Patents

Literature

37results about How to "Realize the output effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic mixing device for colored glaze production

ActiveCN112844193AWell mixedAchieve broken effectTransportation and packagingRotary stirring mixersGlazeEngineering

The invention relates to a mixing device, and particularly relates to an automatic mixing device for colored glaze production. The automatic mixing device for colored glaze production is good in mixing effect, capable of reducing the labor intensity of workers and easy and understandable to operate. The automatic mixing device for colored glaze production comprises a base, a fixed supporting column, a mixing box body, a discharging box, feeding openings, static crushing cutters, a discharging channel and a filter screen, wherein the fixed supporting column is arranged on the base; the mixing box body is arranged at the top of the fixed supporting column; the discharging box is arranged at the top of the mixing box body; the feeding openings are formed in the two sides of the lower part of the discharging box; three static crushing cutters are rotationally arranged on each of the upper side and the lower side in the mixing box body; the discharging channel is arranged at the bottom of the mixing box body; and the filter screen is arranged between the two sides of the discharging channel. By arranging the crushing mechanism, the colored glaze in the mixing box body is more uniformly mixed through the operation of the crushing mechanism, and the crushing effect is achieved.

Owner:高安常莹新型材料有限公司

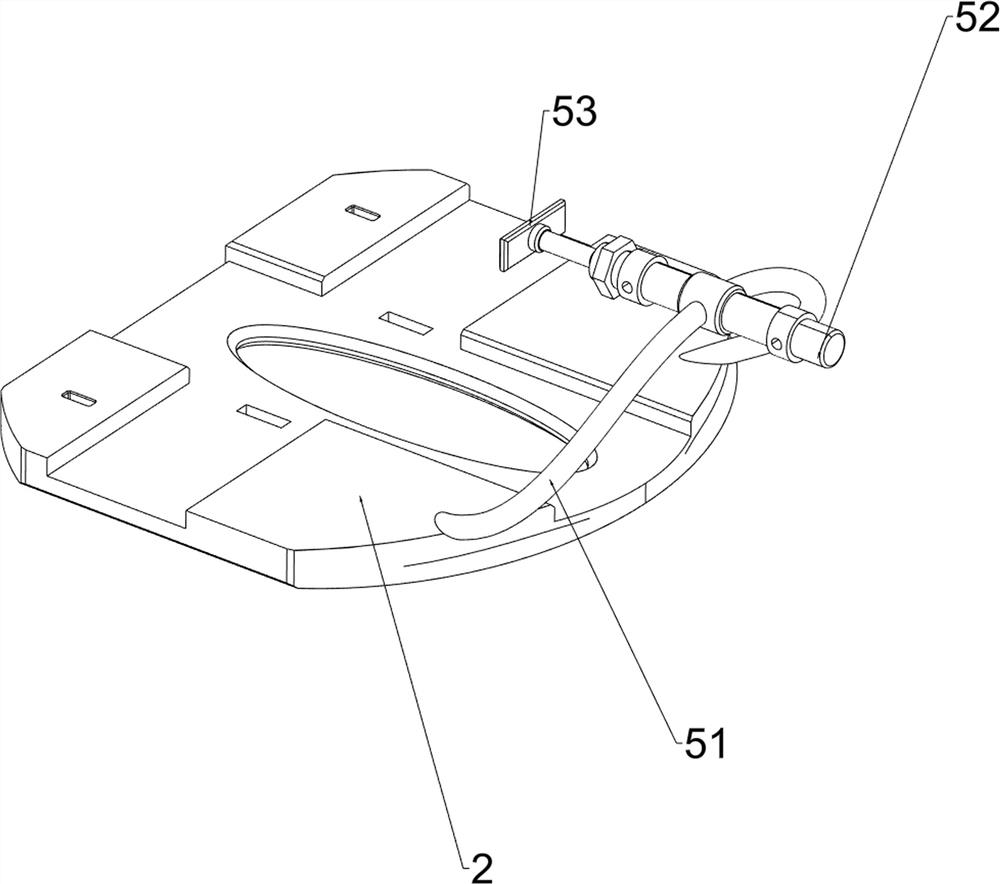

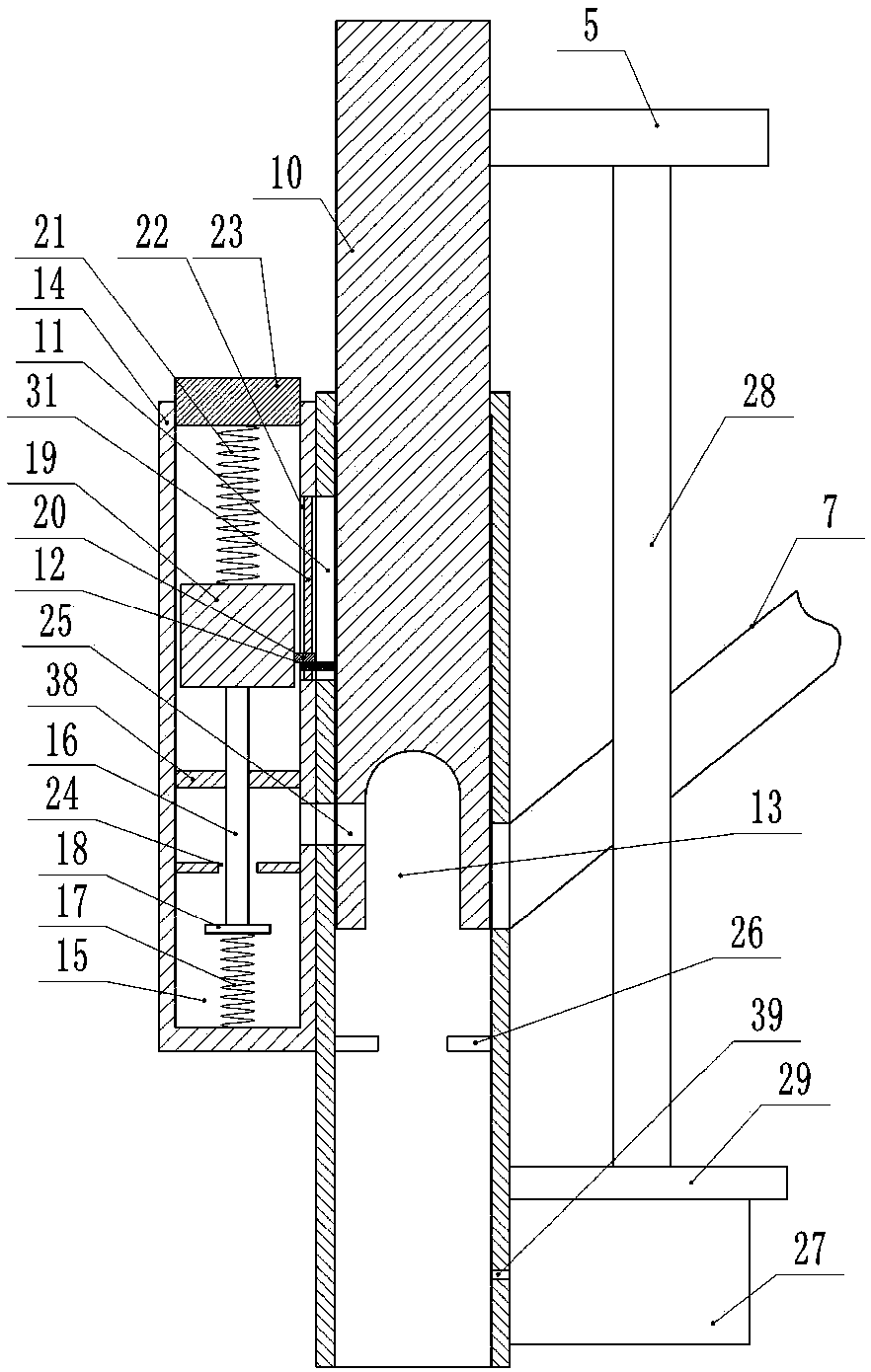

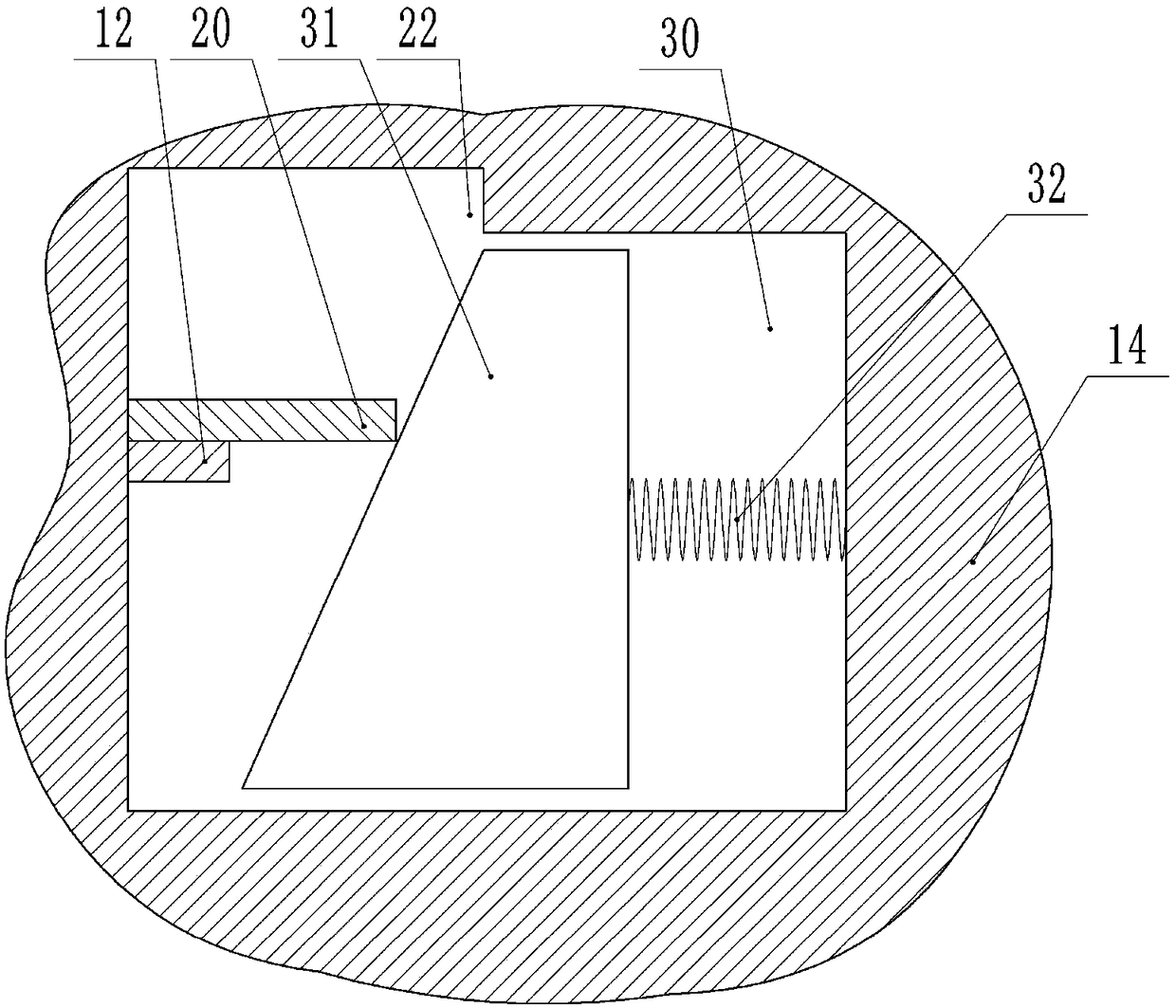

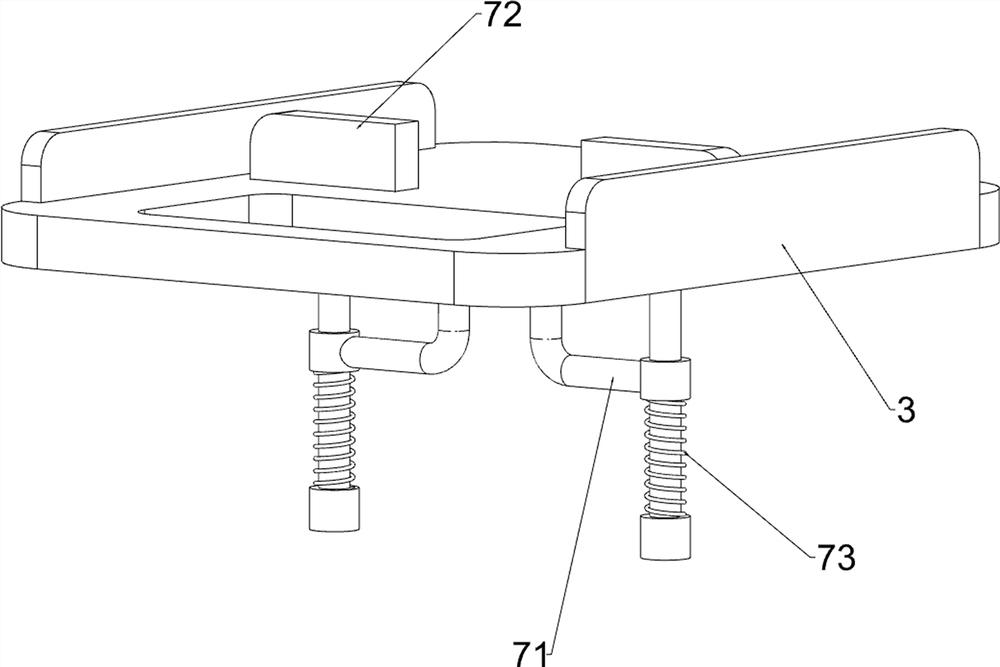

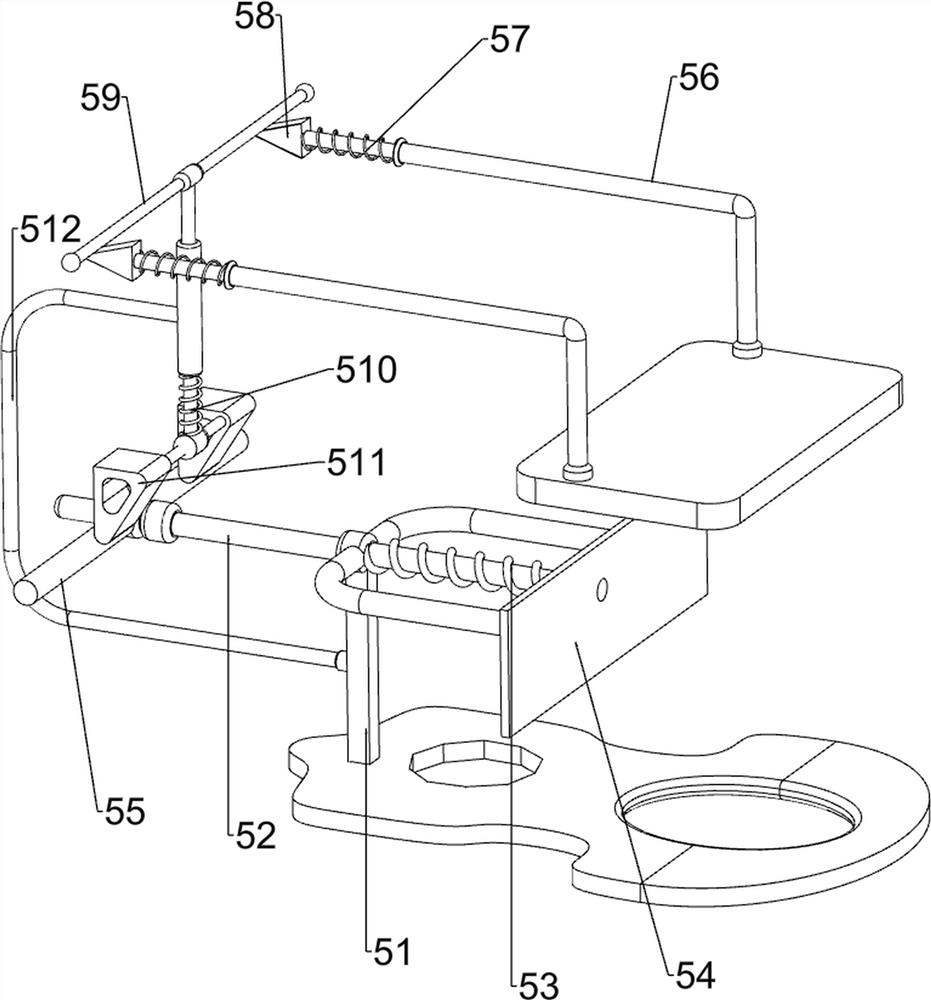

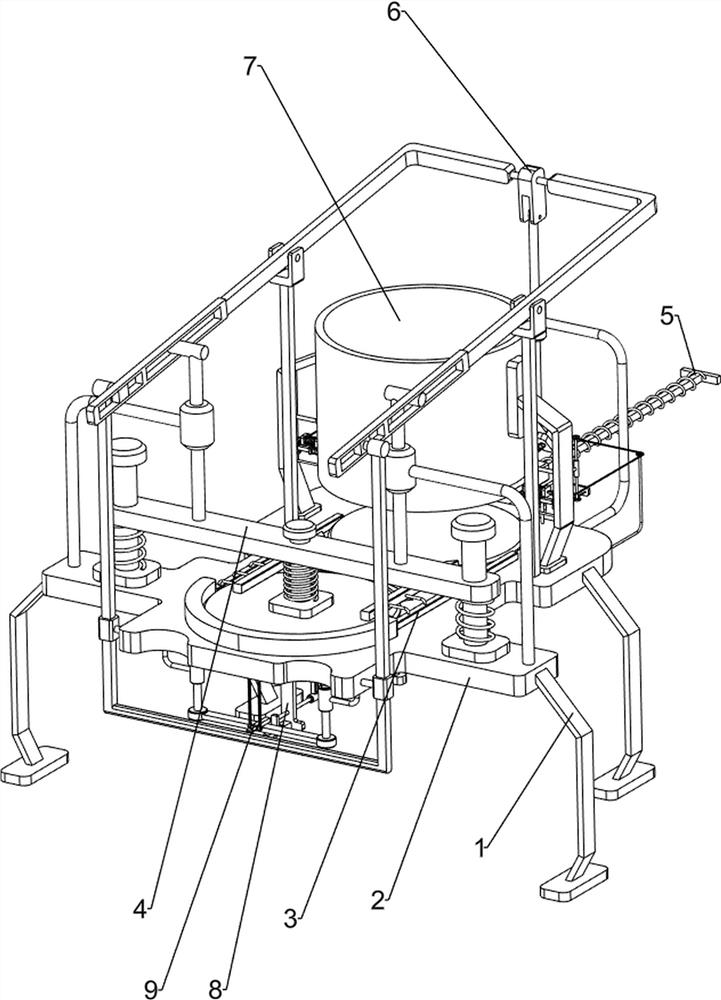

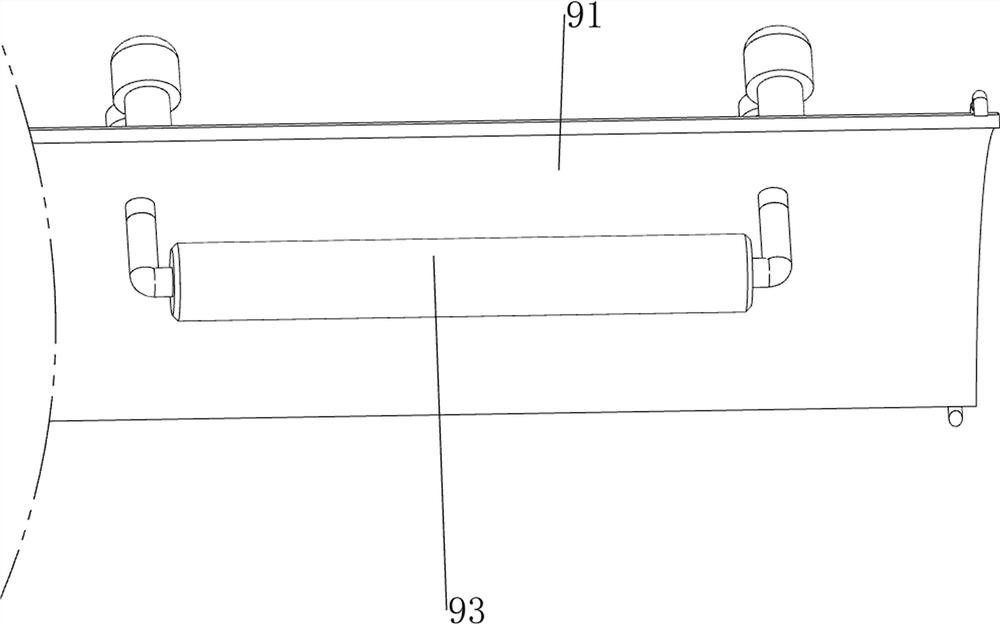

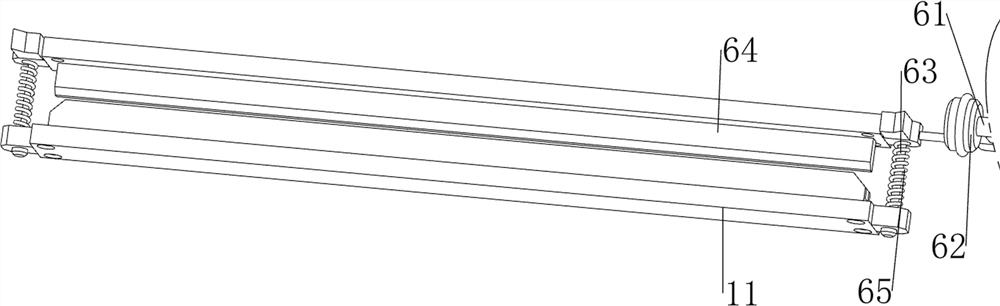

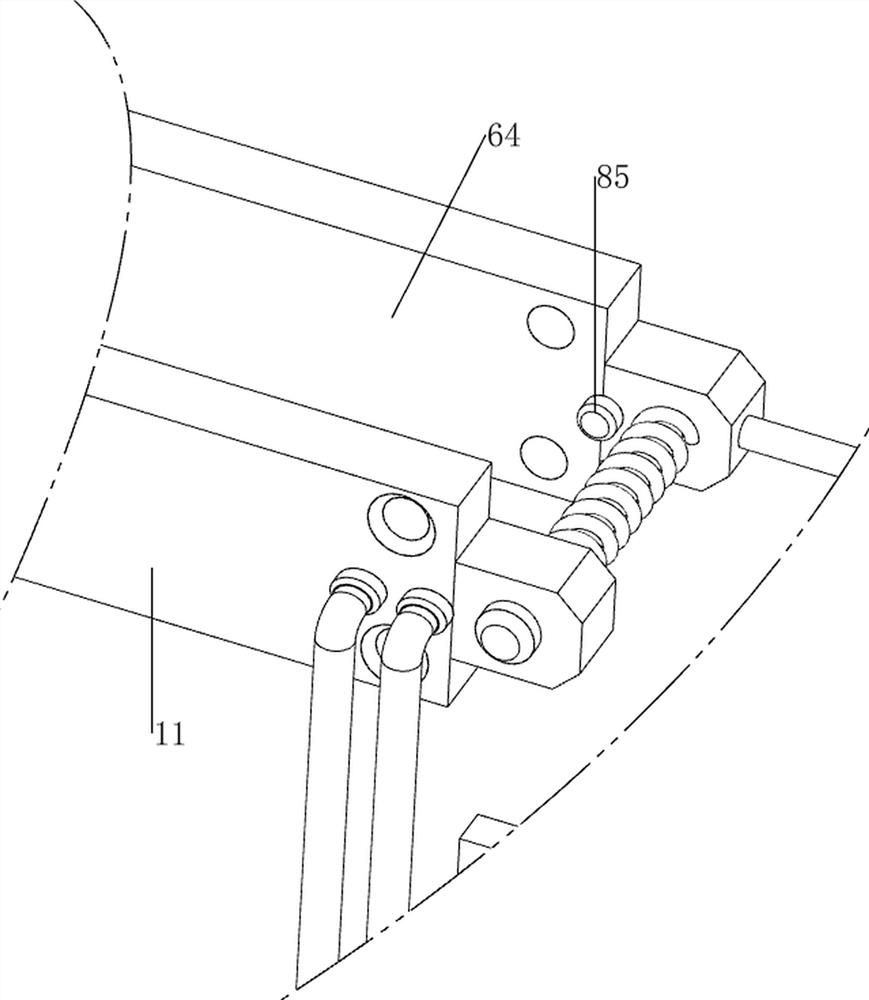

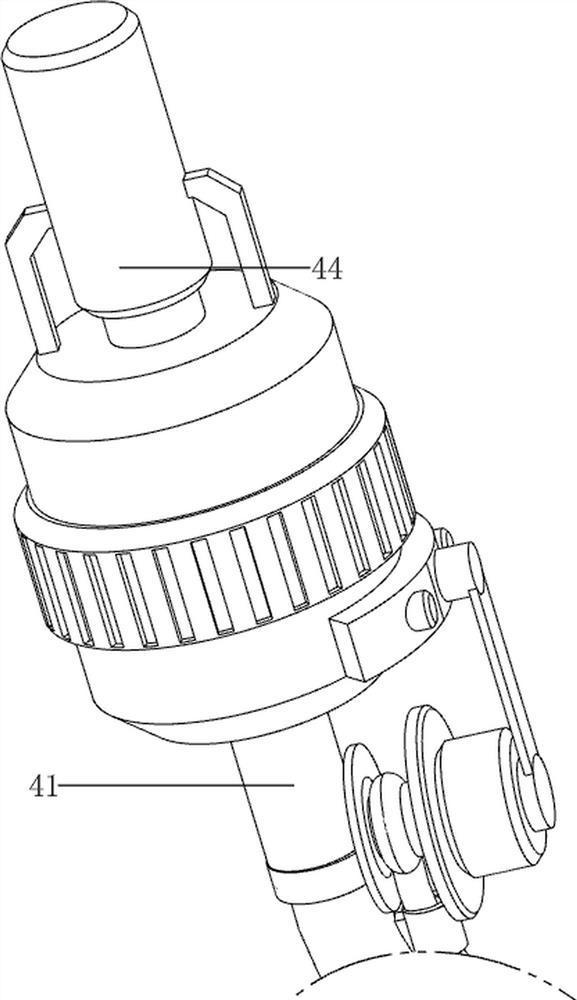

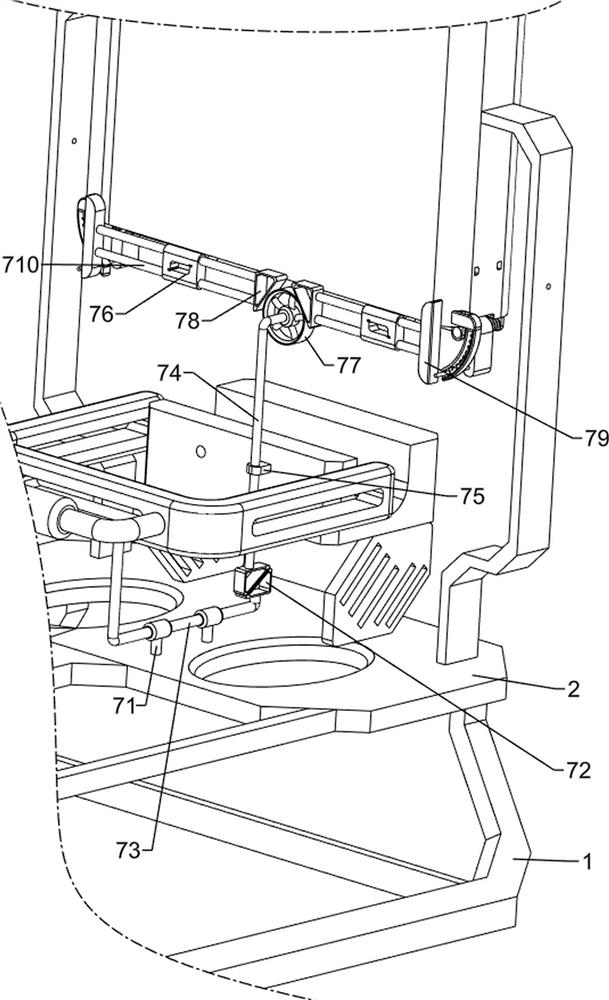

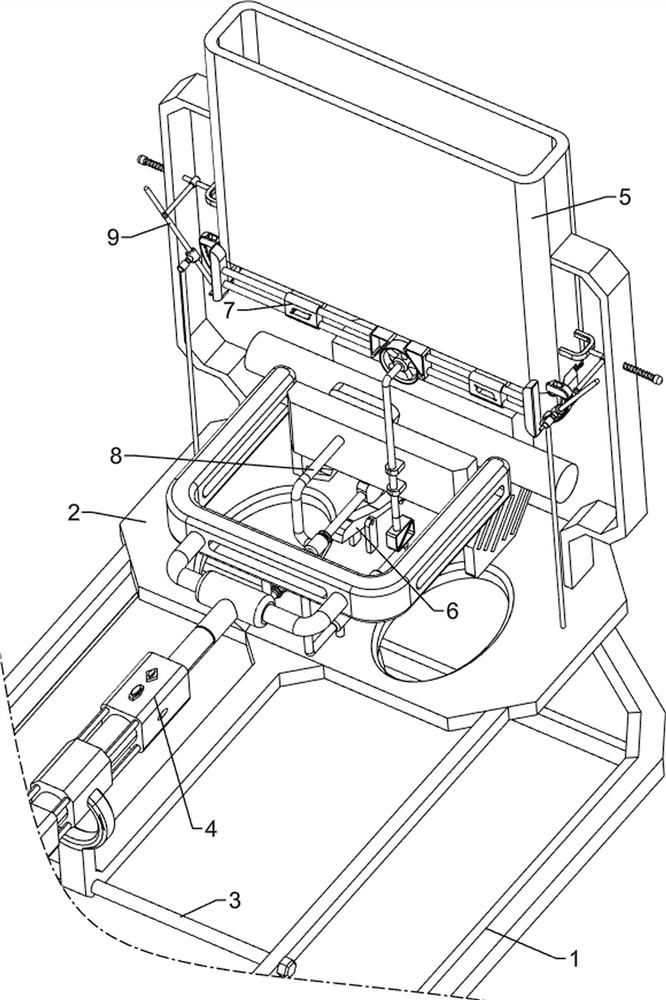

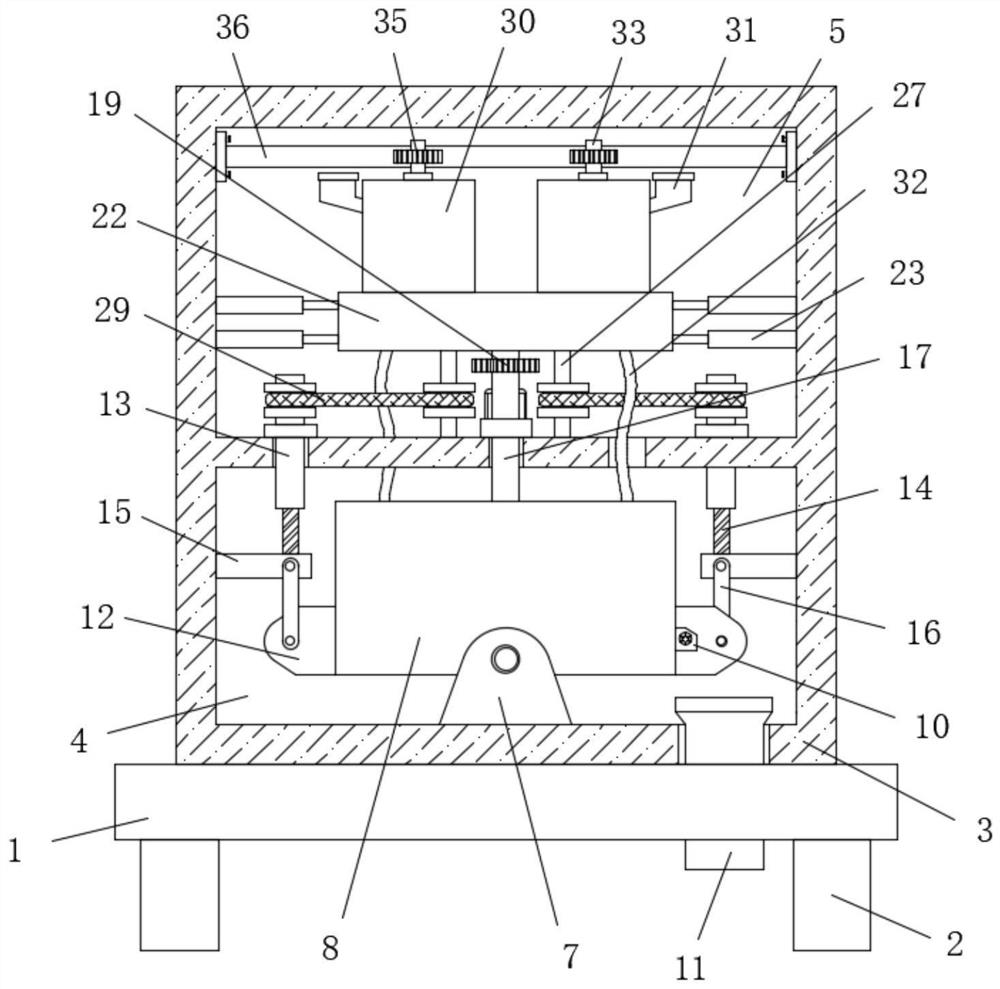

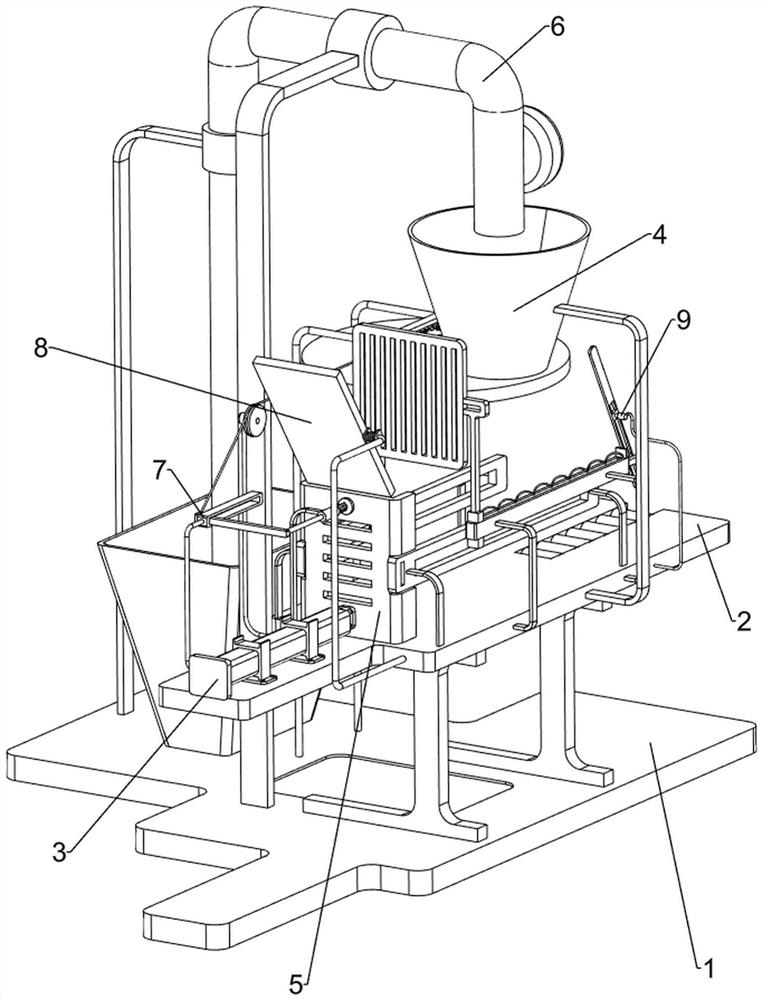

