Patents

Literature

98results about How to "To achieve the locking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

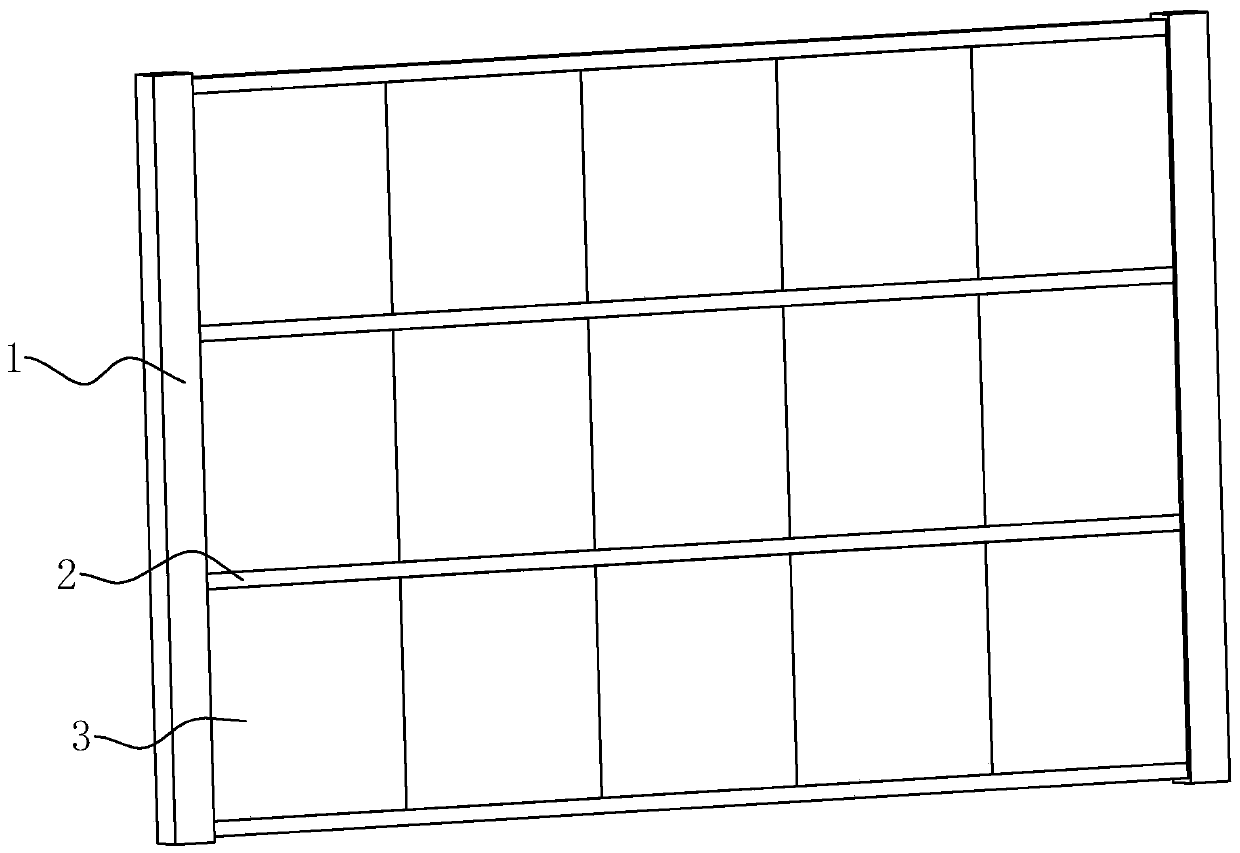

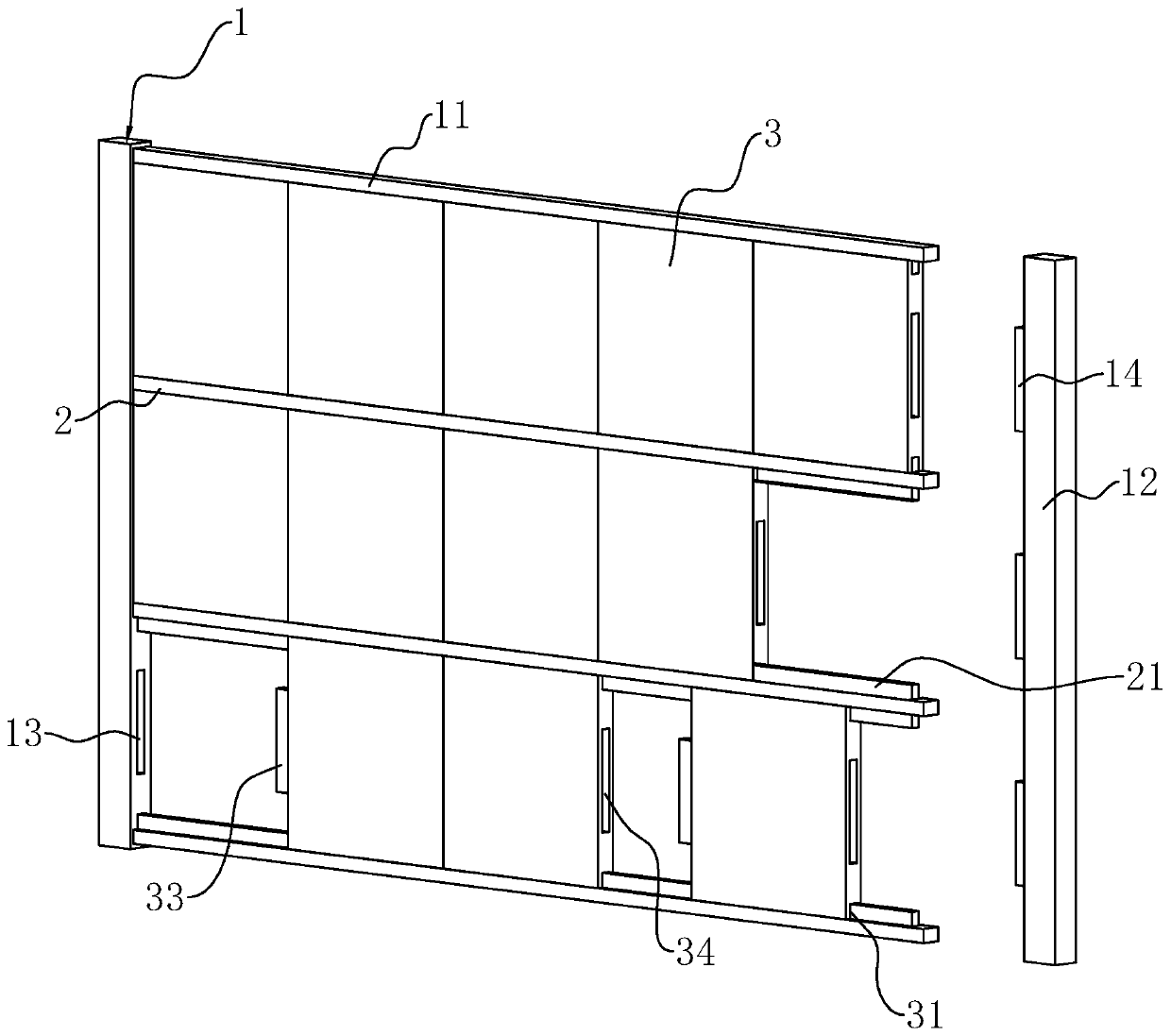

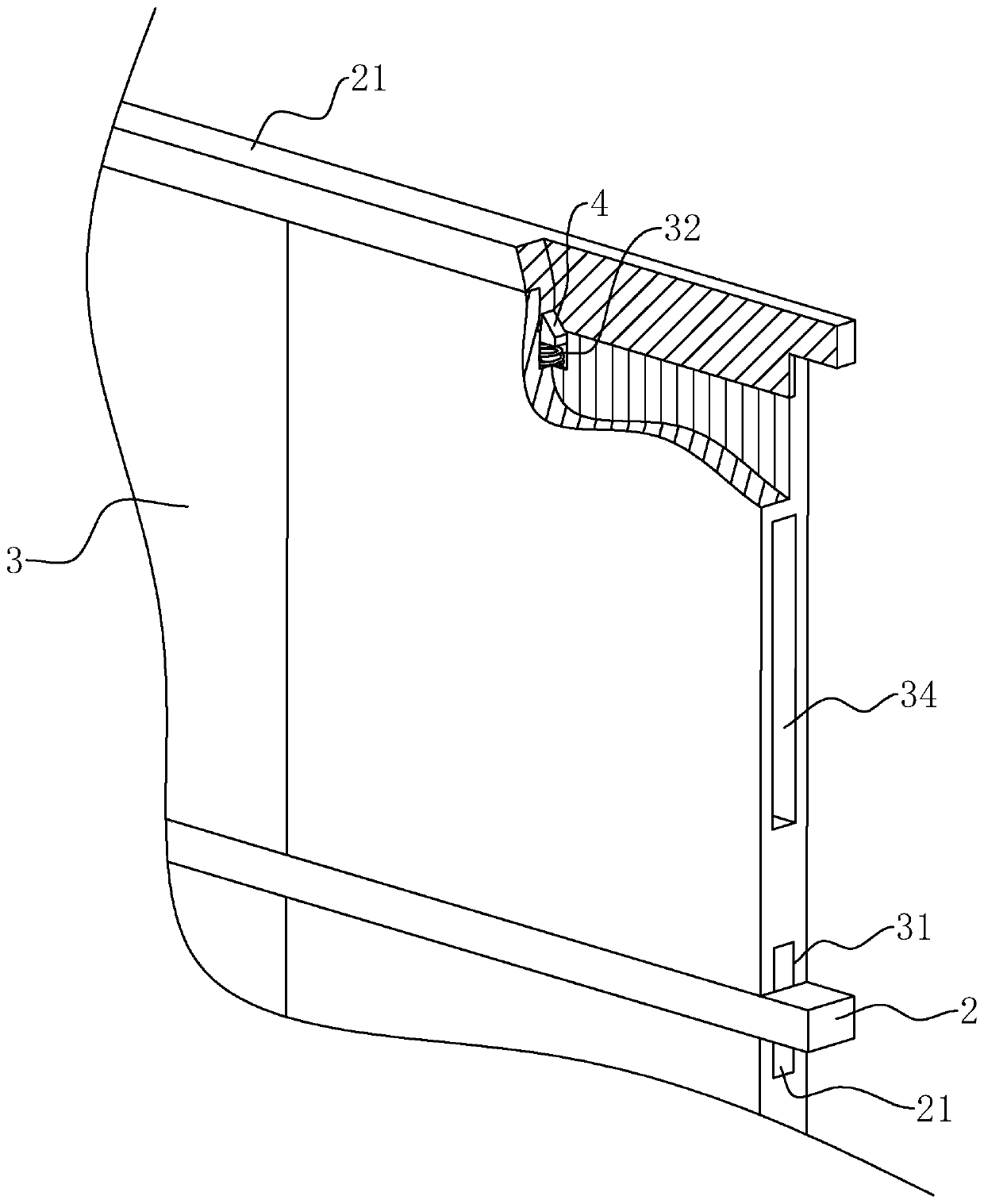

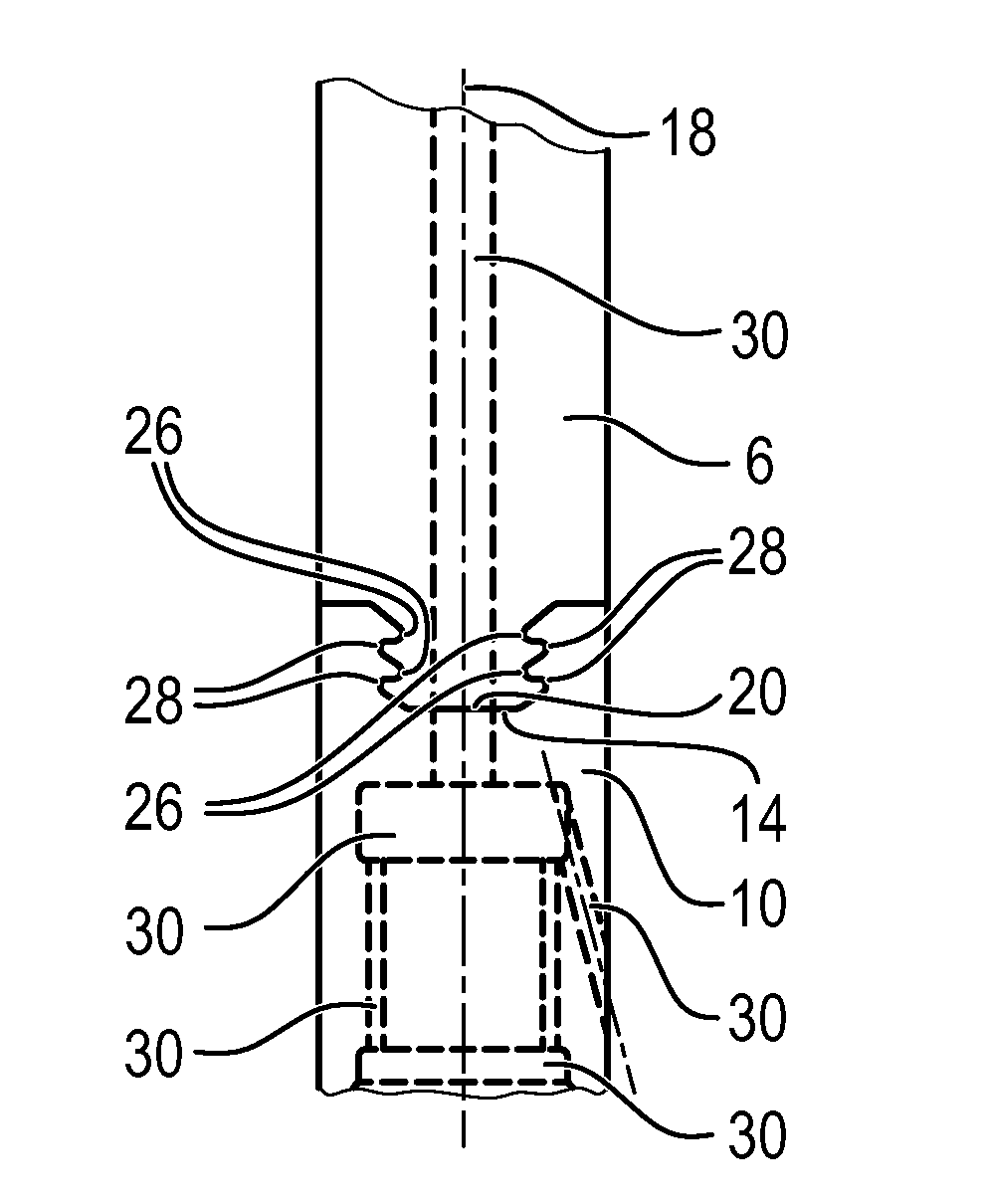

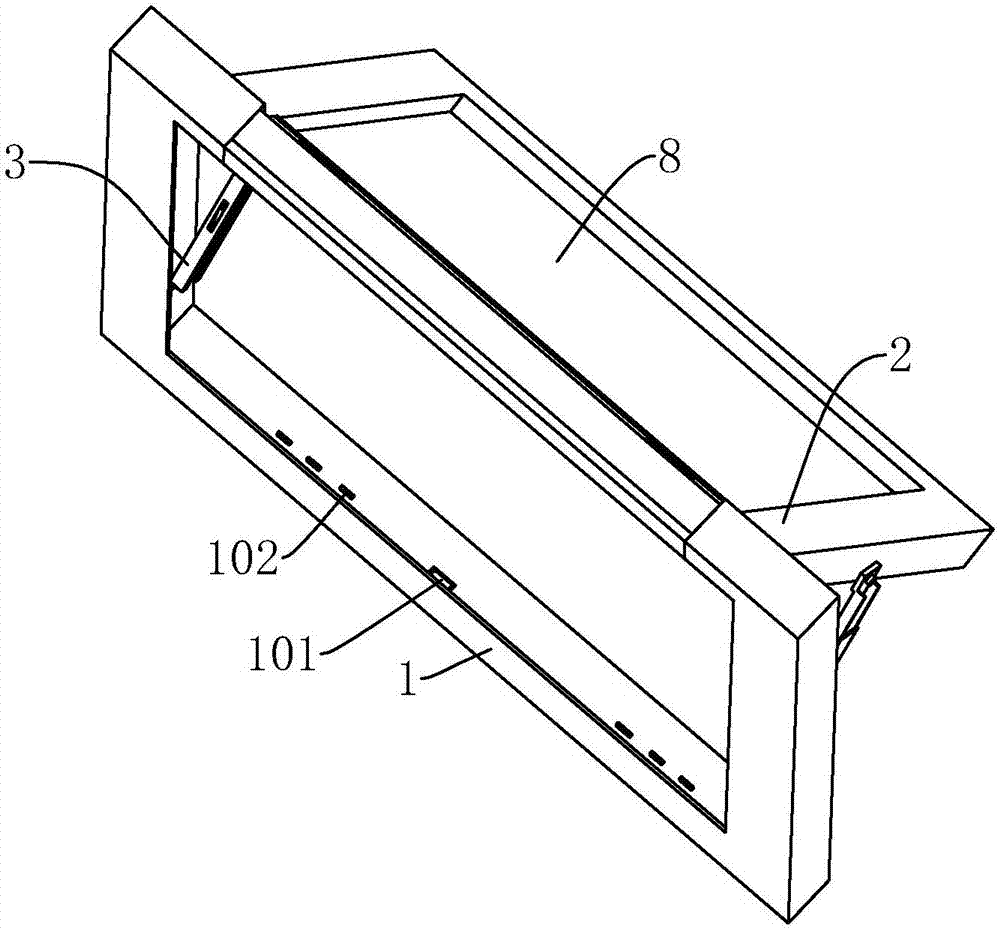

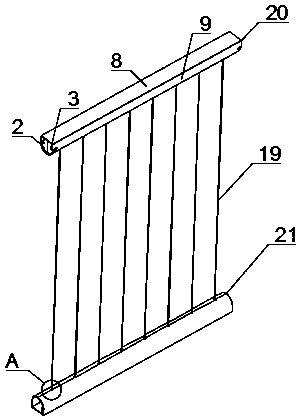

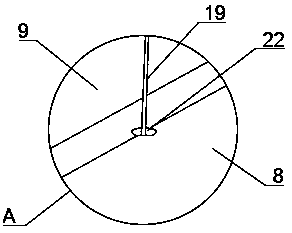

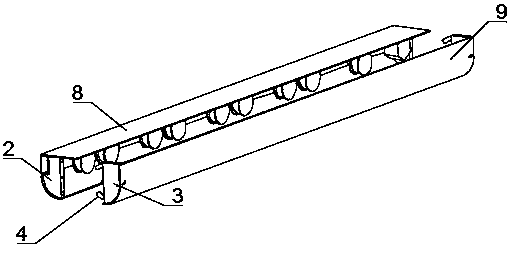

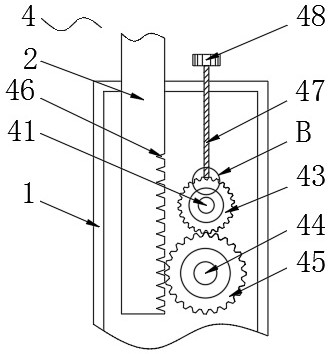

Fabricated ceramic tile wall surface and construction method thereof

InactiveCN109898774ATo achieve the locking effectTo achieve the purpose of directional slidingCovering/liningsKeelSurface construction

The invention discloses a fabricated ceramic tile wall surface and a construction method thereof, and relates to the technical field of building decoration. The fabricated ceramic tile wall surface comprises a main keel with the inner surface installed on a wall body and a plurality of ceramic tile templates installed outside the main keel, a plurality of bearing keels are equidistantly arranged on the main keel, and the bearing keels are arranged parallel to the ground surface; the multiple ceramic tile templates are spliced mutually and are slidably arranged between the upper bearing keel and the lower bearing keel in the length direction of the bearing keels, telescopic buckles are arranged on the side edges of the ceramic tile templates, lock holes corresponding to the telescopic buckles in a one-to-one mode are correspondingly formed in the bearing keels in the length direction, and the telescopic buckles of the ceramic tile templates are correspondingly connected to the inner parts of the lock holes in a clamped mode. The fabricated ceramic tile wall surface has the effects that the rapid installing is realized, the disassembling after the installing is convenient, the construction period is short, and the decoration efficiency and the ceramic tile wall surface construction quality are improved.

Owner:浙江屹立建设有限公司

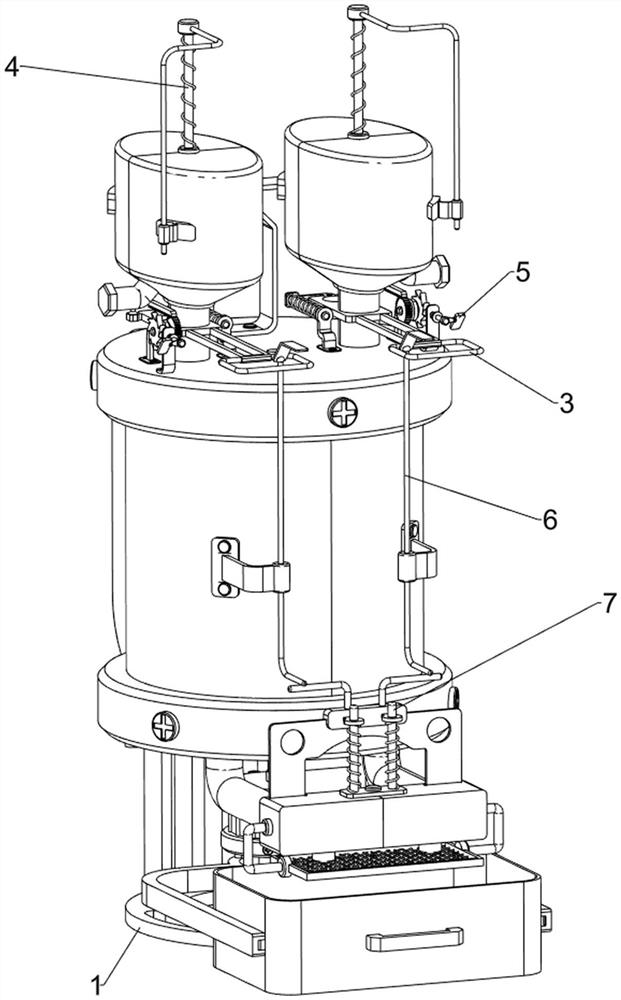

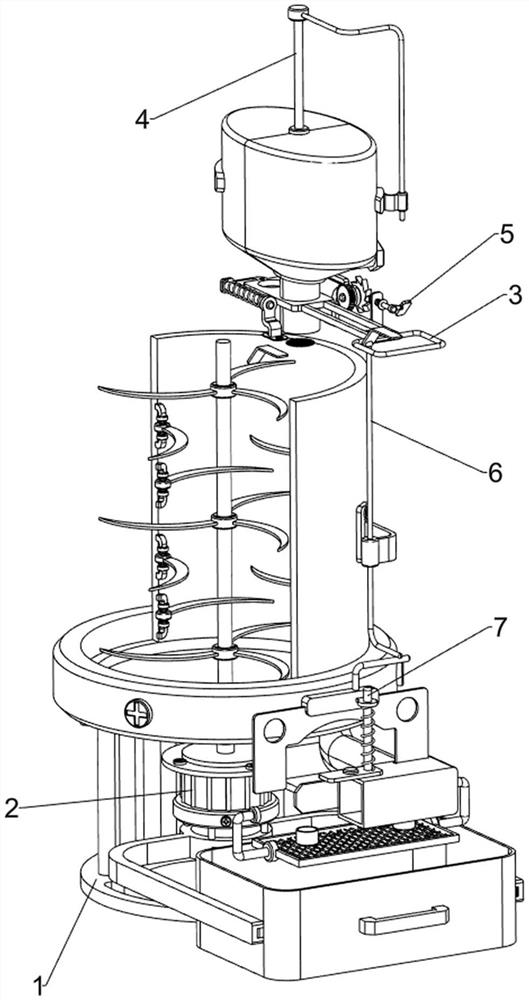

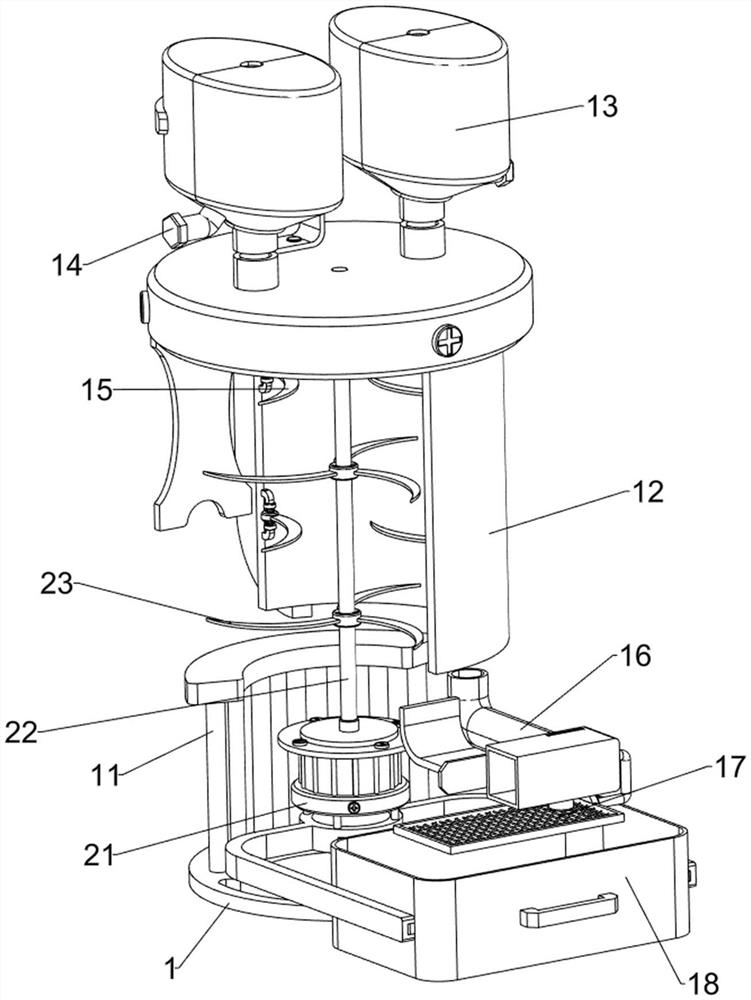

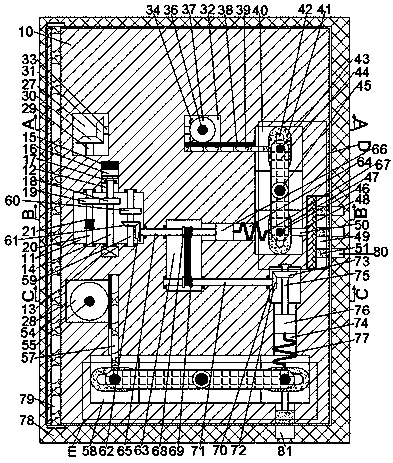

Automatic mixing device for colored glaze production

ActiveCN112844193AWell mixedAchieve broken effectTransportation and packagingRotary stirring mixersGlazeEngineering

The invention relates to a mixing device, and particularly relates to an automatic mixing device for colored glaze production. The automatic mixing device for colored glaze production is good in mixing effect, capable of reducing the labor intensity of workers and easy and understandable to operate. The automatic mixing device for colored glaze production comprises a base, a fixed supporting column, a mixing box body, a discharging box, feeding openings, static crushing cutters, a discharging channel and a filter screen, wherein the fixed supporting column is arranged on the base; the mixing box body is arranged at the top of the fixed supporting column; the discharging box is arranged at the top of the mixing box body; the feeding openings are formed in the two sides of the lower part of the discharging box; three static crushing cutters are rotationally arranged on each of the upper side and the lower side in the mixing box body; the discharging channel is arranged at the bottom of the mixing box body; and the filter screen is arranged between the two sides of the discharging channel. By arranging the crushing mechanism, the colored glaze in the mixing box body is more uniformly mixed through the operation of the crushing mechanism, and the crushing effect is achieved.

