Patents

Literature

103results about How to "Achieve drying effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

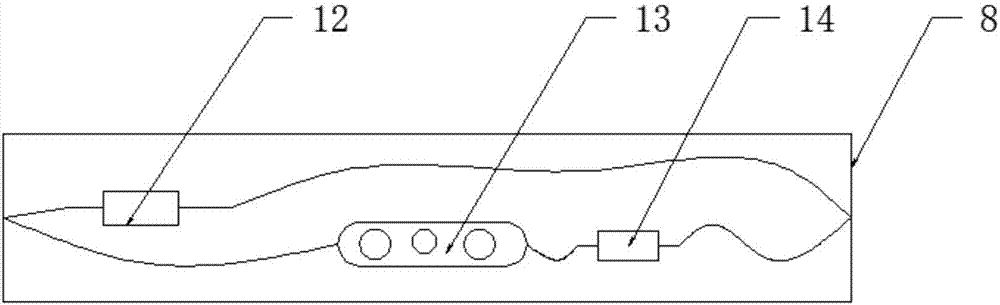

Preparation method and device for carbon fiber-reinforced thermoplastic resin composite material

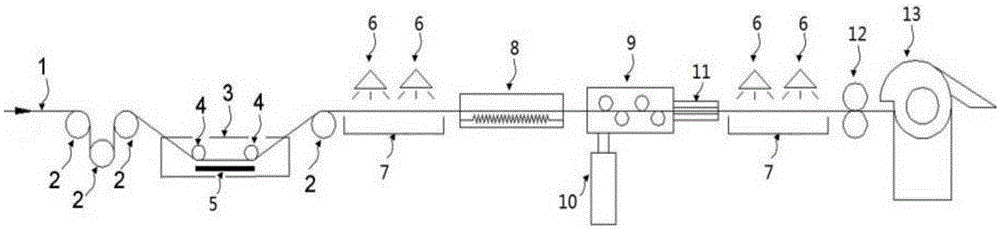

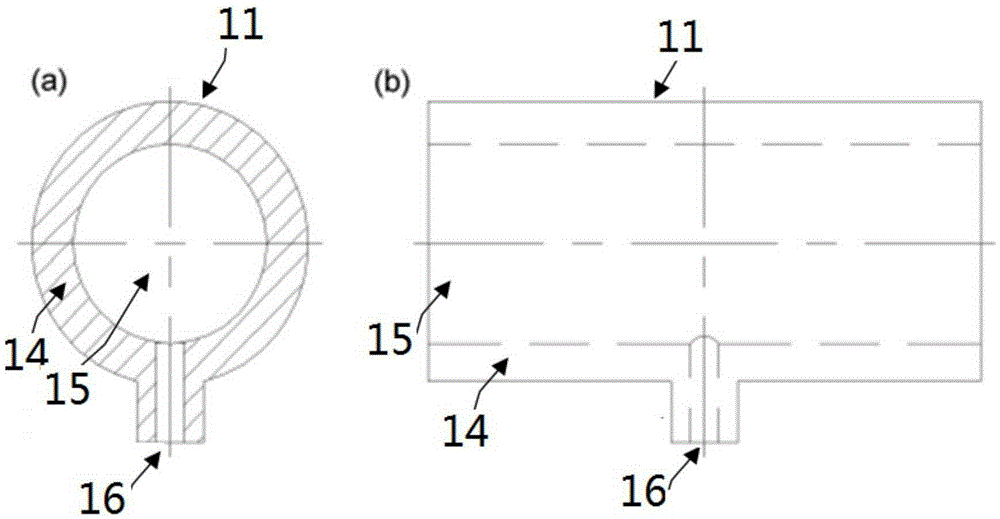

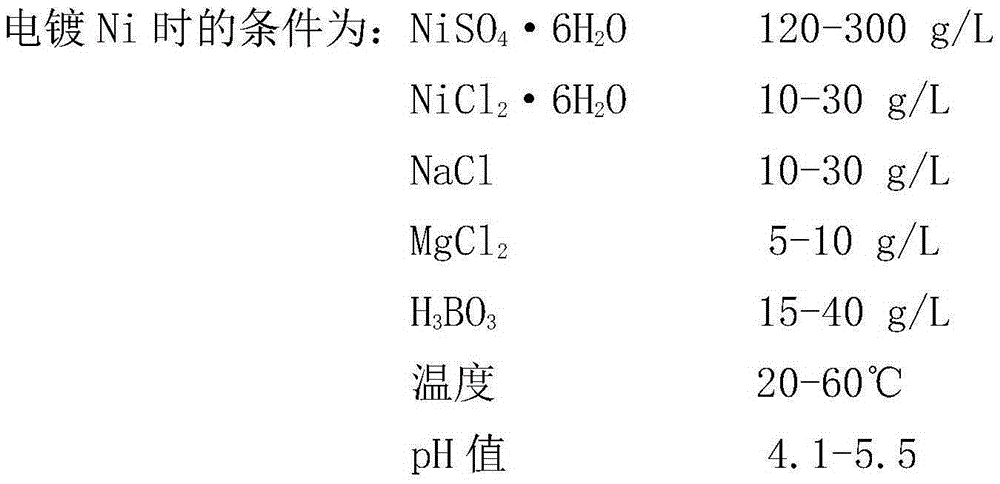

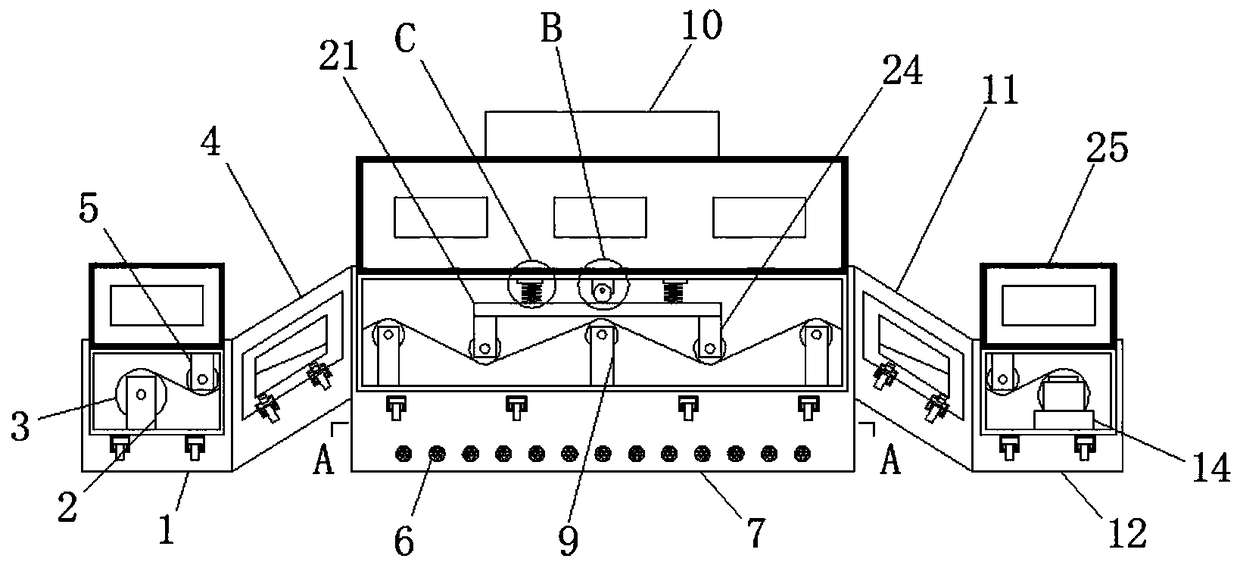

The invention provides a manufacturing method for a carbon fiber-reinforced thermoplastic resin composite material. The method comprises the steps of firstly removing a sizing agent on a carbon fiber surface, then performing metallic coating treatment, water scrubbing and surface heat treatment, leading into a dipping die head containing melt thermoplastic resin in a splitting state, enabling the melt thermoplastic resin to wrap the carbon fiber surface, then performing cooling and grain-size dicing, so that the carbon fiber-reinforced thermoplastic resin composite material is prepared. The method has the advantages of simple and practical process, low cost, stable quality, good mechanical property, good electromagnetic protective property and light weight.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

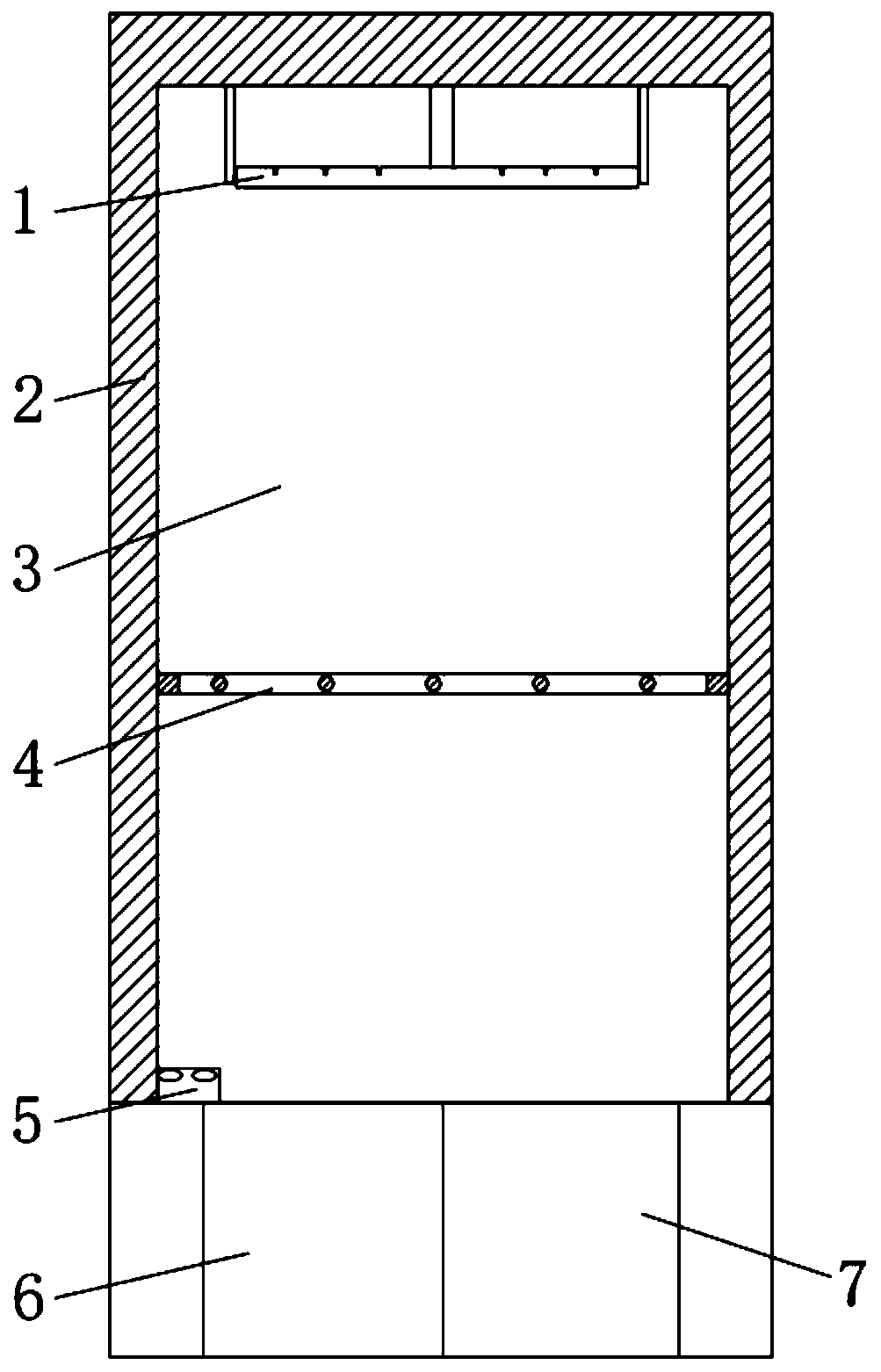

Drying device for cotton cloth processing

ActiveCN108731444ARealize the effect of dischargingImprove drying efficiencyDrying chambers/containersDrying machines with progressive movementsCotton clothMechanical engineering

The invention discloses a drying device for cotton cloth processing. The drying device for cotton cloth processing comprises a loading area, a preheating area, a drying area, a heat dissipating area and a collecting area; the loading area comprises a loading box; the loading box is a box body with two communicating sides; a first support base is fixedly connected to the bottom in the loading box;the top of the first support base is rotationally connected with an emptying roller through a rotating shaft; the preheating area comprises a preheating box; one side of the loading box fixedly communicates with the preheating box; the top in the side, near the preheating box, of the loading box is fixedly connected with a second support base; the bottom end of the second support base is rotationally connected with a first guide roller through a rotating shaft; the preheating box is aslant arranged; the drying area comprises a drying box; the top of the preheating box fixedly communicates withthe drying box; and multiple heating devices are fixedly connected to the bottom in the drying box. The drying device can achieve the cotton cloth drying effect by the preheating box, the drying boxand the heat dissipating box, and meanwhile, can shake cotton cloth in the drying process through a cloth vibration mechanism to accelerate the drying efficiency.

Owner:沛县宏宇纺织有限公司

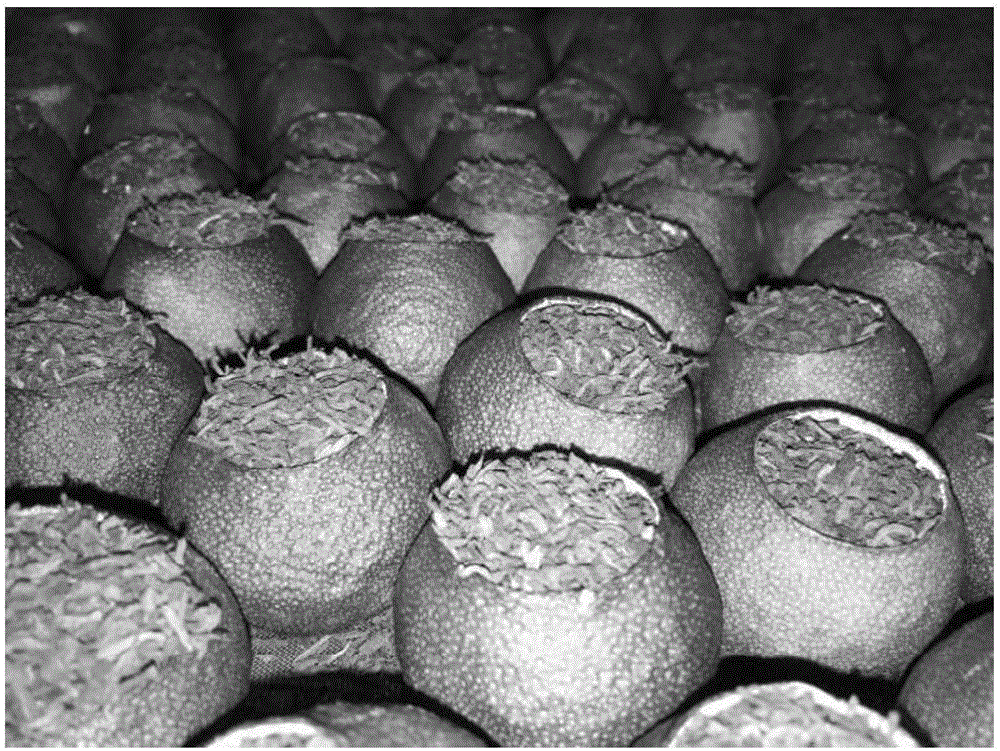

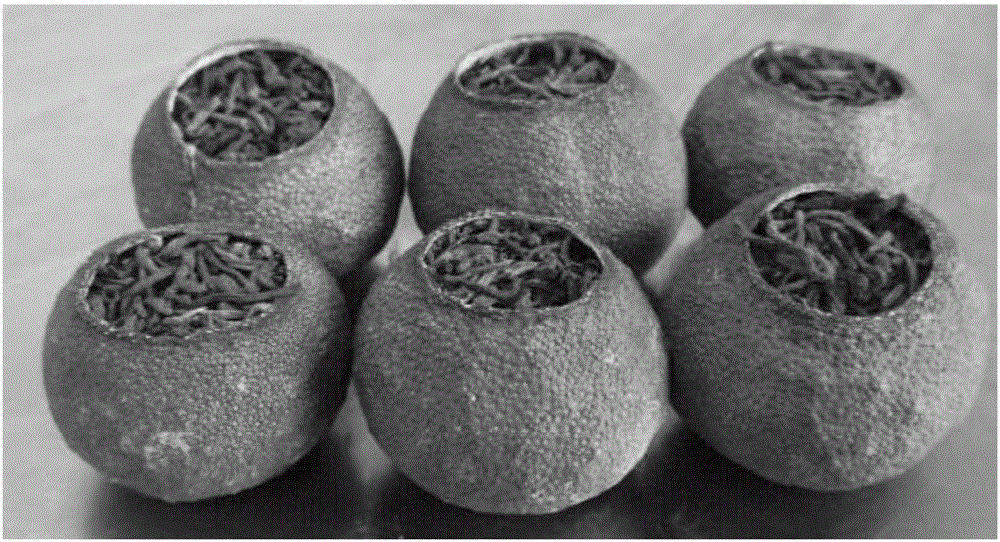

Preparation method of hesperidium aurantium tea

The present invention discloses a preparation method of hesperidium aurantium tea. The preparation method comprises the following steps: 1) fresh hesperidium aurantium is picked, the picked hesperidium aurantium is washed clean, and water content on the surfaces of the washed hesperidium aurantium is drained; 2) an opening is cut out on the hesperidium aurantium and the hesperidium aurantium is divided into two parts of a lid body and a hesperidium aurantium main body; fruit flesh in the hesperidium aurantium main body is dig out to obtain a hesperidium aurantium container; 3) the lid body and the hesperidium aurantium container are dried until no water is left; 4) the hesperidium aurantium container is taken out and filled with the tea leaves to obtain semi-finished products; and 5) the semi-finished products and lid body are put into a dryer; and an air inlet volume of the dryer is adjusted to be 1,500-2,100 m<3> / h, an air outlet volume of the dryer is 760-1360 m<3> / h, a temperature is controlled at 40-45 DEG C, the drying is conducted for 18-26 h, and the finished products are obtained. The preparation is less in steps and simple in processes. The hesperidium aurantium is emerald green in appearance. The hesperidium aurantium tea is uniform in color and luster, maintains the characteristics of the fresh hesperidium aurantium, is good in appearance, at the same time, maximally maintains the original taste of the hesperidium aurantium and tea leaves, and is fragrant, delicate and mellow in smell, and resistant to storage.

