Patents

Literature

88 results about "Wind-sucking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

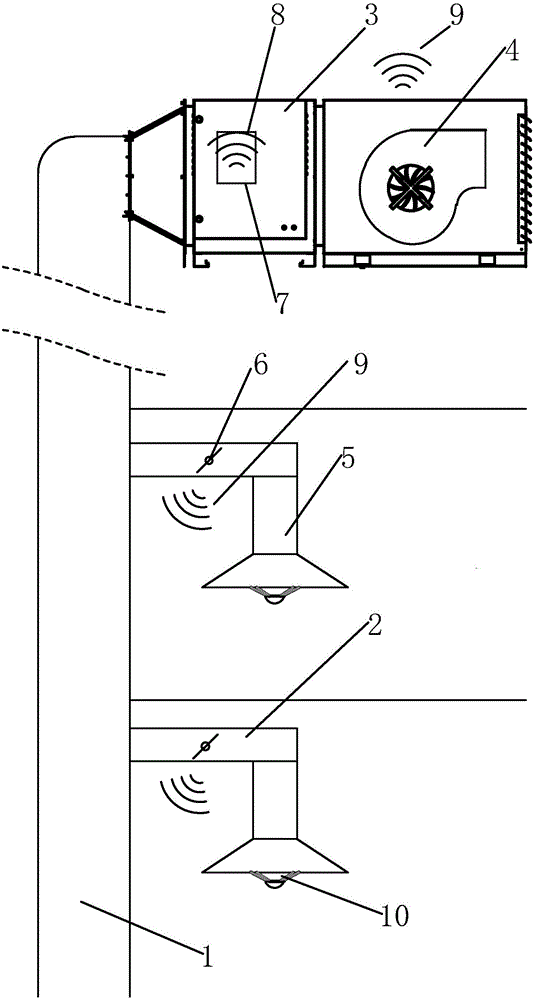

Central oil fume purification system and real-time automatic control mode thereof

InactiveCN106560657ARelieve stressEvenly distributed smoke exhaust effectDomestic stoves or rangesLighting and heating apparatusAir volumeAutomatic control

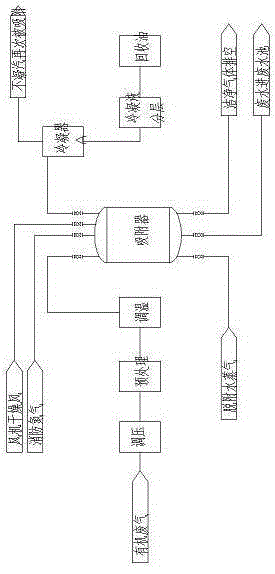

The present invention discloses a central oil fume purification system, which comprises a public flue channel, wherein kitchens in each layer are respectively provided with a connection pipe connected to the public flue channel, the upper end of the public flue channel is connected to an oil fume purifier and a fan in series, the kitchens in each layer are respectively provided with a fume collection cover, and the fume collection covers are connected to the public flue channel through the connection pipelines. The invention further discloses a real-time automatic control mode of the central oil fume purification system, wherein the wind sucking amount can be uniformly distributed by regulating the wind valve opening angles calculated through the formula in different layers. According to the present invention, the pressure in the public flue channel at the cooking peak stage can be eliminated, the fume discharging effect between the high floor and the lower floor can be uniformly distributed, and the fume returning and the odor mixing can be prevented.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

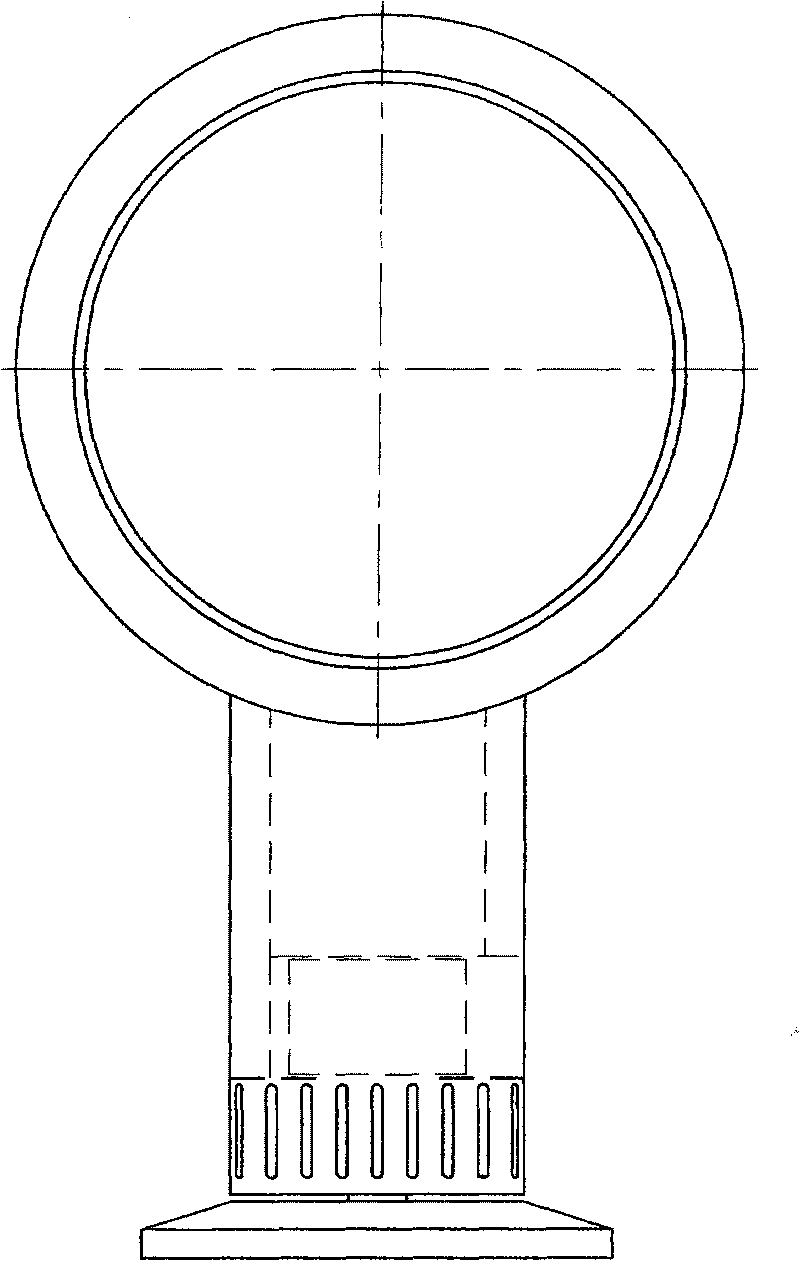

Blade-free electric fan

A blade-free electric fan comprises a base, a machine shell, a fan motor, a centrifugal blade, a blowing head and a small oscillating motor. The blowing head is connected with the machine shell, and four rings of the blowing head form a hollow air passage; the fan motor is coaxially connected with the centrifugal blade; a motor shaft and one end of a centrifugal blade connecting head are provided with safety nuts; the outside of the centrifugal blade is provided with the fan shell which is used for increasing the pressure of wind sucked by the centrifugal blade; the blowing head blows out strong wind through the air passage; the lower part of the shell is provided with an air inlet hole, a shell shaft seat is arranged in the center of the lower end of the shell, and the base is provided with a central shaft and a bearing which is connected rotationally with the shell shaft seat; and the oscillating motor is arranged at the bottom of the base, an oscillating pinion is arranged at one end of an oscillating motor shaft through a key pin, an oscillating gearwheel is engaged with the oscillating pinion and is connected with a shaft through the key pin, the other end of the shaft is provided with a bearing, the bearing is arranged above a support which is connected with the base, and the radius center of the oscillating gearwheel is provided with an oscillating arm which is movably connected with the bottom of the machine shell.

Owner:胡国贤

Vapor brush with function of drying clothes

ActiveCN101603264AReduce lossesSolve the problem that the wet can not be used immediatelyIroning apparatusTextiles and paperEngineeringVapor generator

The invention provides a vapor brush with a function of drying clothes, comprising a water tank arranged in a machine shell, a vapor generator and a wind heating device; wherein, the water tank is communicated with a water inlet of the vapor generator; a gas outlet of the vapor generator is connected with a vapor nozzle through a vapor guild tube; the wind heating device is arranged on the top of the machine shell, comprising a fan and a heating element; the upper part of the wind heating device is provided with a clothes hanger component; a heat storing cavity is formed by the periphery of the vapor generator and the machine shell inner walls through heat storing elements, which is provided with a wind inlet communicated with outside; and a wind sucking opening is arranged on the fan which is corresponding to the heat storing cavity. The invention uses the heat storing elements to store the heat (namely, high temperature air) generated by the vapor generator when heating into the heat storing elements; the heat of the heat storing elements is pumped into cover by the fan when drying function is used, and the residual heat generated by the vapor generator after work is pumped into the cover through the wind inlet around the vapor generator, thus realizing effective resources usage and reducing energy losses. The invention features simple and reasonable structure, simple operation, energy saving, beautiful looking and durability.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

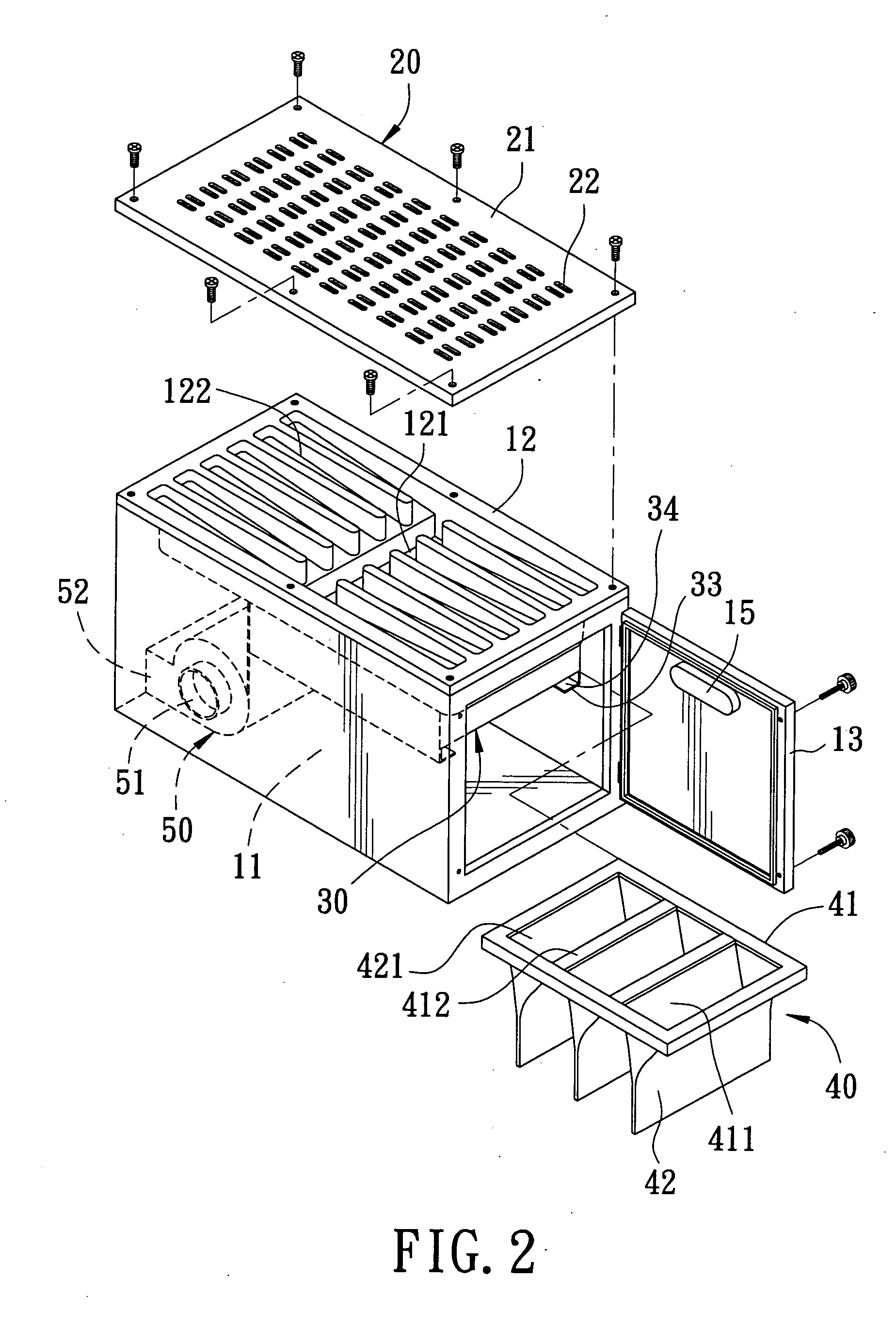

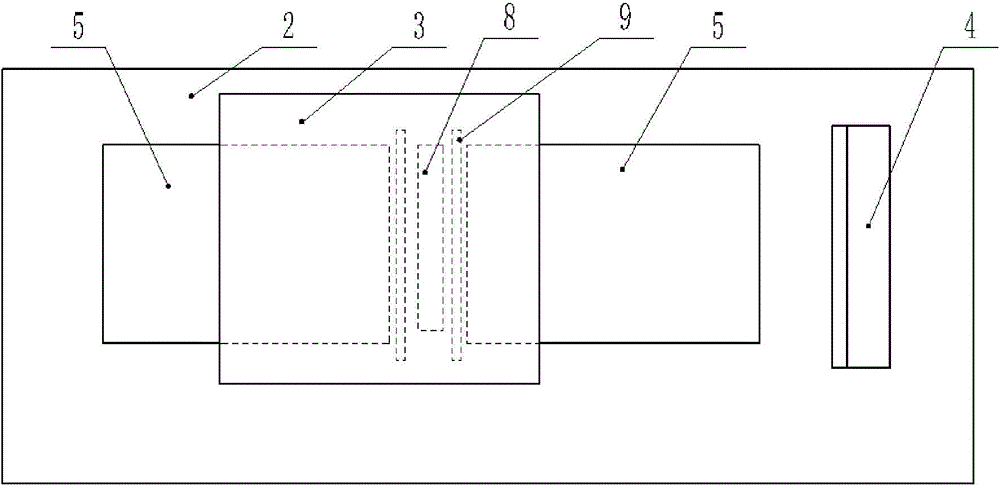

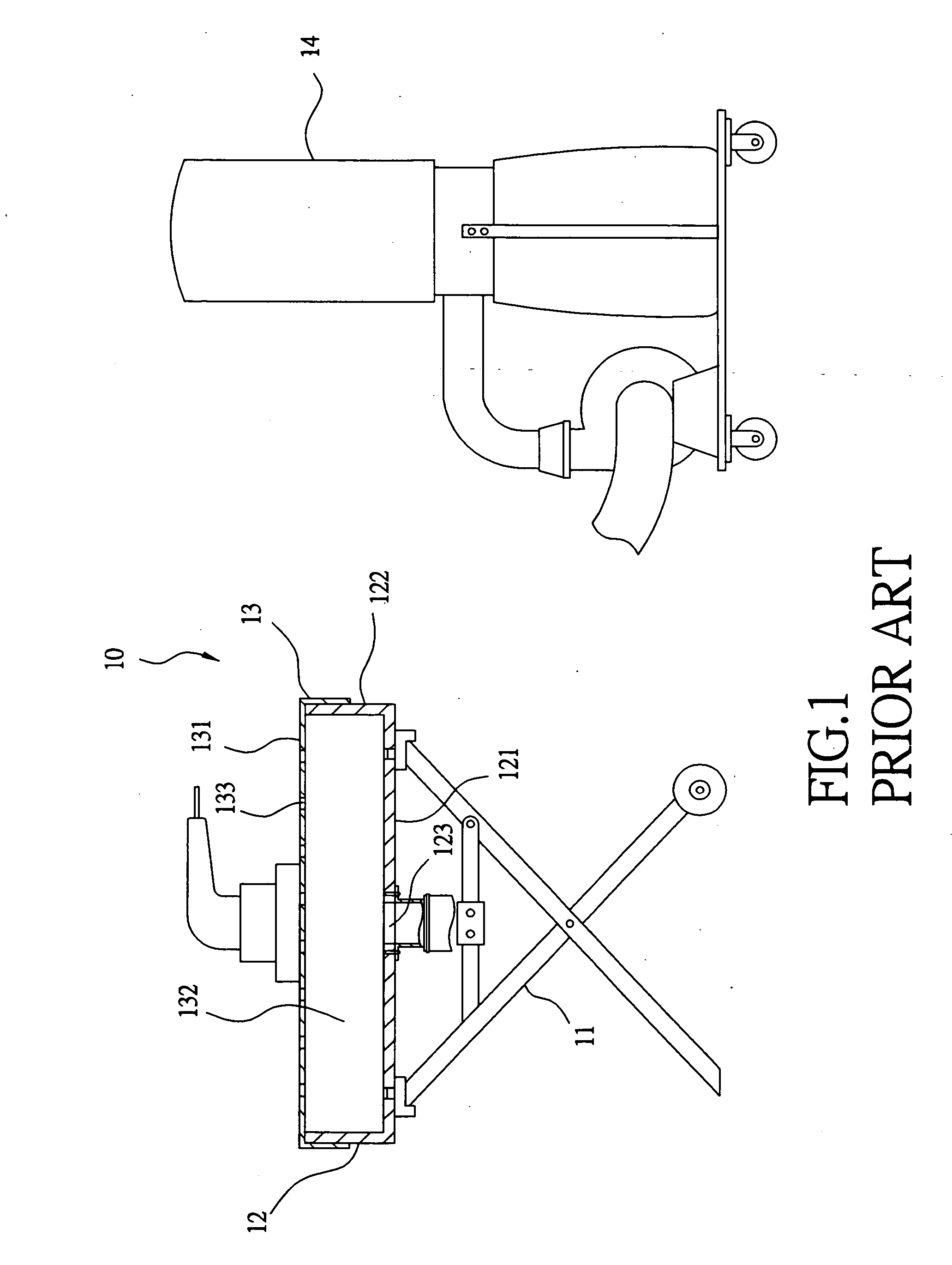

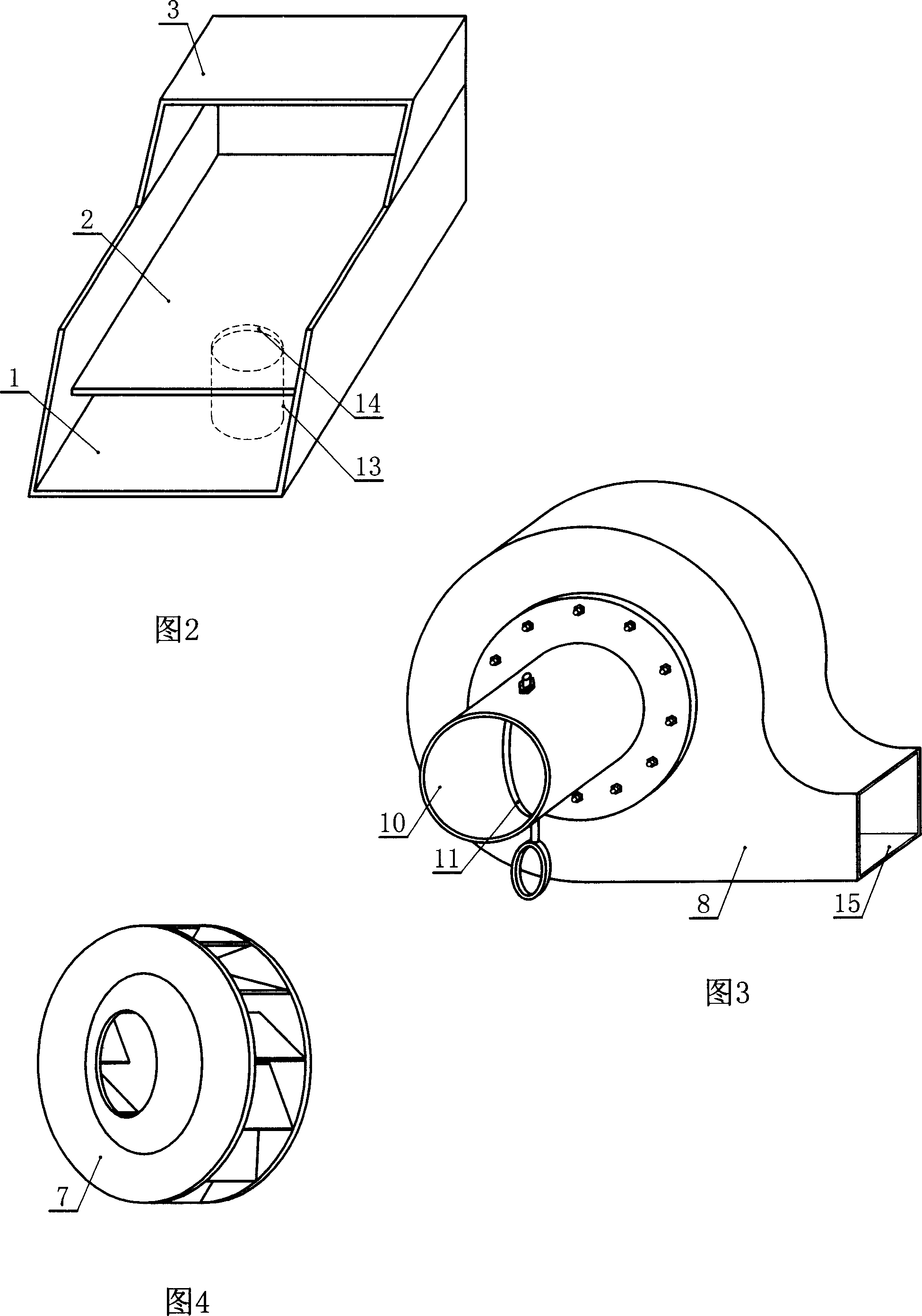

Negative pressure tabletop dust collecting machine

InactiveUS20070151067A1Lower the volumeLess spaceDispersed particle filtrationSuction cleanersInterior spaceSuction force

A negative pressure table-top dust collecting machine includes a machine box formed with an interior space, an operation faceplate assembled on the machine box and bored with numerous wind-sucking vents, a fixing base disposed in the interior space of the machine box, a dust collecting unit fitted with the fixing base and provided with dust collecting bags, and a blower positioned in the interior space of the machine box. When the blower is started to operate, the air in the interior of the machine box is pumped out of the machine box, letting the interior of the machine box produce negative pressure. Simultaneously, through the dust collecting bags and the fixing base, each wind-sucking vent of the operation faceplate will produce a vacuum suction force to suck the dust produced during processing into the dust collecting bags to be gathered.

Owner:SAN FORD MACHINERY

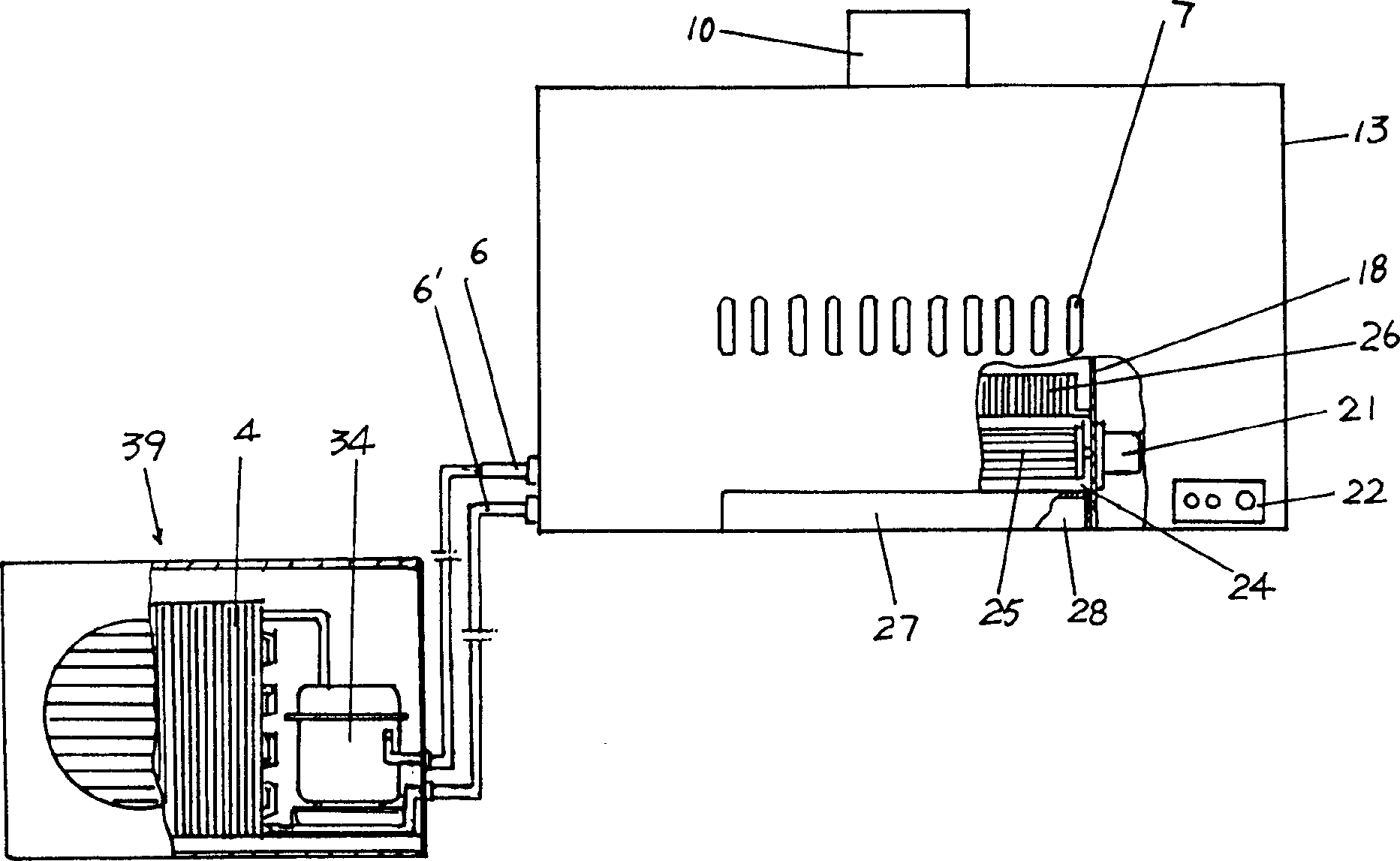

Double-purpose air conditioner and fume exhaust fan

InactiveCN1474097AAdjustable temperatureAdjustable humidityDomestic stoves or rangesLighting and heating apparatusExhaust fumesEngineering

The double-purpose air conditioning and fume exhausting fan is one special apparatus for conditioning air and exhausting fume. It includes casing, fume exhausting fan, fume exhaust channel inside the casing and air conditioner. The air conditioner includes main air conditioning unit comprising fan, evaporator and refrigerating pipeline; subsidiary air conditioning unit comprising fan and evaporator; and refrigerant pipeline connected to the main air conditioning unit. On the casing, there are air intake port and condensating wind sucking port in the lower part of the fan. The present invention has simple structure and low cost, may be installed and operated easily, and can regulate the temperature and humidity of kitchen while exhausting fume from kitchen.

