Commercial dishwasher

A dishwasher and commercial technology, applied in the washing machine/washing machine, application, washing machine/rinsing machine parts of cutlery, etc., can solve the problem of maintaining circulating air, weakening, and unable to achieve drying well requirements and other issues to achieve the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

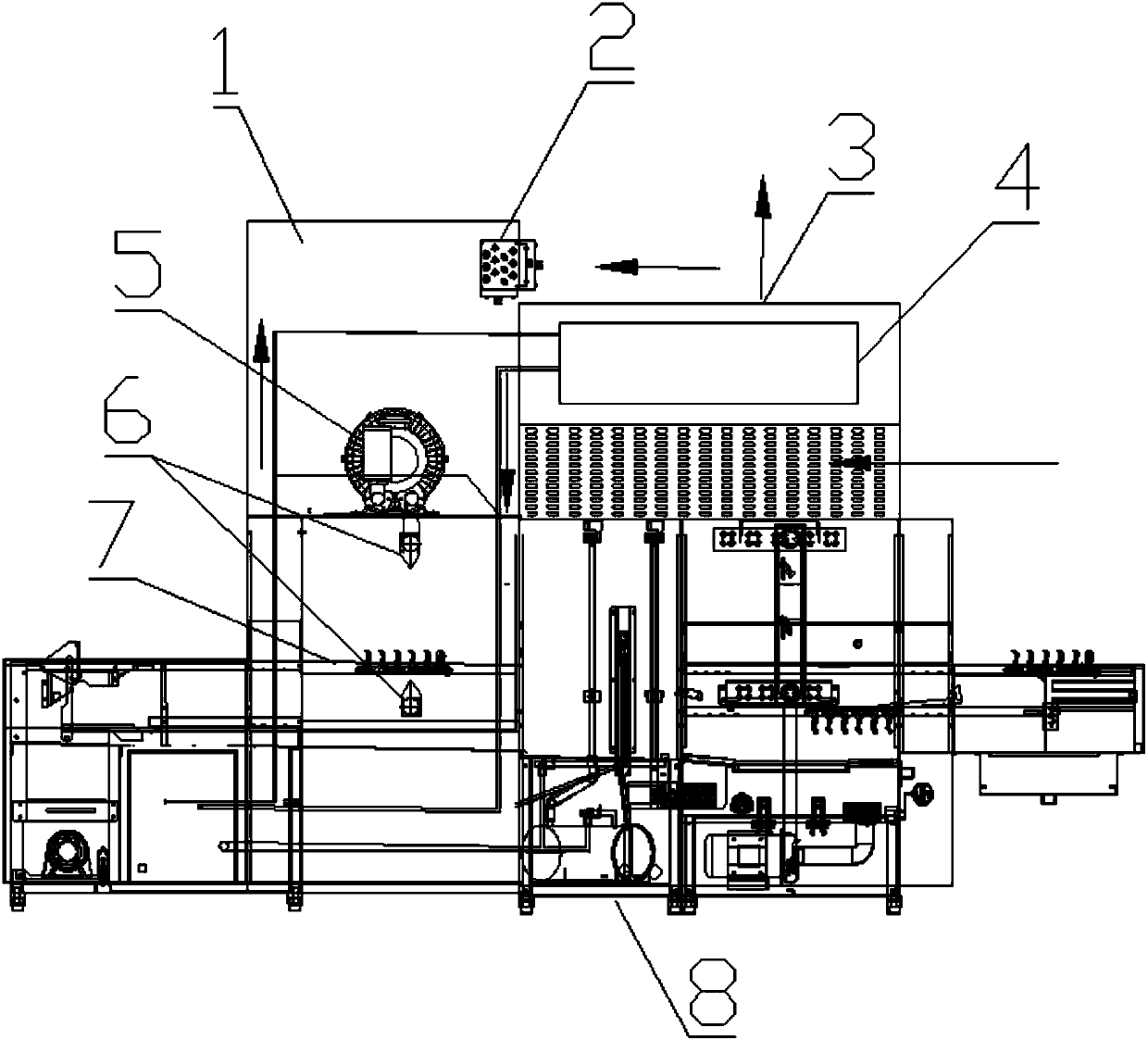

[0020] like figure 1 As shown, a commercial dishwasher includes a dishwasher main body 8, an evaporator 4 is set in the main body 8, and an air outlet 3 after dehumidification is included, wherein the detailed structure of the dishwasher main body 8 can be obtained from the company's declared patent, "A commercial dishwasher", application number: 201611128185.X, it is known that, in addition, the present invention also includes:

[0021] A drying unit for drying tableware;

[0022] Among them, the drying unit includes:

[0023] A heating unit for heating the dehumidified air coming out of the air outlet 3 of the evaporator 4;

[0024] The fan unit is used to deliver the air heated by the heating unit to the dishes.

[0025] In the traditional heating method, the drying system uses a fan to circulate the air in the drying box to take away the moisture on the surface of the dishes. There is a heating device in the air duct to maintain the temperature of the circulating air an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com