Owner:广东省壹柑园食品有限公司

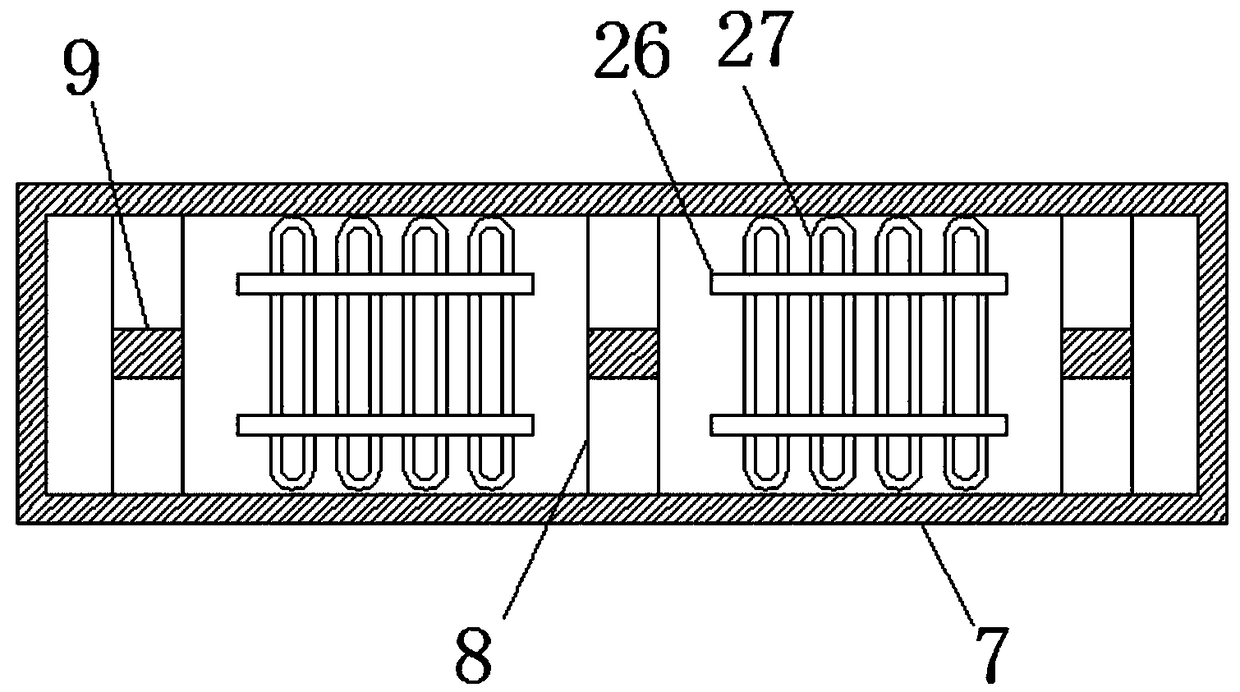

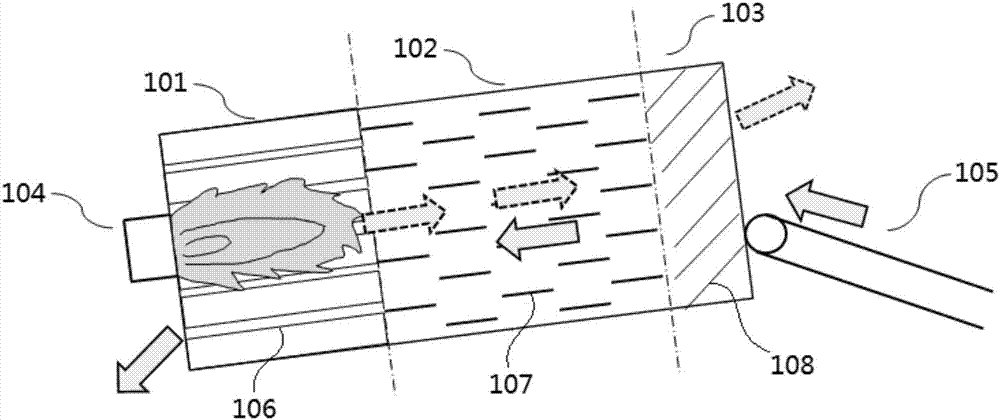

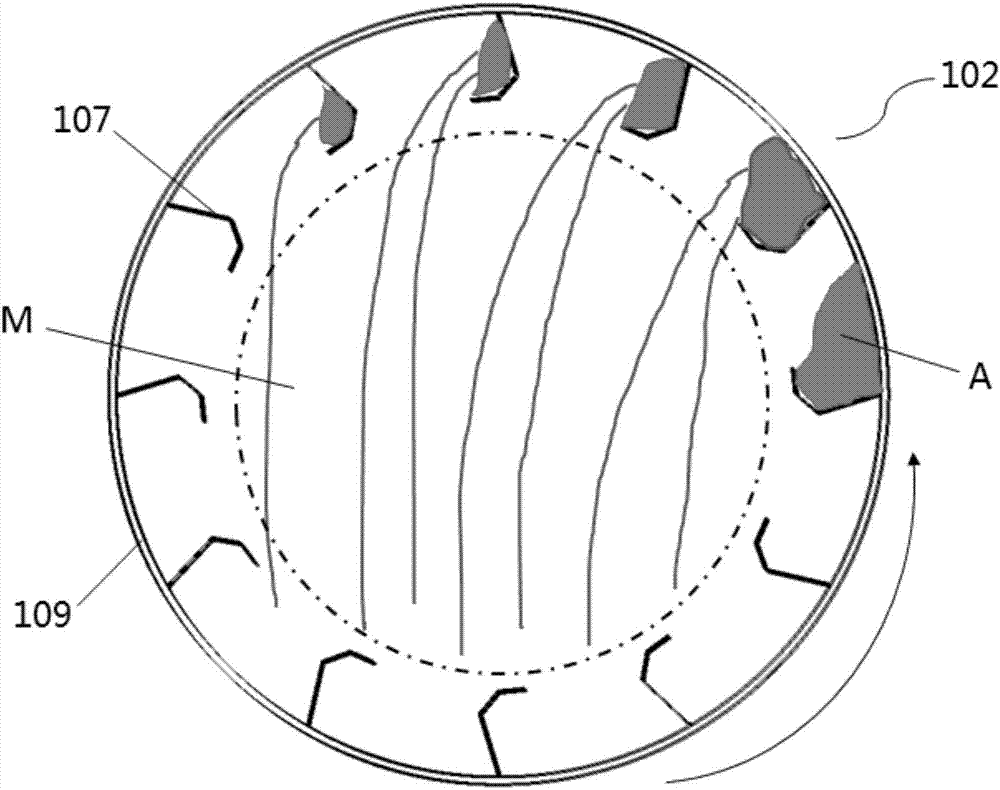

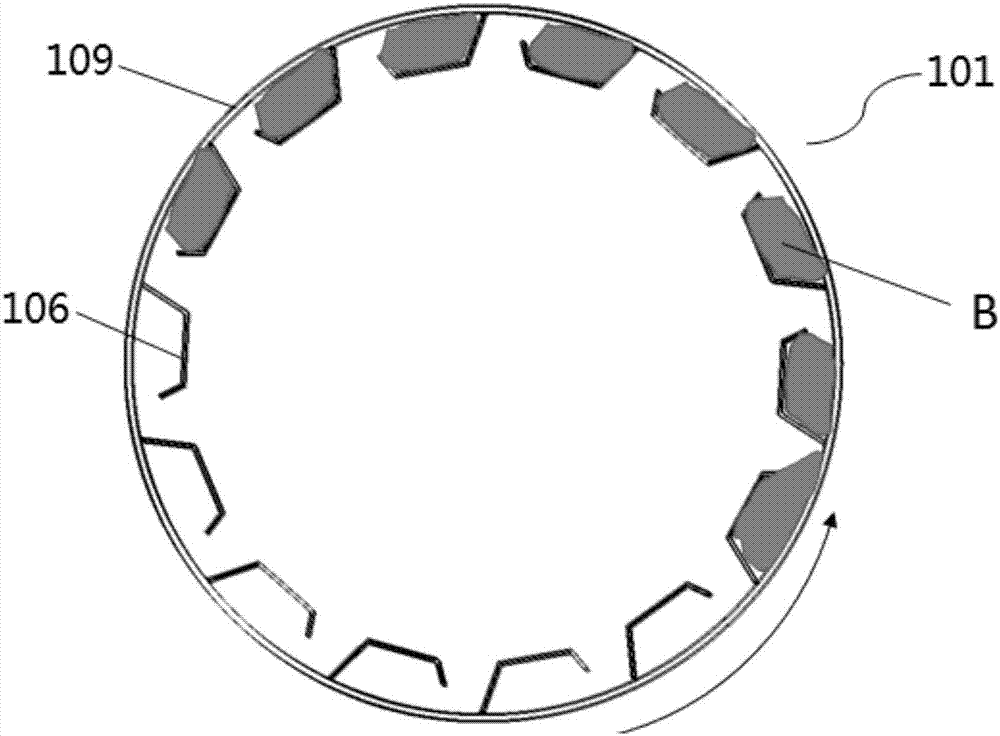

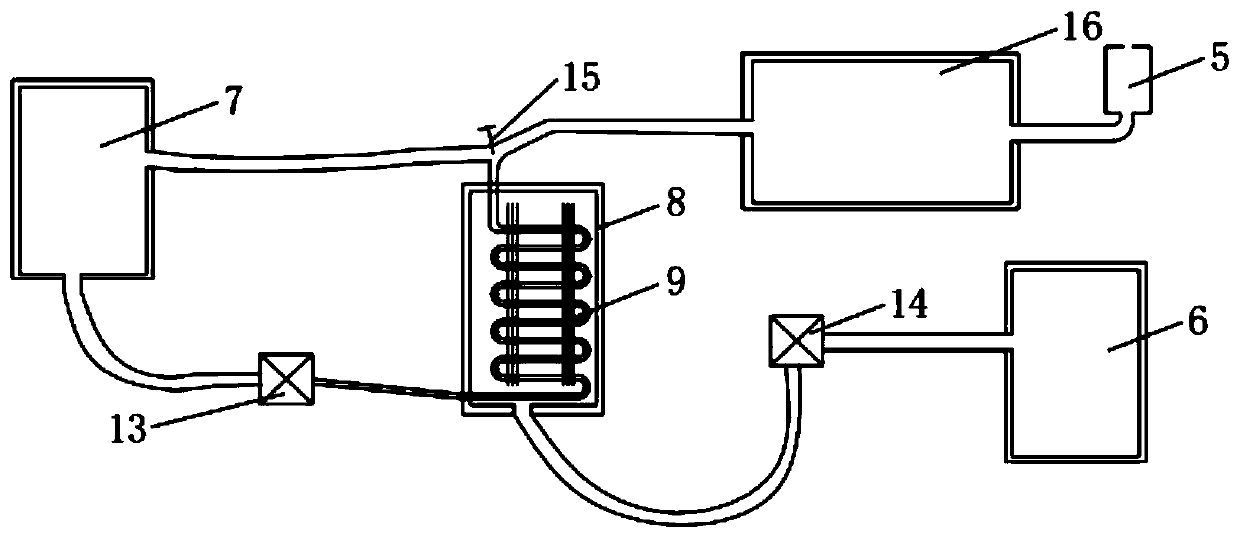

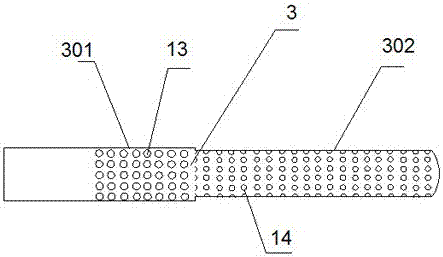

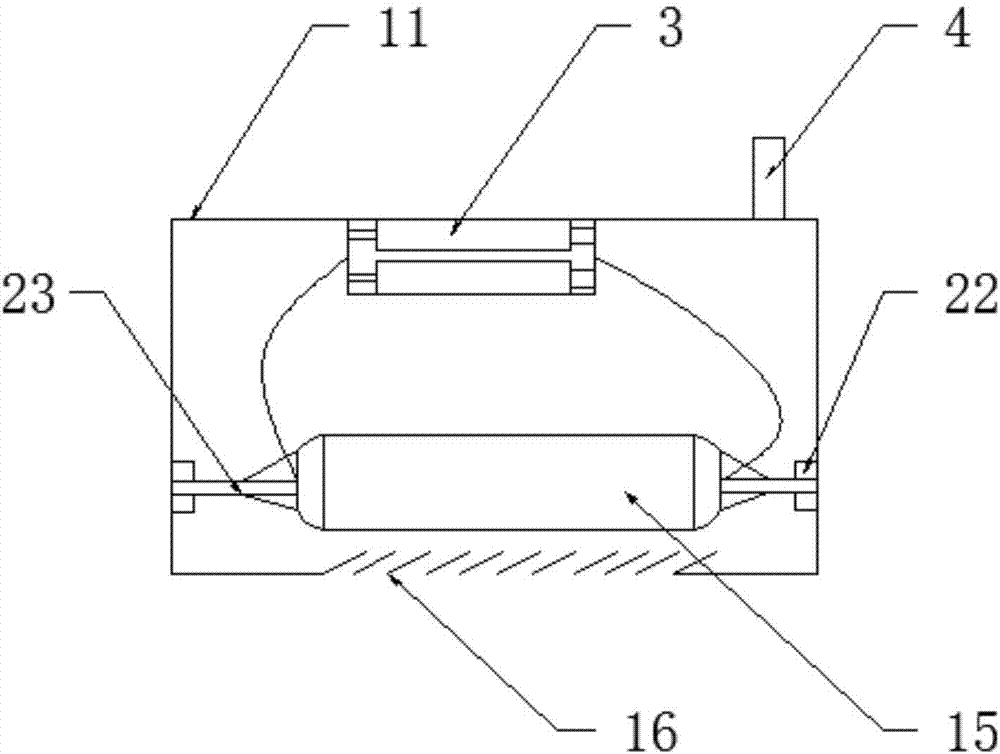

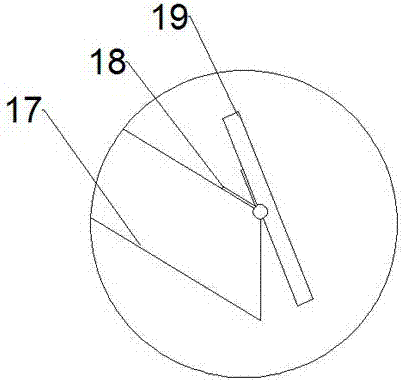

Drying equipment

ActiveCN107328193AAchieve drying effectImprove drying efficiencyDrying chambers/containersDrying solid materialsPulp and paper industry

The invention relates to drying equipment. The drying equipment comprises a burning area (1) and a drying area (2). A roller (6) is arranged in the drying area (2). The inner wall surface of the roller (6) is provided with material lifting blades which are used for lifting up materials conveyed into the roller (6) from the bottom of the roller (6) and enabling the materials to fall off to form a material curtain along with rotation of the roller (6), so that the materials conduct heat exchange with hot gas generated in the burning area (1) in the falling process of the materials. According to the drying equipment provided by the embodiment of the invention, the inner wall surface of the roller is provided with the material lifting blades; the materials can be lifted up from the bottom of the roller and conveyed into the roller through the material lifting blades and can be made to fall off to form the material curtain along with rotation of the roller, so that the materials conduct heat exchange with the hot gas generated in the burning area in the falling process, and then the drying effect of the materials is achieved. The materials are lifted up and fall off through the material lifting blades. The contact area of the materials with the hot gas is increased. The drying efficiency of the materials is improved.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

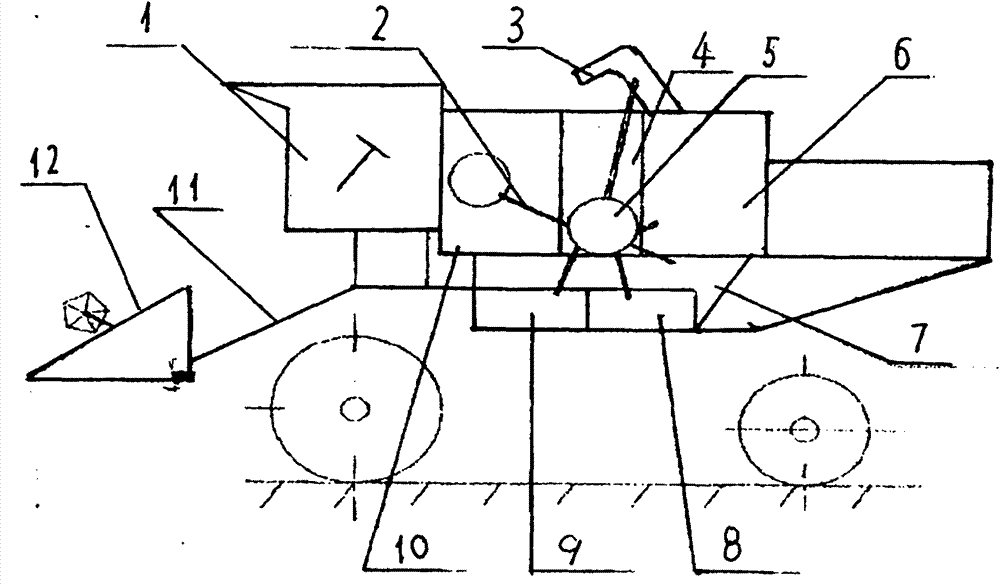

Grain combine harvester with drying function

The invention provides a grain combine harvester with a drying function, and belongs to agricultural machinery. A hot smoke acquiring and distributing device is fitted on a grain harvester combine body and is communicated with a hot smoke exhausting pipe of engine. Hot gas delivering pipes communicate the hot smoke acquiring and distributing device to a threshing device, a separating device, a selecting device, a grain delivering device, a grain bin and a grain discharging device. The heat of hot waste gas exhausted by the engine of the grain harvester combine is utilized, heat is added in each mechanical device for the grains in the grain combine harvester to pass by, accordingly the grains can be dried, parts of free water and combined water in the grains are allowed to evaporate, beneficial conditions are created for post-operation of a drier, and the grain combine harvester has the advantages that novel and reasonable design, fine operating effect, reliability of usage, efficient drying energy and low drying cost.

