Patents

Literature

163results about How to "Improve the effect of spray paint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

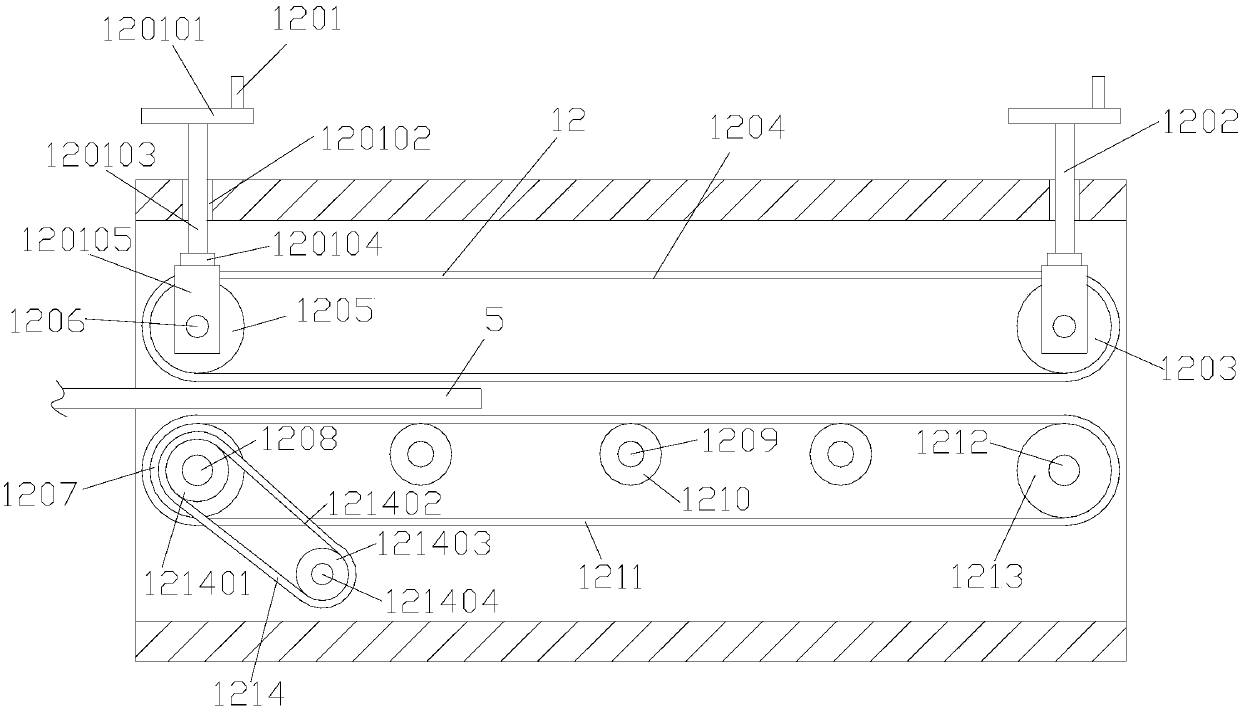

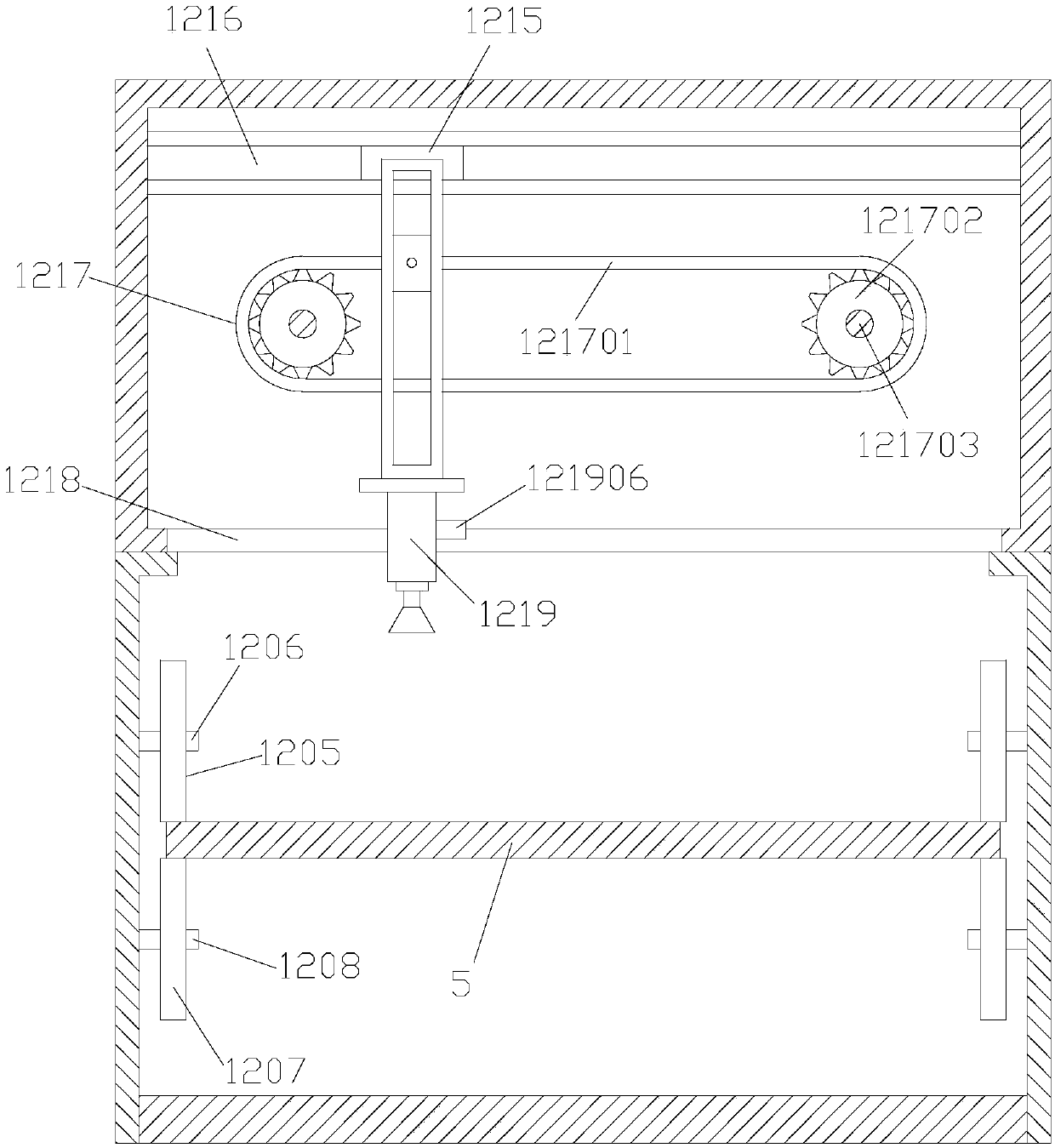

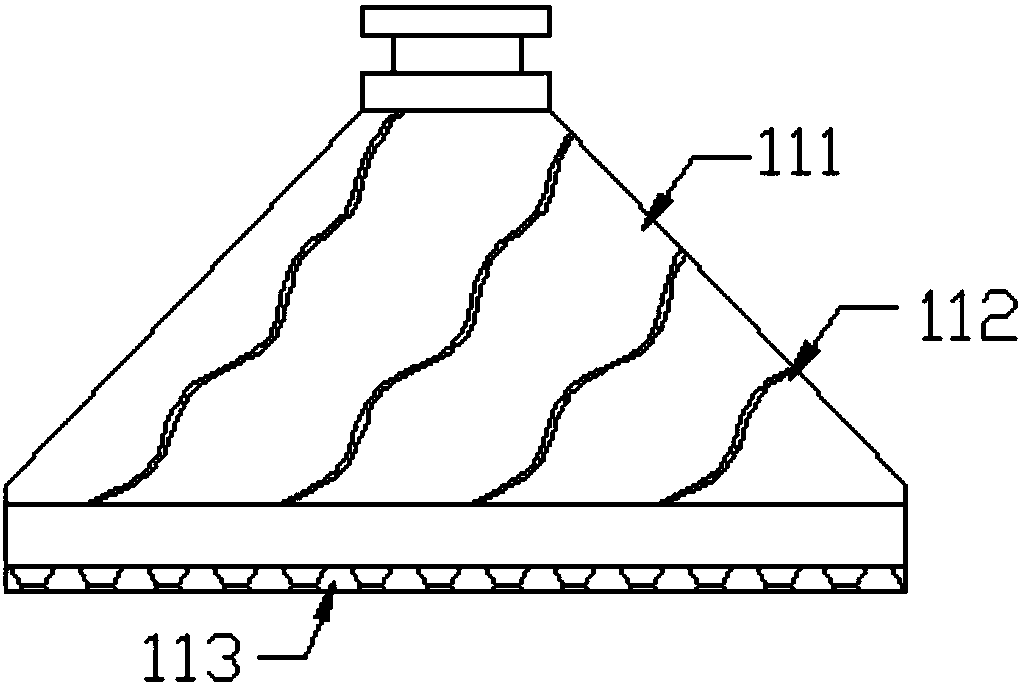

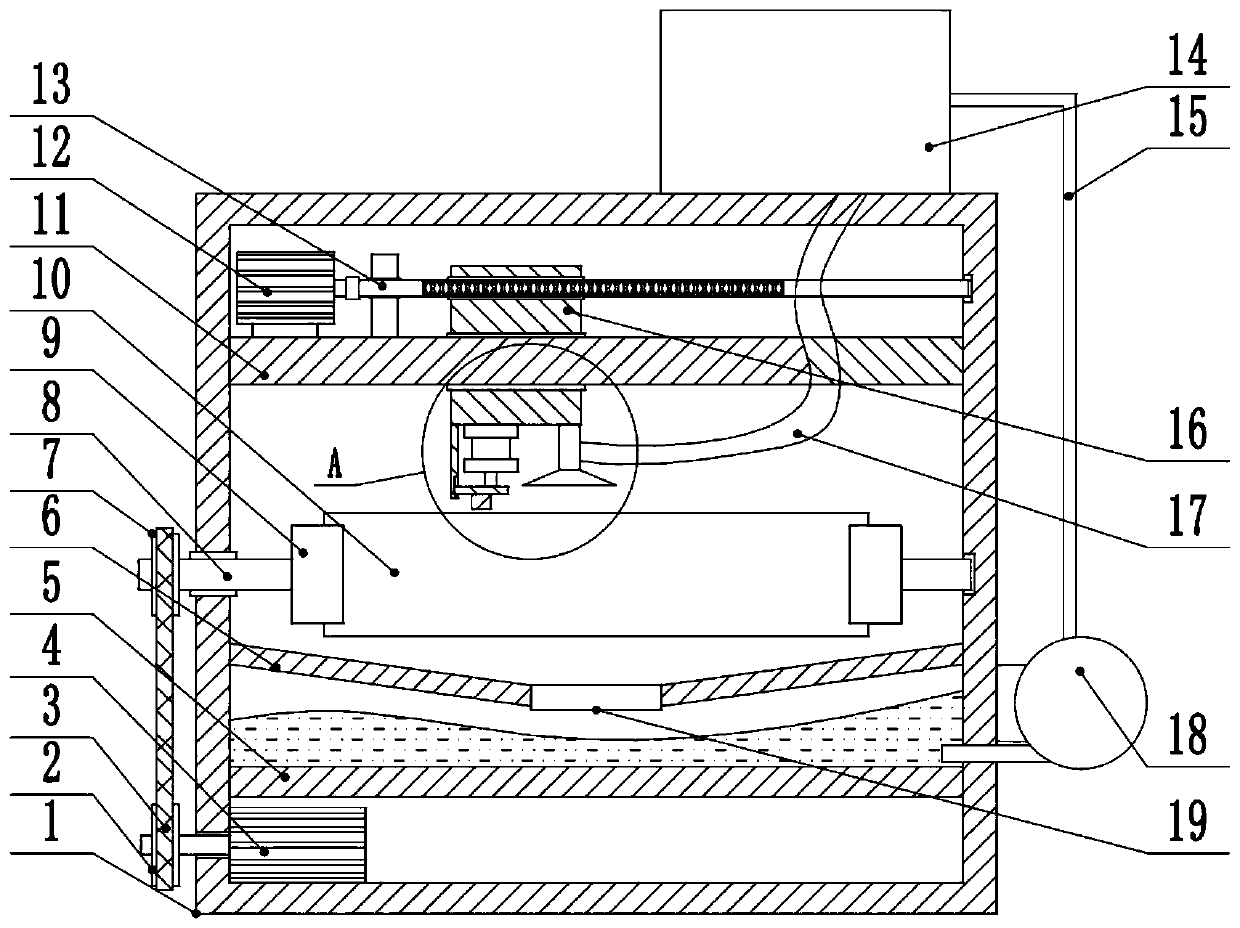

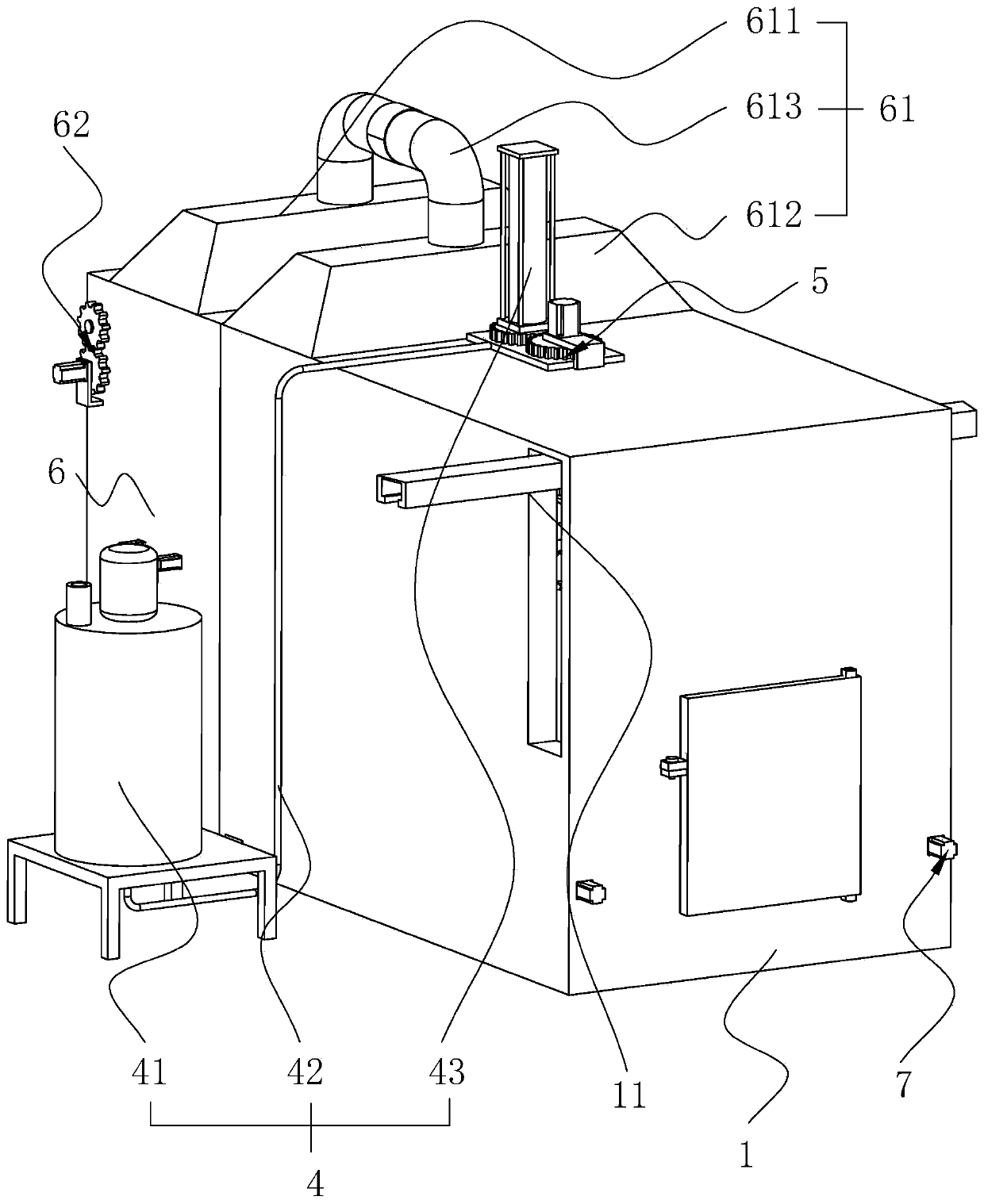

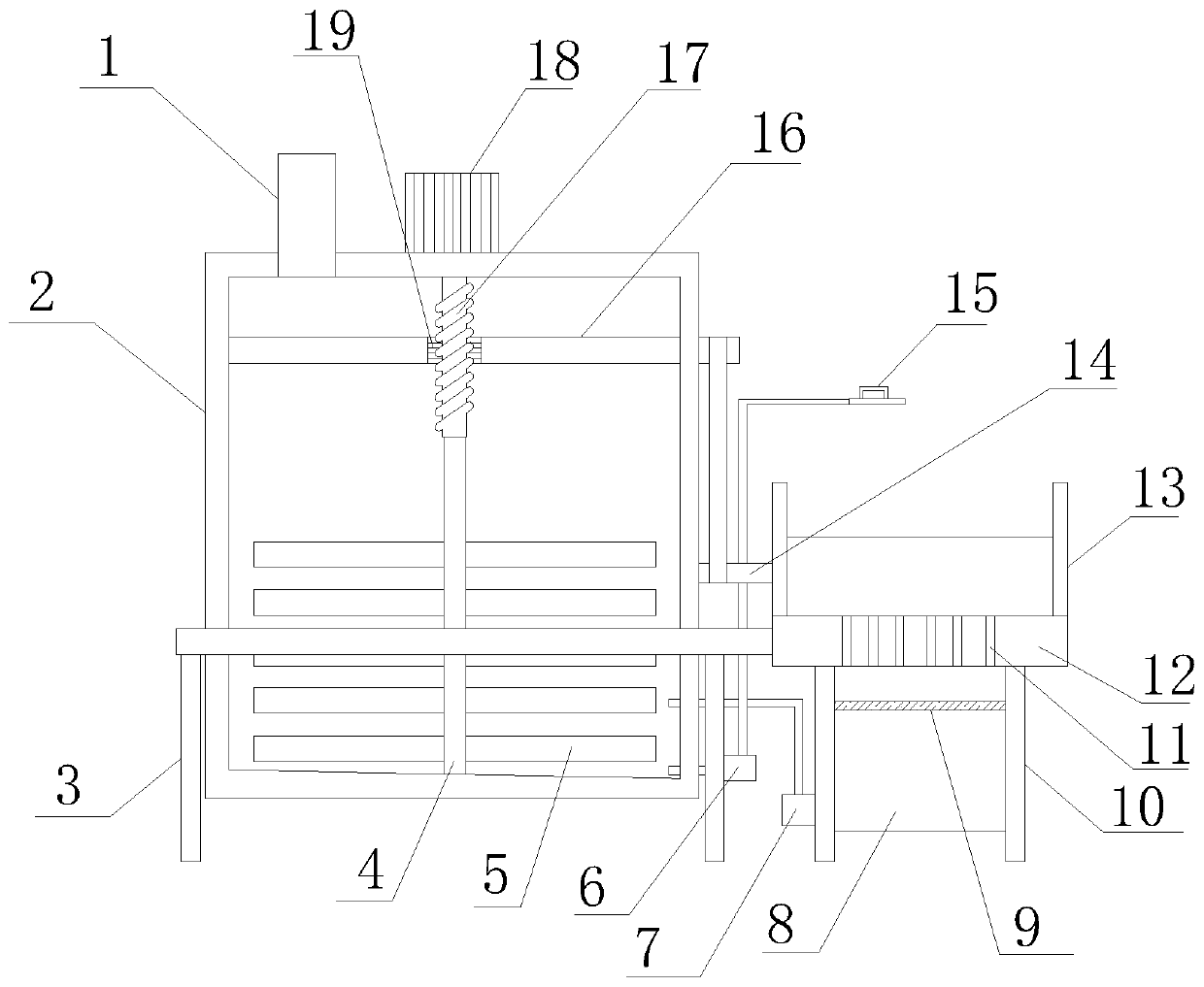

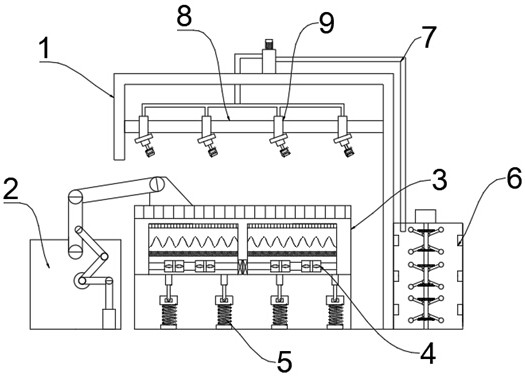

Paint-spraying device with desusting and drying integrated structure

InactiveCN109261416AGuaranteed long-term useSolving Recycling ProblemsPretreated surfacesLiquid spraying apparatusSprayerEngineering

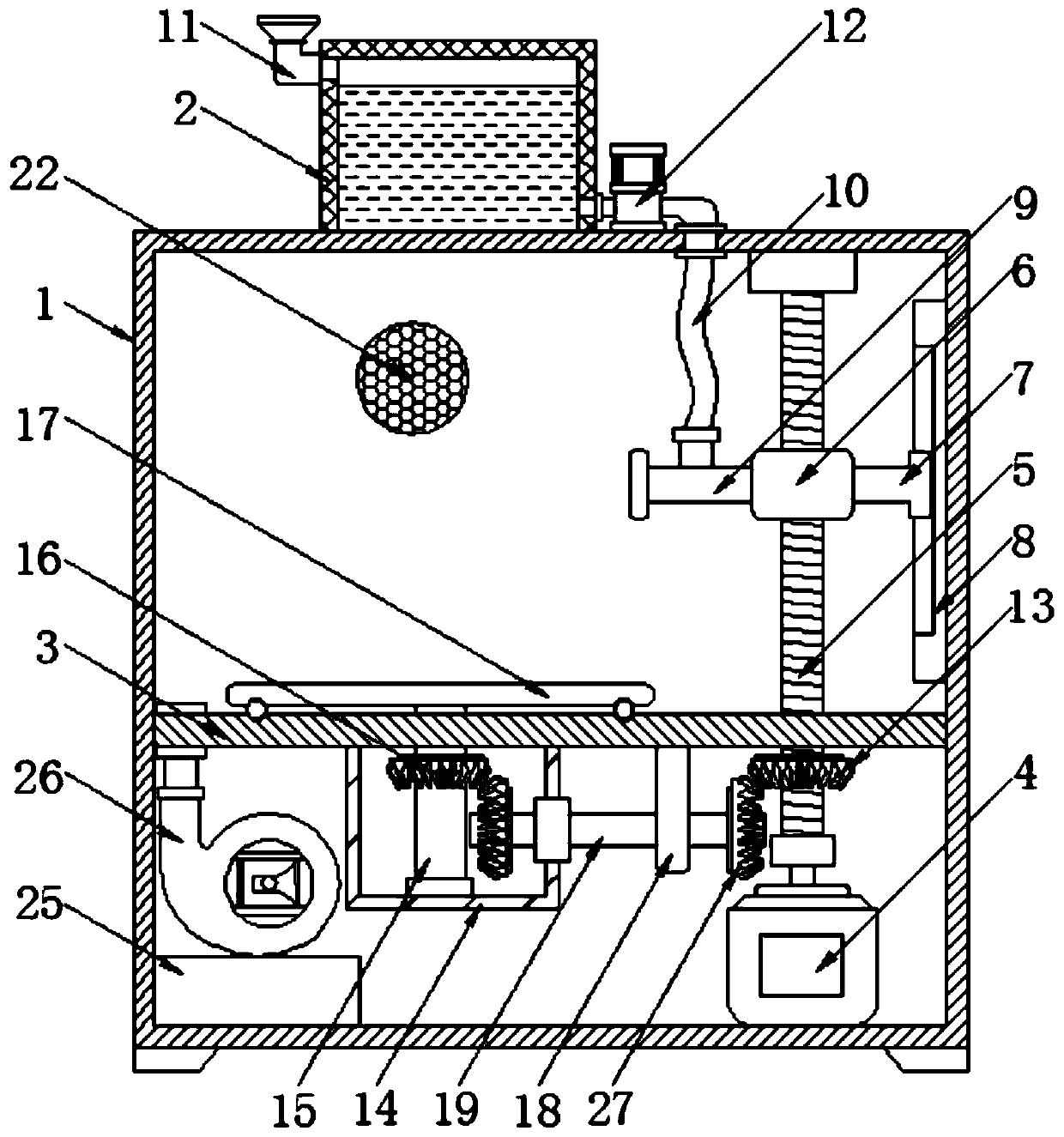

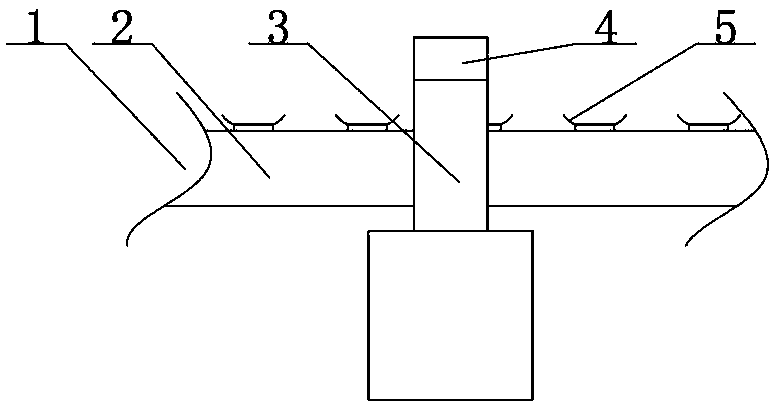

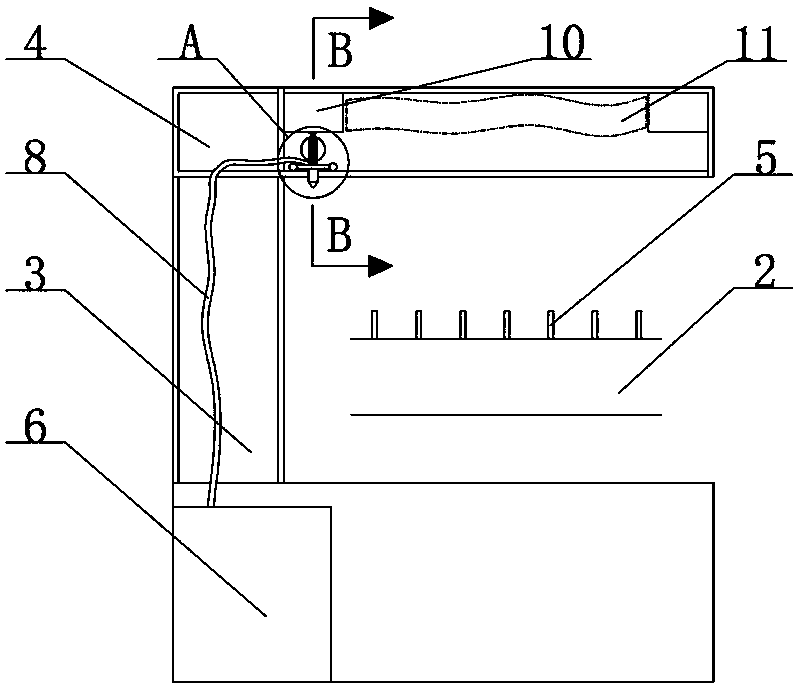

The invention relates to the field of paint spraying, and particularly discloses a paint-spraying device with a desusting and drying integrated structure. The paint-spraying device comprises a shell,a conveying belt, a feeding inlet, a discharging outlet and a paint collection tank, wherein a dust suction hood, an installation support and a drying cavity are arranged / formed above the conveying belt from left to right in sequence; a plurality of brush rollers are arranged below the dust suction hood, the dust suction hood is communicated with a dust suction blower, and the installation supportis fixedly connected with an electrical telescoping rod which stretches and retracts in the vertical direction; a vertical hot air suction pipe is arranged on the outer portion on the left side of the drying cavity, and a wind deflector with adjustable height is arranged on the left side of the hot air suction pipe. By means of the drying cavity, the paint on the surface of wood can be quickly dried, meanwhile, hot air overflows outwards can be recycled, the hot air is prevented from flowing to the position of a paint sprayer, the paint is prevented from being dried in the sprayer, it is ensured that the paint sprayer is used for a long time, and the service life is prolonged.

