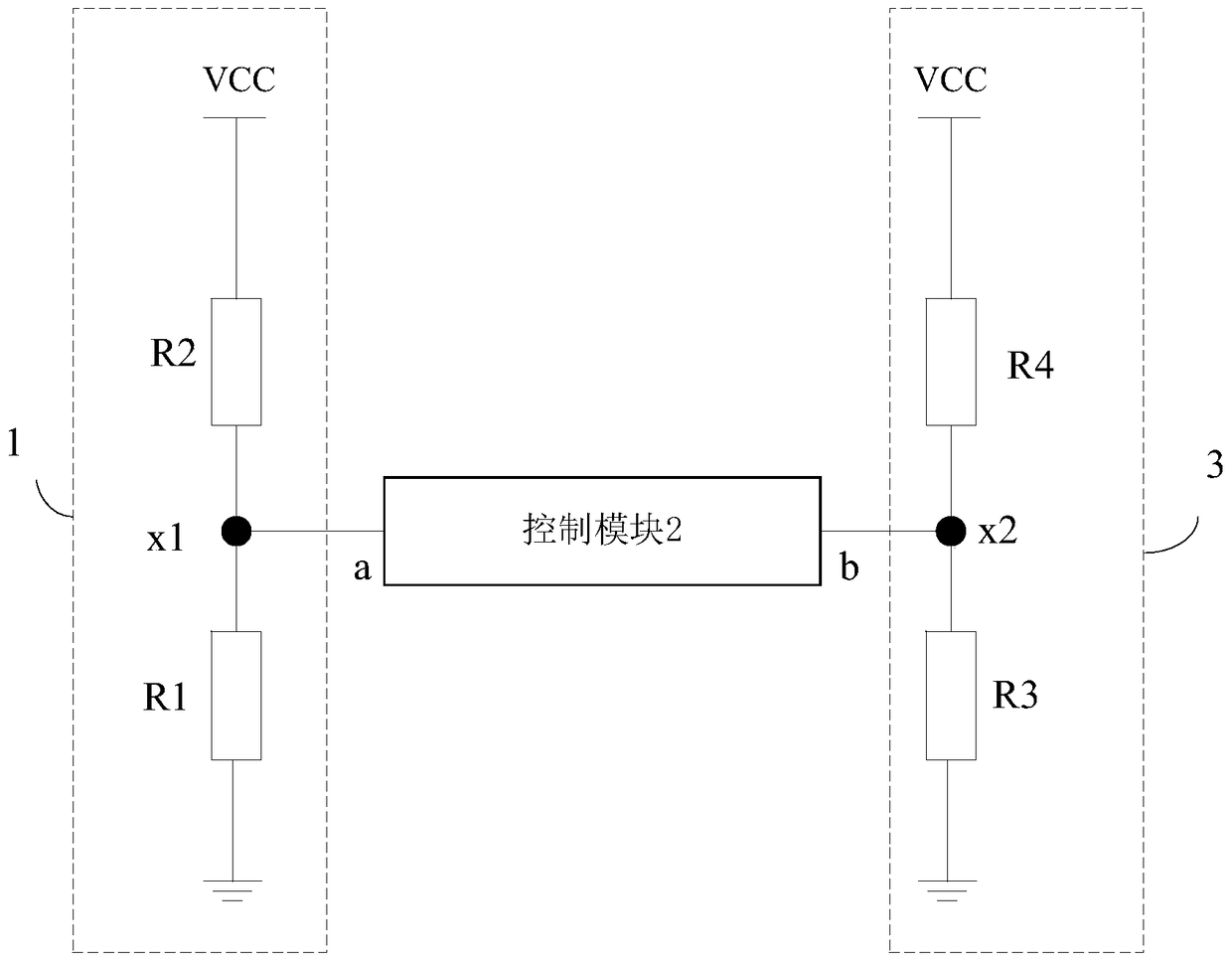

Device and method for controlling electric cooker

ActiveCN105361645AIncrease power modulation ratioSolve after-sales problemsPressure-cookersWarming devicesElectricityComputer module

The invention discloses a device for controlling an electric cooker. The device comprises a first level signal outputting module and a control module, wherein the first level signal outputting module is used for outputting a first level signal; a first port of the control module is connected with the first level signal outputting module; the control module judges whether voltage of a power supply connected with the electric cooker is smaller than preset voltage or not according to the first level signal; and if the voltage of the power supply is smaller than the preset voltage, then the power ratio of the electric cooker can be increased. Accordingly, when a cooking effect is poor, the power ratio of the electric cooker can be increased by the device for controlling the electric cooker, the after-sales problems due to poor cooking effect caused by the using environment can be solved, repairing cost is reduced, and producing and manufacturing costs cannot be increased. The invention also discloses a method for controlling the electric cooker.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

