Patents

Literature

98 results about "Double seam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A double seam is a canning process for sealing a tin can by mechanically interlocking the can body and a can end (or lid). Originally, the can end was soldered or welded onto the can body after the can was filled. However, this introduced a variety of issues, such as foreign contaminants (including lead and other harmful heavy metals). The double seam was later developed as a cheaper and safer alternative and quickly replaced the welded seam.

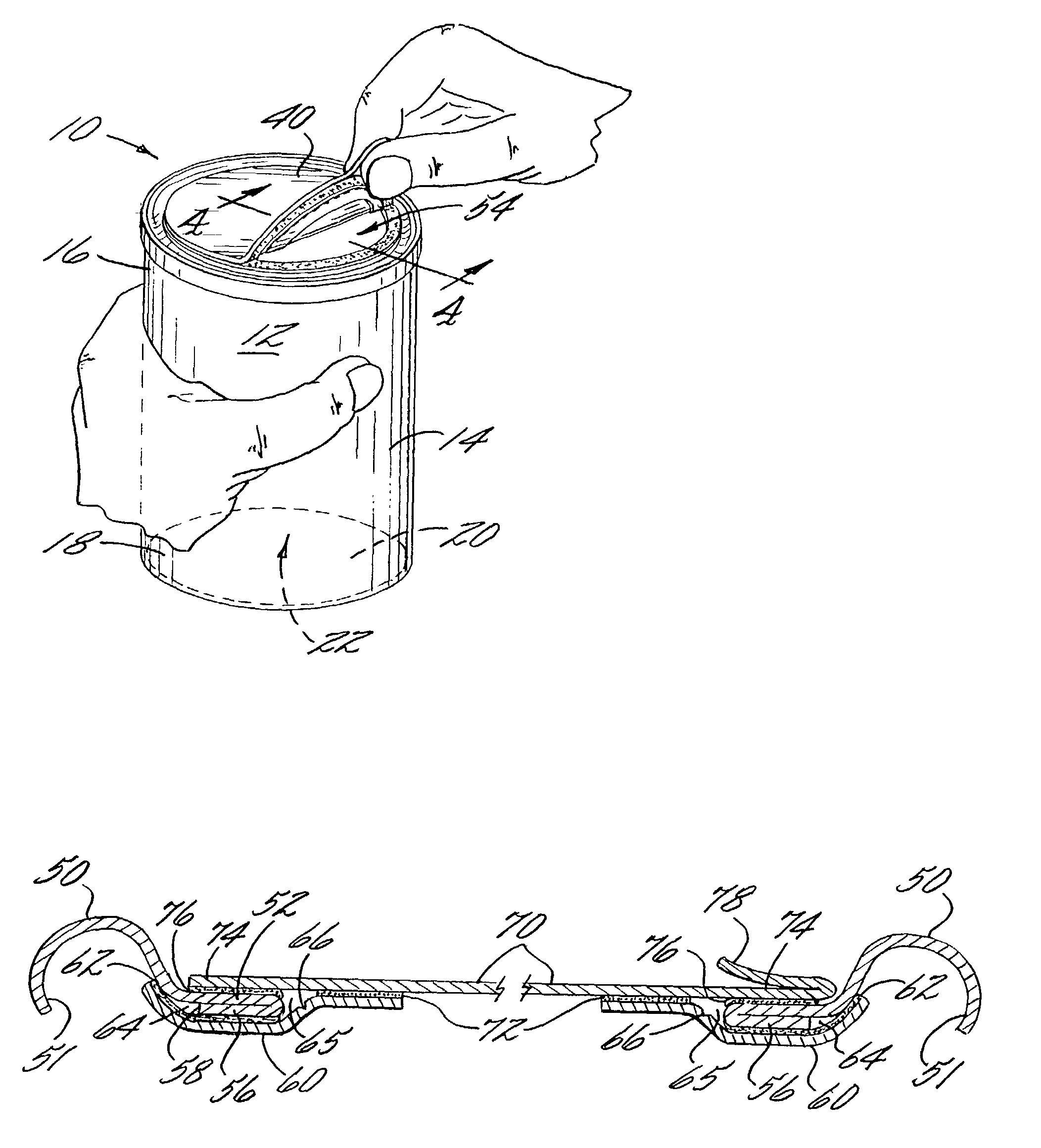

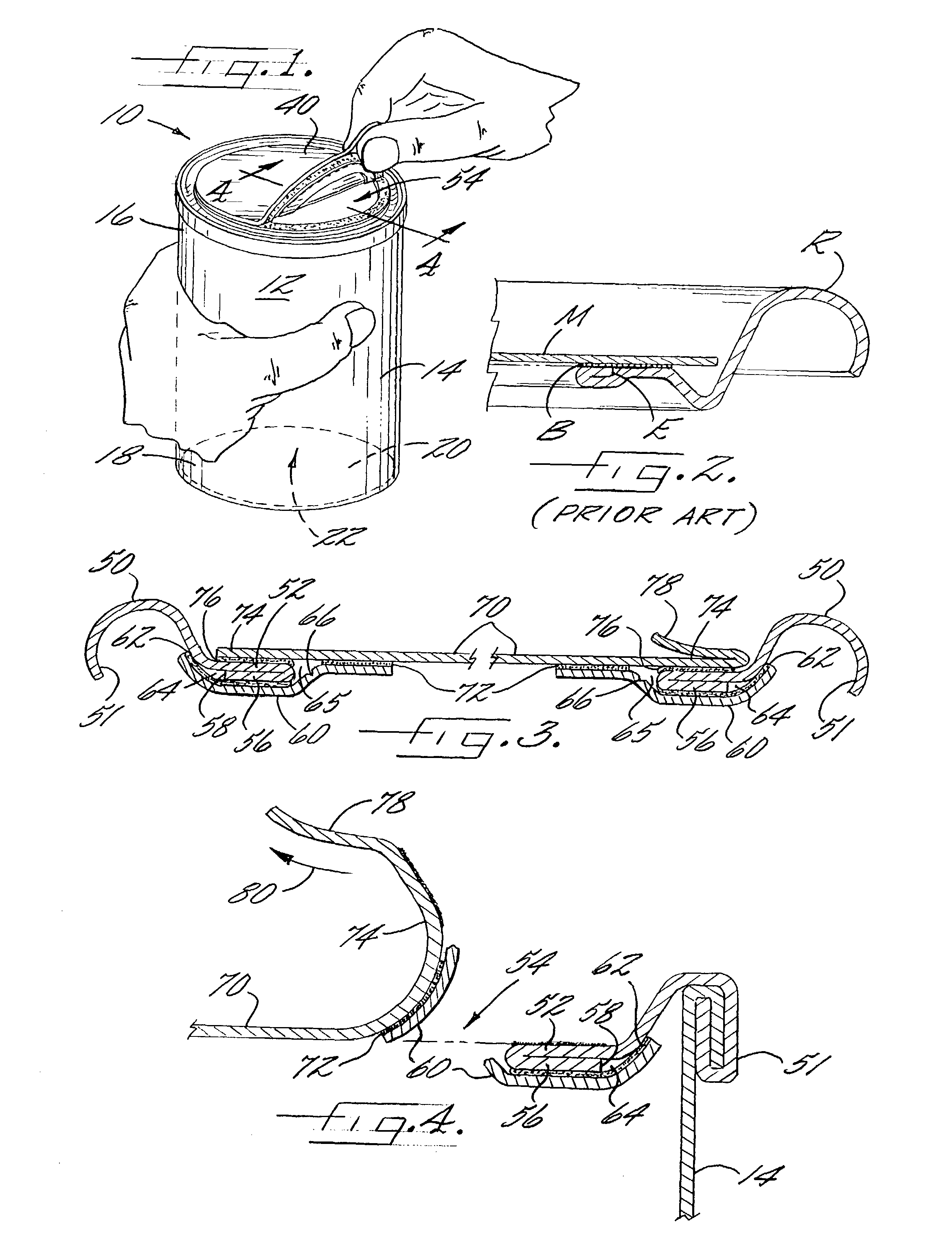

