Ore crushing and refining device used for ore processing

A technology of ore crushing and ore crushing, which is applied in the field of ore crushing and refining devices for ore processing, can solve the problems of inability to achieve full ore crushing and low ore crushing, and achieve the goal of promoting full crushing and refining and promoting crushing and refining Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

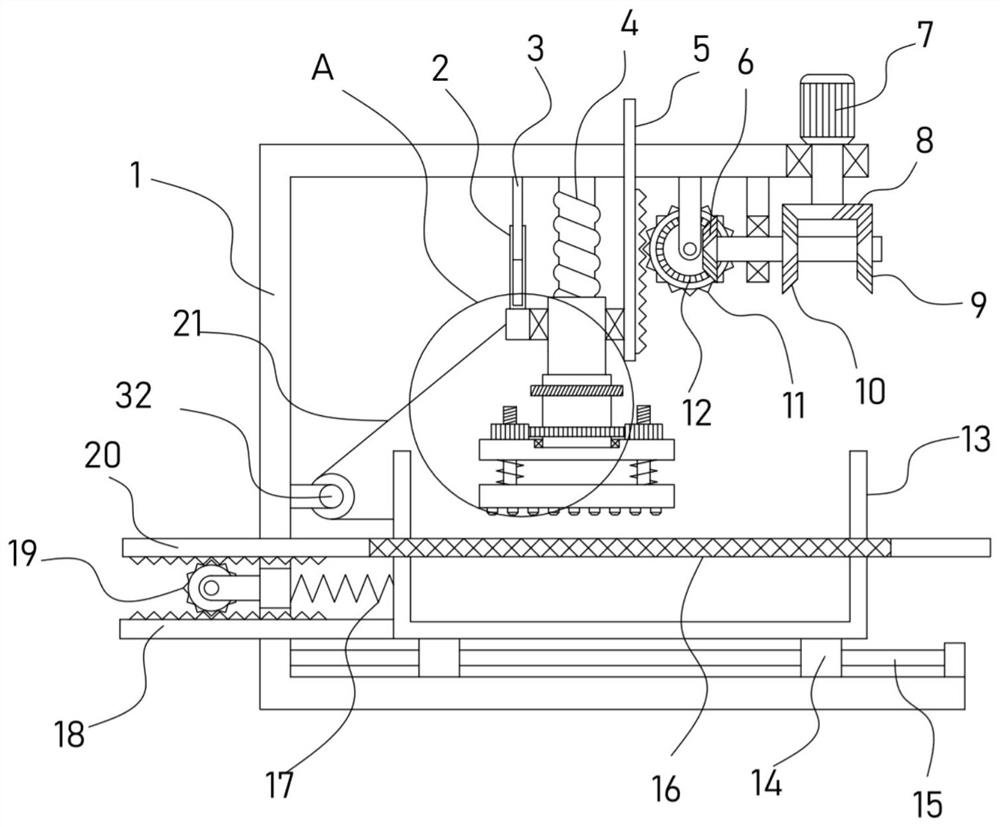

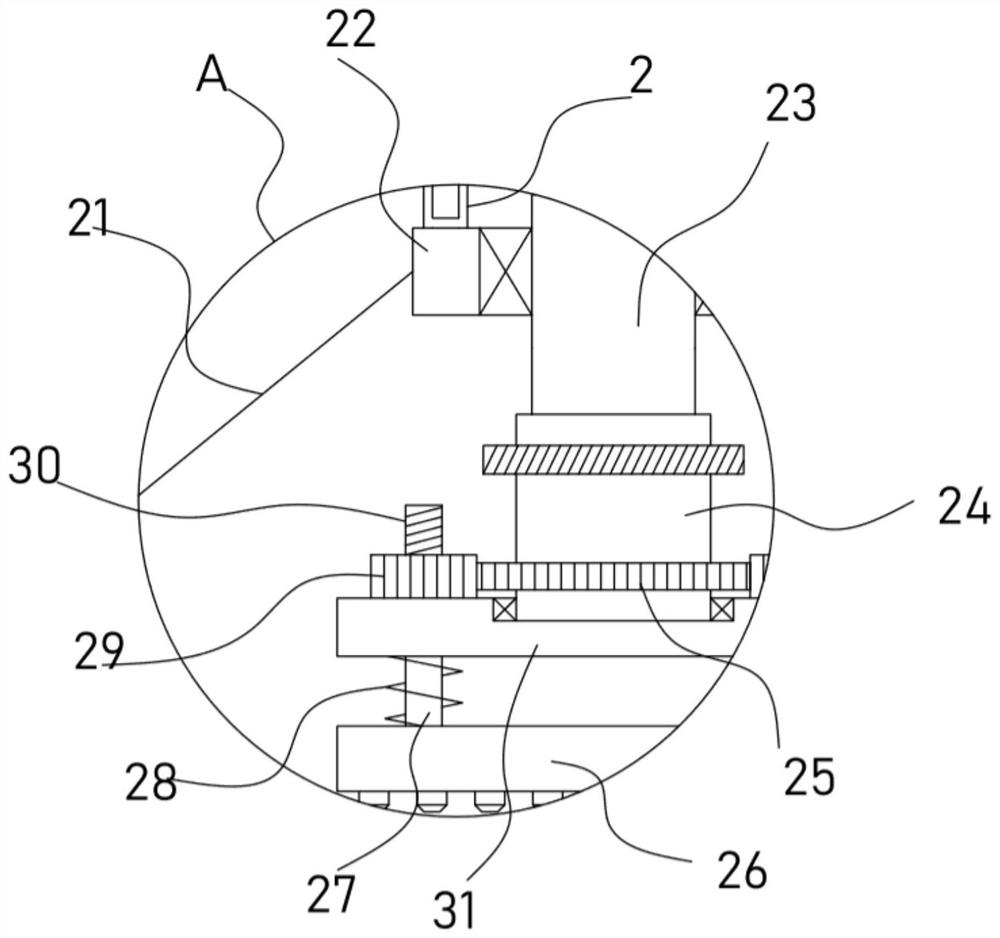

[0022] see Figure 1-3 , an ore crushing and refining device for ore processing, comprising a fixed frame 1, a crushing groove 13 is slidably installed on the fixed frame 1, a metal mesh plate 16 is slidably installed in the crushing groove 13, and a metal mesh plate 16 is fixed on the fixed frame 1 The driving motor 7 is driven and connected with a forward and reverse mechanism, the positive and negative mechanism is driven and connected with a vertical lifting mechanism, and the vertical lifting mechanism is driven and connected with a device for crushing the ore on the metal mesh plate 16. A crushing mechanism, the crushing mechanism is provided with a longitudinal adjustment mechanism, and the fixed frame 1 is provided with a translation mechanism for driving the crushing tank 13 to move laterally.

