Matrix mixing equipment for agricultural seedling tray

A technology of mixing equipment and matrix, which is applied in the direction of mixers, mixers with rotating stirring devices, mixer accessories, etc., can solve the problems of slow feeding speed, etc., and achieve the effect of improving work efficiency and rational utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

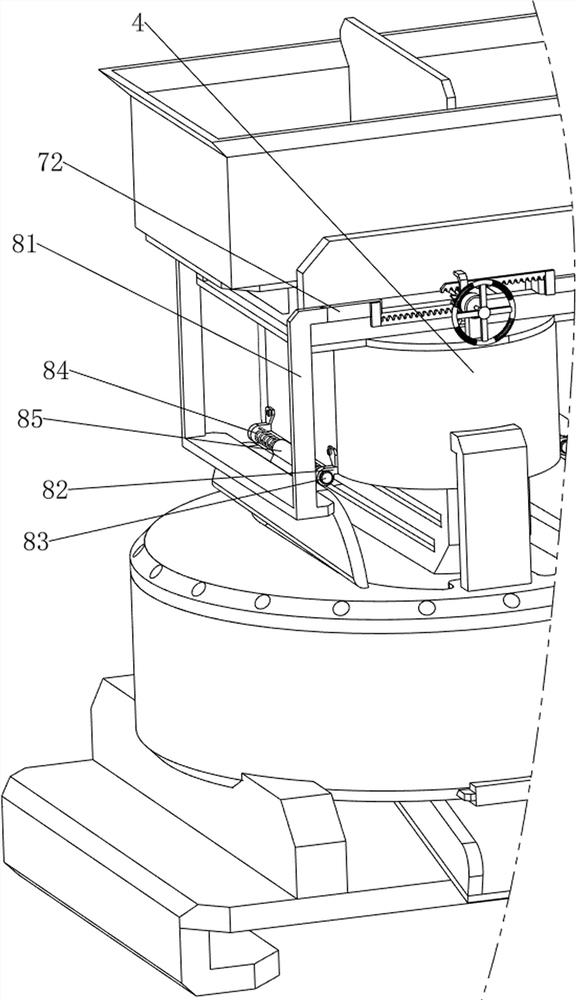

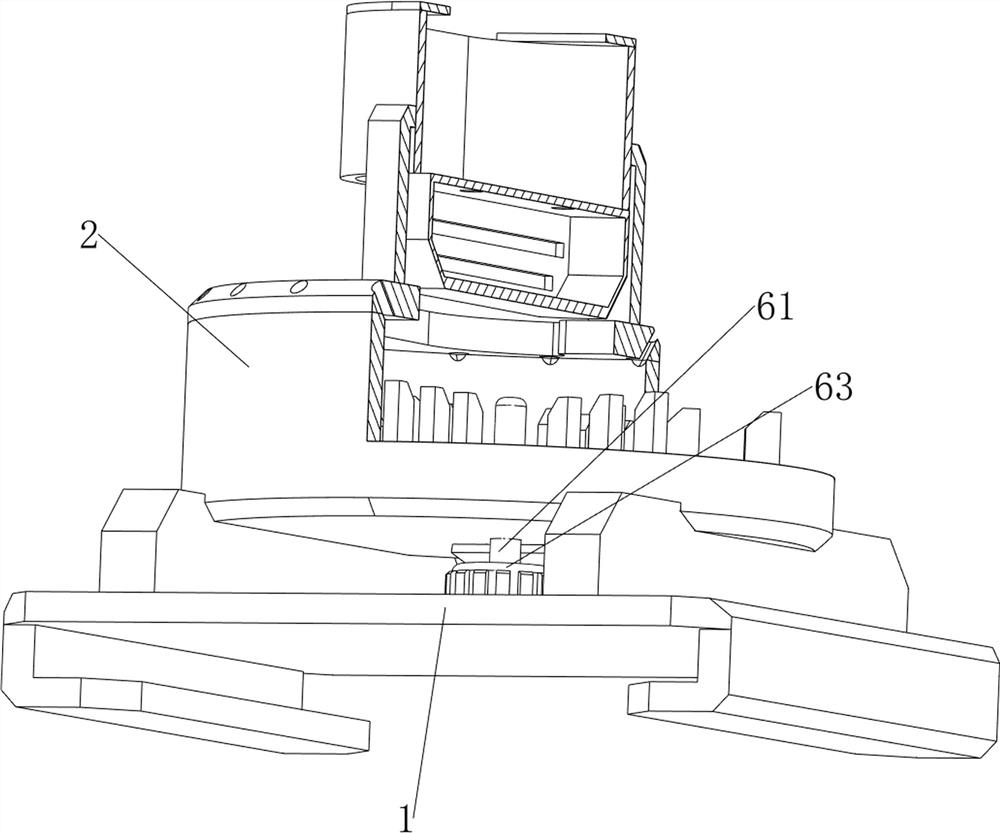

[0070] A substrate mixing equipment for agricultural seedling trays, now refer to Figure 1-2 , including a base 1, a stirring box 2, a first support frame 3, a crushing box 4, a first baffle 41, a crushing mechanism 5 and a mixing mechanism 6, the upper side of the base 1 is provided with a stirring box 2, and the front of the lower part of the stirring box 2 There is a feeding port between the side and the base 1, the upper part of the mixing box 2 is provided with a first support frame 3 on both sides, and a crushing box 4 is welded between the two first support frames 3. The crushing box 4 is divided into upper and lower parts. The front side of the mixing box 2 is slidably provided with a first baffle 41 , the inner and lower side of the crushing box 4 is provided with a crushing mechanism 5 , and a mixing mechanism 6 is provided between the base 1 and the mixing box 2 .