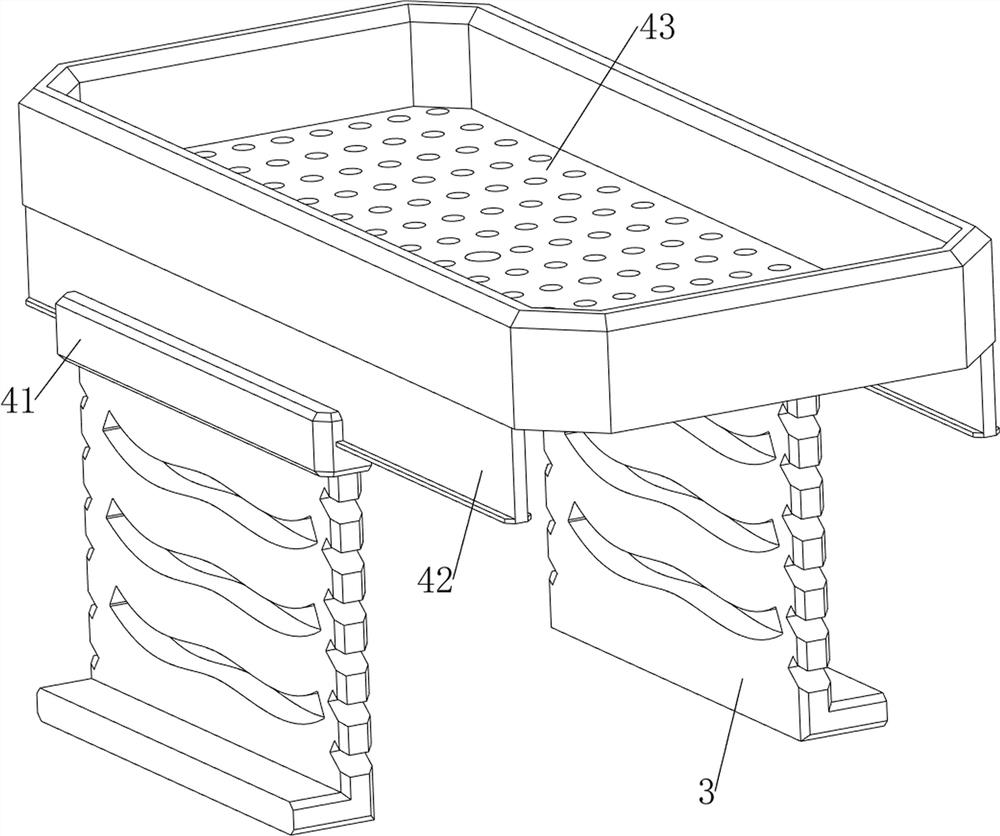

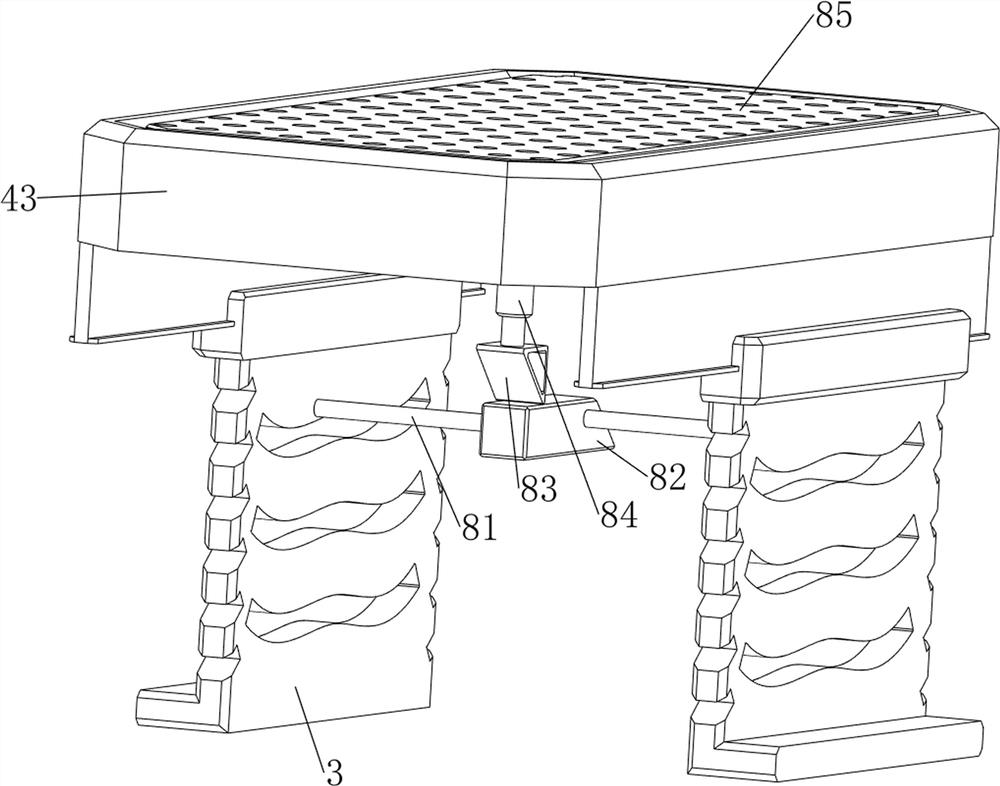

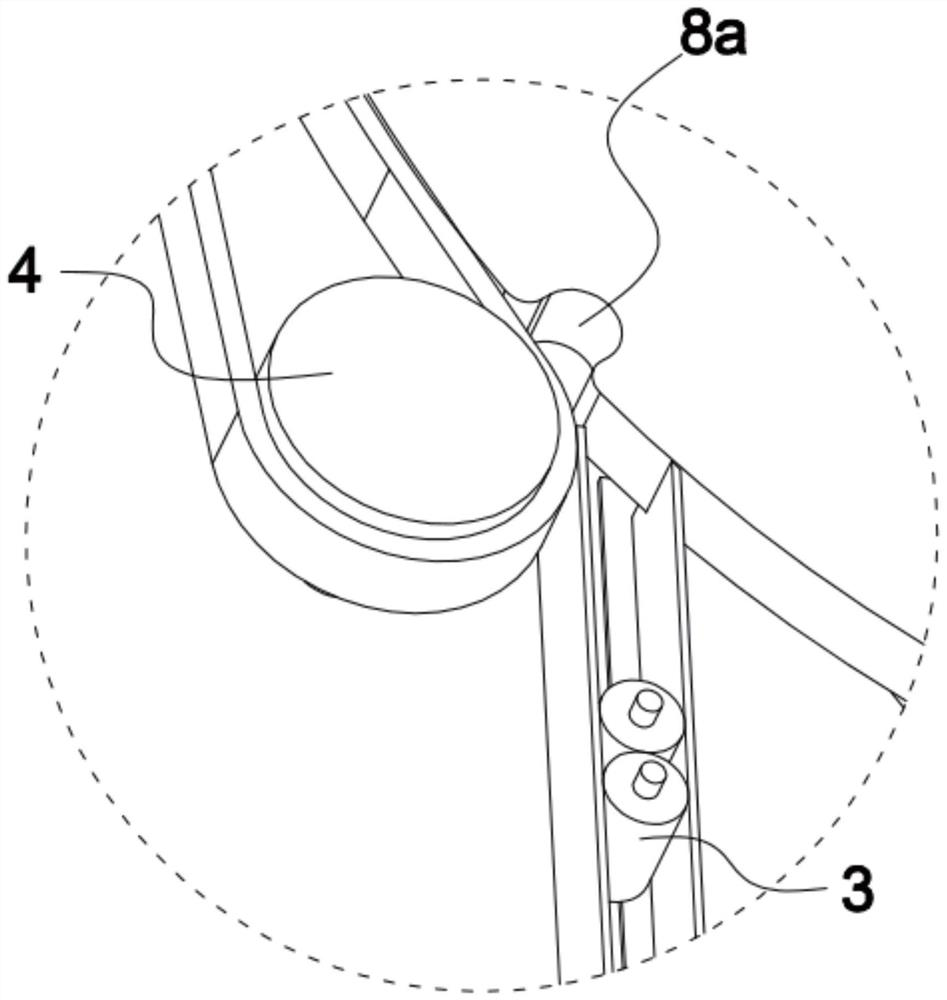

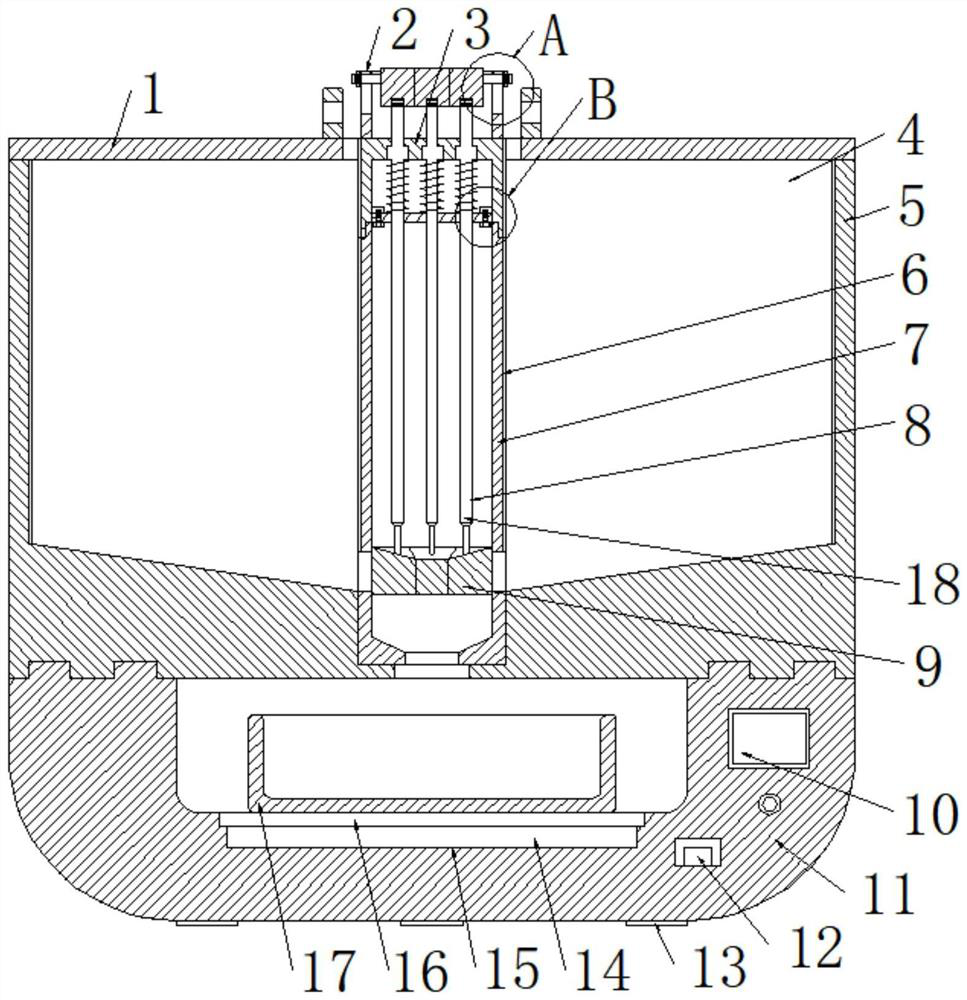

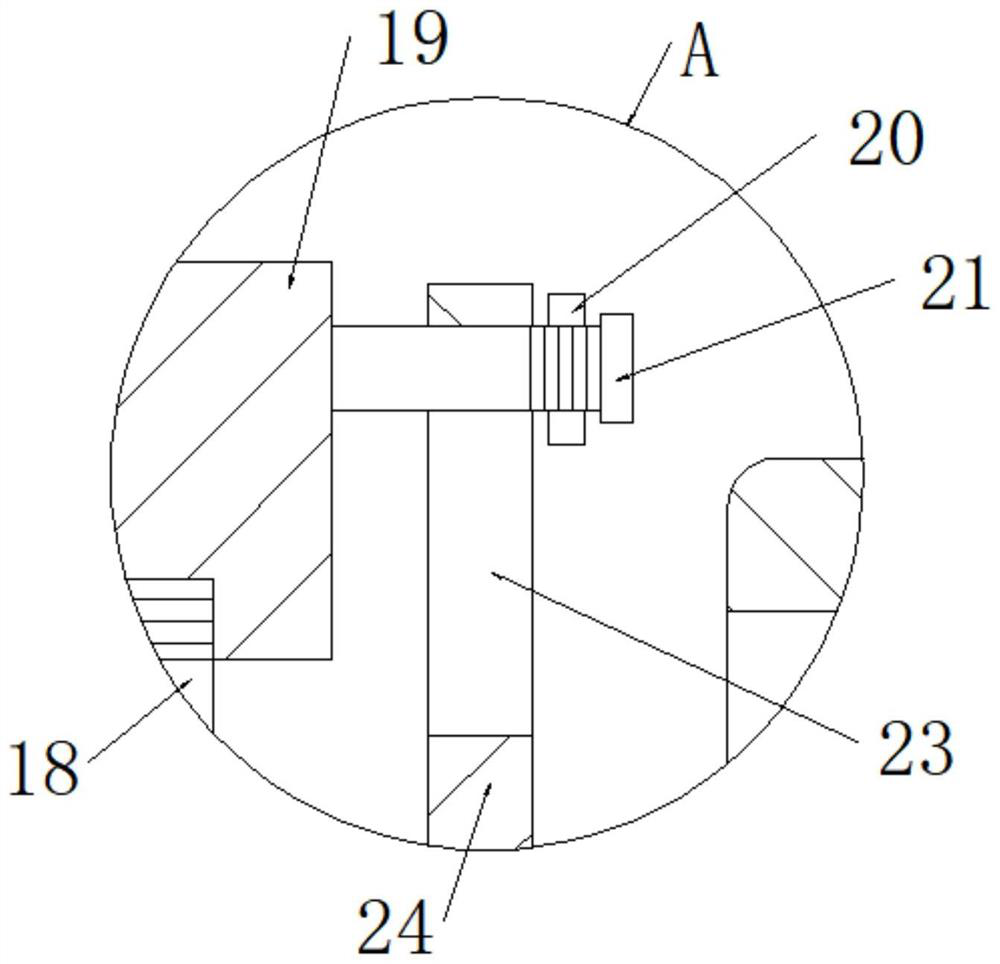

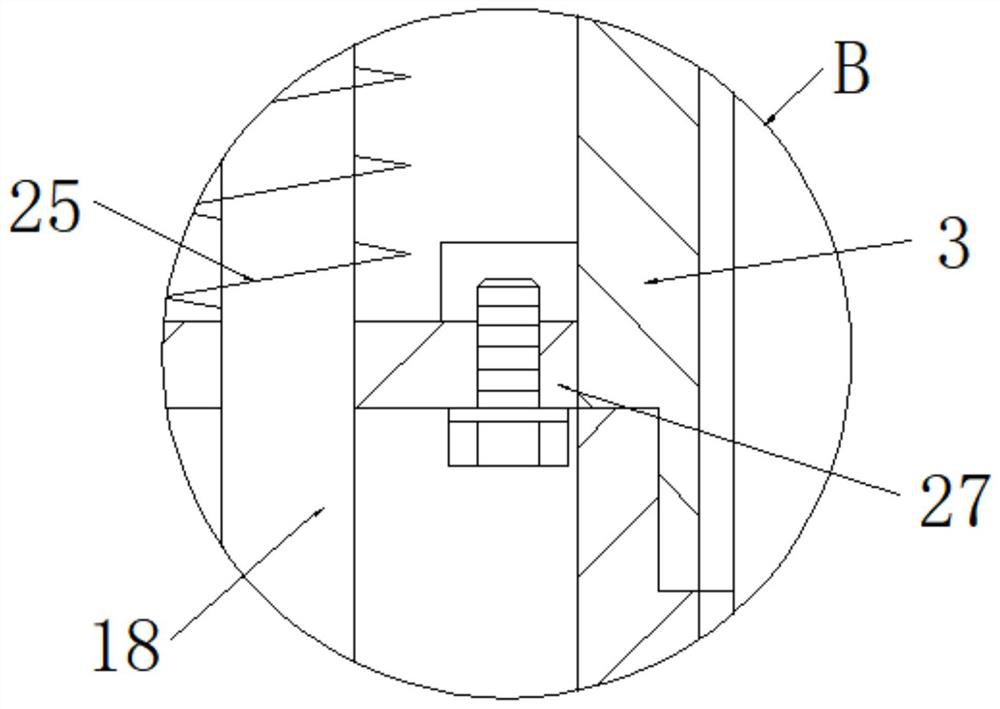

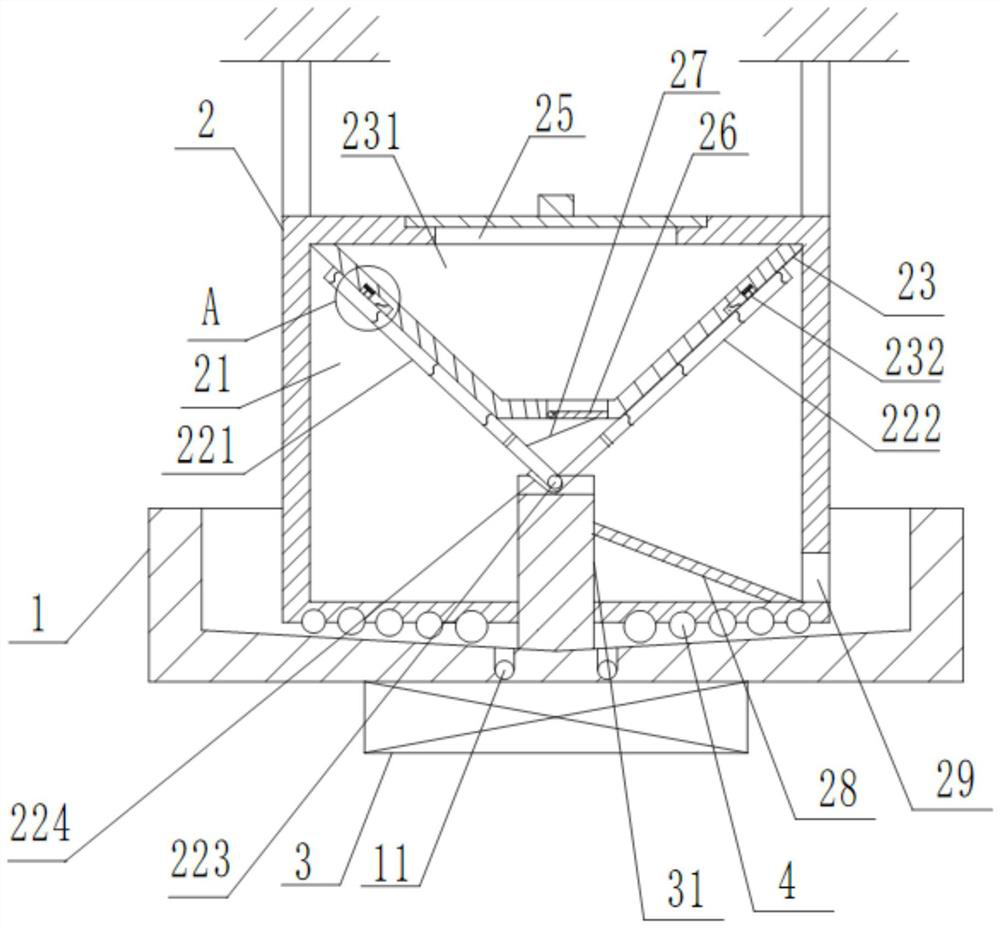

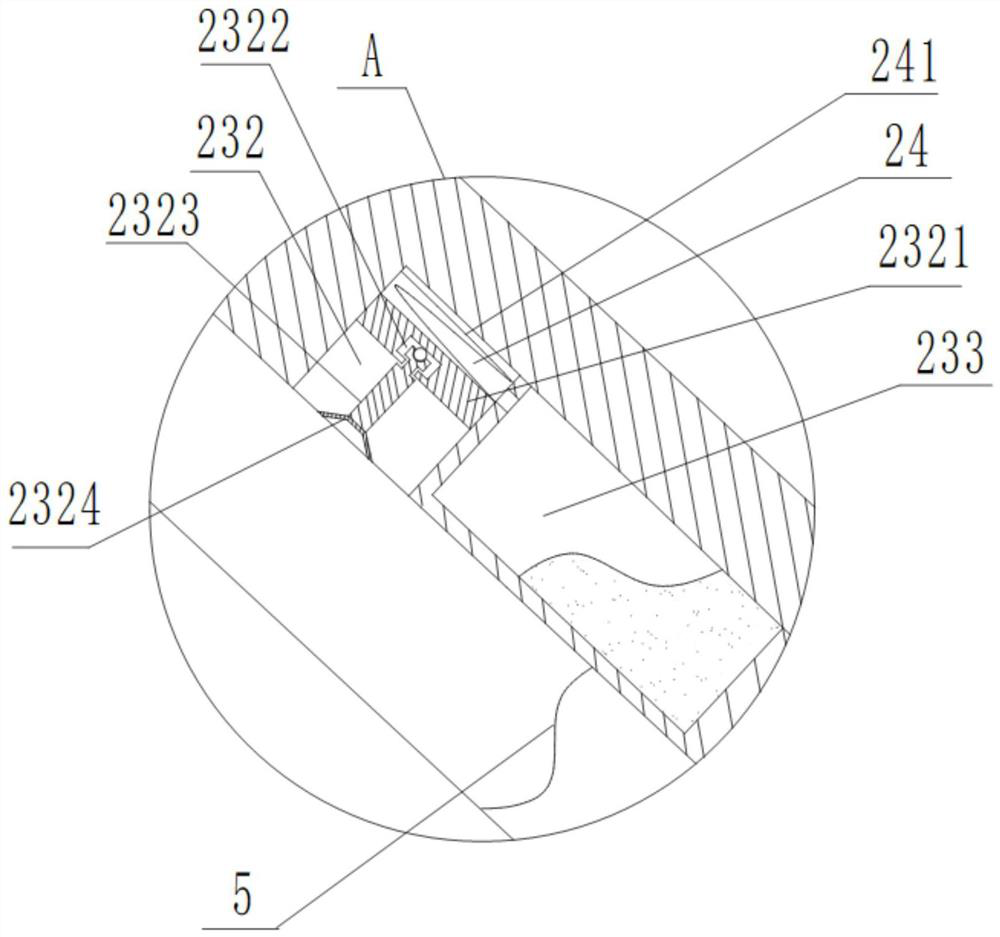

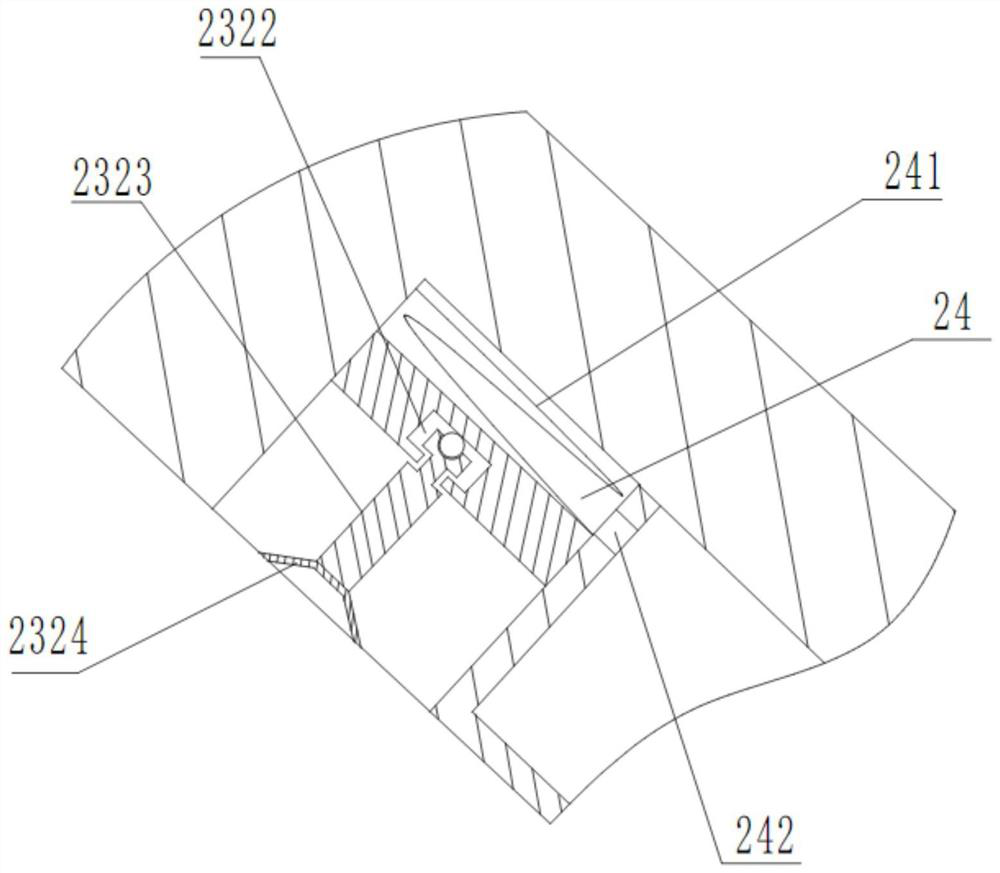

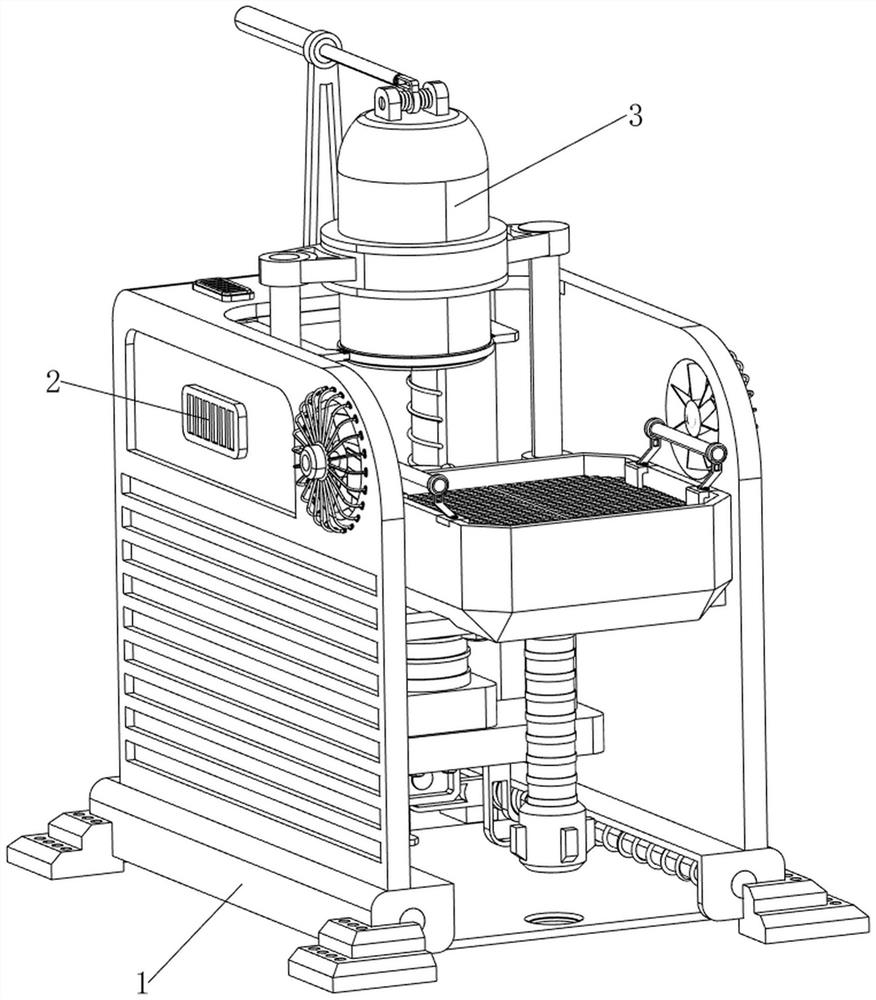

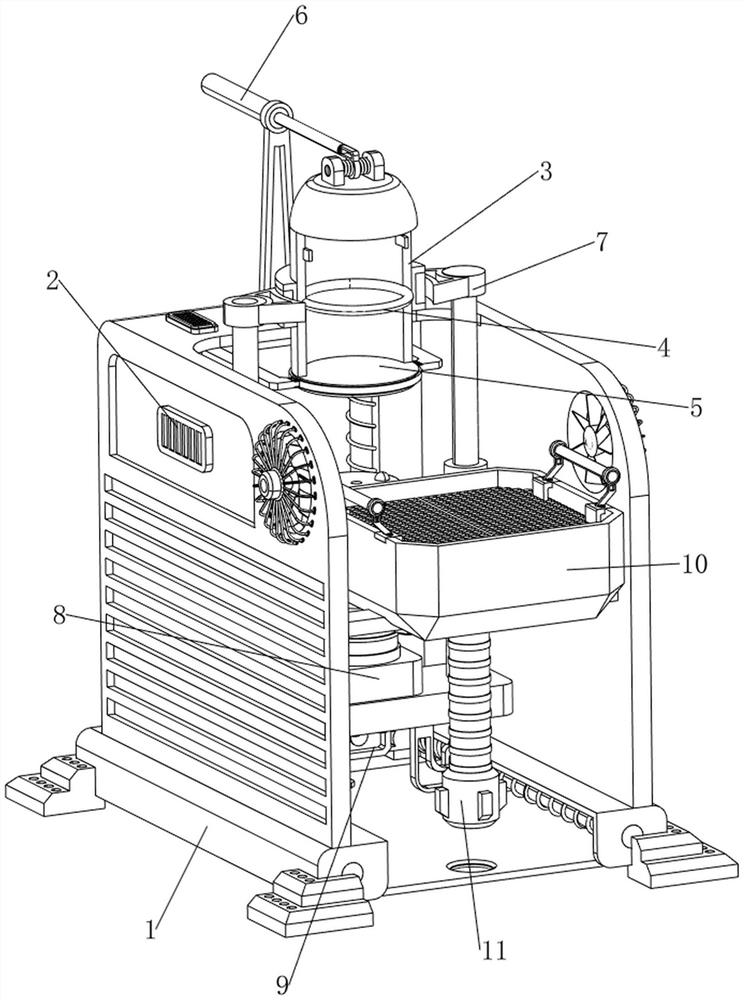

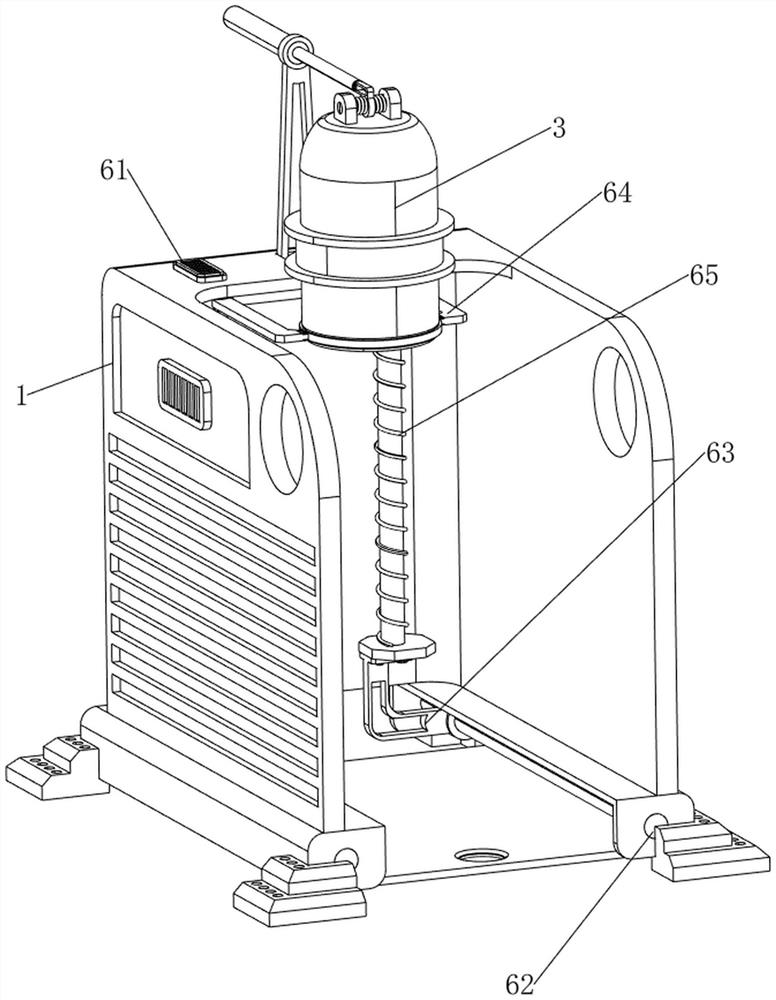

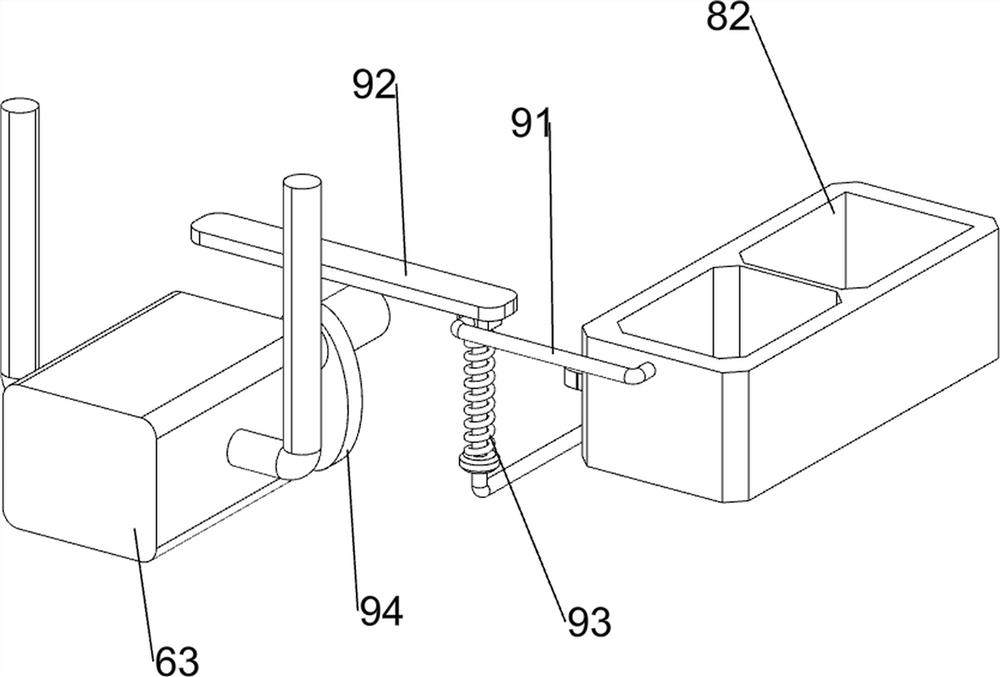

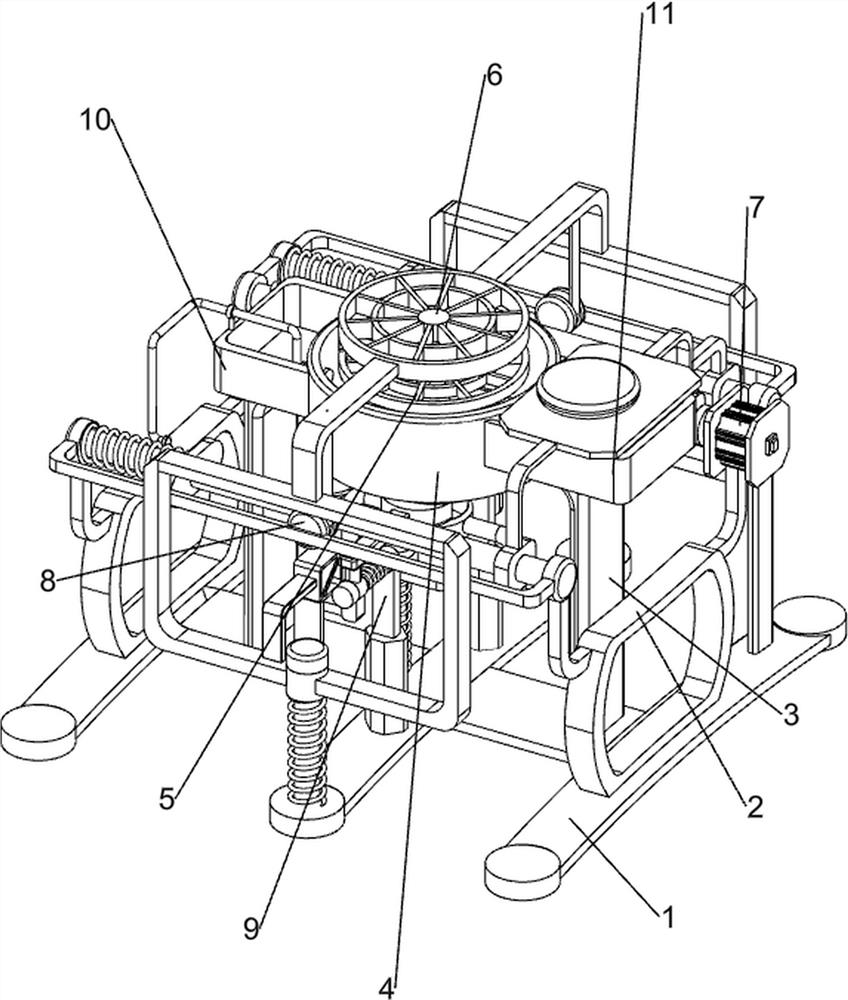

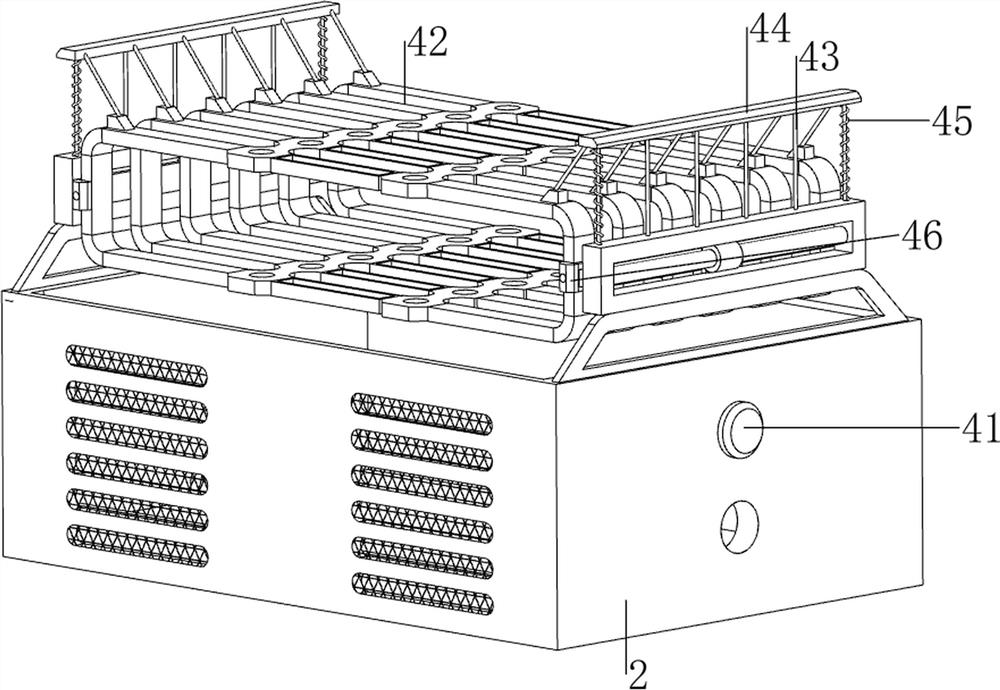

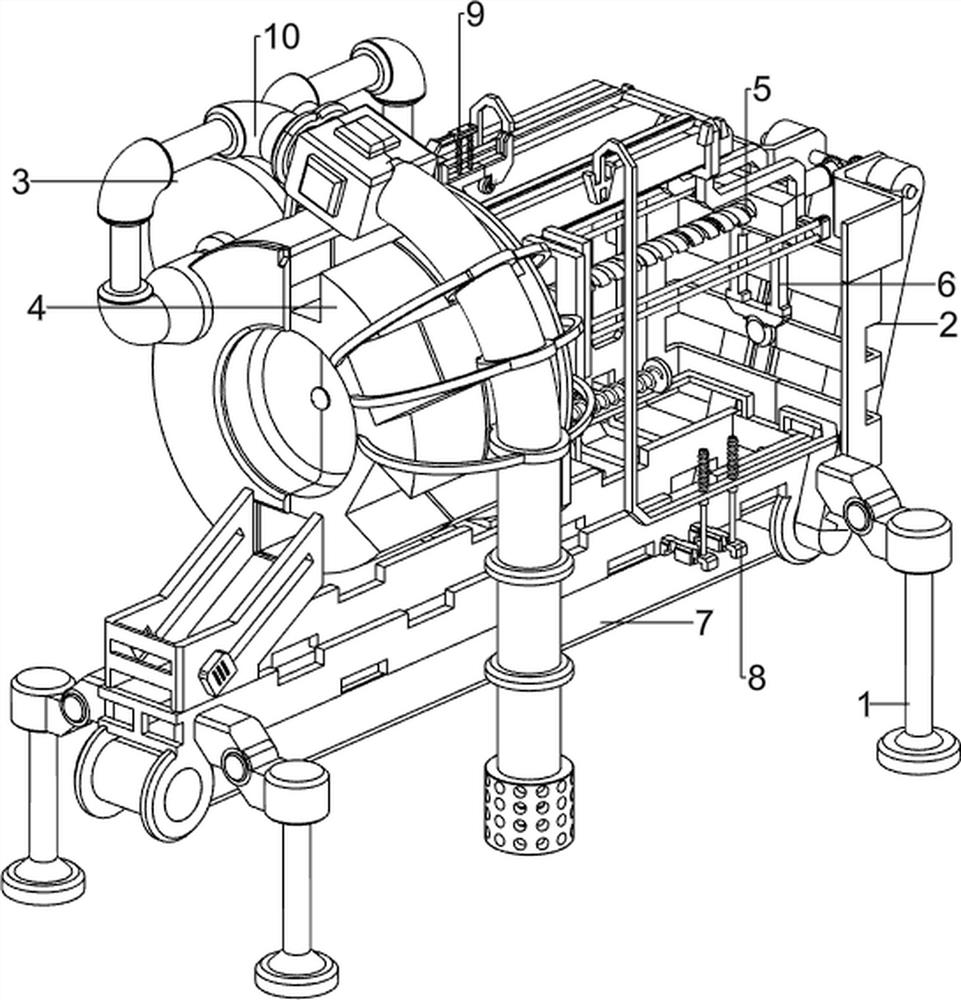

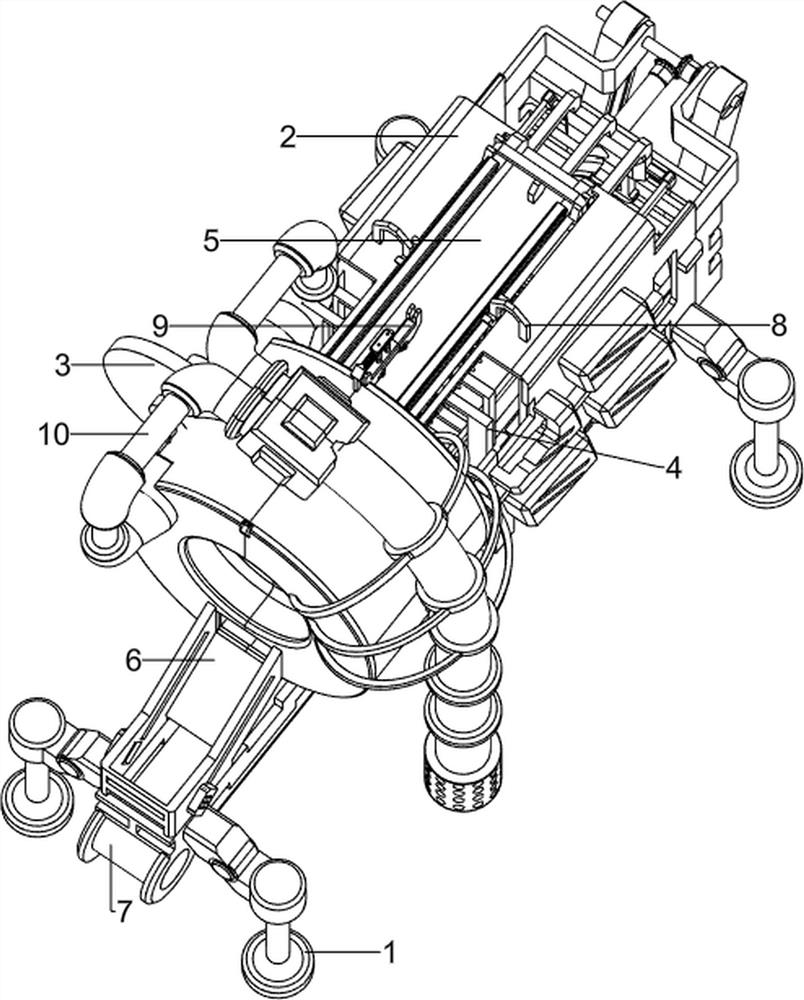

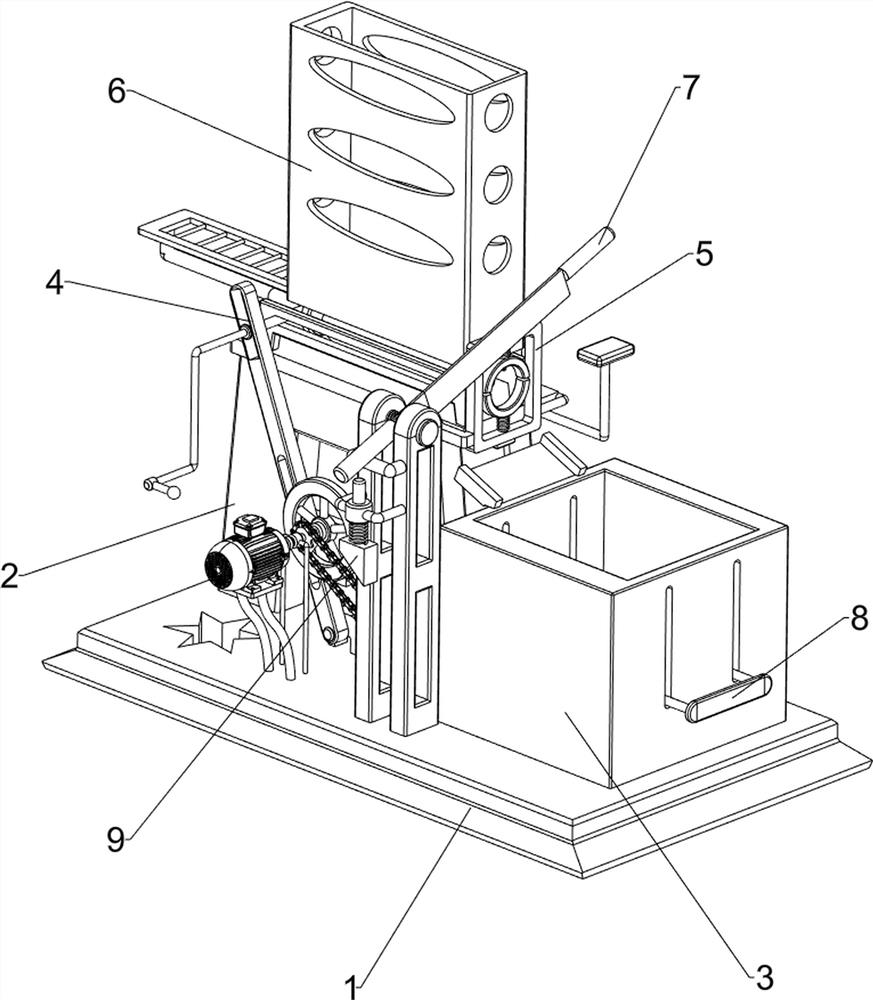

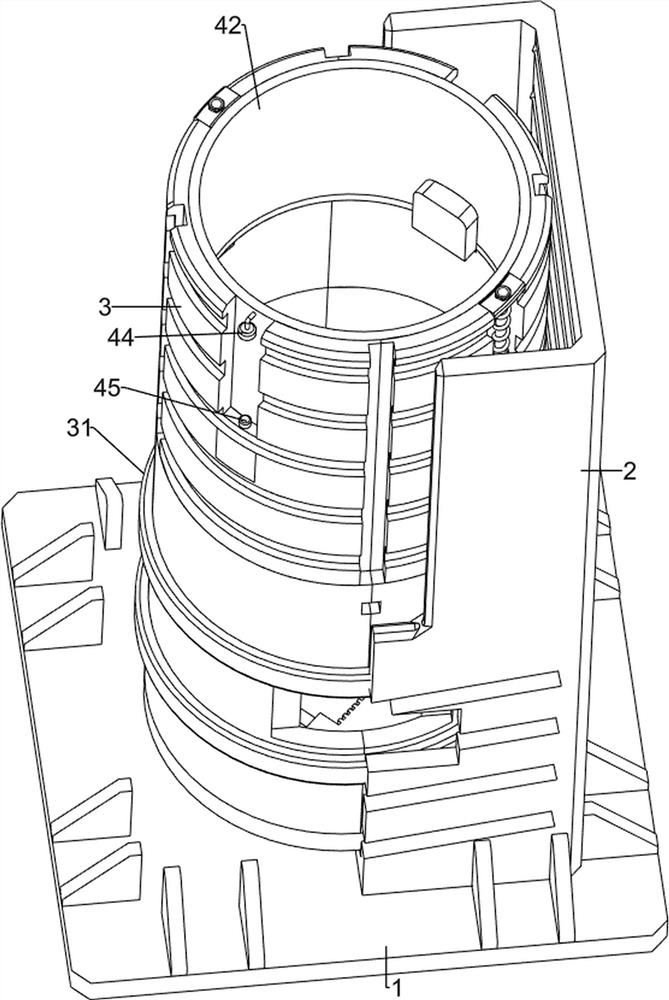

Agricultural organic fertilizer dehydration equipment

InactiveCN112484403ARealize extrusion dehydration effectRealize the output effectDrying solid materials without heatStationary filtering element filtersAgricultural scienceAgricultural engineering

The invention relates to a dehydration device, in particular to agricultural organic fertilizer dehydration equipment. The agricultural organic fertilizer dehydration equipment can be used for discharging organic fertilizer for multiple times, automatically discharging and extruding to dehydrate the organic fertilizer. The agricultural organic fertilizer dehydration equipment comprises a rack anda discharging mechanism; an extrusion dehydration mechanism is arranged on the rear side of the rack; and the discharging mechanism is arranged at the upper part of the rear side of the rack. According to the agricultural organic fertilizer dehydration equipment, an air cylinder telescopic rod extends downwards to drive a pressing plate to move downwards to extrude and dehydrate the organic fertilizer, moisture of the organic fertilizer flows out of a filter screen, and the extrusion and dehydration effect is achieved; and an arc-shaped connecting plate moves downwards, a first telescopic assembly in the contraction state is stretched, a discharging opening between the rack and the arc-shaped connecting plate is opened, and the discharging effect is achieved.

