Omnibearing paint spraying equipment for case shell processing

A technology for chassis shells and painting equipment, which is applied in the direction of spraying devices, can solve problems such as inability to achieve painting effects, and achieve the effects of increasing painting effects, high reliability, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

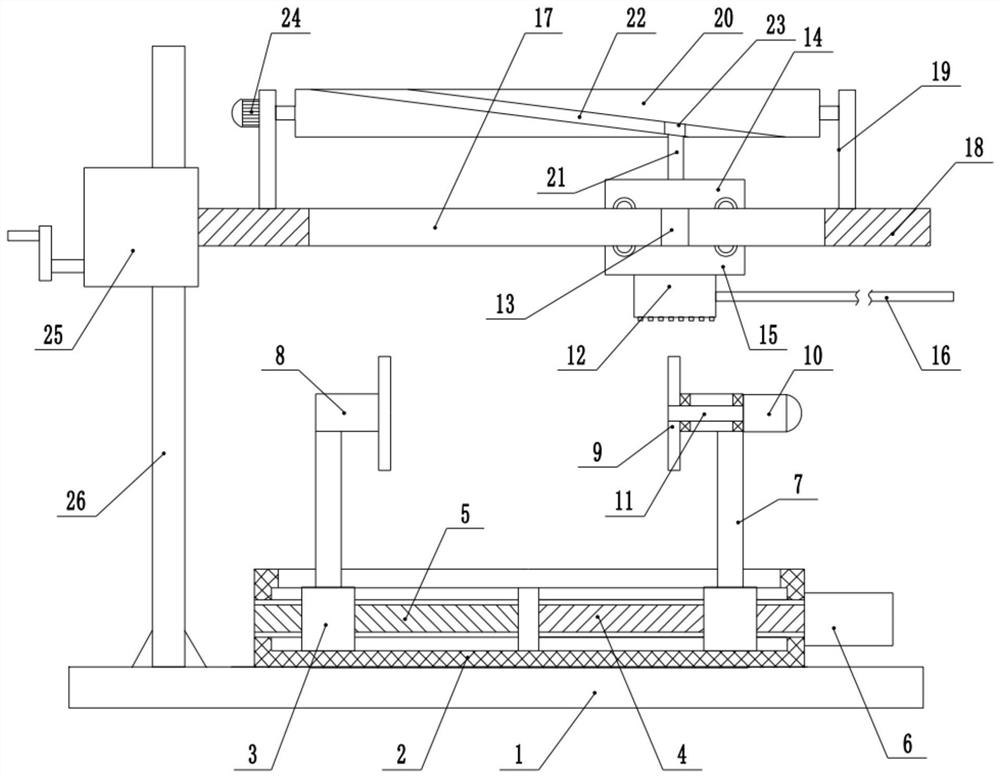

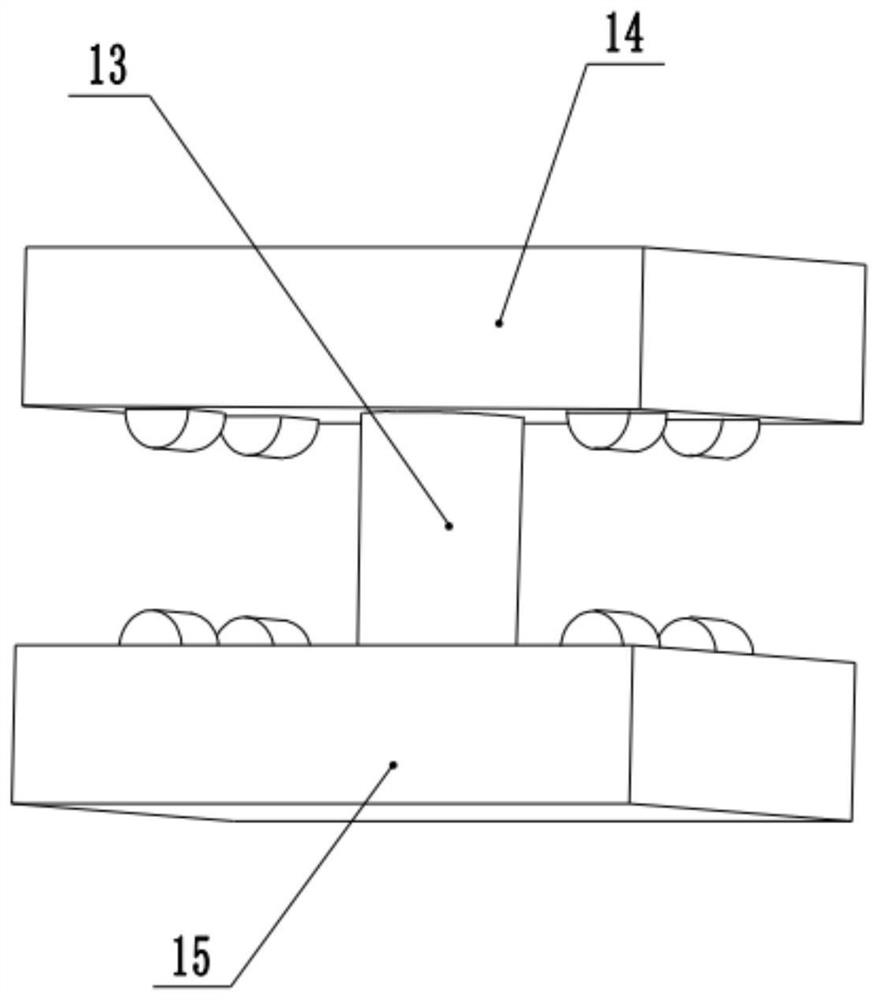

[0030] refer to Figure 1~3 , in an embodiment of the present invention, an all-round painting equipment for chassis shell processing, including a fixed bottom plate 1, a fixed frame 2 is installed in the middle of the upper end of the fixed bottom plate 1, and a left-handed screw 5 and a right-handed screw are fixedly connected inside the fixed frame 2 4. By setting the left-handed screw 5 and the right-handed screw 4, the moving directions of the two moving blocks 3 are opposite during the rotation of the two screws. The right side of the right-handed screw 4 passes through the fixed frame 2 and is connected with The screw motor 6 is used to drive the two screw rods to rotate accordingly. The middle part of the left-handed thread and the right-handed thread is respectively equipped with a moving block 3, and the middle part of the moving block 3 is respectively provided with a left-handed screw 5 and a right-handed screw 4. internally threaded holes, so that the rotational m...

