Heat dissipation frame for new energy automobile battery management

A new energy vehicle and battery management technology, which is applied in the field of heat dissipation frame for battery management of new energy vehicles, can solve the problems of inability to adjust wind power, complicated operation, poor heat dissipation function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

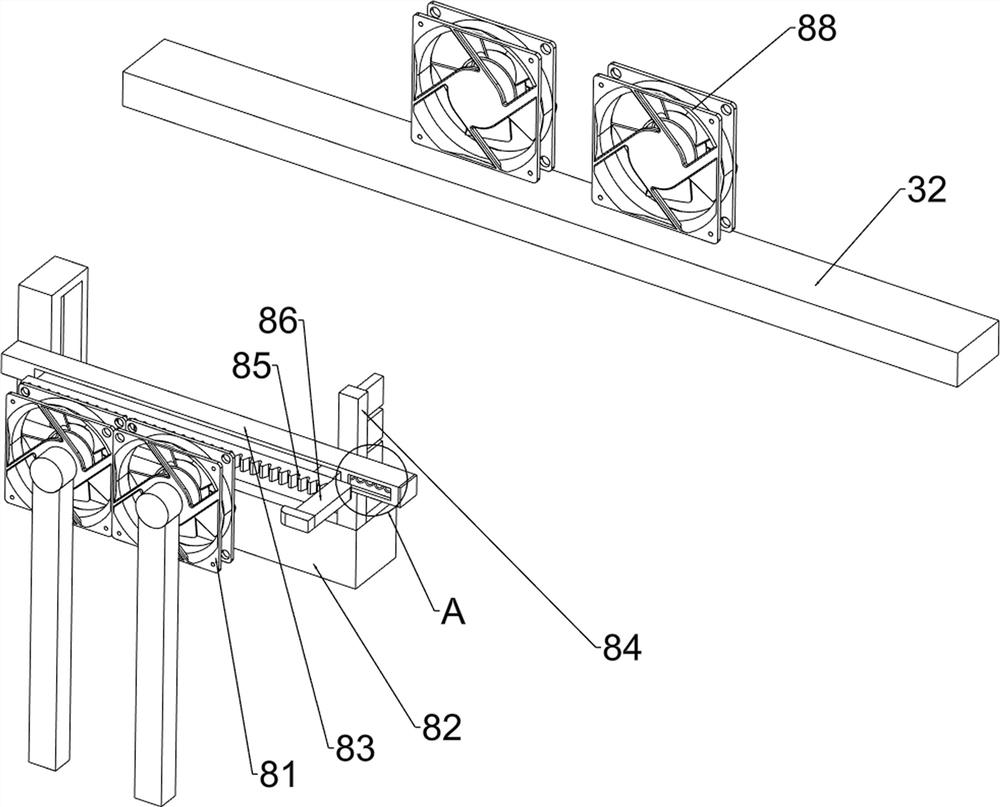

[0030] A cooling frame for new energy vehicle battery management, such as Figure 1-Figure 3 Shown, comprise base plate 1, motor 2, propelling mechanism 3 and launching mechanism 4, base plate 1 upper front side is equipped with motor 2, base plate 1 is provided with propelling mechanism 3, and base plate 1 is provided with launching mechanism 4.

[0031] When people want to dissipate heat from the car battery, they can use this heat dissipation frame for new energy car battery management. First, the user puts the battery on the bottom plate 1, then injects cold water into the water launching mechanism 4, and starts the motor 2. The motor 2 drives the pushing mechanism 3 to run, and the pushing mechanism 3 cooperates with the water launching mechanism 4, so that cold water flows onto the battery through the water launching mechanism 4 to cool down the battery. Motor 2, the above actions all stop.