Owner:冉乾

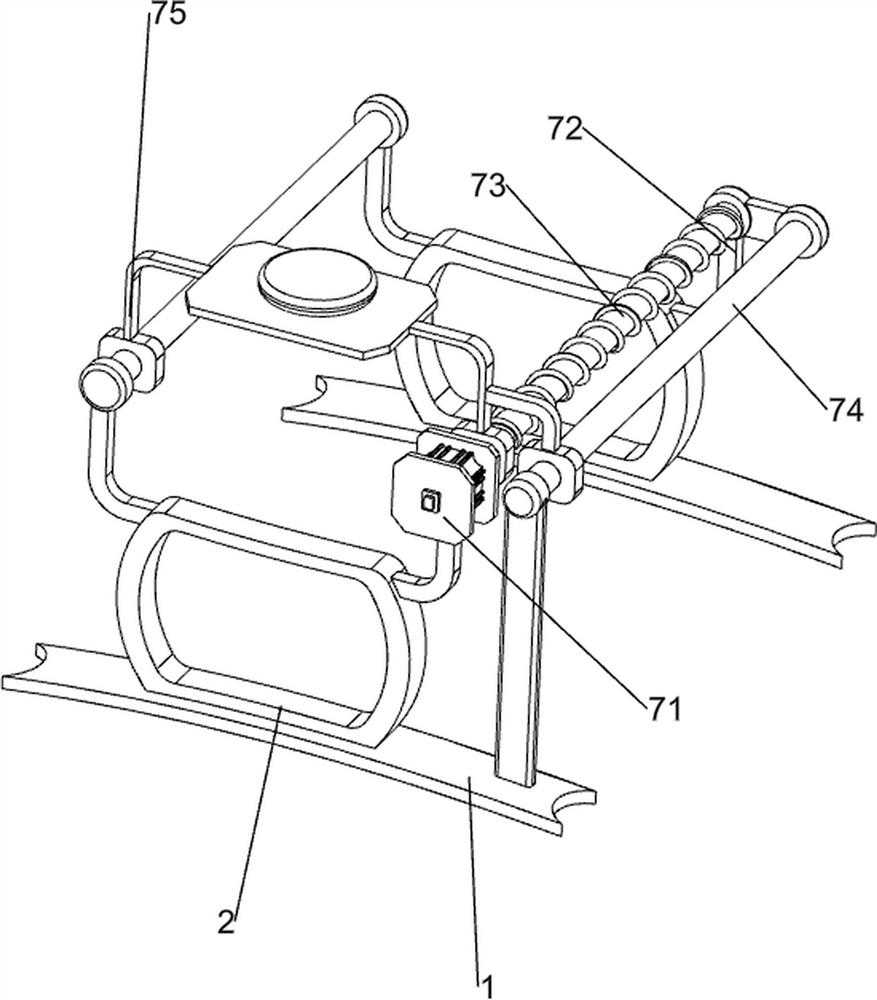

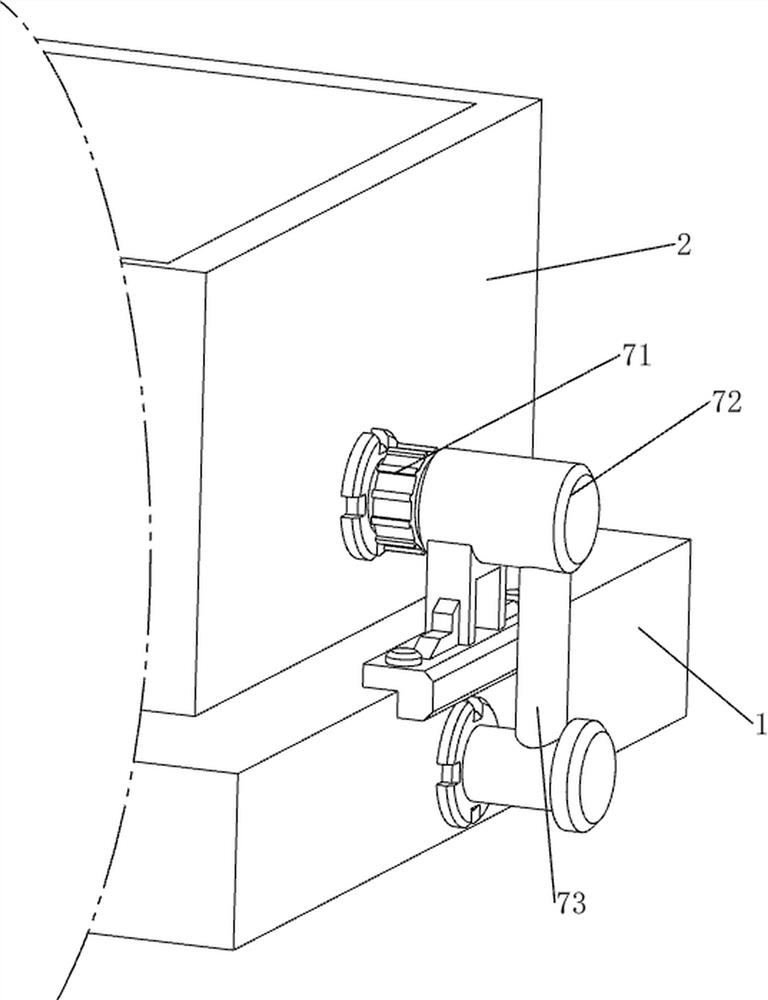

Welding device for high-end equipment manufacturing

PendingCN112743271ARealize the welding effectRealize the driving effectWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to a welding device, in particular to a welding device for high-end equipment manufacturing. The welding device for high-end equipment manufacturing is higher in fixing stability and capable of achieving automatic splicing and automatic welding. The welding device for high-end equipment manufacturing comprises a supporting leg, first supports, a welding mechanism and a pushing mechanism, and a mounting plate is arranged on the supporting leg; each of the left side and the right side of the top of the mounting plate is provided with the two first supports. the welding mechanism is arranged among the four first supports; and the pushing mechanism is arranged on the front side of the top of the mounting plate. A first sliding sleeve is pushed backwards to move backwards, so that an electric welding gun is driven to move backwards, a first spring is stretched, and after the electric welding gun makes contact with two metal plates, the electric welding gun welds the two metal plates, and the welding effect is achieved.

Owner:吴彬

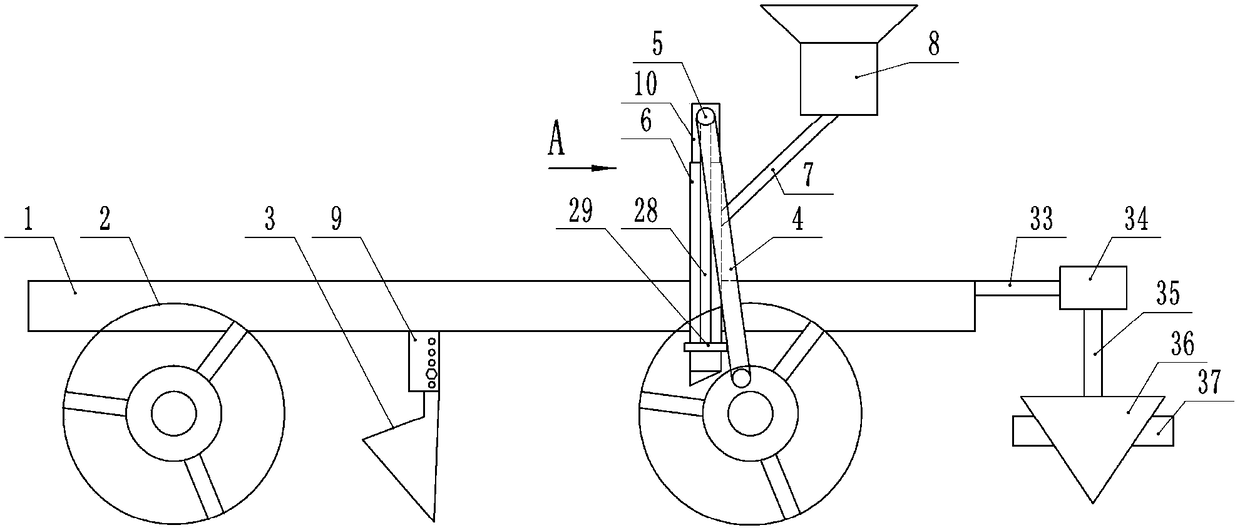

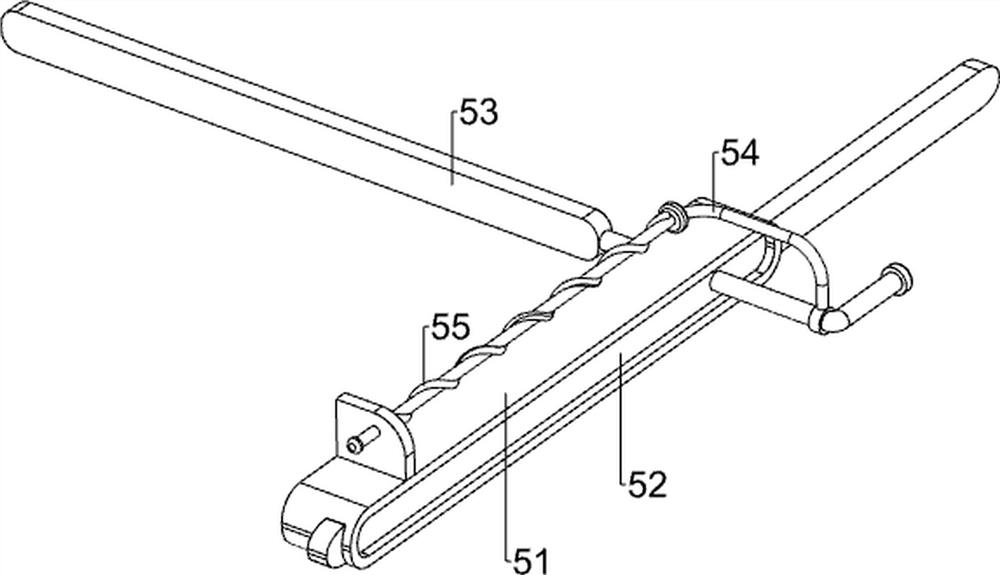

Corn planter

PendingCN108521938ARealize the output effectAvoid wastingPlantingFurrow making/coveringEngineeringHigh pressure

The invention belongs to the technical field of plant planting equipment and specifically discloses a corn planter which comprises a bottom plate, idler wheels, a discharging barrel, a feeding barrel,an auxiliary barrel, a horizontal rod, a supporting rod, a coulter and an earthing part, wherein an top block is arranged in the discharging barrel, and a blind plate, a sliding block, a thimble, a stopping piece and a high-pressure air cavity are arranged on the auxiliary barrel. The corn planter disclosed by the invention is mainly applied to planting corn and solves the problem of seed waste caused by continuous discharging in mechanical sowing.