Owner:高安常莹新型材料有限公司

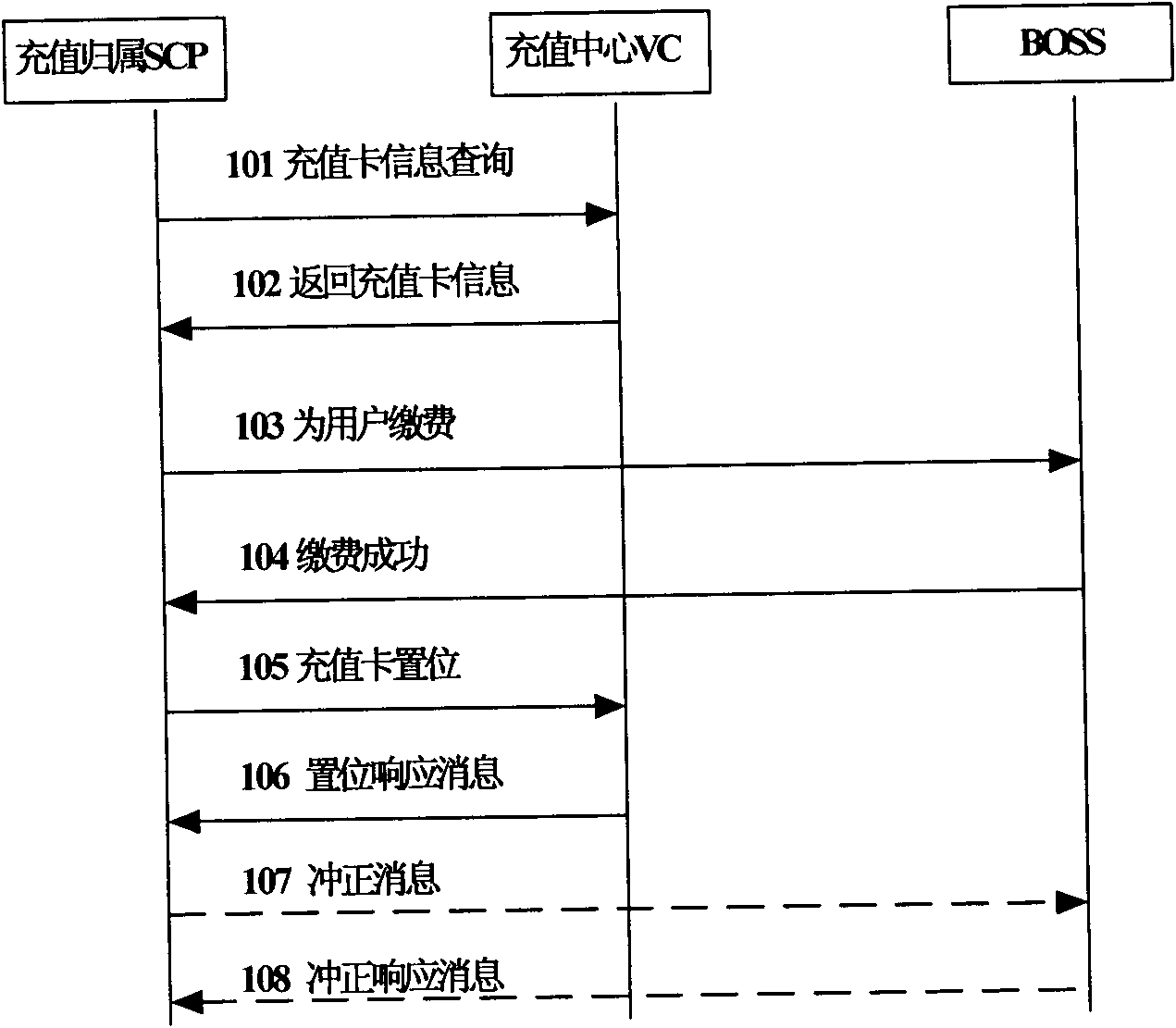

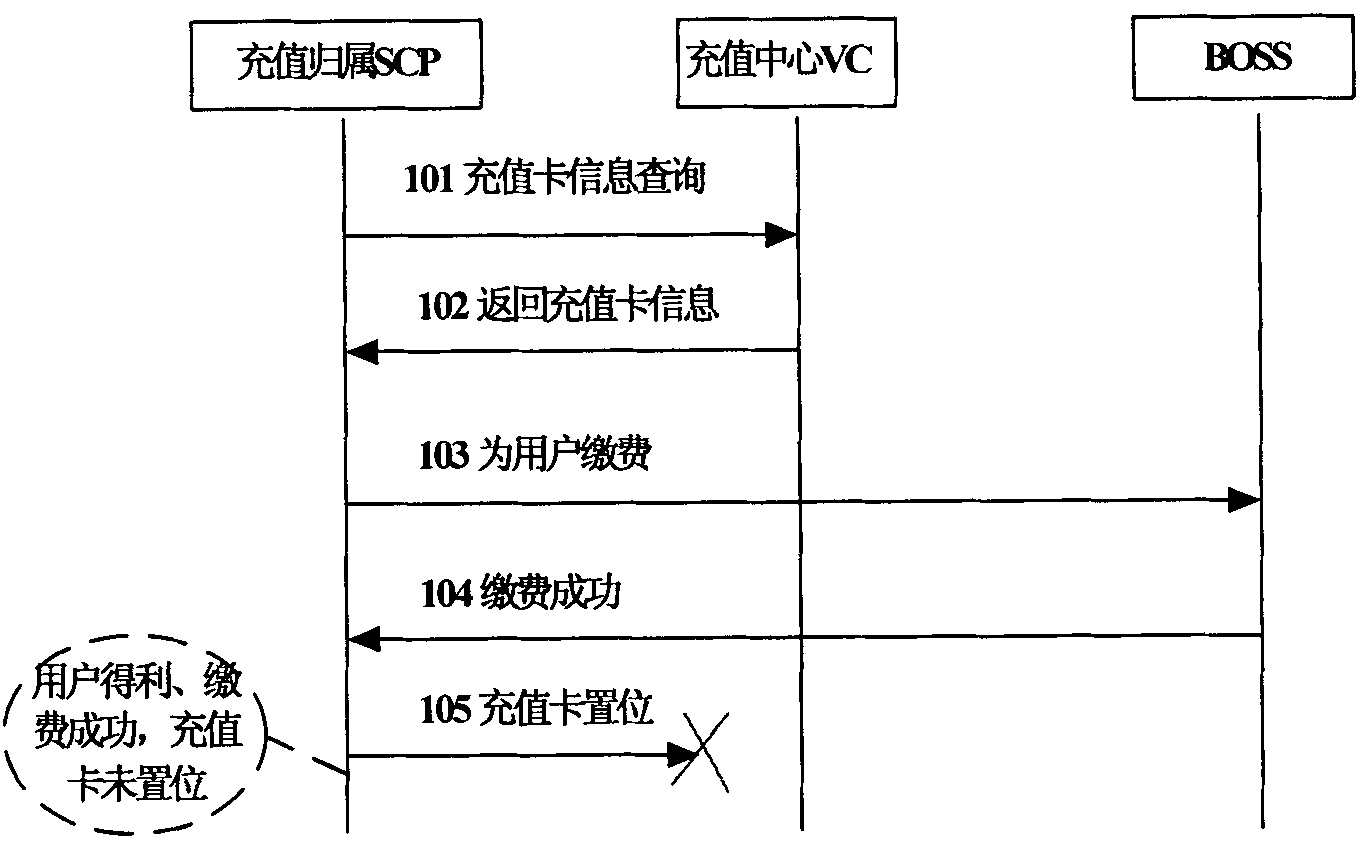

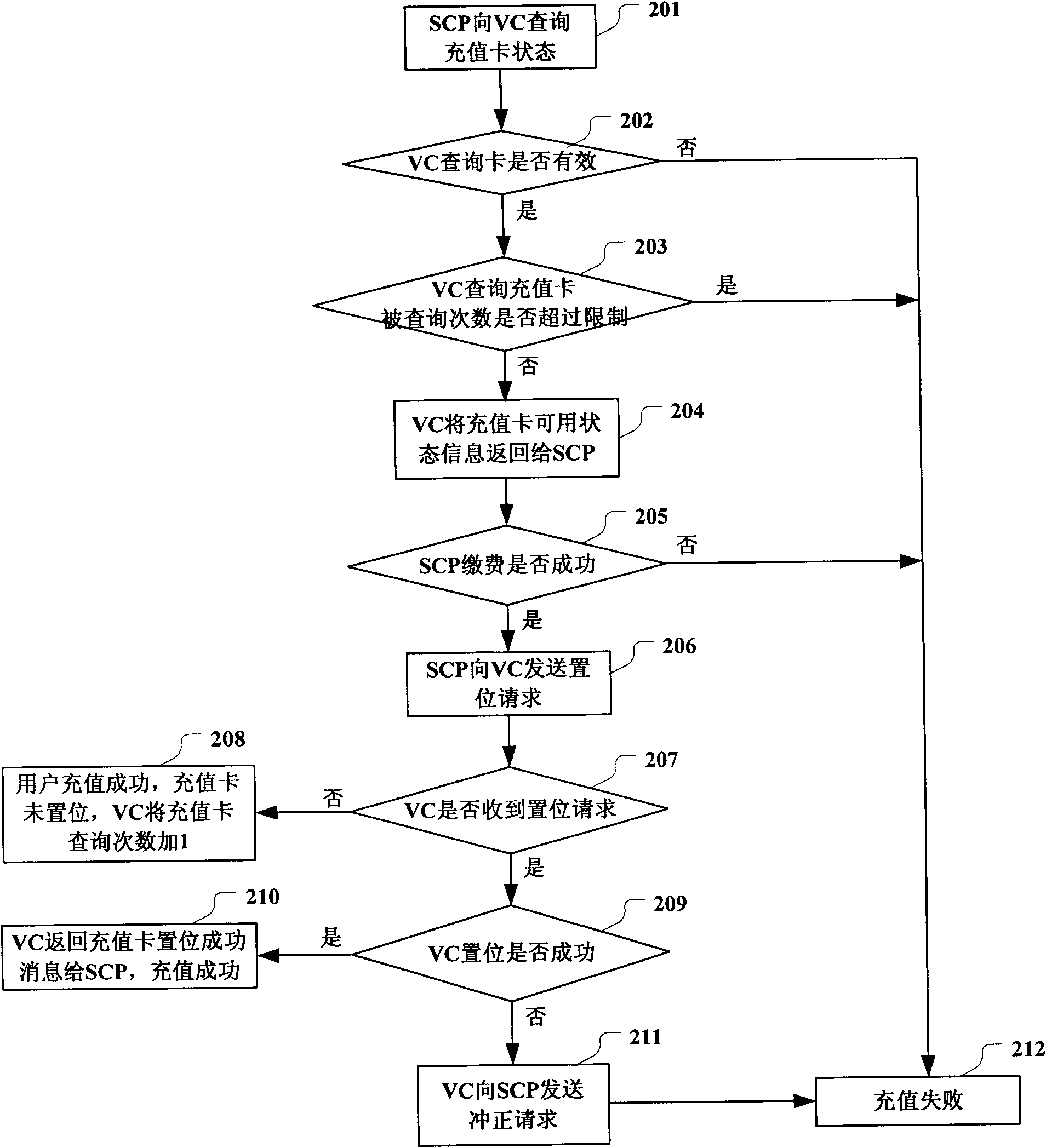

Method, device and system for recharging by using voucher card

ActiveCN102467770ATo achieve the locking effectReduce and timely eliminate the risk of repeated rechargeCoded identity card or credit card actuationComputer hardwareVoucher

The invention discloses a method, a device and a system for recharging by using a voucher card. The method for recharging by using the voucher card comprises the steps that a service control point (SCP) inquires a voucher center (VC) about the inquired times of the voucher card according to received subscriber voucher card information; and when the inquired times of the voucher card reach a preset threshold, the VC locks the voucher card. By using the method, the device and the system, the repetitive recharging risk of the voucher card is effectively reduced and precluded in time, and the situation that great losses are brought to an operator because one voucher card is repetitively used for recharging is avoided.

Owner:CHINA MOBILE GROUP ANHUI

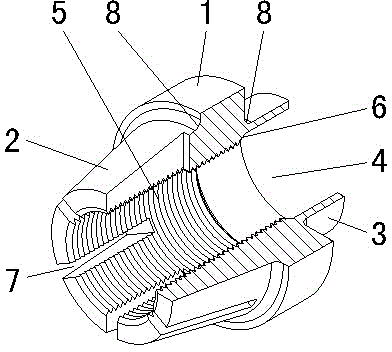

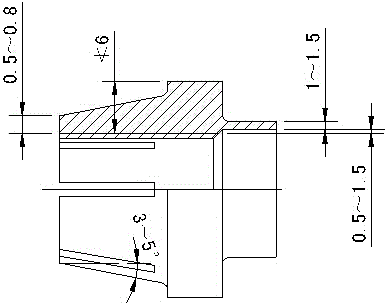

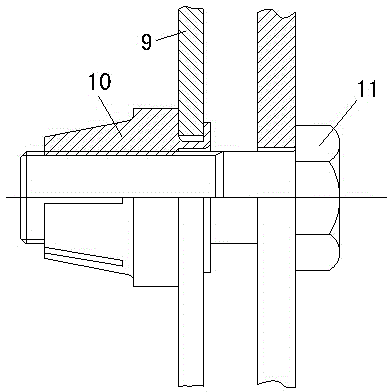

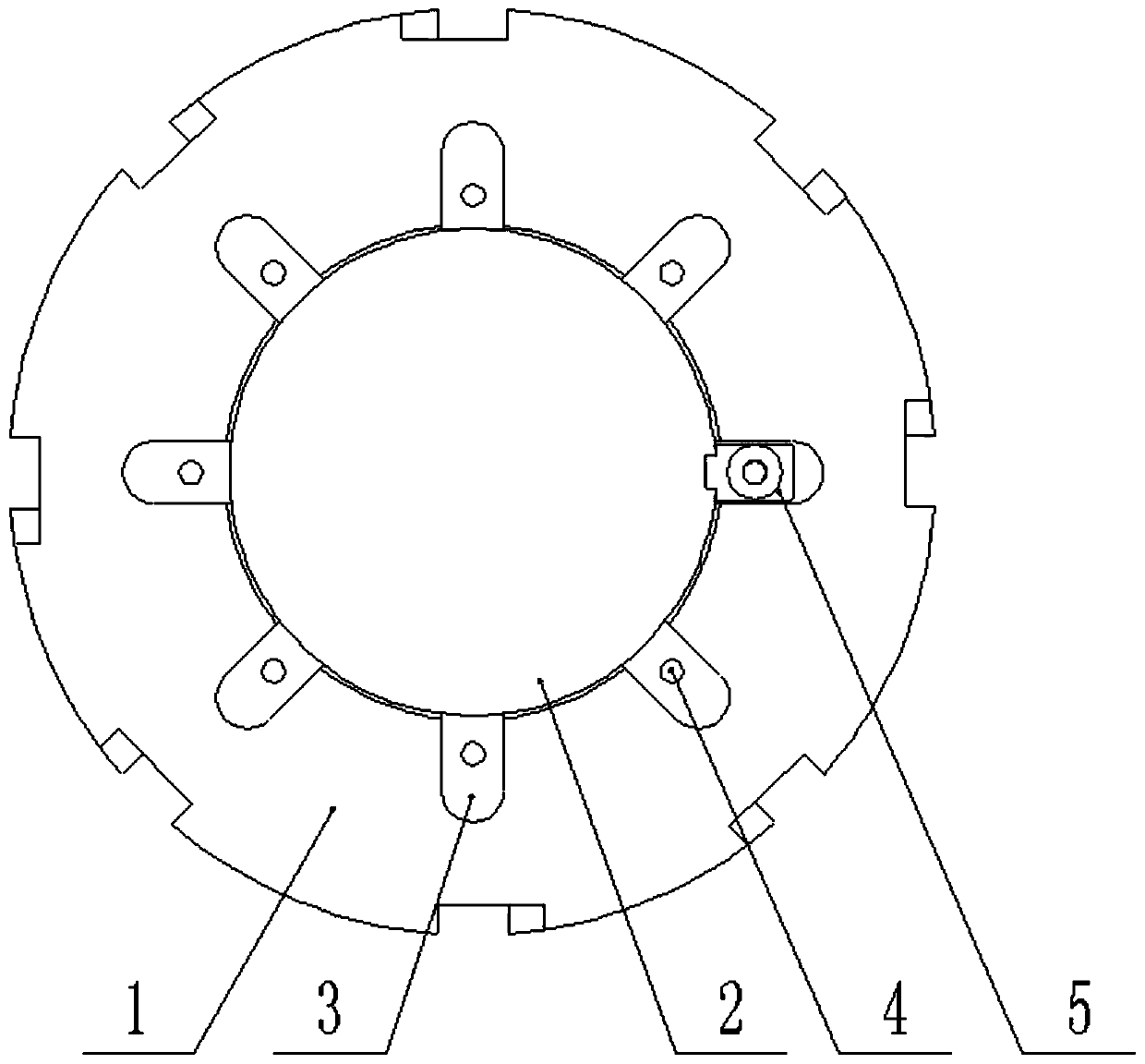

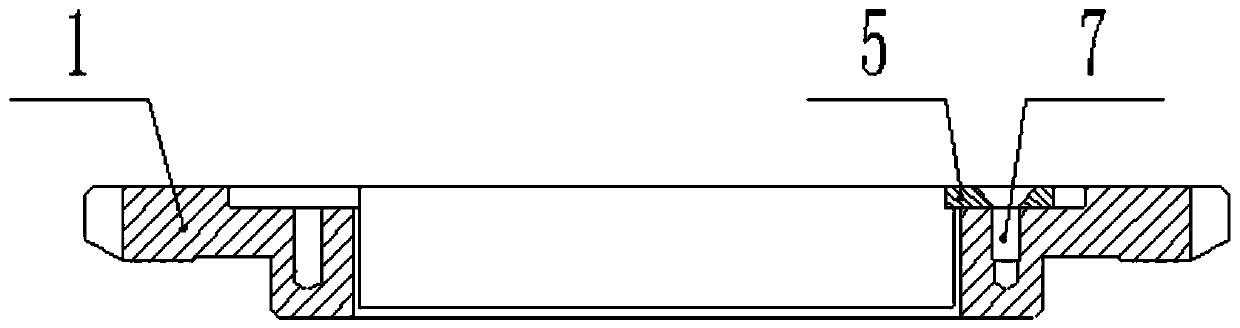

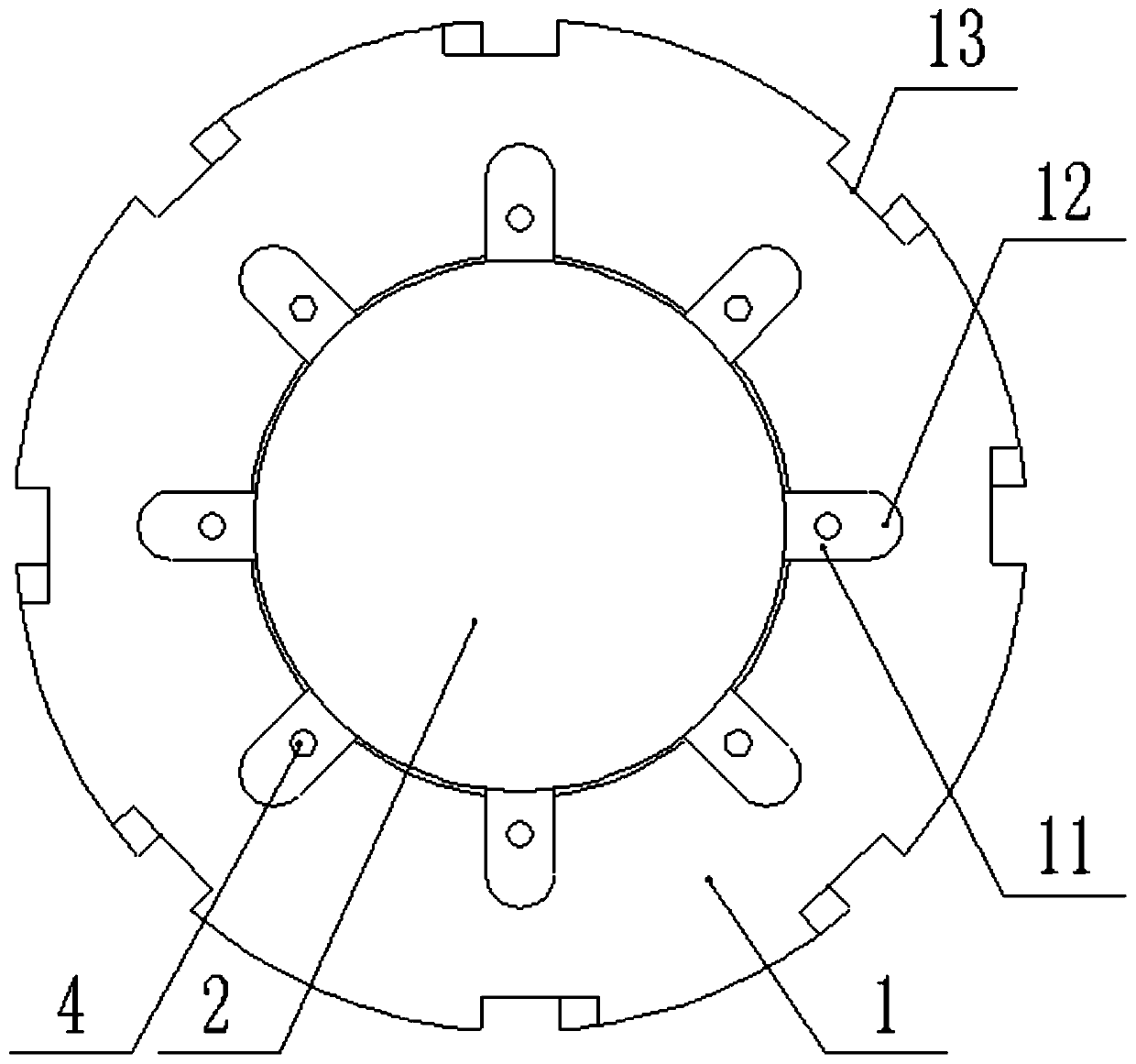

Flanging and riveting self-locking nut and machining method thereof

InactiveCN104963927AIncrease contact areaGood locking performanceNutsBoltsManufacturing engineeringMachining

The invention discloses a flanging and riveting self-locking nut and a machining method thereof. The flanging and riveting self-locking nut is a reducing cylinder body in appearance. The middle section of the reducing cylinder body is a large cylinder 1. A cone 2 is arranged at one end of the large cylinder, and a small cylinder 3 is arranged at the other end of the large cylinder. A reducing hole is formed in the middle of the reducing cylinder body. A large hole 4 is formed in the small cylinder. A small threaded hole 5 is formed in the large cylinder and the cone. The large hole and the small threaded hole are in transition through a chamfer 6. Locking grooves 7 evenly distributed along the circumference are formed in the cone. According to the flanging and riveting self-locking nut and the machining method thereof, an important new product is added to the field of fastening connecting pieces, threaded connecting and riveting are integrated through the structure of the flanging and riveting self-locking nut, threaded screwing can be conducted without the cooperation of external force during assembling, materials are saved in the application of the automatic locking and die forging technology, time is saved, high efficiency is achieved, the safe reliability is high, the mechanical performance is stable, and maintenance is convenient.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

Sift-proof backdoor locking device of compartment

InactiveCN102765569AIncrease cargo volumeSimple structureRefuse transferringStorage devicesLocking mechanismEngineering

The invention discloses a sift-proof backdoor locking device of a compartment, which is characterized by comprising an opening-closing mechanism and a locking mechanism, wherein the opening-closing mechanism is fixed at the top of the compartment backdoor; the locking mechanism is arranged on movable porous plates on two sides of the lower combination place of the compartment backdoor; and the locking mechanism adopts a single cylinder structure locked by symmetrical bolts on left end and right end. The device has the advantages of simple structure, reliable action, low cost and the like.

Owner:广西玉柴专用汽车有限公司

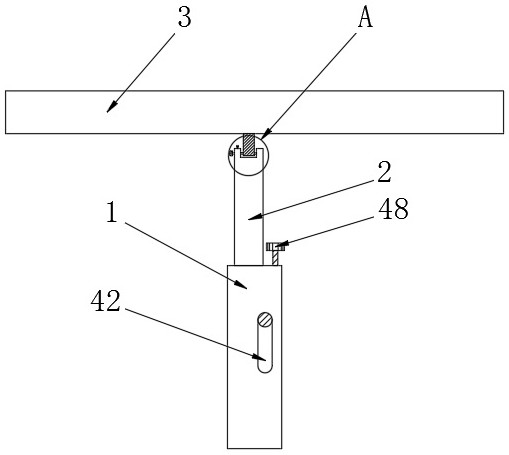

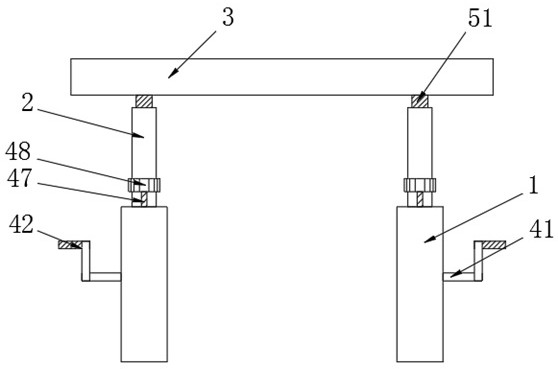

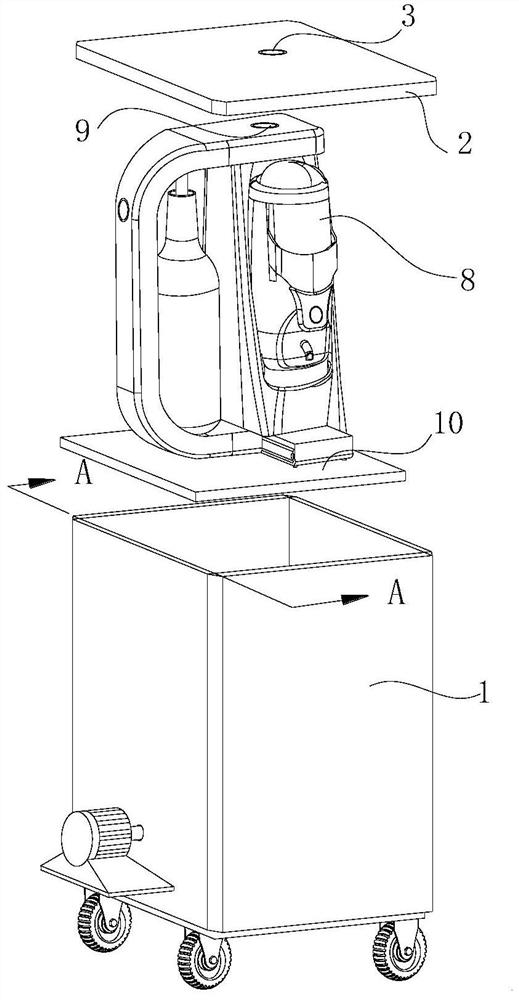

Angle-adjustable supporting mechanism for medical equipment

ActiveCN112128566AAvoid damageHigh utility valueNon-rotating vibration suppressionStands/trestlesMedical equipmentMechanical engineering

The invention relates to an angle-adjustable supporting mechanism for medical equipment, and aims to solve the problems. The angle-adjustable supporting mechanism comprises a medical equipment body and a supporting mechanism, wherein the medical equipment body is arranged on the supporting mechanism, the supporting mechanism comprises an equipment mounting table plate and a base supporting plate,a connecting vertical plate is arranged at the upper end of the base supporting plate, and the upper end of the connecting vertical plate is connected with a No.1 connecting cylinder. According to theangle-adjustable supporting mechanism for the medical equipment, the adjustable supporting mechanism is arranged below the medical equipment body, the medical equipment body is supported, the angle of the medical equipment body can be adjusted, a transmission manual adjusting mode is replaced with a mechanical adjustment mode in the adjusting process, the effects of saving time and labor can be achieved in the adjusting process, the problem that the medical equipment body is damaged due to manual misoperation can be avoided, and therefore, the angle-adjustable supporting mechanism has higherpractical value in practical application.

