Patents

Literature

216results about How to "Realize the rotation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

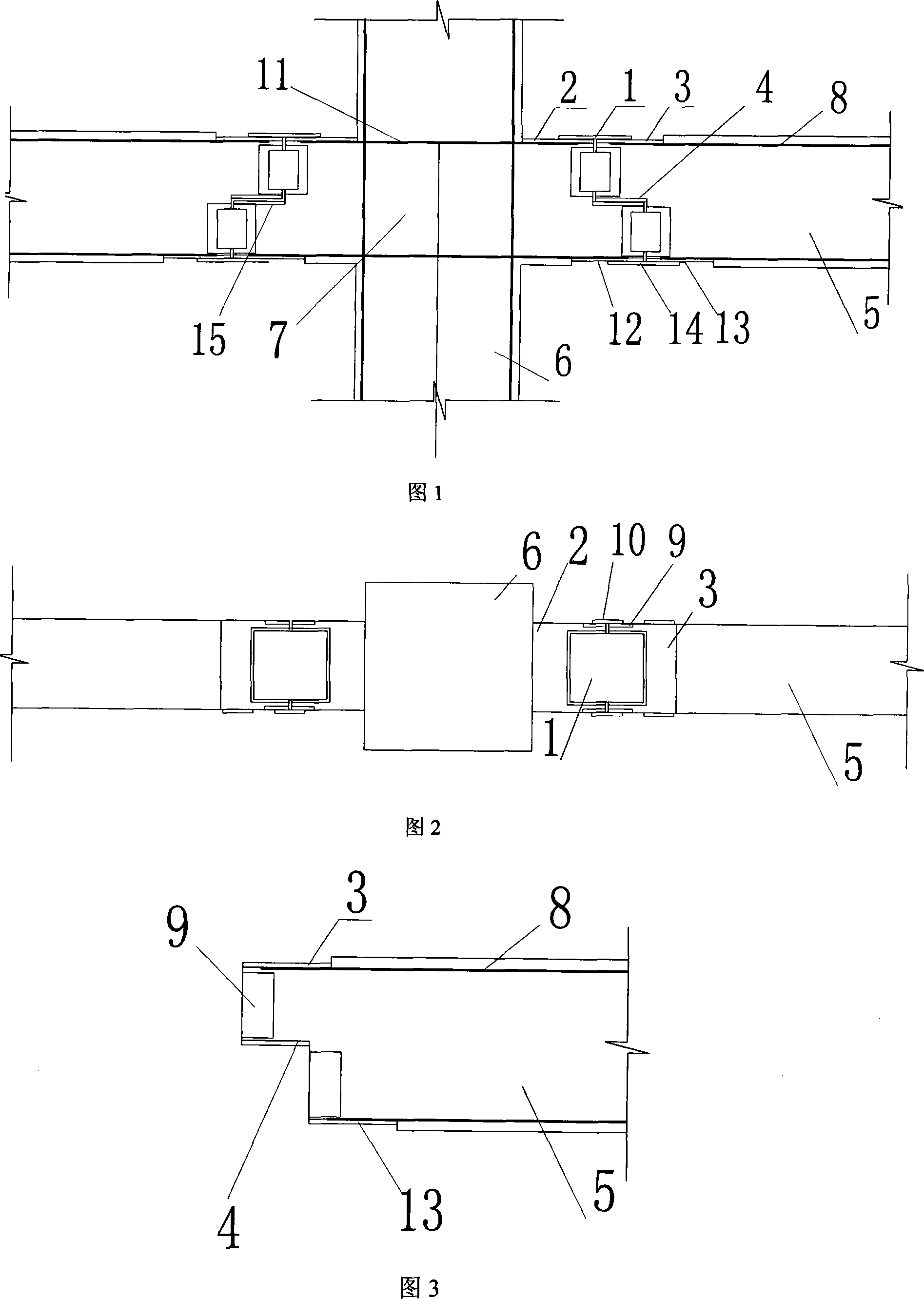

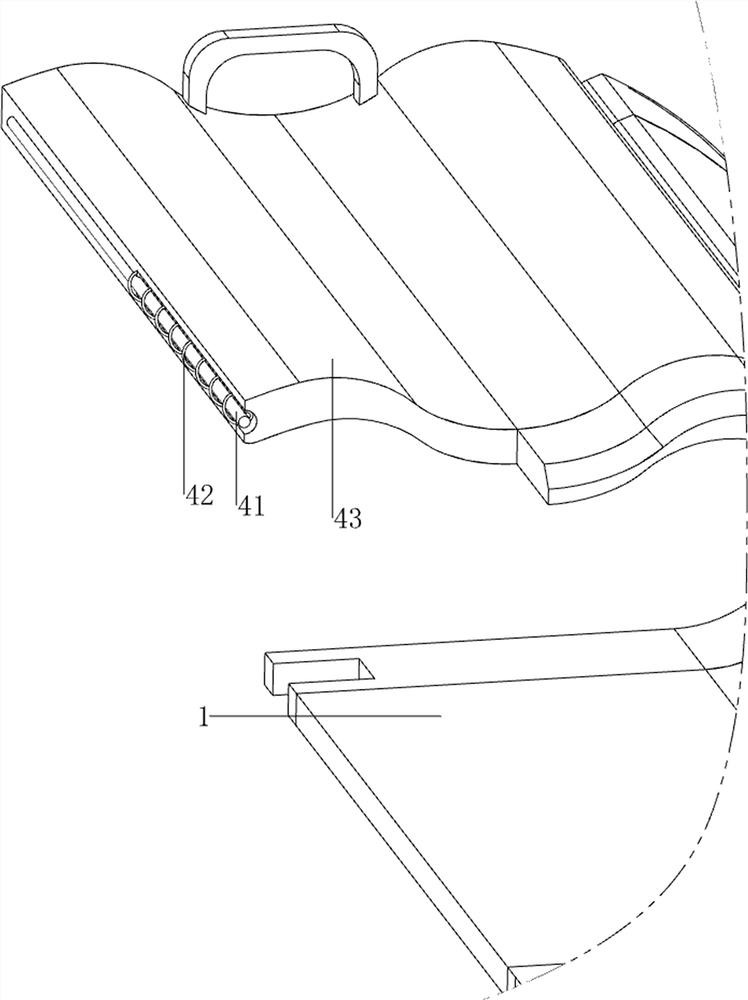

Full-prefabricated assembled concrete frame construction

InactiveCN101113604AHigh strengthImprove reliabilityBuilding constructionsCantileverBuilding construction

The invention discloses a whole precast prefabricated concrete frame structure, consisting of a precast pole and a horizontal beam that are mutually fixed. The precast pole is provided with an exserted level cantilever beam, the end of the exserted side of cantilever beam is provided with a gap; the end of the horizontal beam is provided with a boss that is matched with the gap arranged on the end of the cantilever beam; the horizontal beam and the cantilever beam are fixedly connected after the matching of the boss and the gap. The upper end, the lower end and the side of the cantilever beam ends are respectively provided with preburied metal plates, the upper end, the lower end and the side of the horizontal beam are also provided with preburied metal plates and the preburied metal plates arranged on the cantilever beam ends and the cantilever beam ends arranged on the horizontal beam are fixedly connected through a mental plate arranged on the top. Compared with the prior art, the invention has the advantages of reliable connection, reasonable structure, fast field construction, anti-seismic, etc.

Owner:SOUTHEAST UNIV

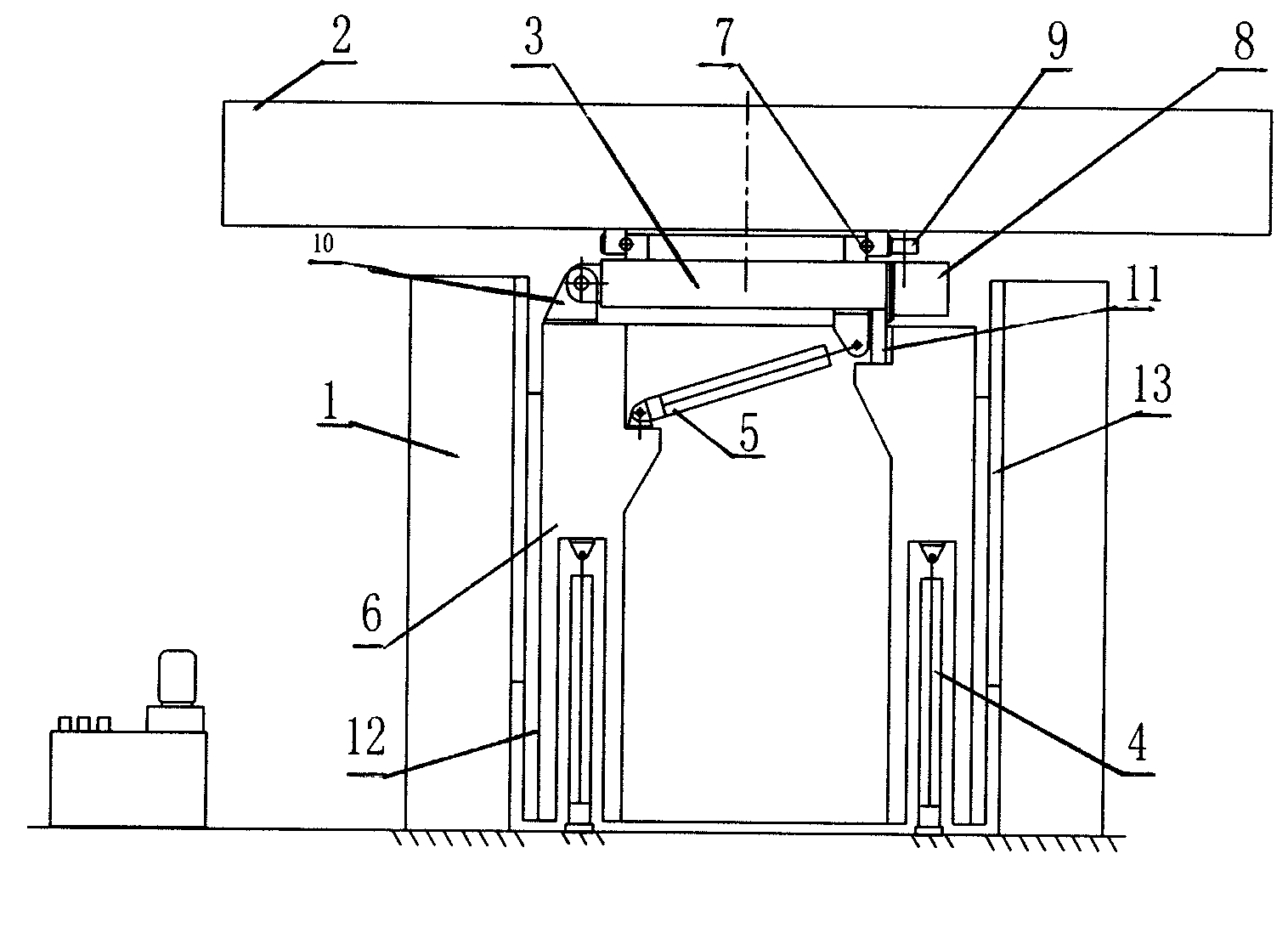

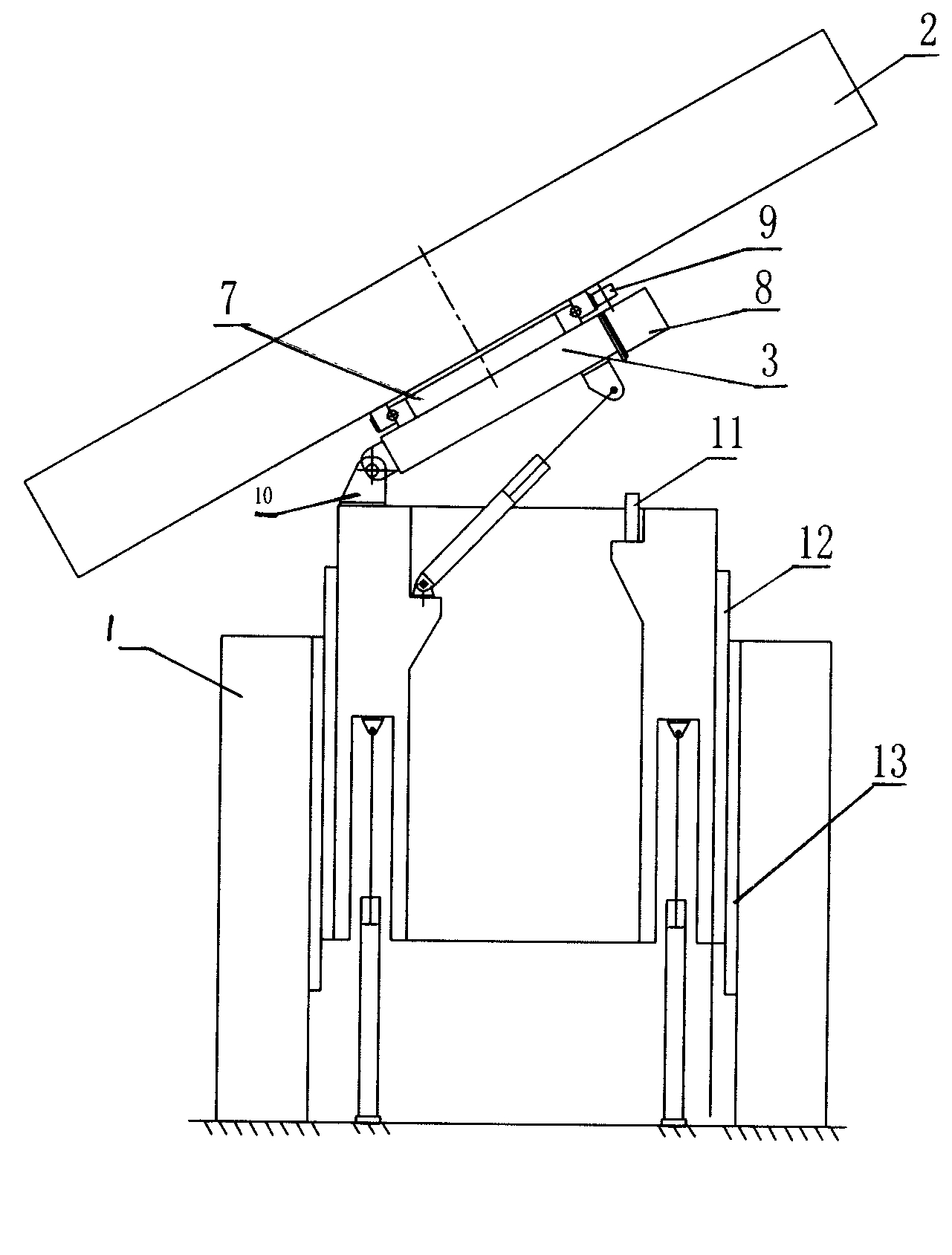

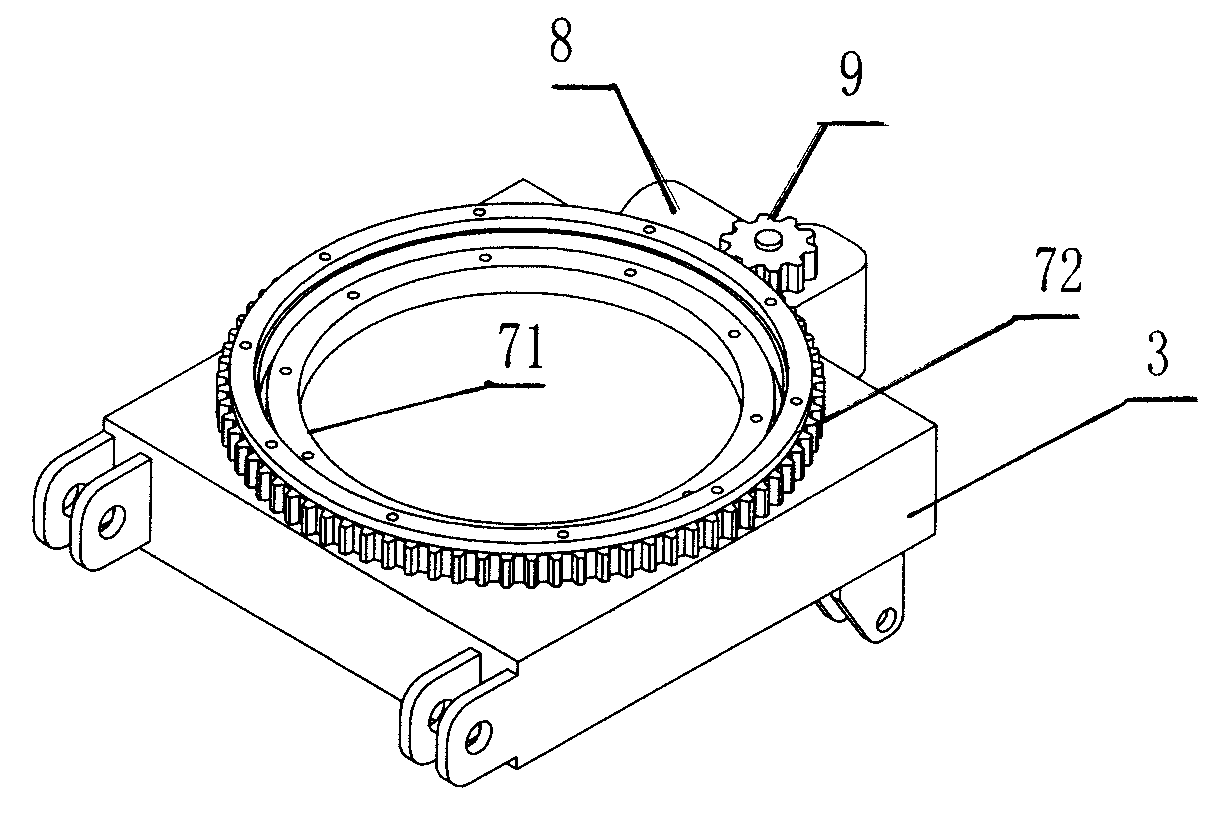

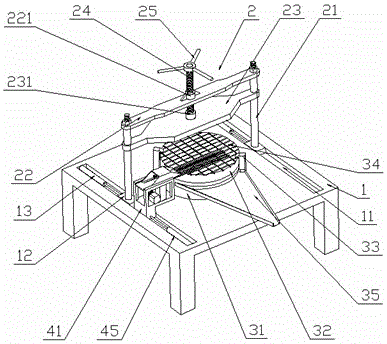

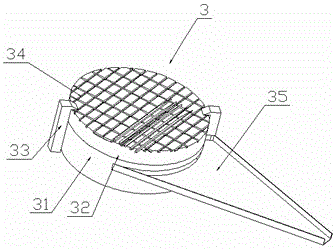

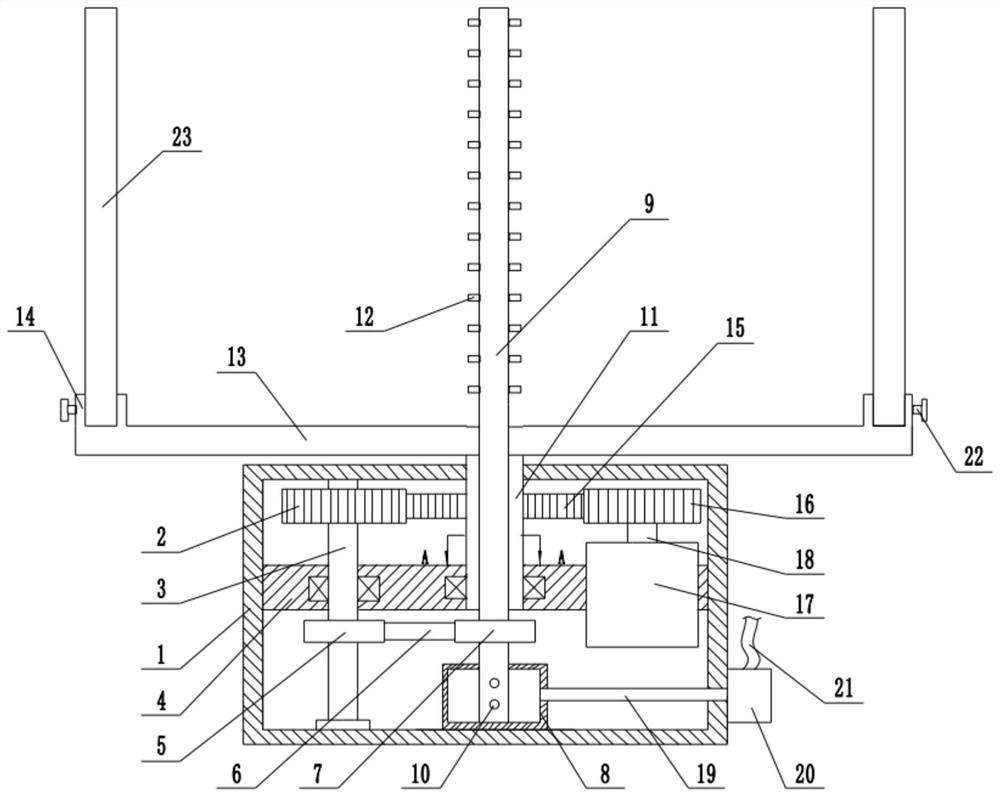

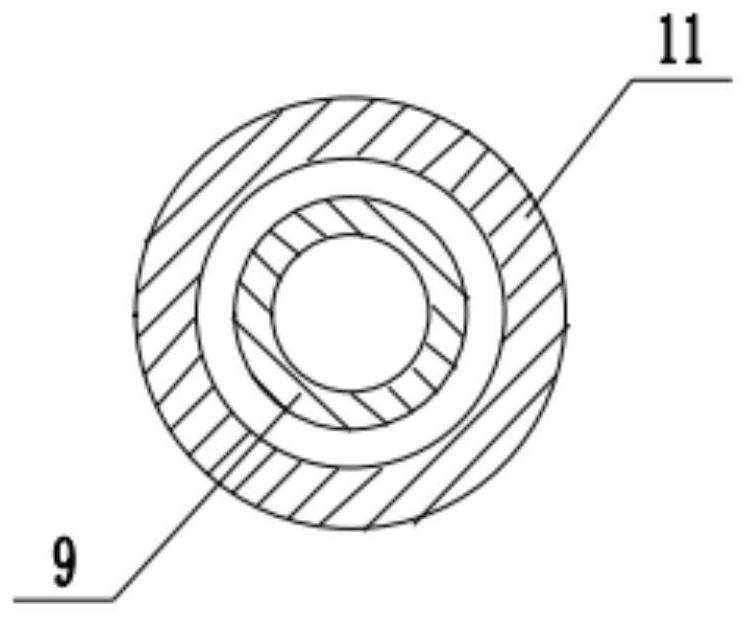

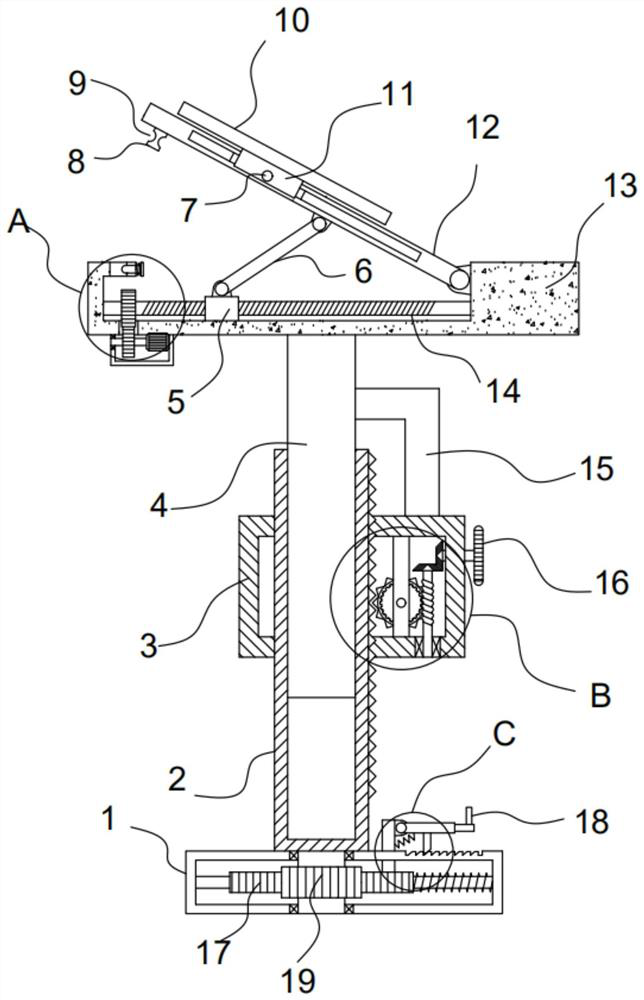

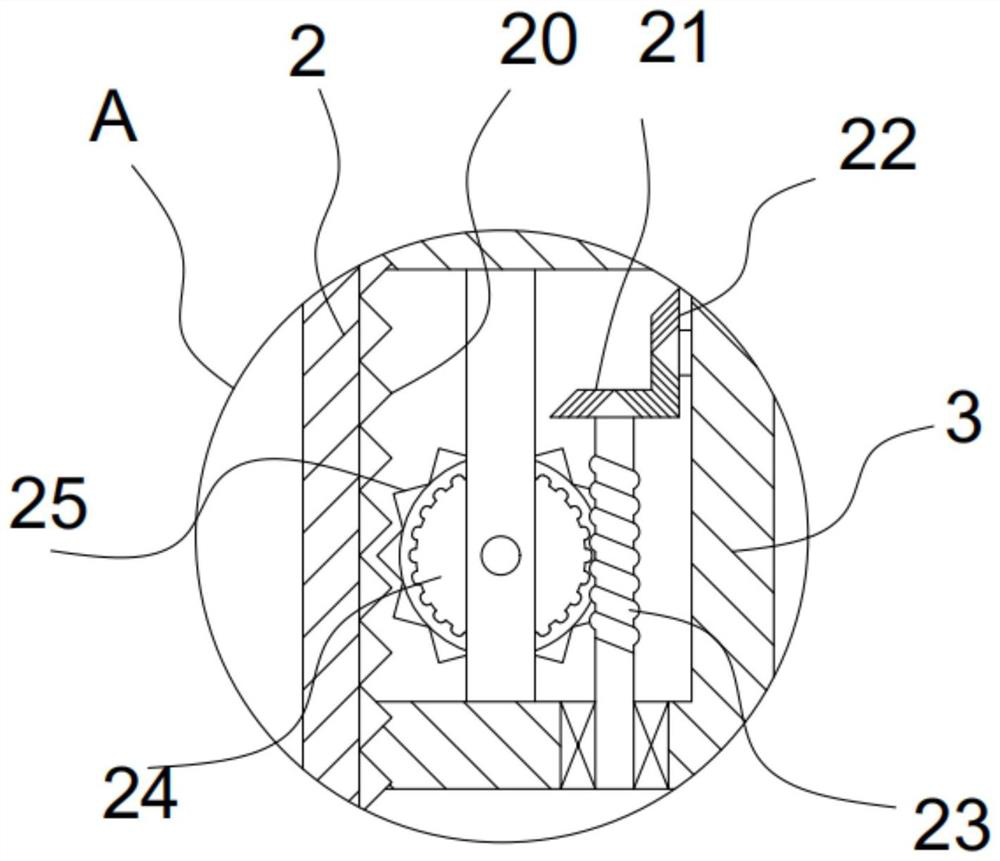

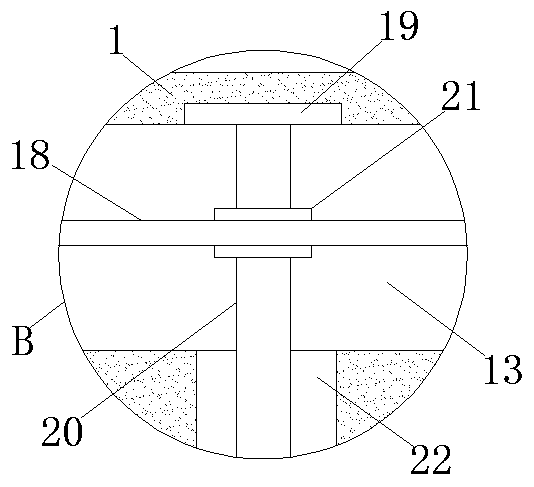

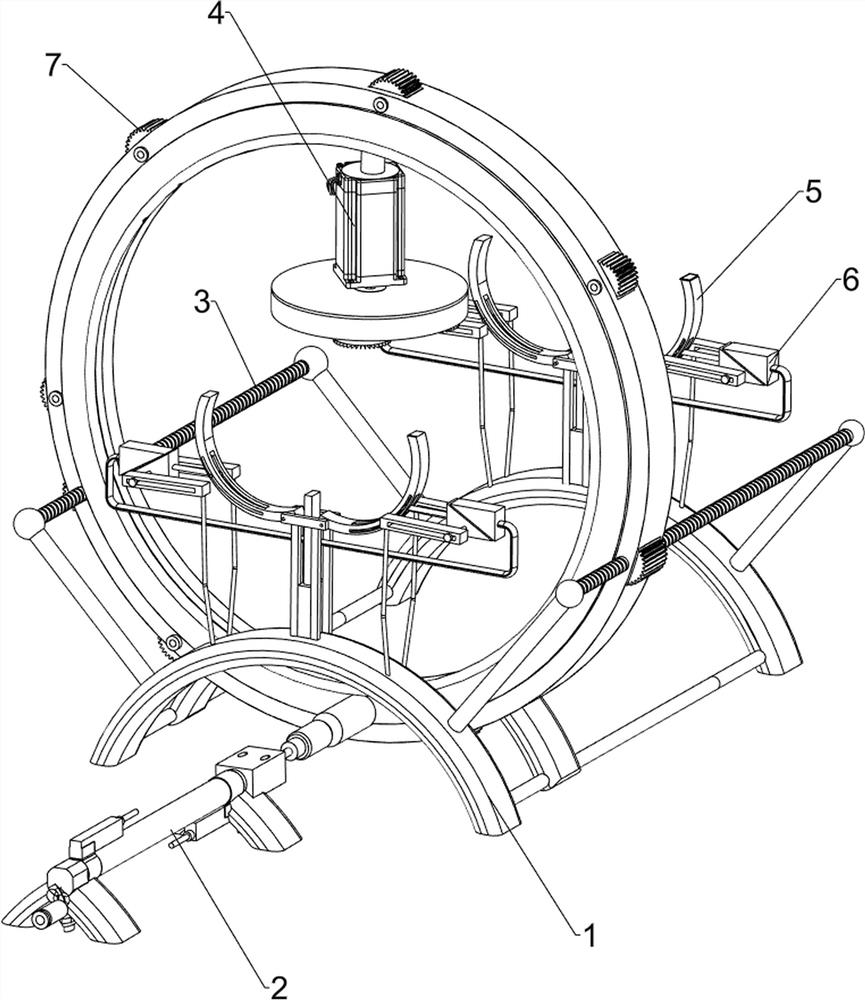

Multi-dimensional dynamic stage

A multi-dimensional dynamic stage comprises a hollow outer frame, a stage, a swing frame, first hydraulic cylinders and second hydraulic cylinders. A crane capable of ascending and descending is arranged in an inner cavity of the hollow outer frame, and piston rods of the first hydraulic cylinders are connected with the lower end of the crane; the swing frame is mounted below the stage and is connected with the stage by a rotary support, a driving motor and a driving gear are mounted on a side surface of the swing frame, and the driving gear is matched with the rotary support; and a first lug is arranged on the upper end surface of the crane, one end of the swing frame is hinged with the crane by the first lug, a step is arranged on the crane, the second hydraulic cylinders are hinged on the step, and piston rods of the second hydraulic cylinders are hinged with the other end of the swing frame. The multi-dimensional dynamic stage has the advantages that ascending, descending, declining and rotating effects can be realized by matching of the crane, the swing frame and the rotary support according to requirements of a story line, audiences feel awed and excited, and performance scenes are abundant.