Embodiment 2

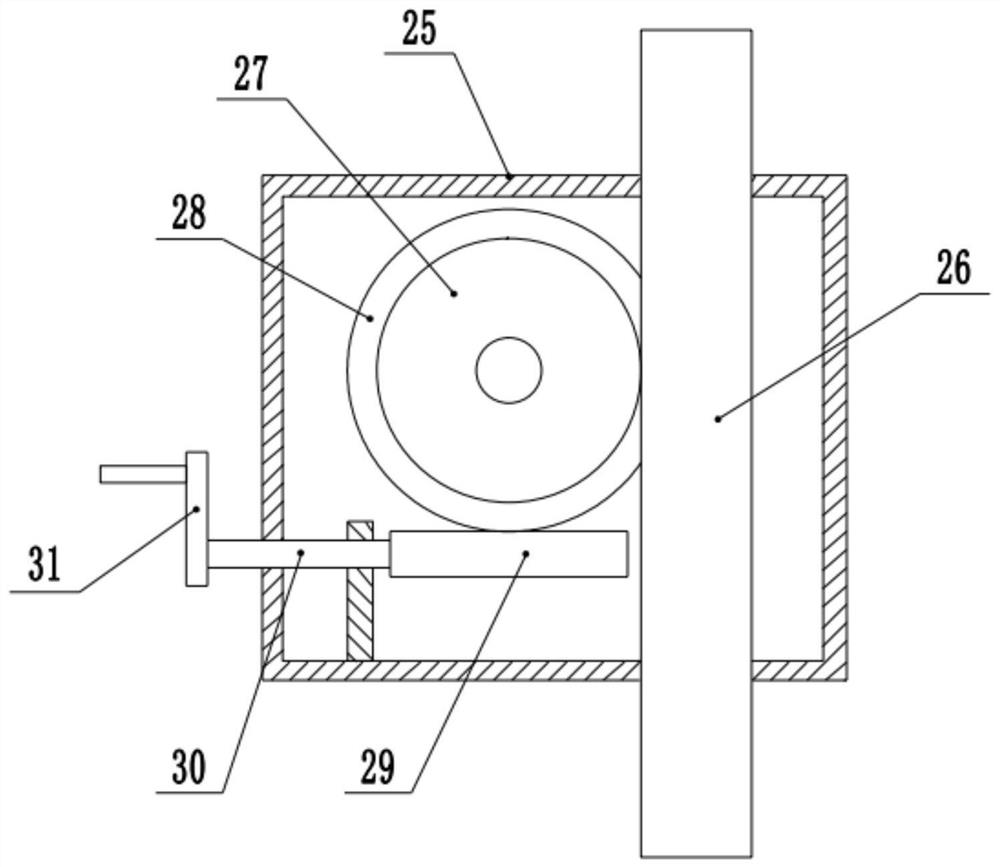

[0032]In another embodiment of the present invention, an all-round paint spraying equipment for the processing of chassis shells includes a fixed base plate 1, a fixed frame 2 is installed in the middle of the upper end of the fixed base plate 1, and a left-handed screw 5 and a left-handed screw rod 5 are fixedly connected inside the fixed frame 2 Right-handed screw 4, the right side of the right-handed screw 4 passes through the fixed frame 2 and is connected with a screw motor 6, the middle part of the left-handed thread and the right-handed thread is respectively equipped with a moving block 3, and the middle part of the moving block 3 is respectively provided with a left-handed screw and a left-handed screw. The screw rod 5 and the right-handed screw rod 4 are internally threaded holes that cooperate with each other. The upper end of the moving block 3 is equipped with a moving frame 7. The upper end of the moving frame 7 is equipped with a rotating cylinder 8. The rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com