Test tube cleaning and drying all-in-one machine for pharmacy department

An all-in-one machine and pharmacy technology, applied in the direction of drying machine, drying, drying gas arrangement, etc., can solve problems such as heavy workload, easy to cut hands, broken test tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

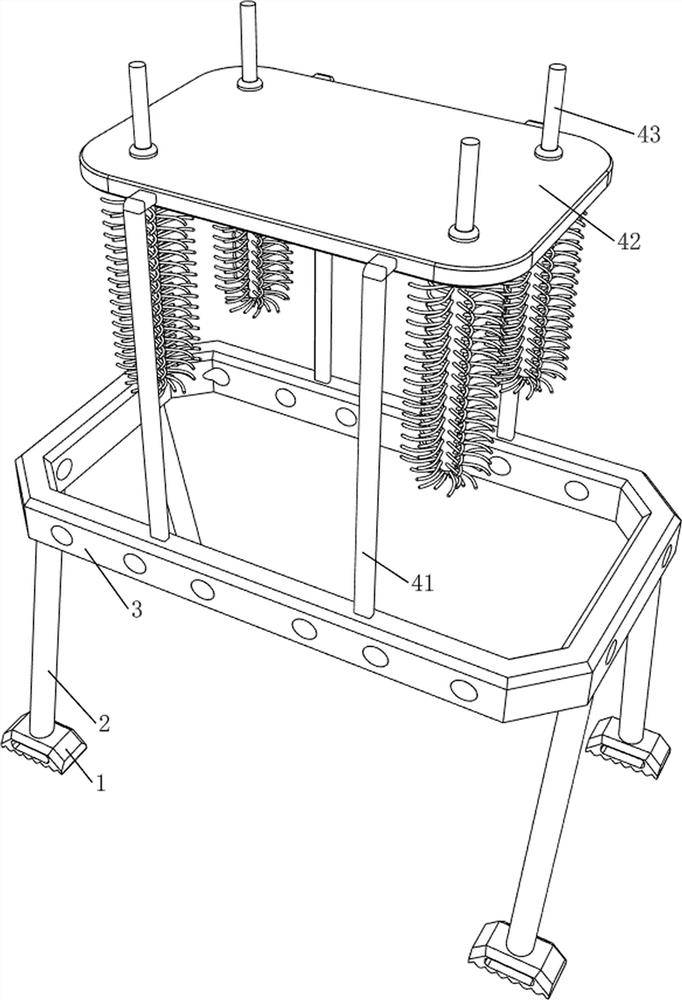

[0072] An all-in-one washing and drying machine for test tubes used in pharmacy, such as figure 1 Shown, comprise the first fixed mount 1, the second fixed mount 2, the third fixed mount 3, the cleaning mechanism 4 and the clamping mechanism 5, all are provided with the second fixed mount 2 on the four first fixed mounts 1, four A third fixed frame 3 is provided between the tops of the second fixed frame 2, a cleaning mechanism 4 is provided in the middle of the top of the third fixed frame 3, and a clamping mechanism 5 is provided on the third fixed inner wall.

[0073] When people need to clean the test tubes used in pharmacy, they can use this all-in-one machine for cleaning and drying test tubes used in pharmacy. First, people put the test tubes into the clamping mechanism 5, and then push the clamping mechanism 5 to move toward the test tubes. Carry out clamping, start clamping mechanism 5 again after clamping is completed, clamping mechanism 5 moves upwards and drives te...

