Workpiece surface paint spraying equipment for machining

A technology of workpiece surface and painting equipment, which is applied in the direction of paint spraying room, pretreatment surface, surface coating liquid device, etc., can solve the problem that cannot meet the quality requirements of large-volume workpieces, cannot be sprayed, and cannot be stably and reliably clamped fixed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

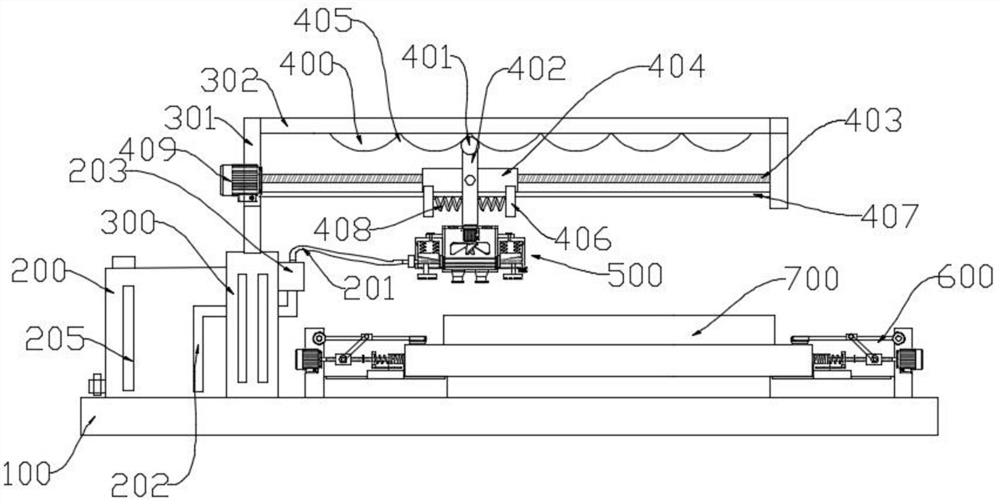

[0035] Such as figure 1 As shown, in the embodiment provided by the present invention, a workpiece surface painting equipment for mechanical processing, the painting equipment includes an equipment base 100, and a hydraulic telescopic cylinder 300 is fixedly arranged on one side of the equipment base 100, and the The telescopic end of the top of the hydraulic telescopic cylinder 300 is fixedly provided with a support column 301, the top of the support column 301 is fixedly equipped with a support frame 302, and the lower surface of the support frame 302 is uniformly and fixedly provided with a plurality of arc-shaped protrusions 400, A guide groove 405 is formed between two adjacent arc-shaped protrusions 400; the lower part of the support column 301 is supported and rotated to be provided with a support screw 403, and a support slider 404 is sleeved on the support screw 403 through a threaded connection. The bottom surfaces of both sides of the support slider 404 are fixedly ...

Embodiment 2

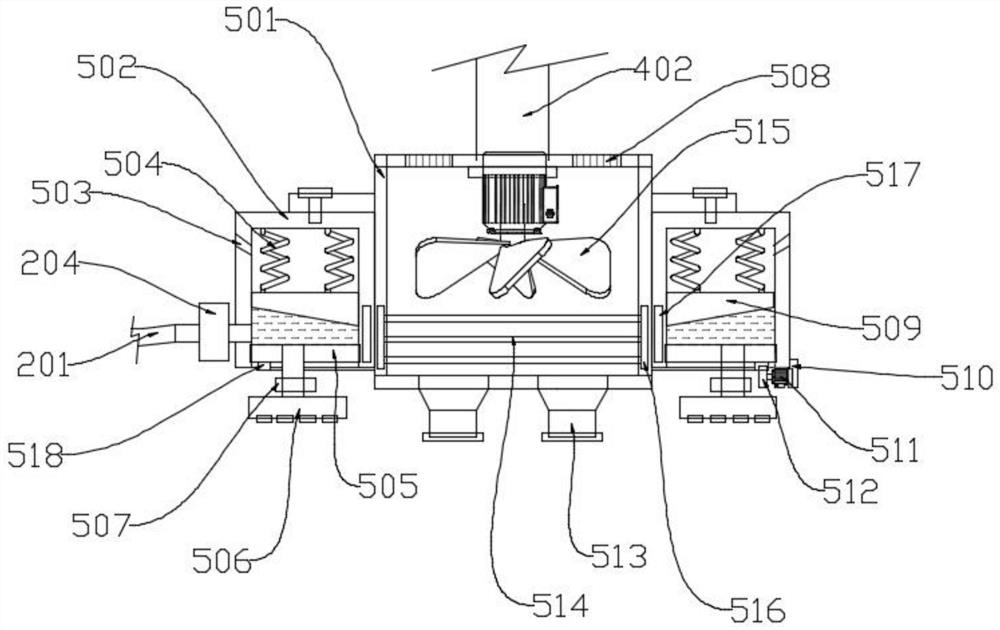

[0041] The difference from Example 1 is that please continue to refer to figure 1 , figure 2 , image 3 and Figure 7 , in the embodiment provided by the present invention, the structure of the painting device 500 is also specifically defined.