[0023] The crushing tank 13 set in this device is used to place the ore to be crushed and refined, and the vertical lifting mechanism is driven by the set positive and negativ...

Embodiment 2

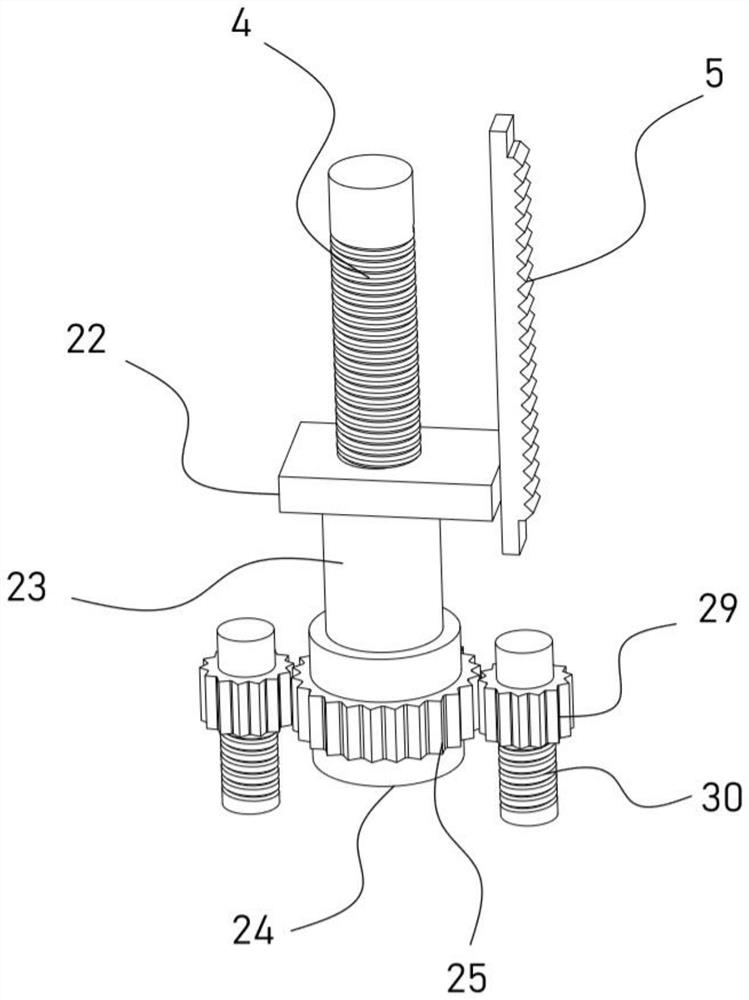

[0029] On the basis of Embodiment 1, in addition, this device is also provided with a longitudinal adjustment mechanism, including a rotating sleeve 24 sleeved on the threaded sleeve 23, and the lower end of the rotating sleeve 24 is connected and installed on the connecting plate 31 with bearings. The main gear 25 is sleeved and fixed on the rotating sleeve 24, the main gear 25 is meshed with a secondary gear 29 which is rotatably mounted on the connecting plate 31, and the internal thread of the secondary gear 29 is connected with a threaded rod 30 coaxially fixed with the connecting column 27 .

[0030] By rotating the rotating sleeve 24, the main gear 25 on it can be driven to rotate, and the main gear 25 drives the auxiliary gear 29 to rotate. It is adjusted, that is, the maximum downward movement position of the crushing platen 26 is adjusted, so as to ensure that the crushing platen 26 can fully crush the ore according to the crushing needs.

[0031] The translation me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com