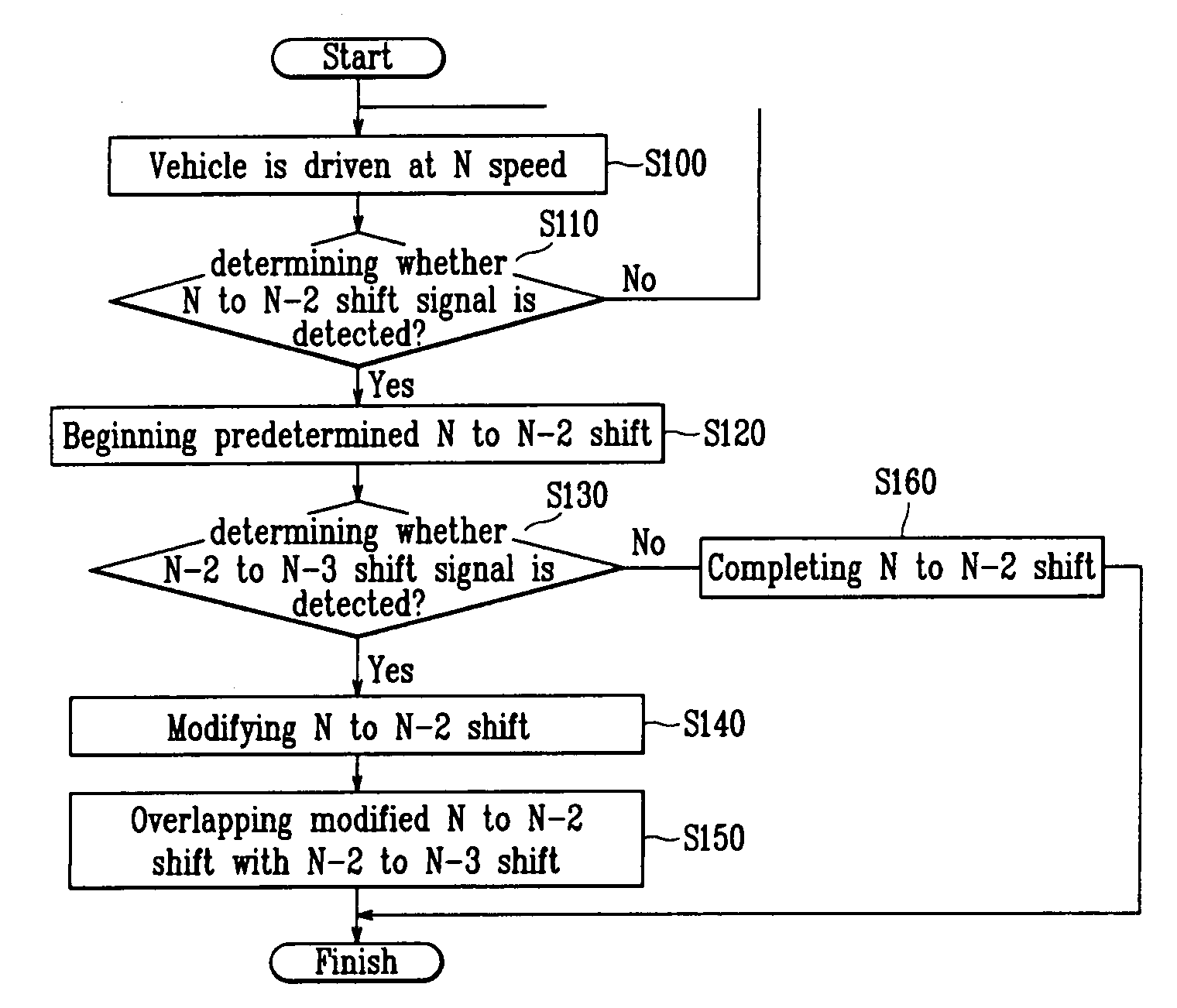

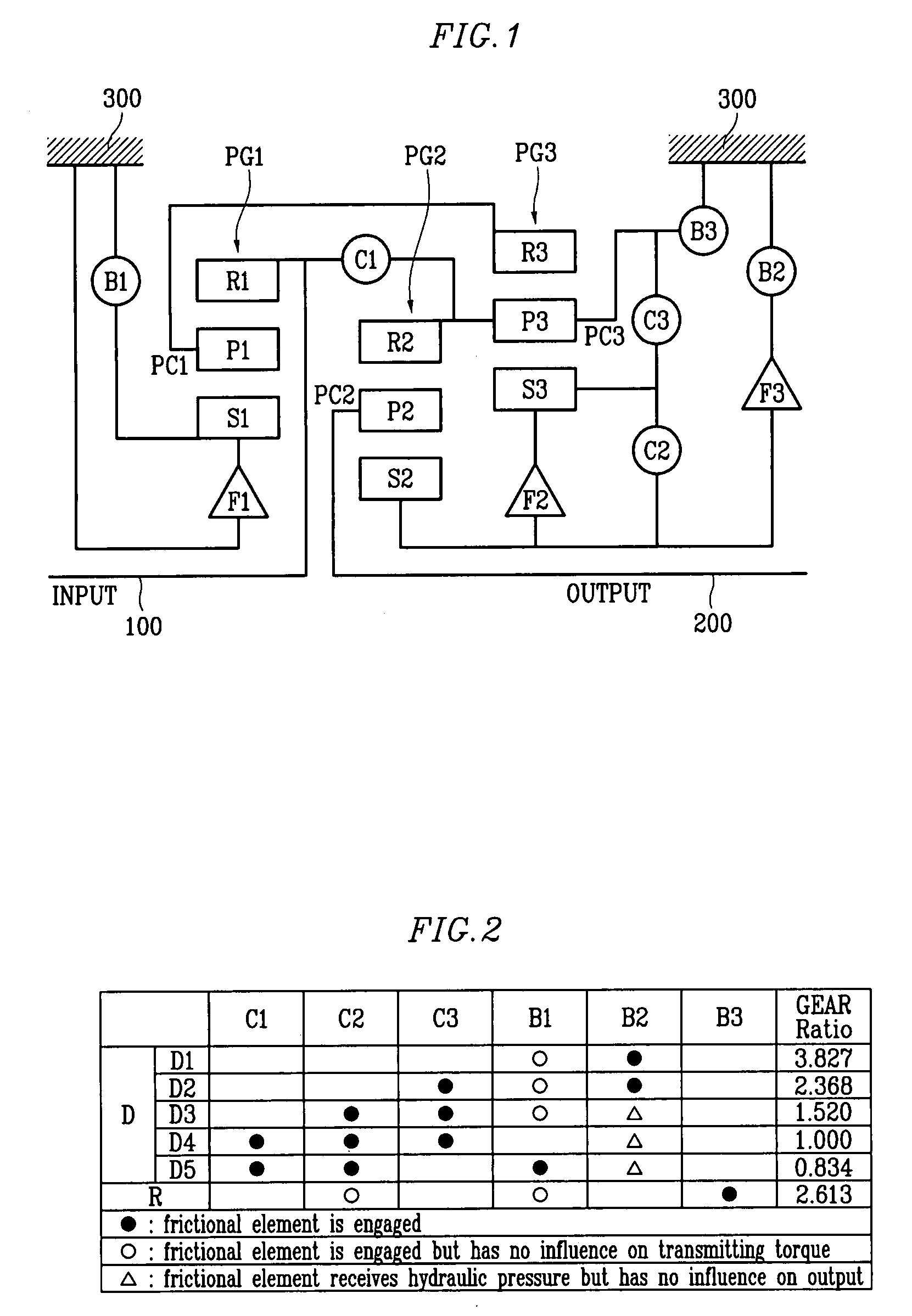

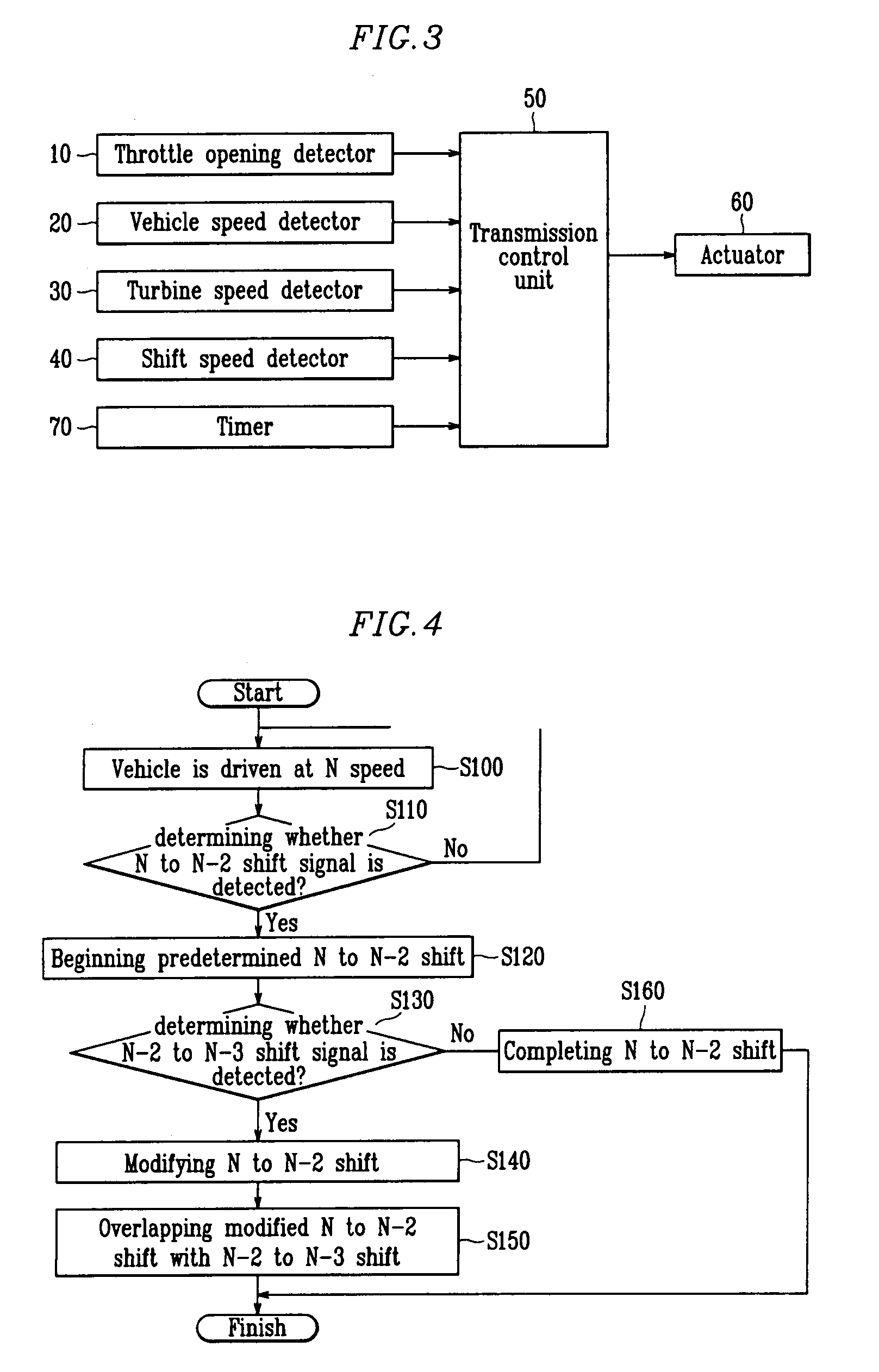

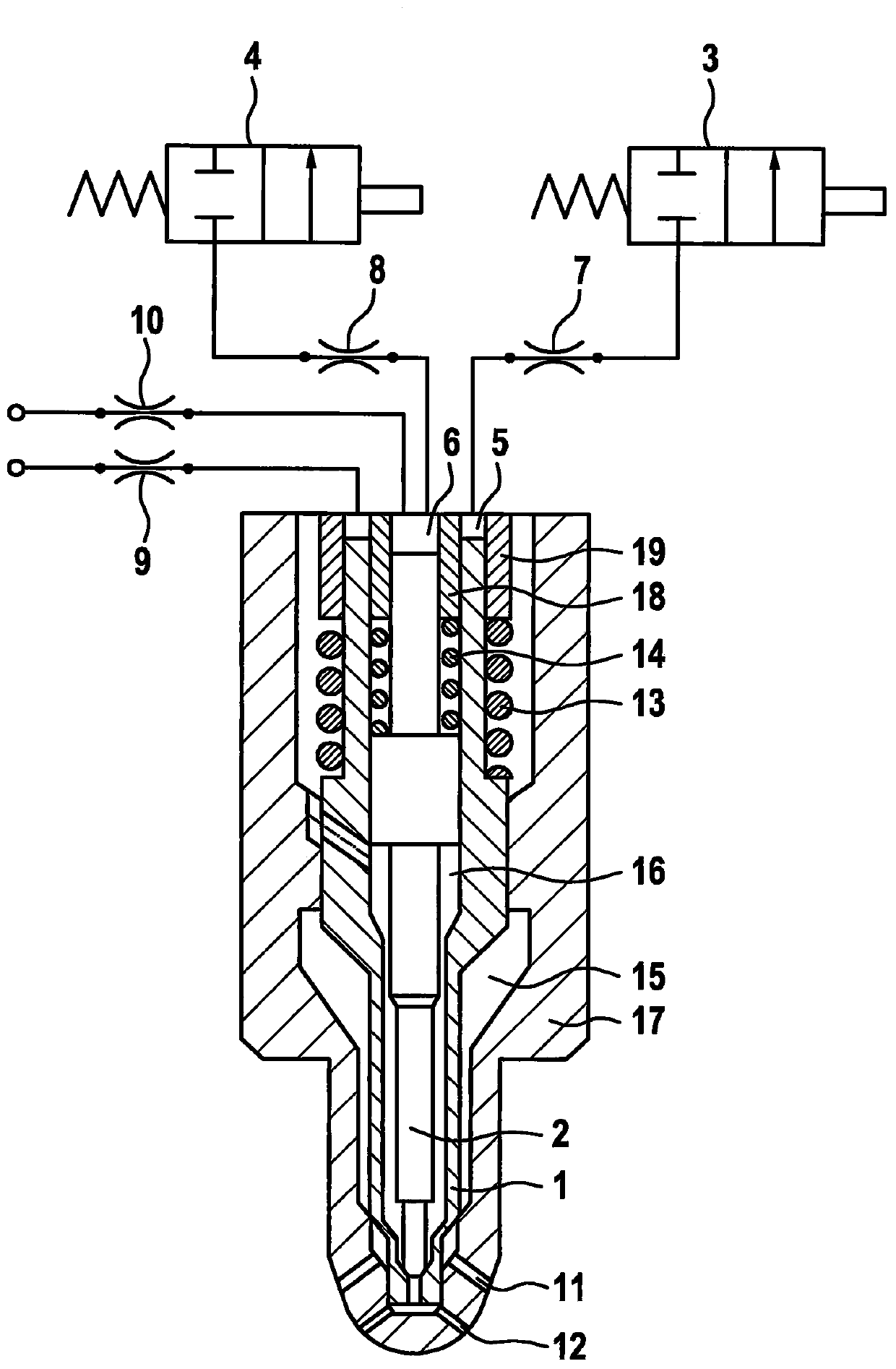

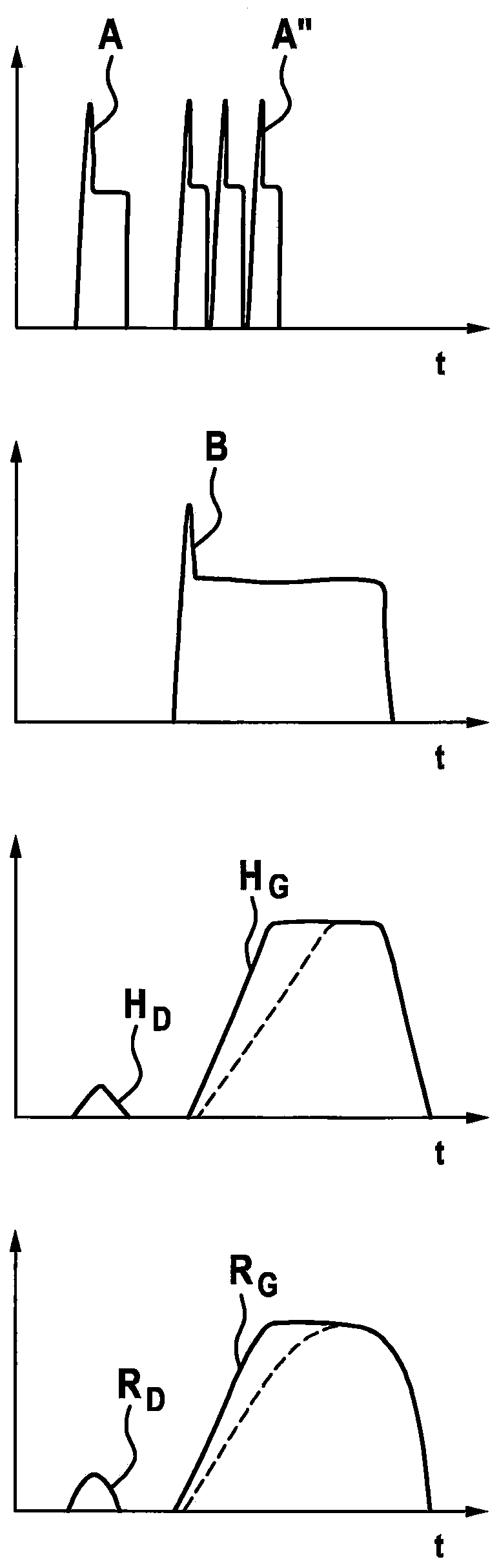

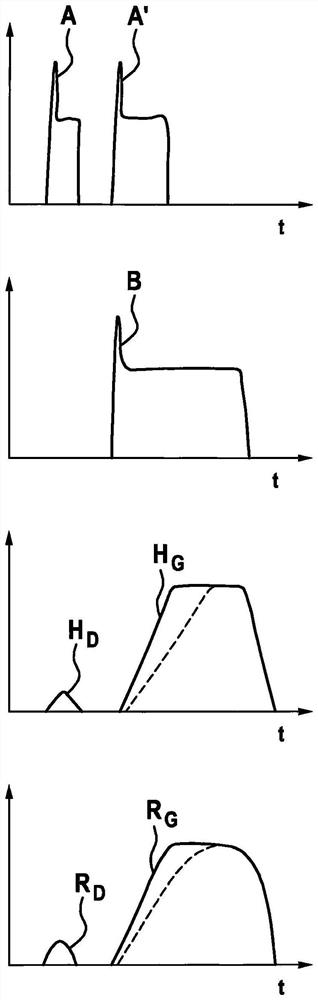

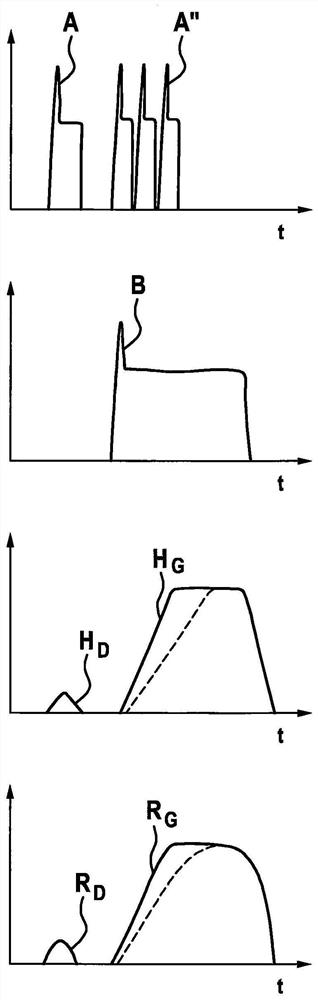

Method for controlling shift during shift of automatic transmission

InactiveUS7769515B2Increase control pressureLow control pressureDigital data processing detailsGearingAutomatic transmissionEngineering

A method for controlling a shift during a shift of an automatic transmission controls to complete an N to N-2 shift and an N-2 to N-3 shift simultaneously such that the shift during a shift is smoothly performed when the N-2 to N-3 shift where one frictional element is released is required to be performed during the N to N-2 shift where another frictional element is released and the other frictional element is engaged. A method for controlling a shift during a shift of an automatic transmission may overlap an N to N-2 shift where a first frictional element is engaged and a second frictional element is released with an N-2 to N-3 shift where a third frictional element is released, wherein a release of the second frictional element begins after an engagement of the first frictional element begins, and a release of the third frictional element begins after an N-2 to N-3 shift signal is detected, wherein the engagement of the first frictional element and the release of the second and third frictional elements are simultaneously completed.