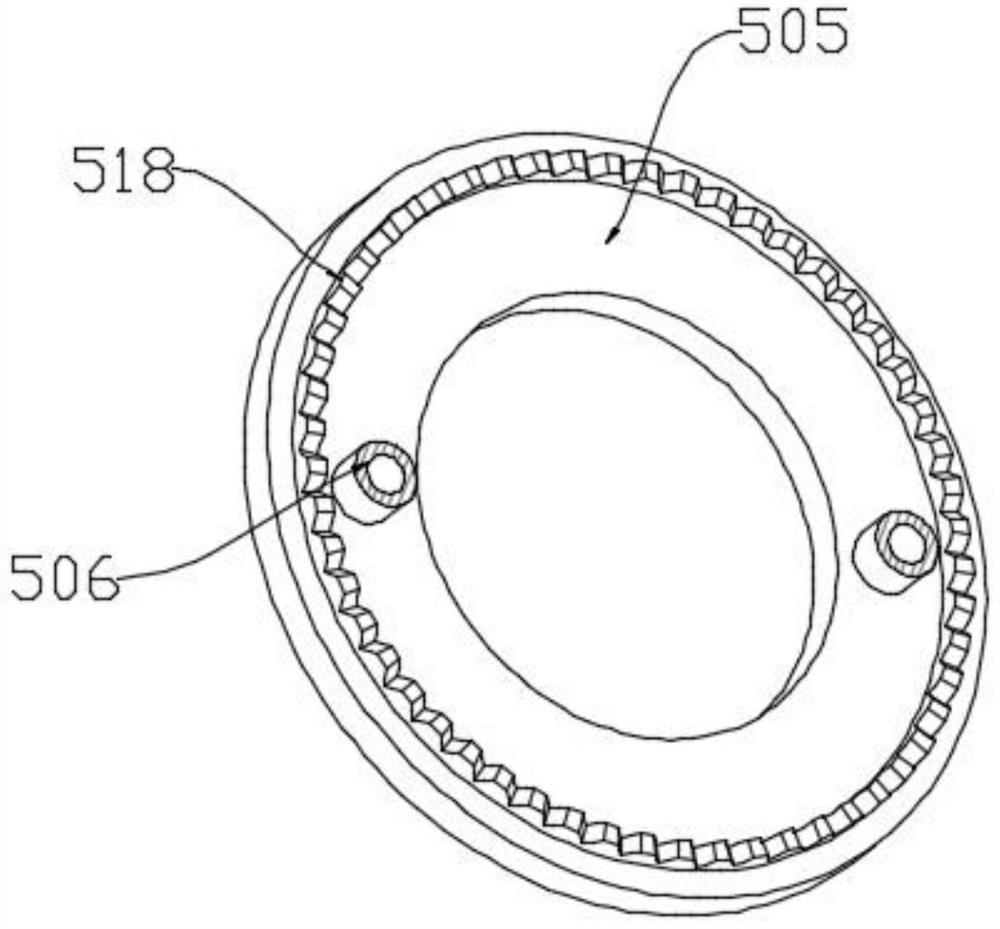

[0042] Specifically, in the embodiment provided by the present invention, the painting device 500 includes a motor base 501 fixedly installed at the bottom end of the support pendulum 402, and the outer ring of the motor base 501 is fixedly sleeved with a ring Box 502, the bottom opening of the annular box 502 is sealed and rotated with a liquid distribution rotating disk 505, and the liquid distribution rotating disk 505 is provided with a paint atomizer for spraying paint liquid in the annular box 502 Nozzle 506, and the liquid inlet part of the paint atomization nozzle 506 is also provided with a booster valve 507 to enhance the effect of the paint atomization nozzle 506 spraying paint; in addition, the bottom outer ring of the ...

Embodiment 3

[0050] Different from Embodiment 2, this embodiment of the present invention also includes a clamping assembly 600 disposed on the equipment base 100, and the clamping assembly 600 is used to clamp and fix a workpiece 700 that needs to be surface painted.

[0051] Specifically, such as figure 1 , Figure 4 , Figure 5 and Figure 6As shown, in the embodiment provided by the present invention, the clamping assembly 600 includes a clamping and fixing base 601 fixedly arranged on the equipment base 100, and a supporting slider is provided on the clamping and fixing base 601 for sliding support. 602, the upper surface of the outer end of the clamping and fixing seat 601 is fixedly installed with a support vertical plate 603, and the second forward and reverse servo motor 604 is fixedly installed on the support vertical plate 603, and the second forward and reverse servo motor The output shaft of 604 is driven and connected with an adjustment rotating shaft 605;

[0052] Furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com