Owner:ZHEJIANG JIAHE CULTURE TECH CO LTD

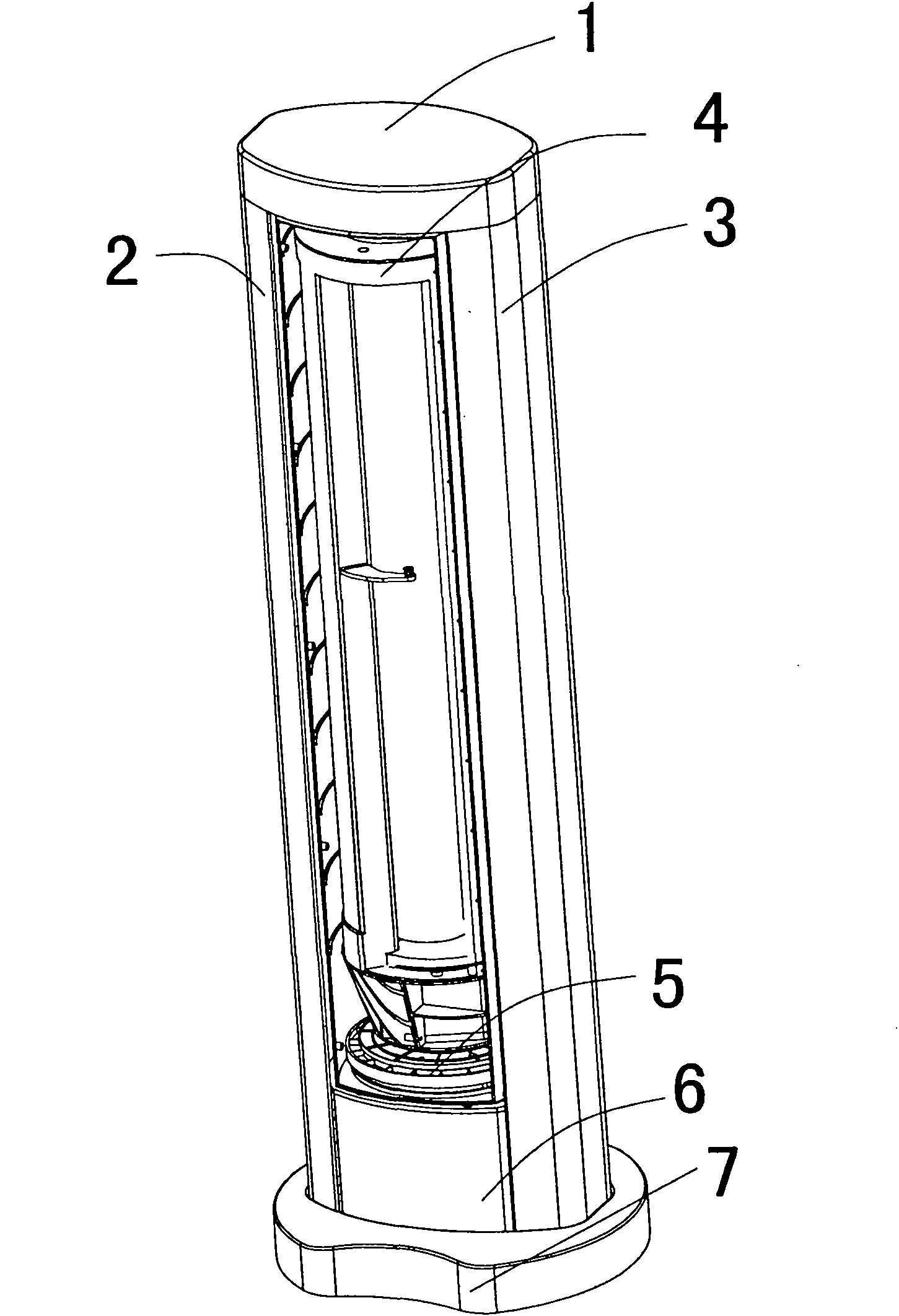

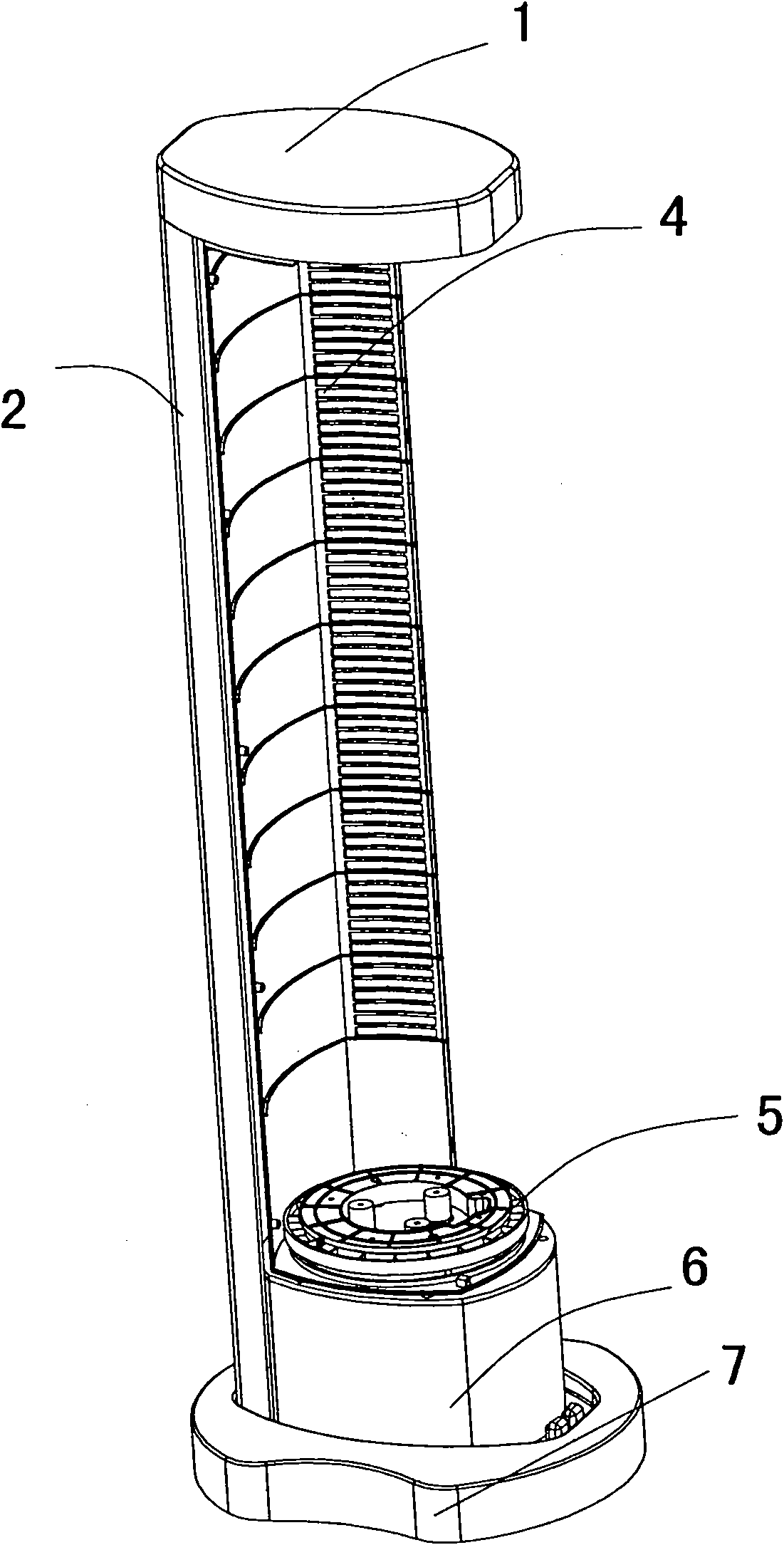

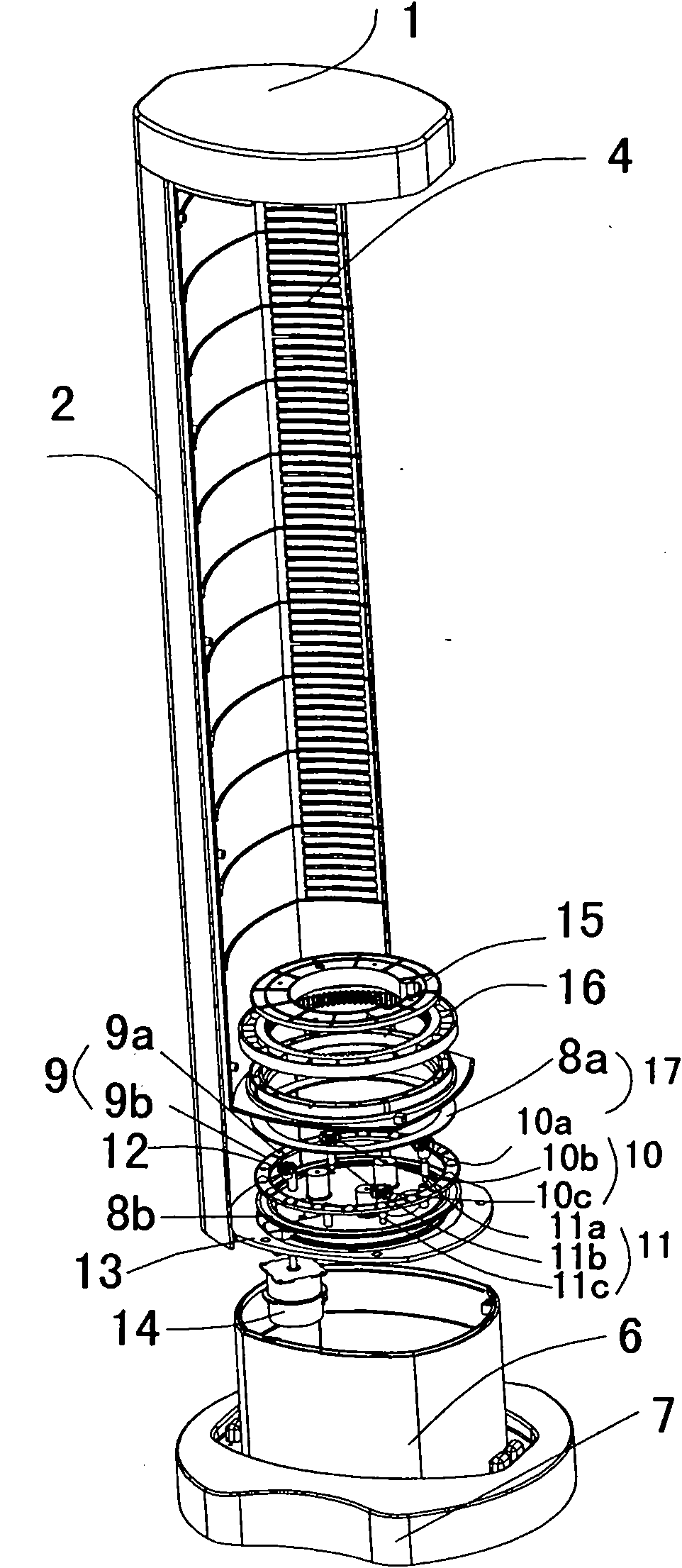

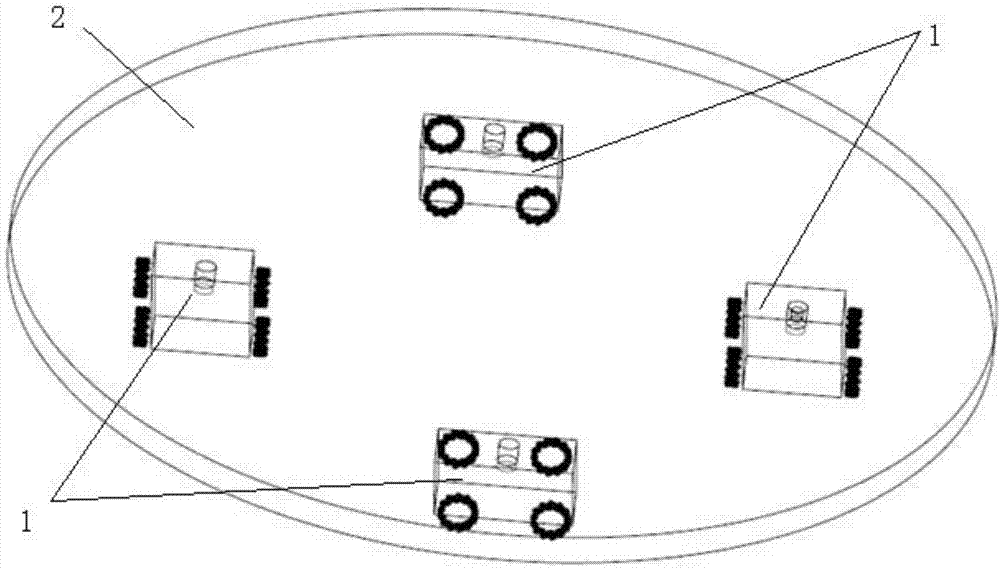

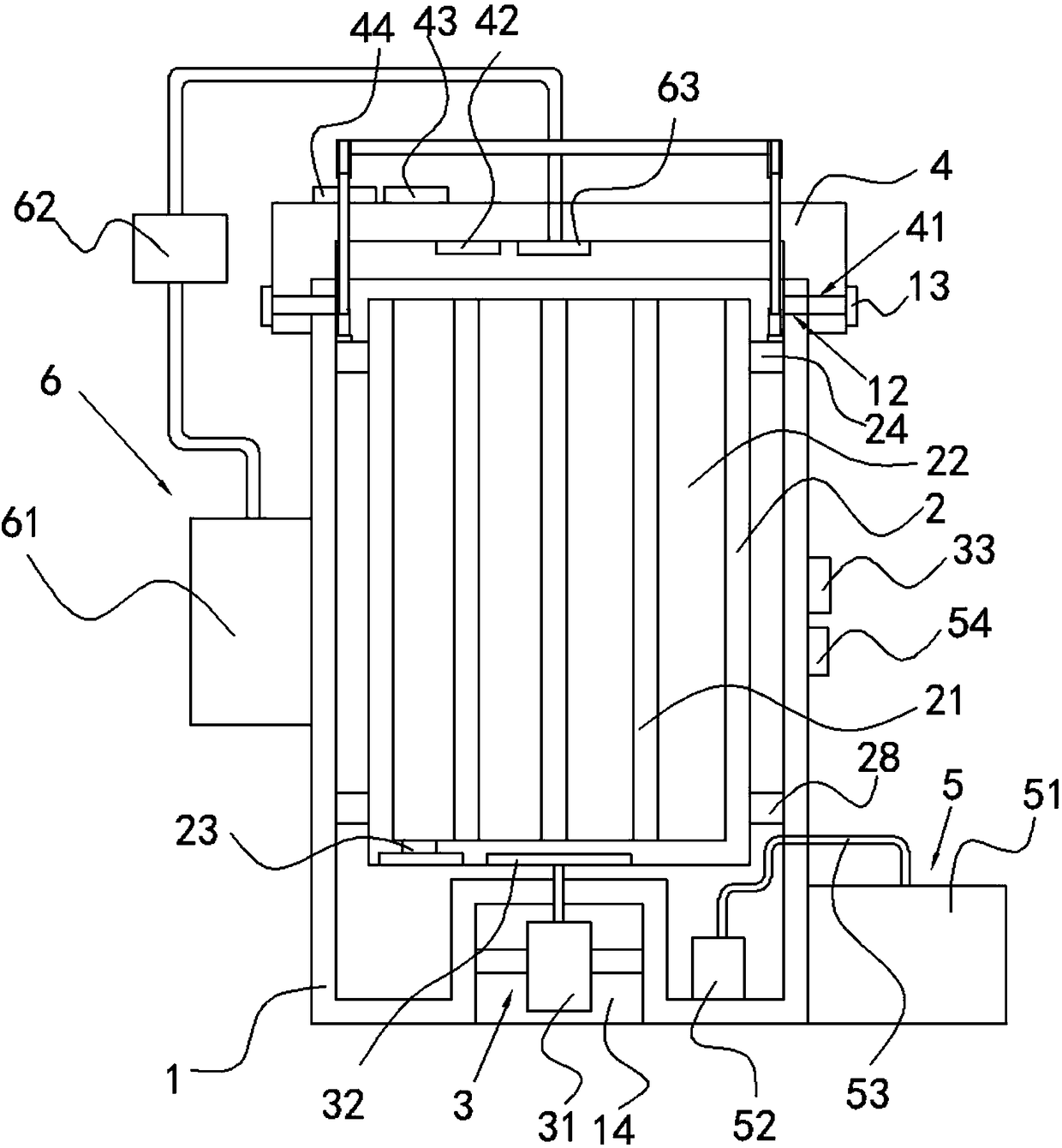

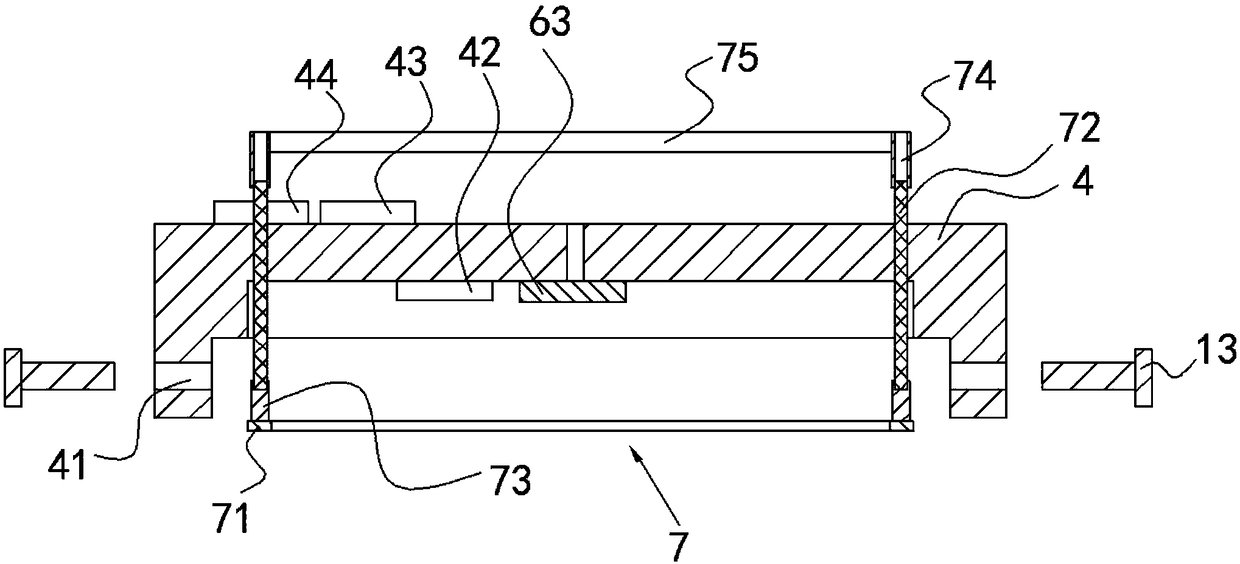

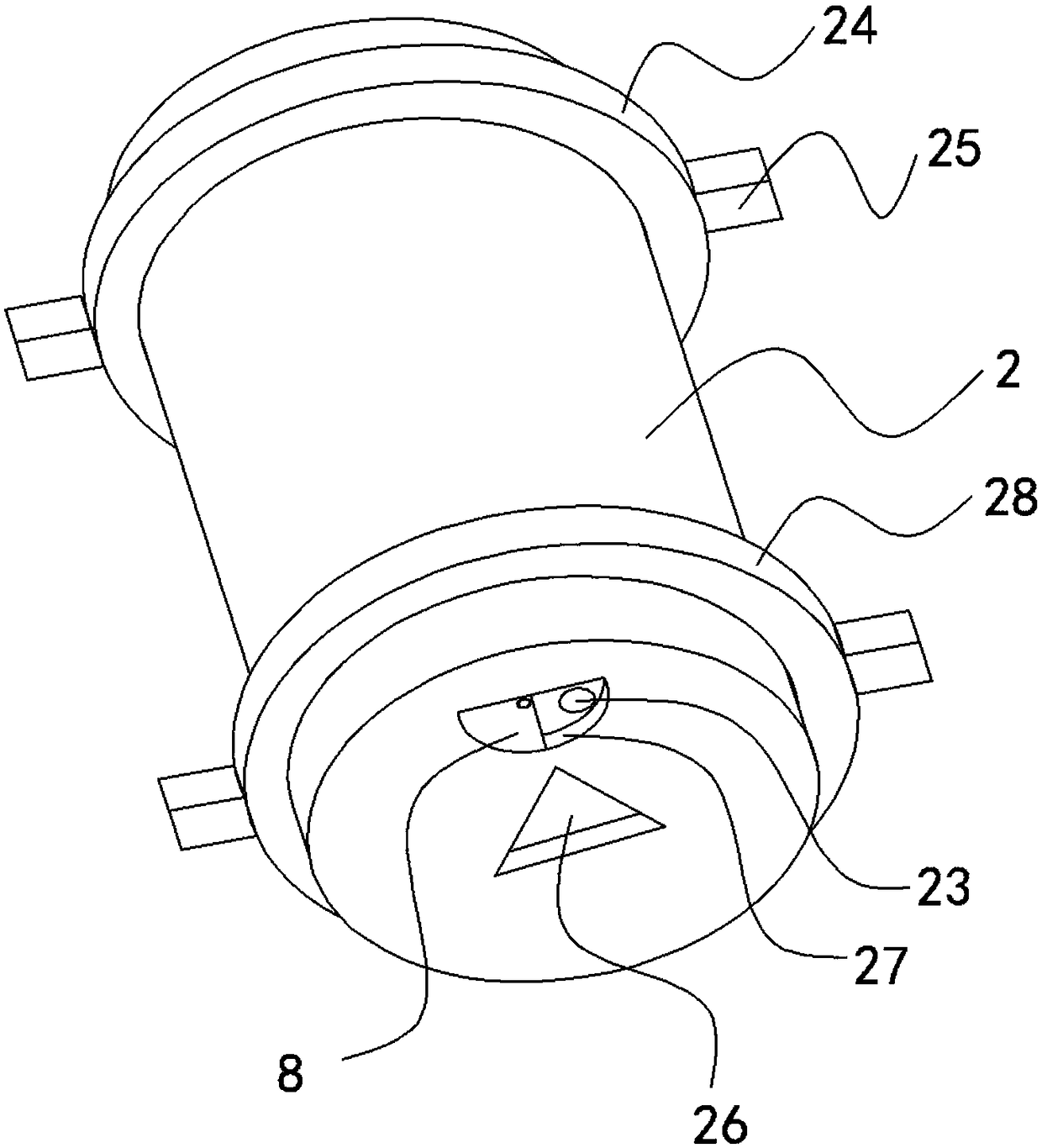

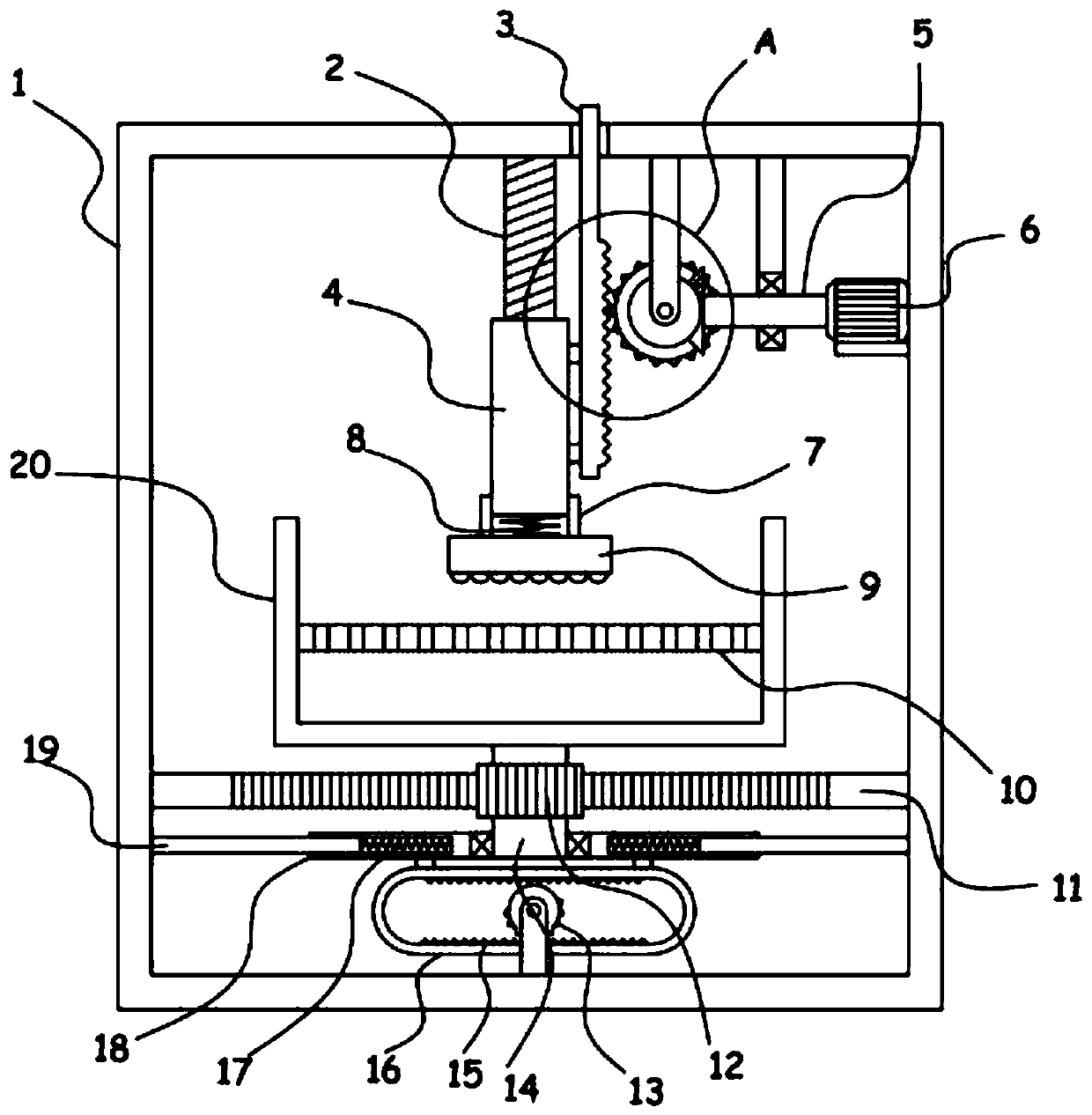

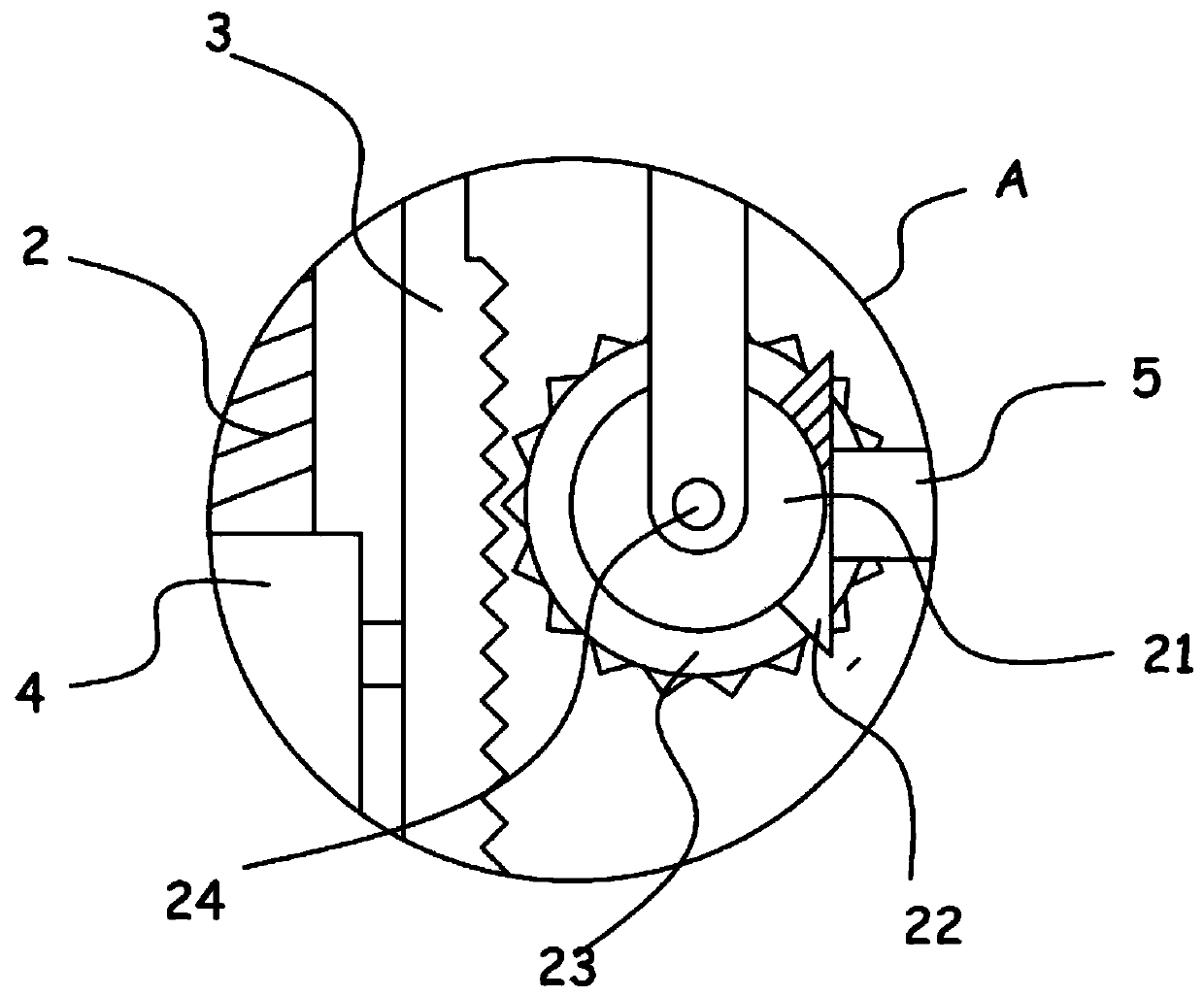

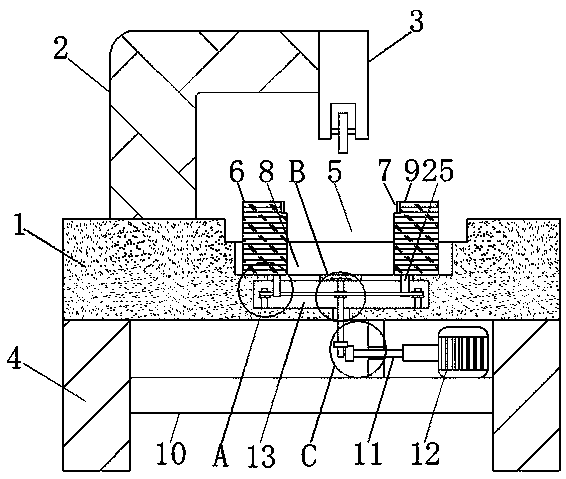

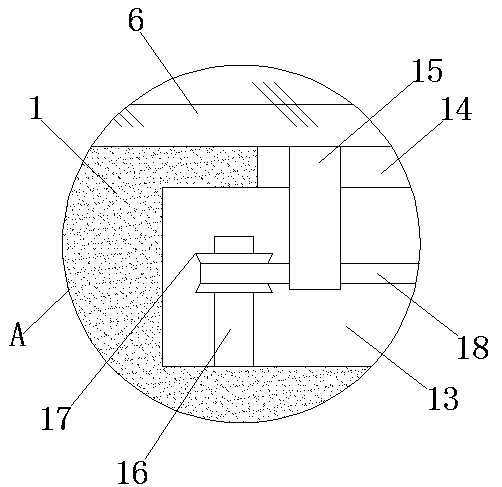

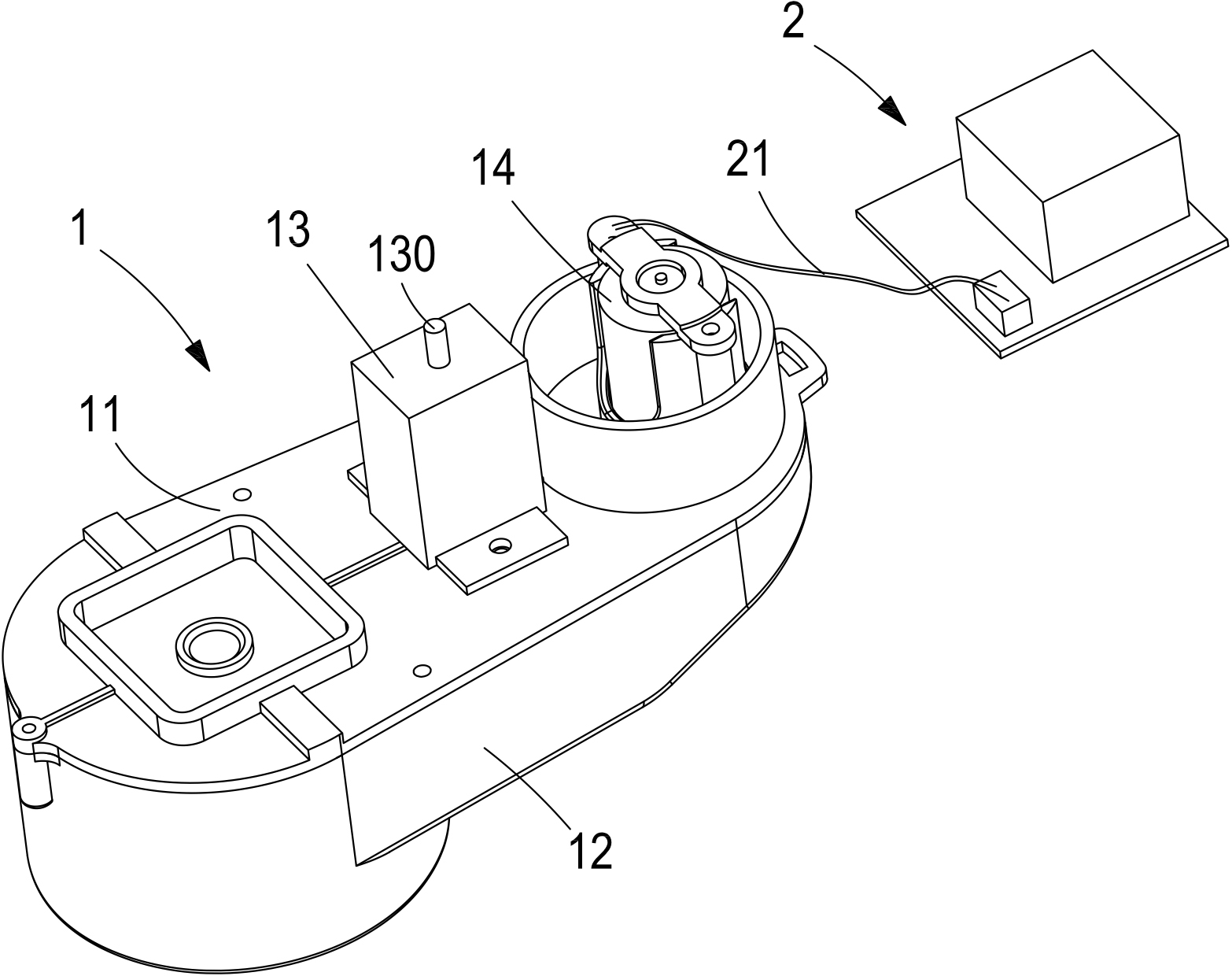

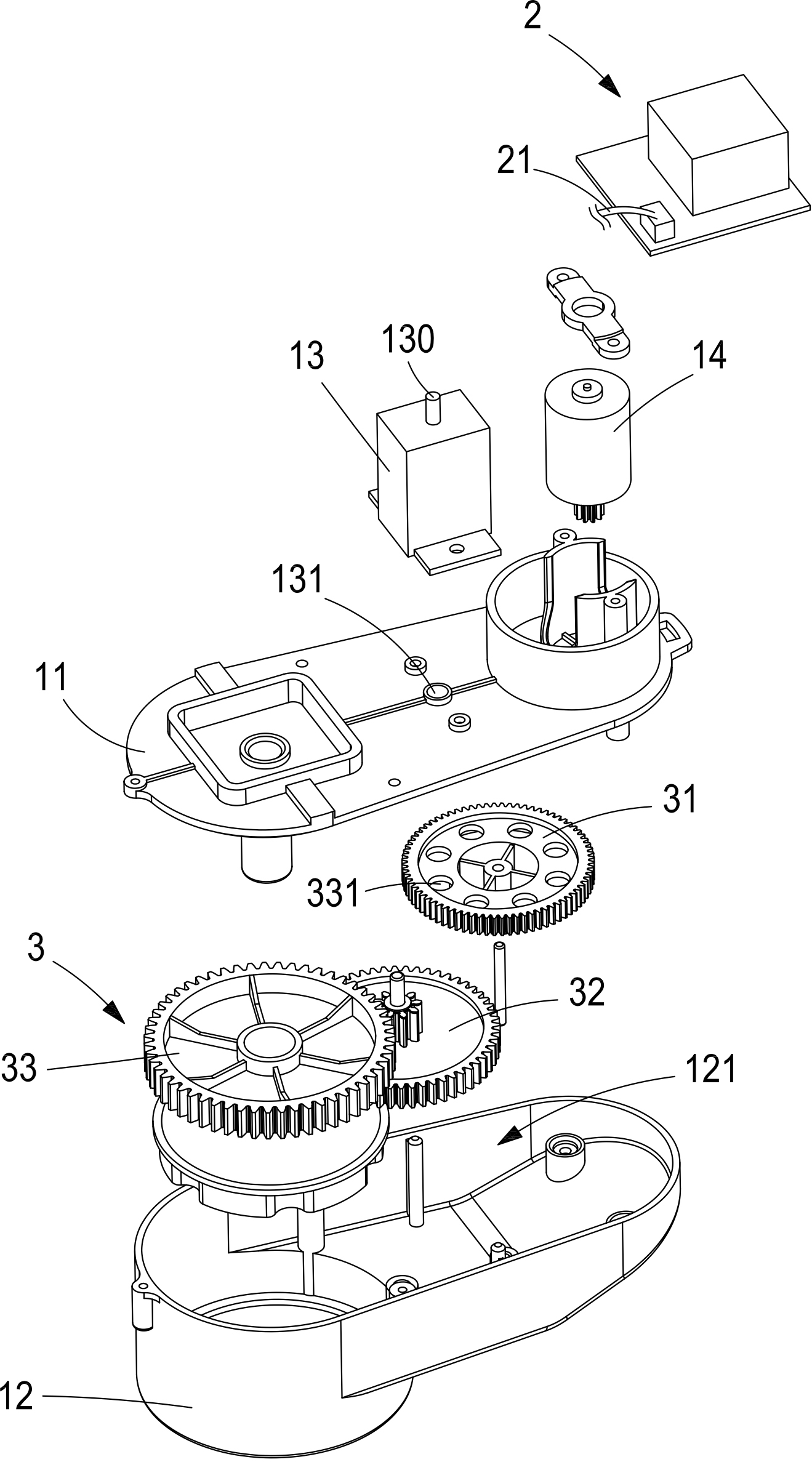

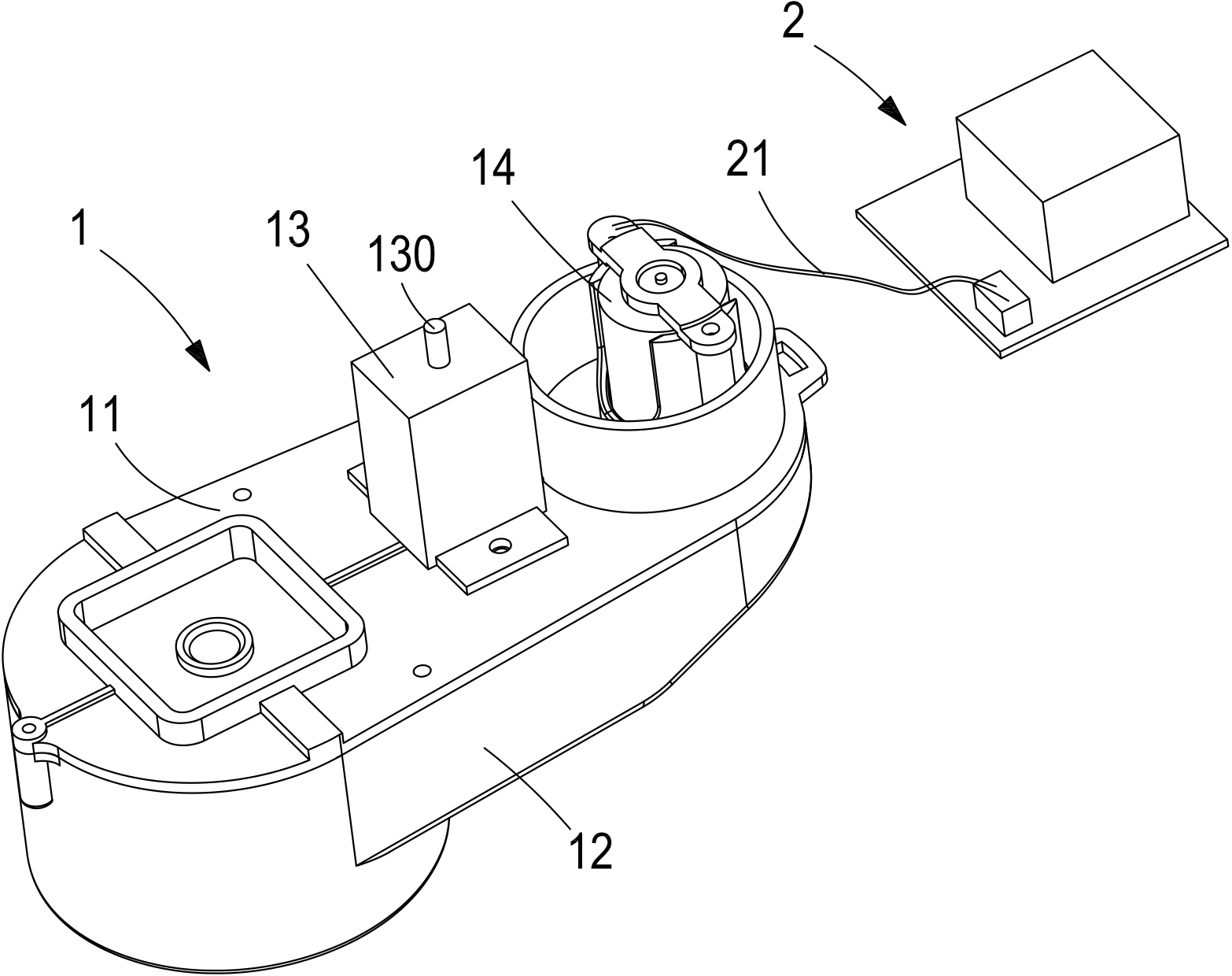

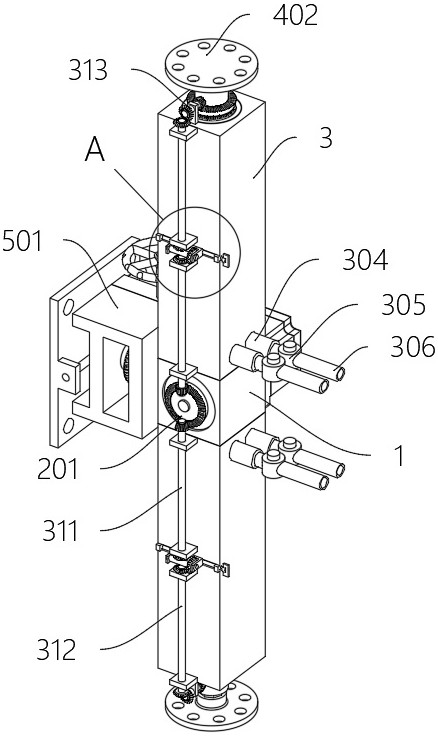

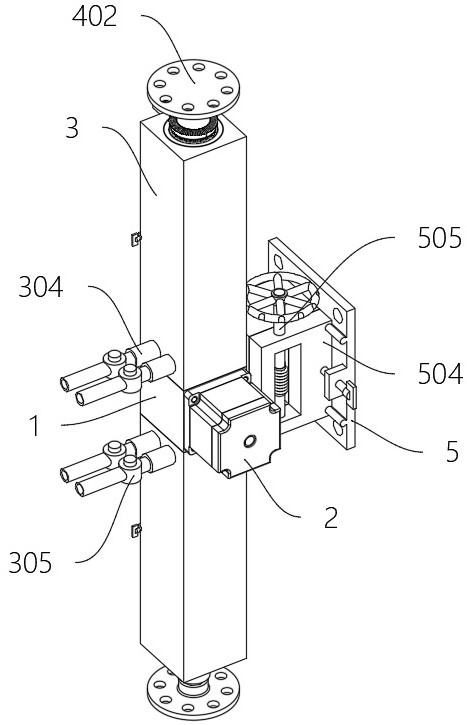

Indoor unit of vertical type air conditioner

ActiveCN102121725ARealize the rotation effectLighting and heating apparatusAir conditioning systemsEngineeringDrive motor

The invention provides an indoor unit of a vertical type air conditioner, which has a novel and effective rotating structure for realizing the rotation of a panel shell, an air inlet and an air outlet on the air conditioner and has the advantages of novel and variable structure so as to meet the requirement of personalized products. The indoor unit comprises a main body part and an outer case, wherein the main body part comprises an inner case, a heat exchange part, a ventilation part and an electrical part; the heat exchange part and the ventilation part are arranged in the inner cavity of the inner case; the inner case is provided with an inner air inlet and an inner air outlet; the outer case is arranged outside the main body part and wholly or partially covers the top part, the bottom part and the side part of the main body part; a gap is reserved between the side part of the outer case and the side part of the main body part; the bottom of the inner case of the main body part is rotatably arranged at the bottom of the outer case through a moving part; the moving part comprises a drive motor and a galactic gear set; the galactic gear set comprises a driving gear, an inner gear and a plurality of planetary gears; and the bottom of the inner case is fastened and connected with the inner gear.