[0071] Reference now Figure 1-3 , the crushing mechanism 5 includes a first motor 51, a first rota...

Embodiment 2

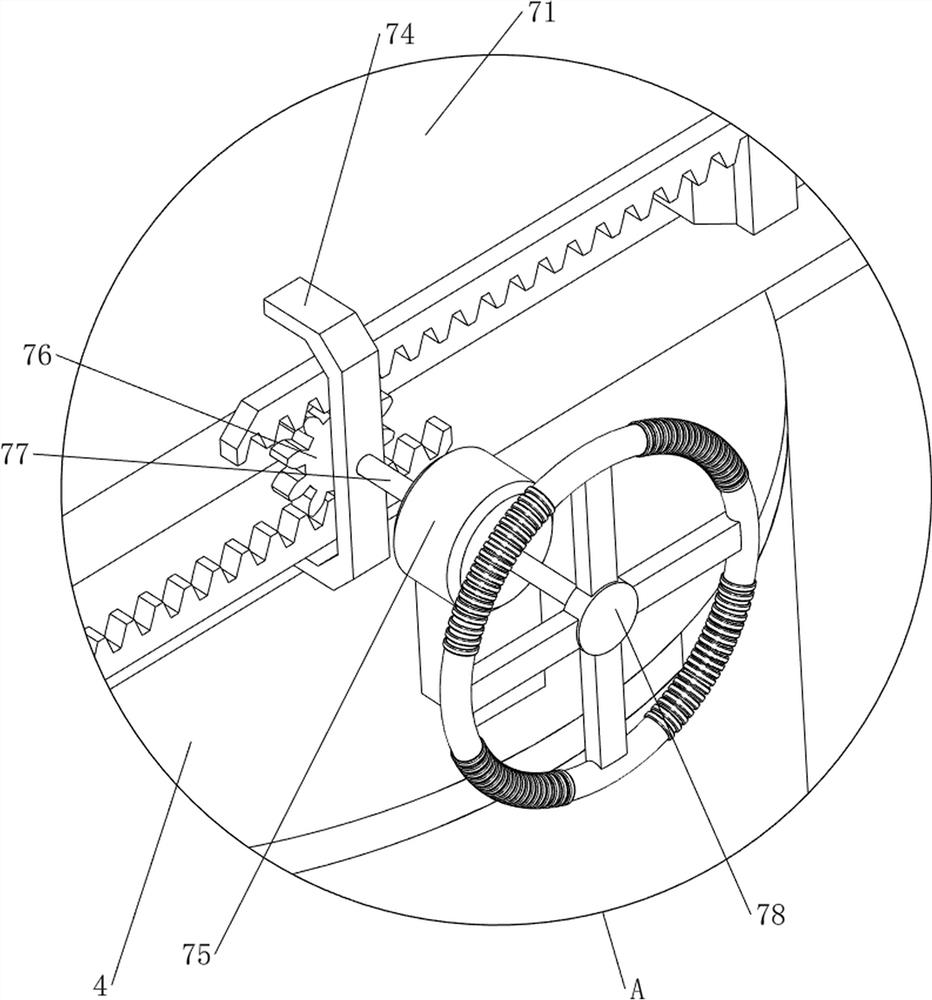

[0075] On the basis of Example 1, now refer to figure 2 , Image 6 , Figure 7 , Figure 8 and Figure 9 , and also includes a material control mechanism 7, and the material control mechanism 7 includes a material control box 71, a material control block 72, a rack 73, a second support frame 74, a first bearing seat 75, a gear 76, a fourth rotating shaft 77 and a rotating Wheel 78, a material control box 71 is welded on the upper side of the crushing box 4, a second support frame 74 is welded on both the front and rear sides of the material control box 71, a first bearing seat 75 is arranged on the front side of the upper part of the crushing box 4, Material control blocks 72 are slidably provided on the lower sides of the left and right sides, racks 73 are provided on both the front and rear sides of the material control block 72, there are four racks 73, and two second support frames 74 are rotatably connected with The fourth rotating shaft 77, the fourth rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com