Owner:HYUNDAI MOTOR CO LTD

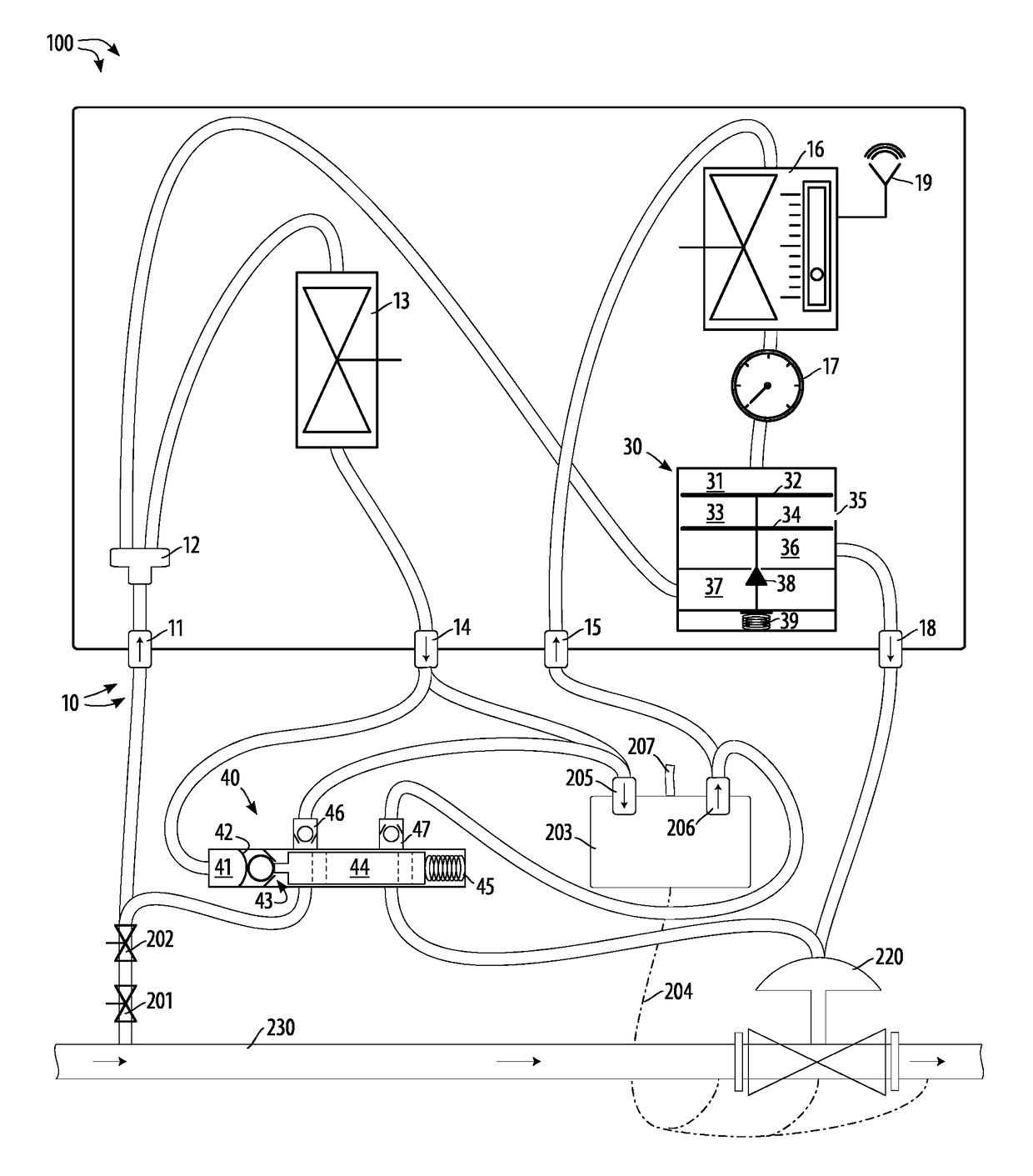

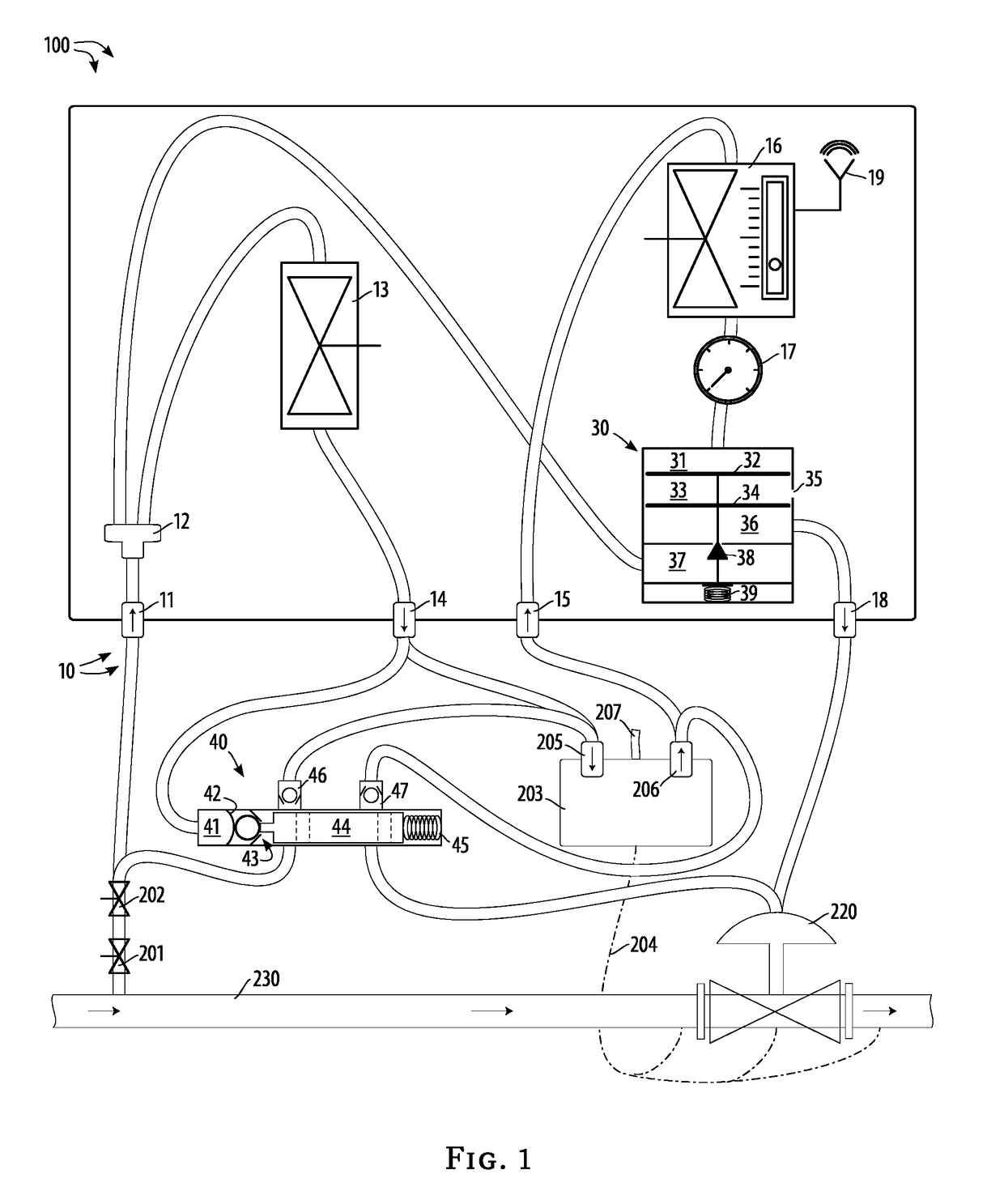

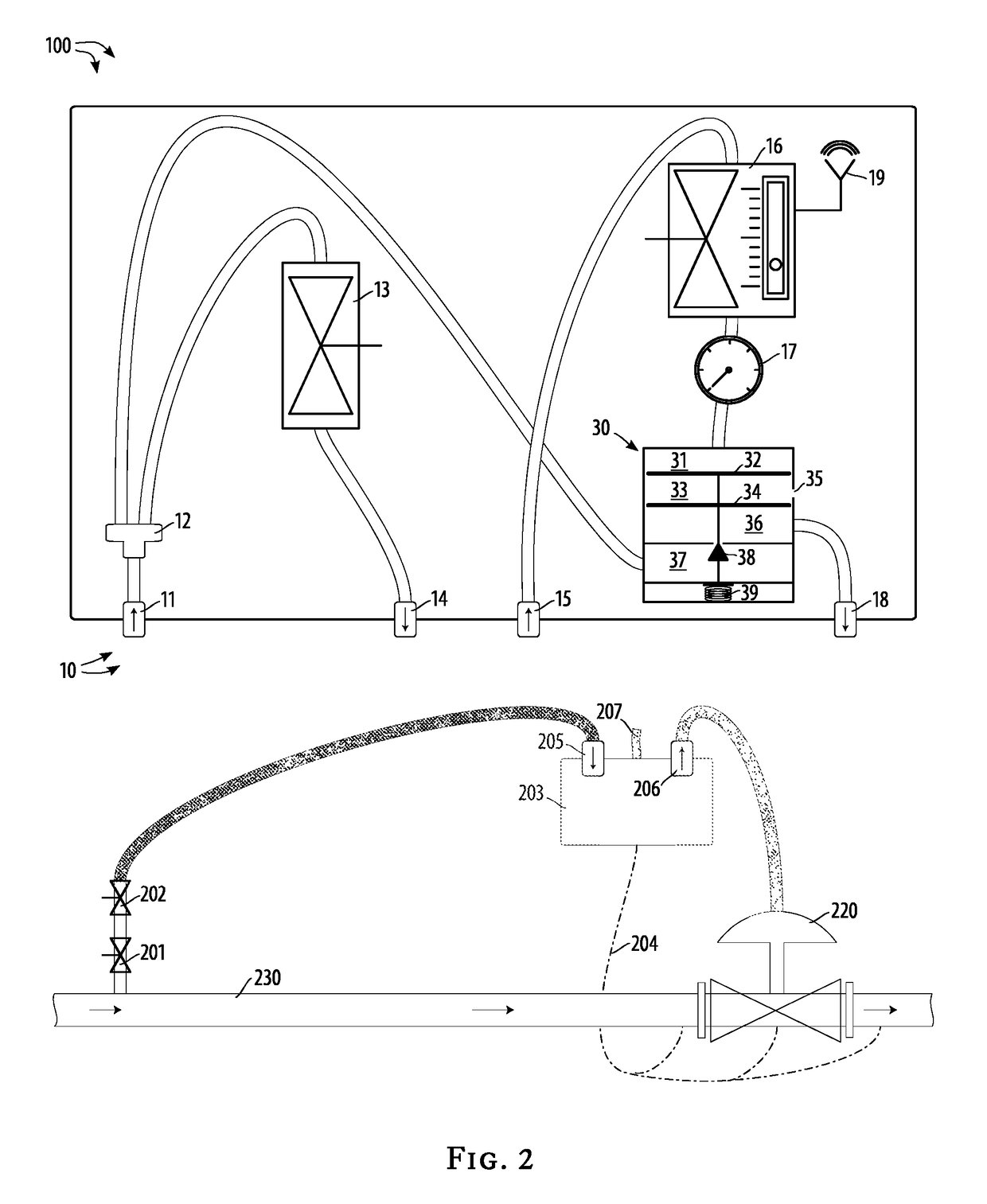

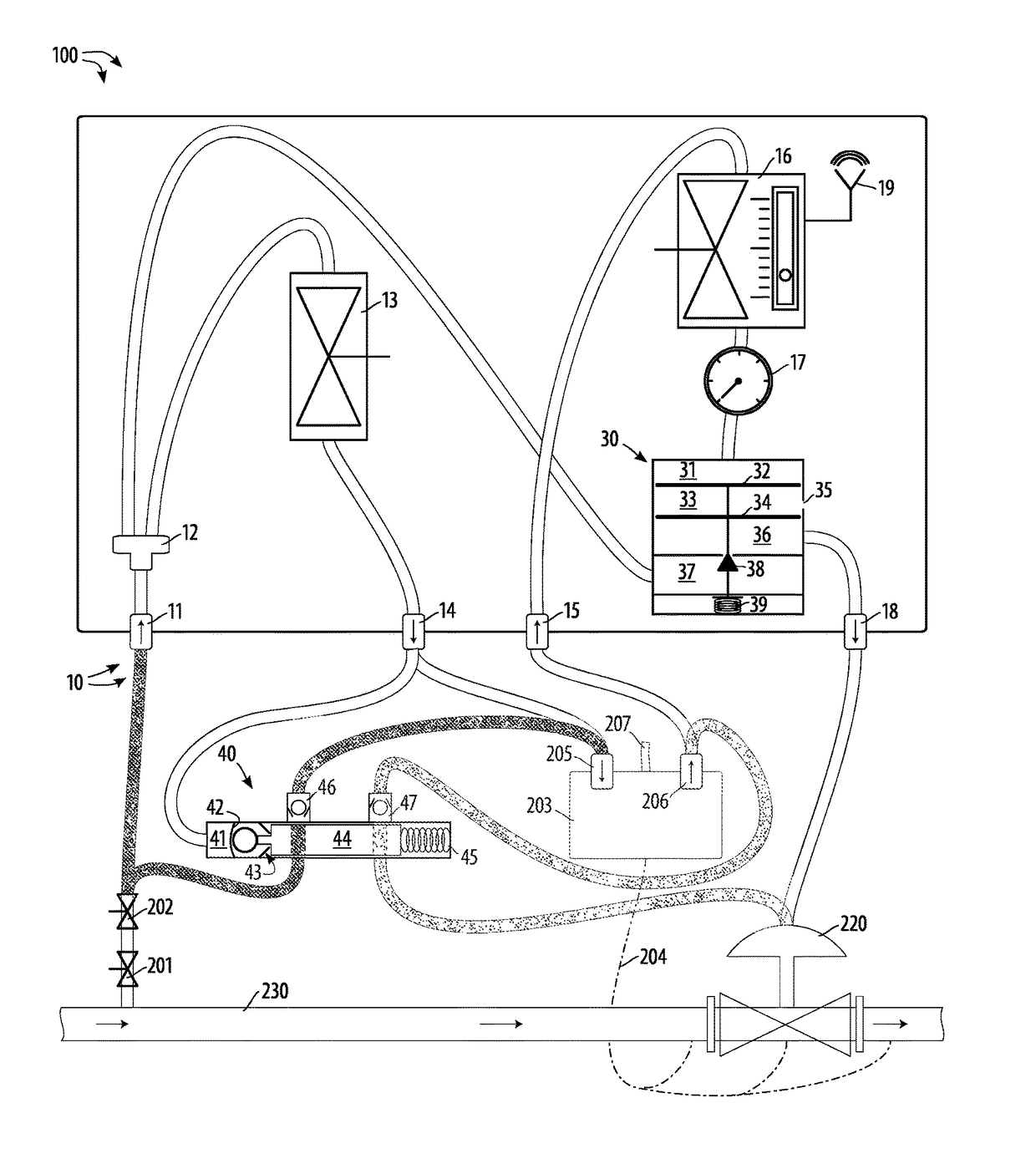

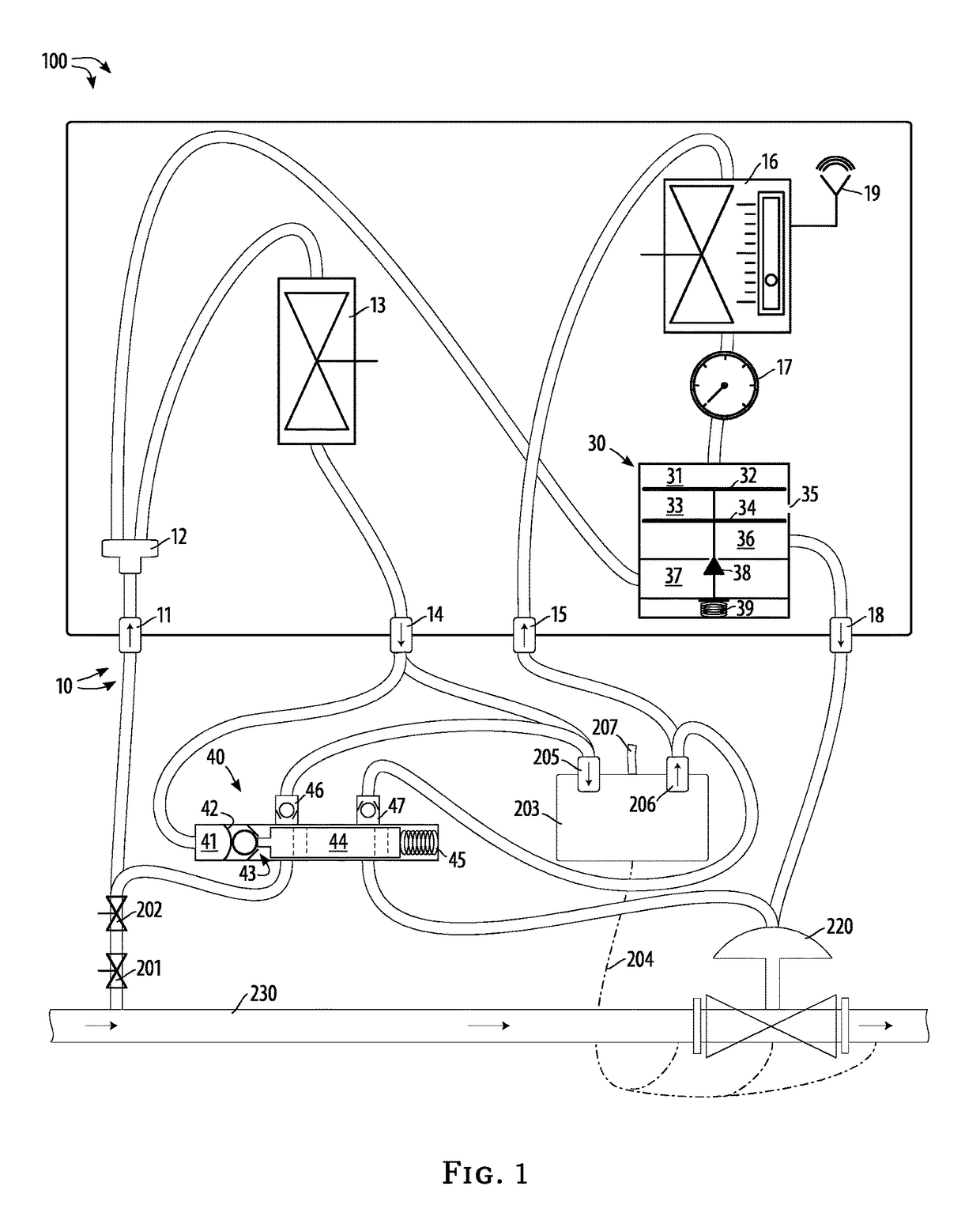

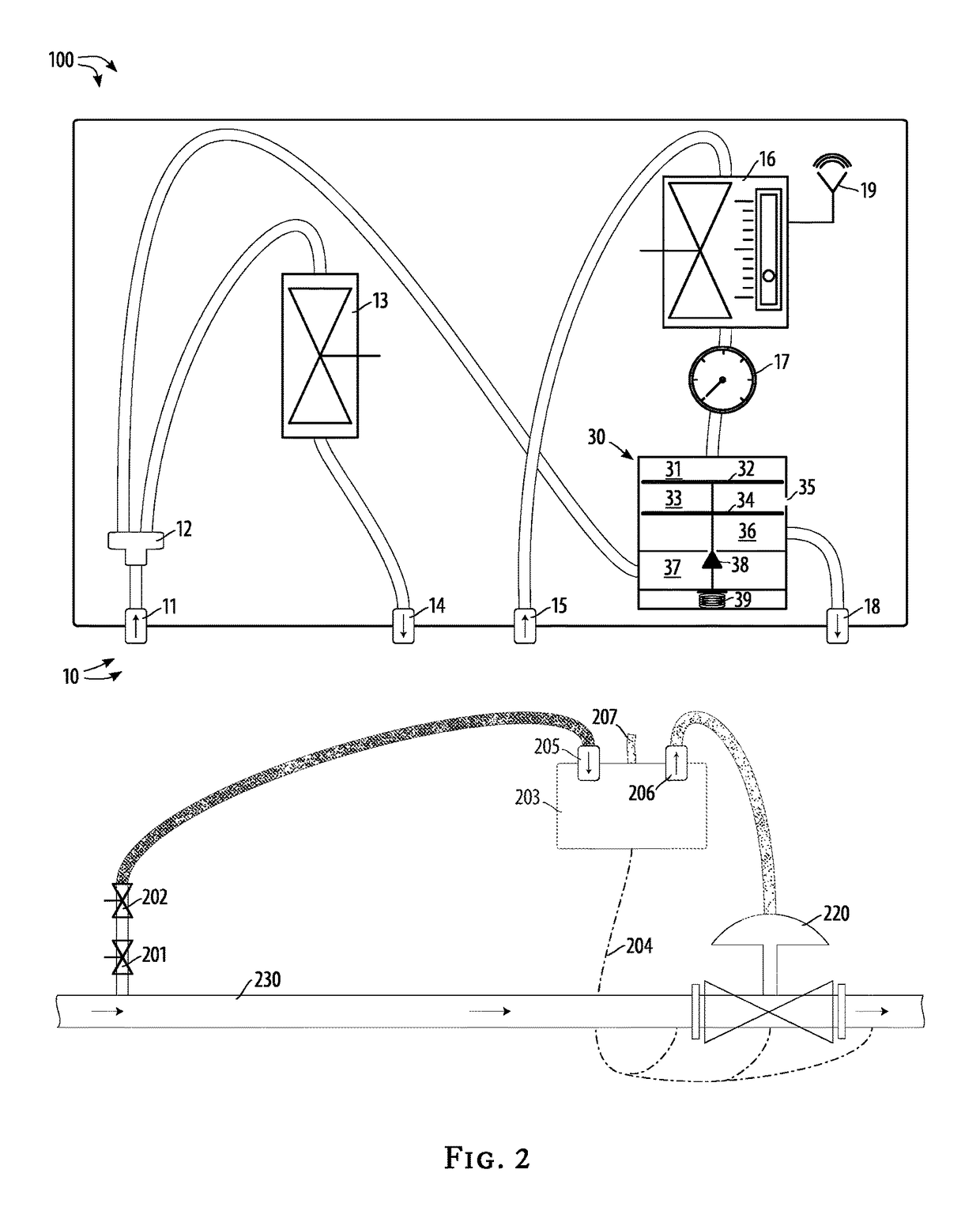

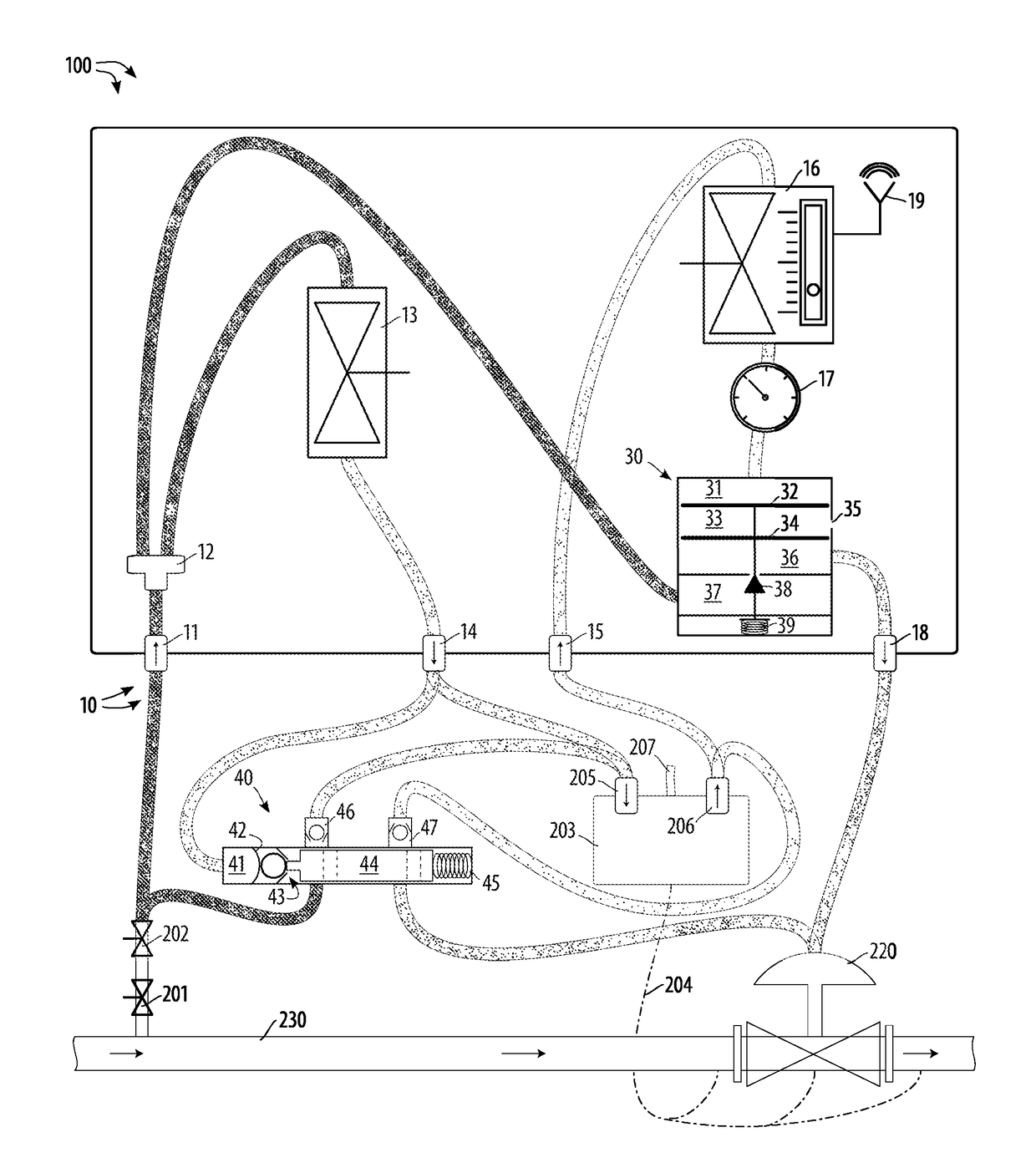

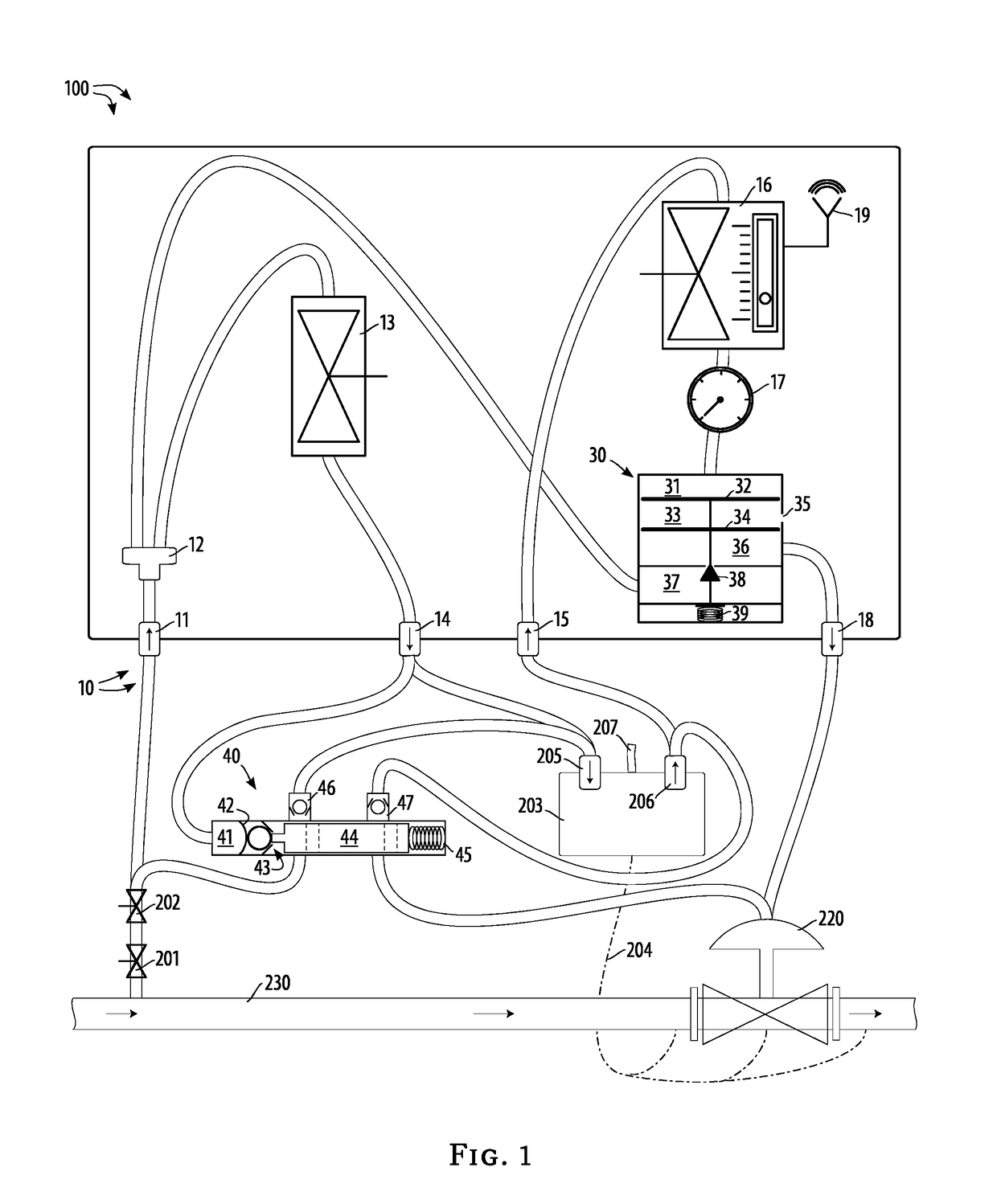

Pipeline-waste-gas reducer apparatus

ActiveUS9695988B2Reduce pressureReduce gas volumeFluid pressure control using electric meansPipeline systemsReducerEngineering

A pipeline-waste-gas reducer apparatus to reduce the amount of gas wasted by existing high-pressure pipelines having existing pipeline controllers and existing actuator-based control valves, by reducing the pressure of gas sent to existing pipeline controllers by a determined factor, consequently reducing the amount of gas wasted by the controllers, and then increasing control pressure returned by the controllers by the same factor, ensuring that the proper control pressure is sent to the existing actuator-based control valves.