Owner:HUZHOU MATERNITY & CHILD CARE HOSPITAL

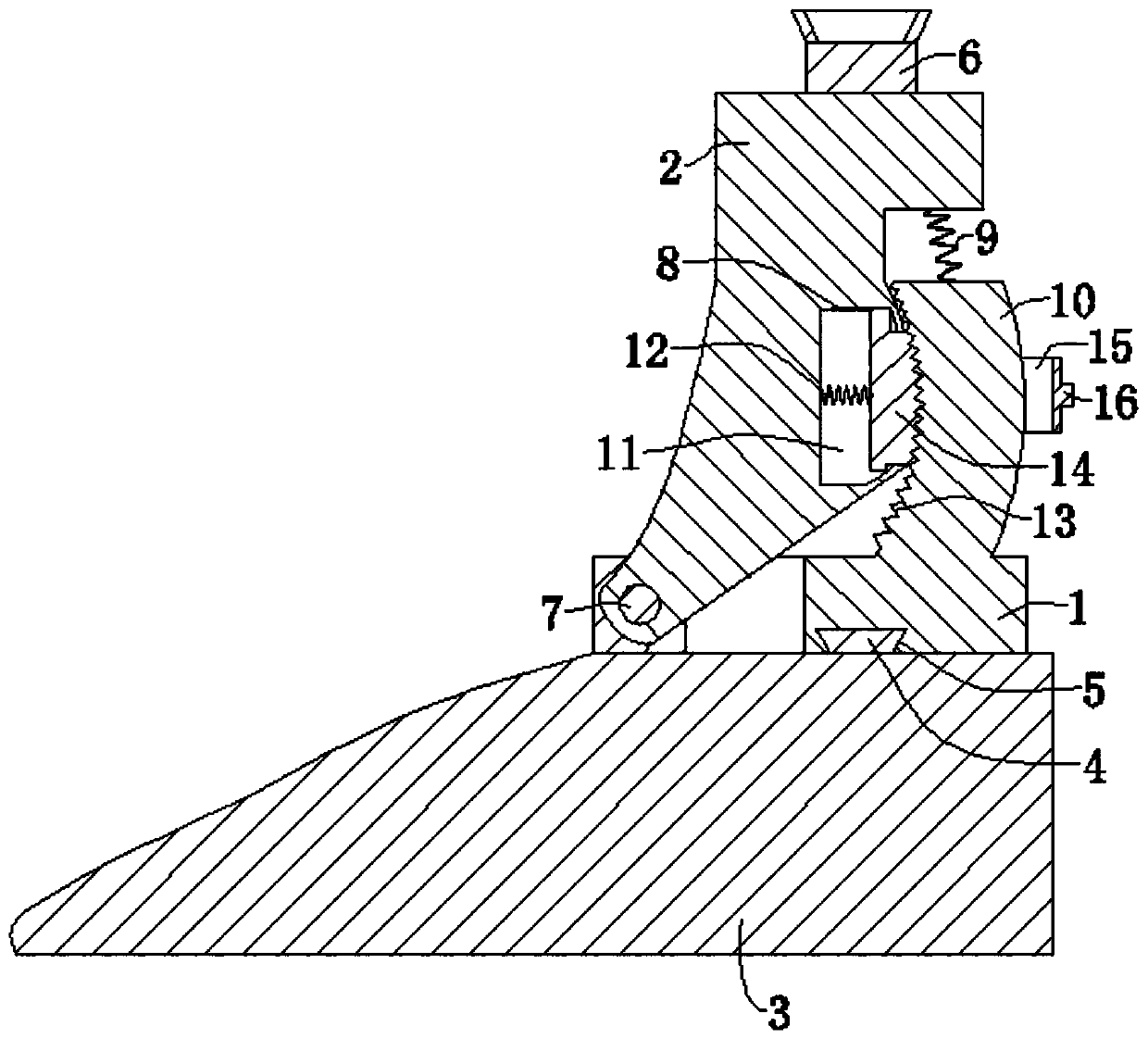

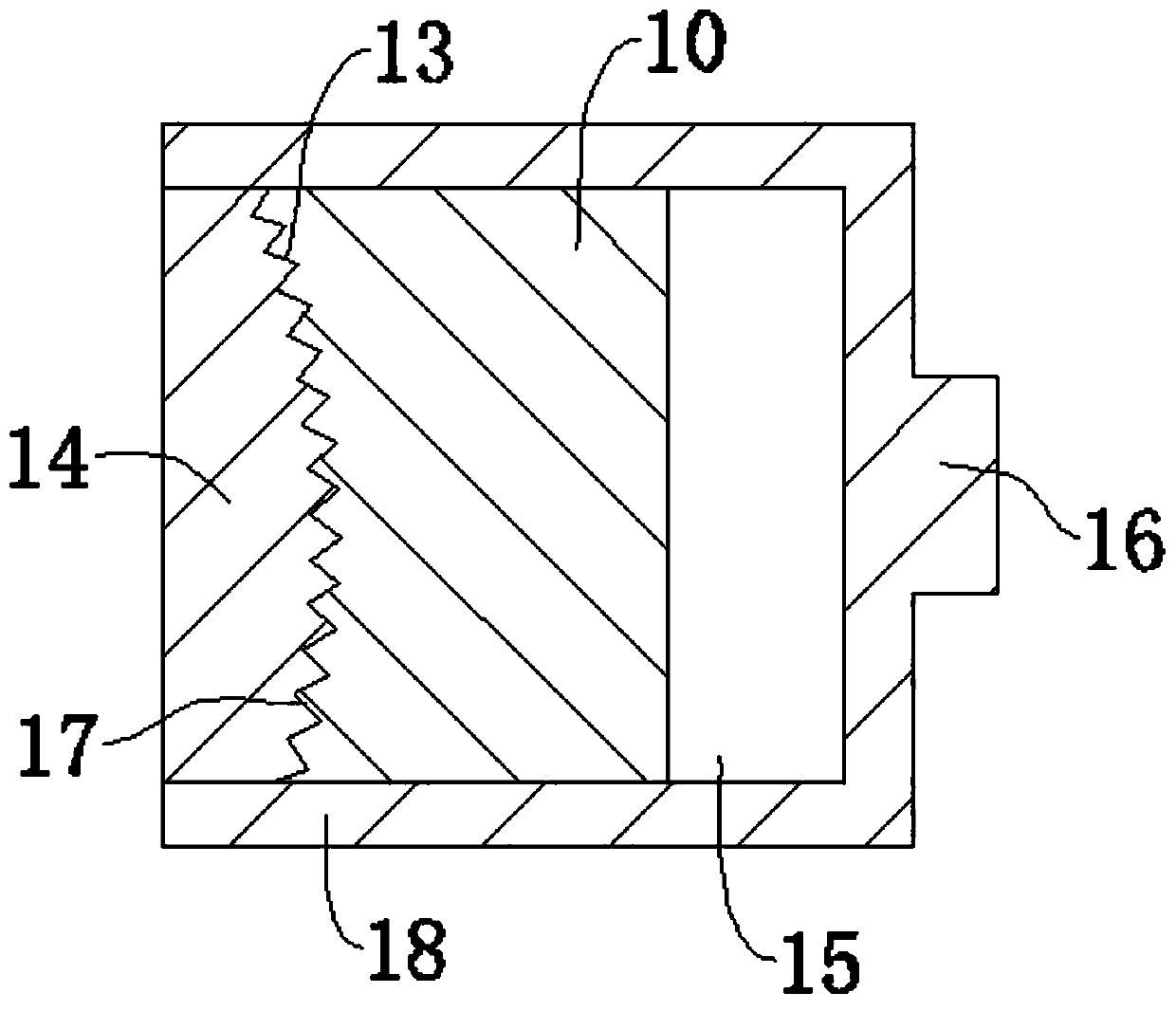

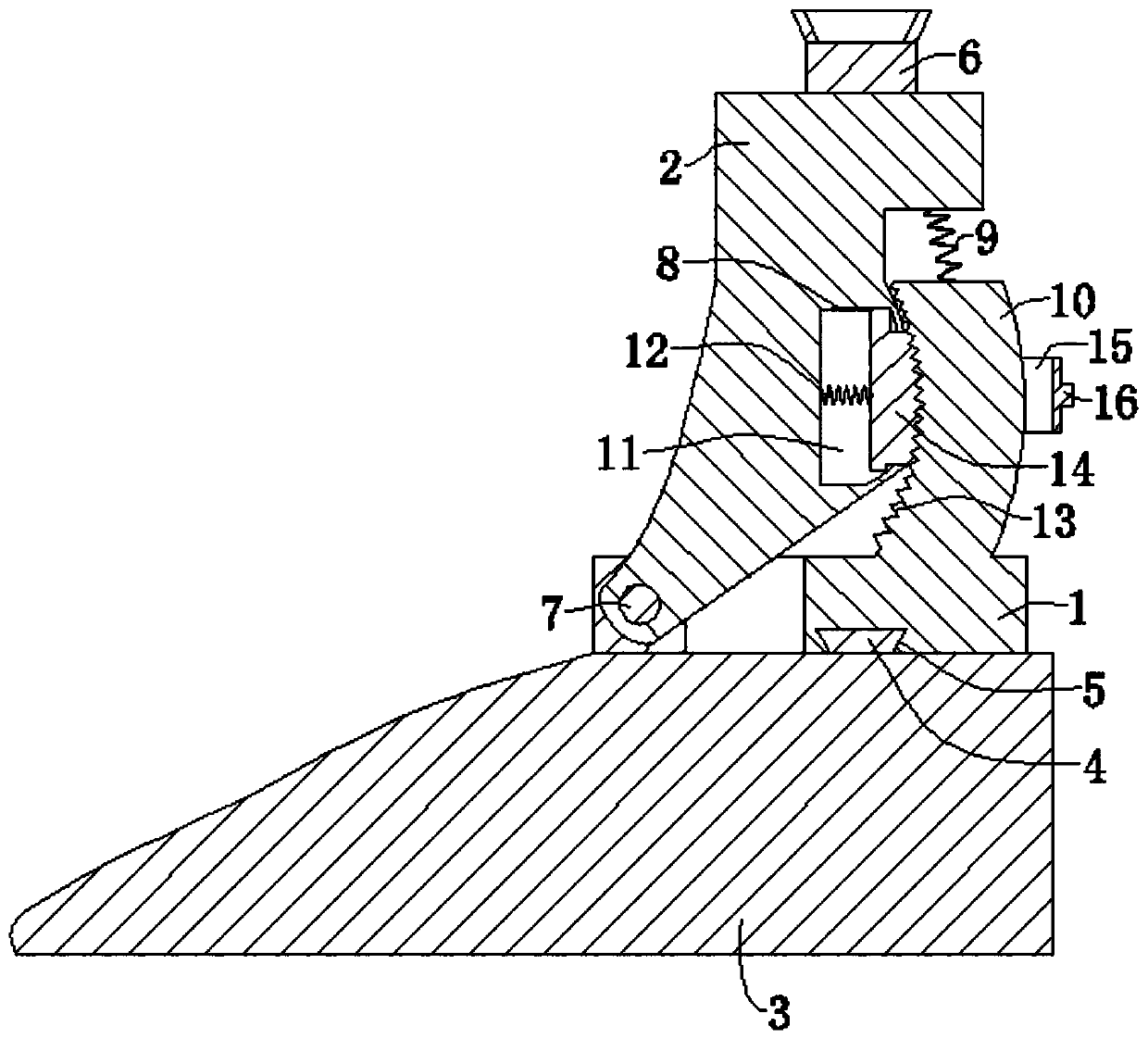

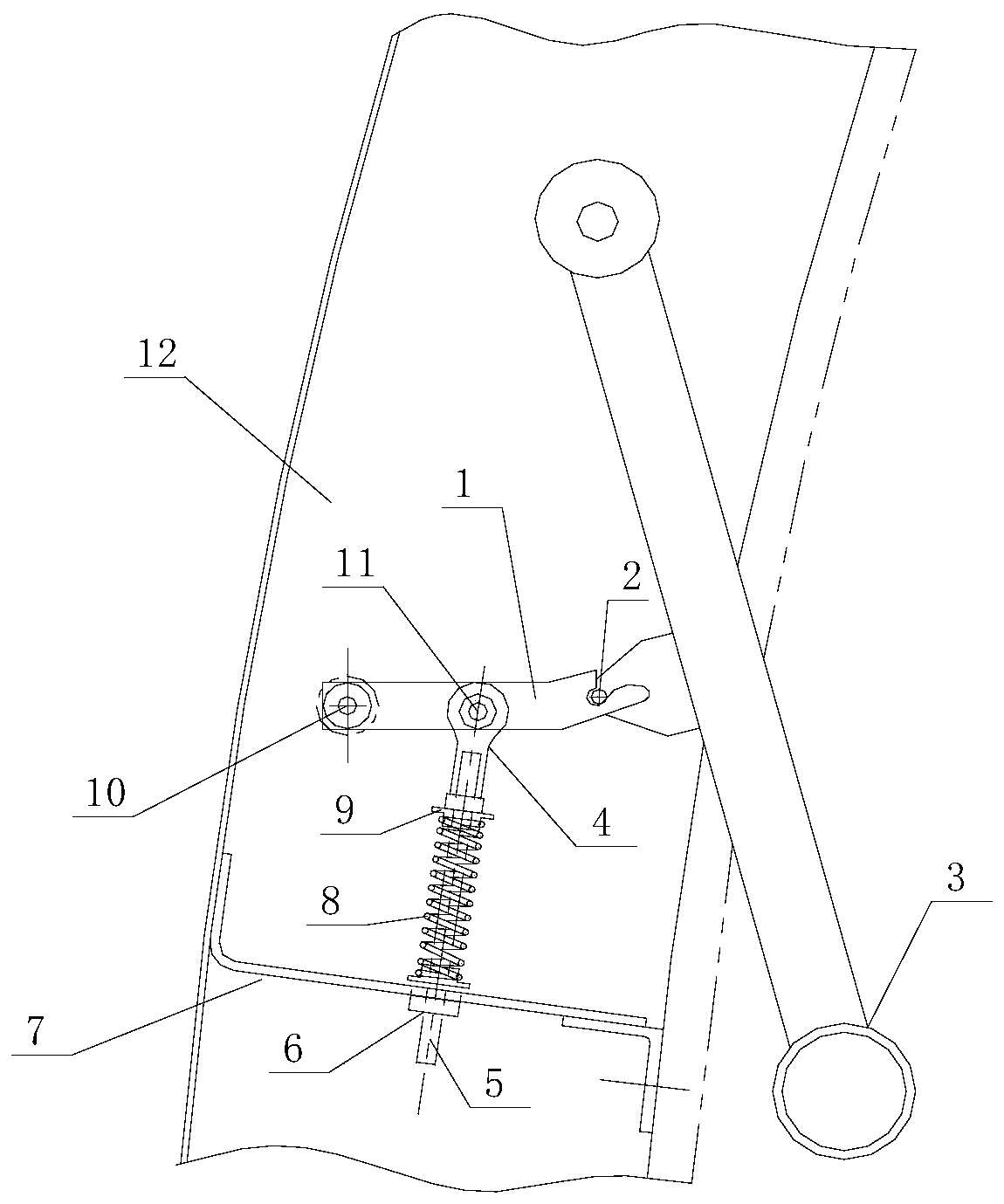

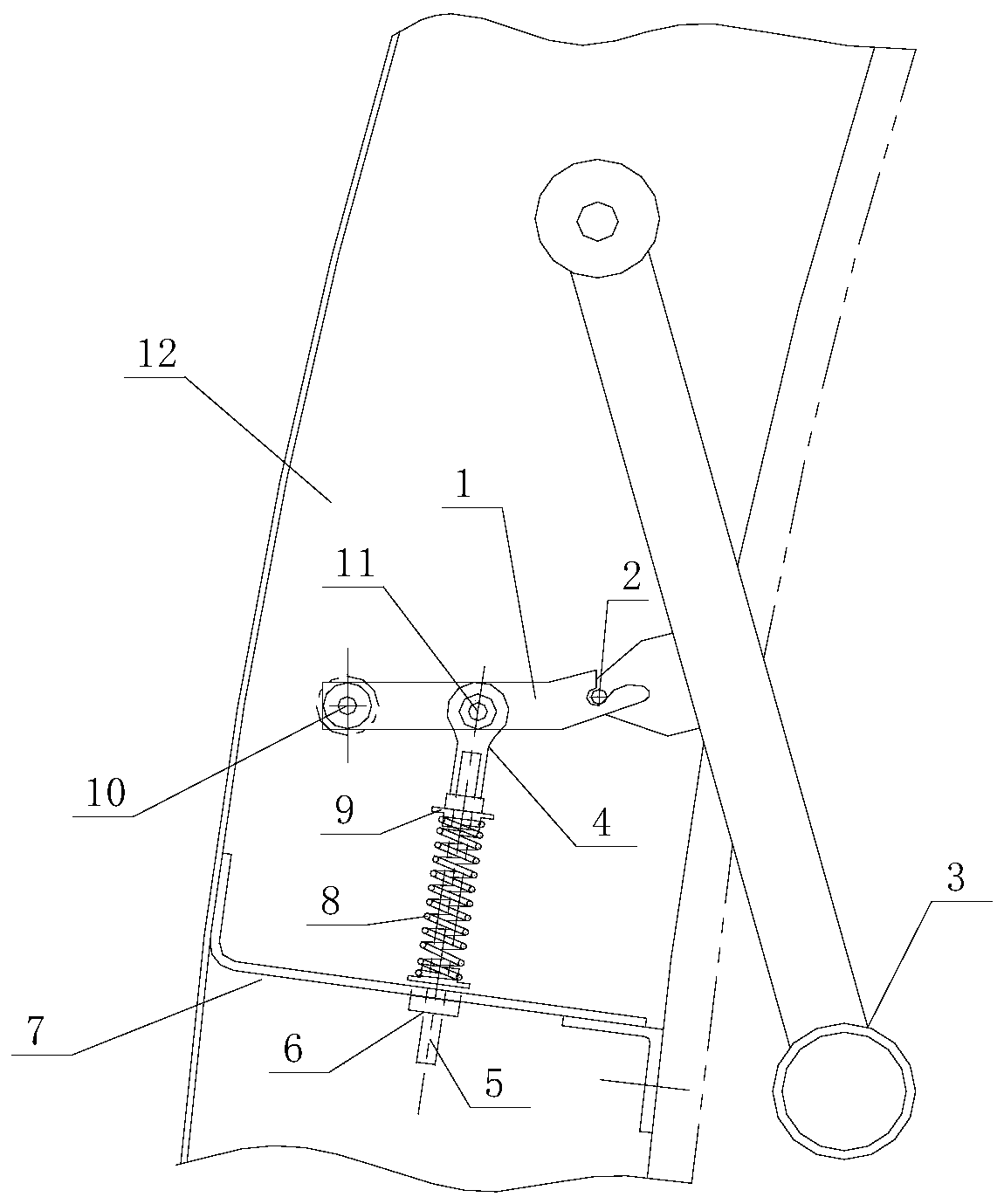

Mechanical adjustment conditioning type artificial limb ankle joint

The invention discloses a mechanical adjustment type artificial limb ankle joint, and belongs to the technical field of artificial limbs. The ankle joint comprises a base, an adjusting seat and an adjusting button, wherein the base is fixed on the artificial foot; a locking seat is fixed to the base; an arc-shaped meshing surface is arranged on one side away from a heel, of the locking seat; the lower part of the front part of the adjusting seat is rotatably connected with the base; an arc surface of which the radian is the same as that of the meshing surface is arranged at the rear part of the adjusting seat, and is in contact with the meshing surface; a cavity is formed in the rear part of the adjusting seat and is opened, and an opening of the cavity is formed in the arc surface of theadjusting seat; a telescopic hole is formed in the middle part of the adjusting button; the adjusting seat penetrates through the telescopic hole up and down; one end of the adjusting button is located in the cavity, and a bite block is fixed to one end of the adjusting button, and is located in the cavity; a compression spring is fixed to one side of the bite block, and bite teeth being meshed with the meshing surface are arranged on the other side of the bite block; and one end of the compression spring is fixed on the inner wall of the cavity, and the other end of the compression spring isfixed on the bite block. Through the adoption of the mechanical adjustment type artificial limb ankle joint disclosed by the invention, the problem that the price of a conventional adjustable artificial limb ankle joint is quite high, so that many amputees cannot afford the conventional adjustable artificial limb ankle joint is solved.

Owner:湖南海弘医疗科技有限公司

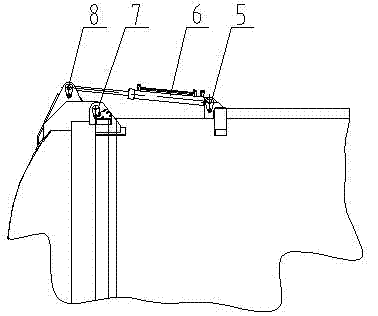

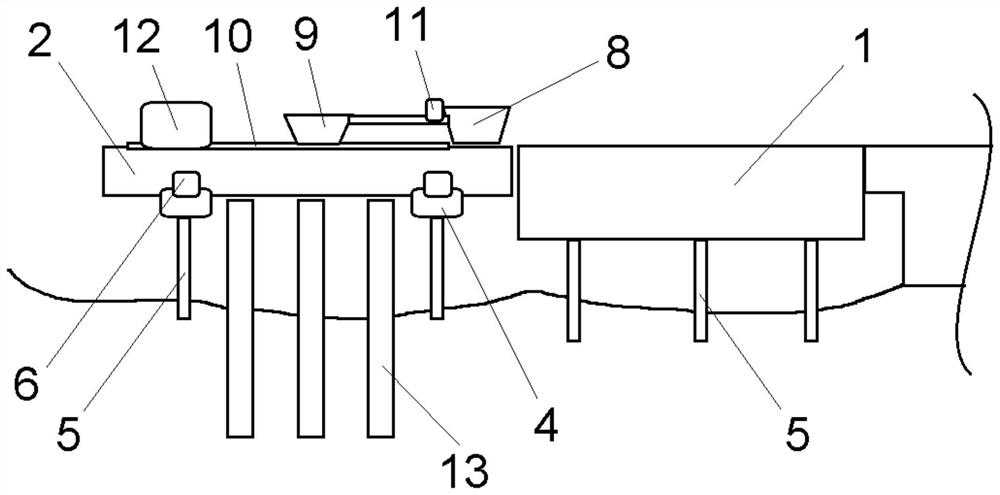

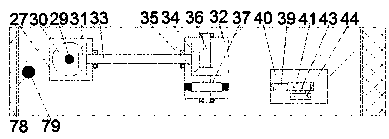

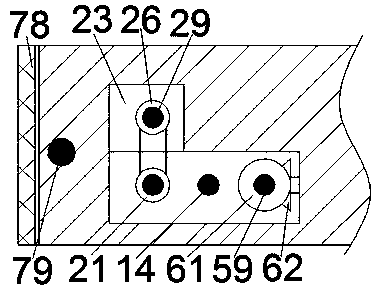

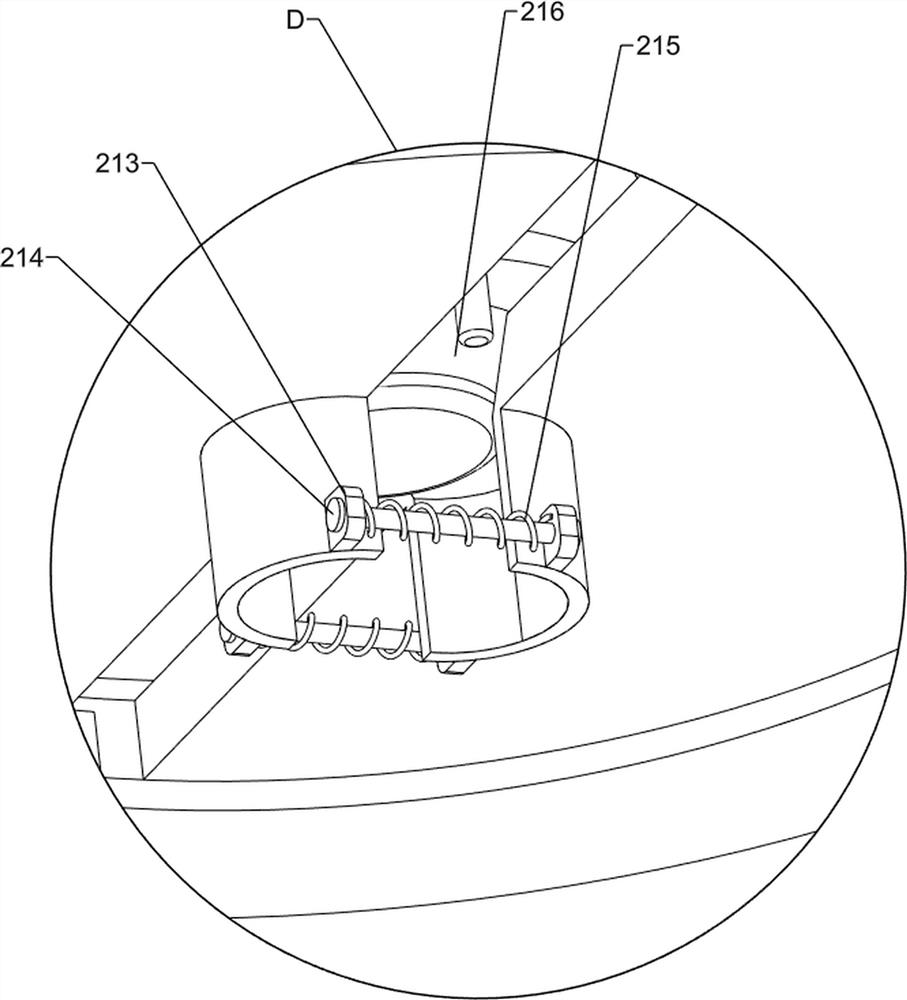

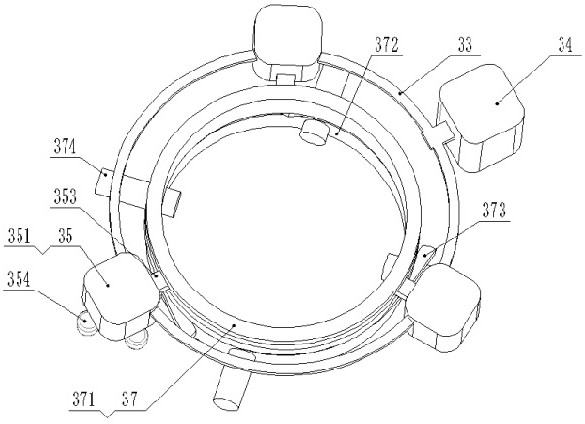

Edge locking clamp for rolling of film rolls

InactiveCN104016171AReach steady edgeTo achieve the locking effectWebs handlingEngineeringMechanical engineering

Owner:永新股份(黄山)包装有限公司

Cutting tool

ActiveUS20150078840A1Enhance bonded connectionImprove the immunityTool workpiece connectionMilling cuttersMachine toolHead parts

The invention relates to a cutting tool, particularly for use in a tool chuck of a machine tool, including a tool shaft with a center longitudinal axis and a tool head. The tool head is connected to the tool shaft via a positive-locking connection, which locks the movement in the direction of the center longitudinal axis and the positive-locking connection is supplemented by a bonded connection, particularly a soldered connection.