Owner:JIANGSU BAIXUE ELECTRIC APPLIANCES

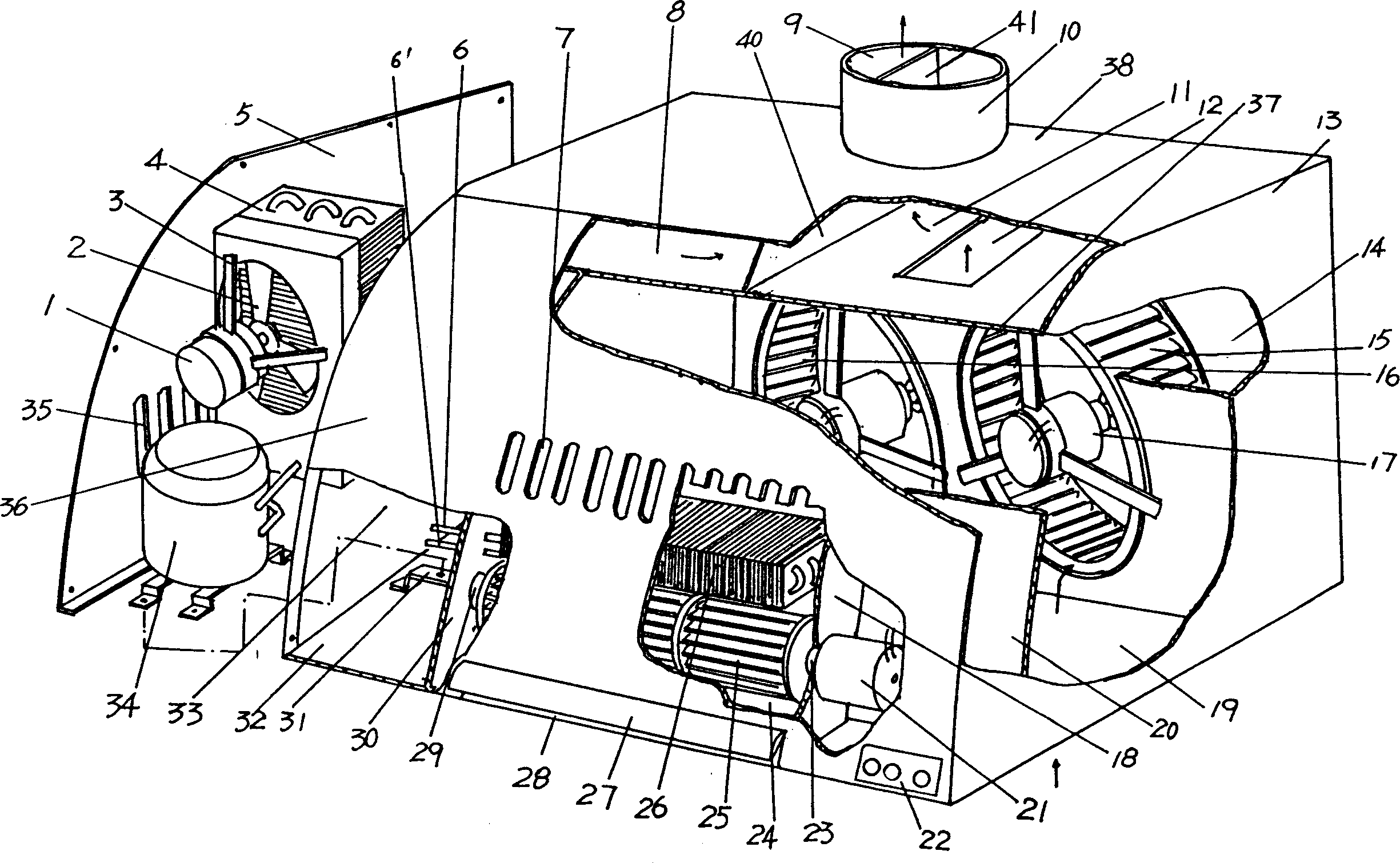

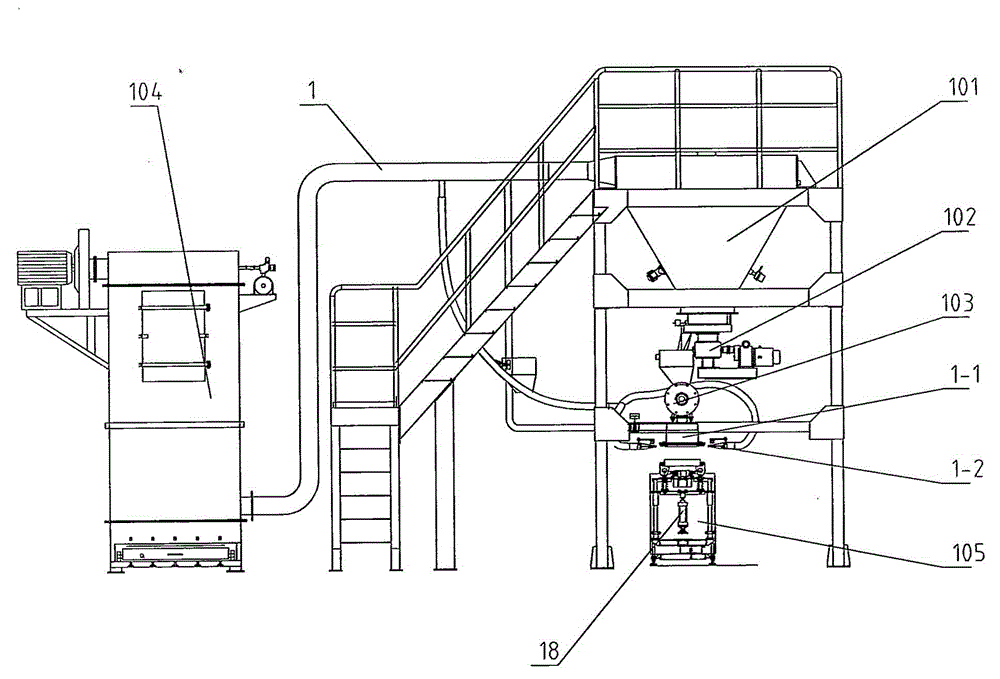

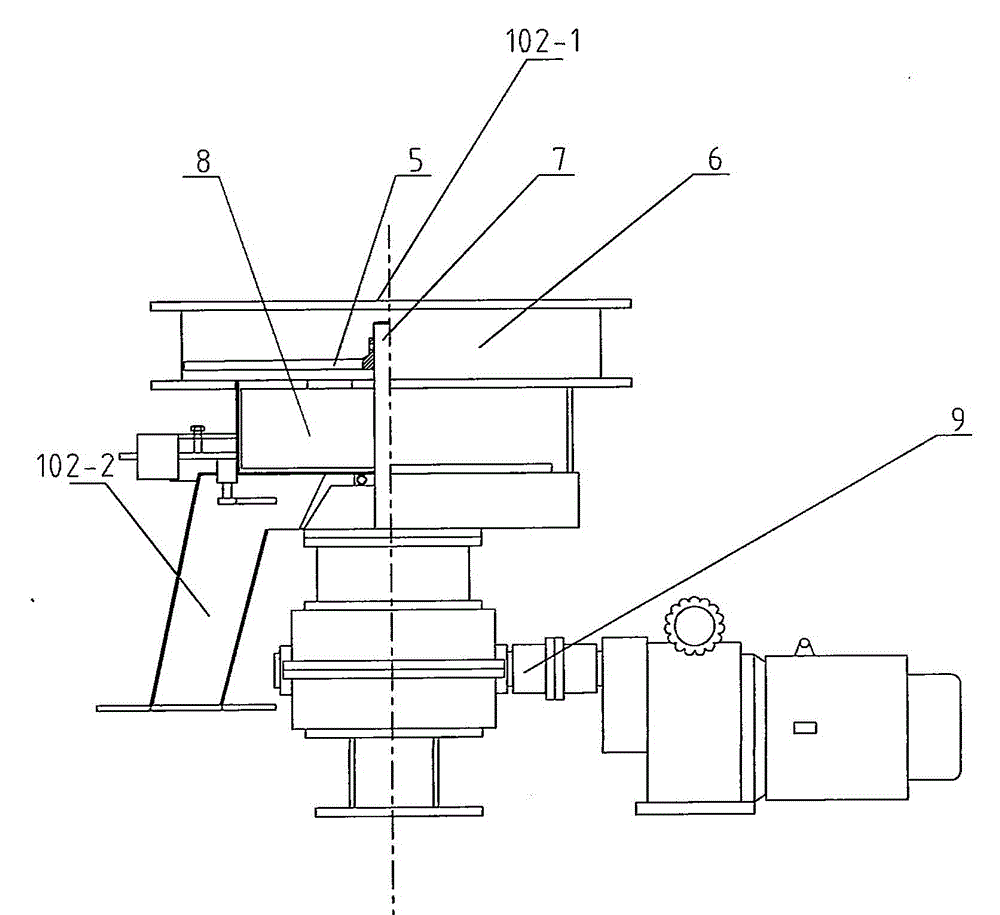

Aluminum powder production device

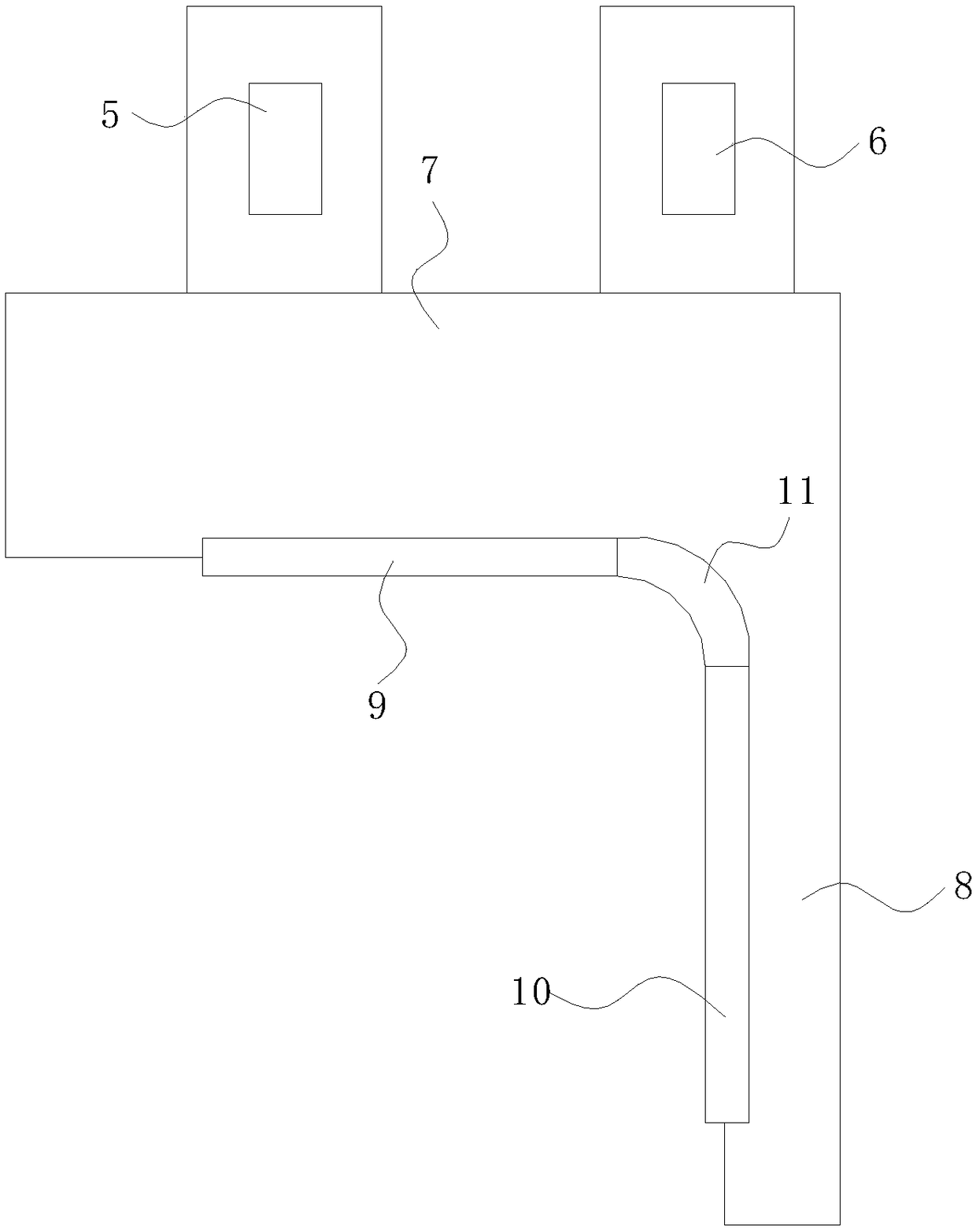

PendingCN106925409AHigh degree of automationReduced footprintGrain treatmentsEngineeringExhaust pipe

The invention relates to an aluminum powder production device. The aluminum powder production device comprises a ball mill, a wind separator, a fan, a dust remover and a polishing machine; a feed port of the ball mill is connected with a feed pipe; the feed pipe is connected with a raw material tank through a conveying device; a discharge port of the ball mill is connected with a cyclone separator through a discharge pipe; the bottom of the cyclone separator is respectively connected with an exhaust pipe of the fan and the feed pipe; the top end of the cyclone separator is connected with the dust remover through a communicating pipe; the upper part of the dust remover is connected with an intake port of the fan through a wind sucking pipe; and the bottom of the dust remover is connected with the polishing machine. The aluminum powder production device reflects the quantity of raw materials in the ball mill through a gravity sensor, charges the materials through an auger conveying device, screens the materials discharged from the ball mill through the cyclone separator, collects separated aluminum powder by the dust remover, performs polishing by the polishing machine, is intensive, is high in automation degree, and effectively reduces the floor area and labors.

Owner:山东盈科新型材料科技有限公司

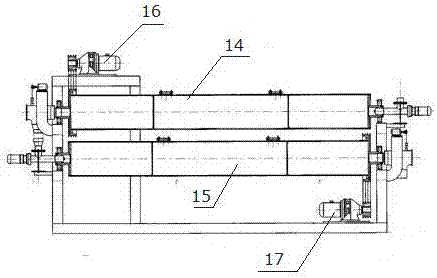

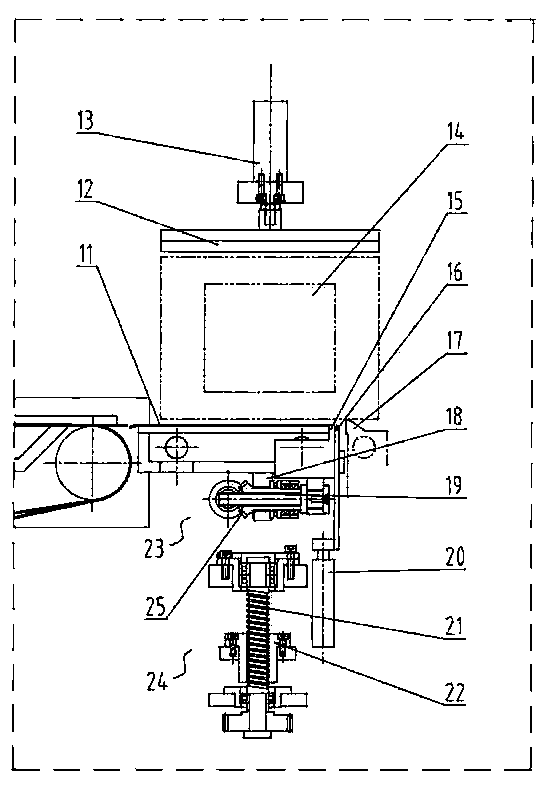

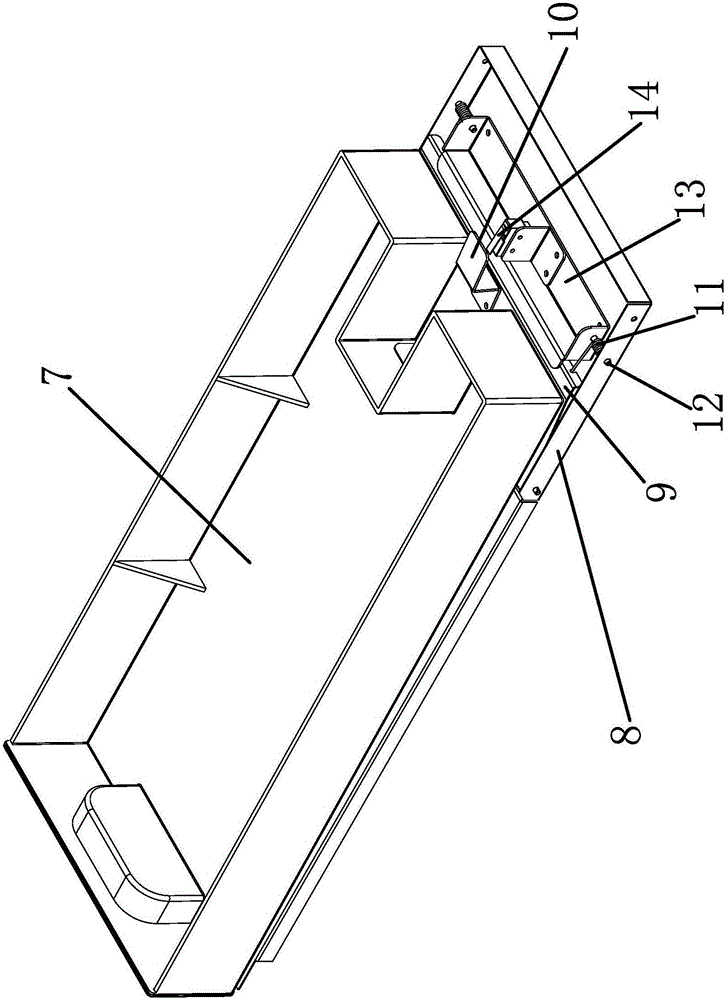

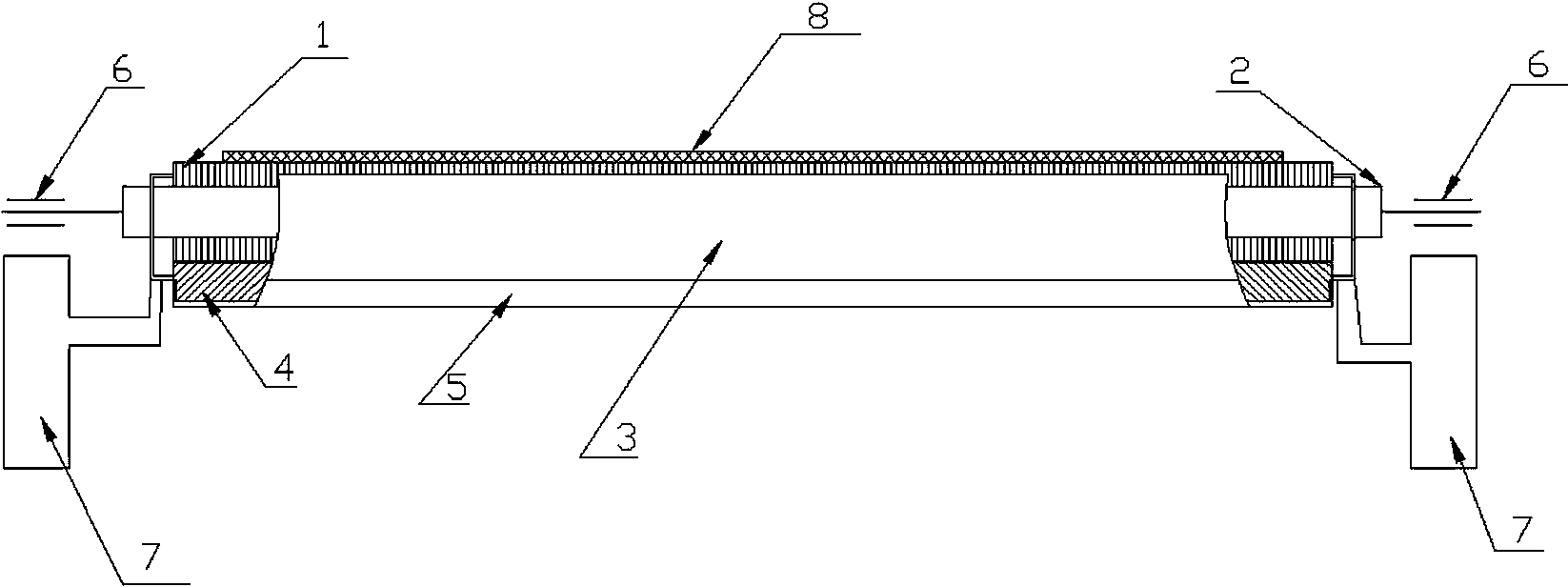

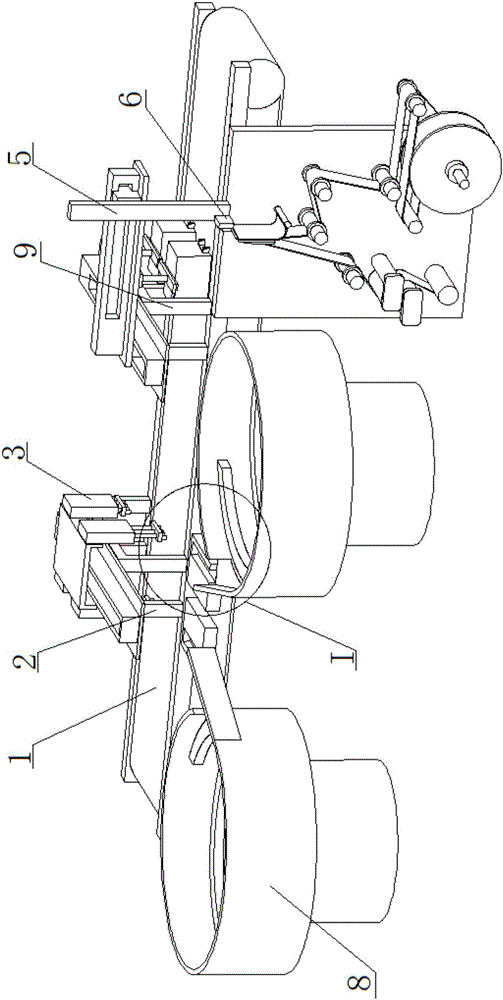

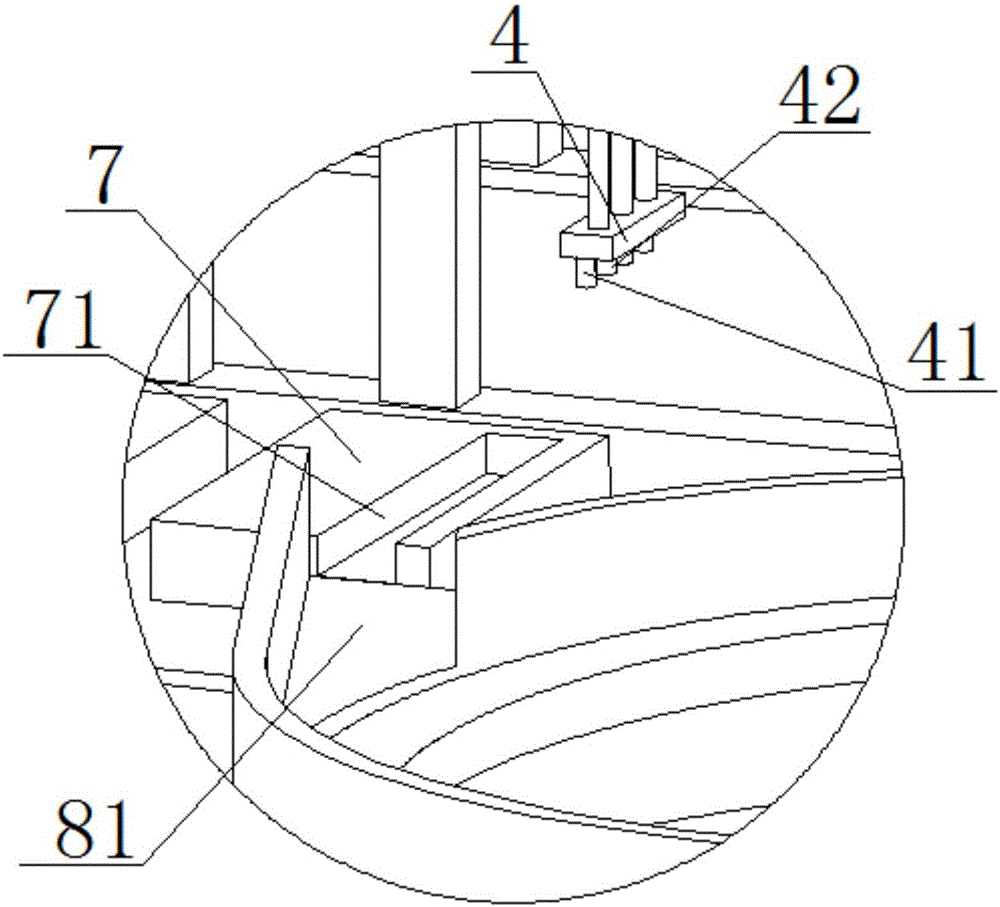

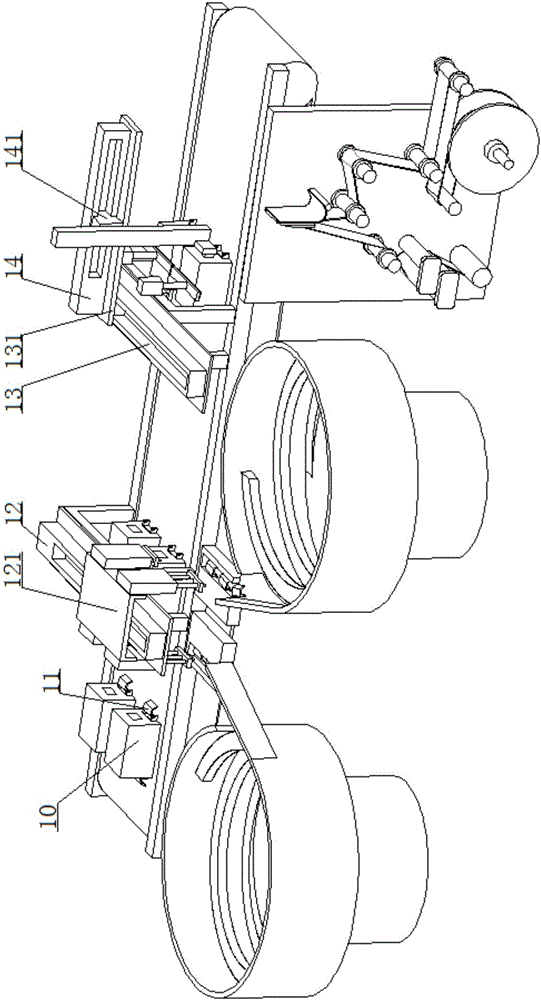

Face paper conveying mechanism for packaging box face wrapping machine

InactiveCN103707554AStable deliveryThe negative pressure belt of the conveying platform conveys the facial tissue horizontally and stablyRegistering devicesArticle feedersPulp and paper industryWind-sucking

The invention discloses a face paper conveying mechanism for a packaging box face wrapping machine. The face paper conveying mechanism is characterized by comprising a frame, a conveying platform and a front lay platform. The front lay platform is arranged in front of the conveying platform. A negative pressure belt is arranged on the conveying platform and divided into a first wind area and a second wind area. The front lay platform is provided with a wind sucking area. During working conditions, the second wind area and the wind sucking area conduct wind sucking operation alternatively. A front lay is arranged in front of the front lay platform, and the front lay platform is arranged on a lifting device. By means of the negative pressure belt of the conveying platform, face paper is conveyed to the front lay platform position horizontally, and the second wind area and the wind sucking area of the front lay platform conduct the wind sucking operation alternatively, so that the face paper is not subjected to the effects of the wind sucking area during horizontal conveying, the face paper is not subjected to effects of the second wind area of the negative pressure belt during vertical conveying, and the face paper can be stable during conveying.