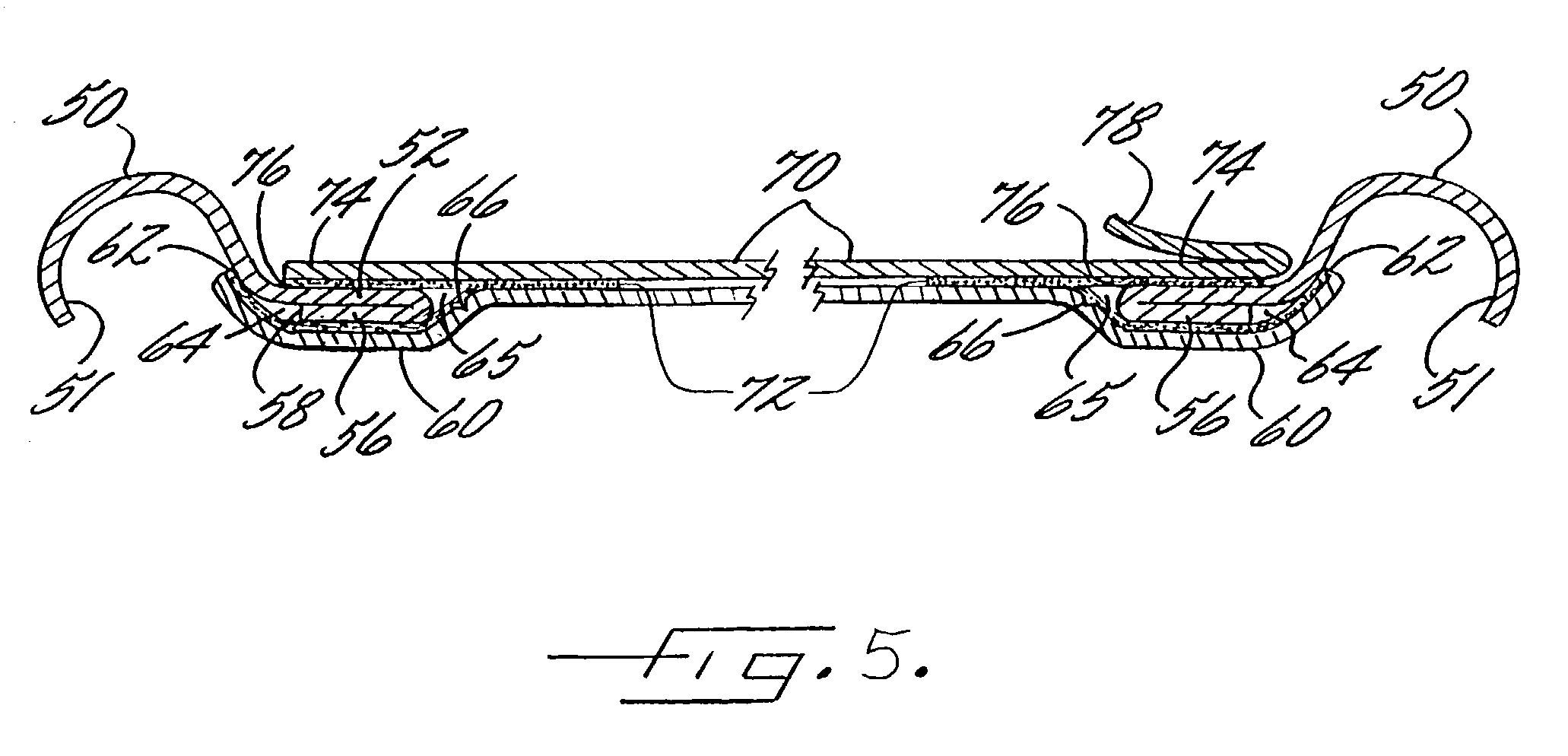

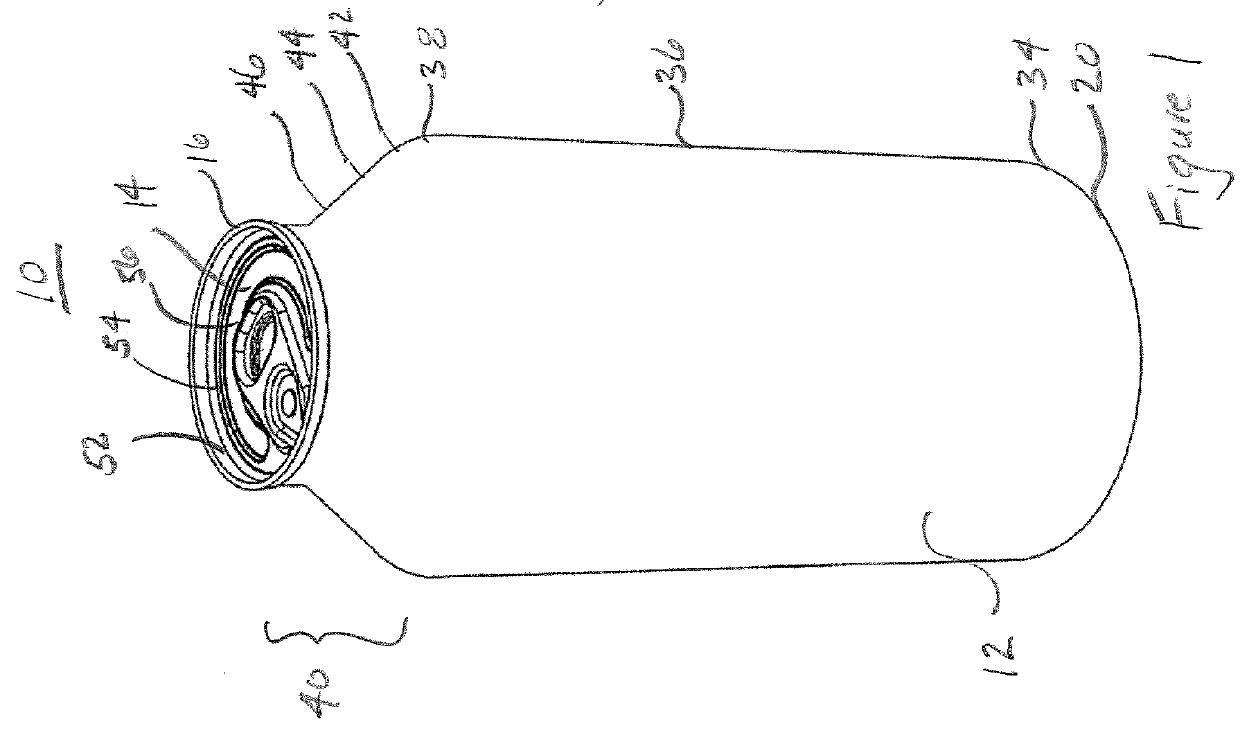

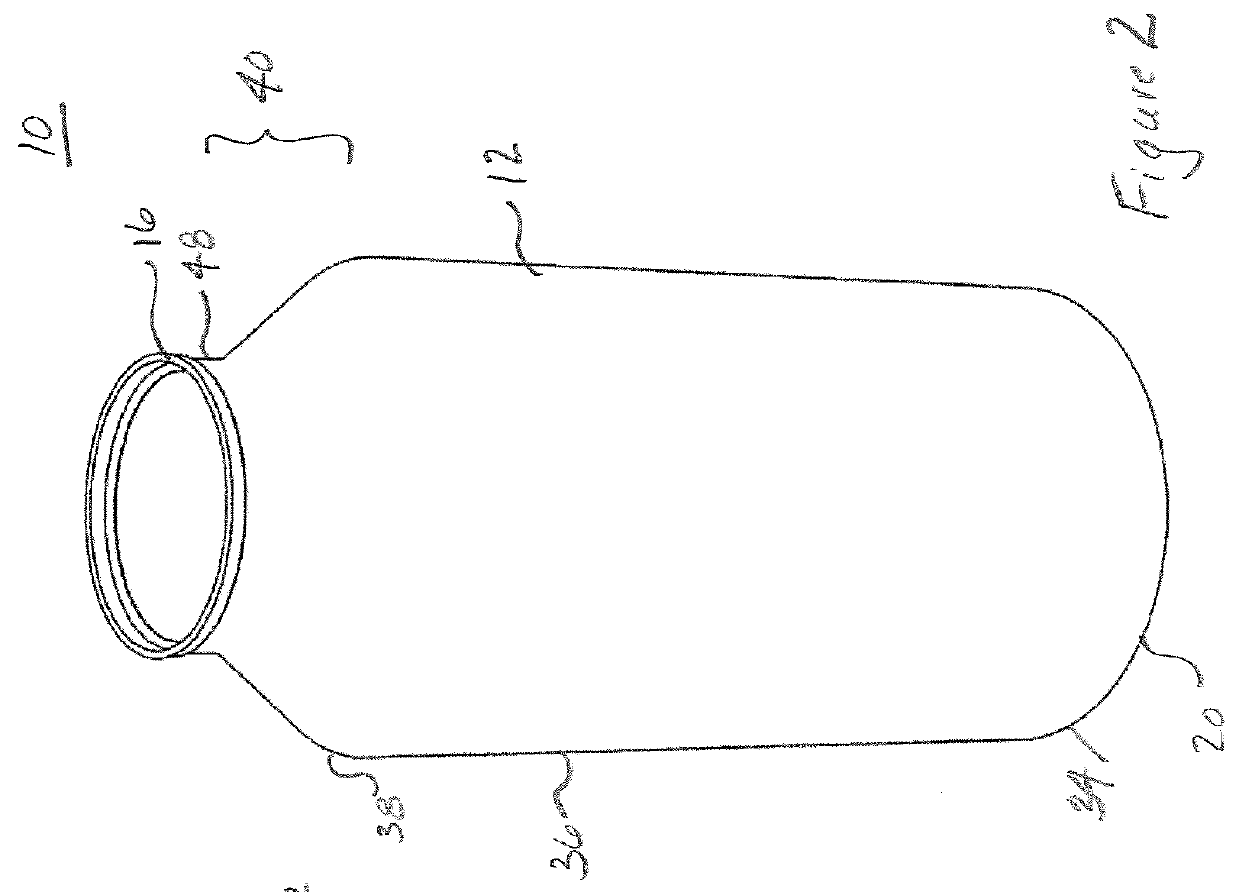

Easy-opening closure for retortable container

A retortable container and an easy-opening closure for hermetic sealing of an open end thereof. The closure includes a metal end ring adapted to be double seamed to an open end of the retortable container, an intermediate area extending radially inward and defining an opening to an interior of the container, and a folded area folded into the interior of the container. The folded area extends radially outward from the opening and substantially parallel to at least an adjacent portion of the intermediate area. A first membrane patch overlaps and is bonded to an under side of the intermediate area of the end ring such that the first membrane patch prevents contamination of contents of the container by the metal end. A second membrane patch covers the opening and is bonded to an upper side of the first membrane patch. The bonds have predetermined shear and tensile force strengths sufficient to withstand shear and tensile forces created during retort processing of the container, while allowing easy-opening of the container by peeling the second membrane patch.

