Sectional type tea drying equipment

A drying equipment and segmented technology, which is applied in the field of green tea making equipment, can solve the problems of low utilization rate of heat energy and poor taste of tea leaves, and achieve the effects of improving utilization rate, saving resources, and strong color and luster.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

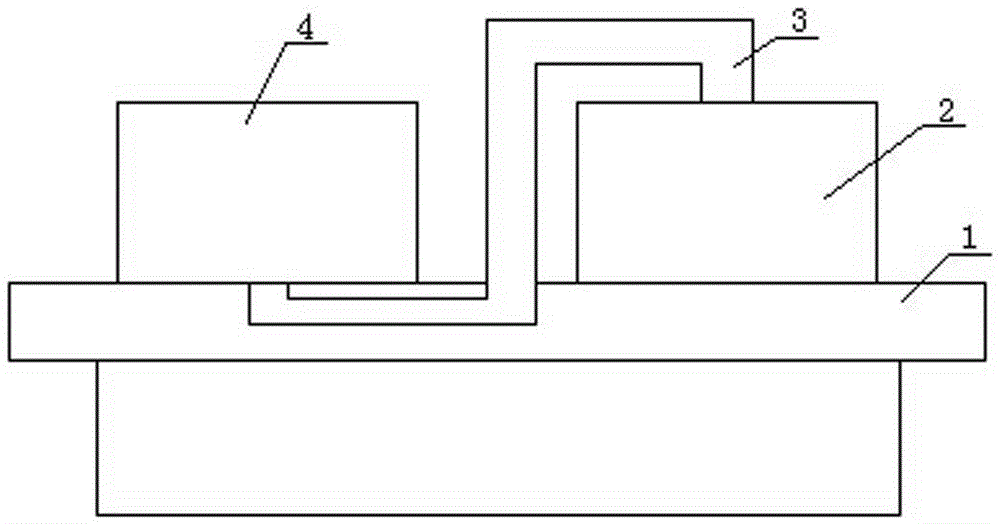

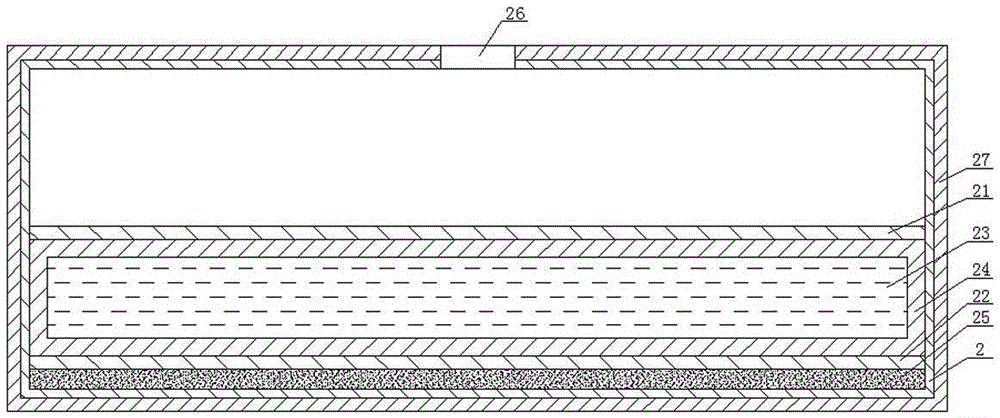

[0037] The sectioned tea drying equipment of this embodiment includes a frame, an oven is arranged above the frame, and a heating device is arranged on the lower bottom surface of the oven, and the heating device includes an upper shell and a lower shell, so The upper shell and the lower shell are connected together to form a vacuum steam chamber, the inner wall of the steam chamber is provided with a liquid-absorbing core, the steam chamber is filled with working liquid, and the lower surface of the lower shell is coated with The electric heating wire layer, the upper surface of the upper shell is used as a drying platform for tea, the frame is also provided with a preheating box, the upper end of the oven is provided with a through hole, and the through hole is equipped with a pipeline. The bottom of the preheating box communicates with the through hole through a pipe.

Embodiment 2

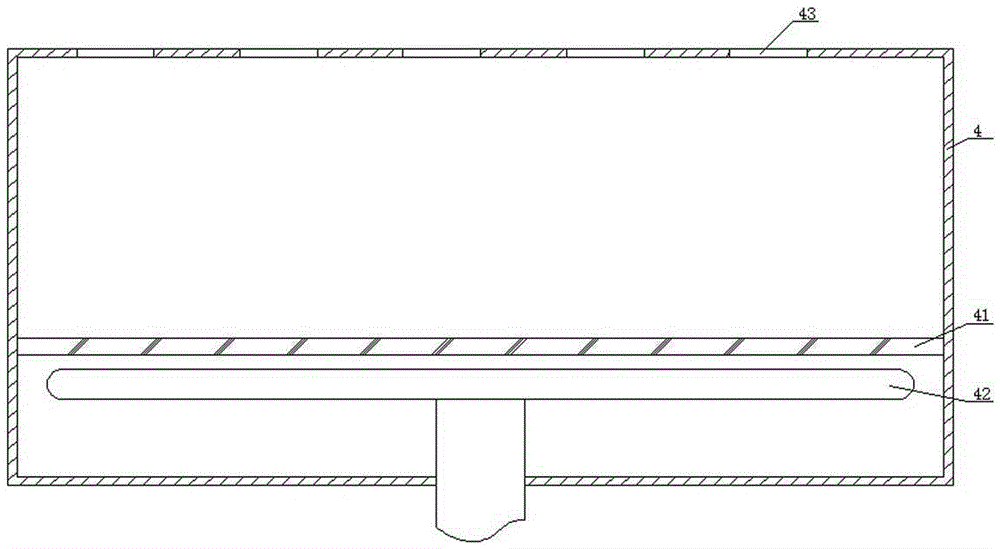

[0039] The sectioned tea drying equipment of this embodiment includes a frame, an oven is arranged above the frame, and a heating device is arranged on the lower bottom surface of the oven, and the heating device includes an upper shell and a lower shell, so The upper shell and the lower shell are connected together to form a vacuum steam chamber, the inner wall of the steam chamber is provided with a liquid-absorbing core, the steam chamber is filled with working liquid, and the lower surface of the lower shell is coated with The electric heating wire layer, the upper surface of the upper shell is used as a drying platform for tea, the frame is also provided with a preheating box, the upper end of the oven is provided with a through hole, and the through hole is equipped with a pipeline. The bottom of the preheating box communicates with the through hole through a pipe; the bottom of the preheating box is provided with a ceramic screen for placing tea leaves.

Embodiment 3

[0041] The sectioned tea drying equipment of this embodiment includes a frame, an oven is arranged above the frame, and a heating device is arranged on the lower bottom surface of the oven, and the heating device includes an upper shell and a lower shell, so The upper shell and the lower shell are connected together to form a vacuum steam chamber, the inner wall of the steam chamber is provided with a liquid-absorbing core, the steam chamber is filled with working liquid, and the lower surface of the lower shell is coated with The electric heating wire layer, the upper surface of the upper shell is used as a drying platform for tea, the frame is also provided with a preheating box, the upper end of the oven is provided with a through hole, and the through hole is equipped with a pipeline. The bottom of the preheating box communicates with the through hole through the pipeline; the bottom of the preheating box is provided with a ceramic screen for placing tea; the lower end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com