Owner:重庆众点农业有限公司

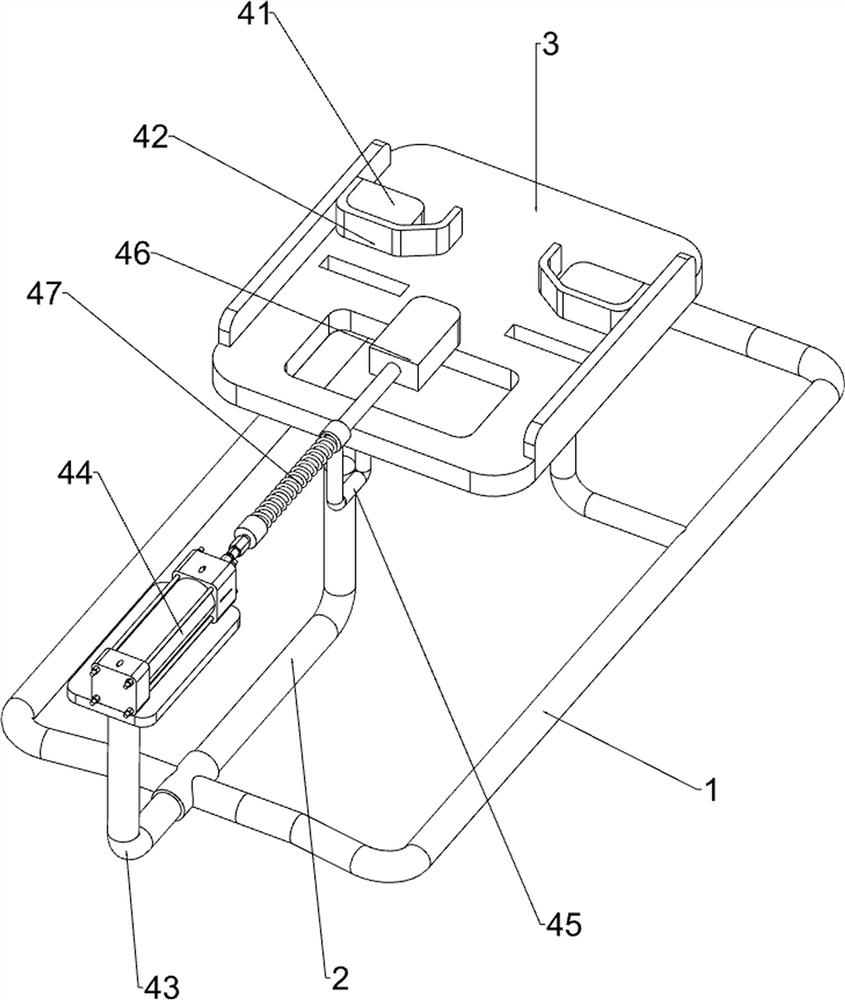

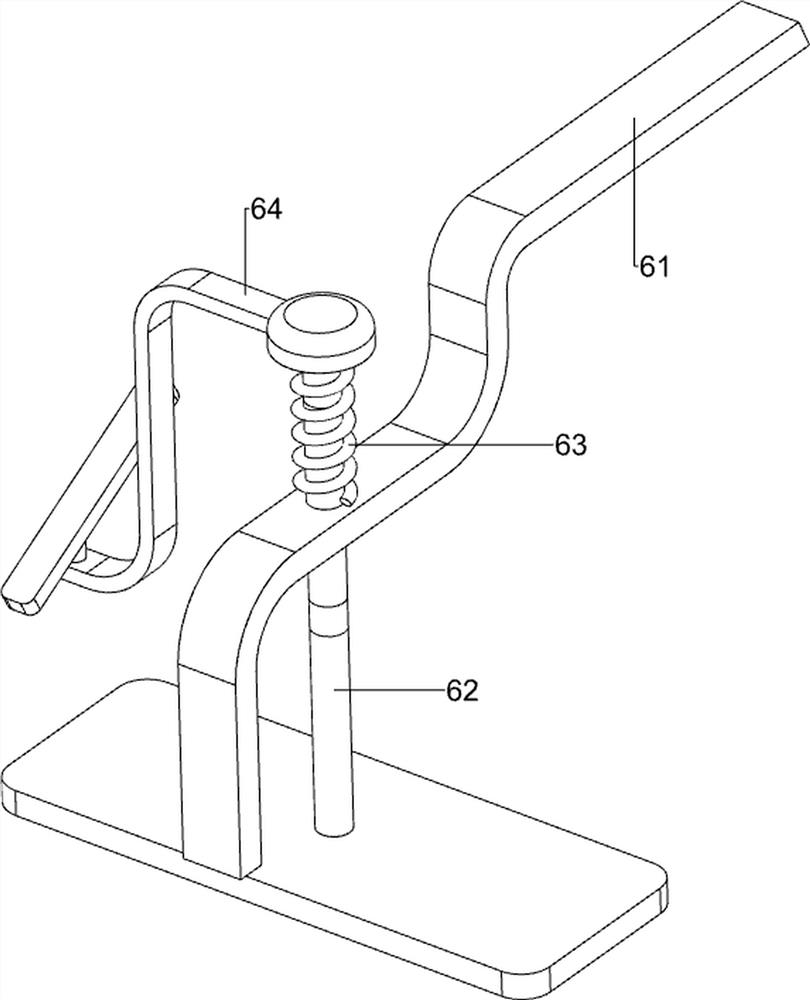

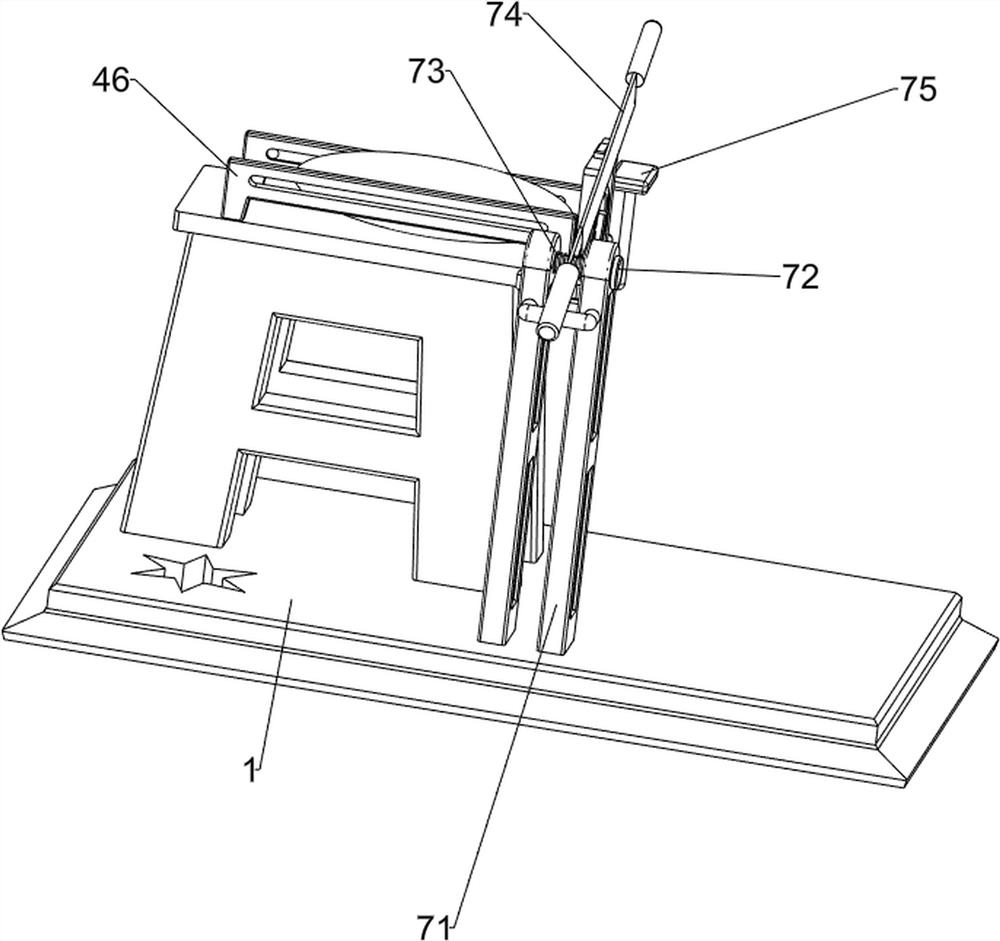

Iron rod bending machine for building construction

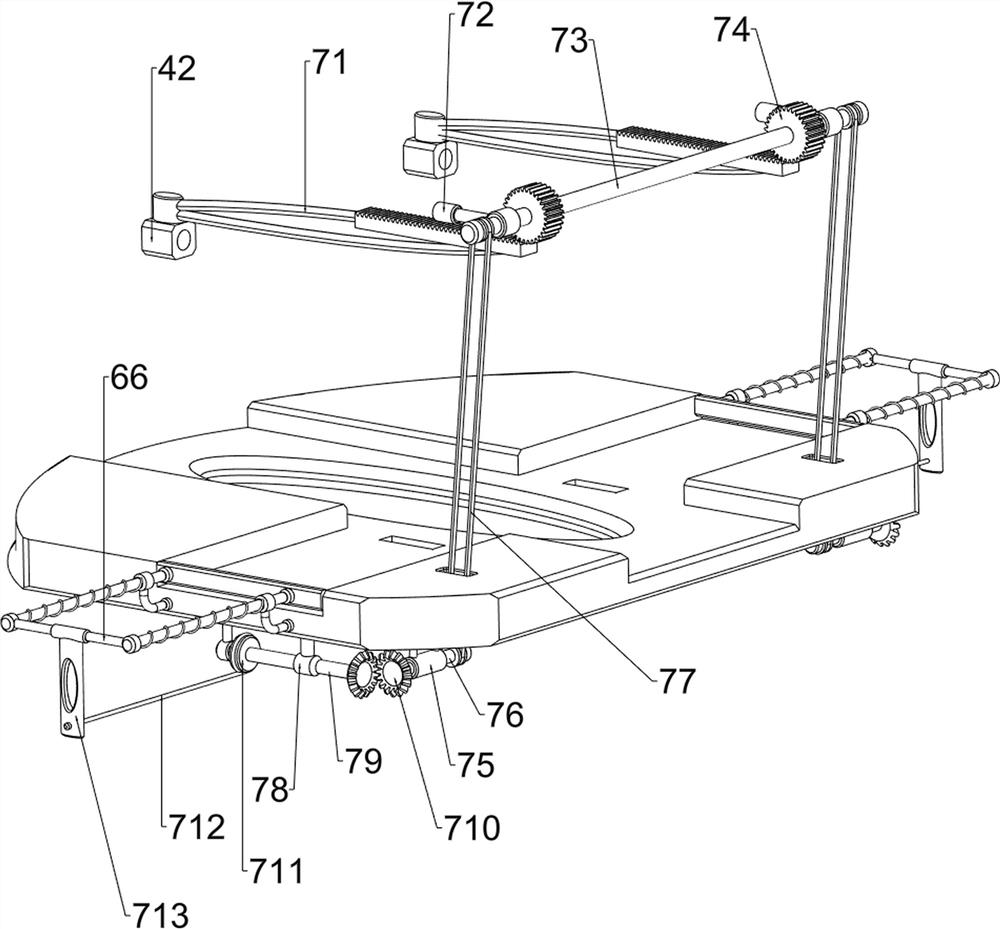

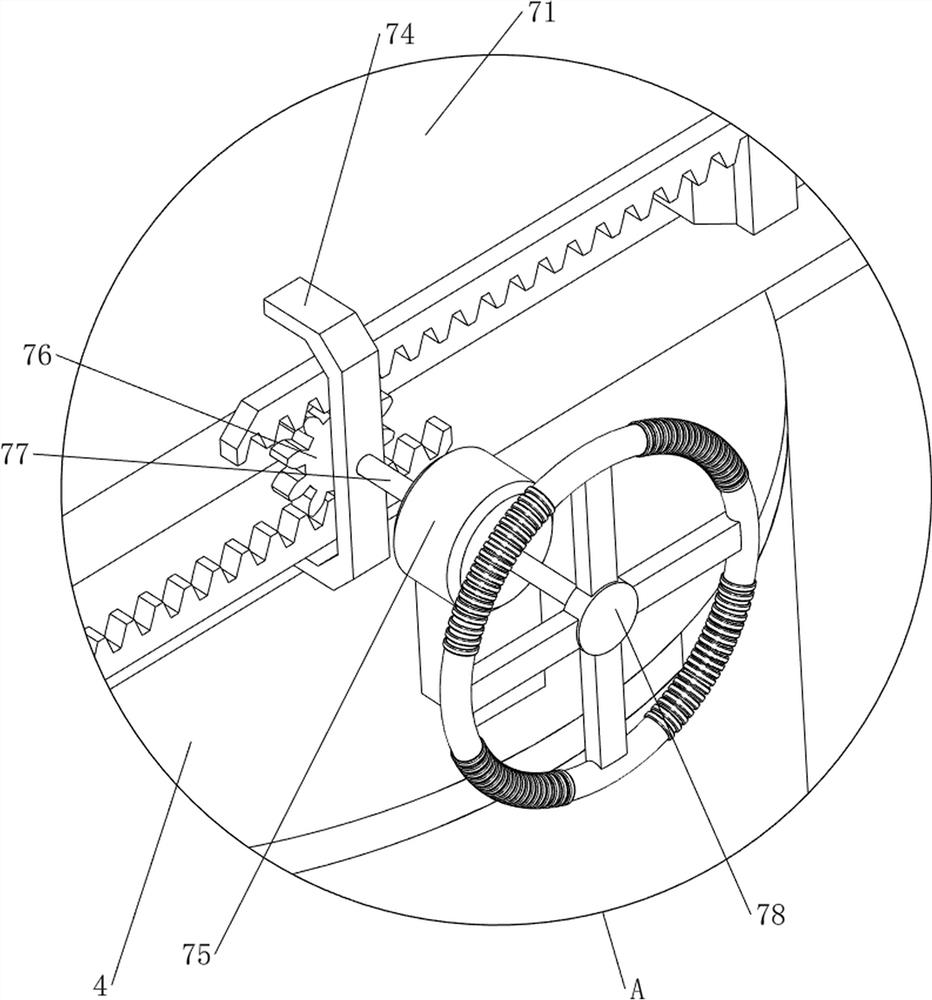

PendingCN112705600ARealize the bending effectRealize the output effectMetal-working feeding devicesPositioning devicesPress brakeRack and pinion

The invention relates to an iron rod bending machine, and particularly relates to the iron rod bending machine for building construction. The invention provides the iron rod bending machine for building construction, the iron rod bending machine for building construction can reduce working time, improve efficiency and accurately bend .iron rods. The iron rod bending machine for building construction comprises a base, a working plate and a bending mechanism, and supporting columns are arranged on the base; the working plate is arranged at the tops of the supporting columns; and the bending mechanism is arranged at the top of the working plate. According to the iron rod bending machine for building construction, the iron rods are bent through the bending mechanism, and the bending effect is achieved; the iron rods intermittently fall into a discharging frame through an intermittent discharging pipe and then fall into the middle of the working plate from the discharging frame, so that the intermittent discharging effect of the iron rods is achieved; and a third connecting rod drives a third supporting rod to move backwards, so that a rack is driven to move backwards, the rack is matched with a straight gear, the straight gear rotates by a quarter of a circle every time the rack moves backwards, and the effect of automatic intermittent discharging of the iron rods is achieved.

Owner:廖天进

Extrusion type modified starch grinding device

PendingCN113083414ARealize the effect of pressing down and crushingGrind evenlyGrain treatmentsComposite materialManufacturing engineering

The invention relates to a grinding device, in particular to an extrusion type modified starch grinding device. The extrusion type modified starch grinding device can improve the production efficiency and has the function of grinding while extruding. The extrusion type modified starch grinding device comprises a first fixing plate, a first supporting plate, a first discharging frame, a pressing mechanism and a material pushing mechanism; the first fixing plate is provided with the first supporting plate; the first discharging frame is arranged on the first supporting plate; the pressing mechanism is arranged on the first discharging frame; and the material pushing mechanism is arranged on the first fixing plate. According to the extrusion type modified starch grinding device, when first connecting rods are pushed by hands to move downwards, first springs are driven to be stretched, and then a grinding plate is driven to move downwards, so that modified starch in the first discharging frame is extruded and ground, and the effects of pressing and grinding are achieved.

Owner:吁红

Automatic stamping mechanism for stainless steel cover machining

PendingCN113183647ARealize the push effectRealize the effect of automatic upward liftingStampingStampingStructural engineering

The invention relates to an automatic stamping mechanism, in particular to an automatic stamping mechanism for stainless steel cover machining. The invention provides the automatic stamping mechanism for stainless steel cover machining which improves the stamping accuracy and the stamping effect and can automatically feed and discharge and automatically stamp. The automatic stamping mechanism for stainless steel cover machining comprises supports, a workbench, stop levers, a stamping mechanism and a pushing mechanism; the workbench is connected to a position among the top ends of the four supports; the stop levers are symmetrically arranged at the top of the workbench; the stamping mechanism is arranged at the top of the workbench; and the pushing mechanism is arranged on the workbench. According to the automatic stamping mechanism for stainless steel cover machining, the pushing mechanism is arranged, people push the pushing mechanism forwards, a stainless steel cover is pushed to a position between the stop rods, and therefore the stainless steel cover pushing effect is achieved.

Owner:叶胡海

Bandage shearing device for emergency department

ActiveCN114452091AAvoid wrinklesRealize the clamping effectBandagesGeneral Emergency DepartmentBandage

The invention relates to a shearing device, in particular to a bandage shearing device for the emergency department. The bandage shearing device for the emergency department is convenient to use, easy to operate and identical in shearing length. The bandage shearing device for the emergency department comprises a fixing piece and a rotating shaft, and the rotating shaft is rotationally arranged on the fixing piece; the clamping mechanism is arranged on the fixing piece; the feeding mechanism is arranged among the fixing piece, the rotating shaft and the clamping mechanism; the fusing mechanism is arranged on the firmware; and the heating plate is arranged on the fusing mechanism. The caliber of the bandage wound on the rotating shaft is continuously increased, the bandage enables the first wedge-shaped block to move outwards, the first spring is stretched, the first wedge-shaped block enables the bandage not to be loosened in the rotating process, and the clamping effect is achieved.

Owner:江苏康康同学科技有限公司

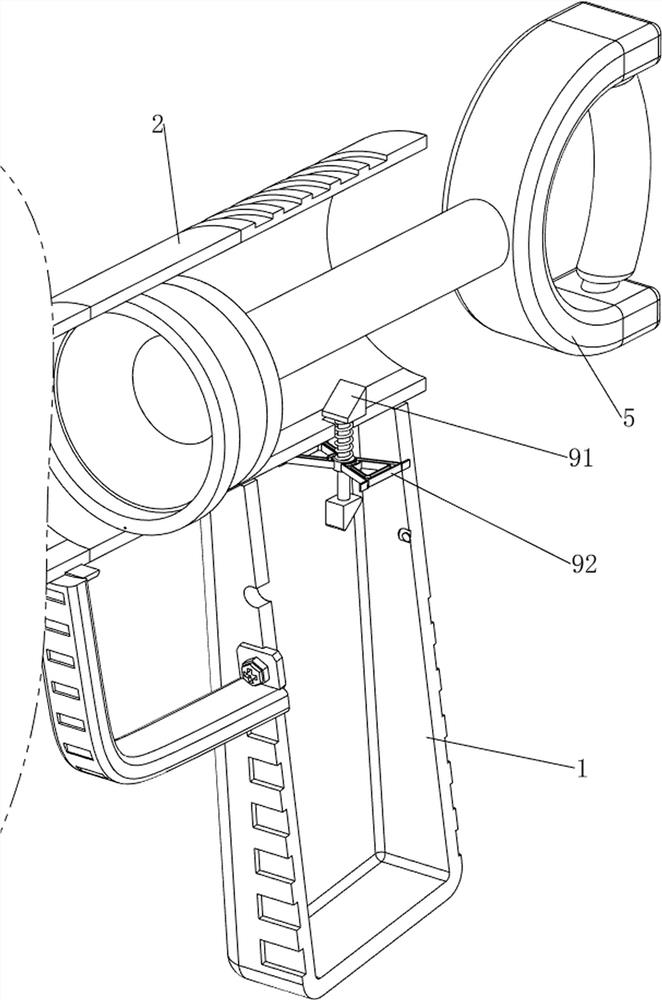

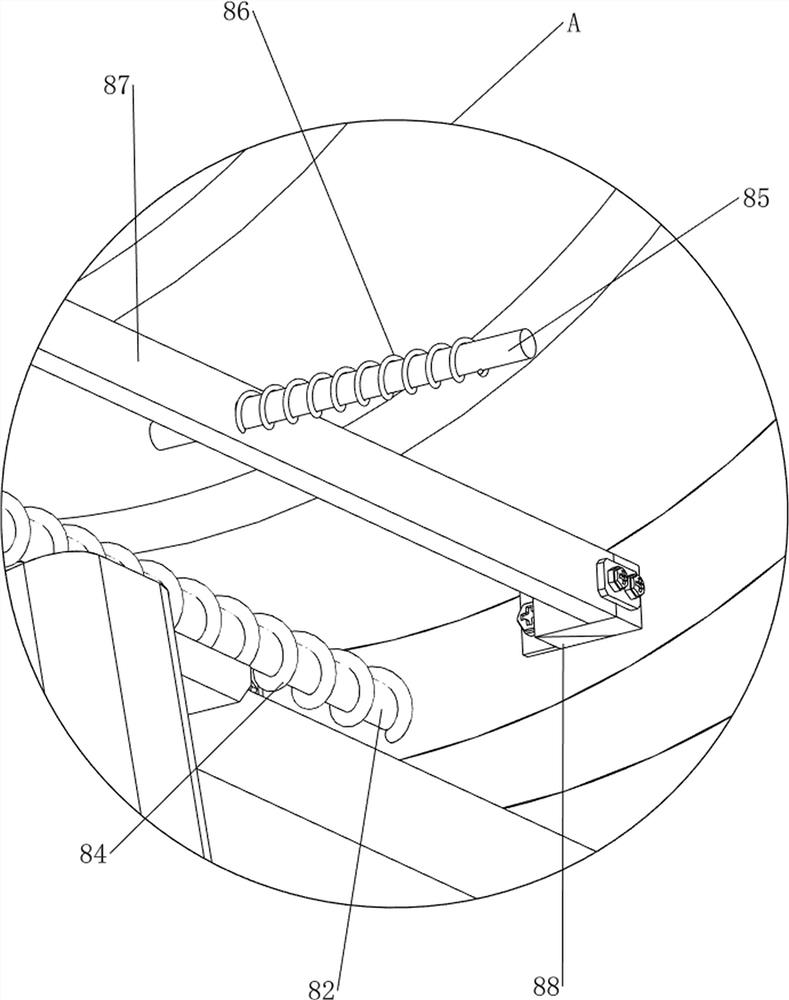

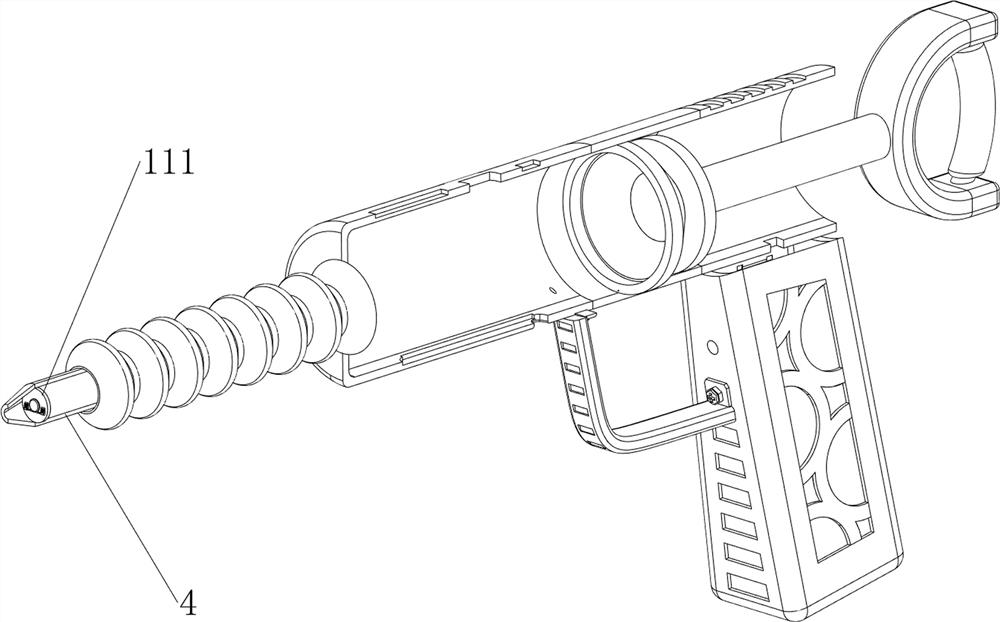

Stripping device of myoma of uterus for gynecology department

ActiveCN113545827ARealize the output effectAchieve cutting effectIncision instrumentsPlastic recyclingEngineeringGynecology department

The invention relates to a stripping device, in particular to a stripping device of the myoma of uterus for the gynecology department. The invention provides the stripping device of the myoma of uterus for the gynecology department, and the stripping device can carry out automatic stripping, can be easily and conveniently used and has small harm to patients. The tripping device of the myoma of uterus for the gynecology department comprises a stripper, a first collecting frame, a discharging mechanism, a cutting mechanism, a cutting component and a feeding mechanism, wherein the first collecting frame is arranged on the stripper; the discharging mechanism is arranged between the stripper and the first collecting frame; the cutting mechanism is arranged on the stripper; the cutting component is arranged on the cutting mechanism; and the feeding mechanism is arranged on the first collecting frame. The telescopic rod of an electric push rod is controlled by a control module to be static for one minute, a gynecologist can screw down a collecting pipe, then, the gynecologist can take out the myoma on the collecting pipe, and a discharging effect is achieved.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

