Solid waste efficient crushing device for environmental protection treatment

A solid waste and crushing device technology, applied in grain processing and other directions, can solve the problems of insufficient crushing effect of solid waste, accumulation, and the inability of crushing blades to crush garbage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

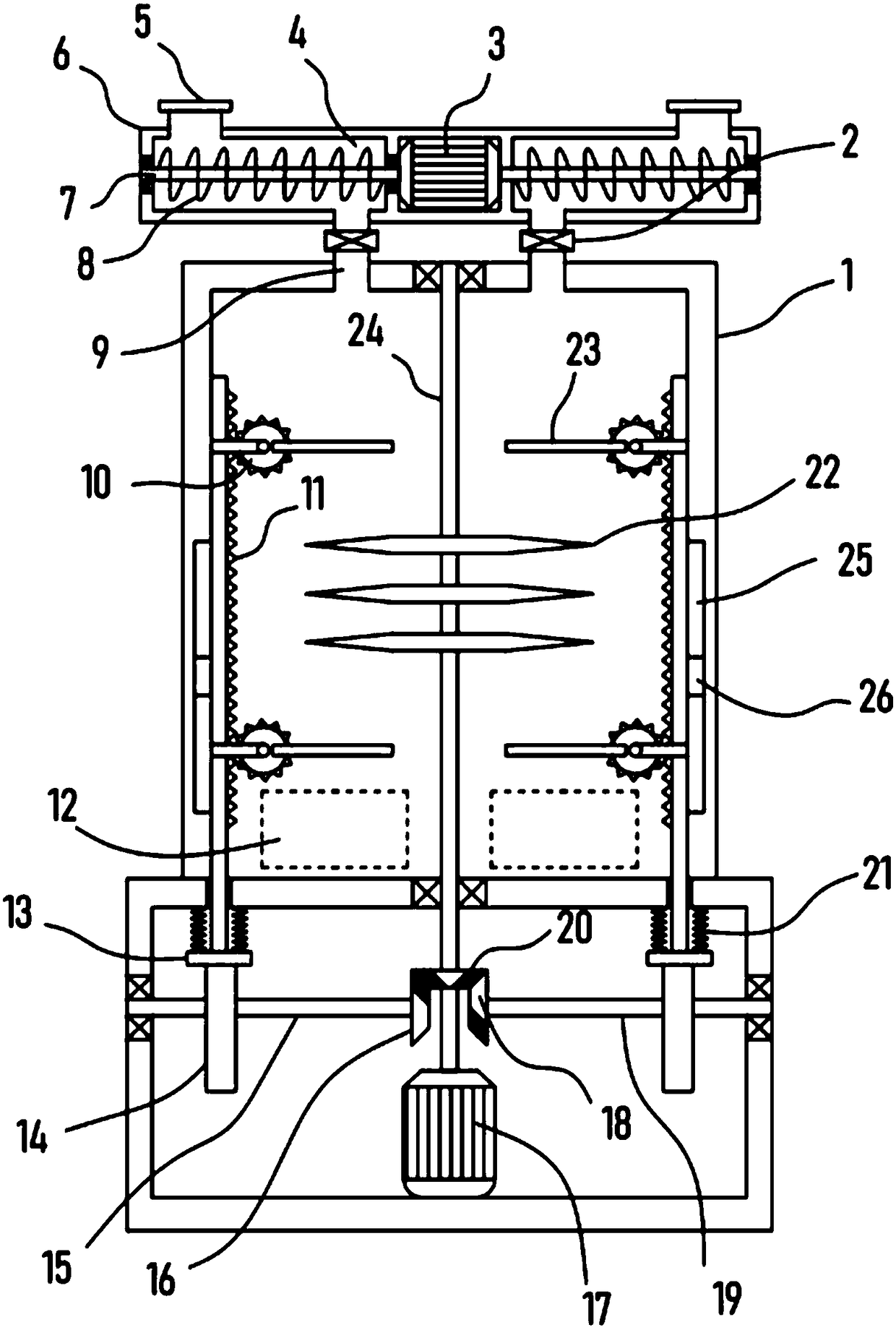

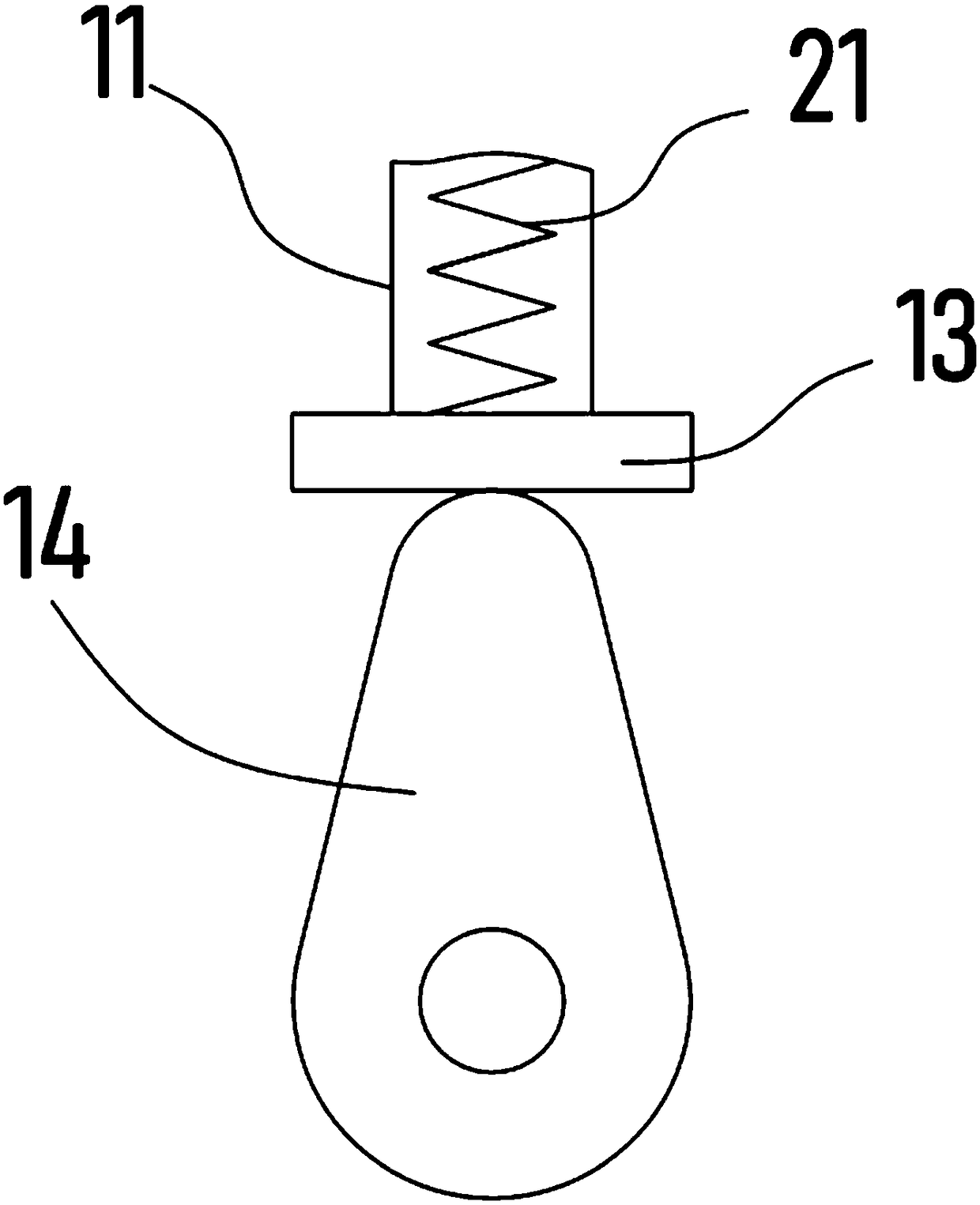

[0021] see Figure 1-3 , a high-efficiency solid waste crushing device for environmental protection, comprising a crushing box 1 and a support frame fixed on the bottom of the crushing box 1, a drive motor 17 is fixed inside the support frame, and a vertical shaft is coaxially fixed to the output shaft of the drive motor 17. Extend upwards to the crushing shaft 24 in the crushing box 1 , and several crushing blades 22 are fixed on the surface of the crushing shaft 24 .

[0022] The provided driving motor 17 is used to drive and rotate the crushing shaft 24, so that the crushing shaft 24 drives the crushing blade 22 to rotate, so as to realize the rotary cutting and crushing effect of the crushing blade 22 on solid waste.

[0023] A driving bevel gear 20 is coaxially fixed on the crushing shaft 24, and an incomplete bevel gear II18 or an incomplete bevel gear I16 meshing with the driving bevel gear 20 is provided on both sides; the incomplete bevel gear II18 and the incomplete ...