Owner:湖南匡沐环保科技有限公司

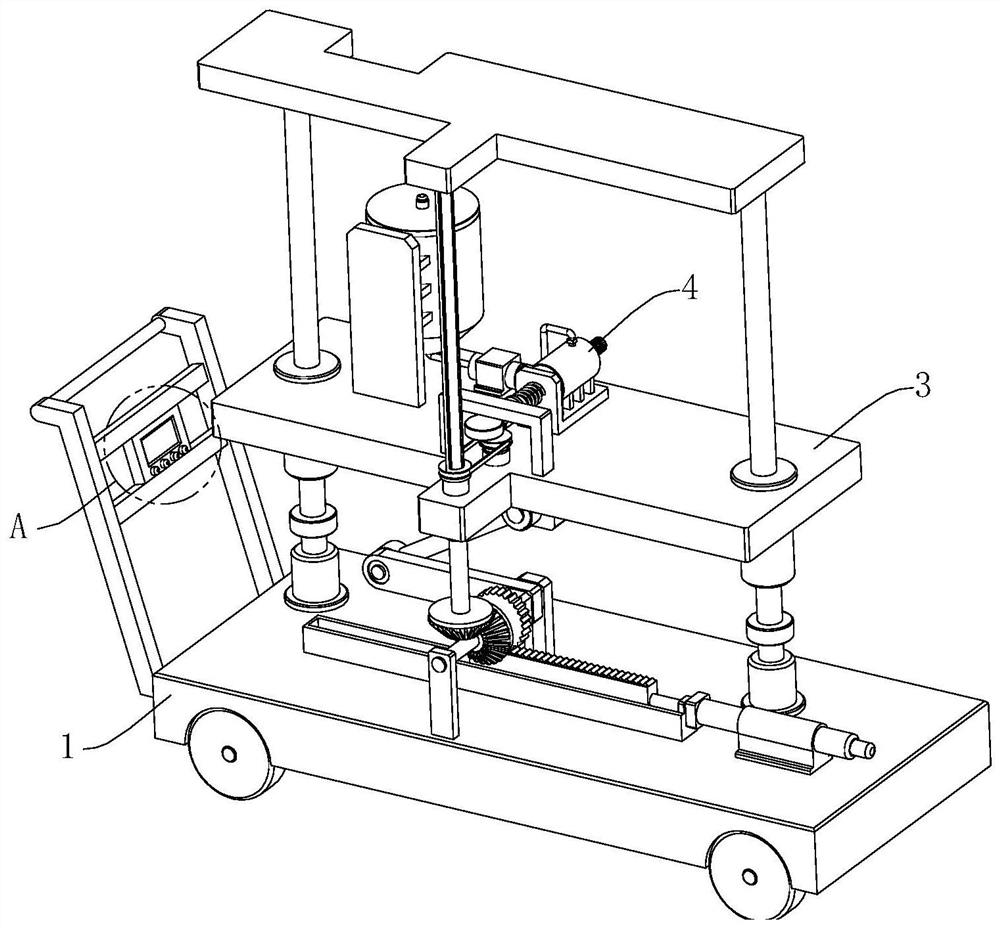

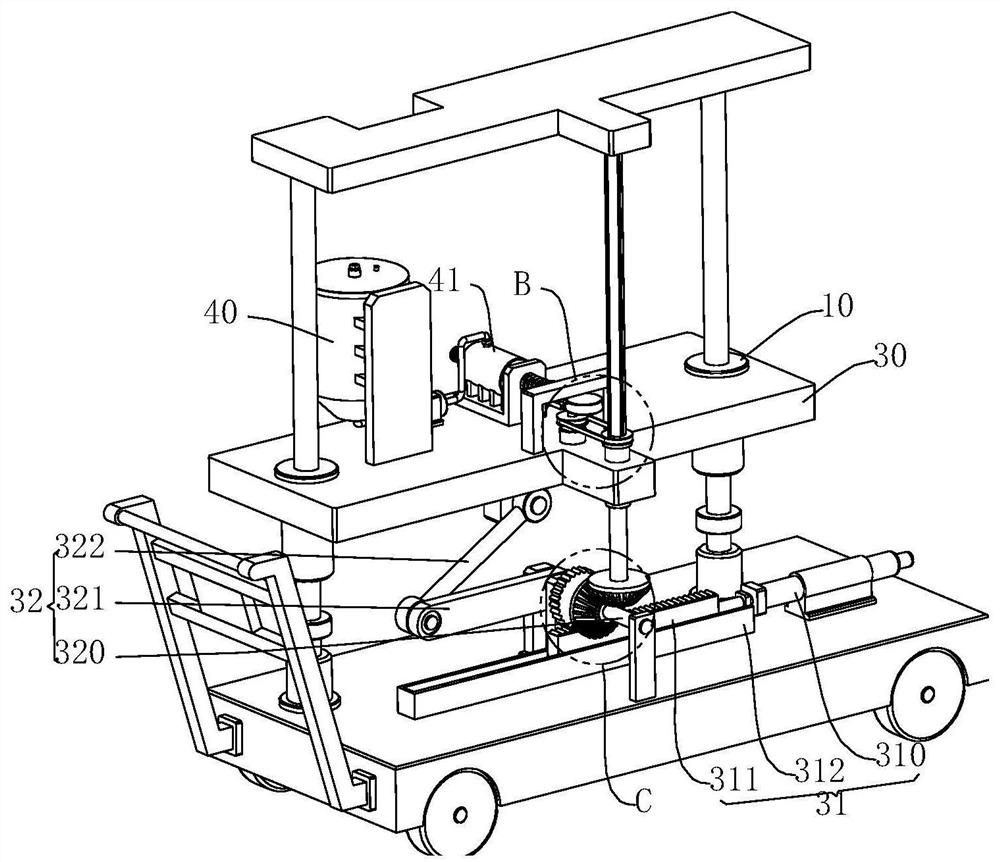

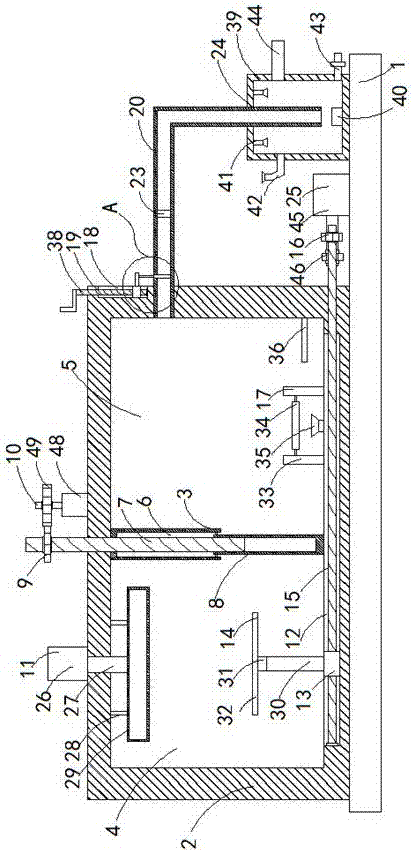

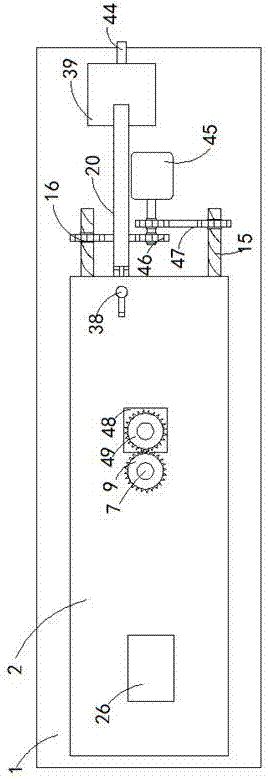

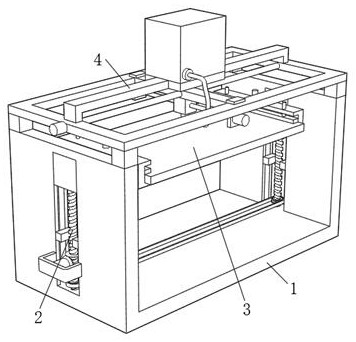

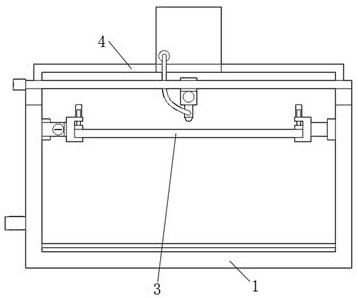

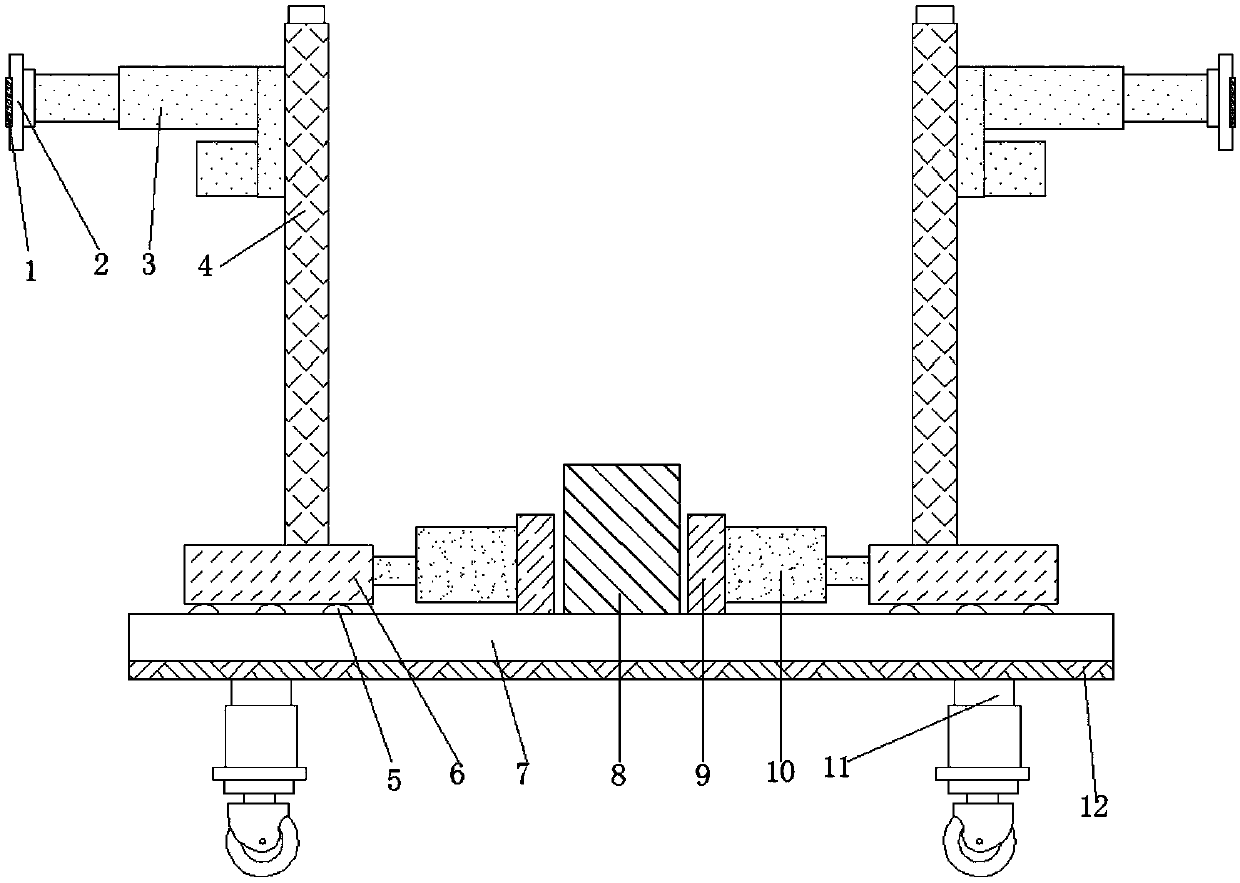

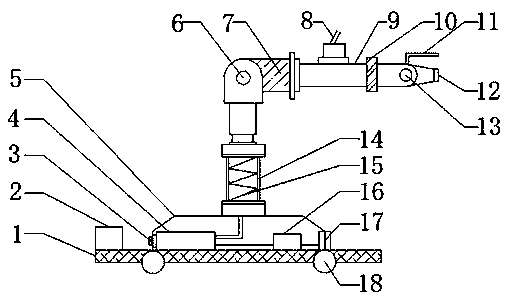

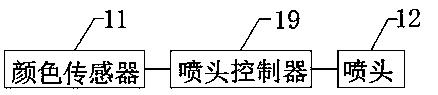

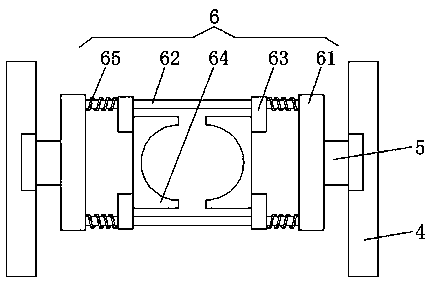

Painting device and method with lifting and spraying-adaptive for indoor decoration

ActiveCN111841927ASpray evenlyAvoid wastingBuilding constructionsLiquid spraying apparatusStructural engineeringAerosolization

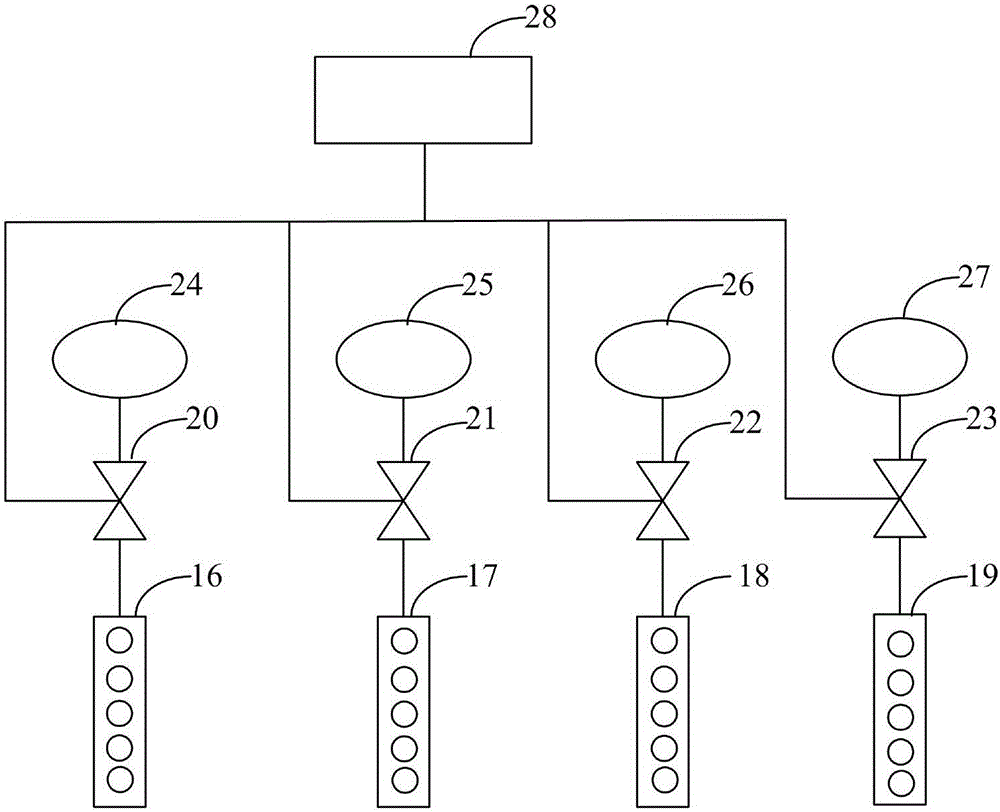

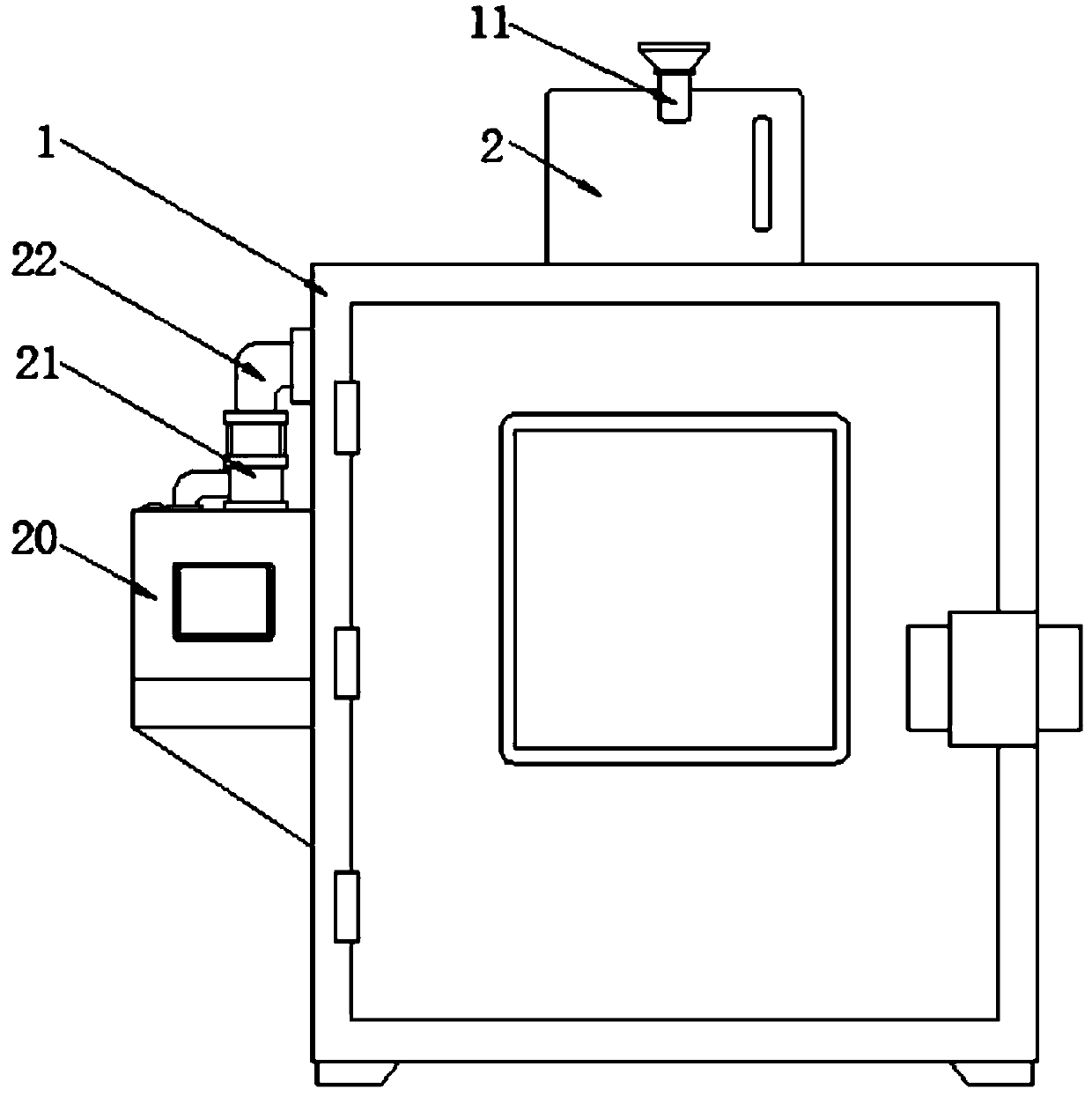

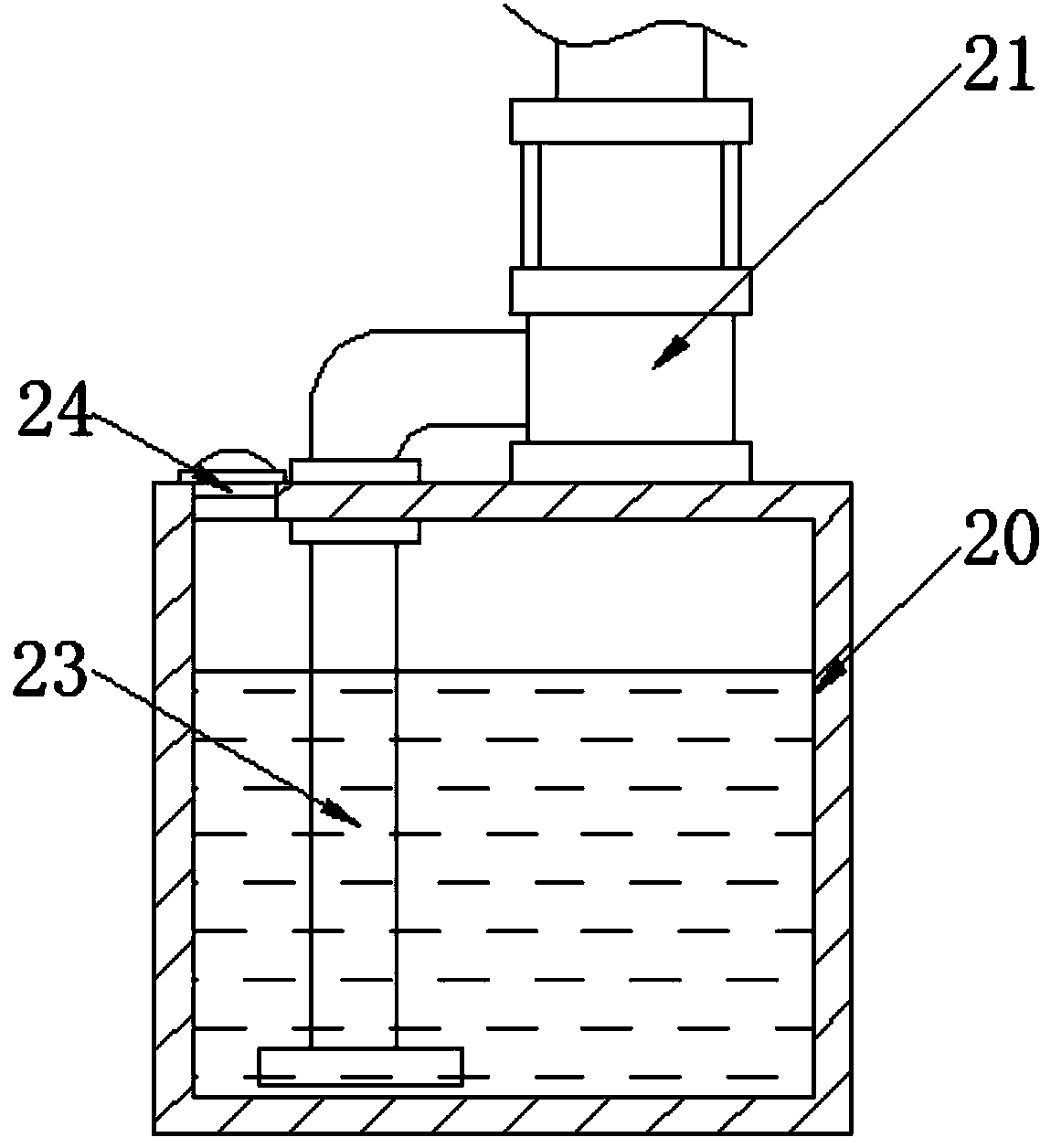

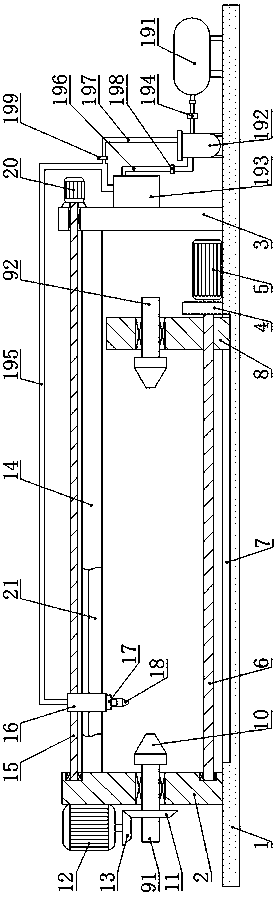

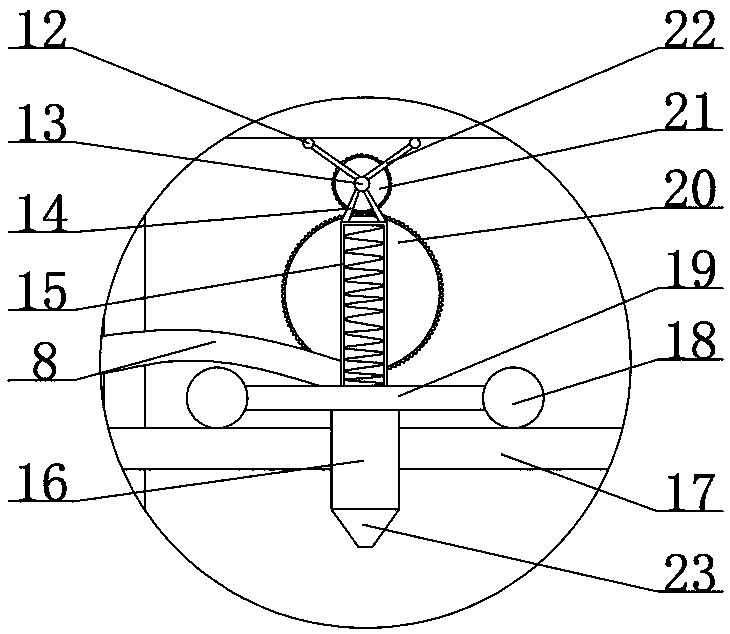

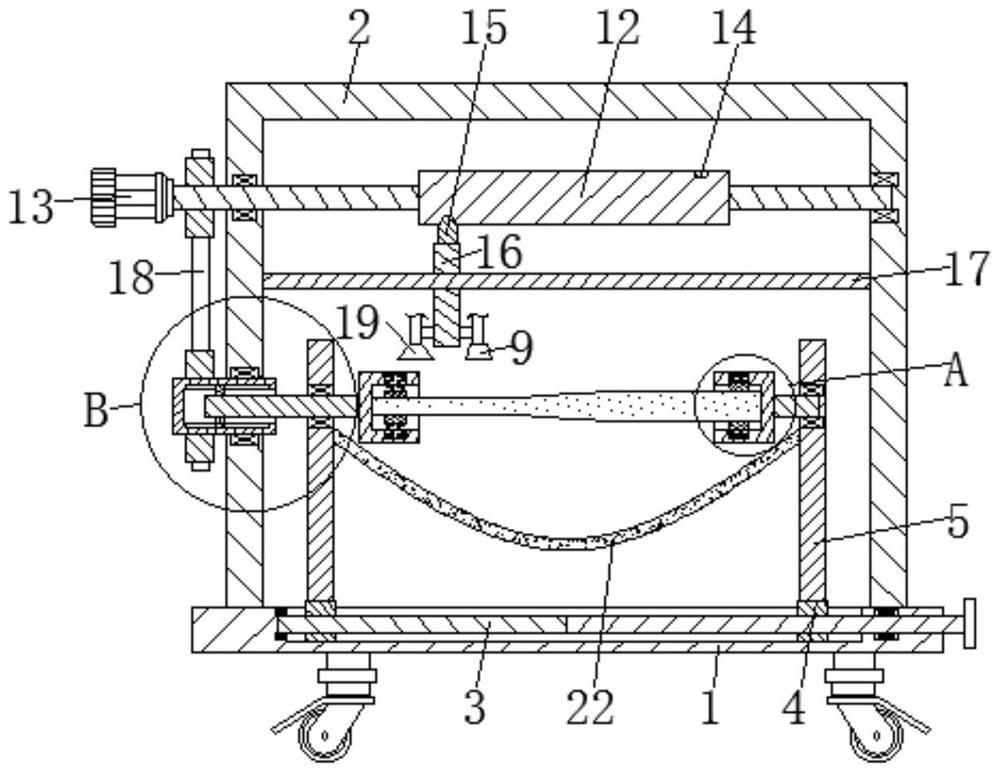

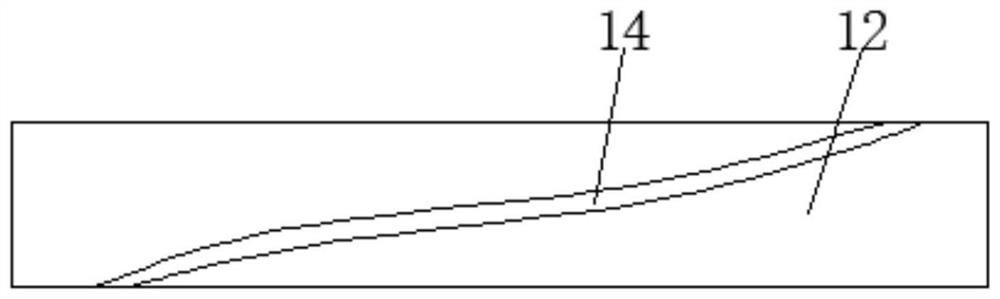

The invention relates to the field of decoration devices, in particular to a painting device and method with lifting and spraying-adaptive for indoor decoration. The device comprises a platform cart,and further comprises a controller, a lifting mechanism and a spraying mechanism, wherein the lifting mechanism is arranged at the top of the platform cart to support lifting of the spraying mechanism; the lifting mechanism comprises a lifting plate, a pushing assembly and a jacking assembly; the spraying mechanism is arranged at the top of the lifting plate for painting the indoor wall surface; and the spraying mechanism comprises a storage barrel, a material receiving pipe, an atomizing nozzle, an extrusion assembly and a conveying assembly, wherein the pushing assembly and the conveying assembly are electrically connected with the controller. According to the painting device and method with lifting and spraying-adaptive for the indoor decoration, the wall surface can be synchronously sprayed when the atomizing nozzle rises, so that the power consumption is small, and in the lifting interval, spraying is in an on-off state, and waste of paint materials is effectively avoided; and meanwhile, when the air temperature is low, the anti-curing function is achieved, and thus the paint spraying efficiency is improved.