Owner:侯林山

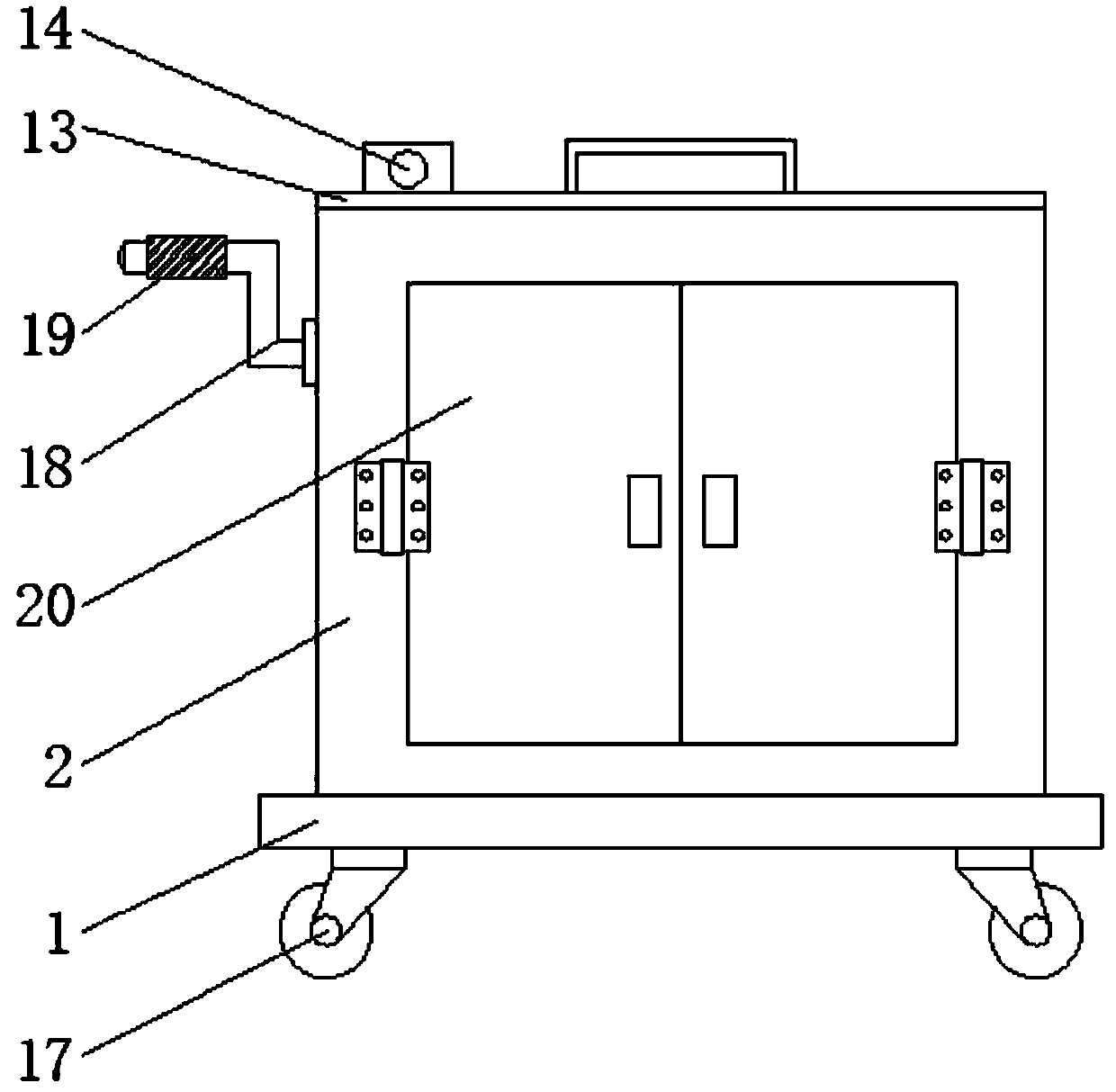

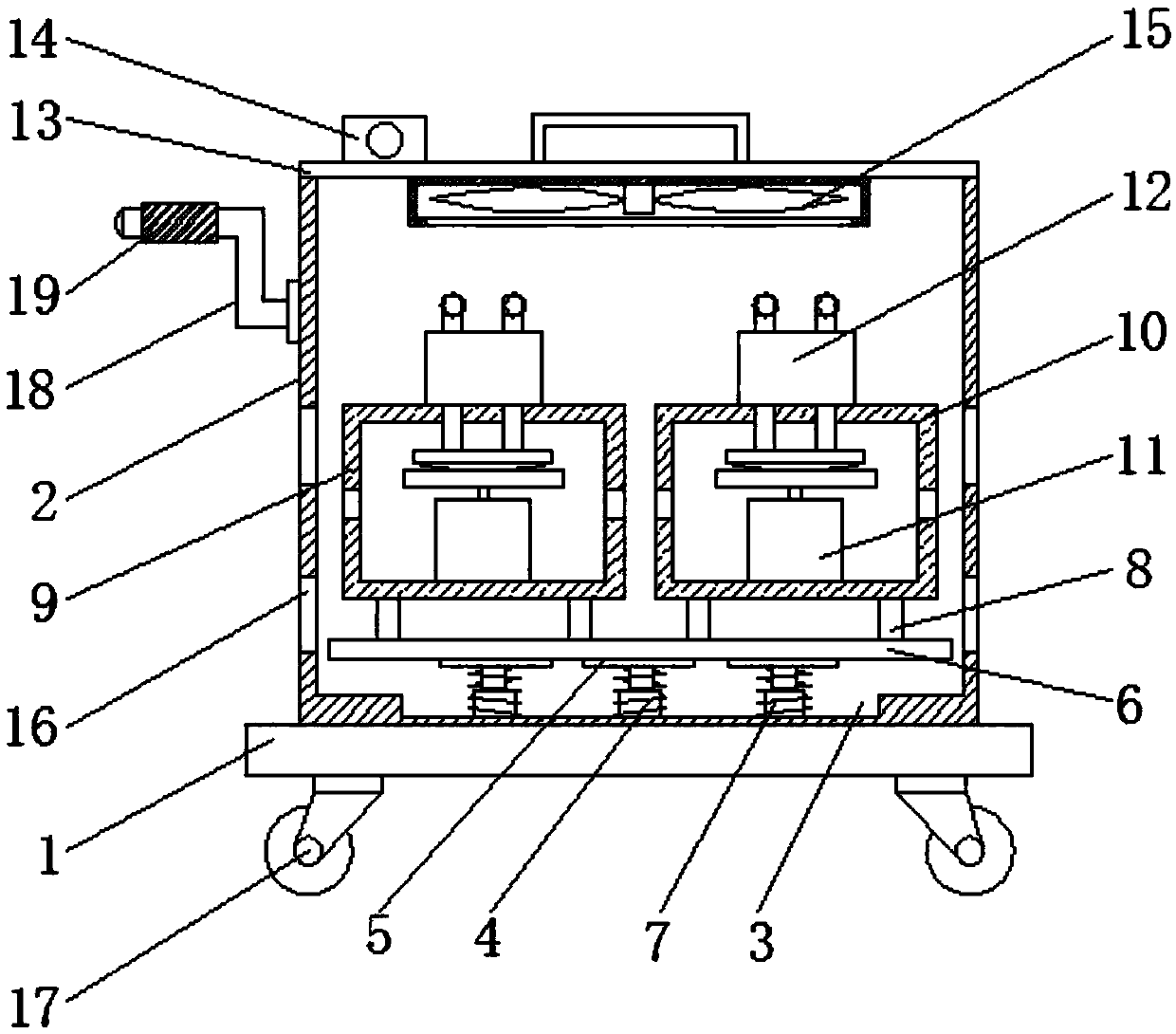

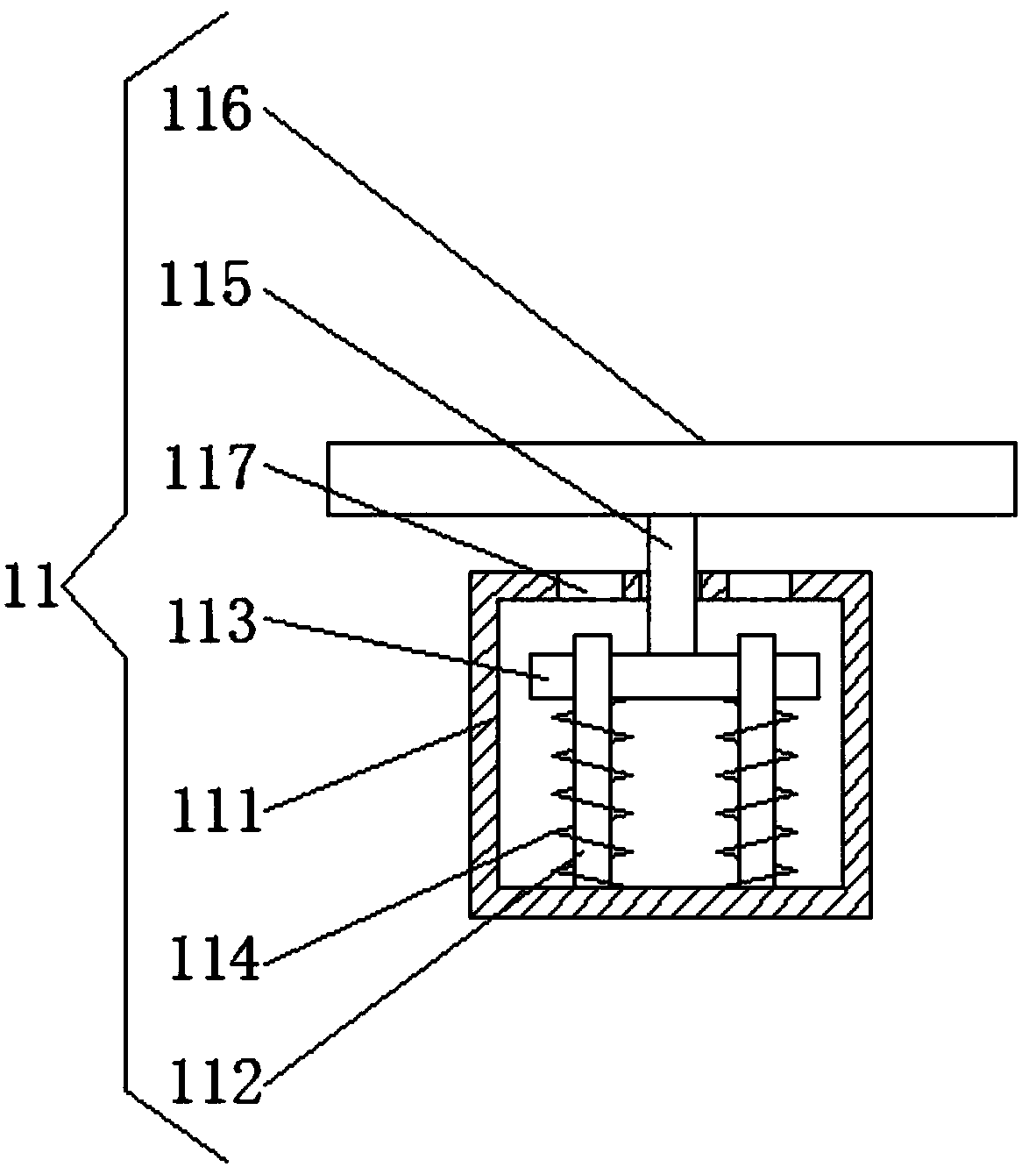

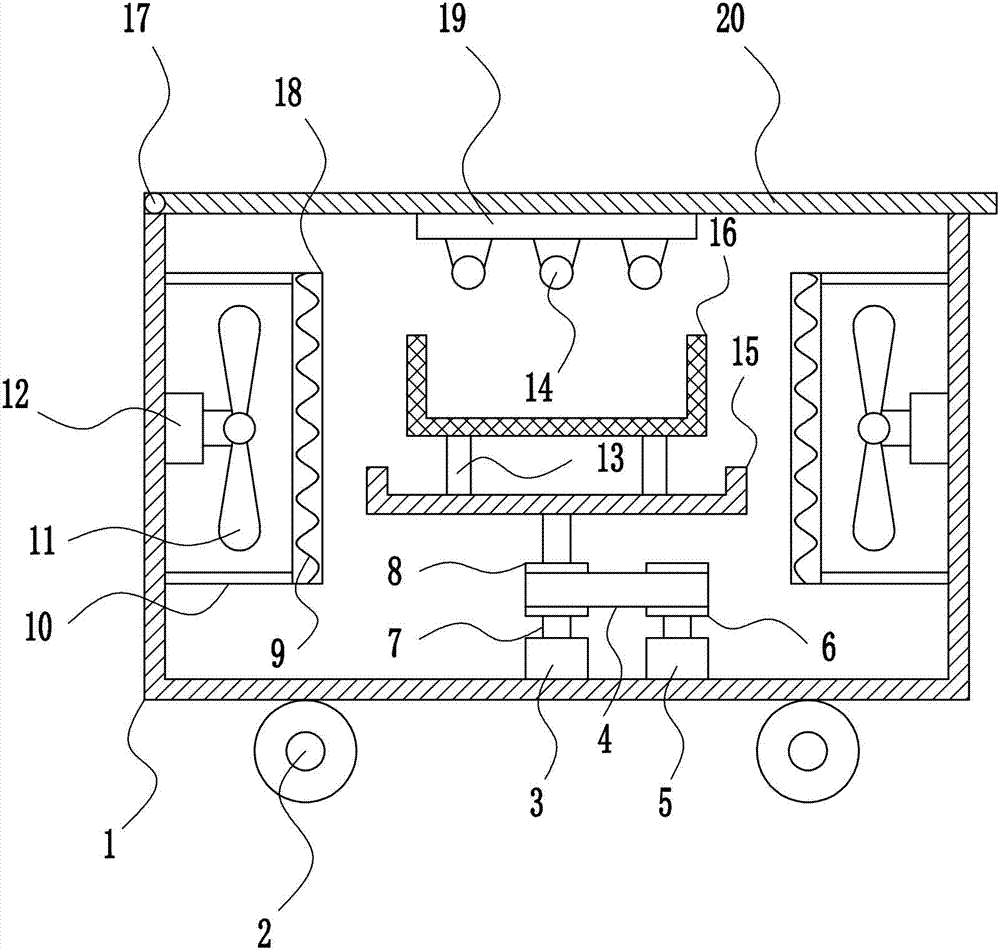

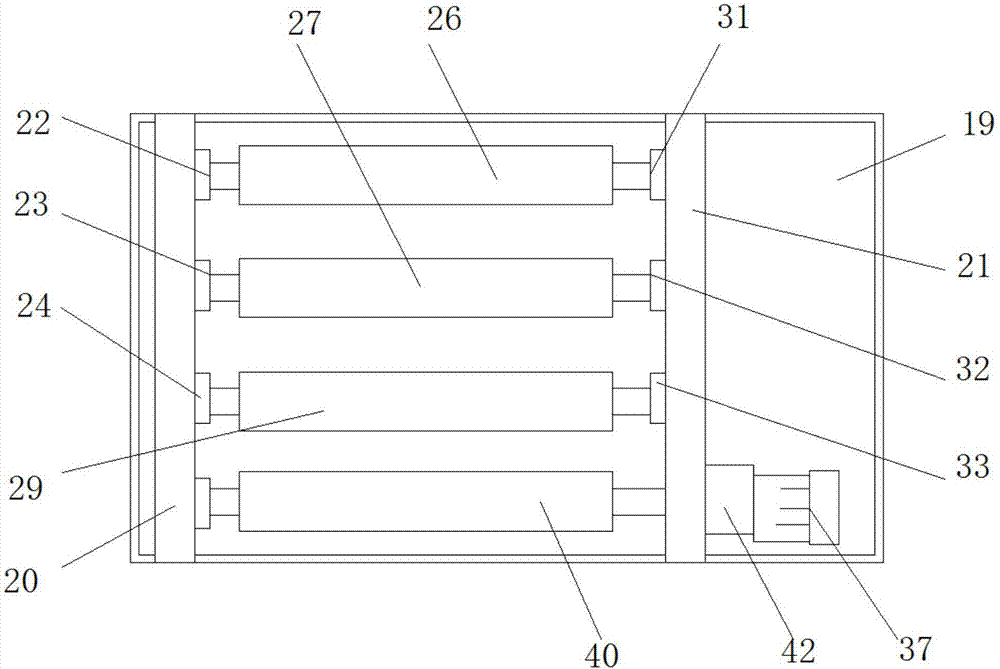

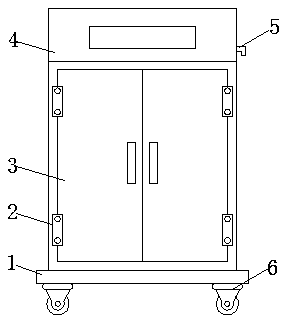

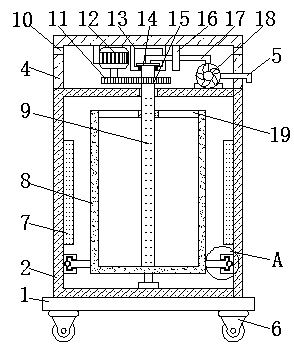

Electronic product storage box

InactiveCN107902230AEasy to fixImprove shock absorptionNon-rotating vibration suppressionClosure with auxillary devicesEngineering

Owner:合肥璨然电子科技有限公司

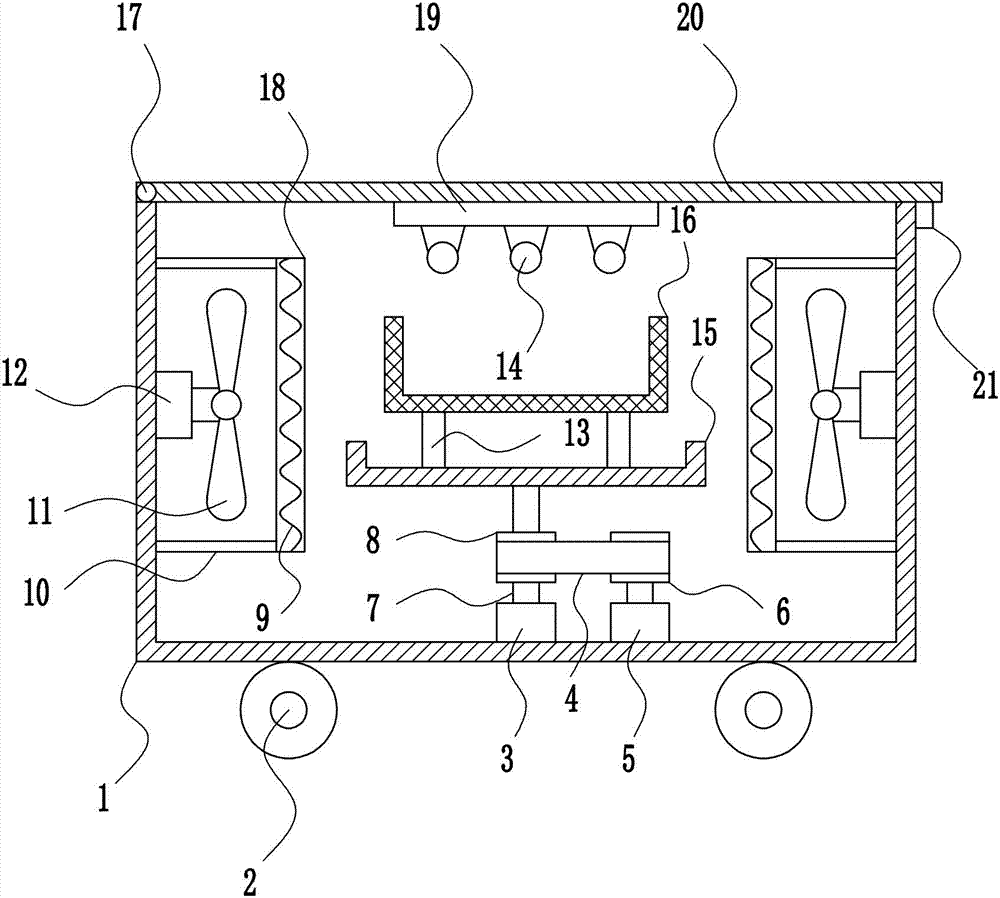

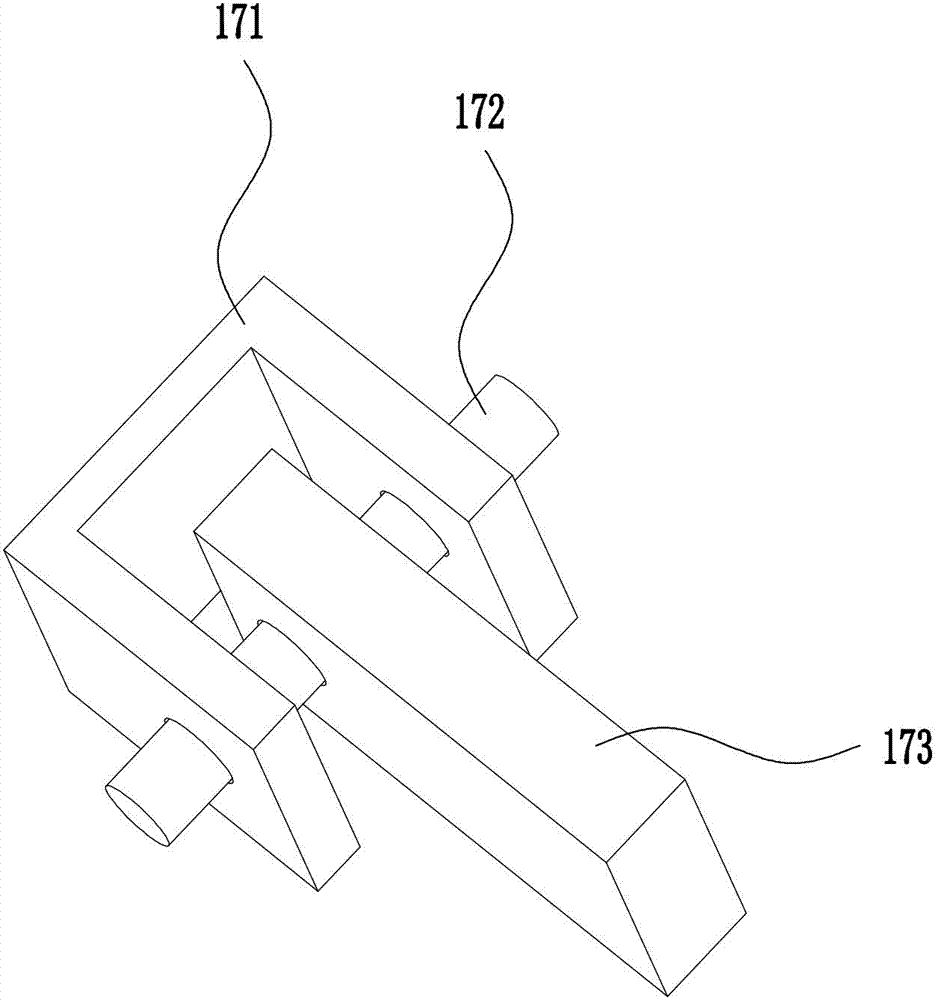

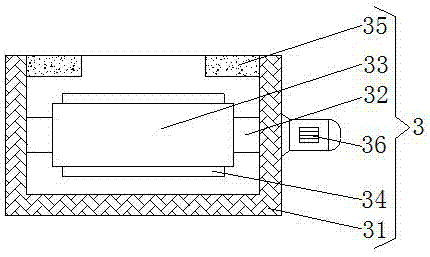

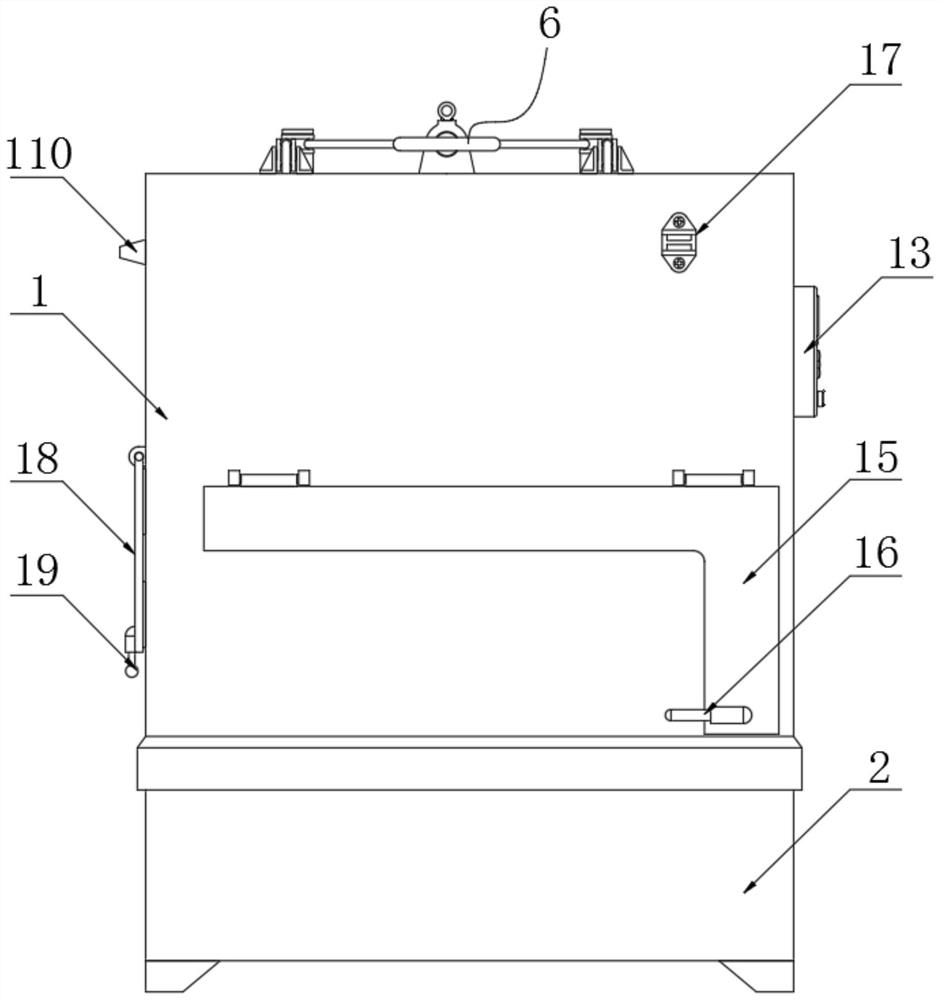

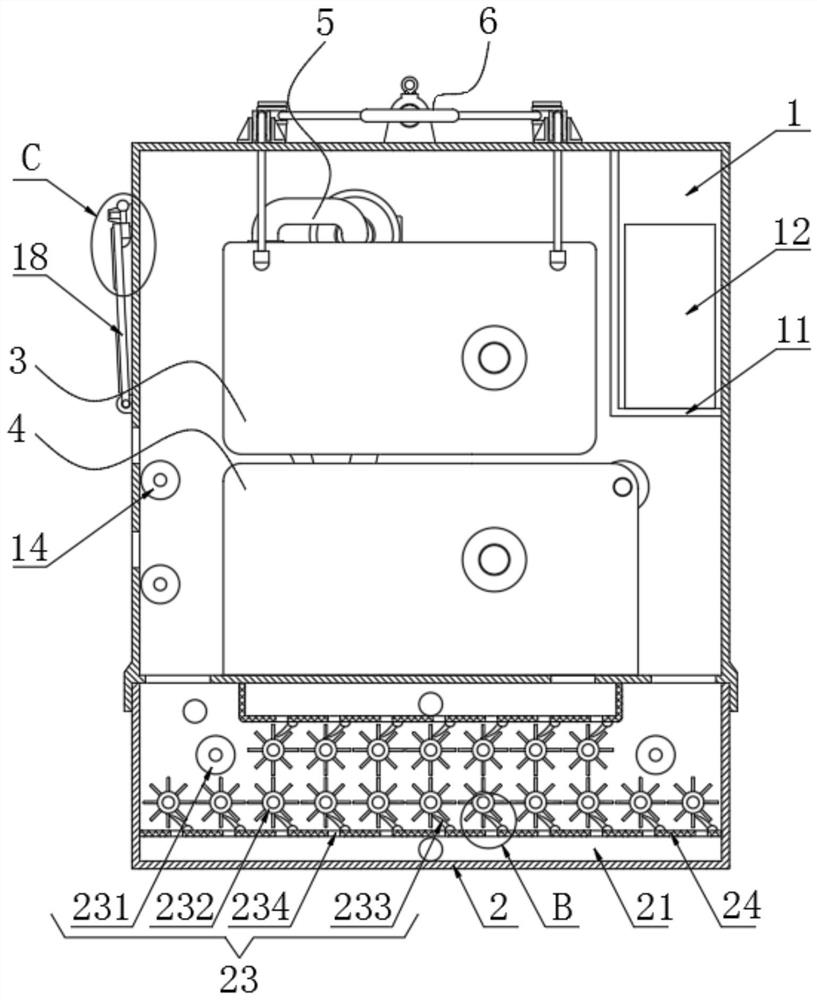

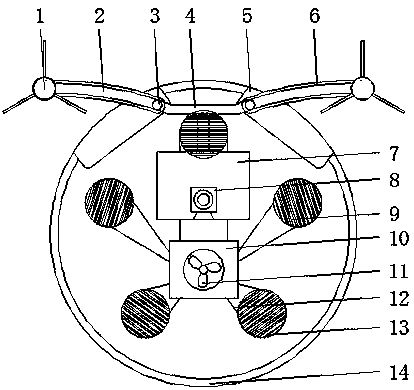

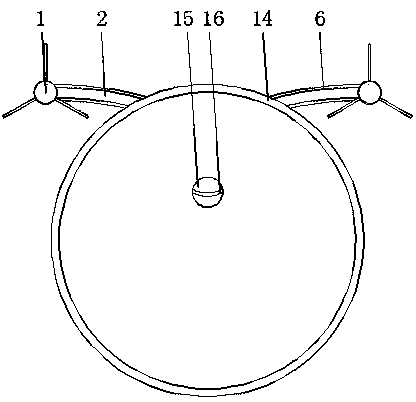

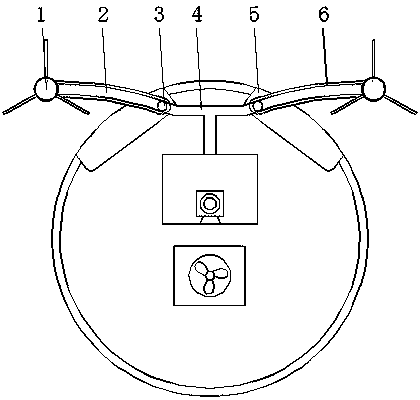

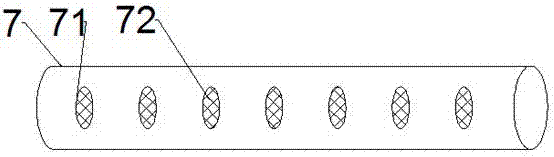

Quick stuffed toy drying equipment with sterilizing device

InactiveCN107270679AFlexible swingExtended service lifeDrying solid materialsDrying machines with non-progressive movementsEngineeringDrying time

The invention relates to a drying device, in particular to a fast drying device for a plush toy with a sterilizing device. The technical problem to be solved by the present invention is to provide a quick drying equipment for plush toys with a sterilizing device, which is convenient in operation, high in drying efficiency, and saves time and effort. In order to solve the above technical problems, the present invention provides such a quick drying equipment for plush toys with a sterilizing device, which includes a housing, a universal wheel, a bearing seat, a flat belt, a first motor, a first pulley, a first The rotating shaft, the second pulley, the heating wire, the fixed frame, the rotating blade, etc.; the outer bottom of the housing is symmetrically connected with universal wheels, and the universal wheels can rotate freely. In the present invention, the heating wire is energized to generate heat, and then the second motor is controlled to rotate, and the second motor drives the rotating blade to rotate, and the rotating blade rotates to blow hot air to the plush toy to achieve the effect of drying.