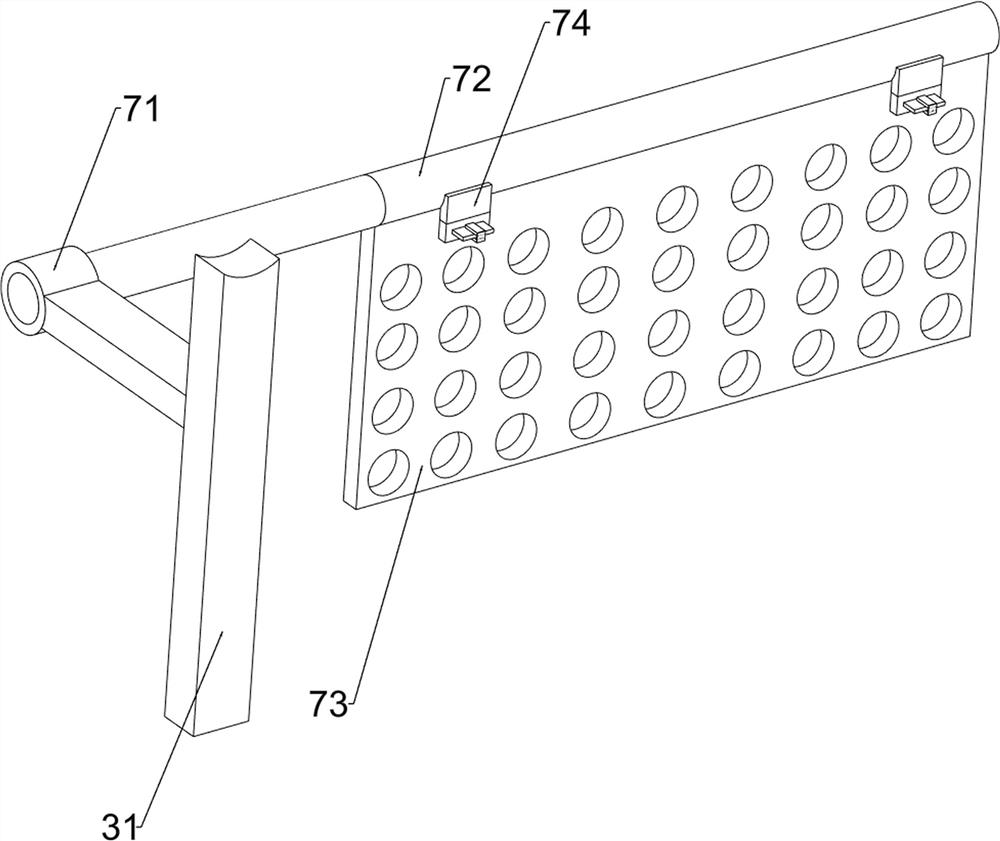

[0032] The pushing mechanism 3 includes a first support frame 31, a first supp...

Embodiment 2

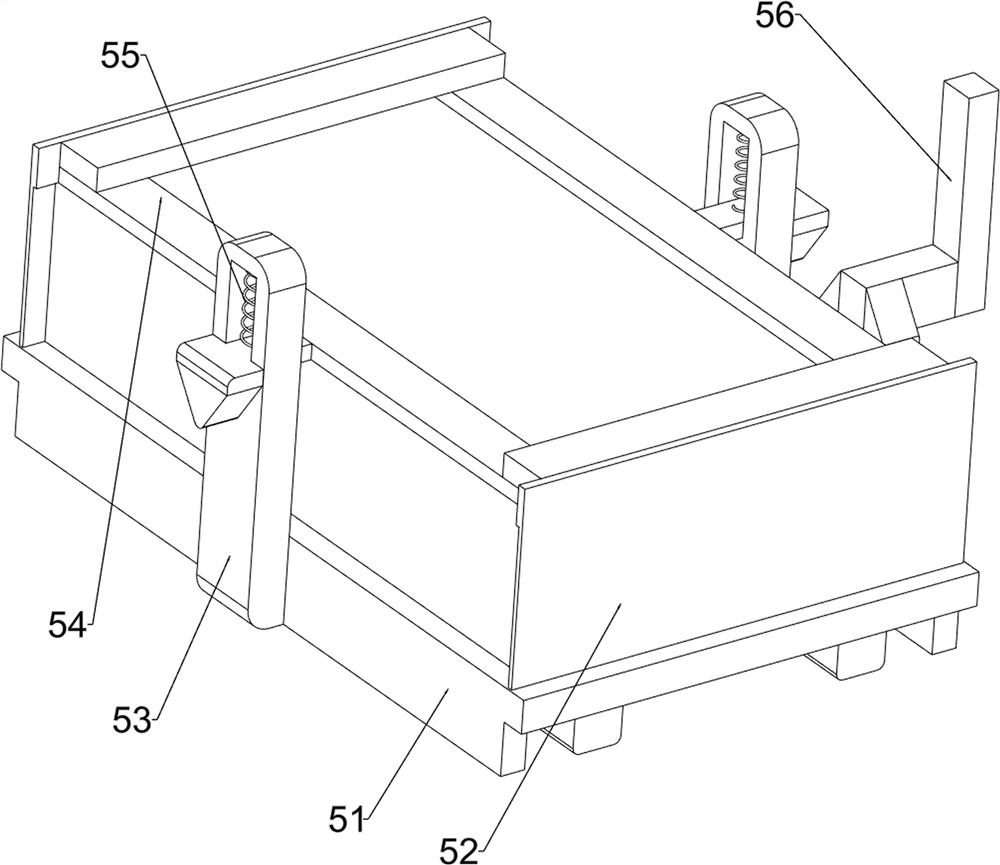

[0037] On the basis of Example 1, such as Figure 4-Figure 11 Shown, also comprise anti-vibration mechanism 5, be provided with anti-vibration mechanism 5 on the first support column 32, anti-vibration mechanism 5 comprises limit frame 51, baffle plate 52, second support column 53, second pressing plate 54, second spring 55 And the 3rd wedge-shaped block 56, the front side of the first support column 32 is provided with a spacer 51, the front and rear sides of the top of the spacer 51 are all provided with baffle plates 52, and the left and right sides of the spacer 51 are all provided with a second support column 53 A second pressure plate 54 is slidingly provided between the two second support columns 53, a second spring 55 is connected between the second pressure plate 54 and the second support column 53, and a third wedge block 56 is provided at the bottom of the push rod 34, The third wedge block 56 cooperates with the second pressing plate 54 .

[0038] When the push ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com