Owner:KENNAMETAL INC

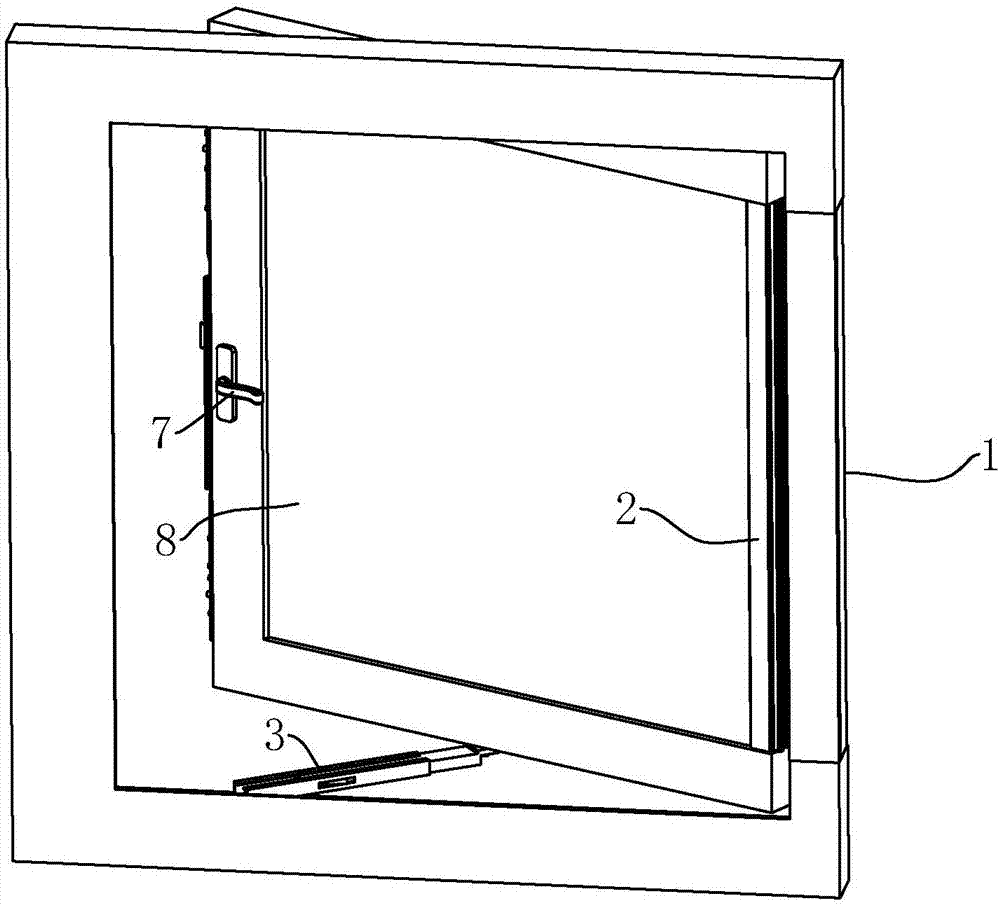

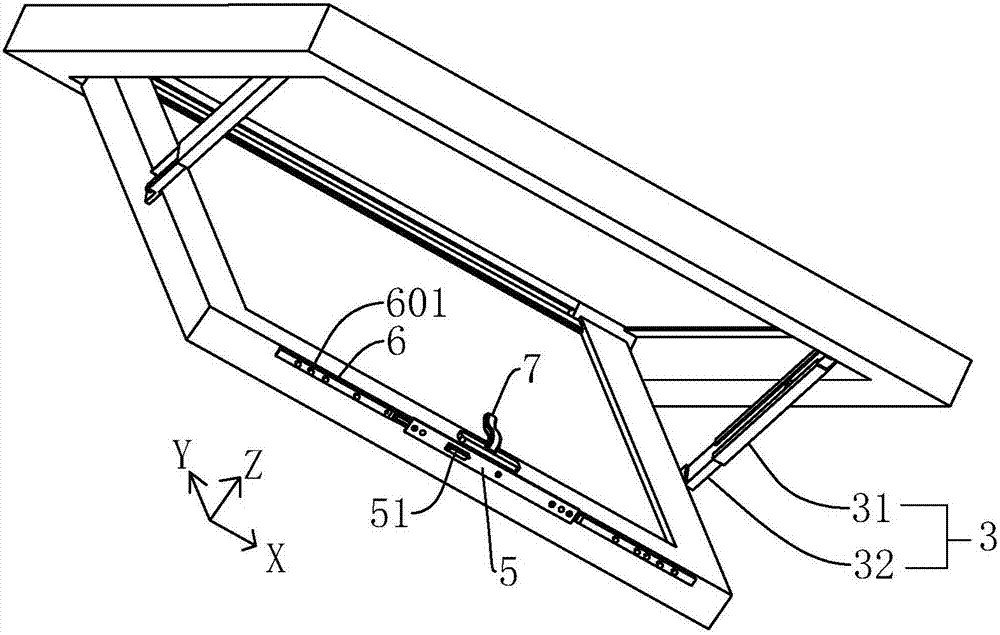

Outward-opening type fire resisting window

The invention discloses an outward-opening type fire resisting window. The outward-opening type fire resisting window comprises a fixing frame and a turning frame, wherein the turning frame is connected in an outward turning mode relative to the fixing frame, and a spring hinge driving the turning frame to close is arranged between the fixing frame and the turning frame; a locking body is arranged at the bottom of the turning frame; a handle and a locking rod are arranged on the turning frame, and the locking rod is driven by the handle to rotate; the locking body comprises a locking case, a rotating piece, a pushing piece and a locking tongue, wherein the rotating piece is driven by the locking rod to rotate; the pushing piece abuts against a clutch of the rotating piece; the locking tongue is connected with the locking case in a slipping mode; the indoor-toward side face of the locking tongue is outdoors inclined ; and a first locking base is arranged on the fixing frame and is used for inserting of the movably locking tongue. When the turning frame is closed relative to the fixing frame, the locking tongue is drawn into the locking case, and the locking tongue is inserted into the first locking base through a first elastic piece, so that automatic locking is achieved.

Owner:南京琪天幕墙科技有限公司

Invisible anti-theft and anti-falling net provided with locking structure and construction method

Owner:安徽长青建筑制品有限公司

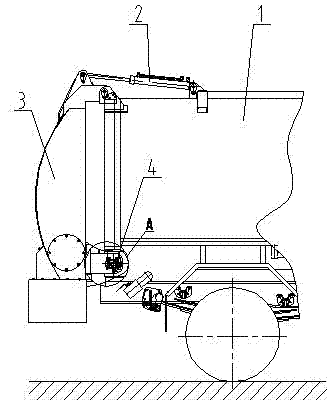

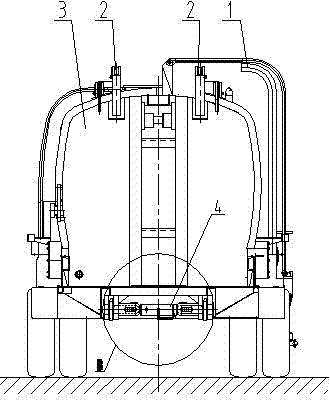

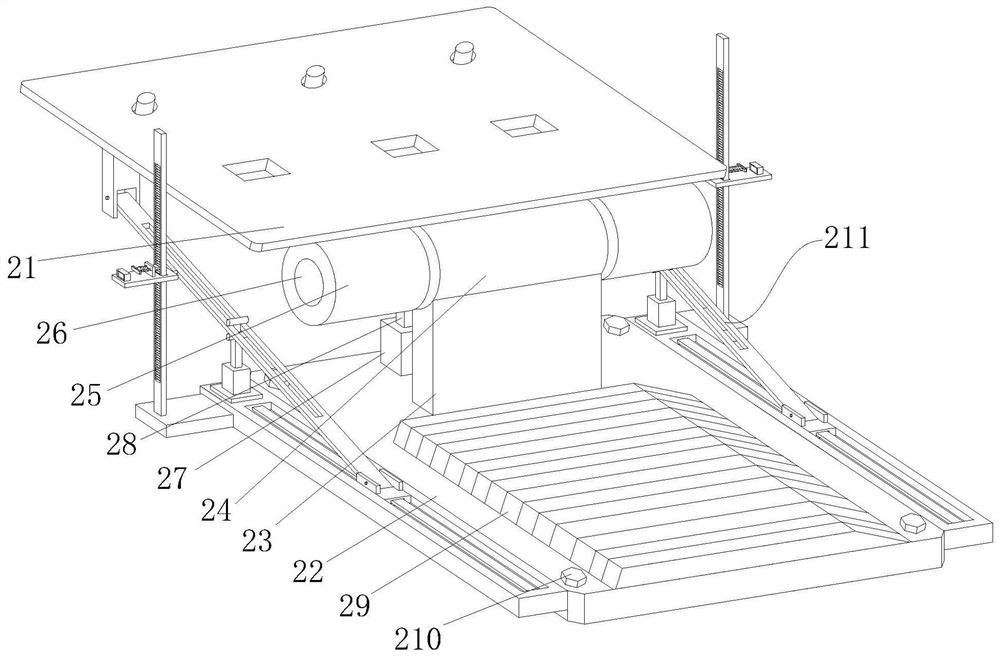

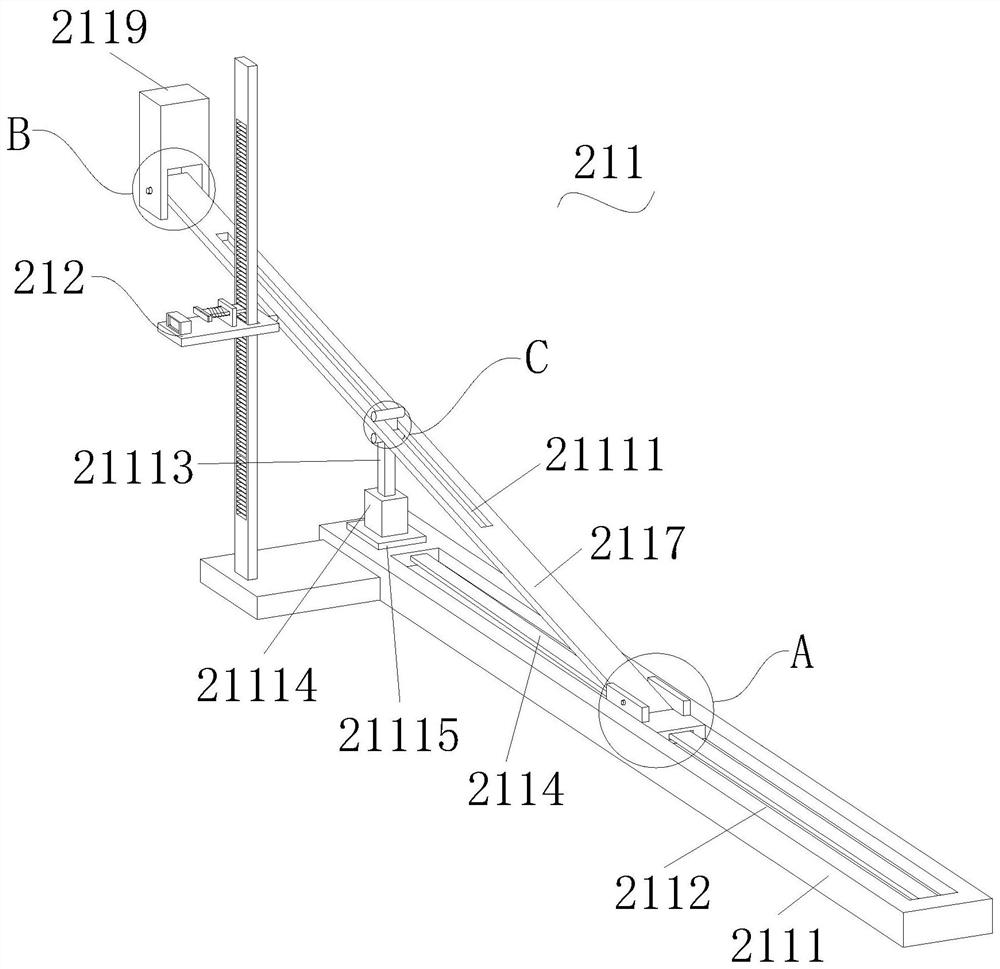

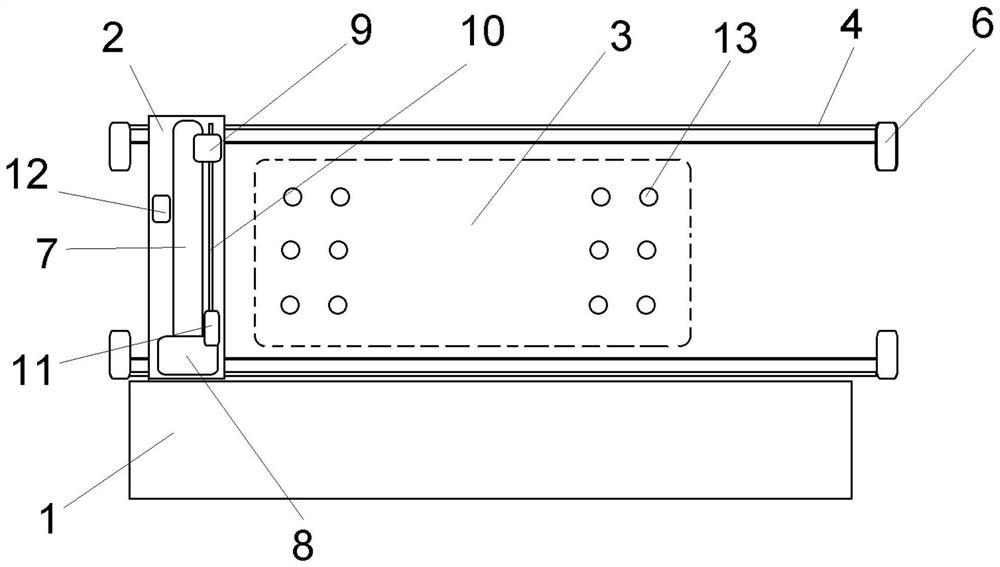

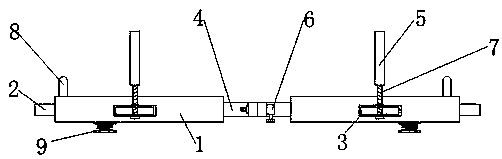

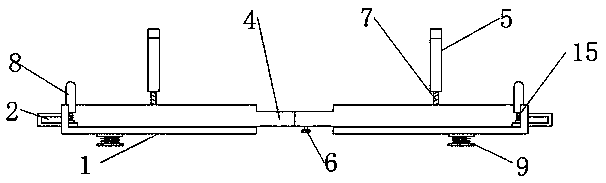

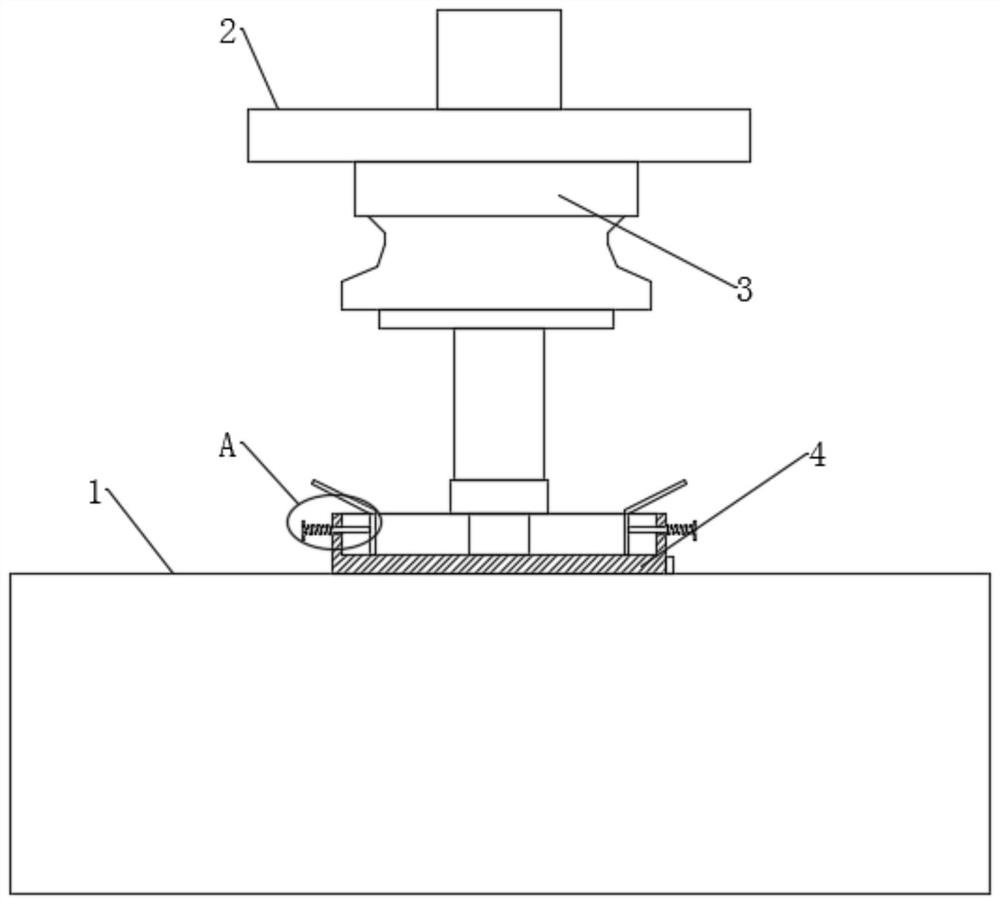

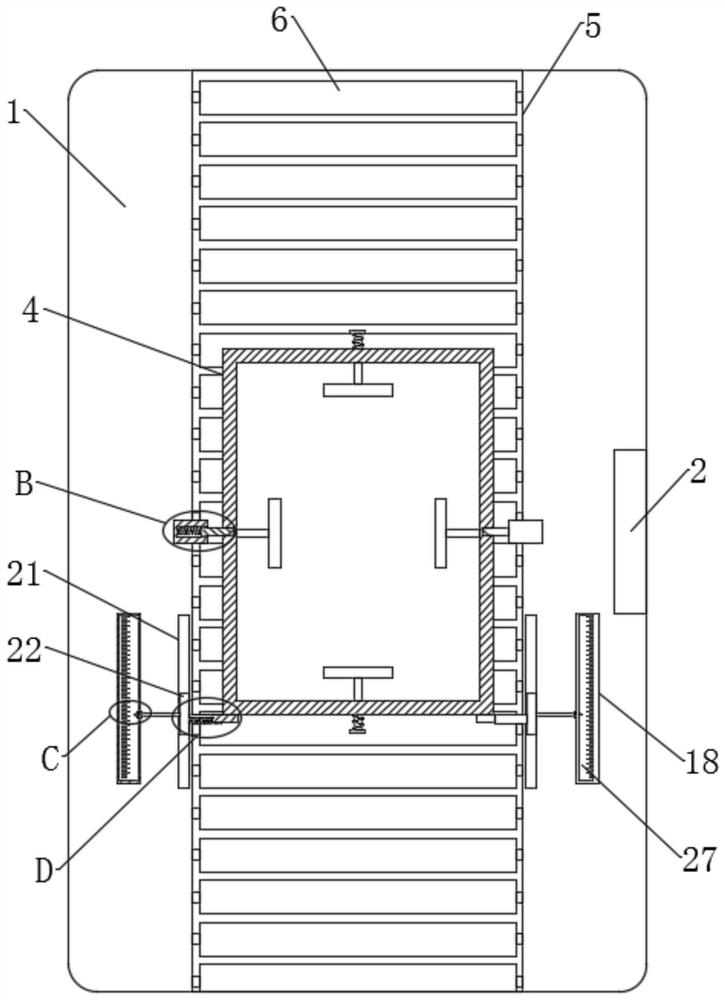

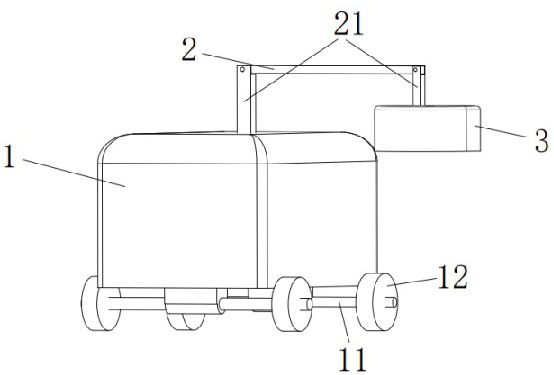

Mobile cast-in-situ bored pile construction platform and method

InactiveCN111851562AEnsure movement stabilityTo achieve the locking effectBridge applicationsBulkheads/pilesArchitectural engineeringStructural engineering

The invention relates to the technical field of bridge construction, in particular to a mobile cast-in-situ bored pile construction platform. The mobile cast-in-situ bored pile construction platform comprises a main trestle, a branch trestle and a continuous construction channel, wherein the main trestle is a horizontal channel bestriding a length direction of a pile foundation construction area and the main trestle is arranged on one side of the pile foundation construction area; the branch trestle is a horizontal channel bestriding the width direction of the pile foundation construction area; any one end off the main trestle is connected to a transportation channel, transverse slide rails in the length direction of the main trestle are arranged at the bottoms of two ends of the branch trestle, and the branch trestle moves freely on the transverse slide rails through a driving device; and the continuous construction channel is formed by the end, close to the main trestle, of the branch trestle and the main trestle. According to the mobile cast-in-situ bored pile construction platform, an existing cast-in-situ bored pile construction mode is improved, so that the use level of materials is reduced and the steps are simplified. Furthermore, the cost is lowered and the construction efficiency is improved.

Owner:CHONGQING COMM CONSTR GRP +1

Self-expanding shooting nail for fixing connecting piece

The invention discloses a self-expanding shooting nail for fixing a connecting piece. The self-expanding shooting nail for fixing the connecting piece comprises an expanding spring ring and a shootingnail; and the shooting nail comprises a nail cap, an expanding nail rod, a transition nail rod and a nail head which are connected in sequence. The self-expanding shooting nail for fixing the connecting piece has the beneficial effects that when a shooting nail is shot into a main substrate, the expanding spring ring enters the main substrate along with the shooting nail until a stop clamping position is in contact with the surface of the substrate, and the shooting nail continues going forwards under force; when the shooting nail continues going forwards to enter the main substrate, a rod part of the expanding nail starts to enter and extrude the expanding spring ring, and the expanding spring ring starts to expand outwards unit the nail cap is in contact with the stop clamping position;the sum of the thickness of a double-layer wall of the expanding spring ring and the diameter of the expanding nail rod is 0.2 mm greater than the maximal diameter of the nail head, so that interference of 0.2 mm is generated between the expanding spring ring and the main substrate, and meanwhile, each of the expanding nail rod and a spring body part is provided with a retreating stop ring to prevent the expanding nail rod and the expanding spring ring from displacing, so that a locking effect is achieved, and the connecting piece is prevented from falling off.

Owner:SICHUAN SHENGYAKAI CO LTD

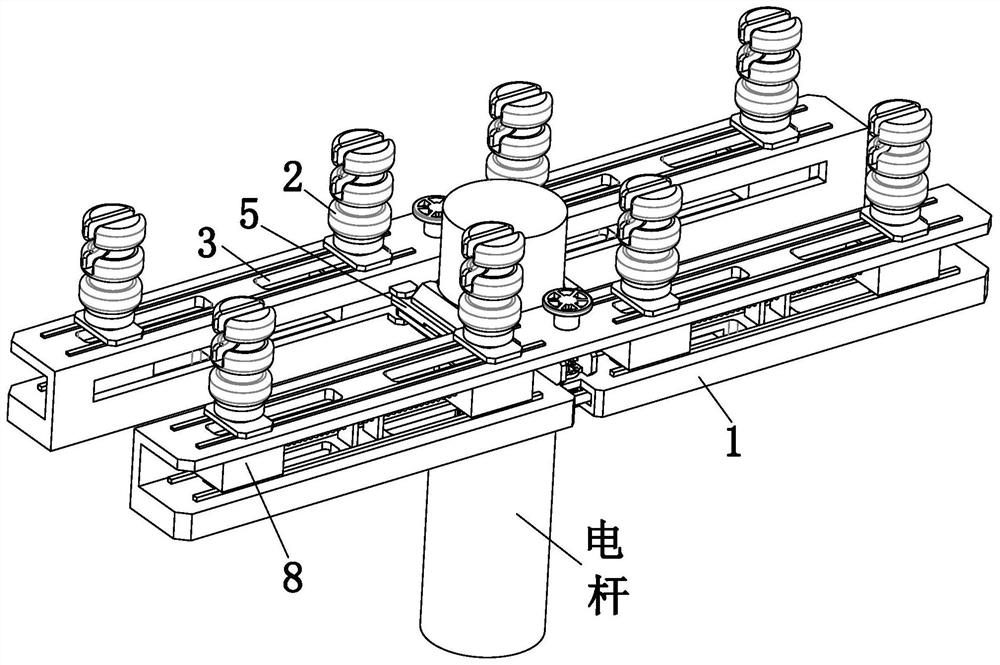

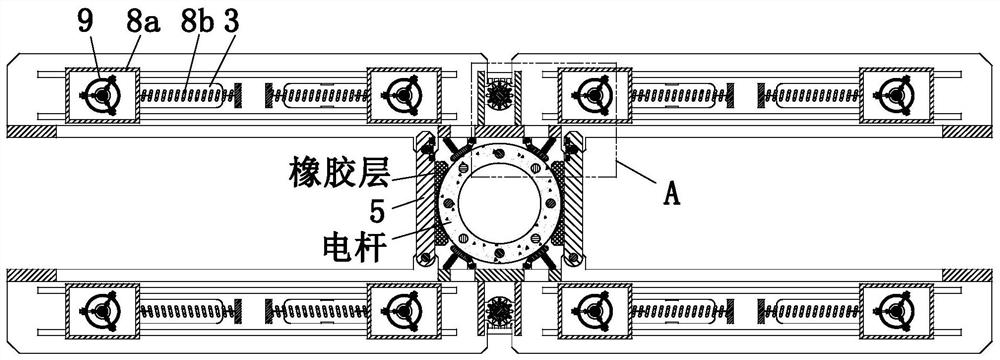

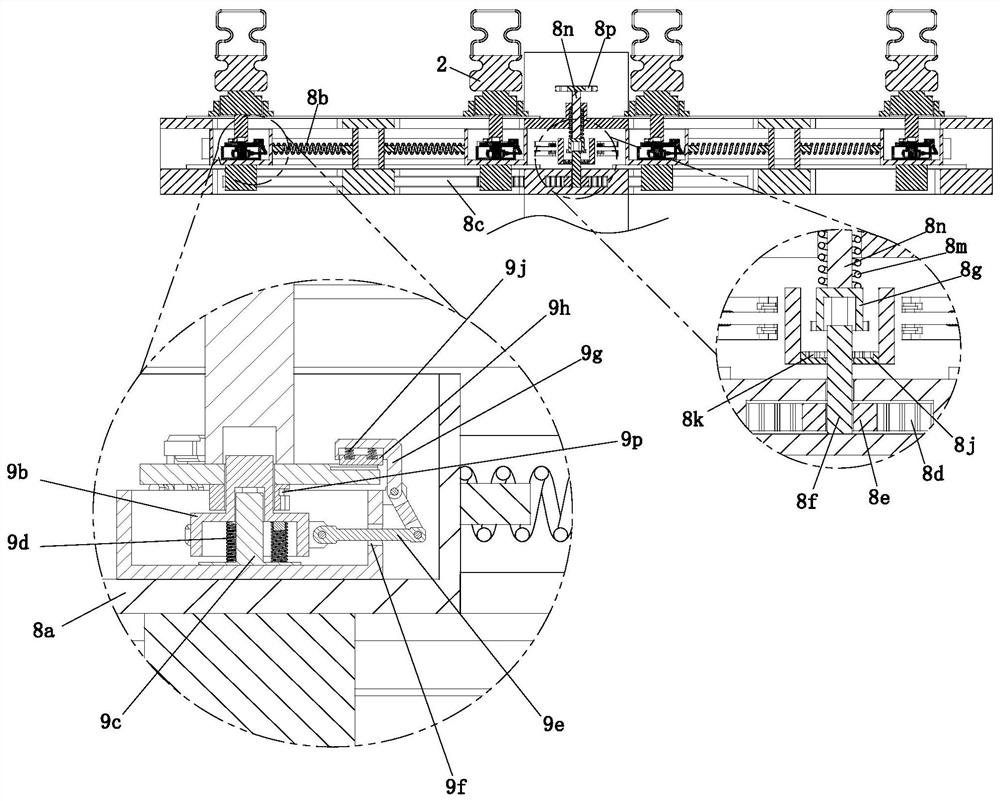

High-voltage overhead line power cross arm

ActiveCN112909871AImprove stabilityReduce workloadSuspension arrangements for electric cablesTowersCable harnessControl theory

The invention provides a high-voltage overhead line power cross arm which comprises a mounting frame, an insulator, a shifting sliding groove, a clamping rotating shaft, a clamping rotating rod, a clamping sliding block, a clamping spring, a shifting mechanism, a positioning mechanism, a supporting seat and a supporting spring. The problems that an existing high-voltage overhead line power cross arm is usually formed by assembling and splicing a single steel structure truss, the spacing distance between insulators is difficult to adjust according to the specification of an actually-installed wire harness to keep a certain safe distance, the power cross arm is always in high-altitude operation during installation and fixation, the number of supporting frames needing to be assembled and fixed is large, the work intensity and work amount of installation work of workers are increased, insulators on the electric power cross arm are generally fixedly installed, special disassembly tools are needed when the insulators are damaged and need to be replaced, the manual work amount is large, and the work efficiency of insulator disassembly and installation work is difficult to improve are solved.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD NANTONG POWER SUPPLY BRANCH

