Patents

Literature

36results about How to "Guaranteed to stop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

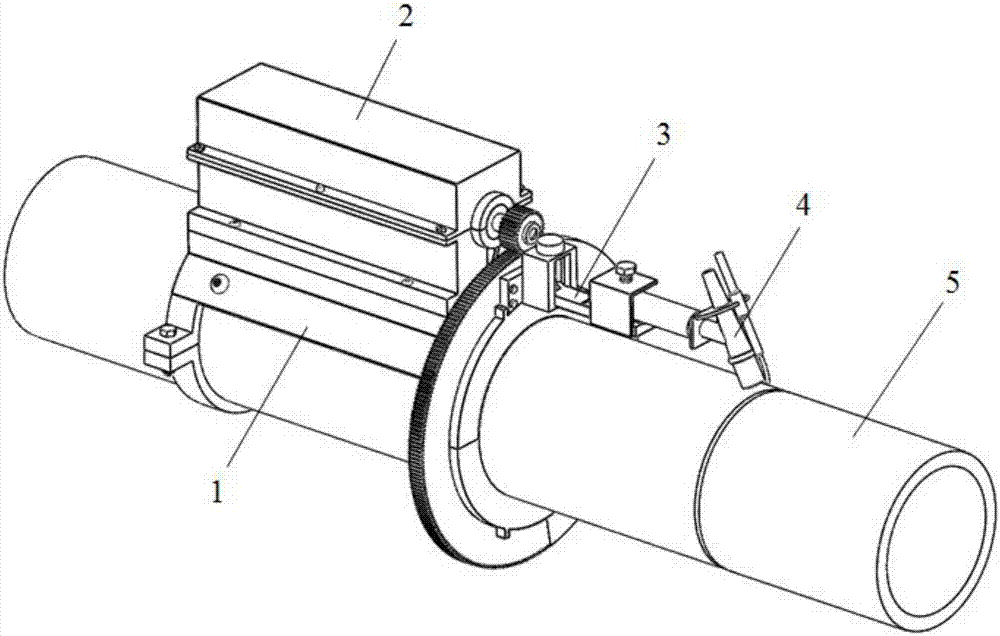

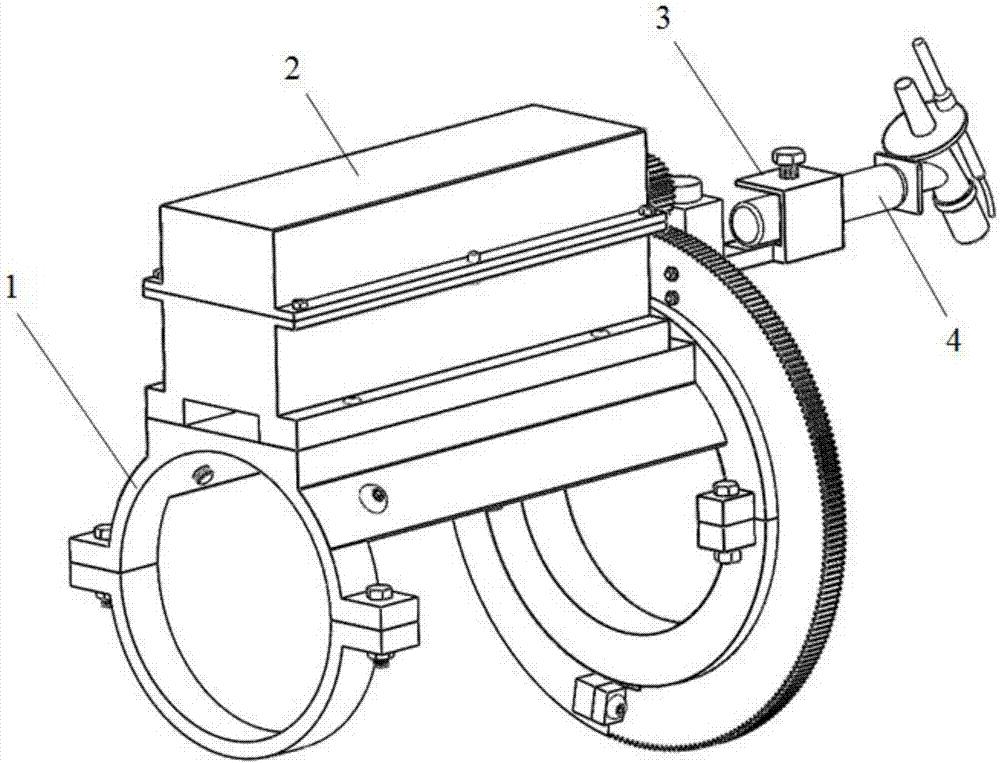

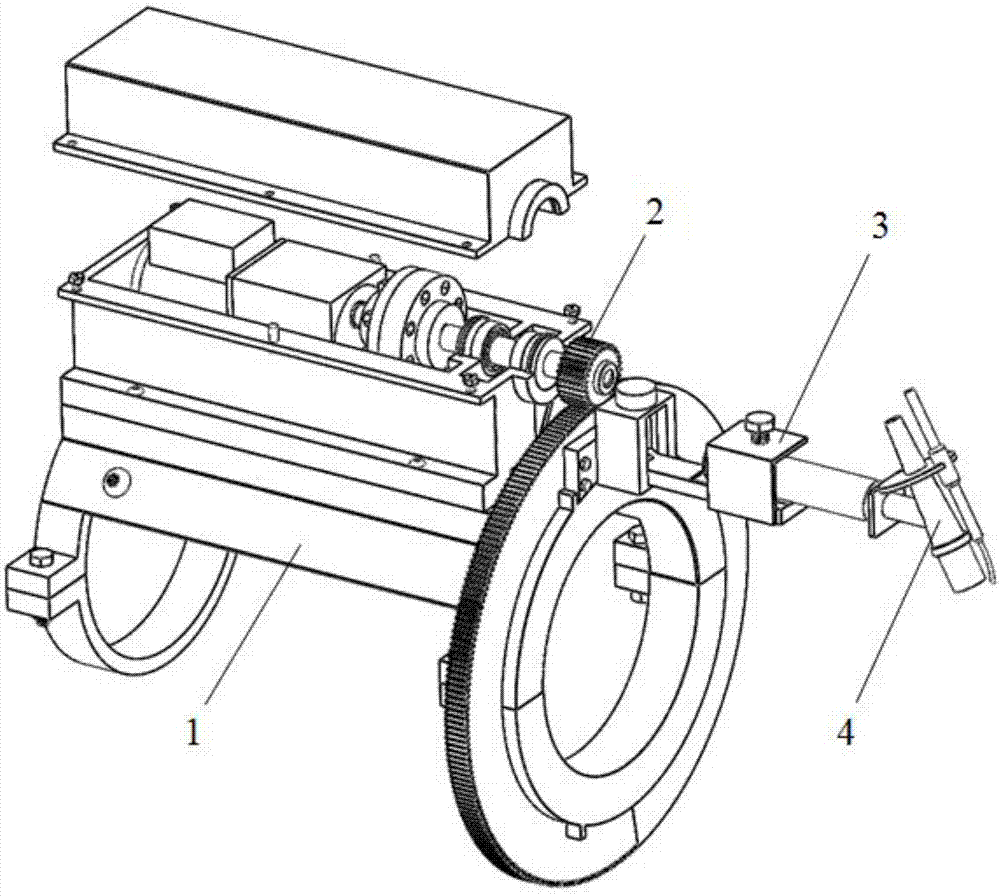

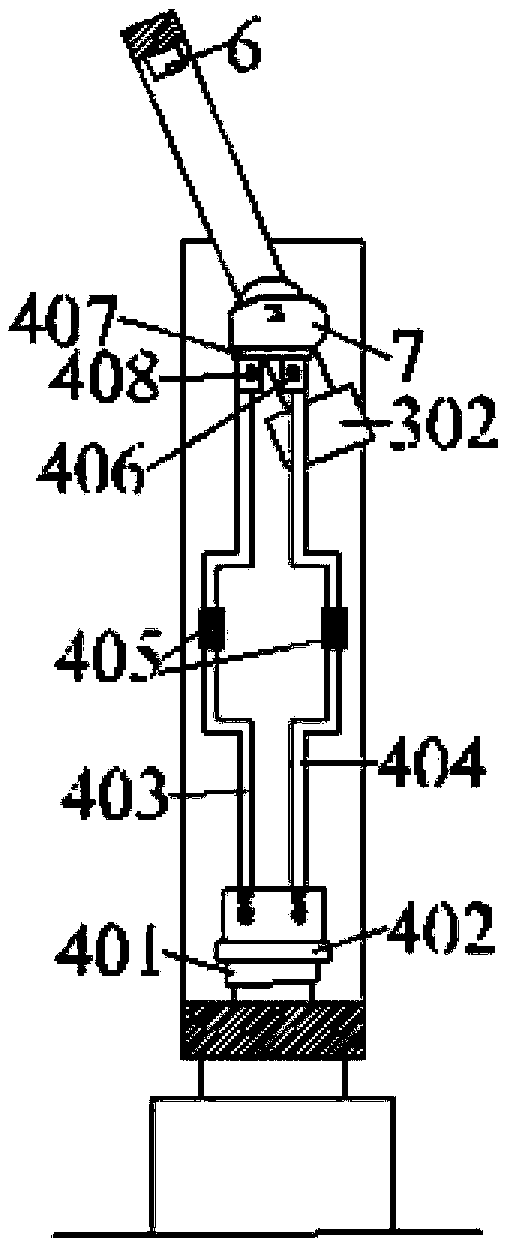

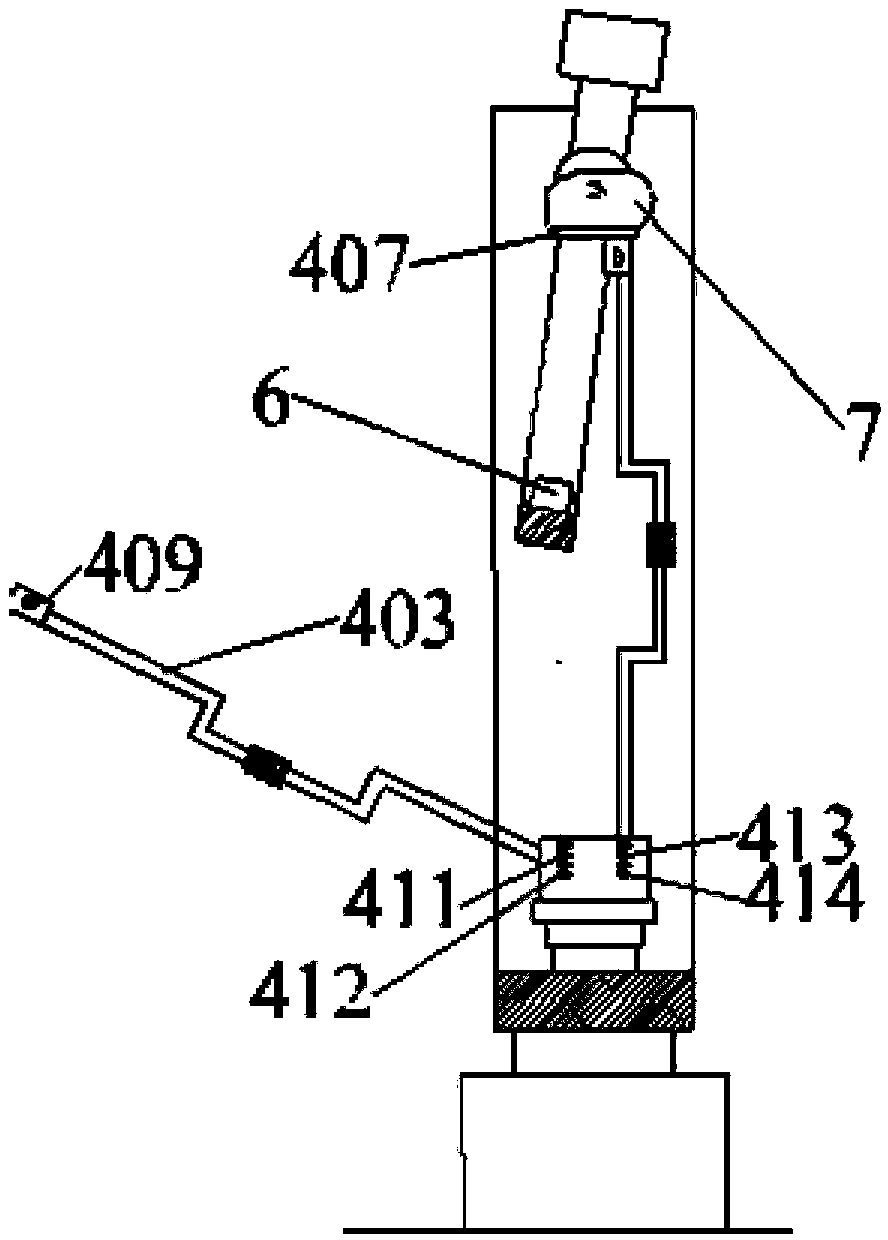

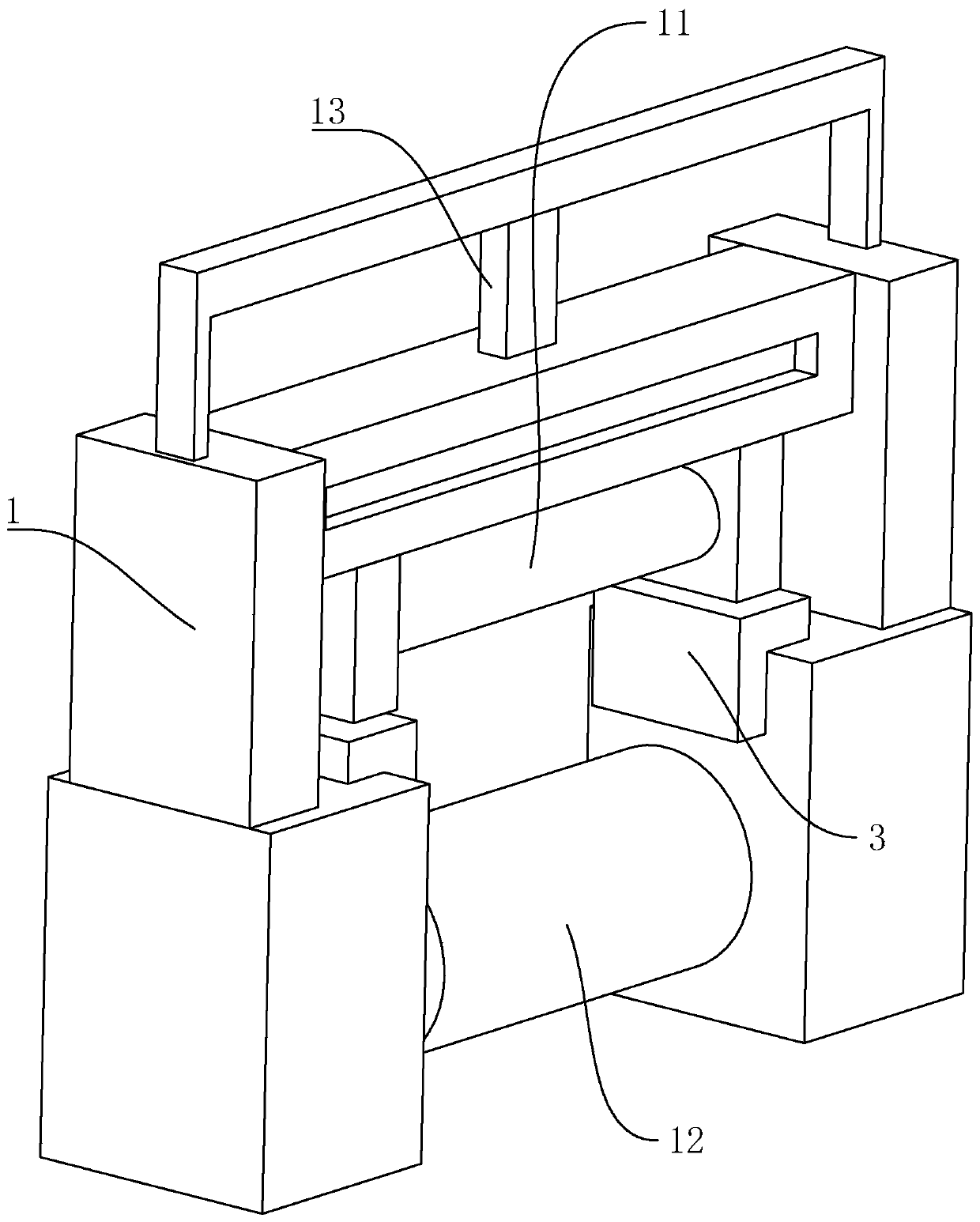

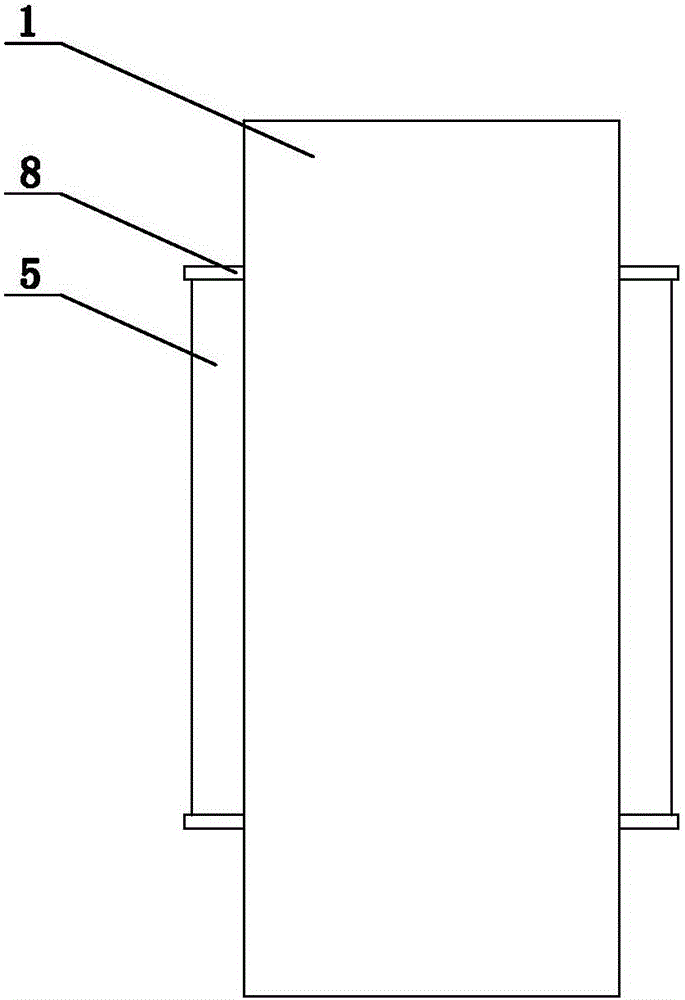

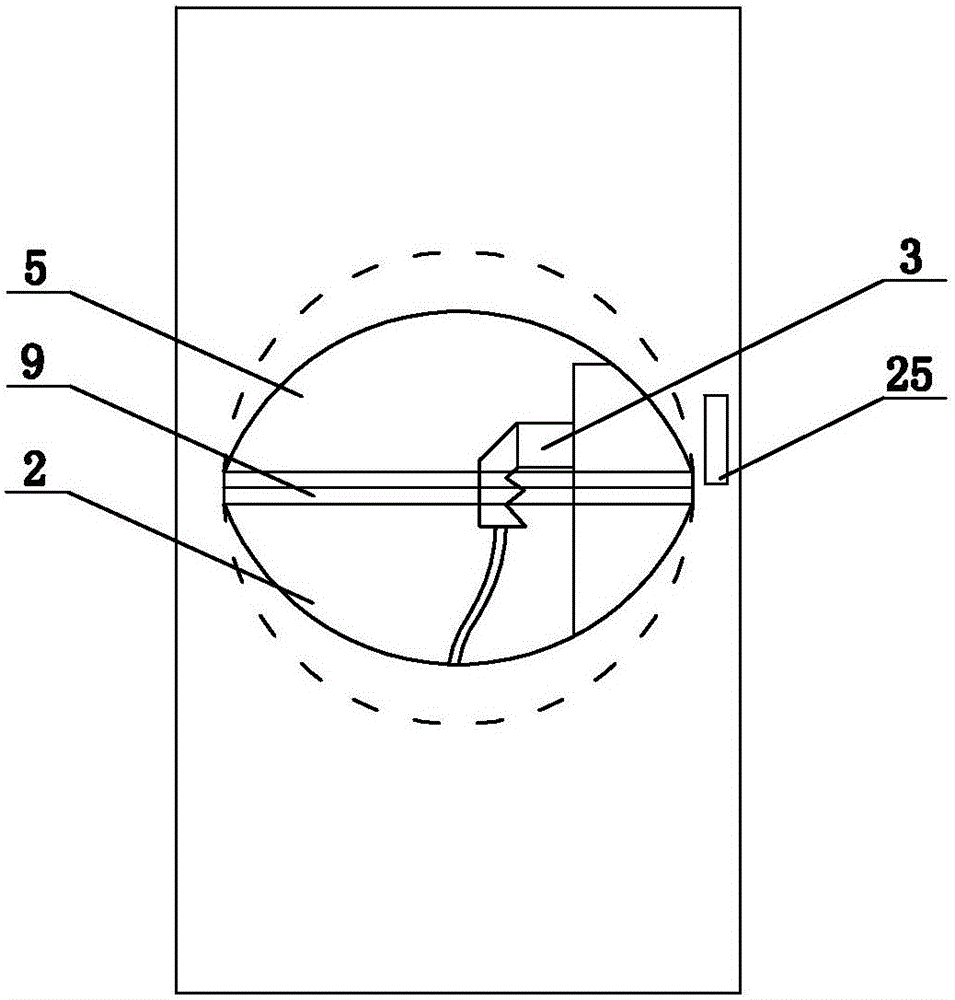

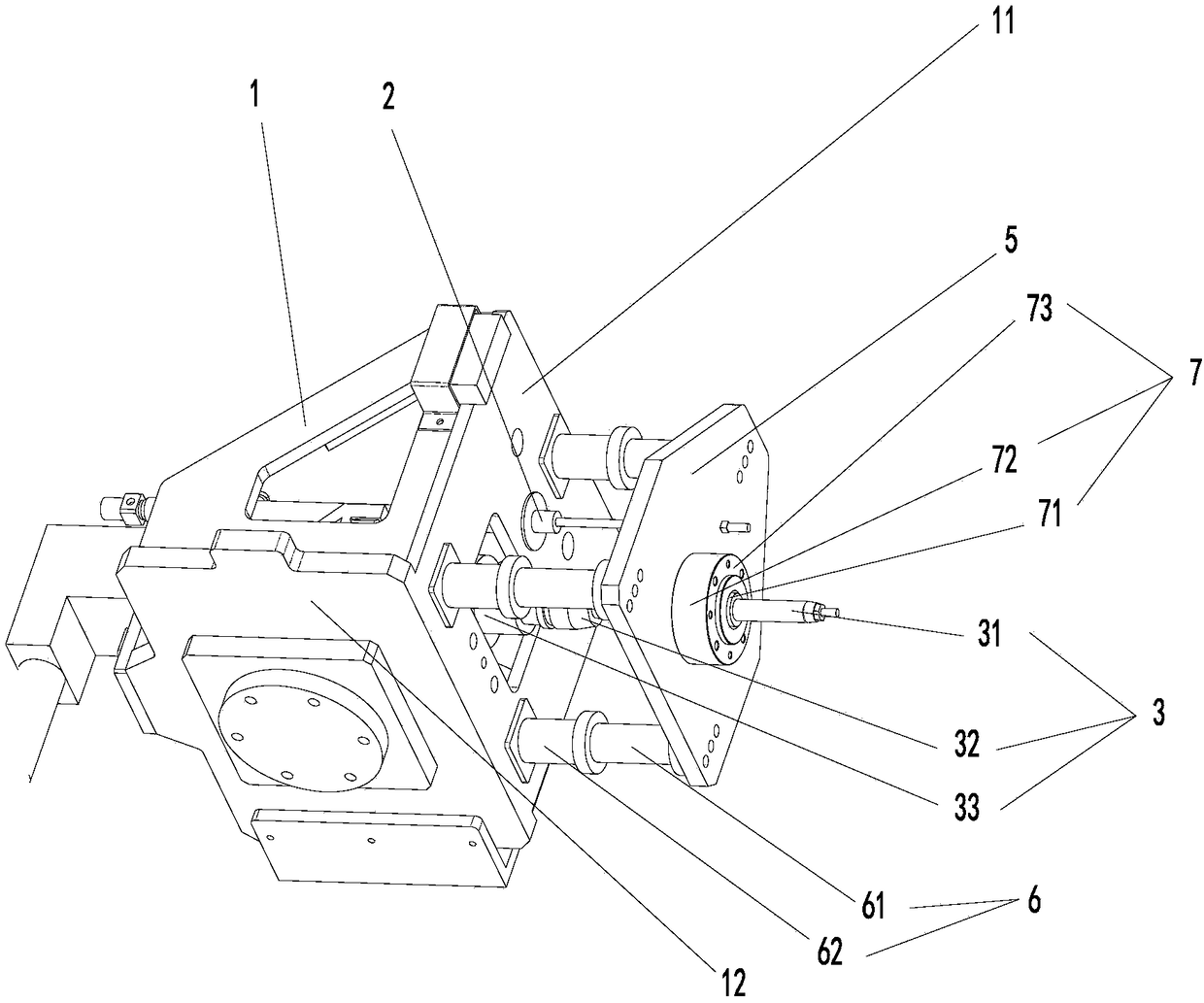

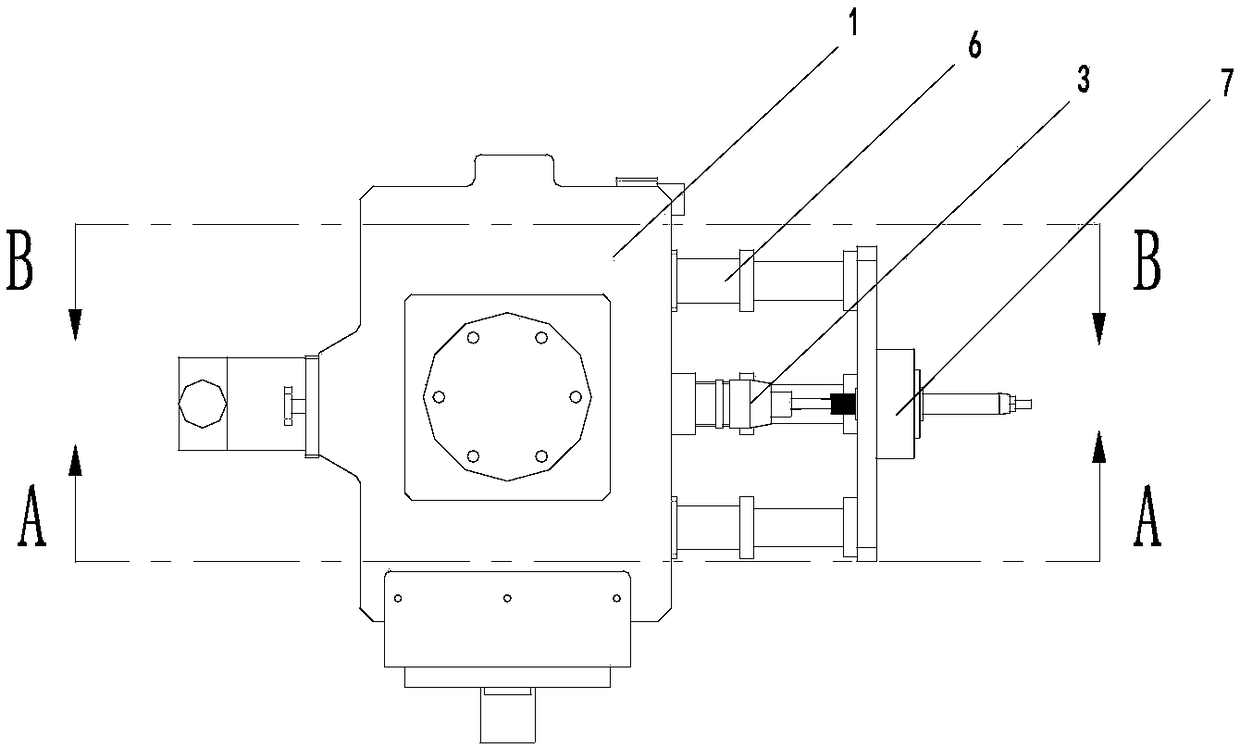

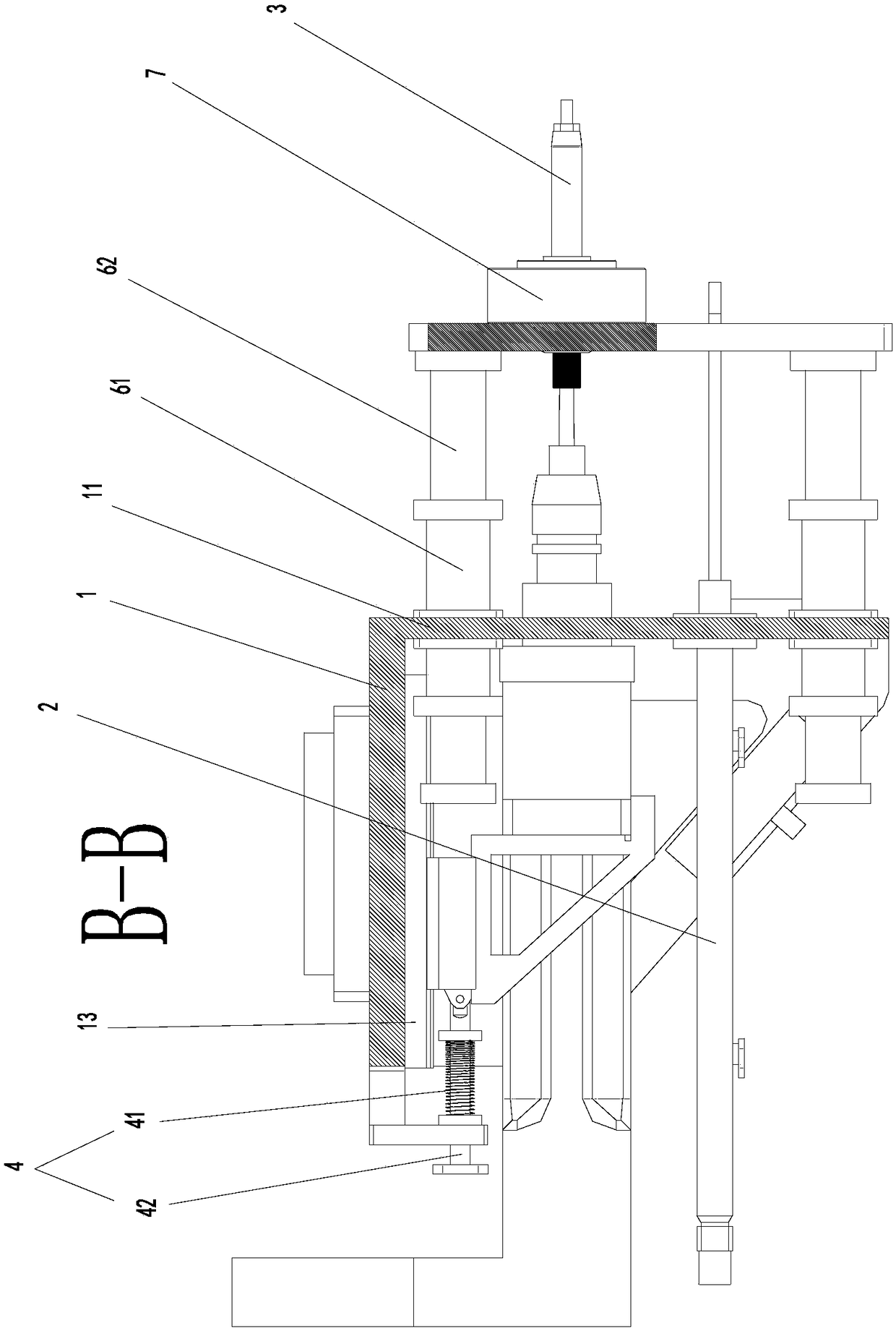

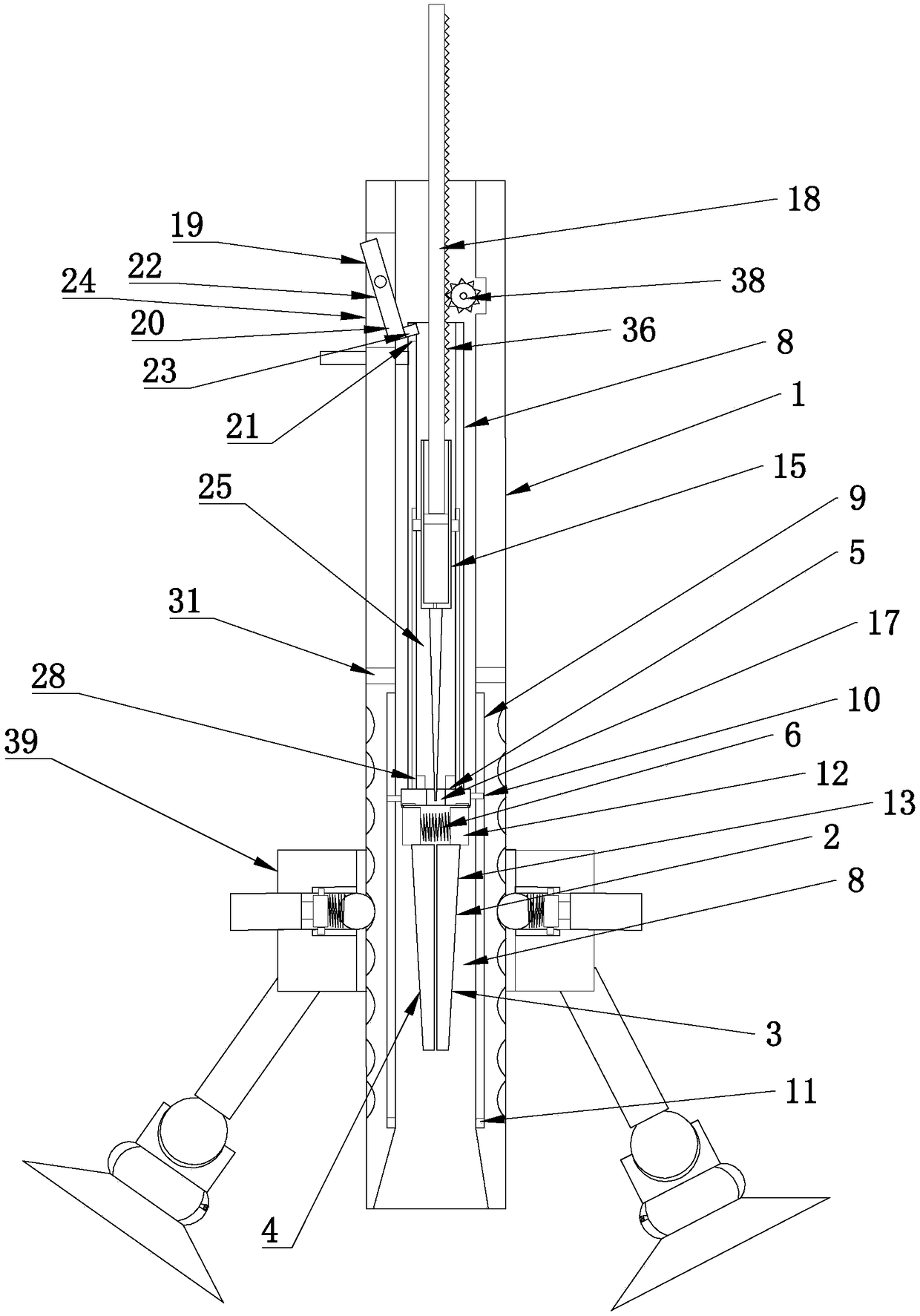

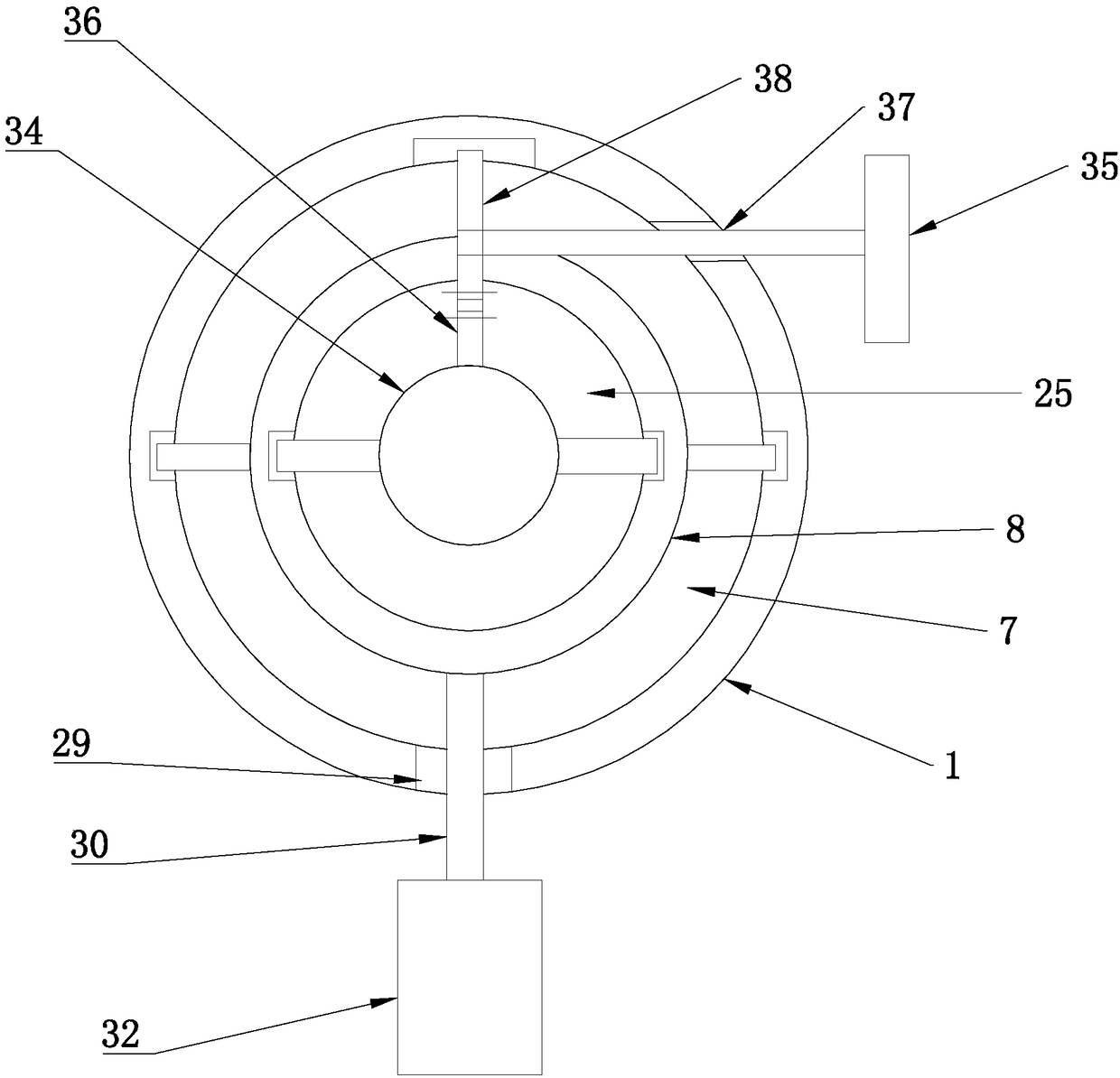

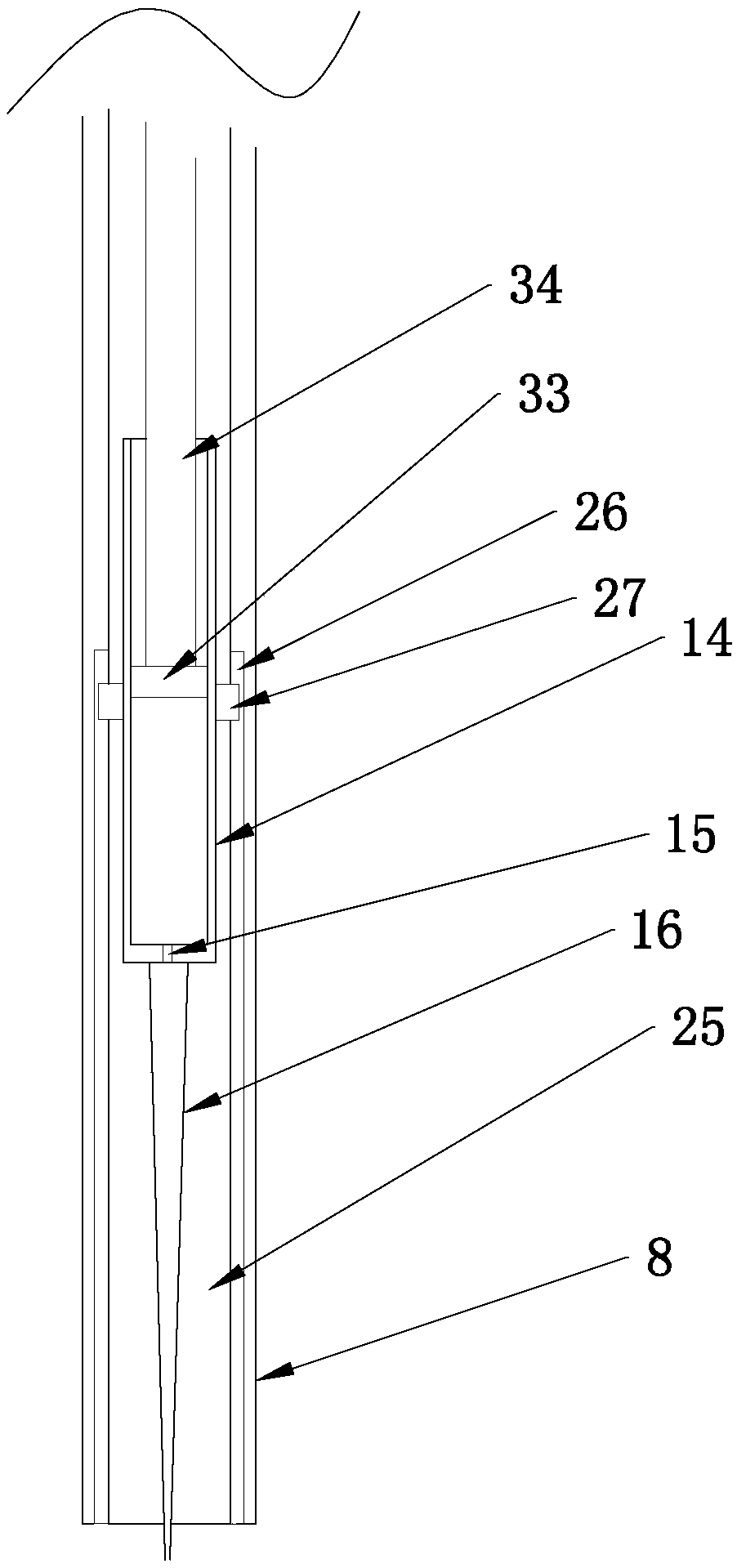

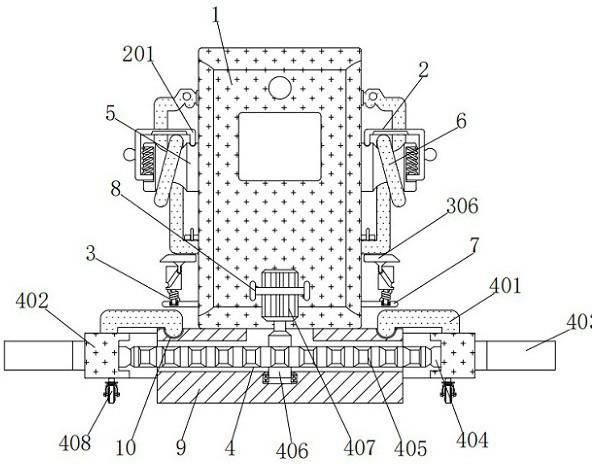

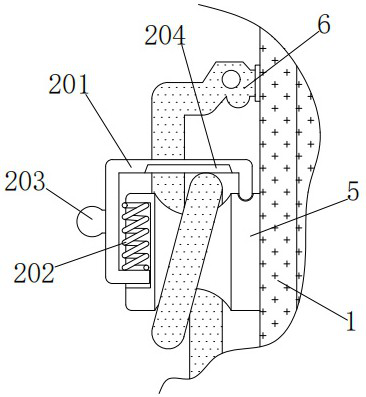

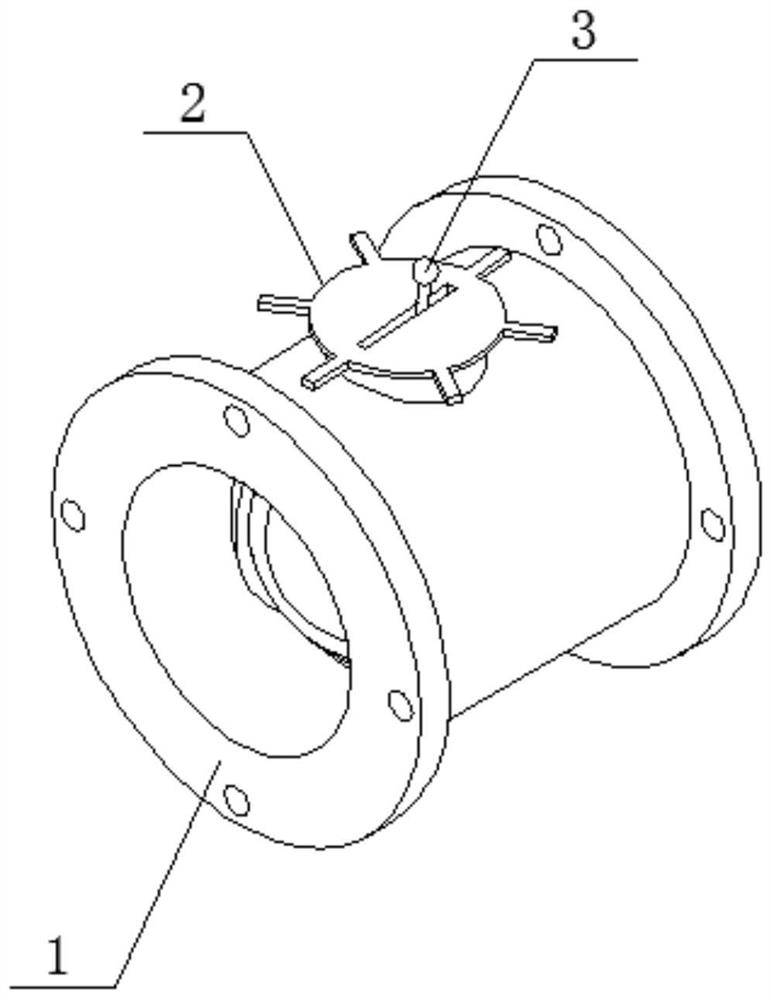

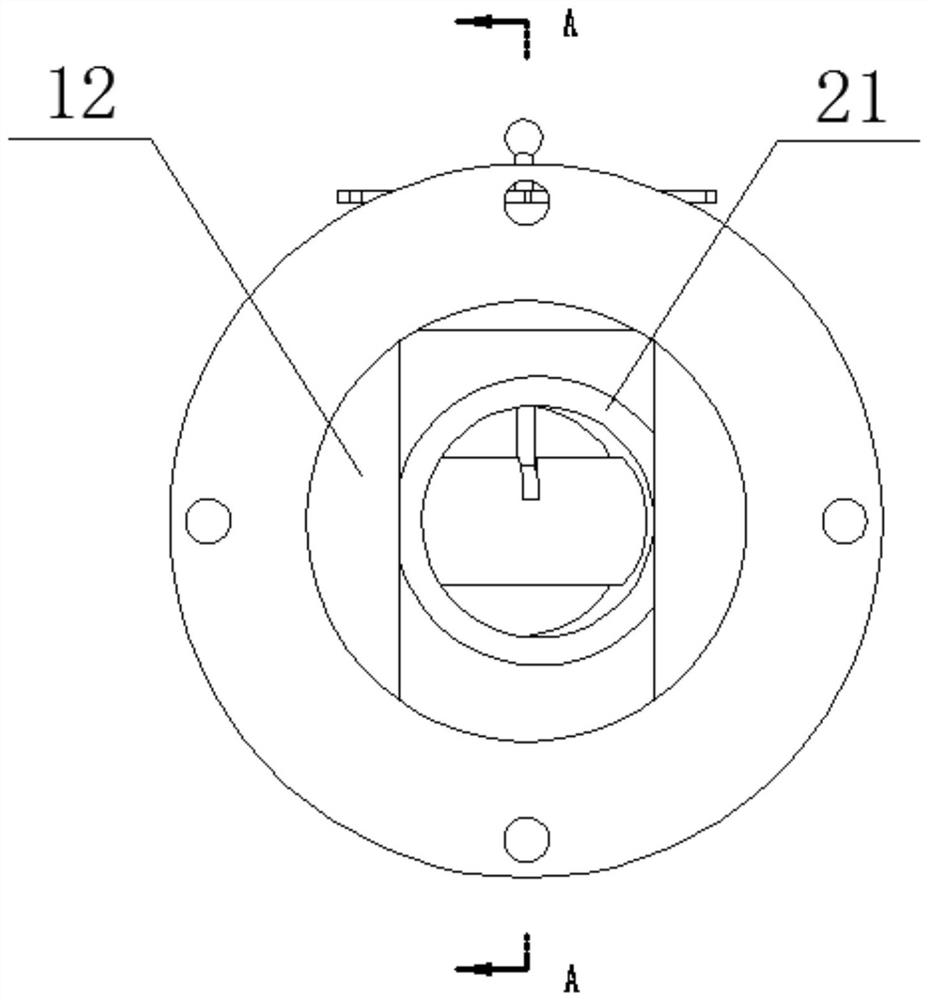

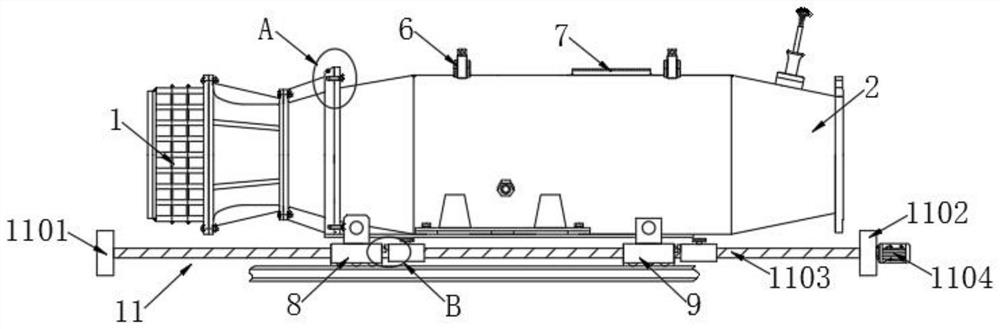

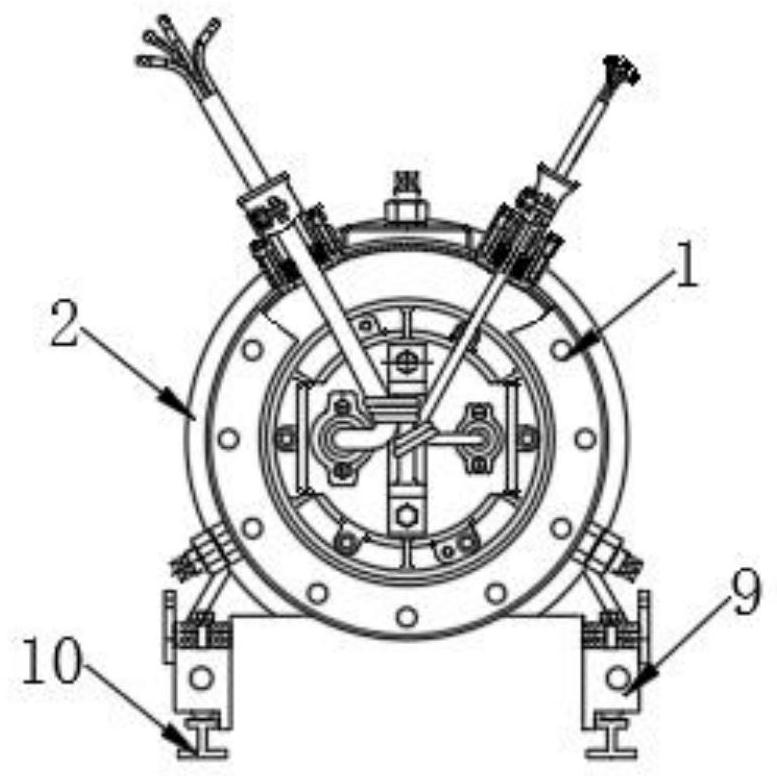

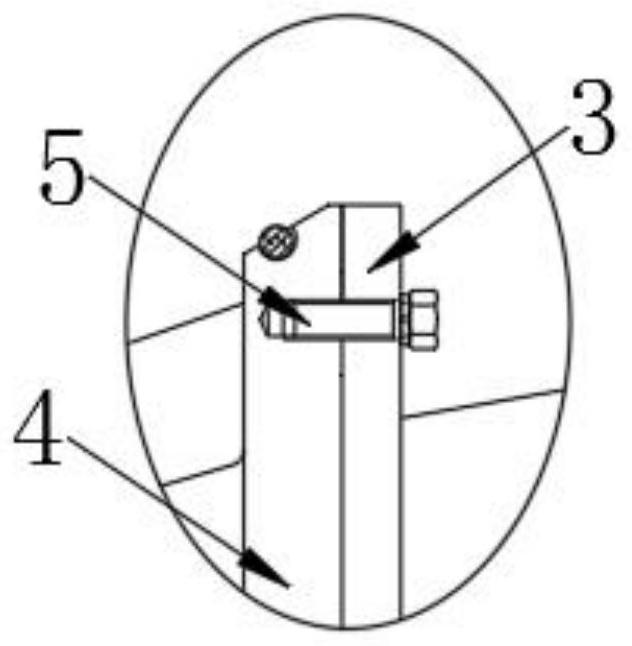

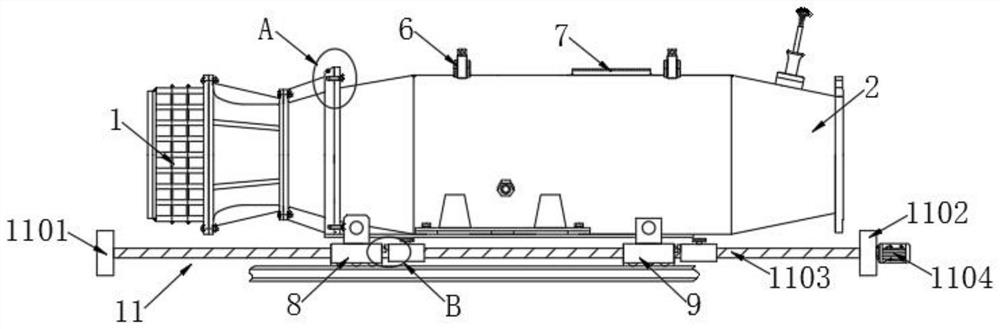