Owner:DEVILLE CHAD +1

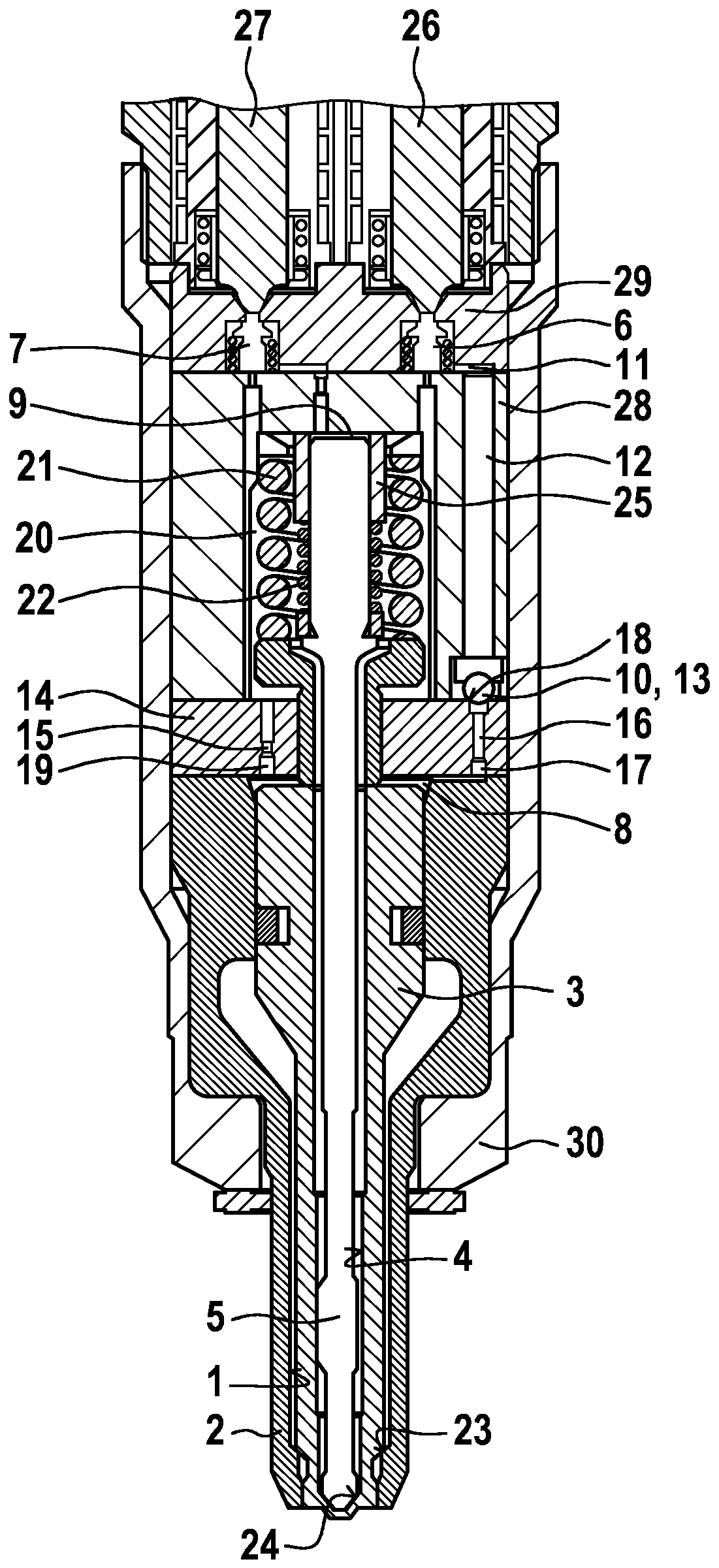

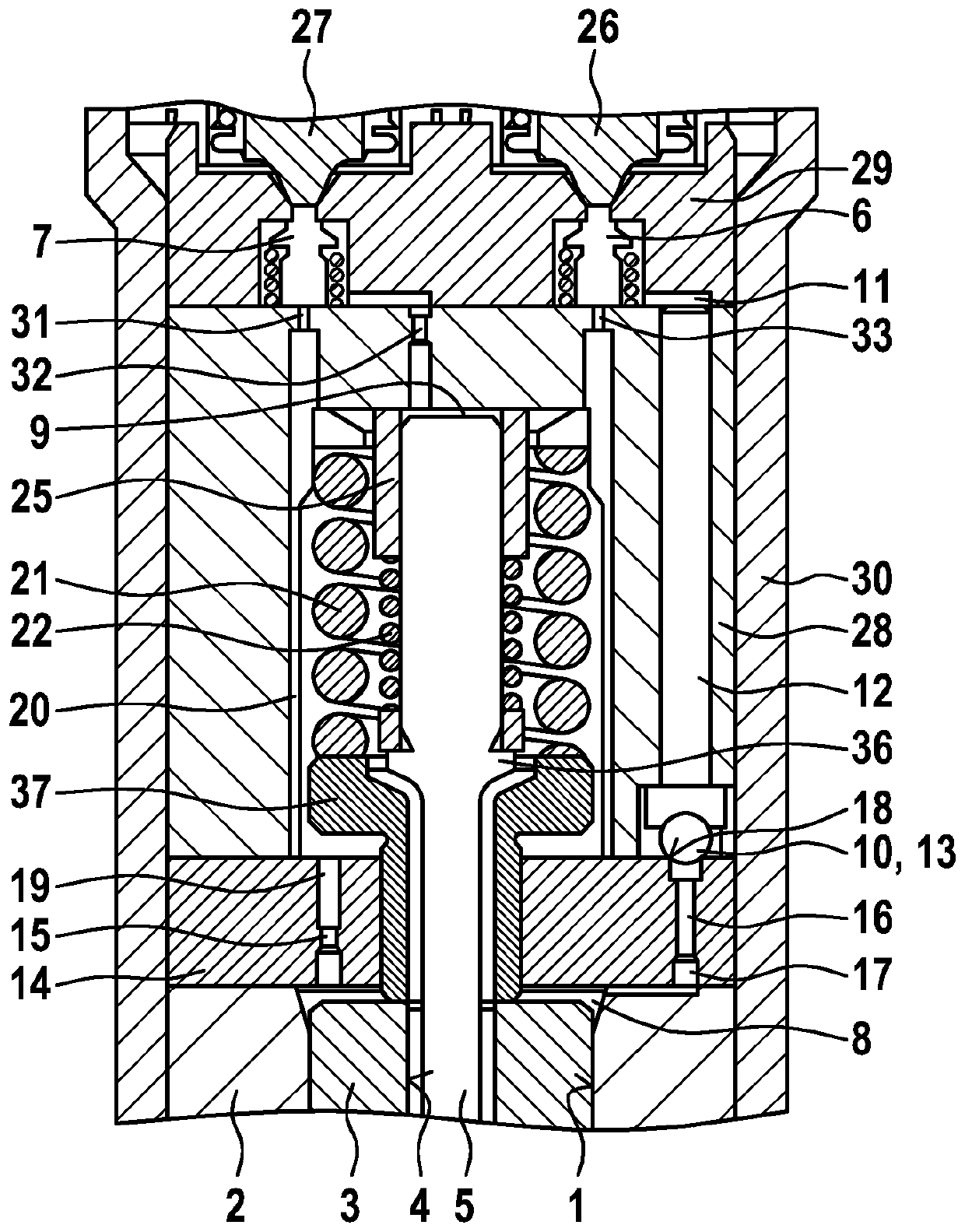

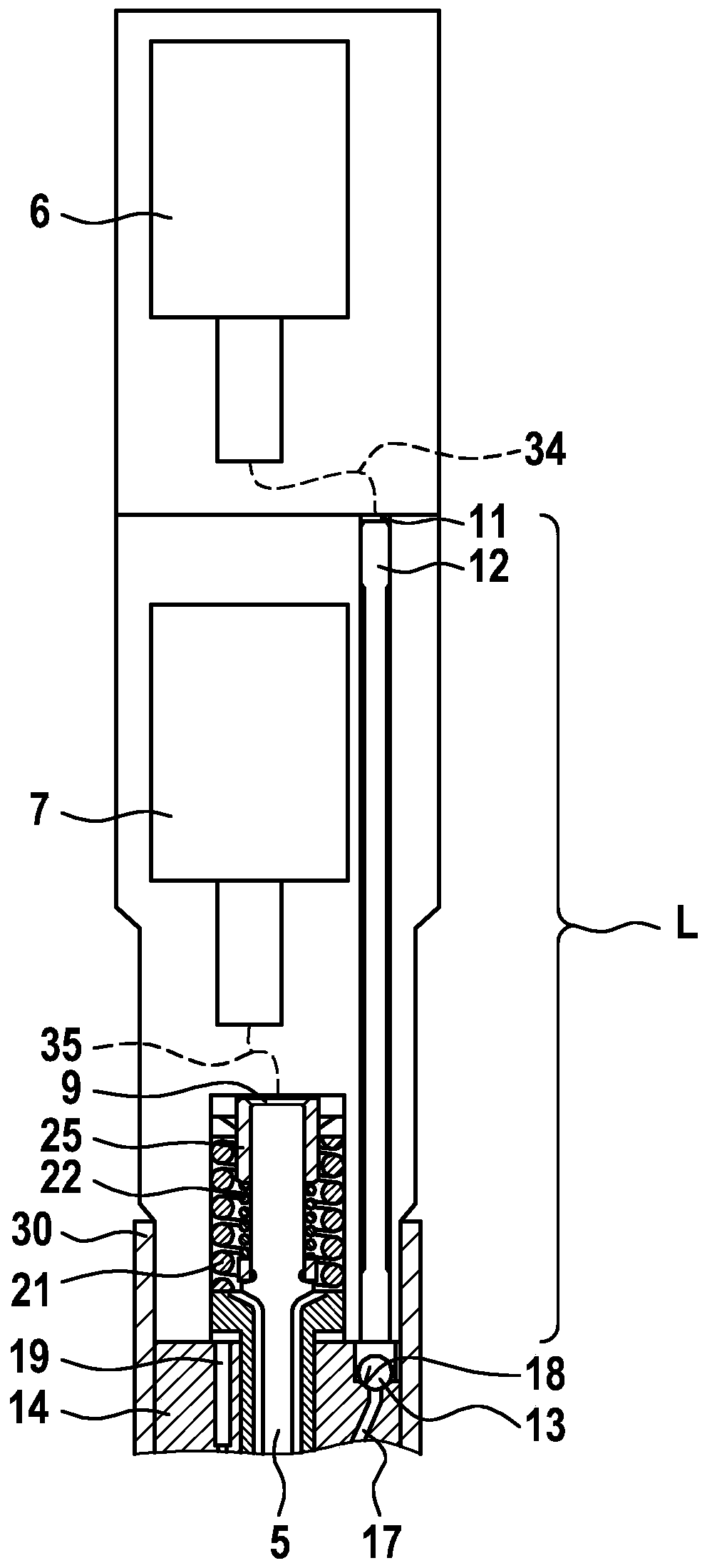

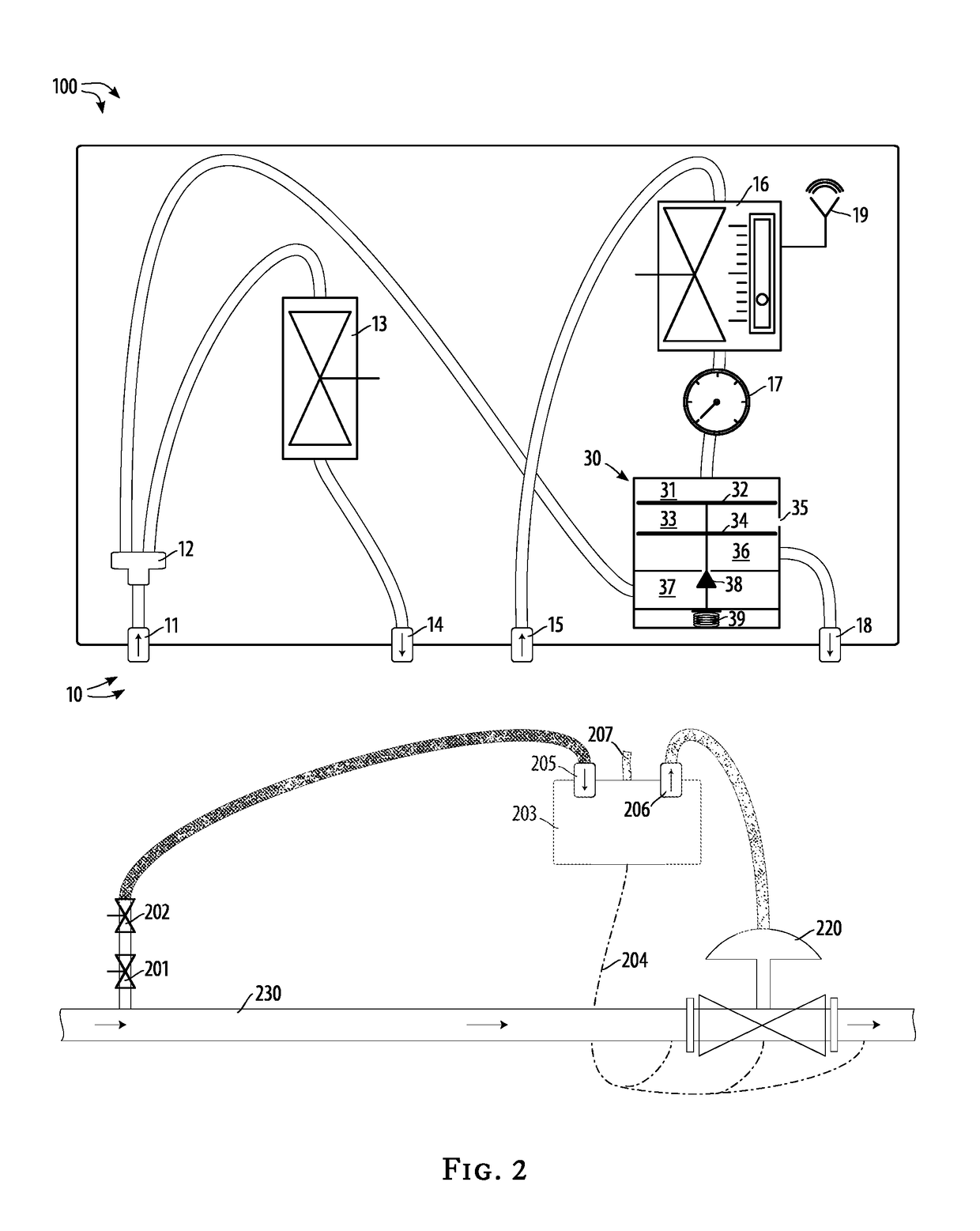

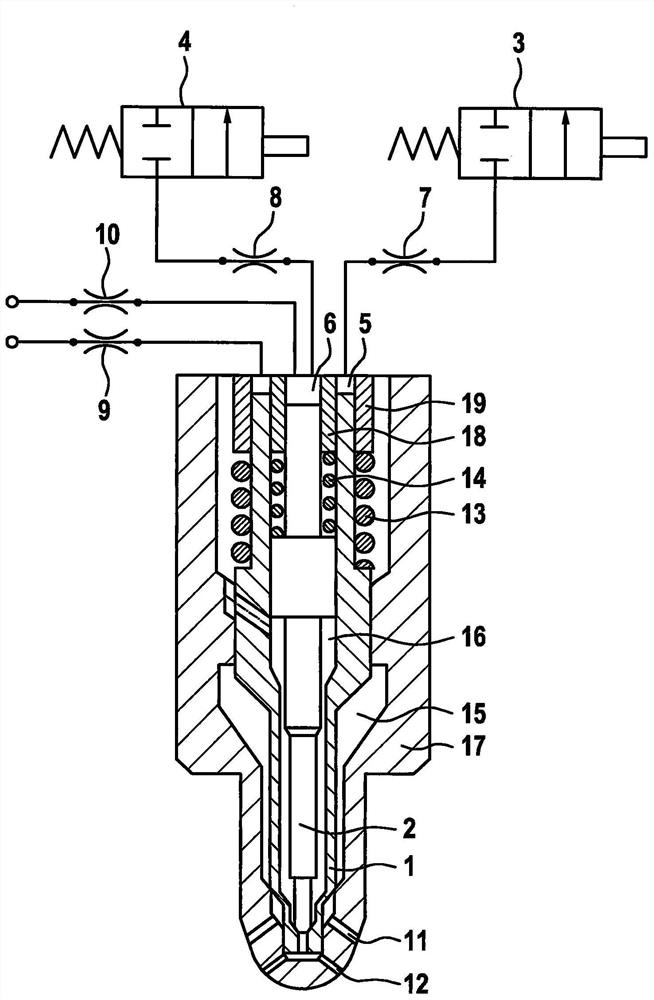

Fuel injection valve for injecting a gaseous and/or liquid fuel

ActiveCN109923296AOpen quicklyFast closing behaviorInternal combustion piston enginesFuel supply apparatusCombustion chamberReciprocating motion

The invention relates to a fuel injection valve for injecting a gaseous and / or a liquid fuel into a combustion chamber of an internal combustion engine, comprising a first valve element (3) accommodated such that the frist valve element can perform reciprocating movements in a central bore (1) of a nozzle body (2), and a second valve element (5) accommodated such that the second valve element canperform reciprocating movements in a central bore (4) of the first valve element (3), and control valves (6, 7) for the hydraulic pilot control of the two valve elements (3, 5), wherein each valve element (3, 5) is assigned a control chamber (8, 9), which can be relieved via a control valve (6, 7). According to the invention, a further valve (10), which can be controlled hydraulically via the control valve (6), is arranged at least between a control chamber (8) and a control valve (6) used to relieve the control chamber (8).

Owner:ROBERT BOSCH GMBH

Pipeline-waste-gas reduction method

ActiveUS9689534B2Reduce the amount requiredReduce pressureOperating means/releasing devices for valvesFluid pressure control using electric meansEngineeringActuator

A pipeline-waste-gas reduction method to reduce the amount of gas wasted by existing high-pressure pipelines having existing pipeline controllers and existing actuator-based control valves, by reducing the pressure of gas sent to existing pipeline controllers by a determined factor, consequently reducing the amount of gas wasted by the controllers, and then increasing control pressure returned by the controllers by the same factor, ensuring that the proper control pressure is sent to the existing actuator-based control valves.