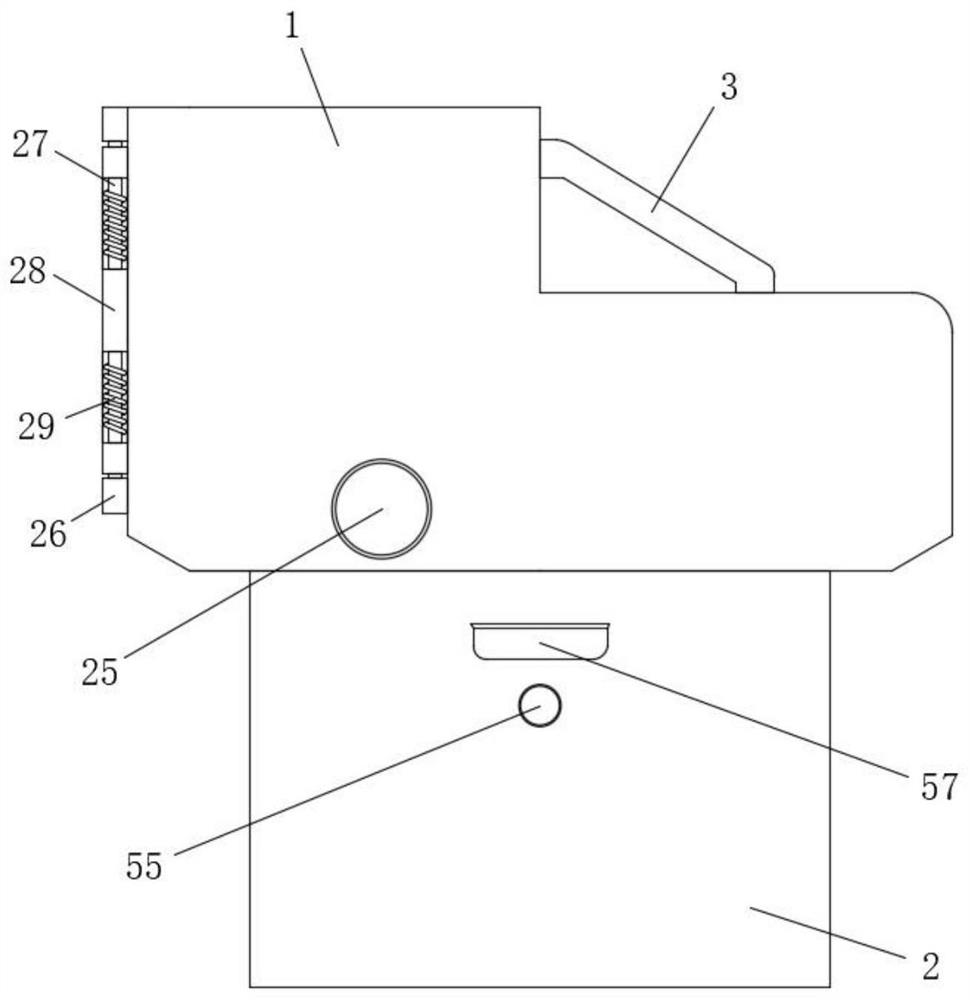

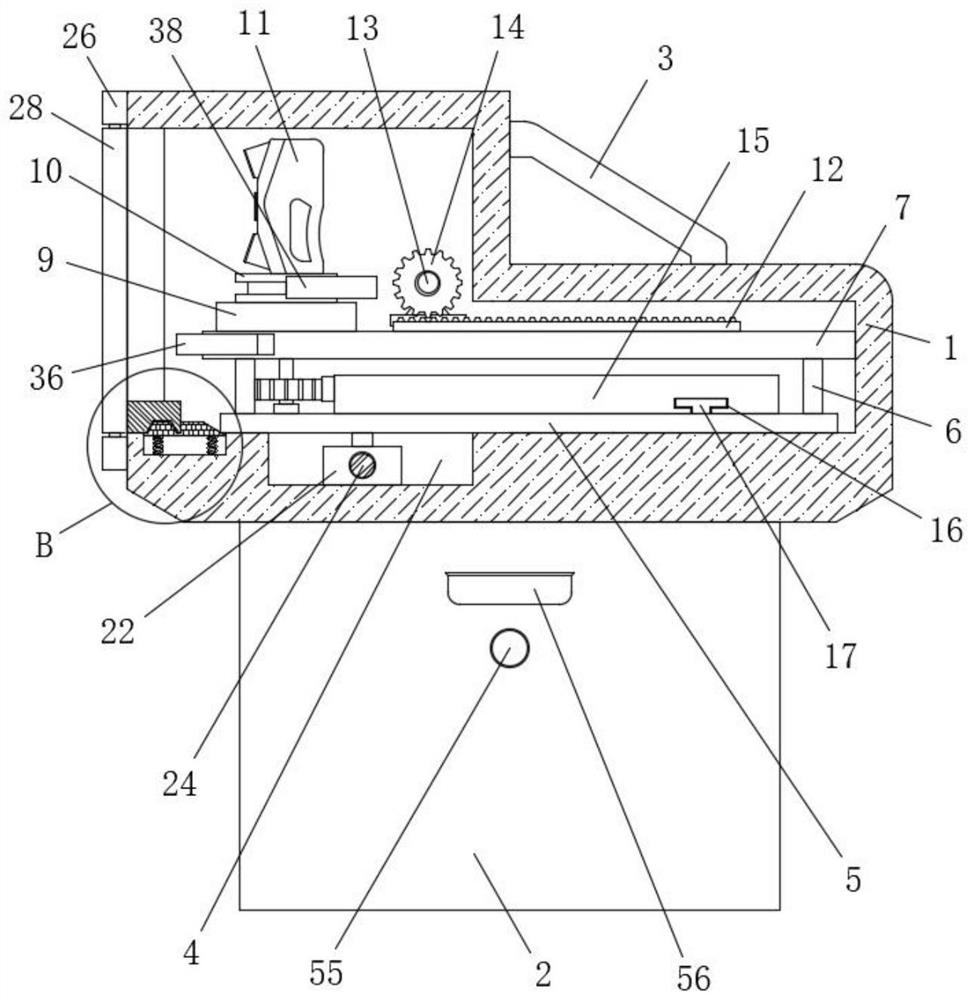

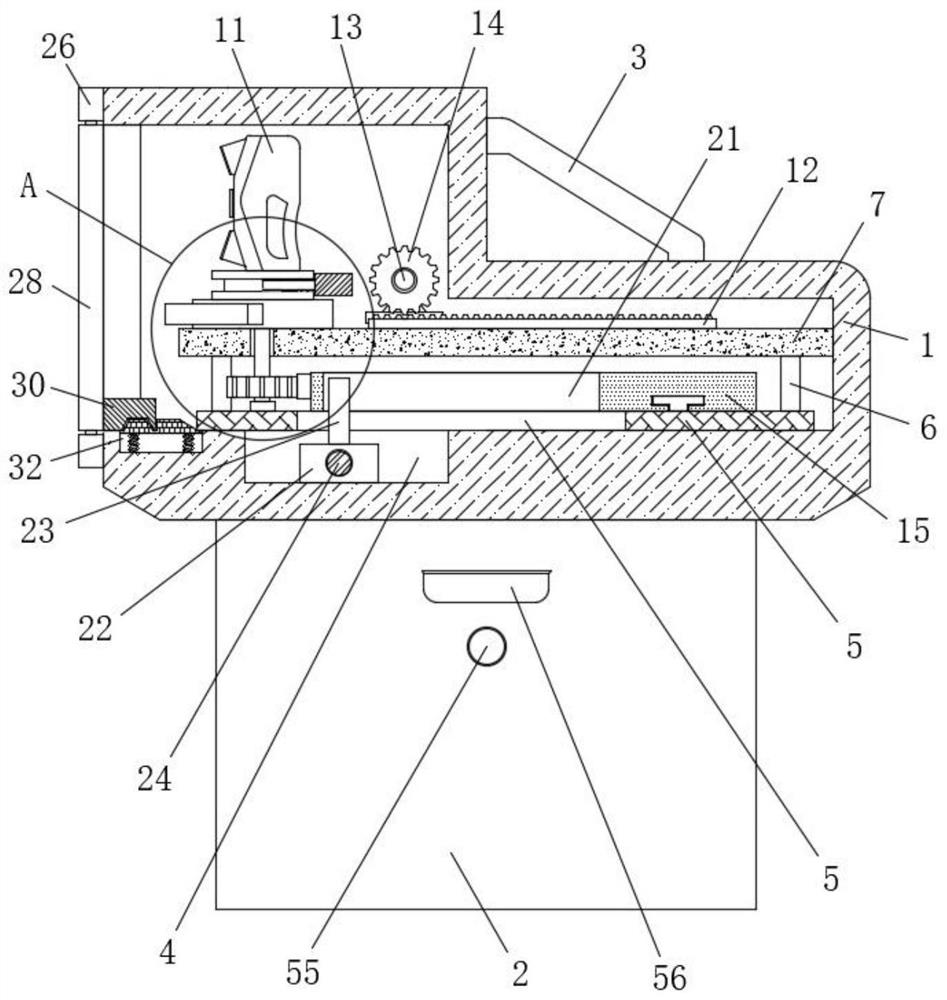

Laser three-dimensional medical image acquisition device

InactiveCN112890778AEasy to useEasy to storeSurgical furnitureDiagnostic recording/measuringApparatus instrumentsImage acquisition

The invention belongs to the technical field of medical instruments, and particularly relates to a laser three-dimensional medical image acquisition device. The device comprises a storage box and a supporting box which is slidably connected to the outer wall of the bottom of the storage box, wherein a bottom plate is slidably connected to the inner wall of the bottom of the storage box, connecting columns are fixedly connected to the four corners of the top of the bottom plate, the same top plate is fixedly connected to the top ends of the four connecting columns, and a rotating shaft is rotatably connected to one side of the top of the bottom plate. Accordingly, by means of the storage box, the effect of facilitating storage of a laser three-dimensional image acquisition device body can be achieved, and the storage stability is good; meanwhile, the automatic door opening and closing function and the box door self-locking function are achieved, the convenience, practicability and safety are greatly improved, the automation degree is high, the manual operation steps are reduced, and time and labor are saved; and the use angle and height of the whole device can be adjusted, the adjustment flexibility is high, the precision is high, placement and use in different environments are facilitated, and use is convenient.

Owner:彭清莲

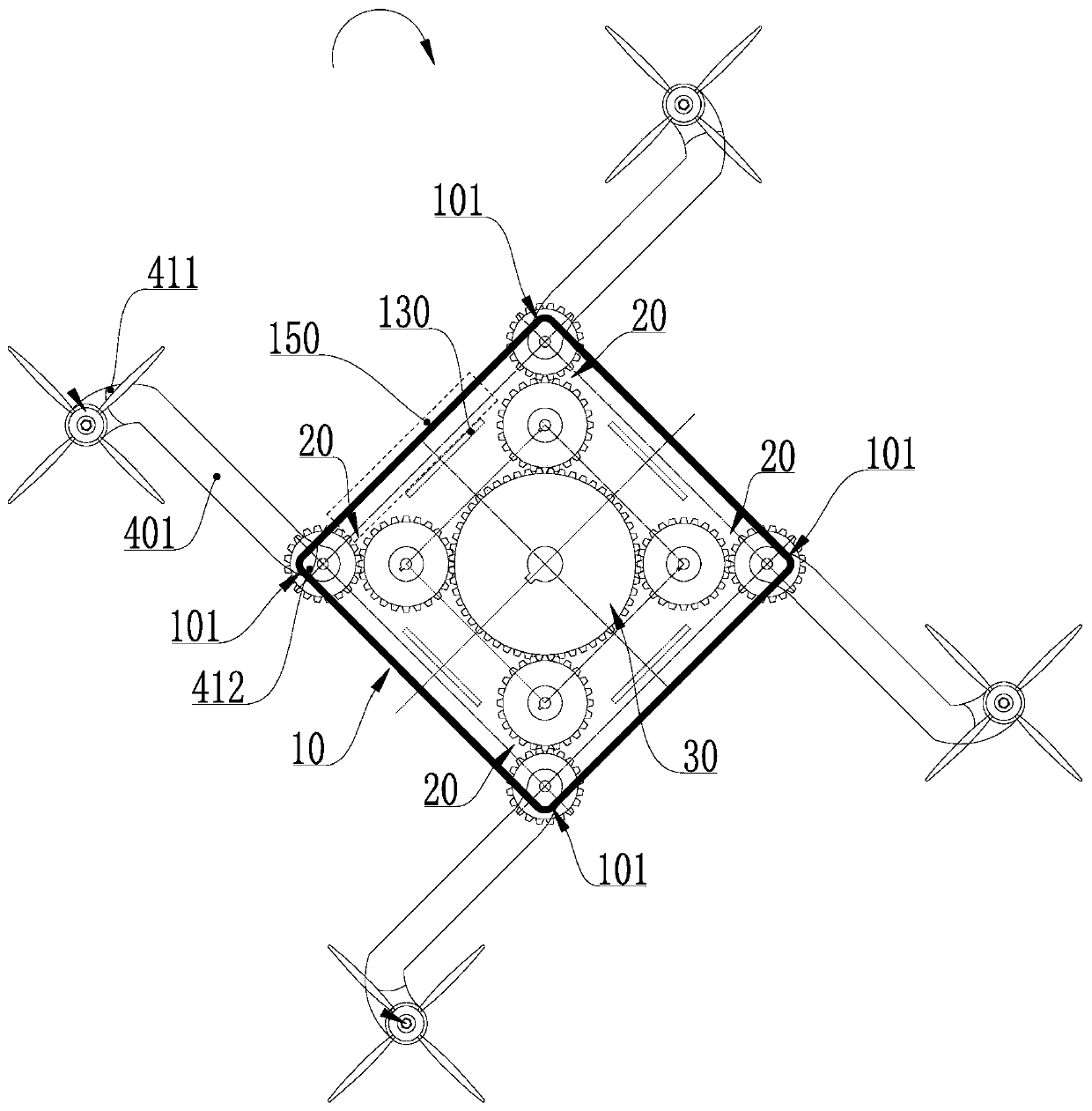

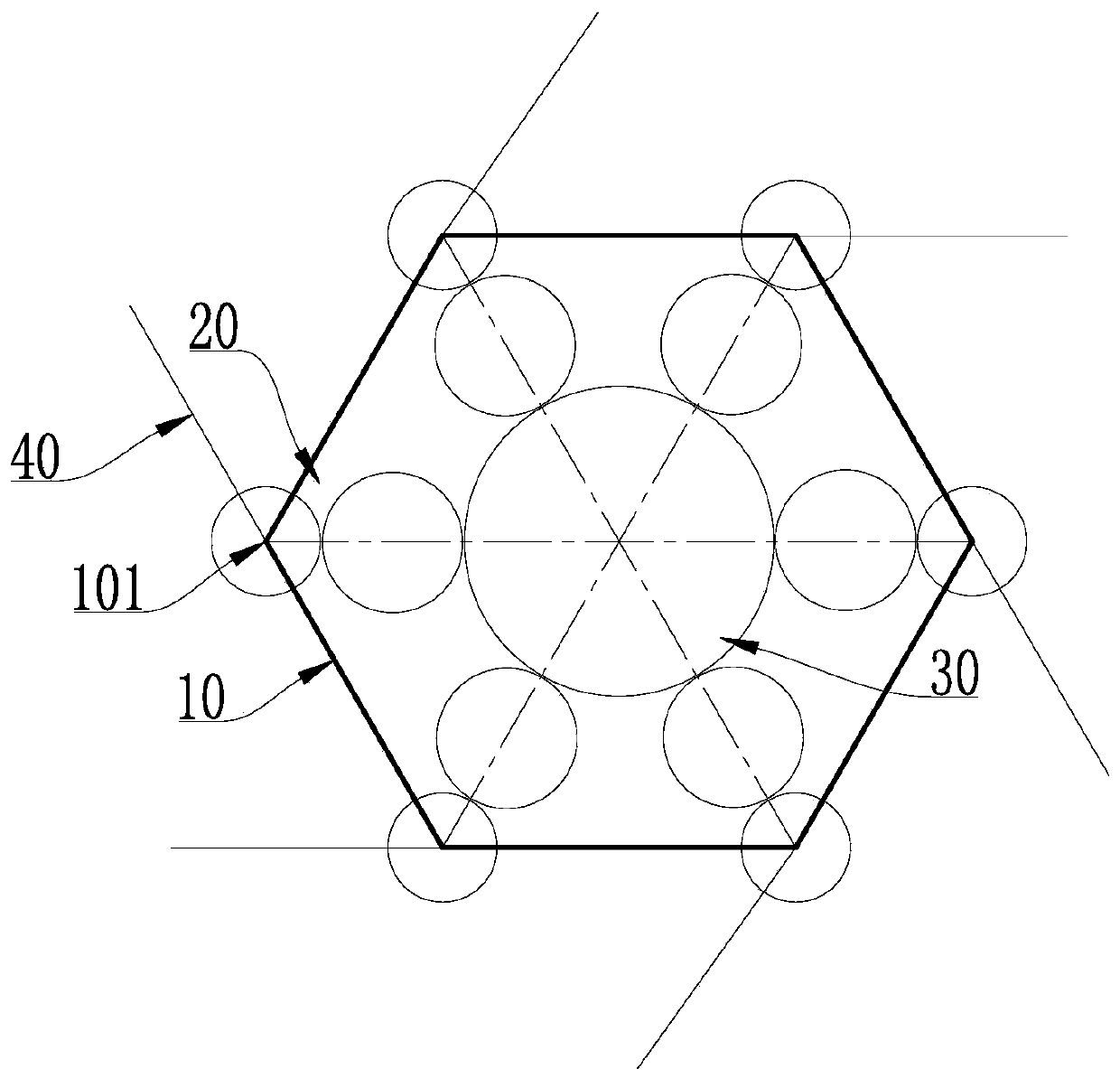

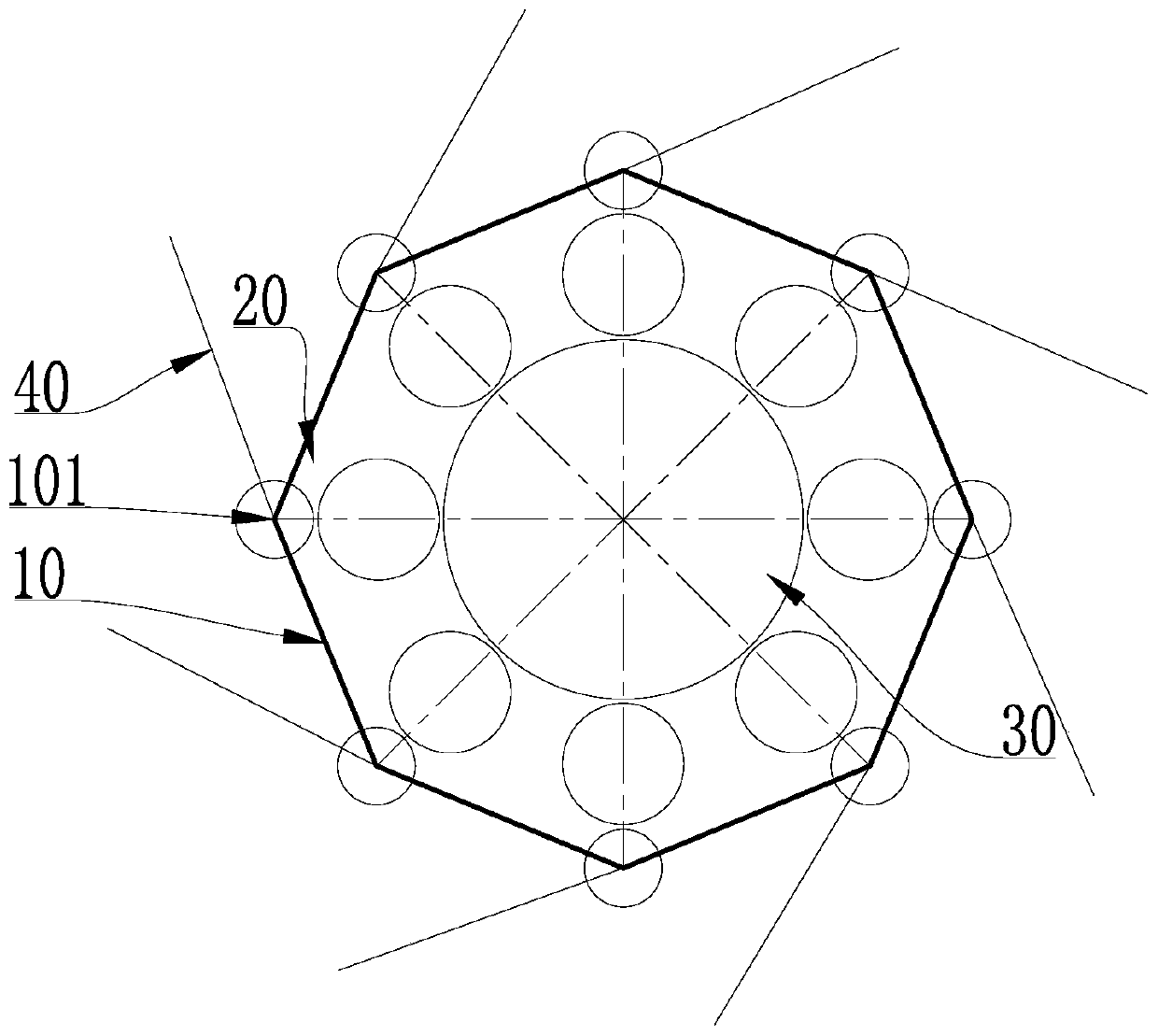

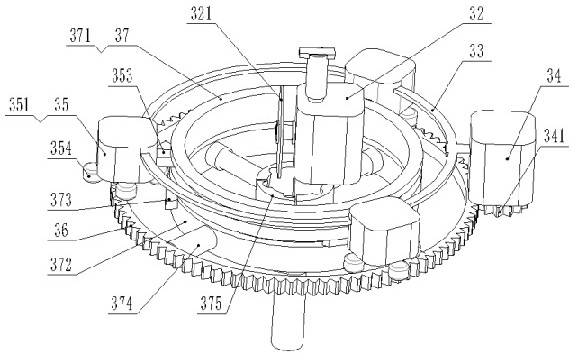

Engine arm synchronous rotation structure and industrial unmanned aerial vehicle with same

PendingCN109911171AReduce volumeImprove foldabilityFuselage framesAir-flow influencersLocking mechanismHelicopter rotor

The invention is an engine arm synchronous rotation structure and an industrial unmanned aerial vehicle with the engine arm synchronous rotation structure, relates to the technical field of industrialunmanned aerial vehicles, and solves the technical problem that the disassembly of the unmanned aerial vehicle wastes operation time. The engine arm synchronous rotation structure comprises a frame body structure, auxiliary transmission mechanisms, a main transmission mechanism, engine arm bodies, and a locking mechanism; the main transmission mechanism is arranged in the middle of the frame bodystructure and is used for simultaneously controlling all the auxiliary transmission mechanisms to rotate in a driving manner; one ends of the engine arm bodies are used for connecting rotor wings, and the other ends are fixedly connected with a group of auxiliary transmission mechanisms; the frame body structure and the engine arm bodies have a folding state and an unfolding state, and the locking mechanism is used for keeping the frame body structure and the engine arm bodies in the folding state or the unfolding state. The engine arm synchronous rotation structure and the industrial unmanned aerial vehicle with the engine arm synchronous rotation structure have the advantages that the operation is fast, no complicated disassembly steps are needed, the operation time is saved, and convenient accommodation and storage are realized.

Owner:杜双昱

Battery supporting device applied to new energy automobile

ActiveCN110525189AEasy to fixEasy to disassembleNon-rotating vibration suppressionElectric propulsion mountingElectrical batteryNew energy

The invention discloses a battery supporting device applied to a new energy automobile. The battery supporting device comprises a main plate, an auxiliary fixing block, connecting rods, a regulating rod, a locking device, a positioning pin, a shock absorber, a skid-proof plate and a rotating rod; one end of the main plate is fixedly provided with a side fixing block; the locking device is arrangedat the ends, far away from the main plate, of the connecting rods and is connected between the two connecting rods; a screw rod vertically penetrates through the auxiliary fixing block; a bolt is horizontally installed between the two connecting rods; the skid-proof plate is arranged at one side, far away from the side fixing block, of the positioning pin; a spring is installed at one end, closeto the main plate, of the positioning pin; the spring is connected between the positioning pin and the main plate; the connecting rods and the regulating rod are arranged for improving the fixation effect, on a battery, of the battery supporting device; the locking device and the screw rod are used for convenient dismounting and replacement of the battery supporting device; gear engagement transmission of the locking device is convenient to operate; the skid-proof plate improves the stability of the battery supporting device; and the shock absorber can realize better protection for a battery component.

Owner:新昌县镇辉机械厂

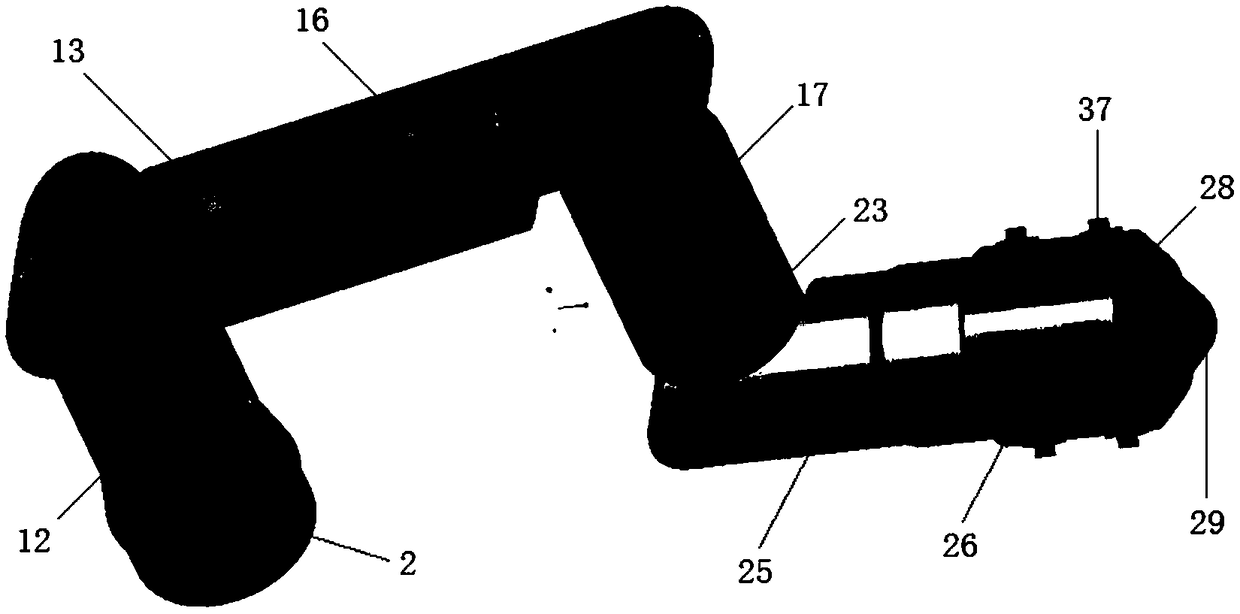

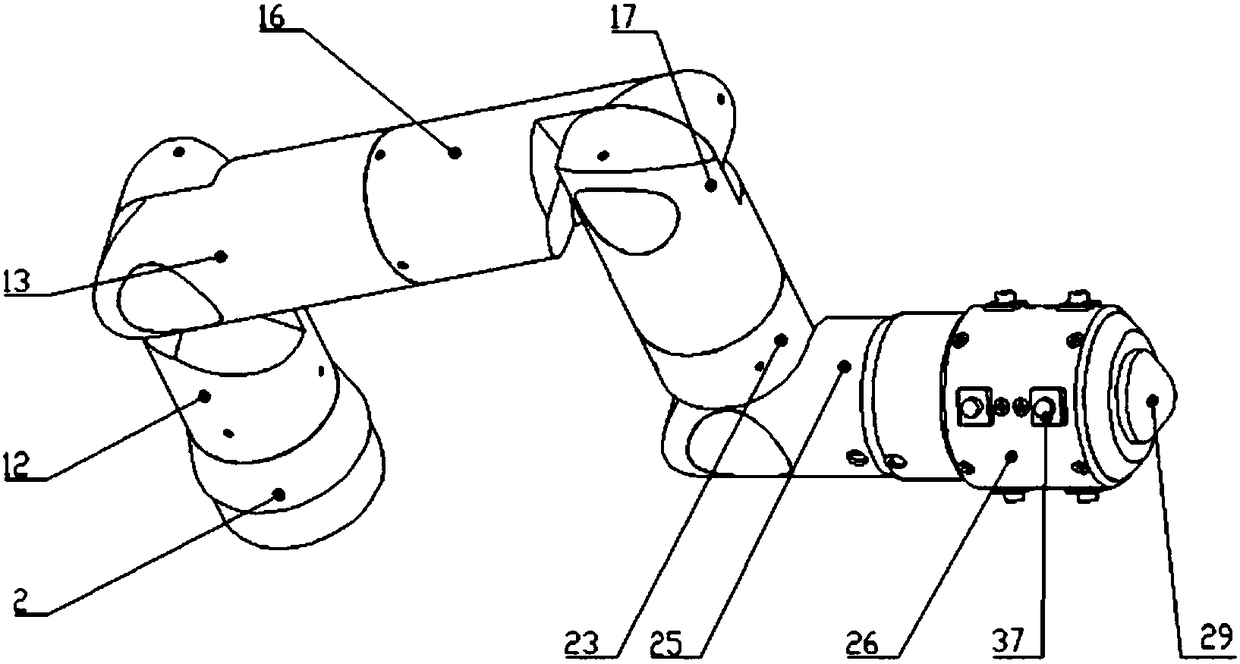

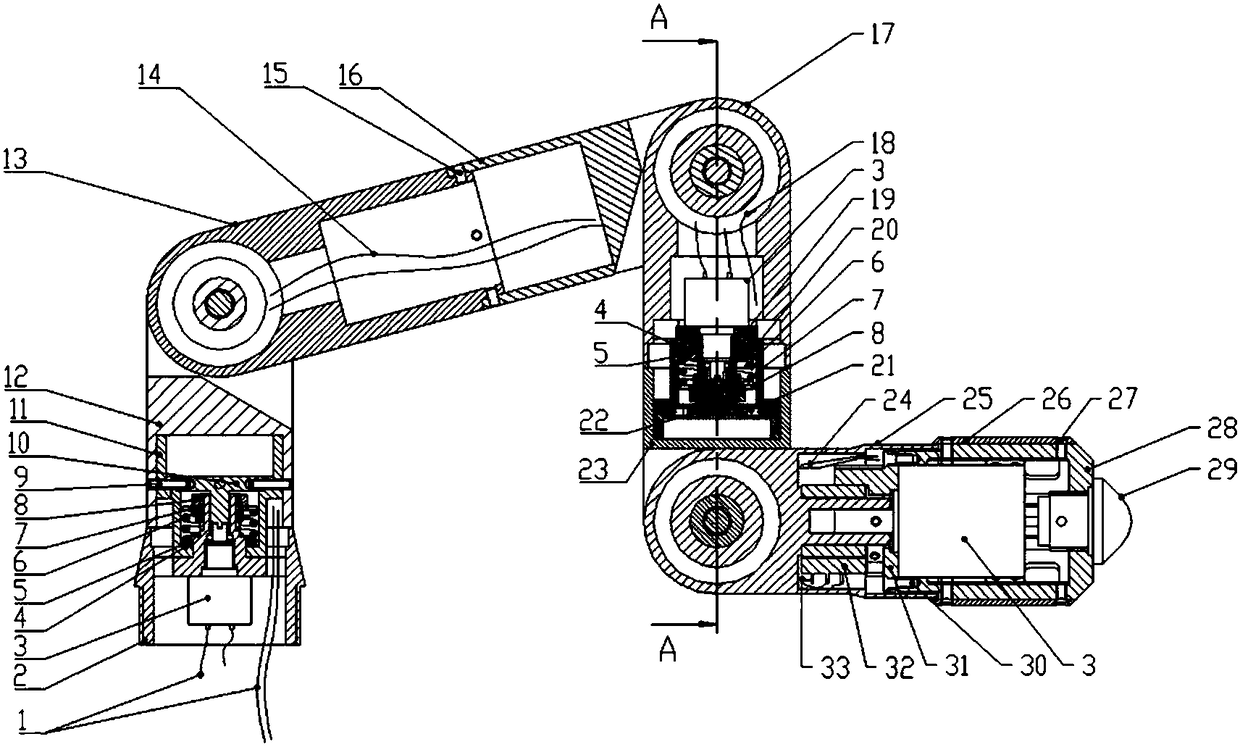

Six-degree-of-freedom control handle

The invention discloses a six-degree-of-freedom control handle. The six-degree-of-freedom control handle comprises a base, a shoulder joint, a large arm joint, a small arm joint, an elbow joint, a wrist joint, a hand claw and sensors. The base, the shoulder joint, the large arm joint, the small arm joint, the elbow joint and the wrist joint are connected mutually and sequentially through rotatingshafts in a two-by-two mode, and do swing movement through the rotating shafts in the two-by-two mode. The sensors are inlaid in the rotating shafts and used for collecting angle signals of swing movement. The wrist joint and the hand claw are connected through the rotating shafts and can do 360-degree continuous rotation, and the sensors are arranged on the rotating shafts and used for obtainingthe angle signal of relative rotating between the wrist joint and the hand claw. The six-degree-of-freedom control handle is provided with the multiple joints and has multiple degrees of freedom and multiple functions, operation and control are flexible, reliability is high, the attractive and elegant effects are achieved, complex control signals can be obtained through simple operation, and the six-degree-of-freedom control handle is especially suitable for master-slave control operation of industrial mechanical arms and underwater mechanical arms.

