Tail anchor steel cable flushing device

A technology of flushing device and steel cable, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc. The cleaning effect is good, the service life is improved, and the labor intensity is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

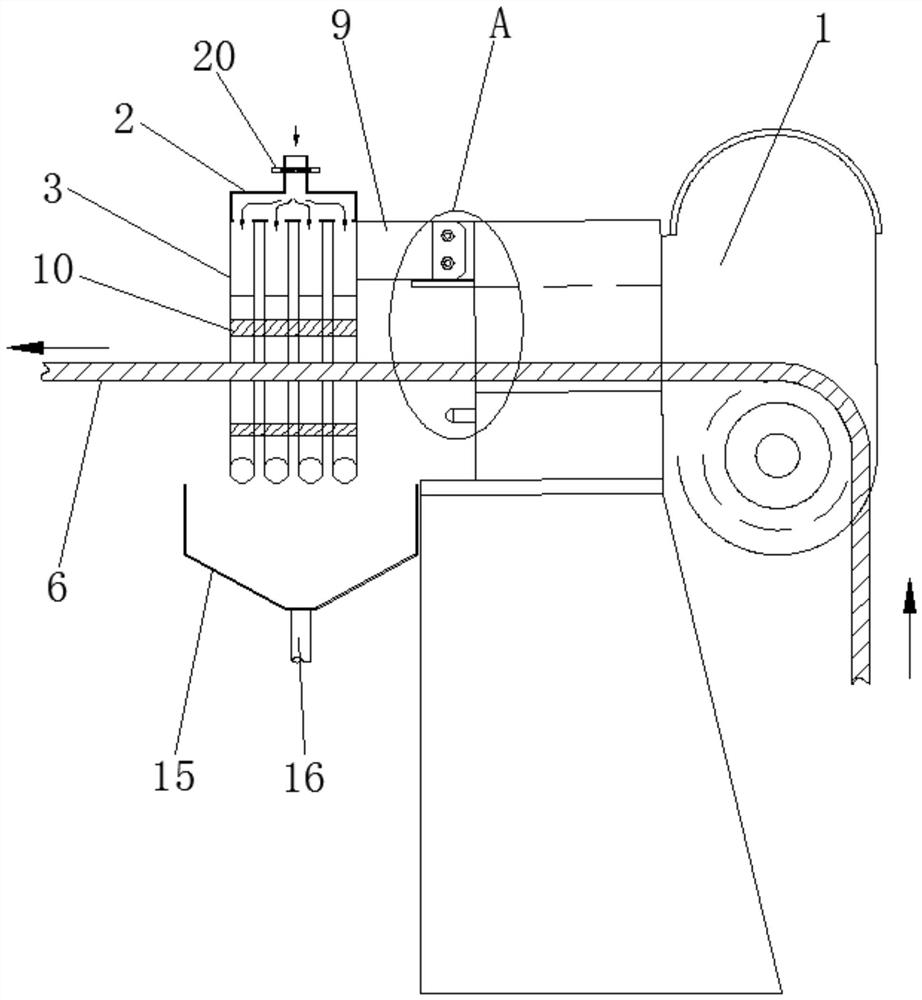

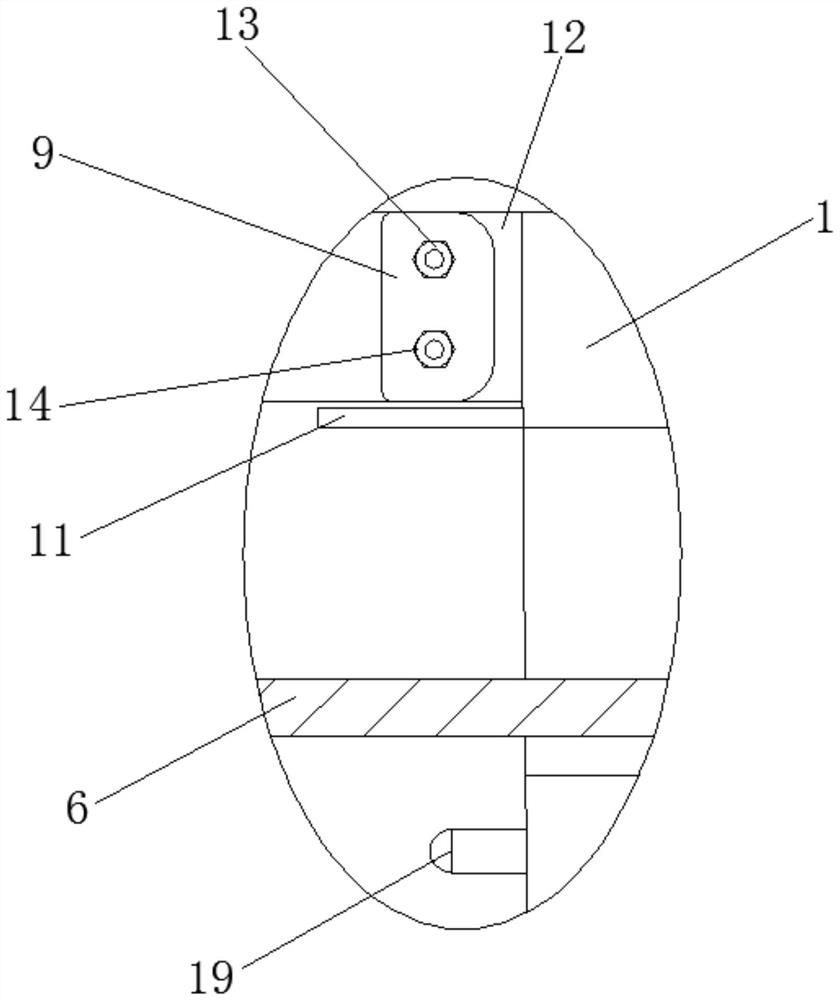

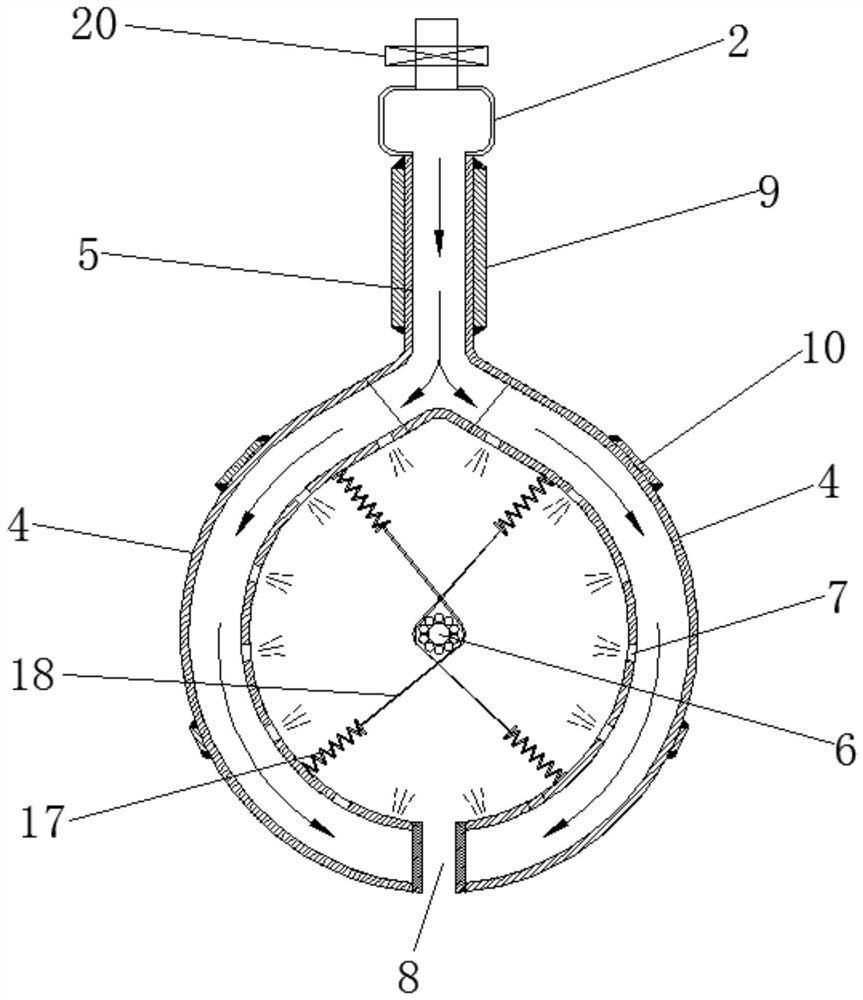

[0025] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

[0026] refer to Figure 1-4 , a stern anchor cable flushing device of the present invention includes a flusher installed on one side of the cable puller 1, the flusher includes a water inlet pipe 2 and a water spray pipe 3, wherein the water inlet of the water inlet pipe 2 is connected to the fresh water pump connected, the water spray pipe 3 is made up of two arc-shaped pipes 4, the bottom of the water inlet pipe 2 is connected with a three-way pipe 5, and one end of the two arc-shaped pipes 4 is respectively connected to the water outlets on both sides of the three-way pipe 5, and the two The arc-shaped tube 4 covers the steel cable 6 in the area surrounded by the two, and there is a gap between the arc-shaped tube 4 and the steel cable 6 to prevent the steel cable 6 from swinging and touching the arc-shaped tube 4 to achieve 360° coverage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com