Owner:GREE ELECTRIC APPLIANCES INC

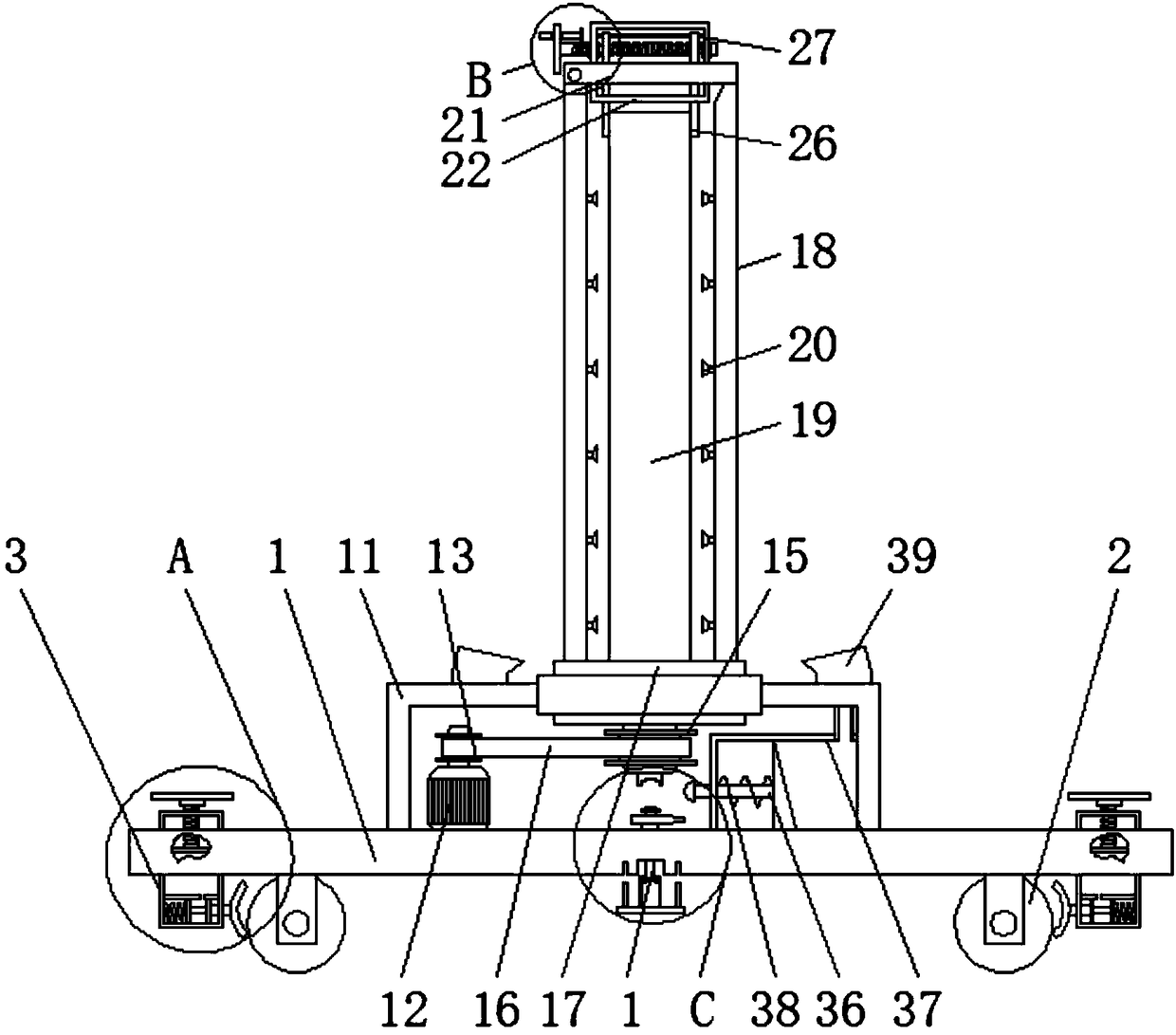

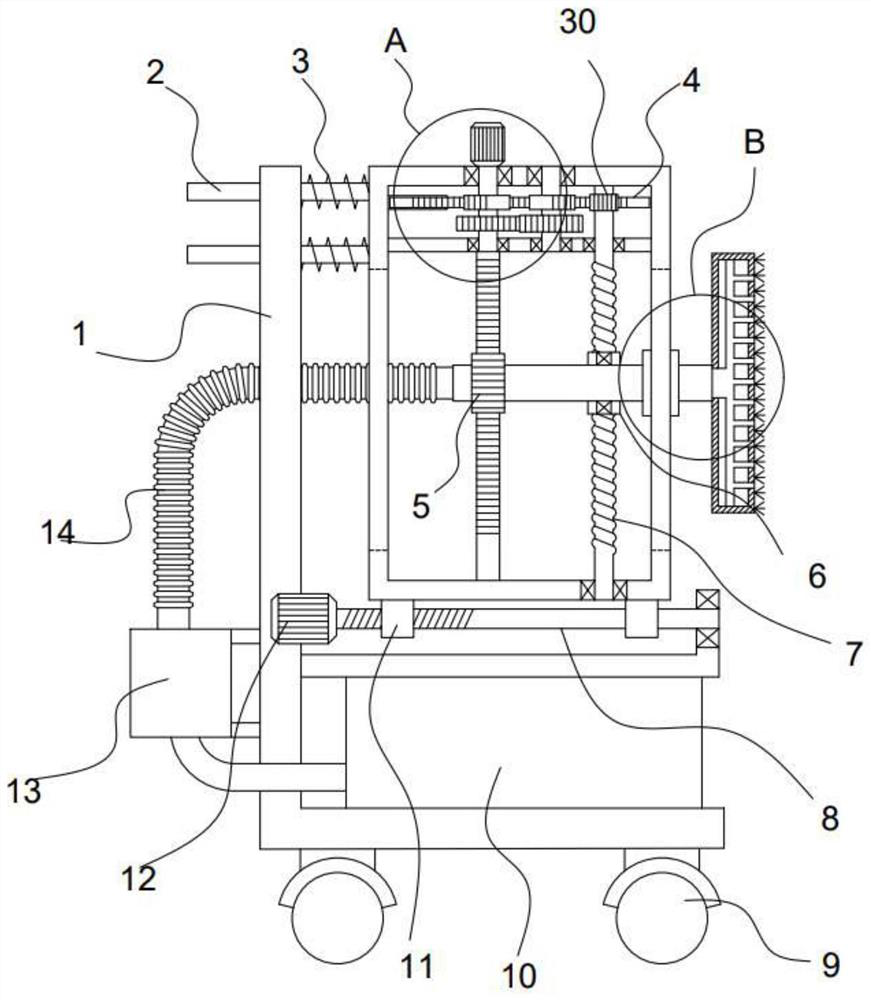

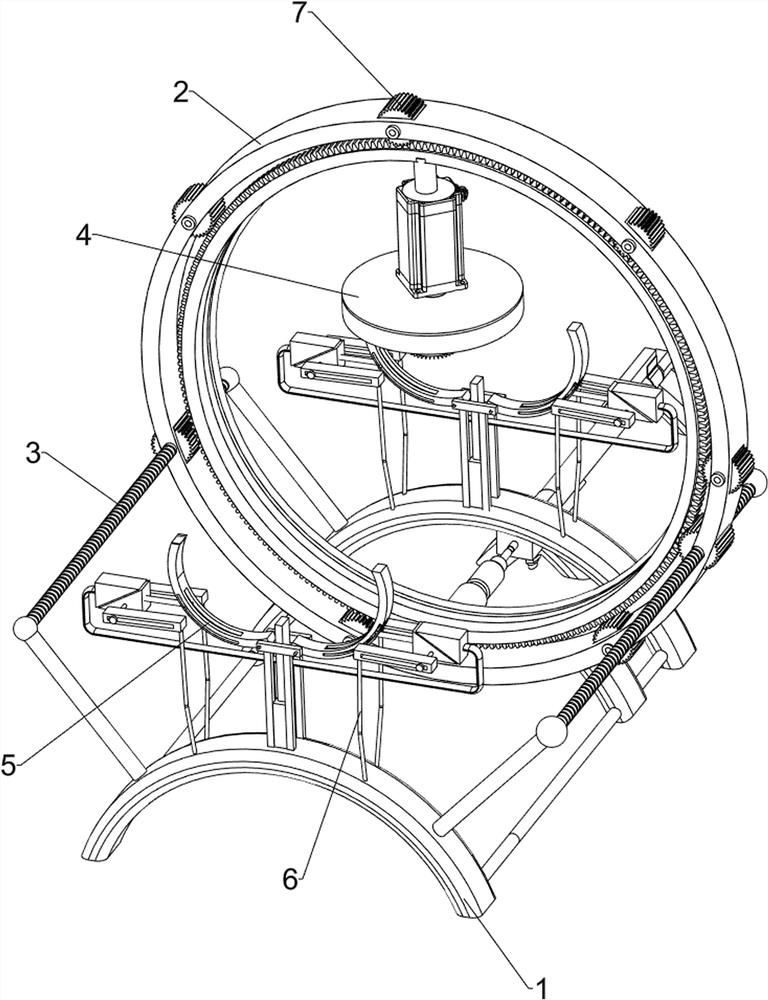

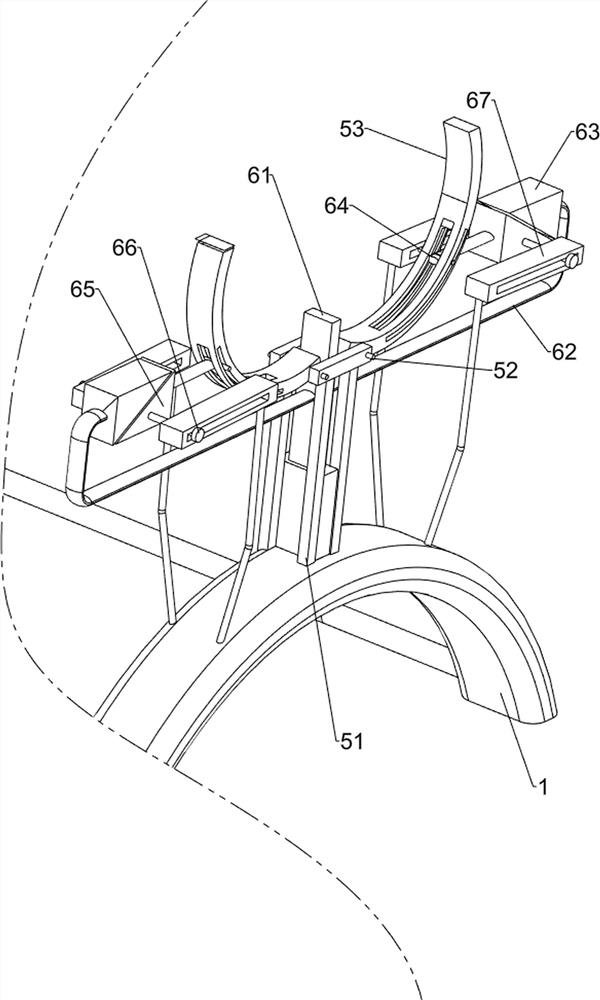

Movable revolving stage and control method thereof

InactiveCN104120898ARealize the rotation effectMobile saves time and effortProgramme control in sequence/logic controllersTheatresAngular degreesEngineering

Owner:WUHAN HANDY ROBOTICS TECH

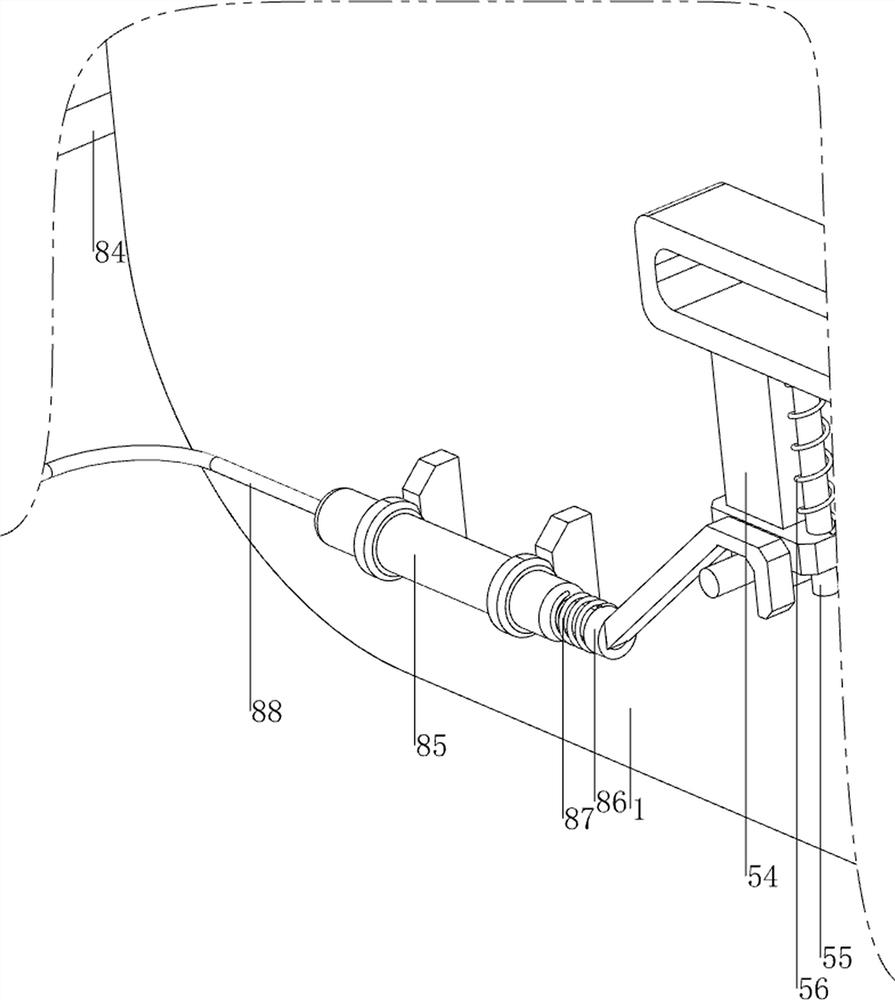

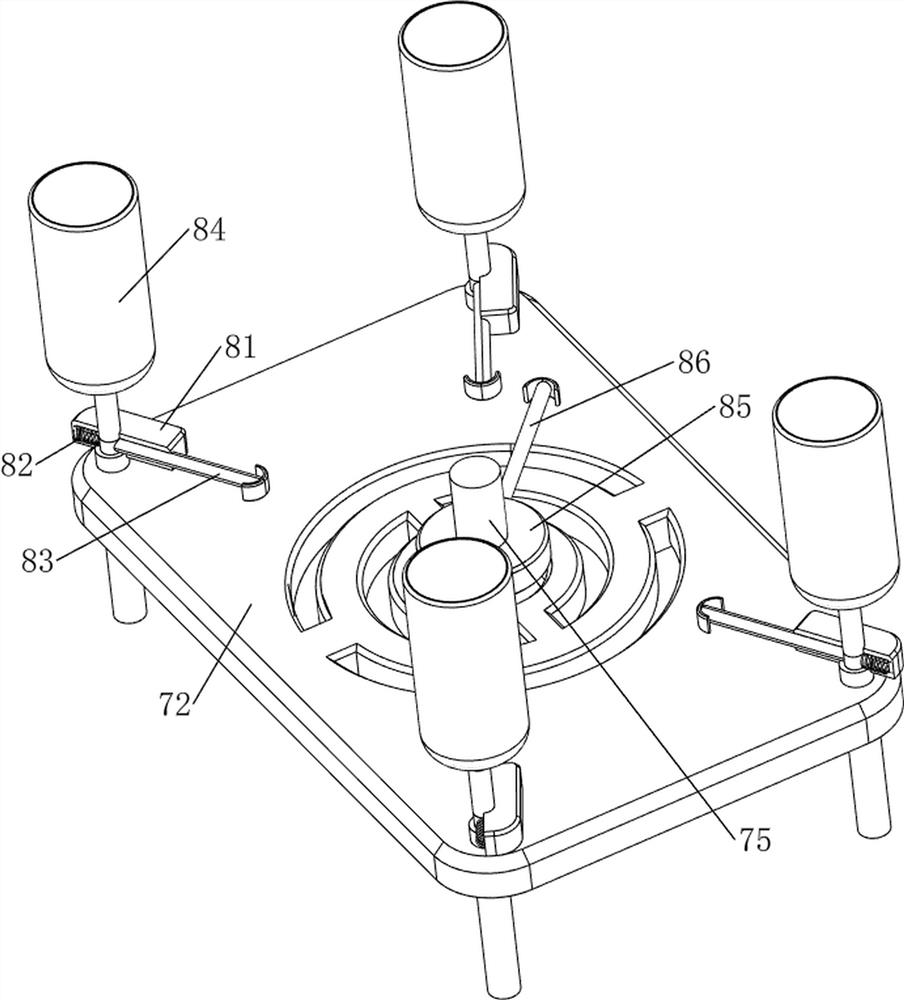

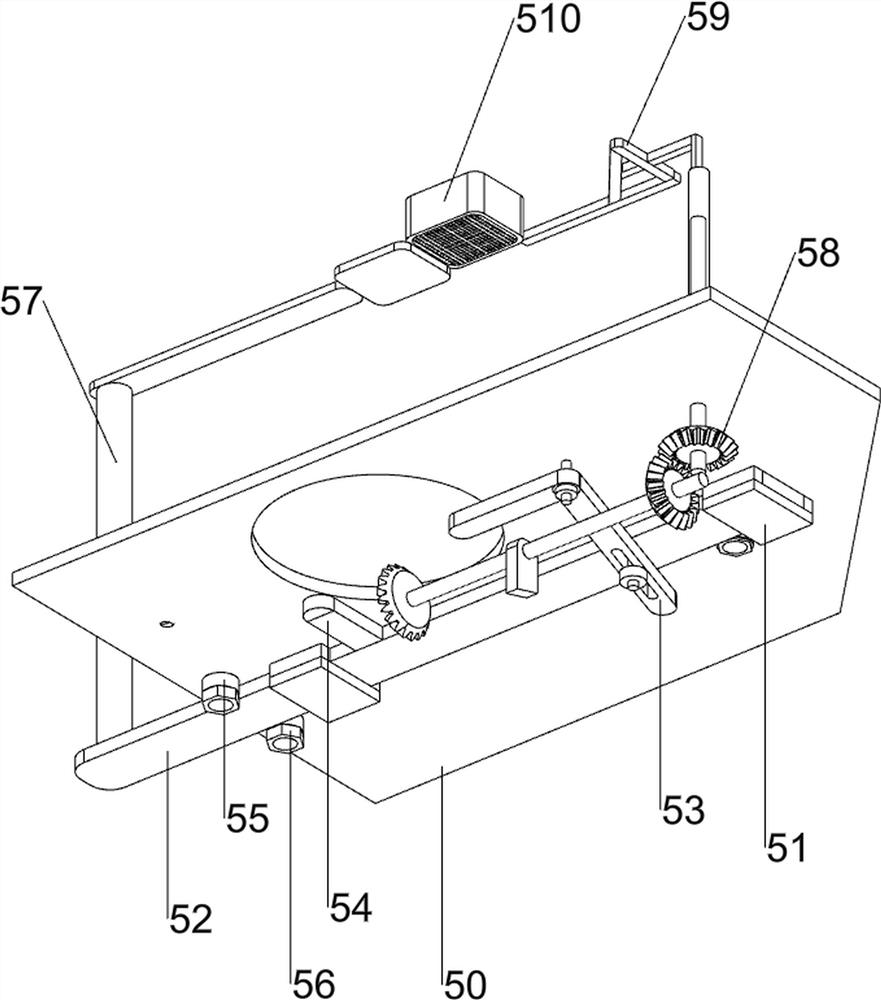

Medical cotton swab medicine applying equipment capable of achieving quick taking and using

PendingCN112807558ARealize the feeding effectRealize the effect of pushing back and forthRotary stirring mixersTransportation and packagingBiotechnologyBiomedical engineering

The invention relates to cotton swab medicine applying equipment, in particular to medical cotton swab medicine applying equipment capable of achieving rapid taking and using. The medical cotton swab medicine applying equipment capable of achieving rapid taking and using is capable of automatically applying medicine, convenient to operate and capable of automatically supplying liquid medicine. The medical cotton swab medicine applying equipment comprises a bottom plate, supporting columns, a feeding mechanism, a pushing mechanism, a rotating mechanism and a medicine applying mechanism, wherein the supporting columns are arranged at the top of the bottom plate; the feeding mechanism is arranged between the tops of the supporting columns on the rear side; the pushing mechanism is arranged between the top of the supporting column on the front side and the lower side of the feeding mechanism; and the rotating mechanism and the medicine applying mechanism are arranged on the pushing mechanism. After a first cotton swab is taken out through a rotating mechanism component, when another cotton swab needs to be taken out, a push rod is manually pulled to move forwards, a contraction spring is compressed, the rotating mechanism can take out the cotton swab again, and the feeding effect is achieved.