Embodiment 2

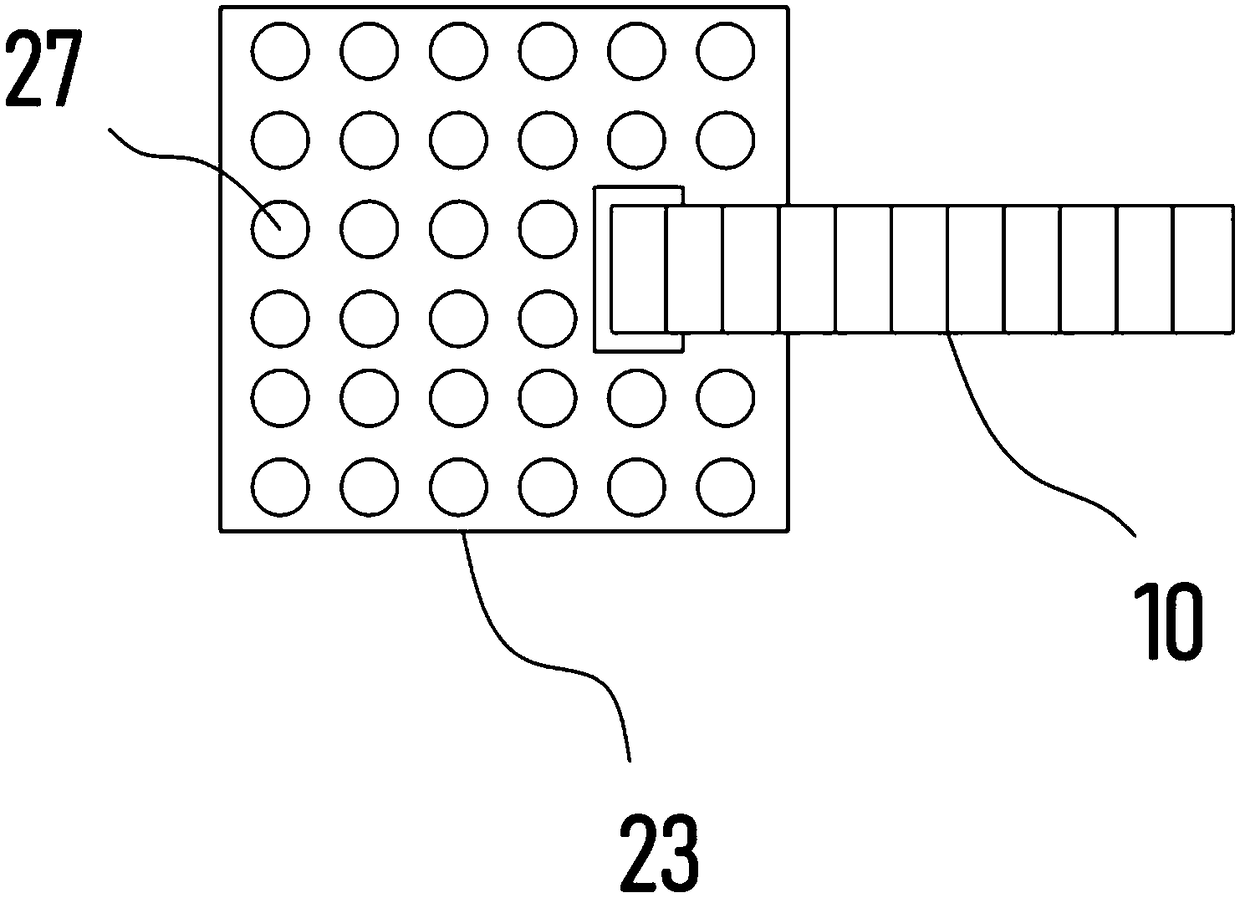

[0028] On the basis of Embodiment 1, in addition, as an improved solution of the present invention: the number of the rotating plates 23 is four, which are respectively located on the upper and lower sides of the crushing blade 22, and several evacuation nets are uniformly provided on the rotating plates 23 Hole 27, the evacuation mesh 27 that is set makes rotating plate 23 swing process, realizes more fully dispersing action to solid waste, has guaranteed that crushing blade 22 is fully crushed to solid waste.

[0029] Further, a coarse crushing cylinder 6 is fixedly installed on the top of the crushing box 1, and a biaxial motor 3 is fixed in the middle of the coarse crushing cylinder 6. There are two symmetrically arranged coarse crushing chambers 4 inside the coarse crushing cylinder 6, and the coarse crushing chamber 4 rotates The formula is provided with a rotating shaft 7 coaxially fixed with the output shaft of the biaxial motor 3, and a helical blade 8 is fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com