Owner:刘宦文

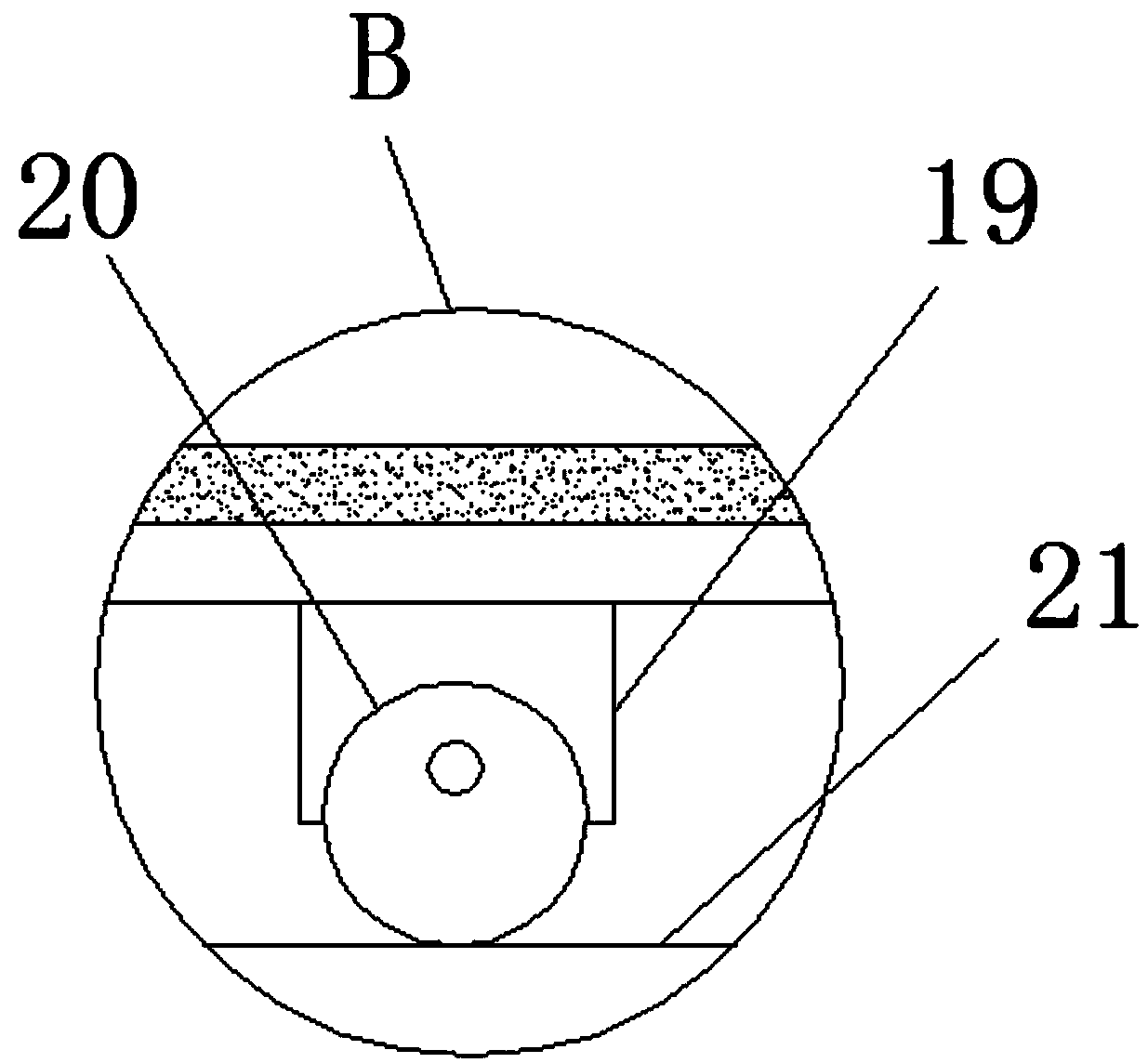

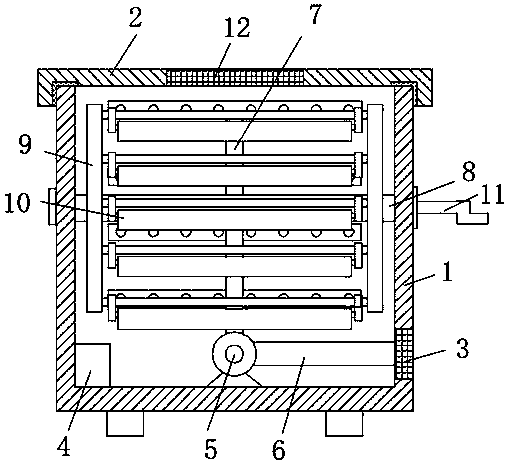

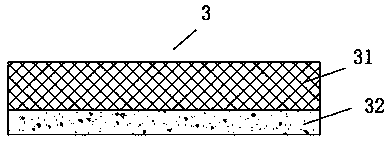

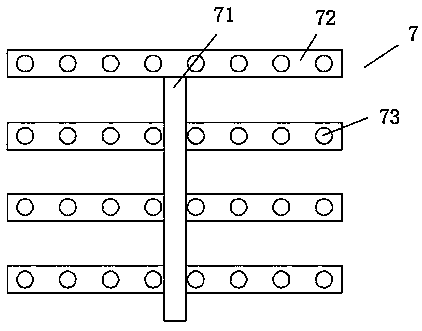

Sectional type tea drying equipment

InactiveCN105318673AIncrease profitSave resourcesDrying machines with local agitationDrying machines with materials at restPulp and paper industryGreen tea

The invention belongs to the technical field of green tea producing equipment, and discloses a sectional type tea dryer. The sectional type tea dryer is used for solving the problems that drying equipment is low in heat energy use ratio and bad in taste of dried tea. The sectional type tea dryer comprises a rack. A drying oven is arranged above the rack. A heating device is arranged on the lower bottom face in the drying oven. The heating device comprises an upper shell and a lower shell. The upper shell and the lower shell are connected together and form a vacuum steam chamber. A liquid absorbing core is arranged on the inner wall of the steam chamber. Operating liquid is filled in the steam chamber. The lower surface of the lower shell is coated with an electric heating wire layer. The upper surface of the upper shell is used as a drying platform for tea. A preheating box is further arranged on the rack. A through hole is formed in the upper end of the drying oven. The through hole is equipped with a pipeline. The bottom of the preheating box is communicated with the through hole through the pipeline.

Owner:雅安市雨城区晏场鹿井茶厂

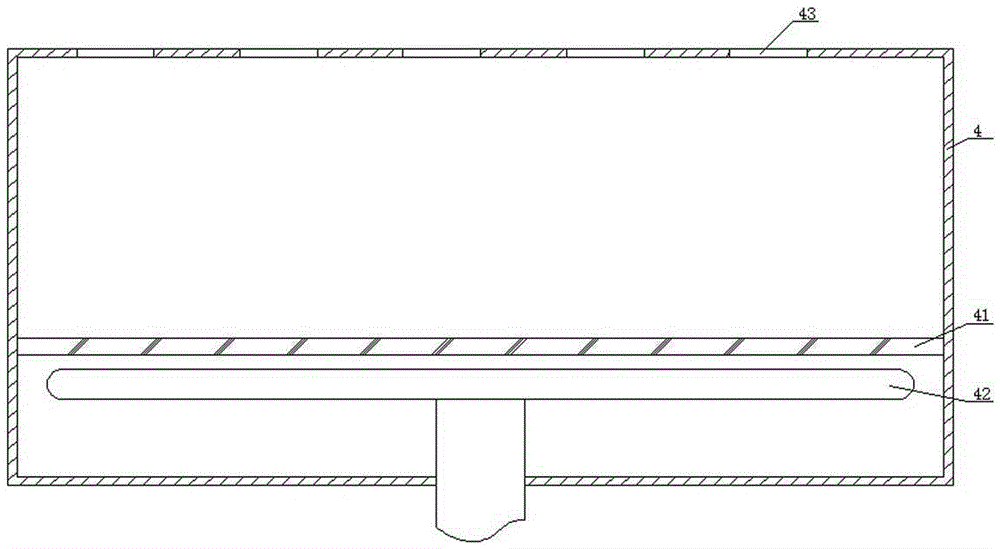

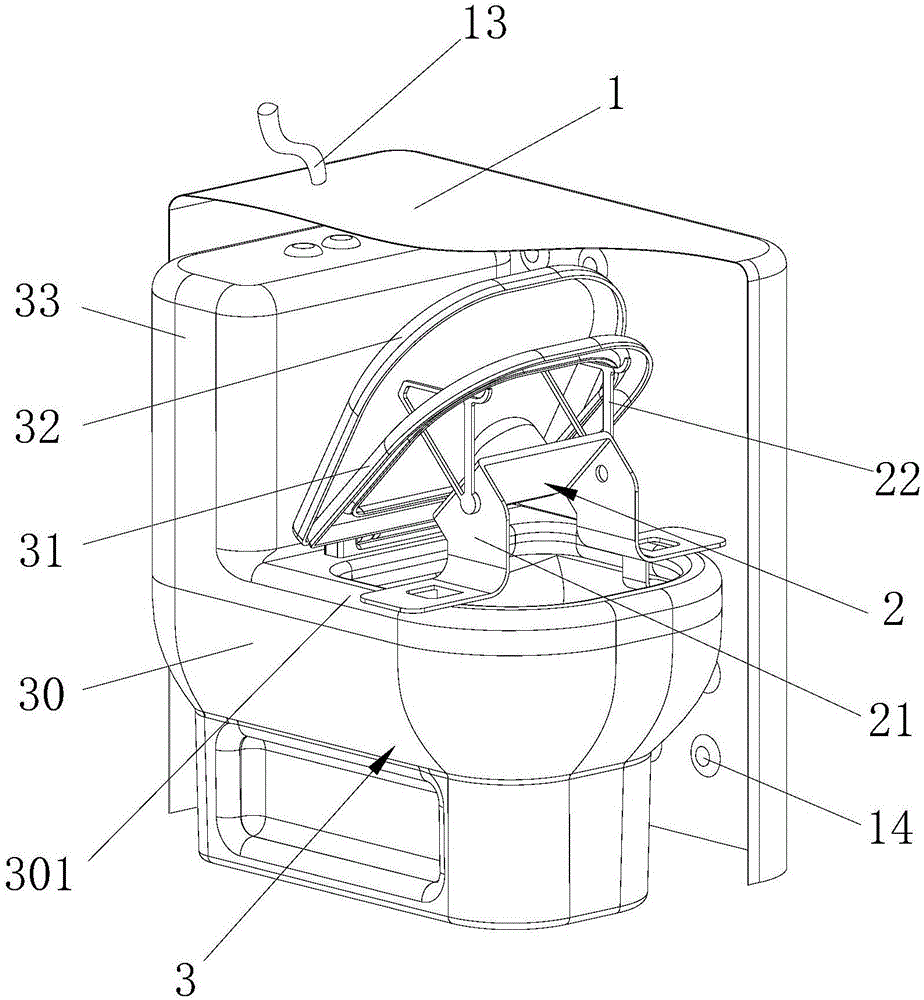

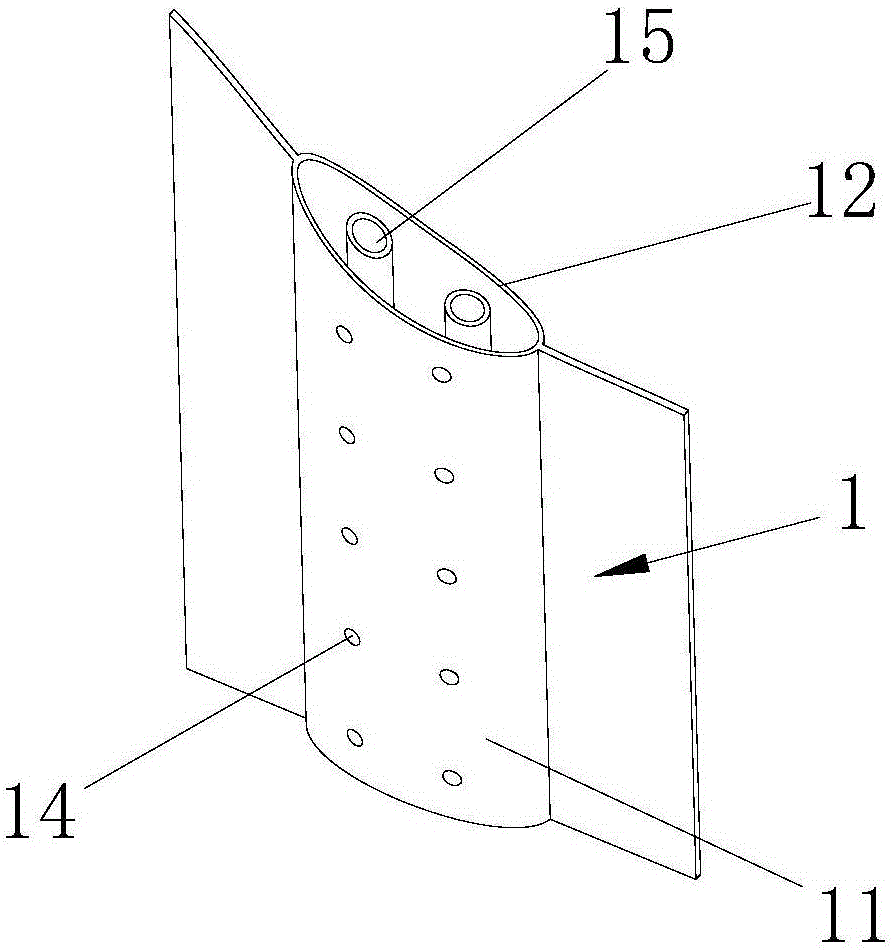

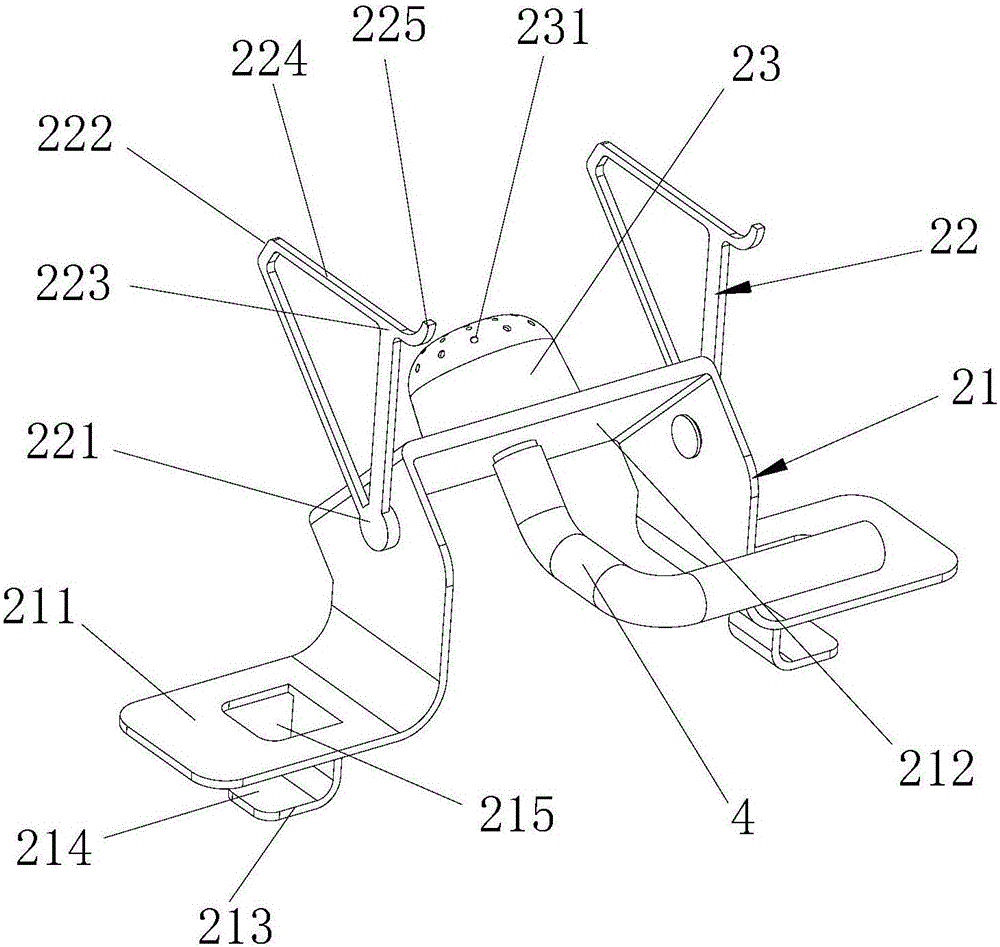

Closestool cleaning device

The invention discloses a closestool cleaning device which comprises a cleaning hood and a supporting seat, wherein the cleaning hood covers a closestool; a spraying cleaning mechanism is arranged in the cleaning hood and sprays cleaning fluid / steam into the closestool in the cleaning hood; the supporting seat supports a closestool washer and a closestool cover, so that the spraying cleaning mechanism can spray the upper and lower surfaces of the closestool washer and the closestool cover; the cleaning hood is of a flexible half-surrounded hood body structure, and is provided with a hood opening of a closed structure; the hood opening corresponds to the outside shape of the closestool and is fitted to the periphery of the closestool tightly; the cleaning hood comprises an inner layer and an outer layer; the spraying cleaning mechanism is arranged between the inner layer and the outer layer; the supporting seat comprises a base supported on a closestool seat and a bracket which is mounted on the base and supports the closestool washer and the closestool cover respectively.