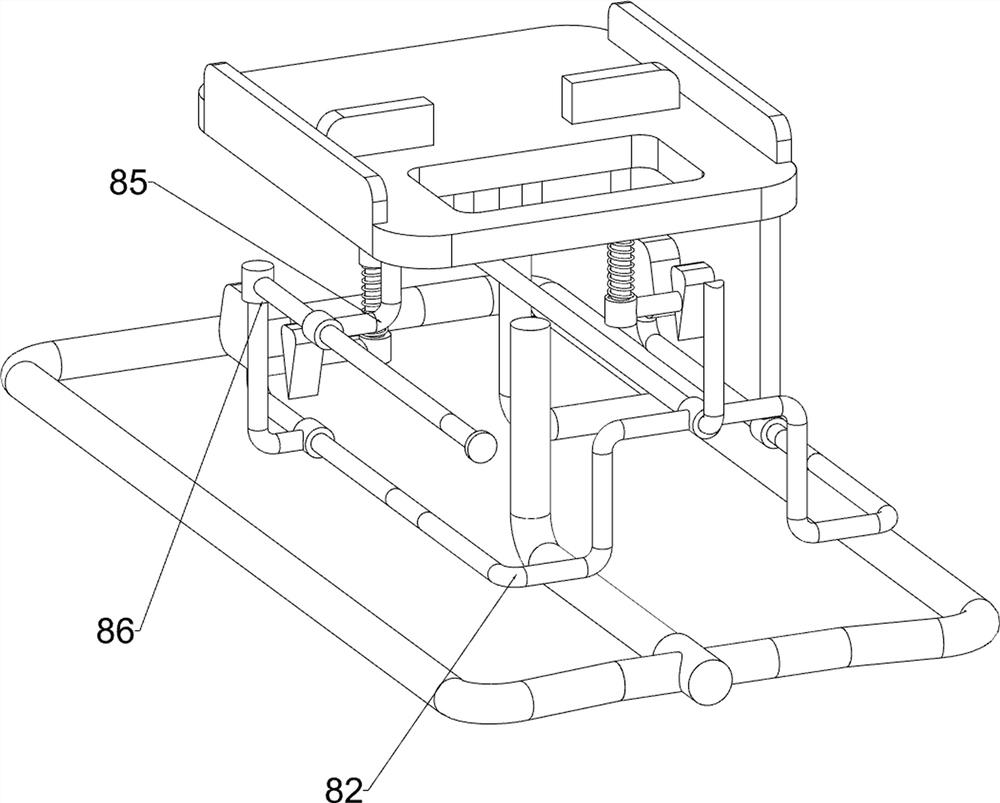

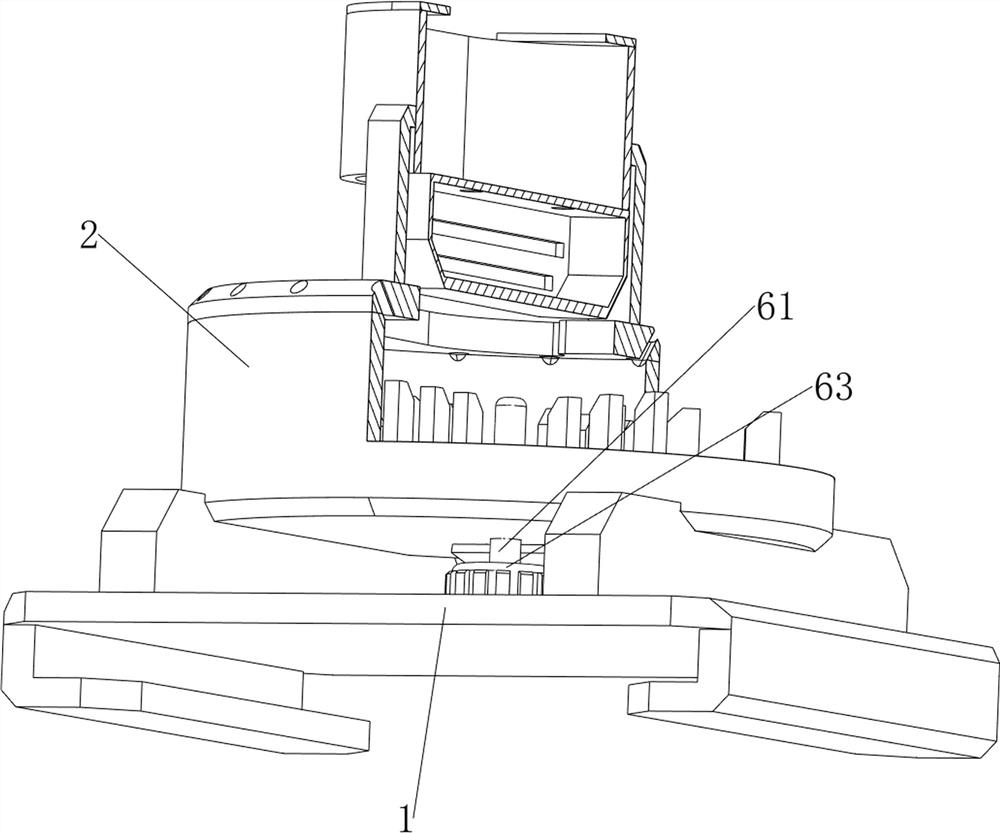

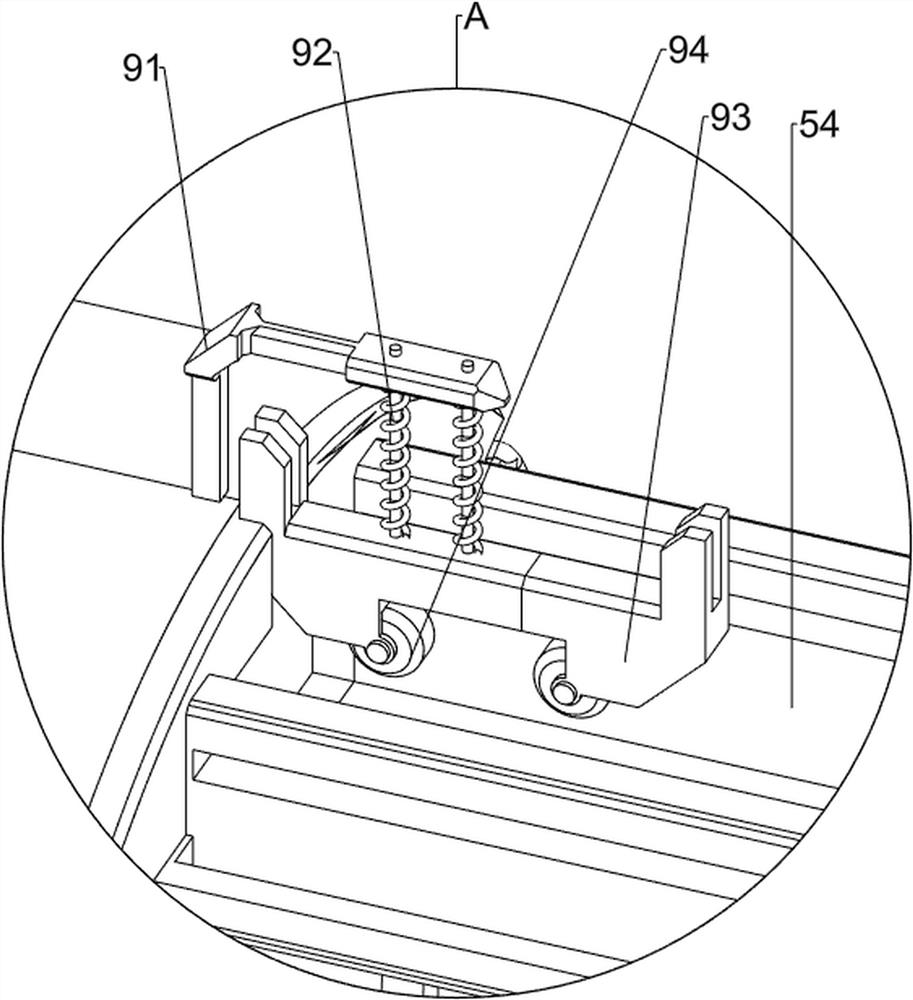

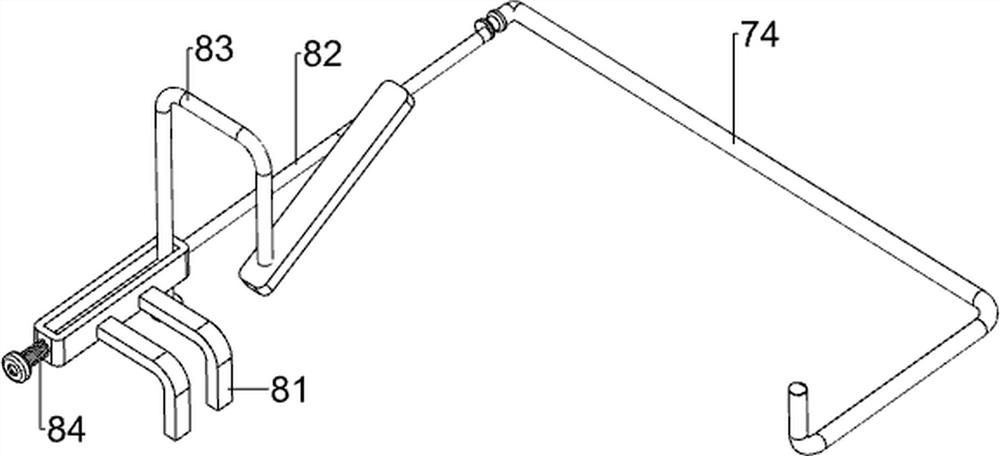

Steel bar two-end bending device for construction site

The invention relates to a bending device, in particular to a steel bar two-end bending device for a construction site. The steel bar two-end bending device for the construction site can bend the two ends of a reinforcing steel bar automatically and reduce errors. The steel bar two-end bending device for the construction site comprises: a first fixing frame and a third fixing frame, wherein the third fixing frame is arranged between the two sides of the upper portion of the first fixing frame. a second fixing frame, wherein the second fixing frame is arranged between the upper side of the third fixing frame and the upper side of the first fixing frame; a bending mechanism, wherein the bending mechanism is arranged on the second fixing frame; and a discharging mechanism, wherein the discharging mechanism is arranged at the top of the second fixing frame. A bending rod is driven to move leftwards through a telescopic rod of an air cylinder, so that the bending rod bends a reinforcing steel bar, and the bending effect is achieved; a shifting block makes contact with a first shifting rod, a shifting block drives a first shifting rod to slide upwards along an arc-shaped sliding rail, automatic material loosening can be achieved, and the material loosening effect is achieved.

Owner:新疆隆泉建设集团有限公司

Processing equipment for degradable plastic bag production and degradable plastic bag production technology

PendingCN113071016ARealize the effect of preliminary stirring and mixingAchieve stirring and mixing effectMechanical energy handlingProcess equipmentElectric machine

The invention belongs to the technical field of plastic production equipment, particularly relates to processing equipment for degradable plastic bag production and a degradable plastic bag production technology, and aims to solve the problems that in the prior art, a traditional stirring and mixing mode is poor in mixing effect, consequently plastic raw materials cannot be well mixed, and the mixing efficiency is low as a premixing function is not available. According to the scheme, the processing equipment comprises a bottom plate, supporting legs are fixedly connected to the four corners of the bottom of the bottom plate, and a box body is fixedly connected to the top of the bottom plate. According to the processing equipment, a first stirring shaft can be driven to rotate by starting a rotating motor, so that the raw materials in the mixing box are stirred; and meanwhile, through cooperation of a movable plate, the mixing box can be driven to swing back and forth, so that the raw materials can be fully mixed, discharging is facilitated, premixing boxes can also be driven to move back and forth through the movable plate, the effect of automatically stirring and mixing the raw materials in the premixing boxes can be achieved, and the mixing efficiency is improved.

Owner:张东越

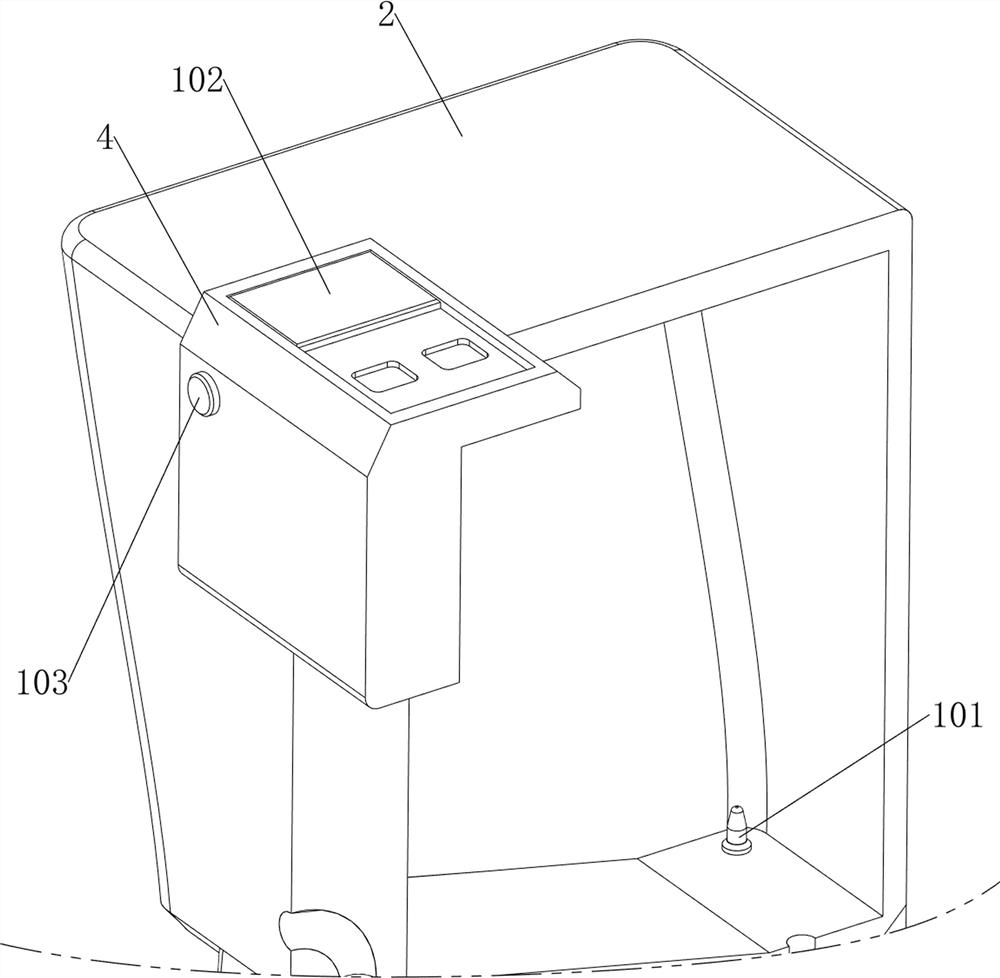

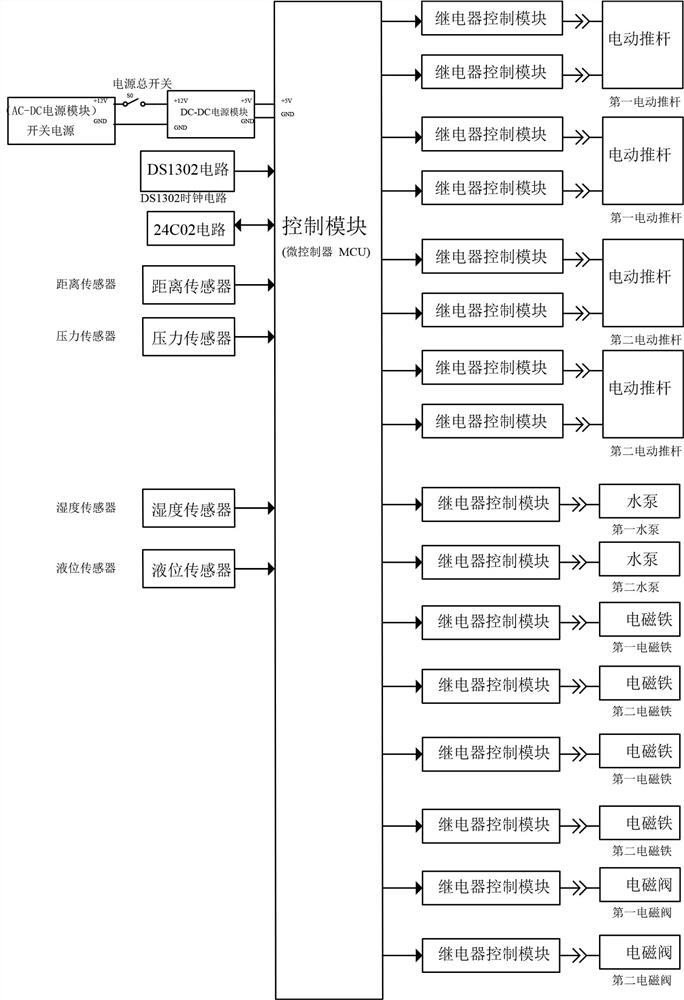

Efficient wall coating device for interior decoration of building

PendingCN113605644ARealize the output effectAchieve liftingBuilding constructionsConstruction engineeringStructural engineering

The invention relates to a coating device, in particular to an efficient wall coating device for interior decoration of a building. The efficient wall coating device for interior decoration of the building can be used for automatically coating, has small influence on a human body and is uniform in coating. The efficient wall coating device for interior decoration of the building comprises a base, a material box and a control box, and the material box is arranged at the top of the base; and the control box is installed on the upper side of the material box, a storage battery, a control module and a power supply module are installed in the control box, the storage battery supplies power to the whole wall coating device, the output end of the storage battery is electrically connected with the power supply module, the power supply module is connected with a power supply main switch through a circuit, and the control module is electrically connected with the power supply module. By arranging a discharging mechanism, people press a discharging mechanism part, the control module controls the discharging mechanism to operate, so that paint in the material box can be pumped to a spray head, the spray head can spray the wall surface, and the discharging effect is achieved.

Owner:华建生

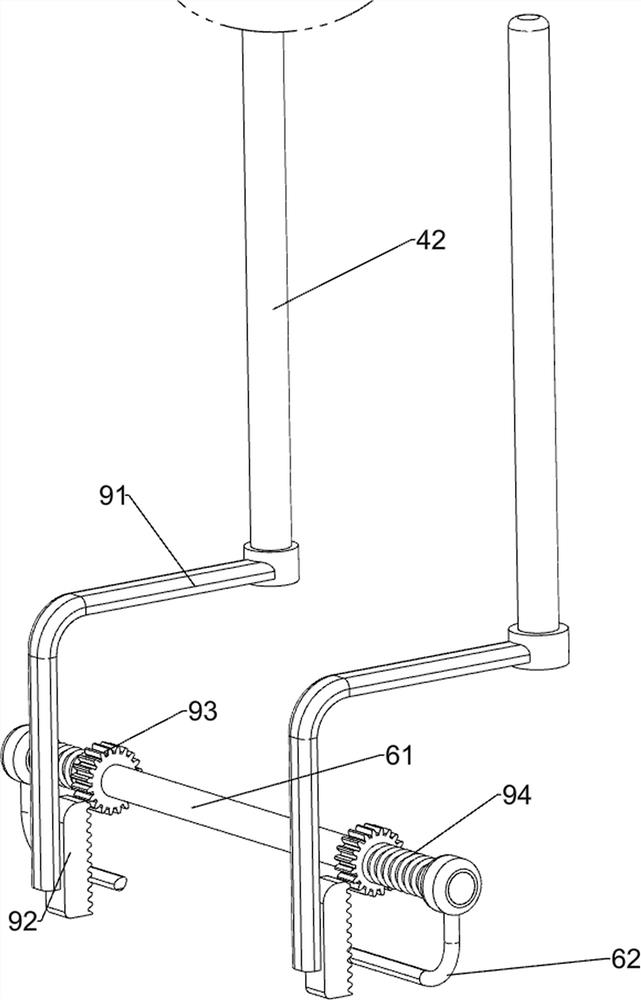

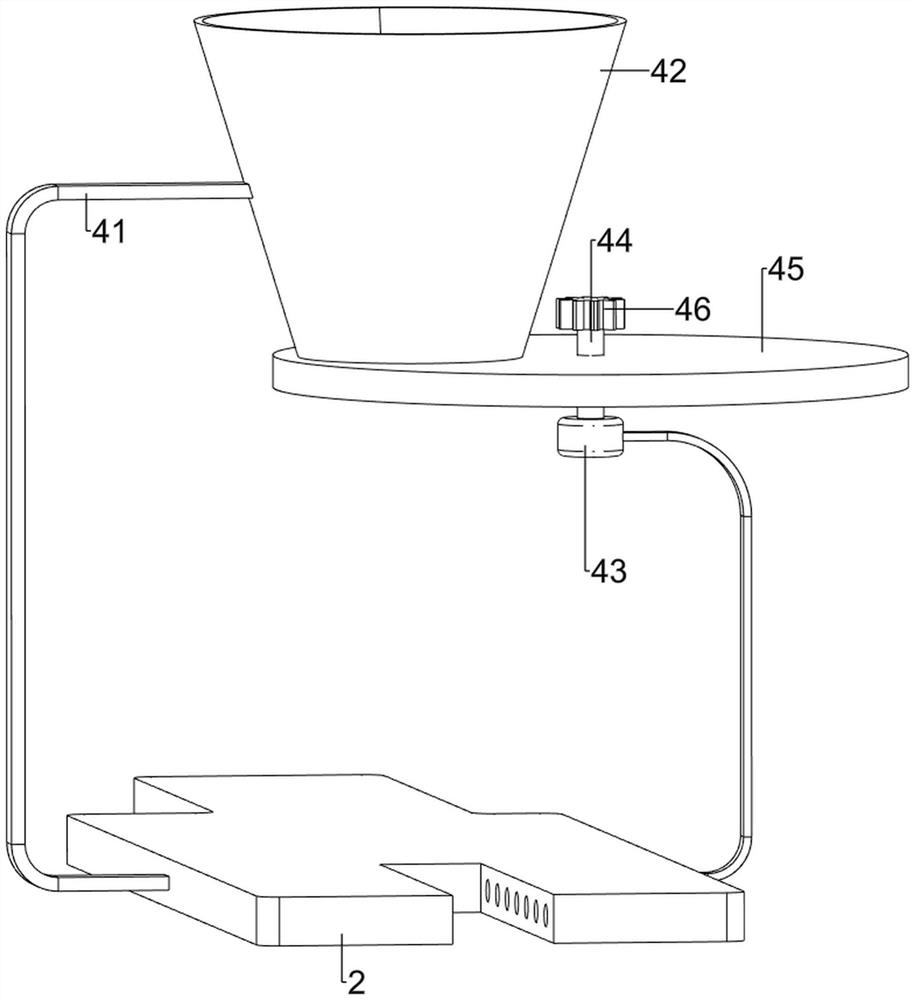

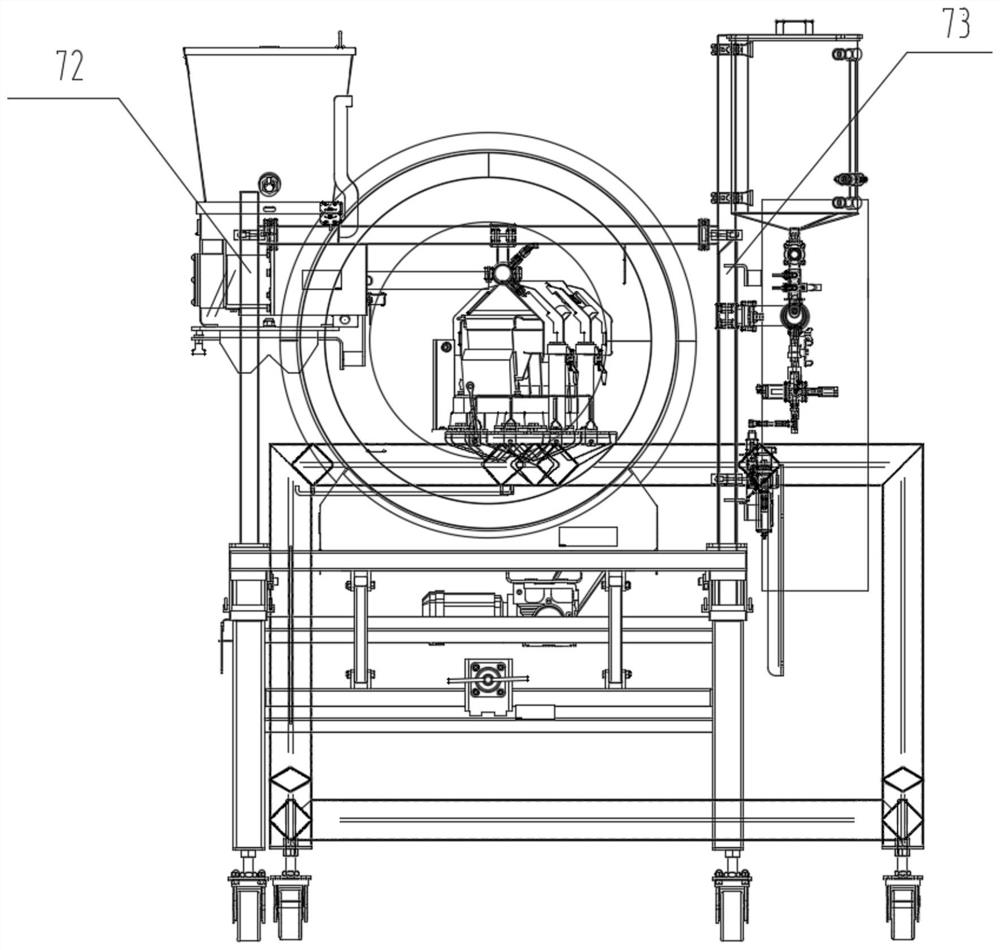

Plastic particle packaging device for resource regeneration

ActiveCN112498829ARealize the output effectRealize push effectSolid materialPlastic packagingGear wheel

The invention relates to a plastic packaging device, in particular to a plastic particle packaging device for resource regeneration. The plastic particle packaging device for resource regeneration isconvenient to operate, low in labor cost and capable of adjusting the discharging flow. The plastic particle packaging device for resource regeneration comprises a bottom plate, an air cylinder, a discharging mechanism and a pushing mechanism. A workbench is arranged on the right side of the bottom plate. The air cylinder is mounted on the front side of the workbench. The discharging mechanism isarranged on the left side and the right side of the middle of the workbench. The pushing mechanism is arranged on the front side of the top of the workbench. According to the plastic particle packaging device, plastic particles are poured into a hopper, then a straight gear is rotated, and therefore a rotating shaft is driven to rotate, then a material closing plate is driven to rotate, a discharging opening is opened, and the discharging effect is achieved; and a telescopic rod of the air cylinder extends backwards, and therefore a push plate is driven to move backwards to push out a carton backwards, and when the carton is pushed to idler wheels, the idler wheels are rotated to drive the carton to move backwards to achieve the pushing effect.

Owner:临沂辰信再生资源有限公司

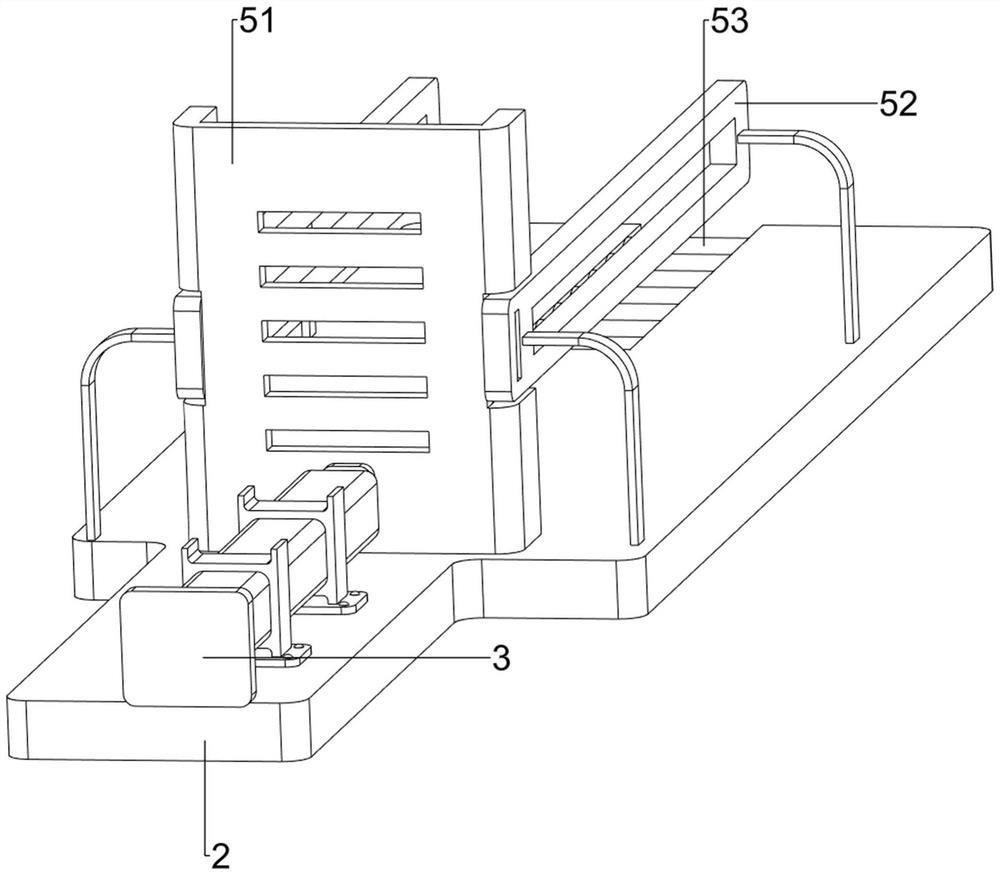

Flour cake screening and removing device

ActiveCN113305007ATo achieve the effect of filtering flourRealize the output effectSievingGas current separationAgricultural engineeringStructural engineering

The invention relates to a removing device, in particular to a flour cake screening and removing device, and provides the flour cake screening and removing device which is good in screening effect and capable of shortening the labor time of workers and reducing the labor expenditure of the workers. The flour cake screening and removing device comprises first fixing frames, second fixing frames, third fixing frames, a filtering mechanism, a discharging mechanism and pushing mechanisms; the two first fixing frames are arranged between the second fixing frames on the two sides; the third fixing frames are symmetrically arranged on the inner walls of the two first fixing frames; the filtering mechanism is arranged between the tops of the third fixing frames on the two sides; the discharging mechanism is arranged between the two first fixing frames; and the pushing mechanisms are arranged on the two first fixing frames. Through arrangement of the filtering mechanism, a worker pushes the filtering mechanism to move left and right to filter and screen caked flour, and the effect of filtering the flour is achieved.