Owner:DEVILLE CHAD +1

Linear-stroke pneumatic actuator

InactiveCN102865402AReduce volumeReduce weightOperating means/releasing devices for valvesRubber layered productsEngineeringPiston rod

The invention discloses a linear-stroke pneumatic actuator. The linear-stroke pneumatic actuator comprises a sealed cavity, an air inlet channel is arranged on one side of the cavity, a piston is arranged in the cavity, a piston rod is arranged in the middle of the piston in a linkage mode, a device which drives a valve to open and close is arranged at one end of the piston rod, which corresponds to a connecting end between the piston rod and the piston, a spring is arranged on the other side of the cavity, the spring abuts against an inner bottom surface of the piston and the cavity, a membrane is installed on the upper portion of the piston, and periphery of the piston and the inner side surface of the cavity are in motive seal fit through the membrane. The fitting structure is adopted, non-contact working of the linear-stroke pneumatic actuator can be achieved, the pneumatic actuator is durable and pressure resistant, and the working time is safe and reliable.

Owner:SHANDONG DINGTAI ENERGY SAVING TECH

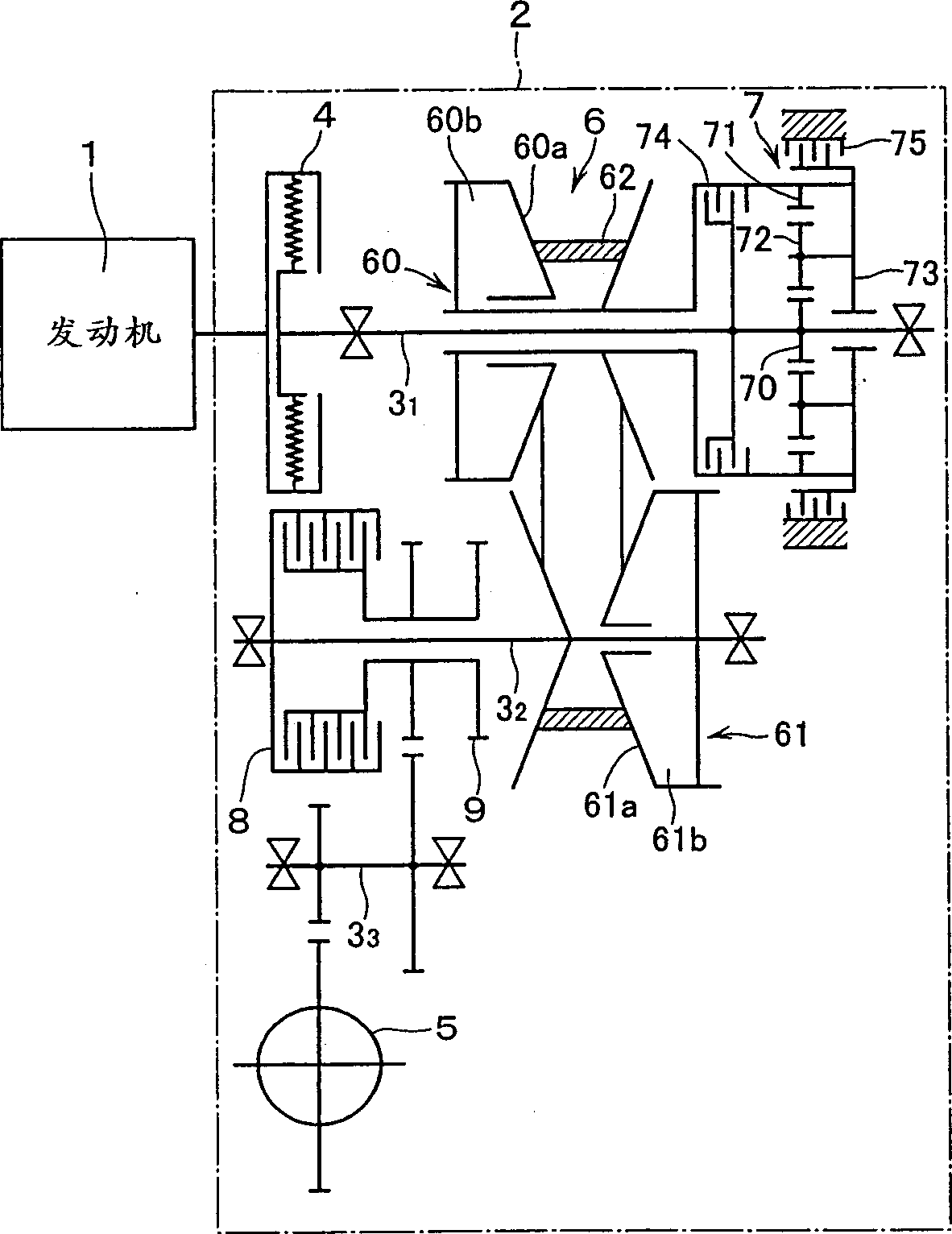

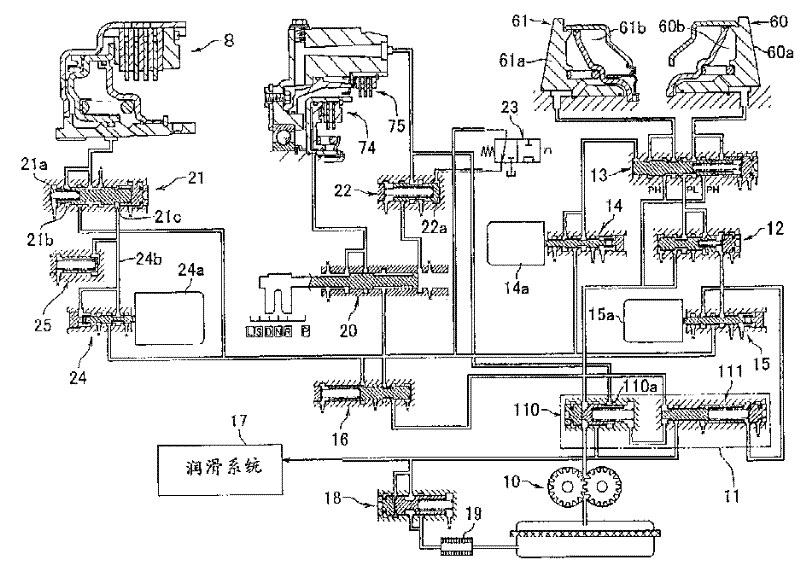

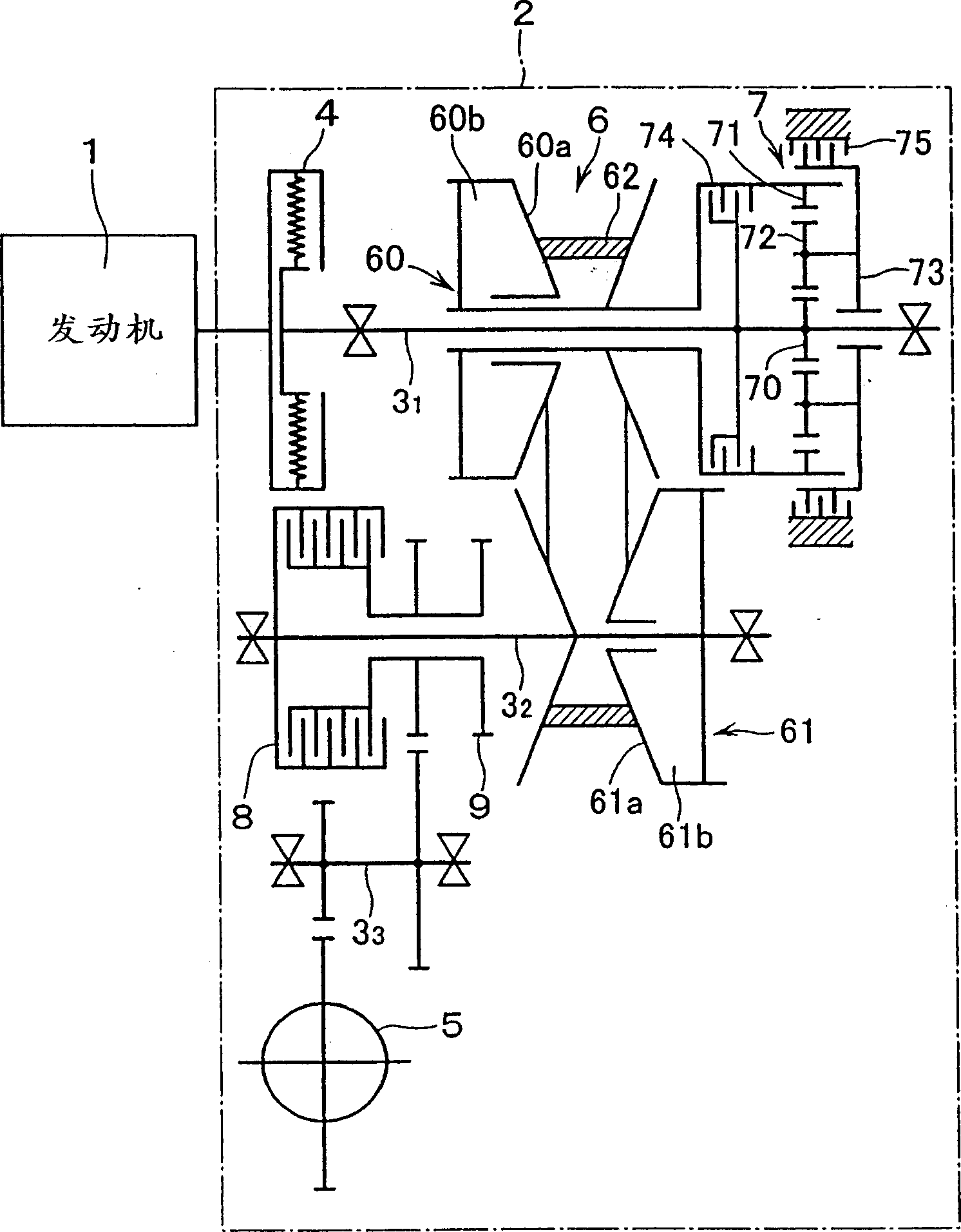

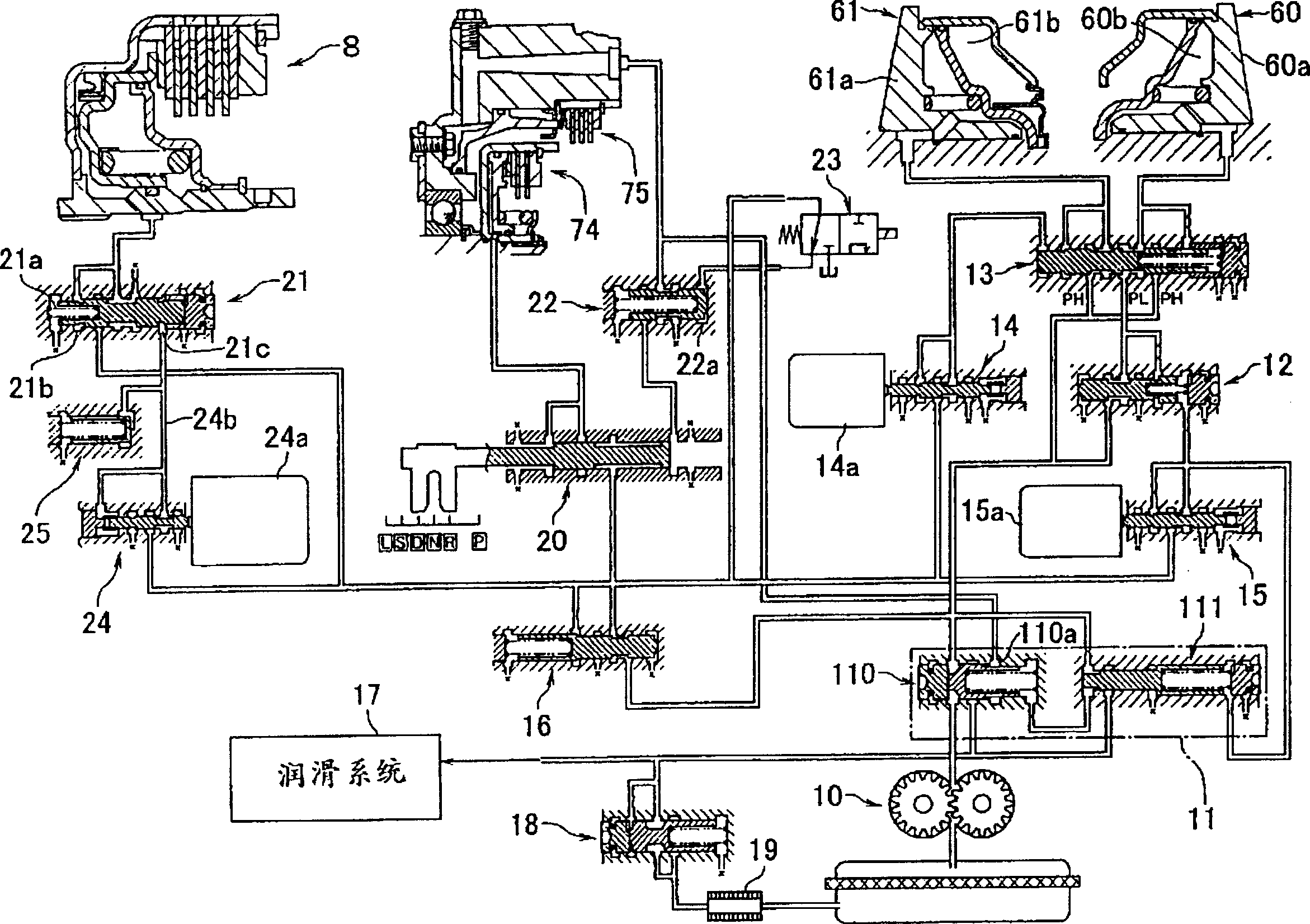

Control device for automatic continuous speed transforming transmission

InactiveCN1342852AIncrease control pressureLow control pressureGearingGearing controlHydraulic cylinderEngineering

In a control apparatus for an automotive continuously variable transmission having a forward-reverse selector mechanism in which a gear ratio for reverse is set closer to a speed reducing side than a gear ratio for forward and a belt type continuously variable transmission mechanism, a PH pressure that is outputted from a first regulator valve and a PL pressure that is outputted from a second regulator valve are changeably supplied to one and the other of a hydraulic cylinder of a drive pulley and a hydraulic cylinder of a driven pulley via a shift control valve. A hydraulic pressure supplied to a reversing hydraulic pressure connecting element from a reversing manual valve is inputted into an oil chamber of a first regulator valve so that the PH pressure is increased with the hydraulic pressure so inputted.