Owner:温州旭弘机械有限公司

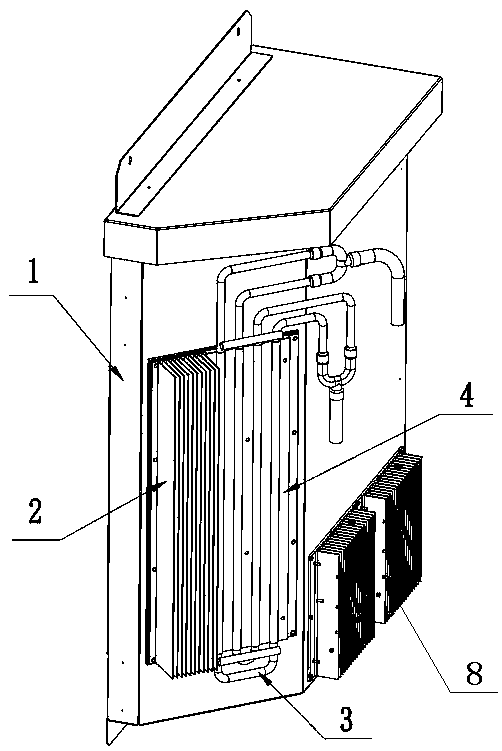

Improved electronic control box for air conditioner outdoor unit

InactiveCN108386926AGuaranteed uptimeReduce resistanceLighting and heating apparatusAir conditioning systemsCooling effectEngineering

The invention relates to an improved electronic control box for an air conditioner outdoor unit. The improved electronic control box for the air conditioner outdoor unit comprises a box body; the cross section of the box body is a corner cut rectangle; the corner cut face is provided with an open hole; a cooling substrate is embedded in the open hole; cooling fins and a cooling pipe are arranged on the outer side face of the cooling substrate; a component for improving the heat value is installed on the inner side face of the cooling substrate; the cooling pipe is of a multi-row pipe structure, and communicates with a refrigerant loop in an air condition unit, and low temperature refrigerants are made to circulate in the cooling pipe, and perform heat exchanging with the cooling substrate;and a cover plate detachably connected with the cooling substrate is arranged on the cooling pipe, and the cooling pipe is made fixed. The improved electronic control box for the air conditioner outdoor unit can reduce the wind sucking resistance, increase the wind speed, can substantially improve the cooling effect due to combination of wind cooling and refrigerant cooling, and guarantees normalrunning of the unit.

Owner:NANJING TICA AIR CONDITIONING CO LTD

Vacuum drying active carbon waste gas management process and vacuum drying active carbon waste gas management apparatus

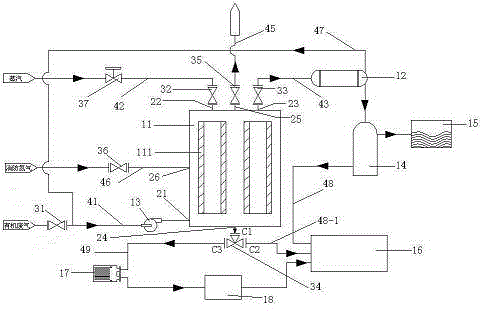

InactiveCN105013288AReasonable designImprove adsorption capacityDispersed particle filtrationVapor condensationFiberCarbon fibers

The present invention provides a vacuum drying active carbon waste gas management process and a vacuum drying active carbon waste gas management apparatus. The vacuum drying active carbon waste gas management process is characterized by comprising a pre-treatment stage, an adsorption stage, a desorption and recovery stage, and a drying stage. The apparatus comprises an adsorber and a condenser, wherein the adsorber comprises an organic waste gas inlet, a steam inlet, a desorption outlet, a drying outlet, a clean gas outlet, a fire fighting nitrogen inlet and active carbon fibers, and the active carbon fibers are arranged inside the adsorber. According to the present invention, the design is reasonable, the adsorption effect is high, and the standard discharge is ensured; and during the active carbon fiber drying regeneration, the vacuum drying way is used and is different from the wind sucking drying of the fan in the prior art, such that the water which can not be blown out by the fan and retained in the active carbon fibers can be effectively removed, the drying efficiency is extremely high, the drying time is short, and the electricity consumption is less so as to save the management cost, reduce the time consuming of the whole process, and improve the waste gas management efficiency.

Owner:江苏中远环保科技有限公司

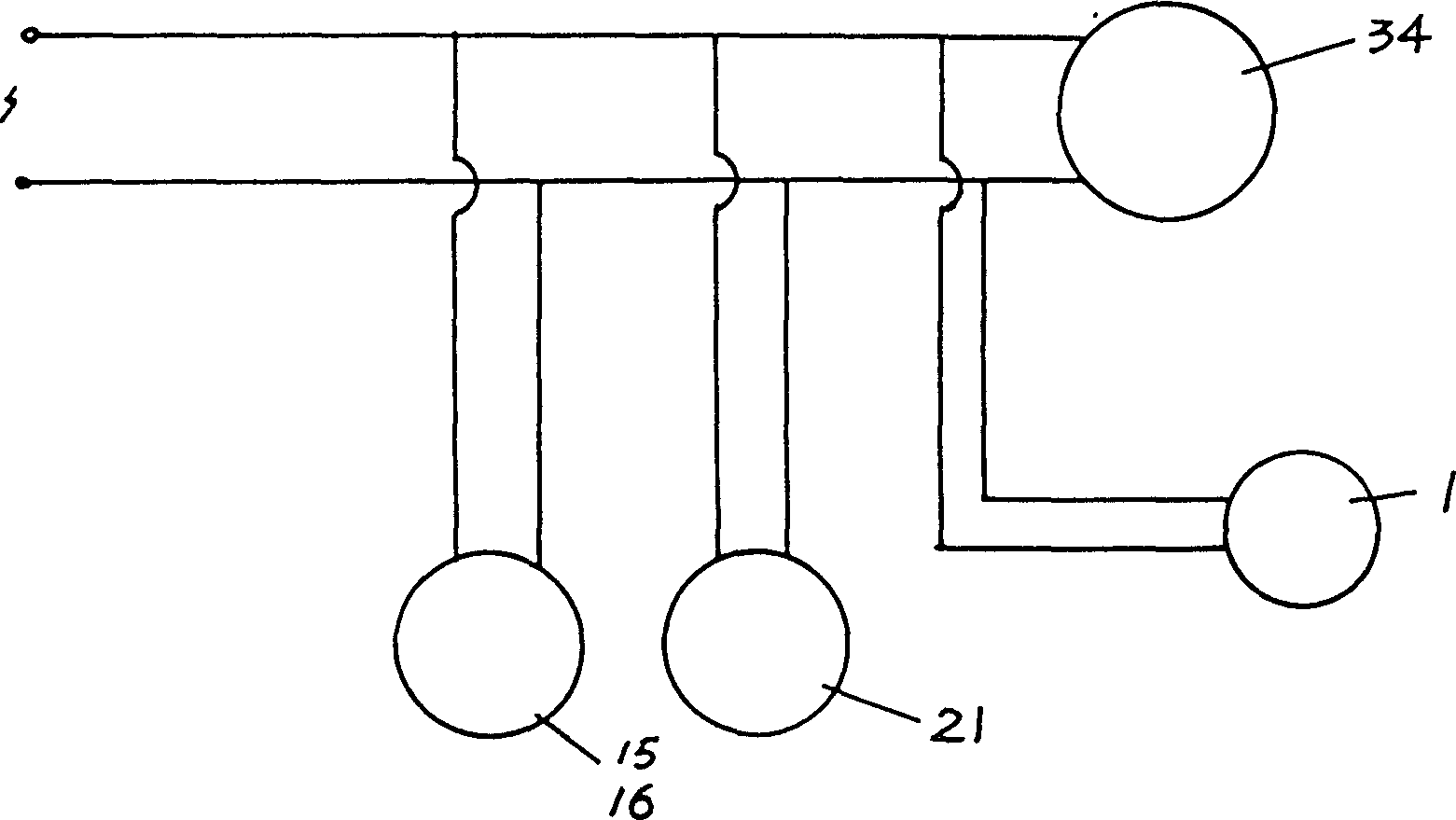

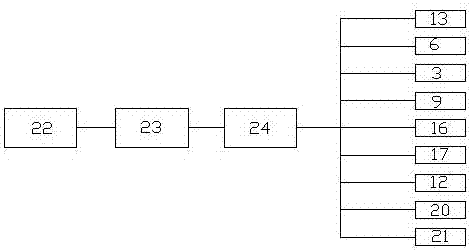

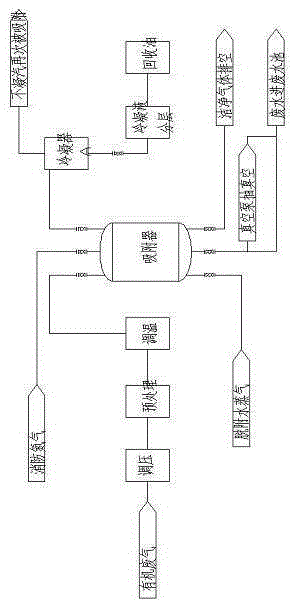

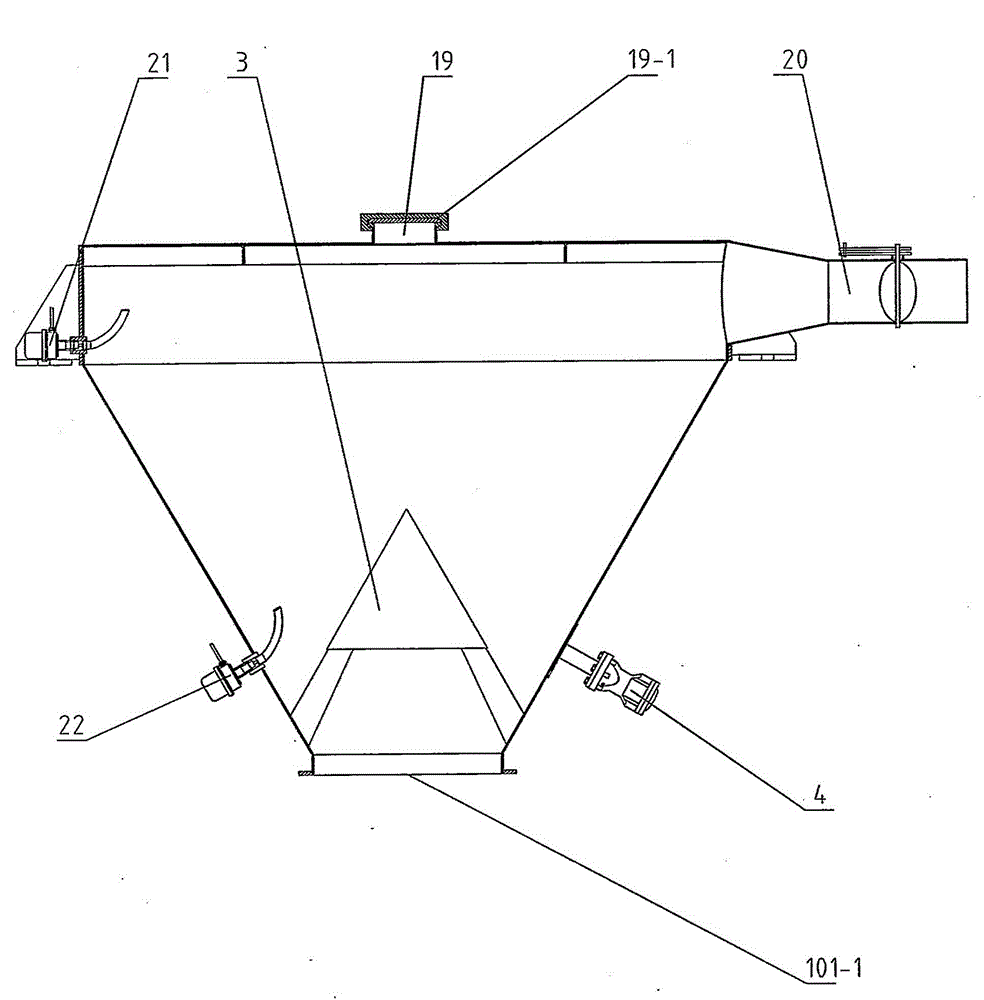

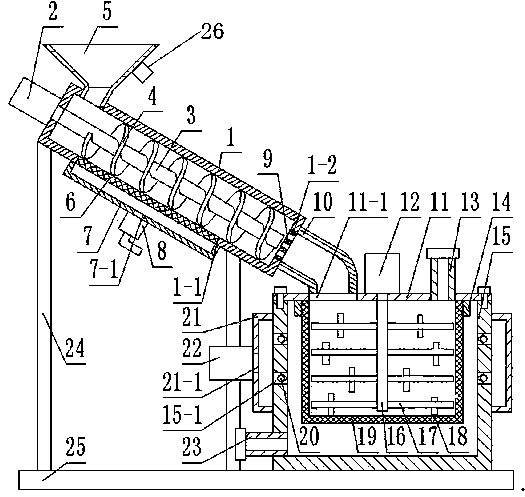

Quantitative ternary-material charging system

ActiveCN102874607AAvoid enteringAvoid pollutionLoading/unloadingEngineeringElectrical and Electronics engineering

The invention discloses a quantitative ternary-material charging system, which comprises a bag-opening material-storing bunker, a uniform discharging device, a material-conveying device, a dust-removing device and a sagger depalletizing machine, wherein the bag-opening material-storing bunker is provided with a bunker discharging opening; the uniform discharging device is provided with a first charging opening and a first discharging opening; the material-conveying device is provided with a second charging opening and a second discharging opening; the dust-removing device is provided with a dust-removing sucker; the sagger depalletizing machine is provided with a sagger; and the bunker discharging opening of the bag-opening material-storing bunker is communicated with the first charging opening of the uniform discharging device, the first discharging opening of the uniform discharging device is positioned over the second charging opening of the material-conveying device, the second discharging opening of the material-conveying device is positioned above the sagger of the sagger depalletizing machine, a wind-sucking cover and a wind-sucking nozzle are communicated onto the dust-removing sucker, the wind-sucking cover is positioned between the sagger and the second discharging opening of the material-conveying device, and the wind-sucking nozzle is positioned at the periphery below the wind-sucking cover. The quantitative ternary-material charging system can be used for automatic and quantitative charging, the manpower labor intensity is lightened, and the labor environment is improved.

Owner:CHANGZHOU YAKUI AUTOMATION EQUIP

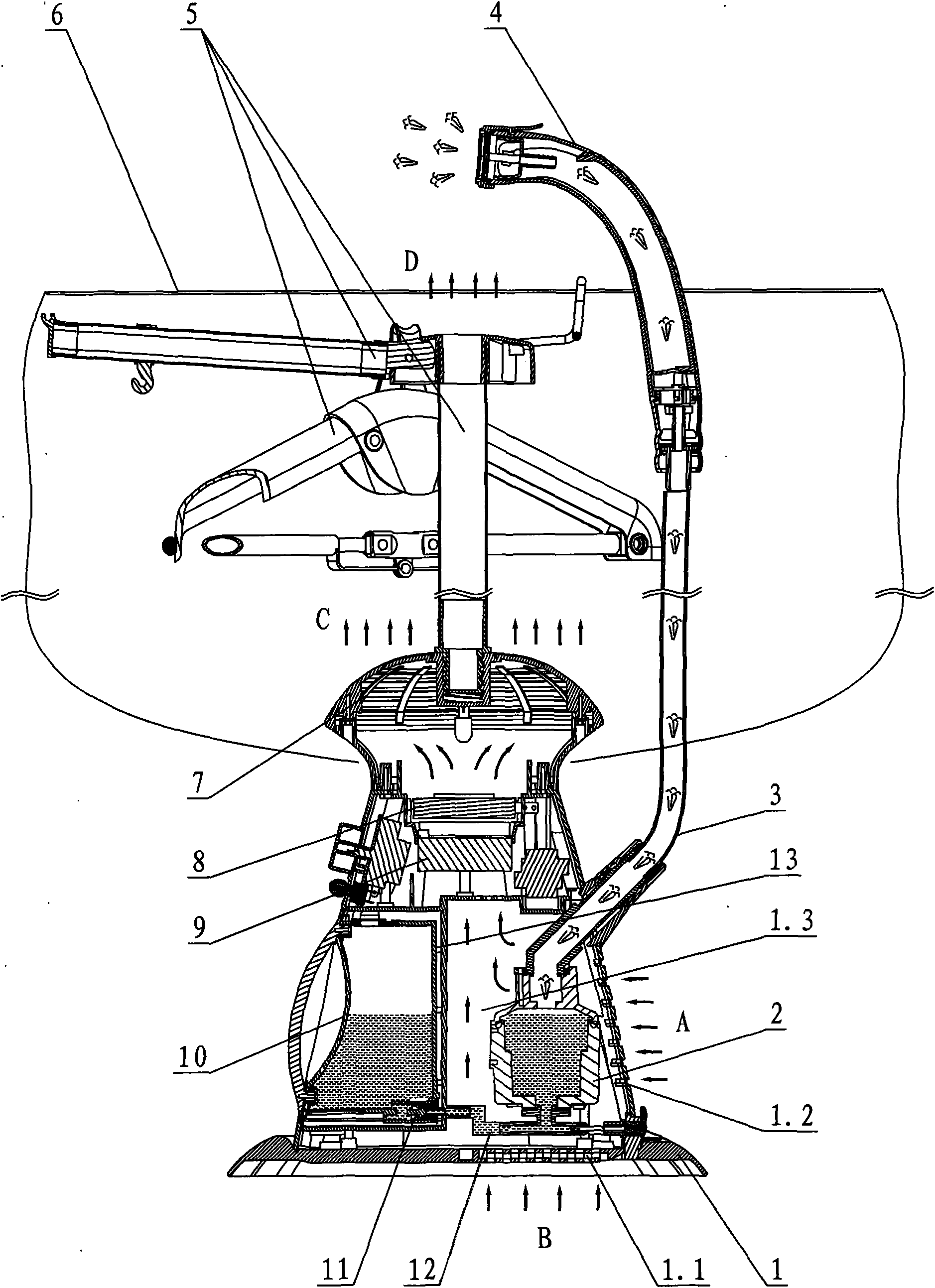

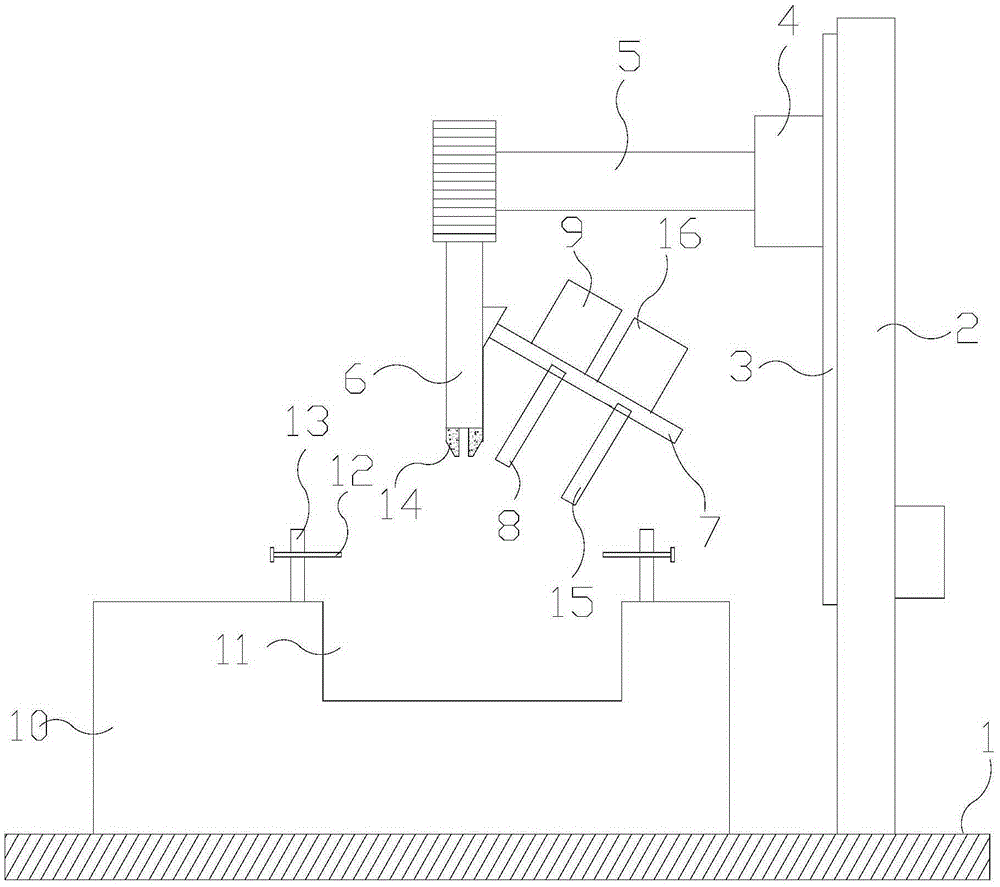

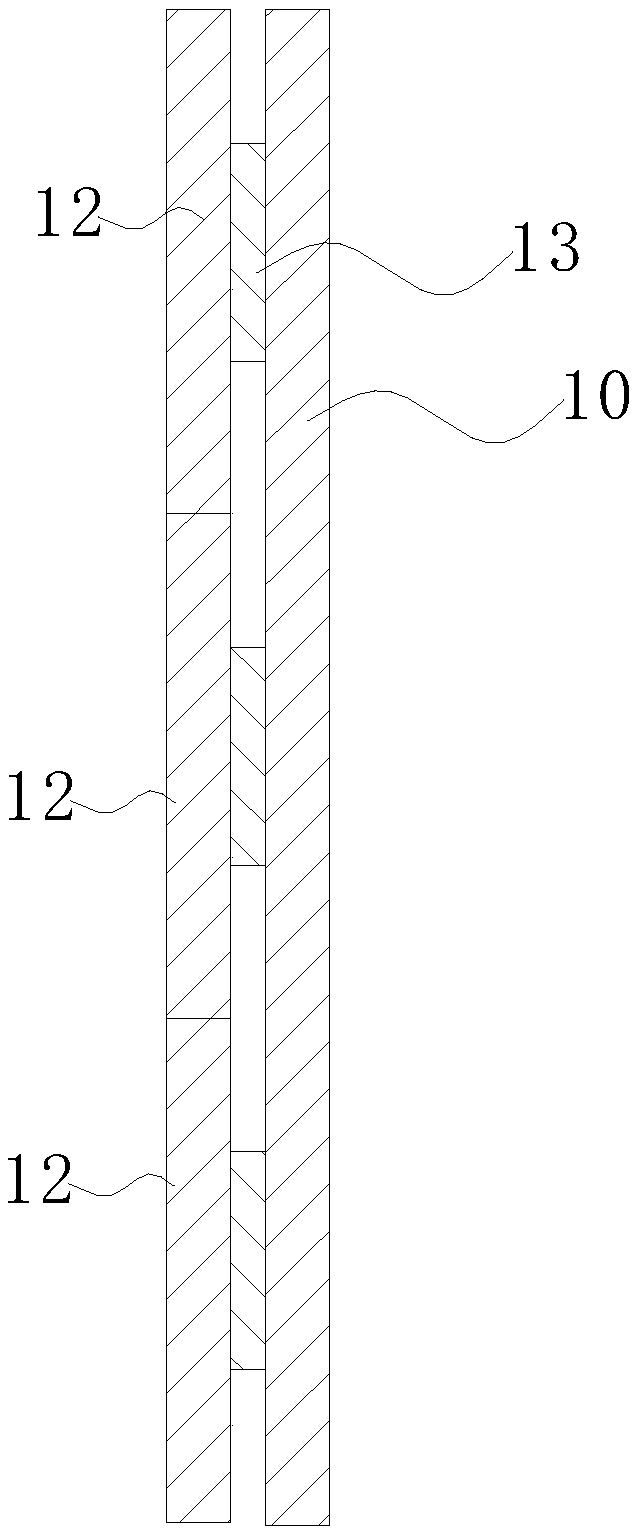

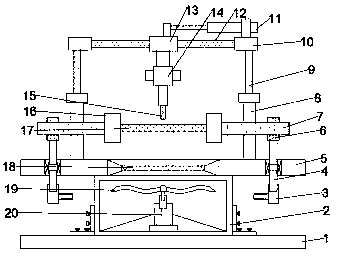

Smoke purifying device for laser welding machine

InactiveCN105414756AImprove purification effectRealize water coolingLaser beam welding apparatusEngineeringDrive motor

The invention provides a smoke purifying device for a laser welding machine. The smoke purifying device comprises a base; a stand column is arranged on the base; a driving motor is arranged on the stand column, and is connected with a laser welding gun through a rotating shaft; the rotating shaft can drive the laser welding gun to rotate; a laser welding head is arranged at the lower end of the laser welding gun; at least one support rod extending outwards is arranged on the outer peripheral surface of the laser welding gun; an air sucking pipe is arranged on the support rod, and is opposite to the laser welding head; a working table is arranged below the laser welding head; a groove for placing workpieces is formed in the working table; and wind sucking pipes are arranged on two side walls of the groove. The device has such advantages as good purifying effect and capability of effectively improving the welding quality.