Owner:万思琦

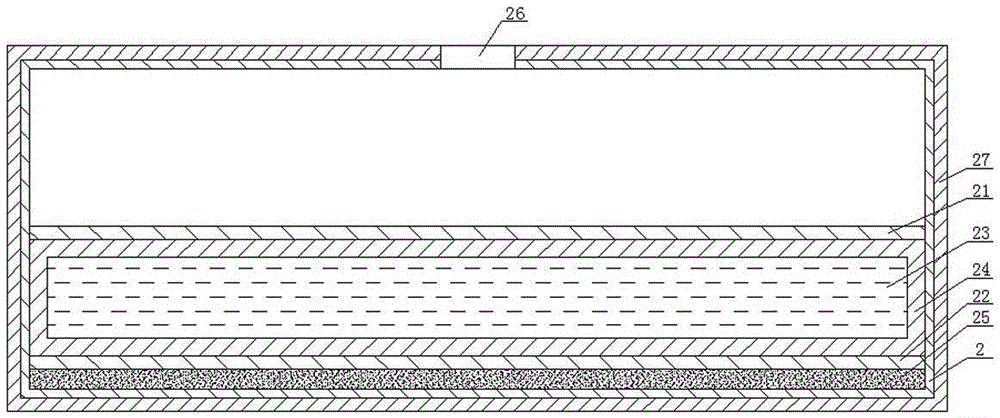

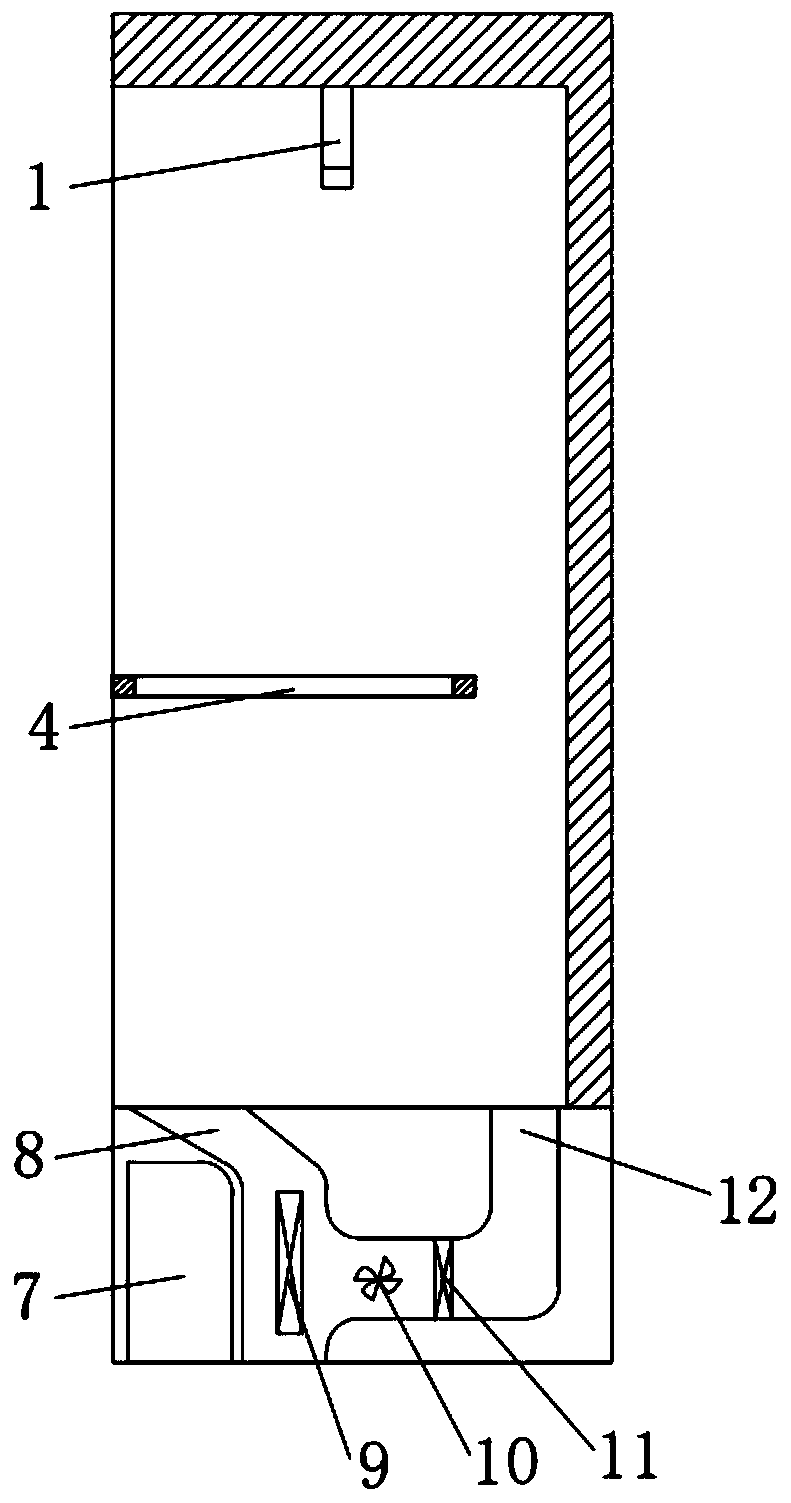

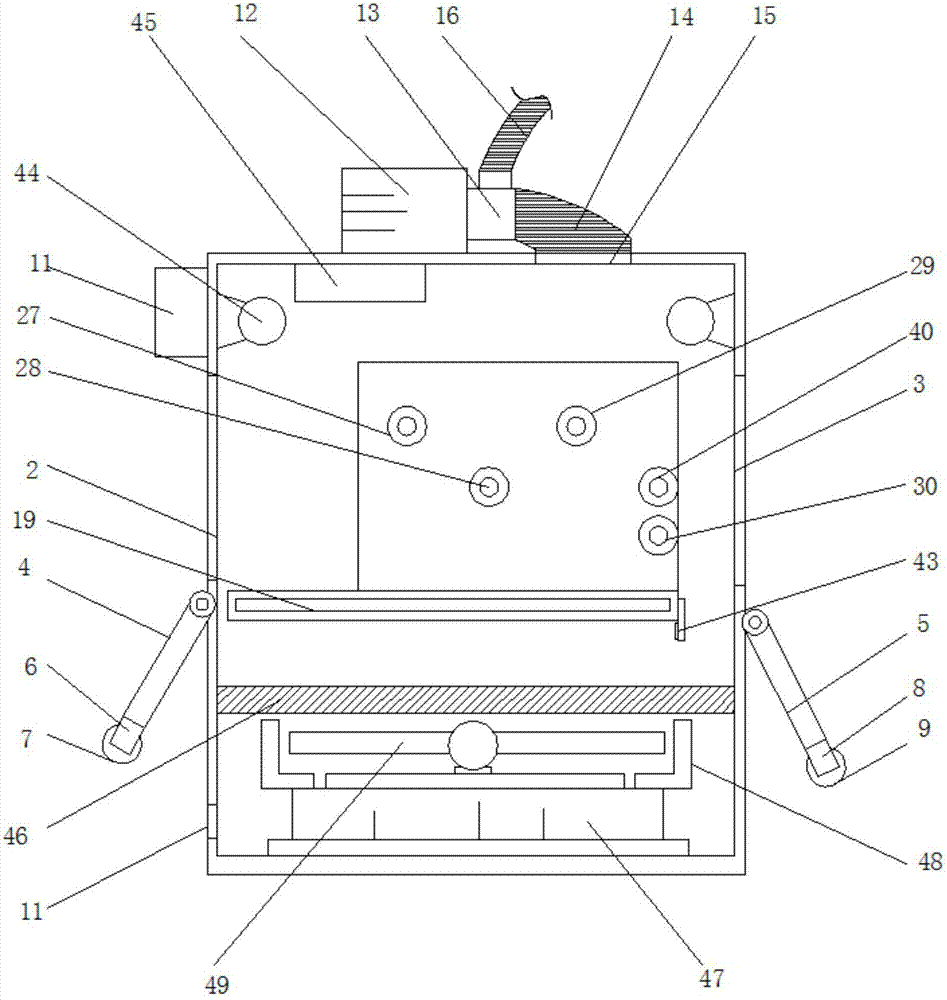

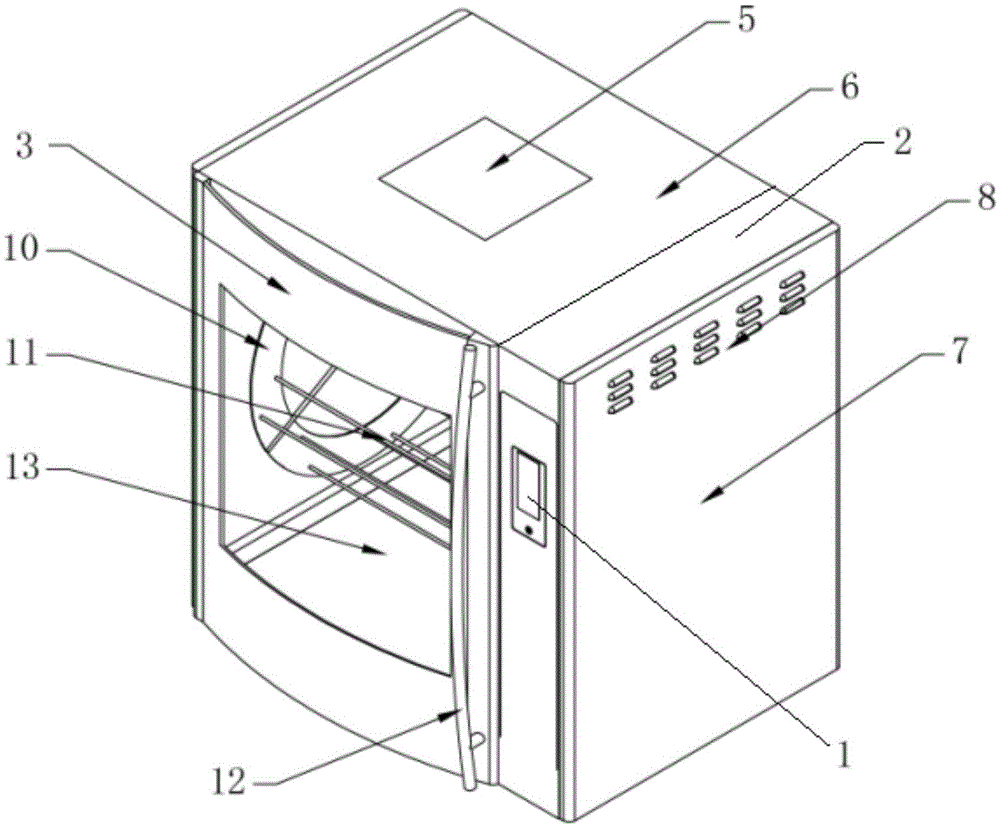

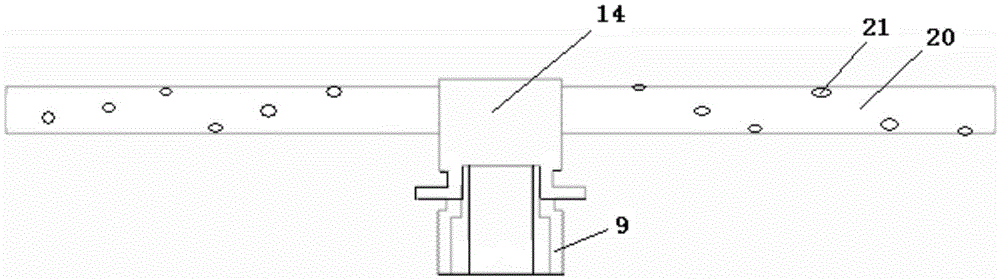

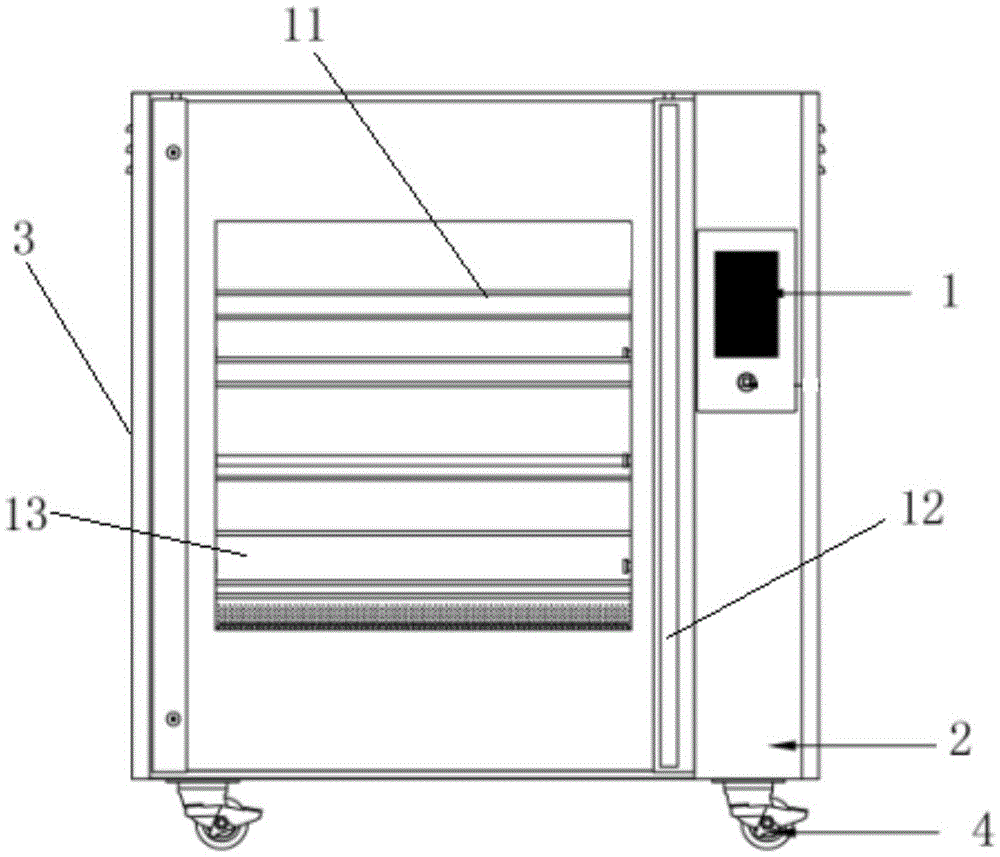

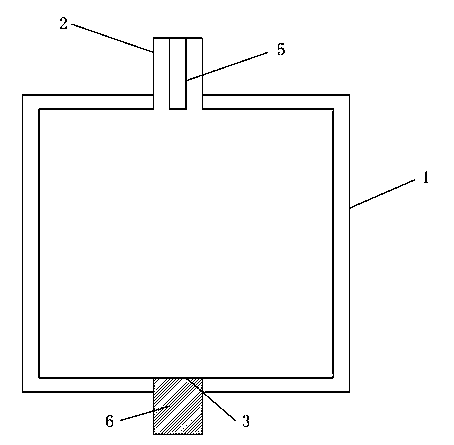

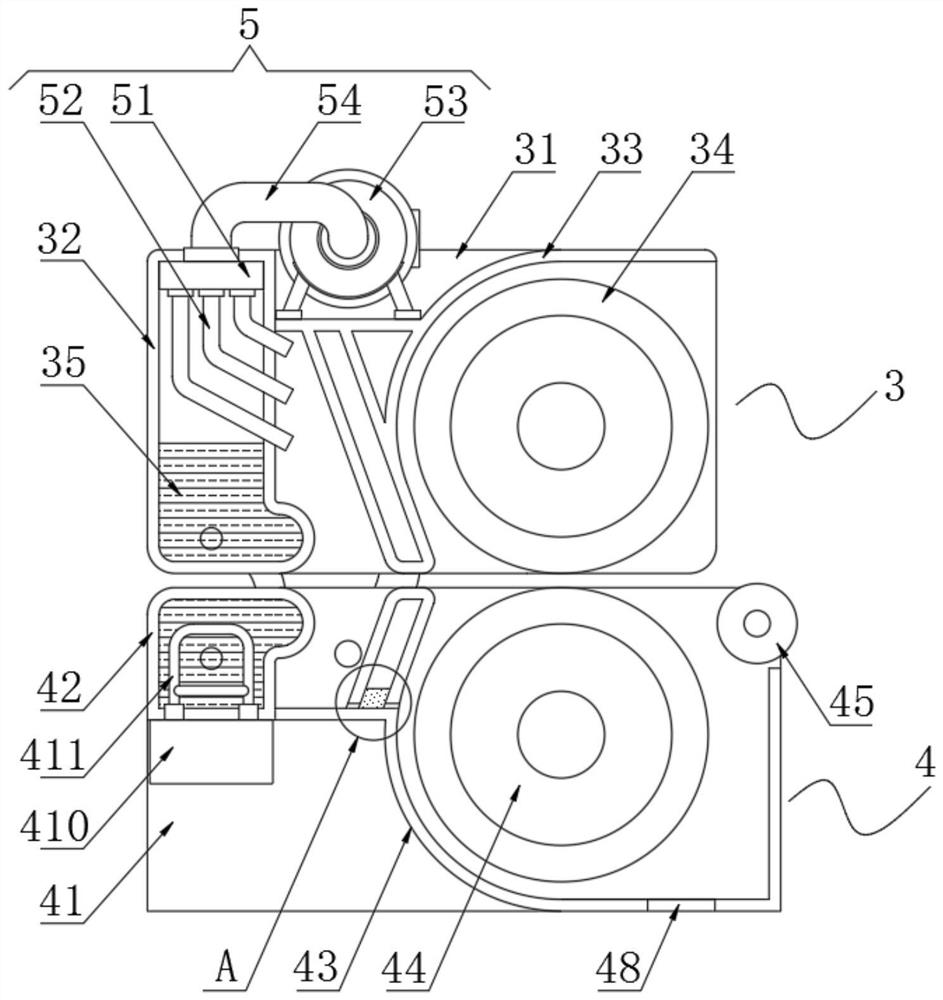

Internal circulation type clothes caring machine capable of recovering moisture in steam

PendingCN110130074AAchieve drying effectAvoid pollutionTextiles and paperLaundry driersWastewaterAir exchange

The invention discloses an internal circulation type clothes caring machine capable of recovering water in steam. The internal circulation type clothes caring machine comprises a box adopting a cavitystructure inside, a steam spraying port, an air return channel and a steam moisture recovery device, wherein a caring chamber is formed in the box; the steam spraying port is formed in the caring chamber, and a steam generator is communicated with a water adding box for containing water through a water guide pipe; the air return channel is formed in the bottom of the caring chamber and communicated with the caring chamber; the steam moisture recovery device is arranged at the bottom of the air return channel. By means of the air return channel communicated with the caring chamber, inside aircirculation is realized through the air return channel, meanwhile, a water condensation pipeline is arranged in the air return channel, high-temperature steam during drying is condensed through watercirculation, and the condensed water is drained to a wastewater drum to be collected; steam in the caring chamber is effectively condensed into dry air, finally, the dry air is heated to realize the drying effect, and pollution caused by air exchange of the caring chamber and surrounding environment is avoided.

Owner:合肥品冠科技有限公司

Surface modification method for diamond micropowder for ultra-fine diamond wire saw

The invention discloses a surface modification method for diamond micropowder for an ultra-fine diamond wire saw and belongs to the technical field of diamond micropowder production. By the adoption of the surface modification method for the diamond micropowder for the ultra-fine diamond wire saw, the problems that in the prior art, diamond micropowder is poor in dispersity and prone to accumulation and agglomeration are solved. The surface modification method comprises the following steps that (1) the diamond micropowder subjected to chemical plating is calcinated; (2) the calcinated diamond micropowder is pickled for activation through composite acid, and filtration and deacidification are conducted after activation; (3) dispersing treatment is conducted on the deacidified diamond micropowder through a cationic surface active agent; and (4) the dispersed diamond micropowder and the cationic surface active agent are added into electroplate liquid and evenly stirred and dispersed for later use. The surface modification method is suitable for surface modification of the diamond micropowder for the ultra-fine diamond wire saw.

Owner:山东山田新材科研有限公司 +1

High-efficiency drying device for organic fertilizer production

InactiveCN109114919AEvenly heatedSolve the problem of incomplete dryingDrying gas arrangementsDrying machines with non-progressive movementsAgricultural engineeringOrganic fertilizer

The invention discloses a high-efficiency drying device for organic fertilizer production. The high-efficiency drying device for organic fertilizer production comprises a bottom plate, supporting columns are fixedly connected to the two sides of the top of the bottom plate, the top of the bottom plate is provided with a stirring box, the stirring box is positioned between the two supporting columns, and a transmission box is fixedly connected to the right side of the top of the bottom plate. According to the high-efficiency drying device for organic fertilizer production, the transmission box,a heater, a fan, a heating column, a first motor, a driving gear, a first transmission column, a driven gear, a second transmission column, a transmission disc, a first transmission pin, a first transmission frame, a second transmission frame, a second transmission pin and a third transmission column are used in a cooperated mode, and the drying effect is achieved through the fan and the heatingcolumn, the third transmission column is pushed to move left and right through the second transmission frame, so that the effect that the organic fertilizer is uniformly heated is achieved. Accordingto the high-efficiency drying device for organic fertilizer production, the problem that an existing drying device is not thorough in drying effect of the organic fertilizer is solved, the practicability of the drying device is enhanced, and the production efficiency of the organic fertilizer is improved.

Owner:湖州怡辉生态农业有限公司

Commercial dishwasher

PendingCN107773187AImprove drying efficiencyImprove drying effectTableware washing/rinsing machine detailsEngineeringWaste heat

The invention discloses the technical field of tableware cleaning machines, and particularly discloses a commercial dishwasher. The commercial dishwasher comprises a dishwasher main body and a dryingunit, wherein an evaporator is arranged in the dishwasher main body and comprises a dehumidified air outlet; the drying unit is used for drying tableware and comprises a heating unit and a fan unit, the heating unit is used for heating dehumidified air coming out of an air outlet of the evaporator, and the fan unit is used for conveying the air heated by the heating unit to dishes. Compared with the traditional heating mode, the commercial dishwasher has the advantages that the heating unit is arranged on the dishwasher main body, the evaporator in the dishwasher main body has high dehumidification effect while absorbing waste heat in the air; the dehumidified air is moderately heated by the heating unit with power of about 3-4.5 kw, hot and dry air is blown out by the fan unit, water drops on the surfaces of the dishes are blown away, the small attached water drops are absorbed by the hot and dry air, the drying effect is achieved, and the commercial dishwasher has the advantages of saving energy and improving drying efficiency.

Owner:宁波吉艾诺节能科技有限公司

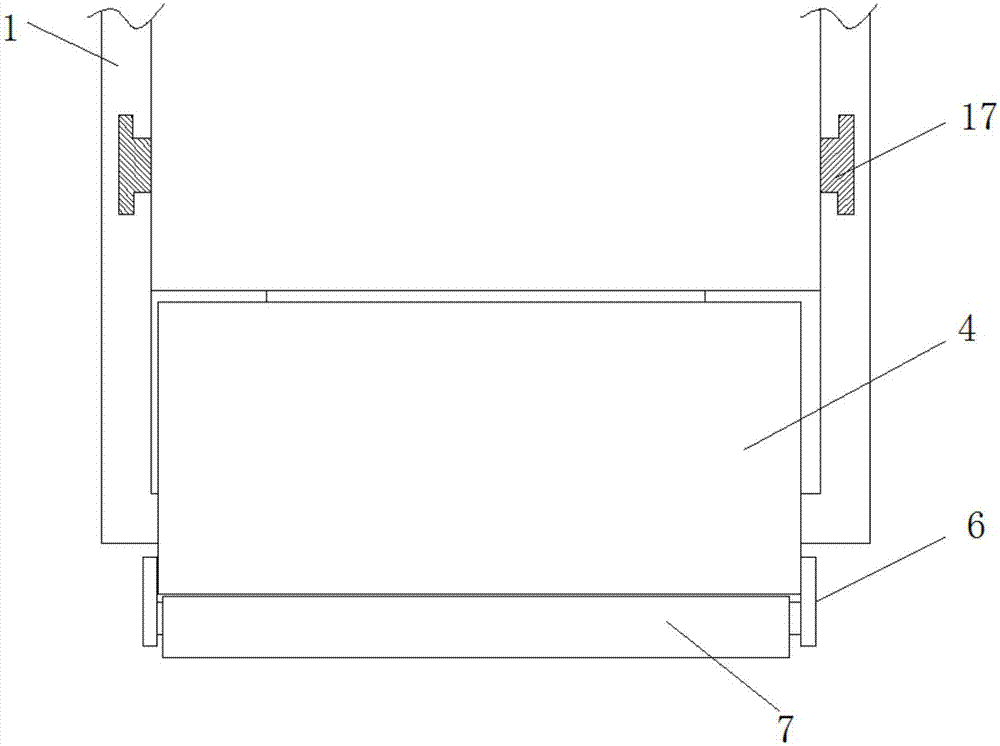

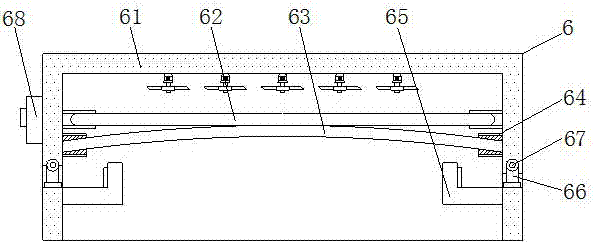

Cloth drying device for spinning

InactiveCN107388775AIncrease the lengthExtension of timeDrying gas arrangementsDrying machines with progressive movementsEngineeringMechanical engineering

The invention relates to the technical field of textile equipment, and discloses a cloth drying equipment for textile, which includes a box body, and two sides of the box body are respectively provided with a material inlet and a material outlet port, and one side of the box body is Hinged with the top of the feed door, and the feed door is located below the feed port, the other side of the box is hinged with the top of the discharge door, and the discharge door is located below the discharge port, the feed The bottom of the door is fixedly connected with a first rotating shaft frame, and a first rotating rod is sleeved inside the first rotating shaft frame. The cloth drying equipment for weaving uses the first rotating shaft, the second rotating shaft, the third rotating shaft, the fourth rotating shaft and the fifth rotating shaft arranged between the first supporting plate and the second supporting plate, The cloth passes through the first rotating shaft, the second rotating shaft, the third rotating shaft and the fourth rotating shaft successively, prolonging the length of the cloth in the dryer and the time for the cloth to pass through the dryer box, so as to enhance the drying efficiency of the cloth Effect.

Owner:范威

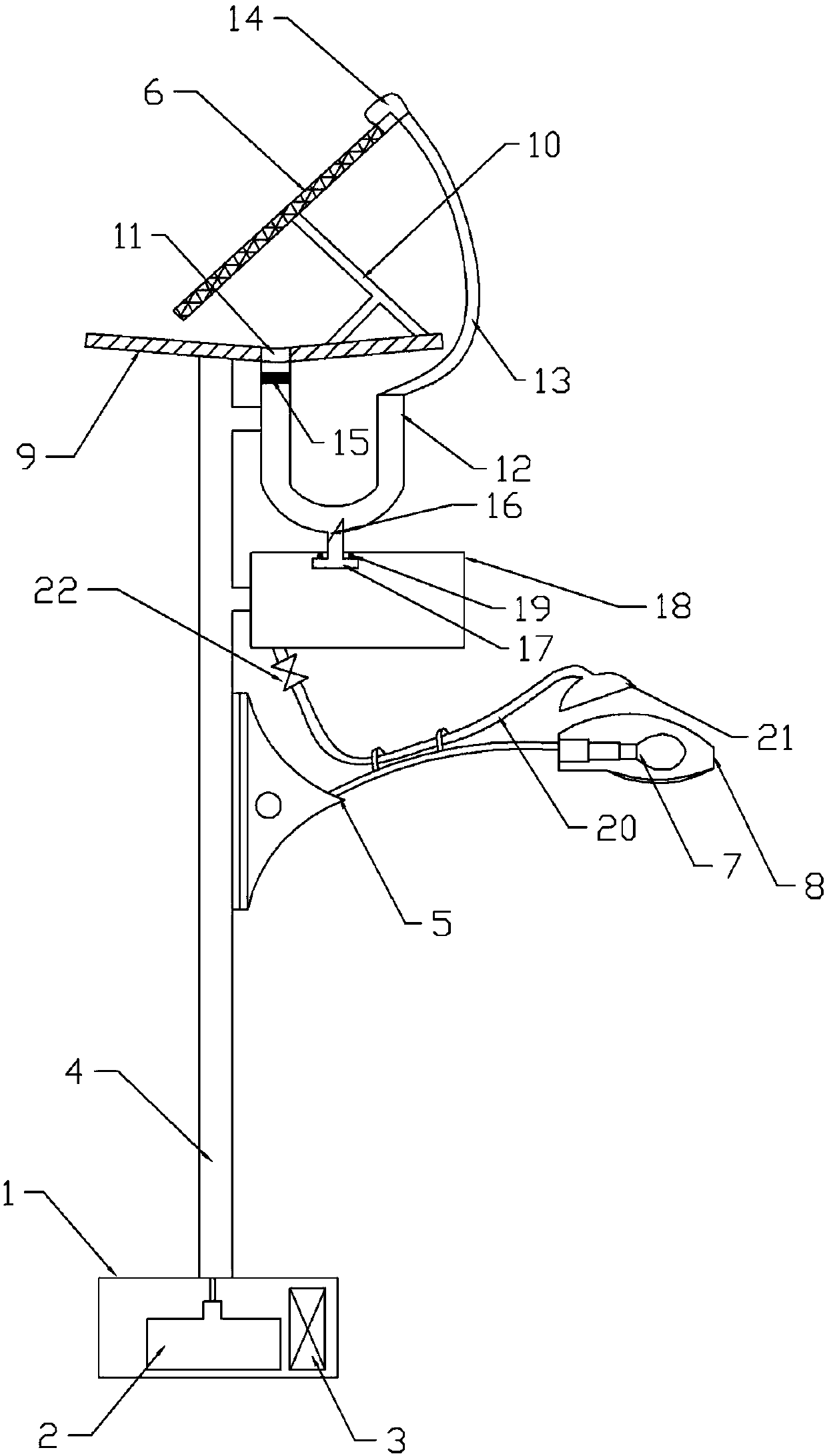

Rain-proof solar street lamp

InactiveCN107631250AAchieve stretchWill not affect normal useOutdoor lightingGas-tight/water-tight arrangementsSolar street lightEngineering

The invention relates to a rain-proof solar street lamp and belongs to the technical field of non-portal illuminating devices or systems thereof. The solar street lamp comprises a base. A storage battery and a controller are arranged in the base. The base is fixedly connected with a support. The support is connected with a lamp pole and a solar cell panel. A lamp is mounted on the lamp pole, and the outside of the lamp is covered with a lampshade. The top end of the support is connected with a supporting seat. The supporting seat is connected with a fixing support. A first through hole is formed in the supporting seat. The lower portion of the supporting seat communicates with a U-shaped tube. The U-shaped tube is connected with a branch tube. The branch tube is connected with an air bag.The air bag is connected to one end of the solar cell panel. A piston is in sliding fit with the interior of the U-shaped tube. The piston, the U-shaped tube, the branch tube and the air bag form a closed cavity. The interior of the closed cavity is filled with carbon dioxide gas, and pressure of the closed cavity and the external atmospheric pressure keep a relative balance. According to the technical scheme, the weight of rainwater in rainy weather is reasonably used to serve as the power source, operation is convenient, the solar cell panel can be protected, the service life of the street lamp is prolonged, and the practicability is high.