Owner:银丰工程有限公司

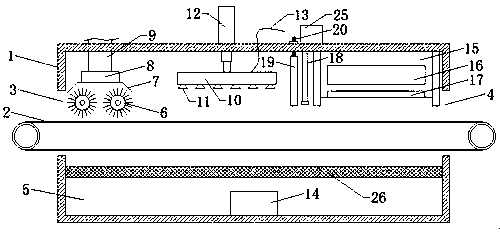

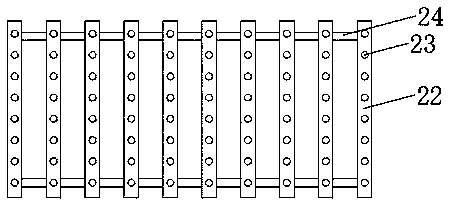

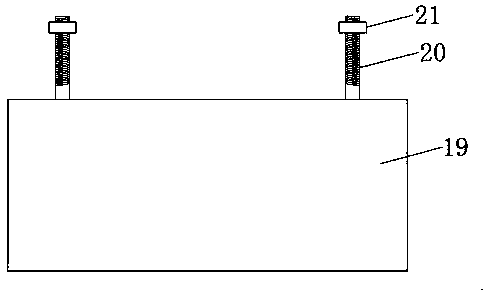

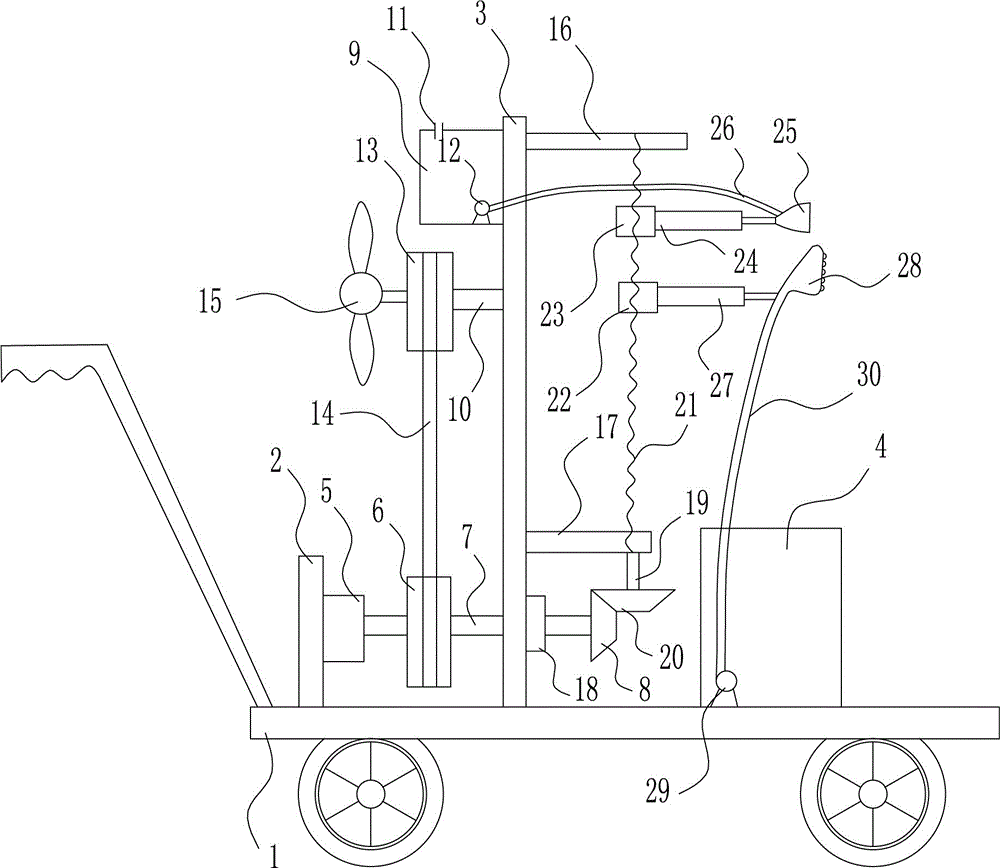

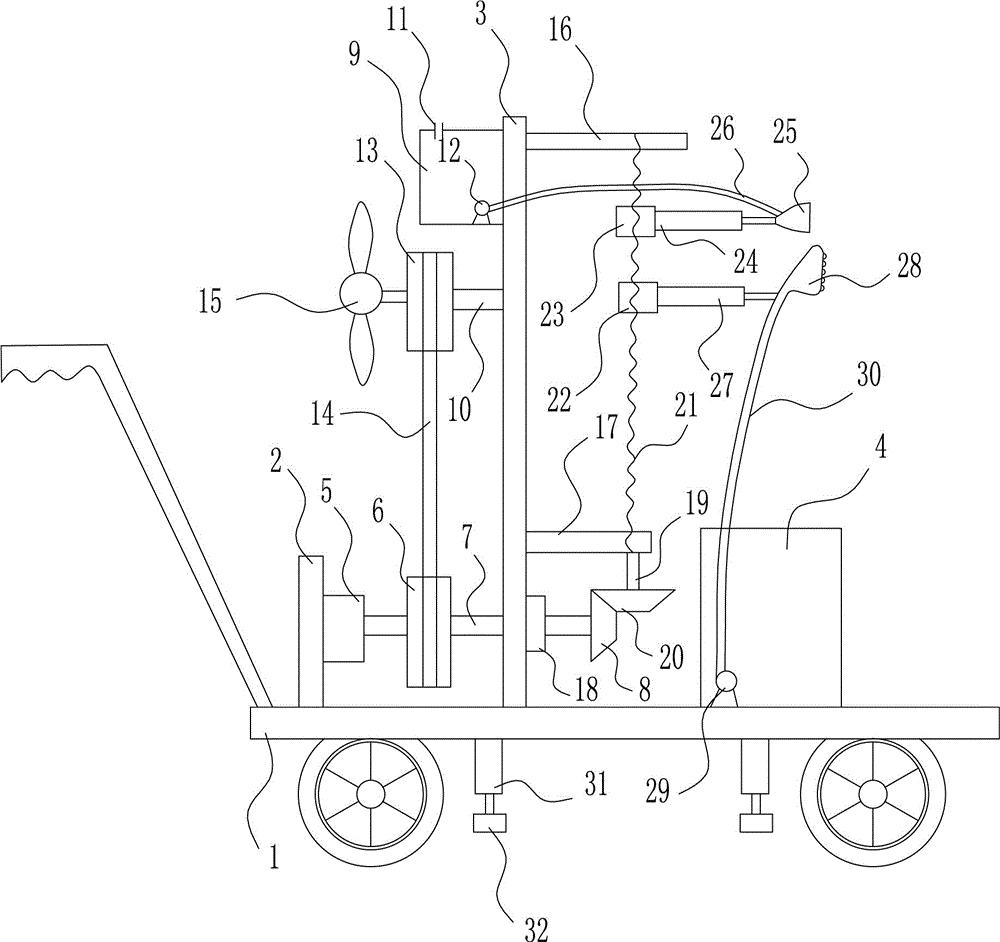

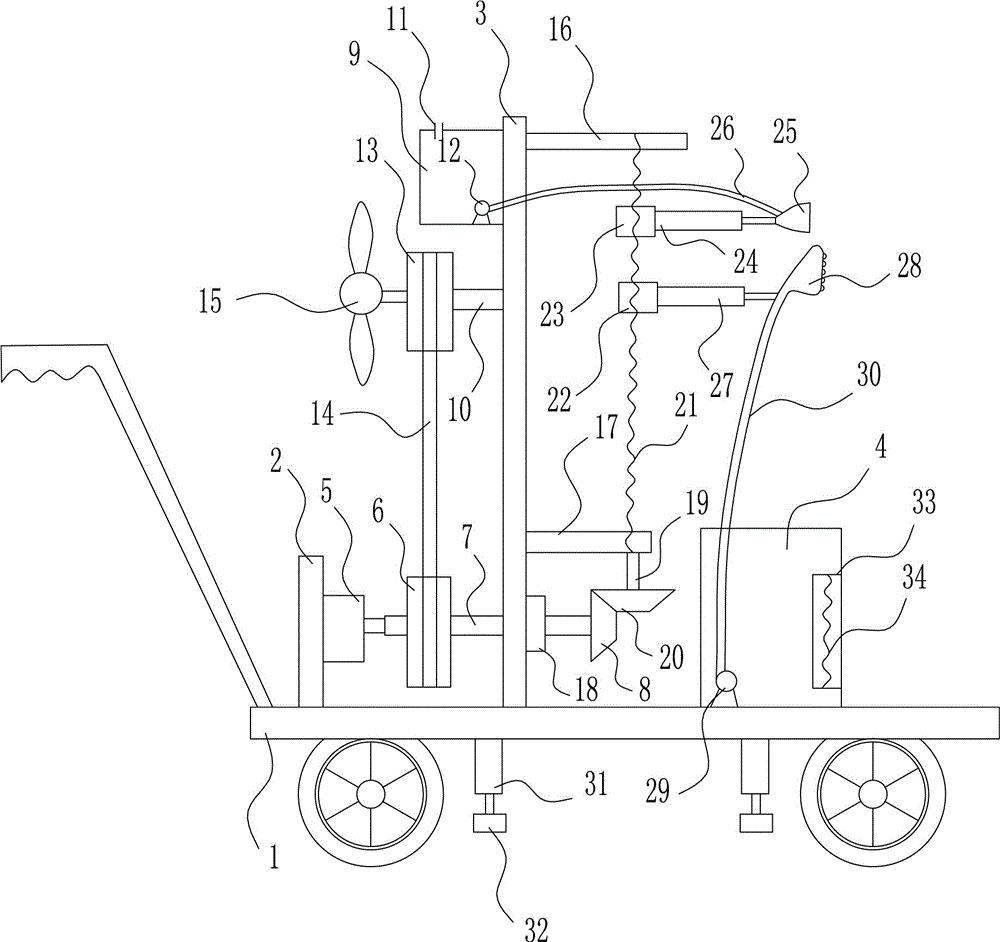

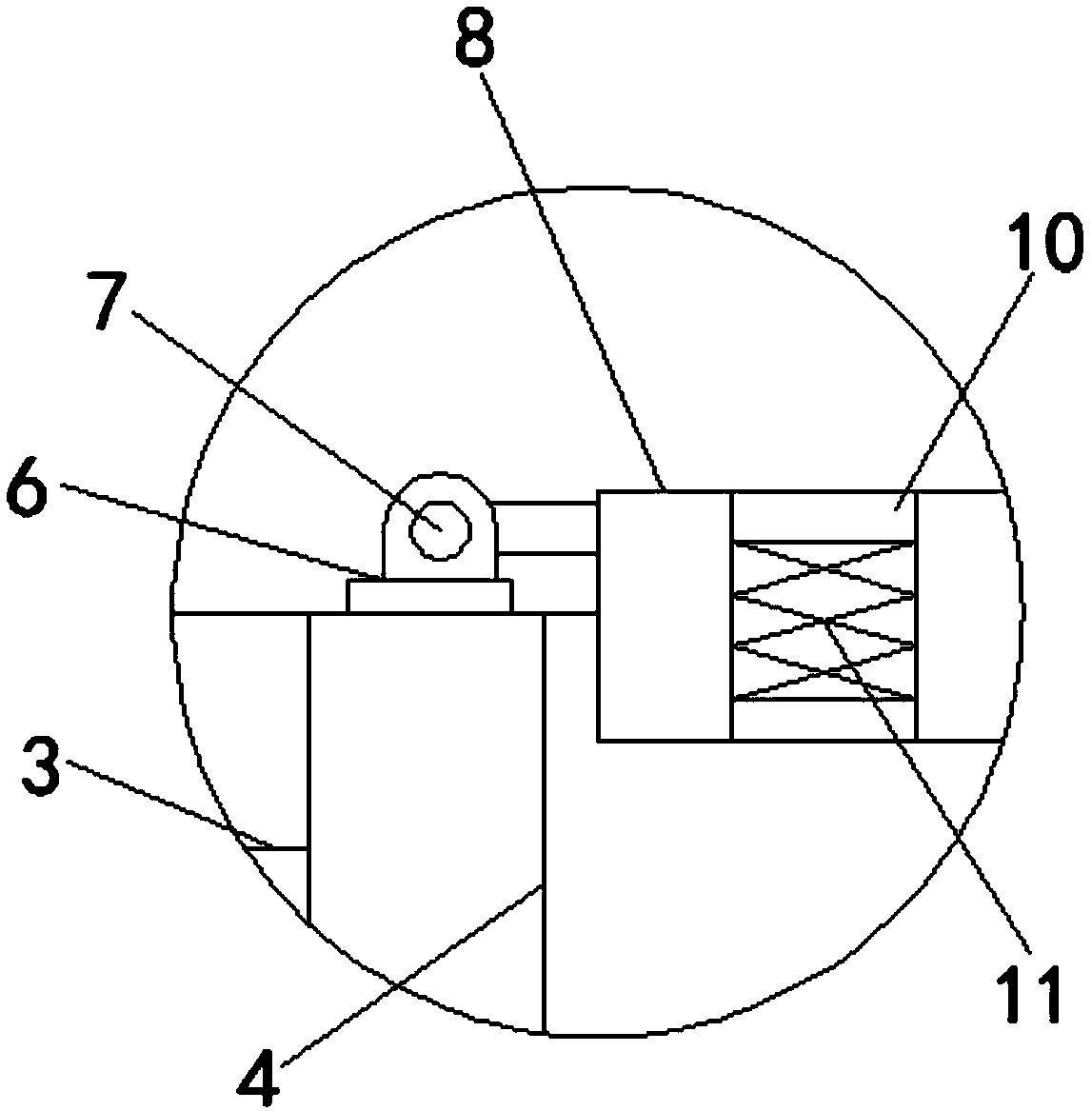

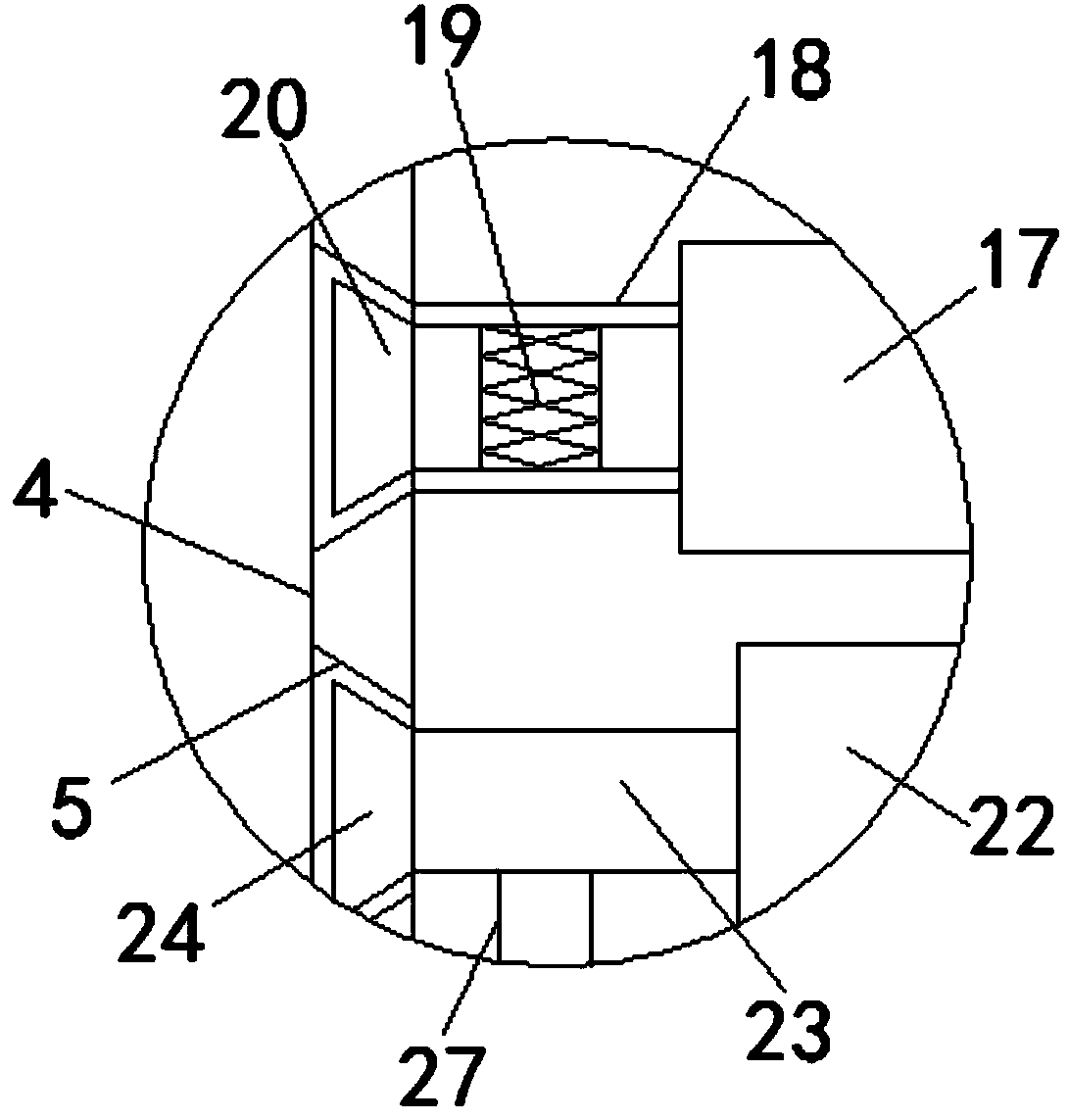

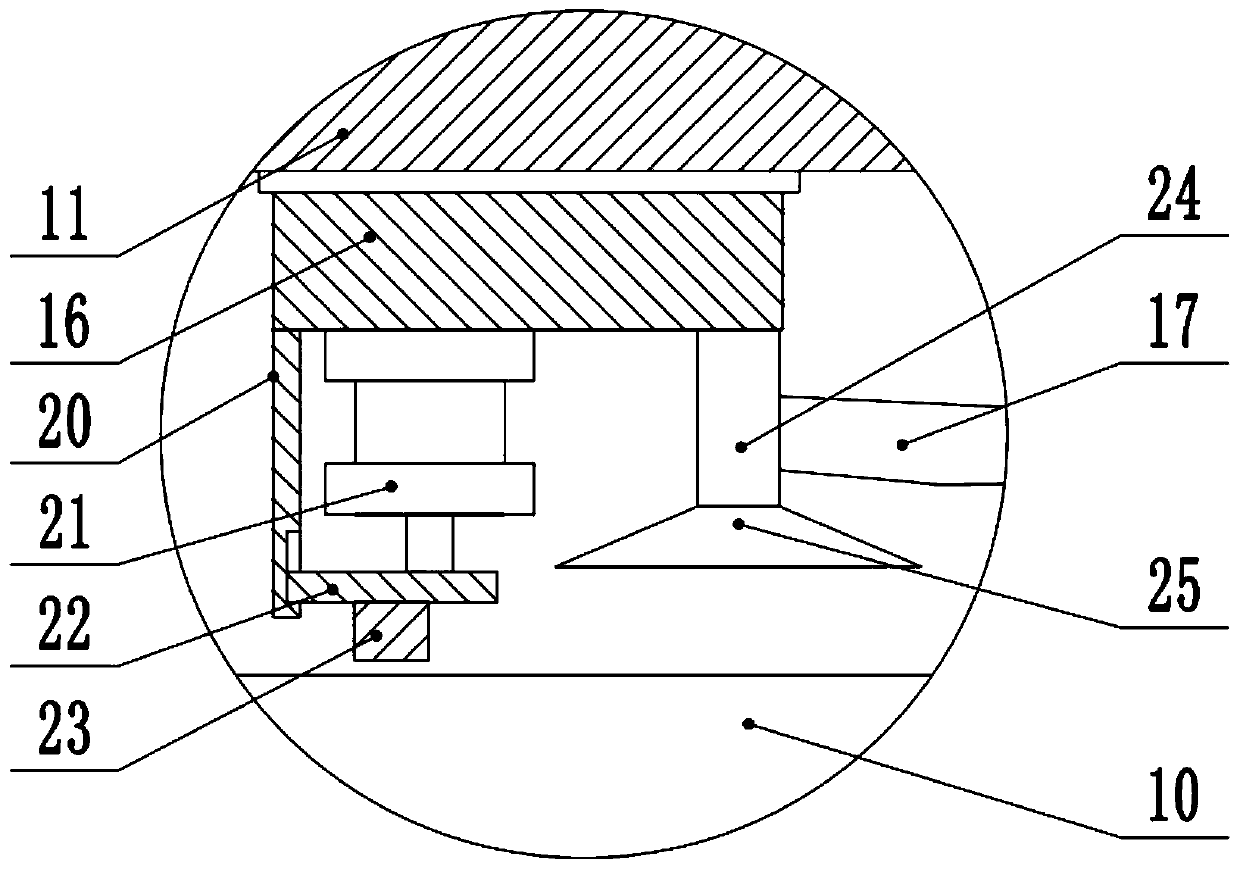

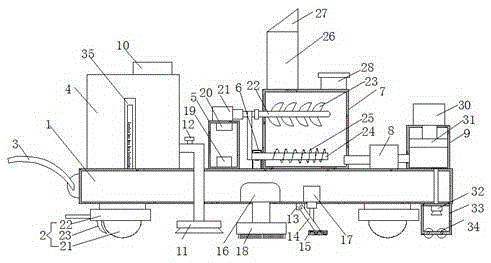

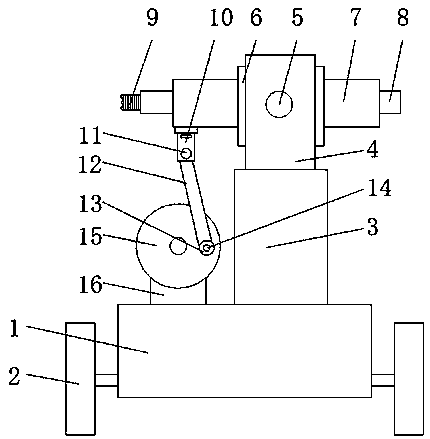

Multifunctional energy-saving paint spraying device for building

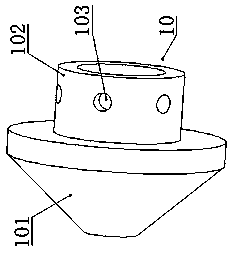

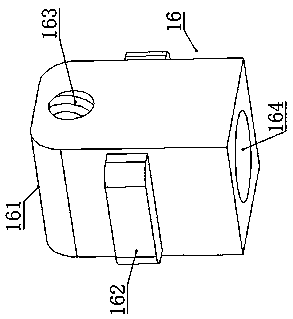

InactiveCN105964467AImprove the effect of spray paintEasy to operatePretreated surfacesCoatingsElectric machineryLeather belt

The invention relates to a paint spraying device, in particular to a multifunctional energy-saving paint spraying device for a building. The multifunctional energy-saving paint spraying device for the building can save time and labor, is easy to operate and can improve the paint spraying effect. In order to achieve the technical goals, the multifunctional energy-saving paint spraying device for the building comprises a cart, a fixing plate, a support, a paint tank, a motor, a large belt pulley, a rotating rod, a first bevel gear, a water tank, a supporting rod, an air exhaust pipe, an air pump, a small belt pulley, a flat belt, a fan, a third bearing block, a second bearing block, a first bearing block, a rotary shaft, a second bevel gear, a screw, a first nut, a second nut, a second air cylinder, an air suction hood, a second hose, a first air cylinder, a sprayer, a liquid pump and a first hose. The fixing plate, the support and the paint tank are arranged on the cart sequentially from left to right. The multifunctional energy-saving paint spraying device for the building can achieve the effects of improving the paint spraying effect, saving time and labor and being easy to operate.

