Chopping board slotting and forming equipment for kitchen

A technology for forming equipment and cutting boards, which is applied in the field of kitchen cutting board slotting and forming equipment, which can solve the problems of many operations, inability to achieve precise slotting, low work efficiency, etc., and achieve the effect of achieving the effect of rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

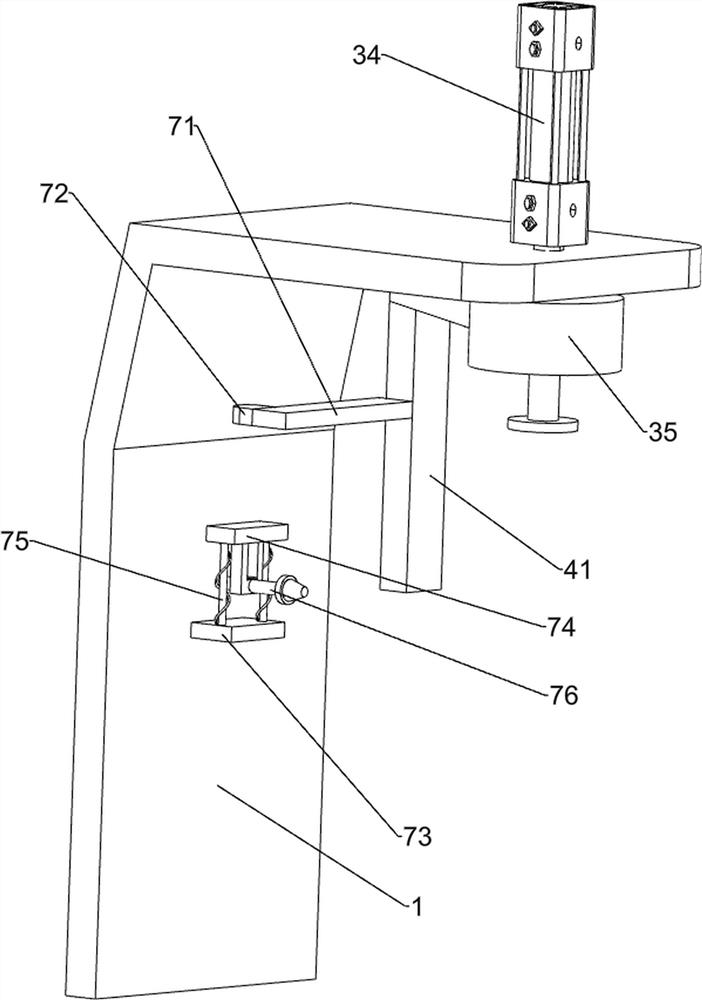

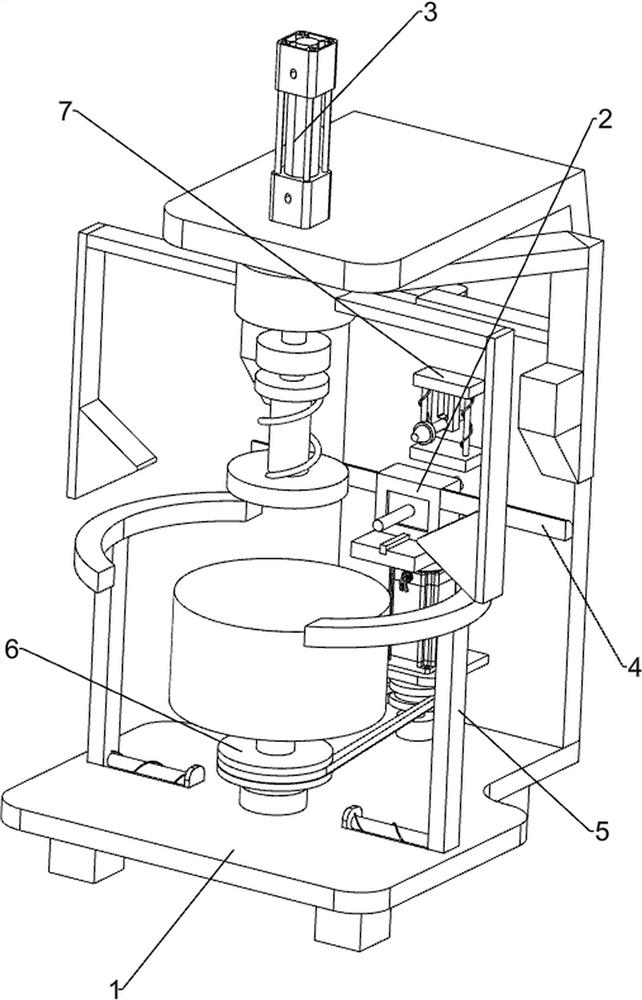

[0065] A cutting board slotting and forming equipment for kitchen, such as figure 1 As shown, it includes a base 1 , a slotting mechanism 2 and a clamping mechanism 3 . The slotting mechanism 2 is provided in the middle of the upper front wall of the base 1 , and the clamping mechanism 3 is provided on the base 1 .