Owner:黄正豪

Cleaning and disinfecting device for anterior rhinoscope for otolaryngology examination

InactiveCN108578736ARealize the effect of rotating cleaning and disinfectionRealize the rotation effectLavatory sanitoryCleaning using liquidsPulp and paper industryENT surgeon

Owner:南通市中医院

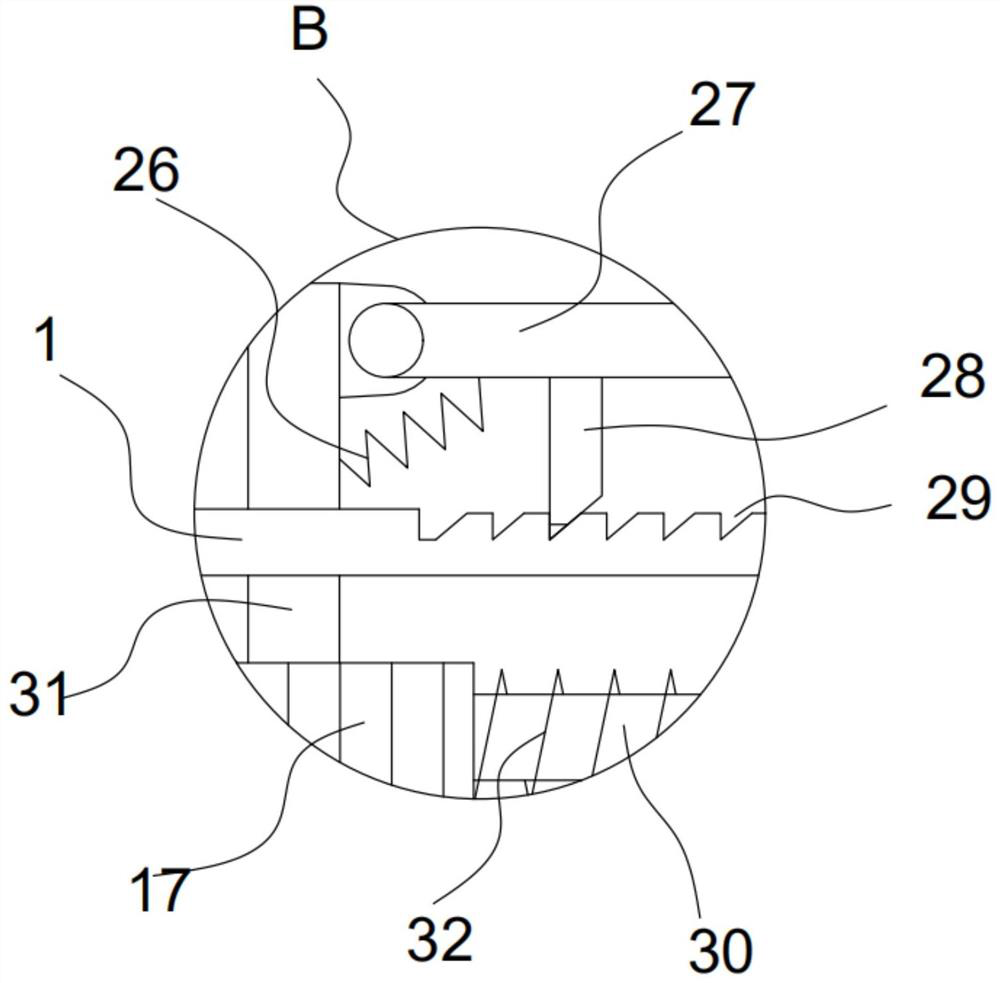

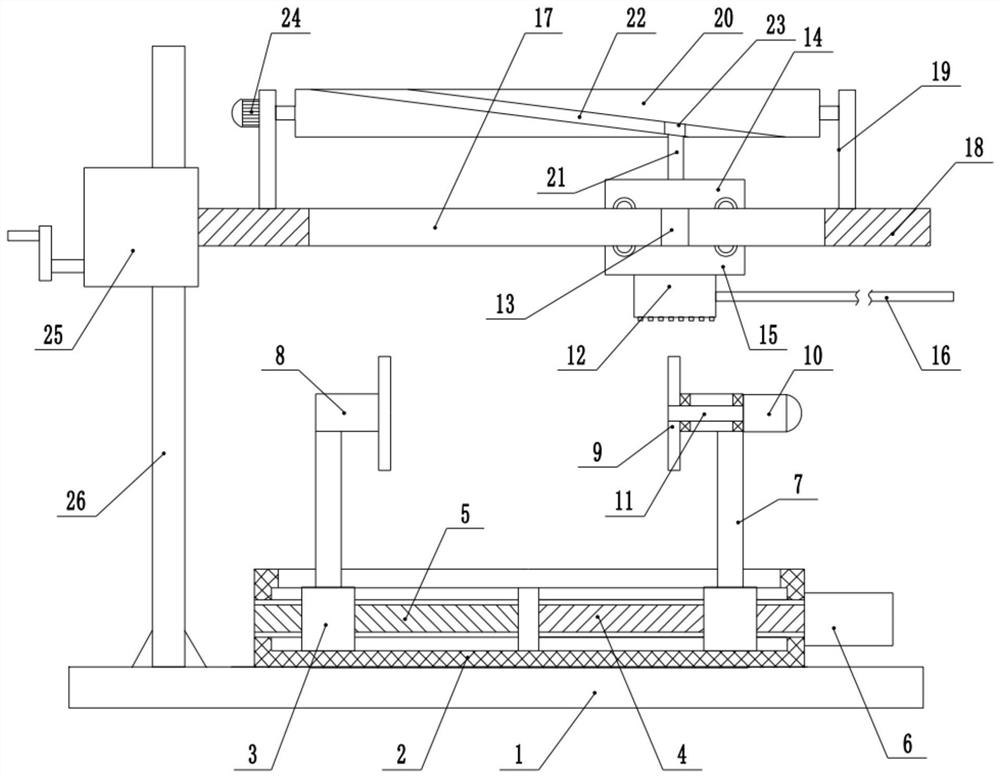

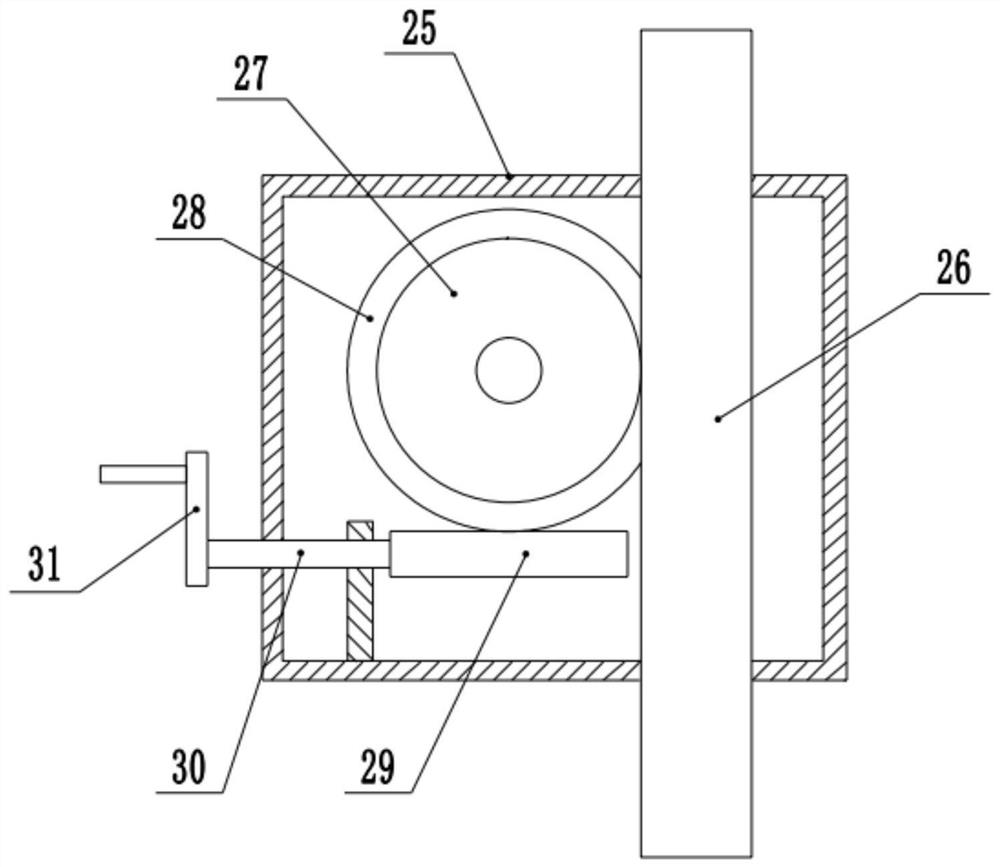

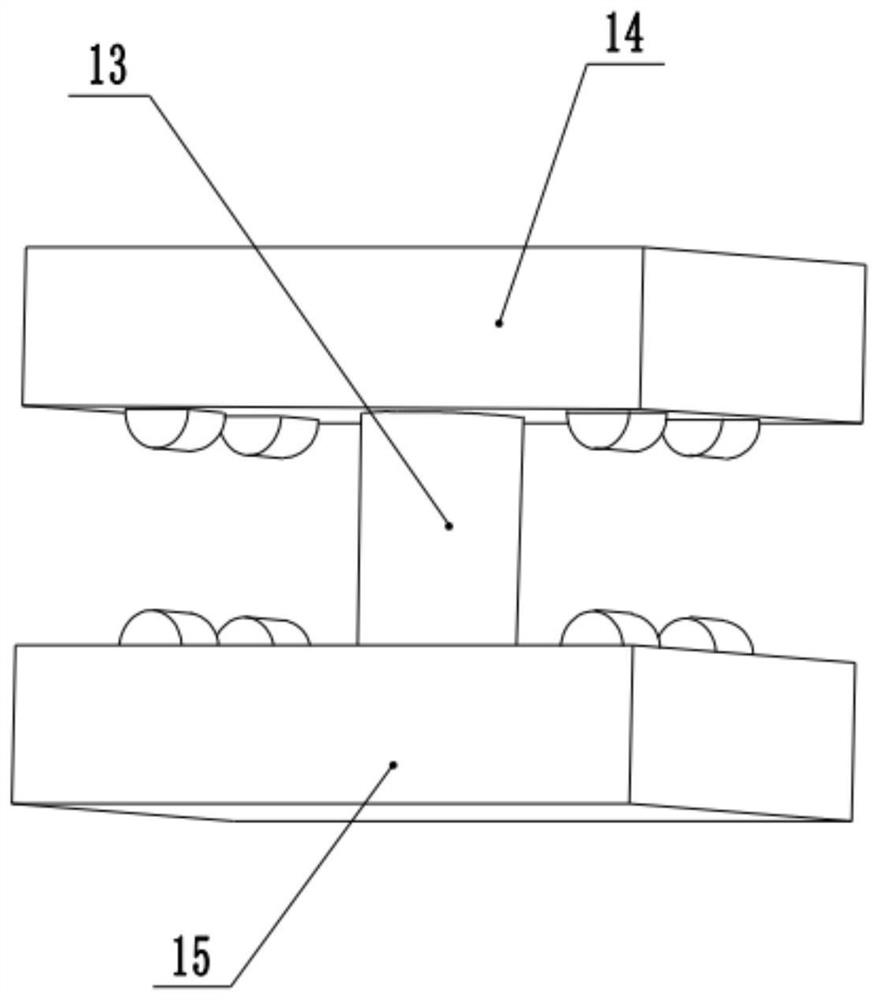

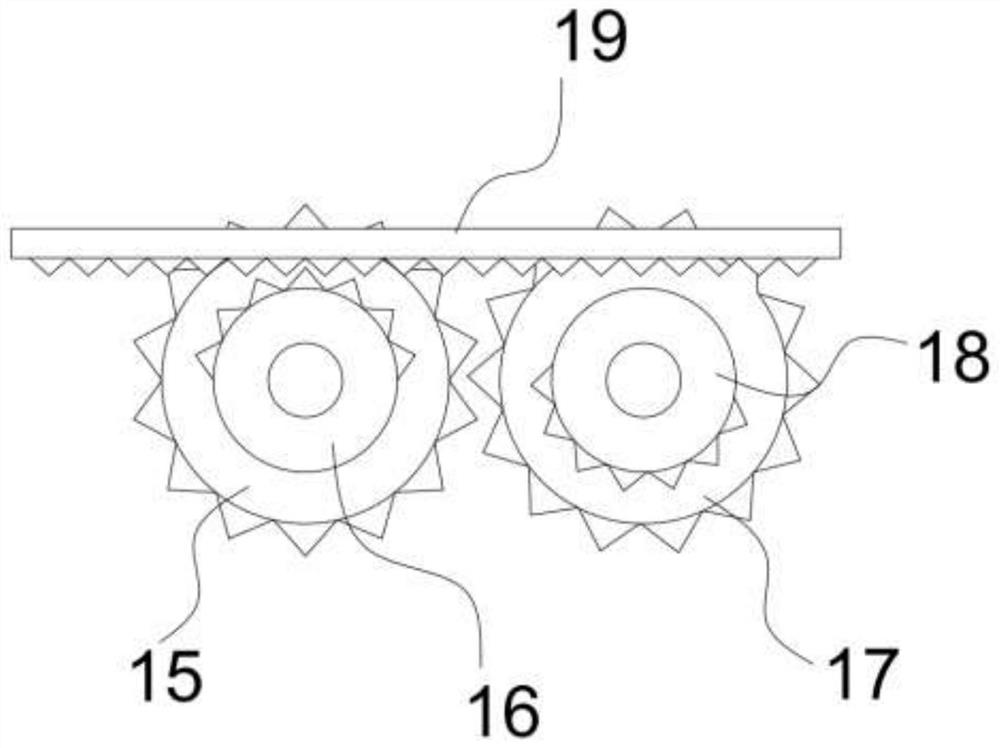

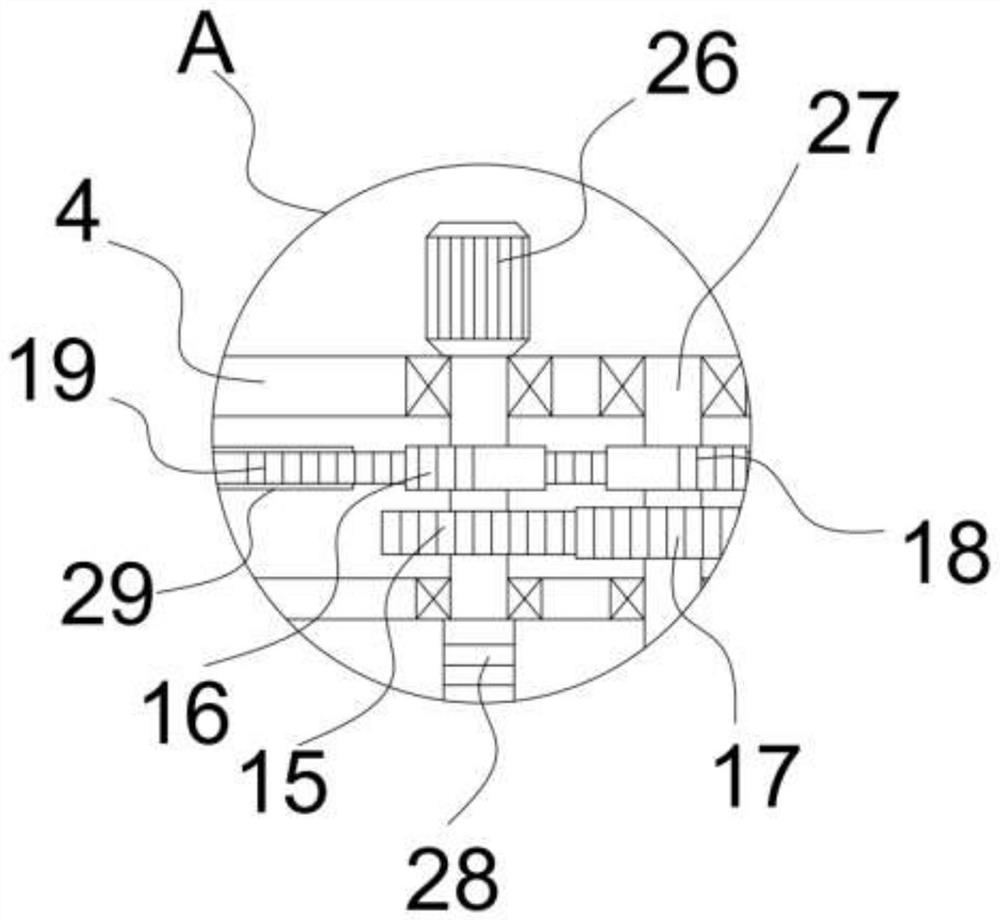

Meat cutting device for producing pork balls

The invention discloses a meat cutting device for producing pork balls and belongs to the technical field of meat, fowl or fish processing equipment. According to the technical scheme, the device comprises a rack, a pressing mechanism, a rotary mechanism and a cutting mechanism, and the pressing mechanism, the rotary mechanism and the cutting mechanism are arranged on the rack. The device has the advantages that a cylindrical table can play a role in fixation and guidance for the movement of a lead screw, pollution caused by artificial contact with pork can be avoided, a limiting piece is used for fixing a turnplate to prevent the turnplate from rotating during cutting, time and labor are saved, and working efficiency is improved.

Owner:新沂市港发商贸有限公司

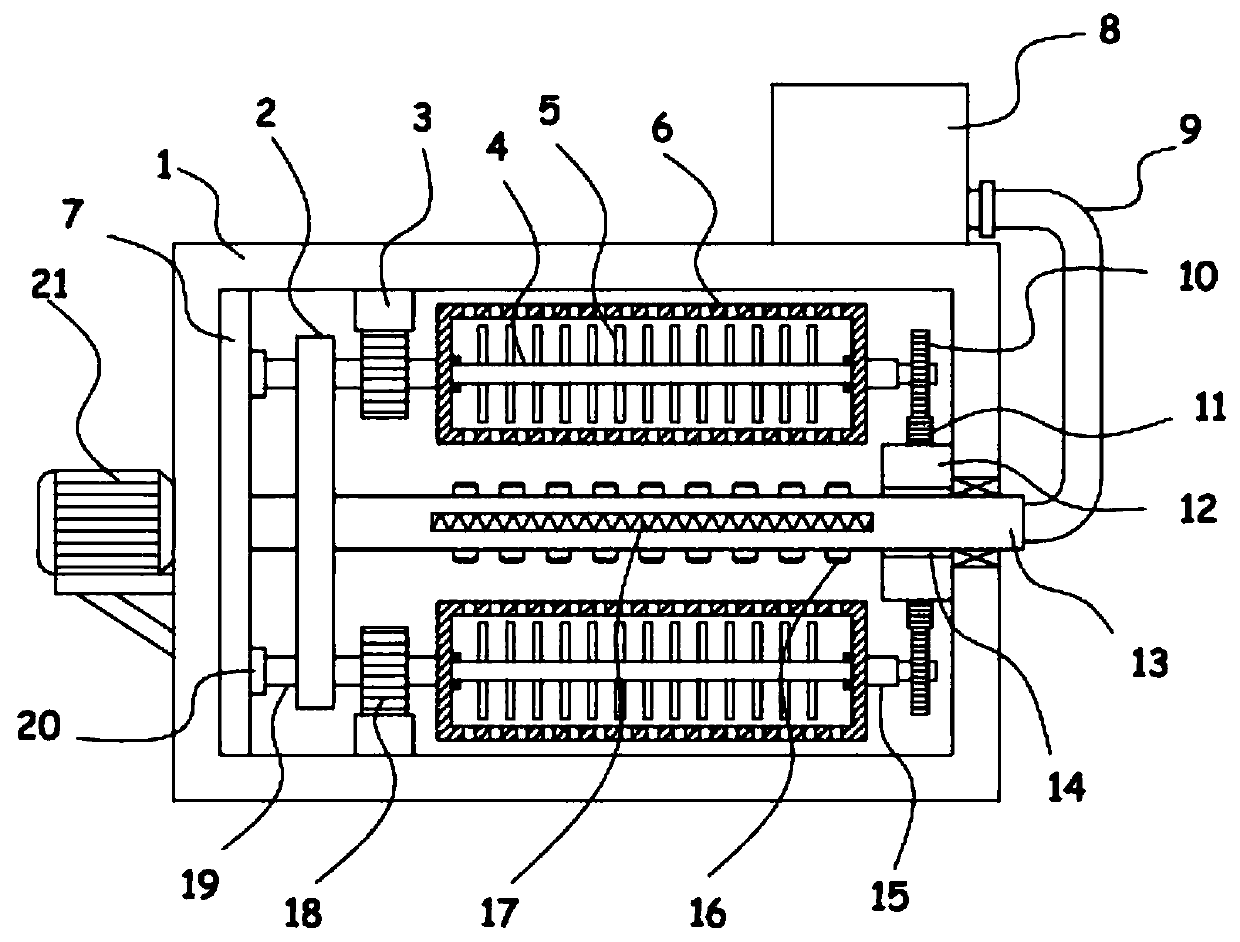

Heat dissipation frame for new energy automobile battery management

PendingCN113078384AAchieve motion effectRealize the cooling effectSecondary cellsCleaning using toolsThermodynamicsAutomotive battery

The invention relates to a heat dissipation frame, in particular to a heat dissipation frame for new energy automobile battery management. The heat dissipation frame for new energy automobile battery management is capable of adjusting wind power, easy to operate and high in heat dissipation function. The heat dissipation frame for new energy automobile battery management comprises a bottom plate, a motor, a pushing mechanism, a water draining mechanism and the like. A motor is installed on the front side of the bottom plate, a pushing mechanism is arranged on the bottom plate, and a water draining mechanism is arranged on the bottom plate. The first conveying assembly drives the lead screw to rotate reversely, the lead screw drives the push rod to move forwards to the original position, and the effect that the lead screw drives the push rod to move is achieved; and the first pressing plate is separated from the water pipe, so that cold water flows onto the battery through the water pipe and cools the battery, and the battery cooling effect is achieved.

Owner:韦龙印

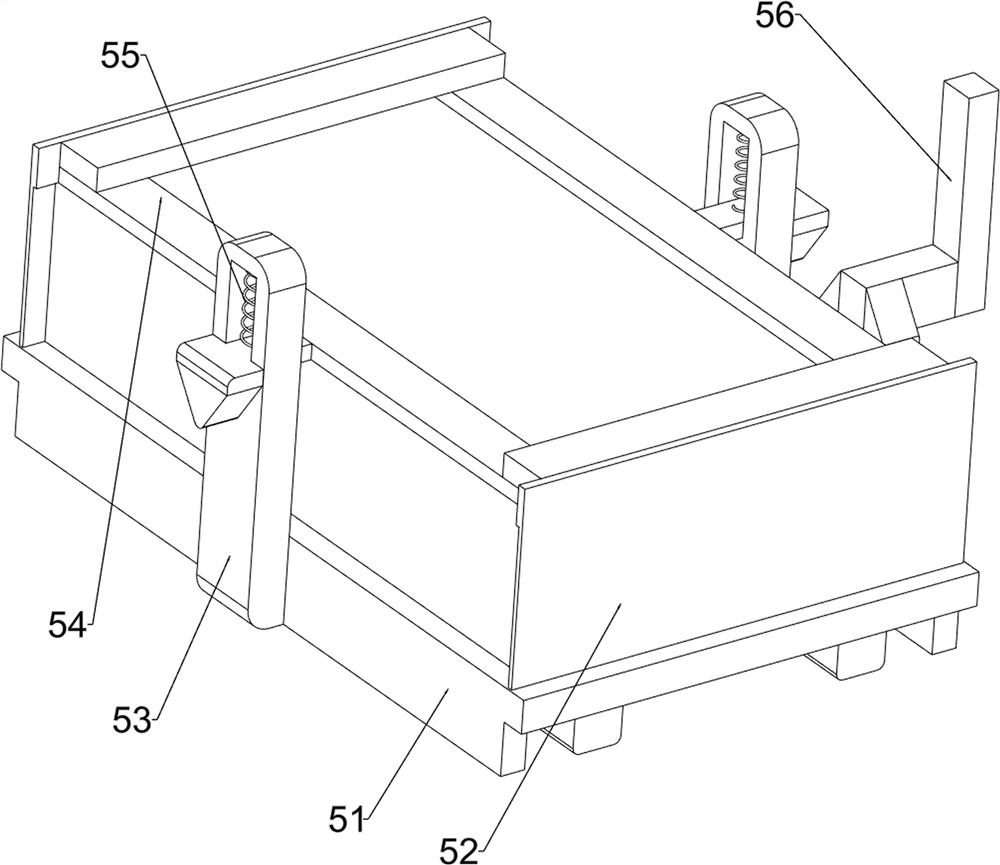

Chopping board slotting and forming equipment for kitchen

ActiveCN112476672AAchieve slotting effectRealize the clamping effectProfiling/shaping machinesWood mortising machinesEngineeringSupport plane

The invention relates to slotting equipment, in particular to chopping board slotting and forming equipment for a kitchen. The chopping board slotting and forming equipment for the kitchen is easy tooperate, high in working efficiency and capable of achieving accurate slotting. The chopping board slotting and forming equipment for a kitchen comprises a base and a clamping mechanism, and a slotting mechanism is arranged in the middle of the upper front wall of the base. and the clamping mechanism is arranged on the base. By starting a rotating cutter, a second supporting frame is pushed forwards, a first telescopic assembly stretches to slot chopping board, and the slotting effect is achieved; and the telescopic rod of an air cylinder extends downwards to drive the push plate to move downwards, then a first connecting rod is driven to move downwards, a second telescopic assembly is compressed, a first pressing plate is driven to move downwards, the first pressing plate makes contact with the chopping board, and the clamping effect is achieved.