Owner:SHANGHAI OCEAN UNIV

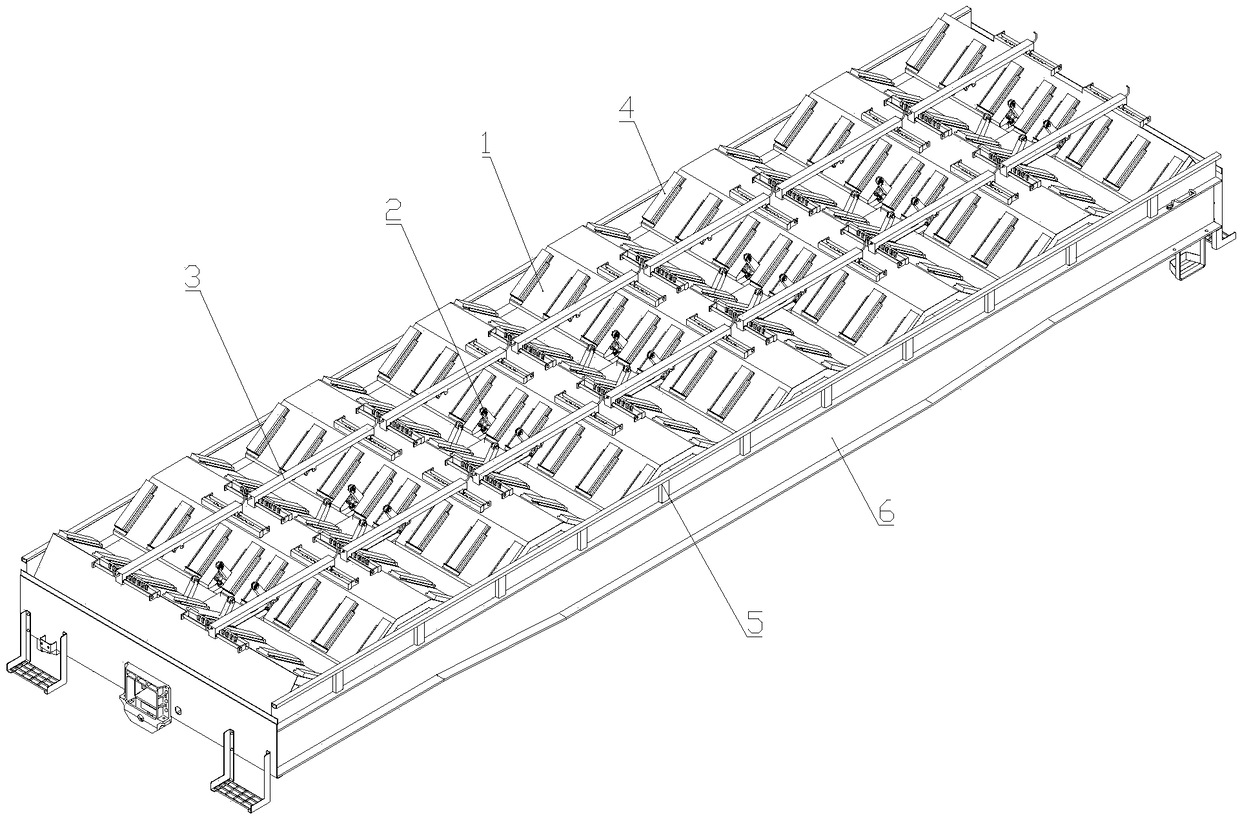

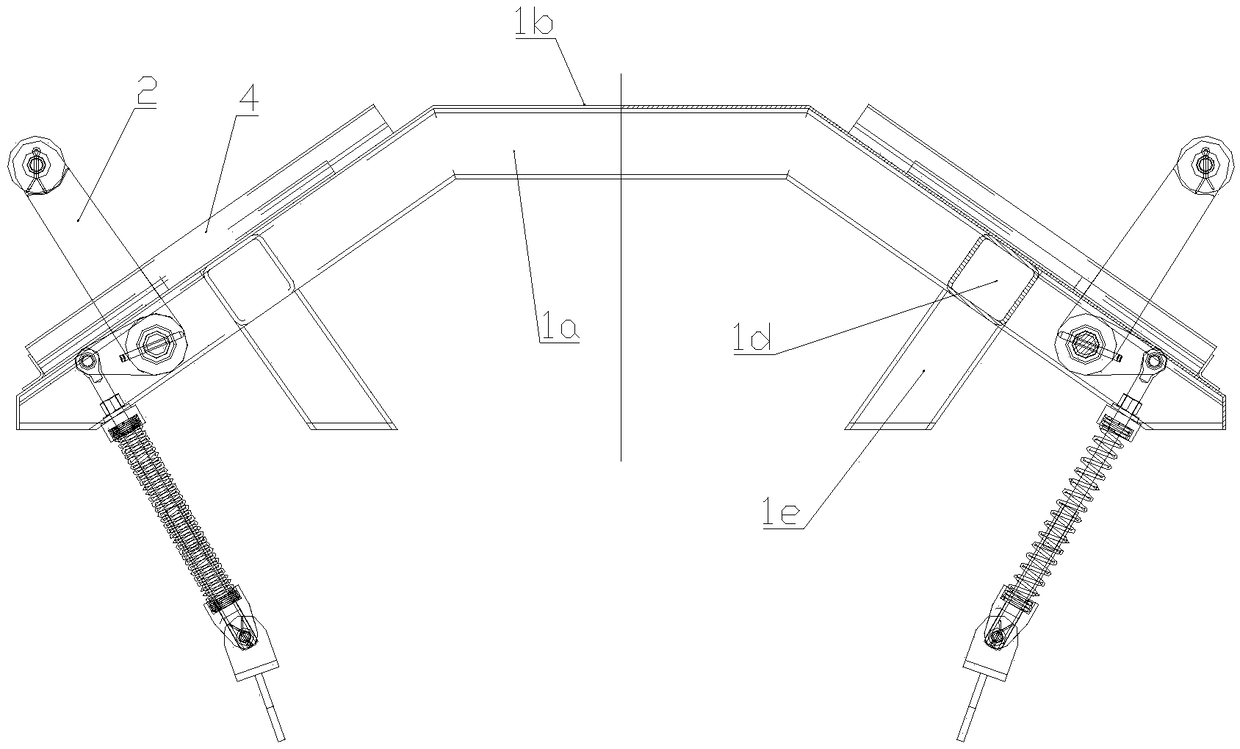

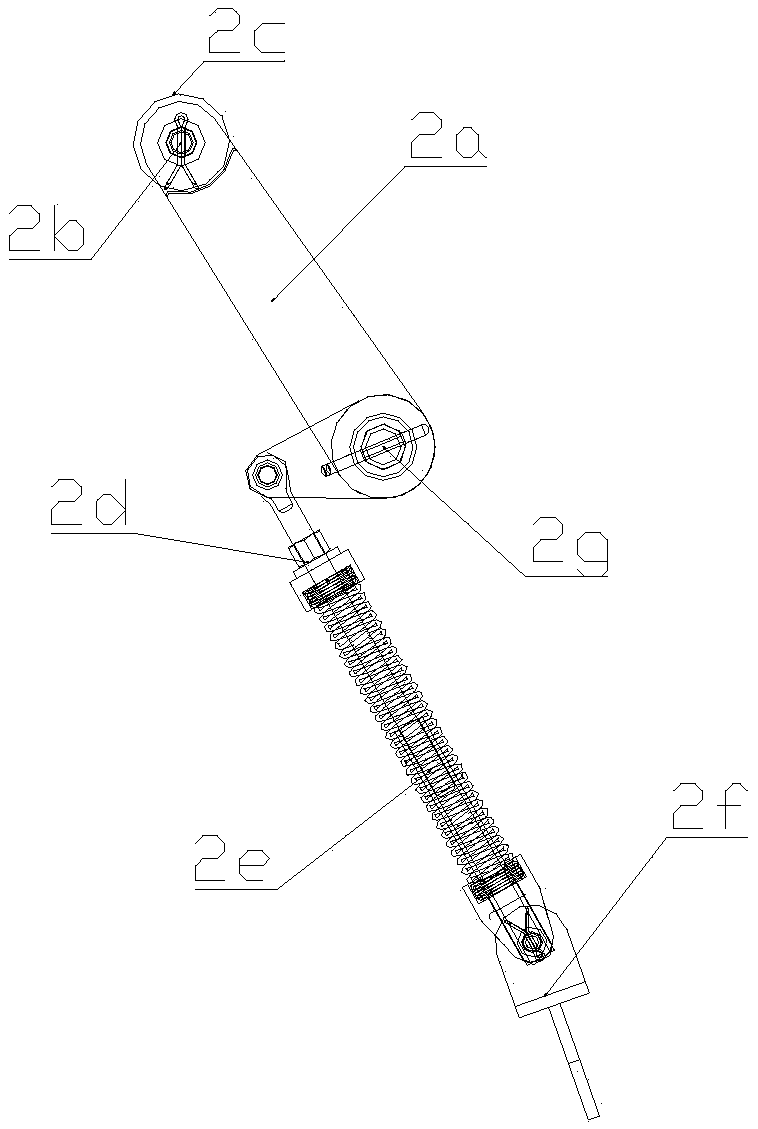

A special railway transport frame for coil materials

ActiveCN108974038AImplement horizontal positioningCreate pollutionUnderframesRailway transportVehicle frameTruck

The invention discloses a special railway transport frame for coil materials and with a transverse positioning device. which comprises a chassis of a flat truck, wherein trapezoidal grooves are arranged on the chassis at intervals, automatic transverse positioning devices are arranged on the inclined surfaces of the trapezoidal grooves, and the automatic devices are crank-link structures arrangedunder the inclined surfaces of the trapezoidal grooves, and telescopic stopper arms can be protruded through the openings arranged on the inclined surfaces for fixing the coils; A manual lateral position device is arranged at that top of the trapezoidal groove, and the manual device is arrange between the top of the trapezoidal groove, and comprises a stopper rod movable and fixed along the top ofthe trapezoidal groove and for fixing the coil material; A trapezoidal groove surface is also provided with a cushioning device. The invention realizes the positioning of various plate wide coil steels by the mutual cooperation of the automatic and manual transverse positioning devices, meets the transportation requirements of high-temperature coil materials, and the cushioning device can be disassembled and replaced. A manual device of that invention can realize unlock and locking by pul the handle on either side, and the automatic device does not need to operate and can meet the fixing or release operation of the coil material with different specifications.

Owner:CRRC MEISHAN

Novel door opening device and application method thereof

InactiveCN109113437ASimple structureEasy to operateNon-mechanical controlsElectric permutation locksDrive shaftPassword

Owner:屠建芳

Convenient-to-assemble photovoltaic module mounting structure

InactiveCN112564605APrevent rotationTo achieve the locking effectPhotovoltaic supportsSolar heating energyMaterial resourcesStructural engineering

The invention discloses a convenient-to-assemble photovoltaic module mounting structure, which comprises two vertical pipes arranged in a front-back symmetrical manner, lifting rods are slidably connected to the tops of the two vertical pipes, the bottom ends of the two lifting rods penetrate through the vertical pipes and extend into the vertical pipes, and a photovoltaic panel is movably connected between the top ends of the two lifting rods. And a lifting mechanism is arranged in the front side vertical pipe. The convenient-to-assemble photovoltaic module mounting structure relates to the technical field of photovoltaic power generation. According to the photovoltaic module mounting structure convenient to assemble, by pressing down a pressing block, the pressing block drives a slidingrod to slide downwards along the inner surface of a second through groove, and meanwhile, a spring is extruded to further pull a fixing block, so that a transverse pipe slides along the inner surfaceof a first through groove, and finally, the transverse pipe is separated from the lifting rods and a rotating seat; and through the arrangement of a disassembly and assembly mechanism, disassembly andassembly of the photovoltaic panel are facilitated, time and labor are saved, the working efficiency is improved, waste of manpower and material resources is avoided, and the practicability is very high.

Owner:司徒玮

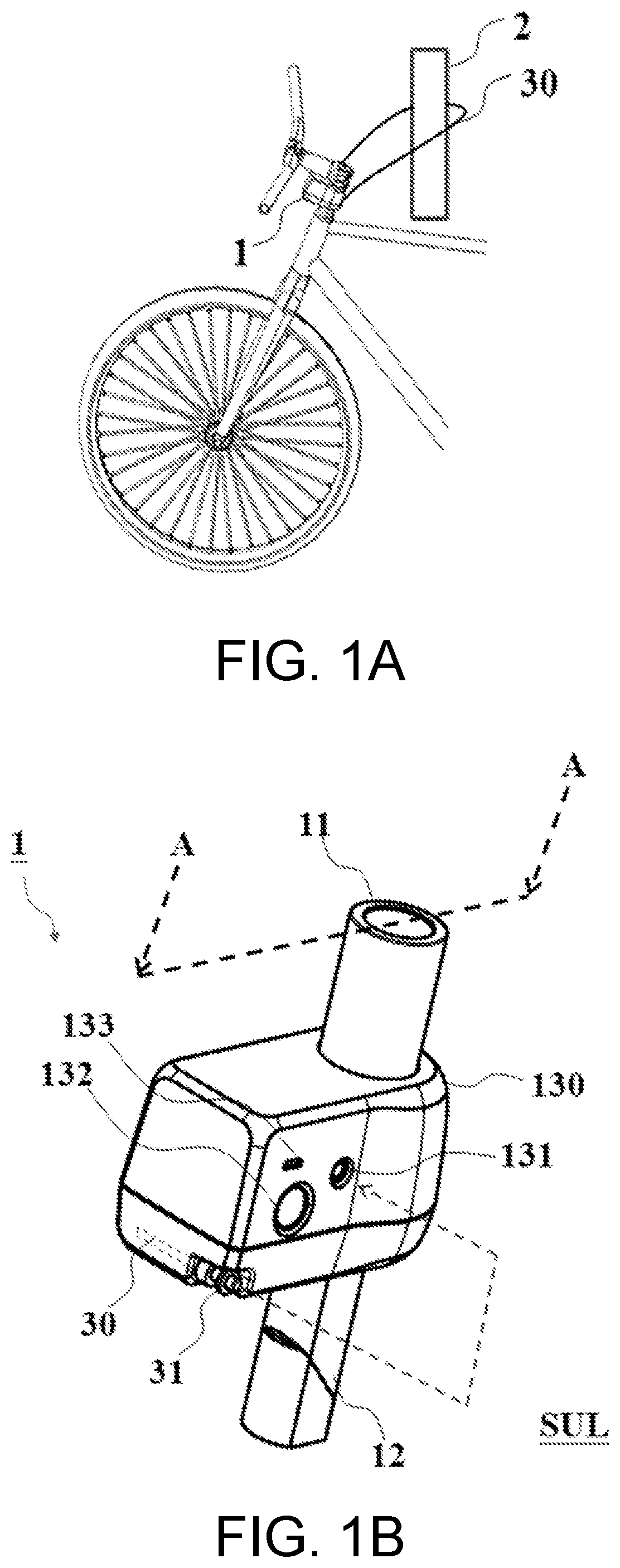

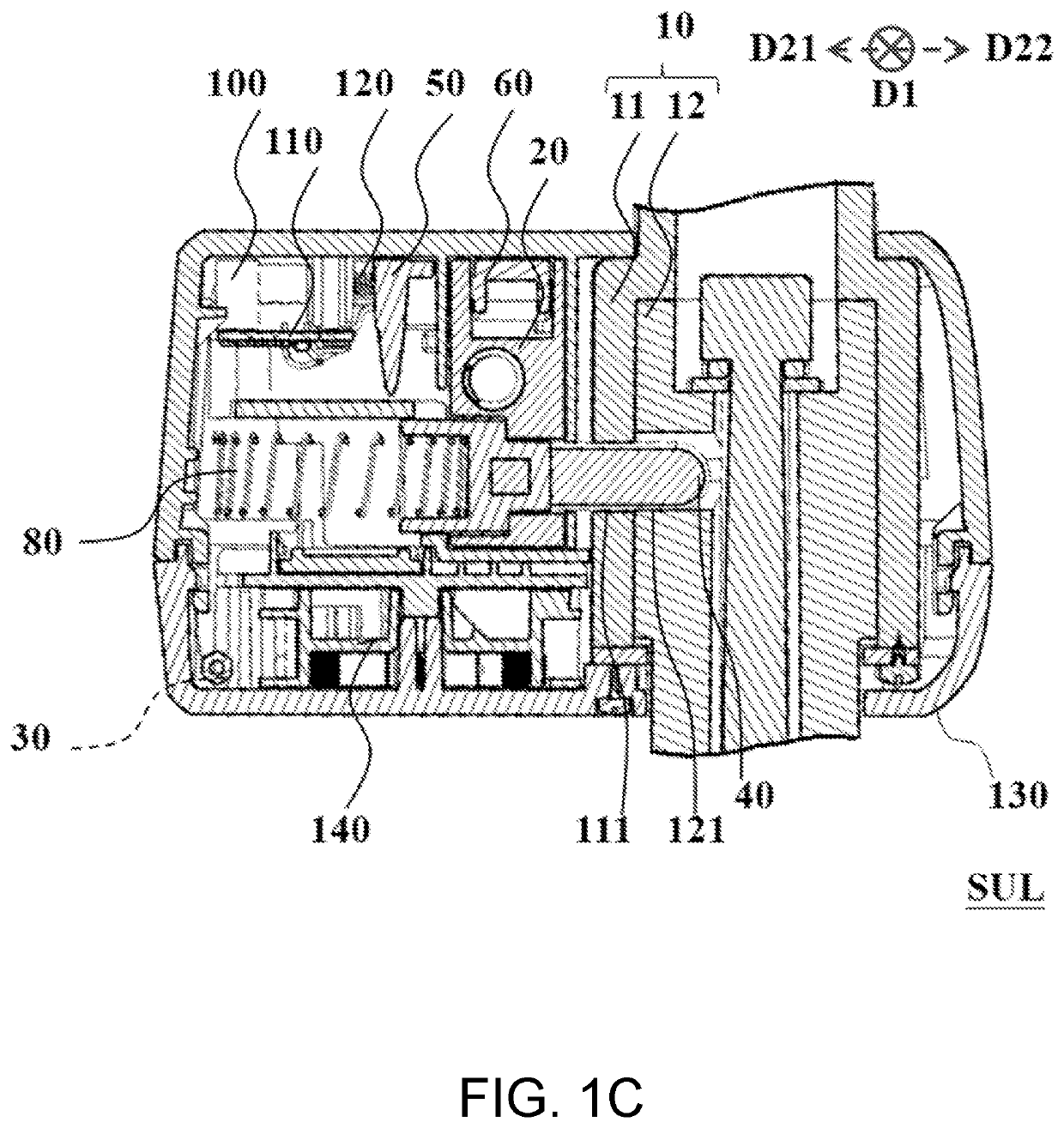

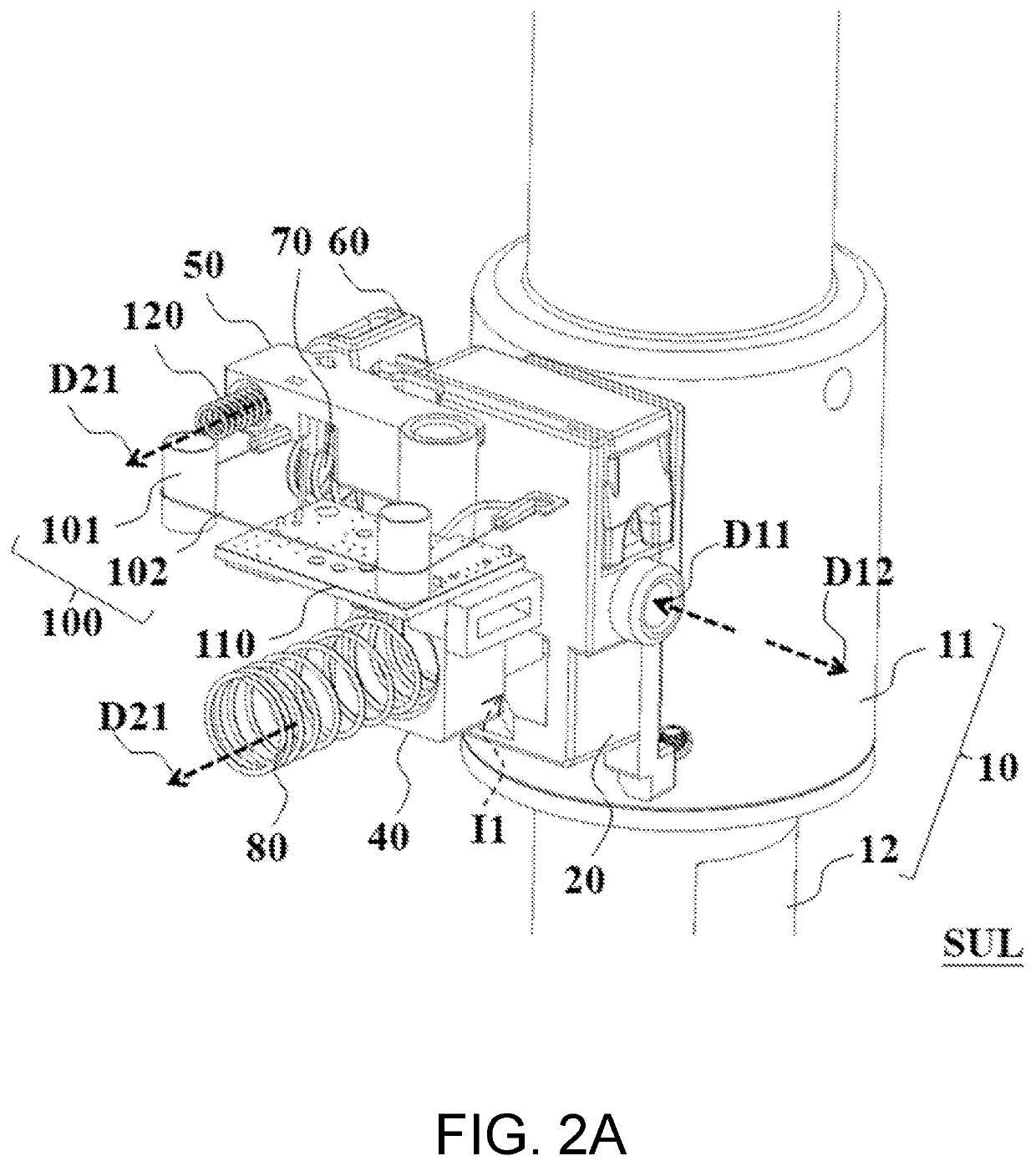

Lock

ActiveUS20220017169A1Avoid damageAvoid problemsBicycle locksAnti-theft cycle devicesStructural engineeringMechanical engineering

A lock for locking a bike is provided. To lock the bike, a user inserts a rope head into a lock through a lock hole. The rope head drives a slider in the lock, and the slider drives a pin, causing an upper-rotation shaft of the lock become not linked to move with a lower-rotation shaft of the lock. Since the upper-rotation shaft and the lower-rotation shaft of the lock are respectively connected to a handlebar and a front wheel of the bike, the user is unable to control the front wheel through the handlebar. The rope head may also be connected to a rope, and when locking the lock, the user pulls the rope out from the lock, wraps the rope around a fixed object, and then inserts the rope head into the lock through the lock hole.

