Chicken roasting furnace with automatic cleaning function

A technology for automatic cleaning and roasting chicken ovens, applied in the field of roasting chicken ovens, can solve problems such as blocked vents, failure to clean up in time, inconvenience for staff, etc., and achieve the effect of improving life expectancy, ensuring beautiful appearance, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

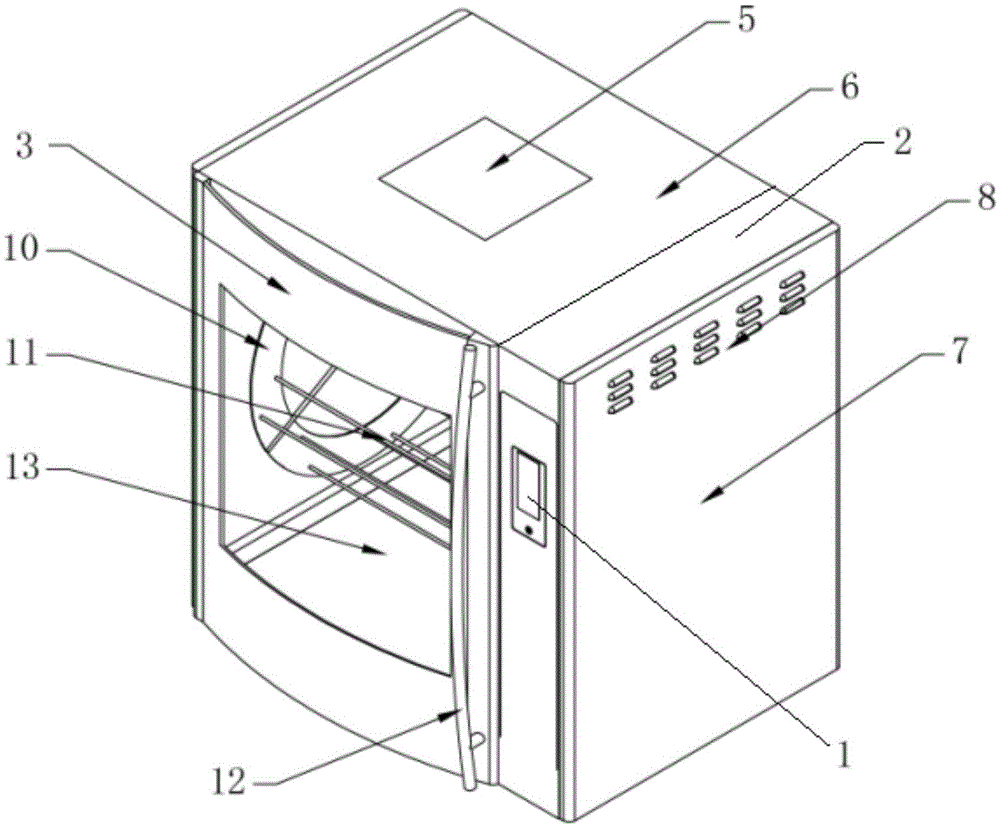

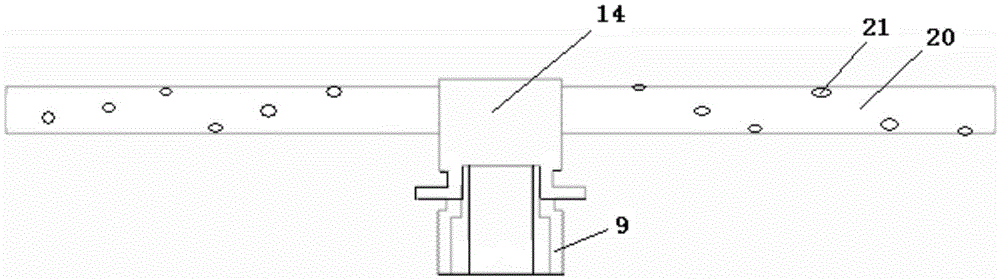

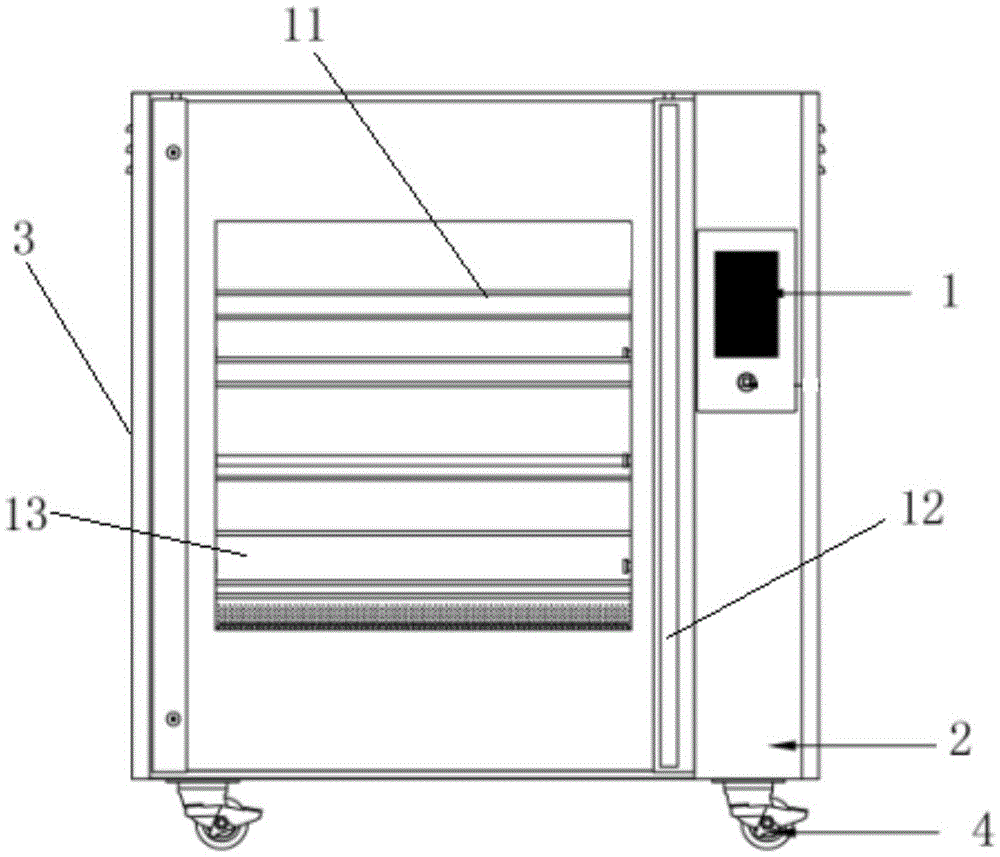

[0026] Such as Figure 1-4 As shown, a self-cleaning chicken oven includes a furnace body 3, a rotating sprinkler is provided at the bottom of the furnace body 3, a fan 19 is provided at the top, and a control room 2 is provided on the side of the furnace body 3. In the room 2, a computer board, a medicine solenoid valve 15, a medicine pipeline 22, a clean water solenoid valve 17 and a clean water pipeline 18 are arranged, and the medicine solenoid valve 15 and the clean water solenoid valve 17 are respectively arranged on the medicine pipeline 22 and the clean water pipeline 18; the control room 2. The outer surface is provided with a control panel 1 connected to the computer board. The rotating water sprayer includes a rotating shaft 14, a water inlet inner wire 9, a water spray pipe 20 and a water spray hole 21; the rotating shaft 14 is fixedly connected to the water inlet The top of the inner wire 9 and the bottom of the body of heater 3 are provided with a water inlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com