Owner:宝鸡周原贡品农业科技有限公司

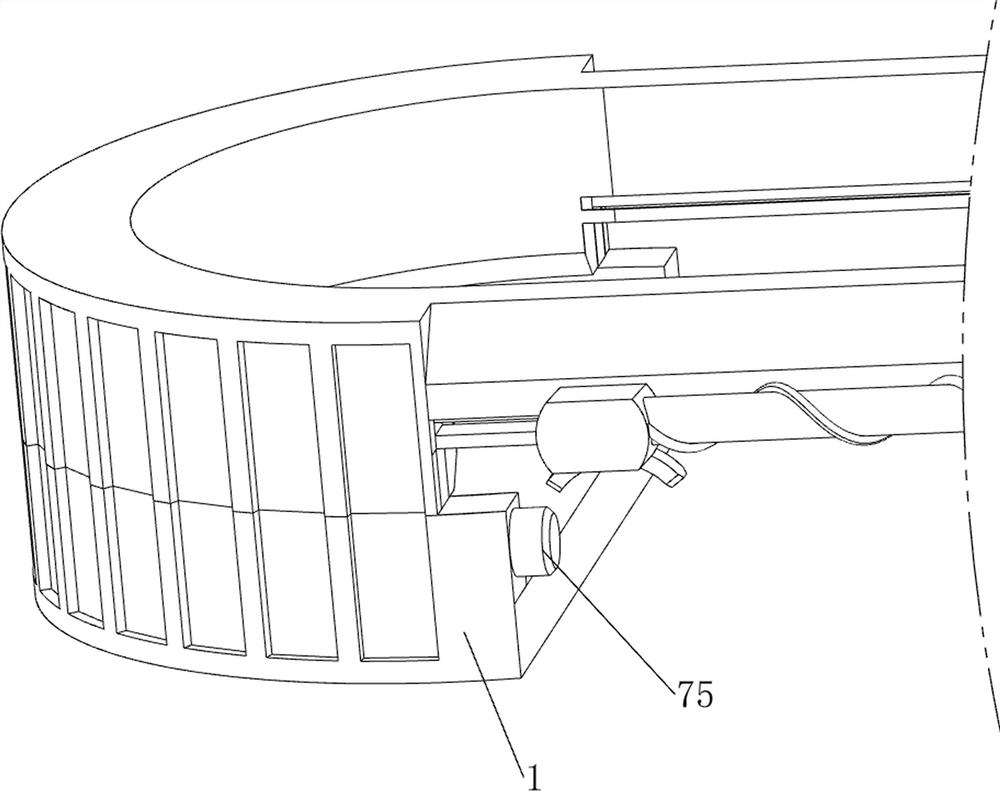

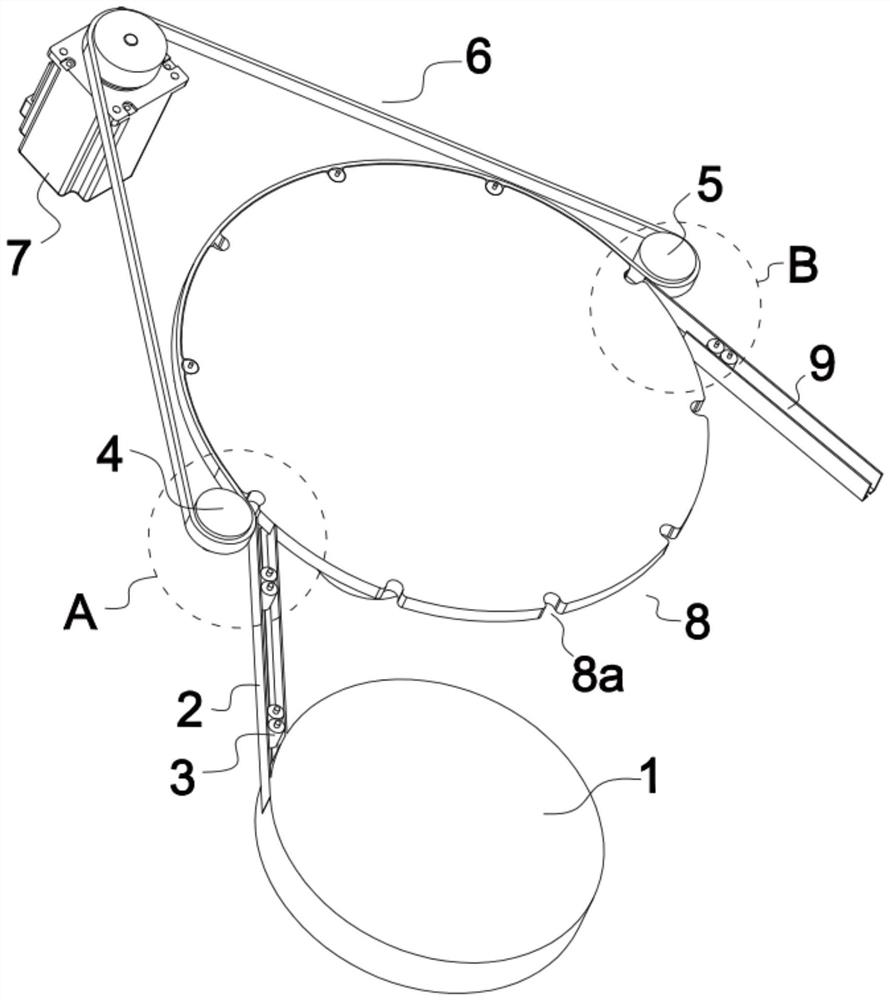

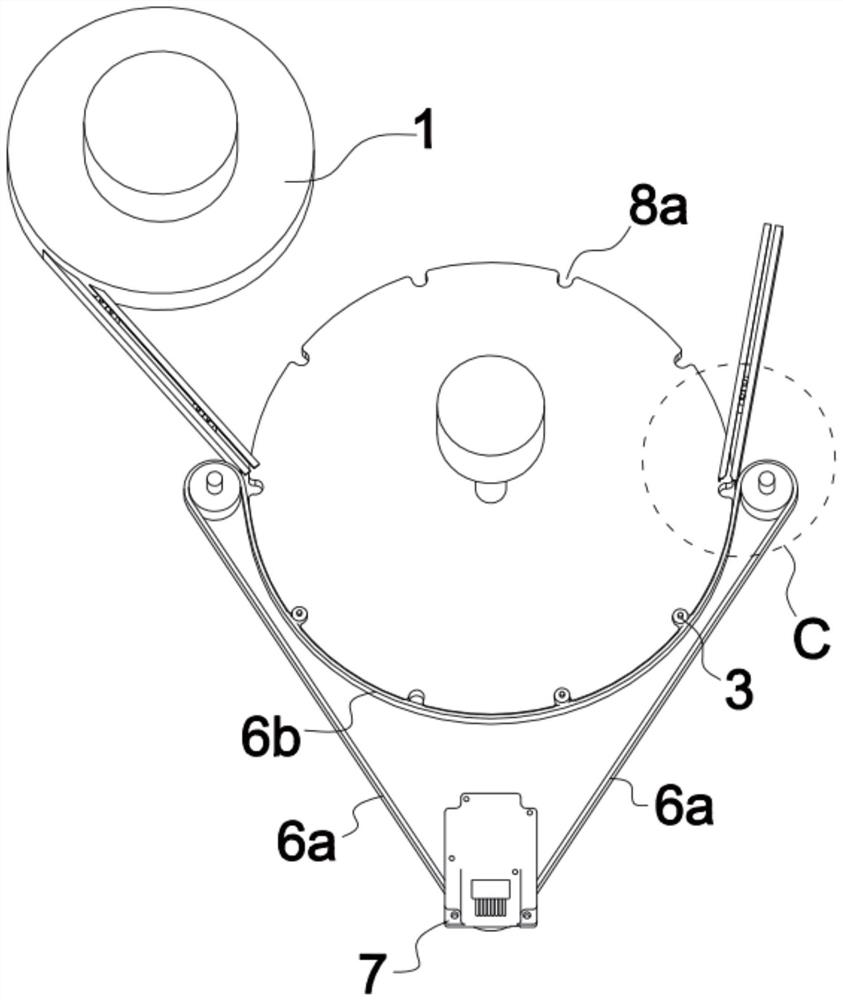

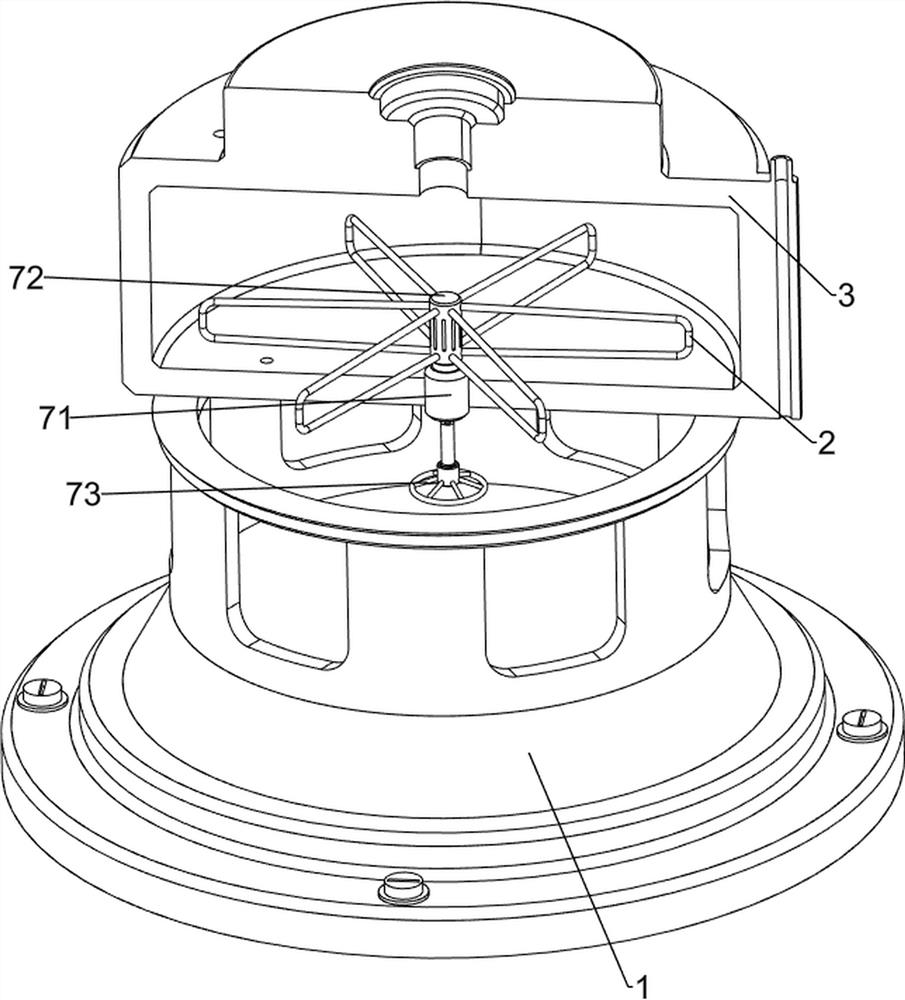

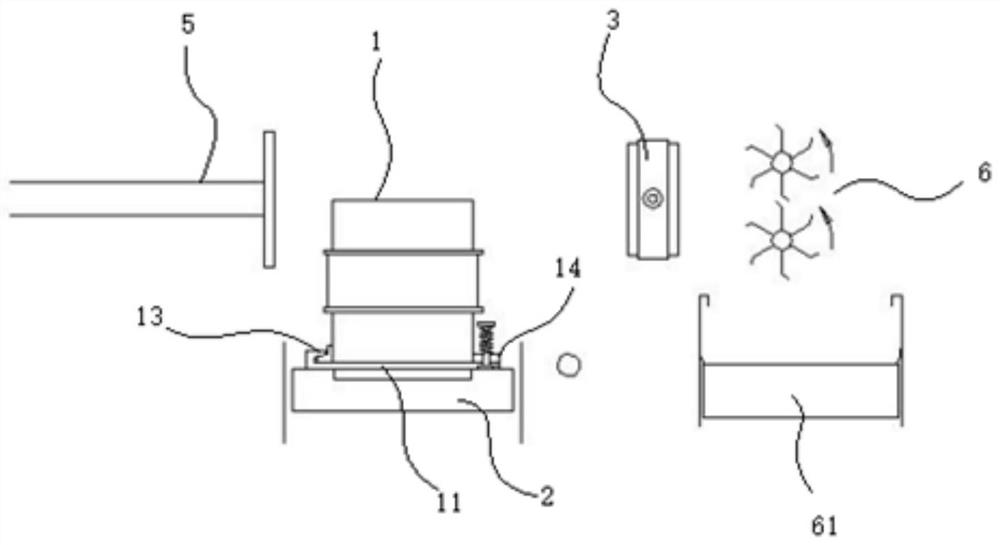

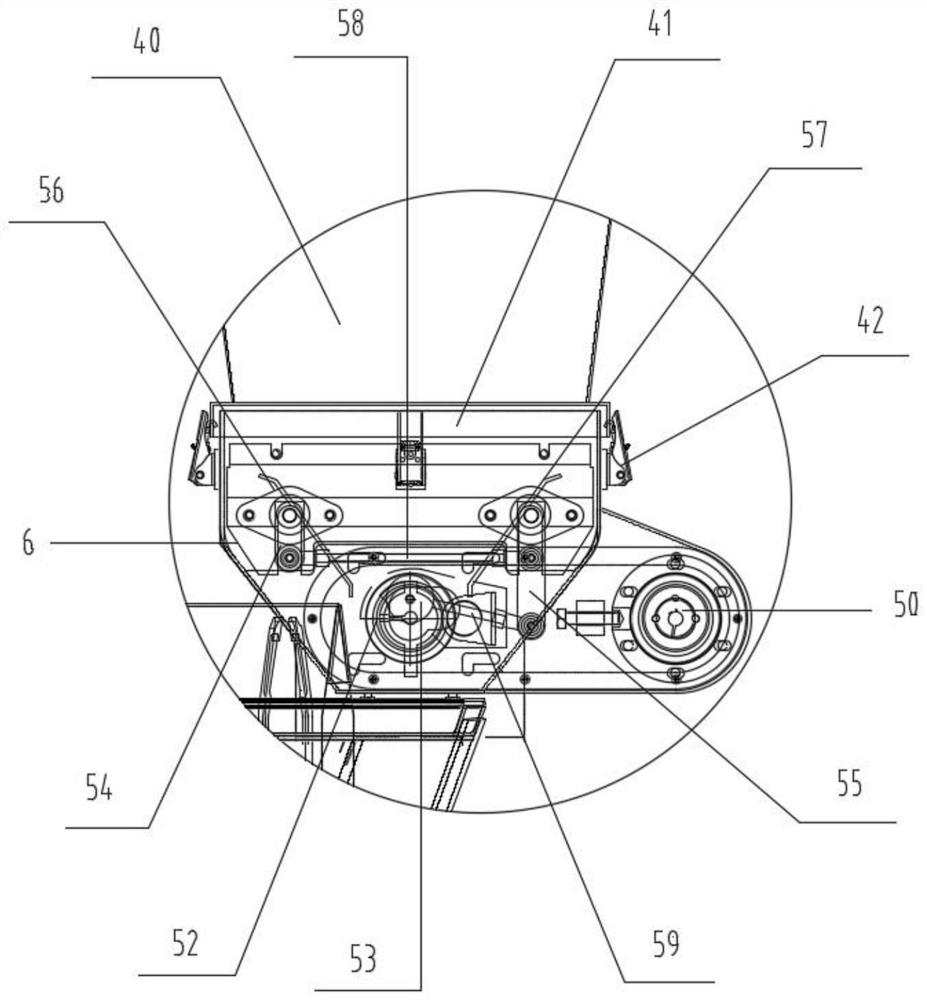

Intermittent rotating tray

PendingCN113526103ARotate synchronouslyEnough contact lengthConveyorsConveyor partsDrive wheelTransmission belt

The invention discloses an intermittent rotating tray. The intermittent rotating tray comprises a rotating tray body, a vibration disc, and a transmission belt, the rotating tray body has the rotating freedom degree around the axis of the rotating tray body, and a plurality of notches for containing products are formed in the edge of the rotating tray body at intervals; the vibration disc is in contact with the rotating tray body through a material conveying rail, and the vibration disc conveys products to the rotating tray body; the transmission belt is in contact with the edge of the rotating tray body, the inner wall of the transmission belt is in contact with a driving motor, a first driven wheel and a second driven wheel, and an arc section and a linear section are formed on the transmission belt except the part in contact with the driving motor, the first driven wheel and the second driven wheel; the portion, between the first driven wheel and the second driven wheel, of the transmission belt is the arc section making contact with the edge of the rotating disc and products in the notch, the portions, between the first driven wheel and the driving motor and between the second driven wheel and the driving motor, of the transmission belt are the linear sections; and one end of the arc section is in contact with the output end of the material conveying rail. According to the intermittent rotating tray, a turntable station is realized by using lower equipment cost, the intermittent conveying of products is realized, and the conveying action is quick and reliable.

Owner:SUZHOU GUANGYUE MICRO NANO TECH CO LTD

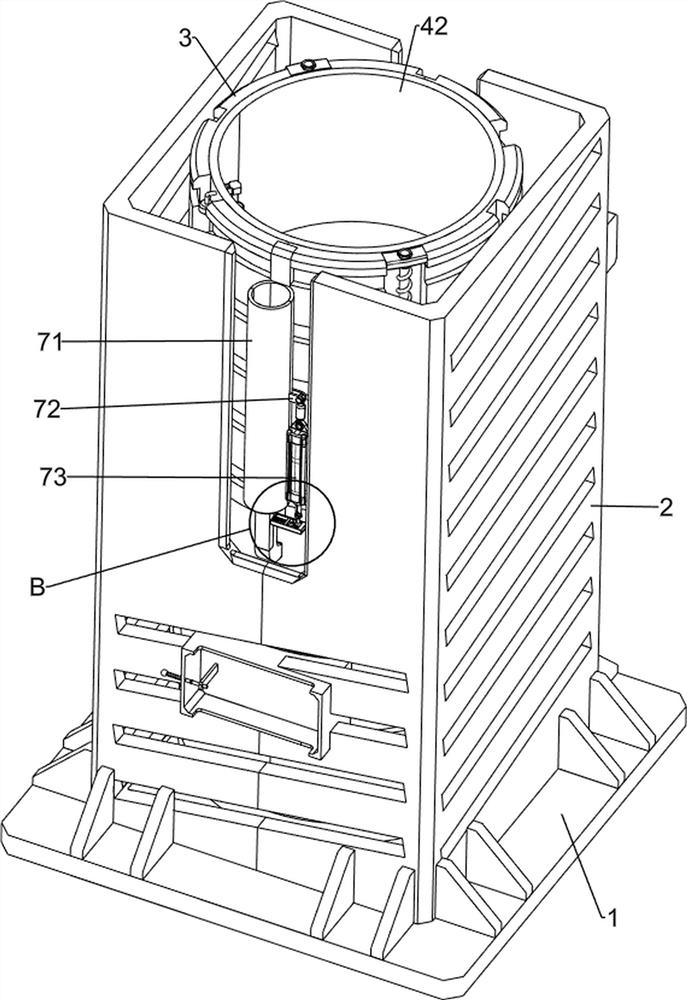

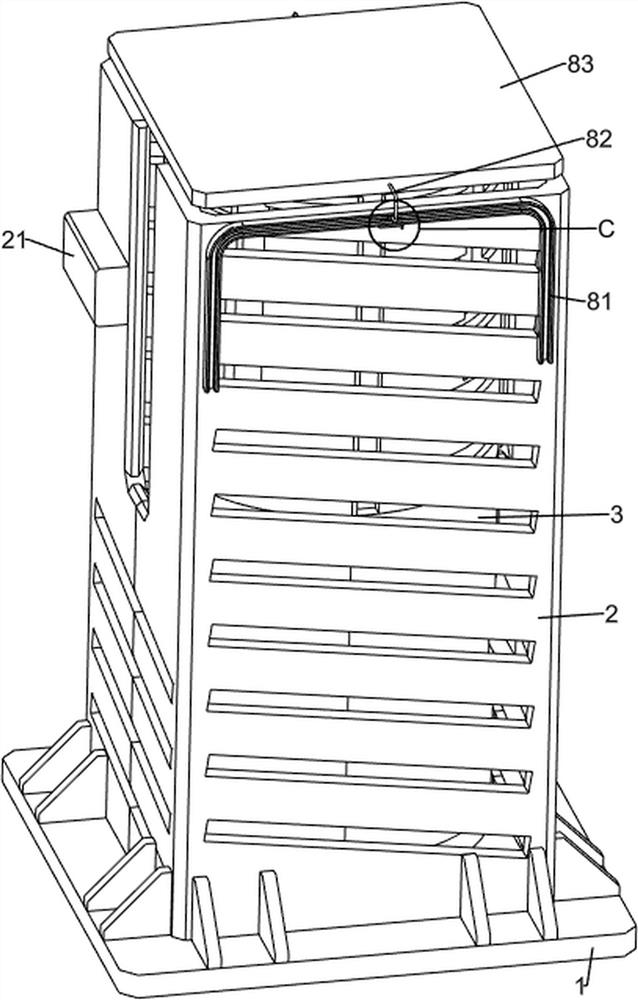

Multi-cavity grain storage barrel

PendingCN114587167AEasy to useRealize the output effectPowdered material dispensingBio-packagingGrain storageEngineering

The multi-cavity grain storage barrel comprises a base, an outer barrel body arranged at the top of the base and a cover arranged at the top of the outer barrel body, an inner barrel body is arranged at the center position in the outer barrel body through a containing groove, and the bottom of the containing groove penetrates through the outer barrel body; a plurality of partition plates are arranged between the inner wall of the outer can body and the outer wall of the inner can body in a sliding mode through sliding grooves, the partition plates divide the inner side of the outer can body into a plurality of cavities, and the inner can body comprises a first inner can body arranged on the outer can body and a second inner can body arranged on the top of the first inner can body. And a through groove is formed in the bottom of the first inner barrel body. The effect of discharging from the lower portion of the barrel body can be achieved by pressing the pressing block on the upper portion of the barrel body, in the using process, a user does not need to open the upper cover, in addition, in the pressing process, the condition that the barrel body moves cannot occur, and use of the user is facilitated to a certain extent.

Owner:安徽丰逸智能家居有限公司

A kind of detection method of cotton plant nitrogen content

ActiveCN108828155BGrind fullySolve decompositionPreparing sample for investigationTesting plants/treesPhysical chemistryDigestion

The invention relates to the technical field of detection, in particular to a detecting method of the nitrogen content of a cotton plant. The detecting method comprises the following steps: step one,sampling: taking fresh cotton plant leaves; step two, preparation of a grinding device: preparing the grinding device; step three, sample treatment: processing the sample obtained in step one by adopting the grinding device, and forming a smashed sample; step four, digestion: adding the smashed sample obtained in step three in concentrated sulfuric acid, and uniformly mixing; then heating the mixed solution, and heating until the solution is a uniform brownish black color after generating white smoke; stopping heating, and cooling; adding hydrogen peroxide after cooling, heating until boiling,and digesting for 6 to 12 minutes; cooling again, and adding hydrogen peroxide; digesting until the solution is colorless or clear, and heating for 10 to 12 minutes again; finally taking and coolingsample liquid; step five, filtering by adopting filter paper or standing and clarifying the sample liquid cooled in the step four, taking clear liquid, and determining the nitrogen content. Accordingto the scheme disclosed by the invention, the problem that decomposition and extraction of plant leaves in the prior art are incomplete is solved.