Owner:湛来

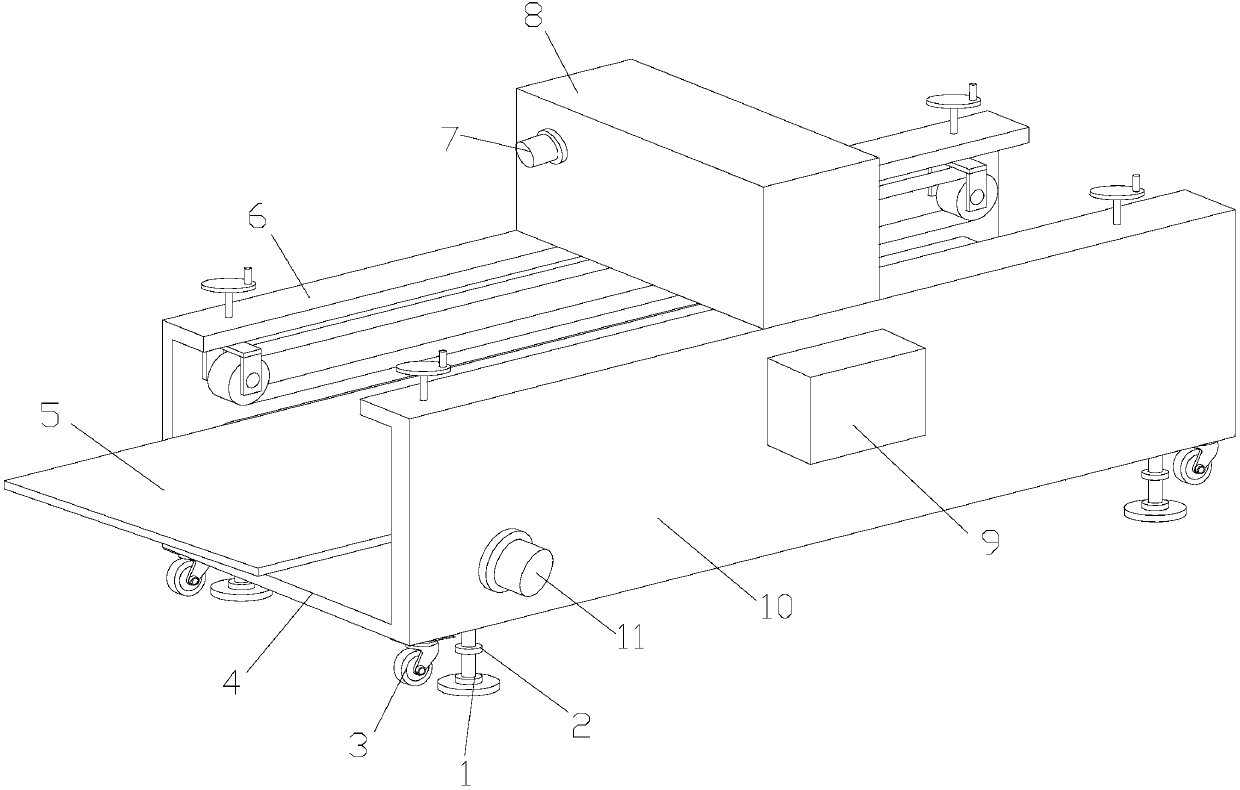

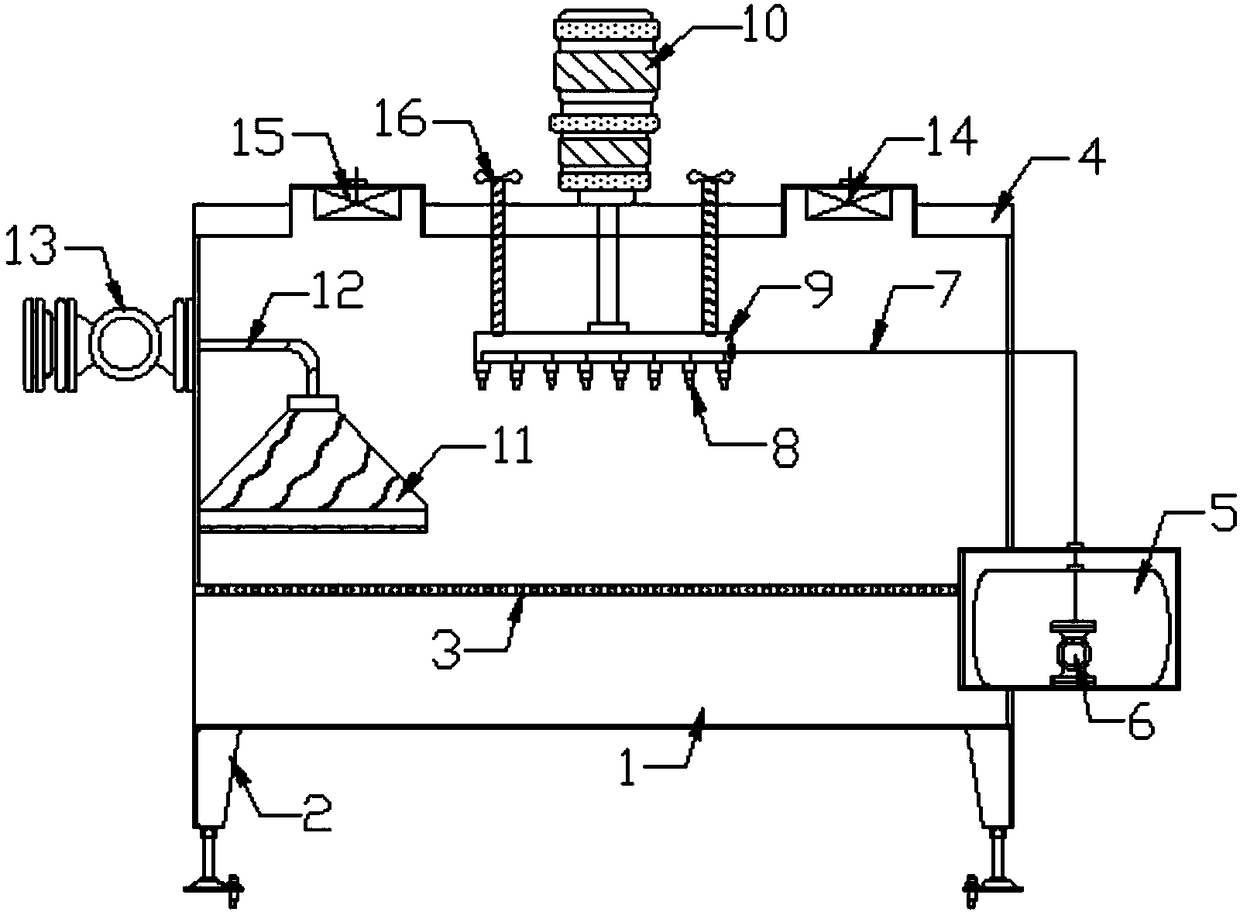

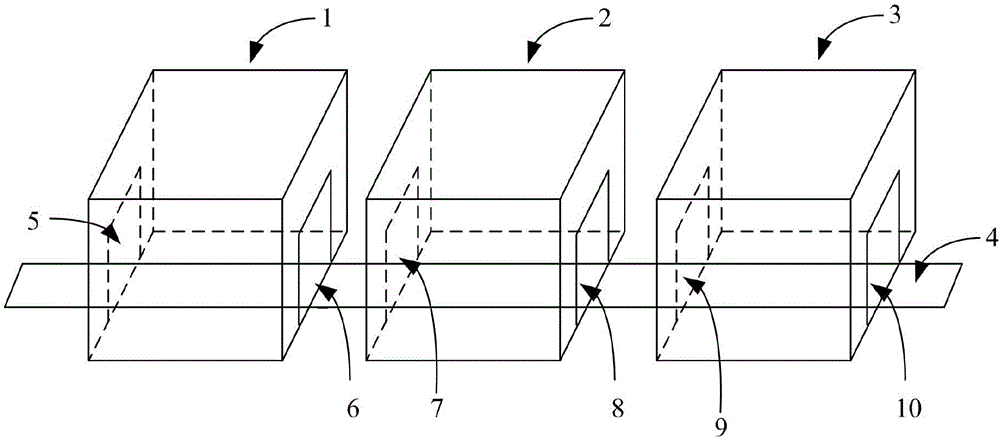

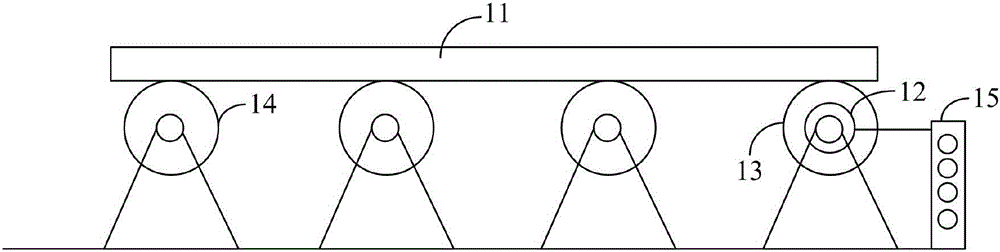

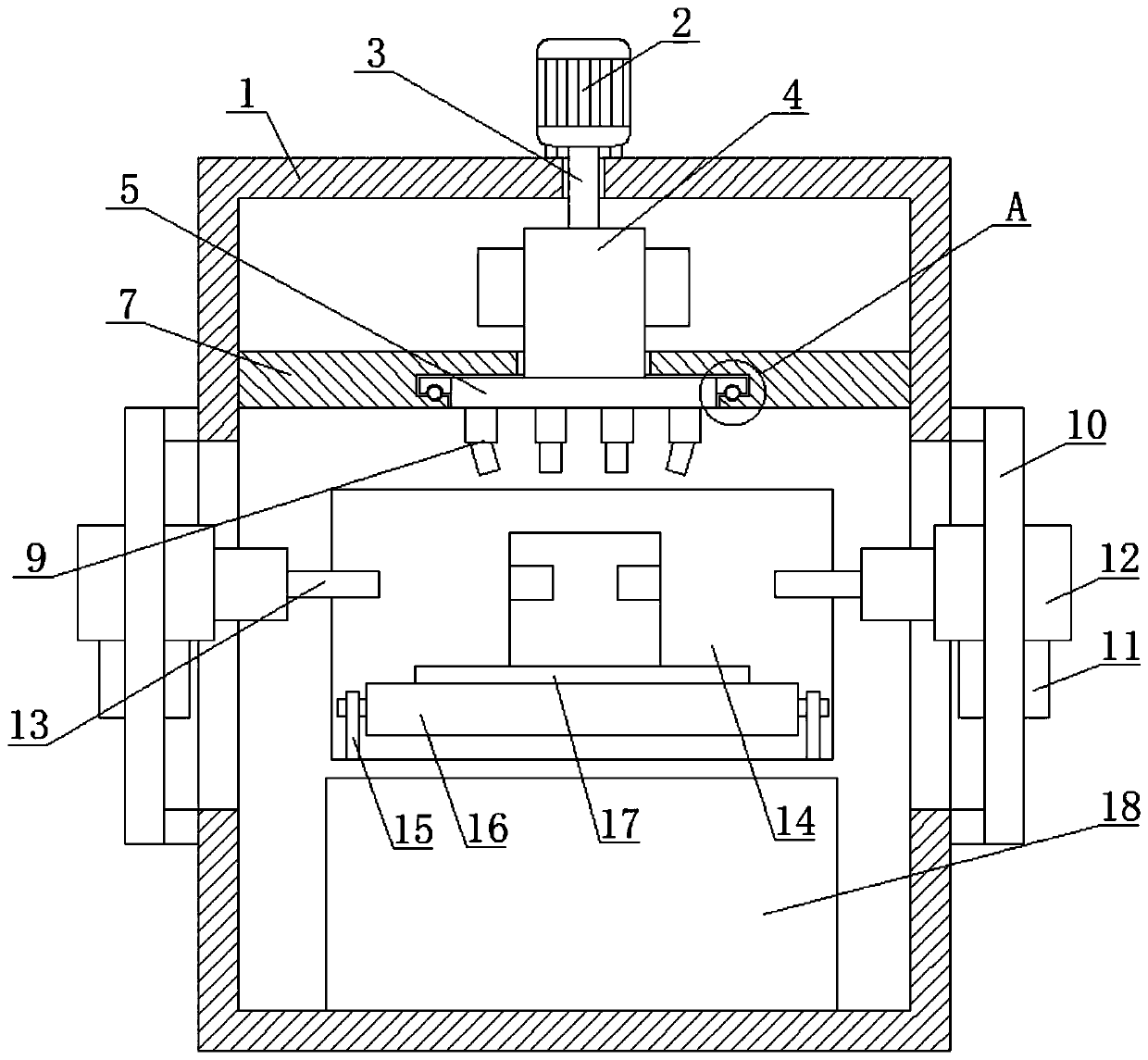

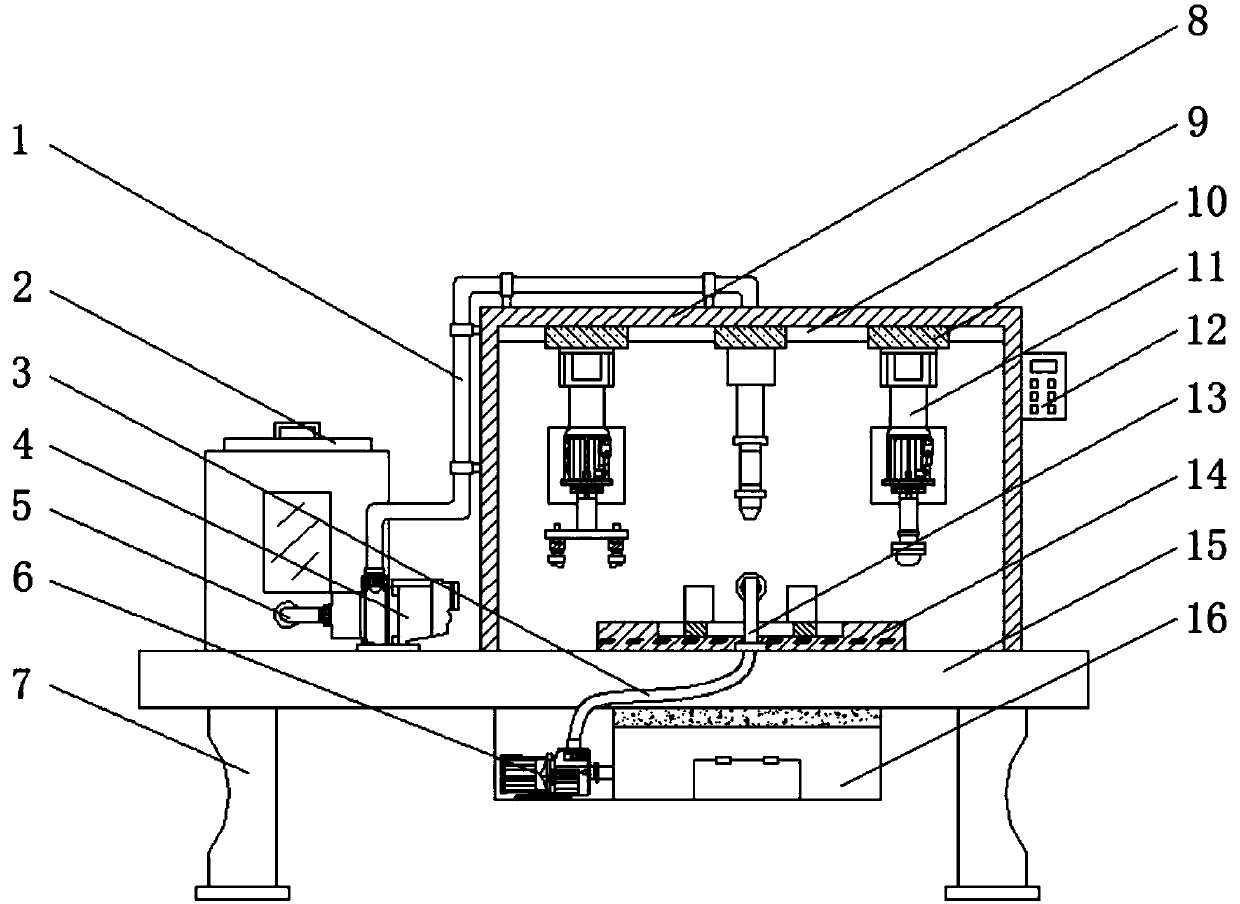

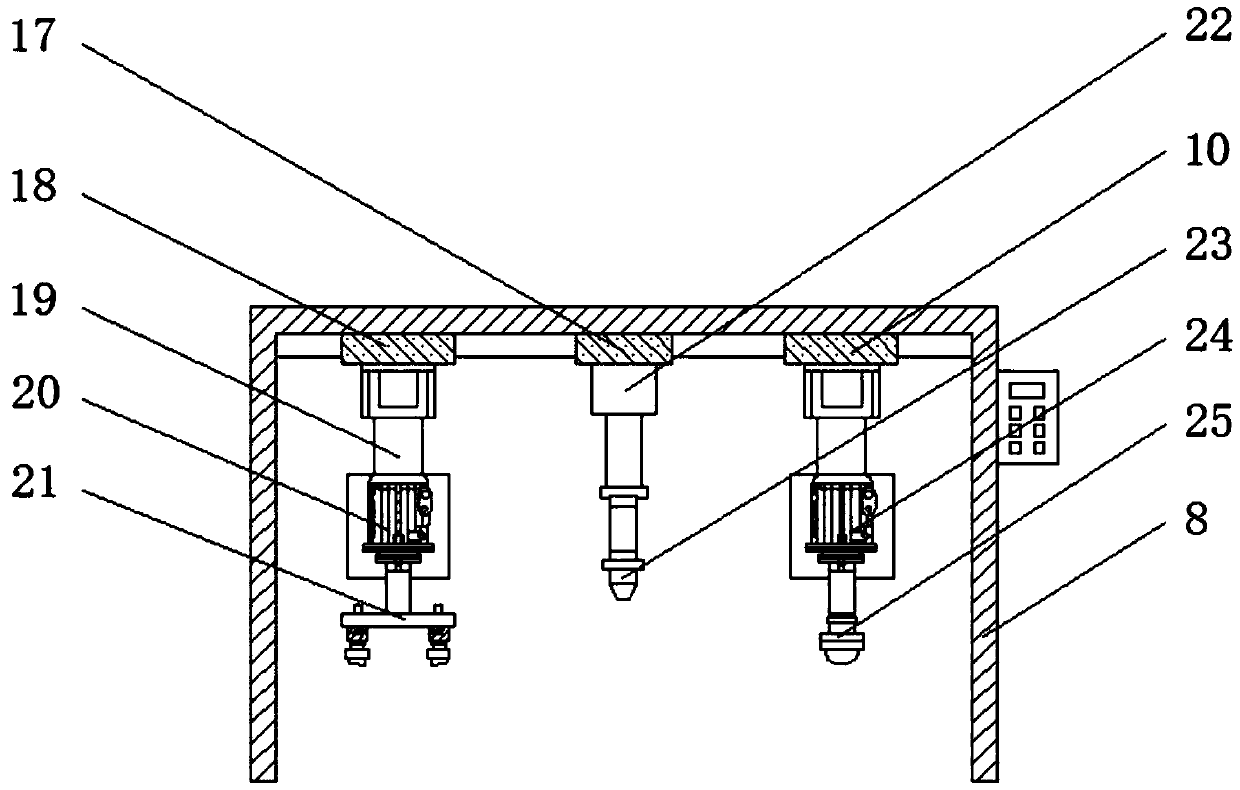

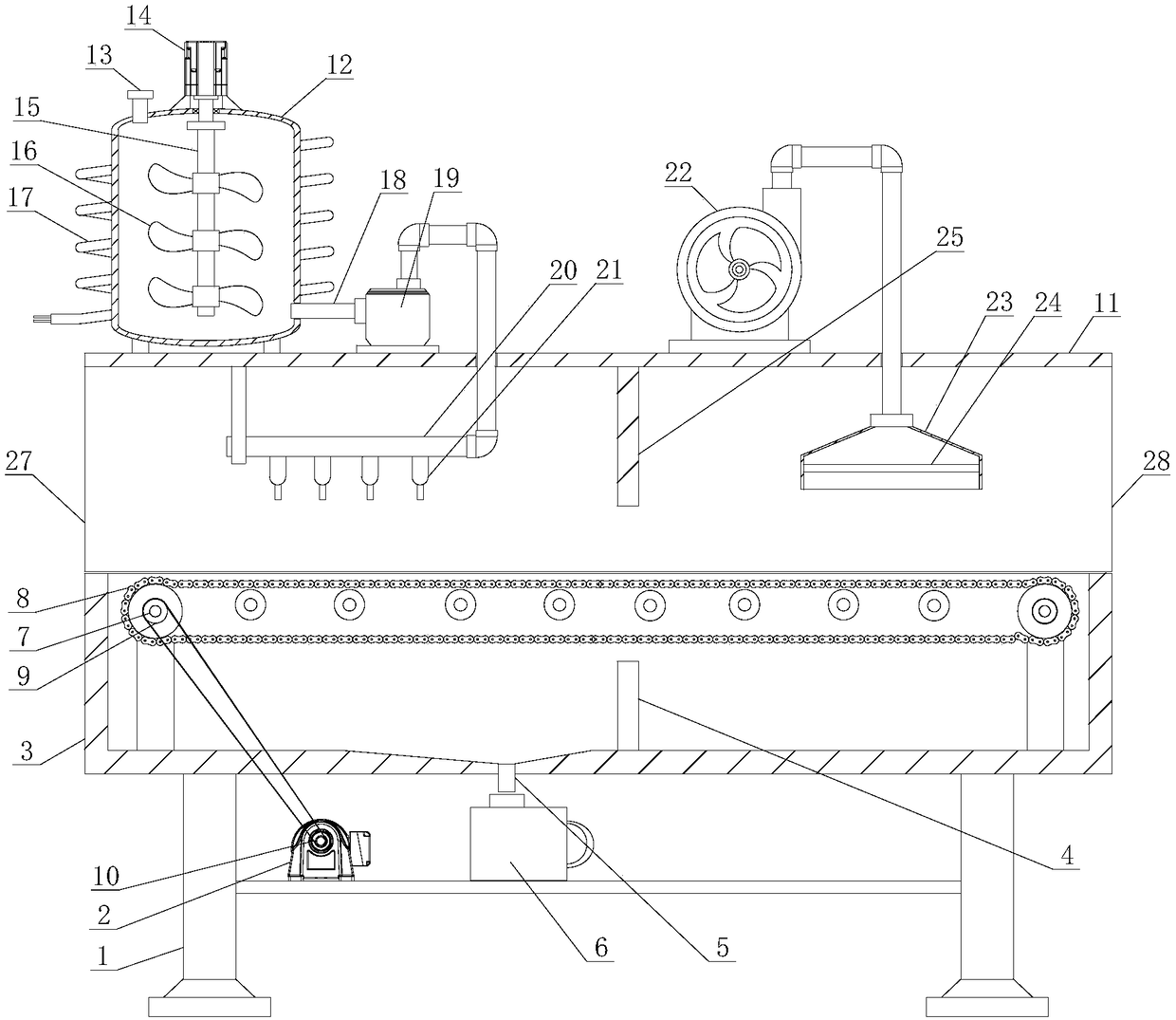

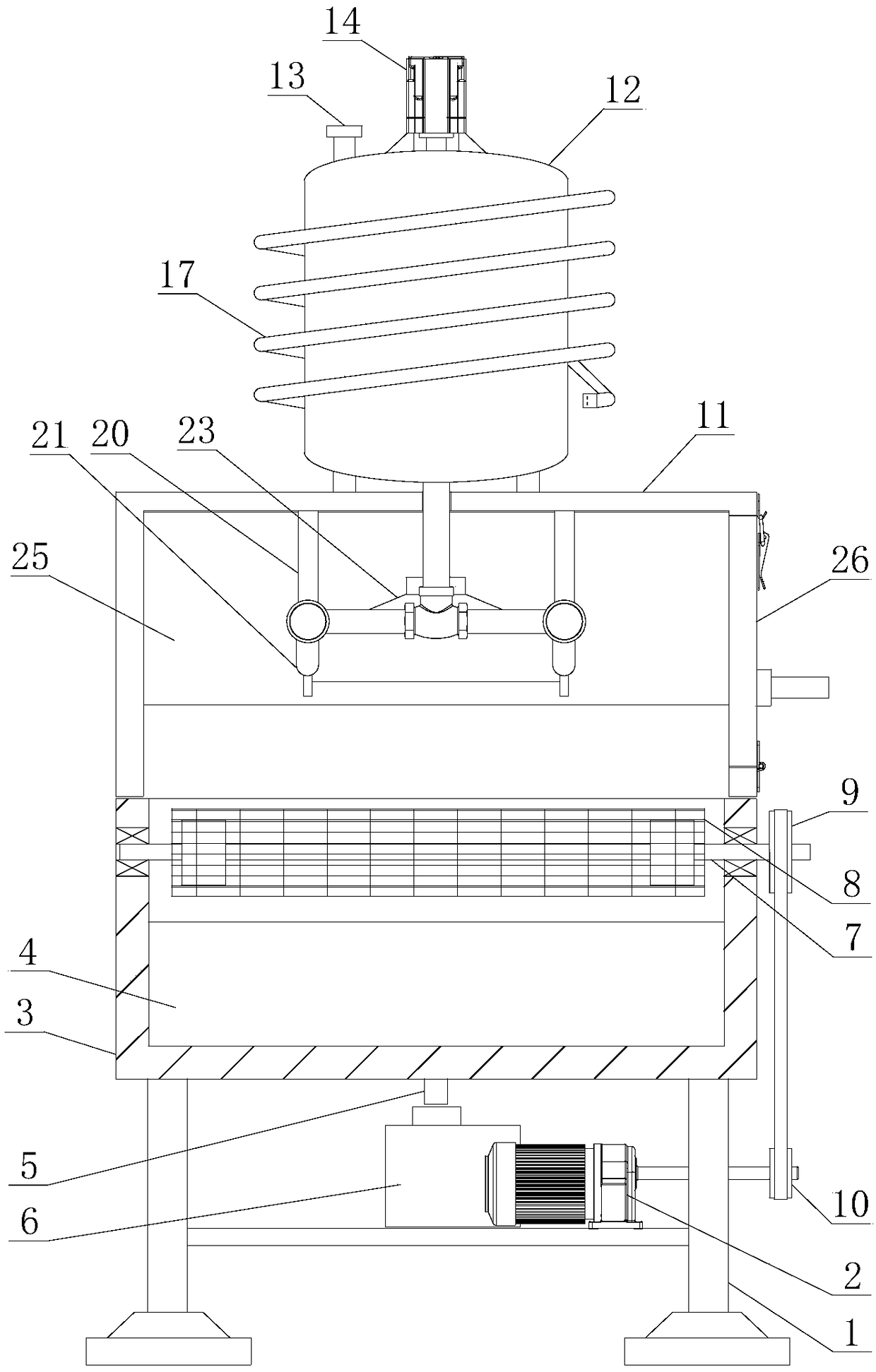

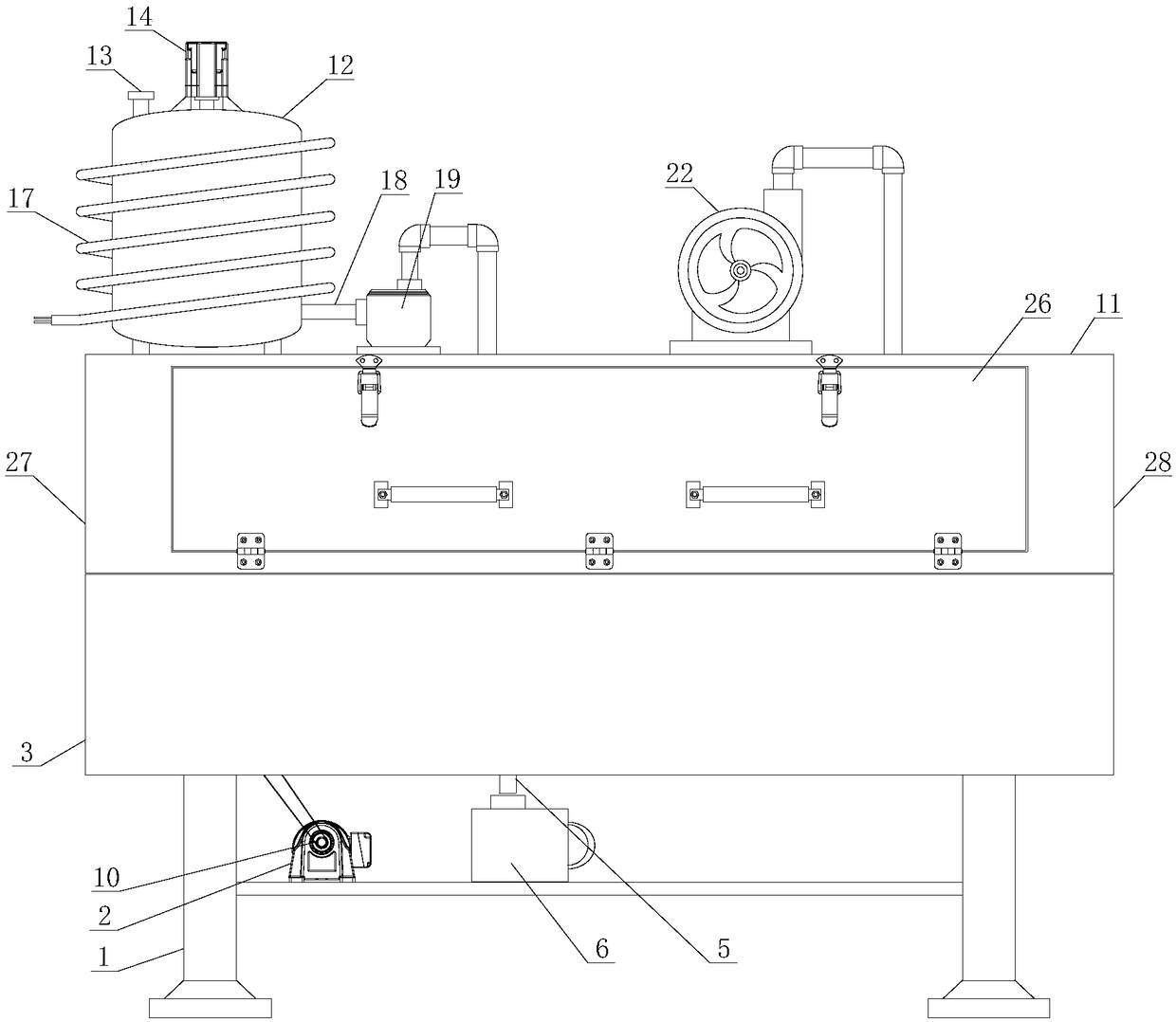

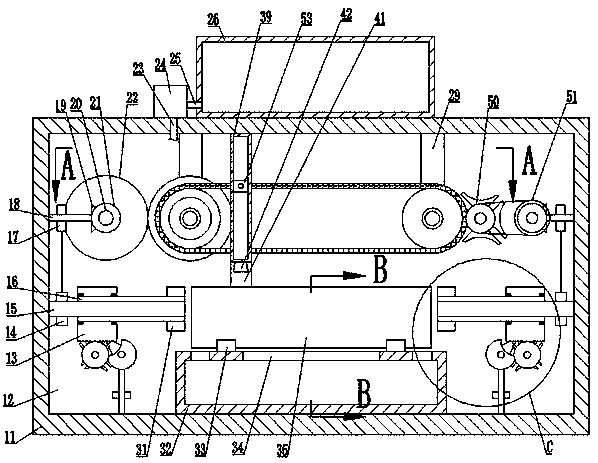

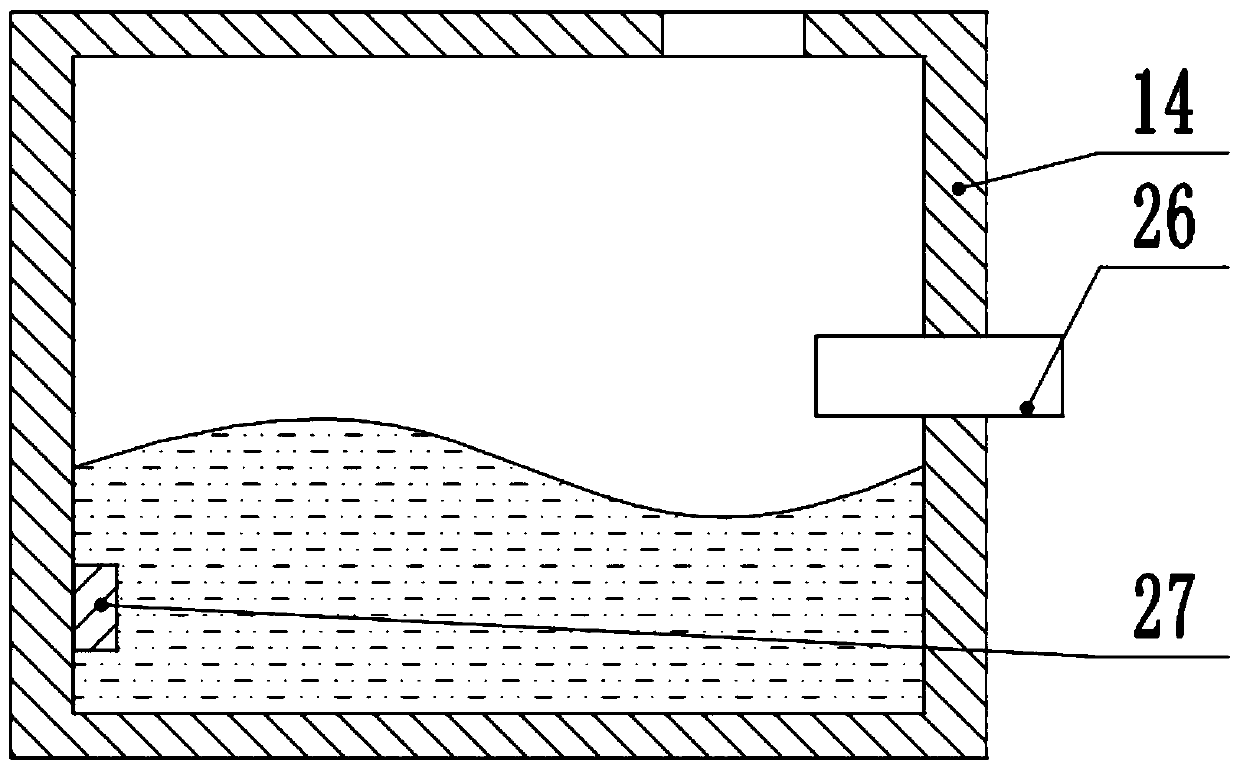

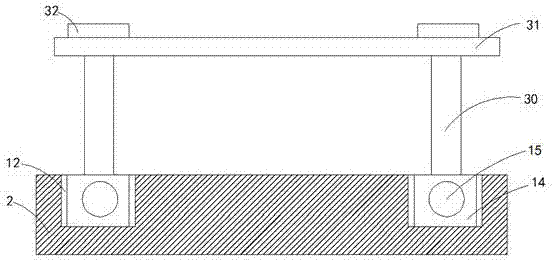

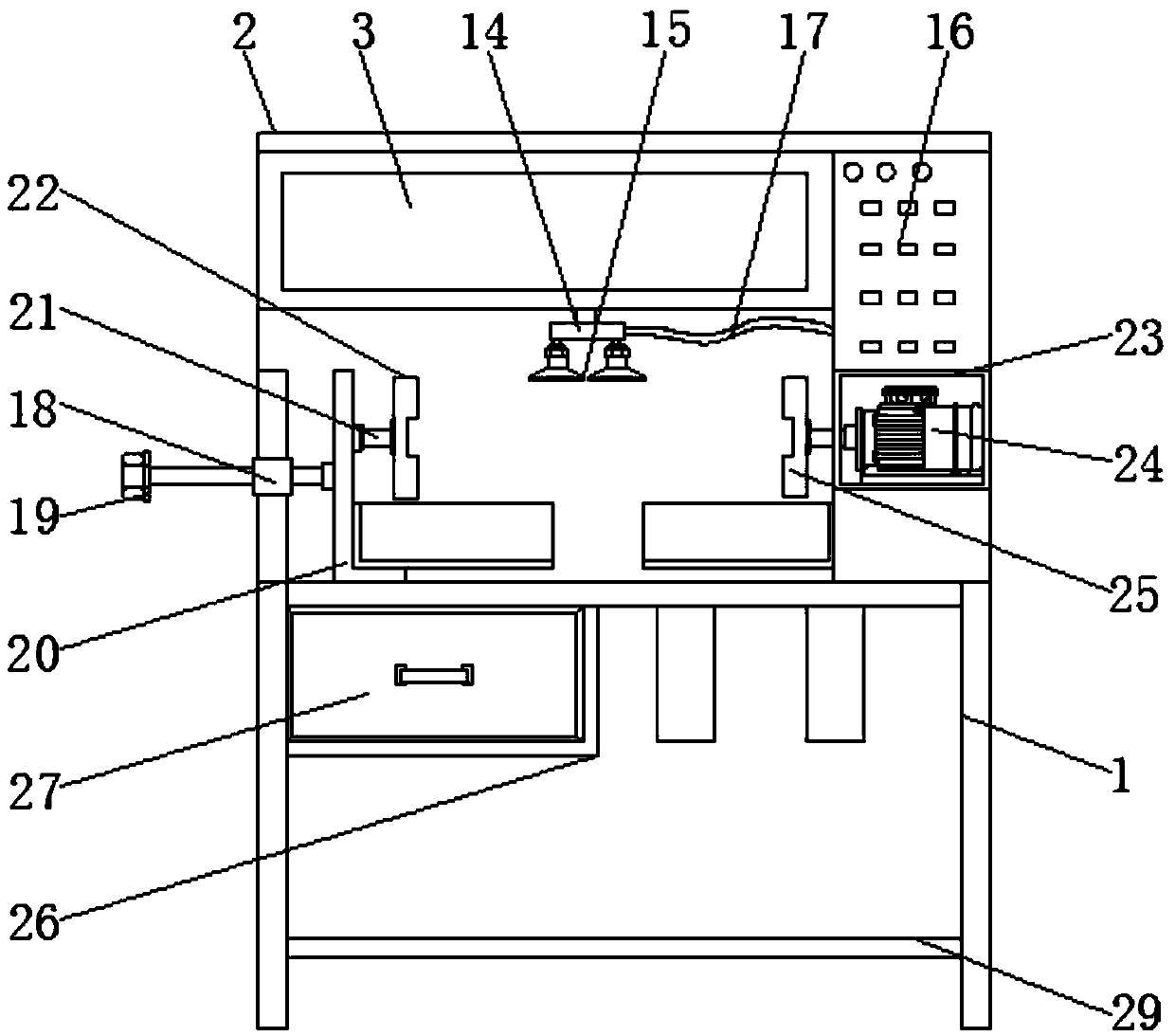

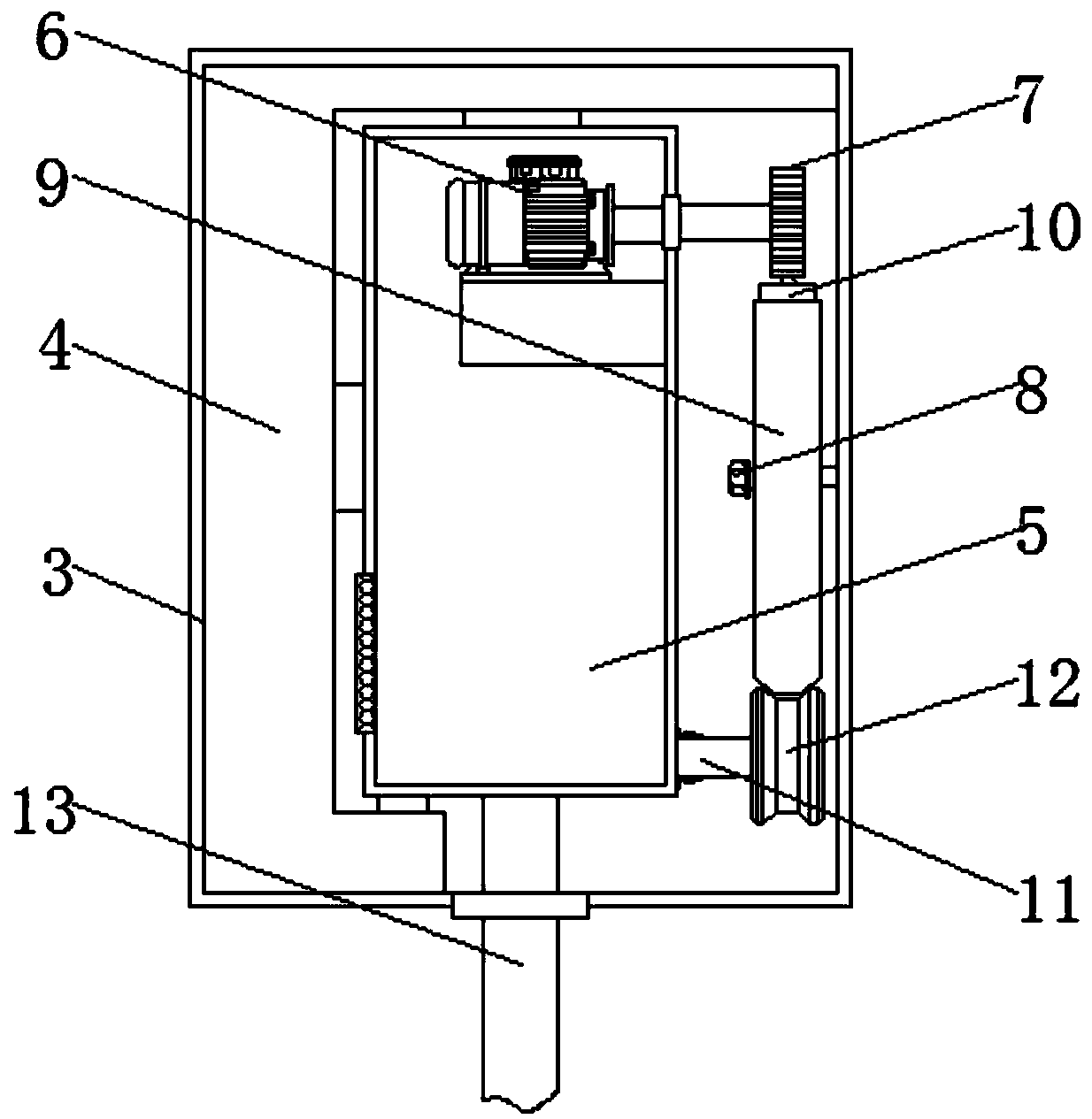

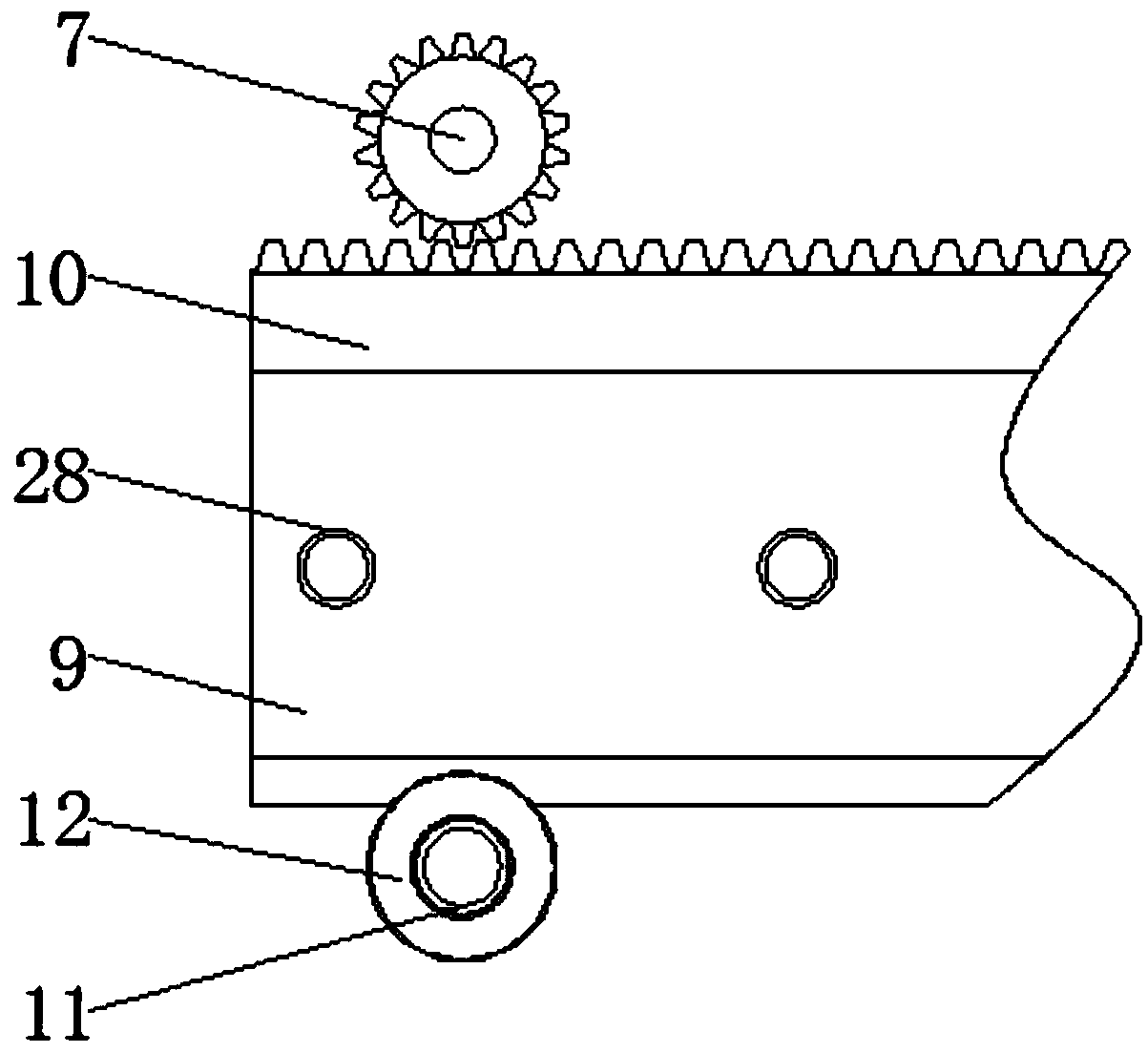

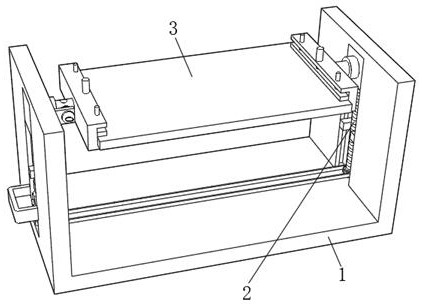

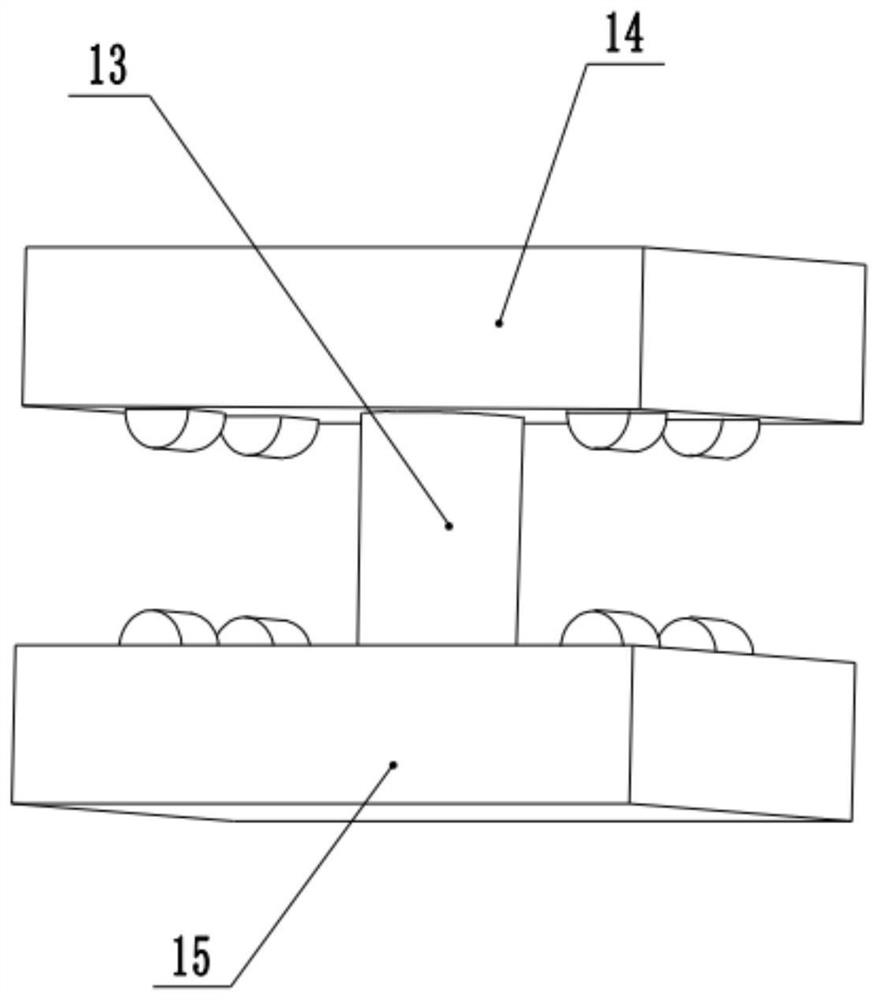

Automatic paint spraying equipment for wood floor

InactiveCN108031590AAvoid jitterSpray the surface evenlySpraying apparatusReciprocating motionElectric machinery

The invention discloses automatic paint spraying equipment for a wood floor. The automatic paint spraying equipment structurally comprises lifting foot cups, adjusting nuts, moving wheels, a bottom plate, the wood floor, a rear side plate, a first motor, a machining box, a control box, a front side plate, a second motor and a machining mechanism. The lifting foot cups are vertically mounted at thebottom of the bottom plate in a bolted connection manner. The four corners of the bottom of the bottom plate are each provided with the corresponding lifting foot cup. The adjusting nuts and bolts onthe lifting foot cups are in threaded connection. The moving wheels are vertically mounted at the bottom of the bottom plate in a bolted connection manner. The four corners of the bottom of the bottom plate are each provided with the corresponding moving wheel. According to the automatic paint spraying equipment for the wood floor, a slow feed manner of clamping the two sides is adopted by the wood floor, then fast reciprocating