Owner:NANJING YUZHI INTELLIGENT TECH CO LTD

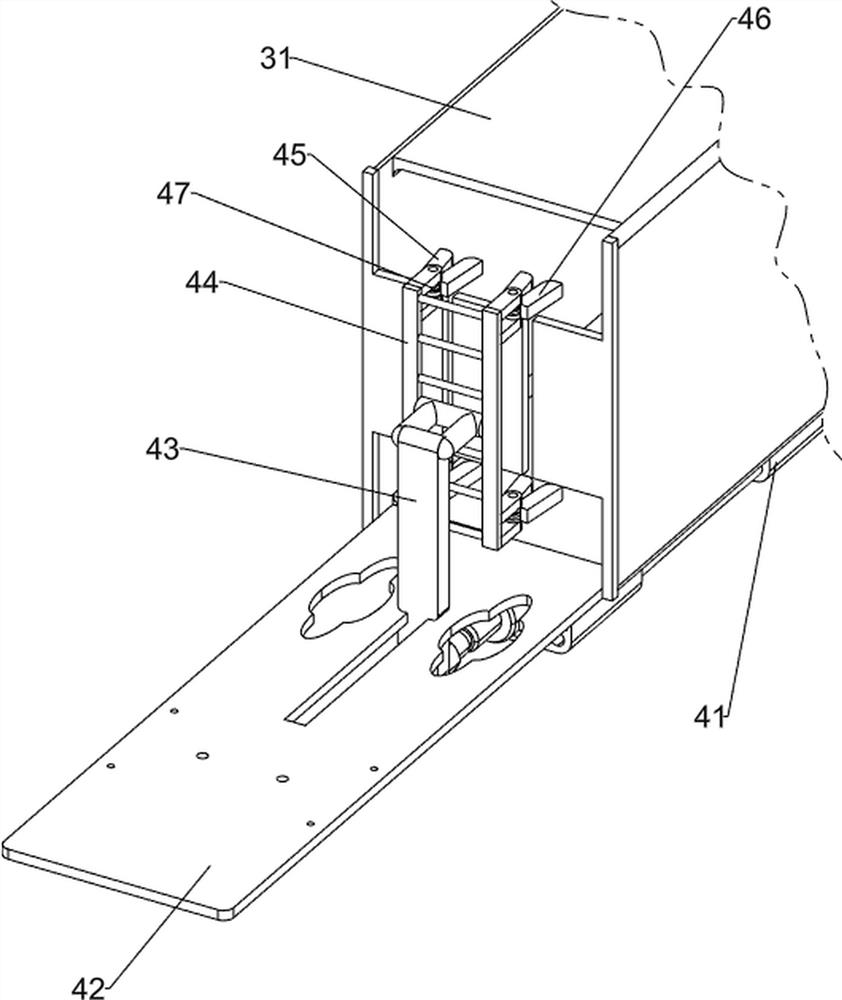

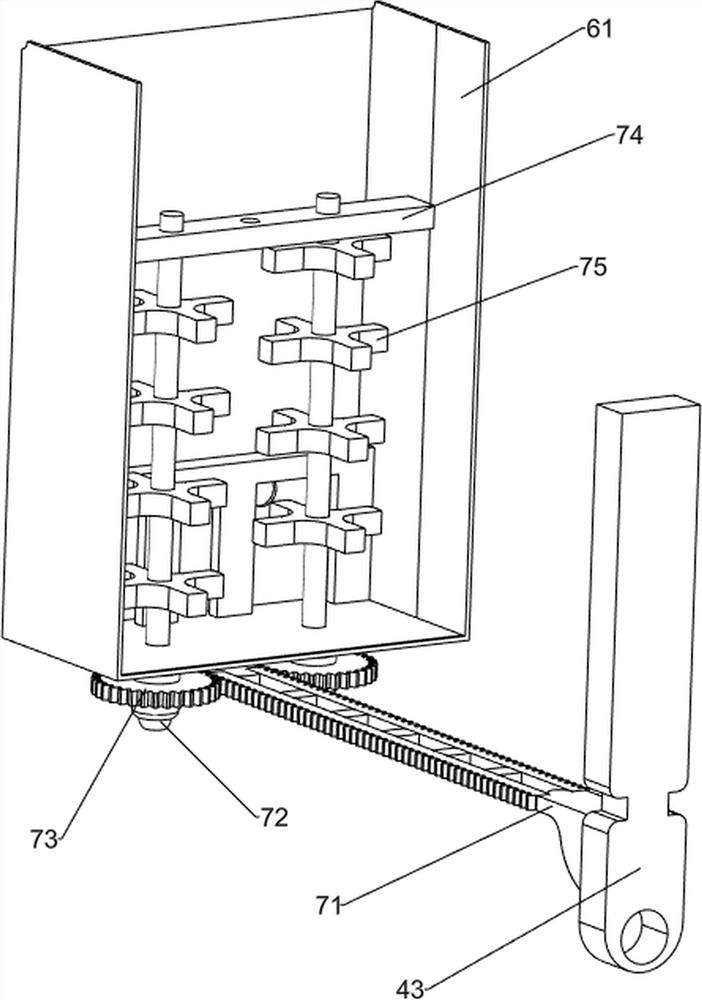

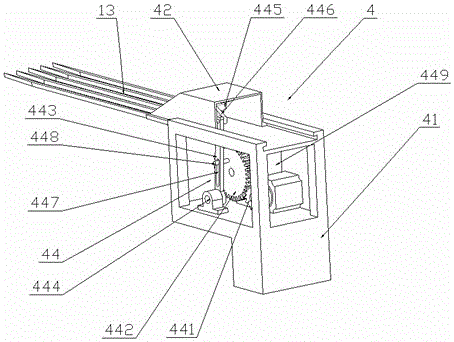

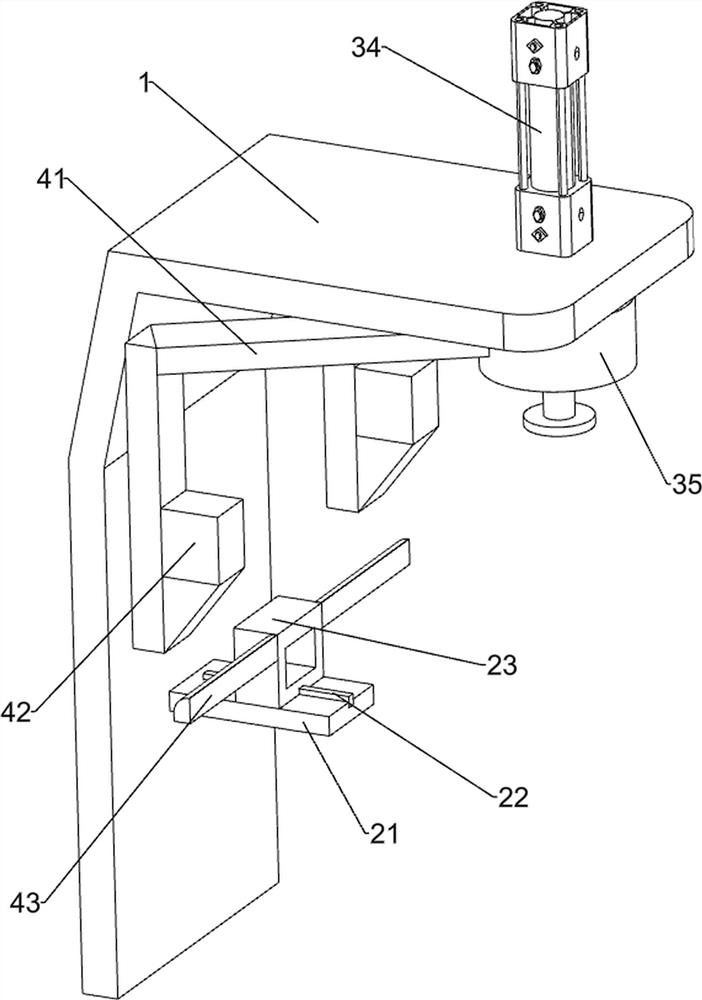

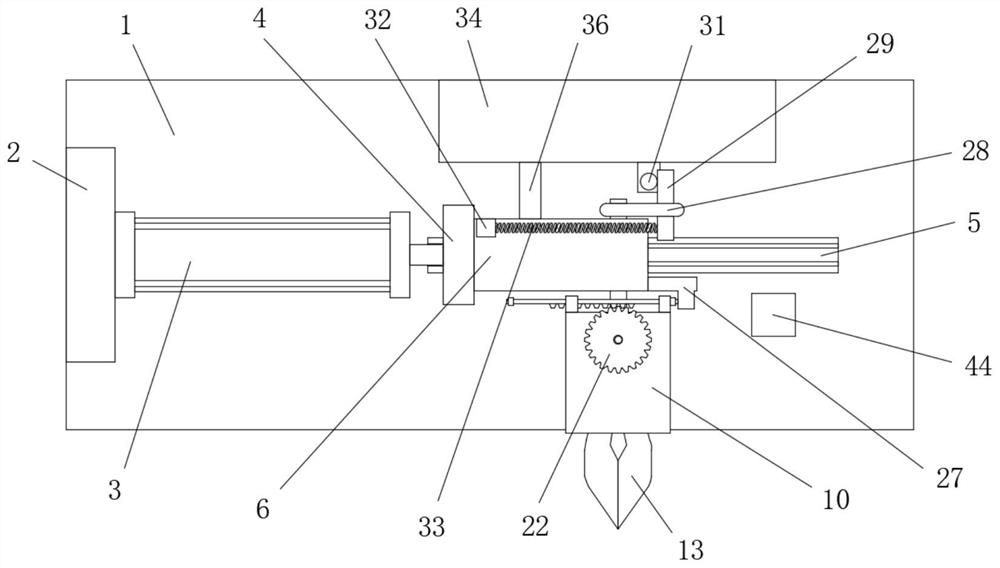

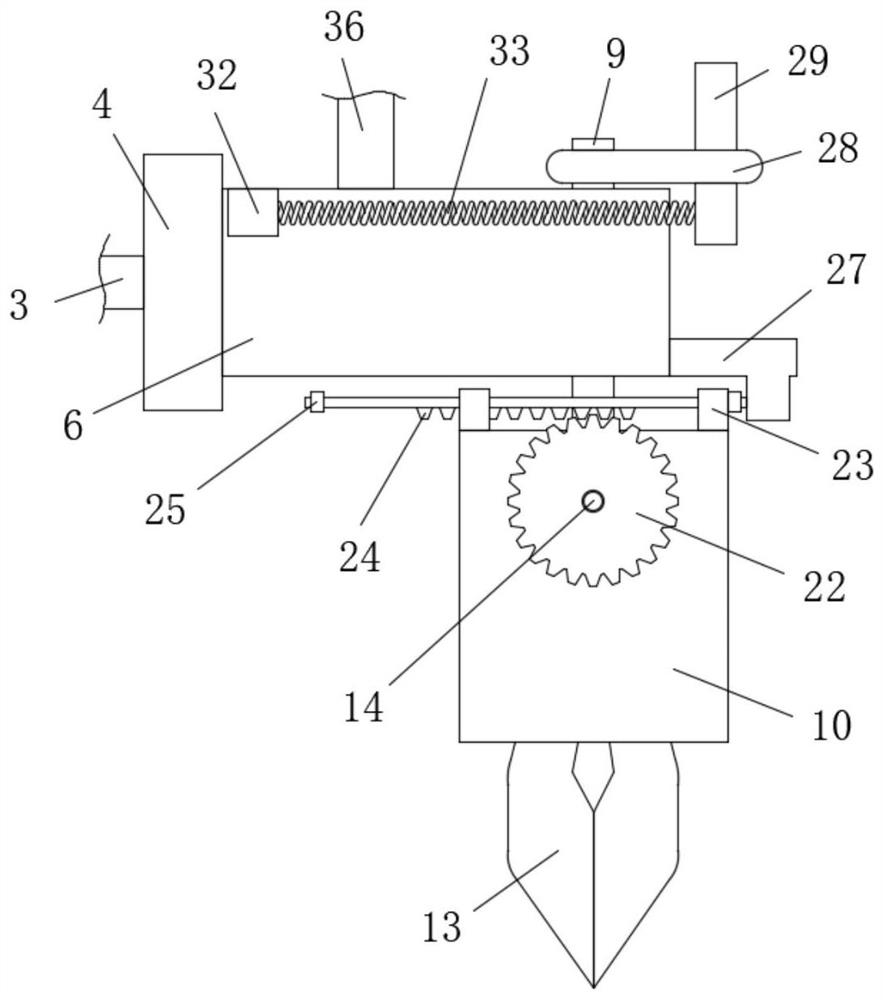

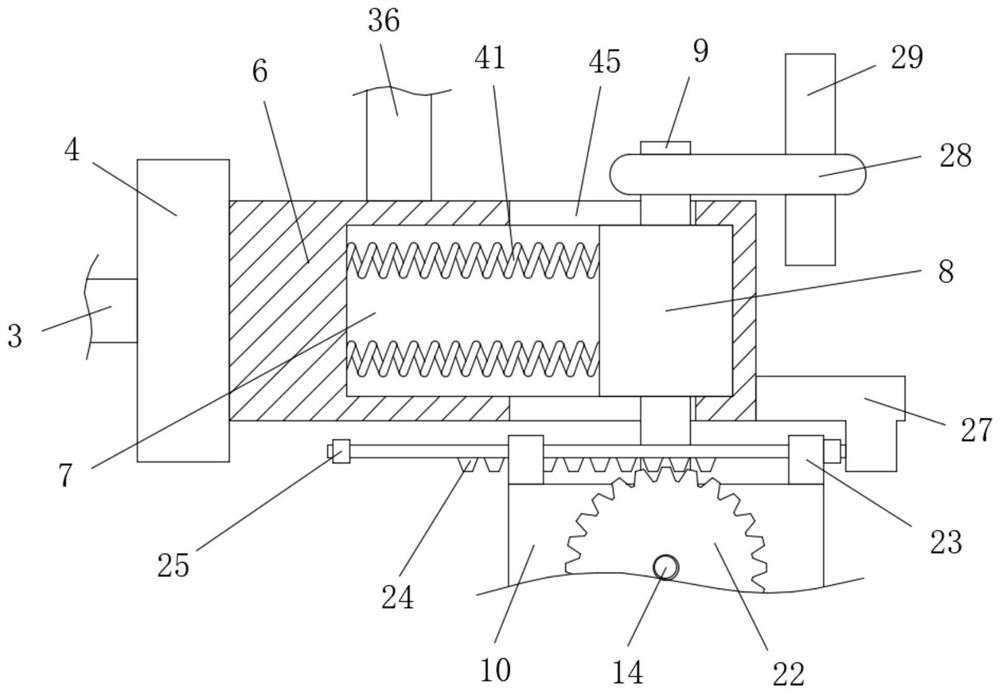

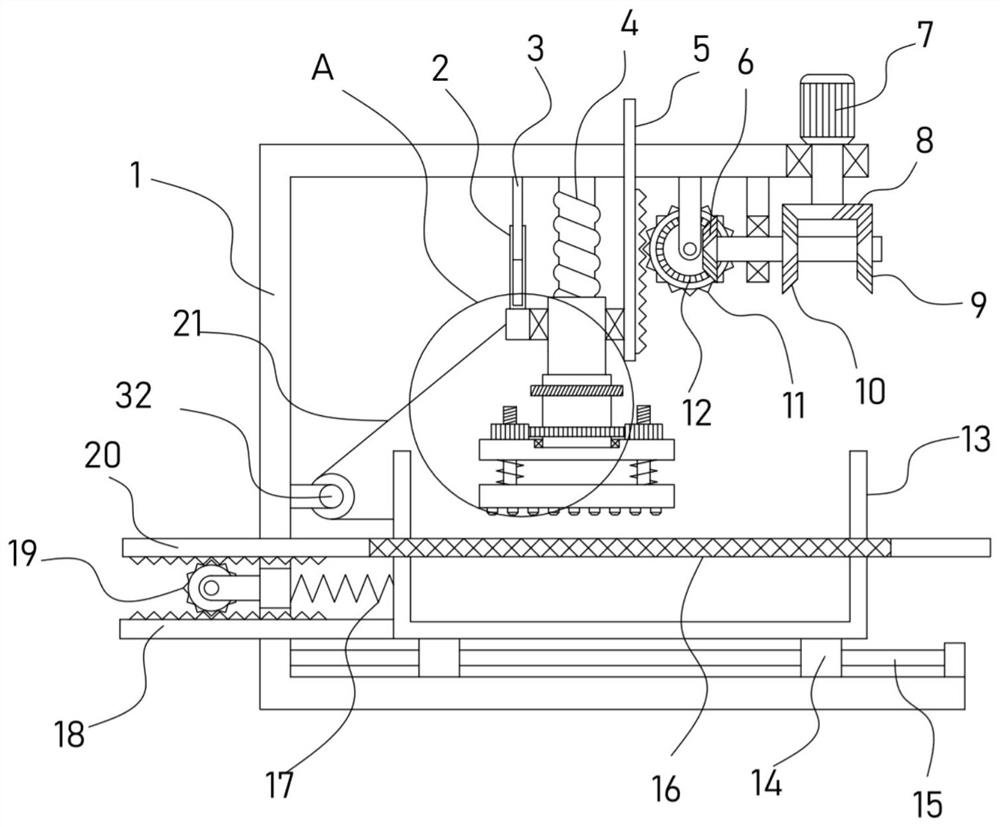

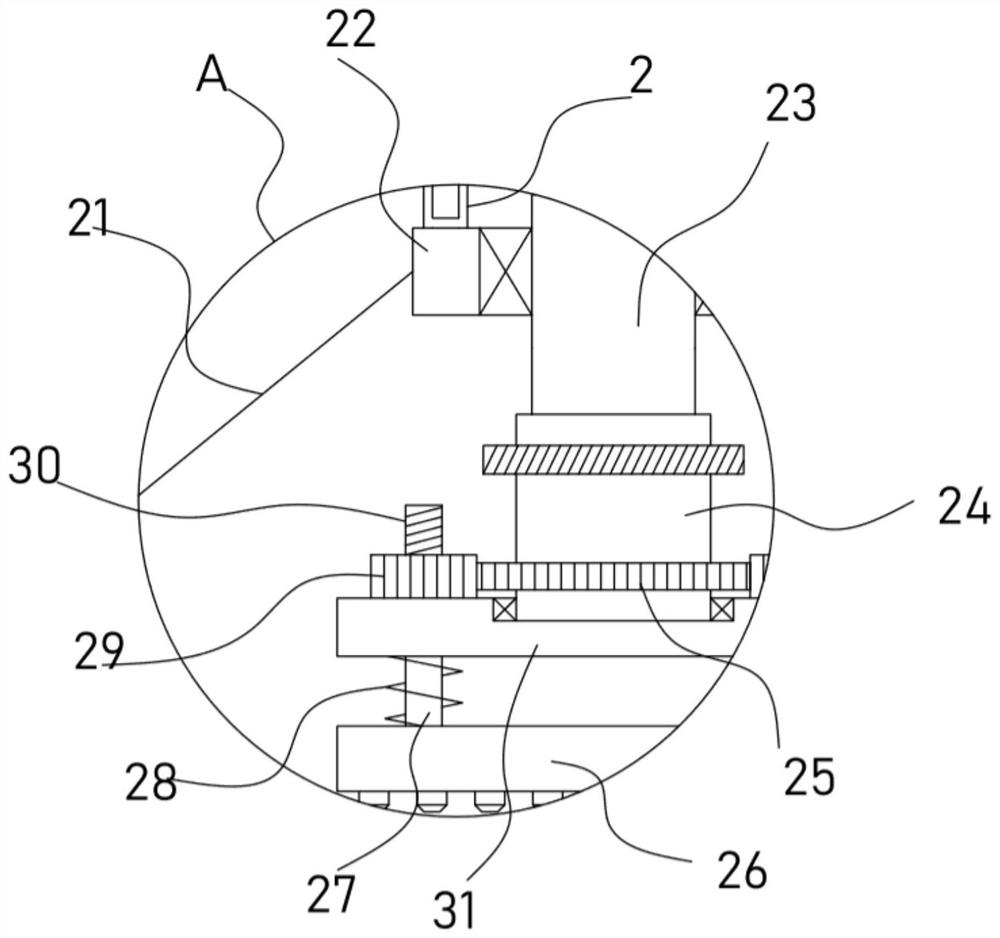

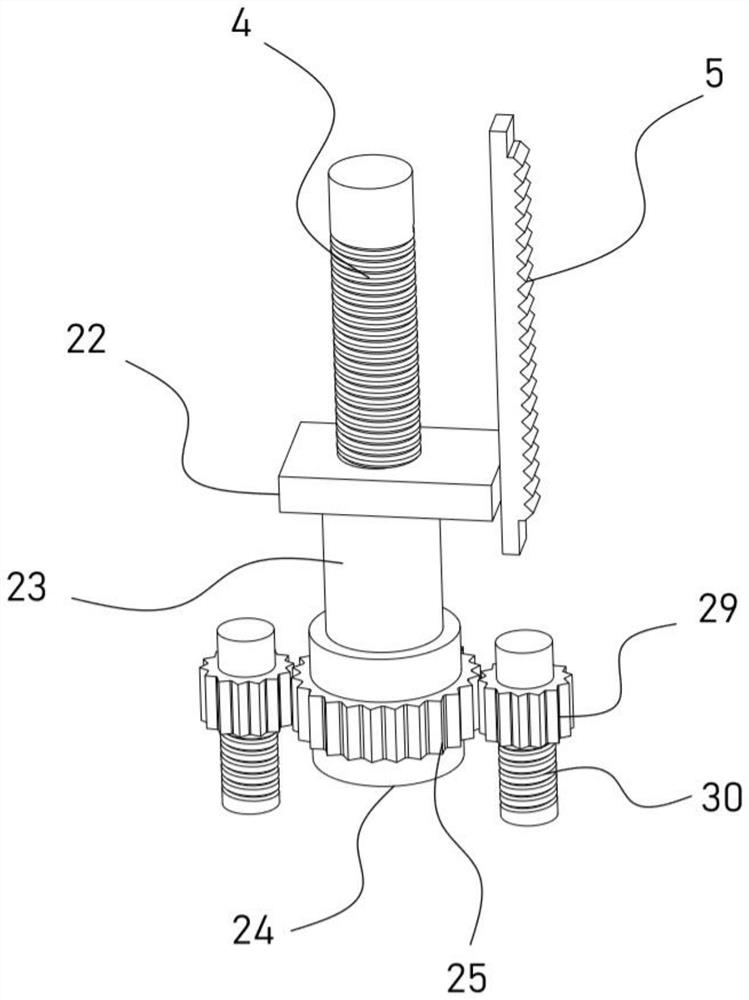

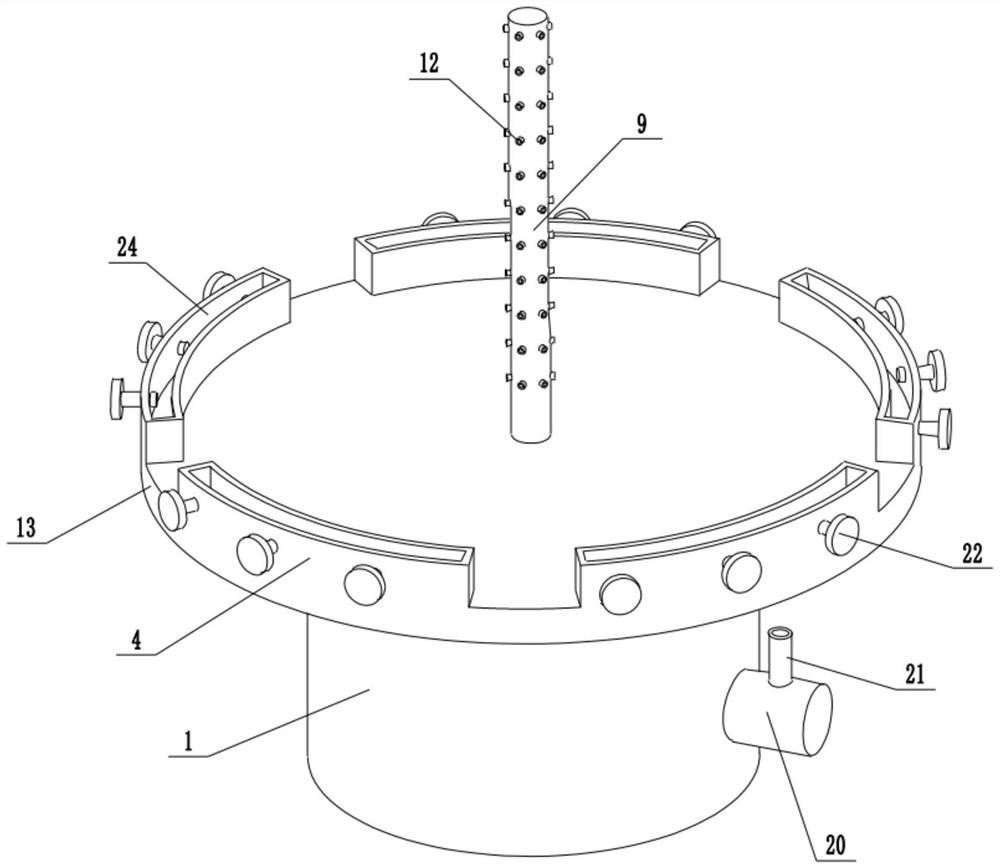

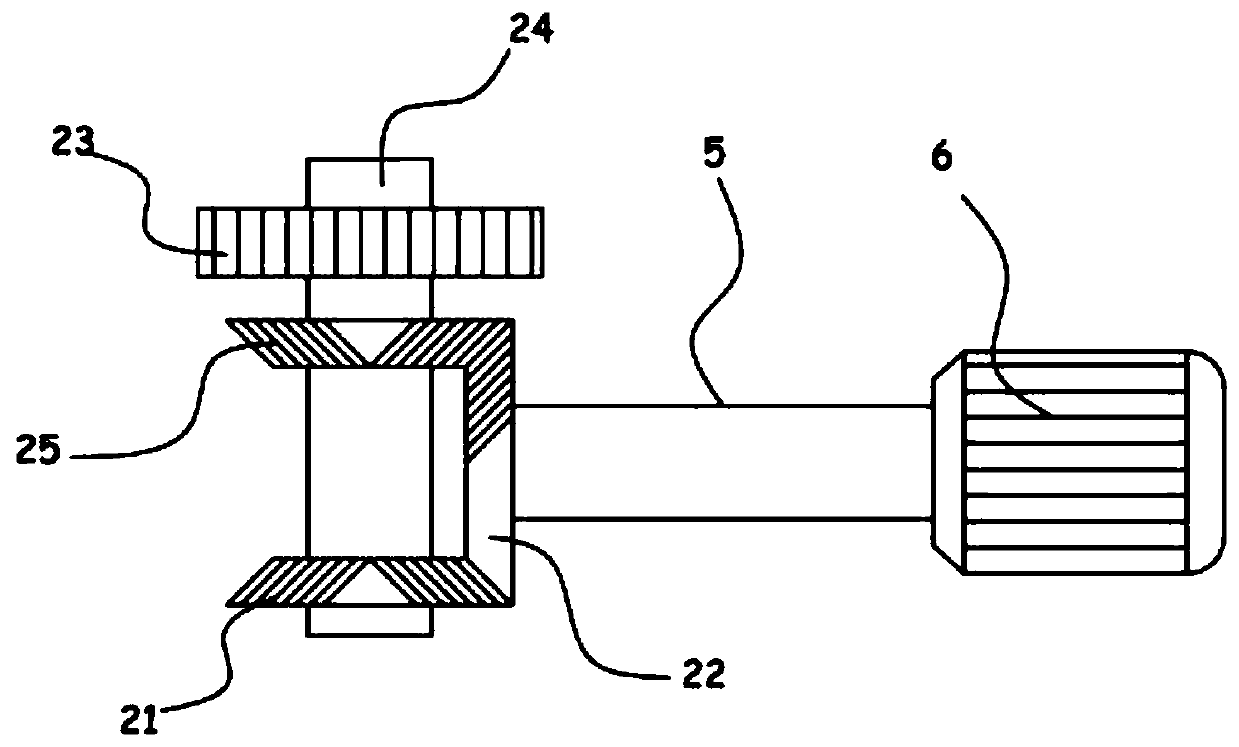

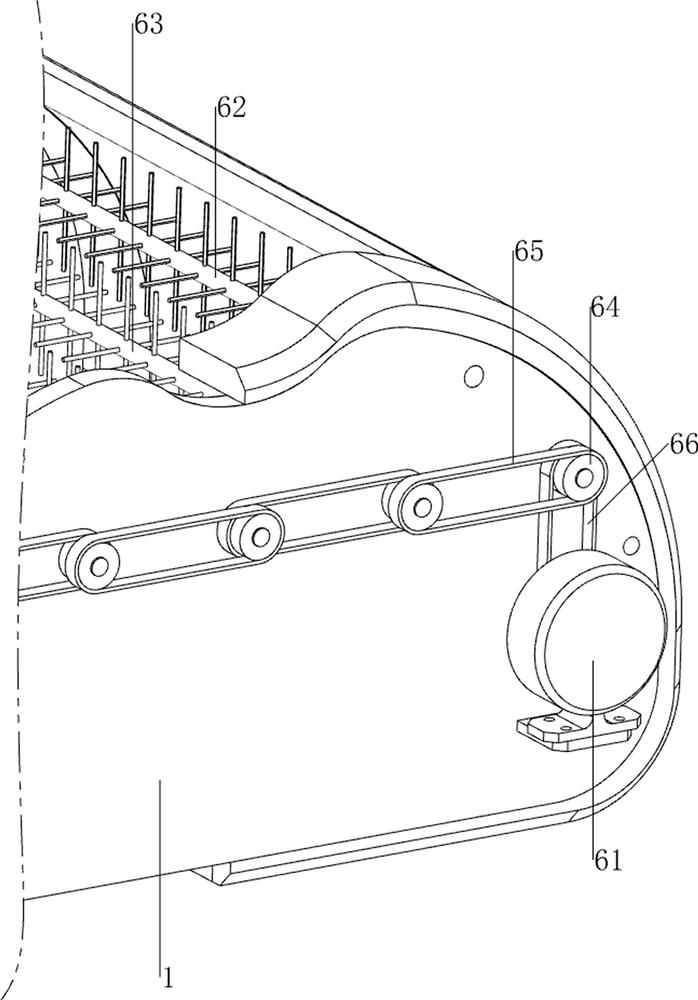

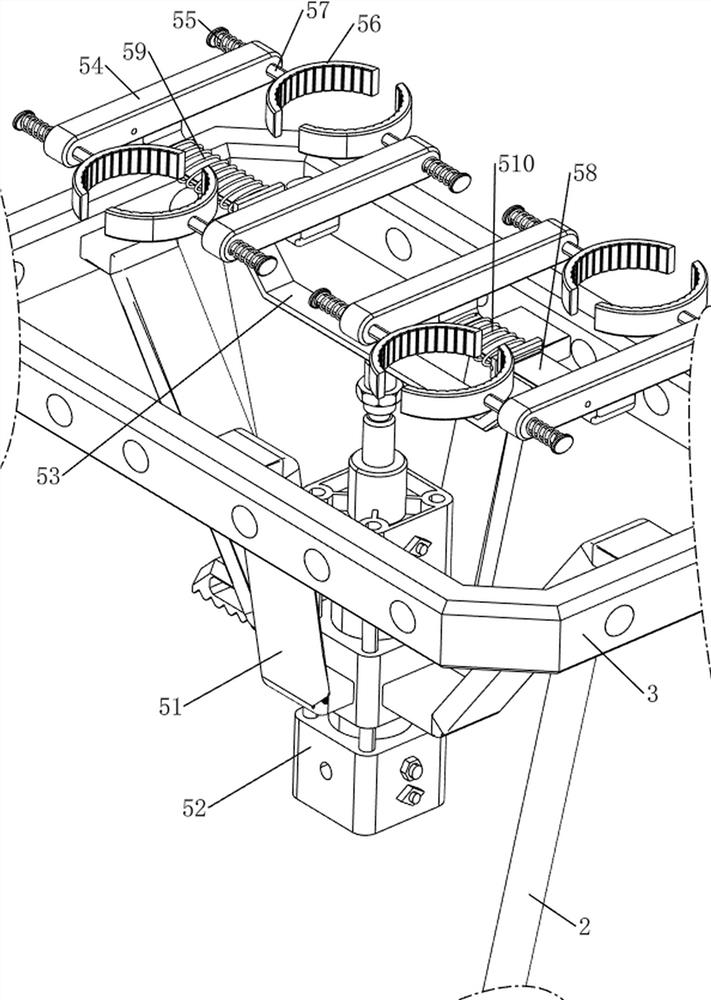

Multifunctional full-automatic rotary material taking and feeding mechanism

The invention belongs to the technical field of machining, and particularly relates to a multifunctional full-automatic rotary material taking and feeding mechanism. For the problems that in the priorart, the operation is tedious, the energy consumption is high, the manufacturing cost and the maintenance cost are greatly increased, the expansion of the scale of an enterprise is not facilitated, and meanwhile, the machining precision is not high due to the fact that an independent system and an independent power source are adopted for independently controlling each operation procedure, now thescheme is proposed as follows: the multifunctional full-automatic rotary material taking and feeding mechanism comprises a base, wherein a sliding rail is arranged at the top of the base; a mountingplate is fixedly connected to one side of the top of the base; and a telescopic cylinder is fixedly mounted at one side, close to the sliding rail, of the mounting plate. The clamping, material taking, feeding and rotating operation procedures can be achieved at the same time through one cylinder, so that an operation system is simplified, the operation mode is simple, the energy consumption is low, the manufacturing cost and the maintenance cost are greatly reduced, the expansion of the scale of the enterprise is facilitated, meanwhile, the machining precision is improved, and the developmentprospect is wide.