Owner:SONOCO DEV INC

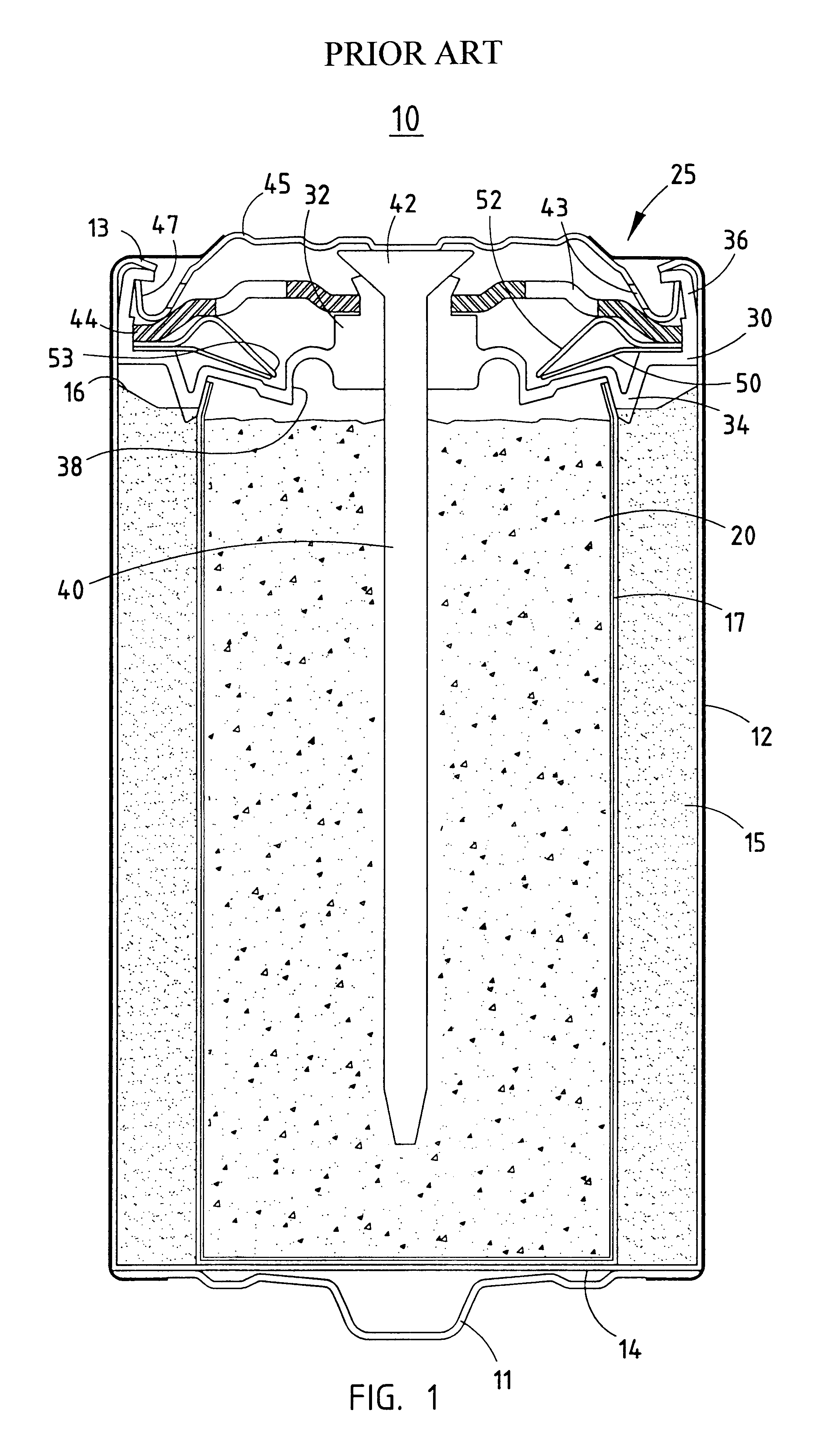

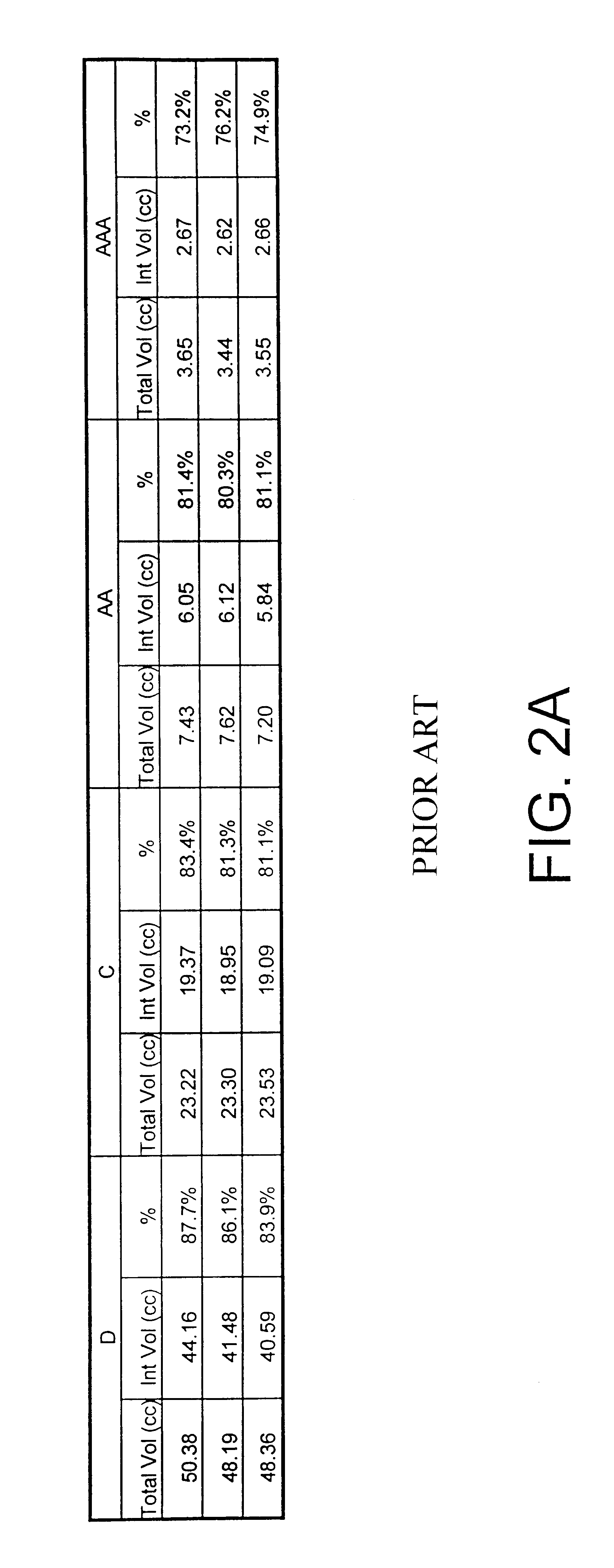

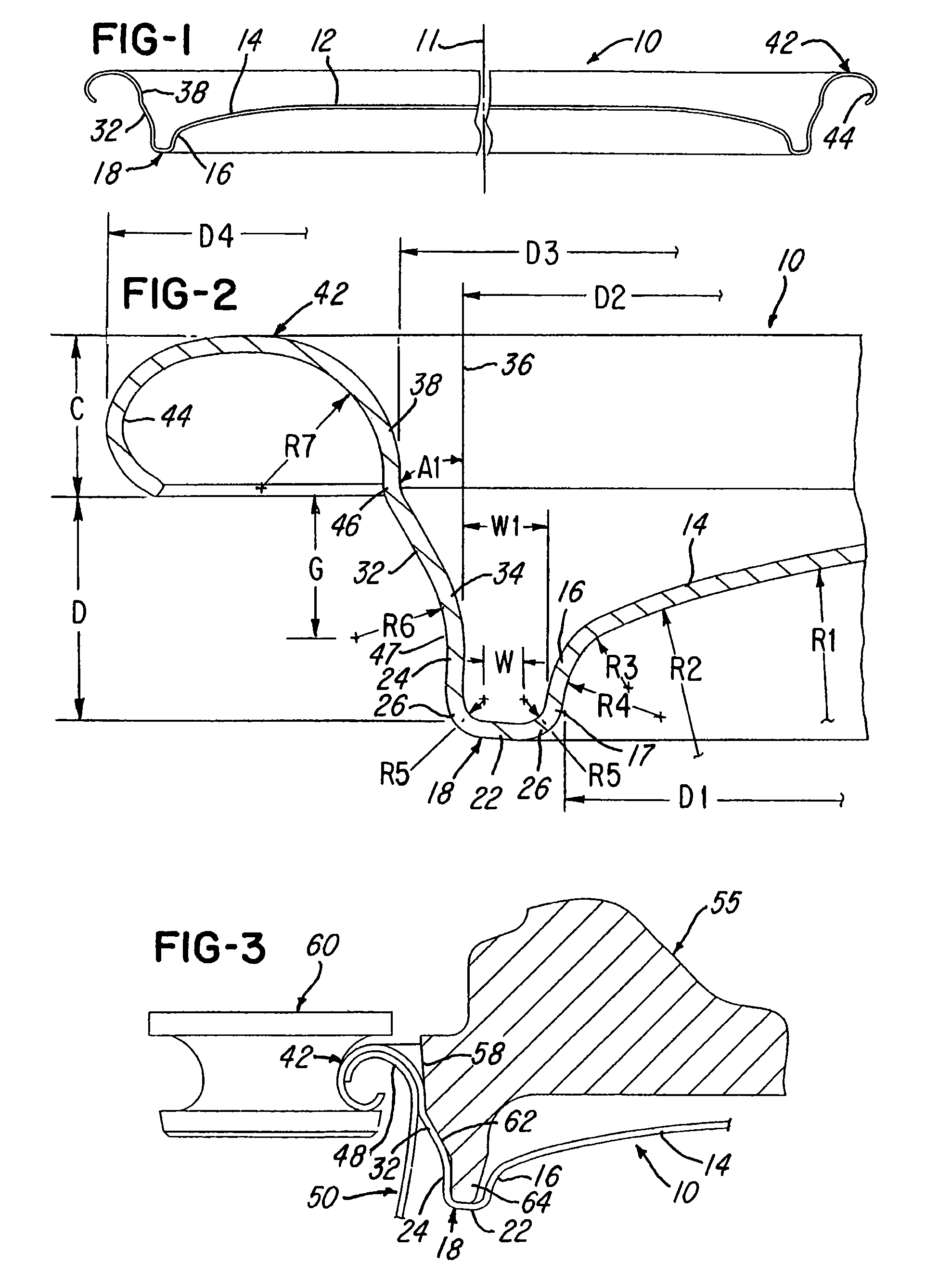