Owner:XINJIANG INST OF ECOLOGY & GEOGRAPHY CHINESE ACAD OF SCI

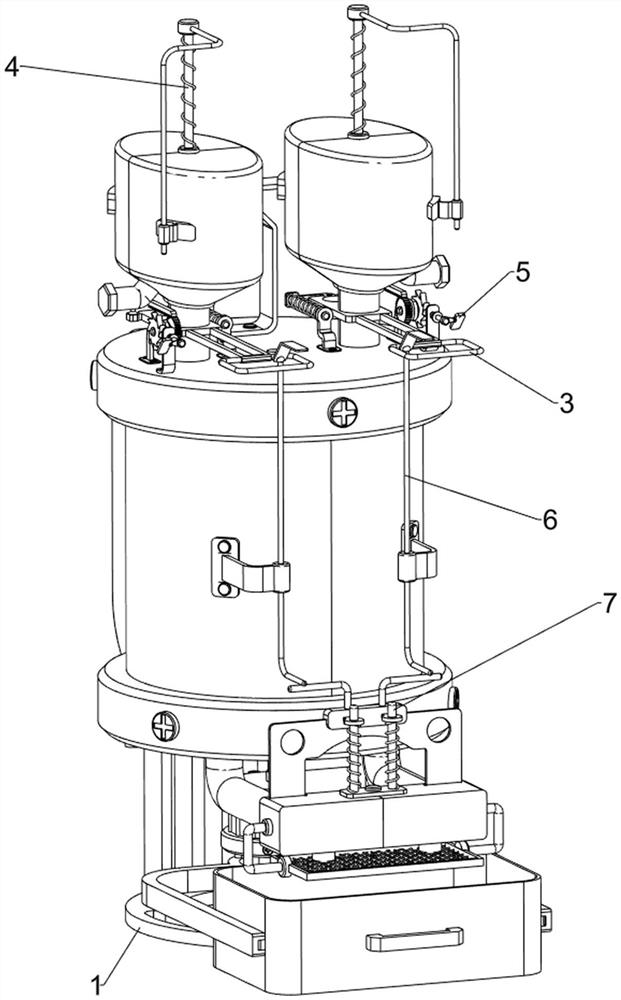

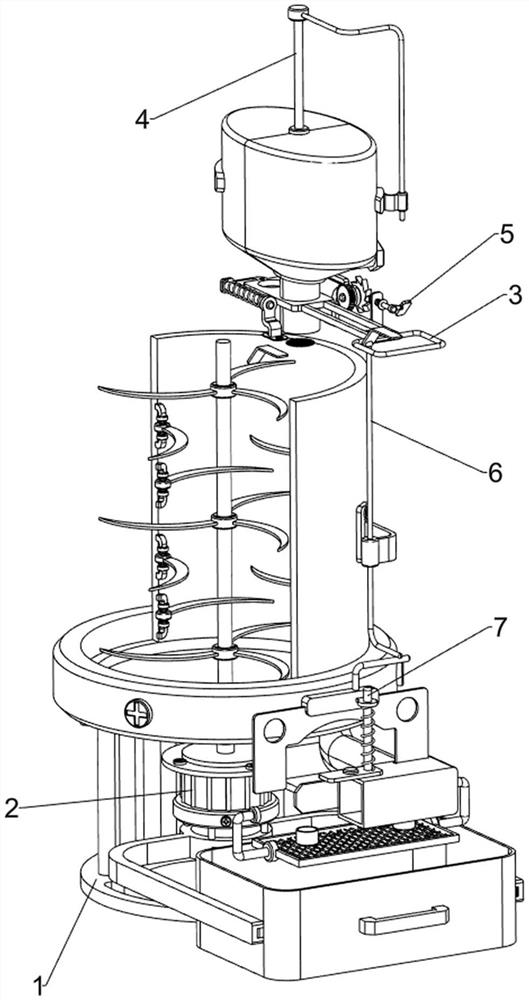

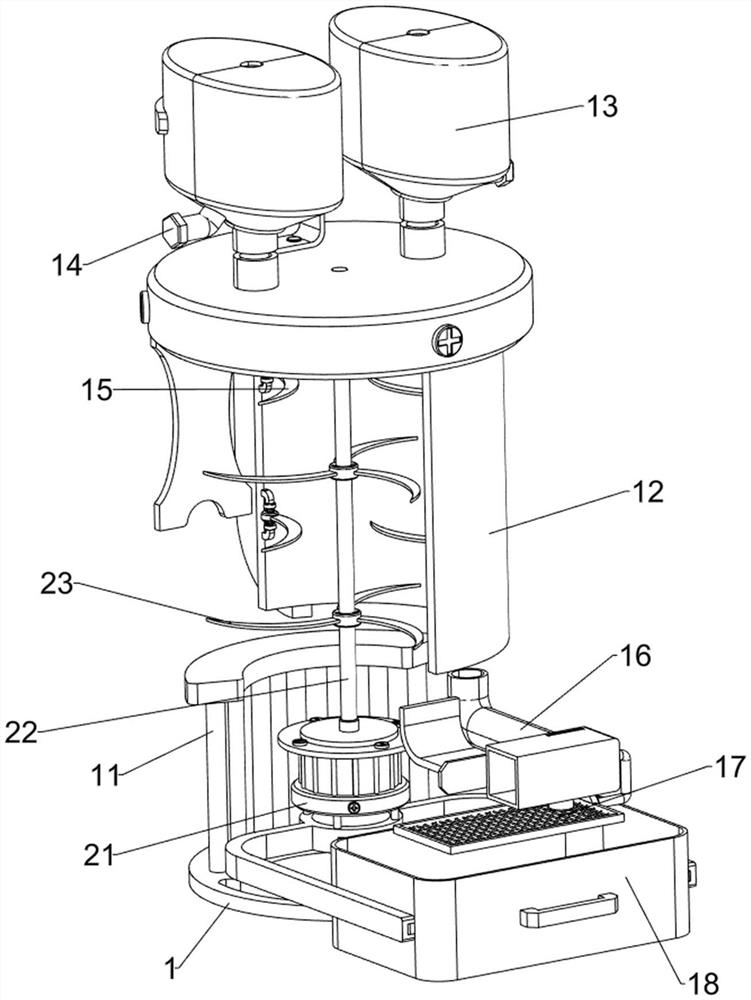

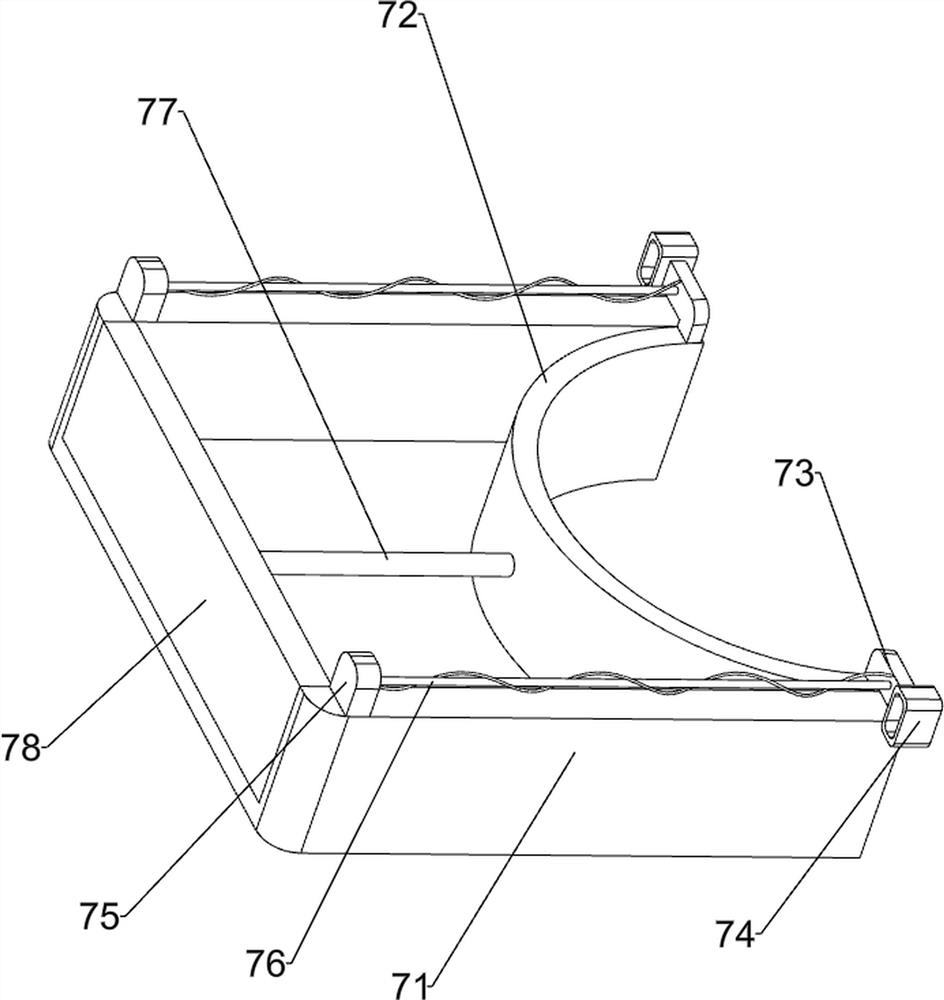

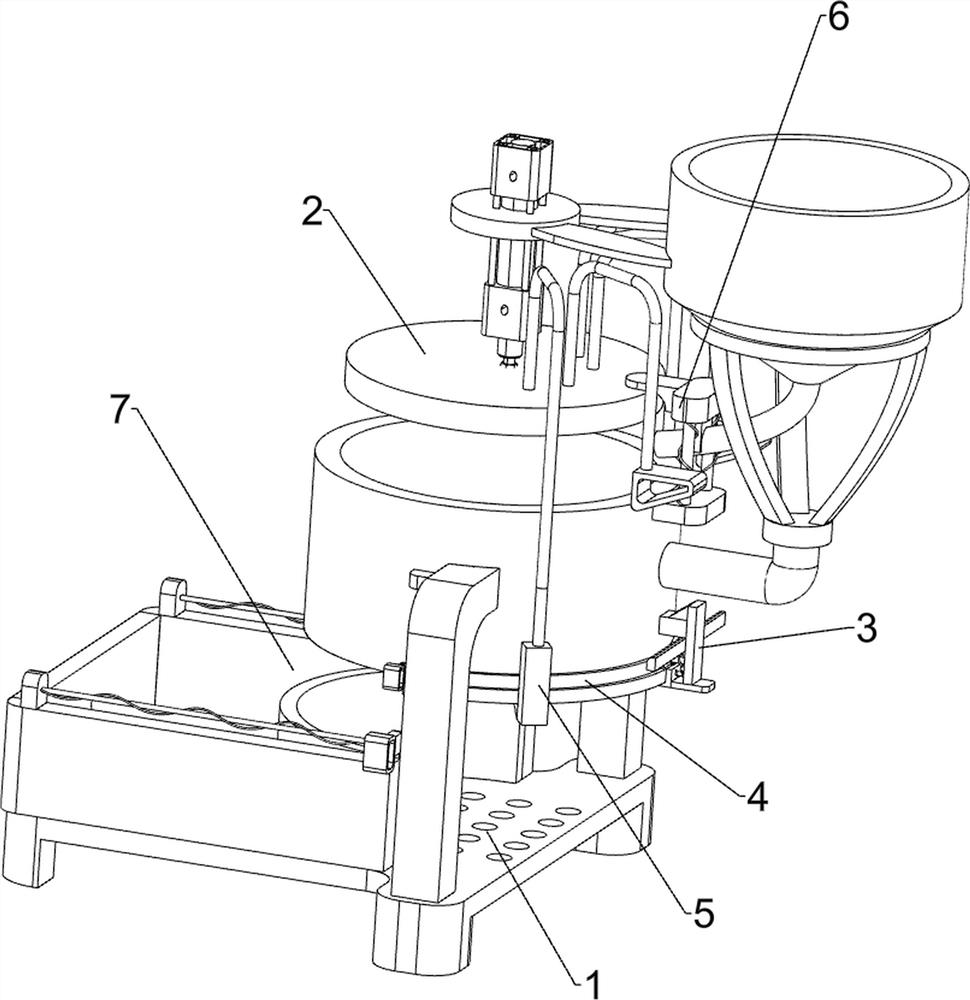

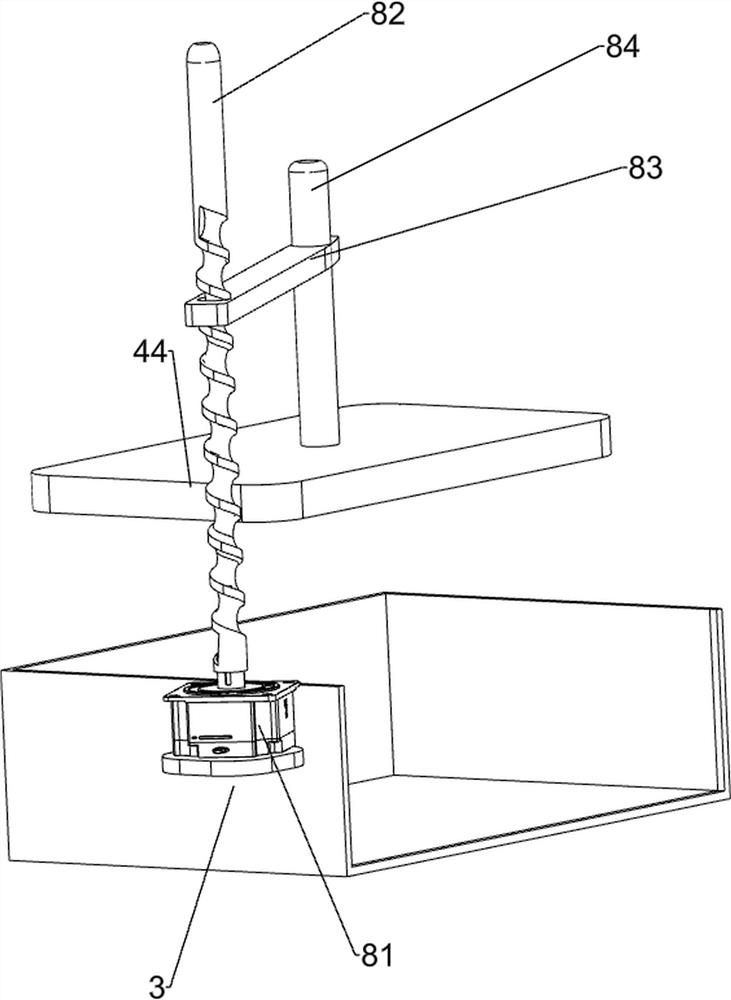

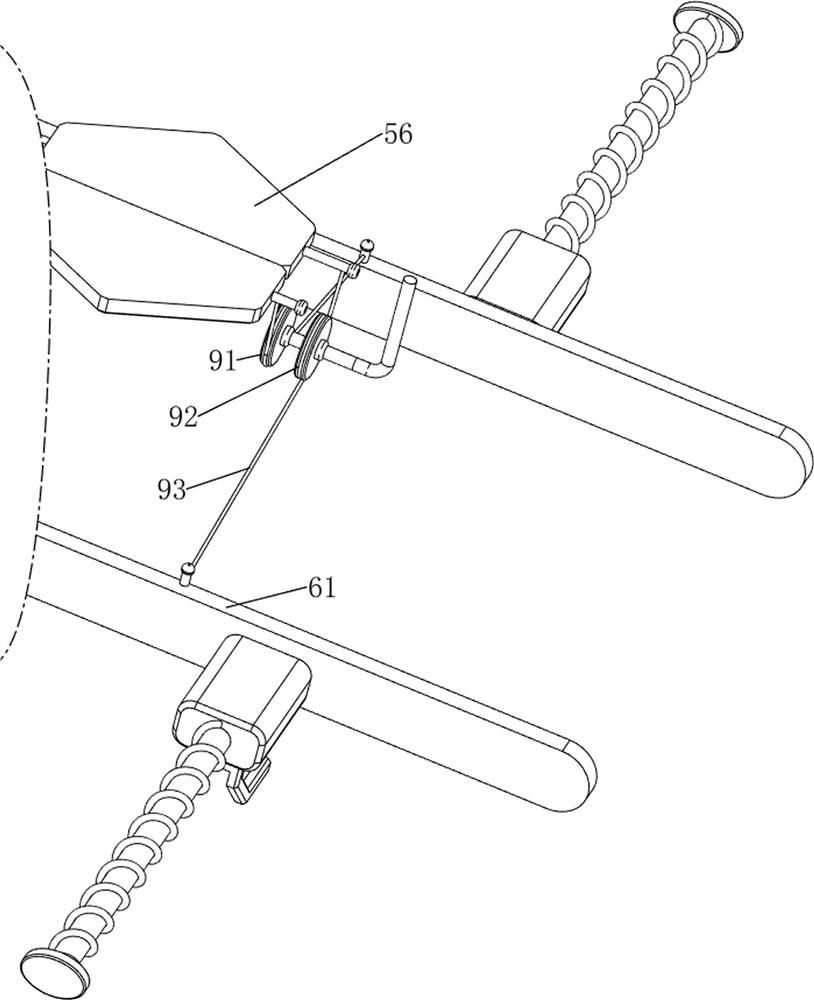

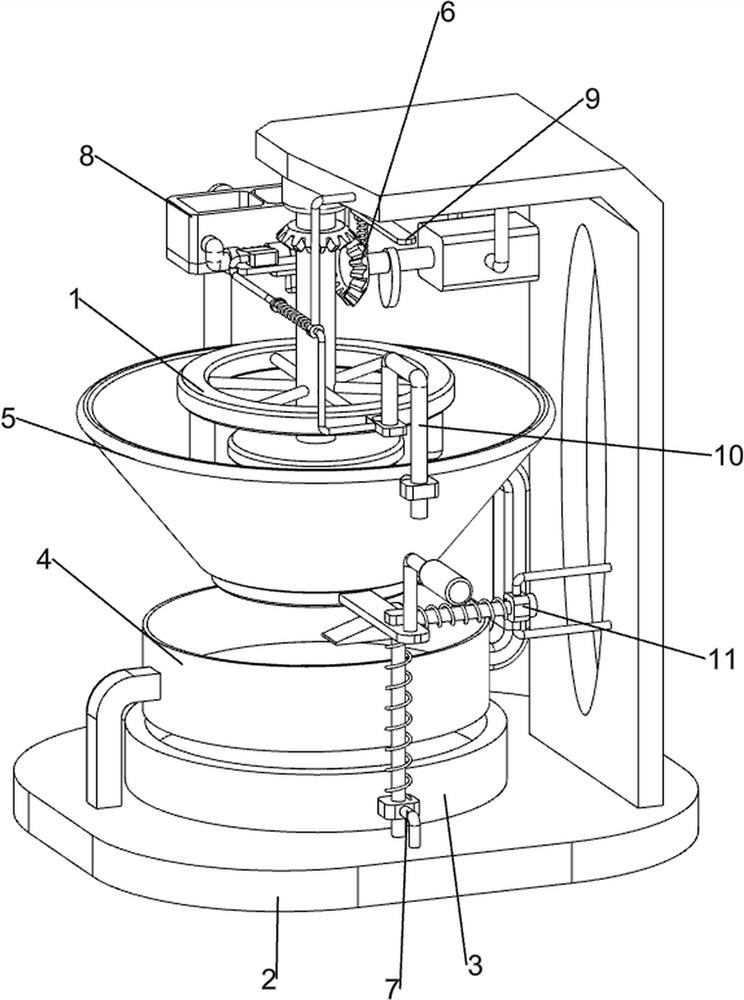

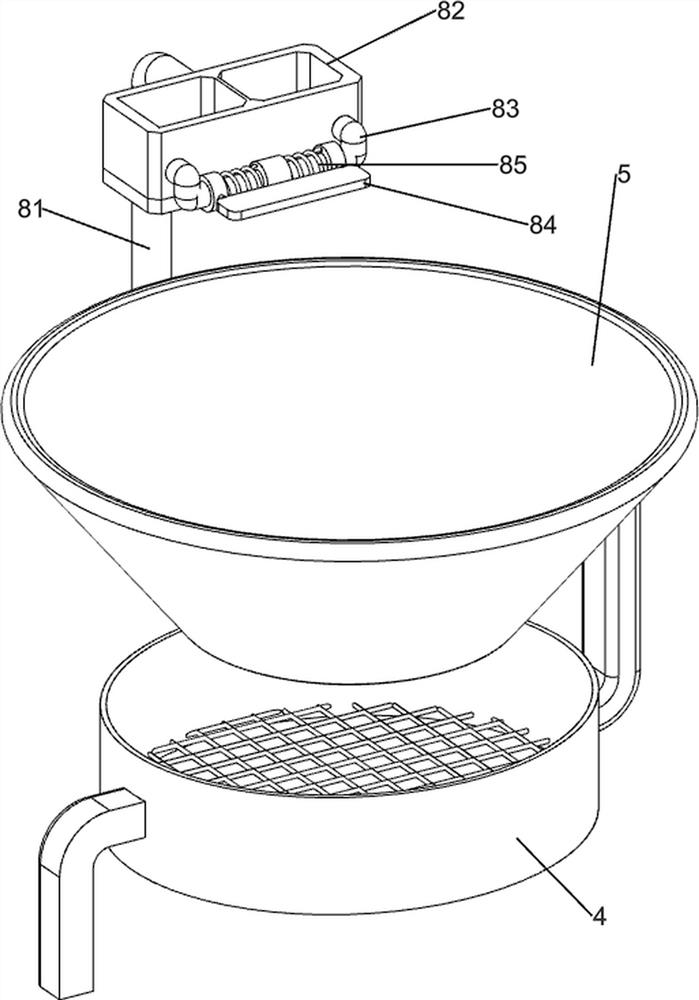

Matrix mixing equipment for agricultural seedling tray

PendingCN114789016ARealize the output effectImprove work efficiencyTransportation and packagingRotary stirring mixersAgricultural scienceAgricultural engineering

The invention relates to matrix mixing equipment, in particular to matrix mixing equipment for an agricultural seedling tray. The invention provides the matrix mixing equipment for the agricultural seedling tray, which is relatively high in discharging speed. Matrix mixing equipment for agricultural seedling trays comprises a base, a stirring box, a first supporting frame, a crushing box, a first baffle and the like. A stirring box is arranged on the upper side of the base, first supporting frames are arranged on the front side and the rear side of the upper portion of the stirring box, a crushing box is connected between the two first supporting frames and divided into an upper layer and a lower layer, and a first baffle is slidably arranged on the lower side of the front side of the stirring box. A first baffle is manually moved forwards by people, meanwhile, an output shaft of a second motor rotates to drive a third rotating shaft to rotate, so that stirring blades rotate, at the moment, a mixed matrix is pushed to the front side of the stirring box under the driving of the rotating stirring blades, the discharging effect is achieved, and the working efficiency is improved.

Owner:李秋玲

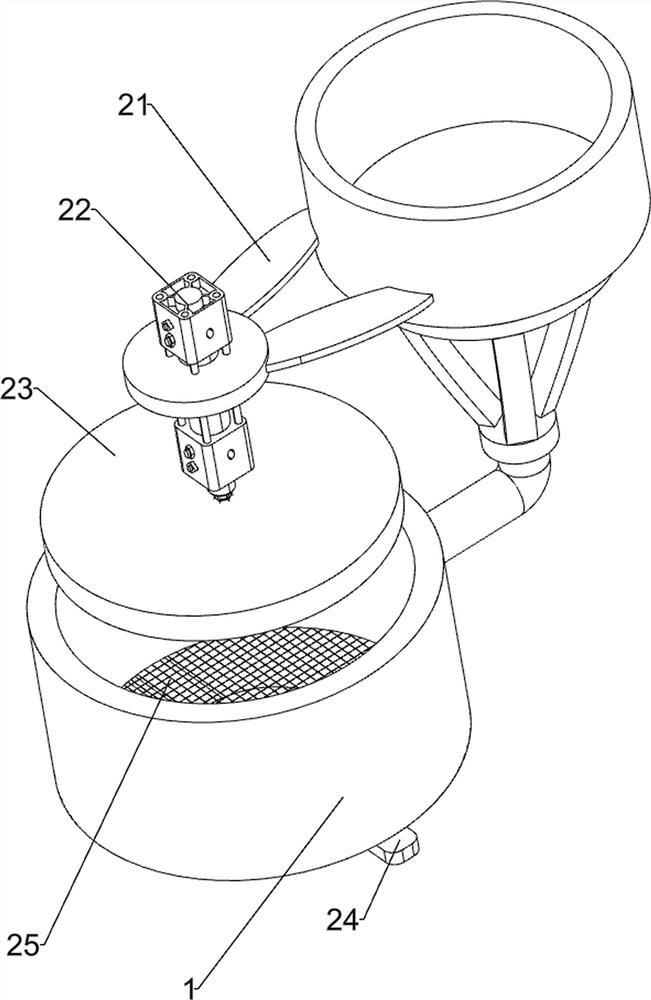

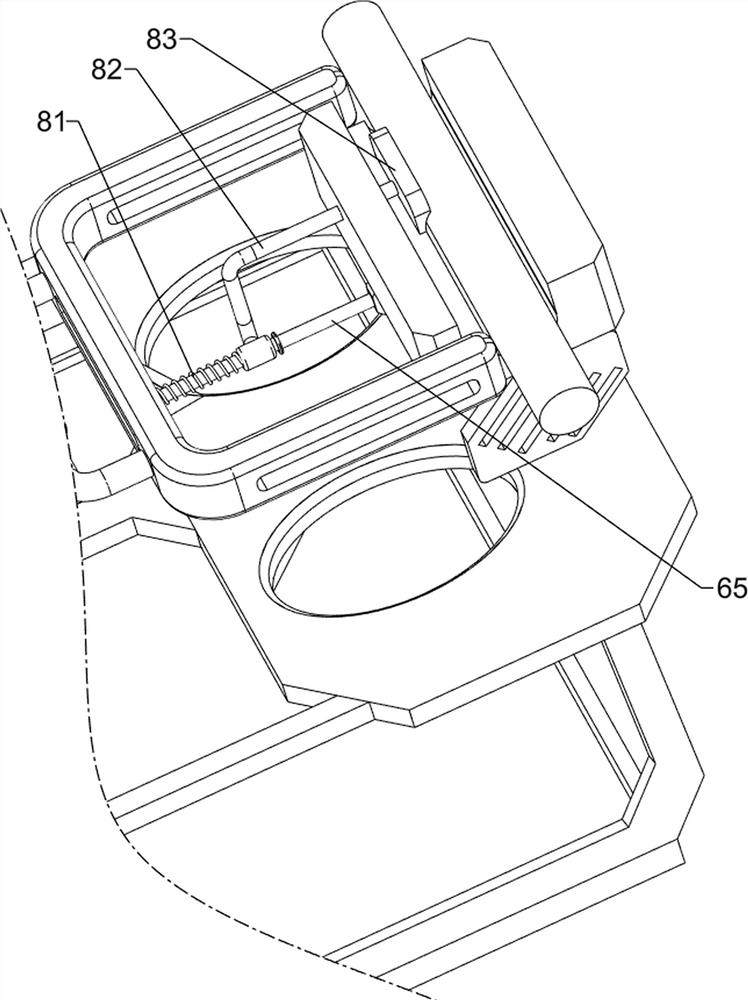

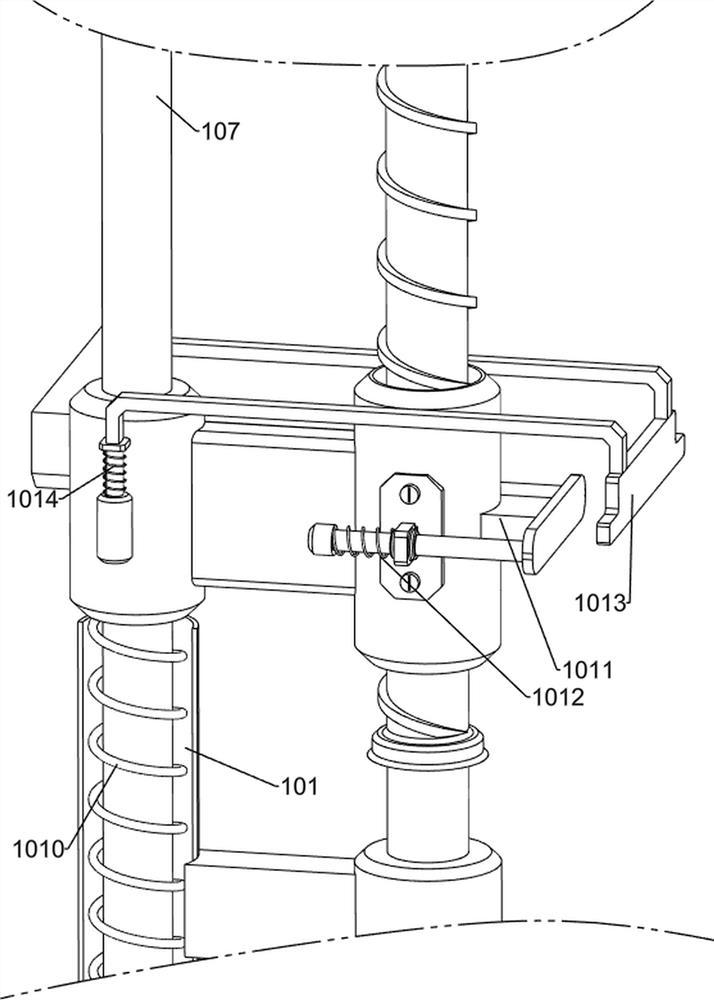

Medicament preparation equipment for oncology department

PendingCN114053911ARealize the effect of intermittent feedingAchieve stirring effectTransportation and packagingMixing methodsPharmacy medicineIntensive care medicine

The invention relates to preparation equipment, in particular to medicament preparation equipment for the oncology department. The oncology department medicament preparation equipment provided by the invention has the advantages of automatic stirring, convenience in use and capability of reducing the labor intensity of medical personnel. The oncology department medicament preparation equipment comprises: a supporting seat and a preparation box body, wherein the preparation box body is arranged on the supporting seat; a stirring mechanism which is arranged on the lower side in the preparation box body; six stirring blades which are arranged on the stirring mechanism; and a feeding funnel which is arranged between the tops of the preparation box body. The feeding port of a blanking port coincides with the discharging port of the feeding funnel, so that powder medicine on the feeding funnel can fall into the preparation box body, if the feeding port of the blanking port rotates and does not coincide with the discharging port of the feeding funnel, the blanking port blocks the discharging port of the feeding funnel, feeding is stopped, and the intermittent feeding effect can be achieved.

Owner:王兰

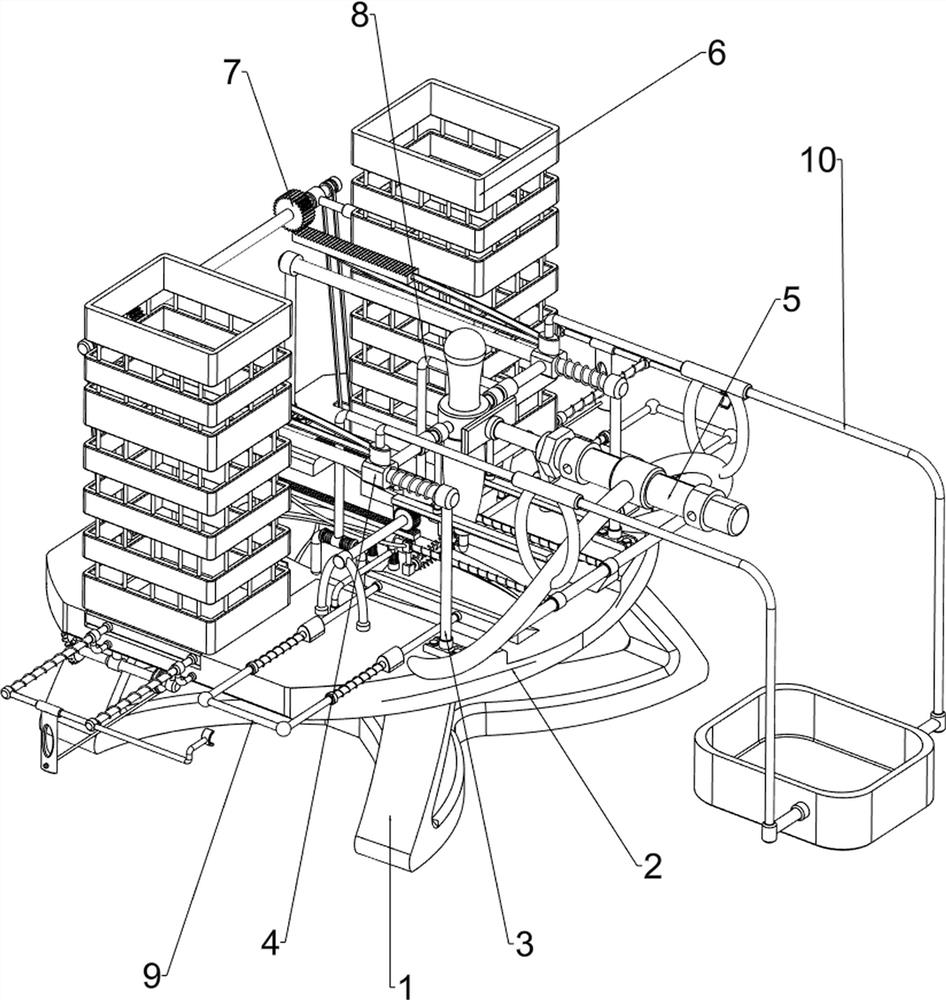

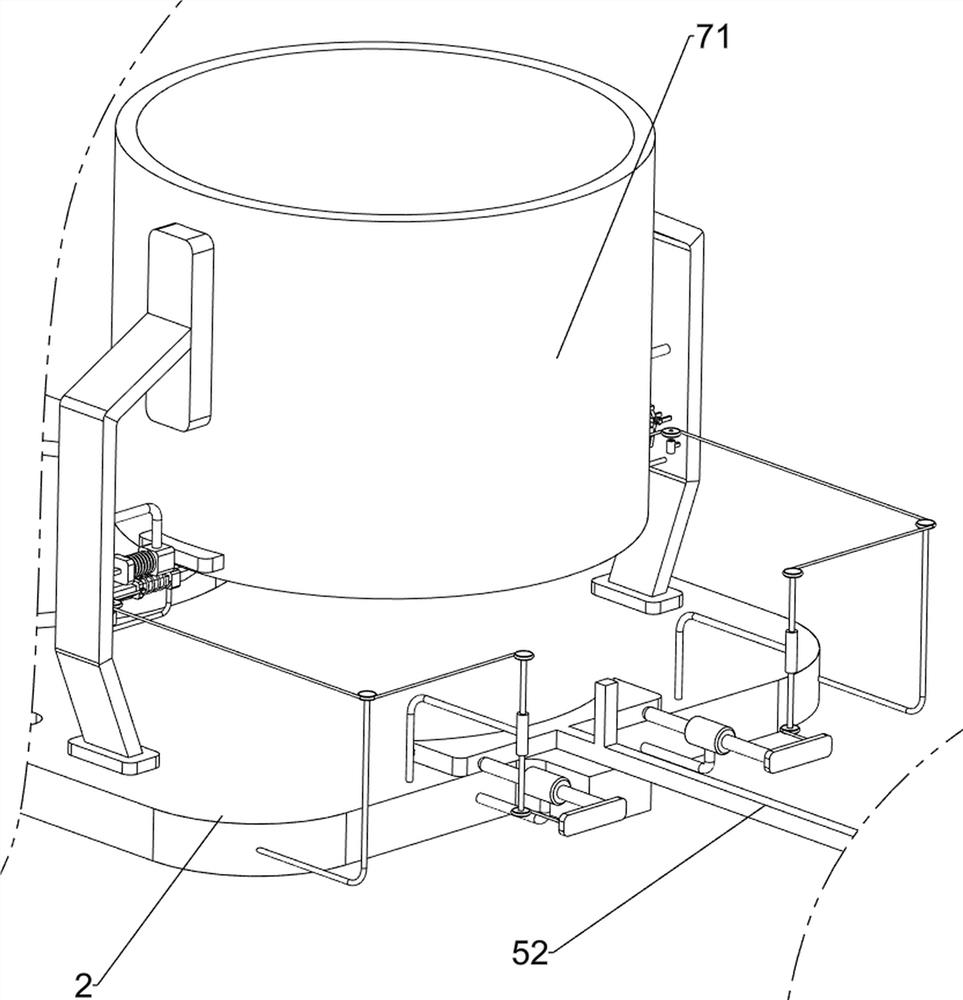

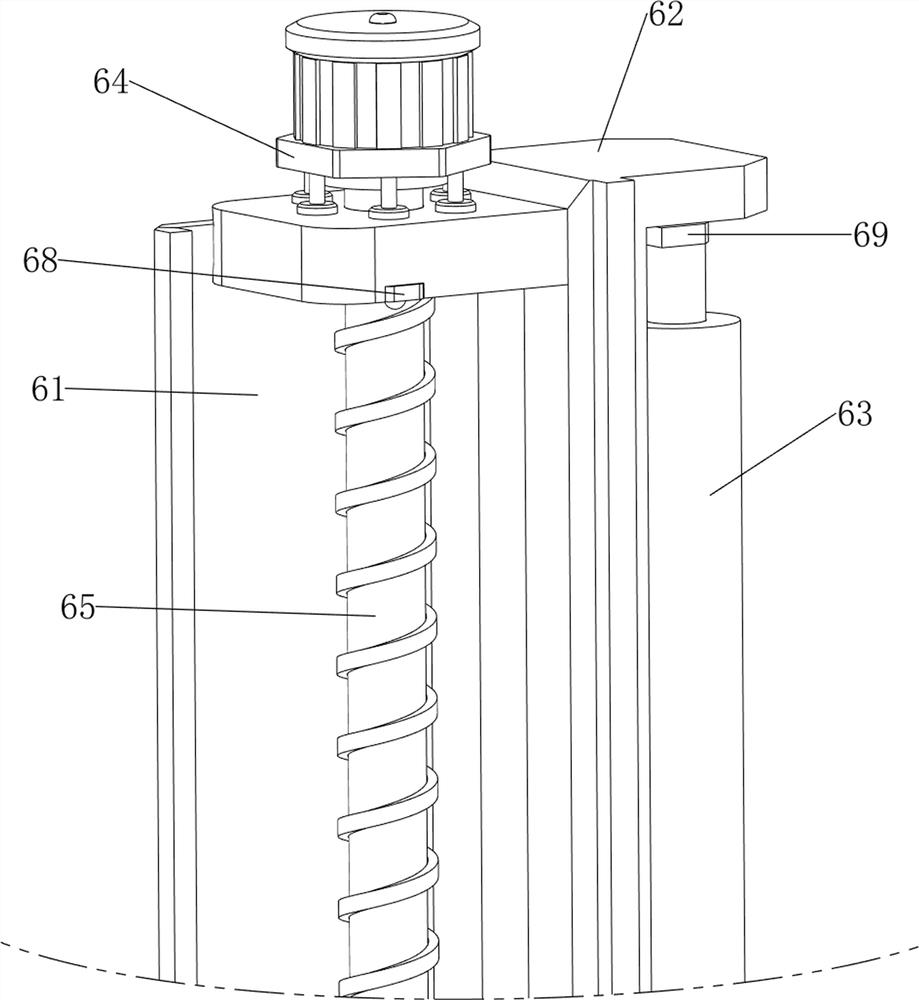

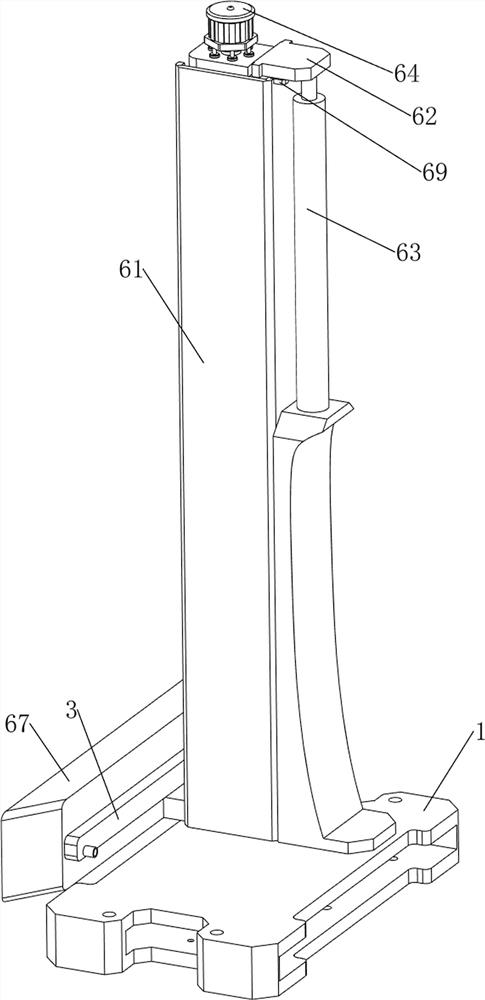

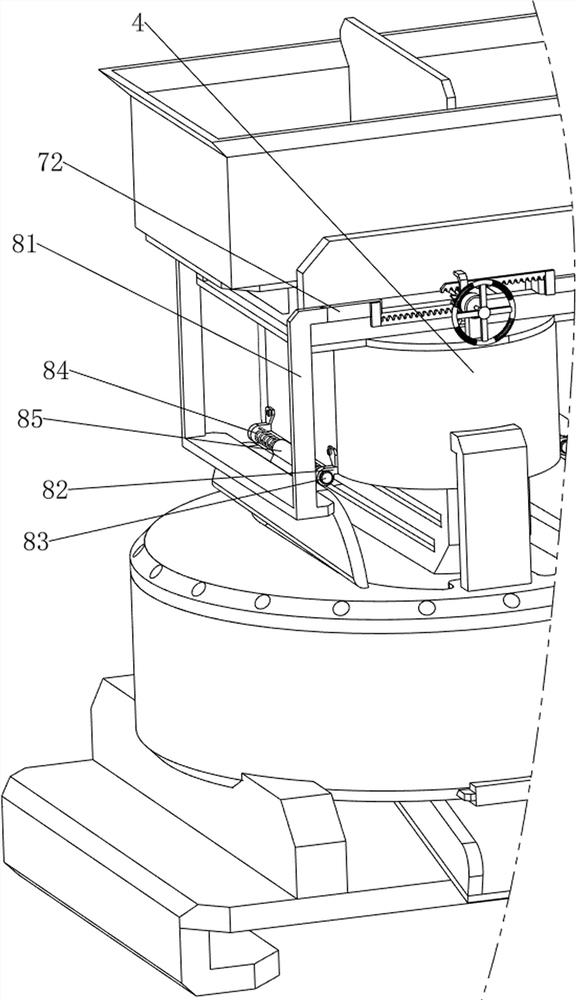

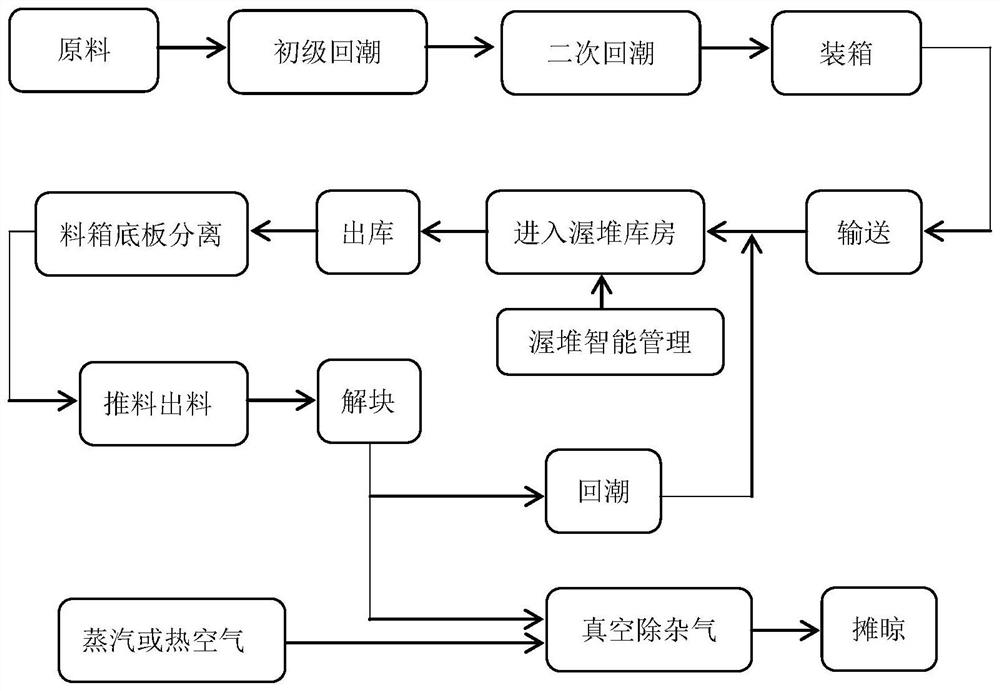

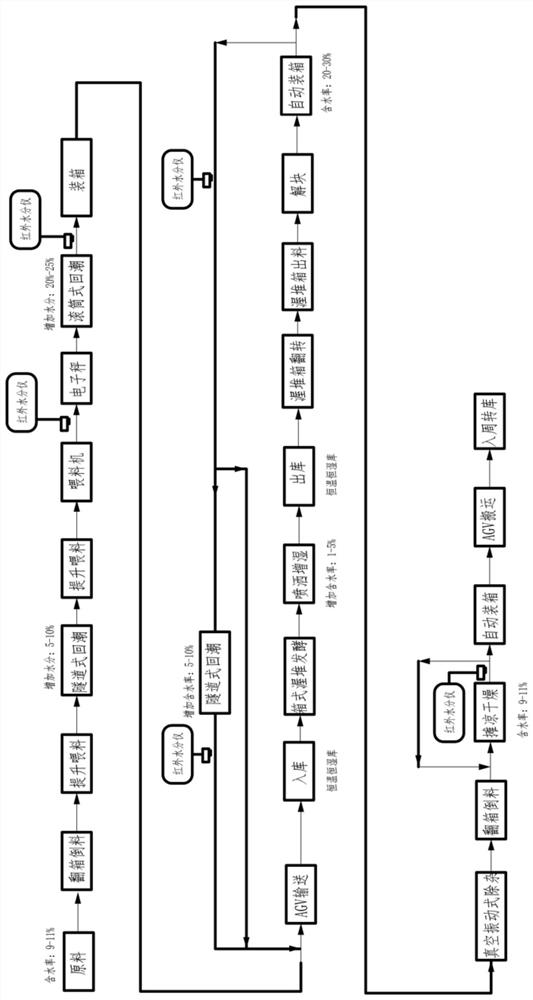

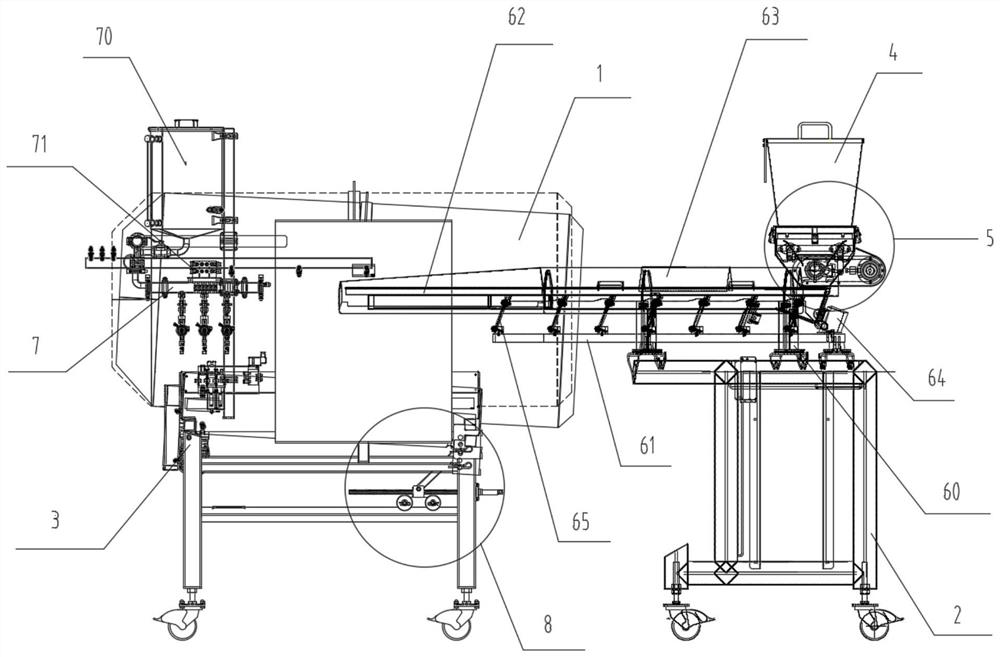

Full-automatic Pu'er tea pile fermentation and airing production and processing technology