Owner:ZHEJIANG DOT LIGHTING

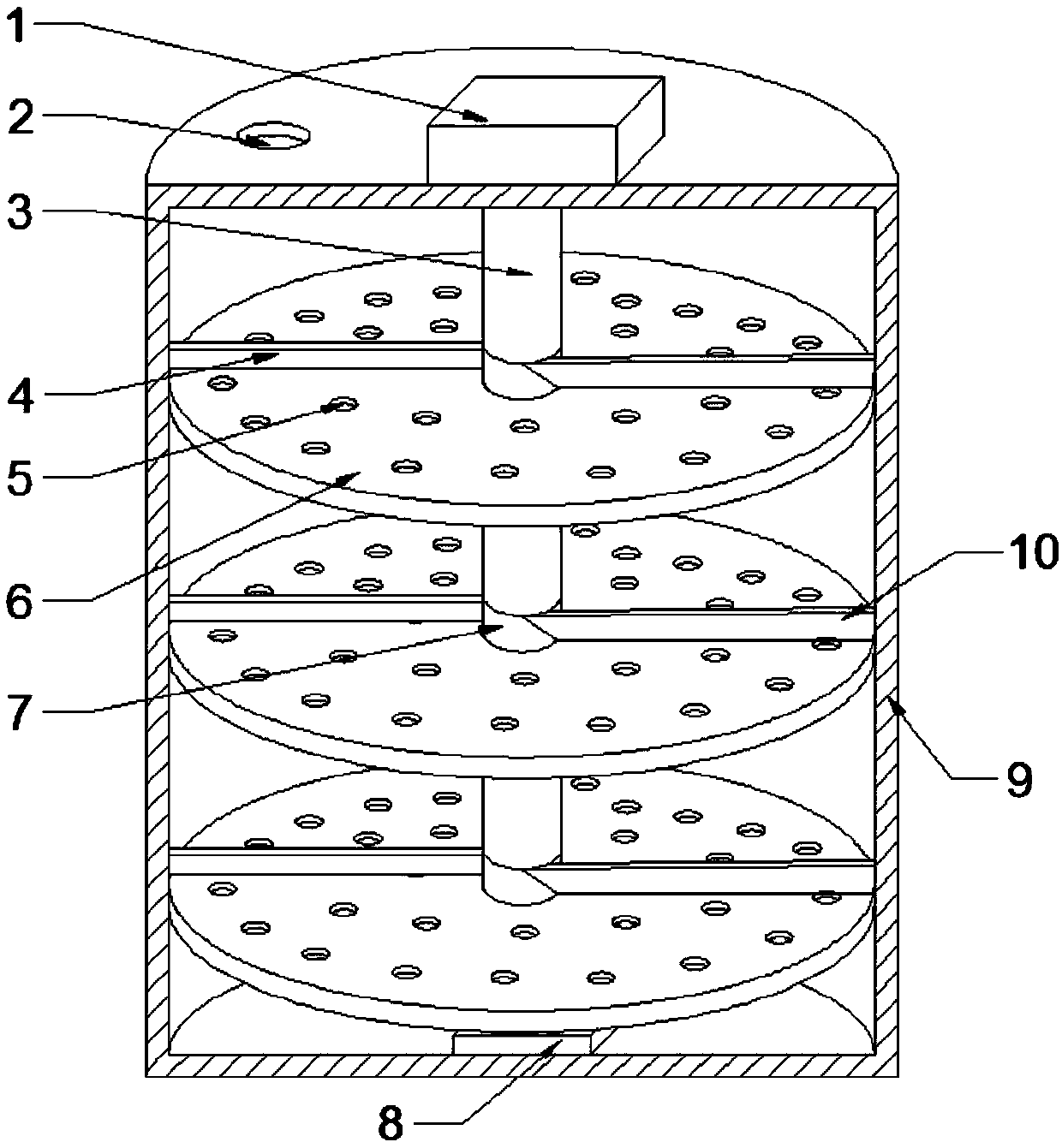

Preserved plum drying box

InactiveCN109566838AUniform moisture contentAchieve drying effectConfectioneryCocoaCircular discElectric machinery

The invention discloses a preserved plum drying box, and belongs to the technical field of preserved fruit processing equipment. The preserved plum drying box comprises a box body, wherein a hot air fan is arranged at the inner bottom of the box body, and an air outlet of the hot air fan is vertically upward. A plurality of transverse discs are arranged in the box body at intervals from top to bottom, the discs are fixedly connected with the inner wall of the box body, the discs are provided with a plurality of vent holes, and through holes are formed in the centers of the discs. A motor is arranged at the top of the box body, and an output shaft of the motor is vertically downward. The output shaft of the motor is fixedly connected with a rotating shaft, and the end, away from the outputshaft of the motor, of the rotating shaft penetrates through the through holes to be rotatably connected to the discs correspondingly. A plurality of rings are arranged on the rotating shaft at intervals, and the multiple rings are correspondingly located above the discs. The multiple rings are fixedly connected with transversely inclined shovel plates correspondingly, and the lower ends of the shovel plates are in sliding contact with the upper surfaces of the discs. The multiple rings are further fixedly connected with push plates, and gaps are left between the push plates and the discs. Thepreserved plum drying box solves the problem that moisture in preserved plums is not uniform after the preserved plums are dried by the drying box.

Owner:习水二郎腾达李子产业发展有限公司

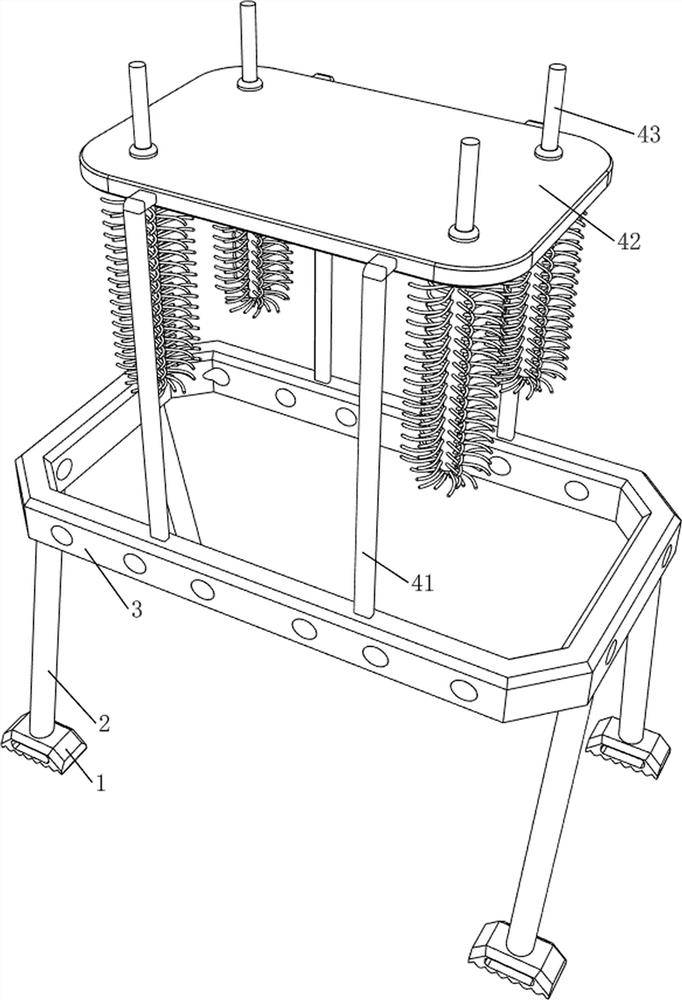

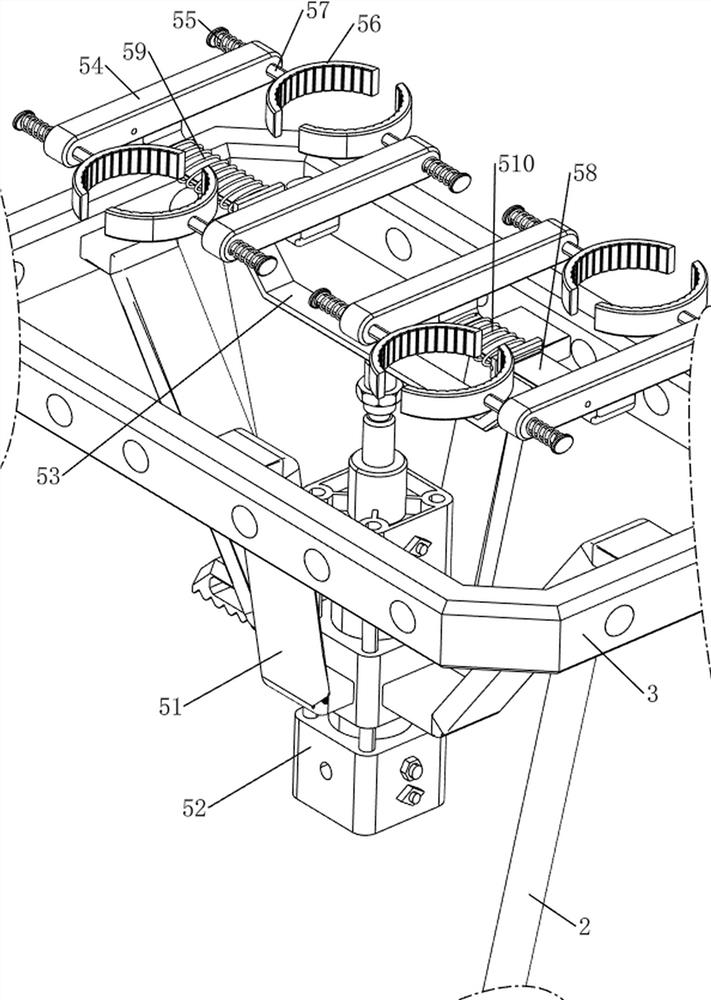

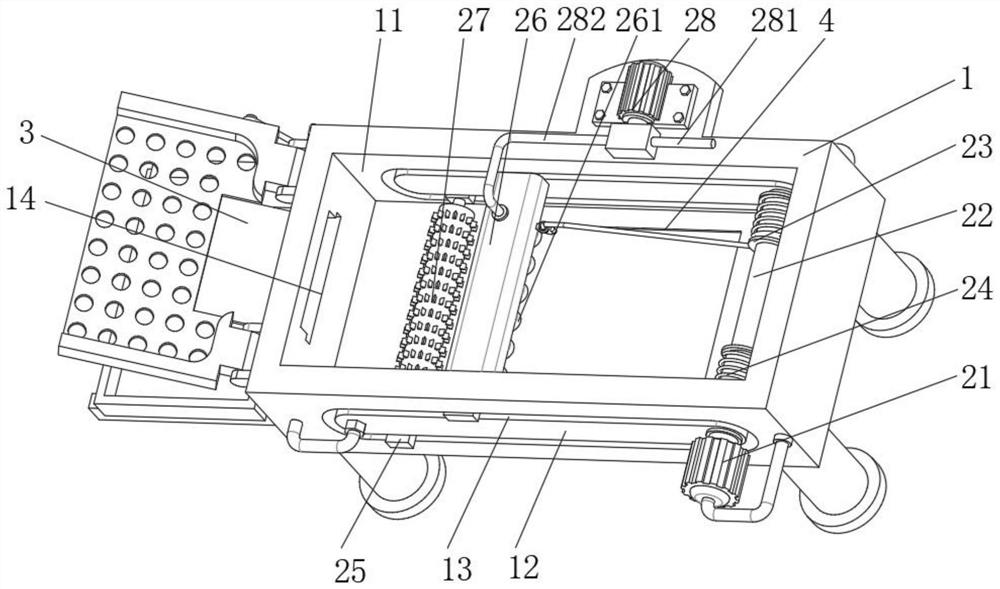

Test tube cleaning and drying all-in-one machine for pharmacy department

ActiveCN113020186ARealize the clamping effectRealize the rotation effectHollow article cleaningDrying gas arrangementsPharmacyBiomedical engineering

The invention relates to a cleaning and drying all-in-one machine, in particular to a test tube cleaning and drying all-in-one machine for the pharmacy department. The test tube cleaning and drying all-in-one machine for the pharmacy department can automatically clean and disinfect, reduces the burden of workers and is convenient to use. The test tube cleaning and drying all-in-one machine for the pharmacy department comprises first fixing frames, second fixing frames, a third fixing frame, a cleaning mechanism and a clamping mechanism, wherein the four first fixing frames are all provided with the second fixing frames; the third fixing frame is arranged among the tops of the four second fixing frames; the cleaning mechanism is arranged in the middle of the top of the third fixing frame; and the inner wall of the third fixing frame is provided with the clamping mechanism. According to the test tube cleaning and drying all-in-one machine, by manually rotating brushes on the two sides, cleaning liquid can flow into a test tube from a small hole, so that the brushes can clean the test tube, and the cleaning effect is achieved.

Owner:南京韵鼎机电工程有限公司

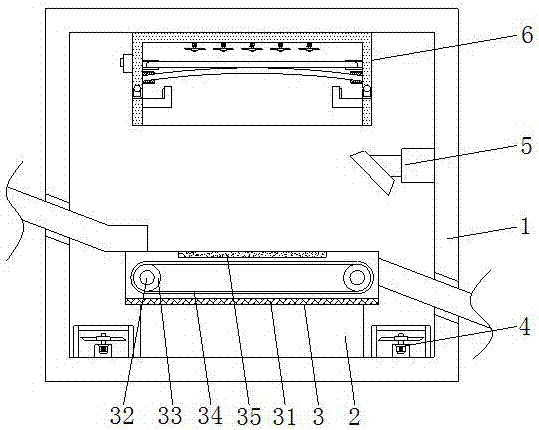

Drying device for printing

ActiveCN106864023AAchieve drying effectAvoid damagePrinting press partsPulp and paper industryAir blower

The invention discloses a drying device for printing. The drying device comprises a shell, a fixing table is fixedly connected to the bottom of the inner wall of the shell, and a conveying device is fixedly connected to the top of the fixing table. A feeding port is formed in the position, corresponding to the conveying device, of one side of the shell, and a discharging port is formed in the position, corresponding to the conveying device, of the other side of the shell. Two air blowers are arranged at the bottom of the inner wall of the shell, and the two air blowers are symmetrically arranged with the conveying device as the central axis. According to the drying device for printing, finished paper products on the conveying device are dried by blowing hot air to the finished paper products through a hot-air blower, hot air with damp rises and then enters a dehumidifying device, the damp is cold-liquefied on a glass water collecting plate, and water generated after liquefying downwards flows to water collecting pools at the two ends under the effect of gravity, so that the effect of drying the finished paper products with ink being not completely dried is achieved, the situation that the finished paper products are damaged due to the fact that the ink is not completely dried is avoided, the time and labor are saved, environmental friendliness is achieved, and working efficiency is promoted to a certain extent.

Owner:贵阳精彩数字印刷有限公司

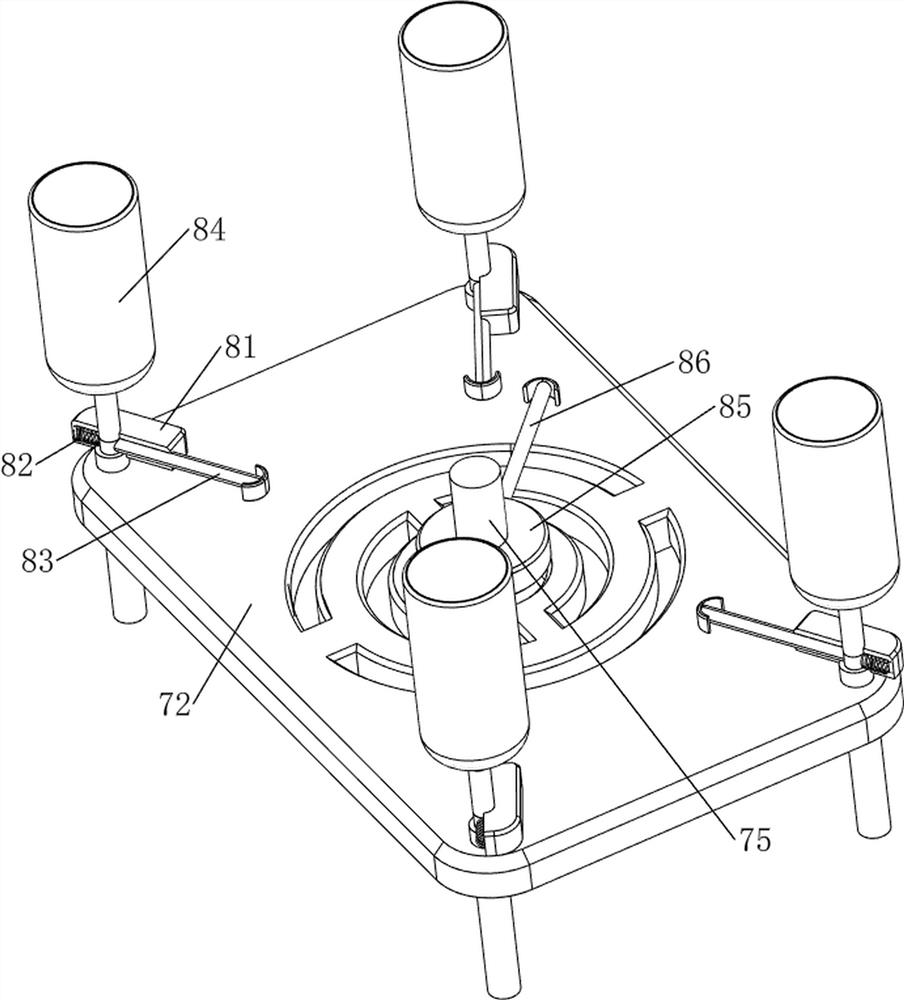

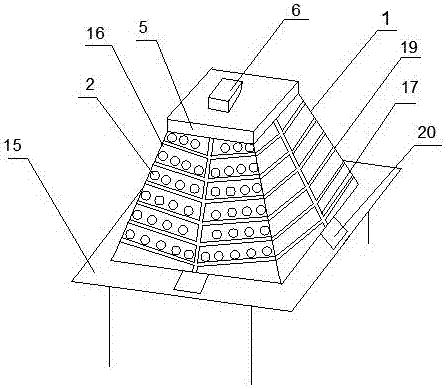

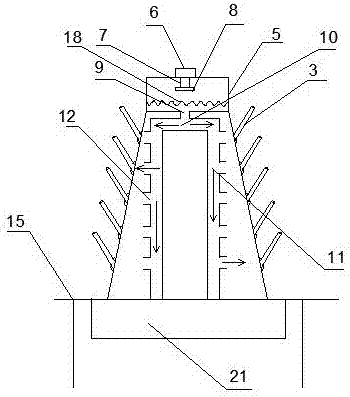

Test tube dryer

InactiveCN106989575AEasy to recycleRealize detachable connectionDrying gas arrangementsDrying machines with local agitationEngineeringTest tube

The invention discloses a test tube dryer. The dryer is of a hollow right quadrangular frustum pyramid structure, each wall board of the dryer is provided with a drainage channel, each drainage channel comprises a vertical drainage groove in the corresponding wall board and a plurality of branch drainage grooves in an upward launching shape towards the two sides of the corresponding wall board, the branched drainage grooves are connected with the corresponding vertical drainage groove, a through hole is formed in each branch drainage groove, a side turning hole plug is embedded on each through hole and is of a middle hollow structure, the diameter of one end of each side turning hole plug is small, the diameter of the other end of each side turning hole plug is large, and the ends, with the small diameter, of the side turning hole plugs are connected with a drying tube through threads; a heating air blowing mechanism is arranged at the top end of the dryer and comprises a shell, a motor arranged on the shell and a fan connected with the motor through a rotating shaft; a heating wire connected to the inner wall of the shell is arranged below the fan, an air outlet communicated with the interior of a dryer cavity is formed below the shell, and is connected with an air supply channel through a divided manifold, the air supply channel corresponds to the inner board face of each wall board through the corresponding branch pipe, the dryer can rapidly evaporate water remaining in the test tube to dryness, and water in the test tube can flow down through the drainage channels and is recycled.

Owner:卢晓鹏

Chicken roasting furnace with automatic cleaning function

InactiveCN105478425AAchieve comprehensive cleaning effectAchieve drying effectHollow article cleaningRoasters/grillsSolenoid valveControl engineering

The invention discloses a chicken roasting furnace with an automatic cleaning function. The chicken roasting furnace comprises a furnace body, wherein a rotary water sprayer is arranged at the bottom in the furnace body, a fan is arranged at the top of the furnace body, a control chamber is arranged on the side edge of the furnace body, a computer panel, an agent solenoid valve, an agent pipe, a clear water solenoid valve and a clear water pipe are arranged in the control chamber, and the agent solenoid valve and the clear water solenoid valve are correspondingly arranged on the agent pipe and the clear water pipe; a control panel connected with the computer panel is arranged on the outer surface of the control chamber; the rotary water sprayer comprises a rotating shaft, a water inlet internal screw, a water spraying pipe and water spraying holes; the rotating shaft is fixedly connected to the top end of the water inlet internal screw, a water inlet pipe is arranged at the bottom of the furnace body, the bottom end of the water inlet internal screw is fixedly connected with the bottom of the furnace body and communicated with the water inlet pipe, and the water inlet pipe is communicated with the agent pipe and the clear water pipe; the water spraying pipe penetrates through the rotating shaft and is communicated with the water inlet internal screw; more than two water spraying holes are spirally formed in the wall of the water spraying pipe; the fan is communicated with the clear water pipe. The chicken roasting furnace can timely clear dirt, and the service life of the chicken roasting furnace can be prolonged.

Owner:NANJING NEWHIGH KITCHEN EQUIP DEV CO LTD

Cotton yarn dryer

InactiveCN103123214AAchieve drying effectImprove drying effectDrying gas arrangementsYarnPulp and paper industry

The invention discloses a cotton yarn dryer which comprises a drying box. An air inlet is formed in the top portion of the drying box, and an air outlet is formed in the bottom portion of the drying box. The cotton yarn dryer is characterized in that a hollow electrical heating tube is arranged in the air inlet, and a blower is arranged in the air outlet. The cotton yarn dryer is good in drying effect.