Owner:SUZHOU RECEN PRECISION MACHINERY CO LTD

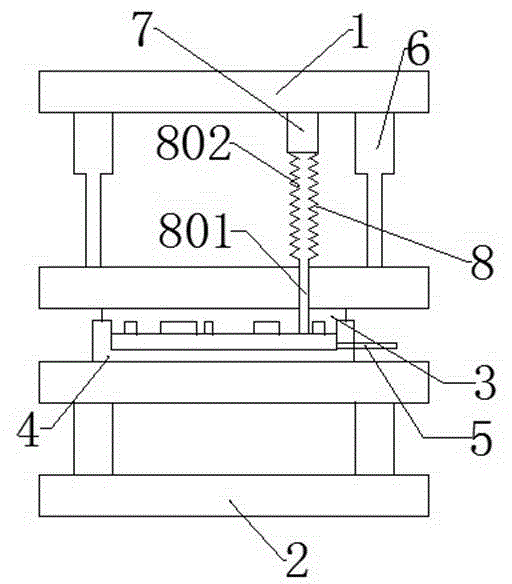

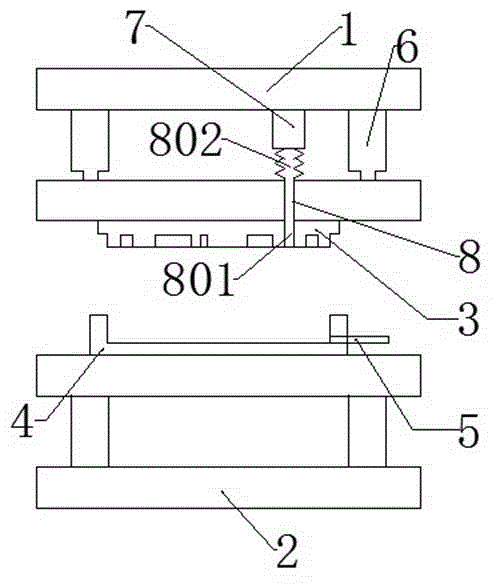

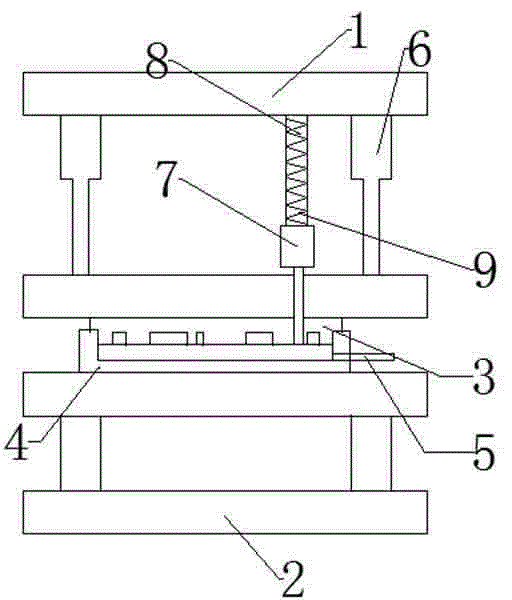

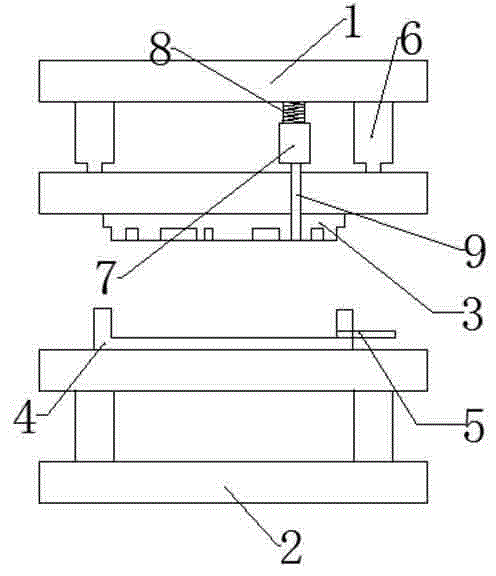

Vacuum die

The invention discloses a vacuum die. The vacuum die comprises an upper die base, a lower die base, an upper die plate arranged under the upper die base, a lower die plate fixed to the lower die base, a telescopic piece connected between the upper die base and the upper die plate, a sprue arranged on the lower die plate, and a wind sucking and blowing assembly connected to the upper die plate; and the wind sucking and blowing assembly comprises a sucking and blowing fan arranged on the upper die plate, and a stretchable wind tube inserted to the upper die plate and connected with the sucking and blowing fan. Vacuum is pumped from a molding tank before injection molding, so a material can conveniently enter the molding tank, and generation of bubbles generated in the molding process of a product or uneven product shape induced by gas pressure is avoided; air is injected to the molding tank during demolding, so the molding tank is opened outward by using an air pressure; complete and efficient demolding avoids pulling damages of the product, so the injection molding efficiency is improved, and the quality of the product is improved; and the wind tube of the sucking and blowing fan is provided with a telescopic fold tube, so the wind tube can change with the elongation or shortening of a telescopic rod.

