Pull rod paint spraying device for luggage production

A technology for trolleys and bags, which is applied to spraying devices, spray booths, and devices for coating liquid on the surface, etc. It can solve the problems of lack of feeding mechanism, time-consuming and labor-intensive drying device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

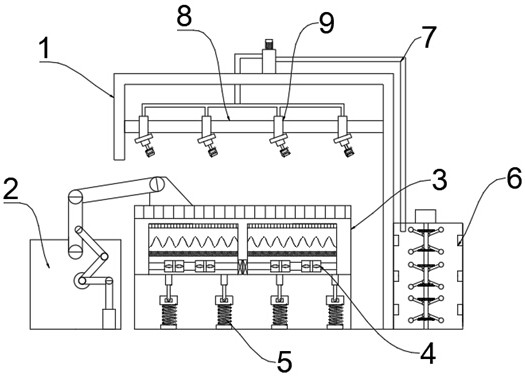

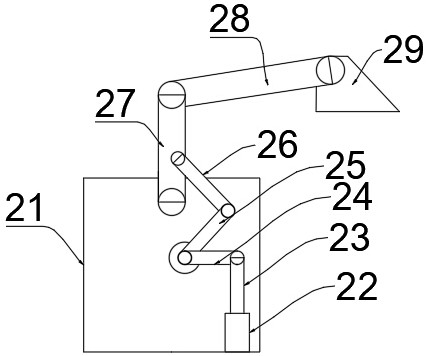

[0028] refer to Figure 1 ~ Figure 4 , a kind of trolley painting device for luggage production, comprising a fuselage 1 and a feeding device 2 and a workbench 3 fixedly installed inside the fuselage 1, the feeding device 2 includes a side plate 21 fixedly installed on the inner bottom surface of the fuselage 1, and the side The side of plate 21 is fixedly installed with hydraulic rod 22, and hydraulic rod 22 is connected with expansion rod 23, and one end of telescopic rod 23 away from hydraulic rod 22 is connected with the rotating rod 24 that is installed on the side of side plate 21, and rotating rod 24 is away from telescopic rod 24. One end of the rod 23 is fixedly connected with a first rotating rod 25, and one end of the first rotating rod 25 away from the rotating rod 24 is rotatably connected with a connecting rod 26, and the connecting rod 26 is connected with a second rotating rod 27 which is rotatably mounted on the side plate 21 side. The end of the second rotati...

Embodiment 2

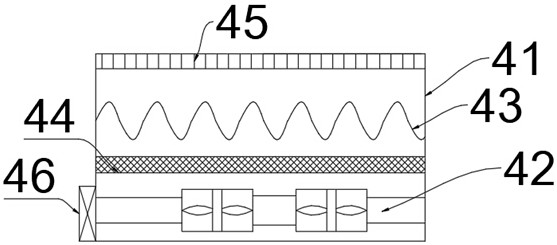

[0035] refer to Figure 4 ~ Figure 5 , a pull rod painting device for luggage production. Compared with Embodiment 1, the end of the stirring rod far away from the stirring shaft 63 is connected with a magnetic ball 64, and the stirring rods arranged on both sides of the stirring shaft 63 are connected with a second Two springs 65, permanent magnets 66 are fixedly installed on the both sides inner walls of the paint bucket 61, and the damping device 5 includes a bottom block 51 fixedly installed on the inner bottom surface of the workbench 3, and the top of the bottom block 51 is connected with a spring 52, and the spring 52 An end away from the bottom block 51 is connected to a middle block 53 , and an end of the middle block 53 away from the spring 52 is connected to a push rod 54 .

[0036] Working principle: when in use, the magnetic ball 64 and the permanent magnet 66 are set to facilitate the swinging of the agitating rod through the magnetic suction force during use, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com