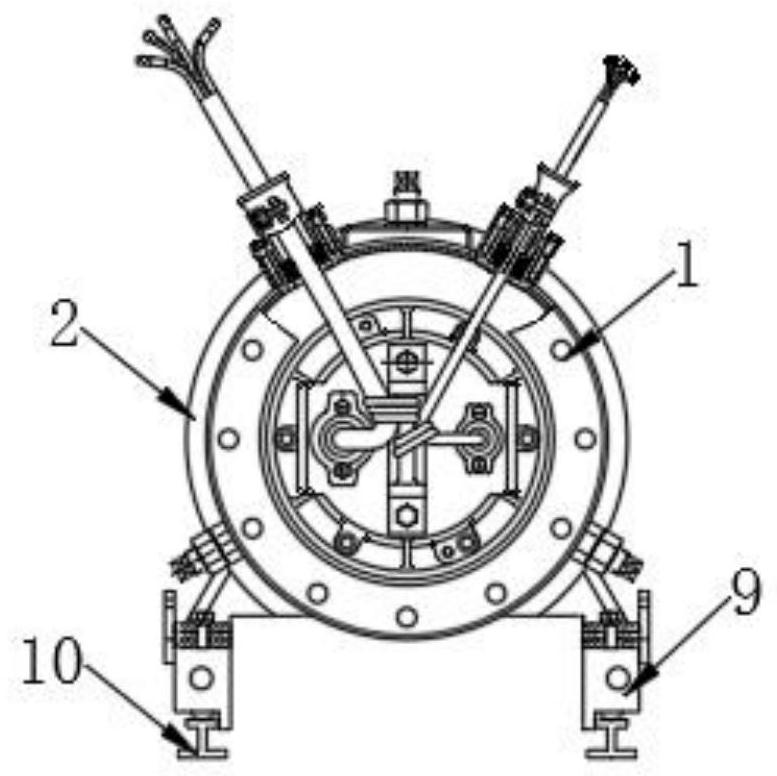

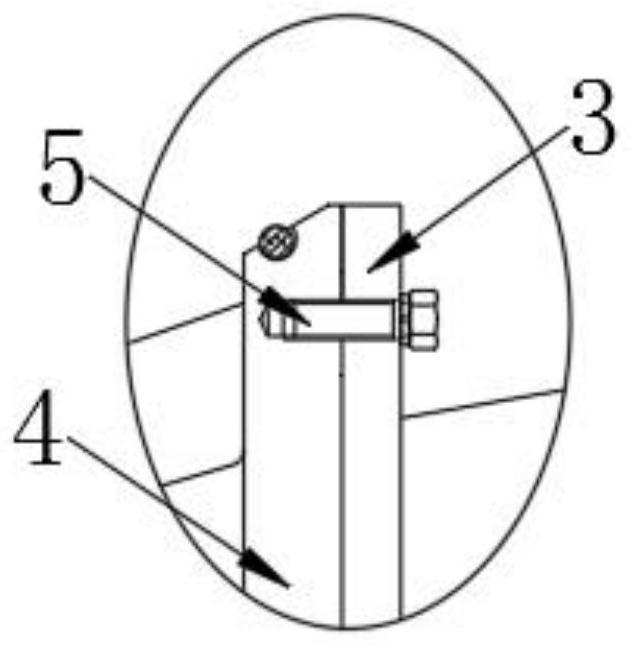

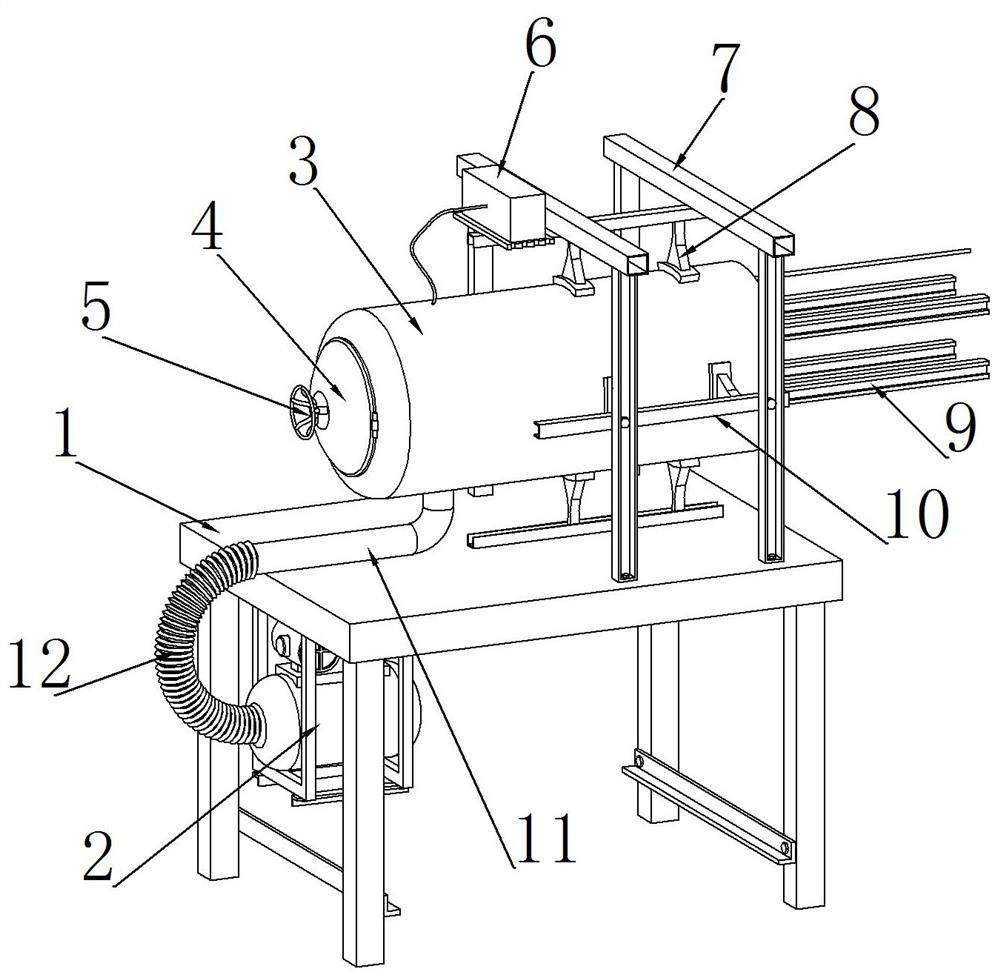

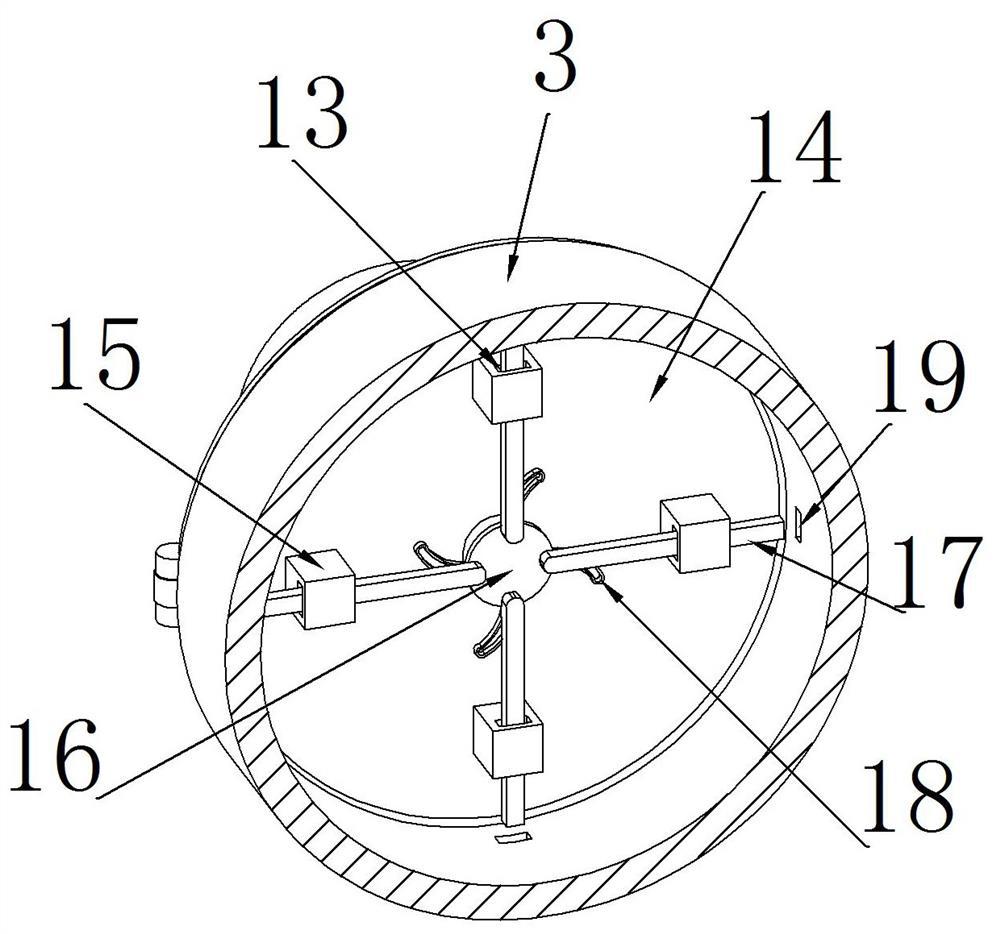

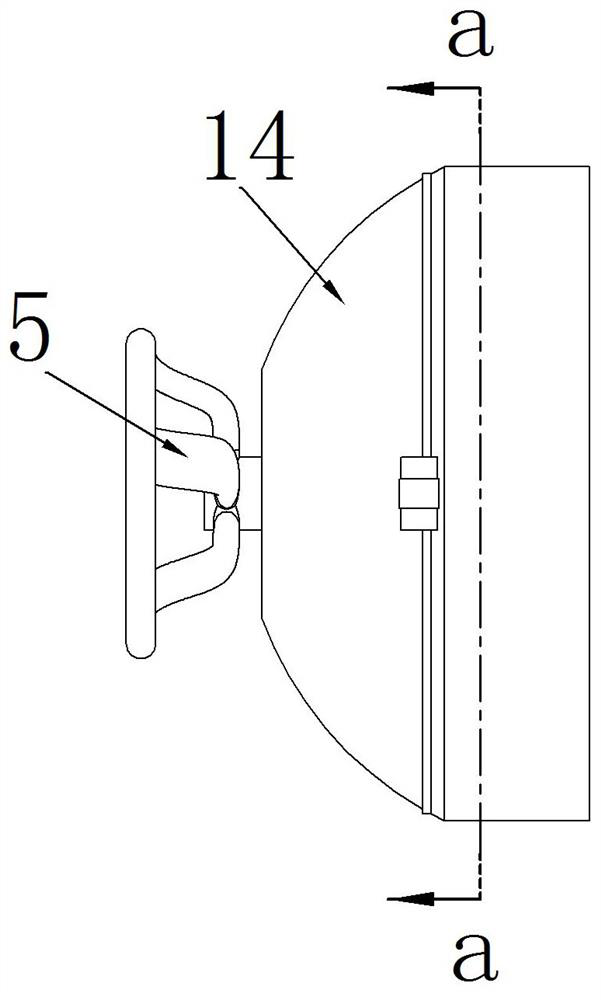

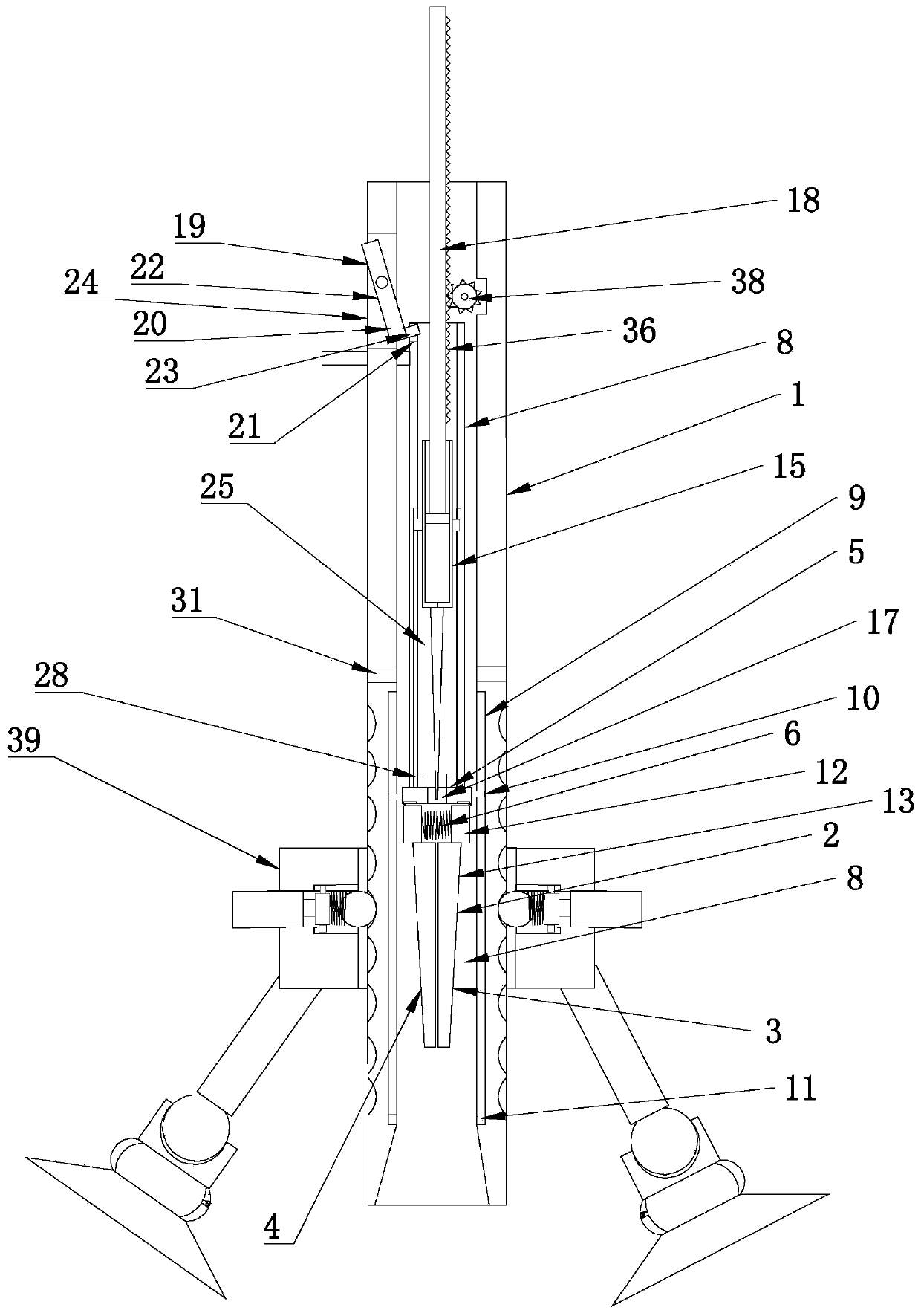

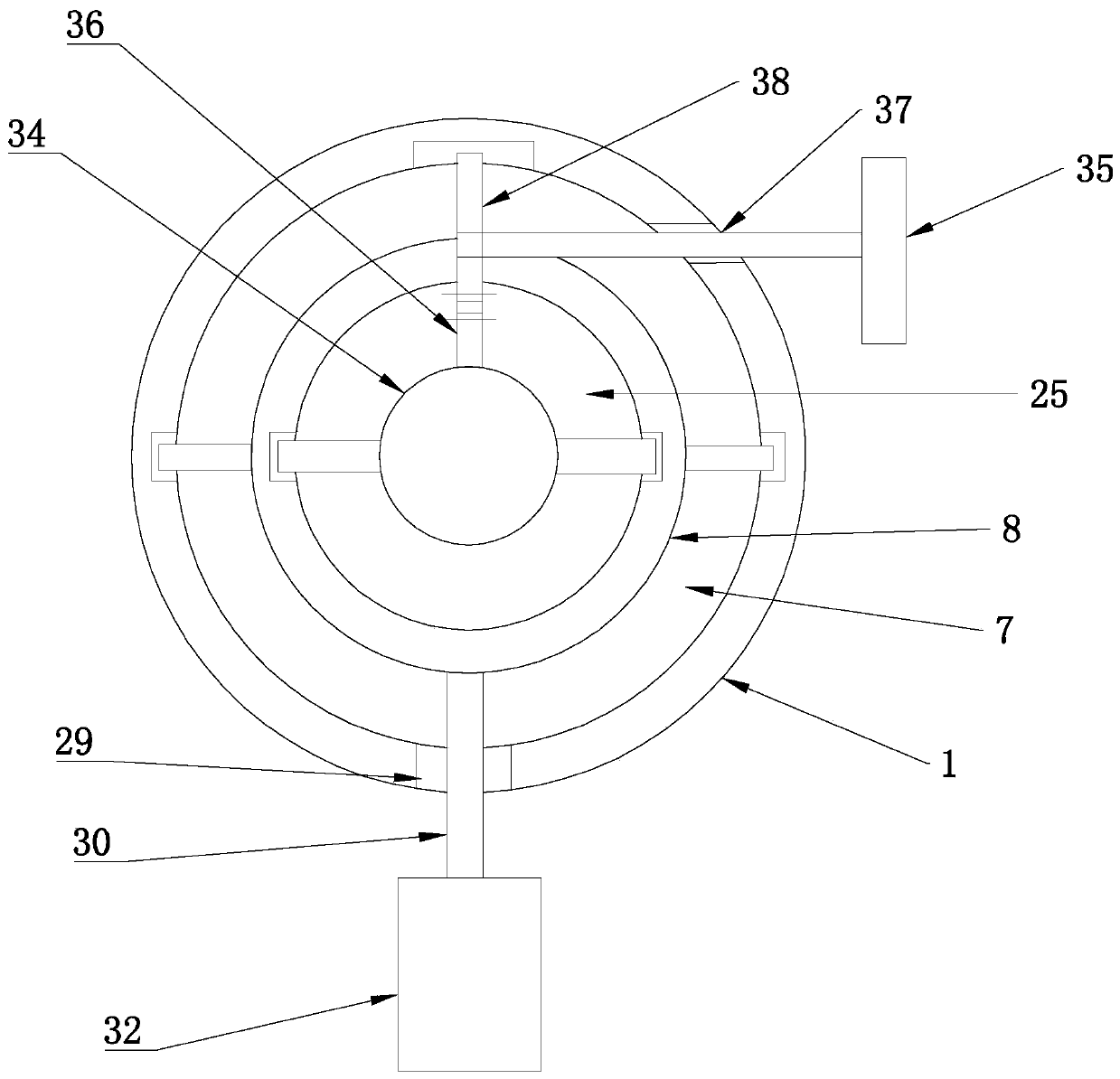

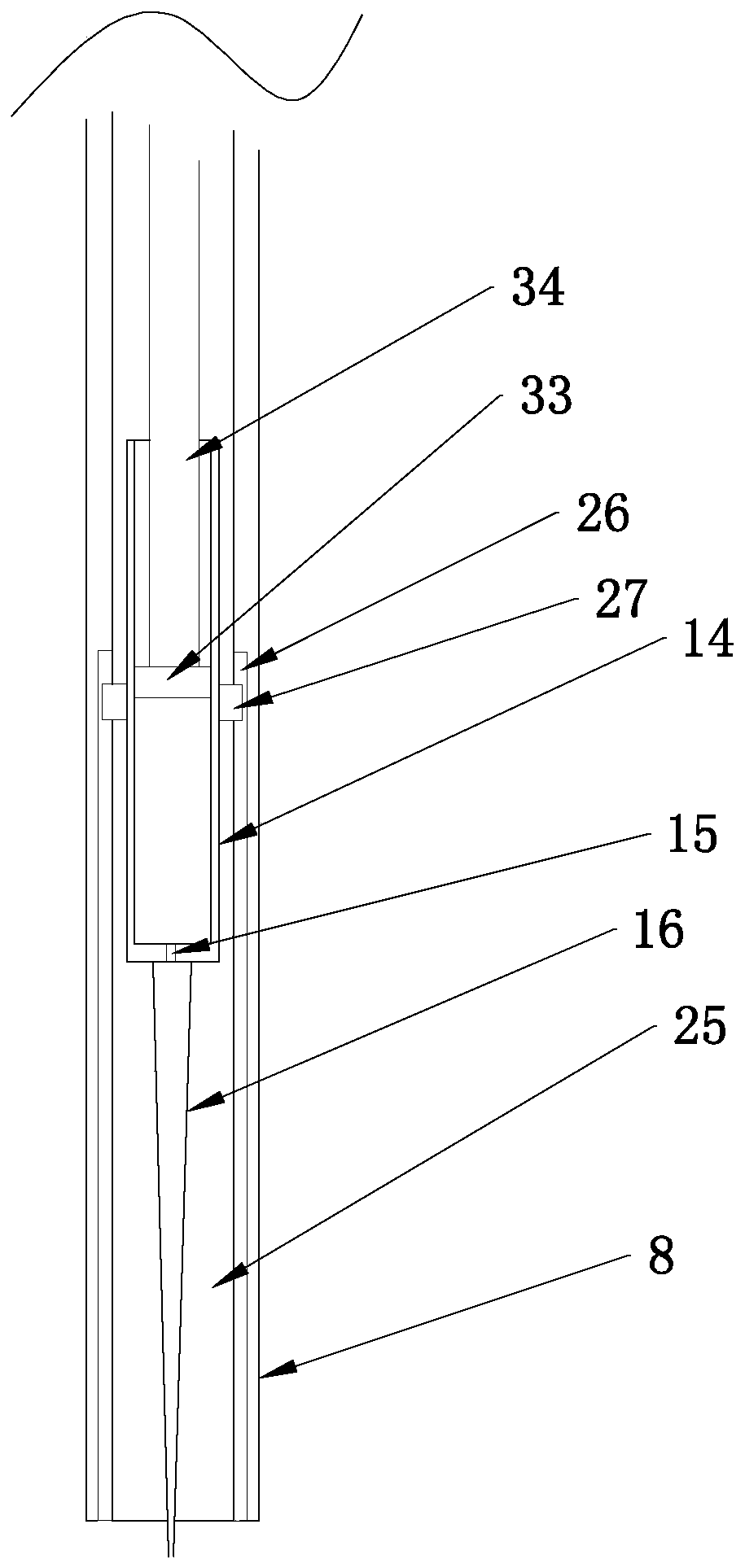

Automatic petroleum pipeline circular seam welding device

ActiveCN107414367ACompact structureReduce volumeWelding/cutting auxillary devicesAuxillary welding devicesControl systemContact type

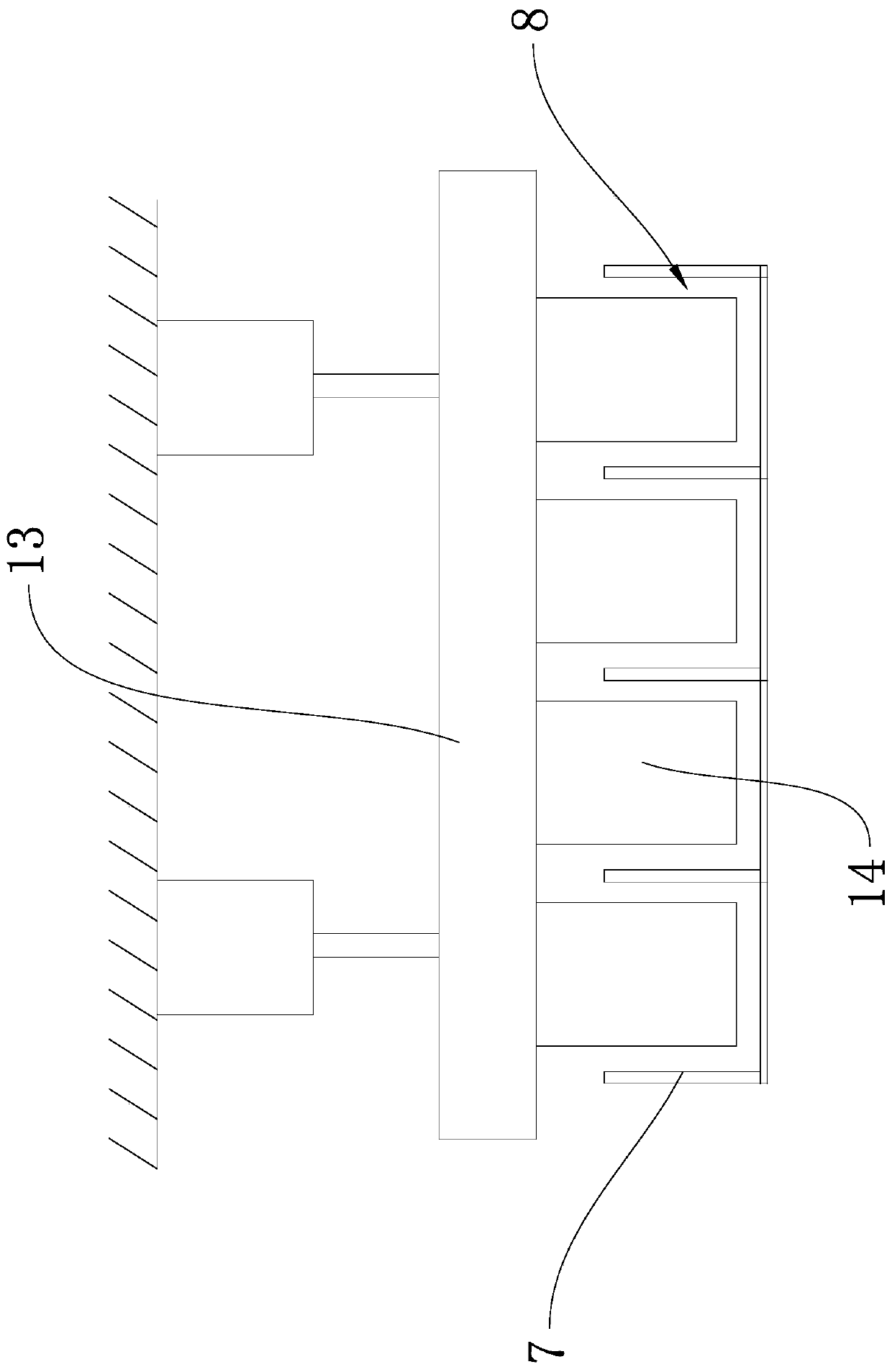

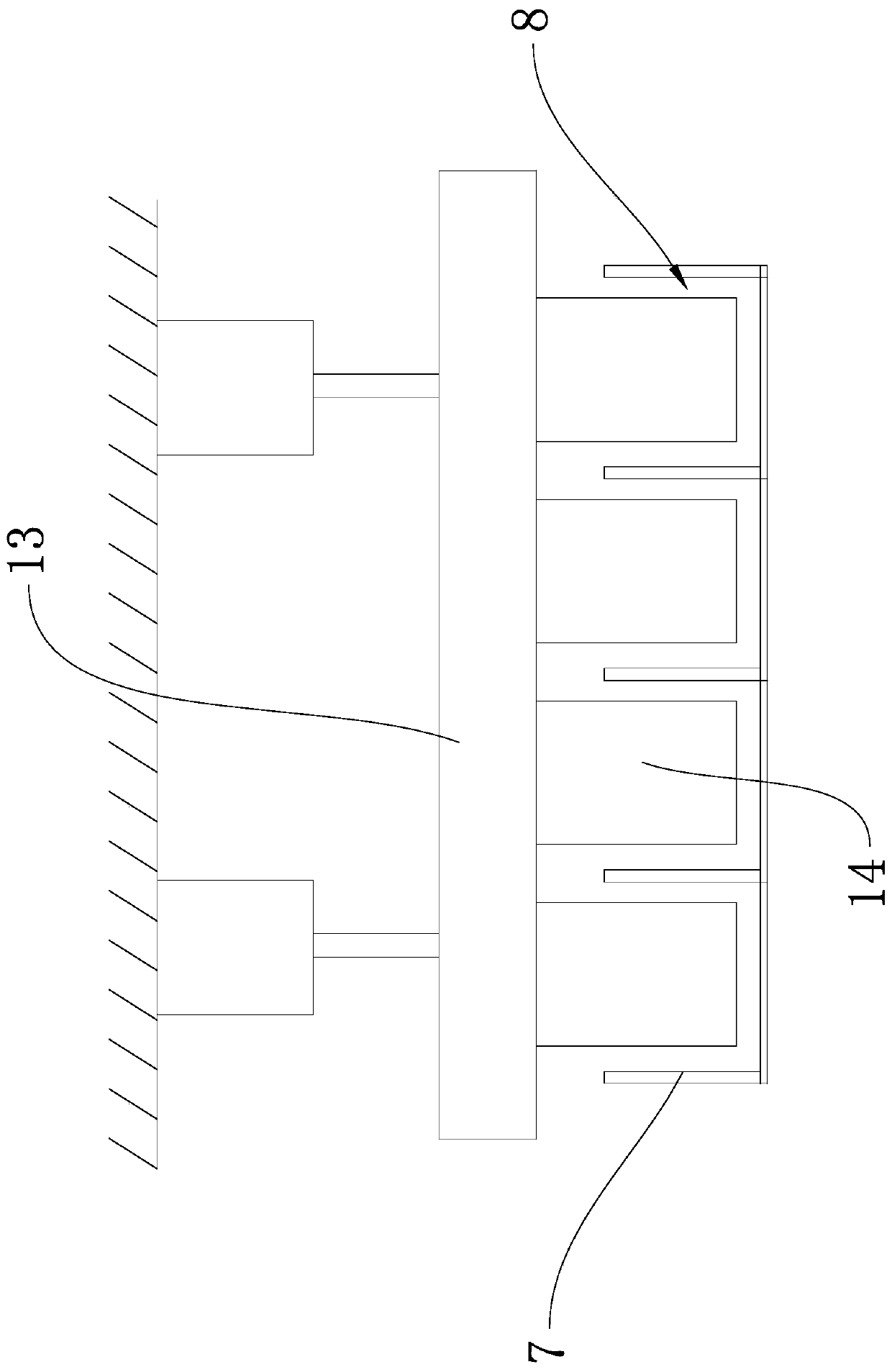

The invention relates to a welding device, in particular to an automatic petroleum pipeline circular seam welding device. The automatic petroleum pipeline circular seam welding device comprises a pipeline clamping system, a power and control system, a welding gun clamping system and a welding gun. The pipeline clamping system is installed on a petroleum pipeline, the power and control system is installed on the pipeline clamping system, the welding gun clamping system is installed on the power and control system, and the welding gun is installed on the welding gun clamping system. The automatic petroleum pipeline circular seam welding device is directly installed on the petroleum pipeline in need of welding, the welding gun is driven to act through gear transmission so as to complete the circular seam welding process. The automatic petroleum pipeline circular seam welding device has the advantages of being simple and compact in structure, small in size, low in cost and high in automated degree. Welding can be stopped automatically through a contact type travel switch when a half circle is welded, the welding process is divided into two steps and completed through welding of the two half circles, and thus welding quality is improved. Spiral transmission is adopted for the welding gun clamping system to adjust the position of the welding gun, the distance between the welding gun and the petroleum pipeline can be adjusted precisely, and the welding quality of a circular seam is further improved.