Owner:TEAM YOUNG TECH CO LTD

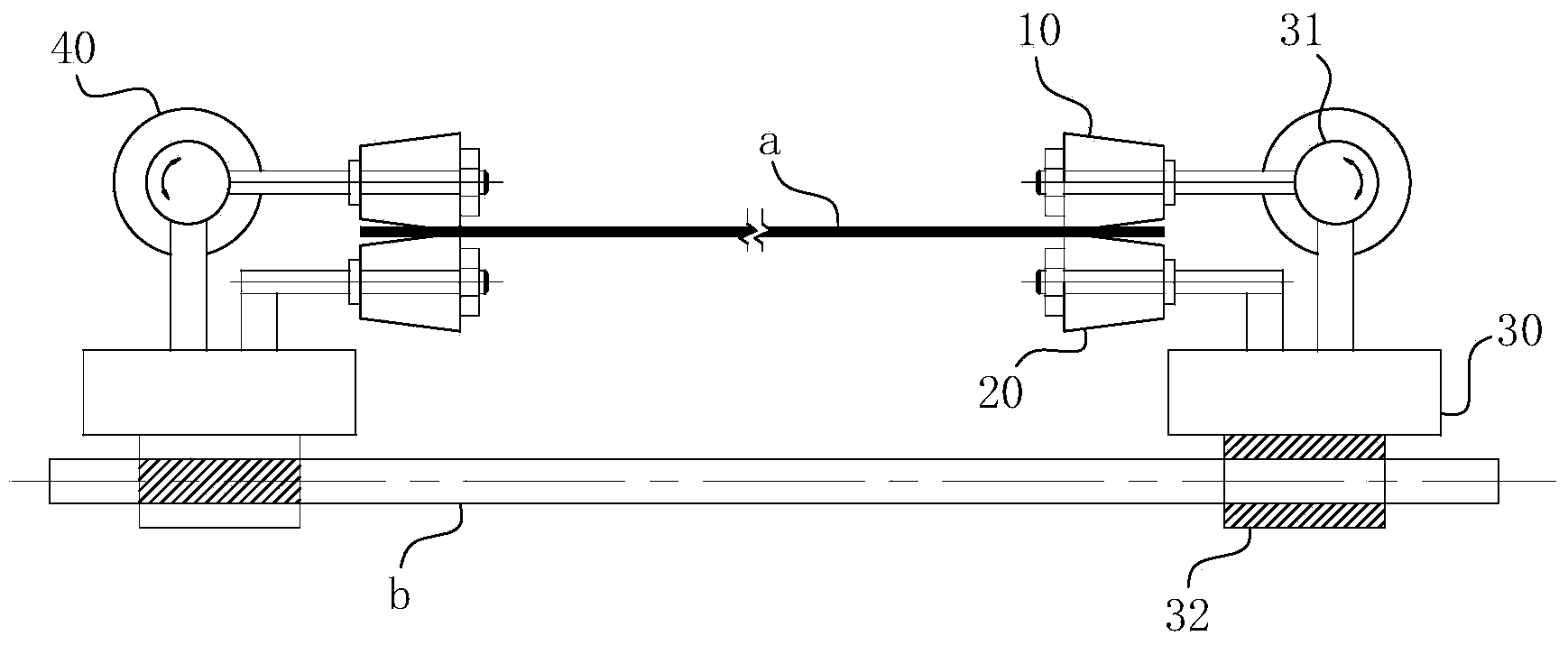

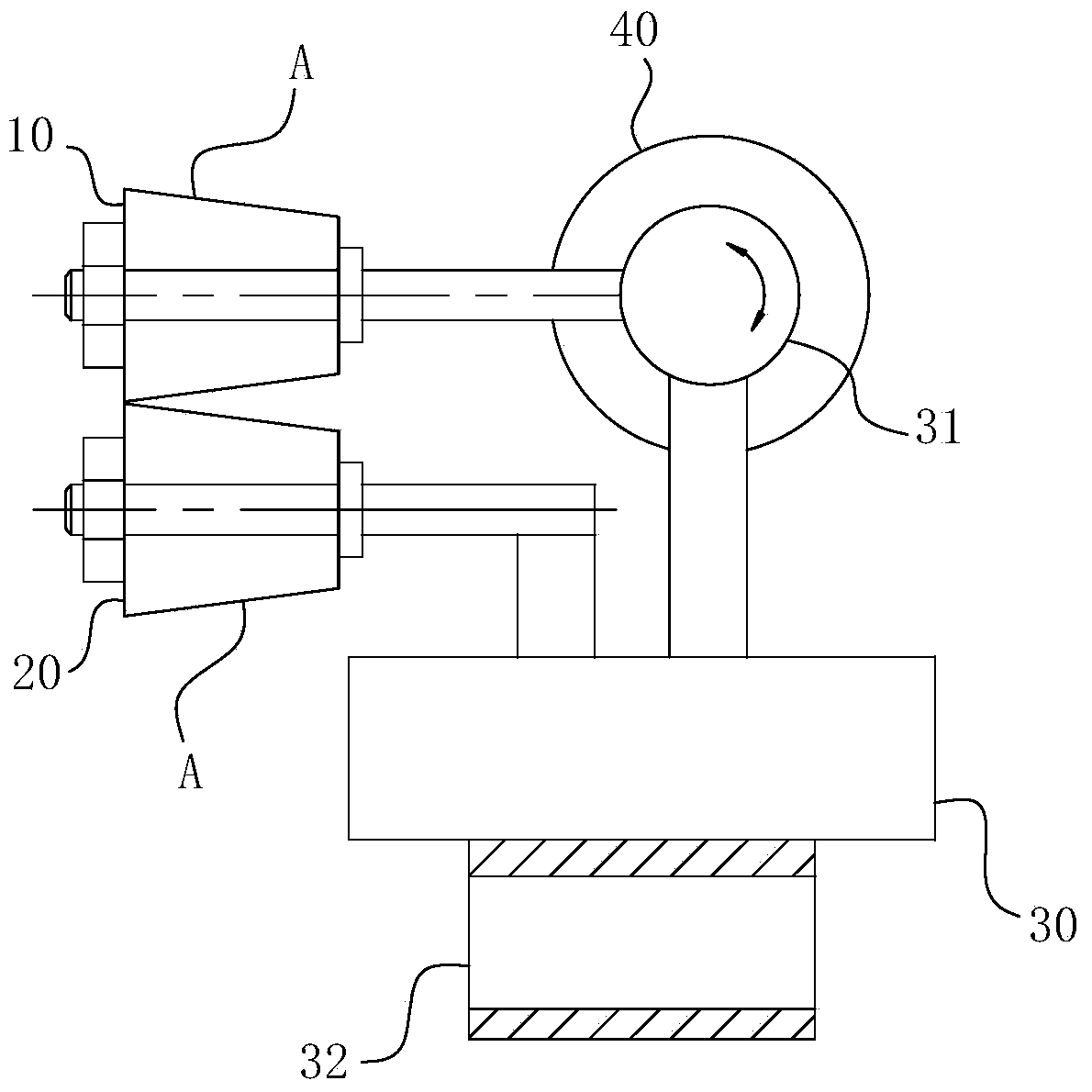

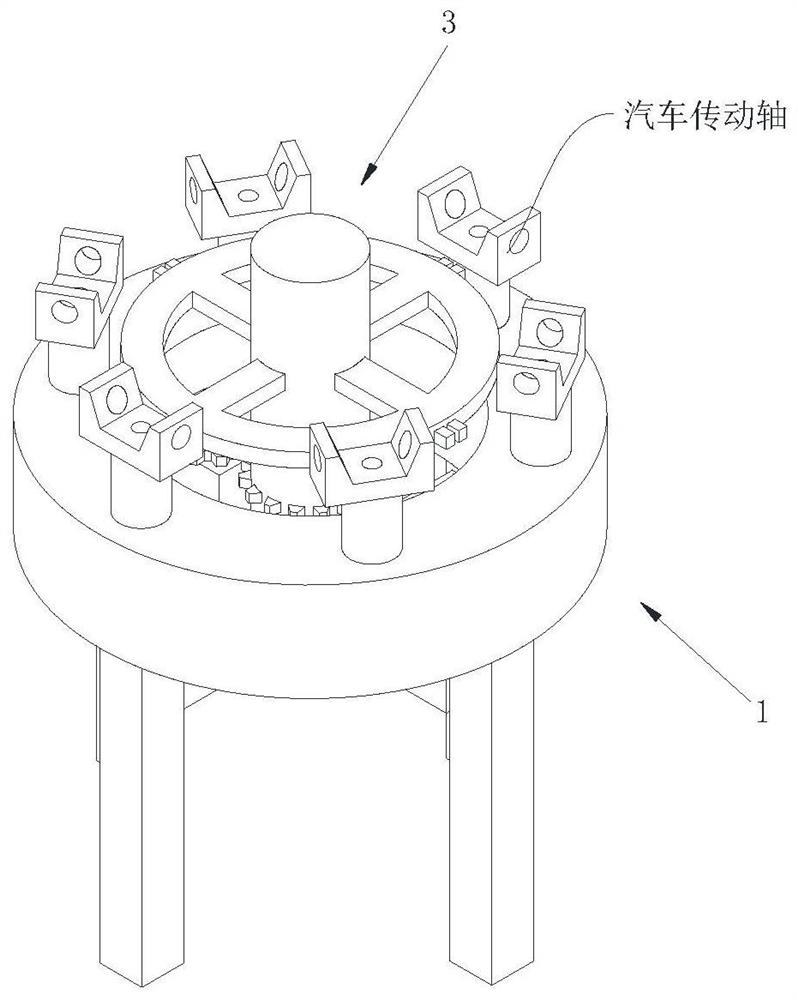

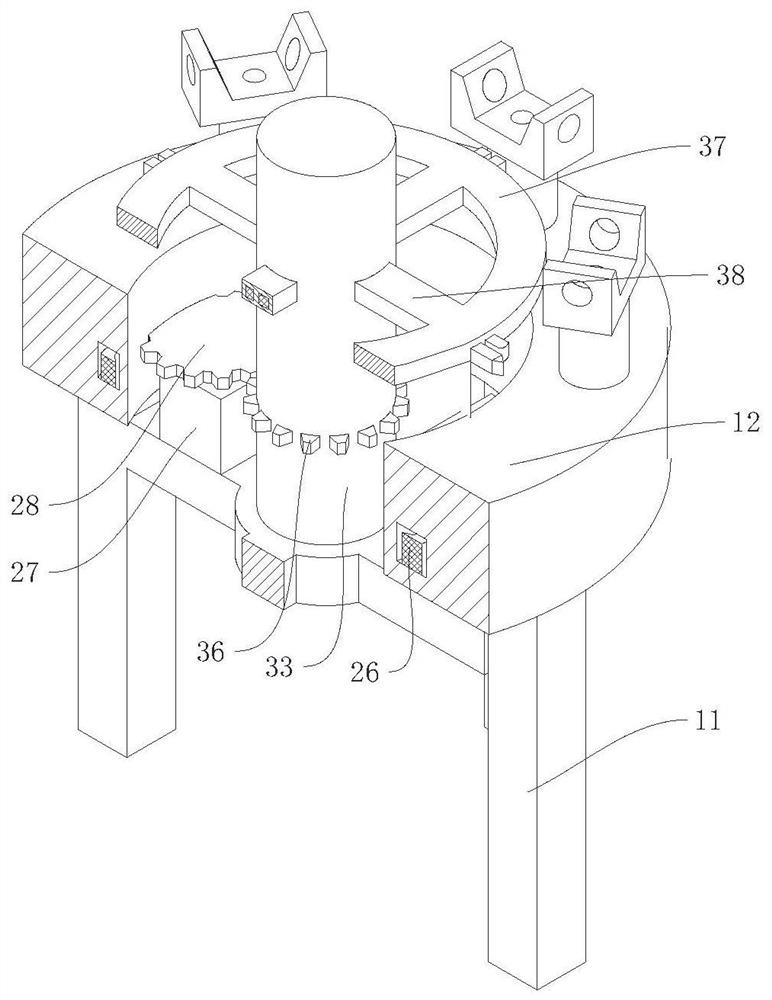

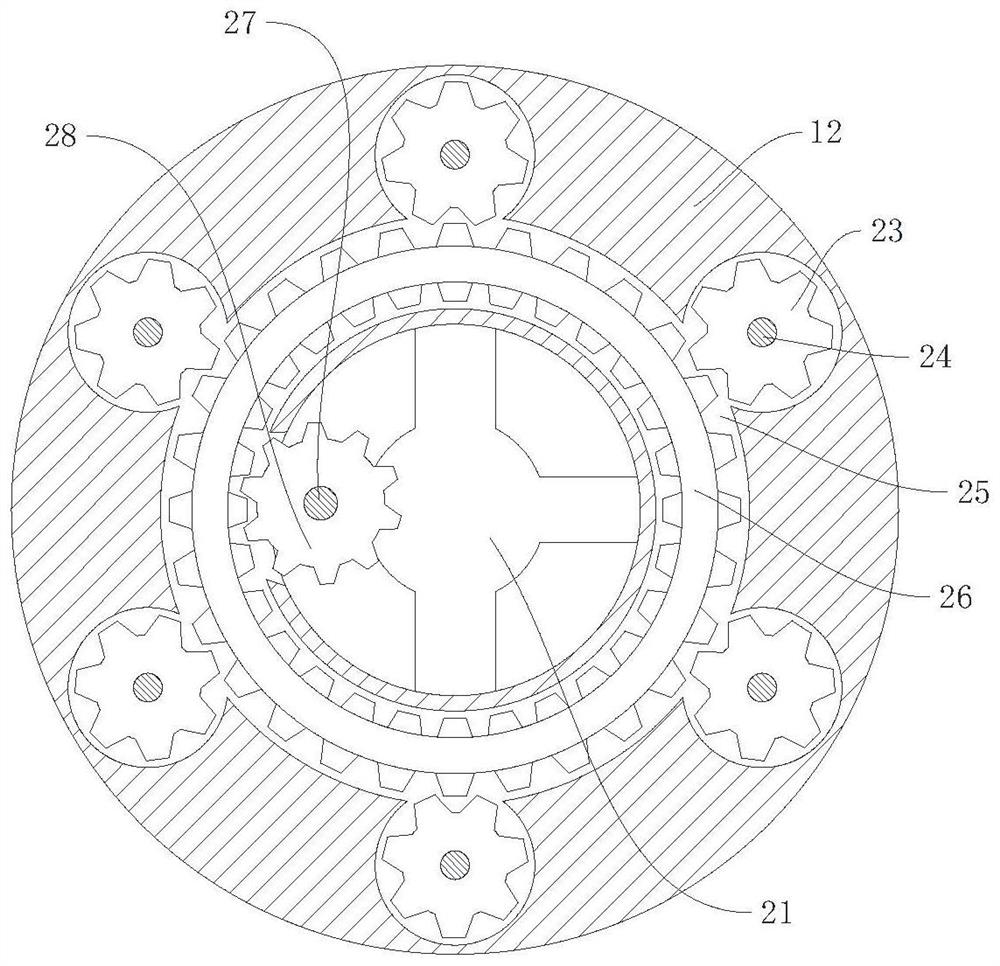

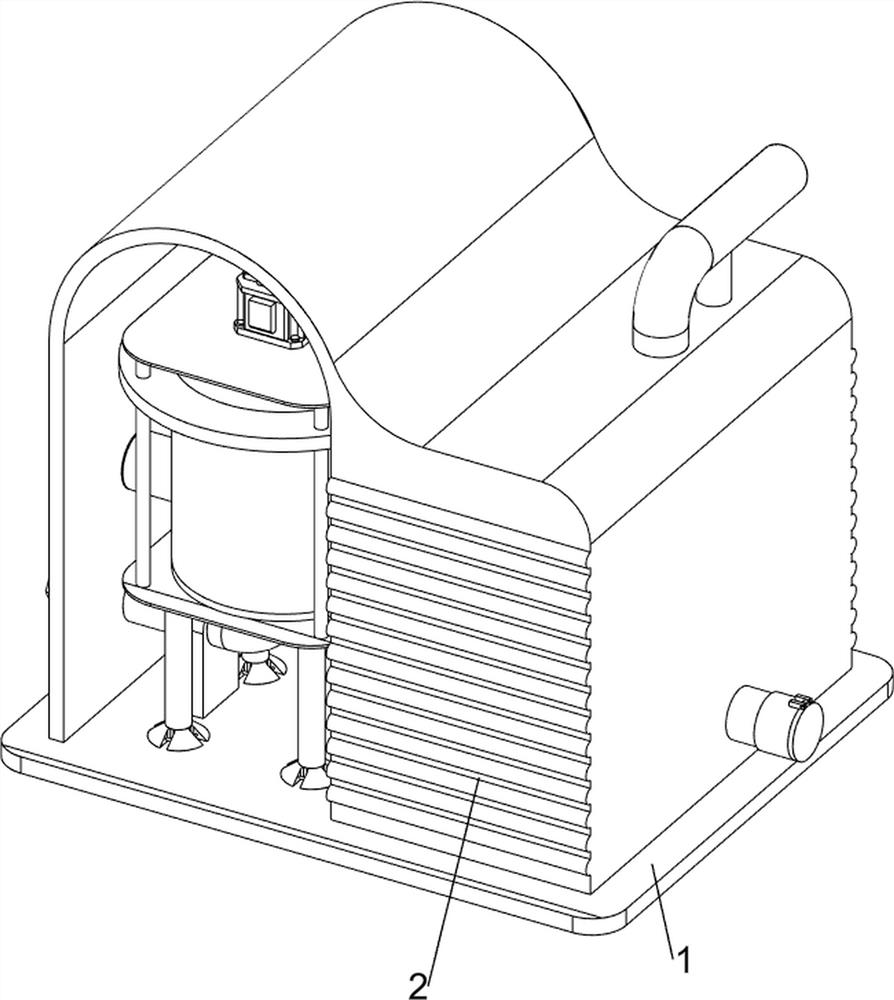

Automobile rotating shaft welding forming surface fine treatment system

ActiveCN112518484AEasy to operateReduce laborEdge grinding machinesGrinding drivesSlag (welding)Drive shaft

The invention relates to the technical field of automobile rotating shaft welding, in particular to an automobile rotating shaft welding forming surface fine treatment system. The automobile rotatingshaft welding forming surface fine treatment system comprises an automobile transmission shaft and further comprises a clamping device used for clamping the automobile transmission shaft, an autorotation device used for rotating the clamping device and a cutting and grinding device used for removing welding slag. The clamping device comprises supporting columns, a mounting table, a clamping groove, a clamping block, a containing groove, a clamping column, clamping torsional springs, clamping plates, stirring strips and an inner supporting mechanism. The autorotation device comprises a supporting frame, a driving groove, autorotation gears, rotating columns, a rack groove, a matching rack, a rotating motor and a driving gear. The cutting and grinding device comprises a combined groove, a rotating table, a mounting column, a telescopic air cylinder, a matching block, driving teeth, a mounting disc, a mounting block and an executing assembly. The automobile rotating shaft welding formingsurface fine treatment system has the effects of multiple functions, automatic polishing and reduction of potential safety hazards to workers.

Owner:天津摩天电子有限公司

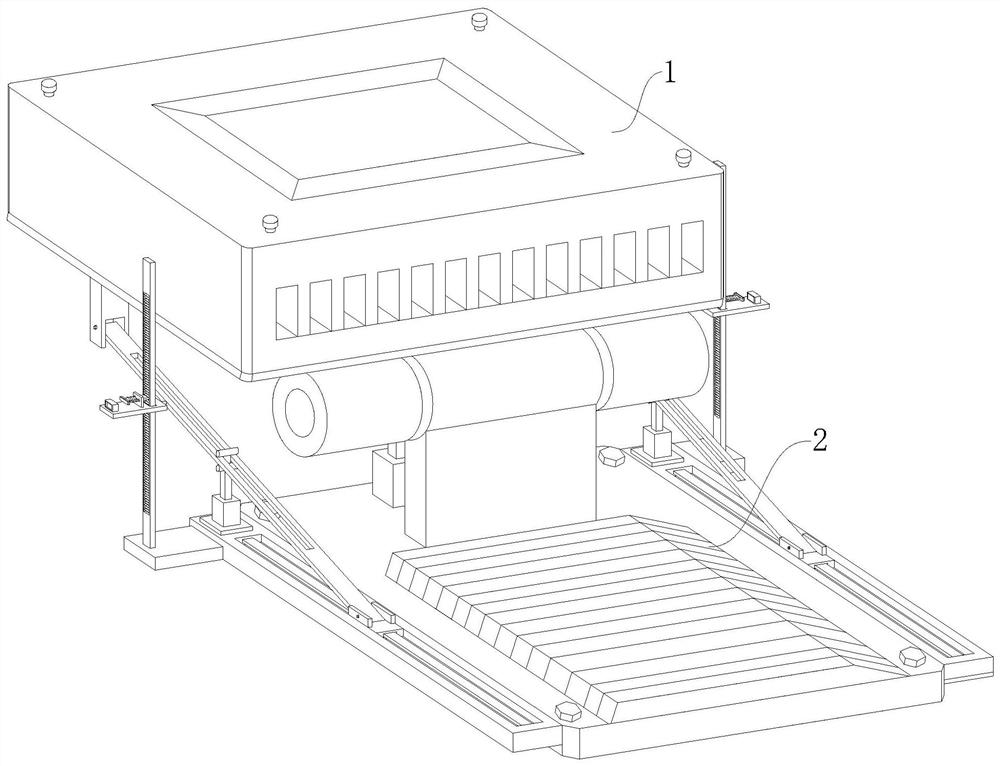

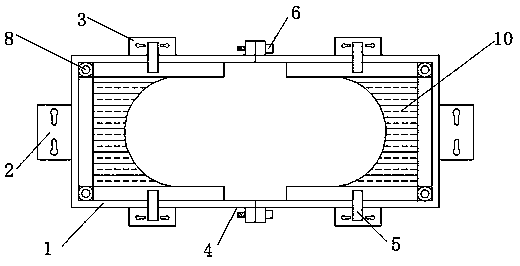

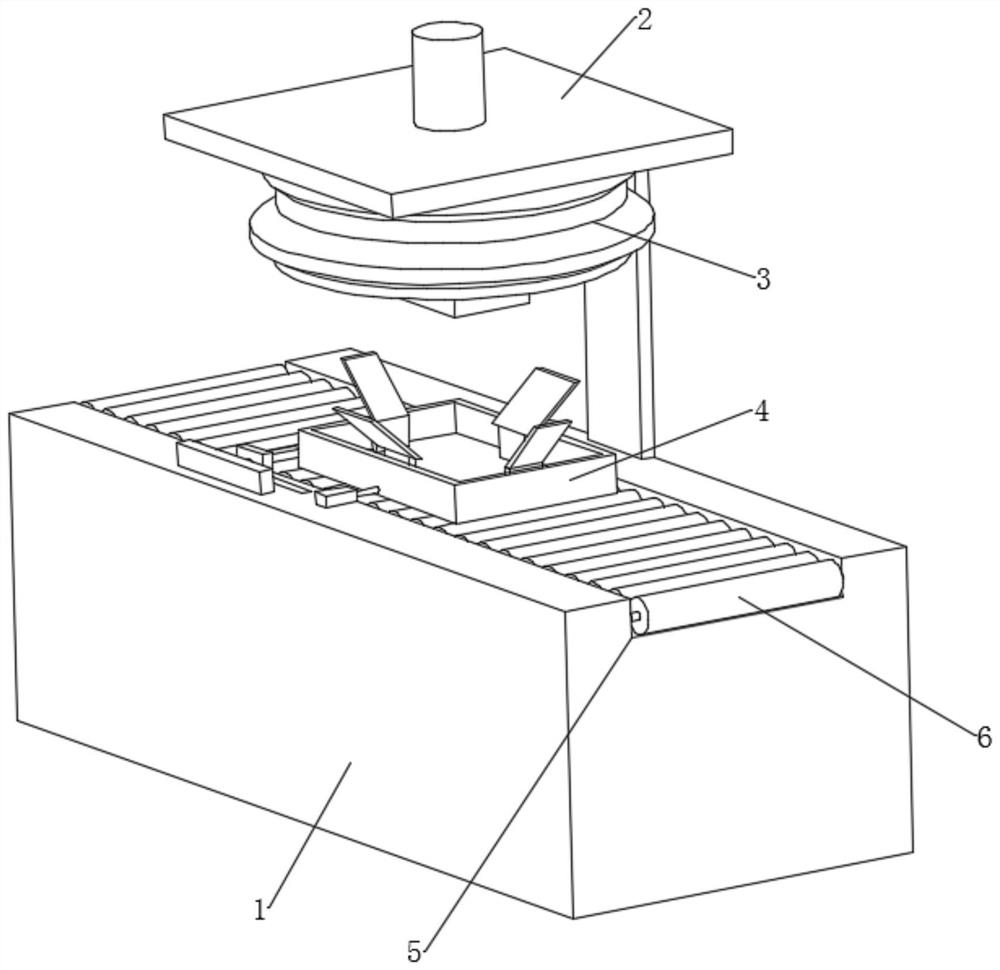

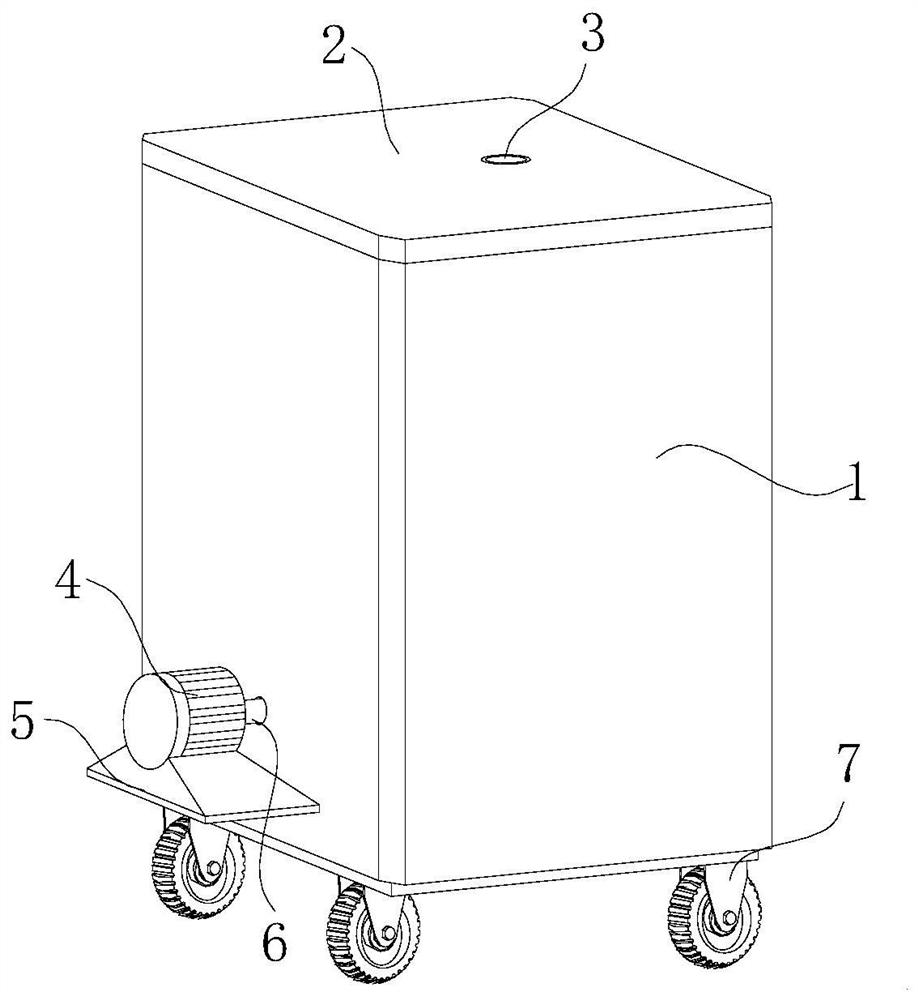

Assembling platform positioning mechanism of full-automatic backlight assembling machine

PendingCN113752192AAchieve initial positioningEasy to placeWork holdersMetal-working hand toolsEngineeringMachine

The invention discloses an assembling platform positioning mechanism of a full-automatic backlight assembling machine, and relates to the field of backlight assembly. The technical scheme adopted by the invention is that the assembling platform positioning mechanism comprises a base and a backlight mounting mechanism, a moving groove is formed in the outer portion of the base, a plurality of moving rollers are rotationally connected into the moving groove, a mounting platform is arranged outside the moving rollers, a limiting unit used for mounting a workpiece is slidably connected into the mounting platform, and a clamping unit used for fixing the mounting platform is arranged outside the base. Preliminary positioning of the workpiece can be achieved through cooperative use of extrusion plates and guide plates in the limiting unit, the guide plates are obliquely arranged relative to the base, and therefore a panel can be conveniently placed. After the workpiece is placed in the mounting platform, due to the fact that the extrusion plates are symmetrically arranged, the workpiece can be located in the center of the mounting platform under the elastic force of a spring a, and then the workpieces of various models can be preliminarily located.