Owner:昆山—邦泰汽车零部件制造有限公司

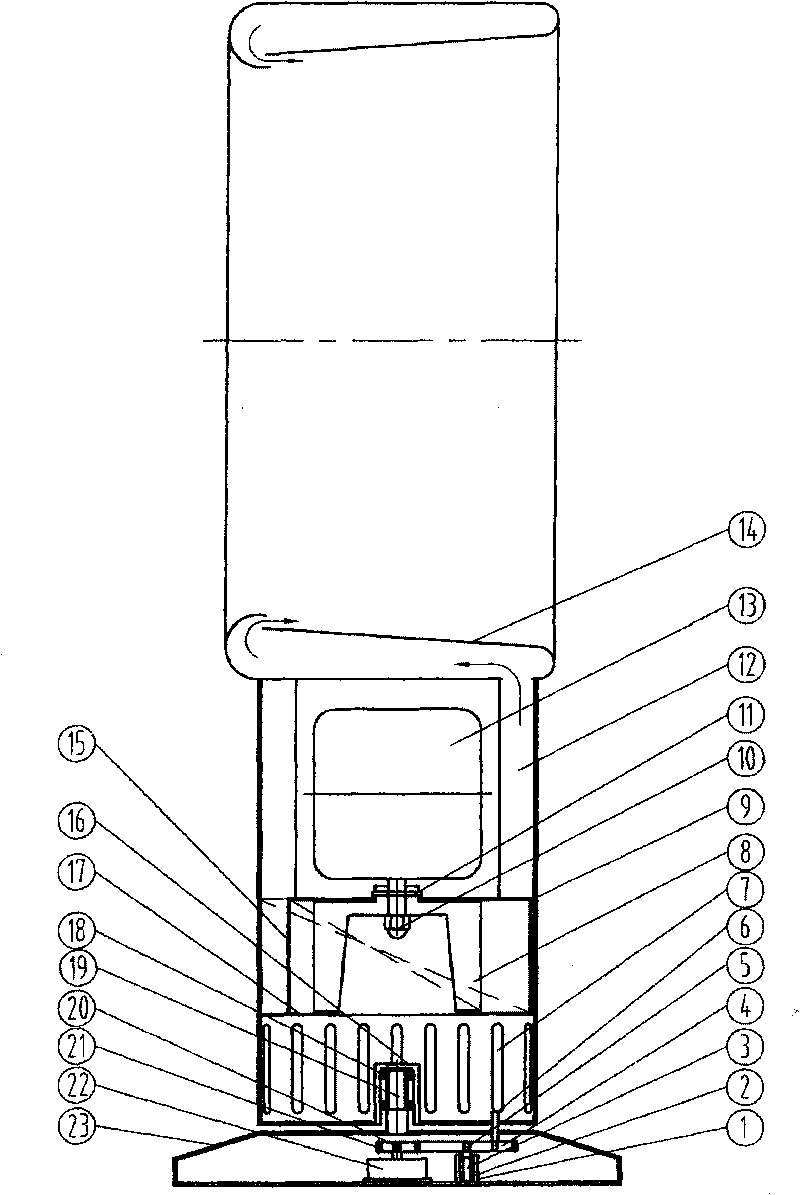

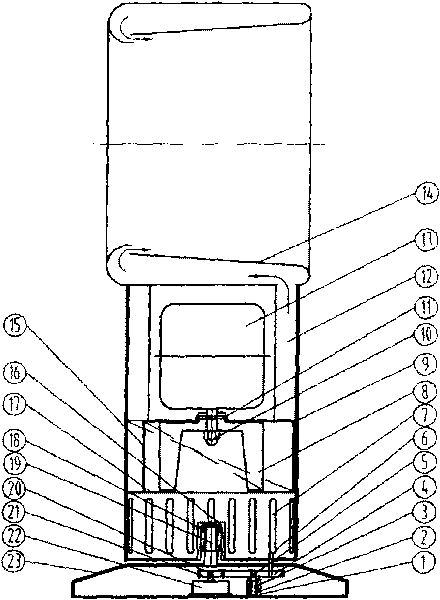

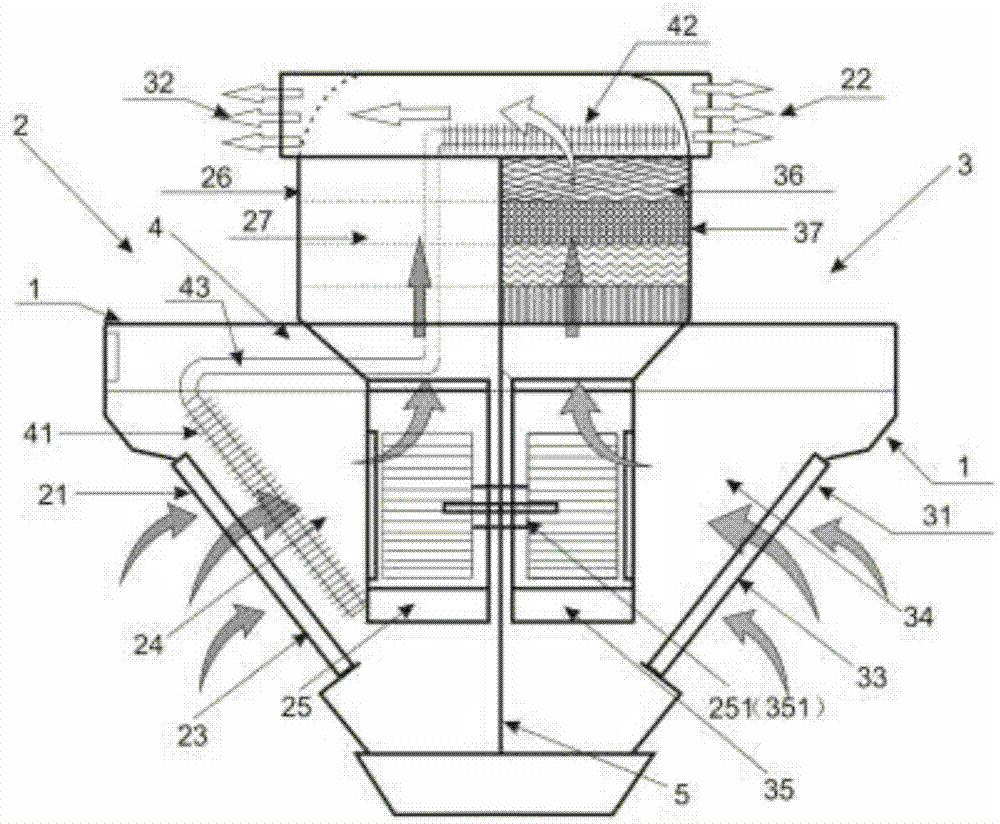

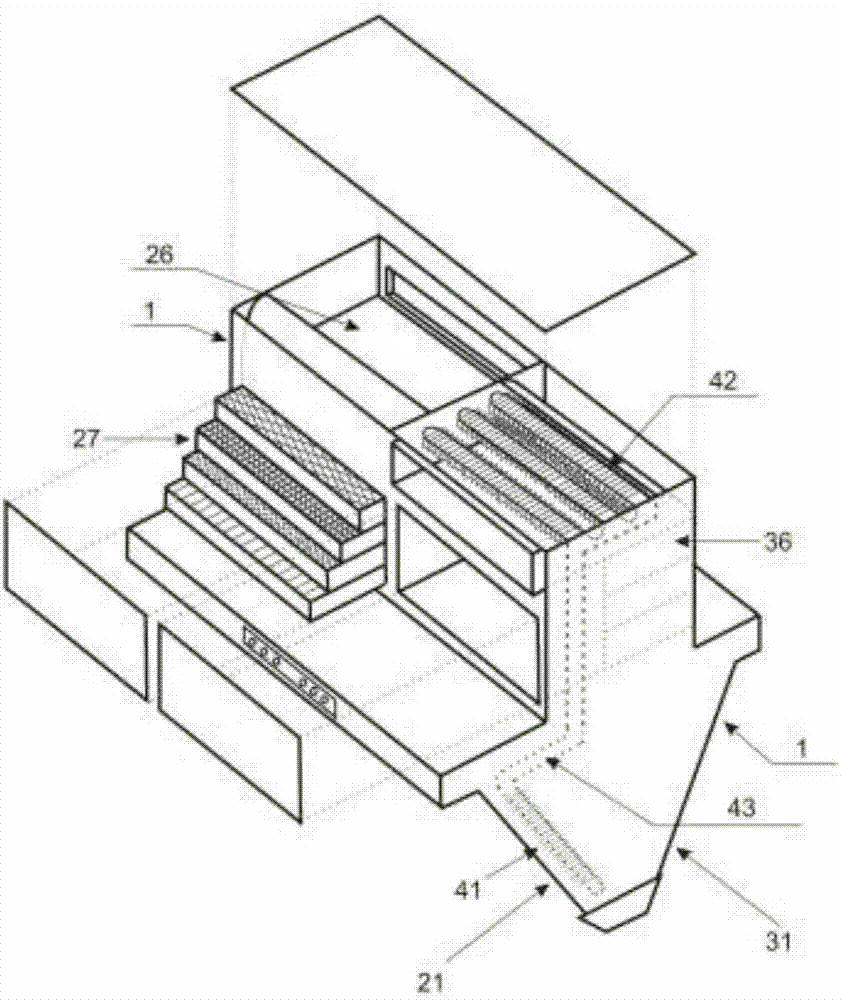

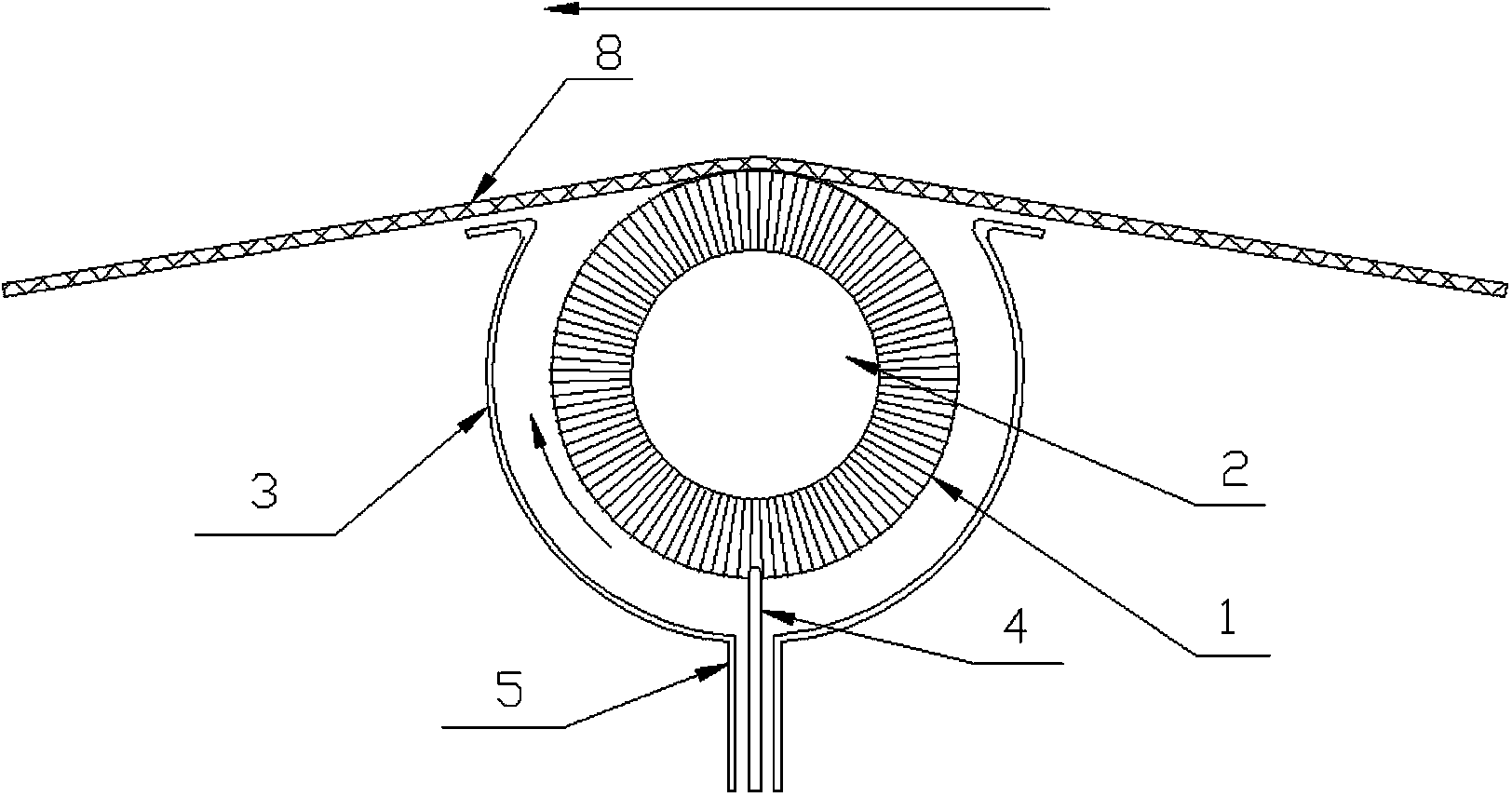

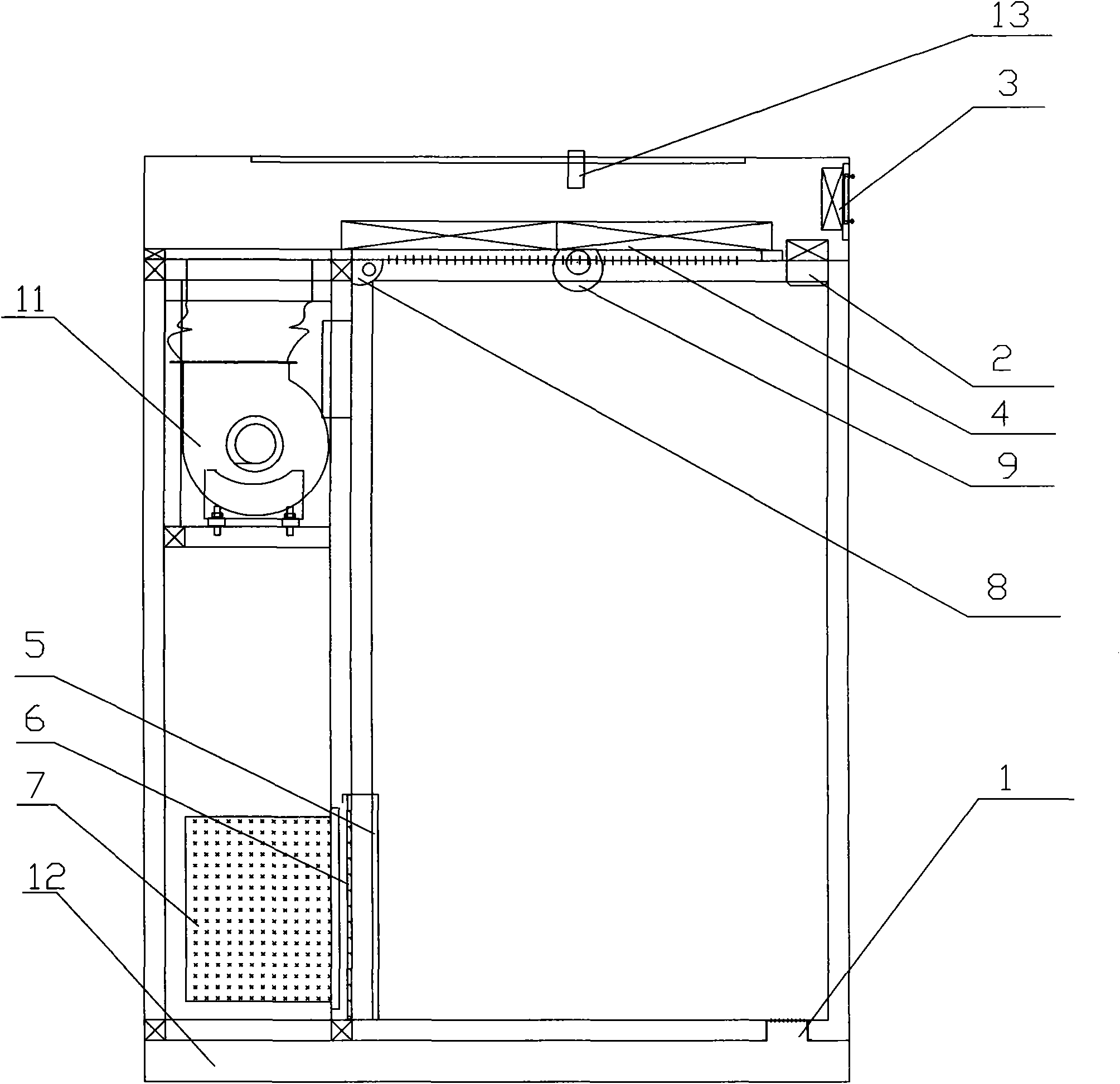

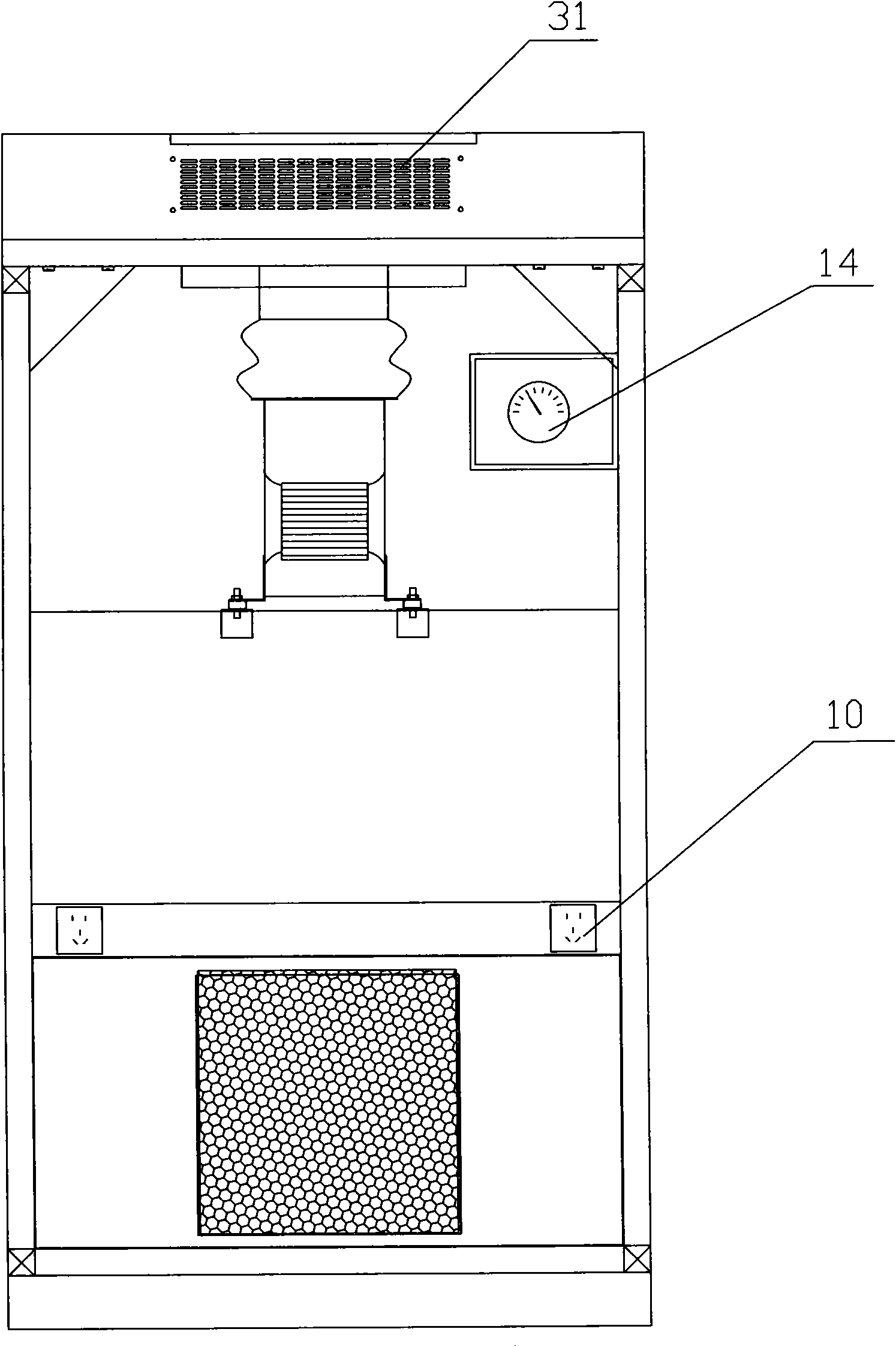

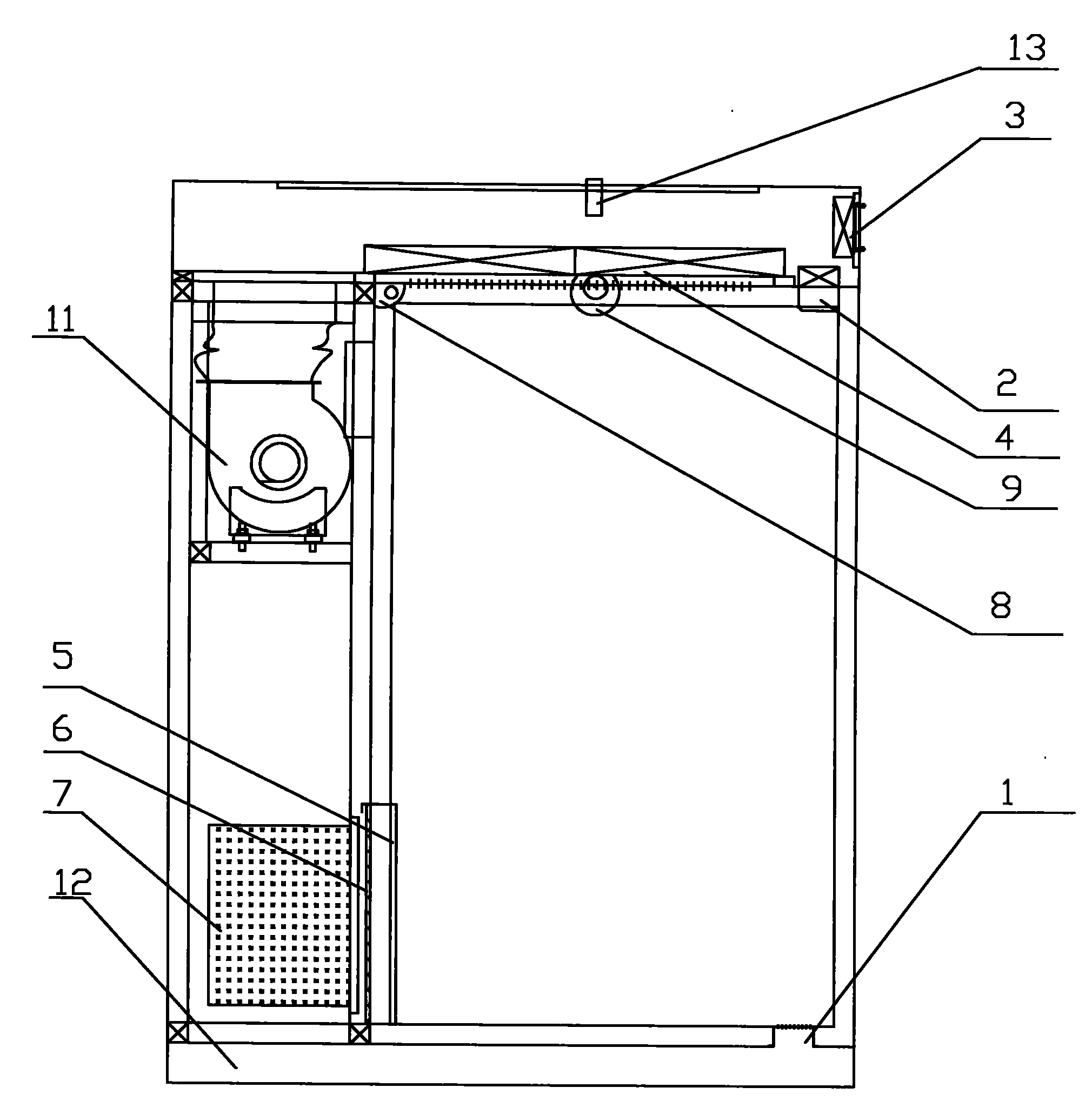

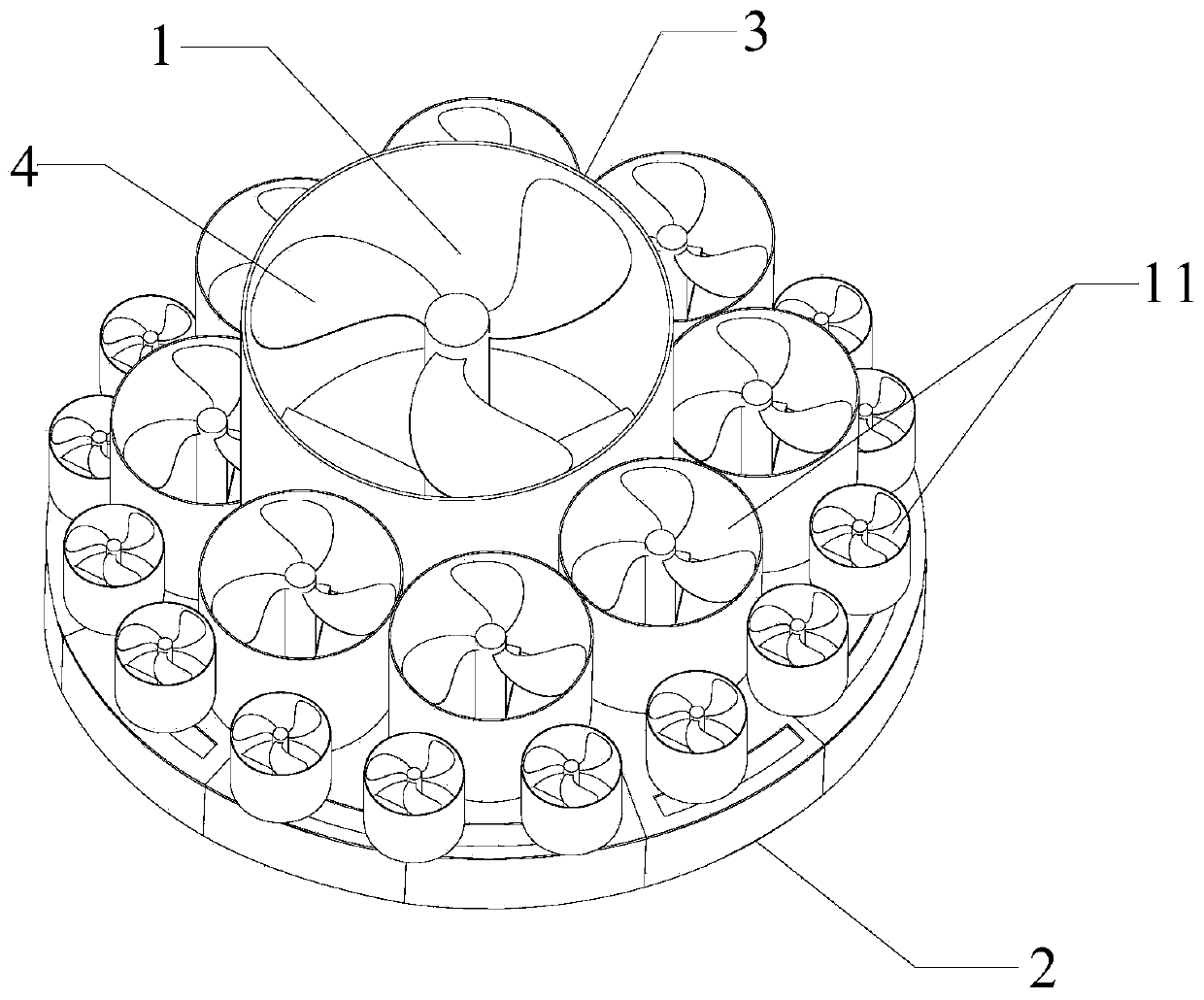

Dual-purpose circular purifying machine

PendingCN107327890AImprove and improve air qualityIncrease net areaDomestic stoves or rangesLighting and heating apparatusDual purposeProduct gas

The invention discloses a dual-purpose circular purifying machine which comprises a shell, a lamp black purifying device, a fresh wind supply device and a heat exchange device. The lamp black purifying device comprises a smoke sucking opening, a first exhausting opening, a grease separator, a smoke sucking cavity, a first fan, a smoke purifying chamber and a smoke purifying filter layer. The smoke purifying filter layer is arranged in the smoke purifying chamber. The fresh wind supply device comprises a wind sucking opening, a second exhausting opening, a dust interception device, a wind sucking cavity, a second fan, a gas purifying chamber and a gas purifying filter layer. The gas purifying filter layer is arranged in the gas purifying chamber. The heat exchange device comprises a heat absorber, a heat dissipater and a circulating pipeline. The dual-purpose circular purifying machine can purify lamp black waste gas in a room, provide purified fresh wind for the interior of the room, utilize waste heat generated in the cooking process, greatly improve social environment and air quality of the room, and meanwhile save energy sources.

Owner:SHANGHAI DUOHUAN OIL SMOKE PURIFICATION EQUIP CO LTD

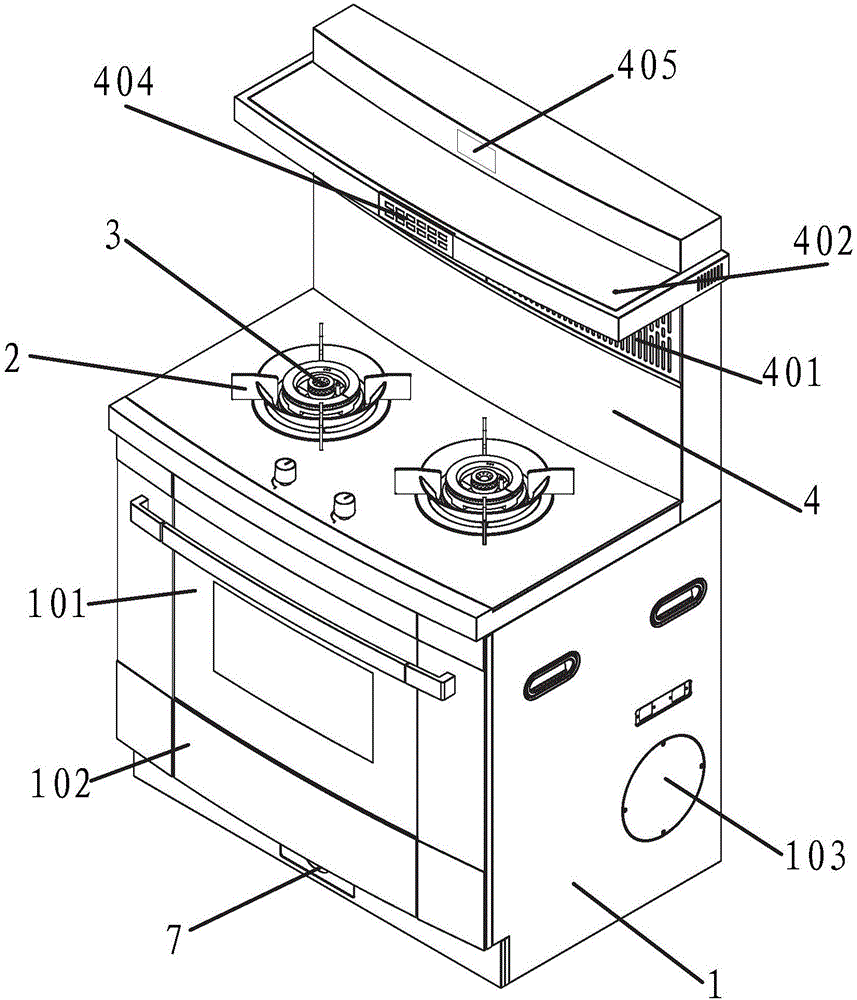

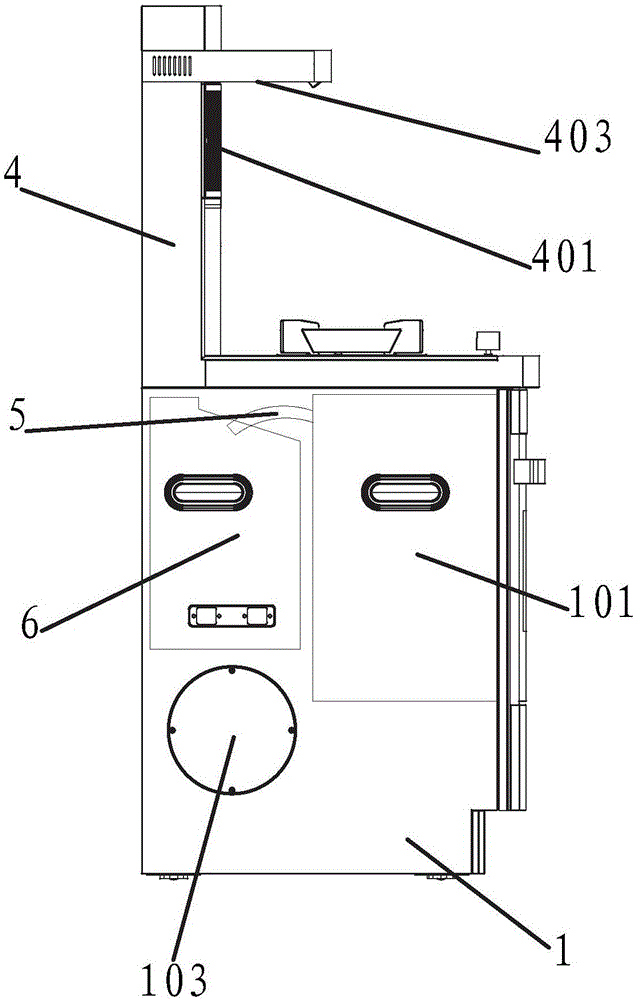

Steaming-baking integrated side sucking integration stove and operation method thereof

InactiveCN106594808AReduce noisePurify the cooking environmentDomestic stoves or rangesLighting and heating apparatusEngineeringMotherboard

The invention provides a steaming-baking integrated side sucking integration stove and an operation method thereof. The steaming-baking integrated side sucking integration stove comprises a cabinet body, a stove body and a side wind sucking device; the side wind sucking device includes a vertical shell and a transverse folding flange; the vertical shell is provided with a wind sucking port towards the side surface of a burner; exhaust ways are formed in the vertical shell and the cabinet body; an exhaust port is formed in the side part of the cabinet body; volute fans are arranged in the exhaust ways; wind boxes coat the outer peripheries of the volute fans; the cabinet body is provided with a steaming-baking integrated machine and a storage cabinet; the steaming-baking integrated machine and the wind boxes are communicated through steam discharge pipes; an oil collecting box is arranged at the bottom of the cabinet body; oil discharge ports are formed in the bottoms of the exhaust ways; the oil collecting box is positioned below the oil discharge ports; one end of the oil collecting box is an oil receiving end; a bearing sensing module is arranged at the bottom of the oil receiving end; a full oil micro switch is arranged on the outer side of the oil receiving end; the bearing sensing module triggers the full oil micro switch in a full filling state of the oil collecting box; a touch control screen is arranged on the front end surface of the transverse folding flange; and a control main board is arranged in the touch control screen.

Owner:浙江优格实业有限公司

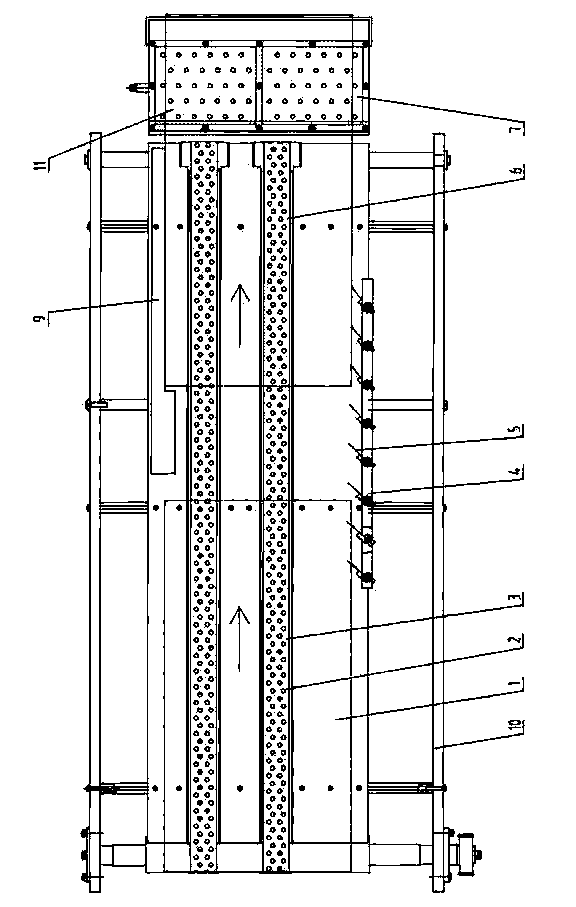

Cleaning device for back face of breathable net belt of artificial board preforming press

The invention belongs to the technical field of artificial board producing machinery and discloses a cleaning device for the back face of a breathable net belt of an artificial board preforming press. The cleaning device comprises a hair brush, a roller, a protective cover, a poking piece, a wind sucking port and a support; the hair brush is arranged on the outer face of the roller; left and right ends of the roller are respectively fixed on the support; left and right ends of the protective cover are fixed on the support and wrap the hair brush and the roller; left and right ends of the poking piece are fixed on the support and are arranged in the middle of the wind sucking port; the wind sucking port is arranged below the protective cover and is in the vertical direction, and a wind gap is downward. According to the cleaning device for the back face of the breathable net belt of the artificial board preforming press, removed fibers can be prevented from returning to the face of the breathable net belt, the hair brush can be cleaned effectively due to the existence of the poking piece, the product quality can be improved, the waste board rate can be reduced and the environment pollution in a workshop can be reduced.

Owner:DAYA WOOD IND JIANGXI +1

Wood processing thicknesser

InactiveCN106272722AEasy to cleanSimple structureThicknessing machinesBark-zones/chip/dust/waste removalPulp and paper industryClassification treatment

The invention discloses a wood processing thicknesser, which comprises a base table, a chip discharging device, a working table arranged on the base table, and a pressing table positioned above the working table, wherein the working table is provided with a conveying belt device, an attachment material scraping plate and a cutter shaft, the conveying belt device is a double-section conveying belt conveying structure and is arranged on the middle portion of the working table, chip discharging grooves, a wind sucking pipe and an exhaust fan are arranged inside the chip discharging device, the two sets of the chip discharging grooves are respectively arranged on both side of the cutter shaft, the lower ends of the two sets of the chip discharging grooves are communicated to the wind sucking pipe, the wind sucking pipe is connected to the exhaust fan, the exhaust fan and a motor belt form a transmission connection through a belt, and the left side of the exhaust fan is connected to a discharging channel. According to the present invention, the structure is simple, the use is convenient, the wood chips produced during the working process of the thicknesser can be effectively cleaned, the wood chips can be subjected to the classification treatment according to the actual needs after the wood chips are centralized, and a lot of the wood chips can be subjected to secondary recycling.

Owner:苏州欧复能新材料科技有限公司

Cleaning working chamber

ActiveCN102313325AFlexibleAdaptableLighting and heating apparatusSpace heating and ventilation detailsPositive pressureEngineering

The invention discloses a cleaning working chamber, which comprises a wind-sucking opening, a first wind-supplying filtering opening, a second wind-supplying filtering opening and an wind-returning filtering opening, wherein the wind-sucking opening is arranged below an inlet of the cleaning-working chamber; the first wind-supplying filtering opening is arranged above the inlet of the cleaning-working chamber, the second wind-supplying filtering opening is adjacent to the first wind-supplying filtering opening, and the wind-returning filtering opening is arranged at the inner side of the cleaning-working chamber; a wind-discharging filtering opening is arranged above the first wind-supplying filtering opening, and a cavity is formed between the first wind-supplying filtering opening and the wind-discharging filtering opening; and a wind-pressure difference is generated between the wind-sucking opening and the first wind-supplying filtering opening. Through the cleaning working chamber disclosed by the invention, a wind wall is formed at the connected part of the working chamber and outside air, an original door curtain can be replaced, and meanwhile, the cleaning-working chamber not only is applicable to positive-pressure environments, but also is applicable to negative-pressure environments and has certain flexibility and adaptability.

Owner:SUZHOU INDAL PARK HJCLEAN TECH

Vacuum injection molding die

The invention discloses a vacuum die. The vacuum die comprises an upper die base, a lower die base, an upper die plate arranged under the upper die base, a lower die plate fixed on the lower die base, a telescopic piece connected between the upper die base and the upper die plate, a sprue arranged on the lower die plate, and a wind sucking and blowing assembly connected to the upper die plate. Vacuum is pumped from a molding tank before injection molding, so a material can conveniently enter the molding tank, and generation of bubbles generated in the molding process of a product or uneven product shape induced by gas pressure is avoided; air is injected to the molding tank during demolding, so the molding tank is opened outward by using an air pressure; and complete and efficient demolding avoids pulling damages of the product, so the injection molding efficiency is improved, and the quality of the product is improved.

Owner:昆山—邦泰汽车零部件制造有限公司

Soybean oil and processing method thereof

InactiveCN107432332AImprove the level ofLight colorFatty-oils/fats refiningFatty-oils/fats productionImpurityPollution

The invention discloses soybean oil and a processing method thereof. The processing method comprises: (1) screening: adding soybeans into a wind sucking flat sieve, removing metals, stones and dust impurities from the soybeans, and screening full soybeans; (2) washing: washing the screened full soybeans by using clear water; (3) air drying: carrying air blowing and air drying on the washed soybeans, and controlling the water content at 3-5%; (4) cold preservation and baking: conveying the air-dried soybeans into a cold storage, carrying out cold preservation, taking out, conveying into a horizontal baking room, and repeatedly baking a plurality of times; and (5) breaking: breaking the soybeans into granules by using a breaking device. According to the present invention, the processing method has characteristics of simple process, good product taste, high extraction rate and high oil product grade, and the produced soybean oil has characteristics of light color, special soybean odor, nutrient retaining, high nutrition value, no pollution, and low energy consumption.