Owner:薛白

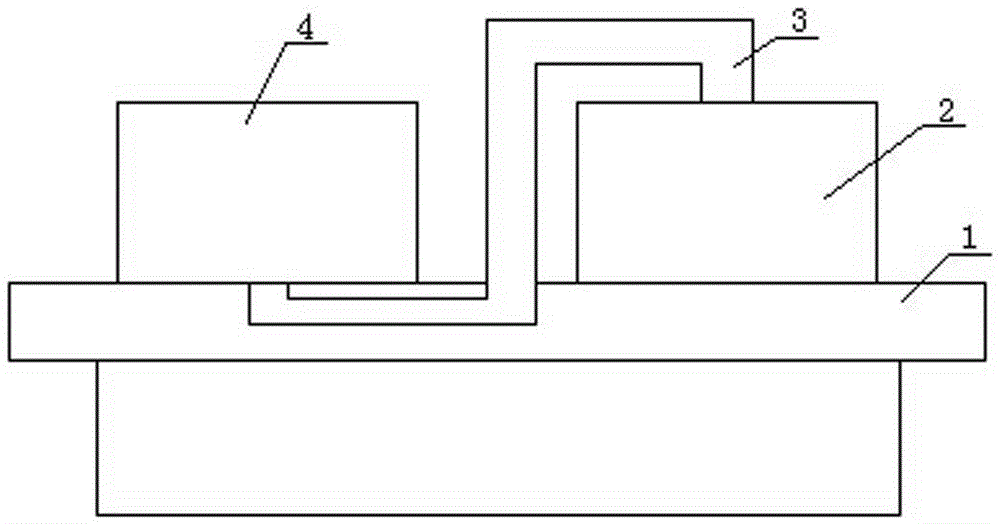

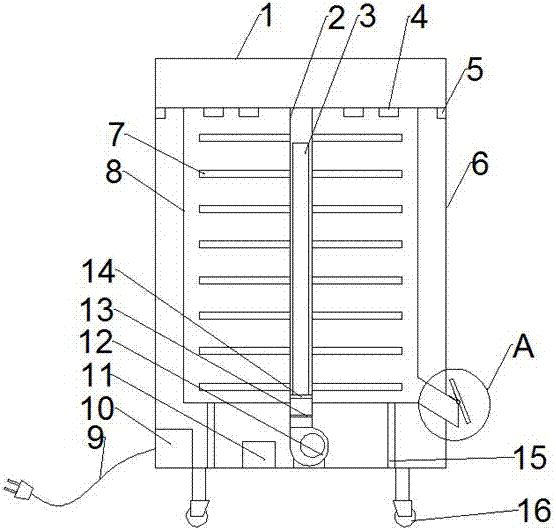

Material damp-proof storage device

PendingCN109398963AAccelerates the removal of moistureAchieve drying effectClosure with auxillary devicesSealingMulti materialArchitectural engineering

The invention discloses a material damp-proof storage device in the technical field of construction engineering. The device comprises a box body and a box cover arranged at the top of the box body, the side wall of the box body is provided with an air inlet plate, and the bottom of an inner cavity of the box body is provided with a drying box and a hot air blower. The output end of the air inlet pipe is connected with an air outlet pipe, and a rotating shaft is inserted in the middle of the inner cavity of the box body. Rotating discs are fixedly connected to the two sides of the outer wall ofthe rotating shaft in a sleeving mode, and a plurality of storage mechanisms are arranged between the two rotating discs. The other end of the rotating shaft is connected with a handle, and the top of the box cover is provided with an air outlet net. The device is simple in structure and novel in design. Filtered air is heated by the hot air blower and then is introduced into the box body, so that the drying effect of a construction engineering material is achieved, the damp-proof effect is good, the moisture removal effect in the box body is greatly improved, and the performance of the construction engineering material stored in the box body is effectively guaranteed. Various materials can be stored in multiple storage boxes, and the storage boxes can circularly move under the action ofthe rotating shaft so that the materials can be conveniently stored and obtained.

