Six-degree-of-freedom control handle

A technology for controlling handles and degrees of freedom, applied in manipulators, manufacturing tools, etc., can solve problems that affect the operation of manipulators, limit the use of occasions, use complex control handles, etc., and achieve the effects of flexible and reliable control, simple appearance, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the specific embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

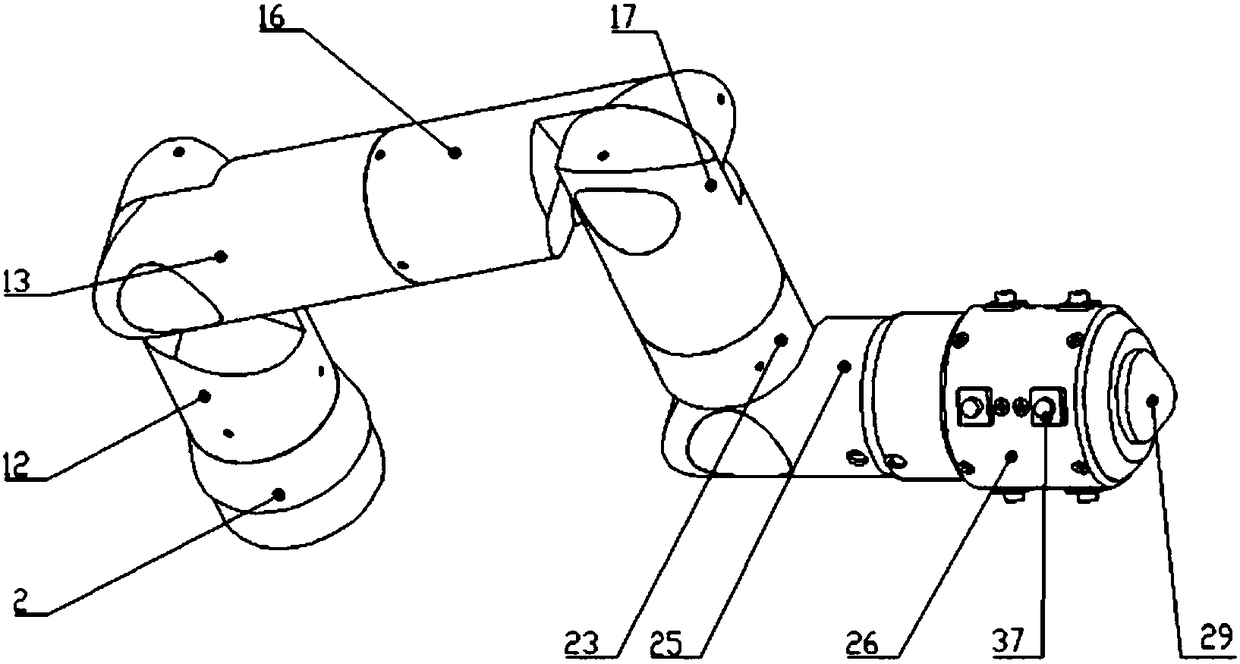

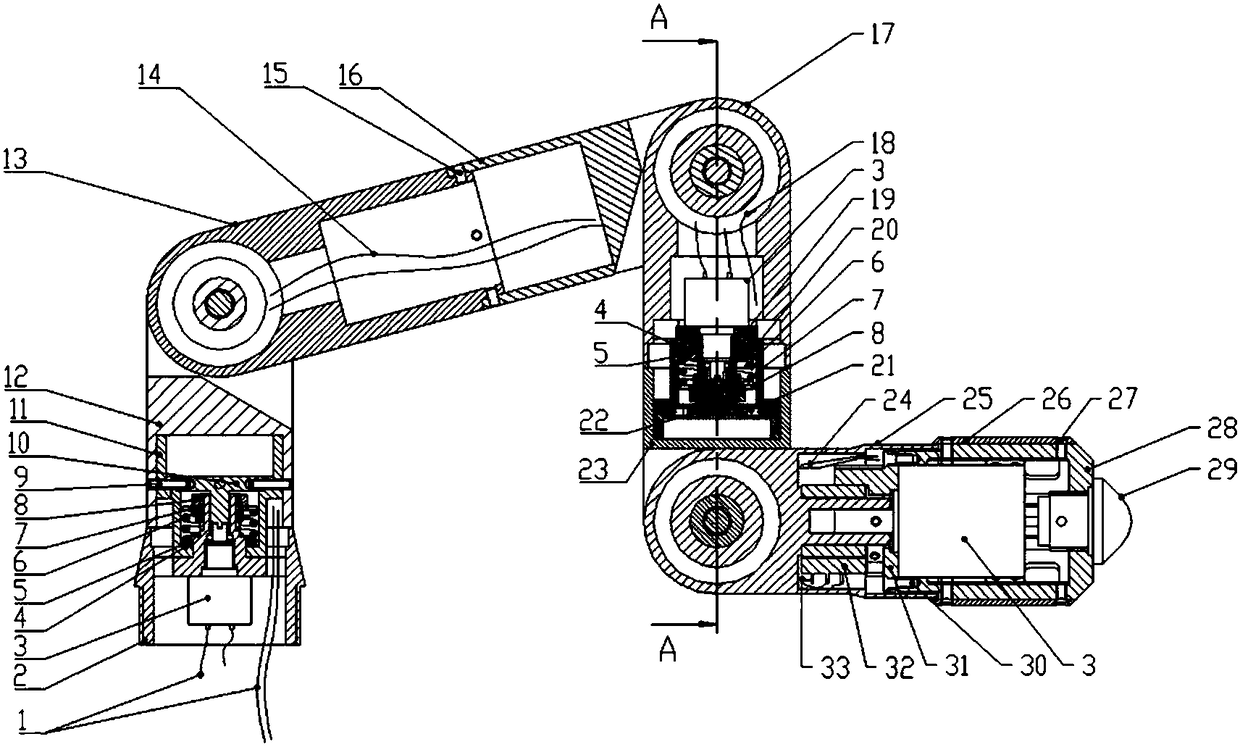

[0028] Such as Figure 1 ~ Figure 3As shown, the present invention discloses a 6-DOF control handle, including a base 2, a shoulder joint 12, a large arm joint 13 and 16, a small arm joint 17, an elbow joint 23, a wrist joint 25, a claw 28 and a sensor 3 ; The base 2, the shoulder joint 12, the upper arm joint 13 and 16, the forearm joint 17, the elbow joint 23, the wrist joint 25 are connected to each other by the rotation shaft in turn, and they are connected by the rotation shaft between the two. Perform swinging motion; the sensor 3 is embedded on the above-mentioned rotating shaft to collect the angle signals of these swinging motions; the wrist joint 25 and the claw 28 are connected by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com