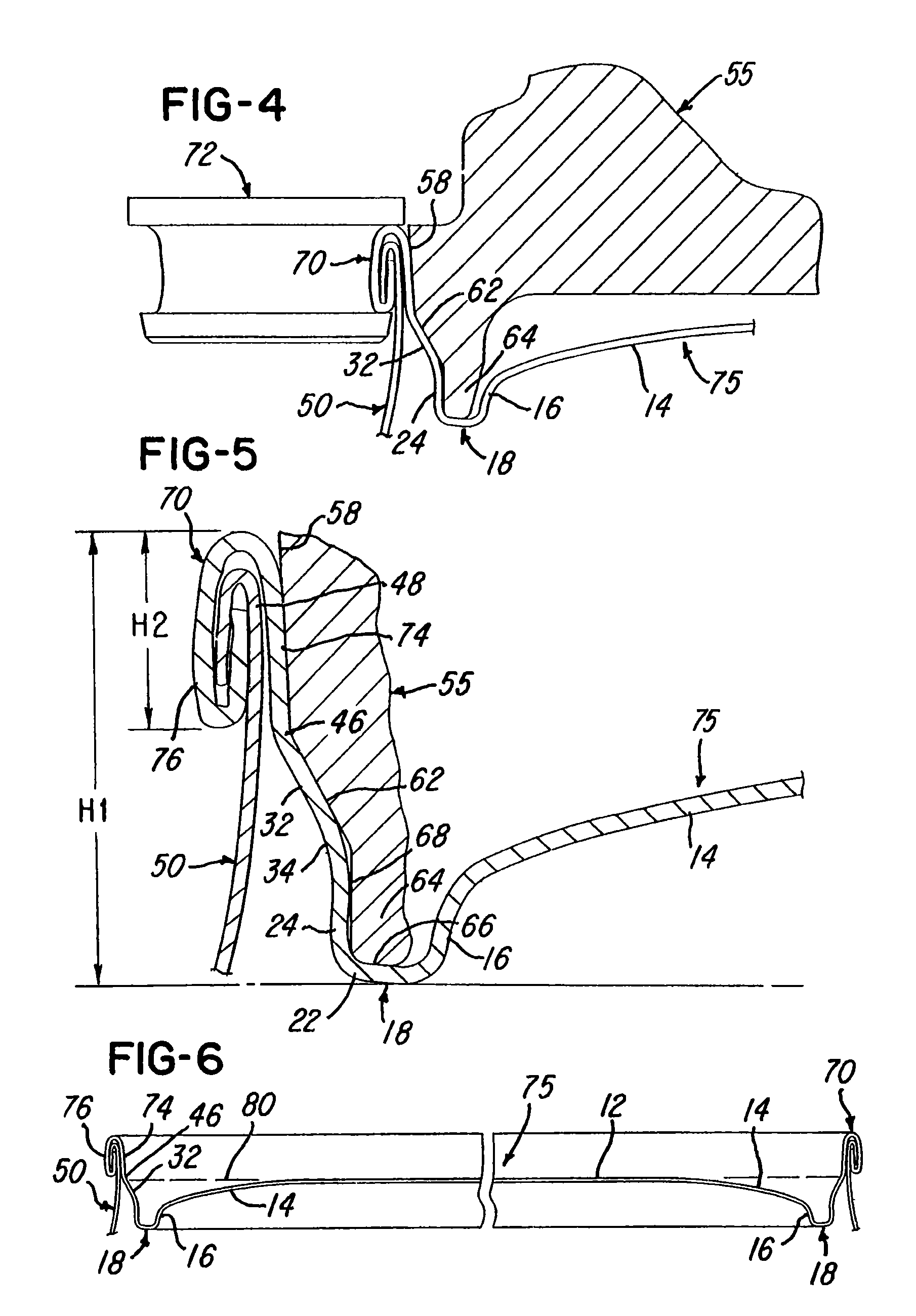

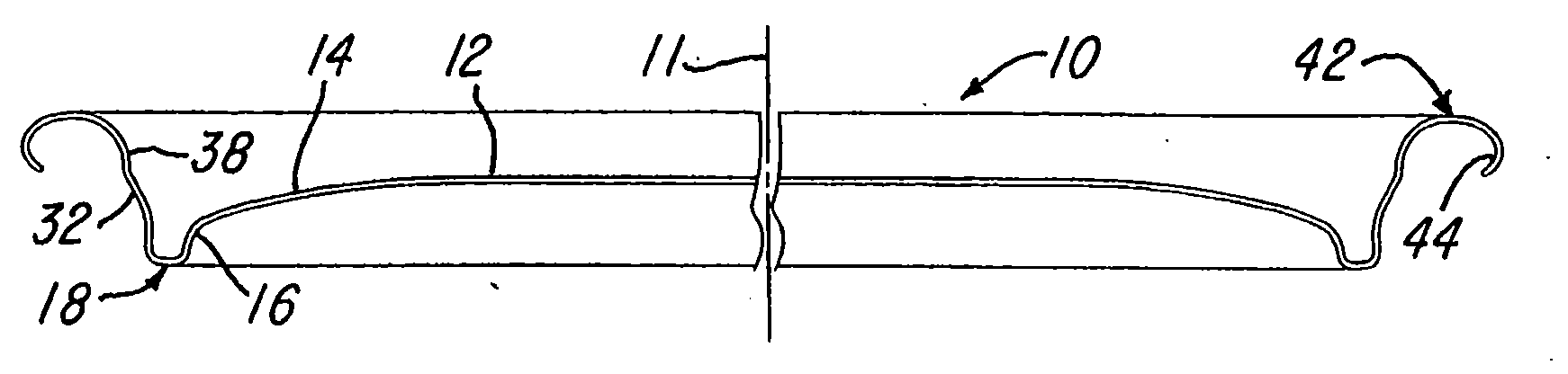

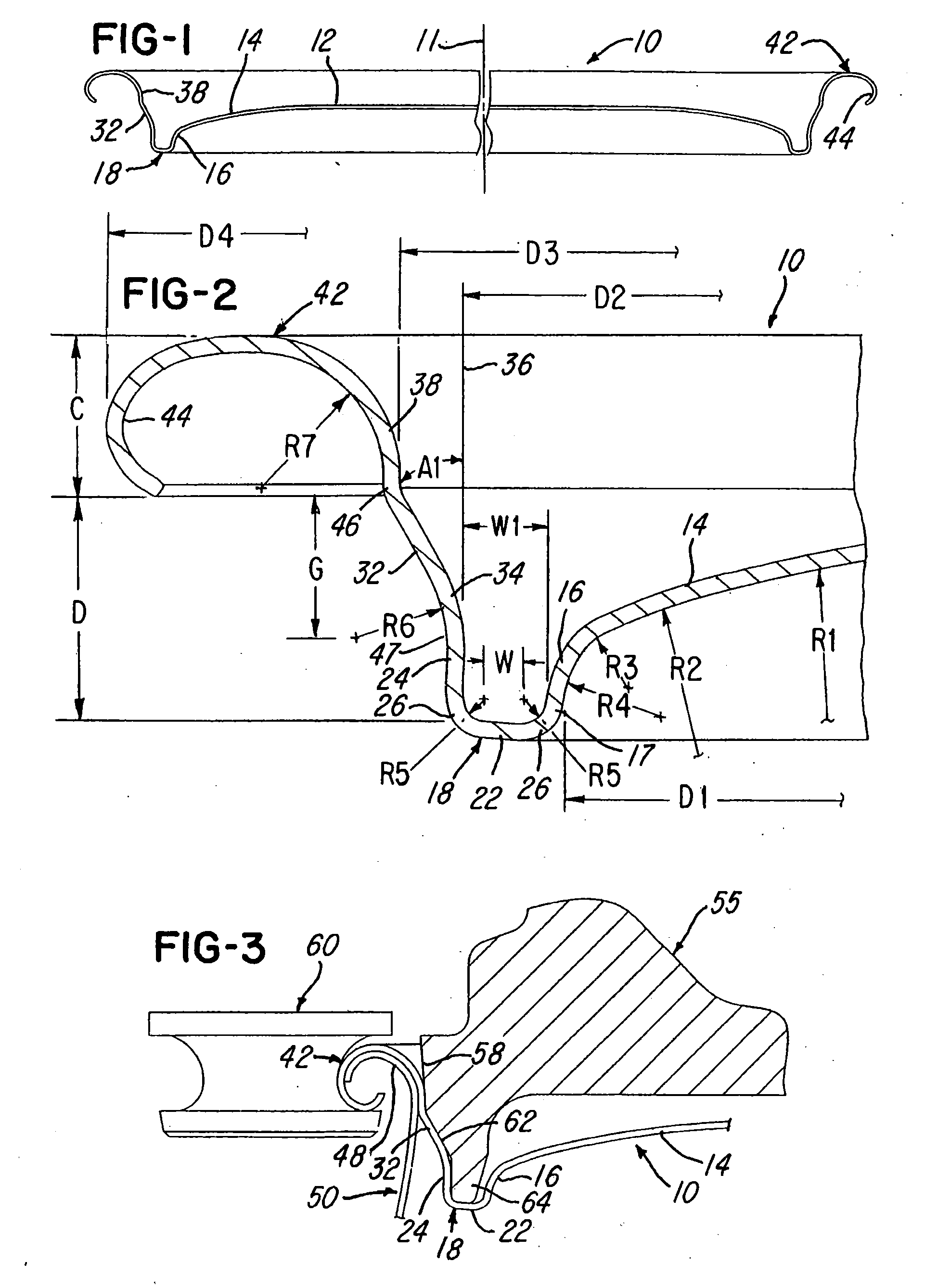

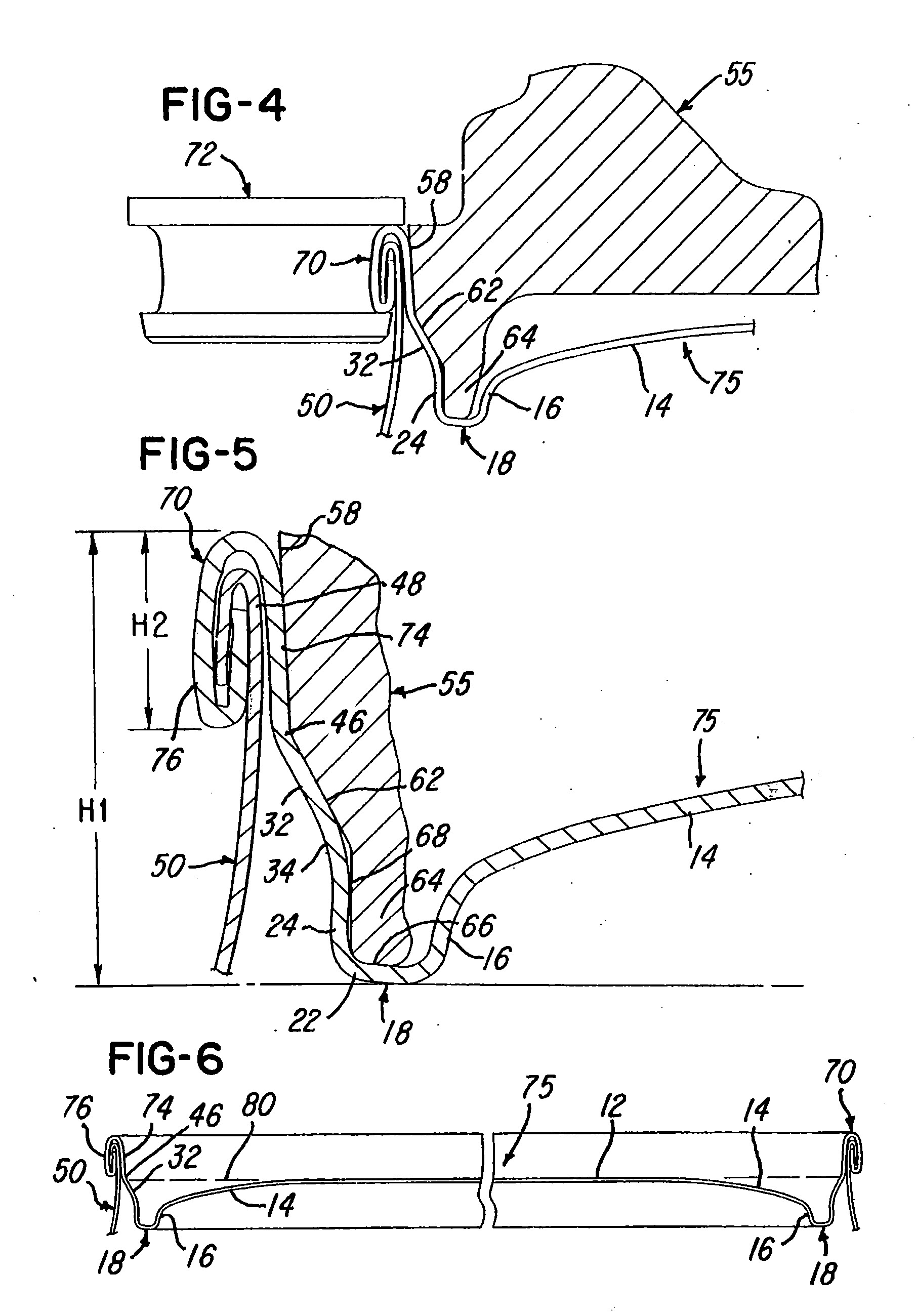

Can shell and double-seamed can end

InactiveUS7341163B2Reduction in blank diameterIncrease strength/weight ratioRigid containersHollow articlesAcute angleAluminum can