Owner:HONDA MOTOR CO LTD

Electro-hydraulic proportional relief valve

InactiveCN102588372BThrust offsetReduce minimum control pressureServomotor componentsPower flowElectro hydraulic

An electro-hydraulic proportional relief valve is provided with a bidirectional proportional electromagnet. An output rod of the proportional electromagnet is axially rigidly connected with a pilot valve spool through a connector so as to drive the pilot valve spool bidirectionally. A spring of the electro-hydraulic proportional relief valve is compressed when no current is led into a coil of the bidirectional proportional electromagnet, the sum of the pretension force generated from the spring and the maximum output force of the proportional electromagnet in the same direction corresponds to the maximum control pressure controlled by the electro-hydraulic proportional relief valve, and the maximum control pressure is higher than control pressure generated when only thrust of the bidirectional proportional electromagnet acts individually. Accordingly, the maximum control pressure of the electro-hydraulic proportional relief valve is increased.

Owner:TAIYUAN UNIV OF TECH

Pipeline-waste-gas reduction method

ActiveUS20170130903A1Reduce the amount requiredIncrease control pressureOperating means/releasing devices for valvesPipeline systemsEngineeringActuator

A pipeline-waste-gas reduction method to reduce the amount of gas wasted by existing high-pressure pipelines having existing pipeline controllers and existing actuator-based control valves, by reducing the pressure of gas sent to existing pipeline controllers by a determined factor, consequently reducing the amount of gas wasted by the controllers, and then increasing control pressure returned by the controllers by the same factor, ensuring that the proper control pressure is sent to the existing actuator-based control valves.

Owner:DEVILLE CHAD +1

Method for operating a fuel injector

ActiveCN110500214AOpen will notIncrease control pressureFuel injection apparatusMachines/enginesCombustion chamberEngineering

The invention relates to a method for operating a fuel injector having two coaxially arranged nozzle needles (1, 2) which are guided one inside the other and which serve for introducing a first fuel,for example natural gas, and a second fuel, for example diesel fuel, into a combustion chamber of an internal combustion engine, in which method the two nozzle needles (1, 2) are opened in a time-offset manner by means of two control valves (3, 4), and the inner nozzle needle (2) is carried along at least over a partial stroke range during the opening of the outer nozzle needle (1). According to the invention, during the activation phase of the control valve (3) assigned to the outer nozzle needle (1) for the purposes of opening the outer nozzle needle (1), the control valve (4) assigned to the inner nozzle needle (2) is at least temporarily likewise activated such that an increase of a control pressure prevailing at the inner nozzle needle (2) is counteracted without opening the inner nozzle needle (2).

Owner:ROBERT BOSCH GMBH

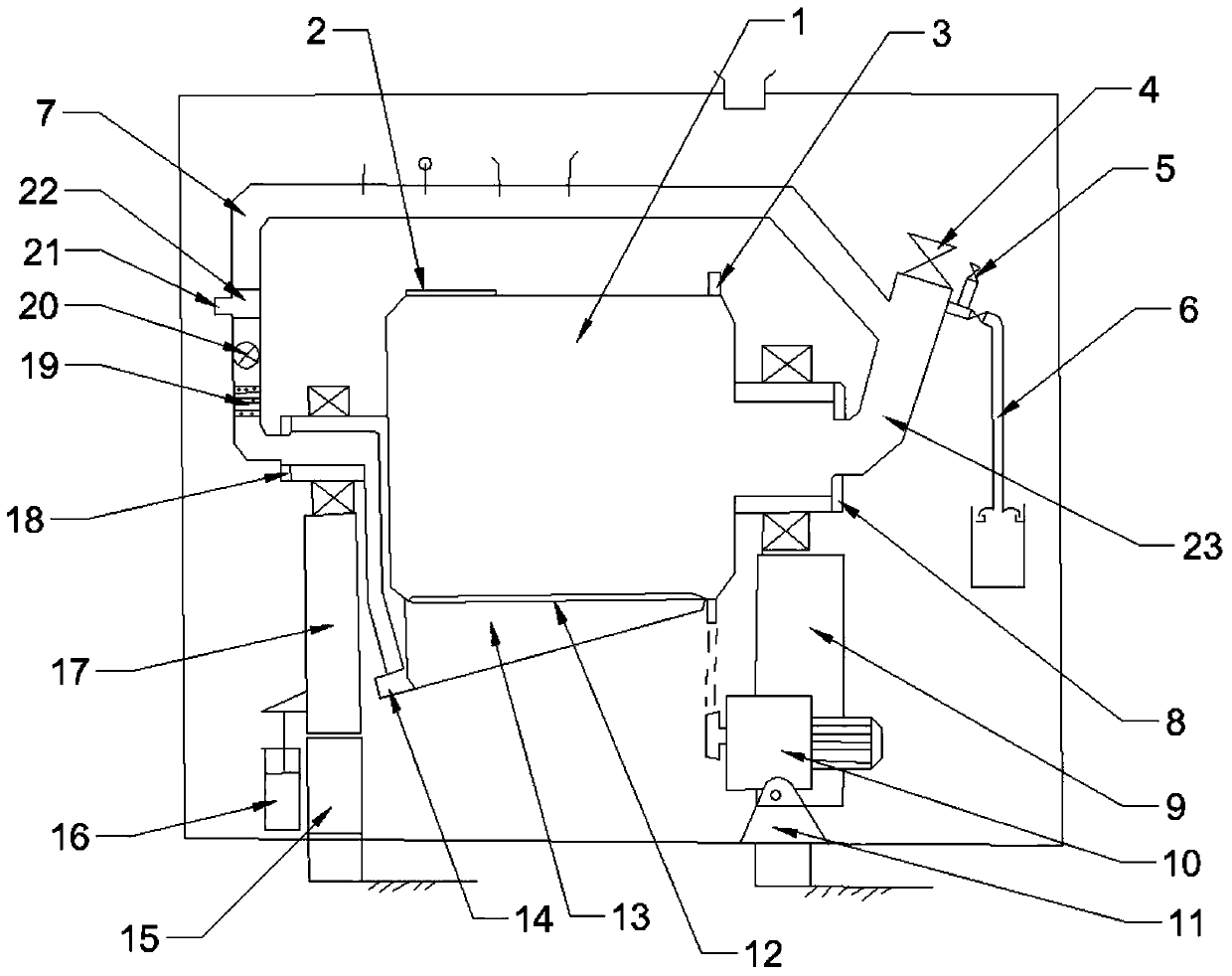

Wet mill

PendingCN111282666ARealize automatic feeding processRealize fully automatic operationGrain treatmentsTemperature controlProcess engineering

The invention discloses a wet mill. The wet mill comprises a ball milling cylinder, the upper portion of the ball milling cylinder is provided with a ball outlet and a chain wheel respectively, the lower portion of the ball milling cylinder is provided with an inclined hopper and a slag discharging port, the lower end of the inner portion of the ball milling cylinder is further provided with a ball barrier, one side of the ball milling cylinder is connected with a feeding pipe, the end, away from the ball milling cylinder, of the feeding pipe is a feeding port, the two sides of the feeding pipe are connected with a circulating pipe and a solvent inlet pipe respectively, one side of the solvent inlet pipe is connected with an exhaust pipe, the other end, away from the feeding pipe, of the circulating pipe is connected with the slag discharging port formed in the lower portion of the ball milling cylinder, a filtering device, a slurry pump and a three-way valve are arranged in a pipe body, close to the slag discharging port, of the circulating pipe respectively. The wet mill has the beneficial effects that automatic feeding, wet milling and exhausting are achieved, slurry temperaturecontrol and in-cylinder pressure monitoring are added, the whole equipment operation process is controlled by a computer, full-automatic operation of the wet mill is achieved, the labor cost of an enterprise is reduced, the production efficiency of the enterprise is improved, and meanwhile the potential safety hazard that a cylinder is prone to explosion is avoided.

Owner:株洲长江硬质合金设备股份有限公司

Pressure control valve with aperture

InactiveUS20120298893A1Increase heightHigh trafficOperating means/releasing devices for valvesFluid pressure controlElectricityEngineering

The invention refers to an electro-magnetic pressure control valve with a magnetic part and a valve part. The magnetic part has at least on coil that can be electrically triggered, a coil core and an armature guided traversingly. The valve part has a feed for the pressurized medium, a return and a consumer connection. The valve part has at least two seat valves that can be closed each by a valve element.

Owner:SVM SCHULTZ VERW

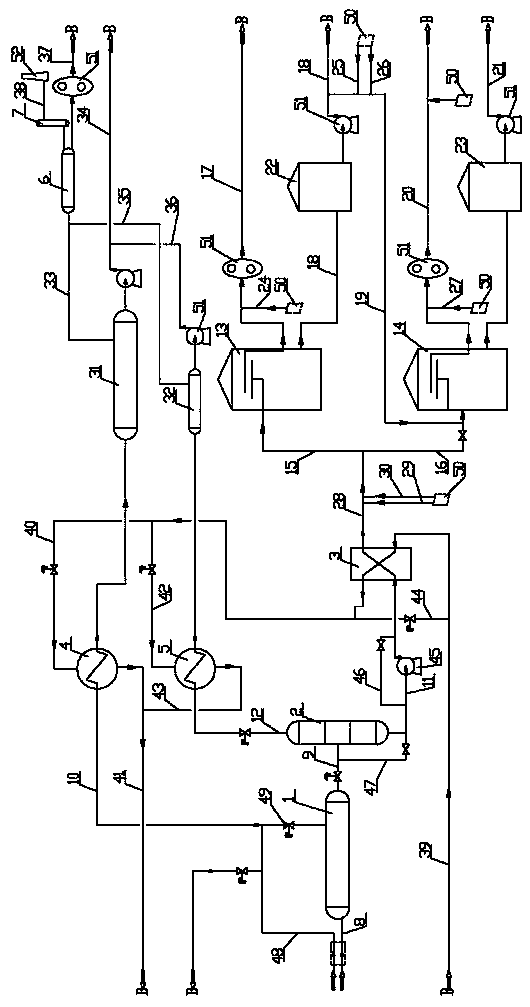

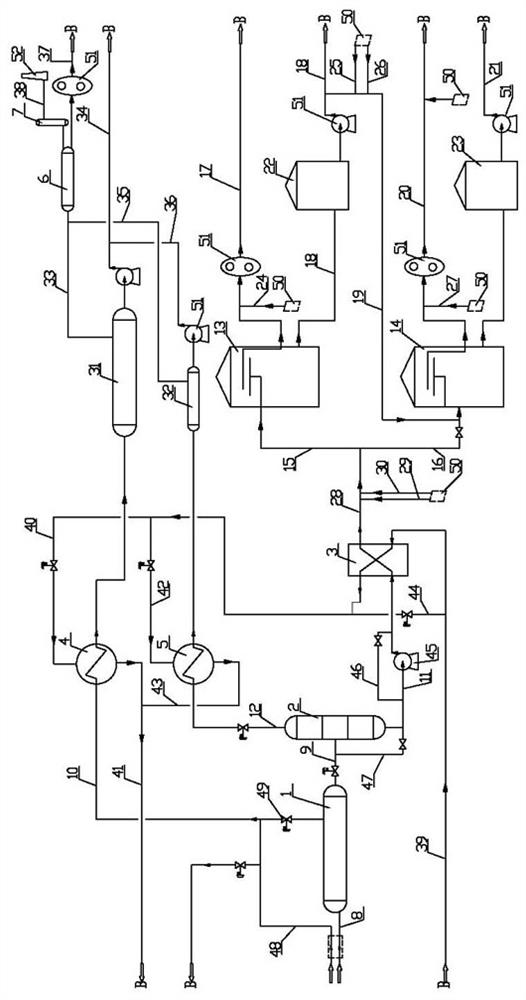

Two-section separation based SAGD produced fluid treatment method and device

ActiveCN108795482AReduce processing costsReduce the total project investmentDewatering/demulsification with chemical meansTreatment with plural serial refining stagesTransport systemGas phase

The invention relates to the technical field of SAGD circulating preheating stage produced fluid treatment, in particular to a two-section separation based SAGD produced fluid treatment method and device. The method is characterized in that high-pressure under-pressure separation and low-pressure flash-evaporation separation are performed on the SAGD produced fluid, and follow-up treatment is thenperformed. A secondary gas-liquid separating process of under-pressure separation and flash-evaporation separation is adopted, wherein the first stage is under-pressure gas-liquid separation with relatively high control pressure, and is mainly used for separating a gas phase carried in the produced fluid, and stabilizing the front end pressure of a collecting and transport system; and the secondstage is used for performing flash-evaporation separation on a first liquid phase, wherein the control pressure is relatively low, the produced fluid is sufficiently subjected to flash-evaporation, the liquid phase is partially gasified and cooled in a flash-evaporation process, and heat exchange difficulty of the liquid phase is greatly reduced; and meanwhile, the gasified gas phase can adopt a more mature gas-liquid heat exchange system, and heat exchange efficiency is higher, so that the SAGD produced fluid is lower in treatment cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

