Rapid surface paint spraying device for hardware plates

A kind of plate, fast technology, applied in the direction of surface coating liquid device, spray device, liquid spray device, etc., can solve the problems of easy precipitation and solidification of paint, affecting the quality of painting, low painting efficiency, etc., to improve the effect of painting, structure Reasonable and simple, fast painting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

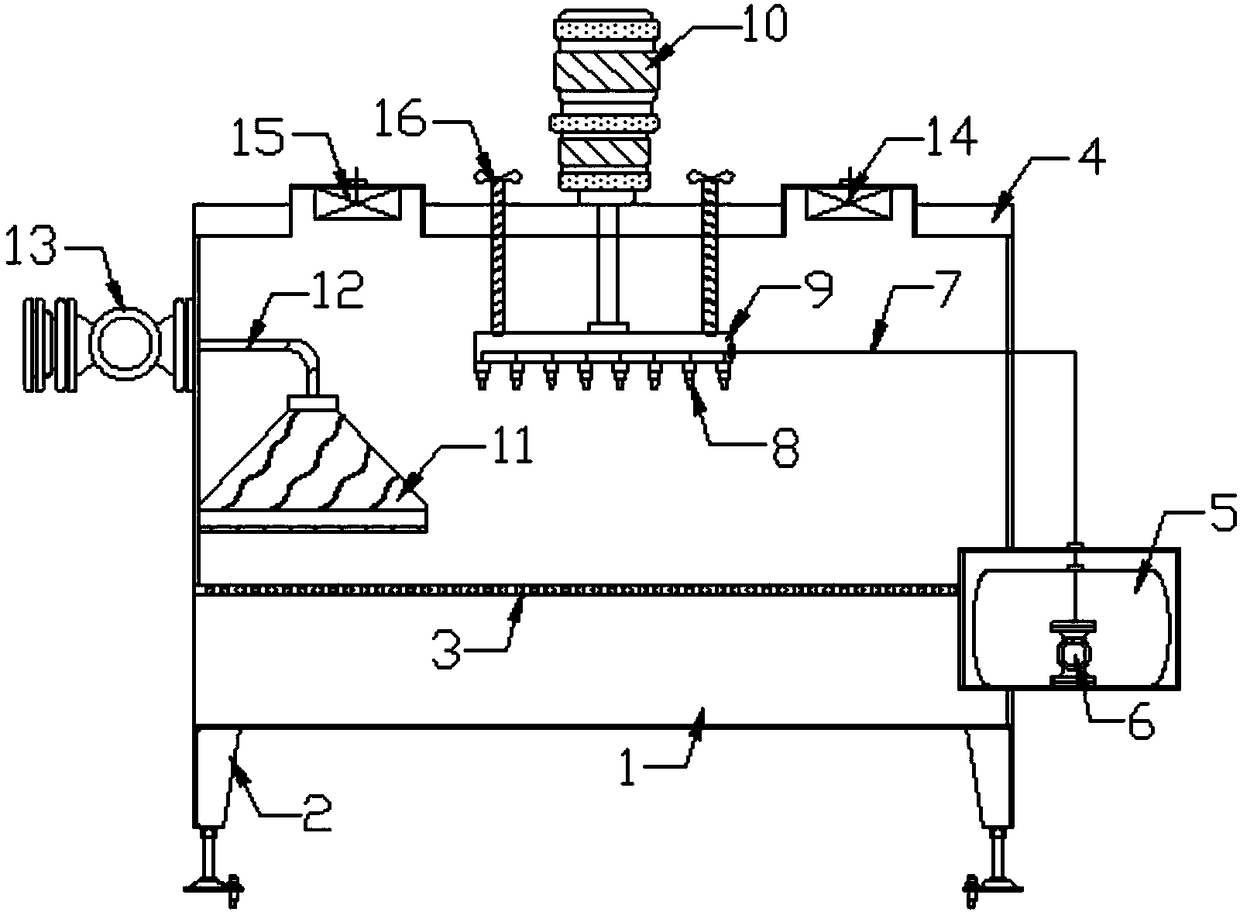

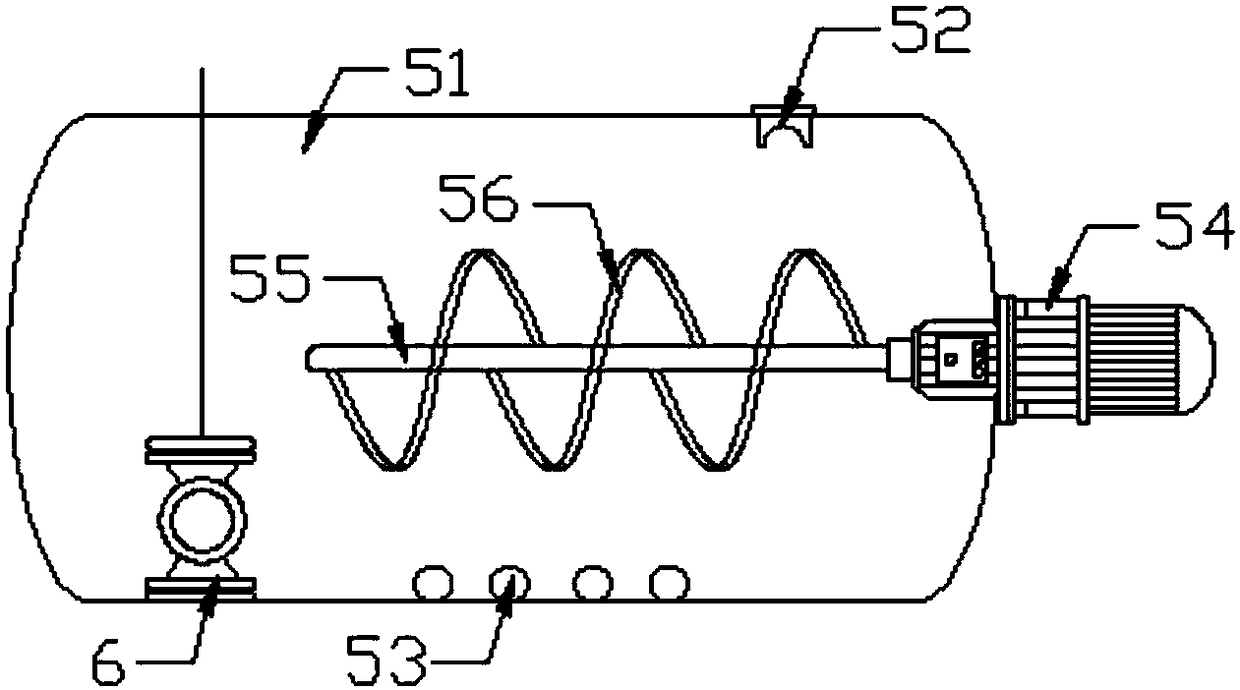

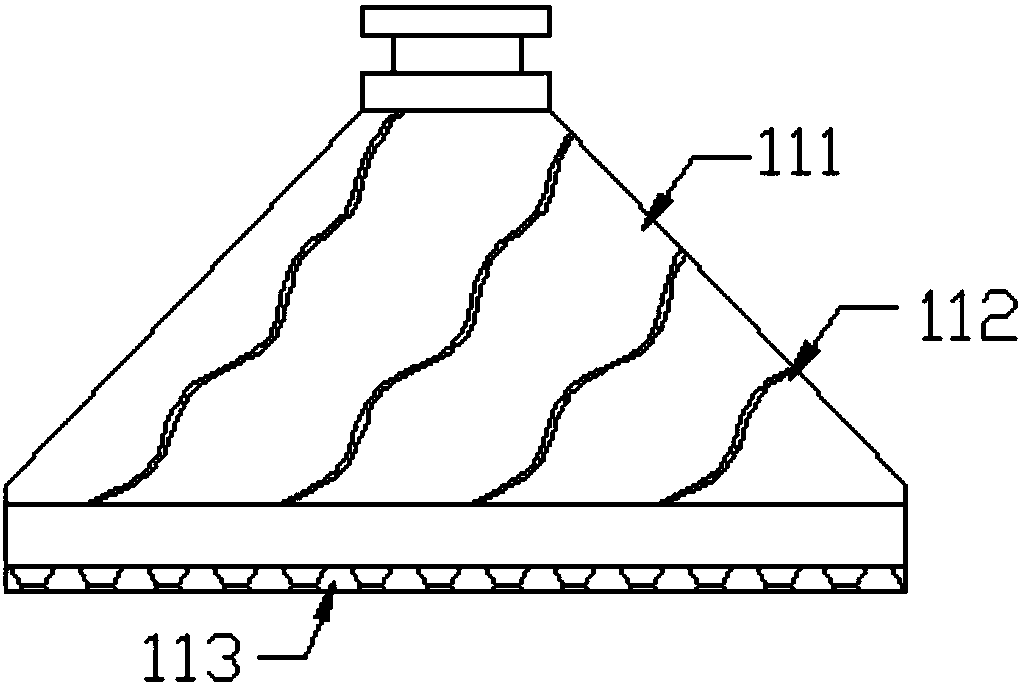

[0020] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a surface rapid painting device for metal plates, including a base 1, a protective cover 4, a paint storage device 5 and a paint spray head 8, the bottom of the base 1 passes through the support seat 2 and the ground are fixedly installed, a conveyor belt 3 is installed on the top of the base 1, the conveyor belt 3 is connected to the motor through a transmission wheel, a protective cover 4 is installed on the base 1, and a Paint storage device 5, the output end of described paint storage device 5 is connected with the input end of the paint nozzle 8 that is installed in protective cover 4 through feed pipe 7, and the input end of described feed pipe 7 is equipped with paint pump 6, The paint sprayer 8 is provided with a plurality, the paint sprayer 8 is fixedly installed on the bottom of the fixed plate 9, the top of the fixed plate 9 is connected with the output end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com