Owner:XUZHOU XINLONG PIPE IND CO LTD

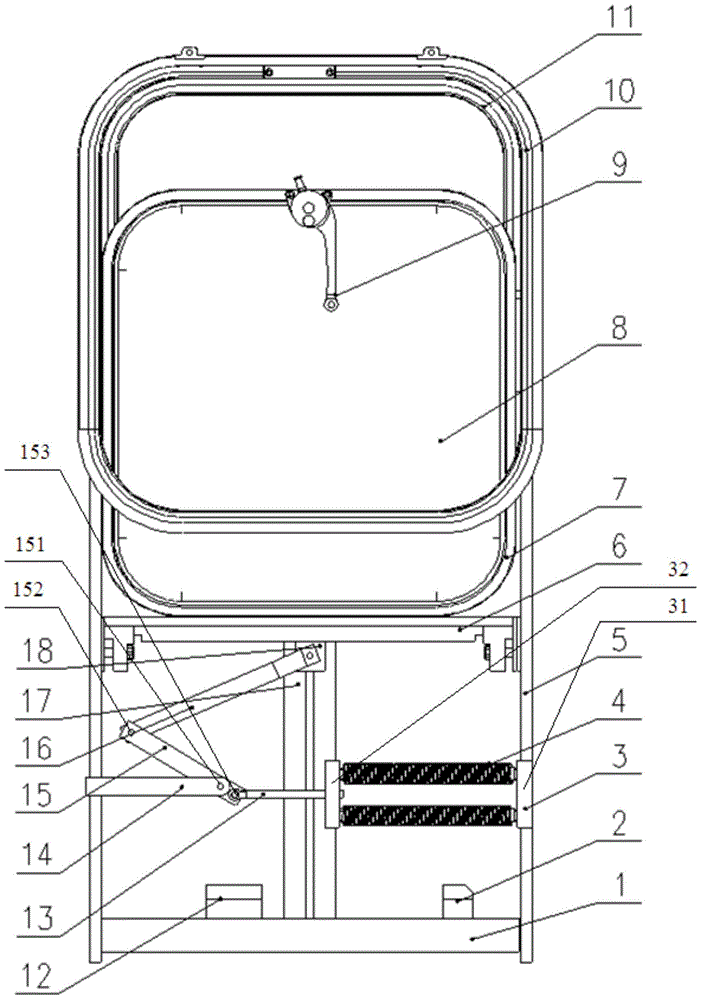

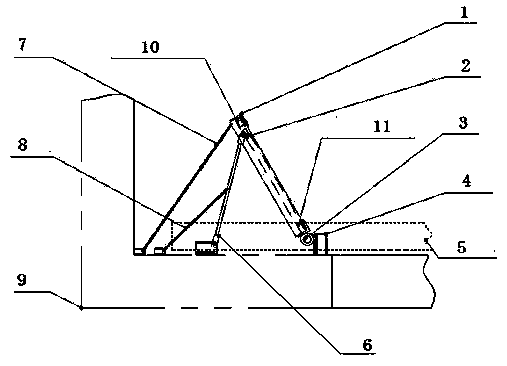

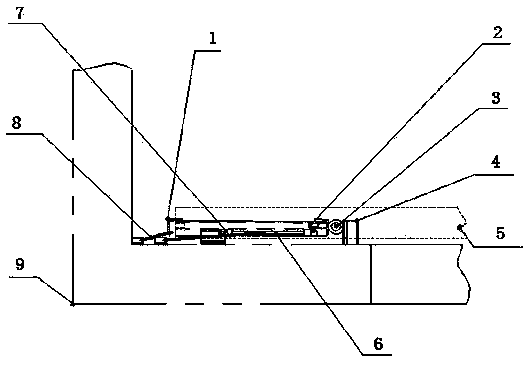

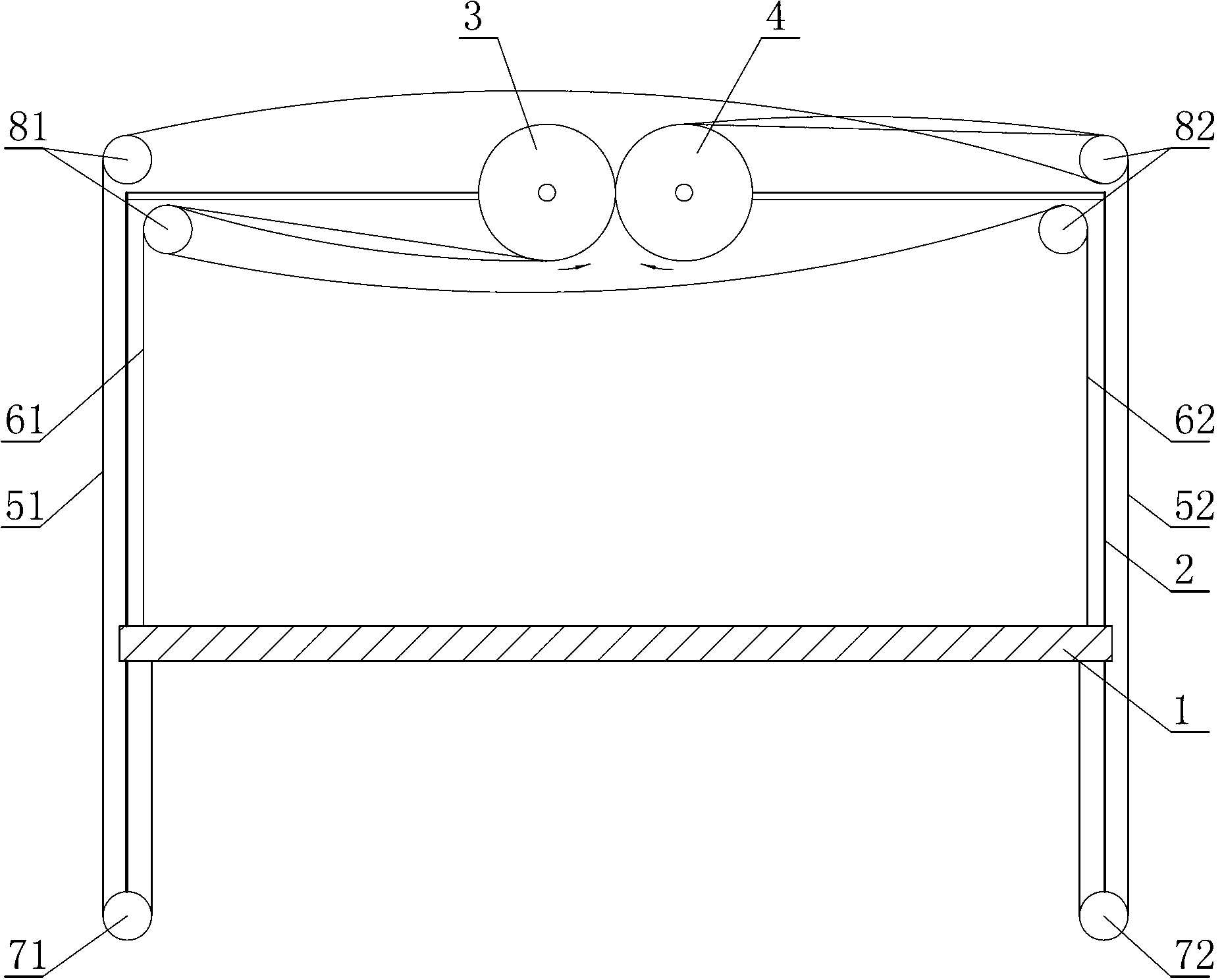

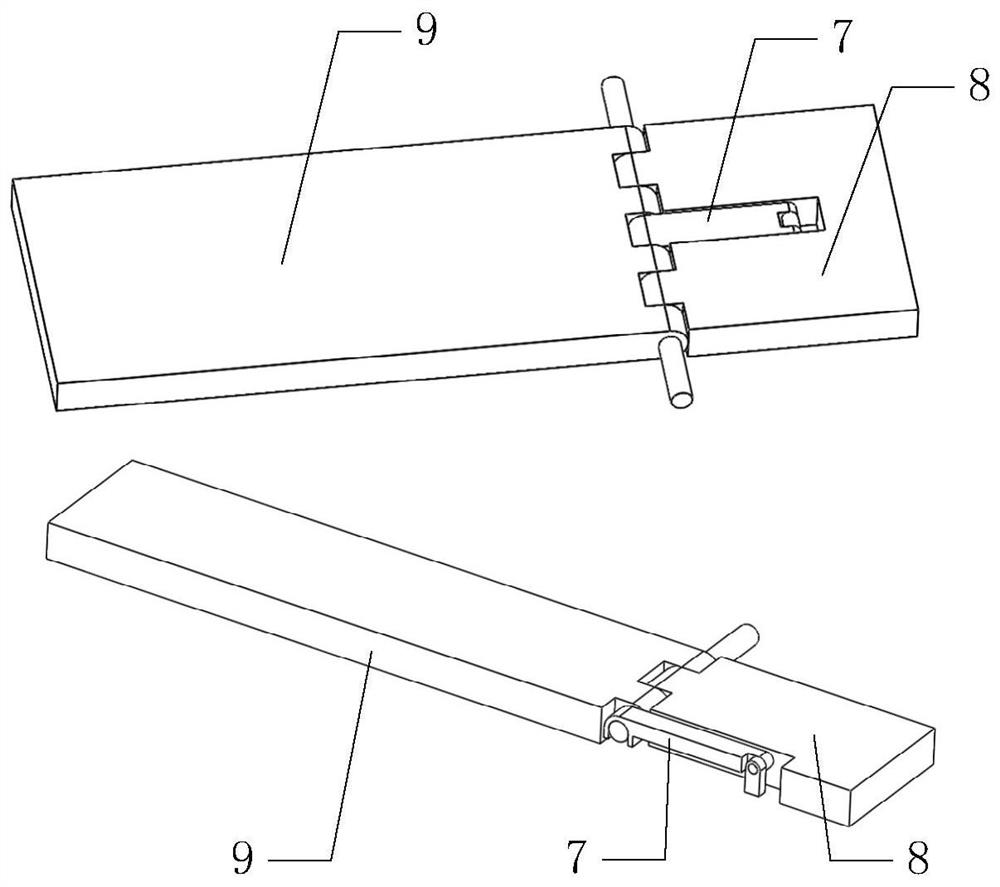

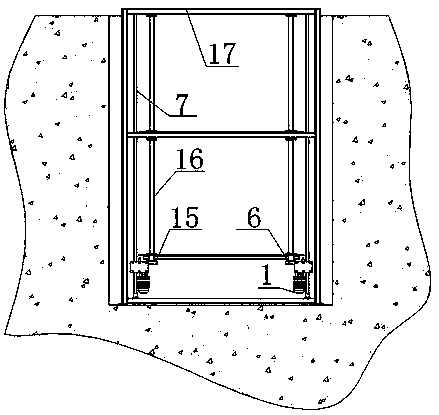

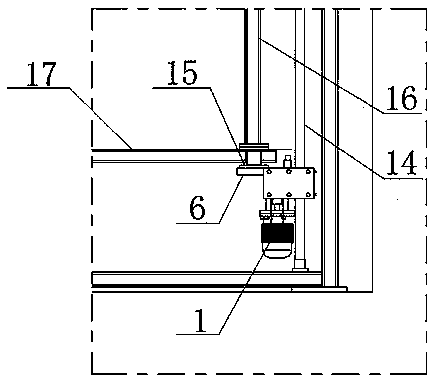

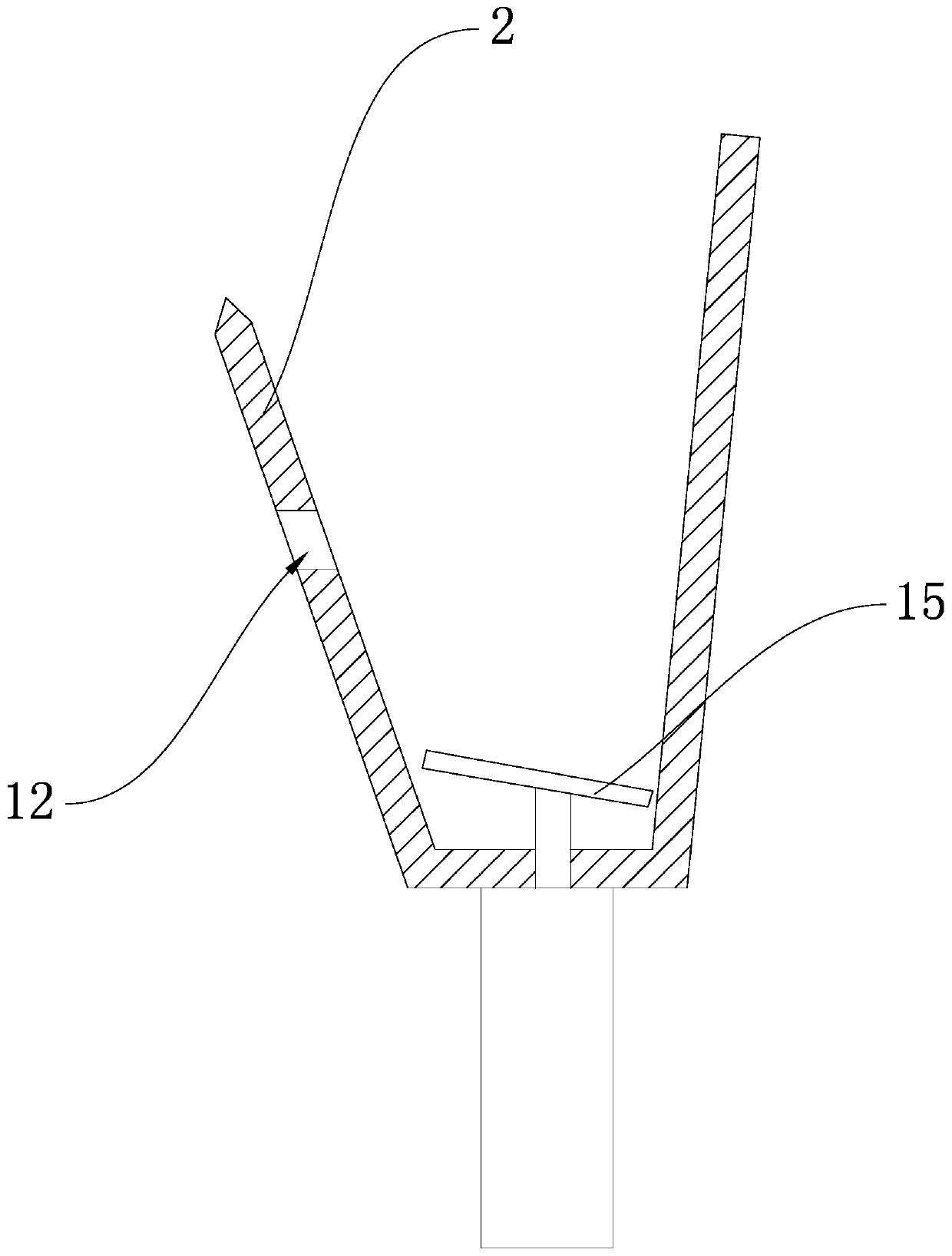

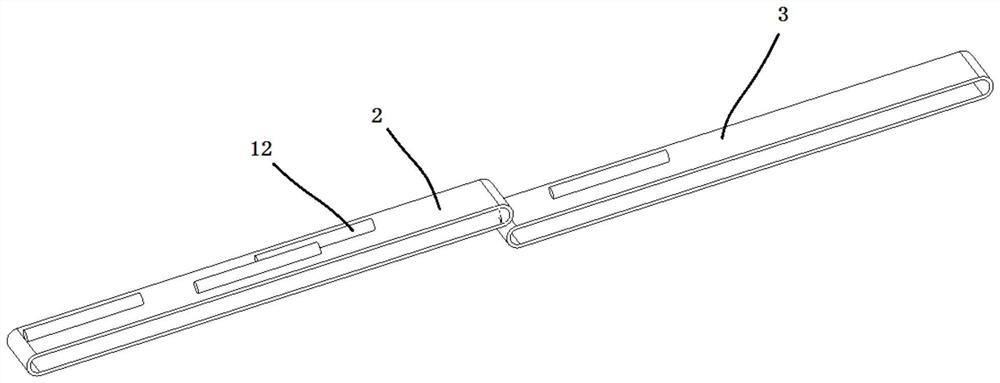

Cab side window for rail transit locomotive

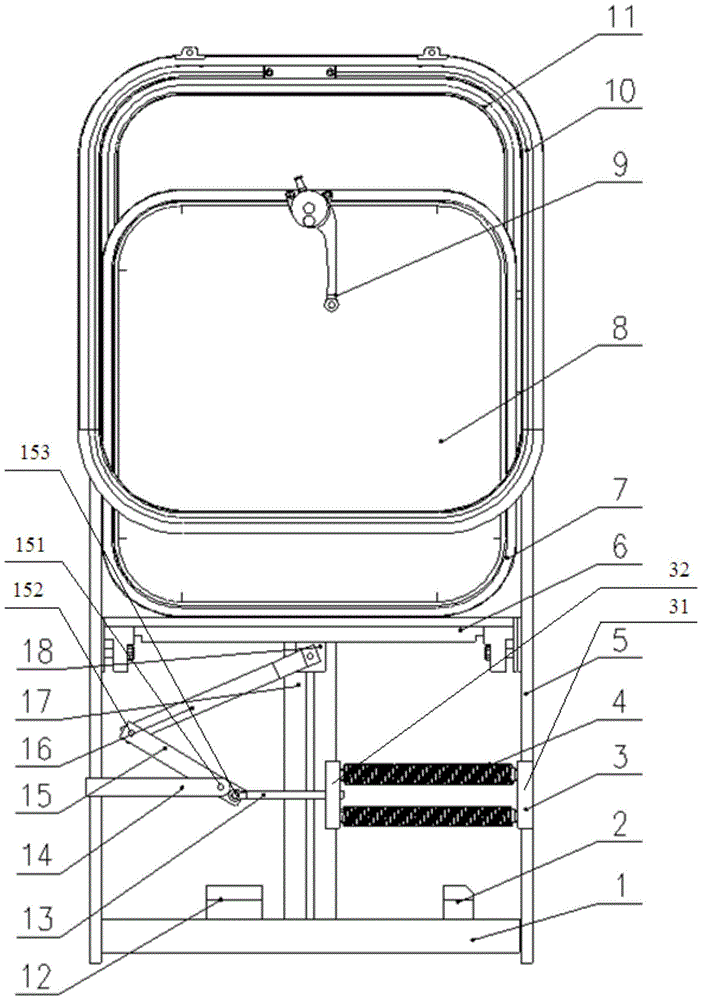

ActiveCN104963591AEven by forceExtended service lifeWing arrangementsWing suspension devicesEngineeringBlock match

The invention provides a cab side window for a rail transit locomotive. The cab side window comprises a bottom cross beam, a side window fixing frame, a glass supporting beam, a glass fixing frame, side window glass, a crank-connecting rod-sliding block mechanism and sliding rails. The length direction of the sliding rails is vertically arranged, the sliding rails are located in the center of the side window fixing frame in the width direction, the bottom ends of the sliding rails are fixedly connected to the bottom cross beam, and the top ends of the sliding rails are directly or indirectly connected to the side wall of a locomotive cab fixedly. A sliding block matched with the sliding rails is connected with the glass supporting beam. One end of a crank-connecting rod assembly is fixedly connected to the side window fixing frame, and the other end of the crank-connecting rod assembly and the sliding block are connected to form the crank-connecting rod-sliding block mechanism so as to support the sliding block to vertically move up and down in the sliding rails along with the side window glass. An existing crank-connecting rod mechanism which is eccentrically stressed is replaced with the crank-connecting rod-sliding block mechanism which is centrally stressed, the improved side window is balanced in stress, abrasion to an aluminum alloy window frame is reduced in the opening and closing processes of the side window, and the normal service life of the side window is prolonged.

Owner:HUNAN LIANCHENG TRACK EQUIP CO LTD

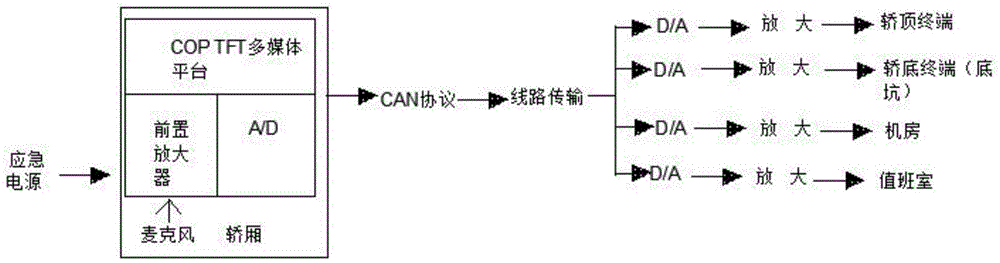

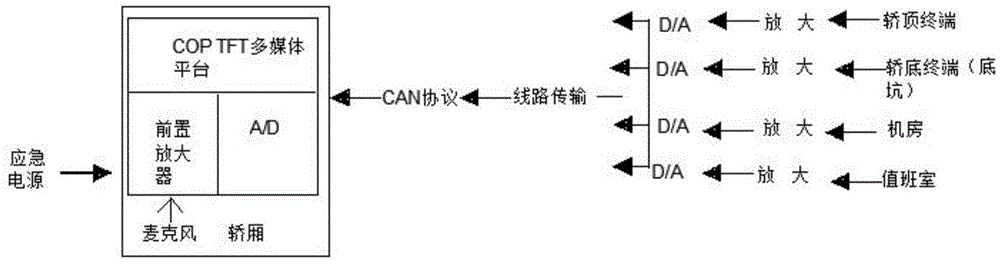

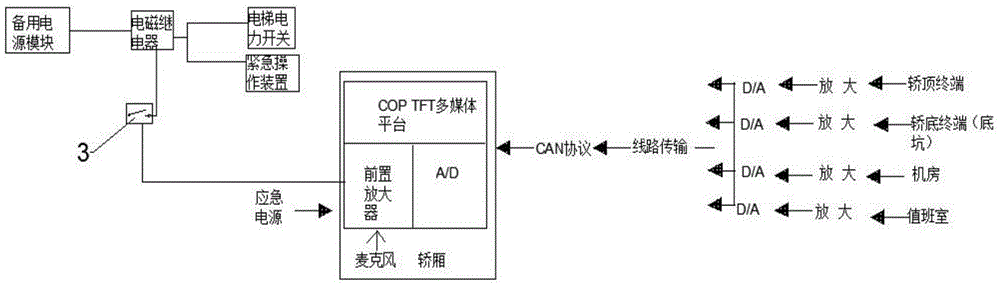

Elevator emergency system

The invention provides an elevator emergency system. The elevator emergency system is characterized in that the elevator emergency system comprises an elevator emergency intercom system and an elevator emergency rescue system, the elevator emergency intercom system is connected with the elevator emergency rescue system through a single switch, and switching-on and switching-off of the elevator emergency rescue system are controlled; the elevator emergency intercom system comprises a car intercom switchboard, a duty room intercom switchboard, a machine room terminal, a car top terminal and a car bottom terminal, and the car intercom switchboard is integrated in a signal-distortion-prevention system; the signal-distortion-prevention system comprises a COP TFT multimedia platform which is provided with multiple peripheral interfaces, and the COP TFT multimedia platform is integrated with a single conversion device and a communication protocol. According to the elevator emergency system, the elevator emergency intercom system and the elevator emergency rescue system are included, when emergency warning or intercom is achieved, the elevator emergency rescue system can be started, emergency rescue can be executed, and the personal safety of passengers is further guaranteed.

Owner:JIANGSU WELM TECH

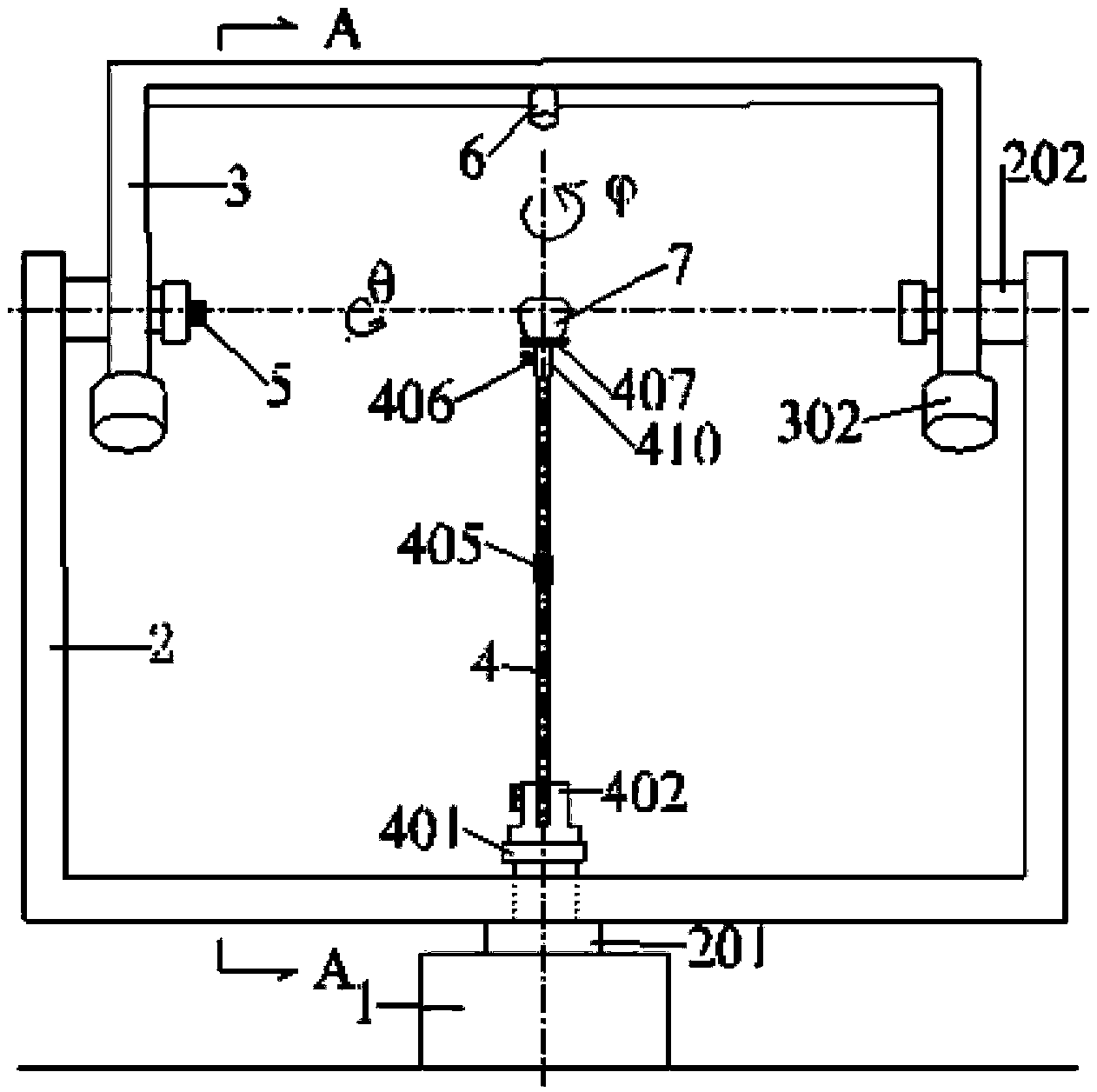

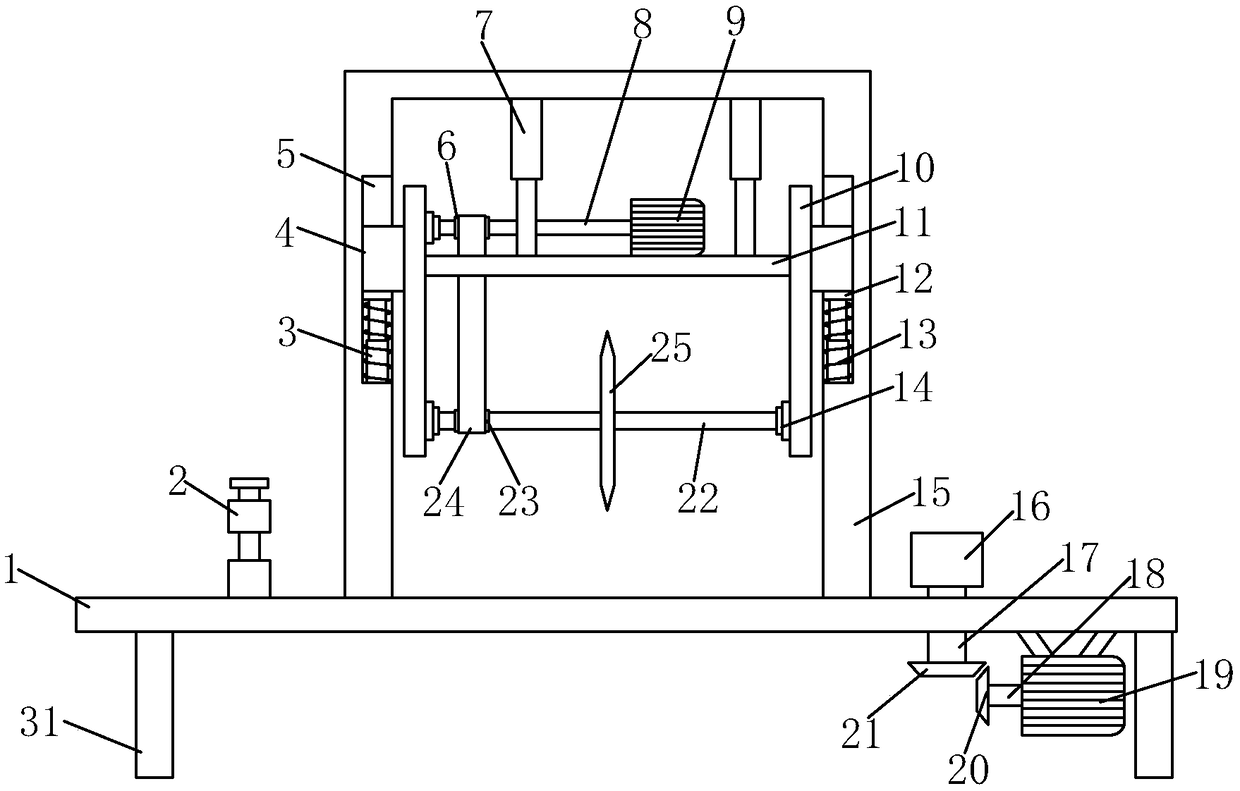

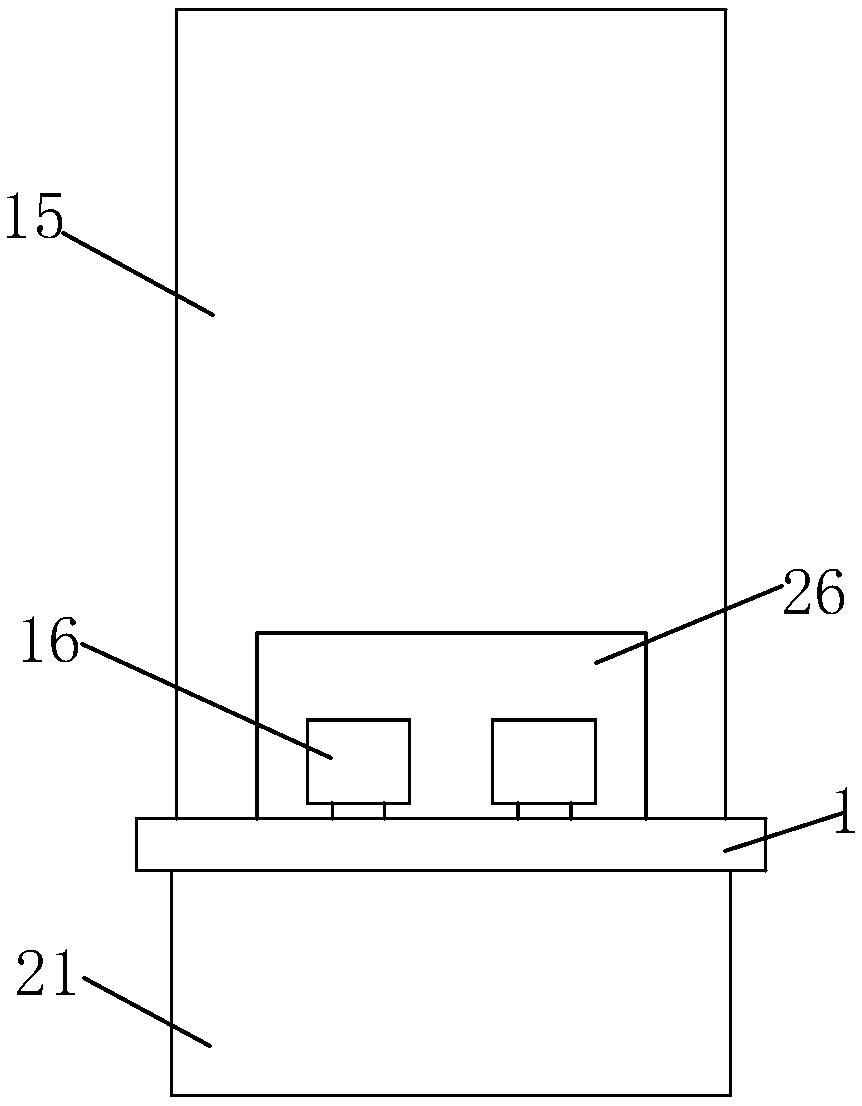

Fixed light source-type full space distribution luminosity measurement instrument

