Electro-hydraulic proportional relief valve

An electro-hydraulic proportional and overflow valve technology, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of not being able to be 0, increase the input power, and limit the maximum value of the control pressure, etc., to achieve Reduce energy consumption, improve pressure control, and reduce heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

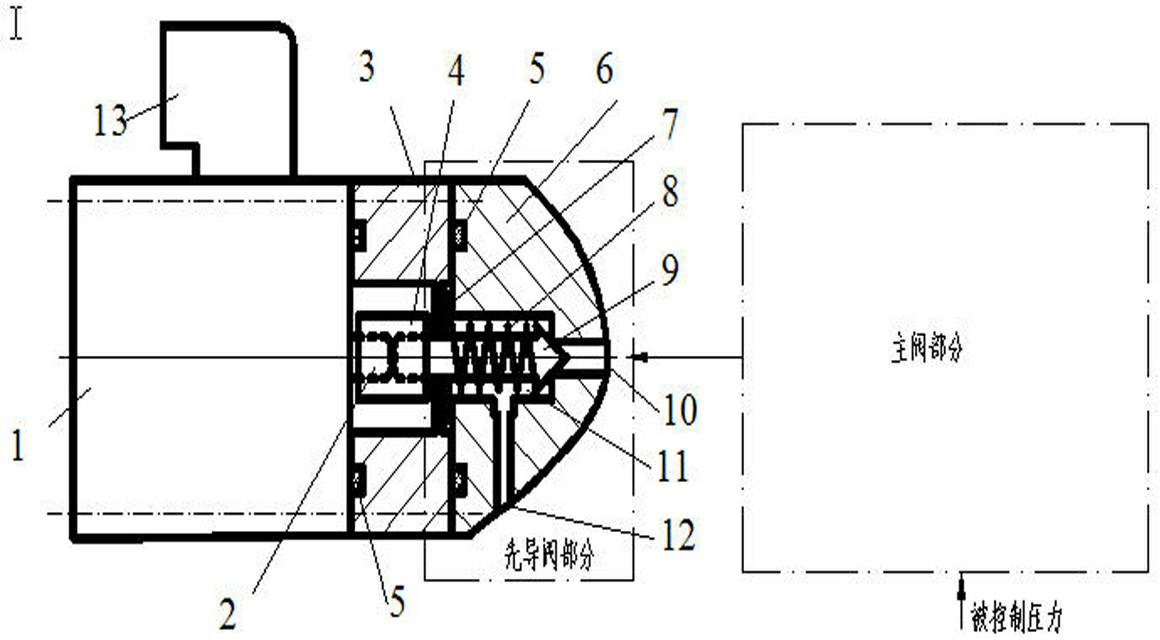

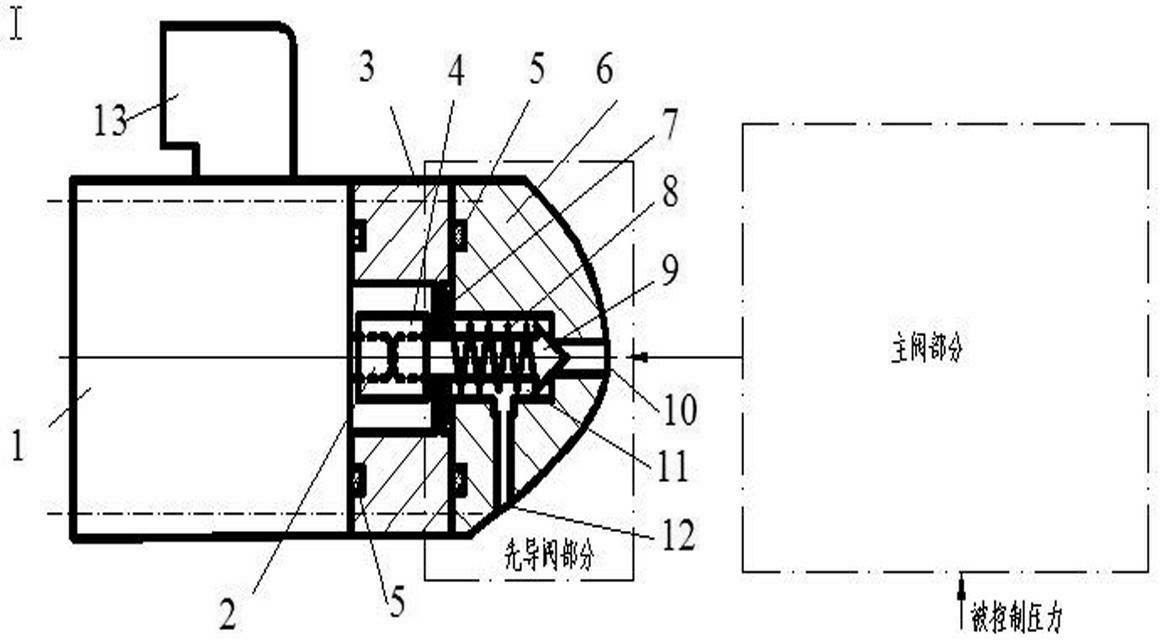

[0055] Such as figure 1 It is a structural schematic diagram of the electro-hydraulic proportional overflow valve designed according to the present invention. The electro-hydraulic proportional overflow valve includes a proportional electromagnet 1, a proportional electromagnet output rod 2, a connecting piece 4 and a spring 8.

[0056] The indicators of the designed electro-hydraulic proportional relief valve include: maximum overflow flow Q mm , pressure control range 0- P sm , according to the characteristics of the present invention, the preset control pressure of the designed electro-hydraulic proportional relief valve is given P s0 .

[0057] Utilize the present invention to design the electro-hydraulic proportional relief valve, in addition to designing according to the existing electro-hydraulic proportional relief valve, it is necessary to determine F k0 and the maximum allowable current of bidirectional proportional solenoid 1 I tm .

[0058] F k0 method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com