Owner:翁宗享

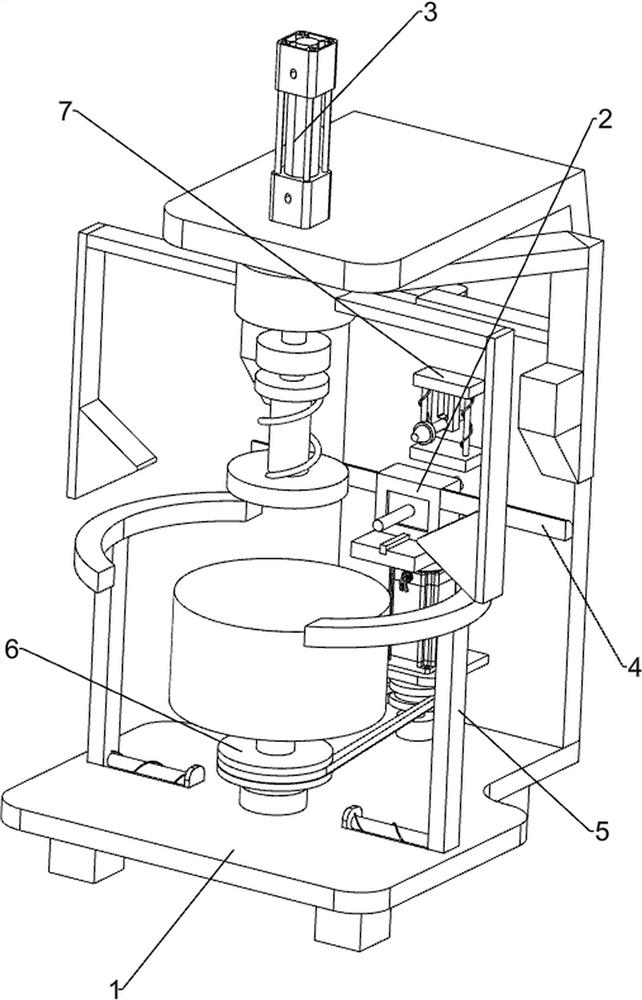

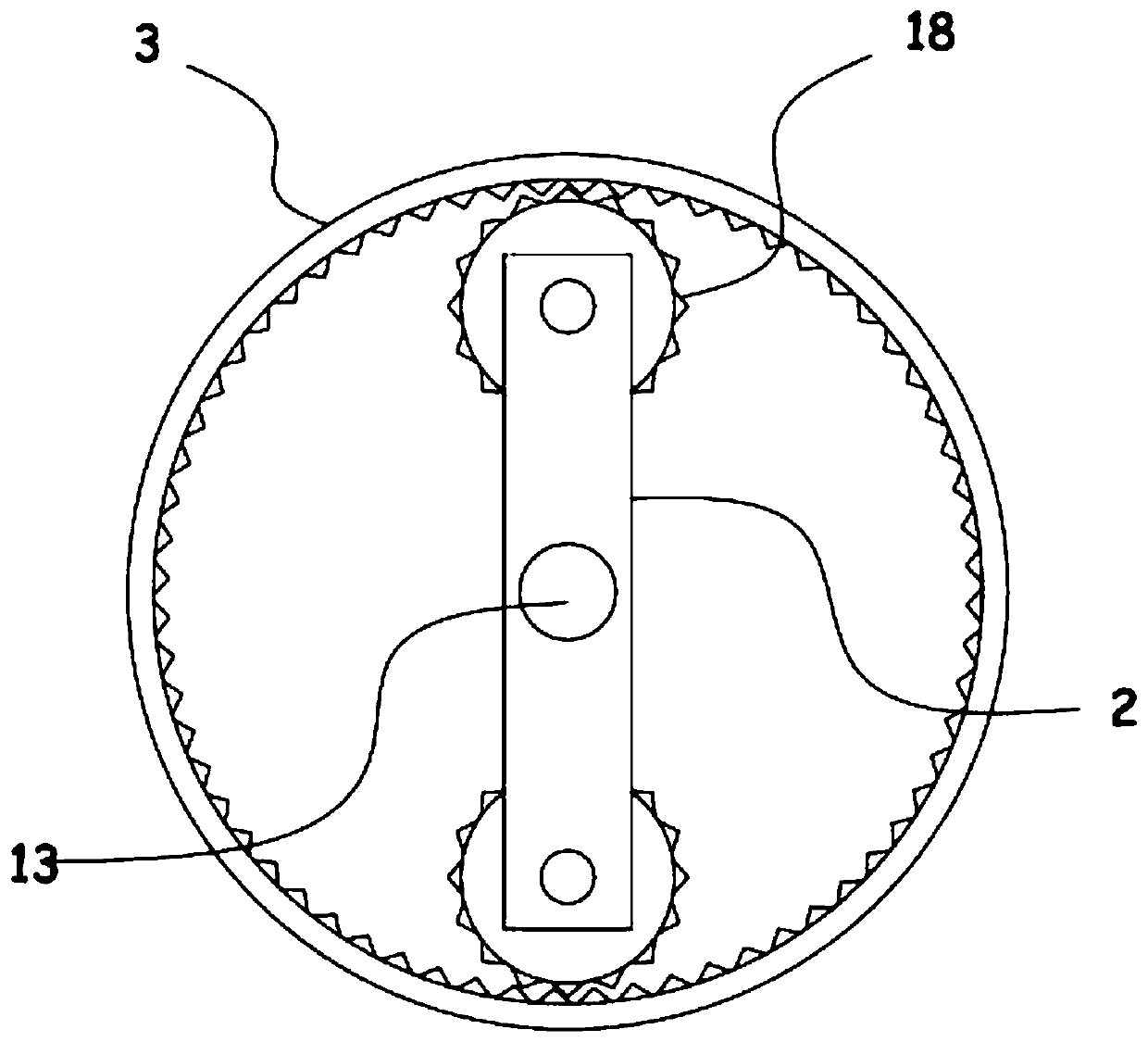

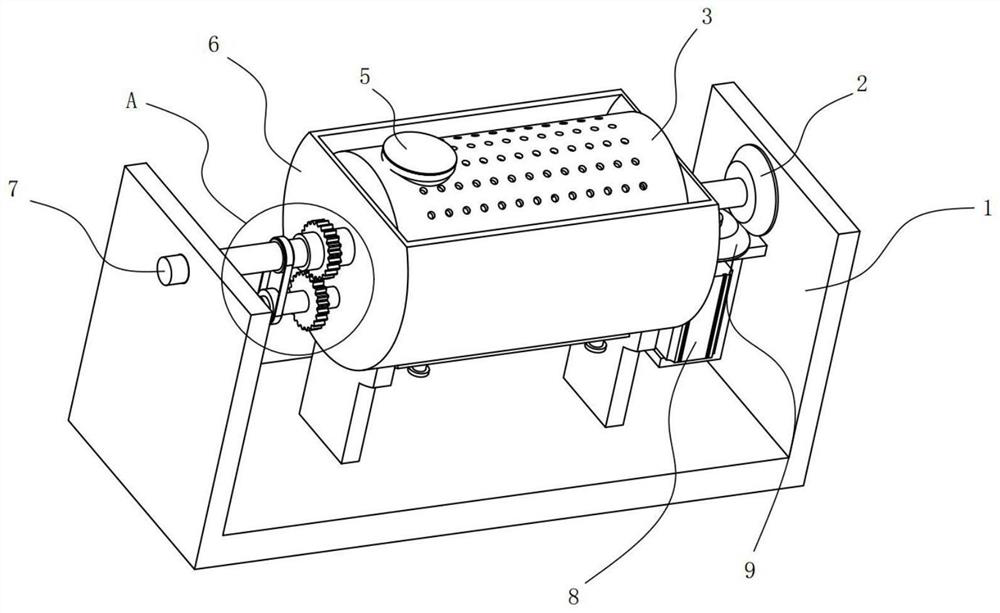

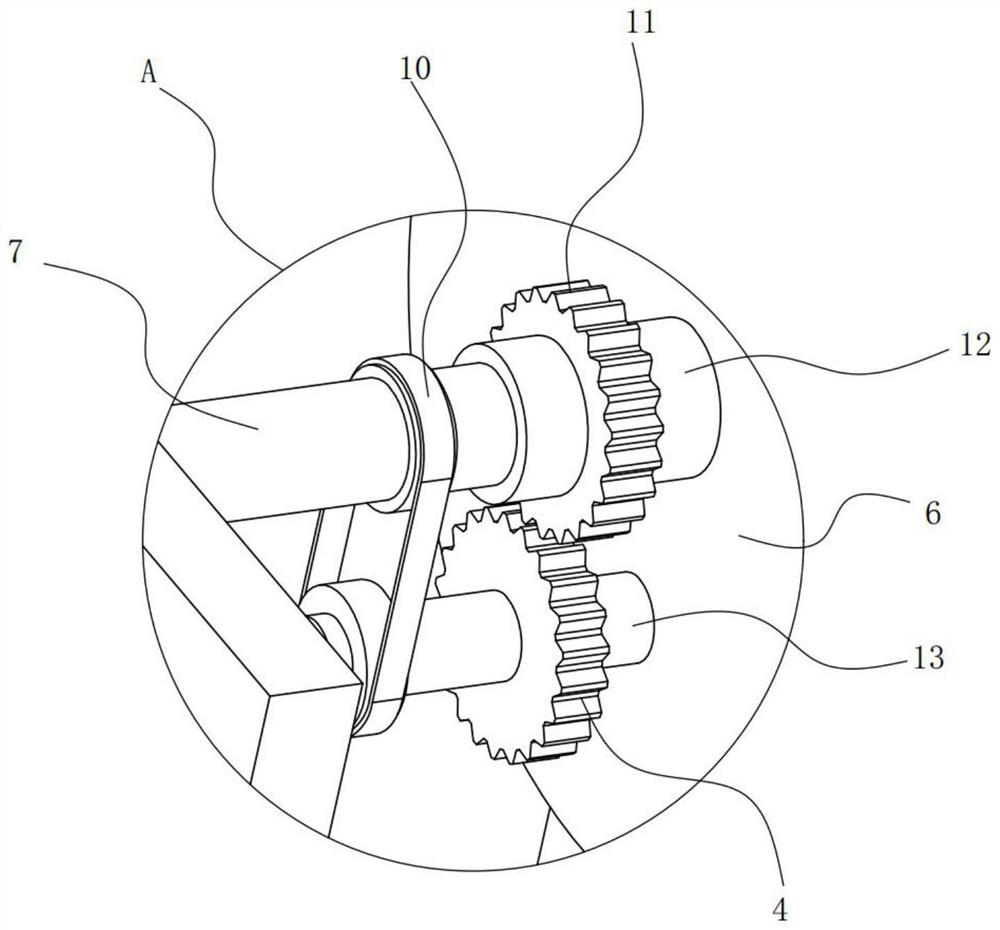

Ore crushing and refining device used for ore processing

InactiveCN112108208AFully crushed and refinedRealize the rotation effectGrain treatmentsMining engineeringReciprocating motion

The invention discloses an ore crushing and refining device used for ore processing, and relates to the technical field of ore processing. The ore crushing and refining device comprises a fixed frame,a crushing tank is installed on the fixed frame in a sliding manner. A drive motor is fixed to the fixed frame. A forward and backward rotating mechanism is in driving connection with the drive motor. A longitudinal regulation mechanism is arranged on the crushing mechanism. A horizontal movement mechanism for driving the crushing tank to transversely move is arranged on the fixed frame. According to the ore crushing and refining device, ore in the crushing tank is impacted and crushed through an arranged crushing mechanism, and in the process that an arranged vertical lifting mechanism drives the crushing mechanism to vertically move, a threaded sleeve and a threaded column are in threaded fit transmission, and therefore the effect that rotation is achieved while the threaded sleeve drives the crushing mechanism to vertically move is achieved, the ore is rotated and rubbed while being impacted and crushed, and sufficient crushing and refining of the ore are promoted; and the crushingtank can be driven to transversely reciprocate through the arranged horizontal movement mechanism, and sufficient crushing and refining conducted by the crushing mechanism on the ore are promoted.

Owner:高全杰

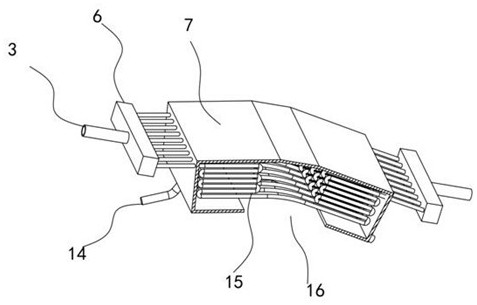

Arc-shaped wood veneer dyeing device for forestry processing

ActiveCN111617900AReasonable structureInnovative designLiquid spraying apparatusWood veneerForest industry

The invention relates to the technical field of forestry wood processing, and discloses an arc-shaped wood veneer dyeing device for forestry processing. The arc-shaped wood veneer dyeing device for forestry processing includes a fixing box; a baffle is installed inside the fixing box; a driving motor is installed in the middle of the right side of the baffle; the output shaft of the driving motoris connected with a driving gear; the left side of the driving gear meshes with an intermediate gear; the middle of the intermediate gear is equipped with a rotating shaft; a cavity is arranged insidethe rotating shaft; a color spray column is arranged inside the cavity; the inside of the color spray column is a hollow structure; a rotating seat is installed on the top of the rotating shaft; a clamping block is arranged outside the upper end of the rotating seat; a feeding box is installed in the middle of the bottom end inside the fixing box; and the top of the color spray column passes through the rotating shaft and the outer side is connected with a number of color spray nozzles. According to the invention, through the mutual cooperation between the arranged rotating shaft and rotatingseat, the rotation of the arc-shaped wood board after clamping and fixing is realized, which ensures that the dyeing paint can be sprayed on the inside of the arc-shaped wood board in the opposite direction; and therefore, the dyeing efficiency and dyeing uniformity are further increased.

Owner:湖南阳明竹咏科技有限公司

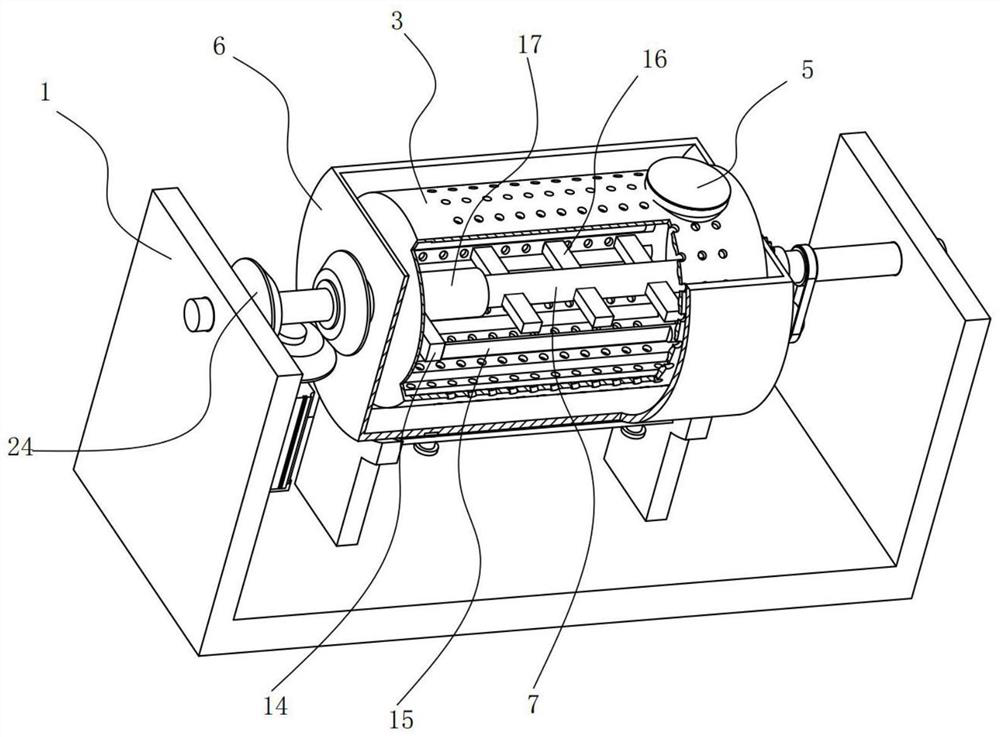

Aluminum fluoride crystal particle limiting crushing device

InactiveCN111389492ARealize the effect of rotary grinding and refinementIncrease the degree of fragmentationGrain treatmentsAluminum fluorideDrive motor

The invention discloses an aluminum fluoride crystal particle limiting crushing device, and relates to the technical field of aluminum fluoride. The aluminum fluoride crystal particle limiting crushing device comprises a supporting frame. A crushing tank which is used for holding crystal particles is arranged in the supporting frame, and a screening plate is horizontally fixed in the crushing tank. A driving motor is fixed to the supporting frame. An impact mechanism which is used for crushing the crystal particles is arranged above the crushing tank. A lifting mechanism which is used for adjusting the impact mechanism to conduct vertical lifting operation is arranged on the supporting frame. According to the aluminum fluoride crystal particle limiting crushing device, the aluminum fluoride crystal particles located inside the crushing tank are subjected to vertical impact crushing operation through the arranged impact crushing mechanism; due to the screw thread fit of a threaded column and a threaded sleeve, the rotary grinding refining effect of a crushing press disc on the crystal particles is achieved, and the crushing degree of the crystal particles is greatly improved; and the arranged crushing tank can be driven by a horizontal movement mechanism to achieve transverse movement and can also achieve the rotating effect, the dispersion effect of the crystal particles on thescreening plate is greatly and effectively improved, and the full and efficient crushing effect of the crystal particles is achieved.

Owner:XINYI DONGFANG SHUOHUA OPTICAL MATERIALS CO LTD

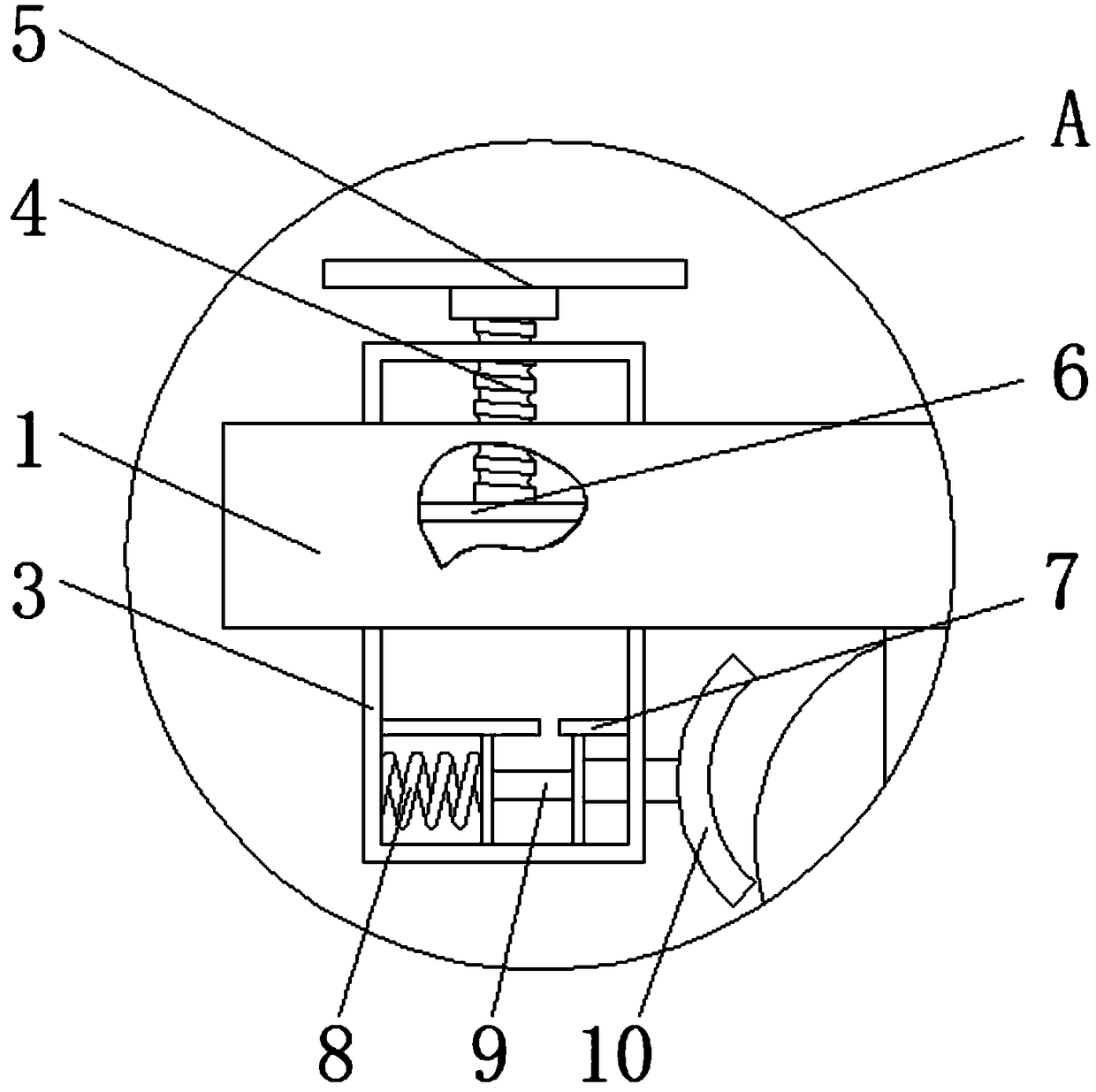

Indoor mobile advertising display stand

InactiveCN108399876ARealize the clamping effectFacilitate publicity workBoardsDisplay deviceEngineering

The invention relates to the technical field of an advertisement display device, and discloses an indoor mobile advertisement display stand. The stand comprises a trolley. Two sets of wheels are fixedly mounted on both sides of the bottom end of the trolley, and the inner fixing set on the top side of the trolley has a mounting box. The inner movable sleeve of the mounting box has a threaded rod I, and one end of the threaded rod I extends to the outside of the top end of the mounting box and is screwed with a threaded pressing rod. The other end of the threaded rod I is fixedly mounted with apiston inside the installation box, and a partition directly under the piston is provided with a partition at the bottom of the inner chamber of the installation box. The indoor mobile advertising display frame can realize the function of clamping the wheel by setting the installation box, the threaded rod I, the threaded pressing rod, the piston, the partition plate, the compression spring, thepush rod and the limiting block, allowing the trolley to stop at any time and achieve the effect of the advertisement for users, with not only the characteristics of mobility but also the better practicability.

Owner:嘉兴环艺文化传播有限公司

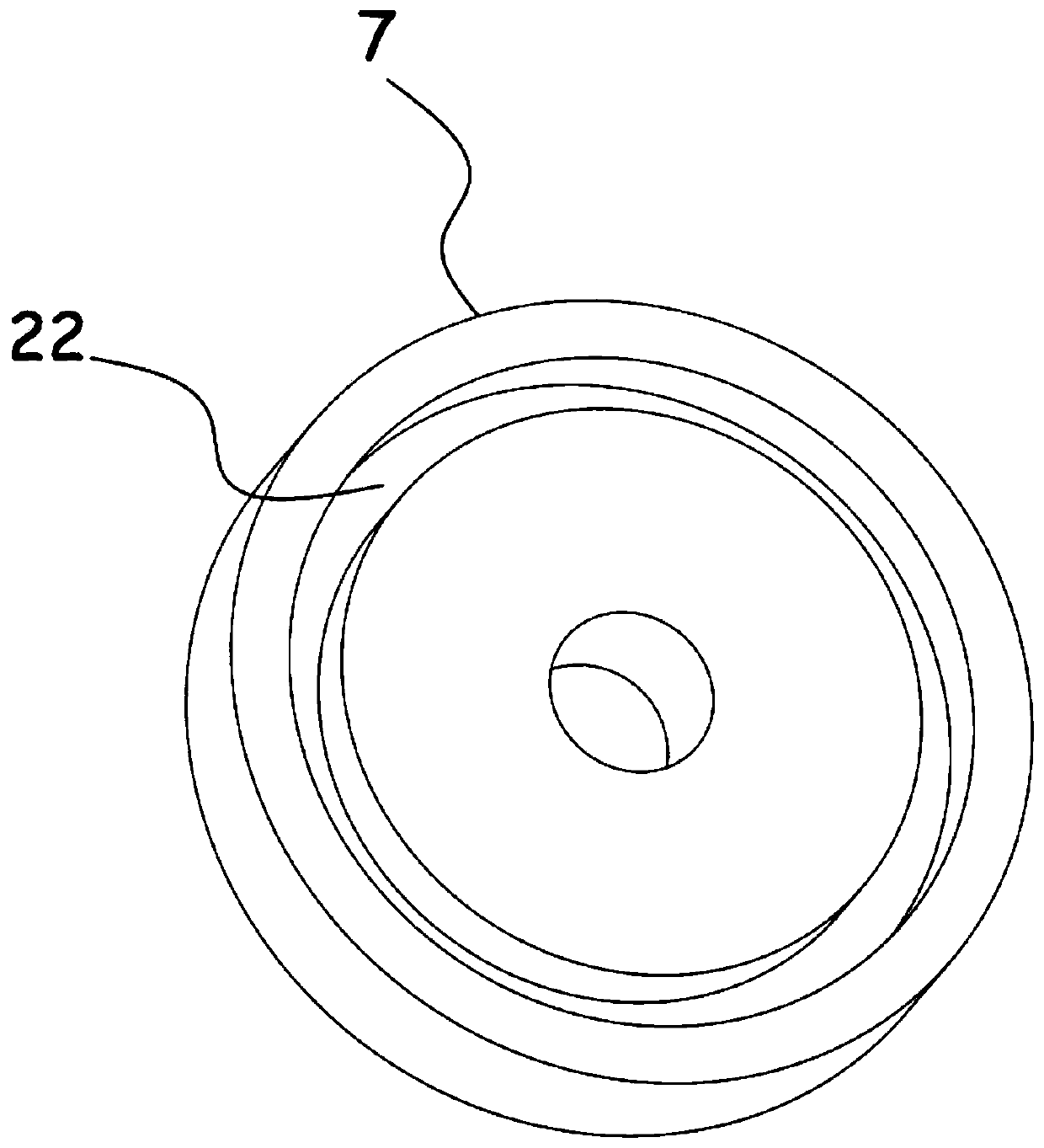

Optical coating material guiding and drying device

InactiveCN111397335ARealize the rotation effectImprove loosenessGranular material dryingDrying gas arrangementsOptical coatingEngineering

The invention discloses an optical coating material guiding and drying device and relates to the technical field of material drying. The optical coating material guiding and drying device comprises asupporting frame; a servo motor and a hot-air blower are fixed to the supporting frame; a hollow shaft is rotationally installed in the center of the supporting frame; a drying mechanism used for drying materials in a net barrel is disposed on the hollow shaft; and a stirring mechanism used for dispersing coating materials is rotationally installed in the net barrel. The optical coating material guiding and drying device is driven by the servo motor, the rotating effect of a rotating frame is achieved, thus the net barrel can be driven by an autoroatation mechanism and a revolution mechanism to perform autoroatation while performing revolution around the hollow shaft, then particle materials in the net barrel can be driven to be fully rotationally dispersed, the materials can be in full contact with the hot air flow, water volatilization is facilitated, meanwhile the stirring mechanism can rotate and disperse the materials in the net barrel while the rotating frame rotates, the dispersed degree of the materials is further improved, and rapid drying of the materials is effectively facilitated.

Owner:XINYI DONGFANG SHUOHUA OPTICAL MATERIALS CO LTD

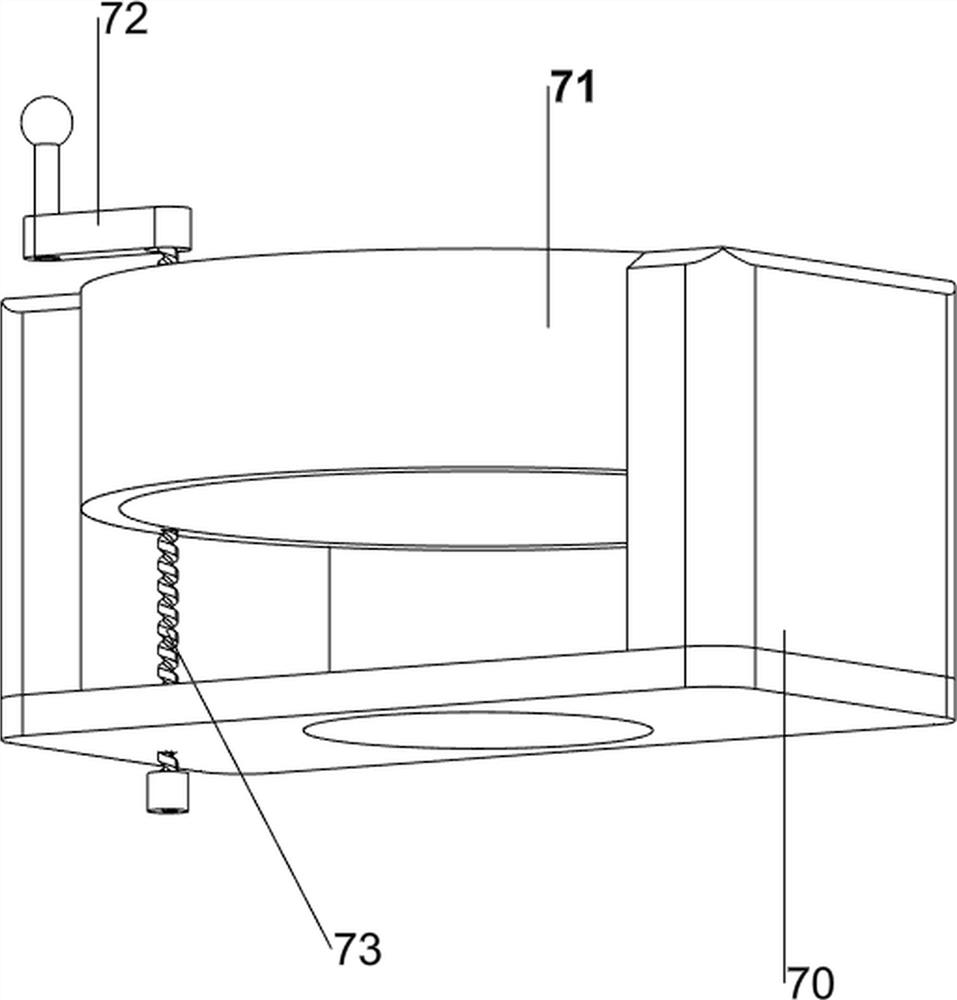

Surgical instrument disinfection device for endocrinology department

PendingCN113797362AAchieve high temperature disinfectionTo achieve the effect of coveringLavatory sanitoryCleaning using toolsSurgical instrumentEngineering

The invention relates to a disinfection device, and particularly relates to a surgical instrument disinfection device for the endocrinology department. The surgical instrument disinfection device for the endocrinology department can achieve automatic disinfection, and is easy to operate and wide in applicability. The surgical instrument disinfection device for the endocrinology department comprises an outer frame, supports, filter frames, a covering mechanism, a turnover mechanism and a rotating mechanism, wherein the two supports are arranged on the two sides of the outer frame respectively; the filter frames are arranged on the two sides of the outer frame in a sliding mode; the covering mechanism is arranged on the outer frame; the turnover mechanism is arranged on the outer frame; and the rotating mechanism is arranged on the outer frame. According to the surgical instrument disinfection device, a covering plate is driven to move forwards through reset of a first spring, so that a feeding port is closed, and the covering effect is achieved; and a belt wheel on the upper side rotates to drive a second brush to rotate, a first brush and the second brush can rotate to brush surgical instruments, and the rotating effect is achieved.

Owner:钟云

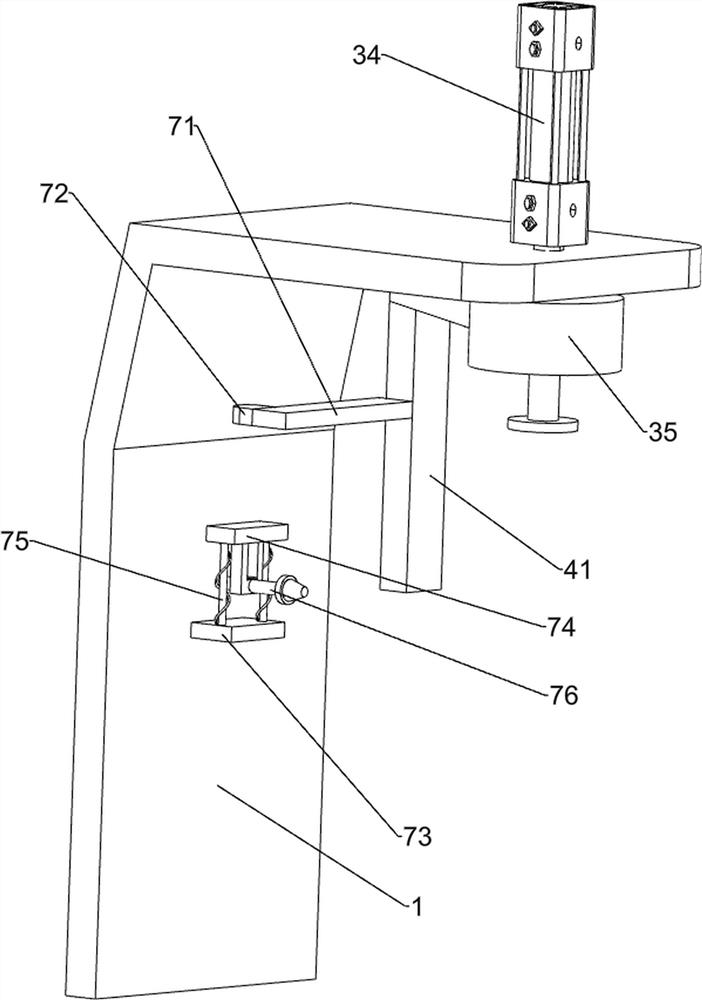

Consultation desk convenient to adjust and used for information technology consultation

InactiveCN112841876ARealize the rotation effectRealize the effect of angle deflection adjustmentOffice tablesVariable height tablesInformation technology consultingDisplay device

The invention discloses a consultation desk convenient to adjust and used for information technology consultation, and relates to the technical field of consultation desks. The consultation desk comprises a supporting fixing seat, a vertical guide limiting sleeve rotationally connected with the supporting fixing seat is vertically arranged on the supporting fixing seat, a servo motor is fixed to the bottom of a supporting table, a deflection mechanism is in driving connection with the servo motor, and a steering mechanism used for driving the vertical guide limiting sleeve to conduct steering adjustment is arranged in the supporting fixing base. The effect of adjusting the vertical height of the supporting table is achieved through the arranged lifting mechanism, the effect of adjusting the height of a display used for information technology consultation on an adjusting rotating plate is achieved, the deflection angle of the adjusting rotating plate can be flexibly adjusted through the arranged deflection mechanism, consulting and using of the display are facilitated, the arranged steering mechanism can achieve the rotating effect of the vertical guide limiting sleeve by pulling a pulling plate, the effect that the supporting table drives the display to conduct circumferential angle deflection adjustment is achieved, and the using and adjusting flexibility of the consultation desk is greatly improved.

Owner:涡阳量子信息科技有限公司

Omnibearing paint spraying equipment for case shell processing

InactiveCN111644292AAchieve clampingRealize the rotation effectSpraying apparatusEngineeringSpray painting

The invention relates to the technical field of case shell processing, and discloses omnibearing paint spraying equipment for case shell processing. The omnibearing paint spraying equipment for case shell processing comprises a fixing bottom plate, wherein a fixing frame is installed in the middle of the upper end of the fixing bottom plate, a left-handed screw and a right-handed screw which are fixedly connected are installed in the fixing frame, moving blocks are respectively installed in the middle of the left-handed thread and in the middle of the right-handed thread, a moving frame is installed at the upper end of the moving block, a rotating cylinder is installed at the upper end of each moving frame, a rotating shaft is installed inside each rotating cylinder, and one end of the inner side of each rotating shaft penetrates through the corresponding rotating cylinder to be connected with a rotating plate. A rack is installed on the left side of the upper end of the fixing bottomplate, a lifting box is arranged in the middle of the rack in a sliding mode, a lifting frame is arranged in the middle of the right side of the lifting box, and supporting frames are arranged on thetwo sides of the upper end of the lifting frame. According to the omnibearing paint spraying equipment for case shell processing, the clamping and rotating effects on the case shell are realized, meanwhile, a paint spraying case can swing left and right through the matching of the rotating cylinder, an upper guide block and a lower guide block, and the omnibearing paint spraying effect on the caseshell in the rotating state is further realized.