PendingCN114027364AEfficient moisture content enhancement effectReduce the number of turningPre-extraction tea treatmentBottle emptyingProcess engineeringTea leaf

The invention discloses a full-automatic Pu'er tea pile fermentation and airing production and processing technology. The technology comprises the steps of tea leaf raw material pile fermentation pretreatment, warehousing pile fermentation, pile fermentation management, pile turning, deblocking and discharging, vacuum impurity gas removal and tea material airing. The technical method and the operation process of automatic discharging are achieved in cooperation with mechanical equipment, so that the working procedure requirement that discharging is difficult to achieve from the charging container can be automatically completed through machinery, the discharging efficiency is improved, manual discharging operation is not needed, and time and labor are saved; the problems that caked and clustered materials are difficult to discharge completely and difficult to discharge are solved; an assembly line production automation mode of raw material preparation, water flushing, boxing, warehousing and pile fermentation, discharged material disintegration and pile turning, moisture regaining, warehousing and pile fermentation, discharged material deblocking, vacuum pile taste removal, spreading and airing, and discharged material warehousing of the Pu'er tea is realized on the whole, and an on-line automatic high-efficiency and high-quality Pu'er tea pile fermentation process is really realized.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

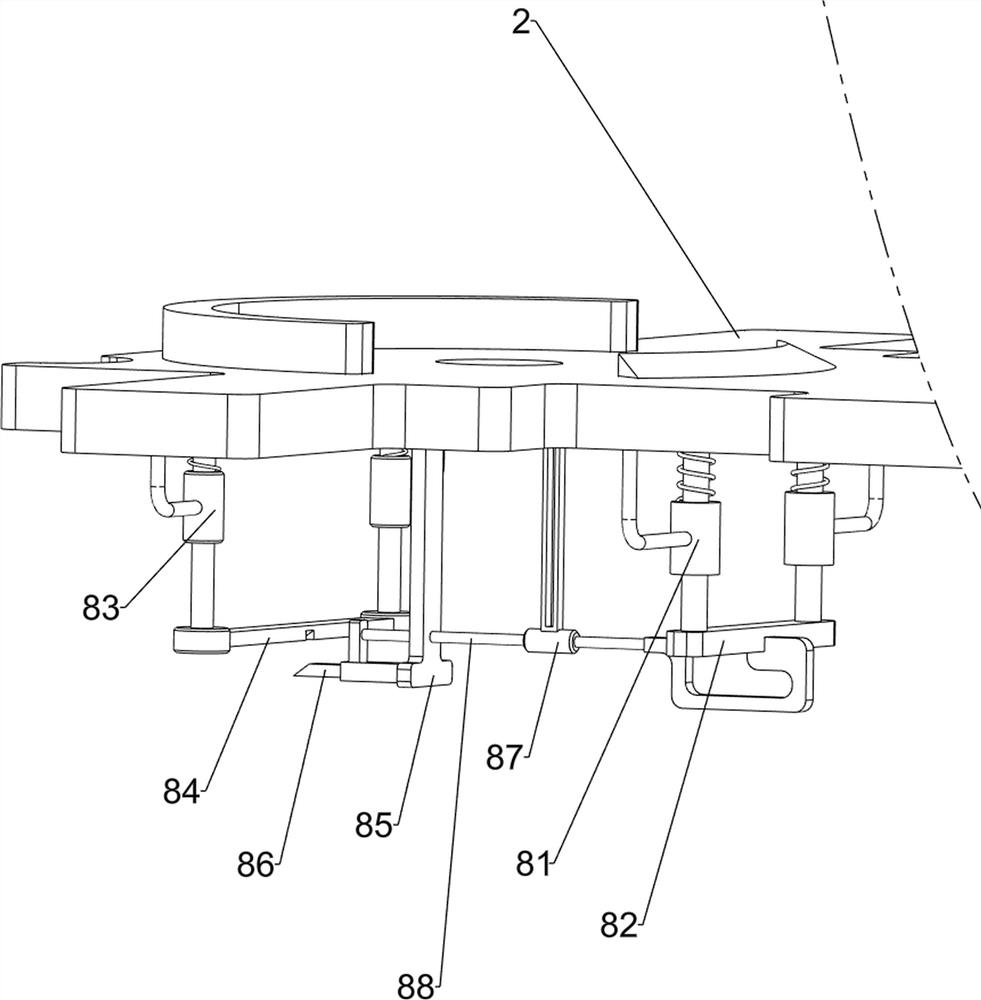

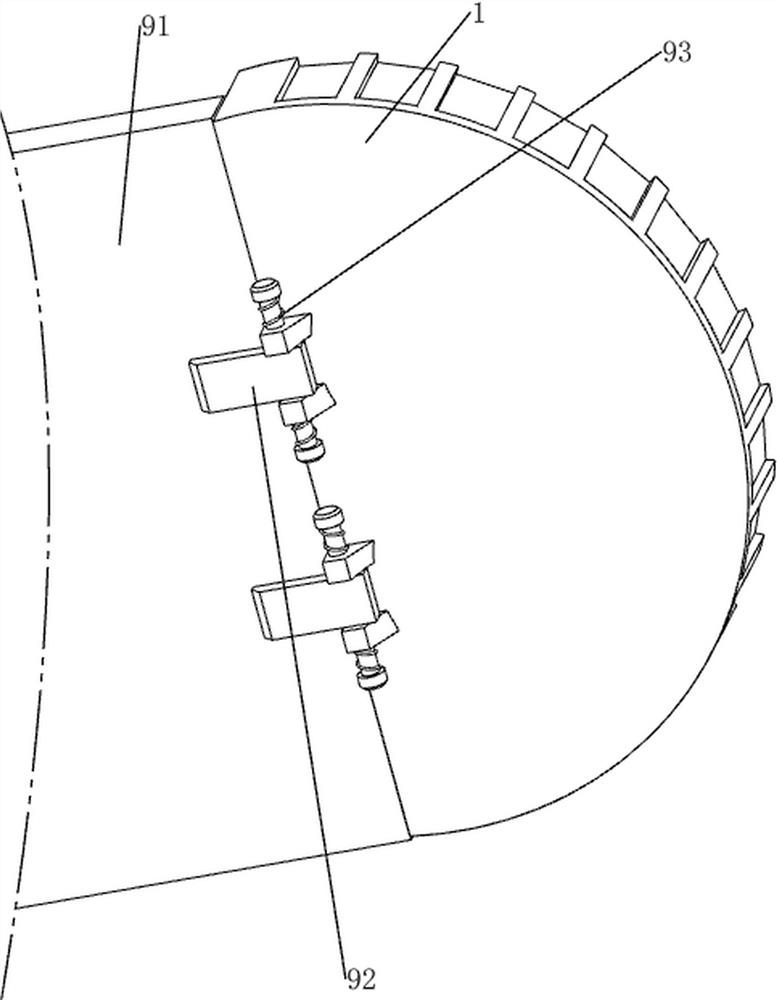

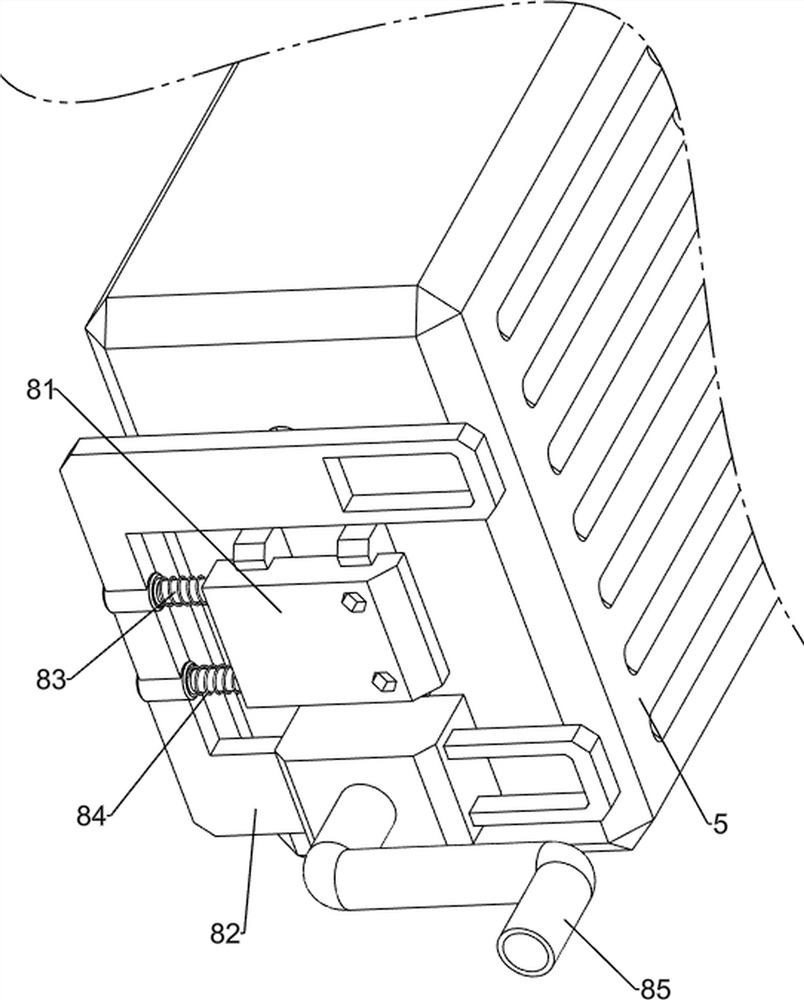

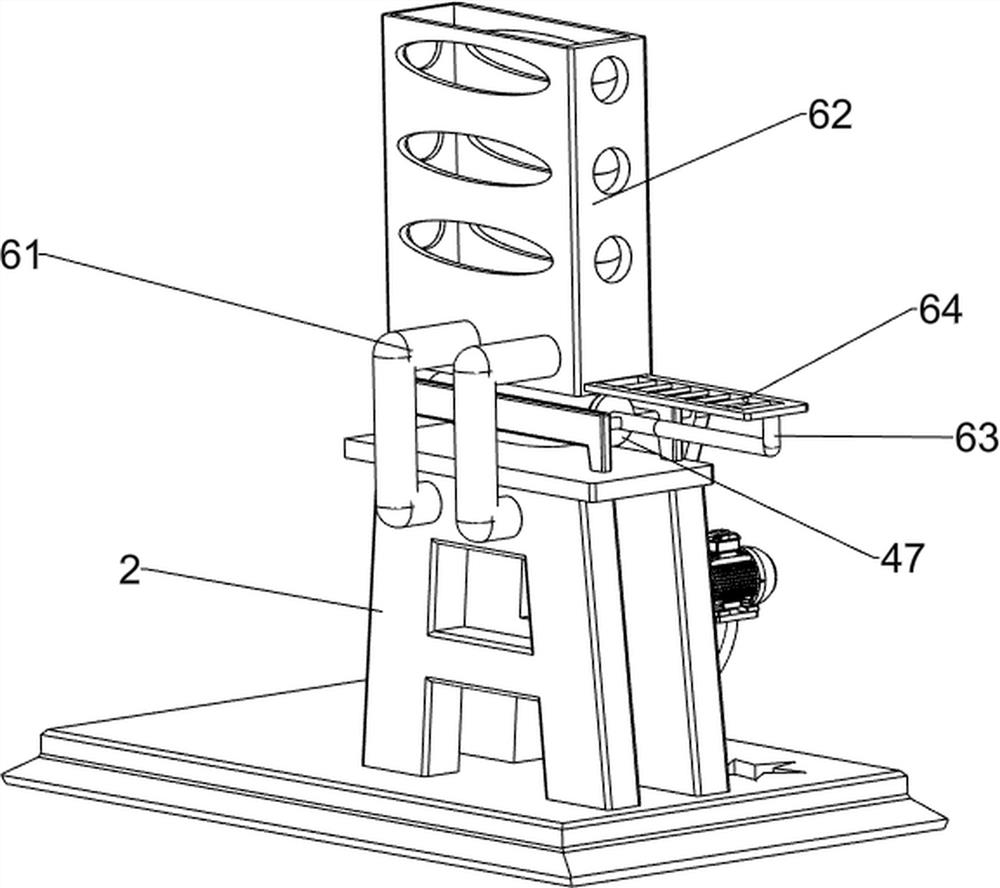

Neodymium iron boron magnetic steel surface oxidation prevention device

InactiveCN113667989AAvoid spillingAntioxidantInductances/transformers/magnets manufactureSurface oxidationMaterials science

The invention relates to a neodymium iron boron magnetic steel surface oxidation prevention device. The invention provides the neodymium iron boron magnetic steel surface oxidation prevention device which is easy to operate, high in automation degree and convenient to install. The neodymium iron boron magnetic steel surface oxidation prevention device comprises an outer frame, a degreasing frame, a heating ring, a rotating plate, a discharging mechanism, a lifting mechanism and an accelerated stirring mechanism, the discharging mechanism is arranged on the outer frame, the rotating plate is arranged on the discharging mechanism, the lifting mechanism is arranged on the lifting mechanism, the degreasing frame is arranged on the lifting mechanism. the heating ring used for heating an oil removing and degreasing agent and the magnetic steel is arranged in the middle of the degreasing frame, and the accelerated stirring mechanism is arranged on the outer frame. When the neodymium iron boron magnetic steel surface oxidation prevention device is used and a cover plate moves forwards to be in contact with the degreasing frame, the degreasing frame enables the cover plate to turn over downwards, a frame opening of the degreasing frame can be covered, and the situation that the oil removing and degreasing agent in the degreasing frame is splashed out in the process of reacting with the magnetic steel, and consequently resources are wasted is prevented.

Owner:JIANGXI YG MAGNET CO LTD

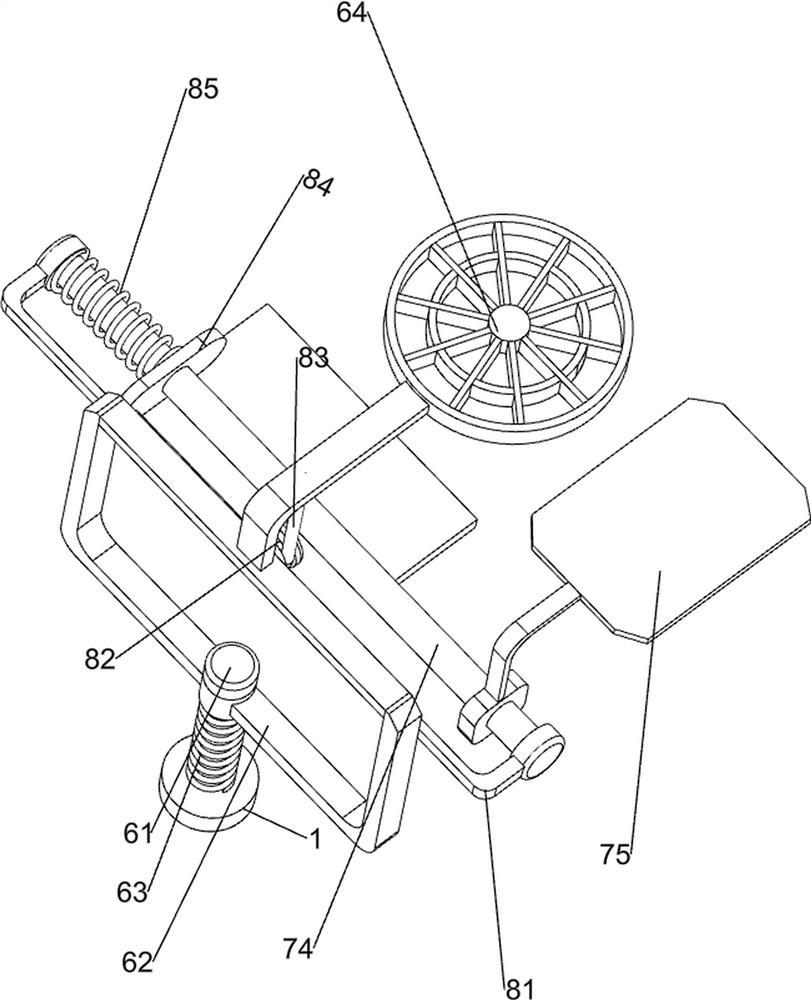

Green leaf pigment extraction device for biological experiment

PendingCN114453101ARealize the rotation effectRealize the output effectGrain treatmentsStationary filtering element filtersElectric machineryBevel gear

The invention relates to a green leaf pigment extraction device, in particular to a green leaf pigment extraction device for biological experiments. The green leaf pigment extraction device for the biological experiment, provided by the invention, has the advantages of automatic grinding, high extraction speed and convenience in use. The green leaf pigment extraction device for the biological experiment comprises a supporting plate and a material collecting frame, and the material collecting frame is placed on the supporting plate; the filtering frame is arranged on the supporting plate; the grinding frame is arranged on the filtering frame; the driving rotating mechanism is arranged on the supporting plate; the grinder is arranged on the driving rotating mechanism; and the discharging mechanism is arranged in the middle of the supporting plate. The output shaft of the motor rotates to drive the bevel gear set to rotate, so that the supporting column is driven to rotate, then the grinder is driven to rotate, the grinder can grind green leaves, and the effect of driving rotation is achieved.

Owner:陈美秀

Black tea making device for food processing

ActiveCN113875835ARealize the effect of pressing downRealize the effect of pressingPre-extraction tea treatmentFood shapingMechanical engineeringBlack teas

The invention relates to a making device, in particular to a black tea making device for food processing. According to the black tea making device for food processing, the labor intensity of people is reduced, the work progress is accelerated, and the manufacturing cost is relatively low. The black tea making device for food processing comprises a supporting bottom plate, supporting blocks arranged on the two sides of the supporting bottom plate, supporting columns arranged on the two sides of the supporting bottom plate, a working barrel arranged between the upper parts of the two supporting columns, and a discharging mechanism that is arranged on the supporting bottom plate and penetrates through the working barrel. A first sliding plate block is manually pushed to move downwards, then a material receiving plate is driven to move downwards, and a first spring is compressed; and when the material receiving plate moves downwards, a black tea cake can be driven into the working barrel, hot water can soak the black tea cake, black tea is formed, and the downward pressing effect is achieved.

Owner:洪江市湘佰农业发展有限公司

Slurry spraying and powder spraying integrated potato chip seasoning device

The invention provides a slurry spraying and powder spraying integrated potato chip seasoning device, which comprises a seasoning tank, a powder spraying device and a control device, and is characterized in that potato chips are contained in the seasoning tank; the powder spraying mechanism is arranged at the top of the first moving frame, the powder spraying mechanism comprises a feeding hopper, powder to be sprayed is contained in the feeding hopper, a switch device is arranged at the bottom end of the feeding hopper, and a vibration conveying device is arranged below the feeding hopper and used for conveying the powder falling from the feeding hopper into the seasoning tank; the slurry spraying mechanism is fixedly arranged on one side of the second moving frame, the slurry spraying mechanism comprises a slurry storage tank, to-be-sprayed slurry is contained in the slurry storage tank, a slurry inlet pipe is arranged on the outer side of the slurry storage tank in a communicating mode, and the end of the slurry inlet pipe extends into the slurry storage tank and is provided with a spray head used for spraying slurry in the slurry storage tank into the seasoning tank; the discharging mechanism is arranged between the seasoning pot and the second moving frame and used for enabling the seasoning pot to move up and down relative to the second moving frame, and therefore the powder spraying and slurry spraying device has the advantage that powder spraying and slurry spraying are achieved at the same time.

Owner:无锡通过机械有限公司

Oral ulcer medicine applying device for stomatology department

PendingCN113926067ARealize the effect of loadingRealize the output effectMedical devicesPharmacy medicineOral ulcers

The invention relates to a medicine applying device, in particular to an oral ulcer medicine applying device for the stomatology department. The oral ulcer medicine applying device for the stomatology department is convenient in medicine applying, clean, sanitary and simple in structure. The oral ulcer medicine applying device for the stomatology department comprises: a grip and a main frame, wherein the main frame is arranged on the grip; a guide pipe which is arranged on the main frame; a hose which is arranged on the guide pipe, wherein the hose is connected with the main frame; a first pressing rod which is arranged on the main frame in a sliding manner; and a charging mechanism which is arranged in the main frame. A doctor can manually pull a first baffle to move rightwards, a first spring is compressed, the first baffle moves rightwards to open a feeding port of a feeding frame, at the moment, the doctor can pour medicine into the feeding frame, the medicine falls into a loading frame through the feeding frame, and the loading effect is achieved.

Owner:邱思敏

Electronic component surface oxide removing device

PendingCN114000156AAchieve rust removal effectRealize the effect of feedingEngineeringElectronic component

The invention relates to a removing device, in particular to an electronic component surface oxide removing device. The electronic component surface oxide removing device is convenient to use, small in damage to the electronic component and capable of reducing the labor intensity of workers. The electronic component surface oxide removing device comprises a first water tank and a second water tank, and the second water tank is arranged on the first water tank; and a rust removal mechanism is arranged on the upper side of the second water tank. According to the invention, the electronic components can be soaked in a rust remover through downward movement of a discharging component, oxides on the surfaces of the electronic components can be removed, and the rust removal effect is achieved; a telescopic rod of a first electric push rod is shortened to slide on a sliding block, so that a discharging plate is driven to move backwards, then electronic components, a pressure sensor and a fixing rod are driven to move backwards, the electronic components can be located in a discharging component by moving the discharging plate backwards, and the feeding effect is achieved.

Owner:于都县八佰贸易有限公司

Rapid equidistant segmentation equipment for marble slabs for building

InactiveCN113967972ARealize the rotation effectNo manual push requiredWorking accessoriesStone-like material working toolsStructural engineeringMechanical engineering

The invention relates to segmentation equipment, in particular to rapid equidistant segmentation equipment for marble slabs for a building. The invention provides the rapid equidistant segmentation equipment for the marble slabs for the building, which has the advantages that the influence on a human body is relatively small, cutting and segmentation angles are uniform, and operation is simple. The rapid equidistant segmentation equipment for the marble slabs for the building comprises supporting columns, a mounting plate frame, an electric cutting knife, a rotating mechanism and a pushing mechanism, wherein two supporting columns are arranged on each of the two sides of the lower part of the mounting plate frame; the electric cutting knife is mounted on the upper side of the mounting plate frame; the rotating mechanism is arranged on the mounting plate frame; and the pushing mechanism is arranged between the mounting plate frame and the rotating mechanism. By using the rapid equidistant segmentation equipment disclosed by the invention, the marble slabs can be driven to rotate through rotation of a second containing rotating block and rotation of a first containing rotating block, so that the marble slabs are in contact with the electric cutting knife and can be cut and segmented through rotation of the electric cutting knife, and the rotating effect is achieved.

Owner:王卫勇

Aluminum scrap loader

The invention relates to a loader, in particular to an aluminum scrap loader. The invention provides the aluminum scrap loader which integrates grinding and compression processing functions so as to save loading space. The aluminum scrap loader comprises a first supporting frame, a second fixed connecting rod, a scrap loading frame, a thinning mechanism and an accelerated discharging mechanism, wherein the second fixed connecting rod is arranged on the first supporting frame; the scrap loading frame is connected between the first supporting frame and the top of the second fixed connecting rod; the scrap loading frame is internally provided with the thinning mechanism; and the top of the scrap loading frame is provided with the accelerated discharging mechanism. According to the aluminum scrap loader, the thinning mechanism is arranged and used for grinding and thinning aluminum scraps, so that the situation that more space is occupied by the aluminum scraps due to the irregular size of the aluminum scraps is reduced.

Owner:杜怡清

Automatic corn stripping and breaking device

PendingCN112753381ARealize the effect of automatic feedingAchieve the effect of automatic peelingThreshersAgricultural engineeringMechanics

The invention relates to a corn breaking device, in particular to an automatic corn stripping and breaking device. The automatic corn stripping and breaking device provided by the invention has the advantages of automatic stripping, thorough stripping and automatic discharging. The automatic corn stripping and breaking device comprises a base, a fixing frame, a collector, a feeding mechanism and a stripping mechanism, wherein the fixing frame is arranged on the base; the collector is arranged at the top of the base; the feeding mechanism is arranged between the top of the fixing frame and the top of the base; and the stripping mechanism is arranged between the upper side of the fixing frame and the feeding mechanism. According to the automatic corn stripping and breaking device provided by the invention, a servo motor is started to drive a first rotating shaft to rotate so as to drive a rotating disc to rotate, then a swing frame is driven to swing leftwards and rightwards, the swing frame drives a push plate to slide leftwards and rightwards in a sliding rail, and the push plate intermittently pushes corn, so that the automatic feeding effect can be achieved.

Owner:李聋折

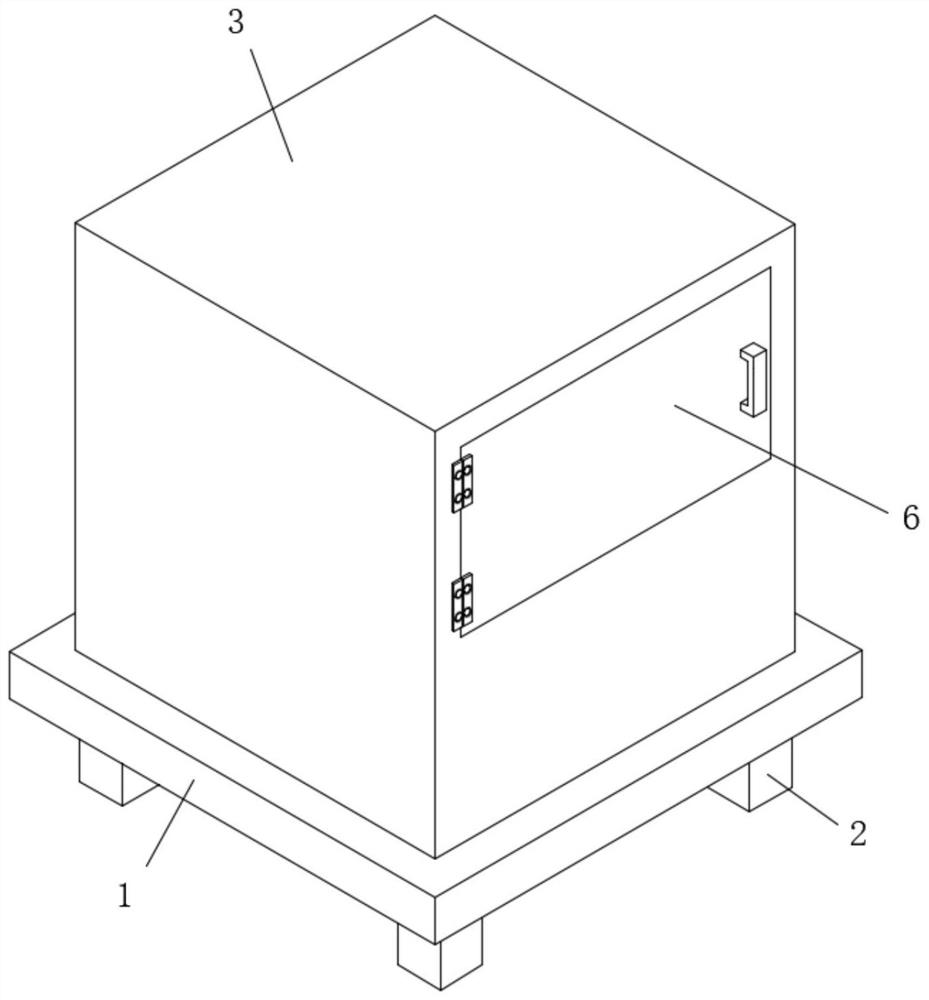

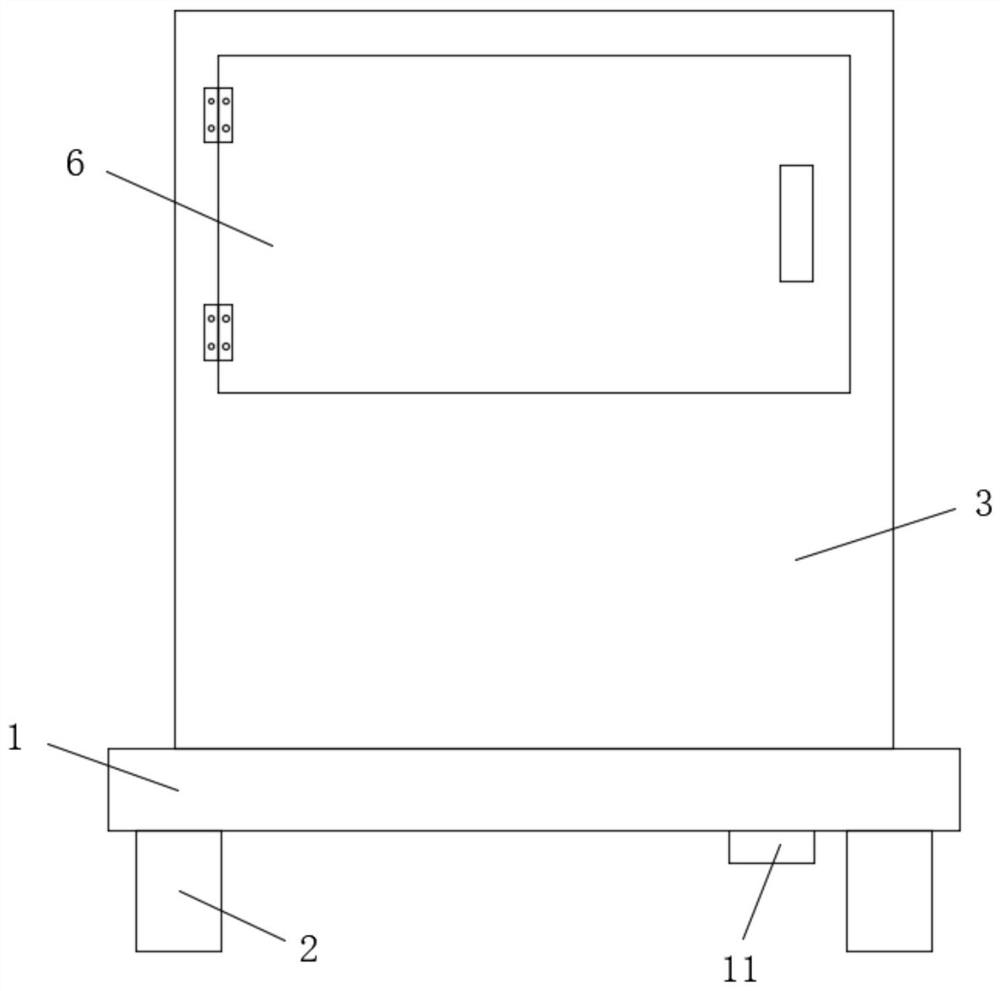

Liquid radioactive waste treatment equipment capable of reducing storage space

PendingCN114512256AProcessing speedAchieving Radiation Treatment EffectsRadioactive decontaminationEnvironmental engineeringRadioactive waste

The invention relates to waste treatment equipment, in particular to liquid radioactive waste treatment equipment with a reducible storage space. The liquid radioactive waste treatment equipment capable of reducing the storage space is small in occupied area, convenient to use, low in operation cost and capable of reducing the storage space. The liquid radioactive waste treatment equipment capable of reducing the storage space comprises a first supporting seat, an external protection frame, an internal reaction frame and the like, the external protection frame is arranged on the first supporting seat, and the internal reaction frame is arranged in the external protection frame. According to the radioactive liquid waste treatment device, the discharge port in the liquid storage frame is opened through clockwise rotation of the first rotating plate, so that radioactive treatment liquid in the liquid storage frame can flow into the internal reaction frame and react with radioactive liquid waste, impurities in the radioactive liquid waste can be treated, and the radioactive treatment effect on the radioactive liquid waste is achieved.

Owner:刘佳丽

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com