Method for operating fuel injectors

A fuel injector and fuel technology, which is applied to fuel injection devices, charging systems, machines/engines, etc., can solve the problems of control pressure rise, hinder the opening of the outer nozzle needle, etc., and achieve the effect of full injection rate and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

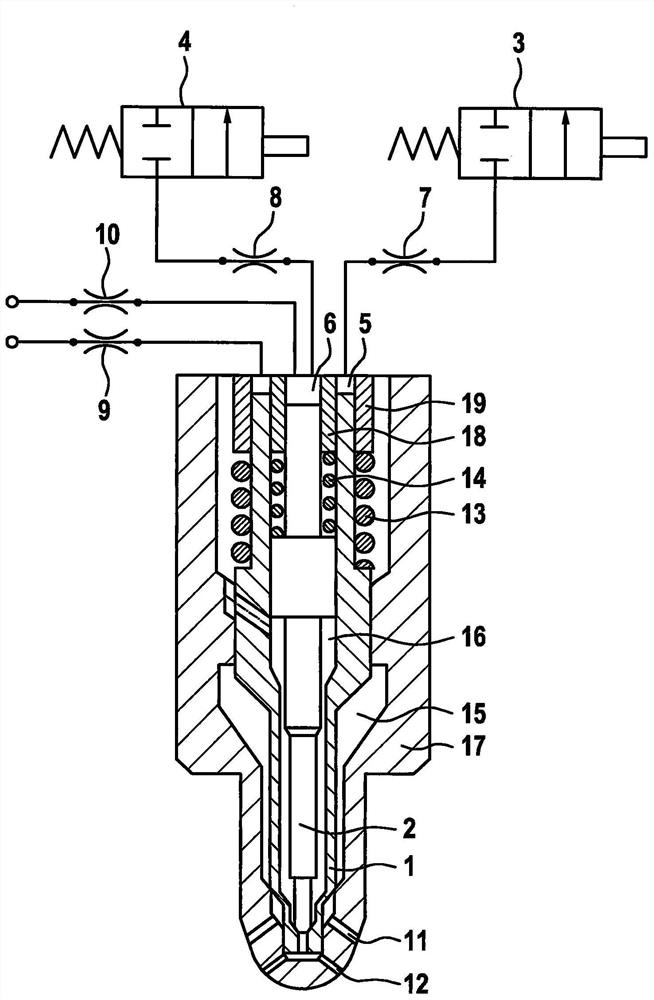

[0021] from figure 1 A fuel injector suitable for carrying out the method of the present invention is known from the schematic diagram of . The fuel injector has a nozzle body 17 and two nozzle needles 1 , 2 which are arranged coaxially and are guided in one another. For this purpose, the outer nozzle needle 1 for releasing and closing the insufflation opening 11 for the gaseous fuel is embodied as a hollow needle. The injection opening 12 for injecting the liquid fuel can be controlled by the inner nozzle needle 2 , which is now completely received in the outer nozzle needle 1 while forming the pressure chamber 16 . Liquid fuel is supplied to the injection openings 12 via the pressure chamber 16 . The gaseous fuel reaches the blow-in opening 11 through a pressure chamber 15 which is bounded on the one hand by the nozzle body 17 and on the other hand by the outer nozzle needle 1 . The liquid fuel can in particular be natural gas or methane, and the liquid fuel can be diesel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com