Owner:宋小航

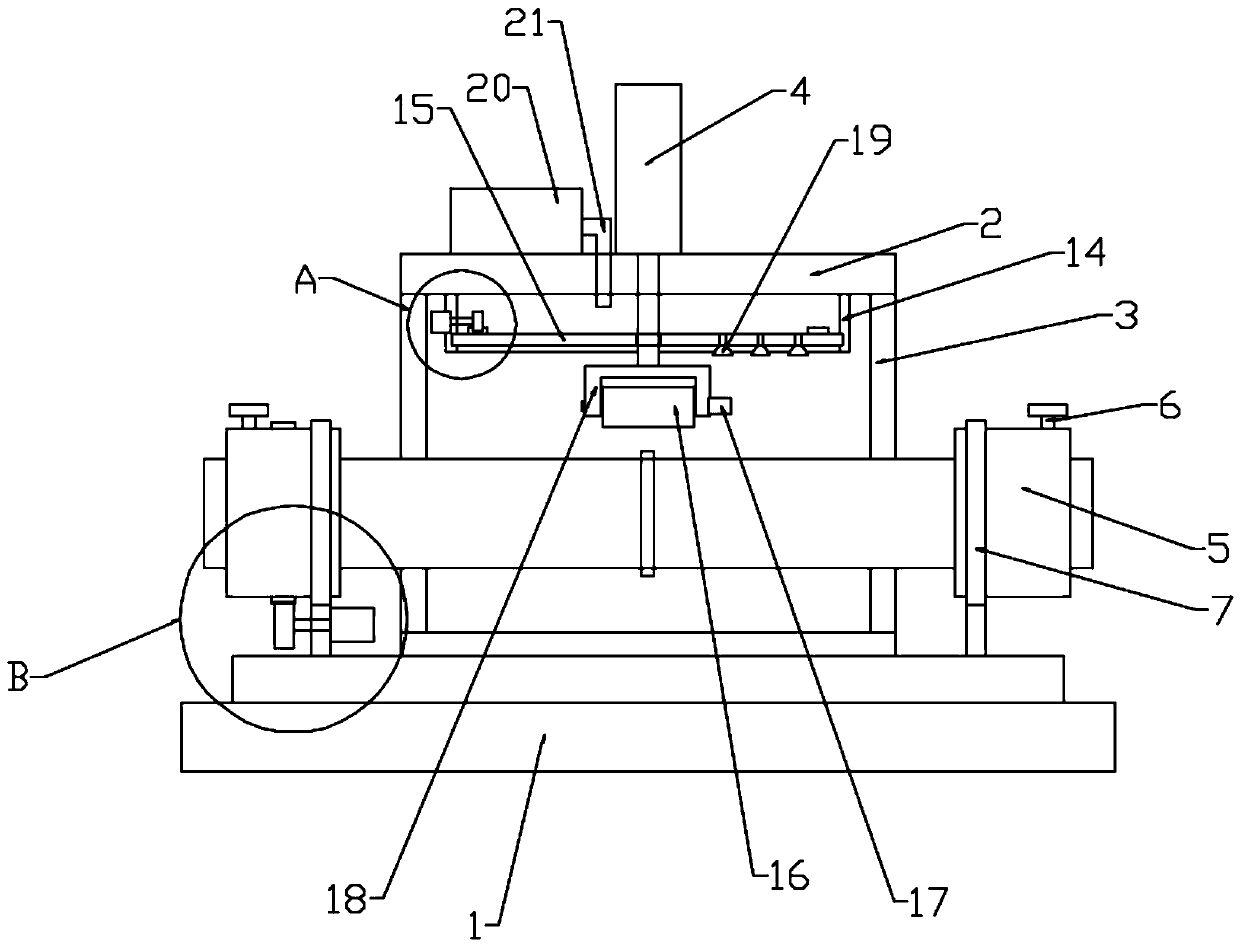

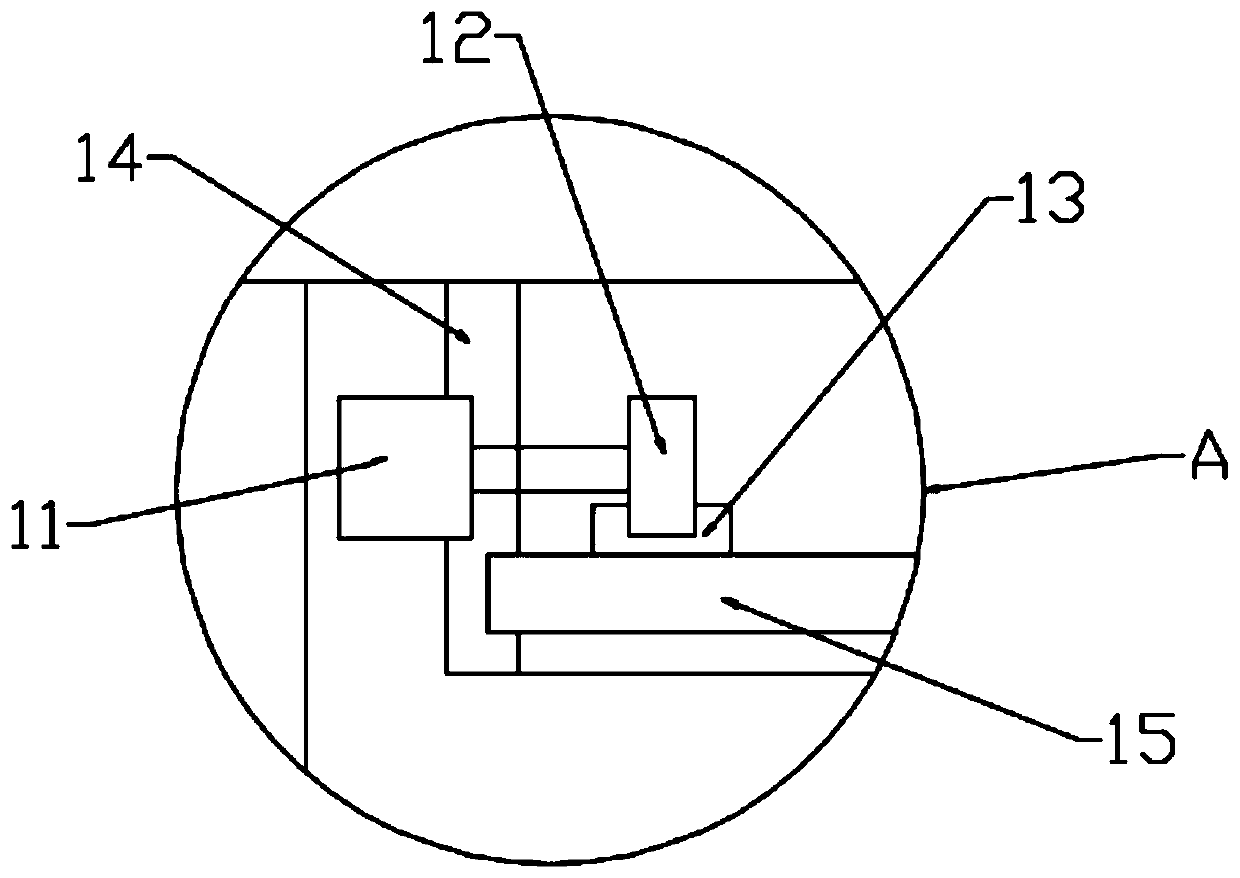

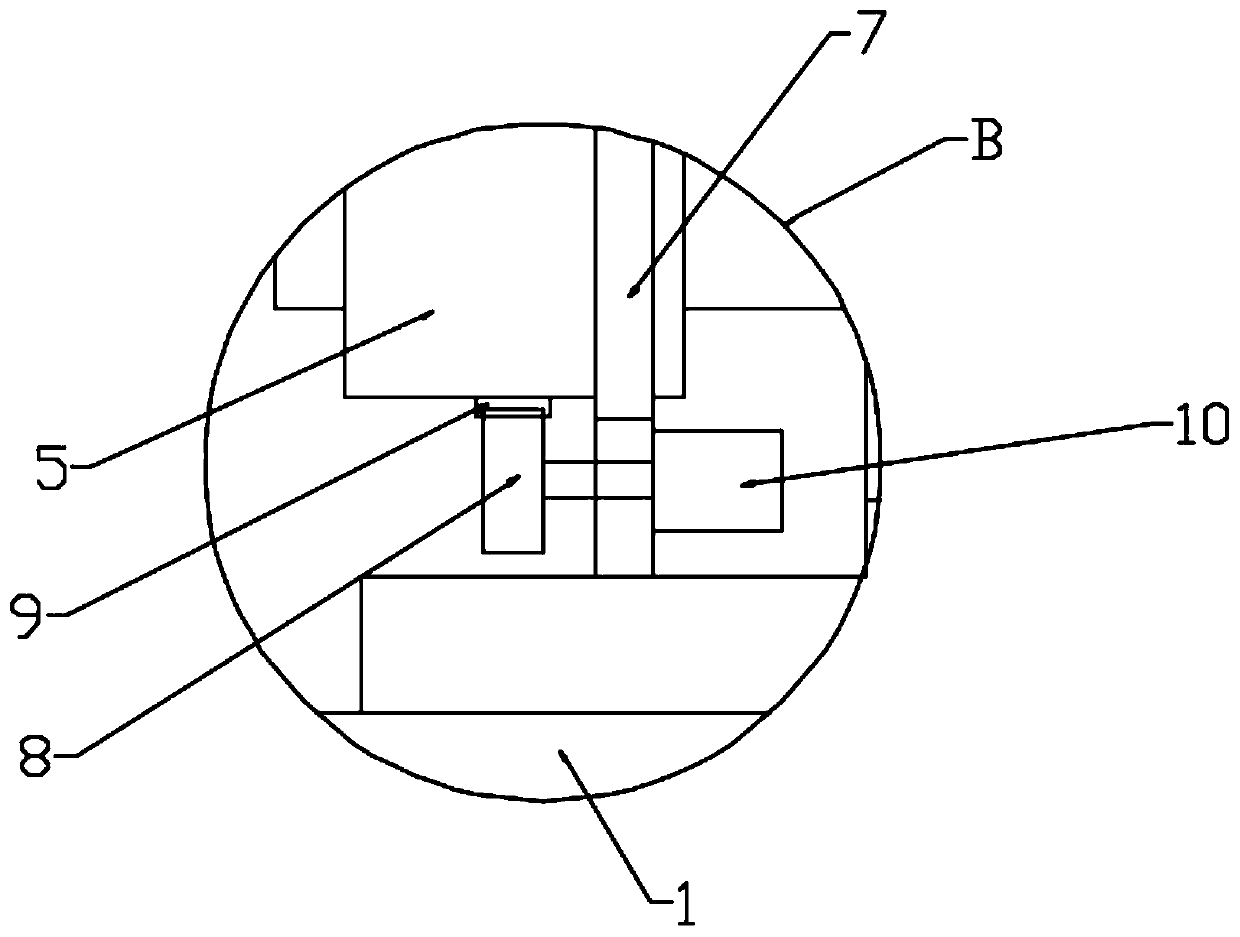

Production device and process method for stainless steel welded pipe for condenser

InactiveCN111015418ARealize the rotation effectWide range of inhalationEdge grinding machinesGrinding drivesSS - Stainless steelWeld seam

The invention relates to the field of stainless steel welded pipe processing, and particularly discloses a production device for a stainless steel welded pipe for a condenser; the production device comprises a base and a protection box; supporting clamps are arranged on the top faces of the two ends of the base; an electric telescopic rod used for adjusting the position of a grinding assembly in the vertical direction is further arranged on the protection box. The embodiment of the invention further discloses a production process method for the stainless steel welded pipe for the condenser. The method comprises the following specific steps: two ends of the stainless steel welded pipe are respectively arranged on the two support clamps; a weld seam of the stainless steel welded pipe is located under the polishing assembly; then, the grinding assembly is pushed to move downwards to make contact with the weld seam through the telescopic function of the electric telescopic rod; and then the grinding assembly is used for grinding the weld seam, meanwhile, a first servo motor is used for driving supporting barrels of the supporting clamps to rotate, the stainless steel welded pipe is made to rotate, and the grinding assembly conducts all-around grinding treatment on the rotating stainless steel welded pipe weld seam.

Owner:广东双兴新材料集团有限公司

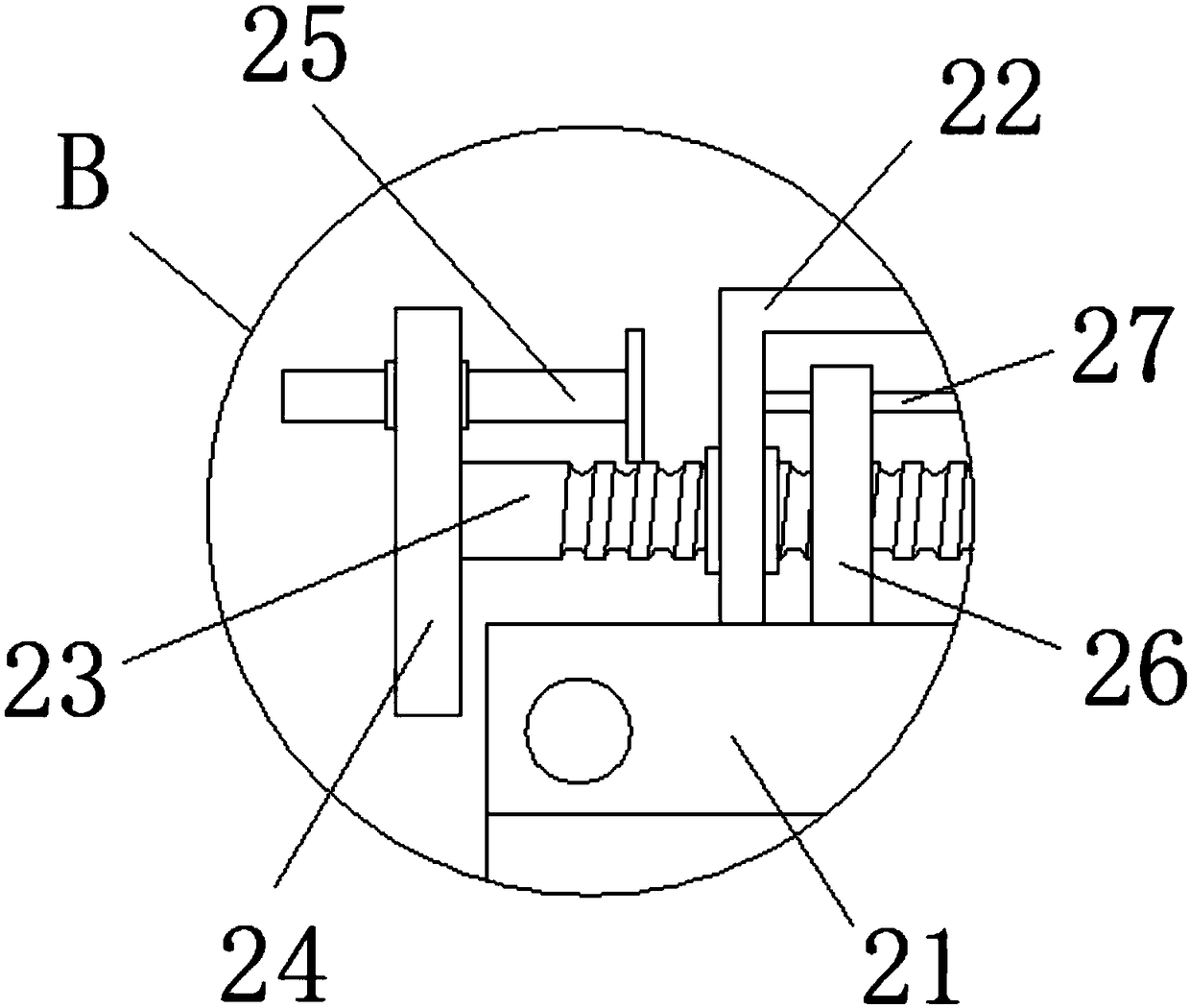

Movable wall surface painting device for indoor decoration

InactiveCN112376862AImprove brushing effectRealize the rotation effectBuilding constructionsElectric machineryEngineering

The invention discloses a movable wall surface painting device for indoor decoration, and relates to the technical field of building decoration. The movable wall surface painting device comprises a moving frame, an output shaft of a driving motor II is in transmission connection with a height adjusting mechanism for driving a brushing mechanism to vertically ascend and descend, and the moving frame is provided with a translation mechanism for driving a transmission box to transversely move. According to the device, transverse movement adjustment can be conducted on the transmission box throughthe arranged translation mechanism, a brush on a rotating disc makes contact with the wall surface in an attached mode, enough pressing force is achieved during wall surface brushing, so that the paint brushing effect is improved; the arranged height adjusting mechanism can drive the rotating disc to vertically ascend and descend in a reciprocating mode under driving of the driving motor II, so that positions at different height of the wall surface can be fully and comprehensively coated with paint; and in the reciprocating ascending and descending process of the rotating disc, a rotating gear is connected with a vertical rack in an engaged mode, then the rotating effect of the rotating disc is achieved, and paint brushing of the wall surface is more sufficient and comprehensive.

Owner:丁廷兵

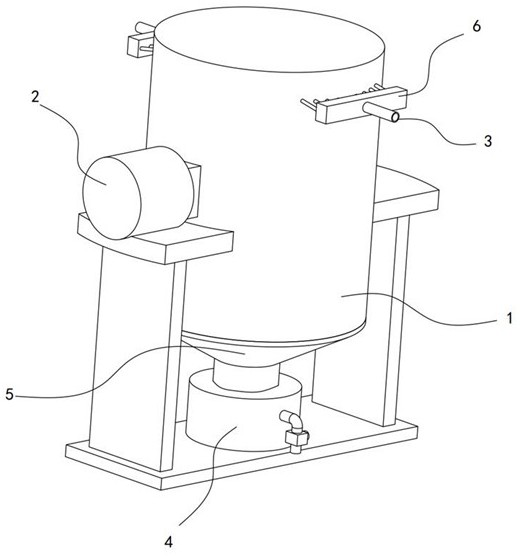

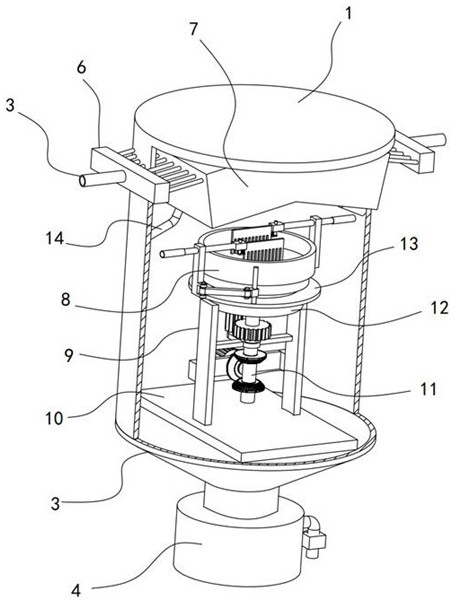

Saponin removal device for chenopodium quinoa willd production

PendingCN114468207AFull rotation agitation effectFull saponin effectFood scienceElectric machineryEngineering

The invention discloses a saponin removal device for chenopodium quinoa willd production, and relates to the technical field of chenopodium quinoa willd processing device.The saponin removal device comprises a rack, a collecting tank is fixed to the rack, a driving sleeve is rotatably mounted on the collecting tank, an extension frame is fixed to the driving sleeve, the driving sleeve and a net barrel are coaxially fixed, a rotating shaft is rotatably mounted in the driving sleeve, and a rotating shaft is rotatably mounted in the rotating shaft; a plurality of pairs of stirring plates are evenly fixed to the side wall of the rotating shaft, a motor is installed on the machine frame, the motor is in driving connection with a reverse rotating assembly, the reverse rotating assembly is used for driving the driving sleeve and the rotating shaft to rotate in the opposite rotating directions, and a plurality of protruding strips are evenly fixed to the inner wall of the net barrel. The rotating shaft and the rotating shaft are driven by the reverse rotating assembly to rotate in the opposite rotating directions, so that the turning rod and the stirring plate rotate in the opposite directions, the sufficient rotating and stirring effect of quinoa in the net barrel is achieved, the quinoa rubs with the protruding strips in the stirring process, the quinoa rubs mutually, and the sufficient saponin effect of the quinoa is achieved.

Owner:SHANXI FUNCTIONAL FOOD RES INST OF SHANXI AGRI UNIV

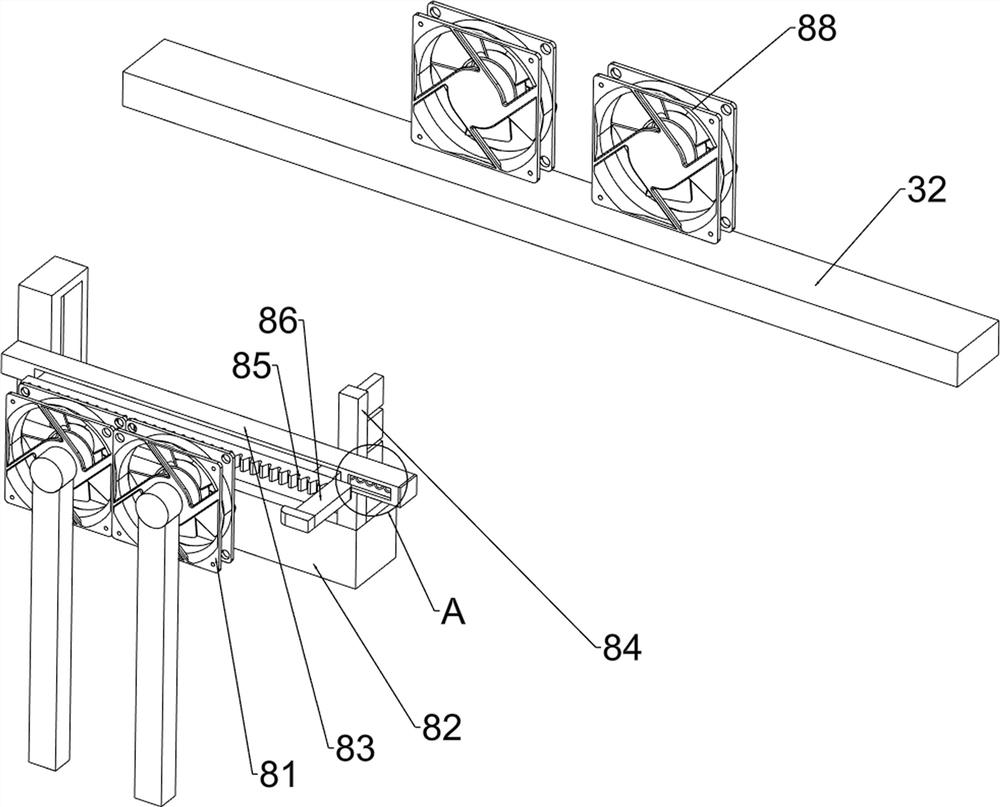

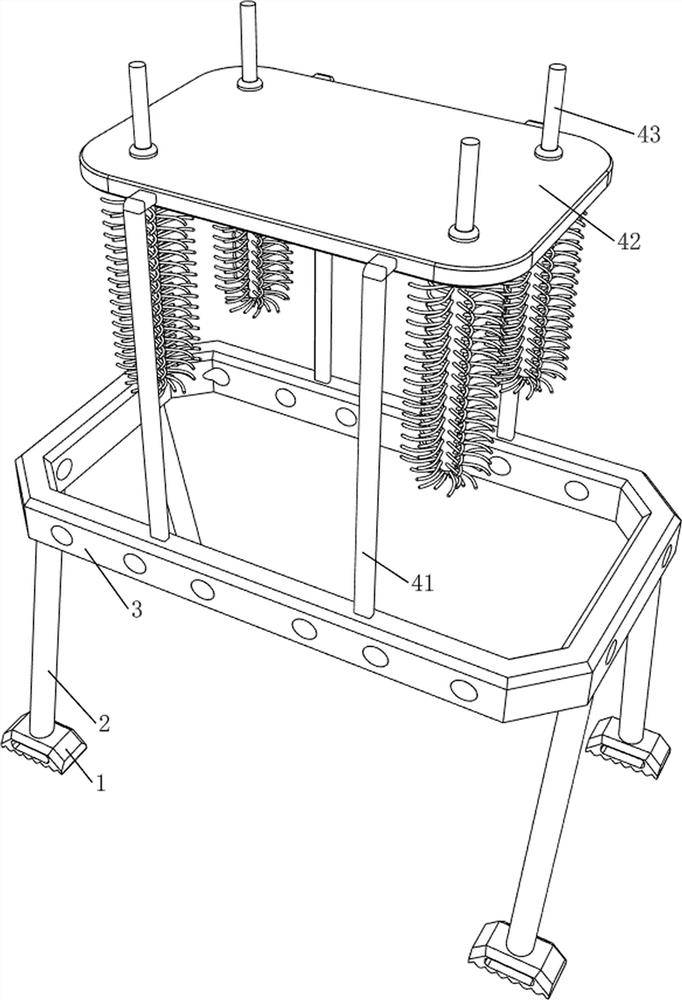

Test tube cleaning and drying all-in-one machine for pharmacy department

ActiveCN113020186ARealize the clamping effectRealize the rotation effectHollow article cleaningDrying gas arrangementsPharmacyBiomedical engineering

The invention relates to a cleaning and drying all-in-one machine, in particular to a test tube cleaning and drying all-in-one machine for the pharmacy department. The test tube cleaning and drying all-in-one machine for the pharmacy department can automatically clean and disinfect, reduces the burden of workers and is convenient to use. The test tube cleaning and drying all-in-one machine for the pharmacy department comprises first fixing frames, second fixing frames, a third fixing frame, a cleaning mechanism and a clamping mechanism, wherein the four first fixing frames are all provided with the second fixing frames; the third fixing frame is arranged among the tops of the four second fixing frames; the cleaning mechanism is arranged in the middle of the top of the third fixing frame; and the inner wall of the third fixing frame is provided with the clamping mechanism. According to the test tube cleaning and drying all-in-one machine, by manually rotating brushes on the two sides, cleaning liquid can flow into a test tube from a small hole, so that the brushes can clean the test tube, and the cleaning effect is achieved.

Owner:南京韵鼎机电工程有限公司

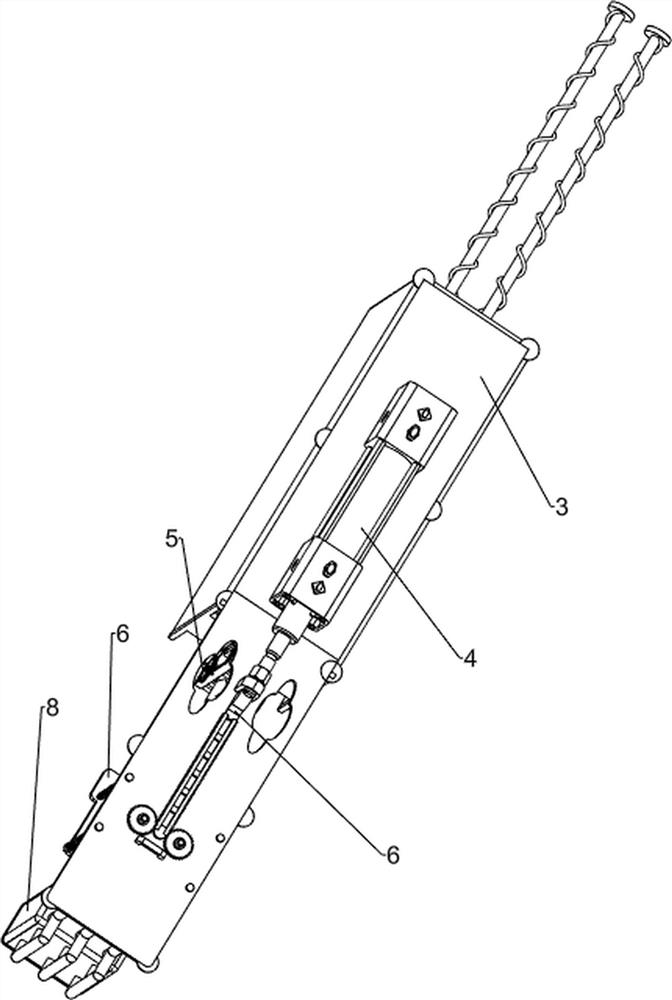

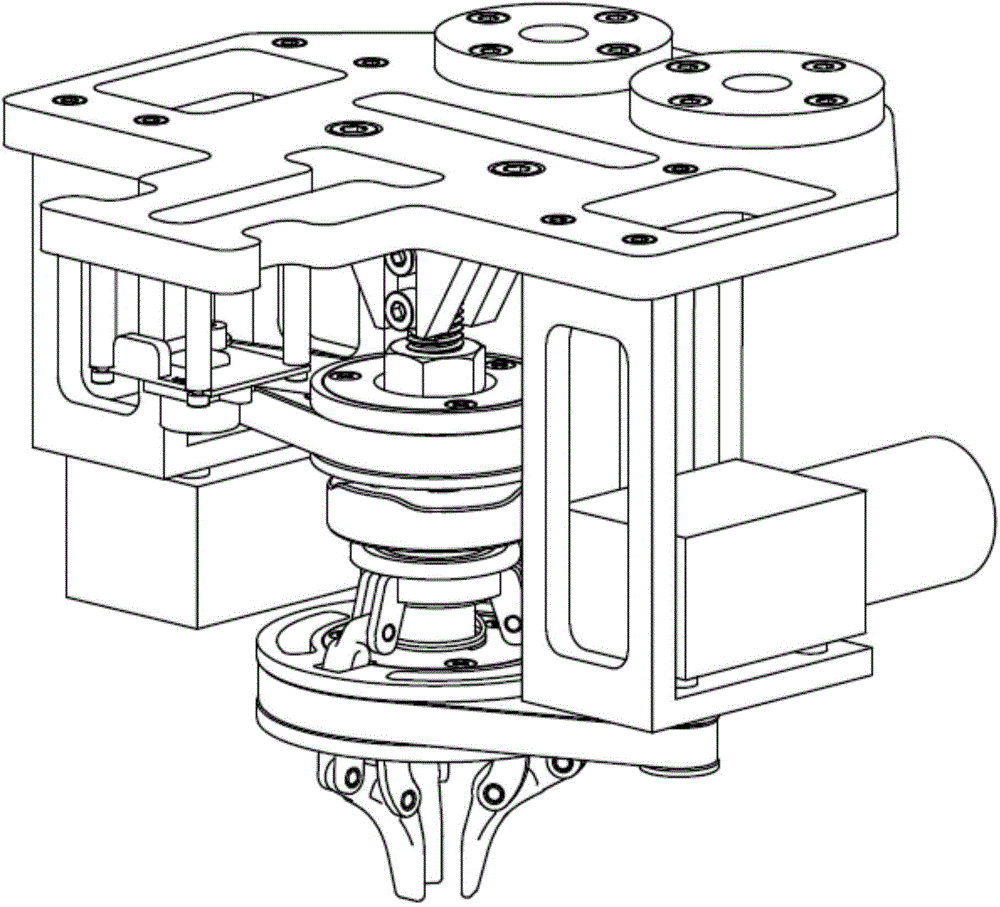

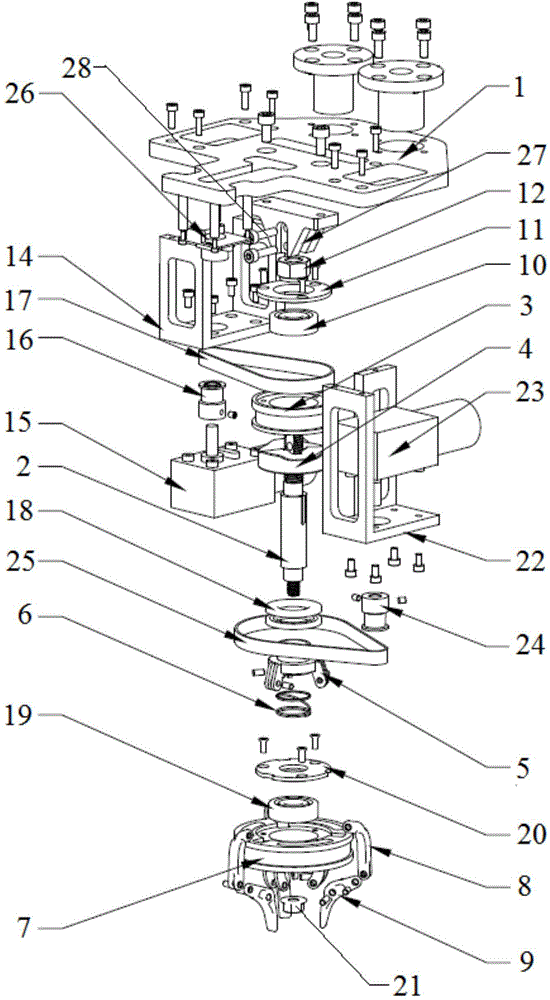

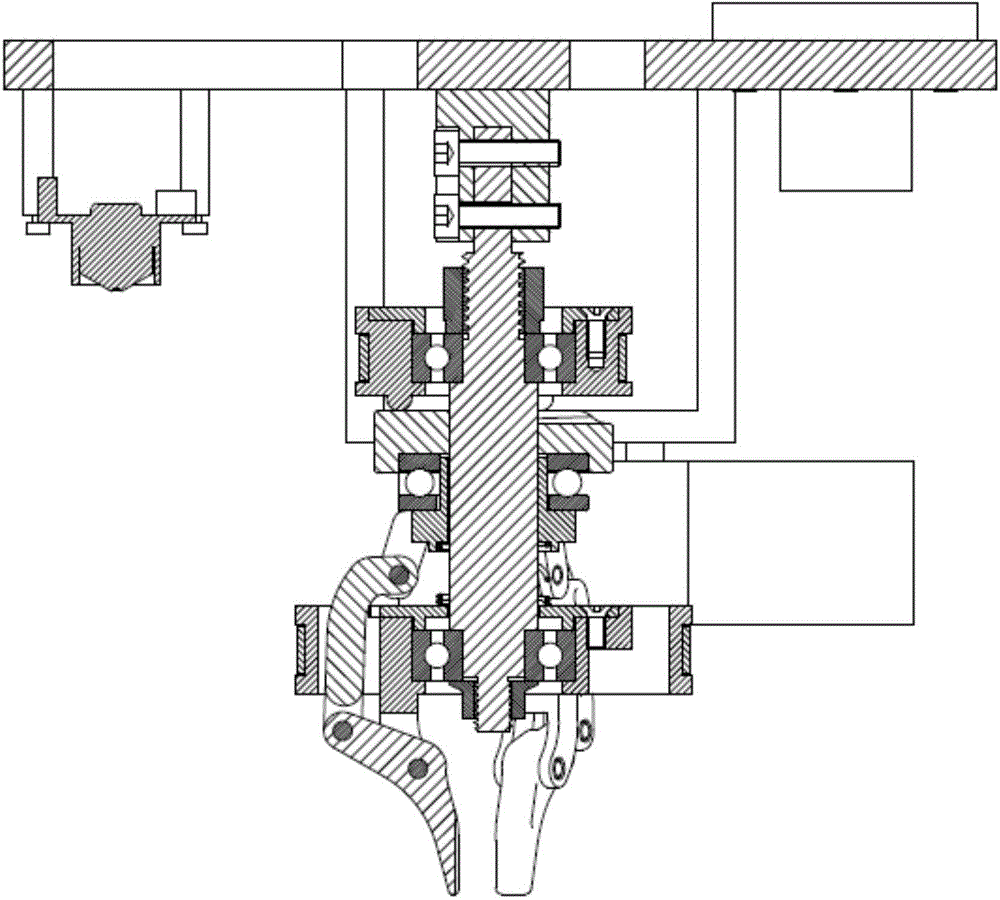

Grabhook and grabhook opening and closing method

ActiveCN104924316ASimple structureLow costProgramme-controlled manipulatorGripping headsCamEngineering

The invention discloses a grabhook and a grabhook opening and closing method. The grabhook comprises a rack, a clamping jaw device and a clamping jaw opening and closing drive device. A clamping jaw is unfolded and folded through matching of a rotating cam, a pressure plate and a pressure spring, and meanwhile the grabbing and autoroatation effects can be achieved just by two motors. The grabhook is simple in structure, low in cost, reliable to operate, suitable for occasions where test tubes are required to be moved frequently and capable of bringing better operation benefits.