Owner:HEBEI JIYUAN ORGANIC OILS FOOD

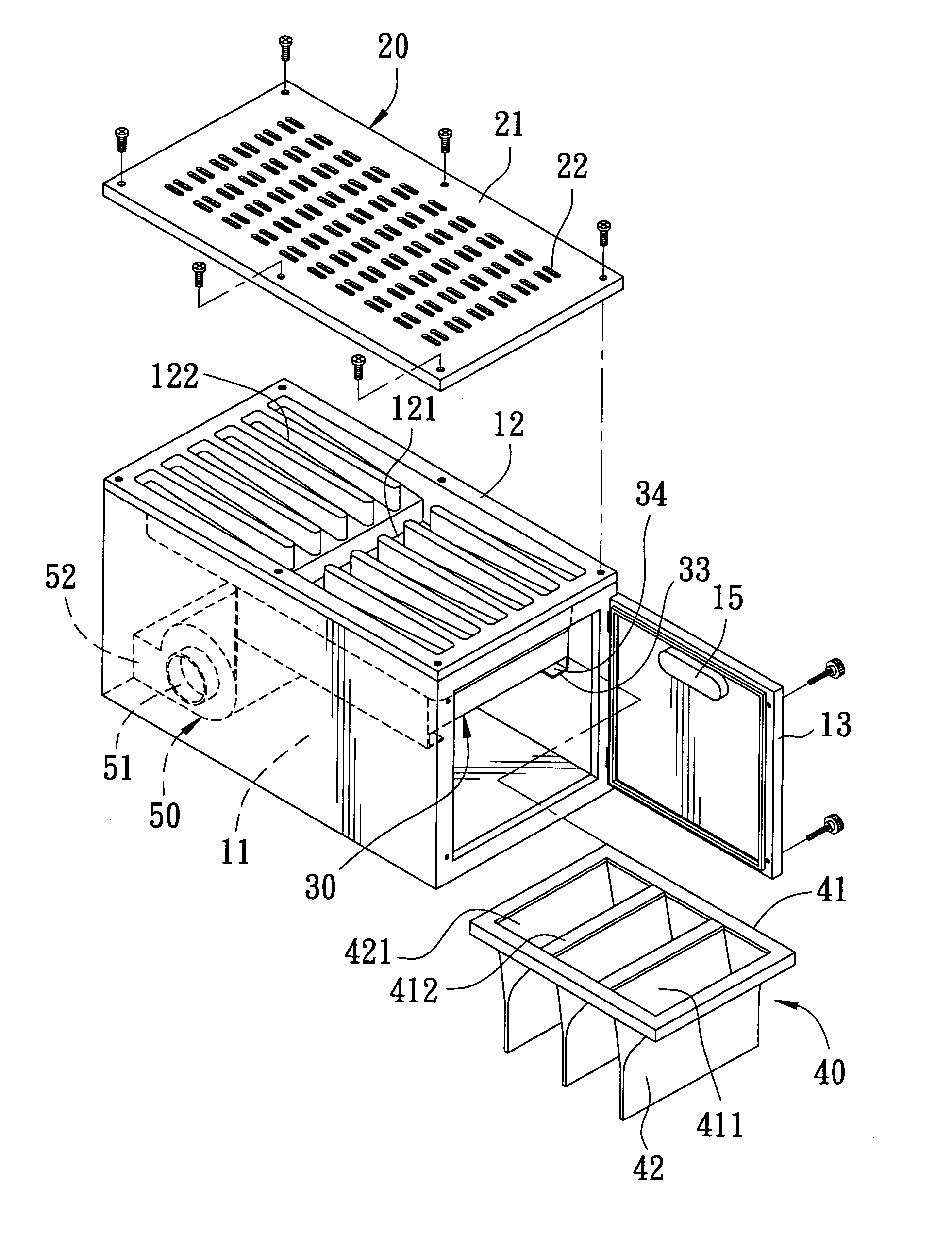

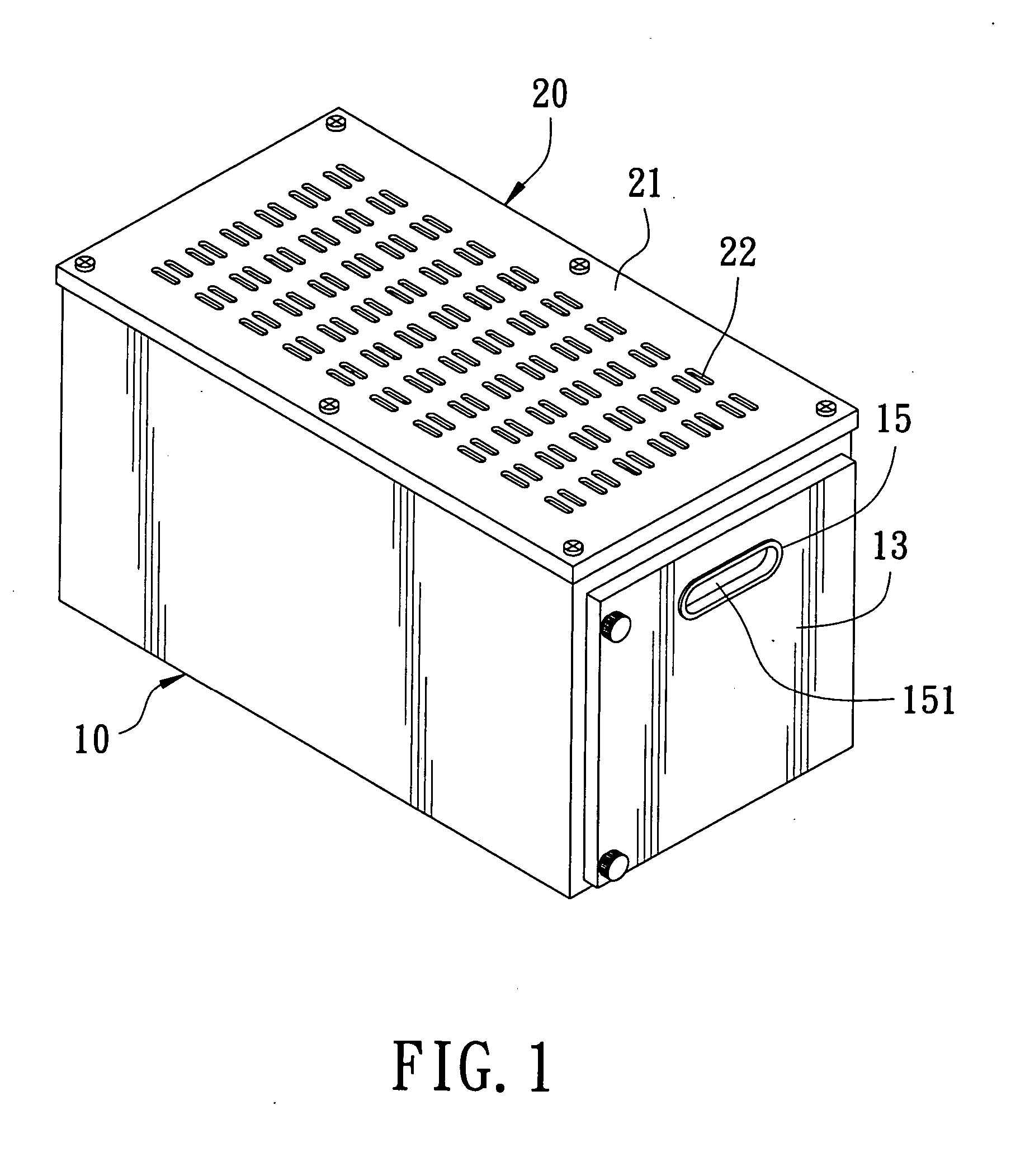

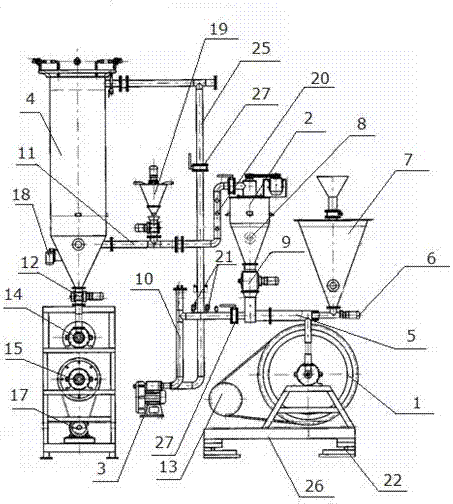

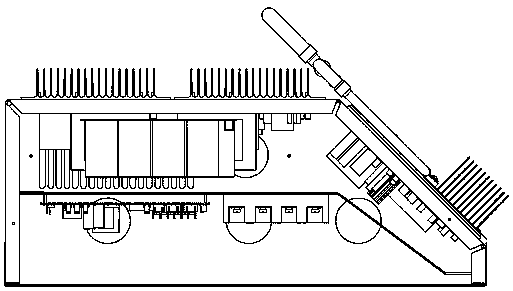

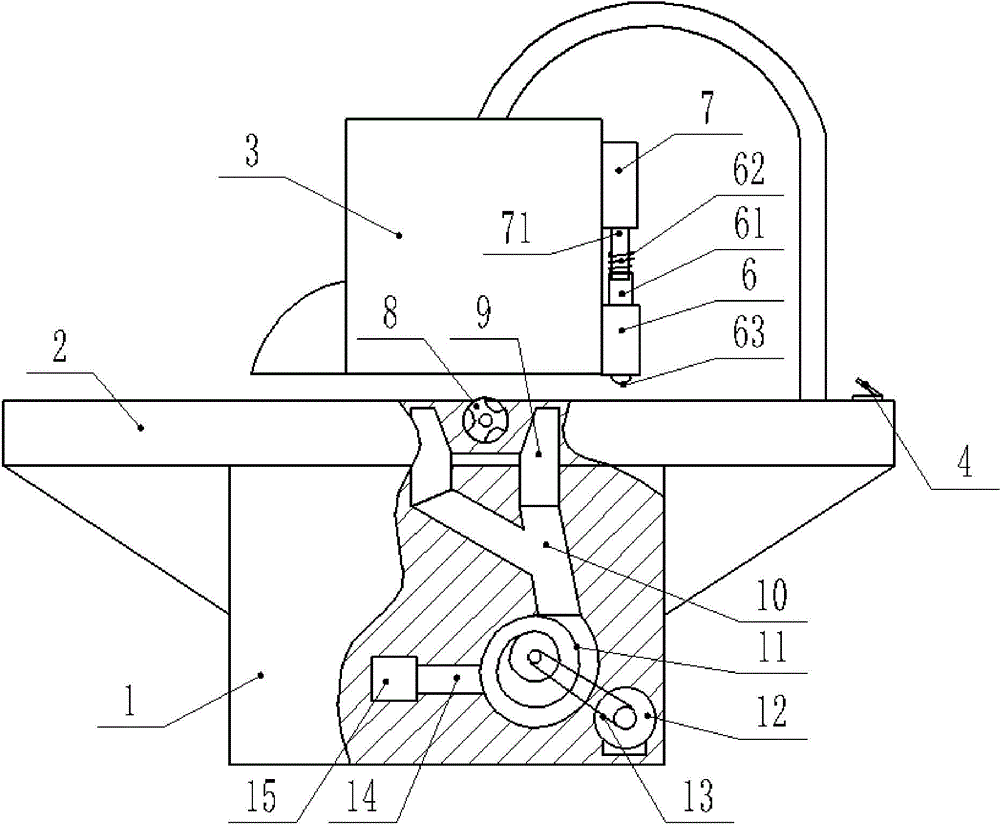

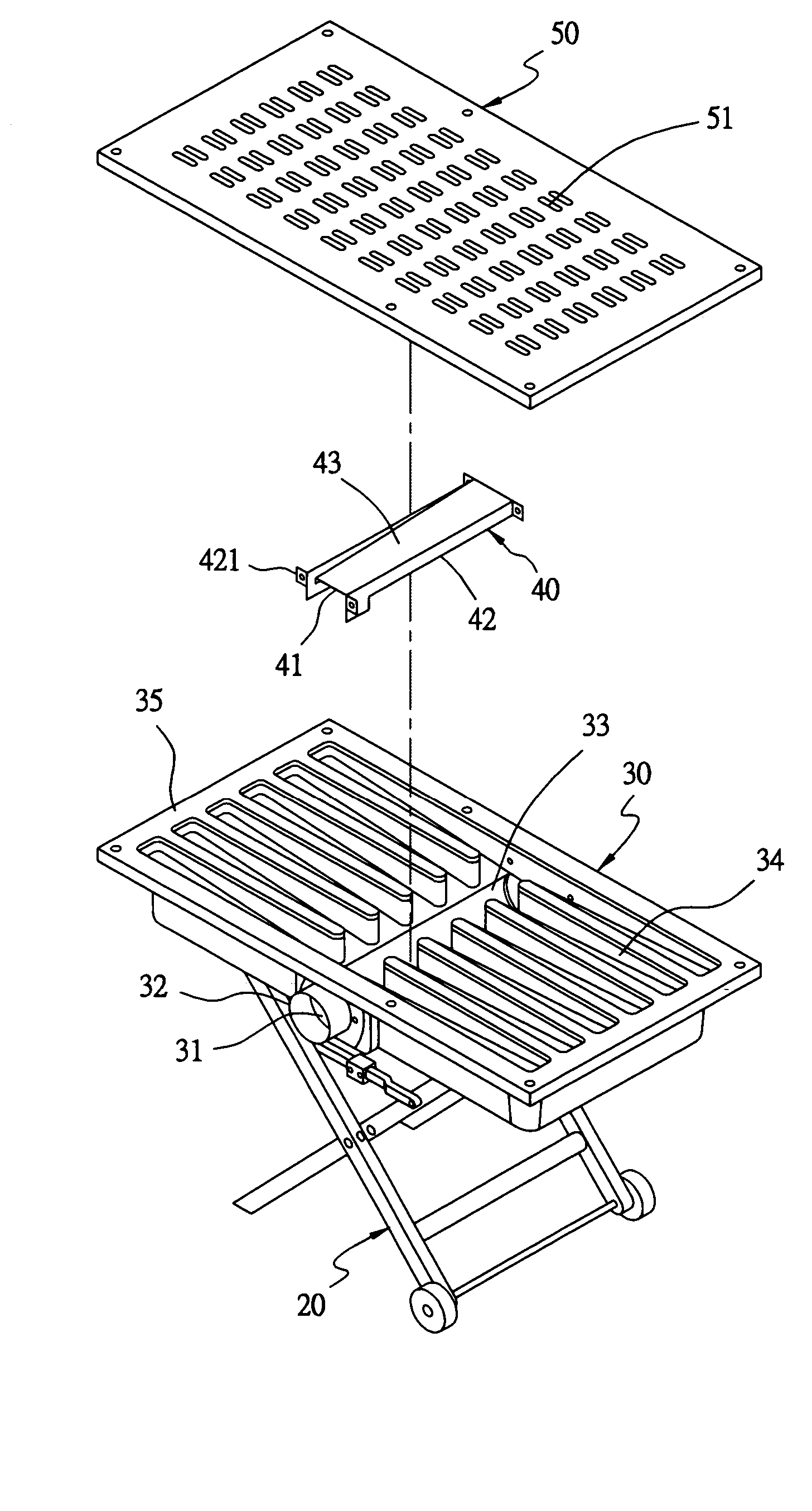

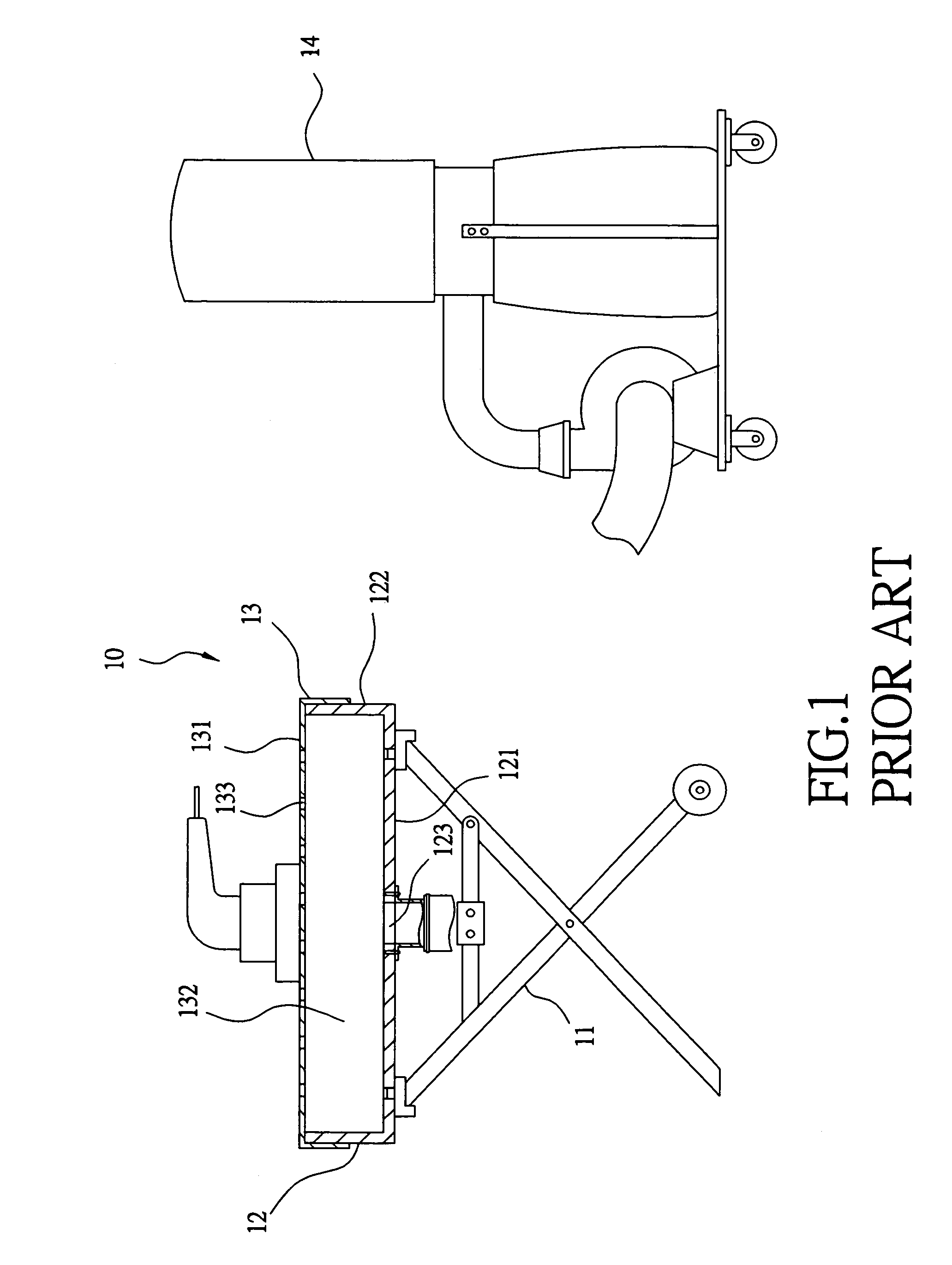

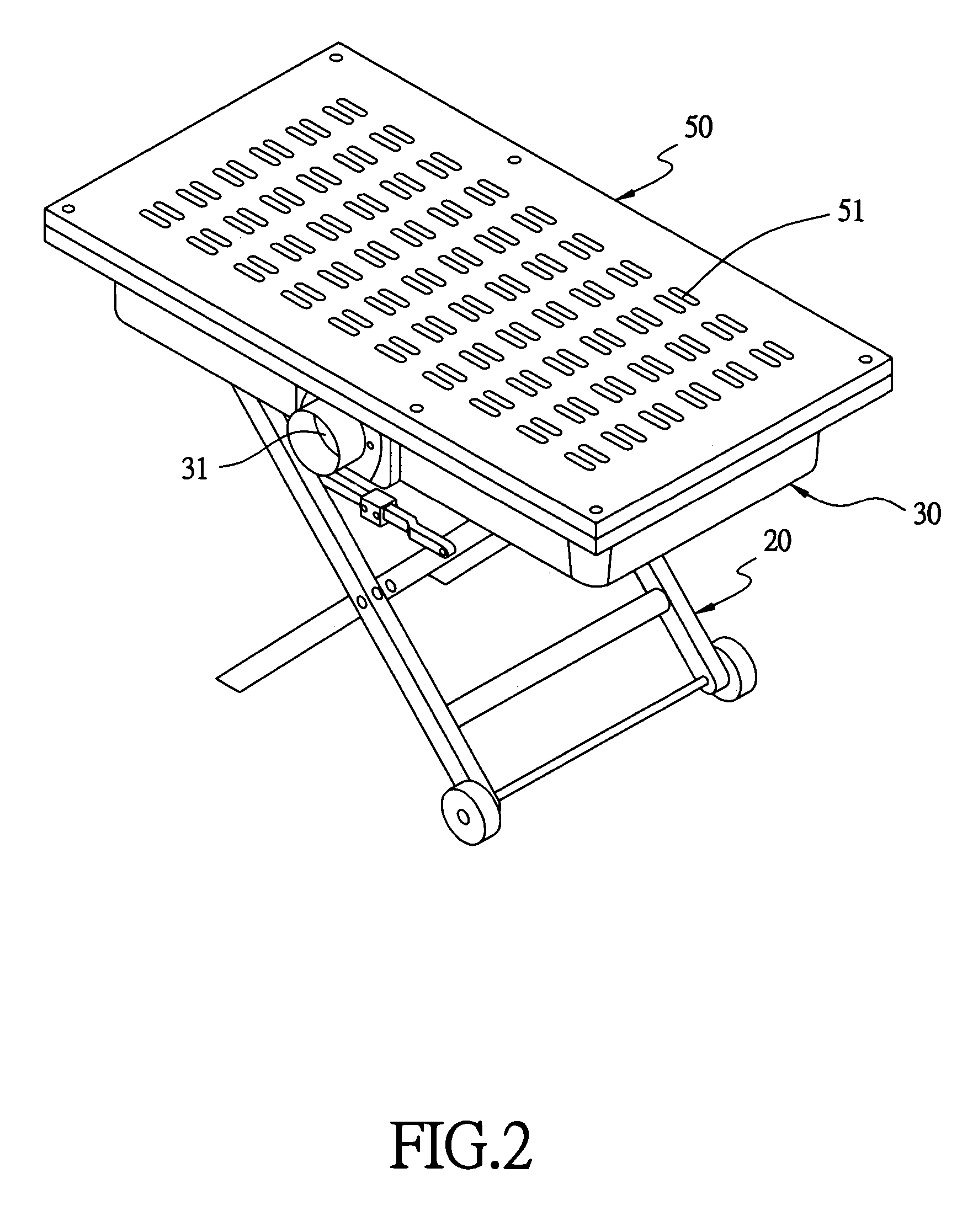

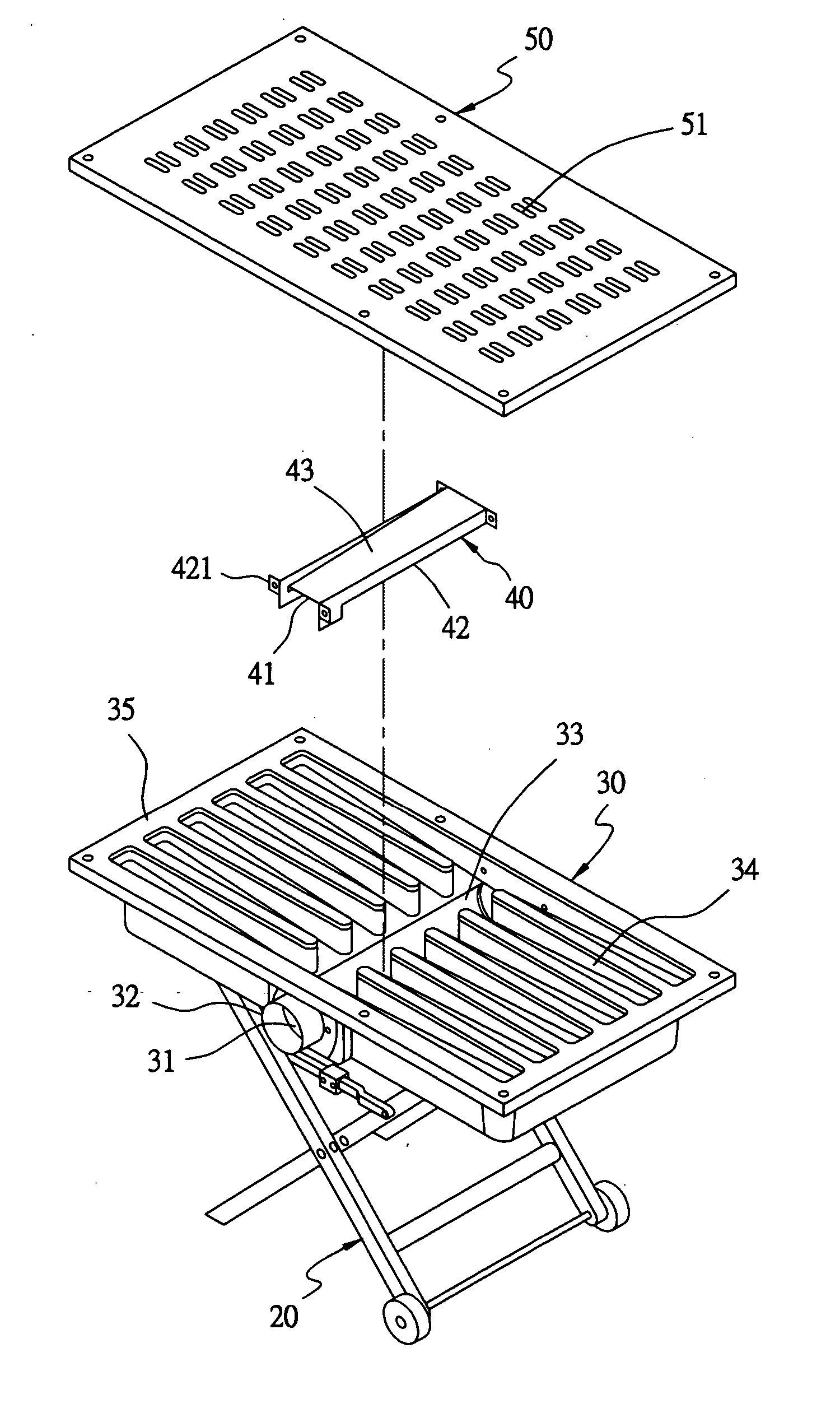

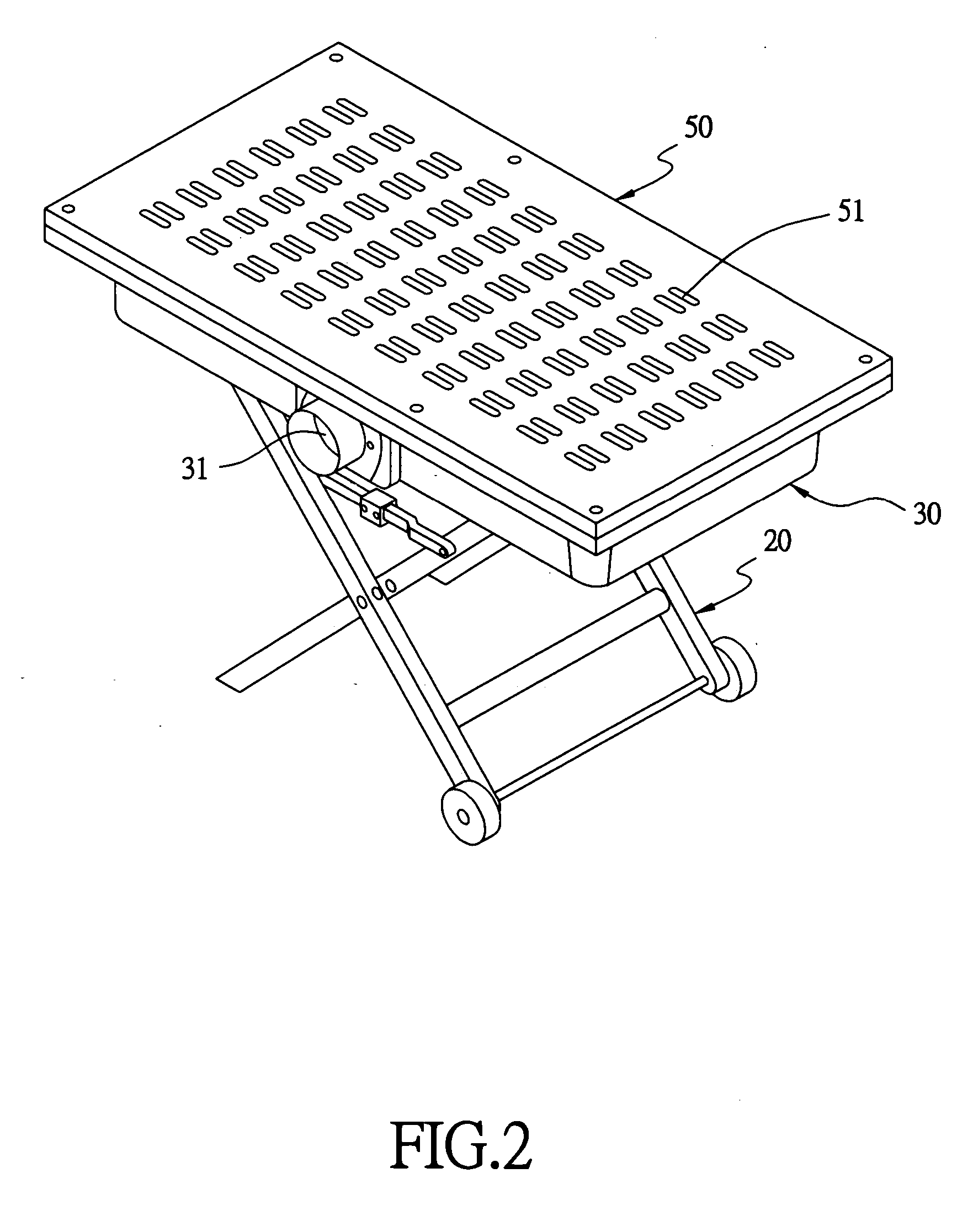

Tabletop wood-waste-collecting machine

InactiveUS7296321B2Improve dust resistanceMechanical cleaningPressure cleaningBraced frameSuction force

A tabletop wood-waste-collecting machine includes a support frame, a machine base, a guide shade, a work faceplate and a dust-collecting unit. The machine base has its opposite upper side bored with plural transverse assistant guide grooves and its central portion bored with a longitudinal lower main guide groove communicating with a connecting opening in the front center. The guide shade covered on the lower main guide groove is formed with an upper guide groove. The work faceplate fixed on the topside of the machine base is bored with numerous wind-sucking vents. When the dust-collecting unit is started to operate, every wind-sucking vent of the work faceplate and the wind-sucking space in the machine base will receive a balanced suction force to let the wood waste produced completely sucked out.