[0066] When people want to slot the chopping board, they can use this kitchen chopping board slotting forming equipment. First, the user places the chopping board that needs to be slotted in the clamping mechanism 3, starts the slotting mechanism 2, and performs the cutting process on the chopping board. Grooving.

Embodiment 2

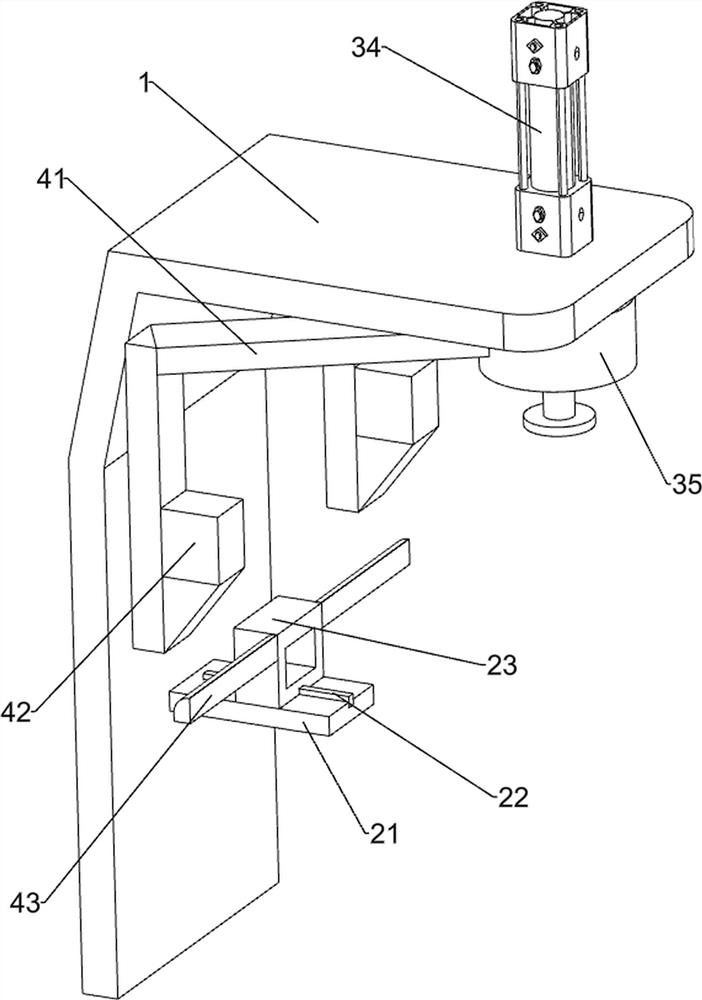

[0068] On the basis of Example 1, such as figure 2 with image 3As shown, the slotting mechanism 2 includes a first support frame 21, a slider 22, a second support frame 23, a rotary cutter 24 and a first telescopic assembly 25, and the middle part of the upper front wall of the base 1 is provided with a first support frame 21, The middle of the first support frame 21 top is provided with a slide block 22, the slide block 22 top sliding type is provided with a second support frame 23, the front side of the second support frame 23 inner wall is rotatably provided with a rotary cutter 24, and the second support frame 23 rear side A first telescopic assembly 25 is provided.

[0069] The user starts the rotary cutter 24, pushes the second support frame 23 forward, and the first telescopic assembly 25 stretches to slot the cutting board to realize the slotting effect. After the slotting is completed, the second support frame 23 is pushed backward, The first telescopic assembly 2...

Embodiment 3

[0073] On the basis of Example 2, such as Figure 4-Figure 7 As shown, a moving mechanism 4 is also included. The rear side of the push plate 35 is provided with a moving mechanism 4. The moving mechanism 4 includes a second connecting rod 41, a first wedge block 42 and an arc block 43. The rear side of the push plate 35 is provided with a The two second connecting rods 41 are provided with first wedge-shaped blocks 42 on the lower front sides of the two second connecting rods 41 , and arc-shaped blocks 43 are provided on the left and right sides of the second support frame 23 .

[0074] When the push plate 35 moves downward, it drives the second connecting rod 41 to move downward, and then drives the first wedge block 42 to move downward. The first wedge block 42 contacts the arc block 43, thereby driving the arc block 43 to move downward. Move forward, and then drive the second support frame 23 to move forward to realize the moving effect. When the push plate 35 moves upward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com