Owner:湖北顺通光电科技有限公司

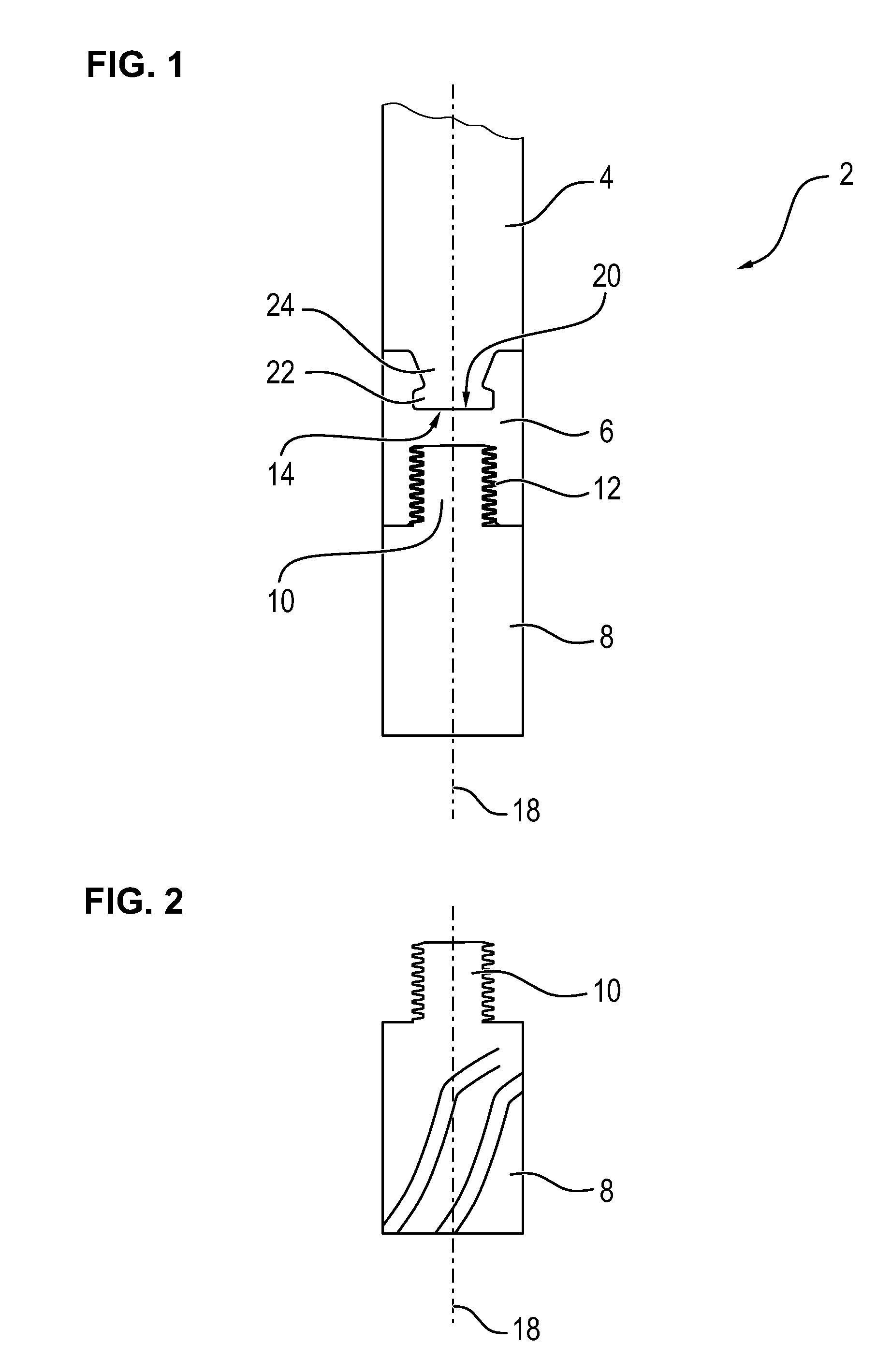

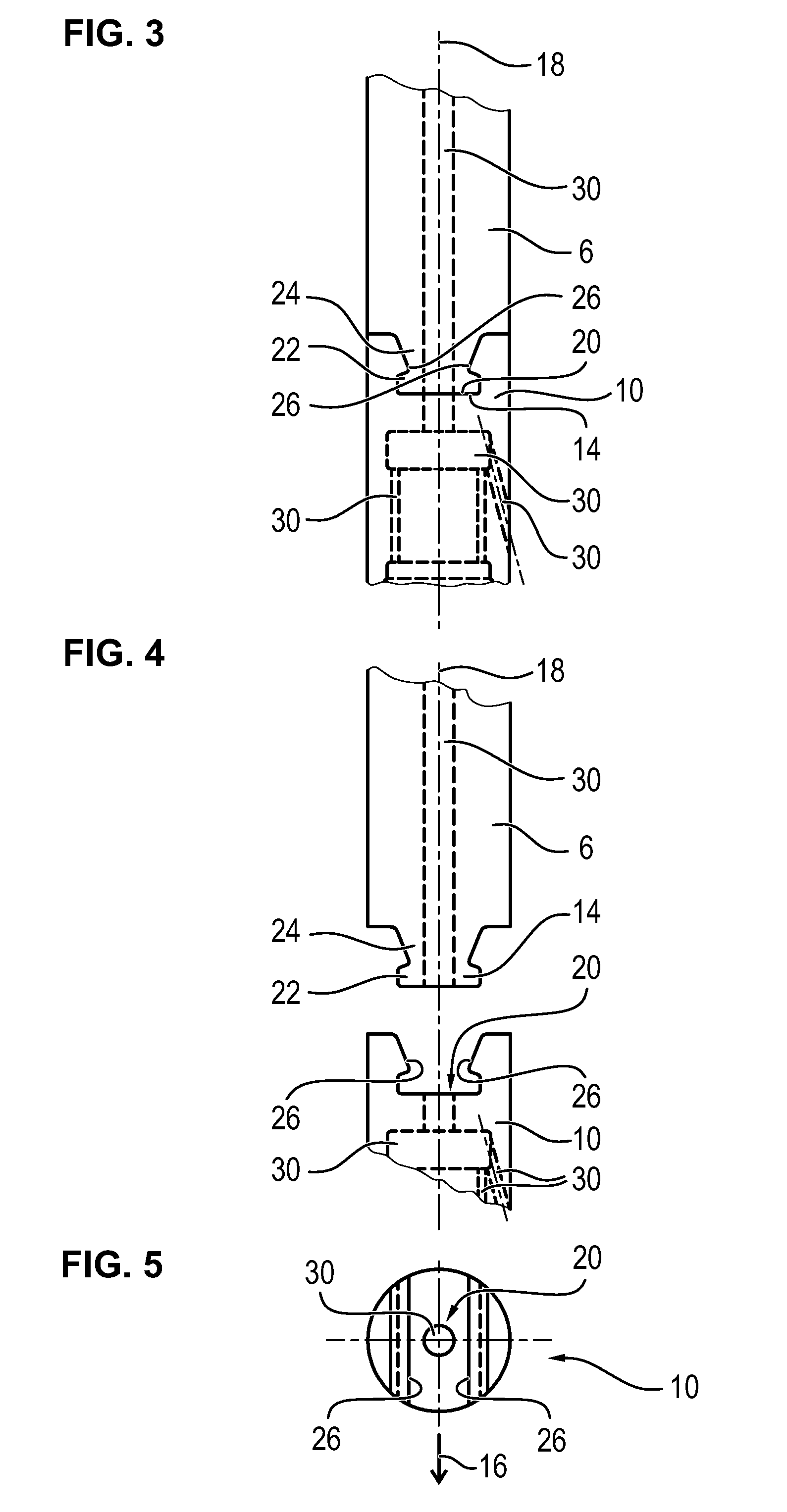

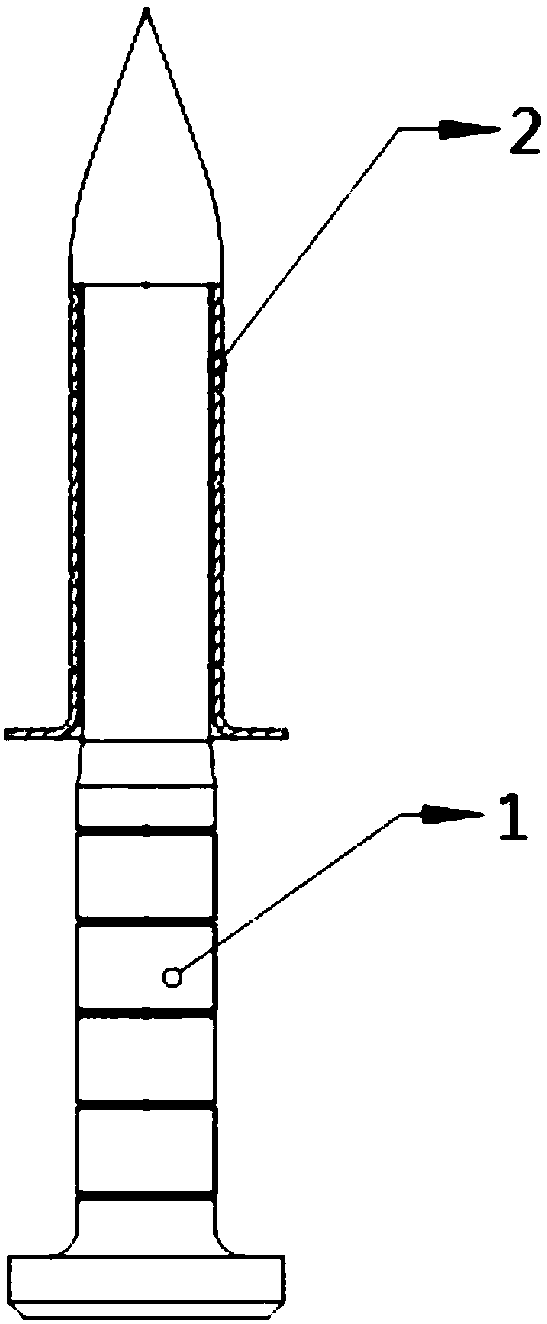

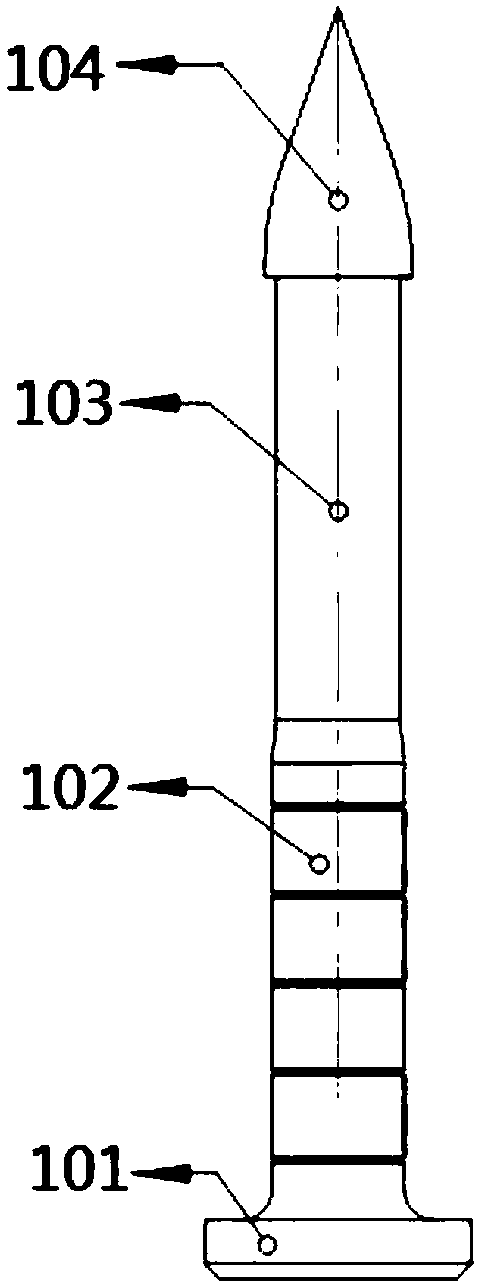

Aircraft handle locking device

ActiveCN111140083ASimple structureSmall footprintAircraft accessoriesKeyhole guardsStructural engineeringMechanical engineering

The embodiment of the invention discloses an airplane handle locking device. The device comprises a locking assembly arranged on an airplane door frame plate and a lock shaft arranged on an airplane handle; the lock shaft comprises a shaft body arranged inside the handle and a locking connector located outside the handle, and the axial movement of the handle drives the lock shaft to axially move;the locking assembly comprises a lock hook and a fixing sleeve used for fixedly connecting the first end of the lock hook to the airplane door frame plate, a hook-shaped lock groove matched with the locking connector for locking is formed in the second end of the lock hook, and the locking connector is clamped into the hook-shaped lock groove in the lock hook when the lock shaft is driven by the handle; and the lock hook assembly further comprises a spring mechanism connected with the lock hook, and the spring mechanism is configured to release the lock shaft by pressing the second end of thelock hook. According to the embodiment, a handle locking device which is simple in structure and light in weight on the premise of meeting the use functions is provided.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

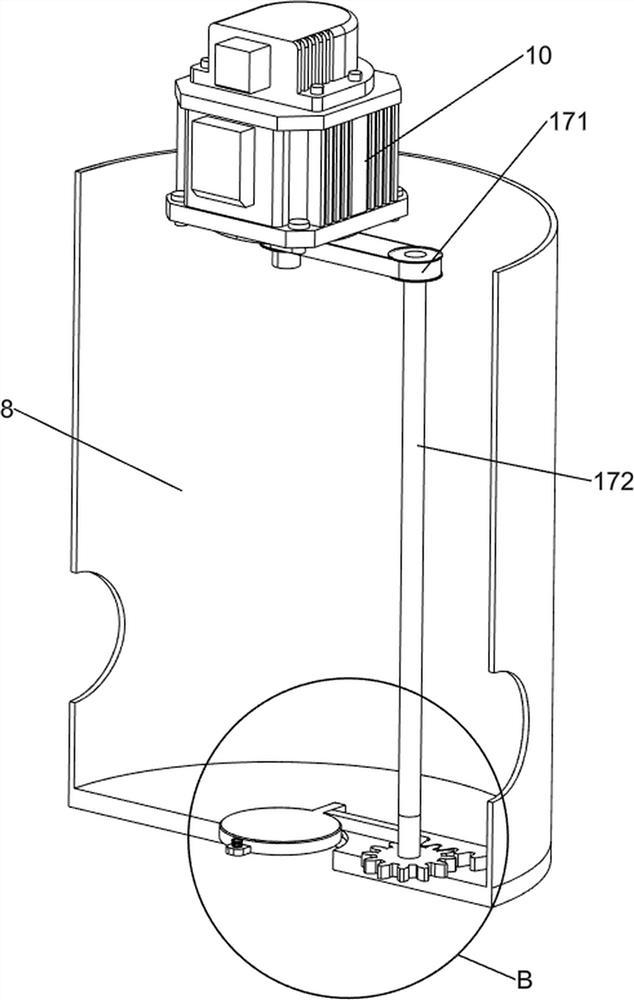

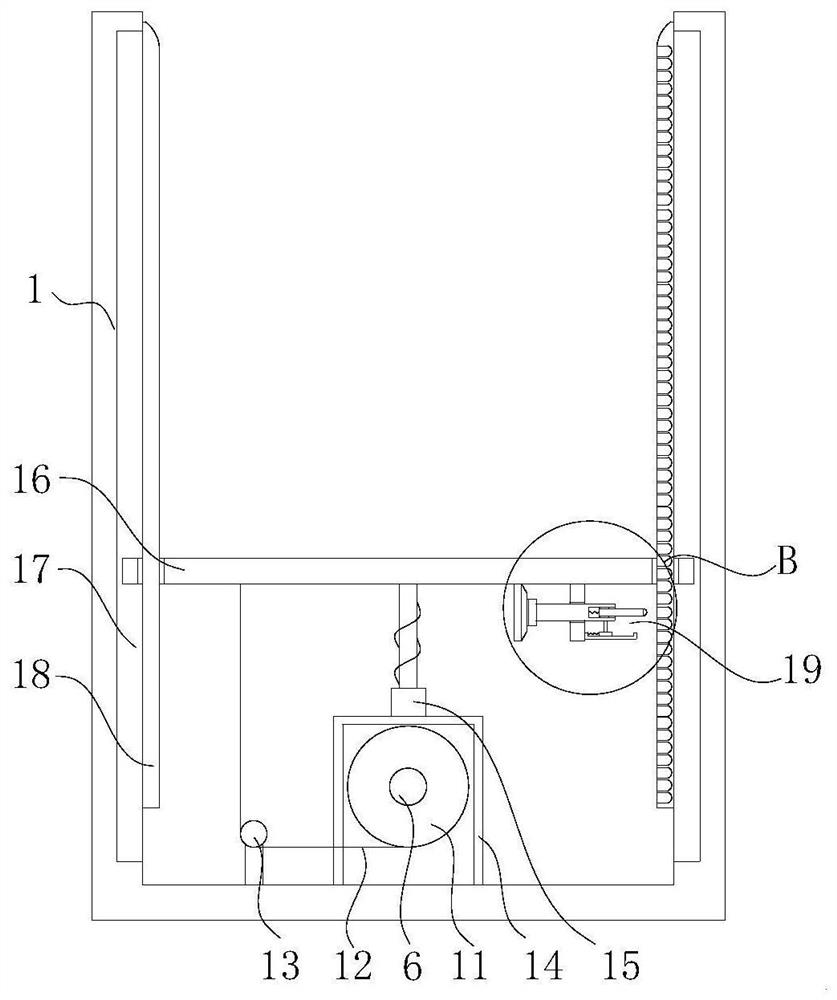

Water-gas separation device for vacuum pumping of suction machine

PendingCN114307439AAchieve separationQuick self-drainPositive displacement pump componentsDispersed particle filtrationGas separationPumping vacuum

The invention relates to a separation device, in particular to a water-gas separation device for vacuum pumping of a suction machine. According to the water-gas separation device for vacuum pumping of the suction machine, water drainage can be accelerated through sponge wiping, and pure vacuum can be obtained through two-stage water-gas separation. A water-gas separation device for vacuum pumping of a suction machine comprises a first bottom plate and a first shell, and the first shell is arranged at the top of the first bottom plate; the first fixing block is arranged on one side of the top of the first bottom plate; the first drainage pipe is arranged in the upper part of the first fixing block; the supporting legs are symmetrically arranged on the two parts of one side of the top of the first bottom plate; and the first-stage separation lower bottom plate is arranged among the tops of the four supporting legs. Through the arrangement of the secondary separation mechanism, small water drops flow downwards into the second drainage pipe along the inner wall of the middle pipeline, and pure vacuum is exhausted through the exhaust pipe, so that the secondary water-gas separation effect can be realized.

Owner:王日俊

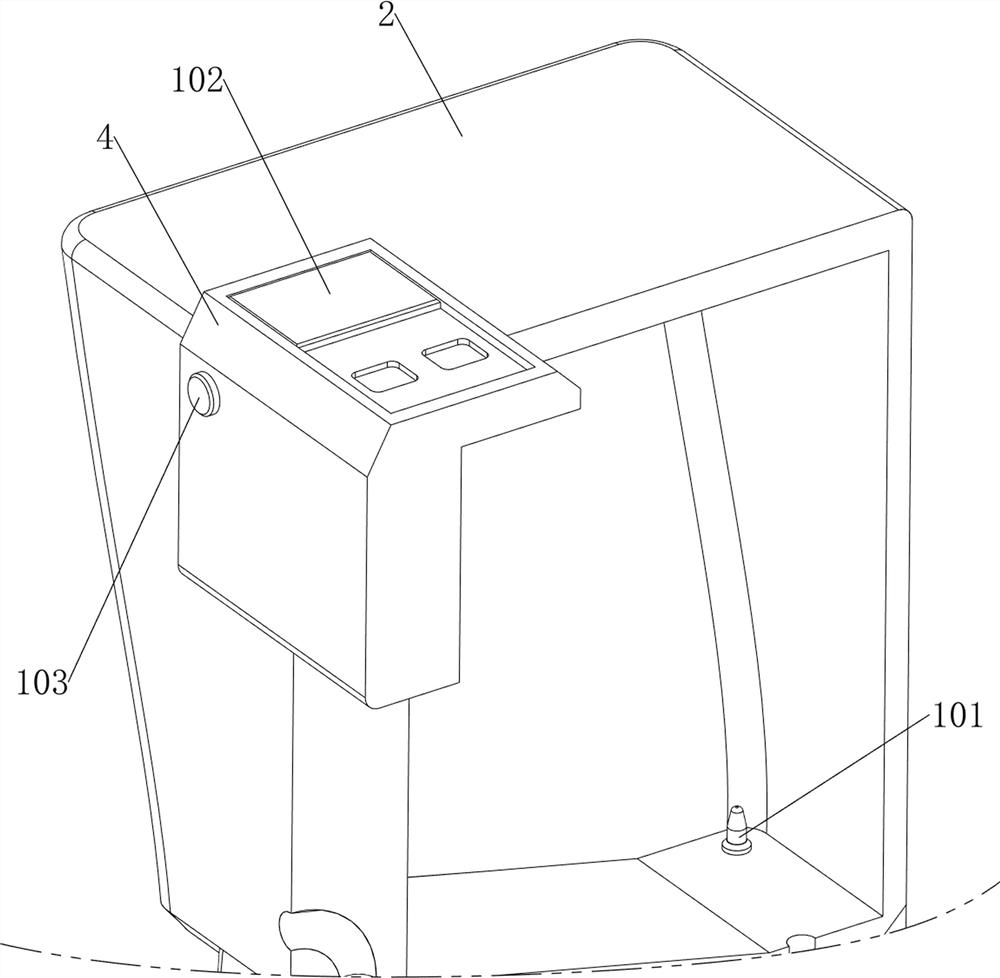

Intelligent coffee machine case

InactiveCN111938439AEasy to place and takeSmooth motionBeverage vesselsProcess engineeringMechanical engineering

The invention relates to an intelligent coffee machine case which comprises a case body and a coffee machine, the coffee machine is movably arranged in the case body, a second water inlet is formed inthe upper end of the coffee machine, the upper end of the coffee machine is connected with a case cover, the case cover abuts against the upper end face of the case body, and a second water inlet isformed in the case cover; by additionally arranging the special case body outside the coffee machine, in the actual working process, the coffee machine can be conveniently taken and placed, meanwhile,the effect that the coffee machine can be stably fixed in the case body can be achieved, and therefore in the coffee machine carrying process, the coffee machine can be prevented from shaking in thecase body; moreover, according to the coffee machine, the box cover is further arranged on the coffee machine and used for blocking the opening in the machine box body, and therefore the effect that the coffee machine is sealed in the machine box body is achieved through the sealing effect.

Owner:LUAN SOYEA ELECTRIC APPLIANCE MFG CO LTD

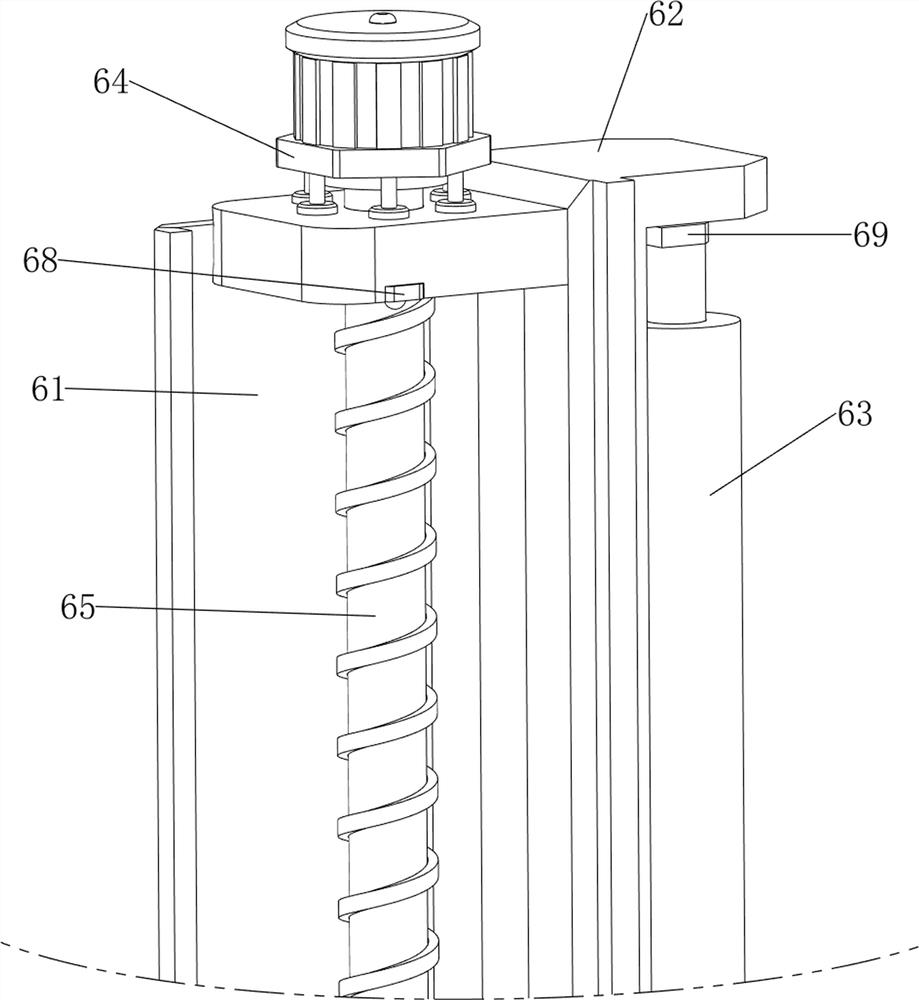

Sliding sleeve screw removing robot

The invention discloses a sliding sleeve screw removing robot. The robot is characterized by comprising a power box, a position adjusting rod and a sleeve removing component, wherein the two ends of the position adjusting rod are connected to the power box and the sleeve removing component respectively; the sleeve removing component comprises a bottomless shell, a grinding motor, a support ring, atorsion motor, an impact component, an annular guide rail and a positioning ring, a grinding piece is arranged on the grinding motor, and the grinding motor is connected to the top in the shell; thetorsion motor is connected to the support ring, and a driving wheel is arranged on an output shaft of the torsion motor; gear teeth meshed with the driving wheel are arranged at the outer side of theguide rail; the positioning ring comprises an upper positioning ring and a lower positioning ring; and the lower positioning ring is provided with four through holes, the four through holes equally divide the lower positioning ring into four parts, a telescopic rod is inserted into each through hole, the end, away from the center of the lower positioning ring, of each telescopic rod is connected to the inner side of the guide rail, a plum blossom locking block is arranged at the other end of each telescopic rod, and an anticlockwise inclined groove is arranged in the inner side of each plum blossom locking block. The robot solves the problem that a screw head slips and cannot rotate.

Owner:冯民荣

Locking structure of slotted nut

The invention relates to a locking structure of a slotted nut. The locking structure comprises the slotted nut, wherein a threaded hole penetrates through the center of the slotted nut, a connecting shaft is screwed in the threaded hole, a clamping vertical groove is formed in the connecting shaft, a plurality of grooves are formed in the upper surface of the slotted nut along the circumference ofthe outer edge of the threaded hole, one end of the grooves communicates with the threaded hole, connecting threaded holes are formed in the grooves, a locking piece is arranged in the groove which corresponds to the clamping vertical groove in the connecting shaft, a counterbore is formed in the locking piece in the mode of corresponding to the connecting threaded hole, countersunk rivets are screwed in the counterbore and the connecting threaded hole, a projecting part is arranged on one side surface, which faces the threaded hole, of the locking piece, and the projecting part is clamped inthe clamping vertical groove in the connecting shaft. According to the locking structure, the slotted nut can be effectively locked, and the slotted nut can be effectively prevented from loosing; compared with other locking modes of the slotted nut, the locking structure has the advantages of simplicity, convenience and simplicity in matching and processing, and the phenomenon of improper lockingdue to the size of a general locking clamp is avoided.

Owner:TIANJIN TEEK TRANSMISSION

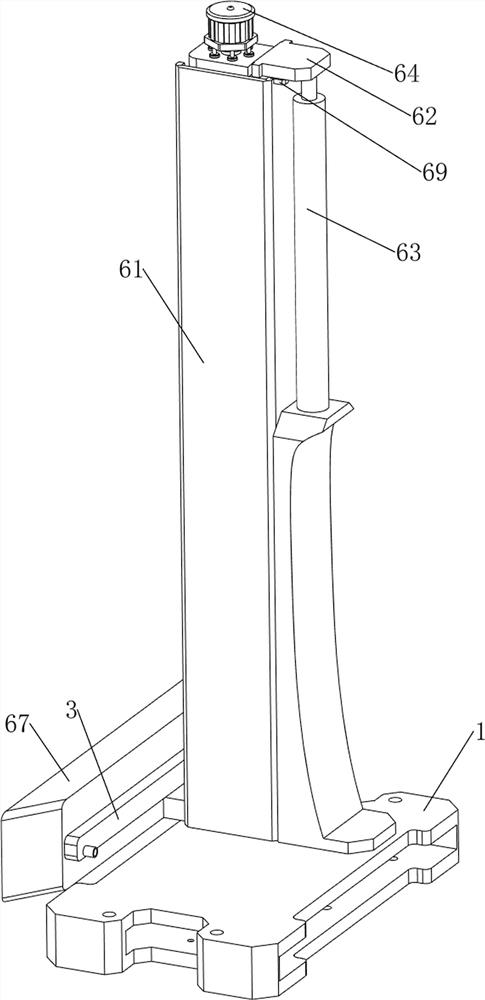

Efficient wall coating device for interior decoration of building

PendingCN113605644ARealize the output effectAchieve liftingBuilding constructionsConstruction engineeringStructural engineering

The invention relates to a coating device, in particular to an efficient wall coating device for interior decoration of a building. The efficient wall coating device for interior decoration of the building can be used for automatically coating, has small influence on a human body and is uniform in coating. The efficient wall coating device for interior decoration of the building comprises a base, a material box and a control box, and the material box is arranged at the top of the base; and the control box is installed on the upper side of the material box, a storage battery, a control module and a power supply module are installed in the control box, the storage battery supplies power to the whole wall coating device, the output end of the storage battery is electrically connected with the power supply module, the power supply module is connected with a power supply main switch through a circuit, and the control module is electrically connected with the power supply module. By arranging a discharging mechanism, people press a discharging mechanism part, the control module controls the discharging mechanism to operate, so that paint in the material box can be pumped to a spray head, the spray head can spray the wall surface, and the discharging effect is achieved.

Owner:华建生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com