Owner:SAN FORD MACHINERY

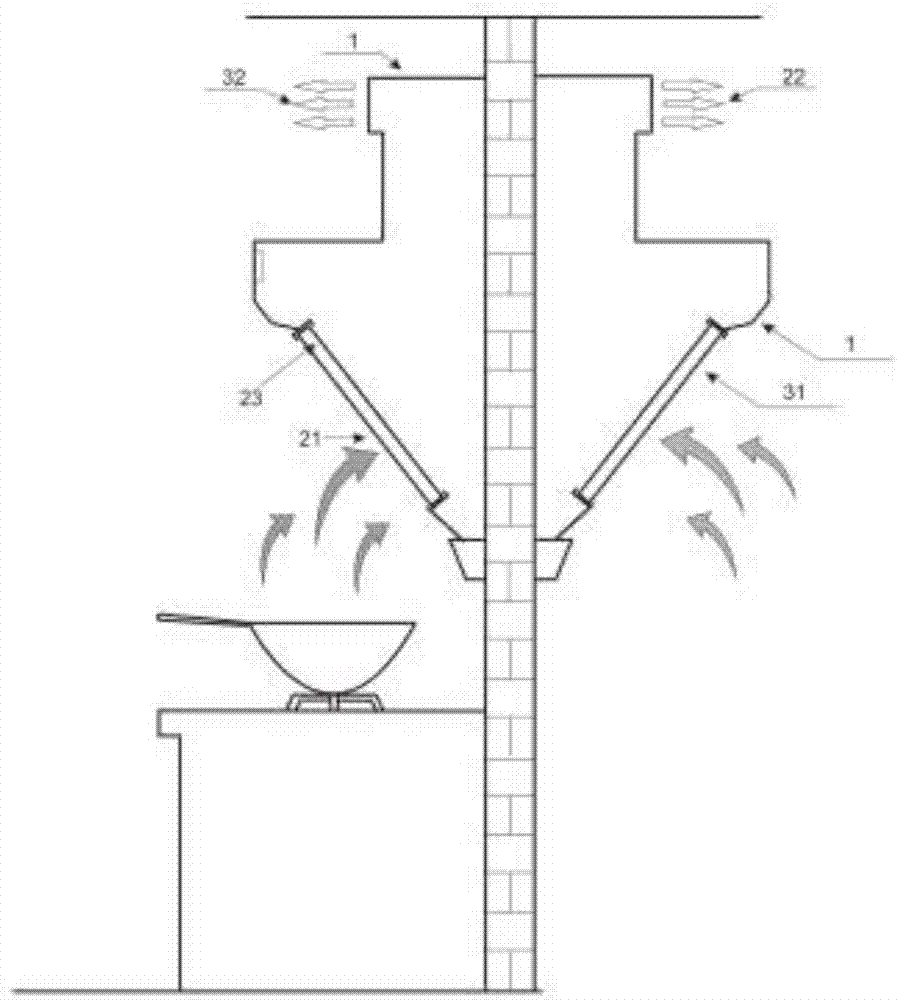

Top smoke sucking and side smoke sucking combined range hood

InactiveCN108151108ASolve the problem of bumping headsReduce spillageDomestic stoves or rangesLighting and heating apparatusEngineeringWind power

The invention discloses a space-saving top smoke sucking and side smoke sucking combined range hood with a double-sided smoke sucking function and a good ventilating effect. The range hood comprises ahood body, the hood body comprises a top wind suction part and a side wind suction part formed by one end, close to a wall body, of the top wind suction part by extending downward; an inner air passage of the top wind suction part and an inner air passage of the side wind suction part are independent from each other; simultaneously all draught fan units are disposed at the upper portion of the hood body. The invention provides the top wind sucking and side wind sucking combined range hood which integrates a top suction type and a side suction type into a range hood, and two exhaust fans are placed on the upper portion of the hood body for air draft to ensure that wind power for the air draft is large enough to satisfy the goal of fully absorbing oil and smokes.

Owner:长春光速科技有限公司

Tabletop wood-waste-collecting machine

InactiveUS20060096054A1Good dust removalImprove dust resistanceMechanical cleaningPressure cleaningSuction forceWaste collection

A tabletop wood-waste-collecting machine includes a support frame, a machine base, a guide shade, a work faceplate and a dust-collecting unit. The machine base has its opposite upper side bored with plural transverse assistant guide grooves and its central portion bored with a longitudinal lower main guide groove communicating with a connecting opening in the front center. The guide shade covered on the lower main guide groove is formed with an upper guide groove. The work faceplate fixed on the topside of the machine base is bored with numerous wind-sucking vents. When the dust-collecting unit is started to operate, every wind-sucking vent of the work faceplate and the wind-sucking space in the machine base will receive a balanced suction force to let the wood waste produced completely sucked out.

Owner:SAN FORD MACHINERY

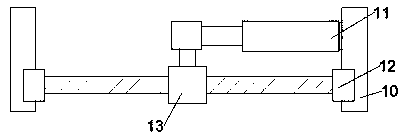

Steel pipe processing device accurate to position

InactiveCN109571080ARealize collection and recyclingPrecise drillingPositioning apparatusMaintainance and safety accessoriesEngineeringSteel tube

The invention discloses a steel pipe processing device accurate to position, belongs to the technical field of processing machineries, and solves the problem that a conventional device cannot recoverdust produced in the drilling process, and serious pollution to environment, of the dust is generated. The steel pipe processing device is characterized by comprising a drilling mechanism, a base, a wind sucking cavity and a dust collecting net plate, wherein the wind sucking cavity is formed in the base; a limiting mechanism is arranged above the wind sucking cavity; the wind sucking cavity is fixedly connected with the supporting platform through bolts; and the dust collecting net plate is arranged at the top of the wind sucking cavity. Through the adoption of the steel pipe processing device disclosed by the invention, accurate drilling can be performed on steel pipes, the stability of the steel pipes during drilling is guaranteed, and dust produced in the drilling process can be adsorbed and recovered.

Owner:青岛瑞吉德精密机械有限公司

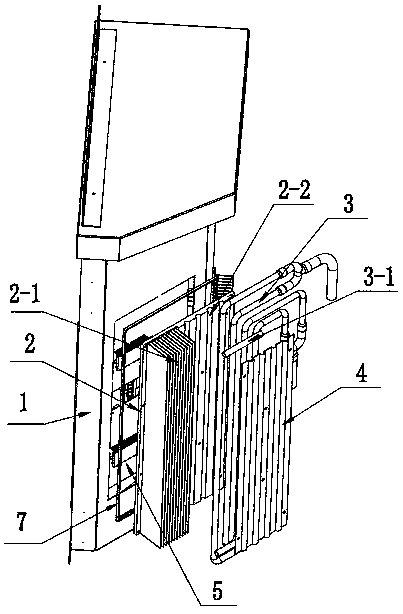

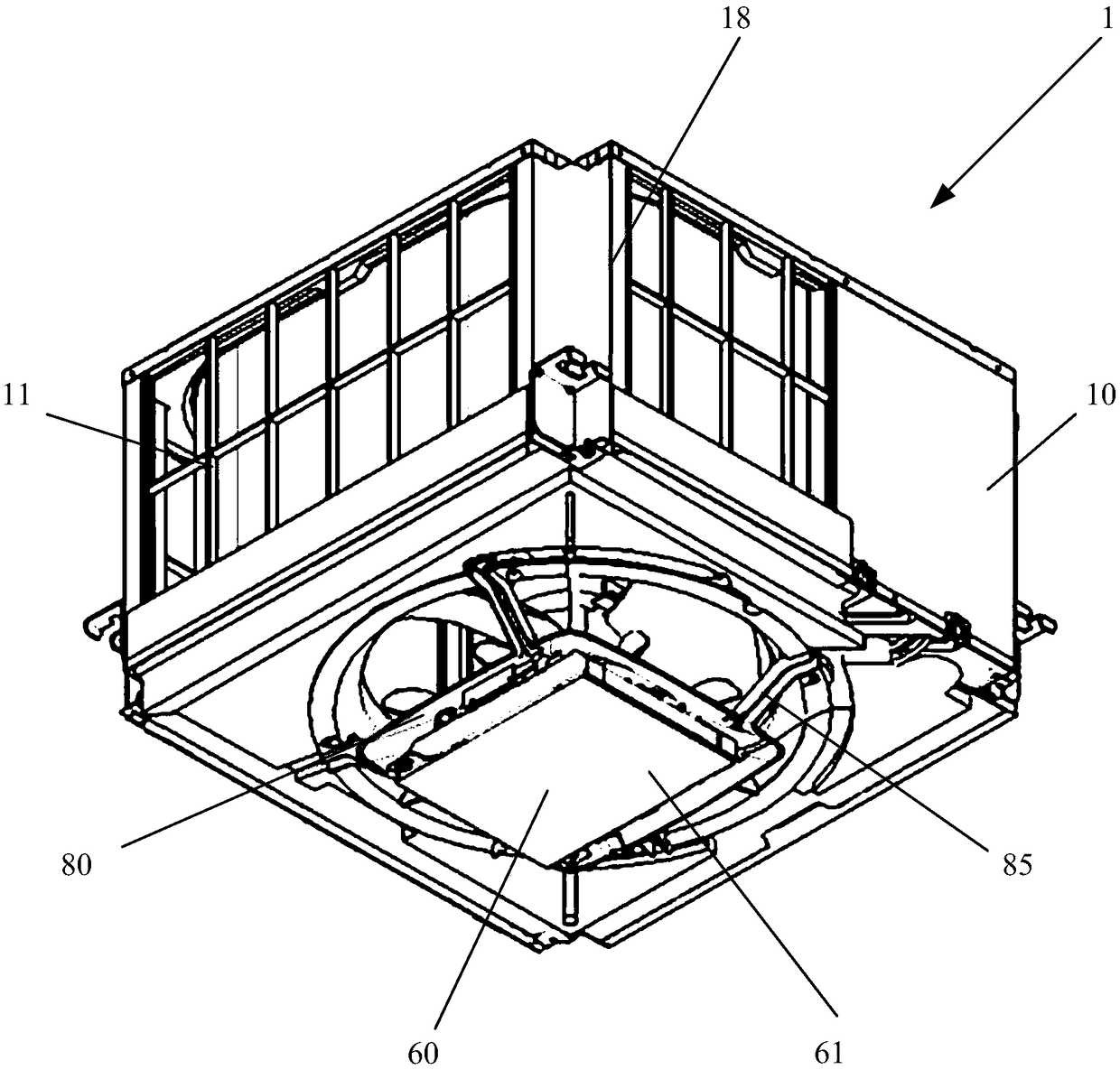

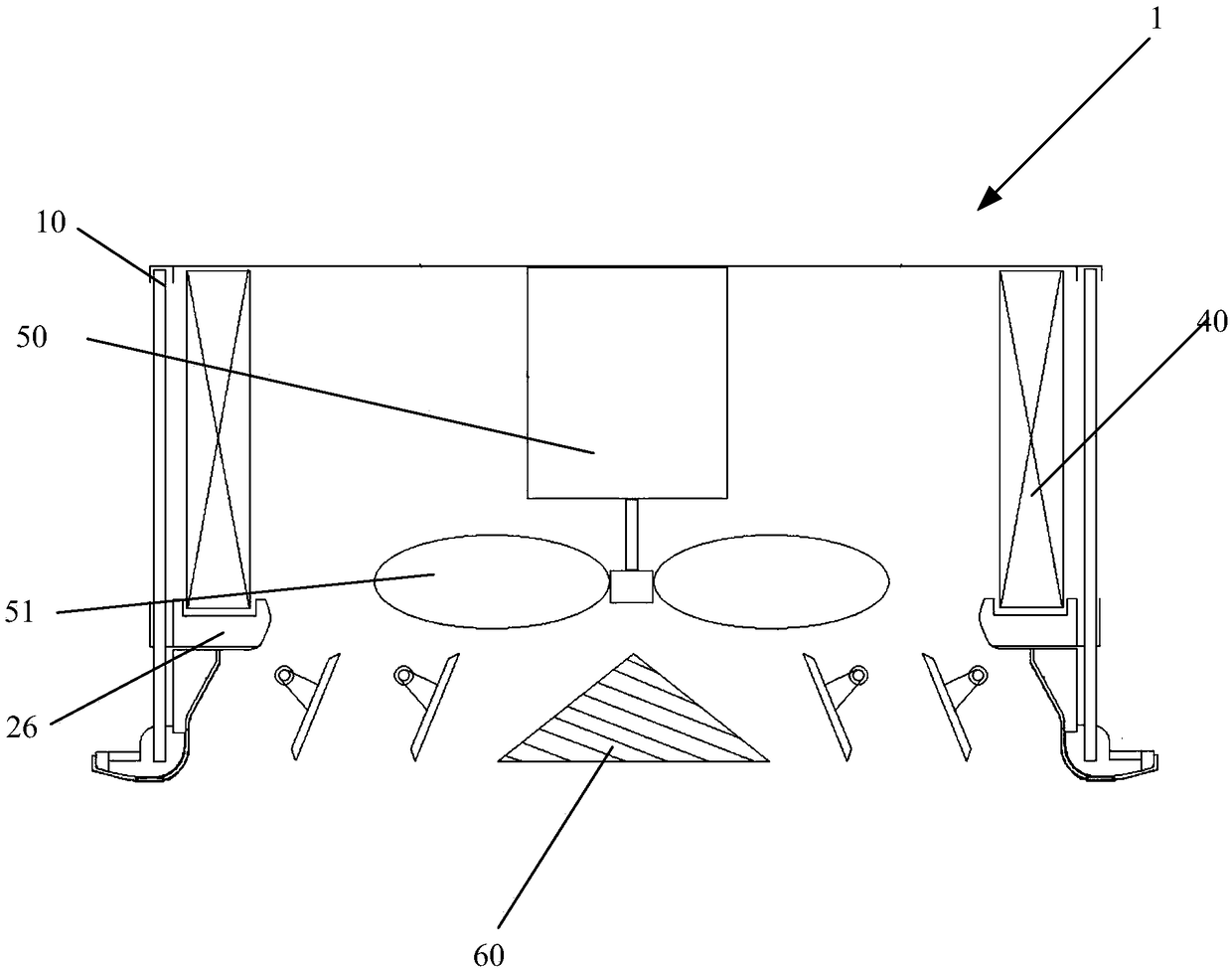

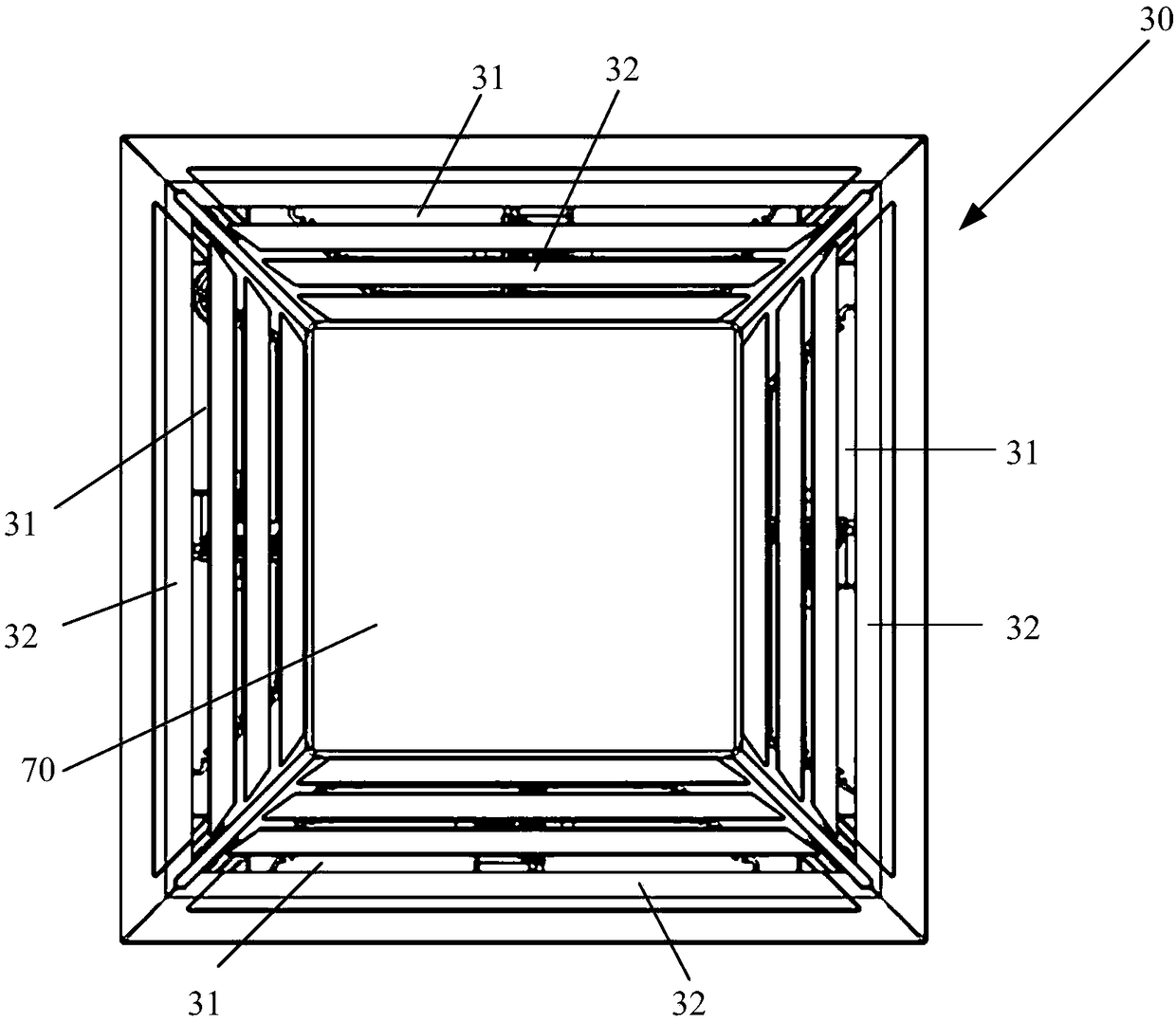

Air-conditioner indoor unit

ActiveCN109425032ASmall sizeReduce the overall heightMechanical apparatusLighting and heating apparatusEngineeringHeat exchanger

The invention discloses an air-conditioner indoor unit which comprises a body and a wind output panel. The body is provided with a top side, a bottom side and a side portion for connecting the top side with the bottom side. The side portion of the body is provided with a wind sucking face. The wind output panel at least partially covers the bottom side of the body. The wind output panel is provided with a wind outlet. The air-conditioner indoor unit further comprises an axial flow fan, a heat exchanger and an electric part, wherein the axial flow fan is arranged in the body, the axis directionof the axial flow fan is perpendicular to the top side, when the axial flow fan rotates, the wind input side and the wind output side are formed, the wind output side is located below the axial flowfan, the wind output side faces the wind output panel, the heat exchanger is located on the inner side of the wind sucking face and is arranged around the axial flow fan, and the electric part is arranged below the axial flow fan. By the adoption of the air-conditioner indoor unit, the height of the whole unit can be reduced, and the electric part can be installed and maintained conveniently.

Owner:DAIKIN IND LTD

Storage box automatic assembly system

ActiveCN106736404AHigh degree of automationReduce laborMetal working apparatusLabelling machinesPiston rodAutomation

The invention provides a storage box automatic assembly system. The system comprises a lifting mechanical arm provided with a labeling sucking head; the labeling sucking head includes a connecting plate fixedly connected with the lifting mechanical arm; a wind sucking hole is formed in the side wall, near a first bracket, of the connecting plate; a labeling pad fixedly connected with the connecting plate is arranged around the wind sucking hole; a label conveying roller set is positioned on one side of a conveying belt, and includes a wedge block opposite to the labeling sucking head; a rubber plate tightly bonded with the wedge block is arranged on a feed side of the wedge block; a handle pressing set is positioned above the conveying belt, and includes a pressing driving cylinder; and a pressing sucking head is mounted at the end part of a piston rod of the pressing driving cylinder. The storage box automatic assembly system is high in automation degree, and can once finish the work of label bonding and handle installation for two storage box bodies. The system needs no manual operation in the whole process, improves the working efficiency when reducing the labor capacity of workers, and guarantees the conveying safety of the storage box bodies.

Owner:禧天龙科技发展有限公司

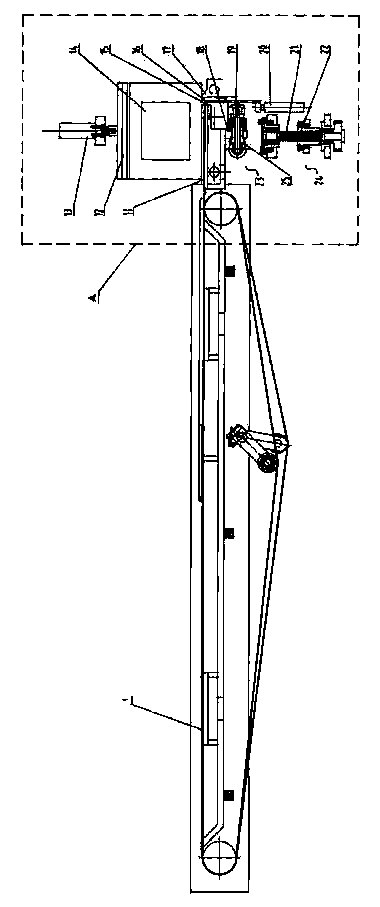

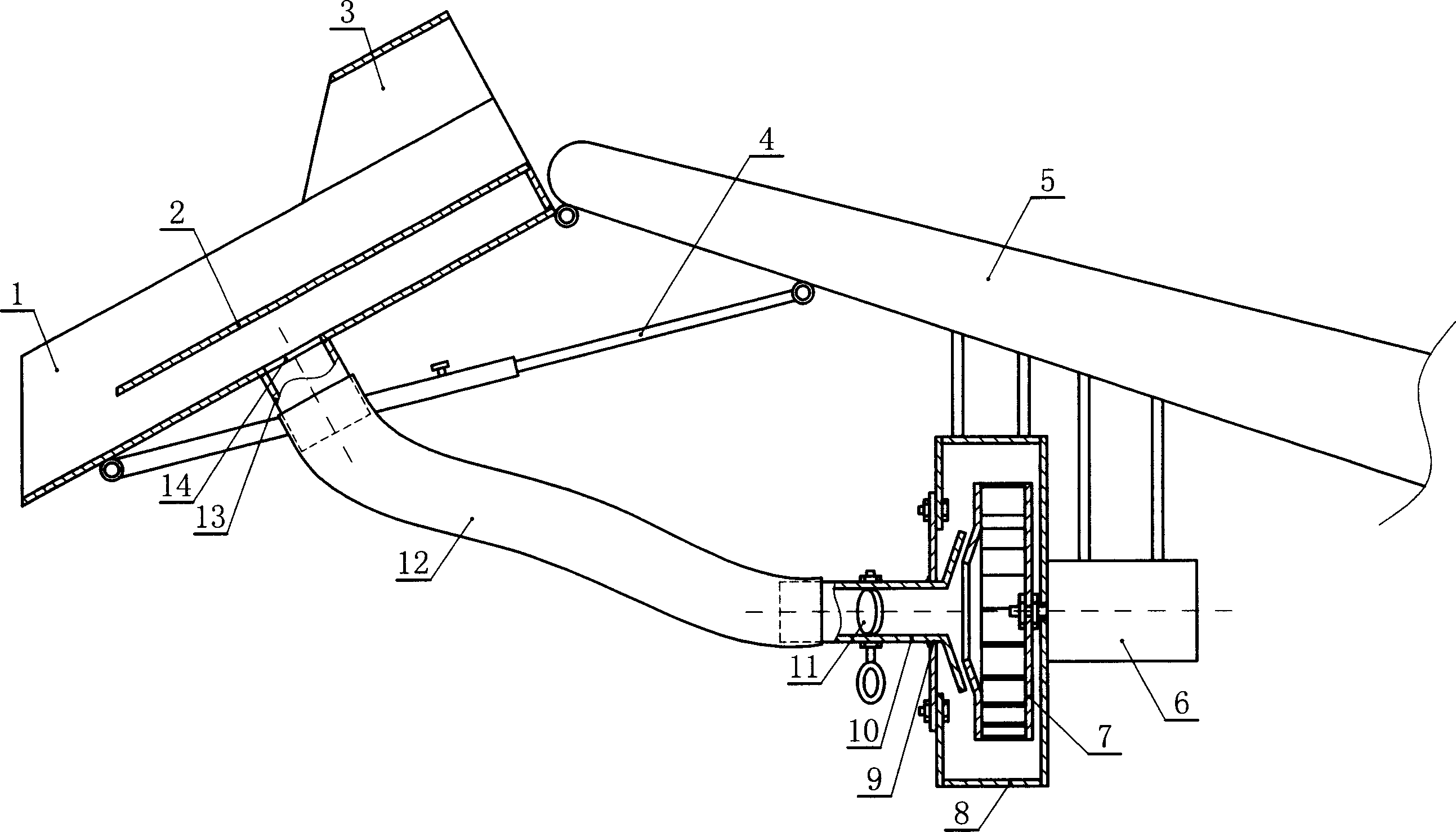

Grain transporter

InactiveCN1884019AReduce pollutionGood effect in removing impuritiesGas current separationConveyor partsGrain storageEconomic benefits

The invention provides a grain conveyor capable of reducing environmental pollution and has good effect on removing impurity. The machine comprise belt conveyer, front end of which is fixedly mounted with wind-sucking bucket in which grain conveying slider is fixedly connected. Grain conveying slider is positioned at upper of lower wall of wind-sucking bucket. Wind-sucking bucket is mounted with wind-sucking hole at lower wall. Wind-sucking hole is at lower part of grain conveying slider. Wind-sucking hole is connected with wind-sucking tube, the end of which is connected with wind-sucking motor. The inventive product remove not only the light impurity such as bran, straw in grain, but the crushed grain granule. The inventive grain conveyor can upgrade grains, increase economic benefit and render grain good air-perviousness, in favor of grain storage.