ActiveCN103674236ASolve the problem that it cannot be adjusted and the center of the light source under test cannot be determinedEnsure spatial positioning accuracyPhotometryVertical planeTester device

The invention provides a fixed light source-type full space distribution luminosity measurement instrument. The luminosity measurement instrument comprises a base, a vertical rotating mechanism, a vertical U-shaped rotating arm, a horizontal rotating mechanism, a horizontal U-shaped rotating arm, a to-be-measured light source correcting bracket, a positioning laser and a light detector, wherein the vertical rotating mechanism is arranged on the base; the vertical U-shaped rotating arm consists of a beam and two arms and is fixed to the vertical rotating mechanism; the horizontal rotating mechanism is arranged inside the two arms of the vertical U-shaped rotating arm; the horizontal U-shaped rotating arm consists of a beam and two arms, and the two arms of the horizontal U-shaped rotating arm are connected with the horizontal rotating mechanism; one end of the to-be-measured light source correcting bracket is fixed in the center of the beam of the vertical U-shaped rotating arm, and the other end of the to-be-measured light source correcting bracket is suitable for holding a to-be-measured light source; the positioning laser is fixed to the horizontal U-shaped rotating arm, and the positioning laser and the horizontal rotating mechanism are in the same axis; the light detector is fixed in the center of the beam of the horizontal U-shaped rotating arm; the central lines of the light detector and the to-be-measured light source correcting bracket are in the same vertical plane. Through the adoption of the novel conception on the structure, the measurement precision can be improved effectively.

Owner:SHANGHAI MOTOR VEHICLE INSPECTION CERTIFICATION & TECH INNOVATION CENT CO LTD

Steel pipe cutting device

InactiveCN109108368AGuaranteed normal cuttingGuaranteed to stopTube shearing machinesShearing machine accessoriesEngineeringAlternating current

The invention relates to the technical field of steel pipe cutting, in particular to a steel pipe cutting device. The device comprises a base. Supporting plates are fixedly mounted on the two sides ofthe lower end of the base correspondingly. A second alternating current asynchronous motor is fixedly mounted on one side of the lower end of the portion, between the supporting plates, of the base.An output shaft of the second alternating current asynchronous motor is fixedly connected with a second driving rotary shaft. A second driven rotary shaft is arranged on the second driving rotary shaft through a first transmission structure, penetrates through the base and stretches to the upper end of the base. A guide wheel is fixedly mounted on the portion, located at the upper end of the base,of the second driven rotary shaft. A cutting frame is fixedly mounted in the position, adjacent to the guide wheel, of the base. Moving plates are arranged in the cutting frame through sliding structures correspondingly. According to the steel pipe cutting device, the second alternating current asynchronous motor is utilized firstly for driving the guide wheel to achieve a guide effect on a to-be-cut steel pipe, the cutting efficiency can be greatly improved, meanwhile, electric telescopic rods drive a fixing plate to move up and down, and it can be guaranteed that a cutting disc starts and stops cutting the steel pipe.

Owner:温州市宇田钢管有限公司

Metal plate bending machine

The invention discloses a metal plate bending machine, and relates to the technical field of metal plate machining equipment. The metal plate bending machine comprises a rack and an adjusting column,a bending column and an air cylinder which are installed on the rack. The rack is provided with a connecting mechanism used for being connected with the bending column. The connecting mechanism comprises a sliding groove perpendicular to the horizontal plane and a sliding block connected in the sliding groove in a sliding mode. Connecting pieces are arranged on the sliding block; and the connecting pieces are detachably connected to the two ends of the bent column. The bending column comprises a working part in the middle and connecting parts at the two ends. The connecting parts are interconnected with the connecting pieces. Each connecting piece comprises a cylindrical connecting column. According to the metal plate bending machine, the operator can conveniently disassemble, replace andadjust the bending column, the bending column surface treatment convenient for operators, the surface flatness of the bending column is ensured with no requirement for too much time for replacement orlong-time shutdown to cause waste of working time, reduction of the overall working efficiency is avoided and the normal production is ensured.

Owner:无锡银宜华机械有限公司

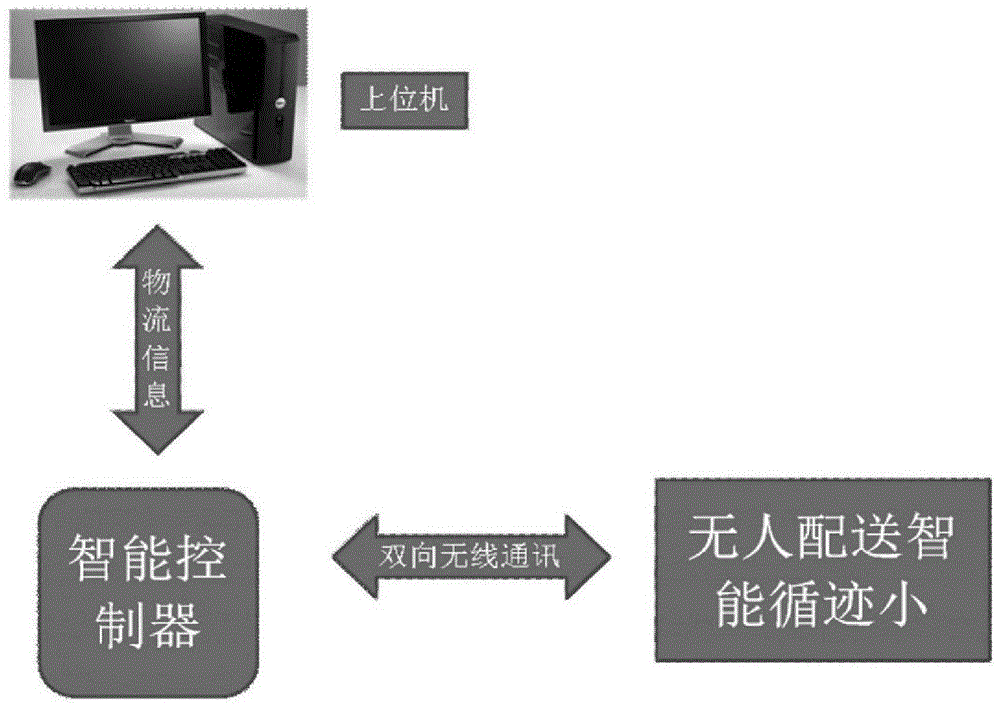

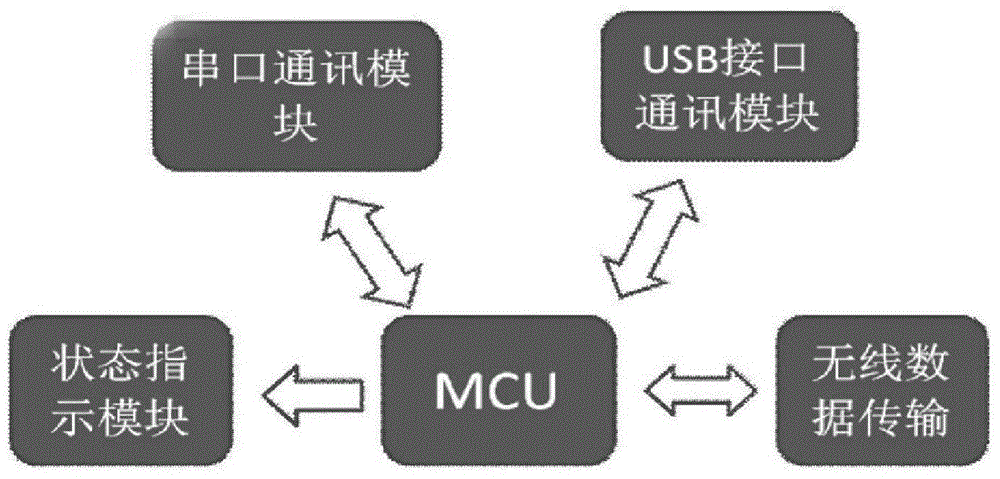

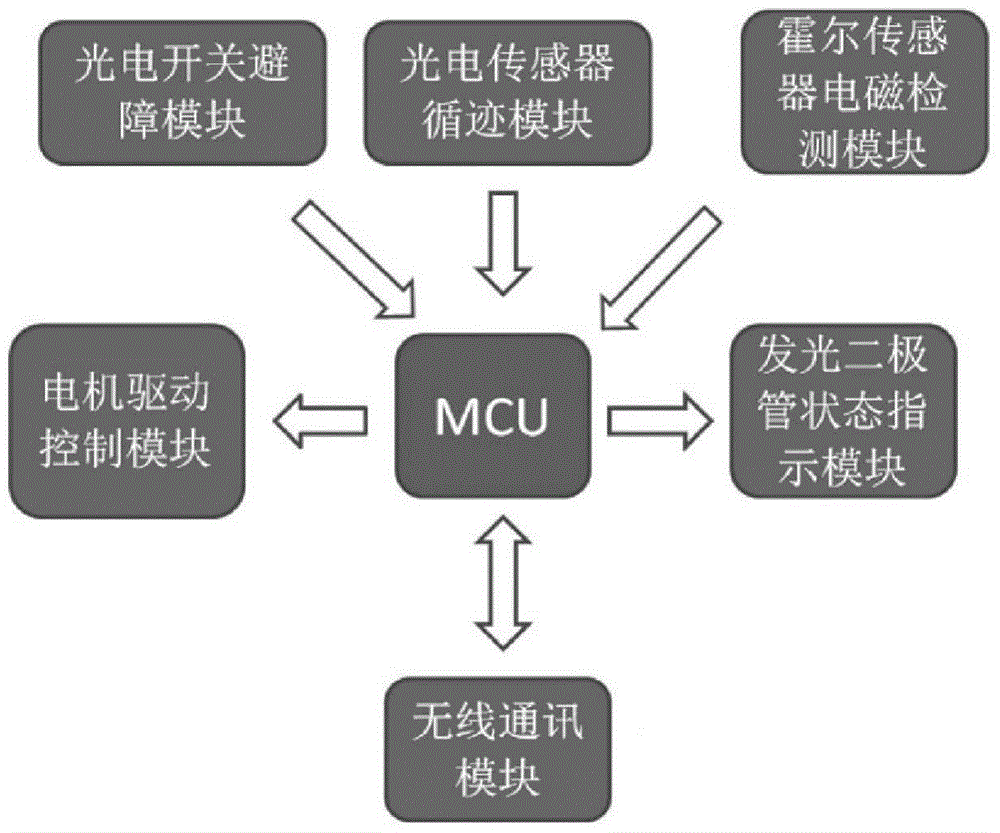

Intelligent logistics tracking trolley and control system thereof

InactiveCN103558855AGuaranteed accuracyNo errorsPosition/course control in two dimensionsControl systemSmart control

The invention discloses an intelligent logistics tracking trolley and a control system thereof. The intelligent tracking trolley and an upper computer used for controlling the intelligent tracking trolley are included, and the upper computer comprises an operating system. The intelligent logistics tracking trolley and the control system thereof are characterized in that the intelligent tracking trolley is provided with the intelligent tracking trolley control system used for controlling the intelligent tracking trolley to move, an intelligent controller is further included, the upper computer transmits signals to the intelligent controller, and after the signals are analyzed by the intelligent controller, the signals are transmitted to the intelligent tracking trolley control system so that the intelligent tracking trolley can be controlled to move. According to the intelligent logistics tracking trolley and the control system thereof, adoptive materials are simple, implementation can be achieved in a programming or designing mode according to the content of the intelligent logistics tracking trolley and the control system thereof, and popularization and application are convenient.

Owner:广西柳工路创制造科技有限公司

Dedicated double-door type protection device for intelligent charging pile of power system

ActiveCN105071479APrevent leakageAvoid touchingBatteries circuit arrangementsElectric light circuit arrangementElectric power systemEngineering

The invention provides a dedicated double-door type protection device for an intelligent charging pile of a power system, and belongs to the field of charging pile protection devices. The device comprises a charging pile, and the body of the charging pile is provided with a through hole. The interior of the through hole is provided with a charging gun and a charging gun holder, wherein the charging fun is located in the charging gun holder. The body of the charging pile is provided with sliding door grooves, and two sides of two ends of the through hole are respectively provided with the sliding door grooves. The interiors of the sliding door grooves are provided with sliding doors, thereby effectively preventing a guest from freely touching the charging gun.

Owner:国网山东桓台县供电公司 +1

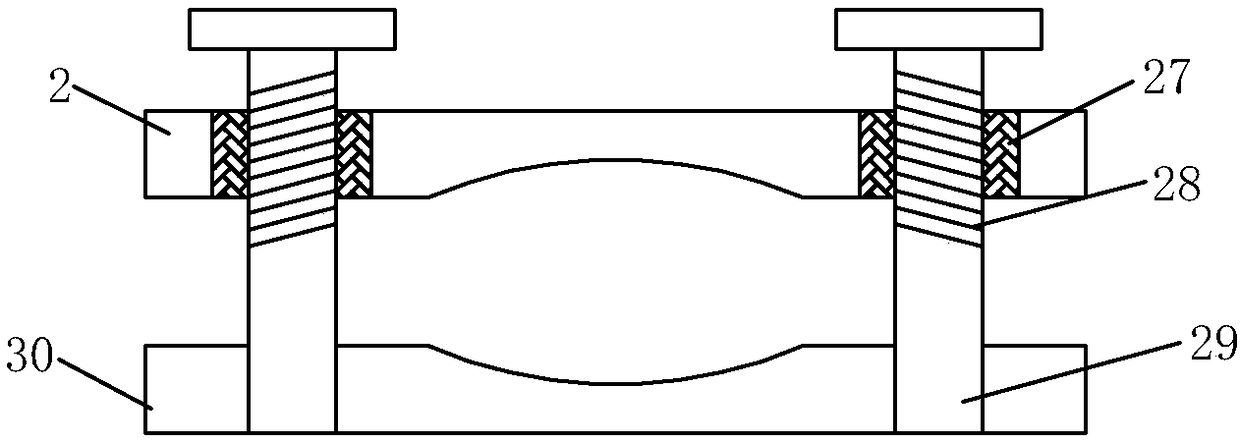

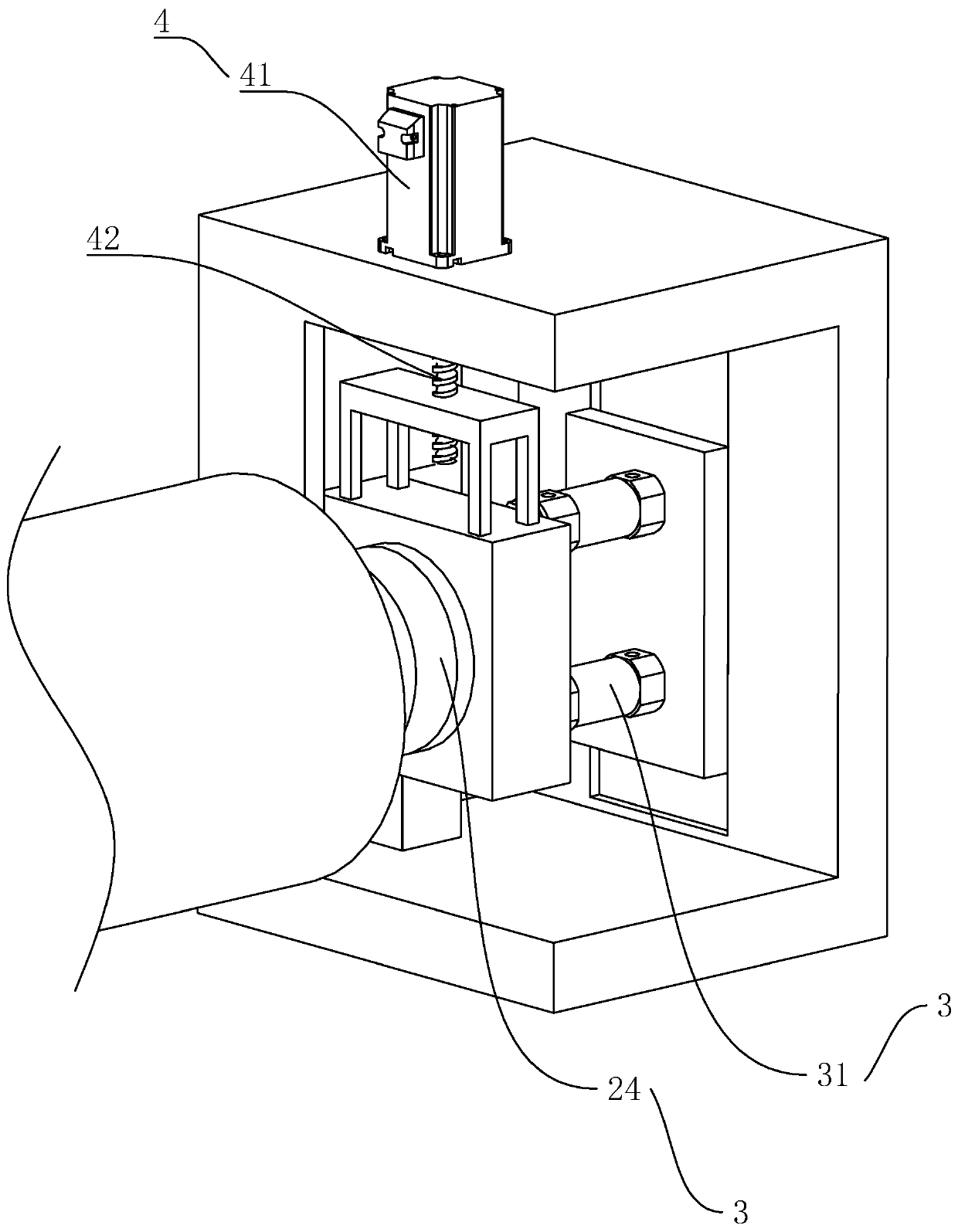

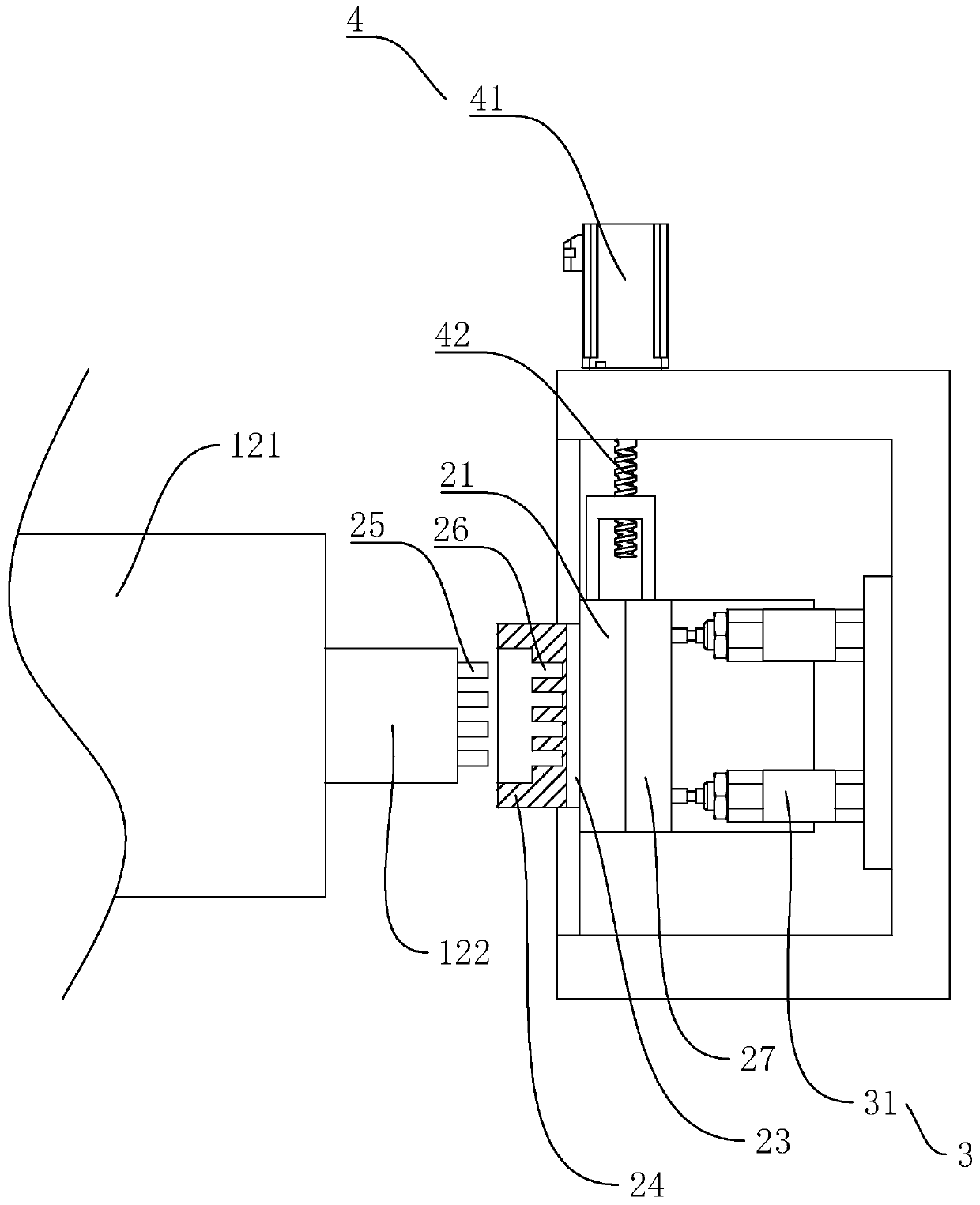

Expansion joint system and expansion joint method

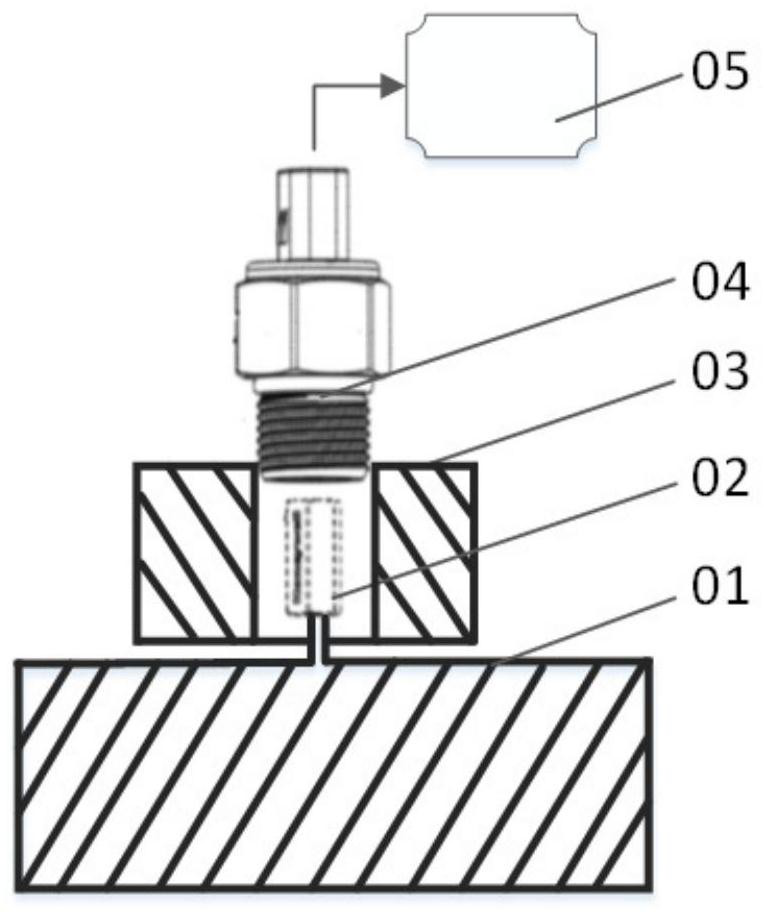

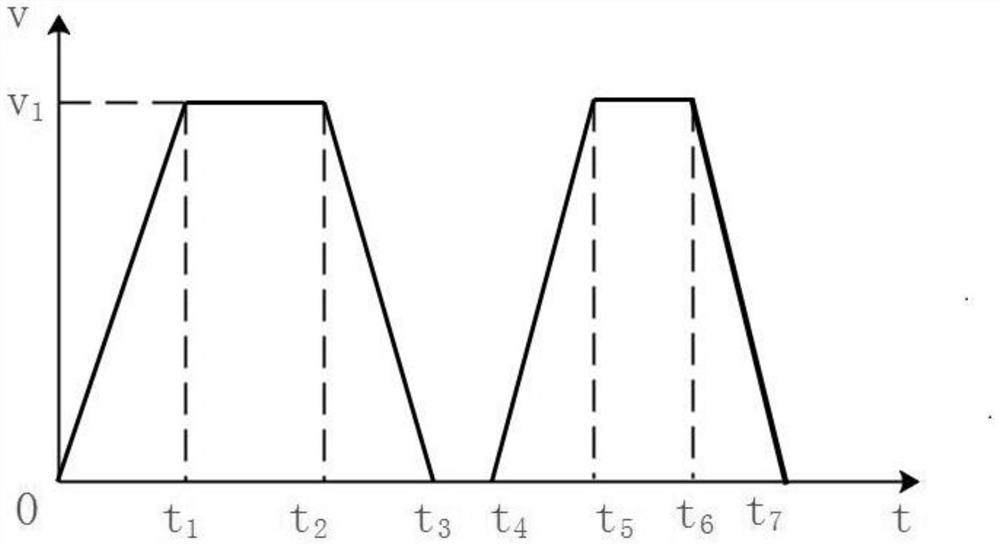

PendingCN108500172AGuaranteed to stopFree expansion actionHeat exchange apparatusStart timeEngineering

The invention provides an expansion joint system and an expansion joint method. The expansion joint system comprises a connecting base and a telescopic drive mechanism. The telescopic drive mechanismis arranged on the connecting base. According to the expansion joint system and the expansion joint method, it can be ensured that an expansion joint mandrel and a pipe expansion head can freely perform expansion joint action and it also can ensured that the expansion joint mandrel stops at any position before entering a pipe to be expanded by using the interaction of the expansion drive mechanismand an elastic mechanism, the expansion joint thrust can be controlled by using the elastic mechanism, and the thrust of an industrial robot is effectively offset, so that the expansion joint systemcan achieve the purpose of simulating manual expansion joint, it can be ensured that a pipe expansion device can act to a certain extent, and it is ensured that the pipe expansion device smoothly enters the pipe to be expanded when the axis of the pipe to be expanded has a deviation from the axis of the pipe expansion head. The linear motion of the pipe expansion device can be ensured by a pipe expansion device extension and contraction device, the expansion joint start time of the pipe expansion device can be controlled by arranging a position sensor, and the controllable purpose of expansionjoint is realized.