motion is carried out through a paint spraying device, up-and-down reciprocating paint spraying is carried out on the wood floor, the spraying surface is more uniform, the paint spraying effect is improved, secondary paint spraying does not need to be carried out on the wood floor, and operation is simple and convenient.

Owner:惠安闽神石材加工设备开发有限公司

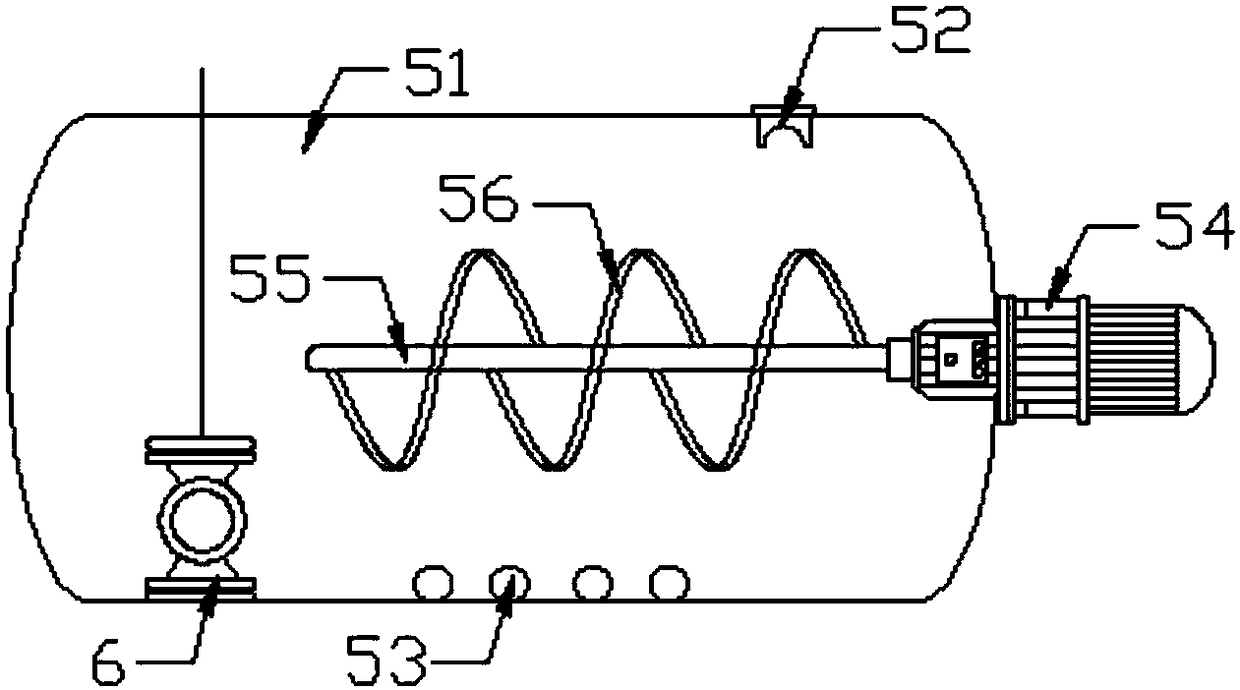

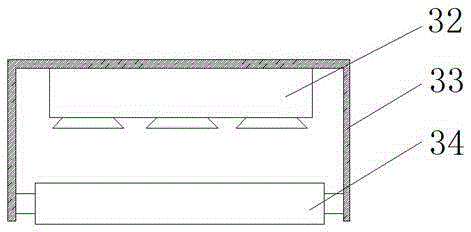

Rapid surface paint spraying device for hardware plates

InactiveCN108284013ASpray evenlyAvoid condensationPretreated surfacesLiquid spraying apparatusSprayerEngineering

The invention discloses a rapid surface paint spraying device for hardware plates. The rapid surface paint spraying device comprises a base, a protective cover, a paint storage device and a paint sprayer; the bottom of the base is fixedly mounted with the ground through the supporting base, the top of the base is provided with a conveyor belt, and the conveyor belt is in transmission connection with a motor through a transmission wheel; and a protective cover is arranged on the base, and the paint storage device is arranged at one end of the base. The distance between the paint sprayer and thehardware plates is adjusted through a telescopic air cylinder, so that the paint spraying area and the paint spraying thickness of the hardware plates can be conveniently adjusted, and paint in a paint tank can be stirred and heated; the paint in the paint tank can be prevented from being precipitated and solidified, or the surface of the paint can be prevented from being condensed into blocks, so that the paint can be uniformly sprayed on the surfaces of the hardware plates; and the quality of the hardware plates paint spraying is effectively improved, and the paint spraying and drying speedof the hardware board is accelerated, so that the paint spraying treatment efficiency of the surfaces of the hardware plates is effectively improved.