Owner:中电湘江数据服务有限公司

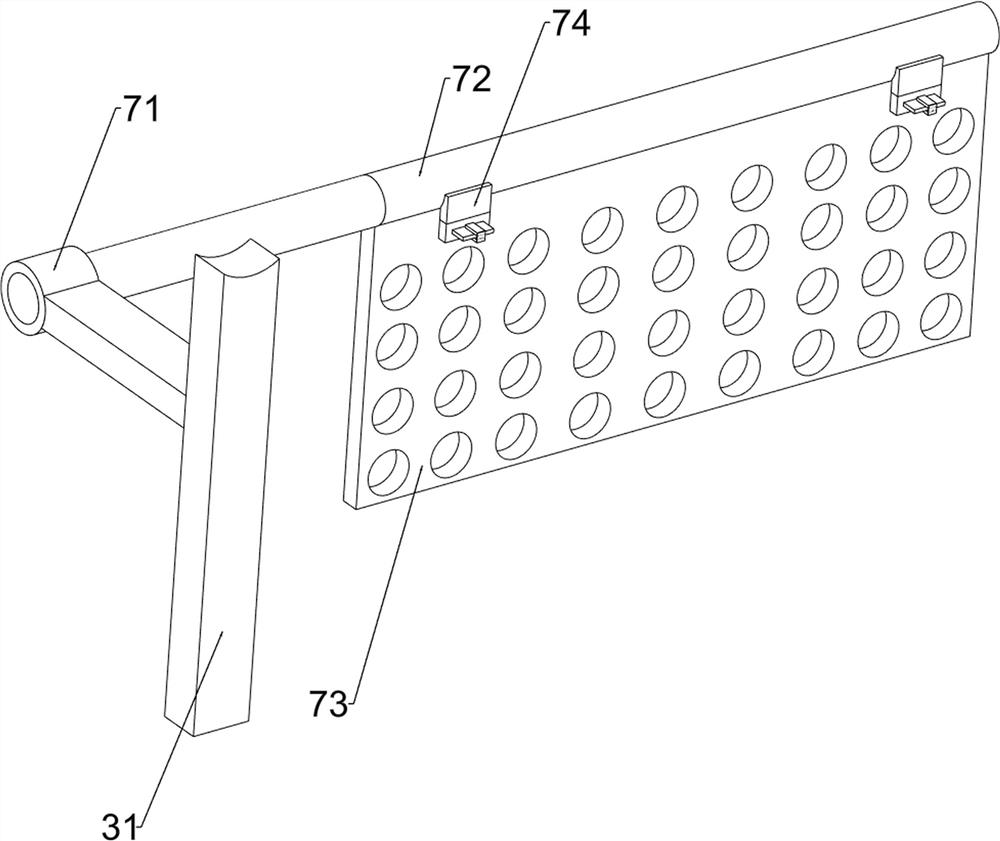

Automatic cutting machine with automatic clamping function

InactiveCN108637391AAvoid damageImprove stabilityPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses an automatic cutting machine with an automatic clamping function. The automatic cutting machine comprises an operation table; a supporting arm is fixedly connected to the leftside of the upper surface of the operation table; a cutting apparatus is fixedly connected to the end, away from the operation table, of the supporting arm; a groove is formed in the right side of theupper surface of the operation table; a sliding groove is formed in the inner bottom wall of the groove; a first clamping block is clamped inside the sliding groove; a second clamping block is arranged on the right side of the first clamping block; the bottom of the second clamping block is clamped in the sliding groove; symmetrical supporting columns are fixedly connected to the lower surface ofthe operation table; a grid baffle is arranged between the supporting columns; and a motor is fixedly connected to the upper surface of the grid baffle. By means of the automatic cutting machine withthe automatic clamping function, damage to workpieces in the clamping process can be effectively reduced, damage to the operation table during operation of the cutting apparatus can be effectively avoided, the automatic workpiece clamping effect is achieved, and the workpieces are prevented from moving in the cutting process, and safety of the cutting machine is improved.

Owner:芜湖撼江智能科技有限公司

Steel tube polishing equipment for building materials

PendingCN112643499AAchieve effectStable effectGrinding carriagesRevolution surface grinding machinesSteel tubeBuilding material

The invention relates to polishing equipment, in particular to steel tube polishing equipment for building materials. The steel tube polishing equipment can achieve uniform polishing and automatic polishing. The steel tube polishing equipment for the building materials comprises a base, a pushing mechanism, a rotating mechanism, a polishing mechanism, positioning mechanisms and the like. The pushing mechanism is arranged on the front side of the base, the rotating mechanism is arranged on the base, the polishing mechanism is arranged on the upper side of the front portion of the rotating mechanism, and the positioning mechanisms are arranged on the tops of the front side and the rear side of the base. According to the equipment, a telescopic rod of an air cylinder drives an arc-shaped frame to move forwards and backwards, the pushing effect is achieved, and manual pushing is not needed; a first straight gear rotates to drive a second straight gear to rotate, so that the second straight gear rotates, and the rotating effect can be achieved; and through mutual cooperation of the positioning mechanisms and a self-locking mechanism, a steel tube can be clamped and stabilized in the positioning mechanisms and the self-locking mechanism, and polishing can be stably conducted.

Owner:刘杰

Rear-slip prevention device of bassinet

InactiveCN102351031ARealize the rotation effectRealize the purpose of brakingChildren cyclesCycle brakesControl powerFree rotation

The invention discloses a rear-slip prevention device of a bassinet, comprising a gear box device connected with wheels, and a circuit board connected with the gear box device and used for controlling power-on condition of the gear box device. The gear box device is provided with a gear box lower shell and a gear box upper shell respectively; the gear box lower shell is provided with a relay, a motor and an axle hole through which a magnetic shaft on the relay passes; the relay and the motor are respectively in electric connection with the circuit board used for controlling on or off of the relay and motor; the gear box upper shell is provided with an upper shell cavity; the upper shell cavity is internally provided with a gear set; the gear set is provided with a plurality of through holes; each through hole respectively corresponds with the axle hole; when the power is off, the magnetic shaft is enabled to pass through the axle hole and is inserted into the through hole corresponding to the axle hole, of a first gear of the gear set, so as to realize the effect of preventing the first gear from rotating; when the power is on, the magnetic shaft is sucked from the first gear to return into the relay to make the first gear be at a free rotation state so as to achieve the purpose of braking an electric simulation automobile.

Owner:佛山市顺德区琪俊玩具有限公司

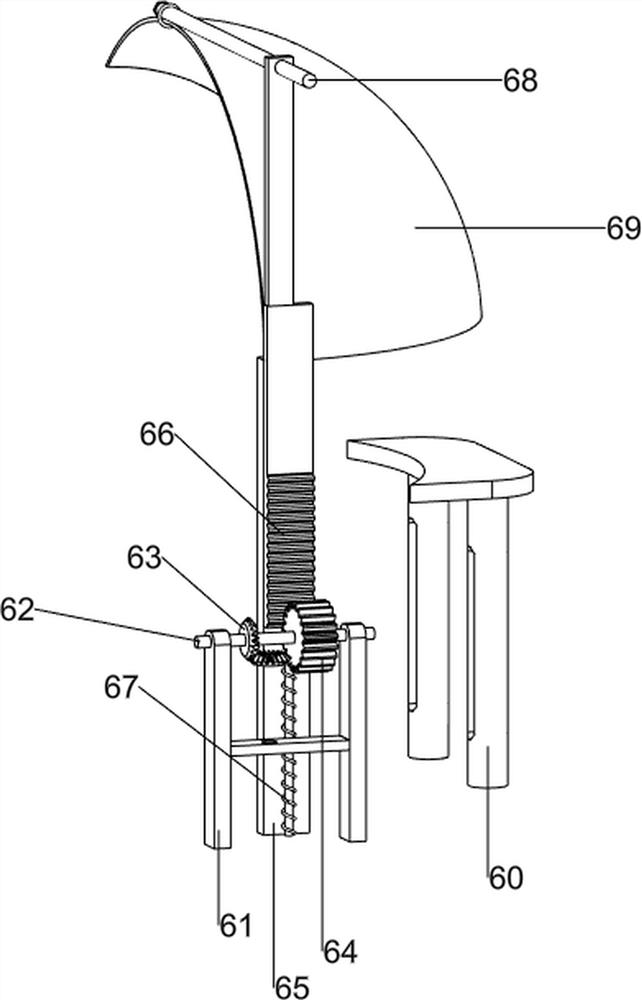

Household meat stuffing mincer

ActiveCN112616895ARealize the rotation effectRealize automatic meat choppingMeat processing devicesEngineeringMechanical engineering

The invention relates to mincers and particularly relates to a household meat stuffing mincer. The household meat stuffing mincer provided by the invention has the advantages that uniform meat mincing and automatic flavoring adding can be achieved, and freshness of meat can be kept. A technical embodiment of the invention is as follows: the household meat stuffing mincer comprises a bottom plate and a first bracket, wherein the first bracket is arranged on the bottom plate; a mincing mechanism, wherein the mincing mechanism is arranged between the bottom plate and the first bracket; and a rotating mechanism, wherein the rotating mechanism is arranged on the bottom plate. Through matching between the mincing mechanism and the rotating mechanism, the effect of automatically mincing the meat and rotating the meat can be achieved.

Owner:新邵笑笑食品有限责任公司

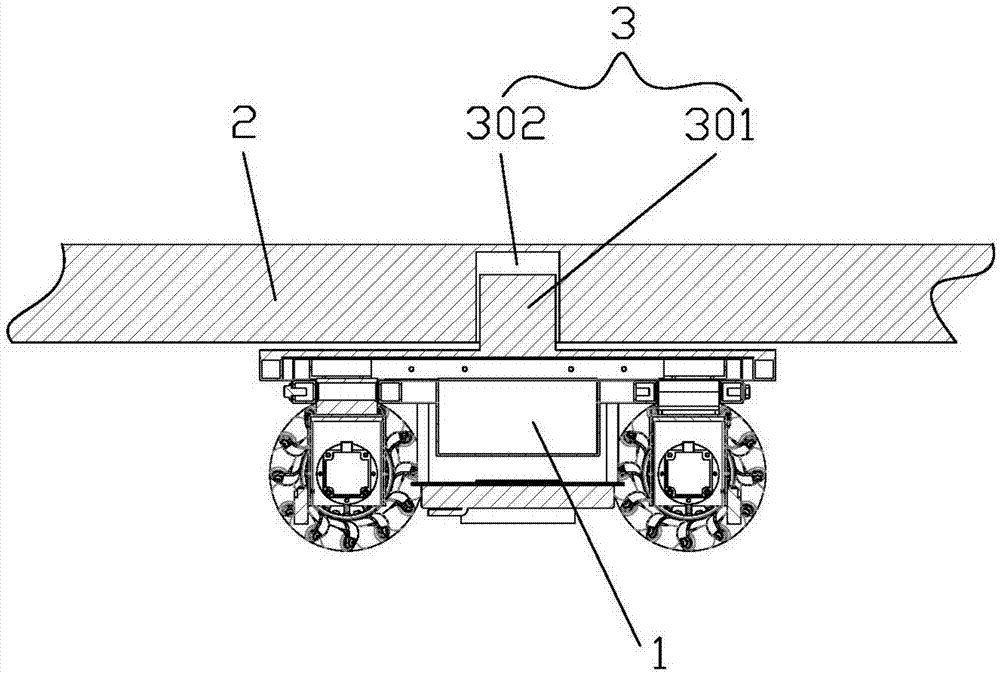

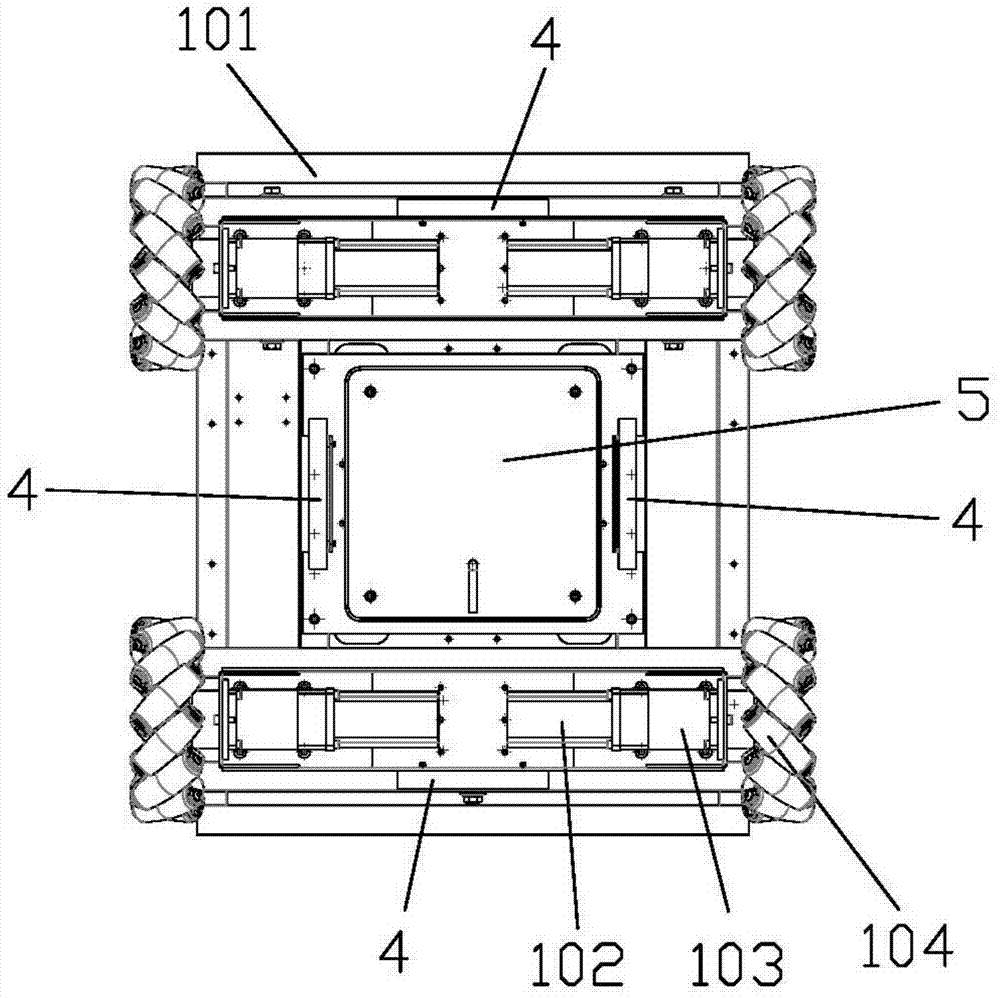

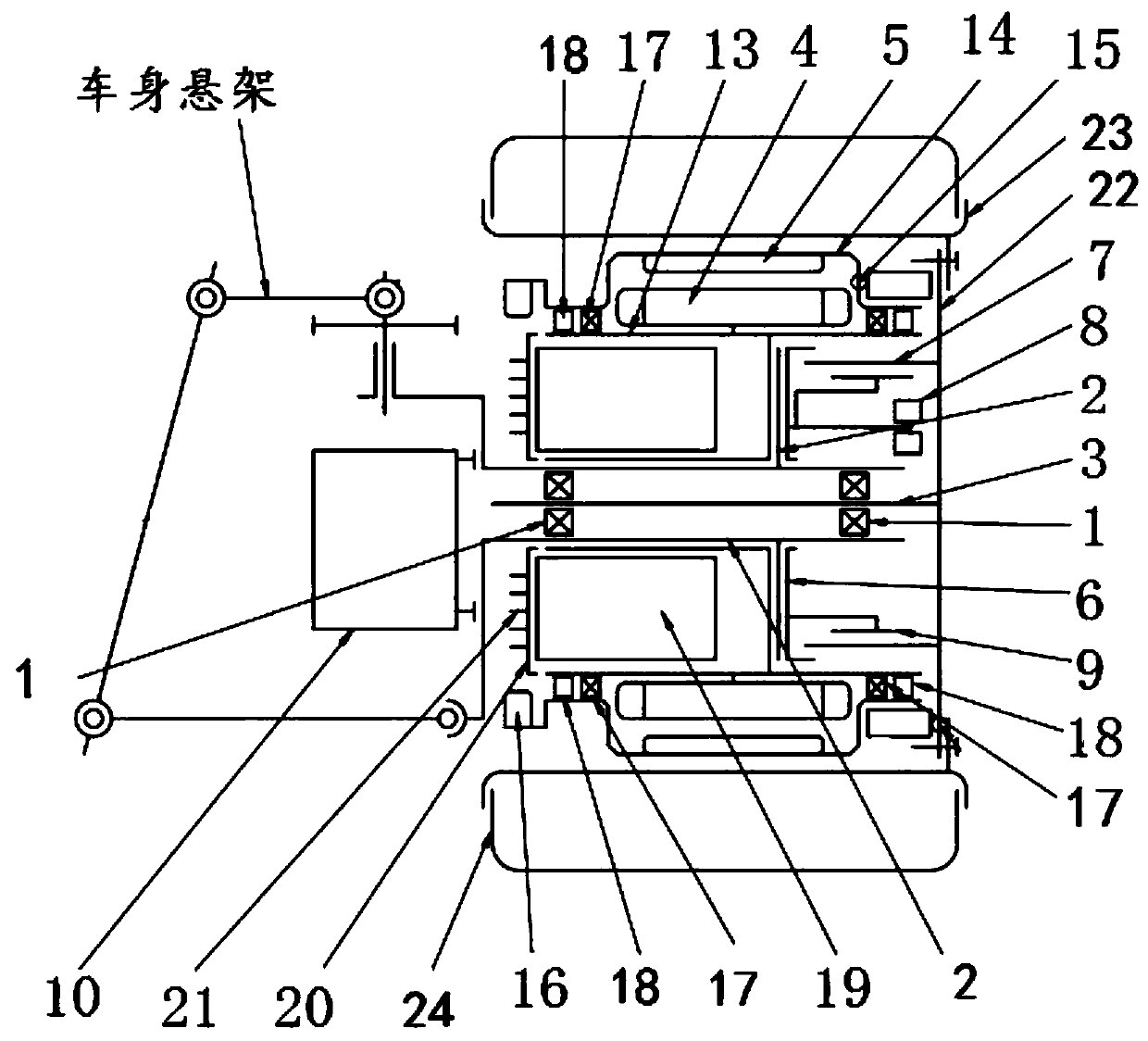

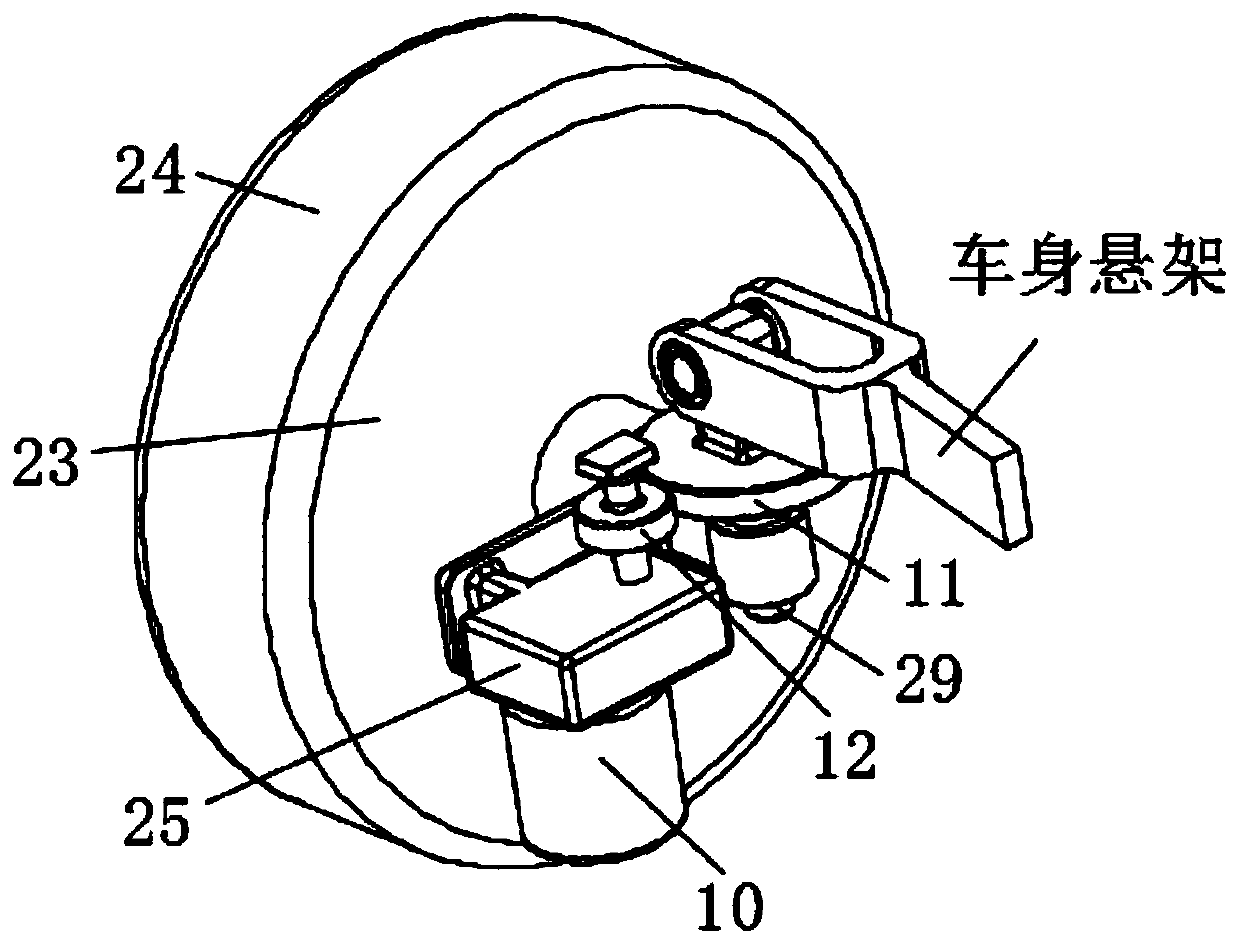

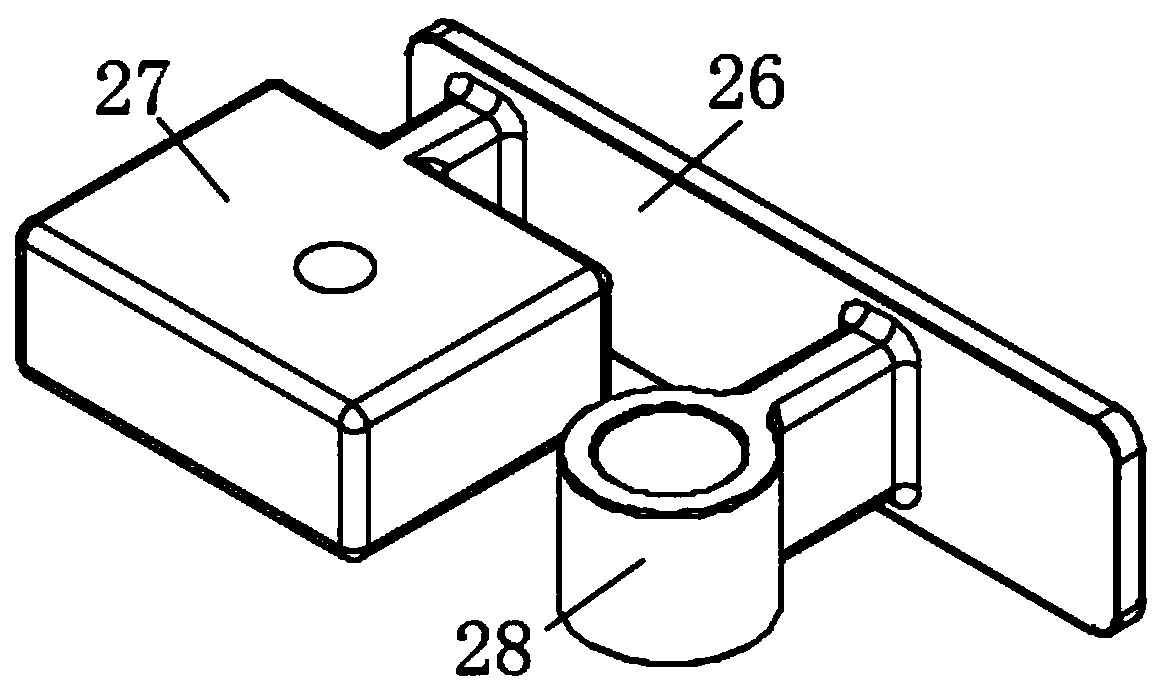

Electric driving wheel assembly integrated with driving system, braking system and steering system

InactiveCN111114294ARealize the rotation effectRealize the role of steeringBraking element arrangementsMechanical steering gearsDrive wheelElectric drive

The invention discloses an electric driving wheel assembly integrated with a driving system, a braking system and a steering system. The electric driving wheel assembly comprises a hub assembly, a driving assembly, a braking assembly and a steering assembly. The hub assembly comprises a hub bearing, a hub bearing outer ring and a hub bearing inner ring, and the hub bearing inner ring is rotationally connected to the inner side of the hub bearing outer ring through the hub bearing; the driving assembly comprises a stator and a rotor, the rotor rotates relative to the stator, the stator is fixedly connected to the outer ring of the hub bearing, and the rotor is fixedly connected to the hub bearing inner ring; the braking assembly comprises a brake disc and a brake hub, the brake hub is fixedly connected with the hub bearing inner ring, the brake disc is fixed to the hub bearing outer ring, a brake shoe is arranged on the brake disc, and a brake electromagnet used for controlling the brake shoe to act relative to the brake hub is fixedly connected to the brake disc. According to the invention, the functions of driving, braking and steering are integrated.

Owner:武汉鲸鱼座机器人技术有限公司

Vacuum low-temperature continuous drying equipment

ActiveCN113983792AAchieve vibrationRealize the vibration effectDrying solid materials without heatDrying chambers/containersEngineeringVacuum pump

The invention discloses vacuum low-temperature continuous drying equipment, and relates to the technical field of drying equipment, the vacuum low-temperature continuous drying equipment comprises a straight barrel and a vacuum pump connected with the straight barrel, a conical barrel is mounted at the bottom of the straight barrel, a horizontal frame is fixed in the straight barrel, a vertical frame is mounted on the horizontal frame, and a plurality of upper convex blocks are uniformly mounted at the bottom of a heating disc in the circumferential direction; a rotating disc is provided with a plurality of lower convex blocks which abut against the upper convex blocks in a sliding mode, the rotating shaft is connected with a rotating mechanism, the rotating mechanism is used for driving the heating disc to rotate, the rotating mechanism is provided with an outer ring plate, the outer ring plate is connected with an evacuation mechanism through a traction mechanism, and the traction mechanism is used for driving the evacuation mechanism to linearly slide relative to the heating disc; the transmission mechanism can drive the rotating disc to rotate, the lower convex blocks and the upper convex blocks on the rotating disc slidably abut against each other so that the heating disc can achieve the vibration effect, materials on the heating disc can be promoted to vibrate, the materials can be turned over and evenly heated, and precipitation of water is effectively promoted.

Owner:ZHUCHENG XINZHENGDA MACHINERY CO LTD

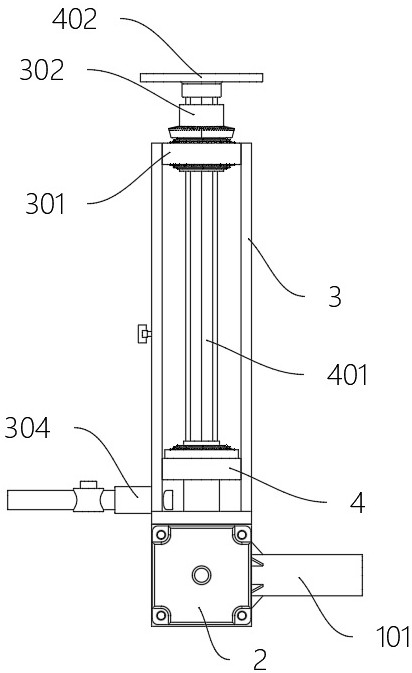

A telescopic rotary hydraulic cylinder for realizing rotary motion

ActiveCN114087255BEffective combinationImprove applicabilityGearingFluid-pressure actuatorsHydraulic cylinderEngineering

The invention provides a telescopic rotary hydraulic cylinder for realizing rotation, which relates to the technical field of hydraulic cylinders and includes: a central component, a through hole is opened in the middle of the central component; a servo motor, the servo motor is fixedly arranged on On the rear side of the center assembly, after the rotating shaft of the servo motor passes through the front end of the center assembly, a bevel gear plate is fixedly arranged; the hydraulic cylinder is fixedly arranged at the upper and lower ends of the center assembly, according to the eighth end of each embodiment of the present invention The polygonal rod and the rotary sleeve provide the function of directly controlling the rotation of the connecting piece during the telescopic process. The servo motor is used to drive the bevel gear to rotate, and the power is transmitted to the rotating sleeve to drive the octagonal rod to rotate directly to realize the rotation of the connecting piece. , the rotation angle is not limited, and the turnover can be repeated, the hydraulic pressure and the rotation force are effectively combined, the applicability is high, and the assembly is convenient, which solves the problem that the existing hydraulic cylinder is inconvenient to directly provide the effect of rotation control during the expansion and contraction process.

Owner:江苏力速达液压有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com