Owner:GREE ELECTRIC APPLIANCES INC

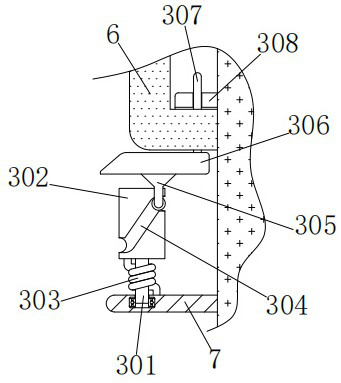

Fetal reduction device

ActiveCN108814692AIncrease destructive powerGuaranteed to stopObstetrical instrumentsPropellerCervix

The invention discloses a fetal reduction device. The device comprises a handle and a strangling assembly disposed at one end of the handle. The strangling assembly is retractably disposed in a firstcontaining cavity in the handle and comprises a first strangling blade and a second strangling blade, and the first strangling blade and the second strangling blade can be retracted and expanded. Thestrangling assembly is retracted in the first containing cavity of the handle before the fetal reducing device is positioned to prevent the strangling assembly from damaging the cervix when the fetalreducing device passes through the cervix, and the first strangling blade and the second strangling blade are expanded when the strangling blades puncture a fetal heart, so that the destructive capability of the strangling assembly is enhanced to ensure that the fetal heart of a fetus subjected to fetal reduction is stopped; moreover, a syringe is arranged in the handle, an injection needle is poked into the fetal heart, and a propeller is pushed for injecting potassium chloride to make the fetal heart stop immediately, so that the two operating means are conveniently switched.

Owner:THE SECOND HOSPITAL AFFILIATED TO WENZHOU MEDICAL COLLEGE

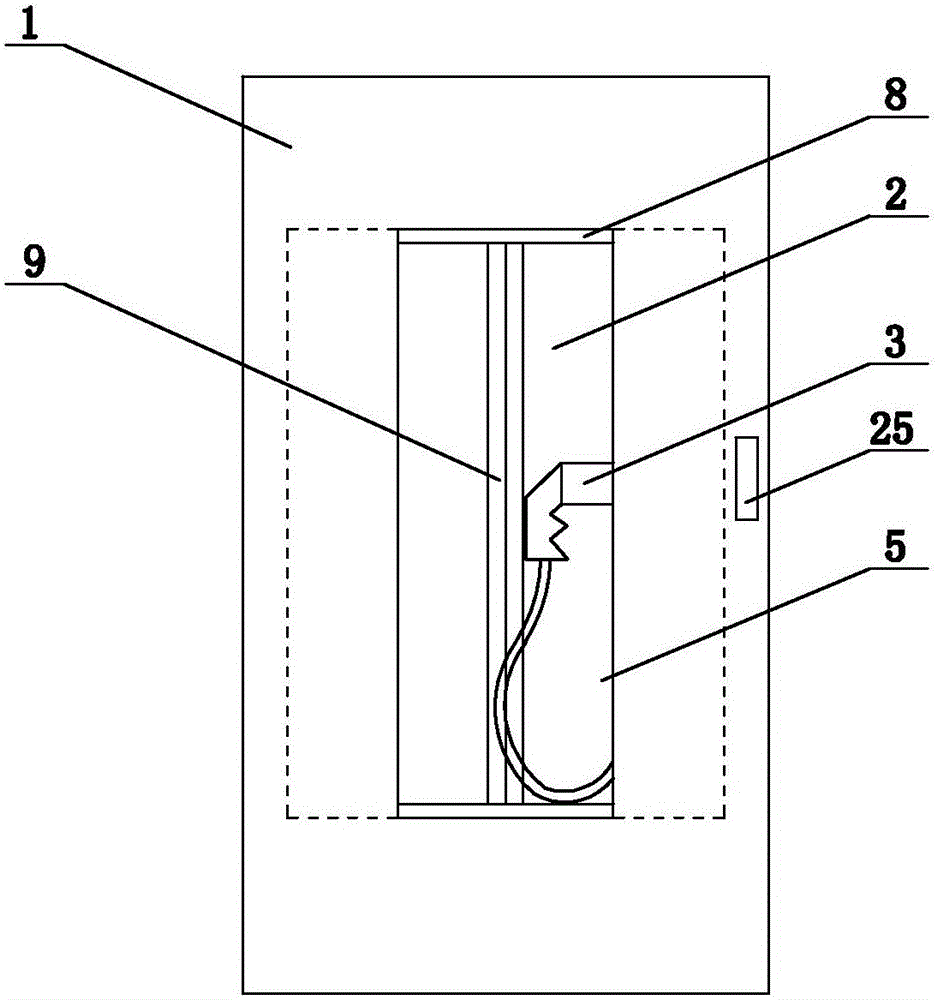

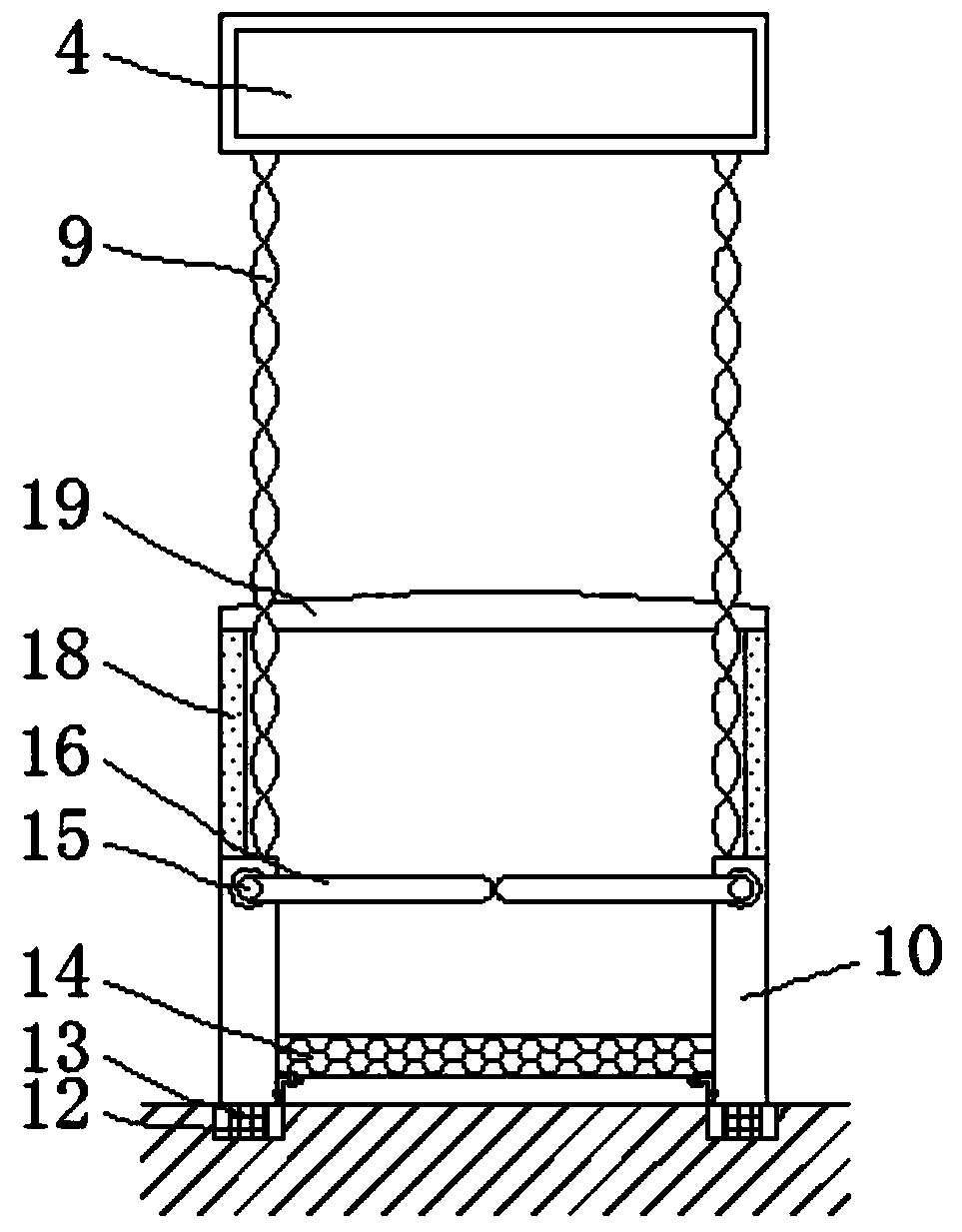

Automatic crawling ladder device used for coming in/out of elevator pit

The invention provides an automatic crawling ladder device used for coming in / out of an elevator pit. The automatic crawling ladder device has an opened state and a closed state relative to an elevator wall. The automatic crawling ladder device comprises a crawling ladder body, a connecting mechanism and a locking device, and further comprises a pull rod, a spring A and a spring B, wherein the connecting mechanism is used for connecting the crawling ladder body with a well enclosure in a rotating mode, the locking device is used for locking the crawling ladder body in the closed state, the pull rod is connected with the crawling ladder body in a sliding mode, the spring A and the spring B are in a stretched state, the other end of the pull rod is connected to the wall enclosure in a rotating mode, the two ends of the spring A are fixed on the crawling ladder body and the wall enclosure respectively, and the two ends of the spring B are fixed on the pull rod and the wall enclosure respectively. Detector switches are installed at the two ends of the crawling ladder body and connected with a control mechanism of an elevator. The two detector switches are used for determining whether the crawling ladder body is completely opened or closed so as to guarantee the safe operation and stopping of the elevator. The automatic crawling ladder device is arranged below a base station hoistway door sill and can be folded and closely attached to the wall enclosure when the crawling ladder body is in a non-work state, and therefore spaces is saved; when the crawling ladder body is in the opened state, the automatic crawling ladder device can be stably fixed in a well.

Owner:GIANT KONE ELEVATOR CO LTD

Automatic lifting type zebra line crossing prevention device for intersection traffic

The invention provides an automatic lifting type zebra line crossing prevention device for intersection traffic and relates to the technical field of zebra line crossing prevention devices for intersection traffic. The zebra line crossing prevention device for intersection traffic comprises a machine body and a top frame, wherein the upper ends of two sides of the machine body are provided with supporting rods, the sides, away from the central line of the machine body, of the supporting rods are provided with a counting-down display screen, the top frame is installed at the upper ends of the supporting rods, and a fixed disc is fixed in the top frame. The automatic lifting type zebra line crossing prevention device has the advantages that extending and contraction of a steel chain can be controlled through rotation of a take-up reel on the fixed disc along a rotary shaft, a baffle can be driven to descend or ascend, and vehicles can be prompted to stop when the baffle descends to the ground, so that the vehicles are can be prevented from running and crossing zebra lines to threaten the safety of pedestrians, the baffle can stop the vehicles even if the speed of each vehicle is excessively high and the vehicle cannot stop, the vehicles can be prevented from colliding the pedestrians on the zebra lines, and accordingly the safety of the pedestrians normally crossing the zebra lines is ensured.

Owner:FOSHAN UNIVERSITY

Travel control device for door body of retractable garage

InactiveCN103015836AGuaranteed to stopGates/doorsPower-operated mechanismMotor driveElectric machinery

The invention discloses a travel control device for a door body of a retractable garage. The travel control device comprises a power supply, a motor and a traction device. The power supply supplies power to the motor through two leads. The motor drives the traction device so as to draw the door body to move. A first moveable breaking microswitch and a second moveable breaking microswitch are respectively connected onto the two leads in series. The traction device comprises a first driving wheel which is driven by the motor. The first driving wheel is coaxially provided with a triggering device capable of being respectively contacted with a contact of the first moveable breaking microswitch and a contact of the second moveable breaking microswitch. With the adoption of the technical scheme, two microswtiches are arranged on the circuit of the motor, and the triggering devices which respectively trigger the two microswtiches are associatively arranged on the traction device of the door body, so that the door is disconnected in the travel limiting position to supply power to the motor, and the door is stopped in the travel limiting position.

Owner:王中好

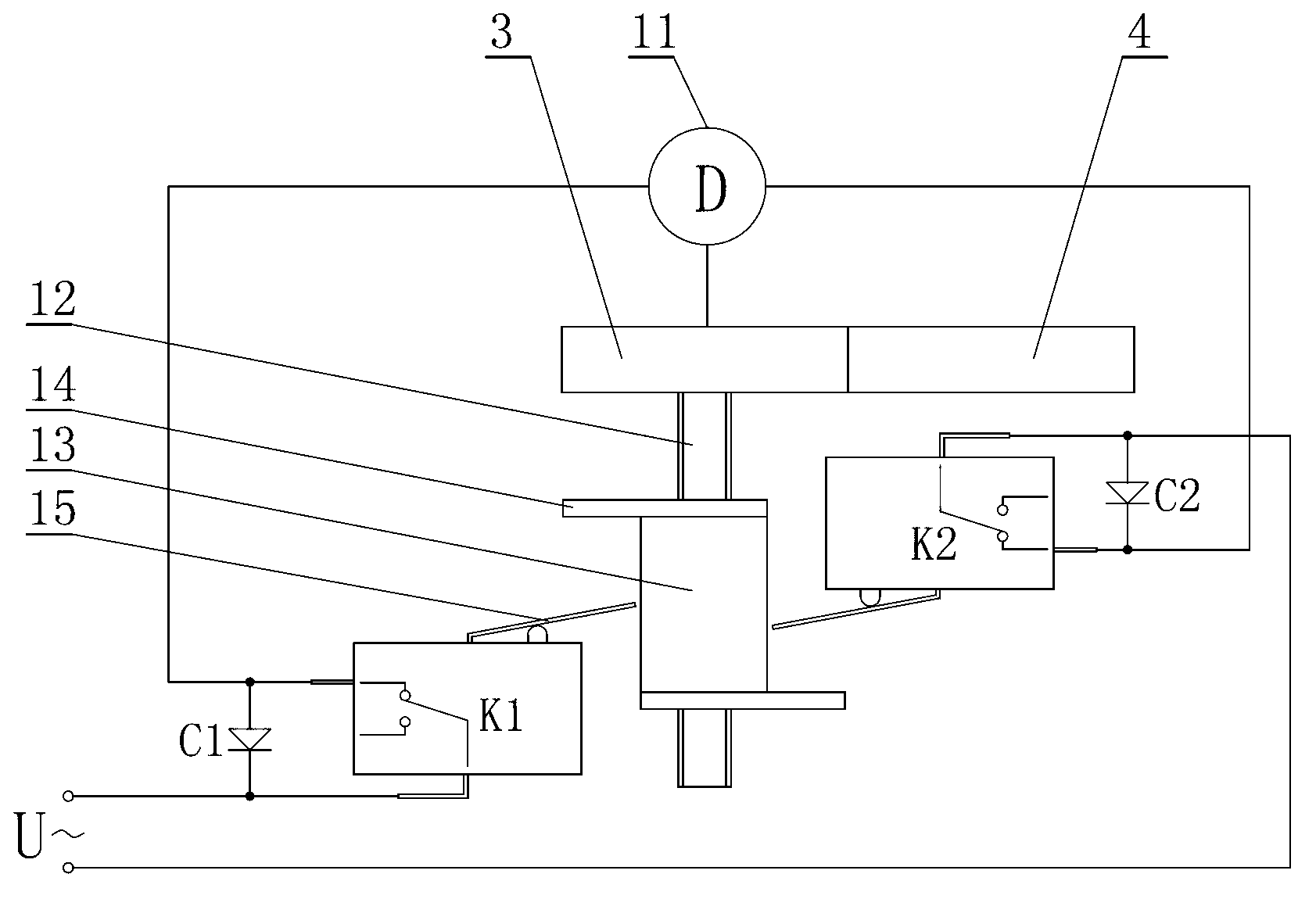

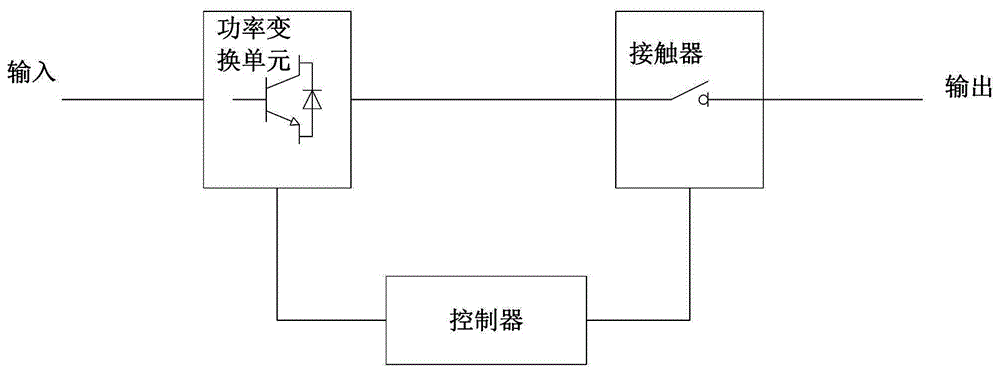

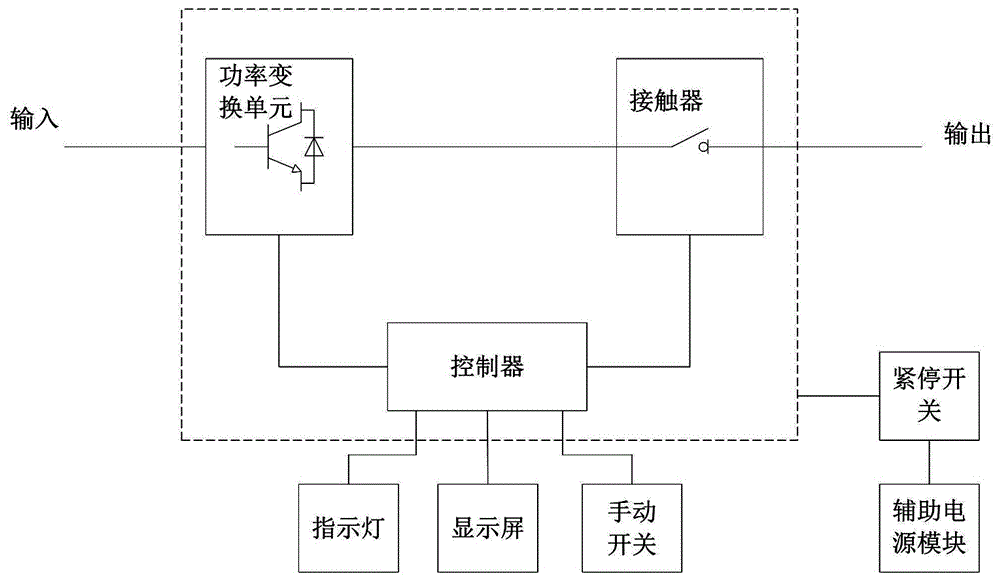

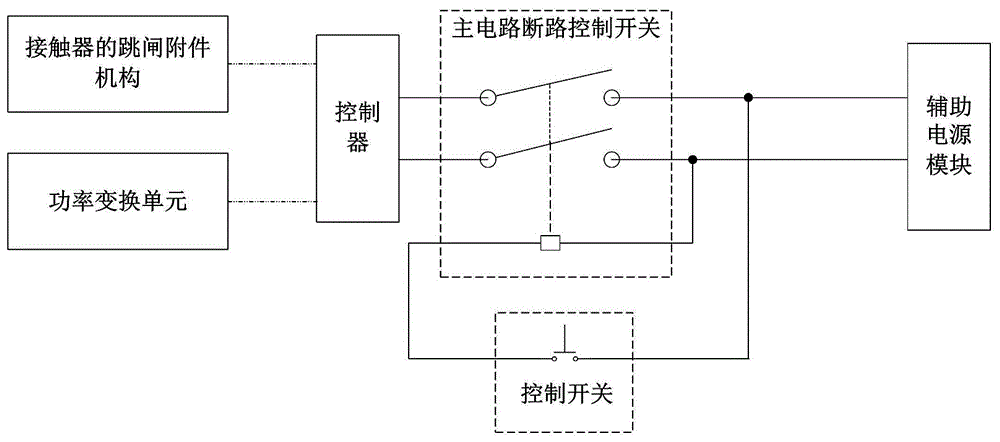

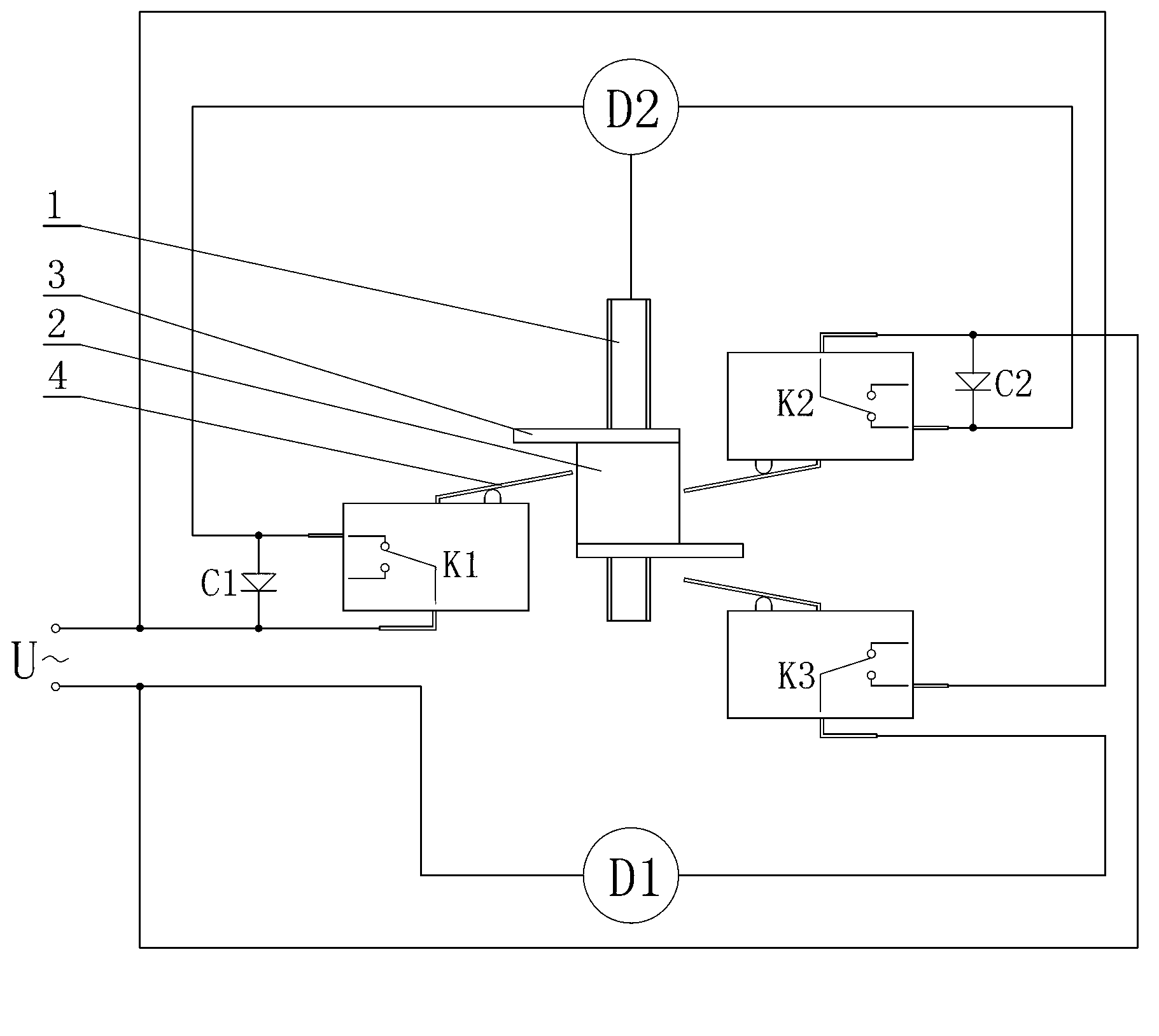

Device and method for controlling on/off of current transformer

ActiveCN106571738AEnsure safetyMake sure to stopPower conversion systemsContactorCurrent transformer

The invention discloses a device and method for controlling the on / off of a current transformer, and the device comprises a power conversion unit, a contactor, a controller, and an auxiliary power module. The electric energy is outputted through a contactor after being converted by the power conversion unit. The controller is connected with the power conversion unit, and is used for controlling the on / off of the power conversion unit. The controller is connected with the contactor, and is used for controlling the on / off of the contactor. The auxiliary power module is connected with the controller and a trip accessory mechanism of the contactor. The controller also comprises a manual switch, a display screen, and an indicating lamp. The manual switch is used for providing a pre-start signal for the controller. The display screen comprises a virtual key control, and is used for providing a start signal for the controller. The indicating lamp is used for displaying the working state of the current transformer. The device is convenient for control, can effectively guarantee the safe start and stop of the current transformer, and meets the frequency switching-on / switching-off operation demands.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

Novel multifunctional new energy automobile charging pile

InactiveCN112339599APrevent slippingEasy to useCharging stationsElectric vehicle charging technologyNew energyGear wheel

The invention discloses a novel multifunctional new energy automobile charging pile which comprises a charging column, grooved pulleys are fixedly connected to the upper portions of the left side andthe right side of the charging column correspondingly, take-up mechanisms are installed on the outer sides of the two grooved pulleys correspondingly, and each take-up mechanism comprises a bent plate, a compression spring, a ball and a rubber pad, wherein the bottom of the bent plate is attached to the bottom of a left notch of the grooved pulley, and the bottom of the inner side of the bent plate is fixedly connected with the bottom of a compression spring. An output line is prevented from slipping off, winding is avoided, normal use of the output line is guaranteed, falling force is buffered, connection abrasion is avoided, the output line is prevented from being broken, maintenance cost is saved, the practicability is improved, an adjusting mechanism gear is matched with a protruding block to drive a groove plate to rotate, position adjustment is achieved, changing can be carried out according to terrains, and the working difficulty is reduced; the working efficiency is improved; through the adjusting mechanism, the groove plate can be finely adjusted in the using process, so that the arc plate is matched with the rear wheel, it is guaranteed that the vehicle body is stably parked, and using and popularization are convenient.

Owner:高洁

Rolling door motor control device for telescopic garage

The invention discloses a rolling door motor control device for a telescopic garage, which comprises a power supply, a rolling door motor and a reel. The power supply supplies power to the rolling door motor by two wires; the rolling door motor drives the reel to rotate; the two wires are respectively connected in series with a first dynamic switching-off microswitch and a second dynamic switching-off microswitch; and the end part of the reel is provided with a trigger device which can respectively in contact with a contact of the first dynamic switching-off microswitch and a contact of the second dynamic switching-off microswitch. Due to the adoption of the technical scheme, two microswitches are arranged on a motor circuit and the trigger device capable of respectively triggering the two microswitches is connected in parallel on a door body traction apparatus, so that the power supply which supplies power to the motor is switched off when a vehicle door is at a limit position of a stroke and the stop of the vehicle door at the limit position of the stroke can be effectively ensured.