Owner:韩建成

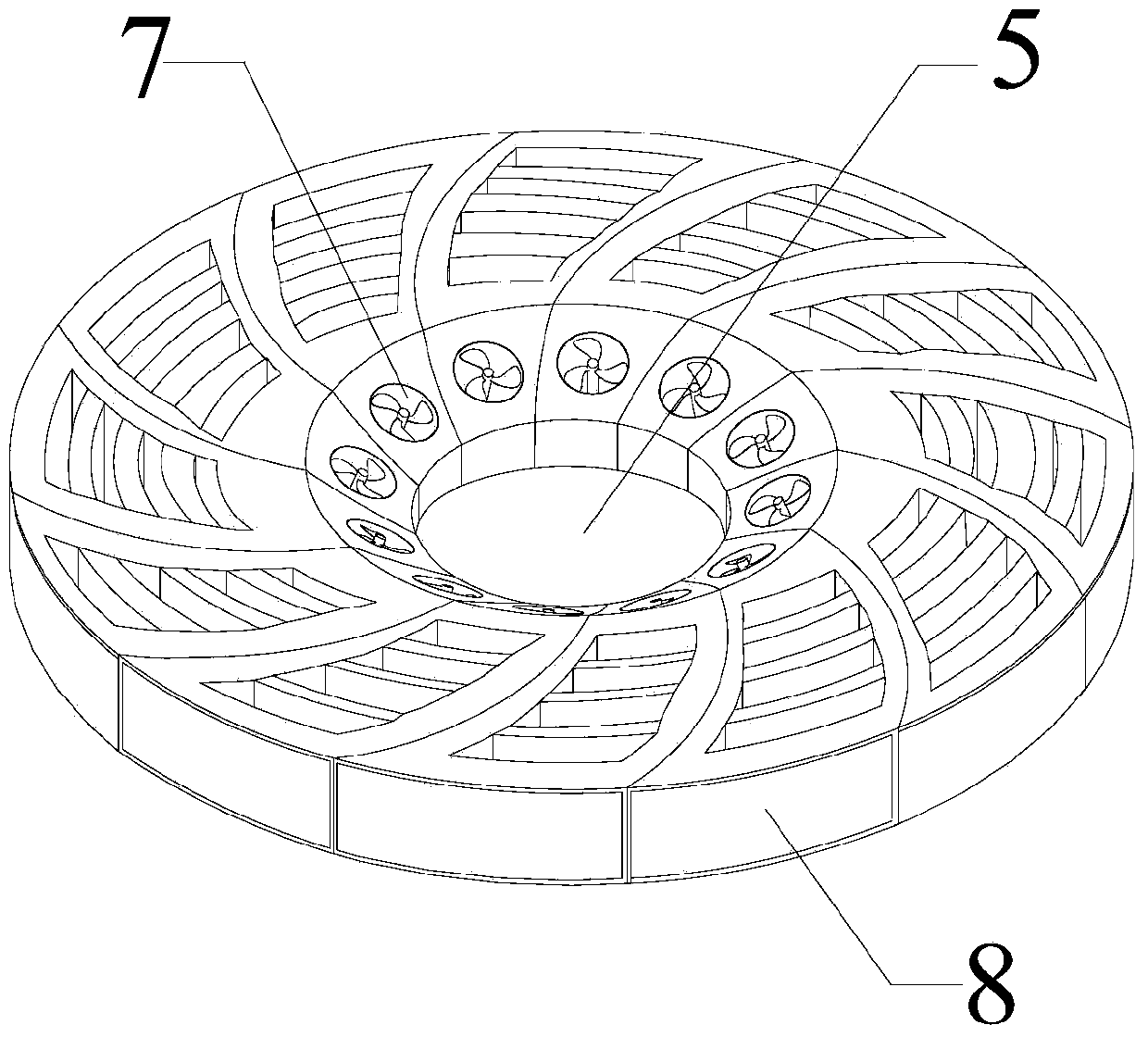

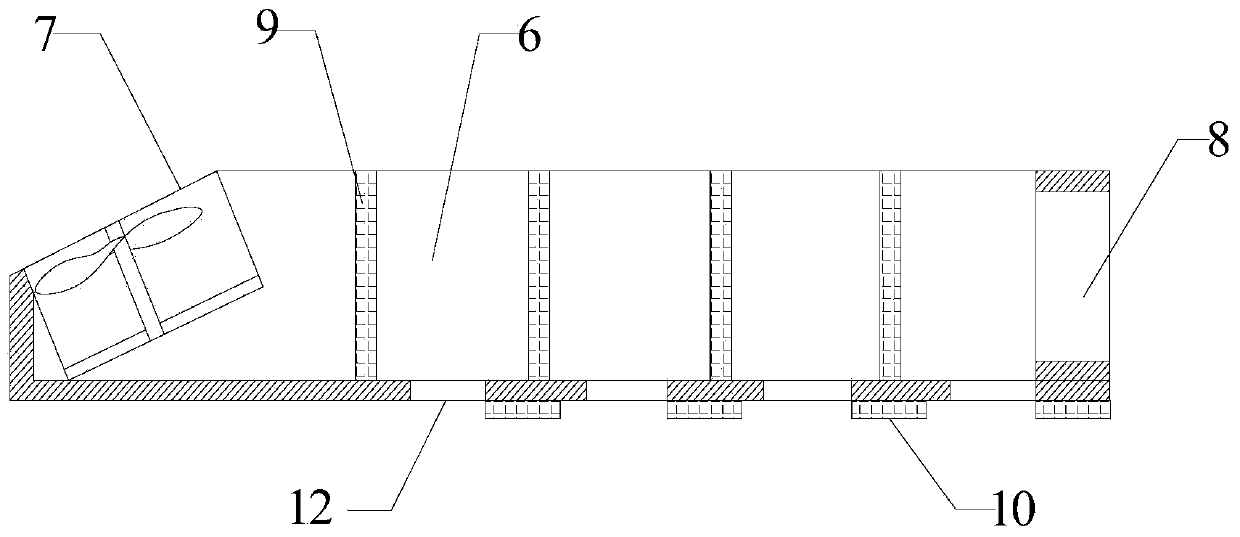

Method and device for weakening tornado

InactiveCN104041360AReduce wind speedReduce destructive powerWeather influencing devicesEngineeringWind speed

The invention relates to the field of disaster-prevention equipment, in particular to a method and device for weakening a tornado. The method for weakening the tornado comprises the following steps that a wind sucking device is arranged in the eye of the tornado, the tornado is balanced with wind exhausted by the wind sucking device, and therefore the tornado is weakened. According to the method and device for weakening the tornado, wind in the tornado eye is exhausted through the wind sucking device to be balanced with the tornado, and therefore the wind speed of the tornado can be reduced and the damage caused by the tornado is reduced to the minimum.

Owner:吕国君

Smashing device used for manufacturing renewable sponge

InactiveCN108748790AEasy to cleanQuality improvementPlastic recyclingDrying gas arrangementsWork siteWind-sucking

The invention discloses a smashing device used for manufacturing renewable sponge. The smashing device comprises a bottom plate. A cylinder body is arranged on the top face of the bottom plate and obliquely arranged downwards. Multiple supporting column bodies are fixed between the cylinder body and the bottom plate. A motor A is fixed to the side face of the cylinder body. The drive end of the motor A extends into the cylinder body. The drive end of the motor A is fixedly connected with a rotating shaft. Spiral blades are fixed to the side face of the rotating shaft. A funnel is fixed to thetop face of the cylinder body in a penetrating manner. The funnel is provided with a vibrating device. A square through hole is formed in the bottom face of the cylinder body. A filter screen is arranged in the square through hole. A cover body fixed to the bottom face of the cylinder body covers the exterior of the square through hole. A wind sucking opening is arranged in the bottom face of thecover body. A dust collector communicating with the wind sucking opening is fixed to the bottom face of the cover body. A through hole is formed in the other side of the cylinder body. According to the smashing device, the cylinder body arranged obliquely and the dust collector are designed, dust in smashed particles of the sponge can be effectively cleared, cleaning liquid is used for washing andremoving bacteria in the box body, the environment of the work site is protected, the quality of the smashed particles of the sponge is improved, and the smashing device is high in efficiency, practical and reliable.

Owner:陈卫

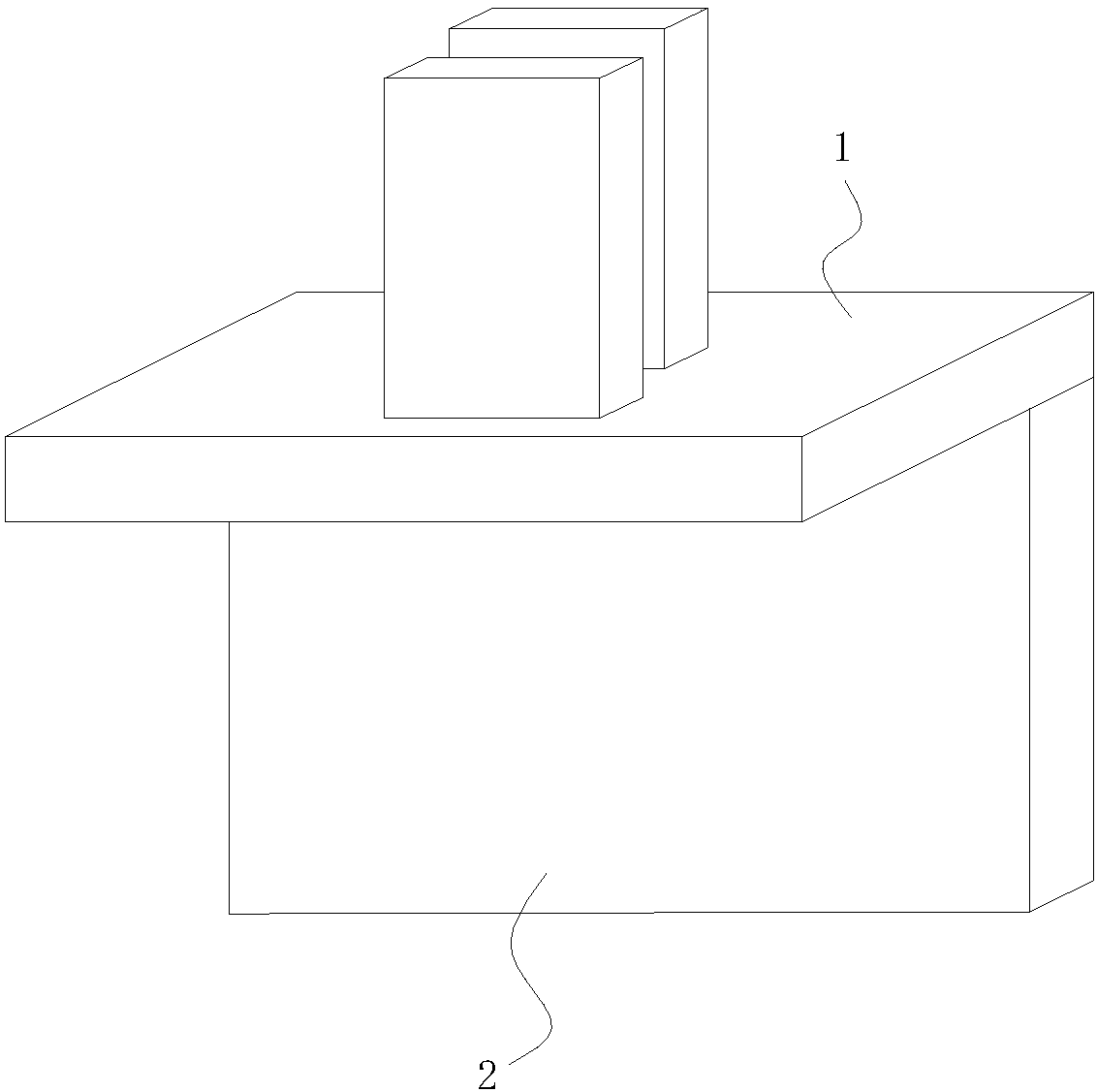

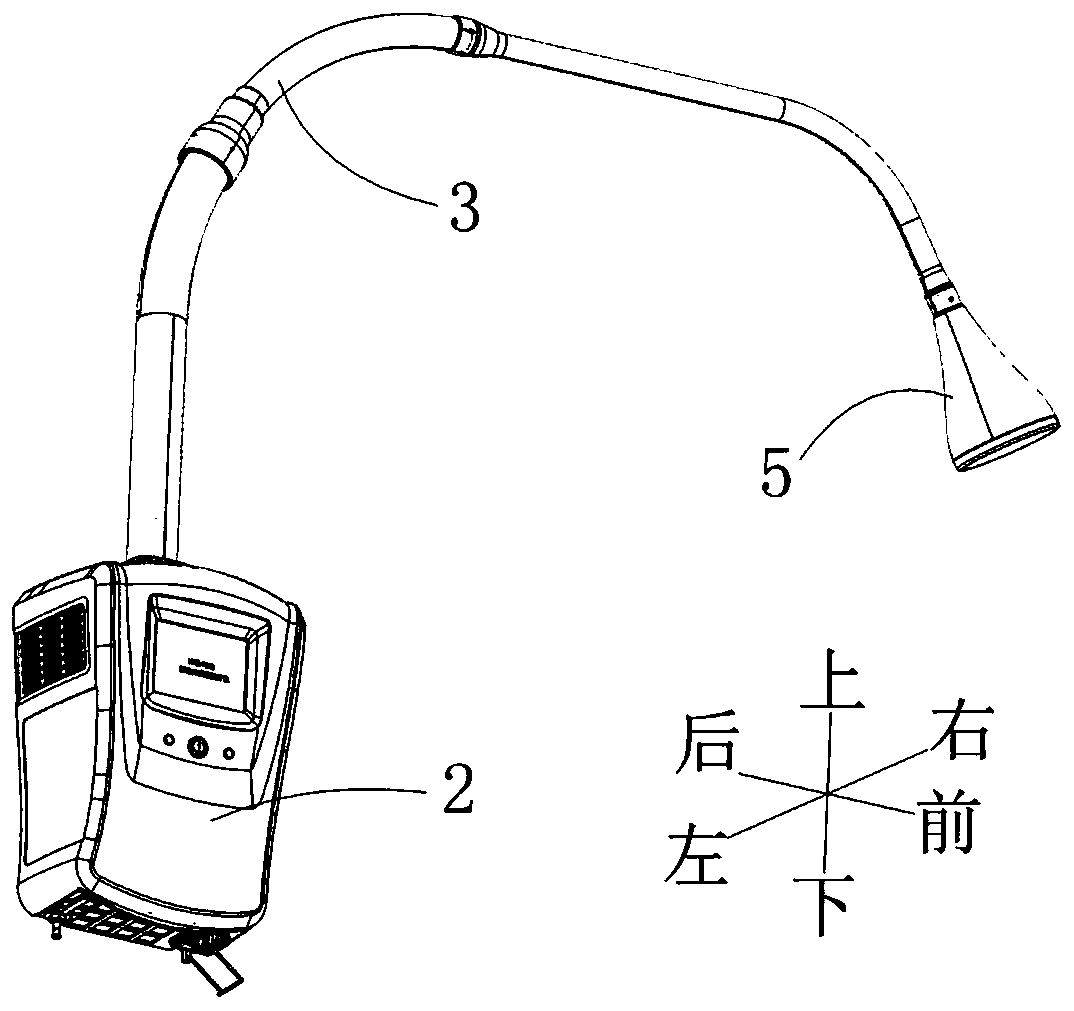

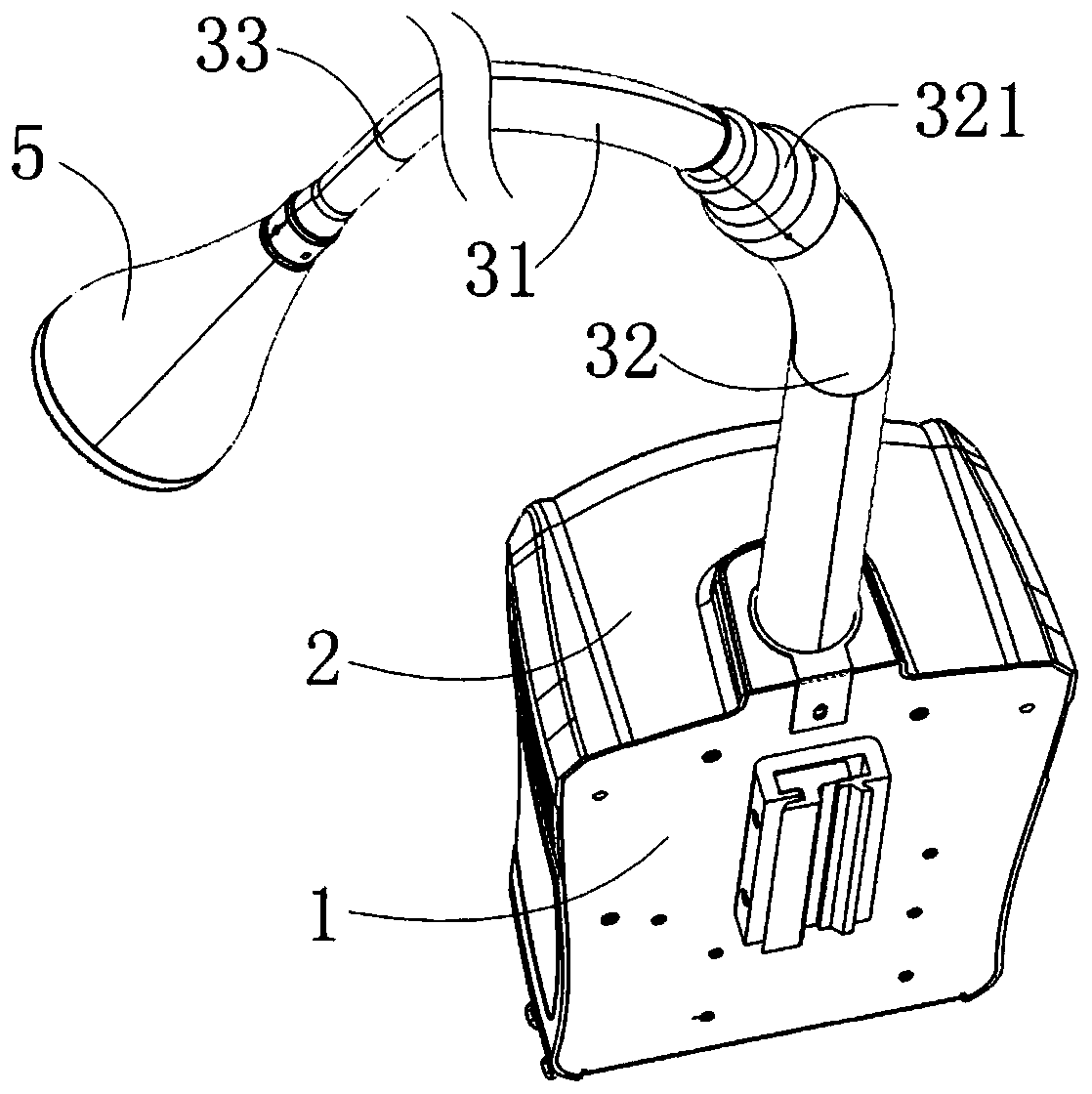

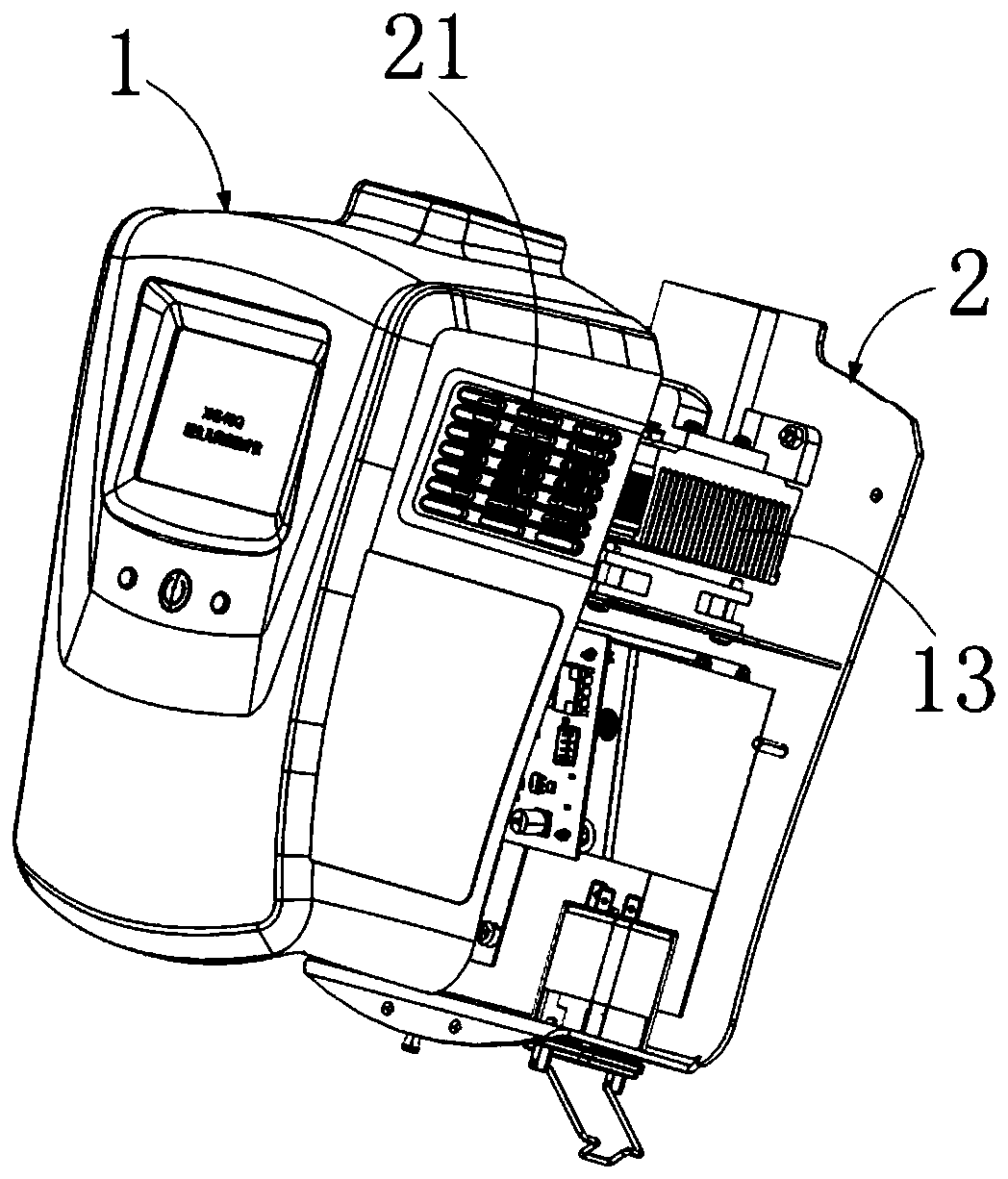

Newborn jaundice treatment instrument

PendingCN110639129AReasonable layoutAvoid repeated mediationDispersed particle filtrationFibre light guidesLight guideGeneral surgery

The invention relates to the technical field of jaundice treatment equipment, in particular to a newborn jaundice treatment instrument. The newborn jaundice treatment instrument comprises a base (1),a housing (2) which is snap fitted to the base (1) and a light guiding assembly which is connected with the base (1), wherein a light source assembly (12), a cooling module assembly (13), a fan(14), awind channel separating plate (113) and a power source module are sequentially arranged on the inner side of the base (1) from top to bottom; and a ventilation hole (1131) is formed in the wind channel separating plate (113), and is formed in a wind sucking opening of the fan(14). According to the newborn jaundice treatment instrument disclosed by the invention, the elements in the machine body of the jaundice treatment equipment are reasonable in layout; and the wind channel separating plate is arranged, so that the situation that air repeatedly circulates in the machine body is avoided, andthe heat dissipation effect is better.

Owner:NINGBO DAVID MEDICAL DEVICE CO LTD

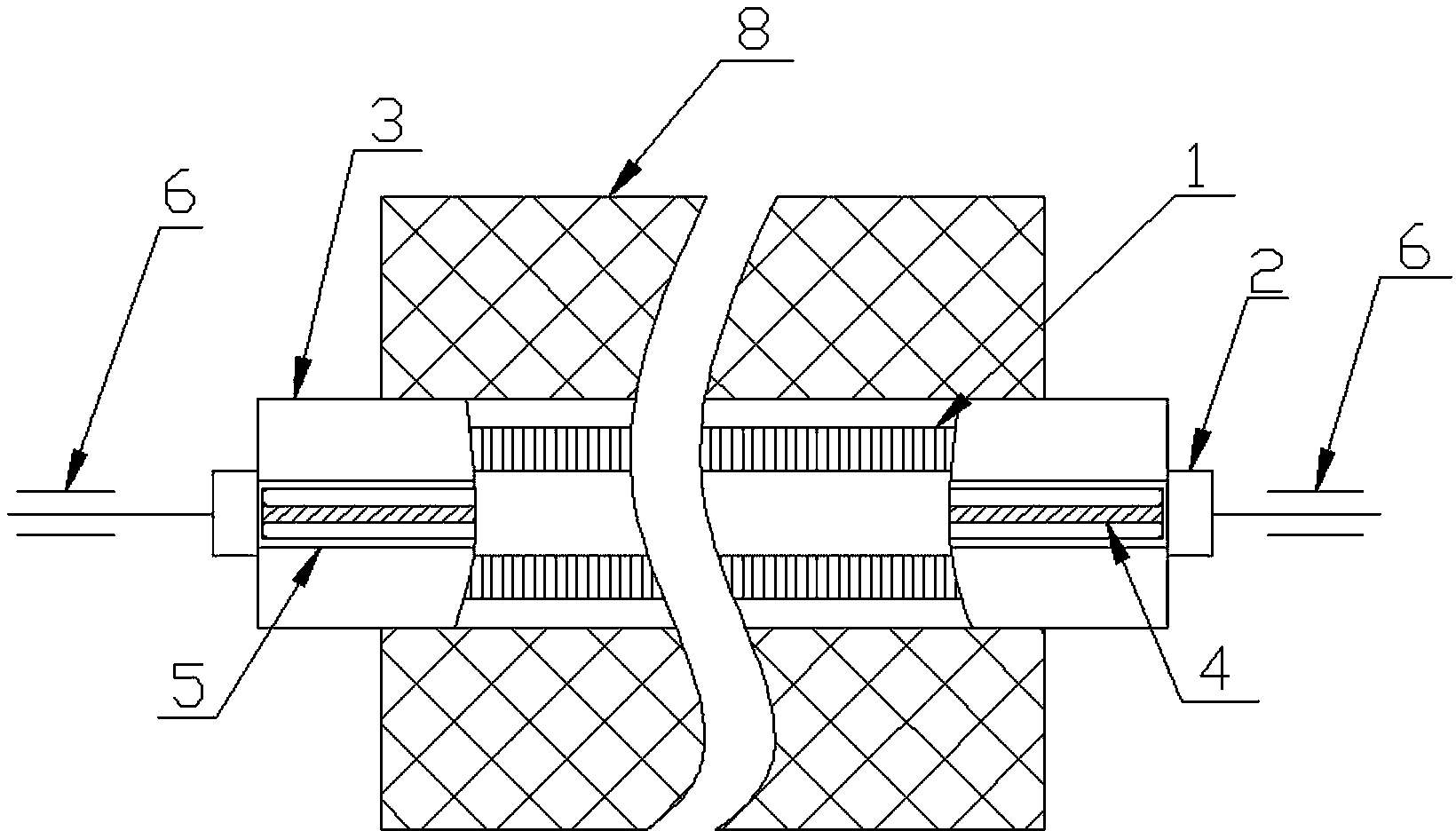

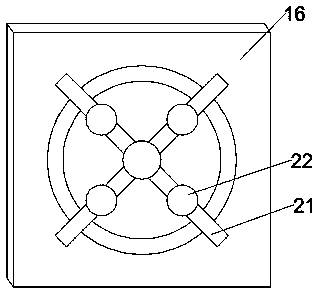

Double seam type air gathering flow guiding apparatus special for gathering sirospun

InactiveCN105239226AReduce negative inspiratory pressureAchieve energy saving effectDrafting machinesYarnFiber

The invention provides a double seam type gas gathering flow guiding apparatus special for gathering sirospun, which is characterized in that the flow guiding apparatus provided herein comprises a flow guiding plate that can be set on an abnormal shape pipe of a sirospun gathering system, wherein the top portion of the the abnormal shape pipe is provided with a gathering groove; a channel for fiber strands penetrating through is formed between the flow guiding plate and the abnormal shape pipe; an inlet and an outlet of the channel for the fiber strands penetrating through are respectively located on front and back ends of the flow guiding plate; at least two wind sucking grooves used for controlling the gathering of the fiber strands are formed in the middle of the flow guiding plate; left and right ends of the flowing guiding plate are sealed structures; and the a wind inlet channel is not formed between the left and right ends of the flow guiding plate and the abnormal shape pipe. According to the invention, the gathering negative pressure is reduced at maximum; and the gathering negative pressure of the two grooves and the consistency of the gathered air flow of the two grooves are controlled effectively, thus ensuring the quality of yarns; and through reducing the gathering negative pressure, the energy consumption is reduced; and the requirement of saving energy is satisfied.

Owner:DONGHUA UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com