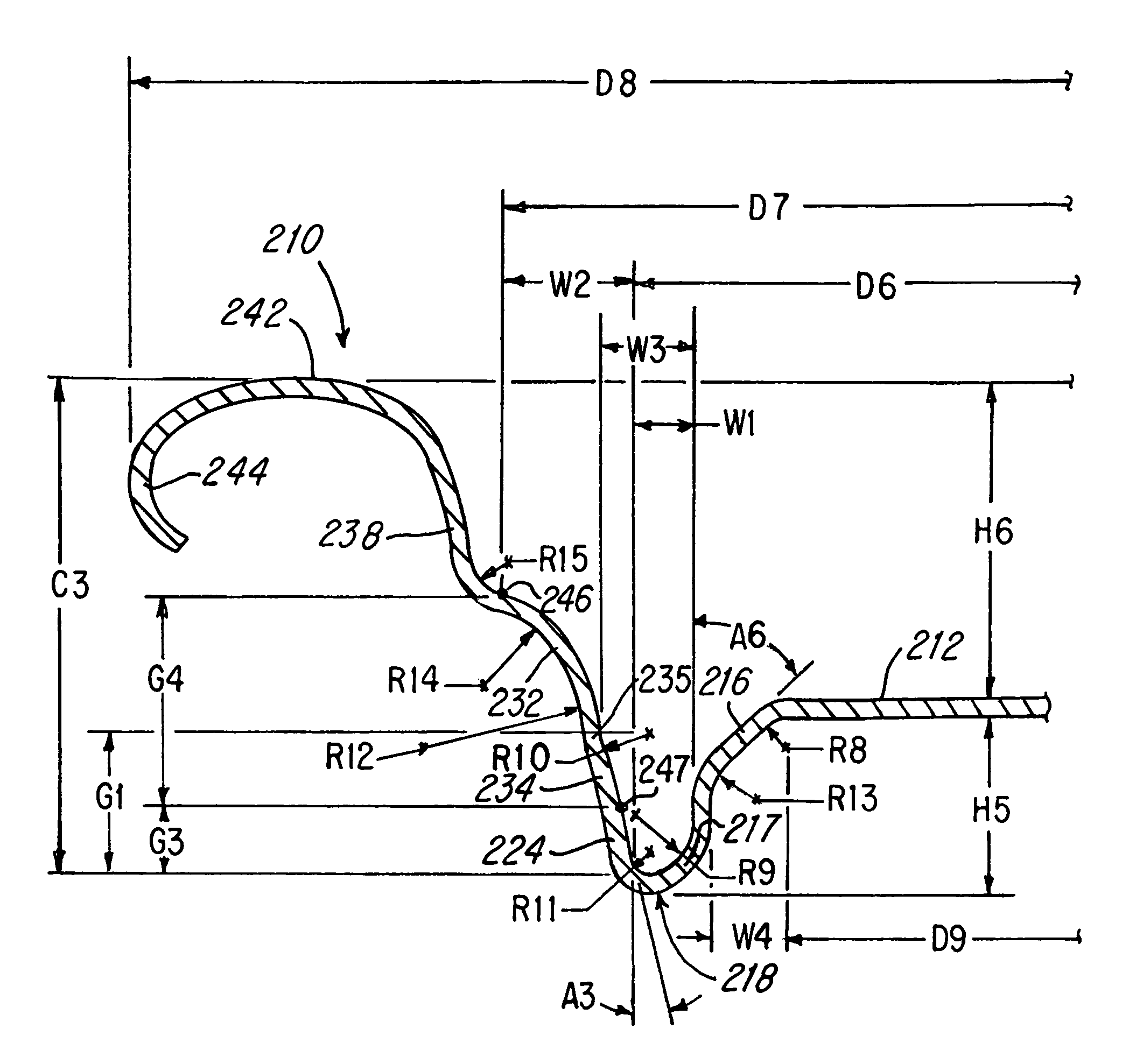

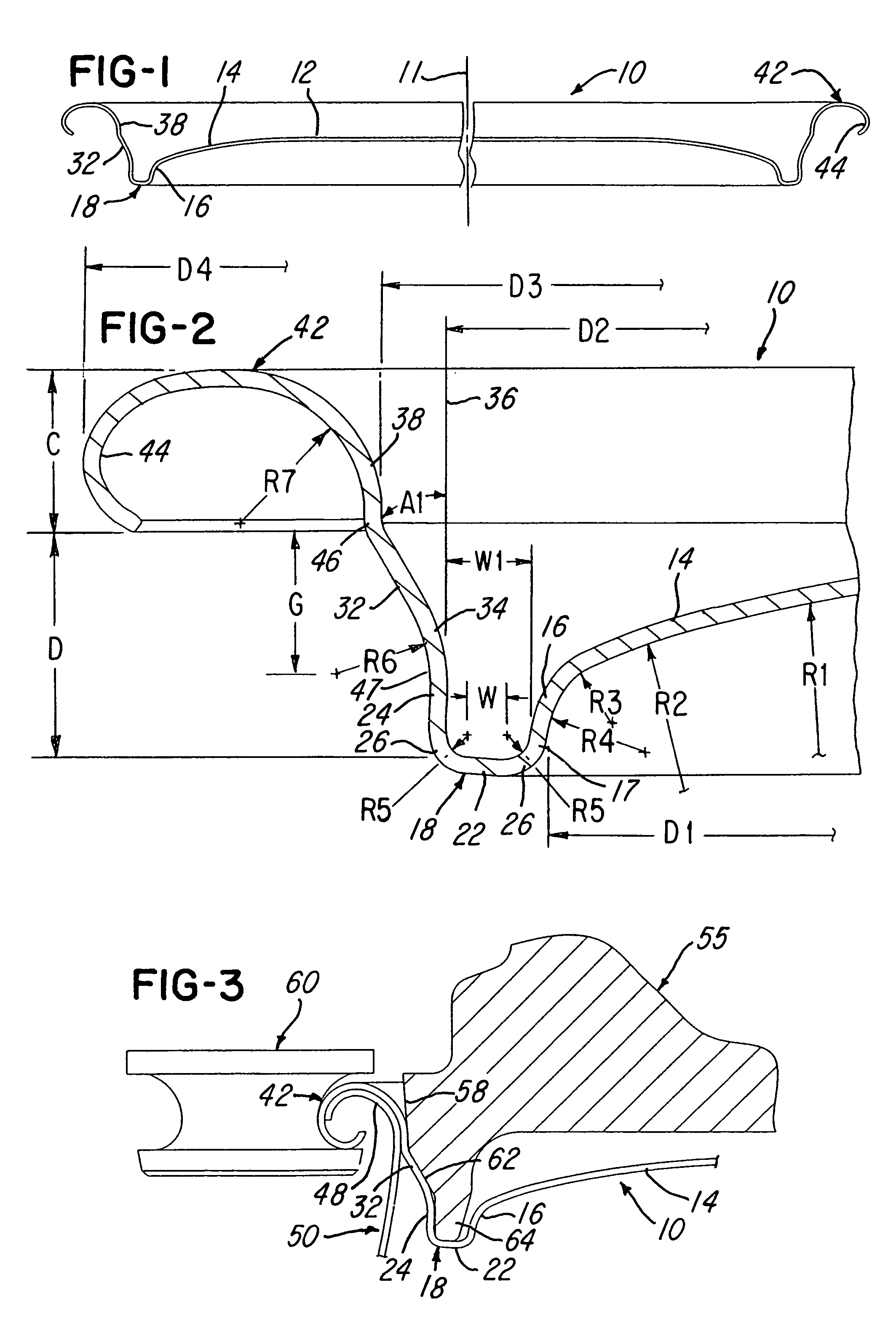

A drawn aluminum can shell has a peripheral crown which is double-seamed with an end portion of an aluminum can body to provide a can end having a generally flat center panel connected by a curved panel wall to an inner wall of an annular U-shaped countersink. The countersink has a generally cylindrical outer wall and an inner width less than the radius of the panel wall. The outer wall of the countersink connects with a frusto-conical chuckwall at a junction below the center panel, and the chuckwall extends to an inner wall of the crown at an angle of at least 16° with the center axis. The chuckwall has an S-curved intermediate configuration, the inner width of the countersink is less than the radius of the panel wall, and the inner wall of the countersink extends at an acute angle relative to the outer wall.

Owner:CONTAINER DEVELOPMENT LTD

Can shell and double-seamed can end

InactiveUS7819275B2Reduce the overall diameterRaise the ratioRigid containersHollow articlesAluminum canEngineering

A drawn aluminum can shell has a peripheral crown which is double-seamed with an end portion of an aluminum can body to provide a can end having a generally flat center panel connected by an inclined curved or straight panel wall to an inclined inner wall of an annular U-shaped countersink. The countersink has an outer wall which connects with an inclined lower wall portion of a chuckwall at a junction below the center panel, and the chuckwall has a curved or inclined upper wall portion which connects