Owner:温岭温高教育科技有限公司

Hardware paint spraying device convenient to use

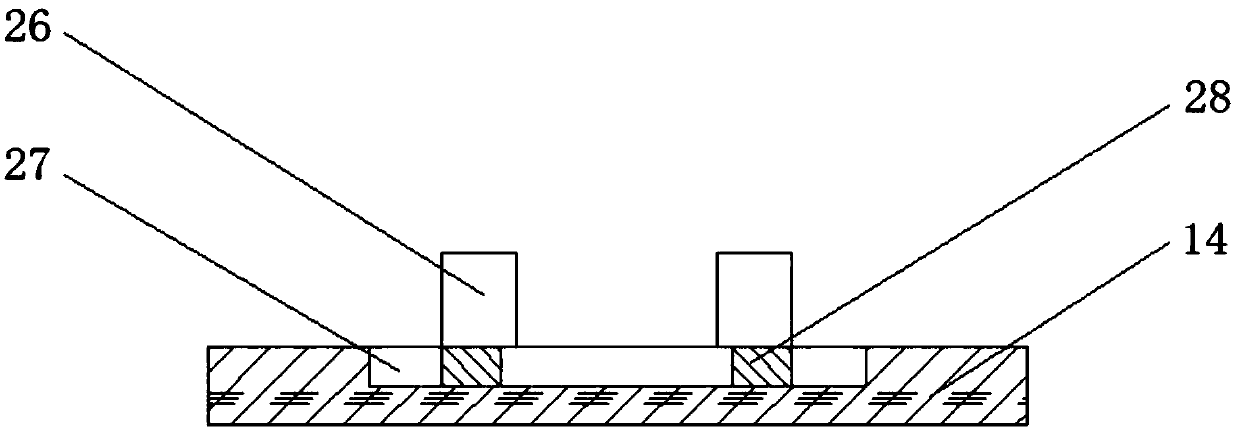

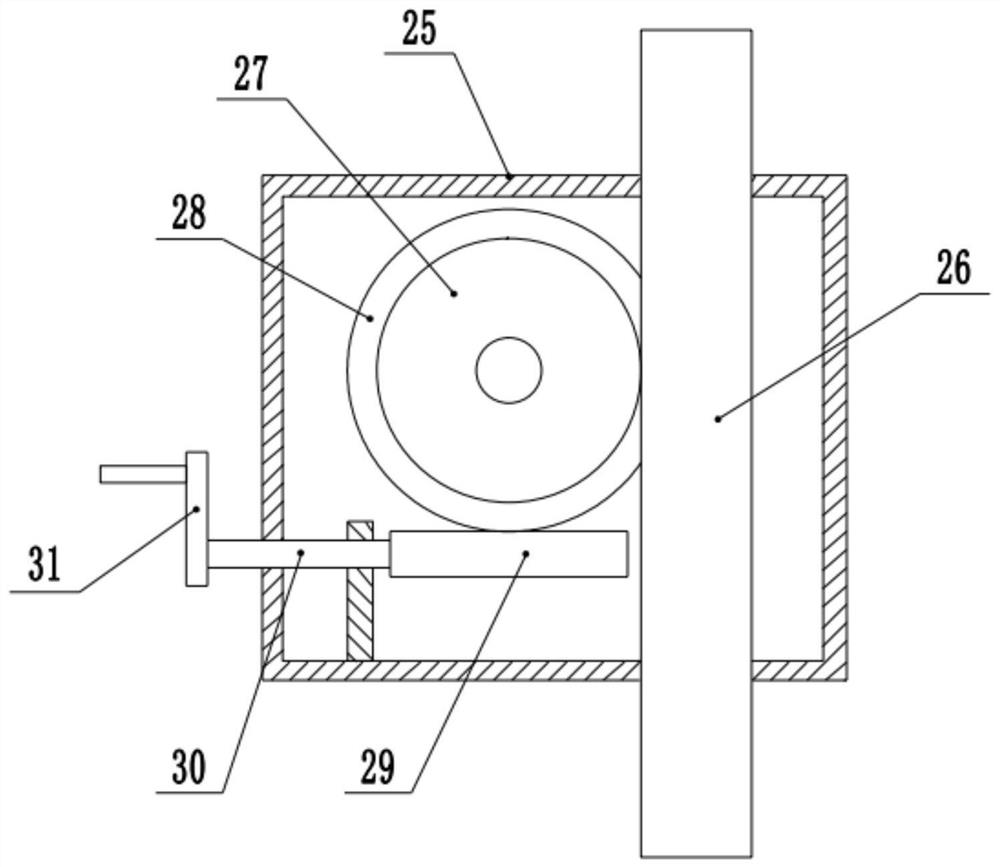

InactiveCN108097499AEasy to useEasy-to-use hardware spray paintPretreated surfacesCoatingsElectric machineryDrive motor

The invention relates to the technical field of hardware, and discloses a hardware paint spraying device convenient to use. The device comprises a bearing plate; two support legs are fixedly mounted on the two sides of the bottom of the bearing plate; an equipment shell is fixedly mounted at the top of the bearing plate; and a shielding sleeve is inserted in the inner top wall of the equipment shell. The hardware paint spraying device convenient to use uses a driving motor for driving a rotating disc to rotate in the shielding sleeve by 360 degrees; hardware materials during rotating are painted through a paint storage tank, a paint spraying pipe and a paint nozzle, so that the hardware materials are effectively and comprehensively painted, and the appearances of the hardware materials areeffectively improved; meanwhile, the driving motor is matched with a hydraulic extension rod for use, so that the problem of partial painting due to too high hardware materials is effectively reduced; and meanwhile, after the hardware materials are painted, the hydraulic extension rod can jack the hardware materials out, so that workers are convenient to take and place the hardware materials.

Owner:魏杰

Electrostatic painting equipment

InactiveCN106694294APainted and compactPerfect painting processLiquid spraying plantsPretreated surfacesElectrostatic coatingEngineering

The invention relates to the field of electrostatic painting technologies, and provides electrostatic painting equipment which comprises a pretreatment chamber, an electrostatic spraying chamber, a high-temperature curing chamber and a travel track. The pretreatment chamber is in an airtight state, inlets and outlets are formed in the pretreatment chamber, the electrostatic spraying chamber and the high-temperature curing chamber, the travel track can penetrate the inlets and the outlets and comprises a power driving mechanism and a conveying caterpillar, the conveying caterpillar is used for carrying painted equipment, an oil removal spray head group, a rust removal spray head group, a phosphorization spray head group and a passivation spray head group are sequentially arranged in the pretreatment chamber along the direction from the first inlet to the first outlet, an electrostatic spraying head group is arranged in the electrostatic spraying chamber, and the high-temperature curing chamber comprises a curing drying tank, a fan tank and a heating tank. The electrostatic painting equipment has the advantages that electrostatic painting can be carried out on the painted equipment, integral painting structures are compact, painting processes can be improved, accordingly, painting effects can be enhanced, the quality of products can be improved, requirements of users on the products can be met, and the labor cost can be saved.

Owner:YANTAI SMITHDE ELECTROMECHANICAL EQUIP MFG

Lacquer spraying device having drying function, for production of robots

InactiveCN110976179AReduced healthImprove working environmentPretreated surfacesLiquid spraying apparatusLacquerDrive shaft

The invention discloses a lacquer spraying device having a drying function, for production of robots. The lacquer spraying device comprises a tank body, wherein a lacquer storing tank is fixedly connected to the top of the tank body; a fixing plate is fixedly connected to the middle part of the inner wall of the tank body; a rotating motor is fixedly connected to the bottom of an inner cavity of the tank body; and a threaded rod is fixedly connected to the output end of the rotating motor through a coupler. The invention relates to the technical field of the production of the robots. Accordingto the lacquer spraying device having a drying function, for production of robots disclosed by the invention, through the rotating of the rotating motor, and through cooperation with the meshing relationship of the threaded rod and a threaded seat, a spray nozzle on the left side of the threaded seat can move up and down, and lacquer spraying treatment can be performed on dead angles including positions below the arms and the like of the robot; then through the cooperation relationship of a rotating shaft, a transmission shaft and bevel gears, the robot on a rotating disk can be driven to rotate at a uniform speed, so that comprehensive lacquer spraying treatment is performed on the robot, a large amount of lacquer is saved, the cost is saved, and the lacquer spraying effect of the lacquer spraying device is improved.

Owner:南京青图信息技术有限公司

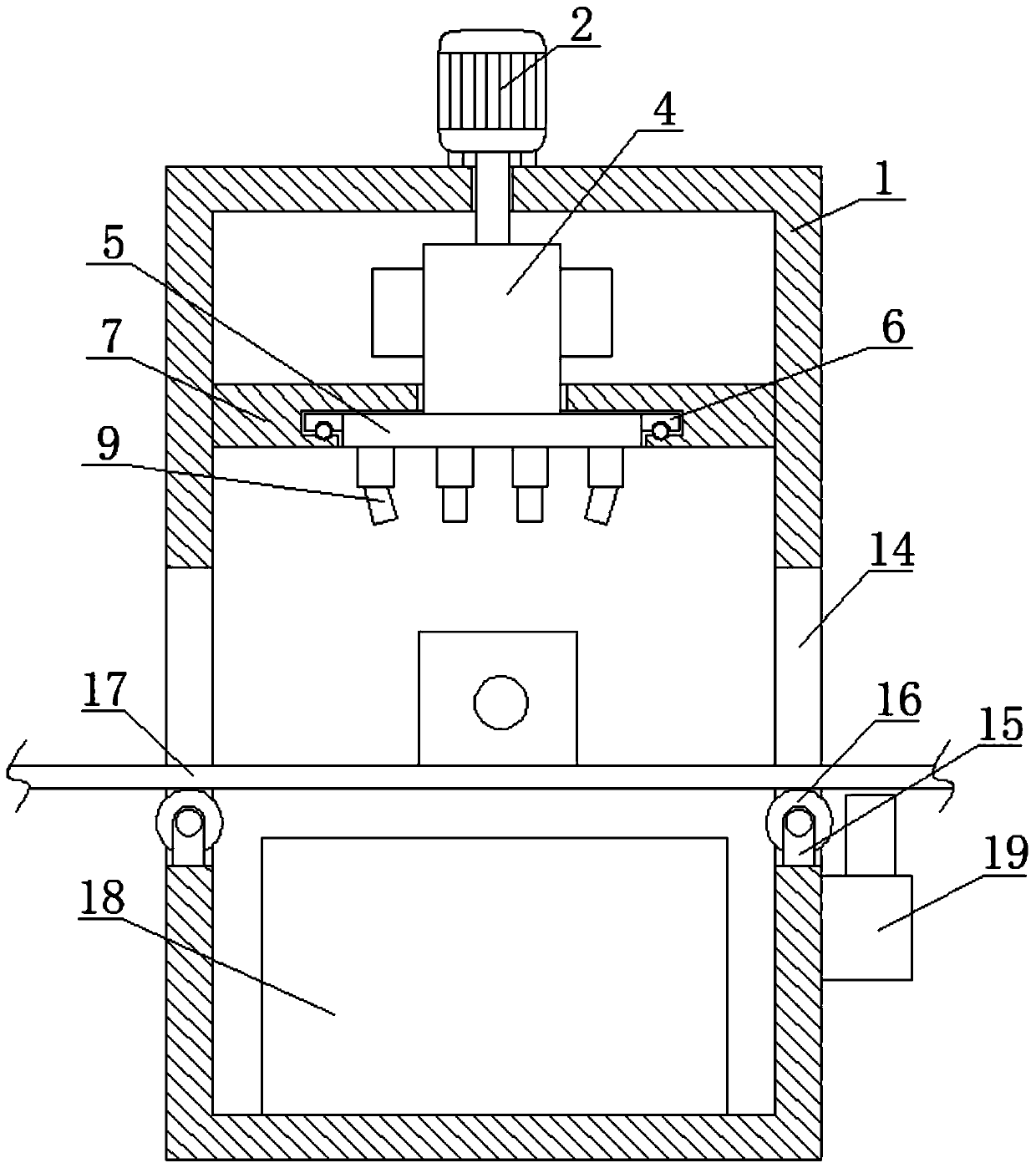

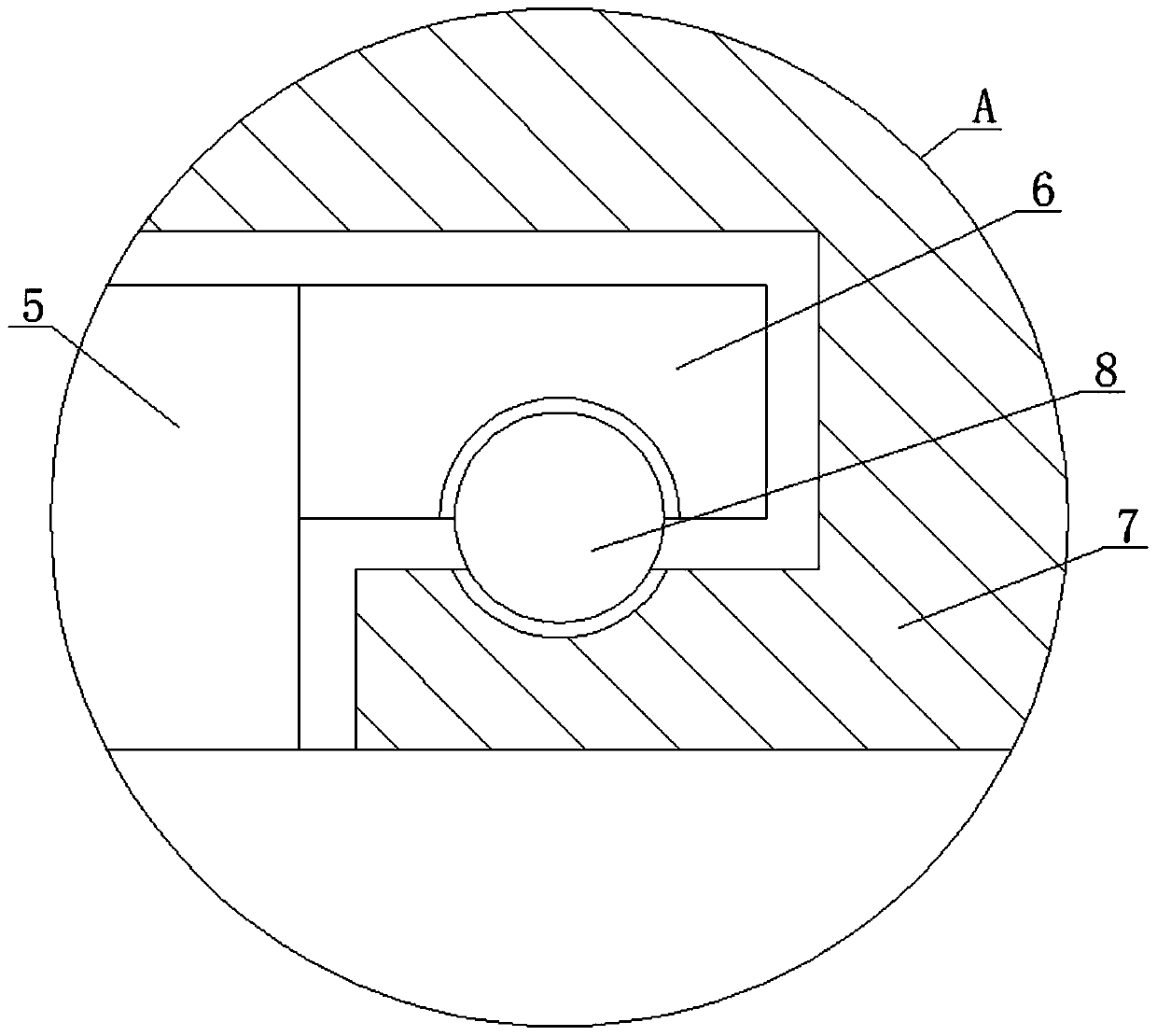

Paint spraying device for production of hardware accessories

InactiveCN110614185AGuaranteed uniformityImprove product qualitySpray boothsEngineeringProduction quality

The invention relates to the technical field of hardware production equipment, and discloses a paint spraying device for the production of hardware accessories. The paint spraying device comprises a box body, wherein a servo motor is fixedly installed in the middle of the top end of the box body, and the bottom end of the servo motor is fixedly connected with a rotating shaft; a paint box is fixedly connected to the bottom end of the rotating shaft, and a rotary table is fixedly connected to the bottom end of the paint box; and clamping blocks are fixedly connected to the two ends of the rotary table respectively, the rotary table is movably sleeved on the middle of a fixed plate, and balls are movably connected to the bottoms of the clamping blocks. According to the invention, through a clamping rod and a lifter, the clamping rod can clamp and hoist the hardware accessories to be painted in a targeted manner, so that the phenomenon of shaking of the hardware accessories during the painting process is avoided; the hardware accessories can be painted while rotating, so that the slots of the hardware accessories can be completely covered by spray paint, the uniformity of spray paintis ensured, the production quality of the hardware accessories is improved, and the rationality and stability of the device are improved.

Owner:江门市新会区司前贸易中心有限公司

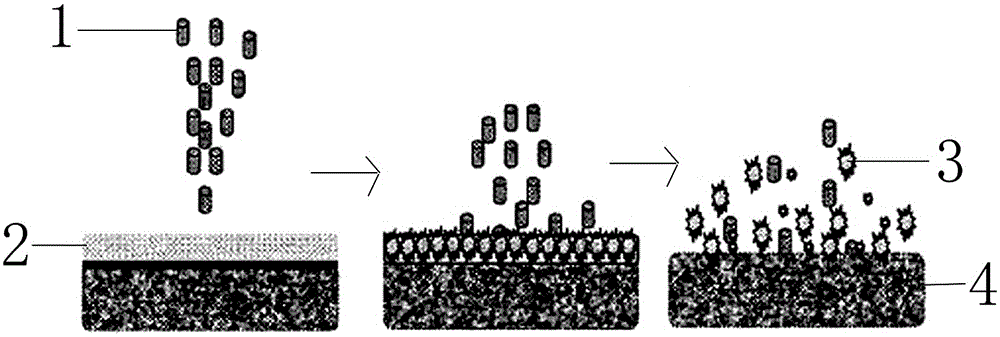

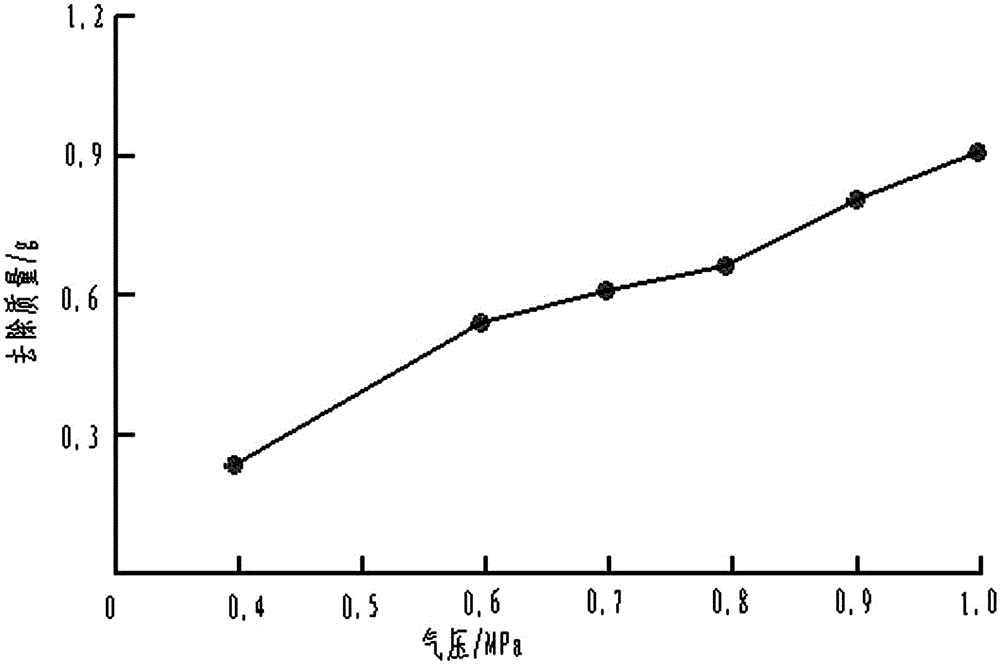

Method for cleaning surfaces of electric device and precise hydraulic part by dry ice

ActiveCN105107795AUnique thermodynamic propertiesExtended service lifeCleaning processes and apparatusEnvironmental resistanceDry ice

The invention belongs to the technical field of precise instrument equipment; and in order to solve the problems of easy rusting of equipment, easy damage of equipment, reduction of assembly precision of equipment and lower safety in a traditional method of cleaning a surface of an electric device or a precise instrument, the invention provides a method for cleaning surfaces of an electric device and a precise hydraulic part by dry ice. Solid spherical dry ice particles with diameters of 2-4 mm are filled in a dry ice cleaning machine; the dry ice cleaning machine is connected with 220 V of voltage and pressure not smaller than 0.8 MPA; after a switch is opened, the pressure of an air compressor is set as 0.4-1 MPa, and the flow is set as 0.5-3.5 m3 / m; a distance from a gun nozzle to a surface to be cleaned is 25 mm; an angle between the nozzle and the cleaned surface is 45 degrees; a button of a spraying gun is pressed for spraying the surface of an object to be cleaned; the ice outlet quantity is 15-50 kg / h; the spraying pressure is 7-8 bar; and the lasting time is 20 s. Compared with a common paint and rust removing technology, the dry ice cleaning has such advantages as environmental protection, economy, high efficiency, long service life and safety.

Owner:SHANXI JINDING GAOBAO DRILLING CO LTD

Household appliance gas stove inner and outer burner cap machining device

InactiveCN107584386AImprove high temperature resistanceImprove aestheticsGrinding carriagesPolishing machinesEngineeringGuide tube

The invention relates to a household appliance gas stove inner and outer burner cap machining device. The device comprises a paint storage cylinder, a mounting frame, a polishing table and a base; supporting legs are installed at the four corners of the bottom of the base, and a dust collecting box is arranged at the position, among the supporting legs, at the bottom of the base; one side of the dust collecting box is provided with a dust suction pump, and a dust outlet of the dust suction pump is communicated with the interior of the dust collecting box through a guide pipe; the polishing table is arranged on the top, above the dust collecting box, on the top of the base; two sides of the polishing table are provided with dust suction heads respectively. A limiting block is installed, andthe limiting block can horizontally slide in a limiting groove so that the distance between positioning plates can be adjusted conveniently, then outer burner caps or inner burner caps with differentsizes can be conveniently clamped, and the application range is wider; the device is provided with a first grinding head and a second grinding head so that the inner burner caps and the outer burnercaps can be conveniently polished respectively, and the grinding effect is better.

Owner:王彩英

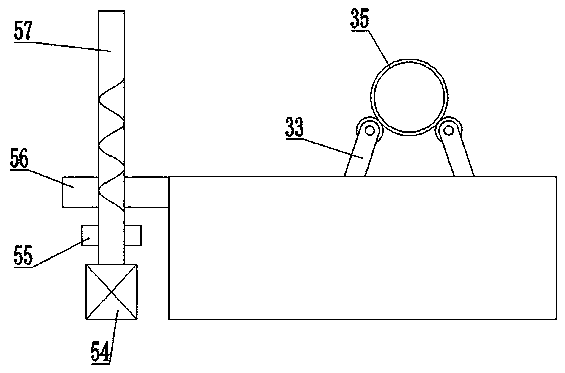

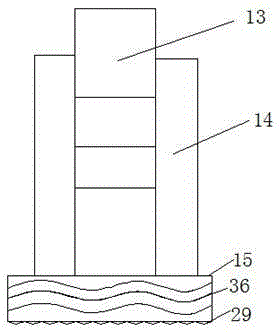

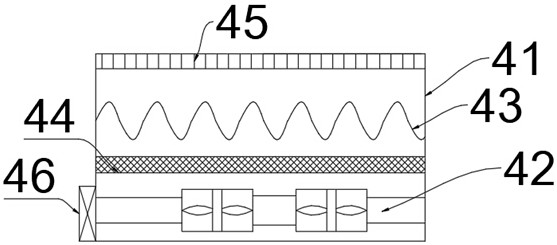

Automatic paint spraying device for panel production

InactiveCN109433453APrevent solidificationQuality improvementPretreated surfacesLiquid spraying apparatusAir volumeElectric heating

The invention discloses an automatic paint spraying device for panel production, and relates to the technical field of paint spraying machines. The automatic paint spraying device comprises a support.A beam of the support is fixedly connected with a first motor. A box is fixedly connected to the top of the support. A first partition plate is fixedly connected to the inner bottom of the box. A discharging pipe is arranged at the inner bottom of the box. A material collecting box is arranged on the beam of the support. The inner wall of the box is fixedly connected with a transmission rod through a bearing, and the outer portion of the transmission rod is sleeved with a conveying belt. According to the automatic paint spraying device for panel production, through the arrangement of a draught fan, a fan cover and an electric heating wire, the effect of rapid drying is achieved; the draught fan is used for conveying air into the fan cover, then electrification is conducted for making theelectric heating wire conduct heating, so that hot air is blown out of the fan cover, hot air drying is conducted on the paint spraying face of a panel conveyed on the conveying belt, the panel paintspraying drying speed is increased, the panel surface paint spraying treatment efficiency and the paint spraying effect can be effectively improved, and the operation efficiency is improved.