Owner:NANJING INST OF TECH

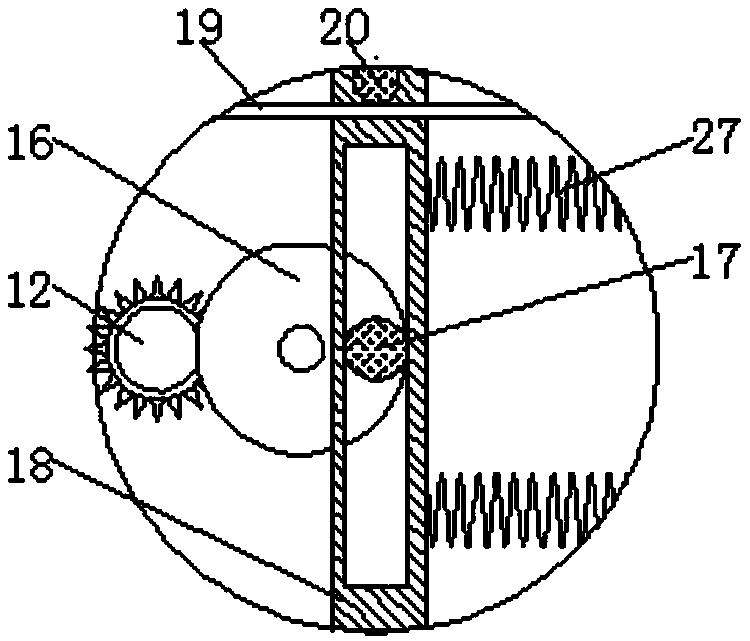

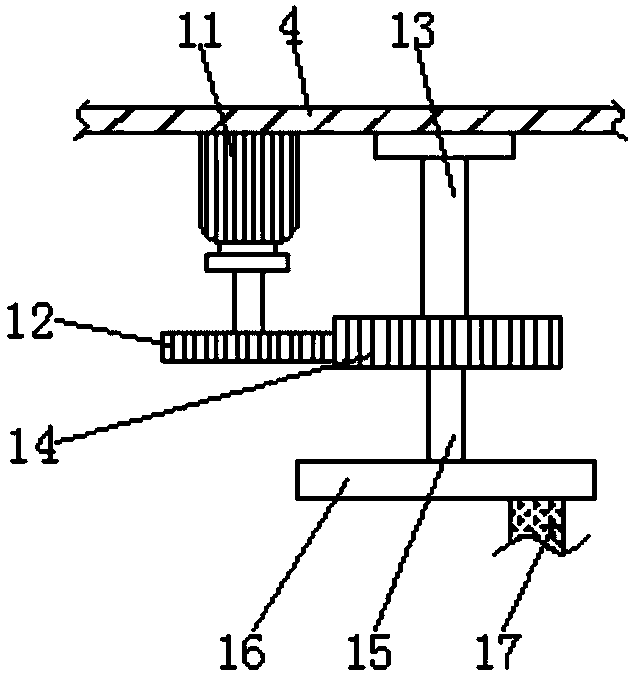

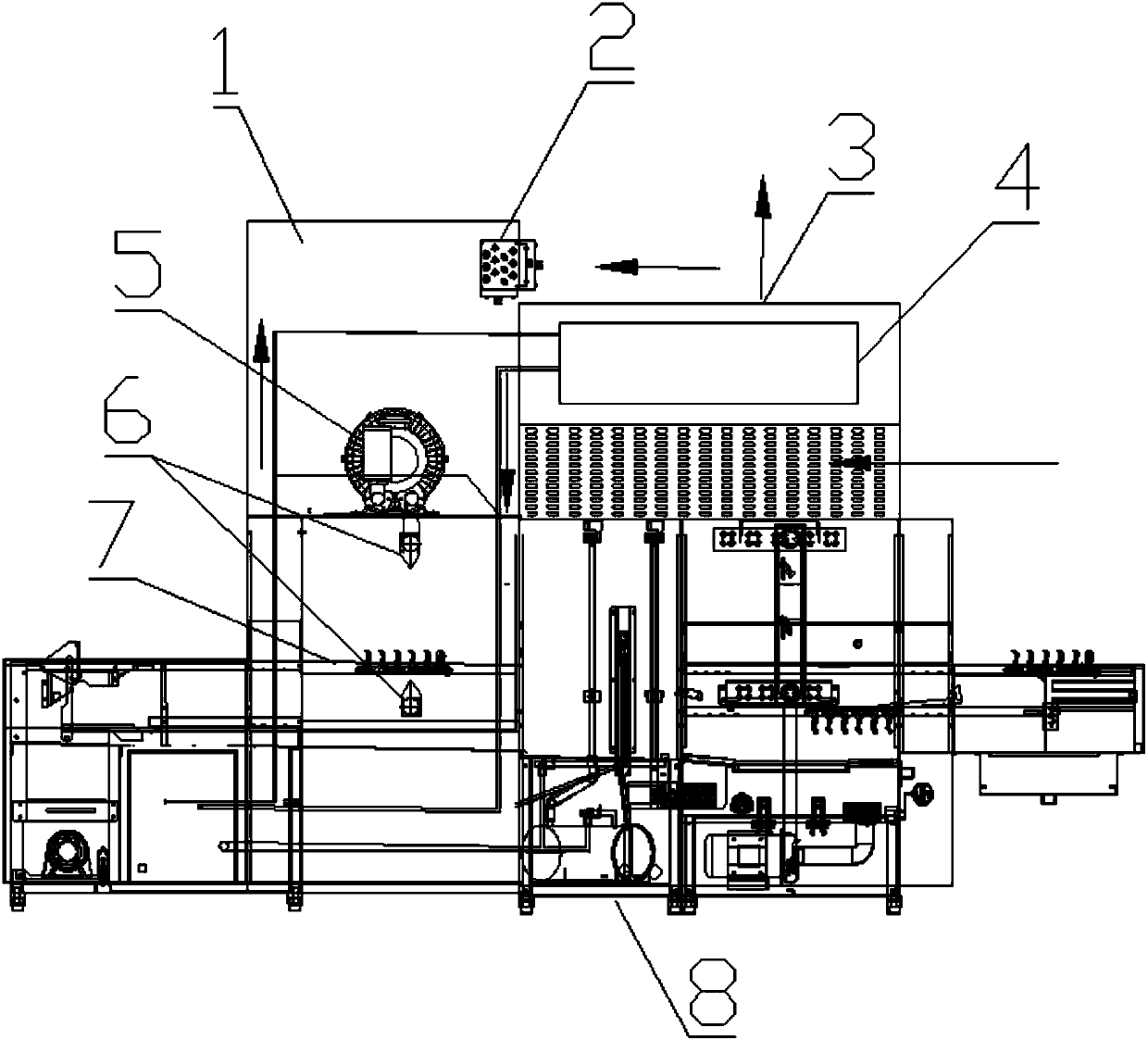

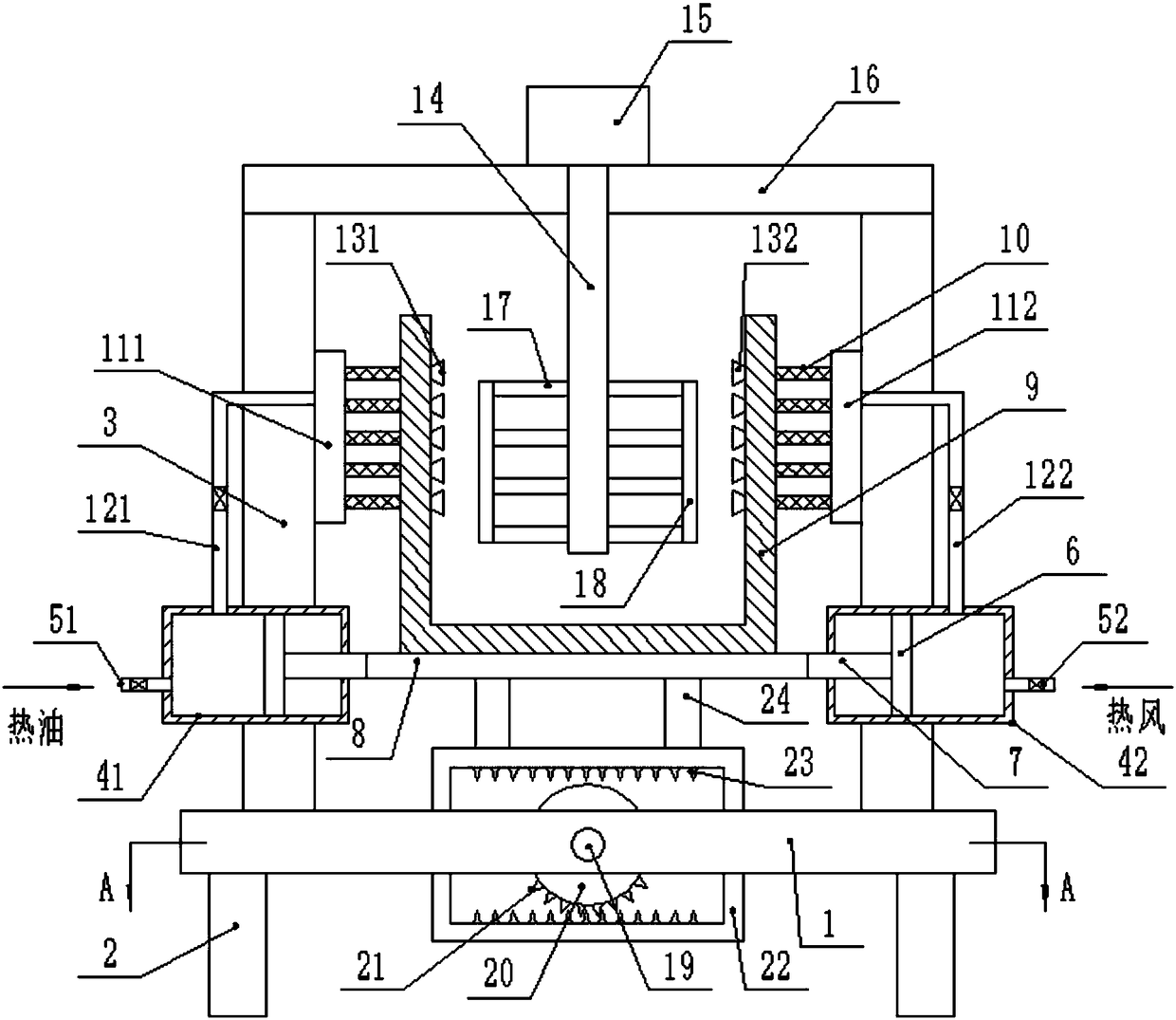

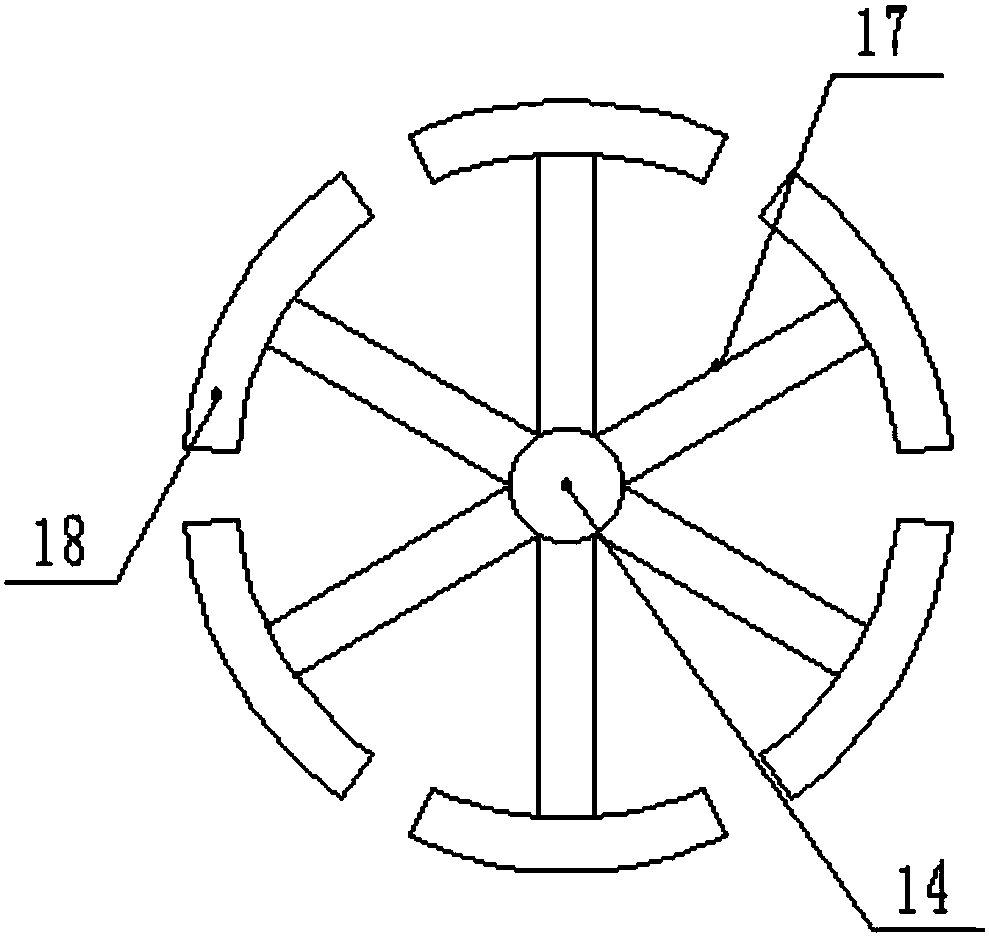

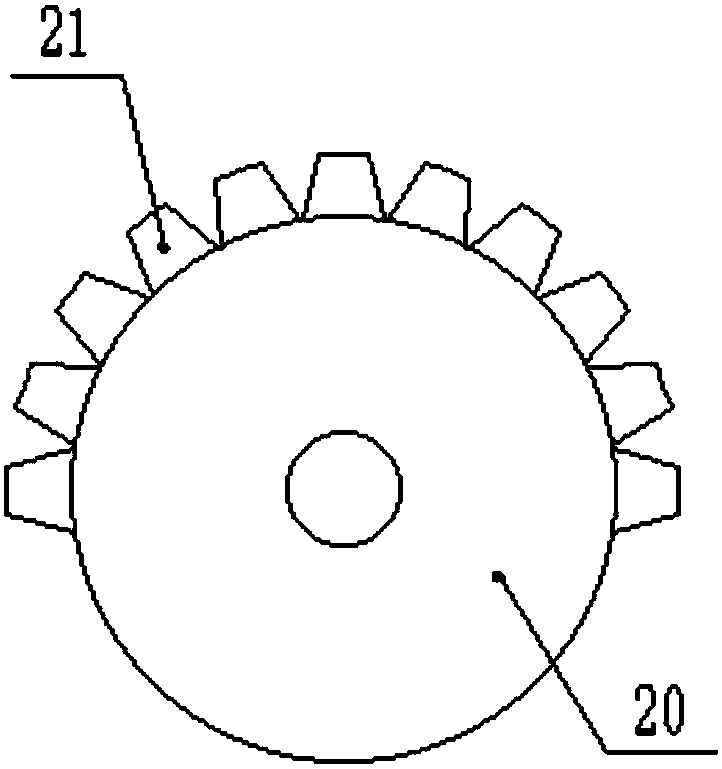

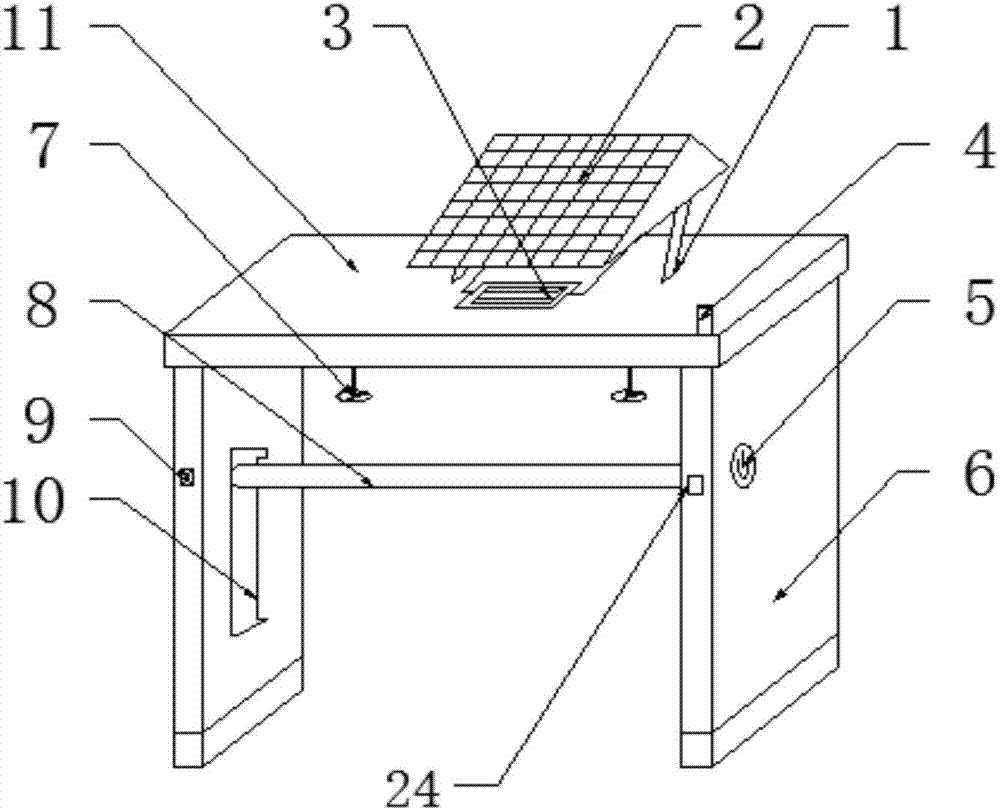

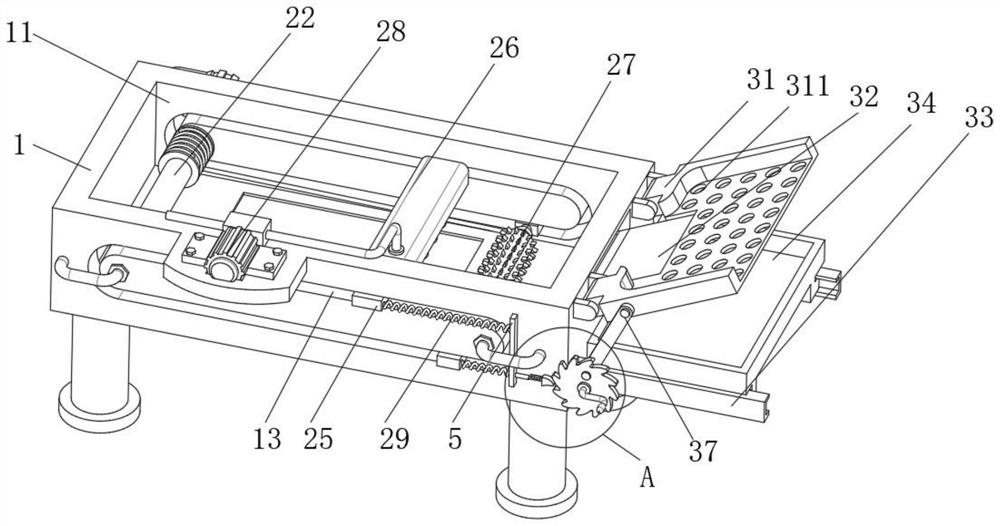

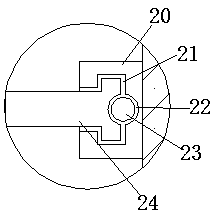

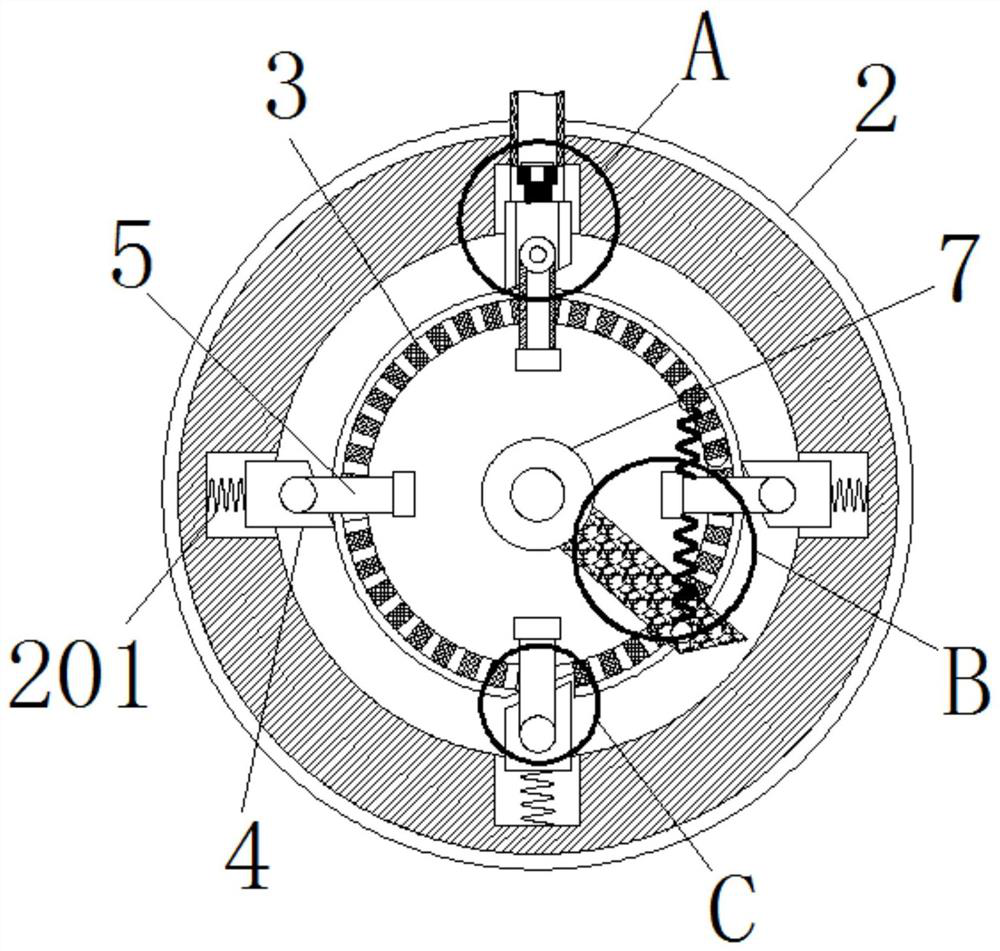

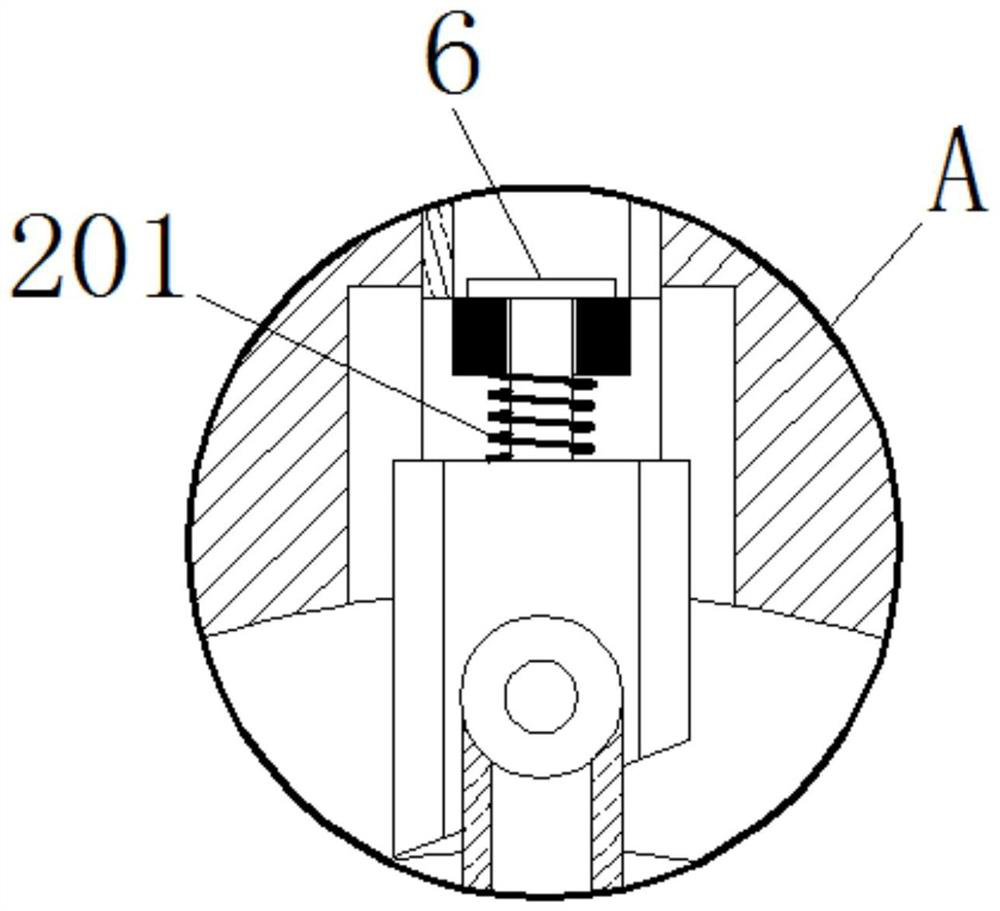

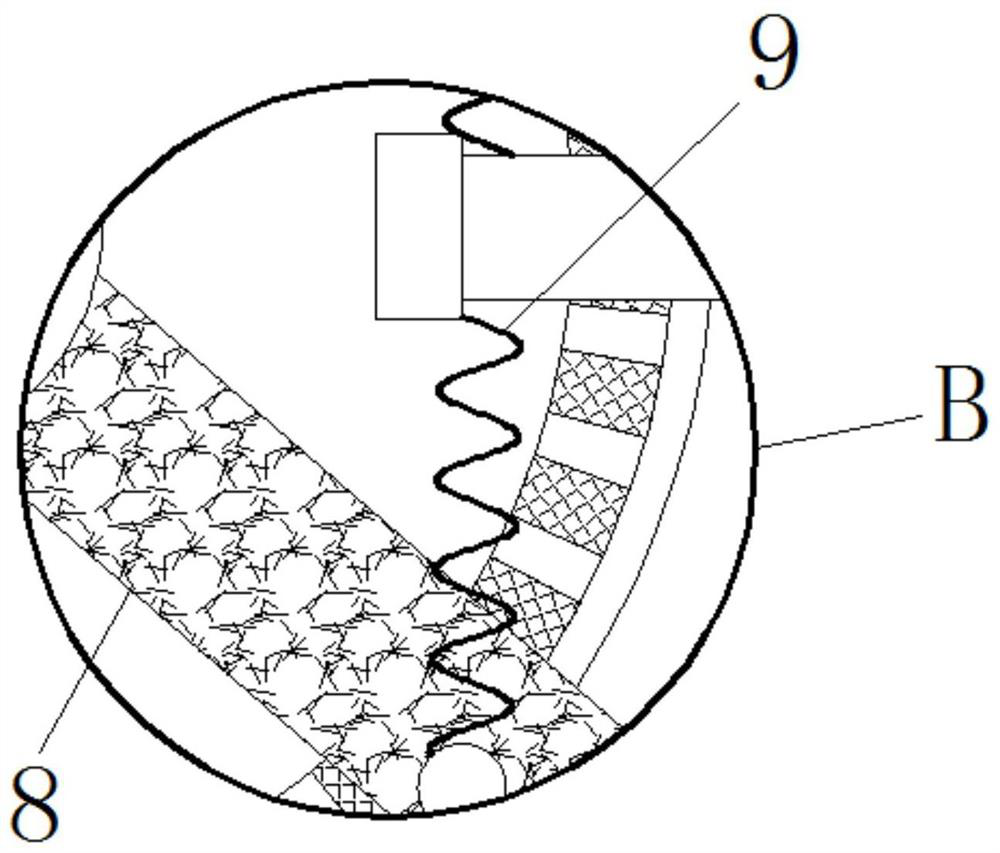

Incomplete gear engagement type composite fertilizer granule anti-caking efficient coating device

InactiveCN108383589AReasonable structureInnovative designLayered/coated fertilisersFertilizer mixturesFertilizerAgricultural engineering

The invention discloses an incomplete gear engagement type composite fertilizer granule anti-caking efficient coating device. The incomplete gear engagement type composite fertilizer granule anti-caking efficient coating device comprises a supporting base; supporting frames are arranged on the two sides of the upper end of the supporting base; the middle part of top end of each supporting frame isconnected with a hybrid motor; a heat oil cylinder is arranged on the middle part of the left-side supporting frame; a hot air cylinder is arranged on the middle part of the right-side supporting frame; piston plates are arranged in the hot air cylinder and the hot oil cylinder; the middle part of the outer side of each piston plate is connected with a piston rod; a guide plate is arranged between the piston rods; a coating barrel is arranged on the middle part of the upper end of the guide plate; an avoiding groove is formed in the middle part of the supporting base; a rotating shaft is arranged in the avoiding groove; an incomplete gear is arranged on the middle part of the rotating shaft; the outer side of the incomplete gear is engaged with a gear frame; and the middle parts of the two ends of the gear frame are connected with guide columns. The incomplete gear engagement type composite fertilizer granule anti-caking efficient coating device realizes oil-spraying and drying effects on composite fertilizer granules in the coating barrel, avoids the phenomenon that the fertilizer granules are caked or spray too much oil, and improves the coating quality and the coating efficiency of the composite fertilizer granules in the coating barrel.

Owner:侯添有

New-energy clothes hanger

InactiveCN107287865AAvoid localized heatAvoid prolonged dryingTextiles and paperDomestic cooking appliancesAir cleanersClothes hanger

The invention discloses a new-energy clothes hanger. The new-energy clothes hanger comprises a device body. The device body is composed of a top board, a solar panel arranged at the top of the top board and a support board arranged at the bottom of the top board. One side of the support board is provided with a telescopic switch, a purifier button and a humidity detector switch. The telescopic switch, the purifier button and the humidity detector switch are embedded into the support board. The new-energy clothes hanger has the following beneficial effects: solar energy is utilized for realizing the clothes-drying effect better; a heat pump dryer and a low-noise axial-flow fan cooperate with each other such that clothes are uniformly heated and precluded from partial heating; meanwhile, a negative ion air cleaner and a timer in a clothes propping rod can effectively dedust and sterilize clothes according to drying time.

Owner:怀燕

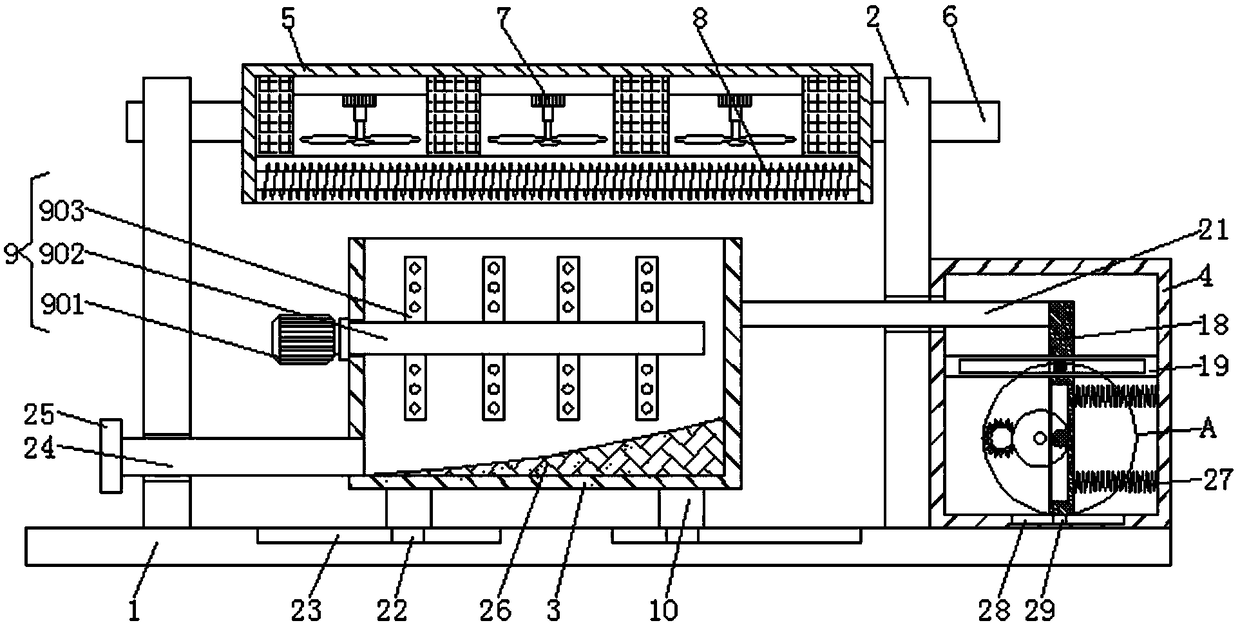

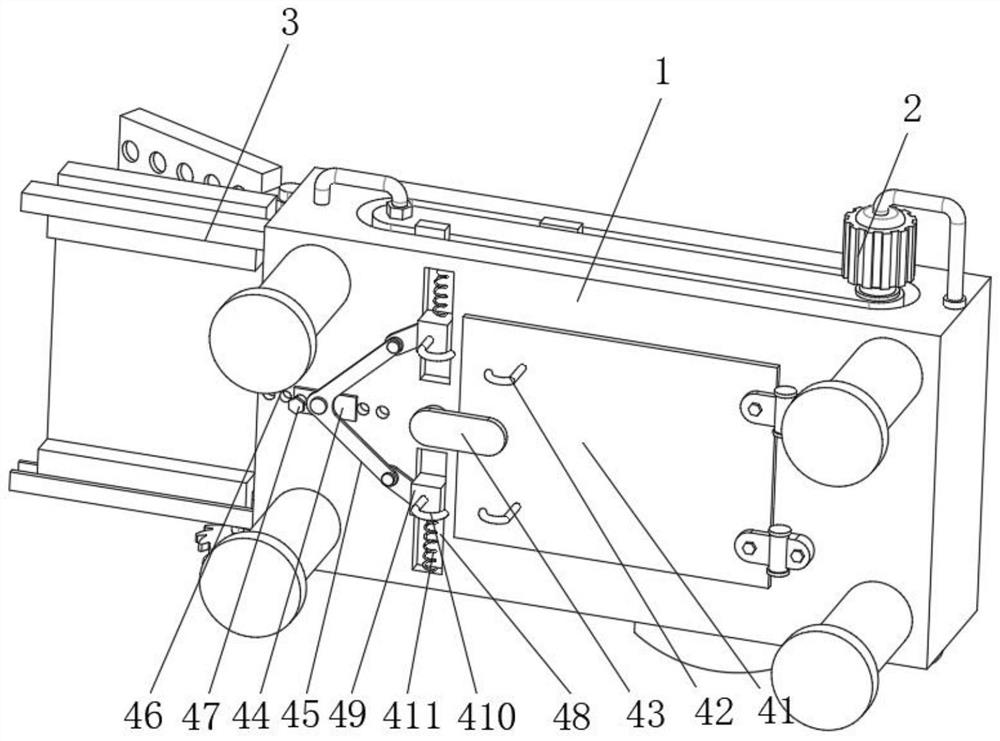

Quick-washing and quick-drying textile non-woven fabric processing equipment

InactiveCN113106670AAchieve drying effectImprove surface qualityMechanical cleaningPressure cleaningNonwoven fabricMechanical engineering

The invention discloses quick-washing and quick-drying textile non-woven fabric processing equipment. The equipment comprises a drying box and a cleaning box fixedly connected with the bottom of the drying box; an upper drying device and a lower drying device are sequentially arranged in the drying box from top to bottom; the upper drying device comprises a front set of first side plates and a rear set of first side plates which are symmetrically arranged. The invention relates to the technical field of fabric processing equipment. According to the quick-washing and quick-drying textile non-woven fabric processing equipment, the upper drying device and the lower drying device are longitudinally distributed; when a fabric passes through the drying devices, most of water in the fabric can be squeezed out through a water squeezing wheel, then the water in the fabric can be blown out through hot air blown downwards by a hot air circulating device, and meanwhile the drying effect is achieved; when the fabric passes through an ironing water tank, the fabric can be ironed by utilizing the temperature of the ironing water tank; the fabric can be ironed to be flat while being further heated, and the surface quality of the fabric can be improved while the fabric is rapidly dried; and the structure is compact, and the operation is coherent.

Owner:马家旺

Feed dryer

The invention relates to the technical field of dryers and discloses a feed dryer which comprises a dryer body. An inner cavity is formed in the top of the dryer body, a drying device is arranged in the inner cavity, a screening device is arranged on the side wall of one side of the outer surface of the dryer body, and a packaging device is arranged at the bottom of the dryer body. A mounting plate is fixedly mounted on the outer surface of the dryer body, the drying device comprises a servo motor, the servo motor is fixedly mounted on the outer surface of the dryer body through a welding column, and the output end of the servo motor is movably connected with a rotating rod which penetrates through the dryer body and is rotatably connected with the inner wall of the inner cavity. By arranging the drying device, a plow harrow roller and spray heads are matched so that screened feed can be tiled, rolled and dried at the same time, a traditional manual drying mode is simulated, the feed is dried more uniformly, and the drying efficiency and quality of the feed are improved.

Owner:罗源县洪洋乡人民政府

Automatic-cleaning floor sweeping robot

InactiveCN108742325AEasy to useAchieve drying effectMachine detailsCleaning equipmentEngineeringAir blower

The invention discloses an automatic-cleaning floor sweeping robot. The automatic-cleaning floor sweeping robot comprises hairbrushes, an air blower and a floor sweeping robot body, wherein fixed blocks are installed on the lower surface of the floor sweeping robot body, connecting rods are connected to the lower surfaces of the fixed blocks through rotating bearings, the hairbrushes are installedon the lower surfaces of the connecting rods, a water tank is installed inside the floor sweeping robot body, a water pump is installed inside the water tank, a three-way pipe is installed on the upper surface of the water tank, water pipes are installed on the outer end face of one side of the three-way pipe, penetrate through the connecting rods, and are connected with the hairbrushes, an air blower case is installed at the portion, located at the lower portion of the water tank, inside the floor sweeping robot body, the air blower is installed inside the air blower case, connecting pipes are installed on the outer end face of one side of the air blower case, and air blowing pipes penetrating through the floor sweeping robot body are installed on the outer end face, different from one side of the air blower case, of the connecting pipes. The automatic-cleaning floor sweeping robot is more conveniently and rapidly used.

Owner:昆山天卓贸易有限公司

Household rice storage box

InactiveCN107264993AEasy to storeEfficient storageClosure with auxillary devicesSeed preservation by dryingElectricityEngineering

The invention discloses a household rice storage box, which comprises an outer box body and a box cover hinged thereto. The box cover is provided with a sterilizing ultraviolet lamp, and the outer box body is provided with a power adapter and a fan. The ultraviolet lamps are all electrically connected to the power adapter, a timer is also electrically connected between the fan and the power adapter, the power adapter is electrically connected to a power line, and the bottom of the outer box is provided with legs, and the legs An inner box body is arranged on the inner box body, and a ventilation pipe is arranged in the inner box body, and one end of the ventilation pipe is connected with a fan, and an electric heating wire is arranged inside the ventilation pipe, and a bracket is arranged above the electric heating wire, and a bracket is arranged on the bracket A metal mesh pipe is provided, the ventilation pipe is provided with a plurality of drying pipes, the drying pipe is provided with a plurality of through holes, the side of the inner box body is provided with a rice outlet pipe, and one end of the rice outlet pipe is hinged There is a baffle, and a return spring is provided at the joint between the rice outlet pipe and the baffle. The device can effectively store rice, prevent insects and moisture, and has good practical effect.

Owner:HUAIAN YUETA RICE IND CO LTD

Drying device for edible mushrooms

InactiveCN108926018ASolve ineffective problemsAchieve drying effectFood treatmentGear wheelFixed frame

The invention discloses a drying device for edible mushrooms. The drying device comprises a base, wherein a drying box is fixedly connected to the top of the base; box doors are respectively and movably connected to two sides of the front surface of the drying box; a housing is fixedly connected to the top of the drying box; a motor is fixedly connected to the left side of the top of an inner cavity of the housing; a first gear is fixedly connected to the output end of the motor; a second gear is meshed to the right side of the first gear; a rotating pipe is fixedly connected to the inner wallof the second gear; and a fixing frame is fixedly connected to the top of the inner cavity of the housing. According to the drying device disclosed by the invention, the base, the drying box, the boxdoors, the housing, a wind sucking pipe, rollers, second heaters, a rotating box, the rotating pipe, heat dissipation holes, the first gear, the motor, the fixing frame, a limiting plate, the secondgear, a first heater, a wind transporting pipe, a fan, feeding openings, fixing blocks, groove bodies, circular grooves, sliding wheels and connecting frames cooperate for usage, so that the problem that a conventional drying device for the edible mushrooms is not high-efficiency is solved.

Owner:甘肃尚珍农产品科技发展有限公司

Textile fabric dyeing device based on intermittent dye feeding

InactiveCN112267230AFully combinedRealize the purpose of intermittent dyeingTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentStructural engineeringTextile dyeing

The invention relates to the technical field of textile dyeing, and discloses a textile fabric dyeing device based on intermittent dye feeding. The textile fabric dyeing device comprises a main frame,and a fixed wheel is rotatably connected to the interior of the main frame. At the beginning of the device, each limiting block at the upper end is in a state of blocking a corresponding feeding pipeand is matched with a rotating shaft to drive a rotating rod to move, and when the rotating rod passes through the corresponding limiting block, the limiting block can be poked upwards to leave a corresponding limiting groove, and then the rotating rod is matched with a corresponding buffer spring to drive a distribution wheel to rotate by 90 degrees until the limiting groove rotates to the upperend, the feeding pipe can be opened, fuel can enter the fixed pipe at the upper end, and then the dye completes the printing and dyeing work of the textile fabric in the time interval from the current moment to the moment when the limiting groove rotates to the upper end position for the next time, so that the purpose of intermittent dyeing is achieved, and the dye is more fully combined with thetextile fabric; and the effect of uniform and sufficient dyeing is achieved.

Owner:肖军香

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com