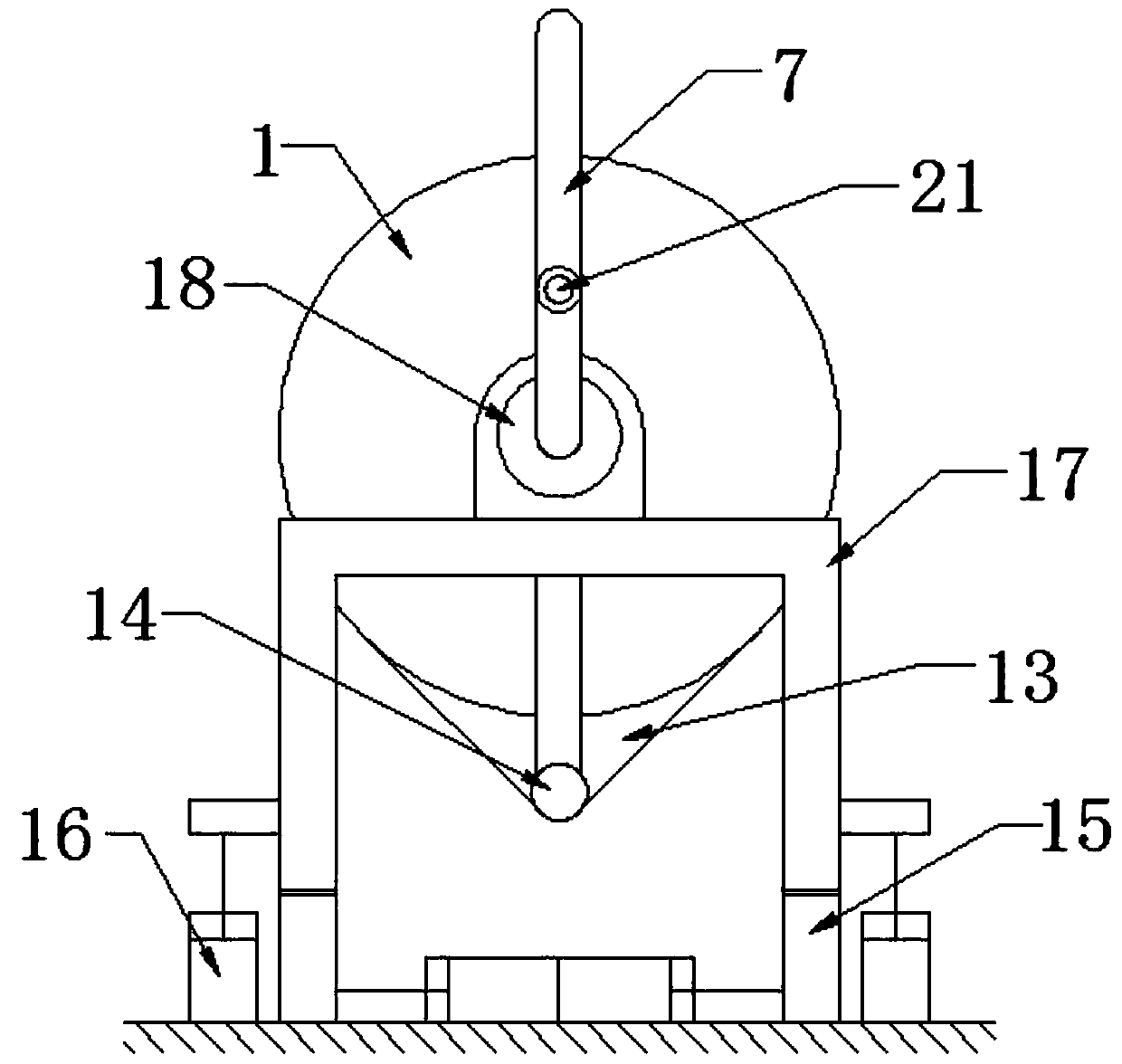

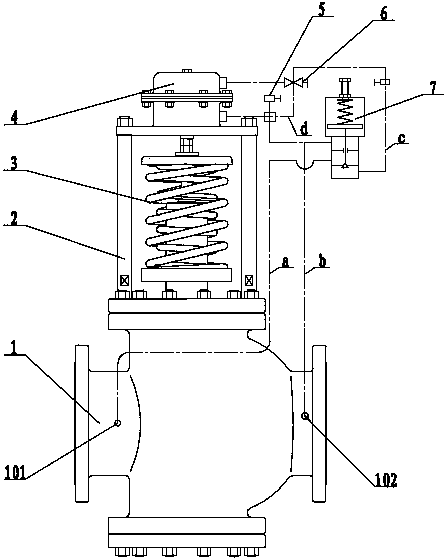

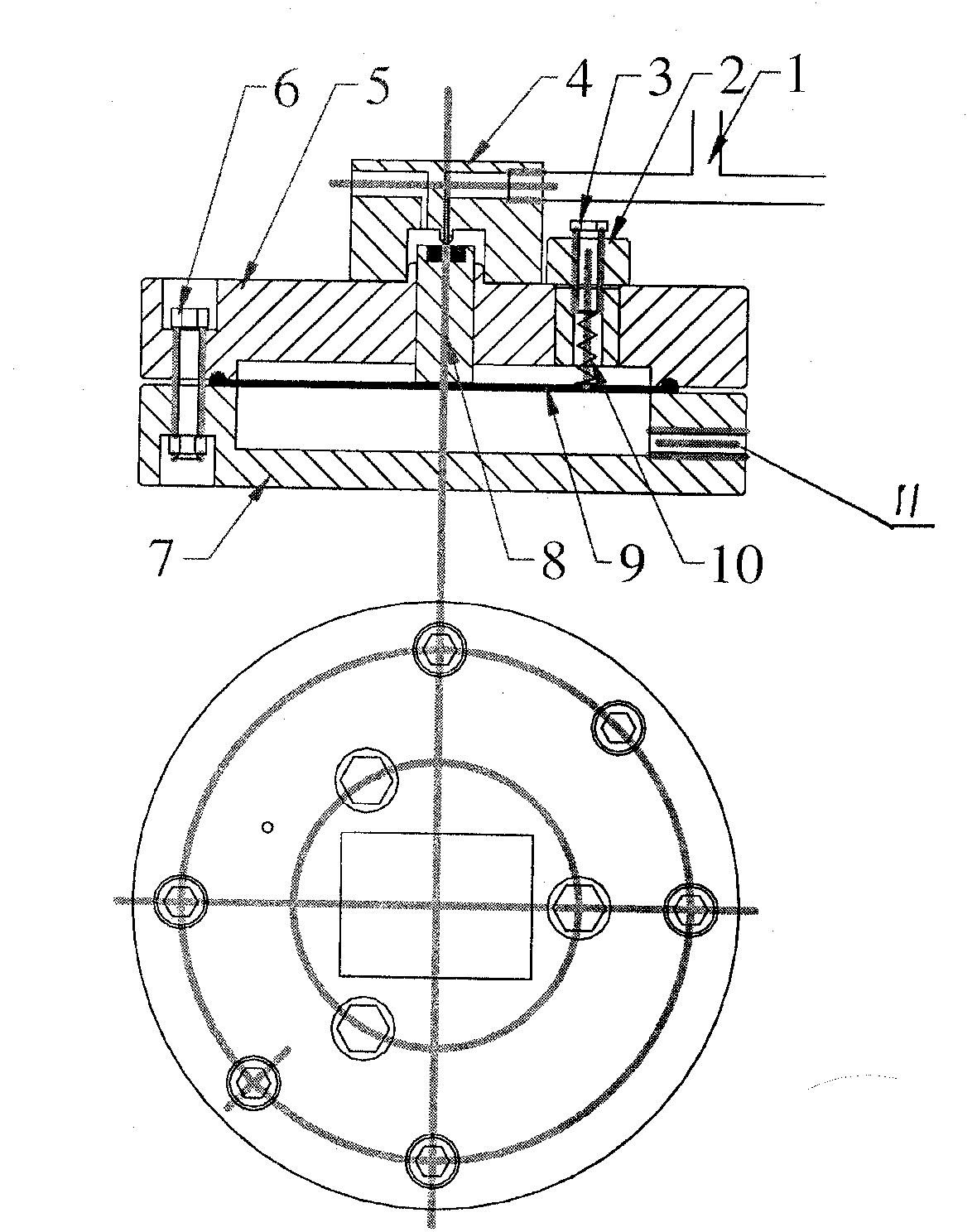

Pressure reducing valve for nuclear power fire fighting

InactiveCN102705549BSimple structureReasonable designOperating means/releasing devices for valvesEqualizing valvesNuclear powerEngineering

The invention provides a pressure reducing valve for nuclear power fire fighting, and belongs to the technical field of valves. The pressure reducing valve comprises a valve body, a multi-diaphragm type actuating mechanism and an elastic element, wherein a valve spool is arranged in the inner cavity of the valve body; the multi-diaphragm type actuating mechanism is arranged above the valve body; the elastic element is connected with the valve body and the multi-diaphragm type actuating mechanism; a water inlet cavity opening and a water outlet cavity opening of the valve body are respectively connected with a cylinder body inlet and a cylinder body control connector of a piston type driving mechanism through a pipeline a and a pipeline b respectively; a cylinder body outlet of the piston type driving mechanism is connected with the multi-diaphragm type actuating mechanism through a pipeline c; the pipeline c is also provided with a fine adjustment type balancing mechanism; one end of the fine adjustment type balancing mechanism is connected with an upper diaphragm chamber of the multi-diaphragm type actuating mechanism; after the other end of the fine adjustment type balancing mechanism is connected with a lower diaphragm chamber of the multi-diaphragm type actuating mechanism through a pipeline d, the fine adjustment type balancing mechanism and the pipeline b form a circulating pipeline. The pressure reducing valve for nuclear power fire fighting is wide in application range and high in adjustment stability, and can be urgently controlled under special work conditions.

Owner:HANGZHOU LIANGGONG VALVES

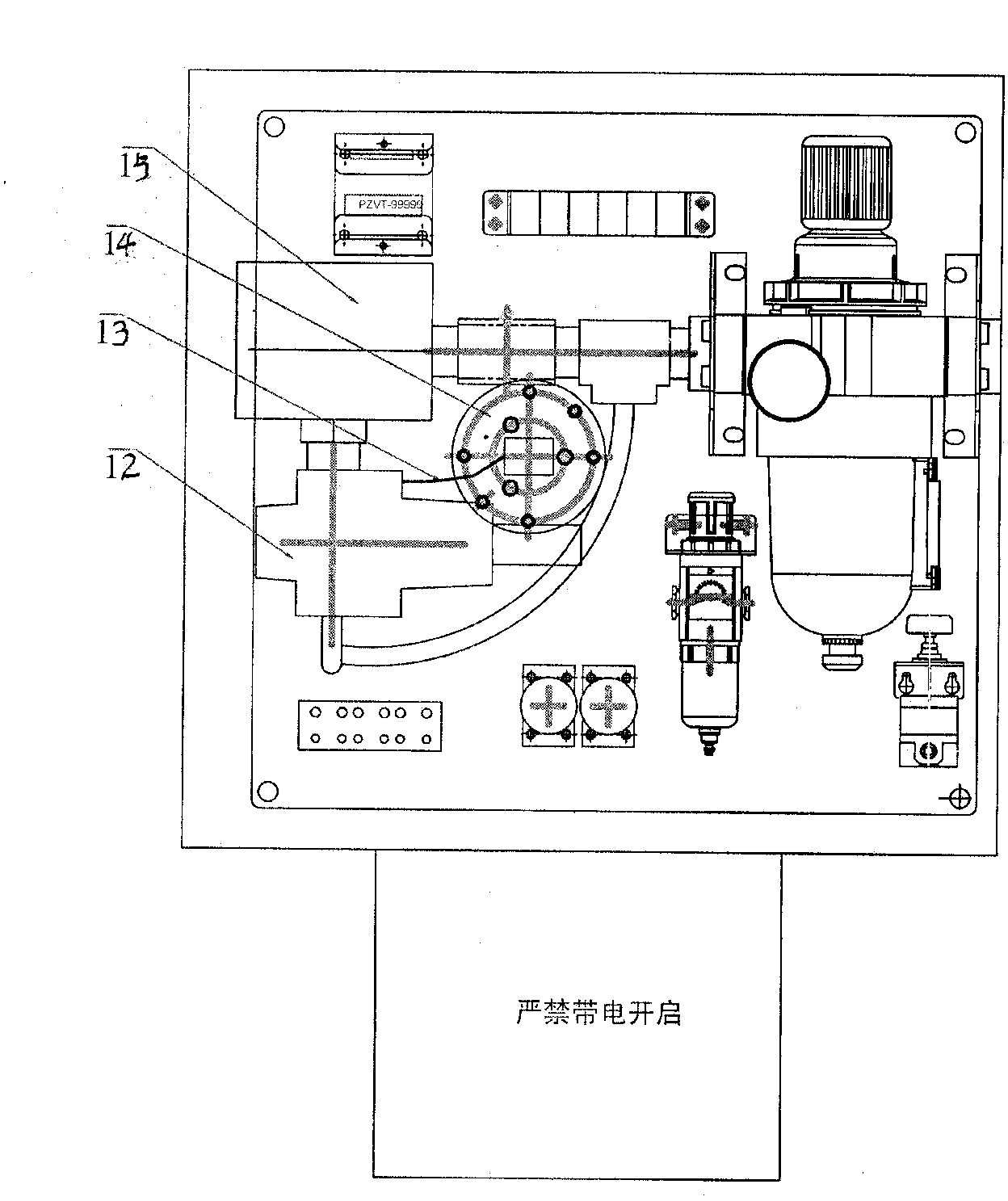

Pneumatic low-pressure sensor

InactiveCN102853959AAvoid misuseGuaranteed uptimeFluid pressure measurement using elastically-deformable gaugesForce sensorPressure sensor

The invention relates to a pressure sensor, and discloses a pneumatic low-pressure sensor. The pneumatic low-pressure sensor is mainly characterized in that the output end of the sensor adopts a three-way connection tube; a diaphragm and a plurality of adjustment springs are used for pressure setting; one outlet of the three-way connection tube is plugged via a plug head; pressure adjustment is performed by means of pure pneumatic signal feedback; the output end of the sensor is controlled by the pressure of a gas which is possible to leak in a shell; displacement for the shell is increased or reduced via a pressure adjustment valve connected with the shell, and then the pressure in the shell is always controlled to fluctuate in the range of plus / minus 5% of the set values (ranging from 100 Pa to 2000 Pa) of the sensor.

Owner:NANYANG ZHENGTONG ELECTRICAL

Control device for electric cooking appliance and control method for electric cooking appliance

ActiveCN105361645BIncrease power modulation ratioSolve after-sales problemsPressure-cookersWarming devicesElectricityPower modulation

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

Method for operating fuel injectors

ActiveCN110500214BOpen will notIncrease control pressureFuel injection apparatusMachines/enginesCombustion chamberInternal combustion engine

The invention relates to a method for operating a fuel injector having two nozzle needles (1, 2) arranged coaxially and guided inside one another, said nozzle needles serving to inject a first fuel For example natural gas and a second fuel such as diesel fuel are introduced into the combustion chamber of the internal combustion engine, in the method the two nozzle needles (1,2) are opened with a time offset by means of two control valves (3,4) , and when the outer nozzle needle (1) opens, the inner nozzle needle (2) is guided along with it at least over the partial stroke range. According to the invention, during the actuation phase of the control valve (3) associated with the outer nozzle needle (1) for opening the outer nozzle needle (1), at least temporarily also actuates the associated inner nozzle needle ( 2) in such a way that the rise in control pressure acting on the inner nozzle needle (2) is resisted without causing the inner nozzle needle (2) to open.

Owner:ROBERT BOSCH GMBH

Control device for automatic continuous speed transforming transmission

InactiveCN1283940CIncrease control pressureLow control pressureGearingGearing controlHydraulic cylinderDrive wheel

Owner:HONDA MOTOR CO LTD

SAGD production fluid treatment method and device based on two-stage separation

ActiveCN108795482BReduce processing costsReduce the total project investmentDewatering/demulsification with chemical meansTreatment with plural serial refining stagesFluid phaseEngineering

The invention relates to the technical field of SAGD circulating preheating stage produced fluid treatment, in particular to a two-section separation based SAGD produced fluid treatment method and device. The method is characterized in that high-pressure under-pressure separation and low-pressure flash-evaporation separation are performed on the SAGD produced fluid, and follow-up treatment is thenperformed. A secondary gas-liquid separating process of under-pressure separation and flash-evaporation separation is adopted, wherein the first stage is under-pressure gas-liquid separation with relatively high control pressure, and is mainly used for separating a gas phase carried in the produced fluid, and stabilizing the front end pressure of a collecting and transport system; and the secondstage is used for performing flash-evaporation separation on a first liquid phase, wherein the control pressure is relatively low, the produced fluid is sufficiently subjected to flash-evaporation, the liquid phase is partially gasified and cooled in a flash-evaporation process, and heat exchange difficulty of the liquid phase is greatly reduced; and meanwhile, the gasified gas phase can adopt a more mature gas-liquid heat exchange system, and heat exchange efficiency is higher, so that the SAGD produced fluid is lower in treatment cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com