Automatic EPE plate grooving device accurate in positioning

A technology for positioning devices and plates, applied in metal processing, etc., can solve the problems of lack of multi-angle positioning devices, unfavorable multi-functional effects of devices, unfavorable slotting processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

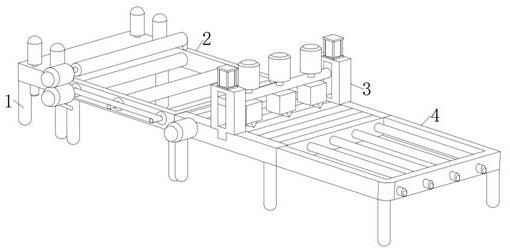

[0026] see Figure 1-6 , the present invention provides a technical solution: an EPE sheet automatic slotting device with accurate positioning, comprising a bracket 1, and also comprising:

[0027] The multi-directional positioning device 2, the function of the multi-directional positioning device 2 is to solve the positioning problem of the prior art device and avoid the phenomenon that the EPE board is raised at any angle; the multi-directional positioning device 2 is installed on one side of the bracket 1;

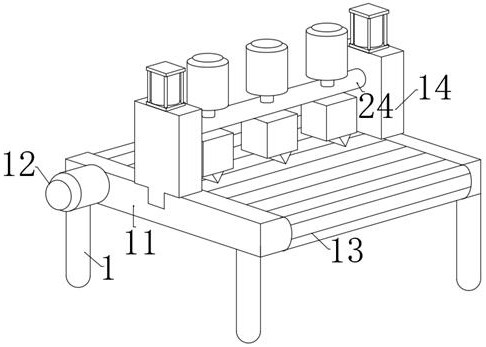

[0028] The slotting device 3 at any angle, the slotting device 3 at any angle includes a desktop 11 fixed on one side of the bracket 1, and the desktop 11 is a support device; a motor 12 is installed on one side of the desktop 11, and a rolling shutter 13 is installed on the inside of the desktop 11. , the motor 12 realizes the conveying effect on the EPE board by controlling the rotation of the roller shutter 13; the two sides of the desktop 11 are plugged and installe...

Embodiment 2

[0031] see Figure 1-6 , according to a kind of accurate positioning EPE plate automatic grooving device of claim 1, it is characterized in that: the two sides of the outer frame 16 are provided with a wing plate 20, and the wing plate 20 is the fixing device of the outer frame 16; The 28 bolts 21 are fixed on one side of the desktop 11, and one side of the outer frame 16 is fixed with a plug 22. The plug 22 is inserted and installed inside the desktop 11. The function of the plug 22 is to ensure the stability of the connection of the outer frame 16.

[0032] A mounting bracket 24 is fixedly connected to the middle part of the sliding block 37 , and the function of the mounting bracket 24 is to install and fix the slotting device.

[0033]The slotting device 3 at any angle also includes a rotor 23 installed on one side of the mounting bracket 24, a drum 25 is installed on the output end side of the rotor 23, and the rotor 23 can control the drum 25 to rotate at any angle; The...

Embodiment 3

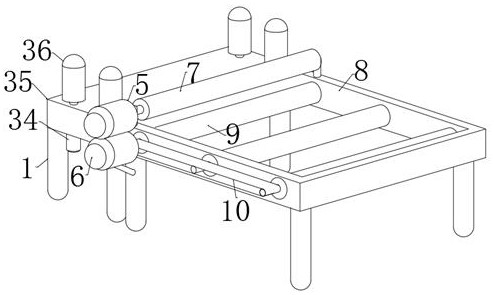

[0038] In conjunction with this application Figures 1 to 6 , when the device is in normal use, in order to solve the technical problems existing in the prior art, the present invention proposes an automatic grooving device for EPE sheets with accurate positioning, which is used to solve the technical problems existing in the comparison documents; The EPE board of the slot is placed on one side of the multi-directional positioning device 2 of the device, and the small motor 34 is activated to make the vertical roller 36 on the top rotate. Since the vertical roller 36 is symmetrically distributed on the side of the board surface 35, the EPE The side of the board will enter the device under the guiding action of the vertical roller 36, which avoids the phenomenon that the EPE board is turned up from the side. However, it is not enough to only limit the side of the EPE board. The clamping motor 5 and the conveying motor 6, the clamping motor 5 and the conveying motor 6 rotate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com