Owner:ZHAOQING LECHUANG TECH CO LTD

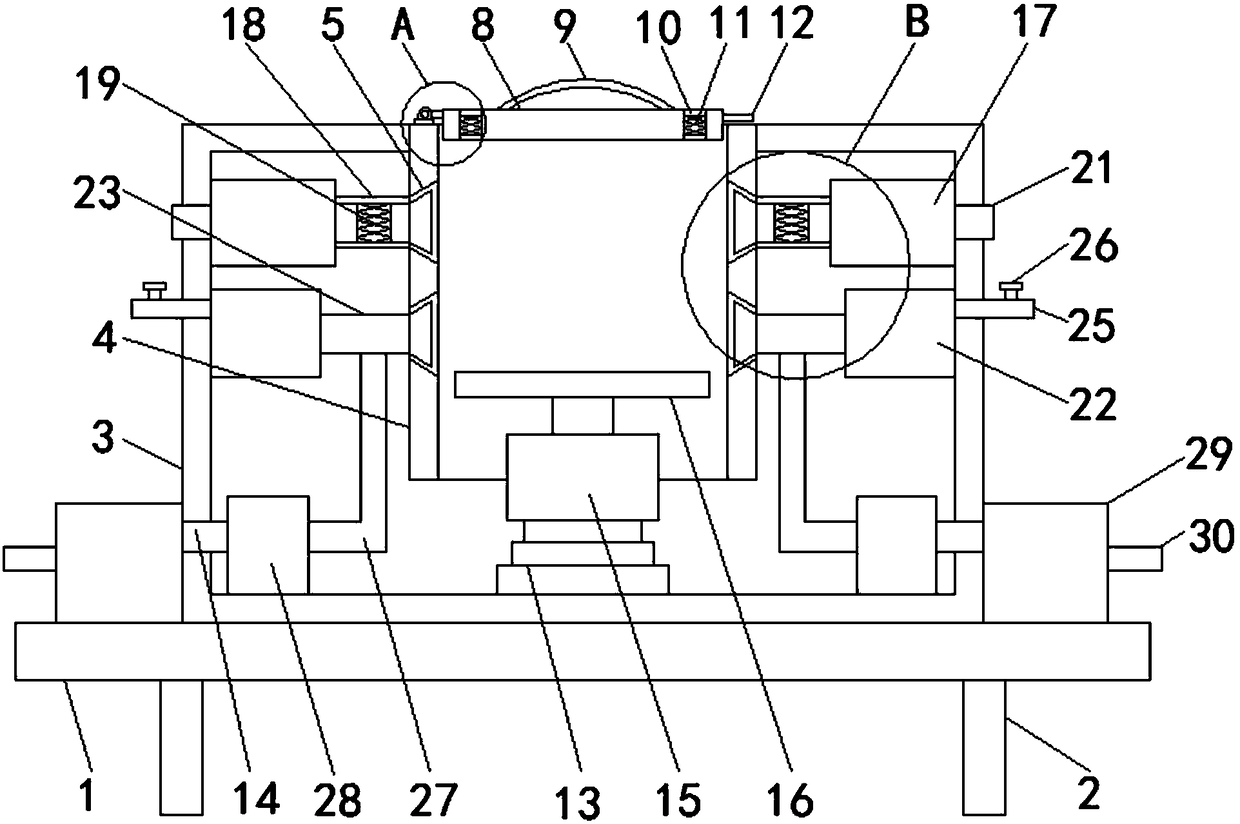

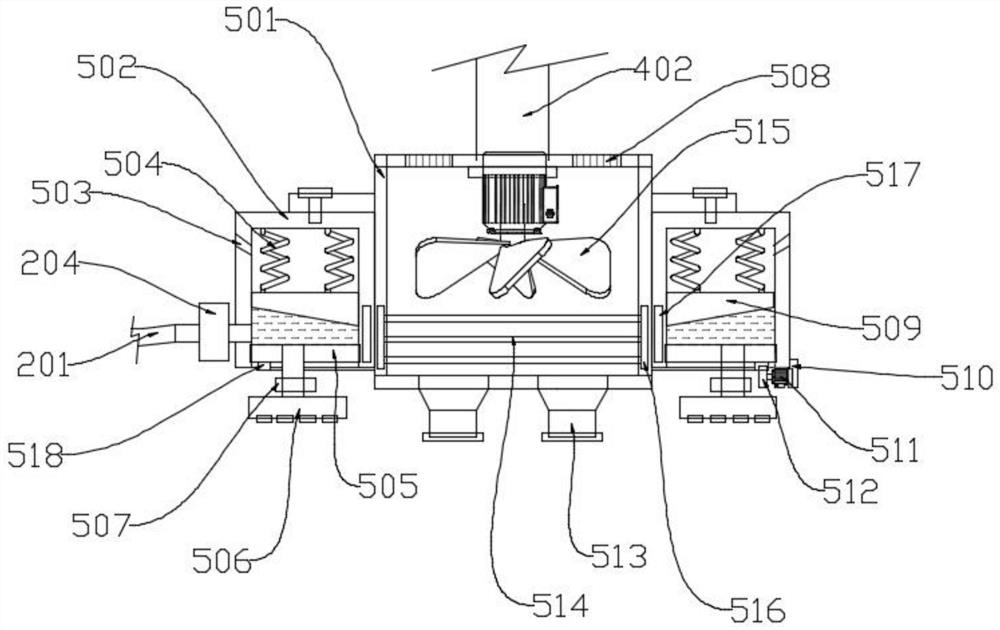

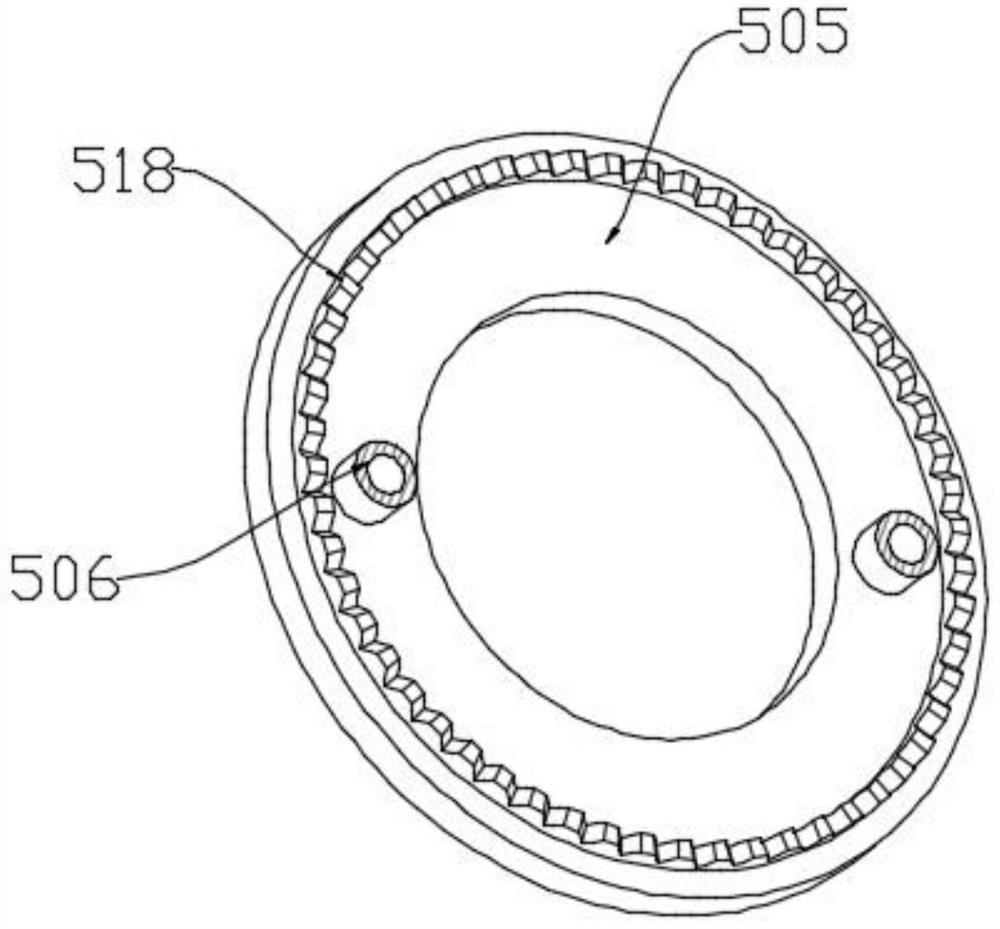

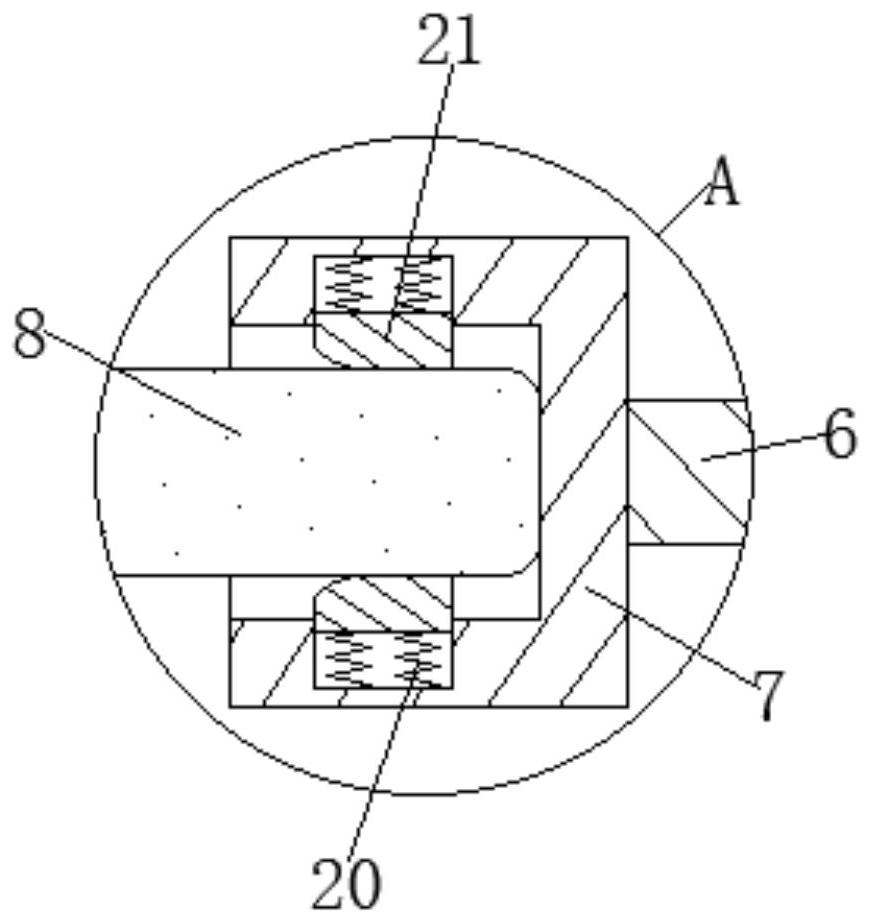

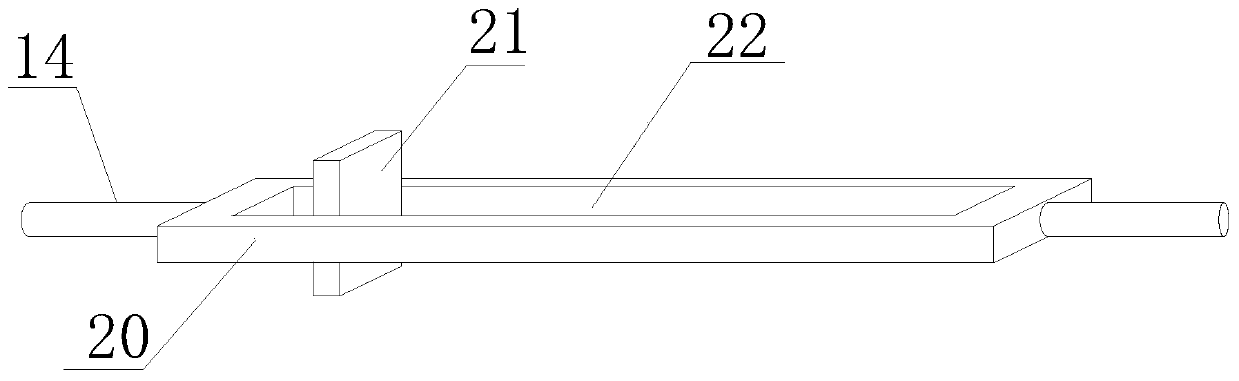

Pipeline surface rust removal and paint spraying device

InactiveCN111318404AUniform derustingEvenly paintedHollow article cleaningPretreated surfacesStructural engineeringIndustrial engineering

The invention discloses a pipeline surface rust removal and paint spraying device. The pipeline surface rust removal and paint spraying device comprises a machine body. A working cavity is formed in the machine body. A rust removal assembly used for removing rust of a pipeline is arranged in the working cavity. The rust removal assembly comprises two connecting shafts which are rotationally connected with the inner walls of the front side and rear side of the working cavity and extend front and back. The connecting shafts are in left-right symmetry relative to the working cavity, and a connecting gear is fixedly connected to the connecting shaft on the left side. When the device works, the pipeline can be driven to ascend through a lifting assembly, so that a rust removal plate is in contact with the pipeline, and a paint spraying assembly is controlled to started. The pipeline can be clamped through a clamping assembly and can be driven to rotate, the pipeline can be rotated through the rust removal assembly, and the rust of the pipeline can be uniformly removed through the rust removal plate. The paint spraying assembly can drive the pipeline to rotate intermittently, and uniformpaint spraying and drying are carried out on the pipeline in a support-free contact mode, so that the paint spraying effect is improved and the paint spraying efficiency is improved.

Owner:福州脉弧科技有限公司

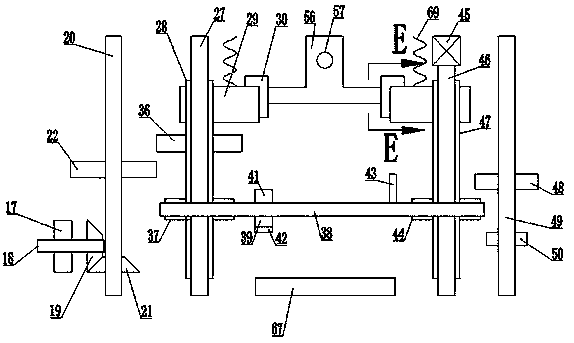

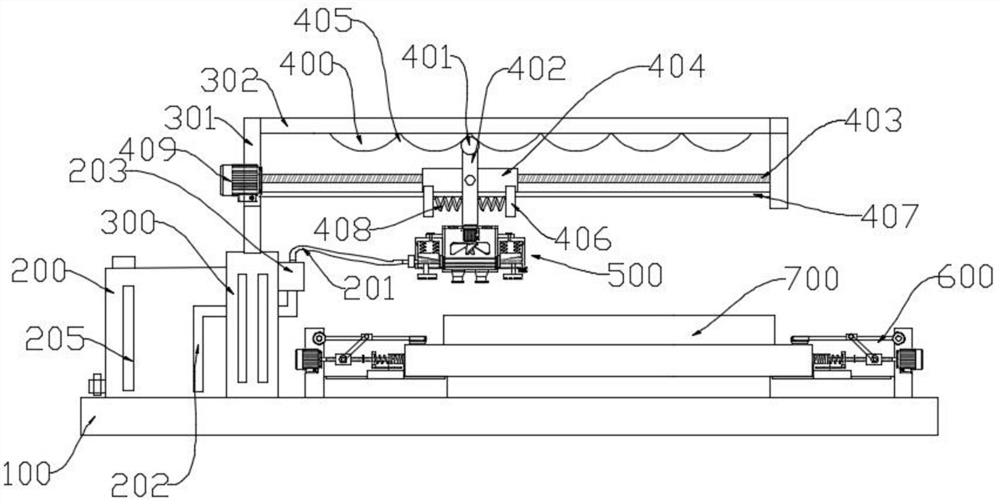

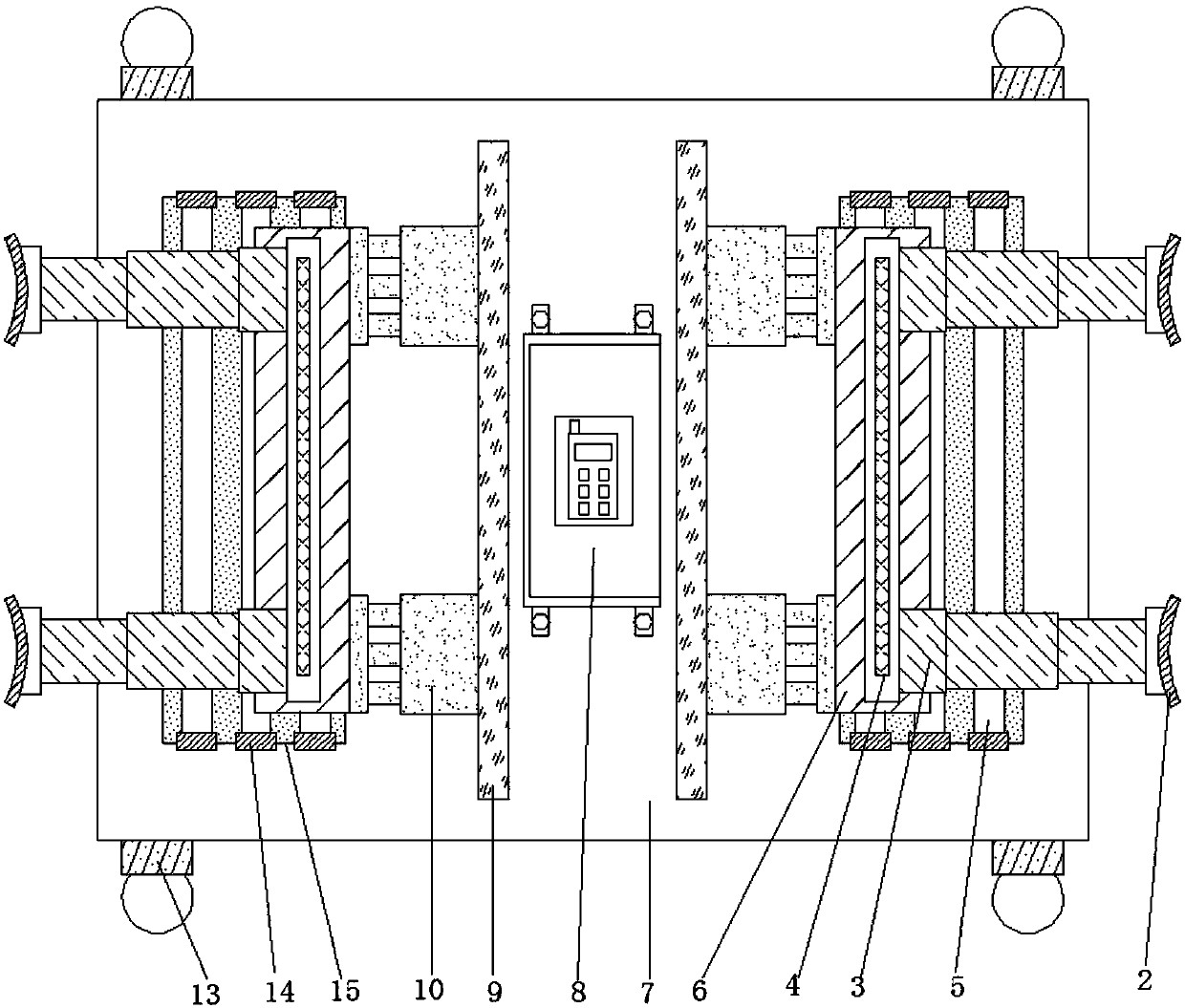

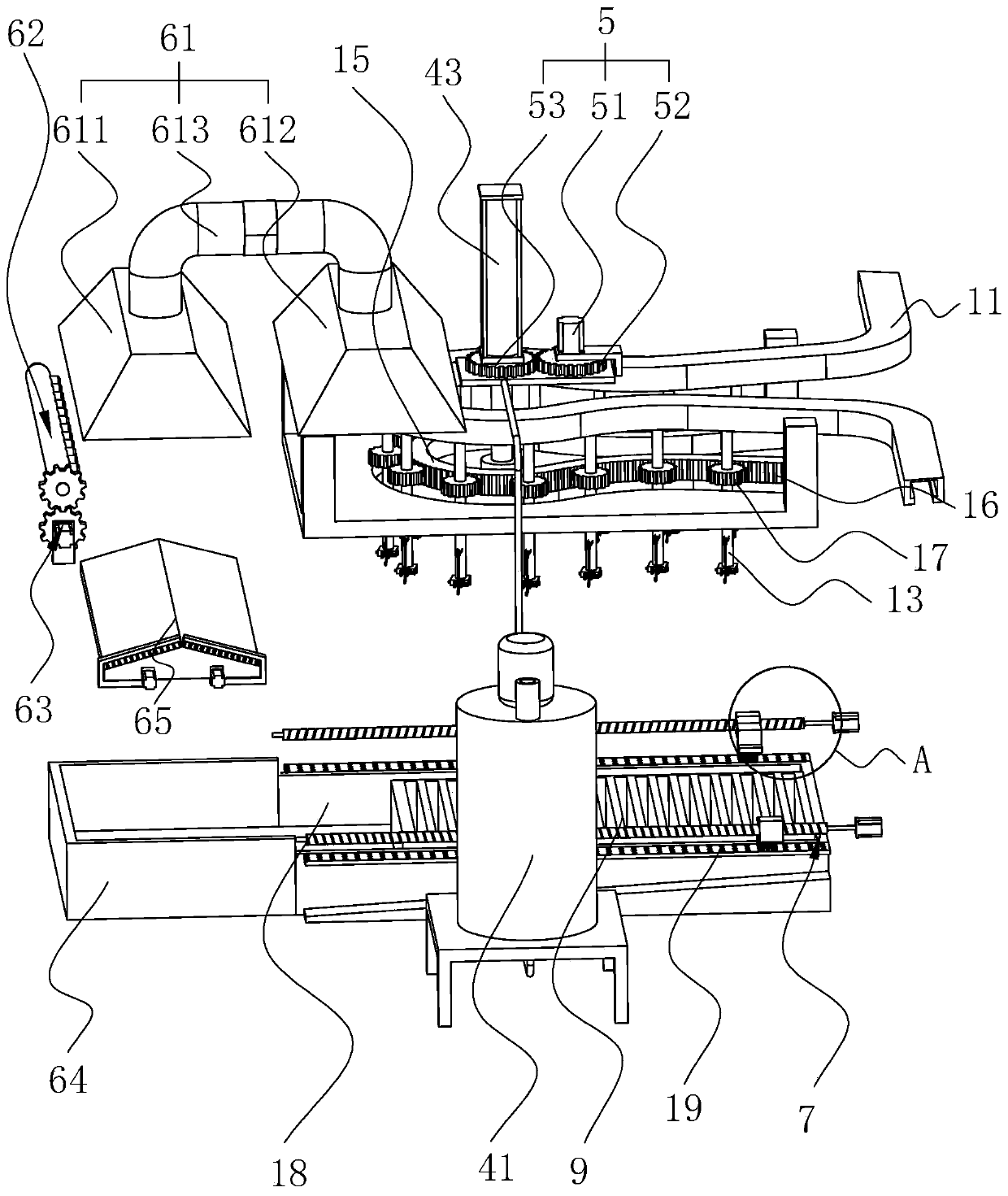

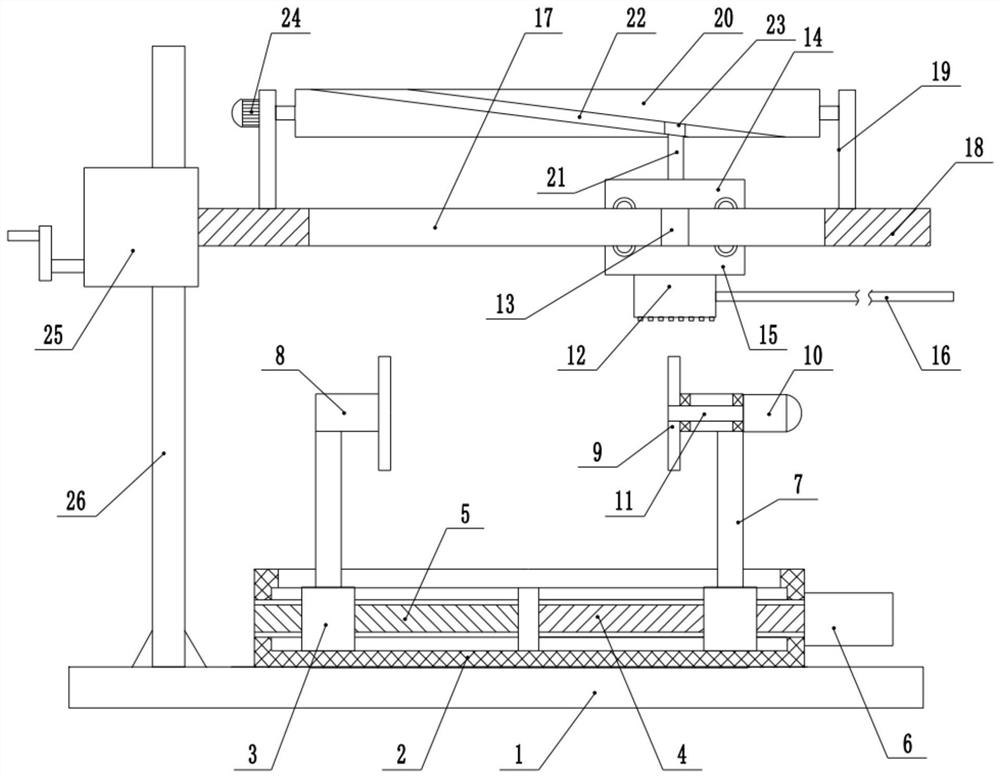

Intelligent environmental-friendly spraying line for combined multi-functional individual comprehensive training device

PendingCN110026835AImprove the effect of spray paintReduce processing timeGrinding carriagesRevolution surface grinding machinesProcessing typeAgricultural engineering

The invention relates to the technical field of paint spraying, and discloses an intelligent environmental-friendly spraying line for a combined multi-functional individual comprehensive training device. The intelligent environmental-friendly spraying line for the combined multi-functional individual comprehensive training device comprises a frame body, wherein rotary shafts are rotatably connected to the left side and the right side of the middle part of the frame body; fixed bases are fixedly connected to one sides, close to the middle, of the rotary shafts, and are fixedly connected with aprocessing piece; a first drive motor is fixedly connected to the left side of the bottom part of the frame body; and a first belt pulley is fixedly connected to an output shaft of the first drive motor and is connected with a second belt pulley through a belt. The intelligent environmental-friendly spraying line for the combined multi-functional individual comprehensive training device provided by the invention is applied to a spraying device; through arranging a screw rod and sliding block, the sliding block can move left and right on the upper part of the processing part; through arranginga grinding head and a spraying head, the process piece can be ground and paint-sprayed in one device, and two processing types can be accomplished through one-time clamping, so that the processing time is saved; in addition, a paint spraying effect of the ground processing piece is remarkably improved, so that the product quality is improved; and the whole device is simple to use, reasonable in design and suitable for popularization and use.

Owner:NANTONG YIDA SPORTS

Furniture paint spraying and drying processing equipment

InactiveCN107470075AEasy to carryIncrease productivityPretreated surfacesCoatingsEngineeringMechanical engineering

The invention belongs to the technical field of furniture producing and processing equipment, and particularly relates to furniture paint spraying and drying processing equipment. The furniture paint spraying and drying processing equipment comprises a base, a chamber is arranged on the base, and a partition plate is arranged on a top plate of the chamber and partitions the chamber into a paint spraying chamber and a drying chamber; a groove is formed in the lower end face of the partition plate, a first threaded hole of which the upper portion and the lower portion communicate with each other is formed in the top face of the groove, a first threaded rod is connected to the interior of the first threaded hole in a threaded mode, the upper end of the first threaded rod penetrates through the top face of the chamber and extends to the exterior of the chamber, a first gear is connected to the end, located outside the chamber, of the first threaded rod, and a first rotating mechanism is arranged on the top face of the chamber and connected with the first gear; and a baffle is slidably connected to the interior of the groove and connected to the first threaded rod in a sleeving mode, and an air supply device is arranged on the chamber. The furniture paint spraying and drying processing equipment has the advantages that not only can the paint spraying and drying operation efficiency be improved, but also harmful gas generated in the drying process can be effectively purified and absorbed.

Owner:FUJIAN ANXI JUFENG ARTWARE

Ship deck painting device with flushing device

ActiveCN105396747ATo achieve a uniform effect of spray paintQuality improvementLiquid surface applicatorsCoatingsMarine engineeringControl valves

The invention discloses a ship deck painting device with a flushing device. The ship deck painting device comprises a base. Sliding devices are arranged at four corners of the bottom of the base. A handle is arranged on the left side of the base. A water tank, a control box, a bearing seat, a storage box, a high-pressure pump and a feeding box are sequentially arranged on the upper surface of the base from left to right. A water inlet is formed in the top of the water tank, the bottom of the right side of the water tank is connected with a spraying head below the base through a water spraying pipe, and the water spraying pipe is provided with a control valve. A connecting block is arranged on the lower surface of the middle of the base, and the surface of the connecting block is connected with a supporting frame through bolts. The ship deck painting device with the flushing device achieves the effect of evenly painting a ship deck, protects a ship body against damage, and improves the quality and durability of the deck. A paint spraying head and a coating roller are improved, the effect of uniform spraying is achieved, and the phenomenon of unevenness is avoided.

Owner:JIANGSU NEW HANTONG SHIP HEAVY IND

Environment-friendly paint spraying equipment with uniform paint spraying function

The invention discloses environment-friendly paint spraying equipment with a uniform paint spraying function, and relates to the technical field of the environment-friendly paint spraying equipment. The equipment comprises a supporting frame, a fixing frame and a fixing box, wherein the top of the supporting frame is fixedly connected with the bottom of the fixing frame, the top of the inner wallof the fixing frame is fixedly connected with the top of the fixing box, a U-shaped sliding rail is fixedly connected to one side of an inner cavity of the fixing box, the inner wall of the U-shaped sliding rail is connected with a motor box through a sliding block in a sliding mode, one side of an inner cavity of the motor box is fixedly connected with a first motor through a supporting plate, and the output end of the first motor penetrates through the motor box and extends to the outside of the motor box. According to the environment-friendly paint spraying equipment with the uniform paintspraying function, paint spraying can be conducted properly on fixed workpieces, the paint spraying on the workpieces is uniform, the paint spraying effect of the equipment is greatly improved, the quality of the workpieces after paint spraying is guaranteed, the influence on use of the workpieces due to uneven paint spraying is avoided, so that the loss of a user is reduced, the automation degreeis high, and the equipment is safe and reliable.

Owner:安徽蓝华科技发展有限公司

Workpiece surface paint spraying equipment for machining

PendingCN111804495AAdjust tilt angleIncrease flexibilityPretreated surfacesCoatingsMachined surfaceStructural engineering

The invention relates to the technical field of surface treatment of mechanical workpiece processing and particularly discloses workpiece surface paint spraying equipment for machining. When the workpiece surface paint spraying equipment utilizes a first forward and reverse rotation servo motor to drive a support screw rod to rotate, the horizontal position of a support sliding block along the support screw rod can be adjusted according to the rotary direction of the support screw rod; a guide roller at the top end of a support swing rod is propped against a guide groove in a sliding manner, the horizontal position of the support sliding block is adjusted to adjust the inclination angle of the support swing rod, the inclination angle of the paint spraying equipment can be further adjusted,the spraying flexibility of the paint spraying equipment can be improved, that is, the paint spraying equipment is adjusted to a designated spot for paint spraying; and in addition, the position of the support sliding block is finely adjusted to adjust the inclination angle of the paint spraying equipment at the designated spot, so that the using flexibility of the surface paint spraying equipment is greatly improved.