Owner:王中好

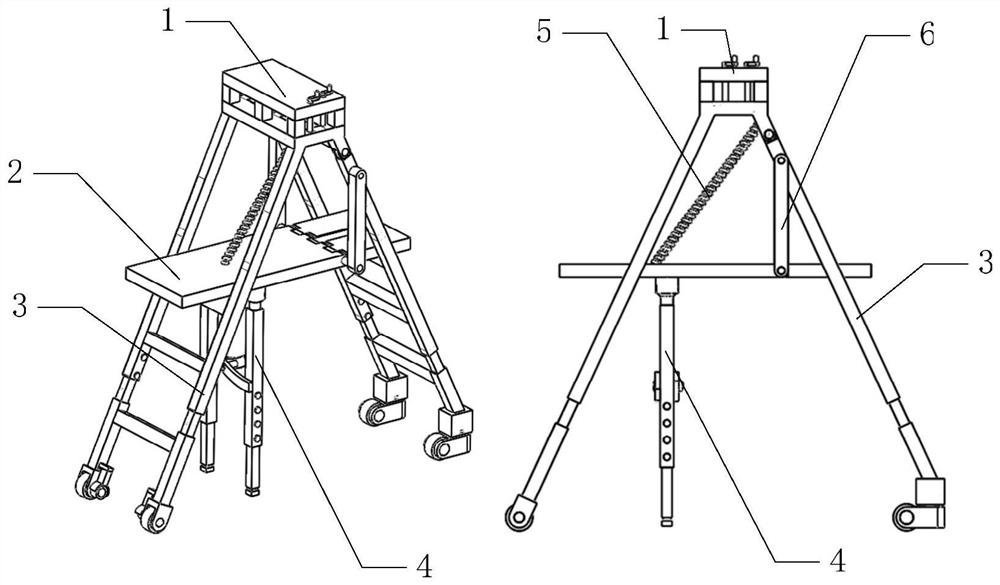

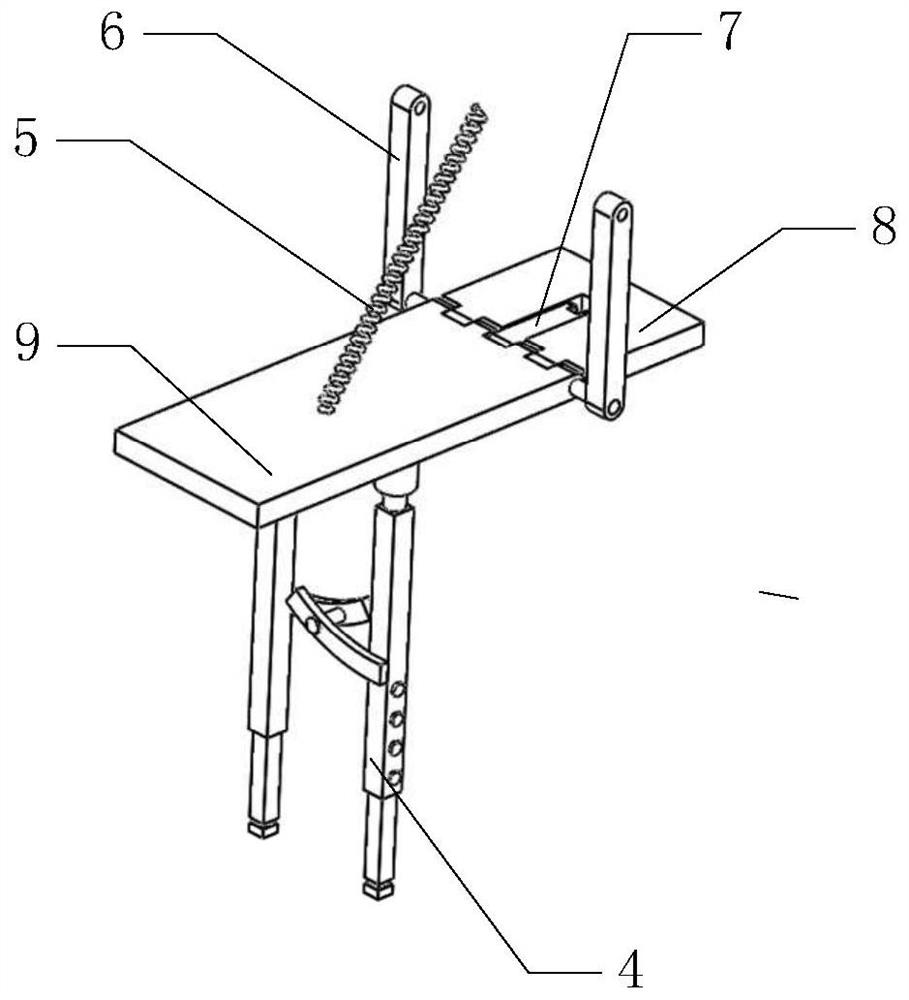

Herringbone ladder for building interior decoration and using method

ActiveCN112796503ARealize the brake functionGuaranteed to stopScaffold accessoriesBrakeStructural engineering

Owner:佛山市缘浩铝梯有限公司

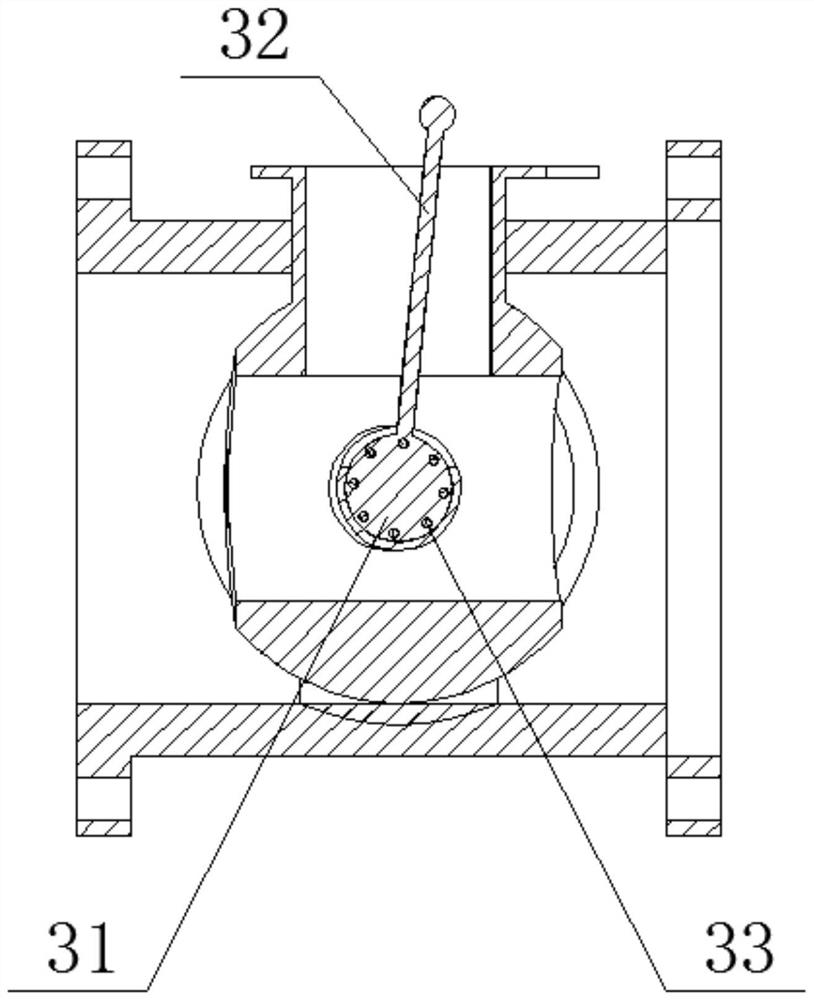

Novel ball valve structure

InactiveCN111692365ASimple structureStable through-flow usePlug valvesOperating means/releasing devices for valvesEngineeringPhysics

The invention discloses a novel ball valve structure. The novel ball valve structure comprises an outer pipe, a switch valve and an adjusting mechanism, wherein the outer pipe comprises a pipe body and inner arc plates, wherein the inner arc plates are symmetrically arranged on the inner side face of the pipe body, the inner arc plates and the pipe body are integrally formed, the switch valve comprises a flow guide ball and an operating mechanism, the flow guide ball is installed in the inner arc plates, the flow guide ball is rotationally connected with the inner arc plates, the operating mechanism is fixedly installed at the upper end of the flow guide ball, a user can stably drive a stand column to rotate through an operating panel conveniently in an actual using process, then the purpose of rotating the flow guide ball is achieved, when a through-flow hole rotates to be consistent with the direction of the pipe body, it is guaranteed that the ball valve can stably conduct through flow in use, when the through-flow hole rotates to be mutually perpendicular to the direction of the pipe body, the through-flow hole can match with the inner arc plates in a sealed mode, and thereforeit can be guaranteed that liquid inside the pipe body is stopped.

Owner:CHANGZHOU INST OF TECH

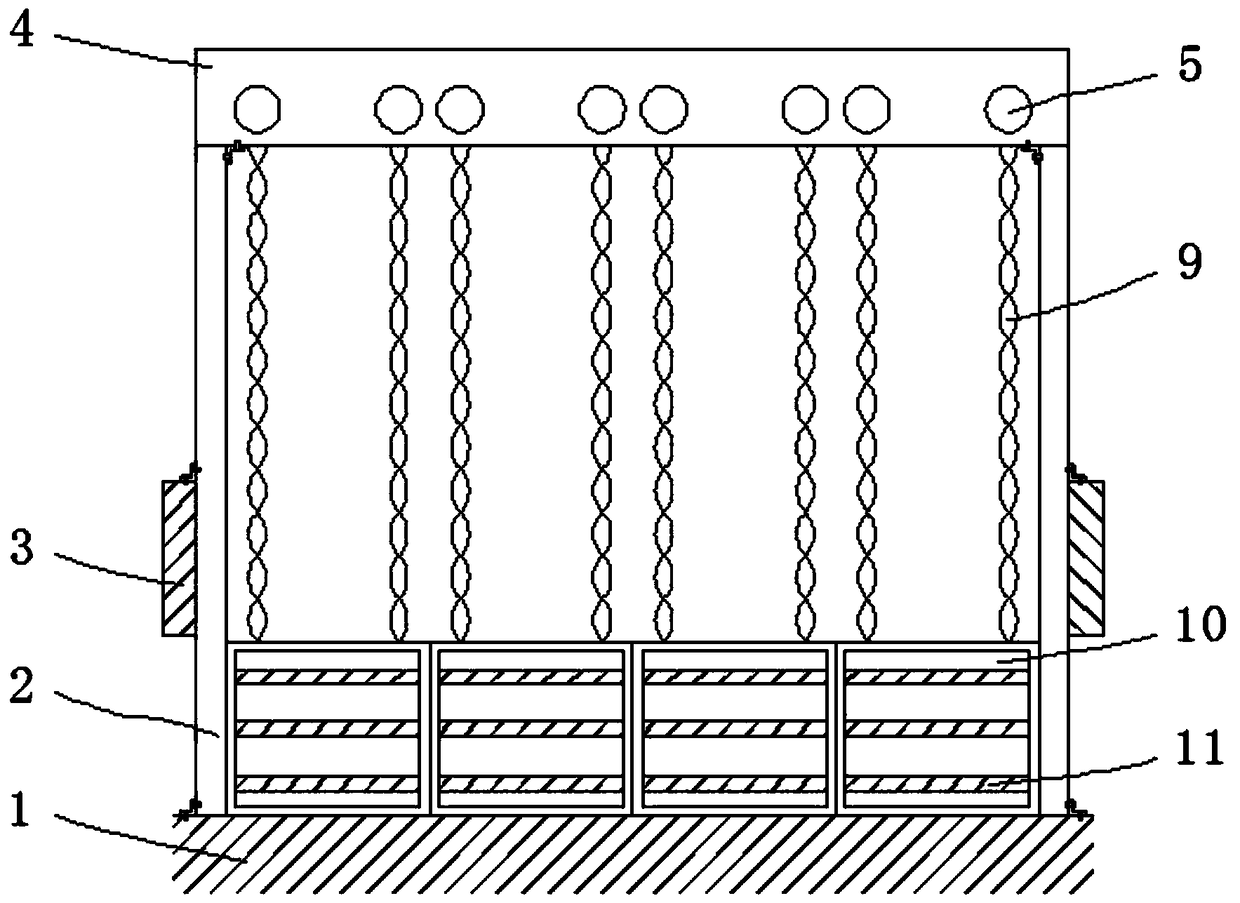

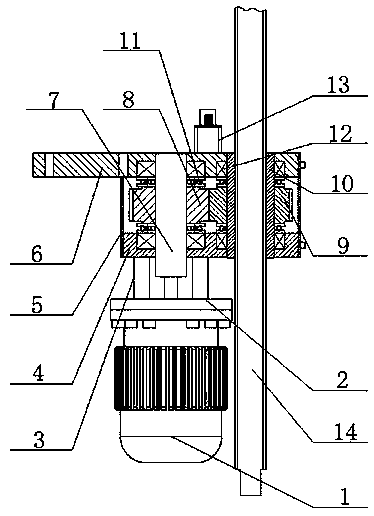

Cable-stayed electric pump mounting device

ActiveCN113323919AReduce fit resistanceEasy to movePump componentsPump installationsStructural engineeringElectrical and Electronics engineering

The invention discloses a cable-stayed electric pump mounting device. The cable-stayed electric pump mounting device comprises an electric pump body, a shell is arranged outside the electric pump body, two symmetrically-distributed first moving assemblies are arranged in the positions, close to the bottom, of one end of the outer surface of the shell, the two first moving assemblies are located at the front end and the rear end of the shell correspondingly, two symmetrically-distributed second moving assemblies are arranged in the positions, close to the bottom, of the other end of the outer surface of the shell, and the two second moving assemblies are located at the front end and the rear end of the shell correspondingly; each first moving assembly comprises a first fixing block, the first fixing block is fixed to one end of the outer surface of the shell, a first retainer is fixed to the bottom of the first fixing block, and a plurality of evenly-distributed first roller paths are formed in the lower surface of the first retainer. The first moving assemblies and the second moving assemblies are arranged, so that the whole device can easily move on a sliding rail, the device is simple in structure and rapid to mount, space is saved, the matching resistance between a first ball and the sliding rail and the matching resistance between a second ball and the sliding rail are small, and the bearing capacity is large.

Owner:HEFEI HENGDAJIANGHAI PUMP IND CO LTD

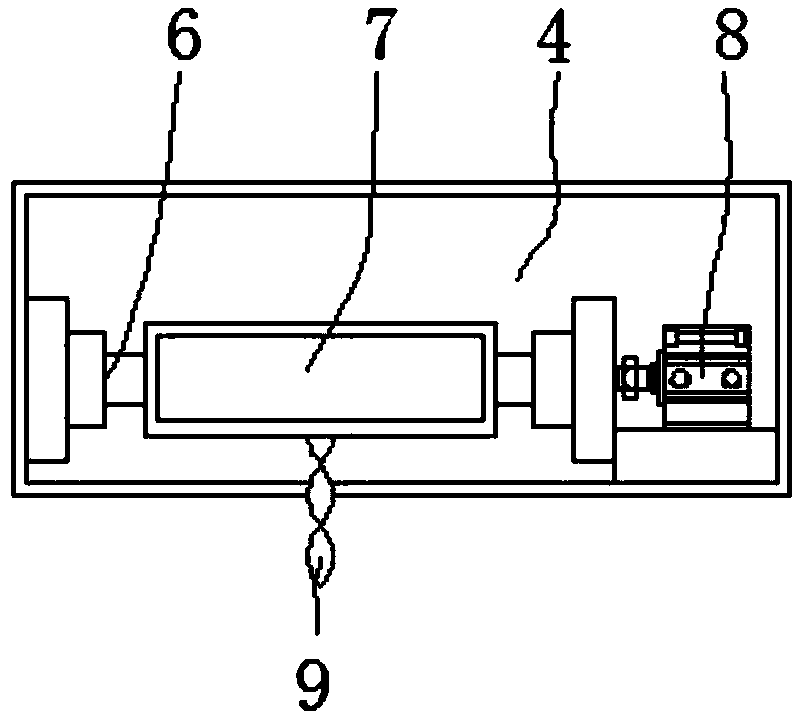

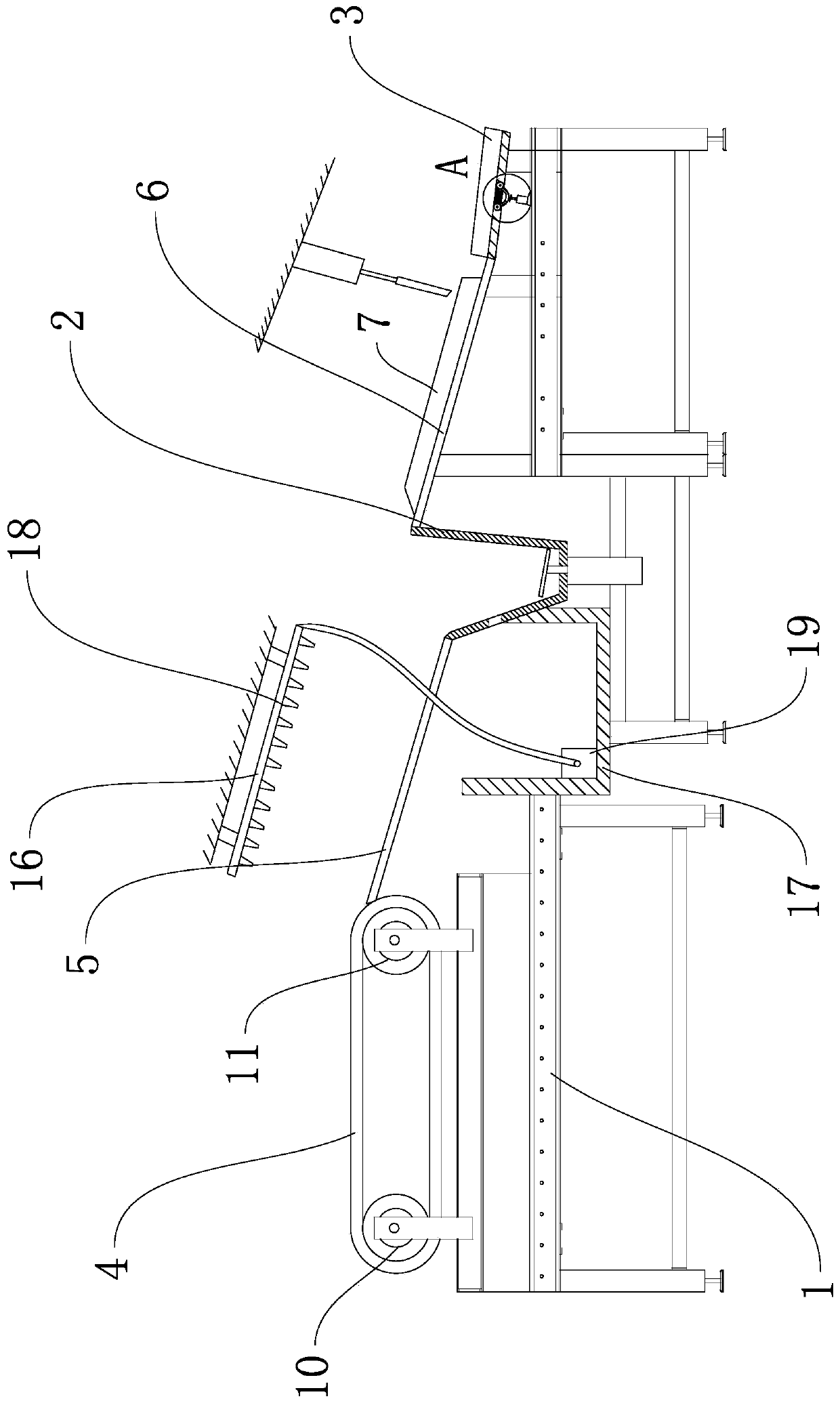

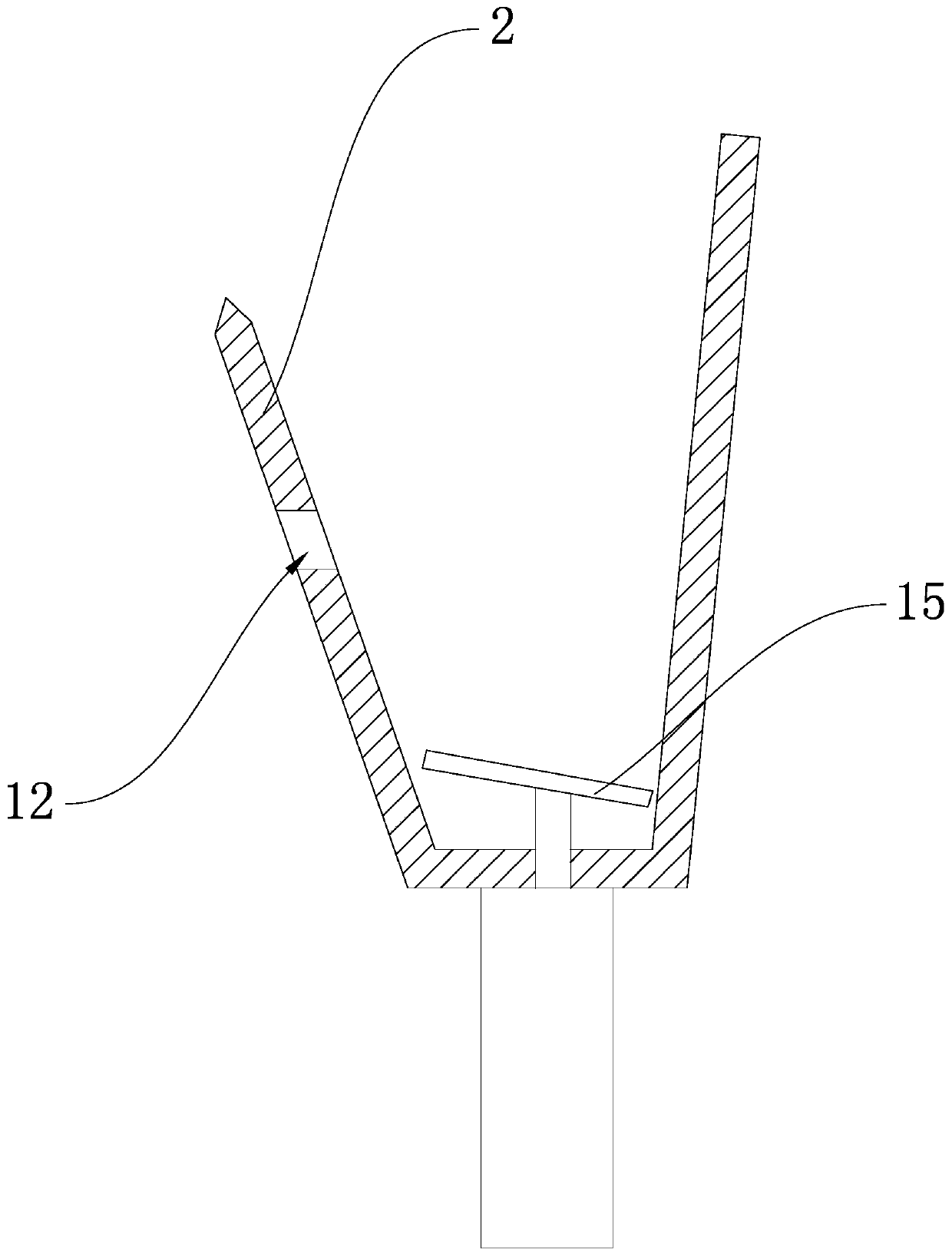

Thread lifting drive device for intelligent underground parking lot

The invention discloses a thread lifting drive device for an intelligent underground parking lot. The thread lifting drive device comprises an electric motor; the electric motor is connected to bracket plates via a flange; the bracket plates are connected with a gear positioning mounting plate, and the outer side of the gear positioning mounting plate is a gear box sealing plate; a gear positioning connecting plate is arranged on the top of the gear box sealing plate; the gear positioning mounting plate, the gear box sealing plate and the gear positioning connecting plate constitute a casing of the entire gearbox; a rotating shaft of the electric motor passes through the gear positioning mounting plate and extends into the casing; the rotating shaft in the casing is sleeved with a drivinggear, the driving gear is engaged with a driven gear, and a lifting nut is inserted into the driven gear.

Owner:贵州华龙智能发展有限公司

Snakegourd fruit washing device

The invention provides a snakegourd fruit washing device, belongs to the technical field of machines, and solves the technical problems that a conventional snakegourd fruit washing device is low in washing efficiency, not thorough in washing and the like. The snakegourd fruit washing device comprises a machine frame, wherein an input mechanism, a water tank and a washing tank are sequentially arranged on the machine frame; the input mechanism comprises a conveyer belt; the conveyer belt is connected with the lower side of the water tank through a guide plate I; a sprinkling mechanism for washing snakegourd fruits is arranged above the guide plate I; the washing tank is connected with a higher part of the water tank through a guide plate II; a plurality of fixing plates are fixedly arrangedon the guide plate II; a guide channel is formed between every two adjacent fixing plates; and a pushing mechanism for pushing the snakegourd fruits in the water tank to the guide plate II is arranged at the bottom of the water tank. The snakegourd fruit washing device disclosed by the invention has the advantages of being high in washing efficiency and thorough in washing.

