Displacement control system for variable displacement compressor

一种容量控制、压缩机的技术,应用在压缩机、不可逆循环的压缩机器、液体变容式机械等方向,能够解决探测吸入压力、很难波纹管、膜片小型化限制等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

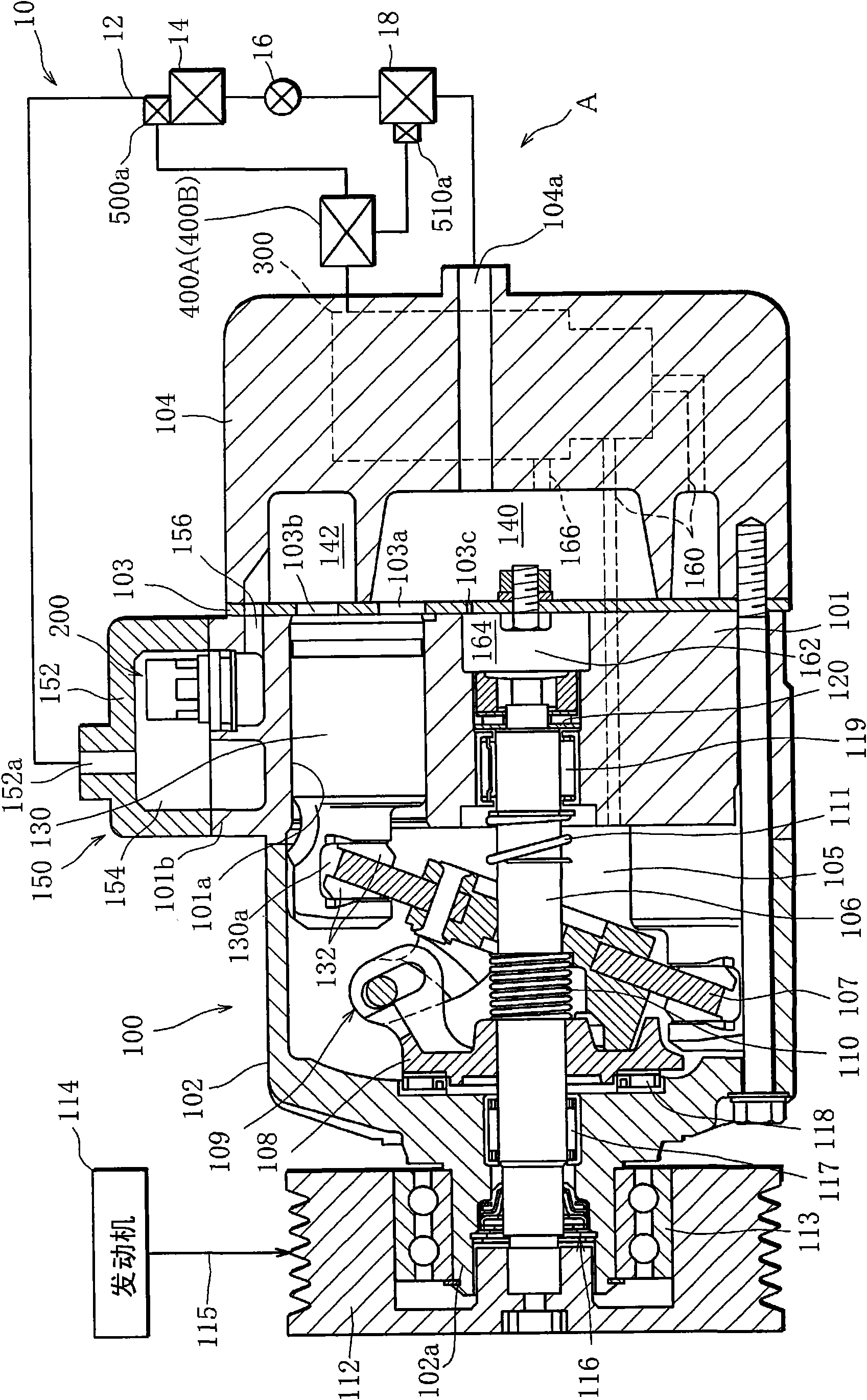

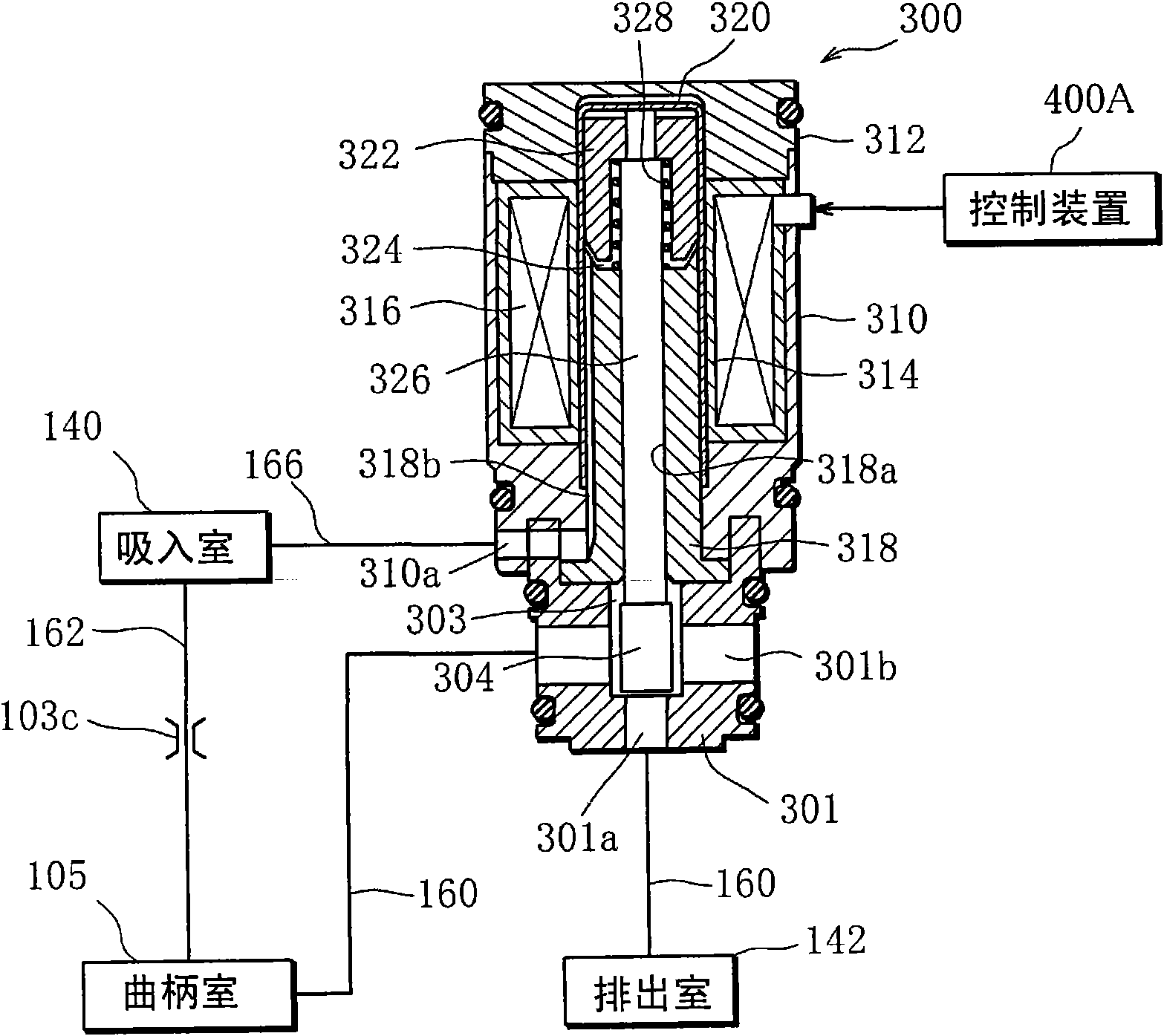

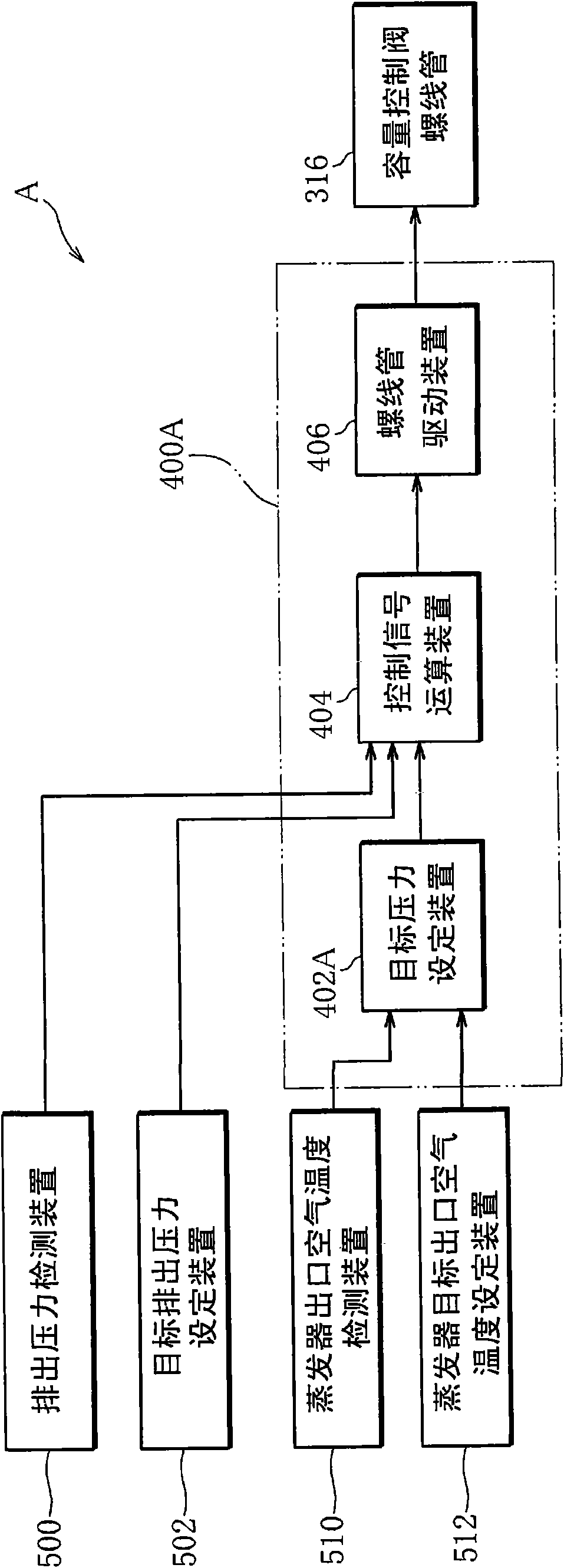

[0112] figure 1 A refrigeration cycle 10 of a vehicle air-conditioning system is shown, and the refrigeration cycle 10 includes a circulation path 12 in which a refrigerant as a working fluid circulates. Viewed from the flow direction of the refrigerant, a compressor 100, a radiator (condenser) 14, an expander (expansion valve) 16, and an evaporator 18 are sequentially inserted in the circulation path 12. When the compressor 100 works, the refrigerant circulates Loop 12. That is, the compressor 100 performs a series of processes including a suction process of refrigerant, a compression process of the suctioned refrigerant, and a discharge process of the compressed refrigerant.

[0113] The evaporator 18 also constitutes a part of the air circuit of the vehicle air-conditioning system, and the airflow passing through the evaporator 18 is cooled by the refrigerant in the evaporator 18 deprived of the heat of vaporization.

[0114] The compressor 100 to which the capacity cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com