Owner:陶唤唤

Workpiece surface paint spraying equipment for mechanical processing

ActiveCN112439599AEasy to sprayImprove the effect of spray paintLiquid spraying apparatusElectric machinerySlide plate

The invention discloses workpiece surface paint spraying equipment for mechanical processing, and belongs to the technical field of mechanical processing. The equipment comprises a supporting mechanism, wherein a lifting mechanism is arranged in the supporting mechanism, a clamping mechanism is rotatably connected to the interior of the lifting mechanism, a spraying mechanism is fixedly mounted atthe top end of the supporting mechanism, the supporting mechanism comprises a U-shaped supporting frame, and strip-shaped grooves are formed in one pair of opposite inner walls of the U-shaped supporting frame; a motor frame is fixedly mounted on the outer surface of the U-shaped supporting frame, a first driving motor is fixedly mounted on the motor frame, a first bevel gear is fixedly mounted at the output end of the first driving motor, the lifting mechanism comprises two first threaded lead screws, and the first threaded lead screws are rotatably connected to the interiors of the strip-shaped grooves; and a sliding plate is slidably connected to the outer sides of the first threaded lead screws. The paint spraying device not only can spray paint on the upper surface of a workpiece, but also can spray paint on the lower surface and the side surface of the workpiece, so that the applicability of the paint spraying device is greatly improved.

Owner:河北翼凌机械制造总厂

Paint spraying device for machining

InactiveCN110465435ARealize the effect of all-round paintingImprove practicalitySpray boothsDrive motorBevel gear

The invention discloses a paint spraying device for machining. The paint spraying device comprises a case, a driving mechanism and a paint spraying mechanism. The driving mechanism is arranged on theright side of the case, and the paint spraying mechanism is arranged at the top of the box. According to the paint spraying device for machining, a case, a driving motor, a driving rotating shaft, anoval block, a supporting plate, a first rolling bearing, a first supporting shaft, a driven bevel gear, a driving bevel gear, a first transmission wheel, a second rolling bearing, a second supportingrotating shaft, a carrying plate, a second transmission wheel, a belt, a paint box, a paint pump, a conveying pipe, a paint spraying pipe, first spraying heads, a hose, a connecting pipe, a second spraying head, a first supporting rod, a top plate, a reset spring and a roller are in cooperation, the effect of carrying out all-dimensional painting on a workpiece is achieved, the angle of the workpiece does not need to be adjusted by a user multiple times, time and effort are saved, the painting efficiency and the painting effect are effectively improved, and the practicability of the painting device for machining is greatly improved.

Owner:刘涛

Metal pipeline corrosion preventing treatment device

InactiveCN109351526AEvenly paintedImprove the effect of spray paintSpraying apparatusMotor driveEngineering

The invention discloses a metal pipeline corrosion preventing treatment device. According to the metal pipeline corrosion preventing treatment device, a first lead screw is rotationally supported between a supporting base and a first supporting column, and a first motor drives the first lead screw to rotate; a supporting sliding column arranged in a first slide groove in a base is in threaded connection with the first lead screw; rotating shafts are rotationally supported on the supporting sliding column and the first supporting column, and the ends, in opposite directions, of the two rotatingshafts are provided with pipeline abutting connection heads; a second motor drives one rotating shaft to rotate; a cross beam is provided with a second slide groove; a second lead crew is rotationally supported on the first supporting column and the second supporting column, and a third motor drives the second lead screw to rotate; a movable threaded block arranged in the second slide groove is in threaded connection with the second lead screw; a paint spraying gun is arranged at the bottom of the movable threaded block; and the base is provided with a paint spraying device communicating withthe paint spraying gun. The metal pipeline corrosion preventing treatment device is convenient to use, and suitable for performing corrosion preventing treatment on the exterior of a metal pipeline.

Owner:荣成市天健管道防腐保温器材有限公司

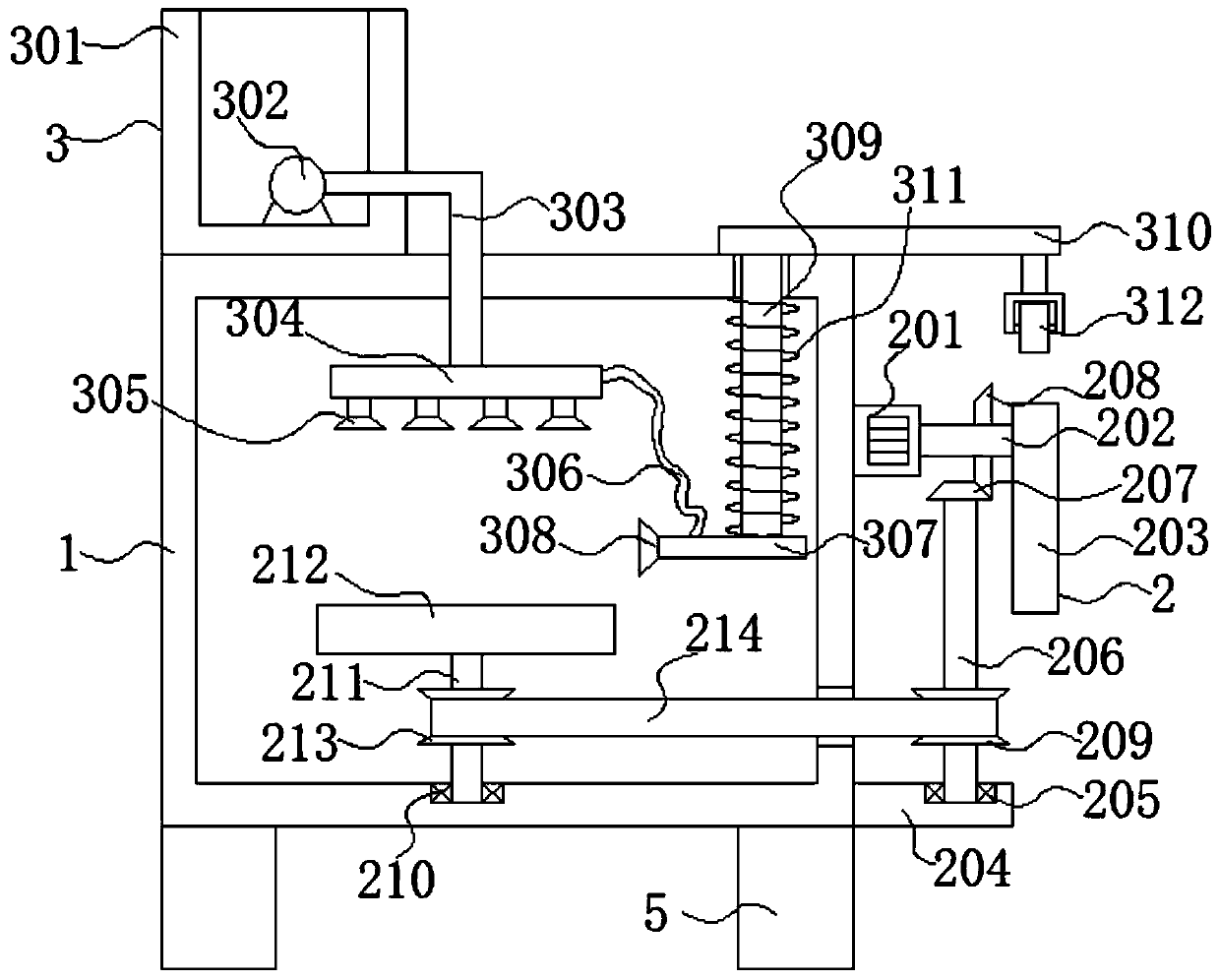

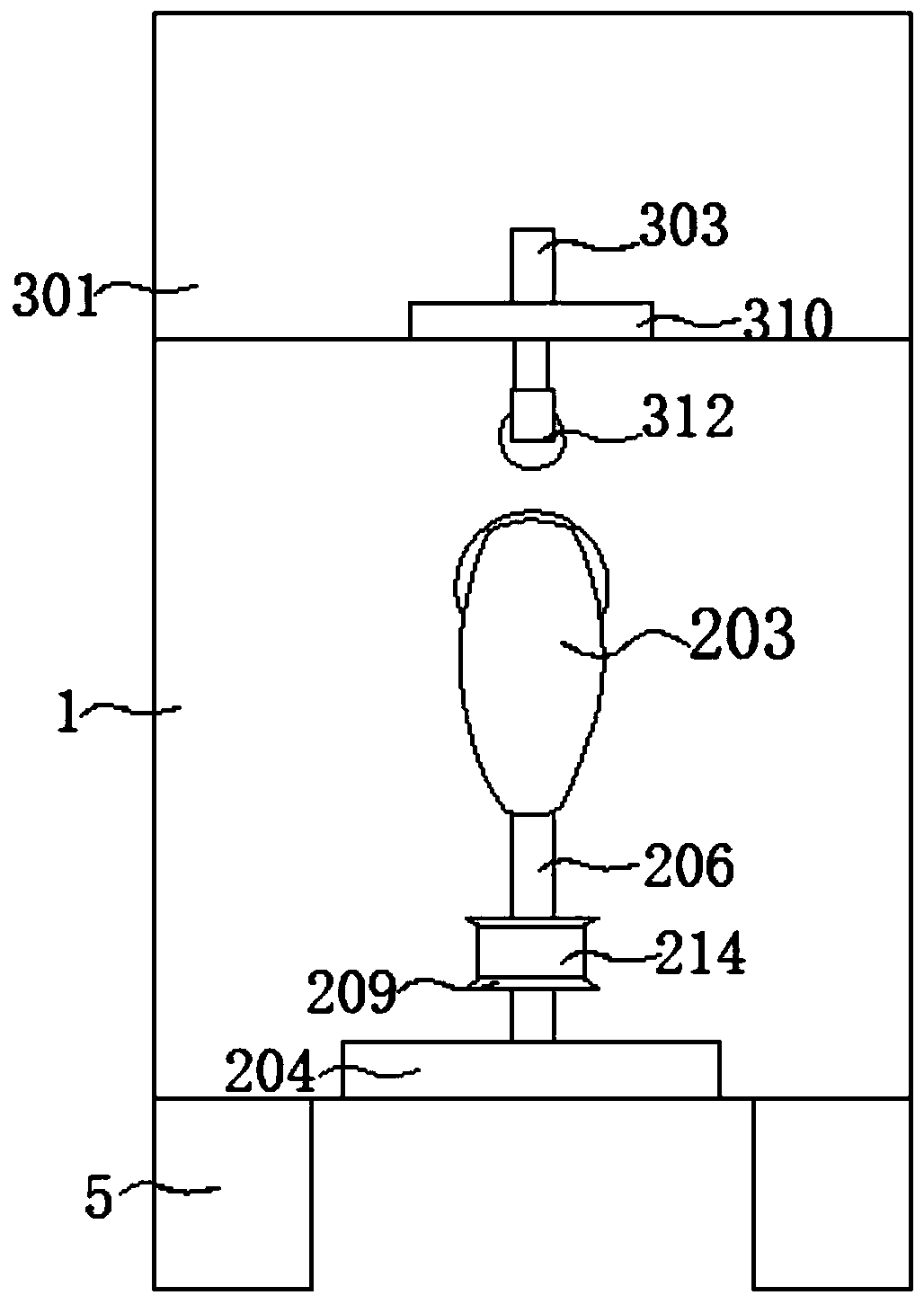

Surface paint spraying device for baseball bat processing

InactiveCN112090662AImprove the effect of spray paintSpeed up the drying ratePretreated surfacesCoatingsBaseball batStructural engineering

The invention discloses a surface paint spraying device for baseball bat processing. The surface paint spraying device comprises a bottom plate, a fixing frame is fixed to the upper surface of the bottom plate, a groove is formed in the upper surface of the bottom plate, and a two-way screw is rotatably connected to the inner wall of the groove. Two moving sleeves are connected to the surface of the two-way screw in a threaded mode, moving plates are fixed to the surfaces of the moving sleeves, rotating shafts are rotatably connected to the surfaces of the two moving plates, and fixing cylinders are fixed to the opposite ends of the two rotating shafts. A baseball bat is placed between the two fixing cylinders, and a rotating assembly for driving the rotating shaft located on the left sideto rotate is rotatably connected to the side face of the fixing frame. According to the surface paint spraying device for baseball bat processing, through the cooperation of the structures, baseballbats with different sizes can be clamped and fixed, and the clamped baseball bats can be driven to rotate; and meanwhile, under left-right reciprocating paint spraying of a paint spraying head, paintspraying can be comprehensively and uniformly carried out on the surfaces of the baseball bats, and the paint spraying effect on the surfaces of the baseball bats is improved.

Owner:TIANCHANG ZHENGMU ALUMINUM TECH

Fixing clamp for spraying paint to car shell

Owner:肇庆市荣信精密机械制造有限公司

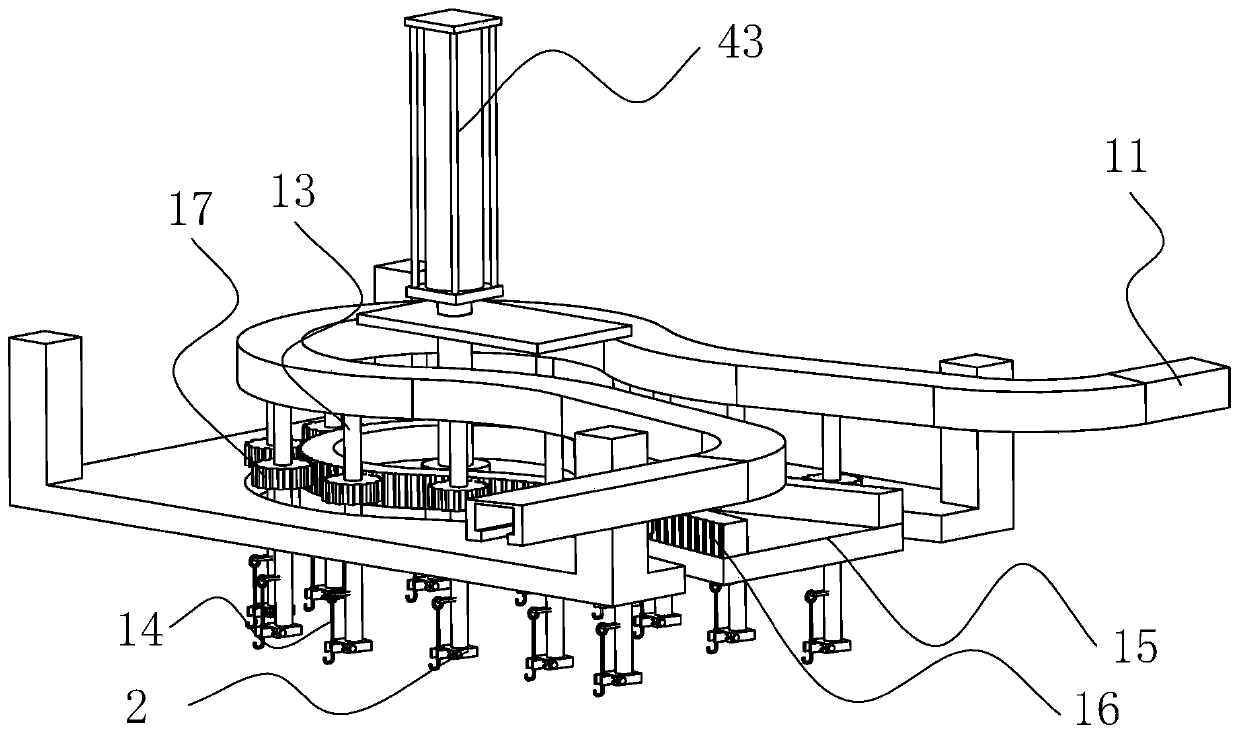

Paint spraying equipment for motor shell

ActiveCN110976137AImprove stabilityImprove the effect of spray paintSpraying apparatusExhaust fumesElectric machinery

The invention relates to the technical field of motor paint spraying, in particular to paint spraying equipment for a motor shell. The paint spraying equipment comprises a paint spraying room. The paint spraying room is provided with a sliding rail. A chain is arranged inside the sliding rail. A fixing block is arranged on the chain. A connecting rod is arranged on the fixing block. A hook is arranged on the connecting rod. A paint spraying mechanism is arranged inside the paint spraying room. A waste gas processing device is arranged on one side of the paint spraying room. A fixing mechanismis arranged on the connecting rod. The fixing mechanism comprises a connecting block arranged on the connecting rod. A first clamping arm and a second clamping arm are arranged on the connecting block. The connecting block is provided with a first adjusting assembly. The first adjusting assembly can adjust the distance between the first clamping arm and the second clamping arm. By means of the fixing mechanism arranged on the equipment, the stability during moving of a motor can be improved, and then the paint spraying effect is improved.

Owner:绍兴市雪花机电有限公司

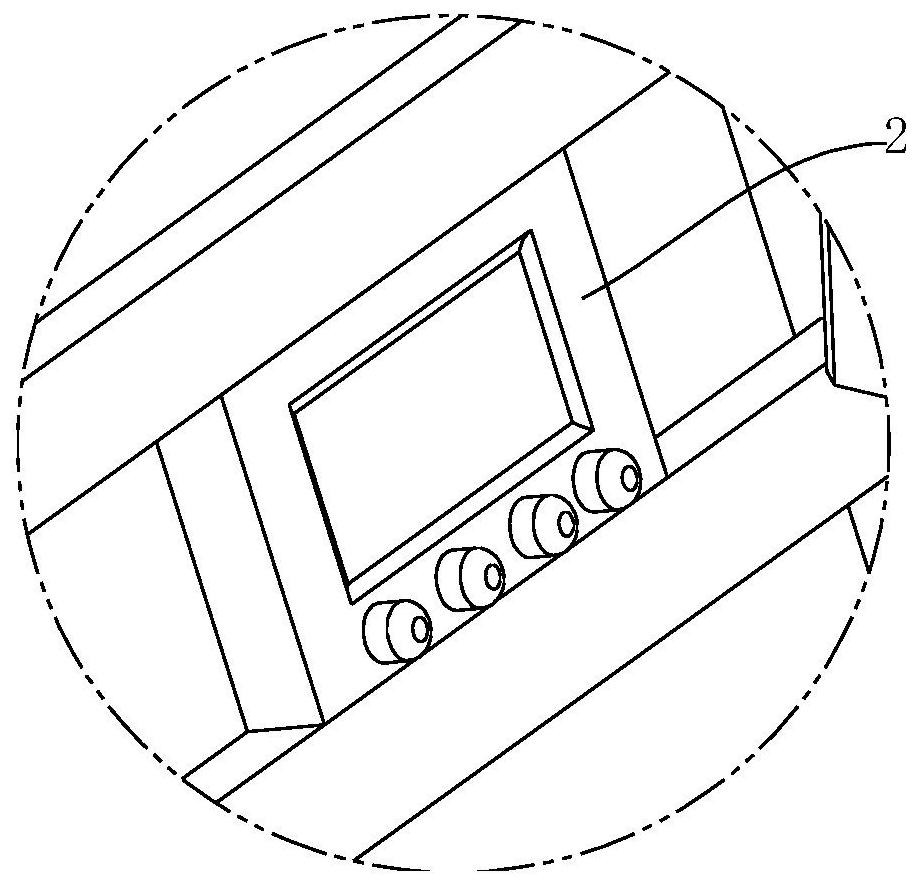

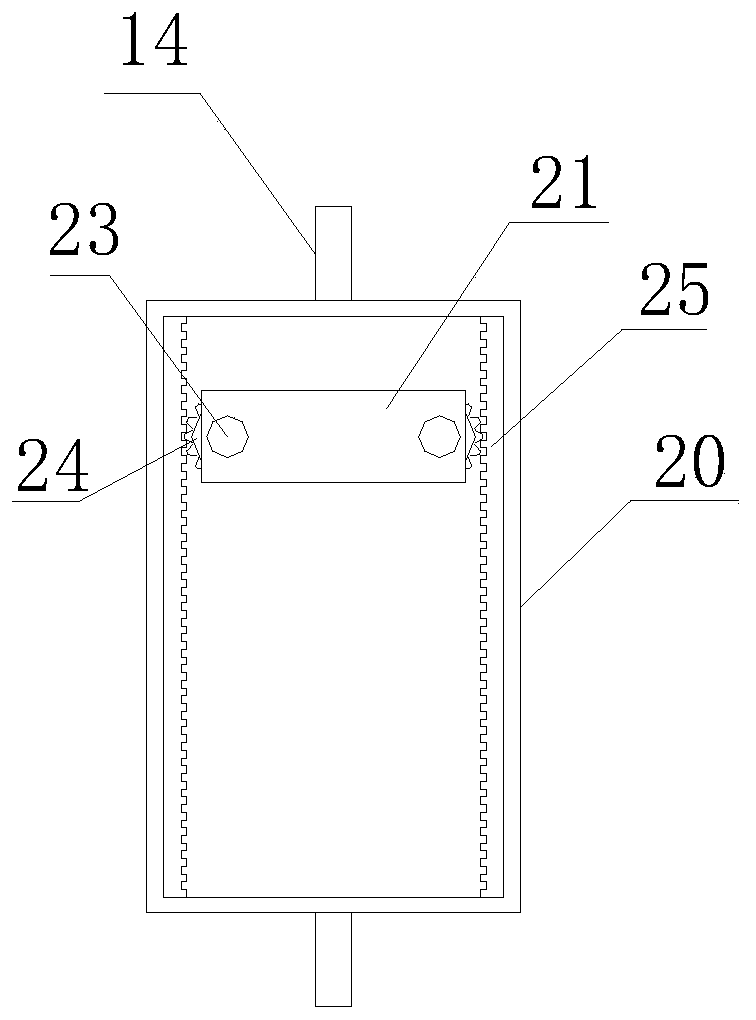

Paint spraying device for controller production

InactiveCN109701781AImprove fluencyImprove uniformityLiquid spraying apparatusDrive shaftProduction effect

The invention relates to a paint spraying device for controller production. The paint spraying device for controller production comprises a paint barrel, a stirring shaft, a mixing blade, an output pump, a circulation pump, a working table, a bracket, a rotating shaft, a spray gun, a driving shaft, a worm, a driver, a turbine, and a synchronous belt, wherein the paint barrel is arranged on the bracket which is at the top of supporting legs; the worm is fixedly connected with the mixing shaft; the mixing blade is arranged on the mixing shaft; the turbine meshes with the worm; the spray gun is connected to the bottom of the inside of the paint barrel through the output pump; a recovery tank is connected to the inside of the paint barrel through the circulation pump; the rotating shaft is rotatably connected to the bracket; the left end of the rotating shaft penetrates through the bracket and extends to the left side of the bracket; and the right end of the driving shaft penetrates through the paint barrel and is connected with the rotating shaft through the synchronous belt in driving mode. The paint spraying device for controller production is good in structure, excellent in equipment, easy and convenient to operate, and high in degree of equipment fitting; the cost and manpower are saved, the production effect and paint spraying efficiency are improved, and the device has widerange of application prospects and is highly creative.

Owner:天长市龙亨电子有限公司

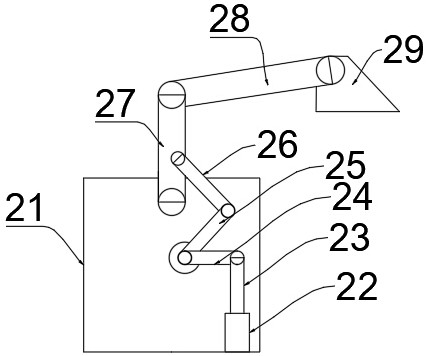

Painting robot arm device

InactiveCN108993801AImprove efficiencyAvoid uneven paintingSpraying apparatusManipulatorPaint robotDrive motor

The invention discloses a painting robot arm device. The painting robot arm device comprises a base, a casing and an air cylinder; the lower portion of the base is connected with universal wheels through bearings; a balancing weight is welded and fixed to the upper portion of the base; the casing is welded and fixed to the upper portion of the base; an air pump is mounted in the casing; an air inlet is mounted on the left portion of the air pump; a processor is mounted on the side, away from the balancing weight, of the air pump; an operation panel is mounted on the left side of the processor;the air cylinder is mounted on the upper portion of the casing; a telescopic spring is mounted in the air cylinder; a rotator is mounted on the upper portion of the air cylinder; a driving motor is mounted on the right side of the rotator; a horizontal pipe is mounted on the right side of the driving motor; the upper portion of the horizontal pipe is provided with a paint inlet pipe; and an adjustment knob is mounted on the right side of the paint inlet pipe. Operation of the device is not limited by the volume, the application range is wide, the rotator is arranged, the angle of a nozzle canbe finely adjusted, the painting effect is good, and the painting operation efficiency is improved.

Owner:SUZHOU HONGMIAO INTELLIGENT TECH CO LTD

Omnibearing paint spraying equipment for case shell processing

InactiveCN111644292AAchieve clampingRealize the rotation effectSpraying apparatusEngineeringSpray painting

The invention relates to the technical field of case shell processing, and discloses omnibearing paint spraying equipment for case shell processing. The omnibearing paint spraying equipment for case shell processing comprises a fixing bottom plate, wherein a fixing frame is installed in the middle of the upper end of the fixing bottom plate, a left-handed screw and a right-handed screw which are fixedly connected are installed in the fixing frame, moving blocks are respectively installed in the middle of the left-handed thread and in the middle of the right-handed thread, a moving frame is installed at the upper end of the moving block, a rotating cylinder is installed at the upper end of each moving frame, a rotating shaft is installed inside each rotating cylinder, and one end of the inner side of each rotating shaft penetrates through the corresponding rotating cylinder to be connected with a rotating plate. A rack is installed on the left side of the upper end of the fixing bottomplate, a lifting box is arranged in the middle of the rack in a sliding mode, a lifting frame is arranged in the middle of the right side of the lifting box, and supporting frames are arranged on thetwo sides of the upper end of the lifting frame. According to the omnibearing paint spraying equipment for case shell processing, the clamping and rotating effects on the case shell are realized, meanwhile, a paint spraying case can swing left and right through the matching of the rotating cylinder, an upper guide block and a lower guide block, and the omnibearing paint spraying effect on the caseshell in the rotating state is further realized.

Owner:宋小航

Pull rod paint spraying device for luggage production

The invention discloses a pull rod paint spraying device for luggage production. The pull rod paint spraying device comprises a machine body, a feeding device and a workbench, the feeding device and the workbench are fixedly installed in the machine body, the feeding device comprises a side plate fixedly installed on the inner bottom face of the machine body, a hydraulic rod is fixedly installed on the side face of the side plate, the hydraulic rod is connected with a telescopic rod, the end, away from the hydraulic rod, of the telescopic rod is connected with a rotating rod rotatably installed on the side face of the side plate, and the end, away from the telescopic rod, of the rotating rod is fixedly connected with a first rotary rod. By arranging the feeding device, a pull rod can be conveniently fed in a using process, by arranging a paint mixing device, paint can be conveniently mixed in a paint spraying process, by arranging a drying device, the painted pull rod can be conveniently dried, the paint spraying effect can be conveniently improved, and by means of up-down stretching and contracting of the hydraulic rod, the telescopic rod is driven to move up and down.

Owner:永新县鹃花皮具箱包有限公司

Automatic paint spraying device for automobile part machining

InactiveCN109530137AImprove the effect of spray paintImprove practicalitySpraying apparatusMotor driveSpray nozzle

The invention relates to the technical field of automobile part machining equipment, and discloses an automatic paint spraying device for automobile part machining. The automatic paint spraying devicefor automobile part machining comprises a machine table, wherein the side surface of the machine table is movably sleeved with moving wheels through a rotating shaft; a supporting table is fixedly installed at the top end of the machine table; a clamping plate is fixedly installed at the top end of the supporting table; the clamping plate is in transmission connection with a spray gun adjusting device through a positioning shaft; the middle part of the spray gun adjusting device is movably sleeved with a spray gun; a spray nozzle is fixedly installed on the side surface of the spray gun; theother end of the spray gun is fixedly sleeved with a guide pipe; and a fixed block is fixedly connected to the bottom of the one end, close the guide pipe, of the spry gun through screws. According tothe automatic paint spraying device for automobile part machining, a motor drives a rotating disc to rotate, a transmission plate drives the fixed block to drive the spray gun to move up and down, and a positioning shaft is used as a fulcrum, so that the angle of the spray gun is adjusted; and meanwhile, the rotation of the rotating disc is used for forming a paint spraying range which is automatically adjusted up and down, so that the paint spraying effect is improved, and the cost is saved.

Owner:扬州明成机械新技术研发服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com