Embodiment 2

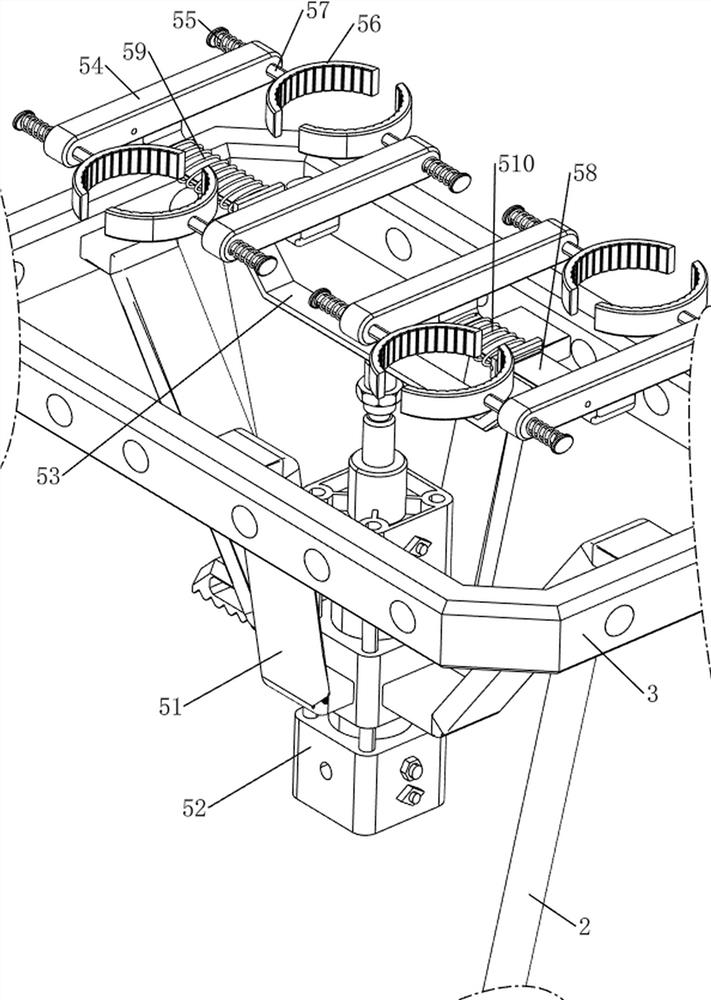

[0075] On the basis of Example 1, such as figure 2 and image 3 As shown, the cleaning mechanism 4 includes a fourth fixed mount 41, a first fixed plate 42 and a hair brush 43, and the left and right sides of the third fixed mount 3 are symmetrically provided with the fourth fixed mount 41. A first fixed plate 42 is arranged between the inner walls of the upper side of the frame 41, and two hair brushes 43 are evenly arranged on the left and right sides of the first fixed plate 42, and the brushes 43 are uniformly provided with small holes.

[0076] When the clamping mechanism 5 clamped the test tube and moved upwards, because the hairbrush 43 was hollow, and there were many small holes on the hairbrush 43, people could pour the cleaning solution from the hairbrush 43 upper side, and then rotate the two sides Hairbrush 43, cleaning liquid can flow in the test tube in the small hole, makes hairbrush 43 can clean test tube, realizes the effect of cleaning, and people stop rota...

Embodiment 3

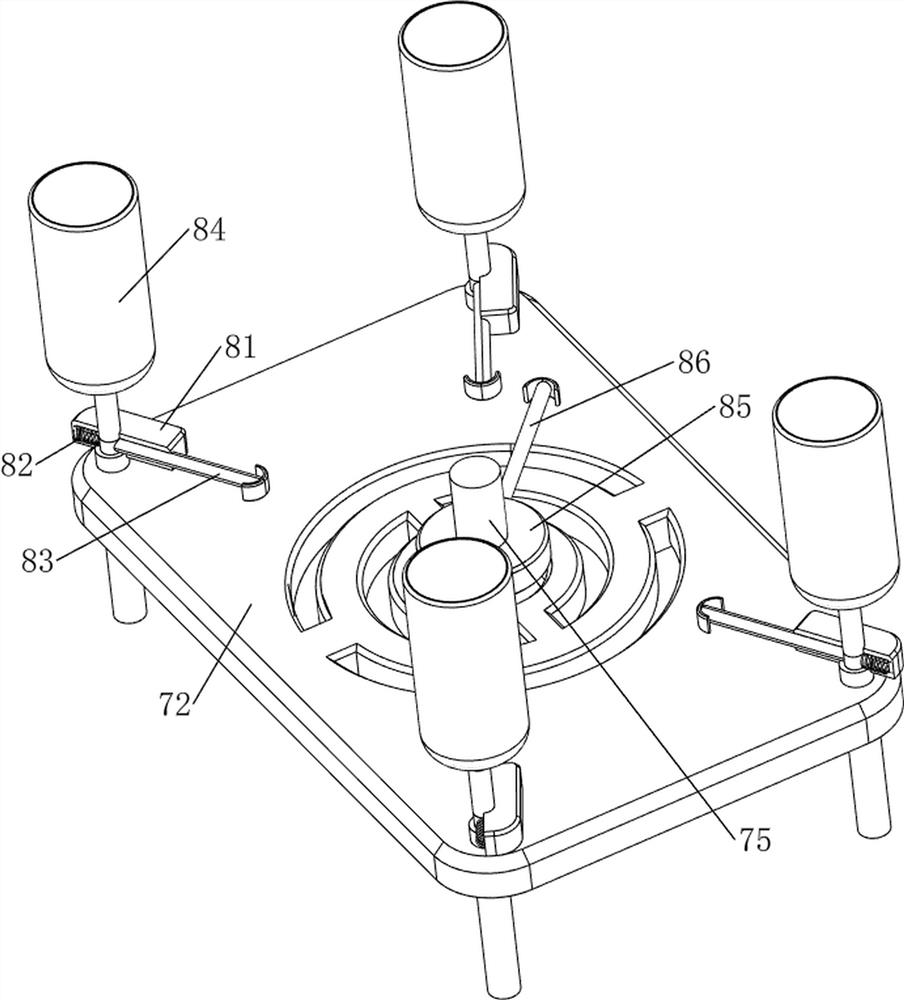

[0080] On the basis of Example 2, such as Figure 4-Figure 7 As shown, a clamping mechanism 6 is also included, and the clamping mechanism 6 includes a third fixed sleeve 61, a fourth spring 62, a second connecting rod 63, a first jacking block 64, a second jacking block 65, a third connecting rod 66. The fifth spring 67, the second sliding rod 68 and the first wedge-shaped block 69. The third fixing sleeve 61 is provided in the middle of the second fixing sleeve 54 at the left and right ends, and the inner walls of the third fixing sleeve 61 on both sides slide between them. The second connecting rod 63 is provided in the formula, and the fourth spring 62 is connected between the middle of the left and right sides of the second connecting rod 63 and the top of the inner wall of the third fixed sleeve 61 on the same side, and the left and right sides of the second connecting rod 63 are provided with Two first jacking blocks 64, the first jacking block 64 is in contact with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com