Jean clothing hole breaking equipment

A clothing and hole-breaking technology, applied in textile and papermaking, fabric surface trimming, thorn patterns, etc., can solve the problems such as the inability to automatically clamp denim clothing, the inability to automatically transport denim clothing, and the inability to precisely pierce denim clothing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

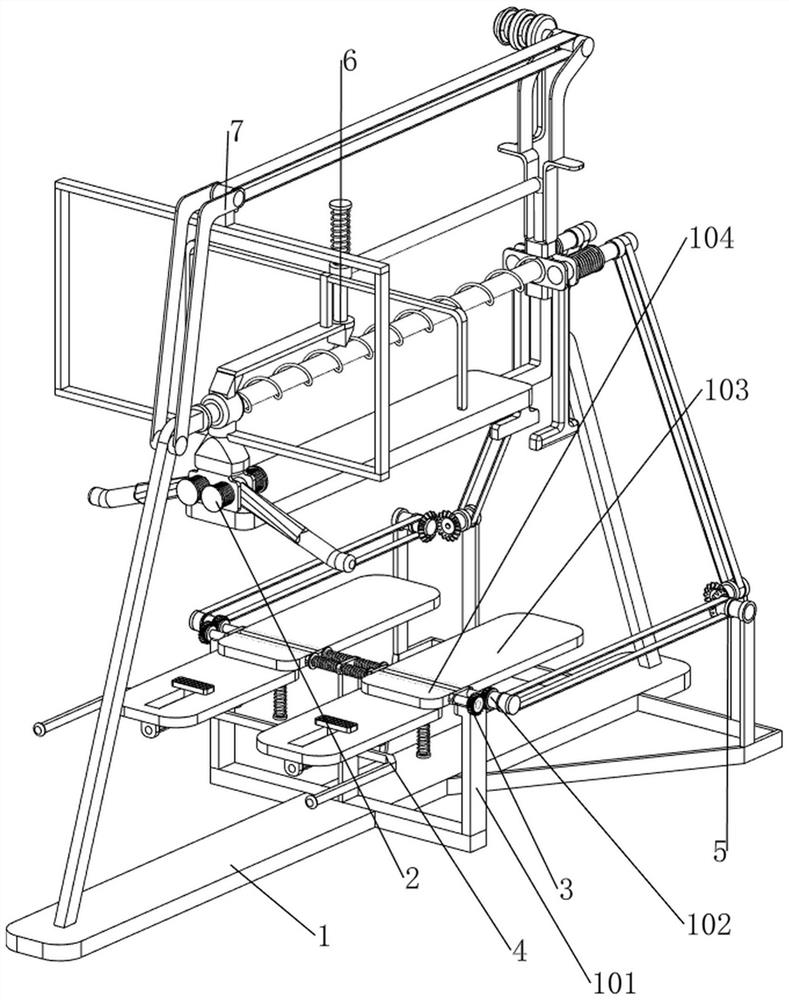

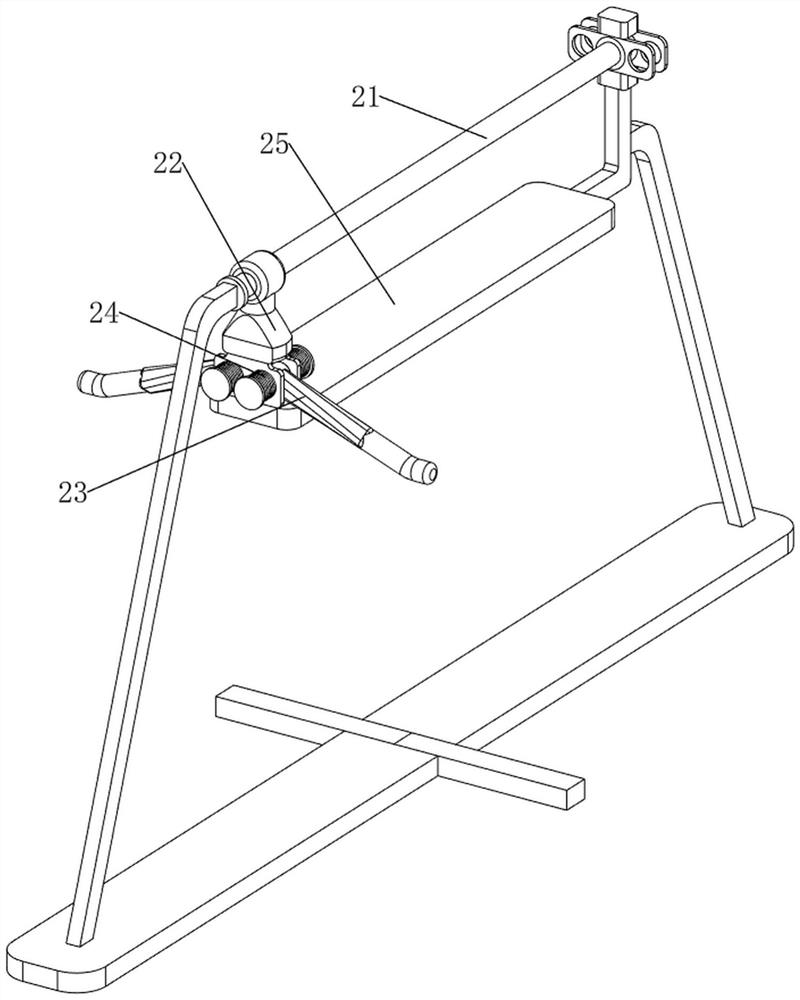

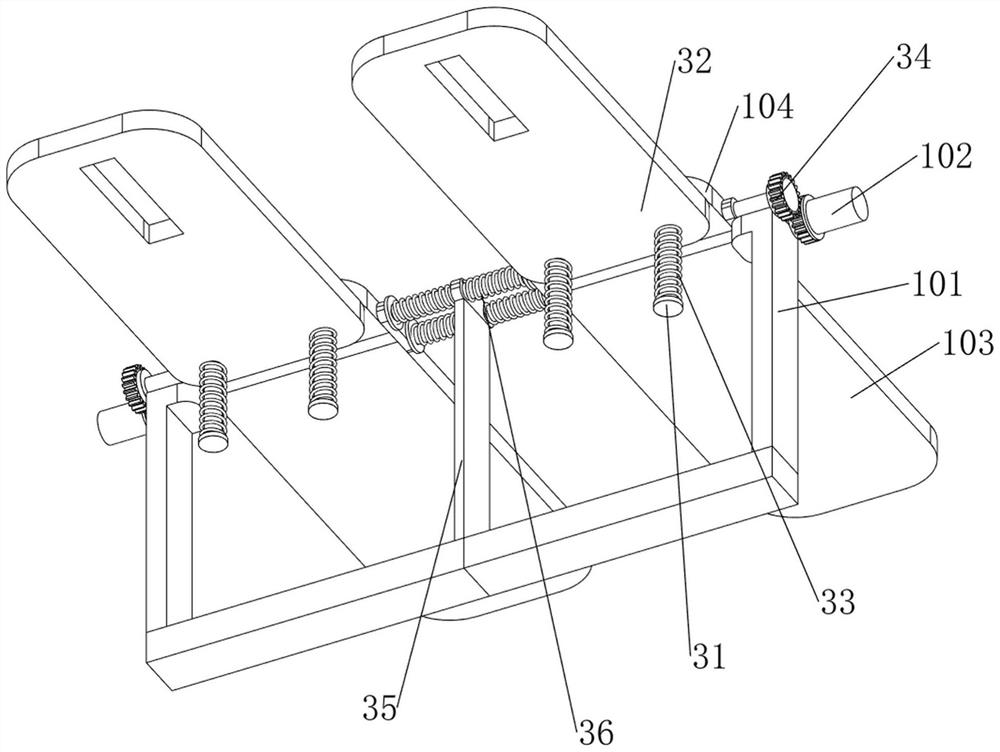

[0065] A denim clothing hole device, such as Figure 1-Figure 3 As shown, it includes a base plate 1, a rotating support rod 101, a first rotating shaft 102, a first rotating clamping plate 103, a second rotating clamping plate 104, a clothes putting mechanism 2 and a rotating clamping mechanism 3, and the upper, middle, left and right sides of the base plate 1 Rotating support rods 101 are arranged on both sides, and the first rotating shaft 102 is rotationally connected between the upper parts of the two rotating supporting rods 101. The number of the first rotating shafts 102 is two. The clamping plate 103 is provided with a second rotating clamping plate 104 on the first rotating shaft 102 on the front side, the clothes putting mechanism 2 is provided on the bottom plate 1 , and the rotating clamping mechanism 3 is provided on the rotating support rod 101 .

[0066] When people want to break copper on denim clothing, they can use this denim clothing hole-breaking device. F...

Embodiment 2

[0072] On the basis of Example 1, such as Figure 4-Figure 7 As shown, a hole scraping mechanism 4 is also included, and a hole scraping mechanism 4 is provided between the two second rotating clamping plates 104. The hole scraping mechanism 4 includes a first sliding sleeve 41, a sliding scraper 42 and a second spring 43 , the front sides of the bottoms of the two second rotating clamping plates 104 are provided with a first sliding sleeve 41, and a sliding scraper 42 is slidably connected between the two first sliding sleeves 41, and the left and right sides of the sliding scraper 42 are wound with The second spring 43 is connected to the first sliding sleeve 41 and the sliding scraper 42 at both ends of the second spring 43 respectively.

[0073] After the jeans are clamped by the first rotating clamping plate 103 and the second rotating clamping plate 104, when the second rotating clamping plate 104 is turned to a vertical angle, the user pulls the sliding scraper 42 upwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com