Owner:安徽省怡果生态科技有限公司

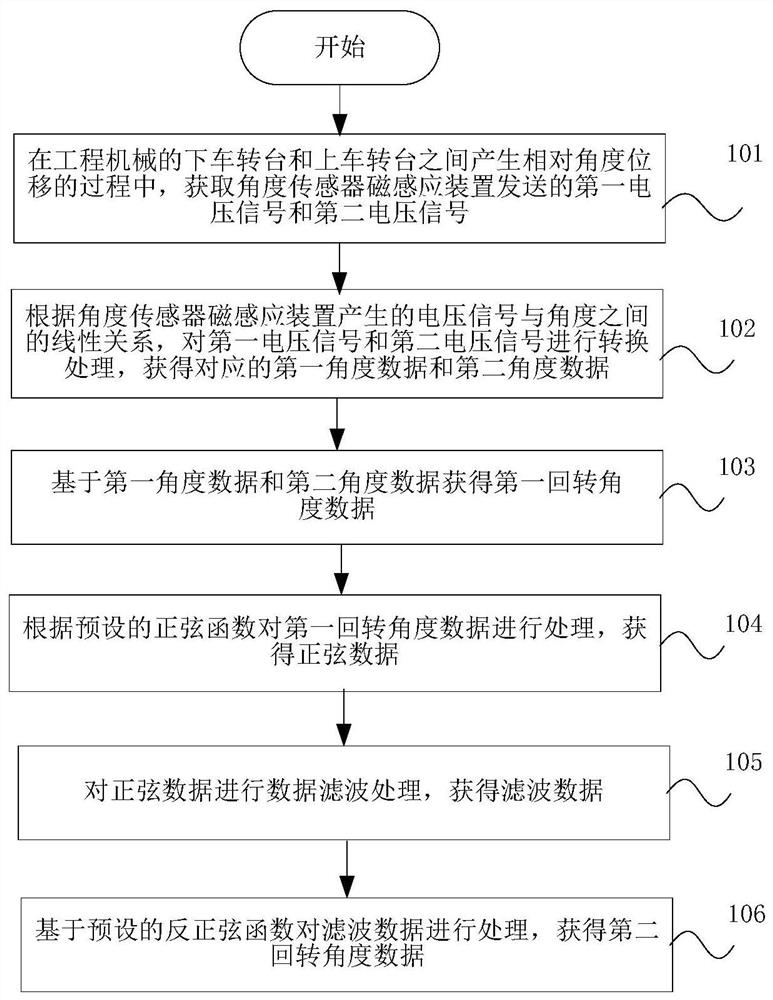

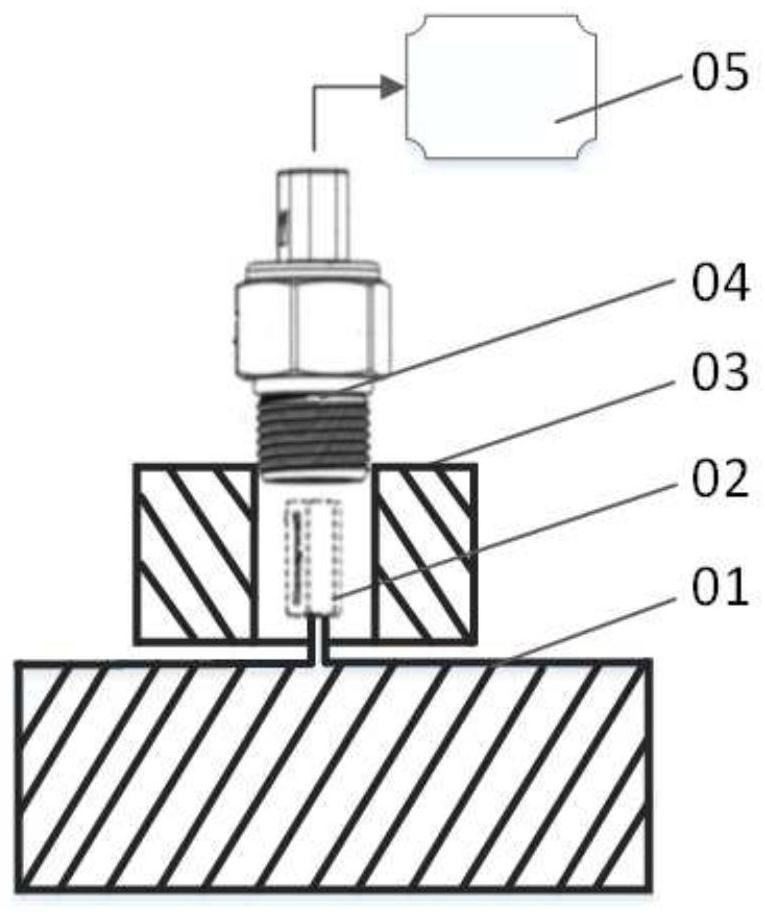

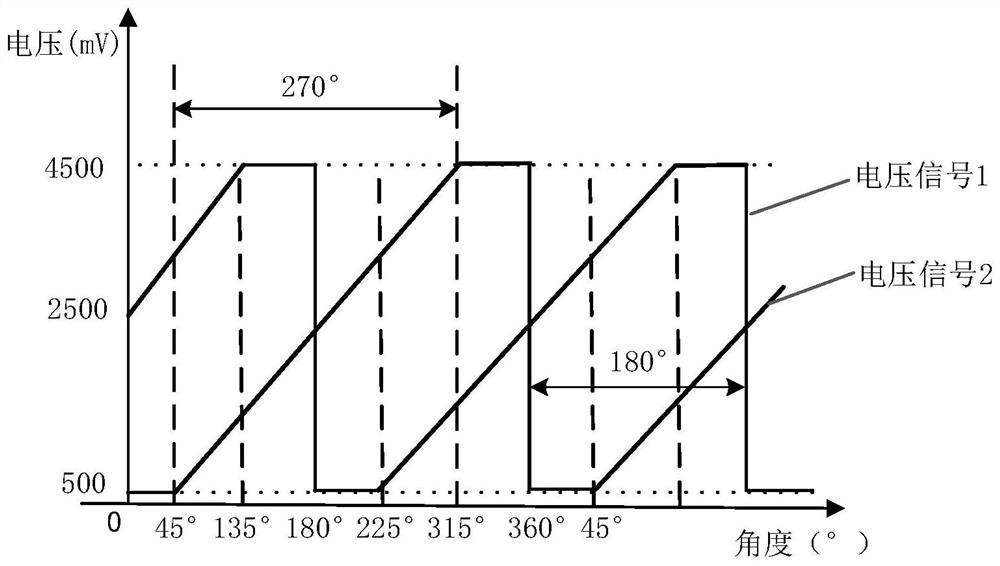

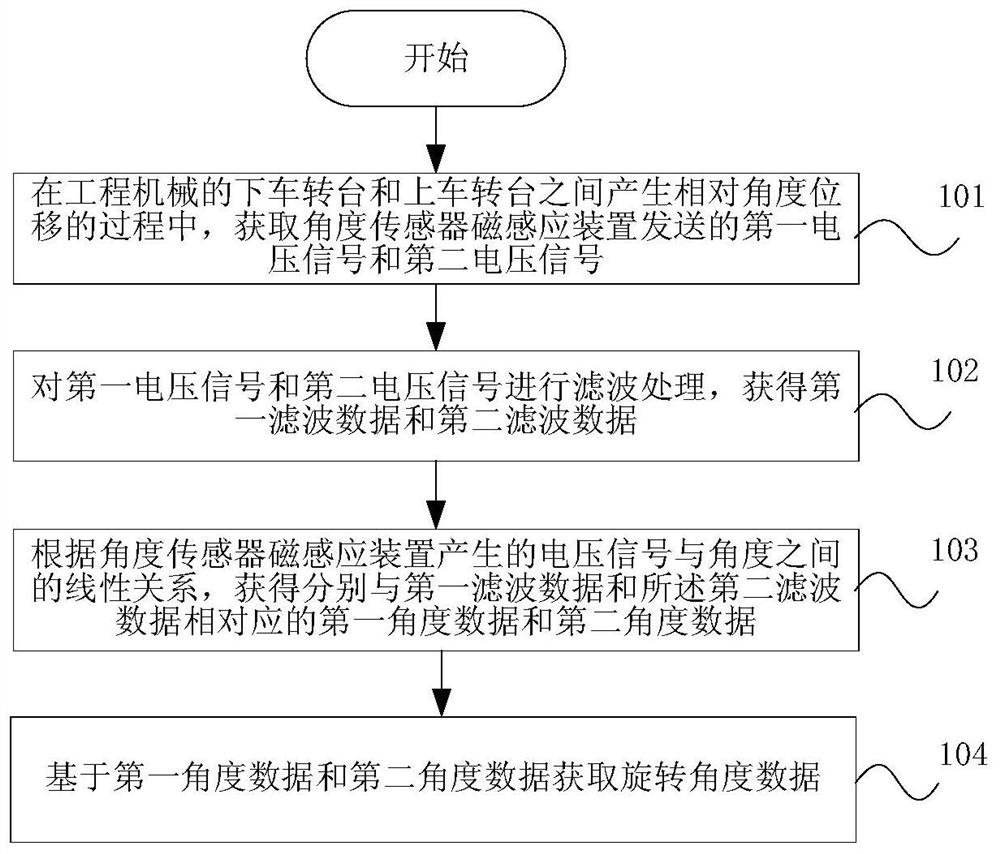

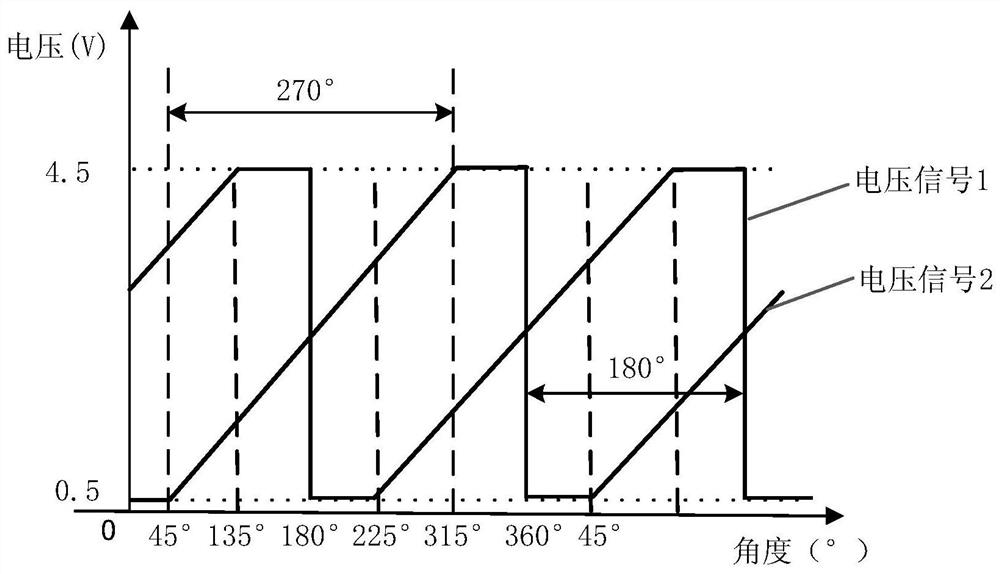

Vehicle body rotation angle data processing method and device, controller and medium

PendingCN112560762ASensitive measurementShorten the production cycleCharacter and pattern recognitionSoil-shifting machines/dredgersSignal responseSimulation

The invention provides a vehicle body rotation angle data processing method and device, a controller and a storage medium, and relates to the technical field of engineering machine. The method comprises the steps: obtaining a first voltage signal and a second voltage signal sent by an angle sensor magnetic induction device, obtaining corresponding first angle data and second angle data according to the linear relation between the voltage signal generated by the magnetic induction device of the angle sensor and the angle; obtaining first rotation angle data and sinusoidal data, and performing data filtering processing on the sinusoidal data to obtain filtered data; and processing the filtering data based on a preset arcsine function to obtain second rotation angle data. According to the method and device, the controller and the storage medium, the rotation angle data of the vehicle body can be rapidly and sensitively measured; the magnetic induction angle sensor is adopted to measure the rotation angle of the vehicle body, installation is convenient, implementation cost investment is small, signal response is sensitive, and mechanical control precision and control comfort can be improved.

Owner:XCMG EXCAVATOR MACHINERY

A cable-stayed electric pump installation device

ActiveCN113323919BReduce fit resistanceEasy to movePump componentsPump installationsEngineeringStructural engineering

Owner:HEFEI HENGDAJIANGHAI PUMP IND CO LTD

Rotation angle data processing method and device for engineering machinery and medium

ActiveCN112556570AImprove the level of intelligent controlSensitive measurementUsing electrical meansSignal responseControl engineering

The invention provides a rotation angle data processing method and device for engineering machinery, a controller and a storage medium, and relates to the technical field of engineering machine. The method comprises the steps: acquiring a first voltage signal and a second voltage signal sent by an angle sensor magnetic induction device; filtering the first voltage signal and the second voltage signal to obtain first filtering data and second filtering data; obtaining first angle data and second angle data corresponding to the first filtering data and the second filtering data respectively, andobtaining rotation angle data based on the first angle data and the second angle data. According to the method, the device, the controller and the medium, the rotation angle data of the vehicle bodycan be rapidly and sensitively measured; the magnetic induction angle sensor is adopted to measure the rotation angle of the vehicle body, installation is convenient, implementation cost investment issmall, signal response is sensitive, and mechanical control precision and control comfort can be improved.

Owner:XCMG EXCAVATOR MACHINERY

Processing technology of snakegourd fruit brewing powder capable of reducing internal heat

InactiveCN109730268AHas heat-clearing and detoxifying effectsGood product benefitFood treatmentToxic materialDrying time

The invention provides a processing technology of snakegourd fruit brewing powder capable of reducing internal heat and belongs to the technical field of snakegourd fruit processing. The processing technology of the snakegourd fruit brewing powder capable of reducing the internal heat is characterized by comprising the following steps of S1, preparation of raw materials; S2, cleaning, wherein peels of snakegourd fruits, dried raspberries, cloves, cassia twigs, lotus seed cores and sugarcane leaves are put into a cleaning machine for cleaning and then dried, the drying temperature is controlledat 60-80 DEG C, and the drying time is 3-4 hours; S3, raw material treatment; S4, smashing; S5, checking; S6, packaging. The processing technology has the advantages of considerable product benefitsand great efficacy of clearing away the internal heat and toxic materials.

Owner:安徽省怡果生态科技有限公司

Cab side window for rail transit locomotive

ActiveCN104963591BSimple structureAdjust the forceWing arrangementsWing suspension devicesAlloyEngineering

The invention provides a cab side window for a rail transit locomotive. The cab side window comprises a bottom cross beam, a side window fixing frame, a glass supporting beam, a glass fixing frame, side window glass, a crank-connecting rod-sliding block mechanism and sliding rails. The length direction of the sliding rails is vertically arranged, the sliding rails are located in the center of the side window fixing frame in the width direction, the bottom ends of the sliding rails are fixedly connected to the bottom cross beam, and the top ends of the sliding rails are directly or indirectly connected to the side wall of a locomotive cab fixedly. A sliding block matched with the sliding rails is connected with the glass supporting beam. One end of a crank-connecting rod assembly is fixedly connected to the side window fixing frame, and the other end of the crank-connecting rod assembly and the sliding block are connected to form the crank-connecting rod-sliding block mechanism so as to support the sliding block to vertically move up and down in the sliding rails along with the side window glass. An existing crank-connecting rod mechanism which is eccentrically stressed is replaced with the crank-connecting rod-sliding block mechanism which is centrally stressed, the improved side window is balanced in stress, abrasion to an aluminum alloy window frame is reduced in the opening and closing processes of the side window, and the normal service life of the side window is prolonged.

Owner:HUNAN LIANCHENG TRACK EQUIP CO LTD

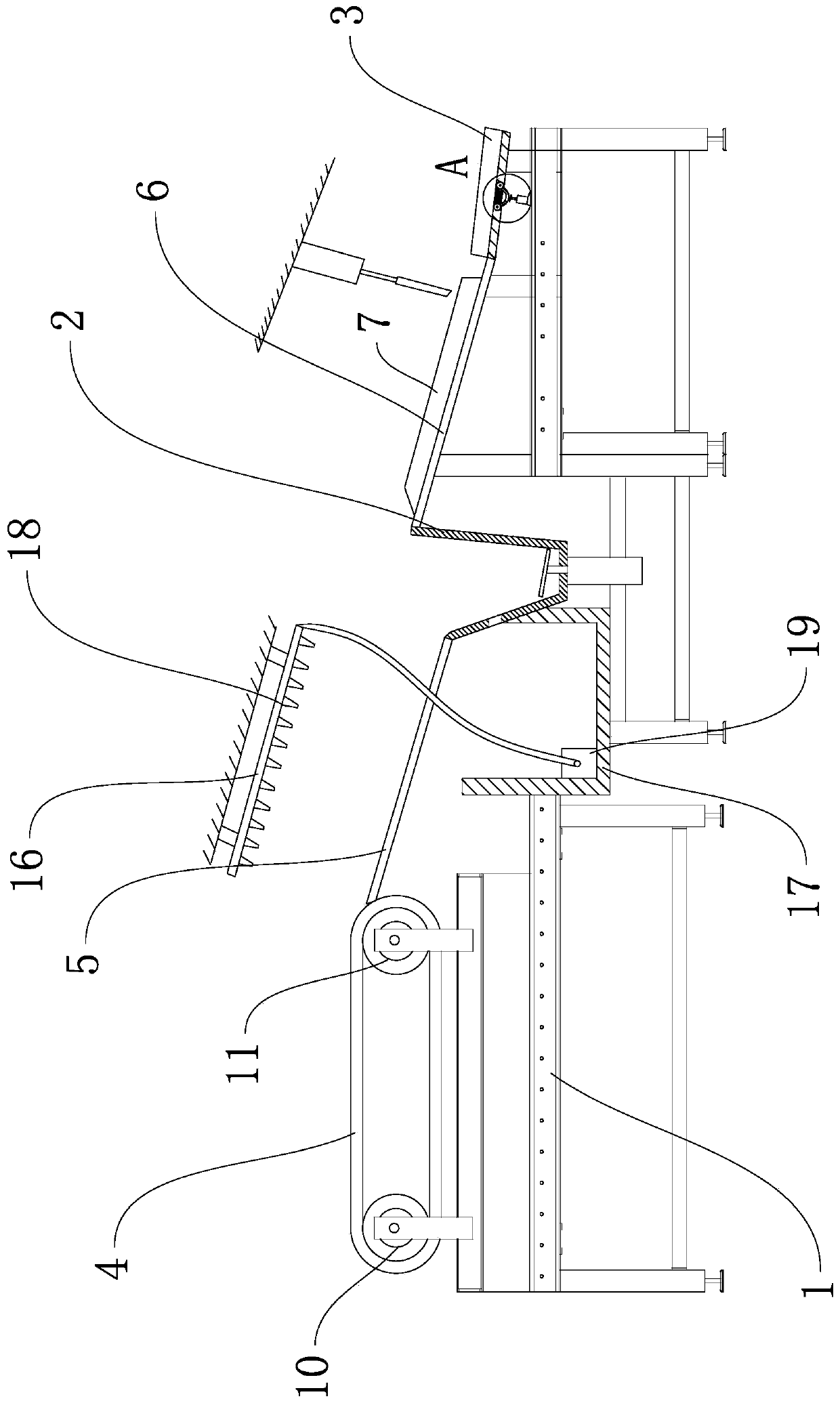

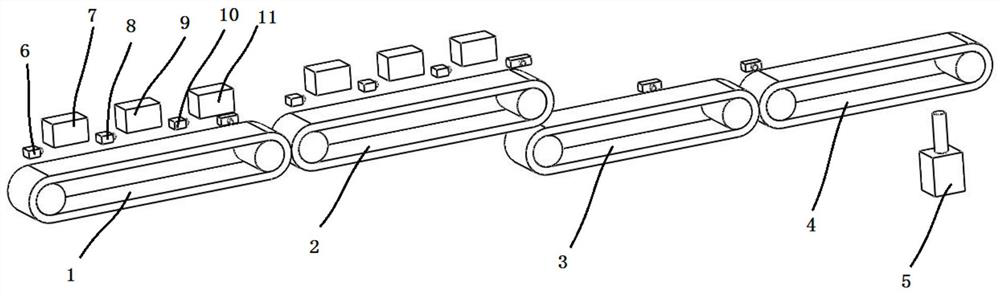

An operating method for preventing a multi-stage conveying device from running without load

ActiveCN110789959BAchieve service lifeAvoid running without loadConveyorsControl devices for conveyorsProcess engineeringMechanical engineering

The invention relates to a system and method for preventing a multi-stage conveying device from running in a no-load mode. The system comprises a conveying device and a plurality of discharging mechanisms arranged above the conveying device, wherein the conveying device comprises a plurality of stages of conveying mechanisms; the discharging mechanisms are distributed on each stage of conveying mechanism; the discharging mechanisms are sequentially marked as the first discharging mechanism, the second discharging mechanism to the M discharging mechanism in the advancing direction of the conveying device; the conveying mechanisms receive cloth bundles conveyed out by the conveying mechanism on the previous stage through the corresponding X discharging mechanism, and the value of X is 2-M. A detection mechanism is arranged at an outlet of each discharging mechanism; the detection mechanisms can detect that the cloth bundles enter the conveying mechanisms from the discharging mechanisms; the conveying detection time set after discharging of the first discharging mechanism, the second discharging mechanism to the M discharging mechanism is sequentially decreased progressively, and the conveying detection time is the time from discharging of the cloth bundles from the discharging mechanisms to conveying of the cloth bundles out of the conveying mechanisms.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

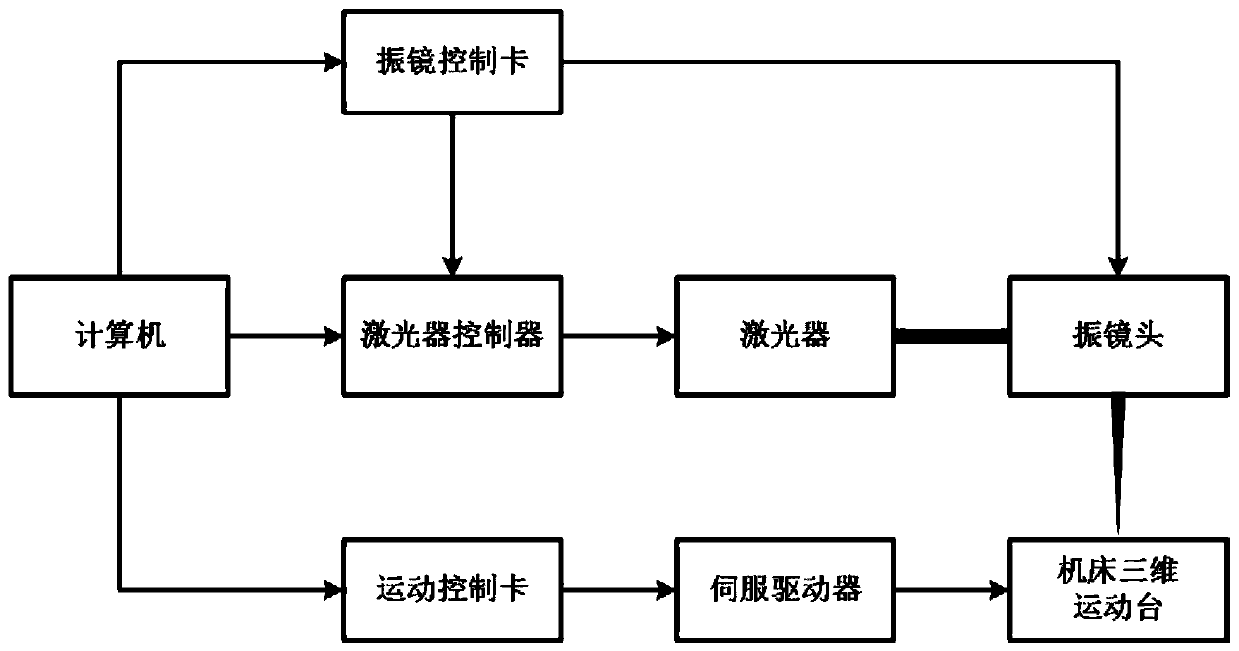

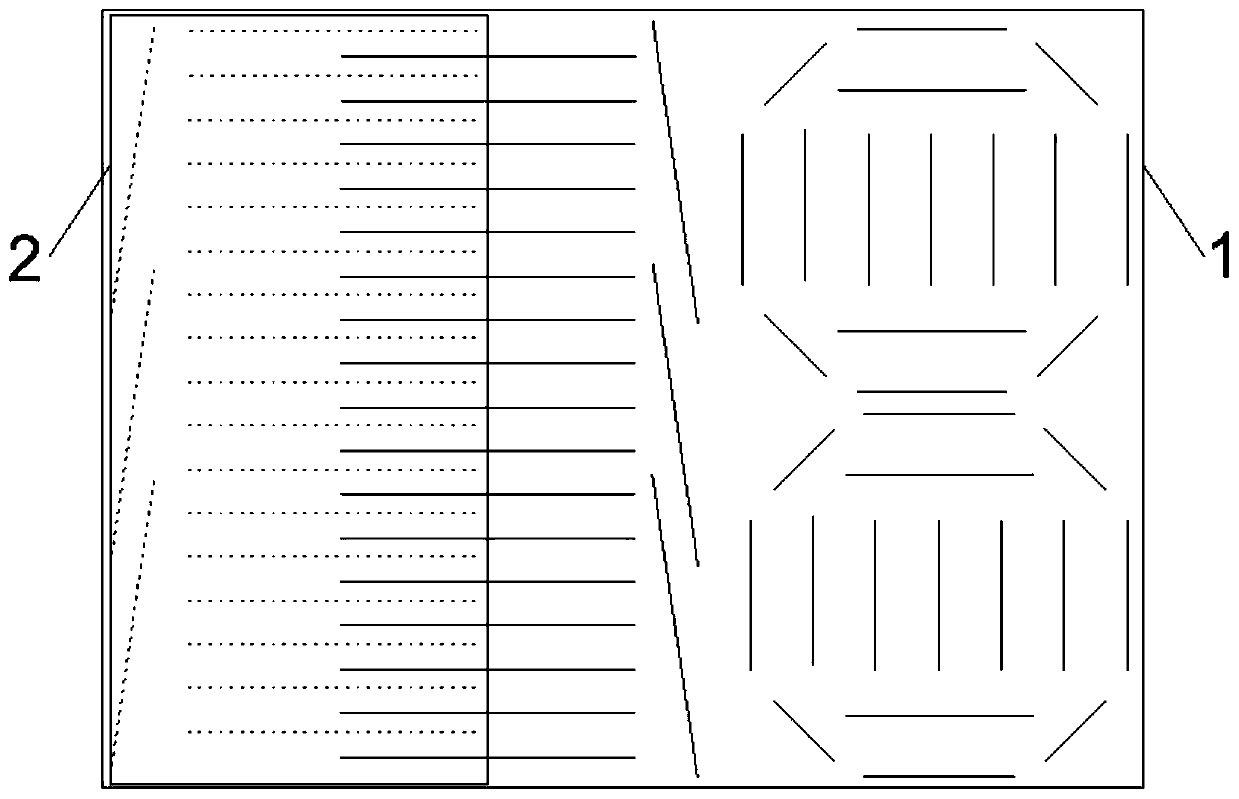

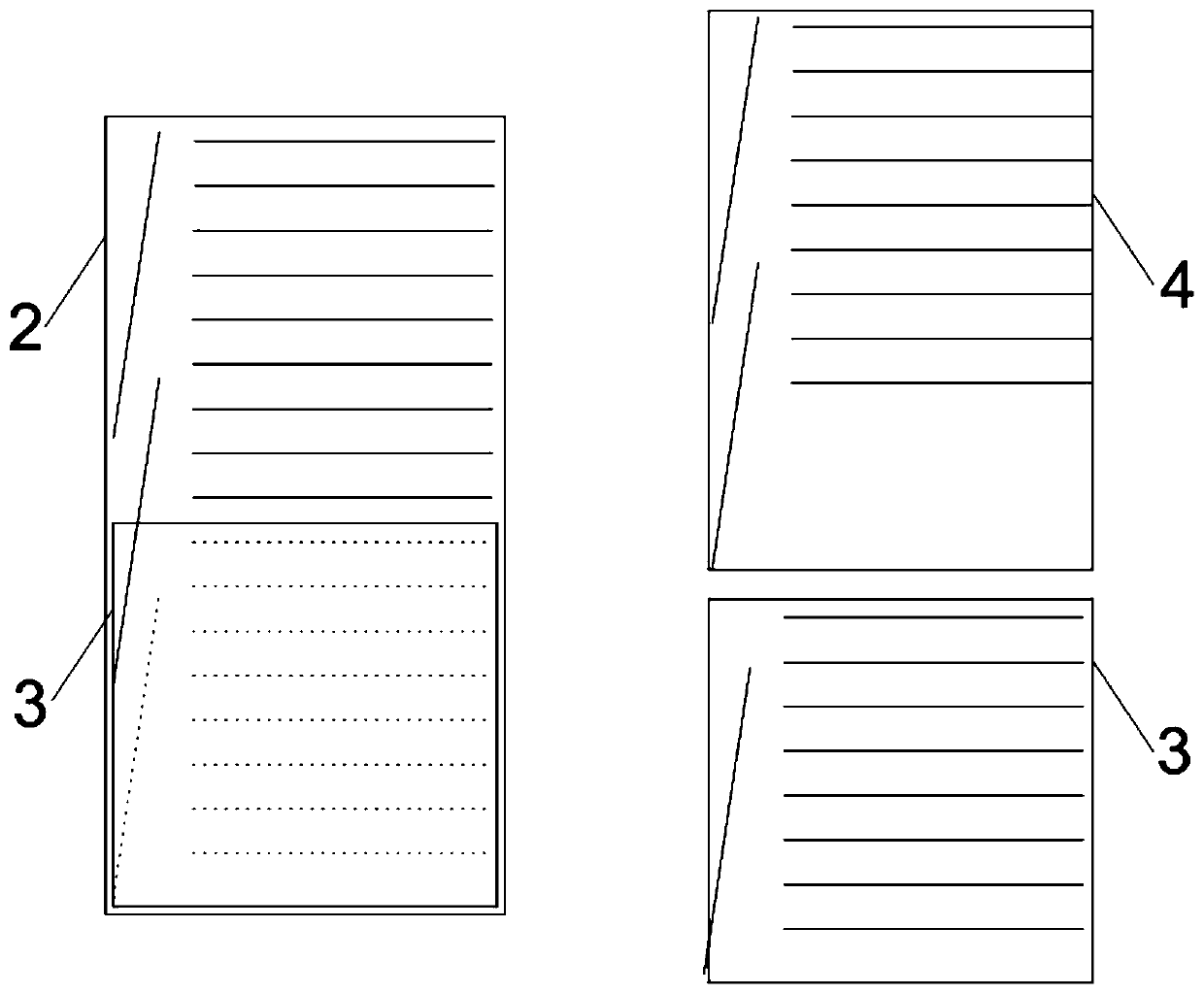

A large format laser processing method

ActiveCN110076458BReduce splicing timesIntegrity guaranteedLaser beam welding apparatusEngineeringAutomated segmentation

The invention discloses a large-format laser processing method. The large-format laser processing method is suitable for processing a laser processing machine tool with galvanometer processing as a main processing mode, the laser processing machine tool comprises a laser, a galvanometer, a light path system, a machine tool three-axis motion platform, a motion control card, a galvanometer control card and a computer. According to the large-format laser processing method, the processing graph exceeding the processing amplitude of the galvanometer is automatically divided into a plurality of small areas smaller than the processing amplitude surface of the galvanometer, the processing positioning point of each area is obtained, and then optimizing the processing track of each area and a positioning movement track among the small areas, positioning is carried out according to the optimized processing sequence of each small area, and the pattern of each small area is processed through the galvanometer until all the small areas are processed. According to the large-format laser processing method, automatic segmentation, trajectory optimization and processing process control of a large-format graph are realized, the processing process of the large-format graph is simplified, and the processing quality and the processing efficiency are improved.

Owner:无锡超通智能制造技术研究院有限公司

Rapid transportation pneumatic pipeline conveyor

ActiveCN113233201ATo achieve the mobile effectTo achieve the locking effectBulk conveyorsPneumatic tubeAir compressor

The invention relates to a rapid transportation pneumatic pipeline conveyor. The conveyor comprises a transportation workbench, a pipeline fixing frame is fixedly connected to the transportation workbench, a pneumatic pipeline is arranged on the pipeline fixing frame, a plurality of pipeline fixing cross beams are arranged on the pneumatic pipeline, the pneumatic pipeline is connected with the conveying workbench and the pipeline fixing frame through the pipeline fixing cross beams, the pipeline fixing cross beams are connected with a conveying pipeline supporting frame, the pipeline fixing cross beams are connected with the pneumatic pipeline through the conveying pipeline supporting frame, the pipeline fixing cross beam located at the uppermost end is fixedly provided with a PLC, a material taking assembly is fixedly installed at one end, away from the pipeline fixing frame, of the pneumatic pipeline, a conveying rail assembly is arranged in the pneumatic pipeline, the PLC is electrically connected with the conveying rail assembly, an air compressor is fixedly installed at the lower end of the conveying workbench, and the air compressor communicates with the pneumatic pipeline. According to the conveyor, the current situation that no equipment capable of efficiently transporting quality-inspected products exists at present can be solved.

Owner:山东泛泰数控机械设备有限公司

A tire reducing device

ActiveCN108814692BIncrease destructive powerGuaranteed to stopObstetrical instrumentsCervixPropeller

The invention discloses a fetal reduction device. The device comprises a handle and a strangling assembly disposed at one end of the handle. The strangling assembly is retractably disposed in a firstcontaining cavity in the handle and comprises a first strangling blade and a second strangling blade, and the first strangling blade and the second strangling blade can be retracted and expanded. Thestrangling assembly is retracted in the first containing cavity of the handle before the fetal reducing device is positioned to prevent the strangling assembly from damaging the cervix when the fetalreducing device passes through the cervix, and the first strangling blade and the second strangling blade are expanded when the strangling blades puncture a fetal heart, so that the destructive capability of the strangling assembly is enhanced to ensure that the fetal heart of a fetus subjected to fetal reduction is stopped; moreover, a syringe is arranged in the handle, an injection needle is poked into the fetal heart, and a propeller is pushed for injecting potassium chloride to make the fetal heart stop immediately, so that the two operating means are conveniently switched.

Owner:THE SECOND HOSPITAL AFFILIATED TO WENZHOU MEDICAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com