with an inner wall of the crown. The chuckwall also has an intermediate wall portion forming a break, and the inner bottom width of the countersink is less than the radial width of the panel wall. The inclined upper wall portion of the chuckwall extends at an angle greater than the angle of the inclined lower wall portion of the chuckwall.

Owner:BALL CORP +1

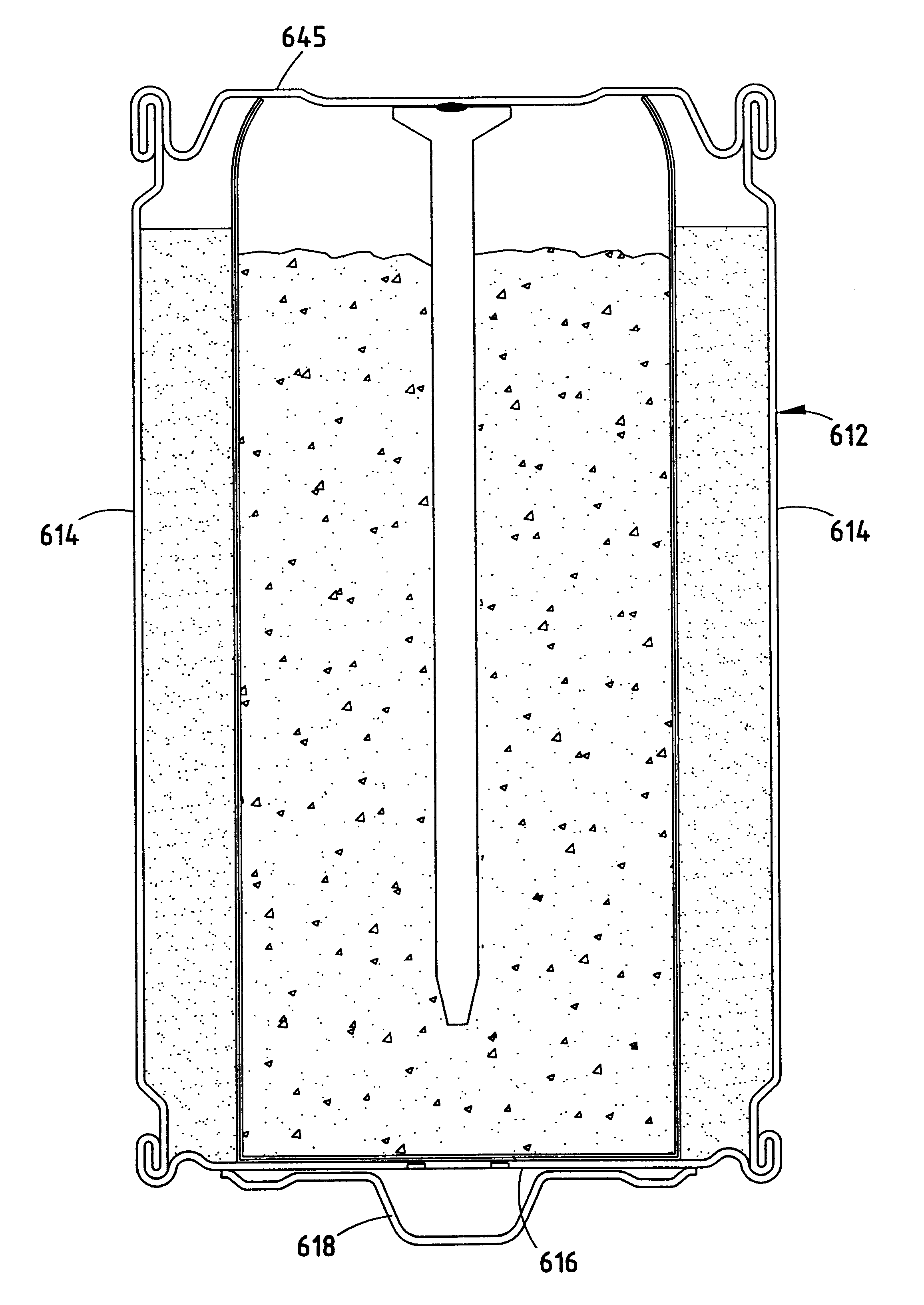

Battery construction having double seam cover closure

InactiveUS6410186B1Low profileLess spaceSmall-sized cells cases/jacketsElectrode carriers/collectorsInternal pressureElectrochemical cell

An electrochemical cell constructed in accordance with the present invention includes a can for containing electrochemical materials including positive and negative electrodes and an electrolyte, the can having an open end and a closed end; a pressure relief mechanism formed in the closed end of the can for releasing internal pressure from within the can when the internal pressure becomes excessive; a first outer cover positioned on the closed end of the can to be in electrical contact therewith and to extend over the pressure relief mechanism; a second outer cover positioned across the open end of the can; and an insulator disposed between the can and the second outer cover for electrically insulating the can from the second outer cover. According to another embodiment, the second cover is dielectrically isolated from a current collector. The second cover is fastened to the can by the use of a double-seamed closure.

Owner:ENERGIZER BRANDS

Necked beverage can having a seamed-on end

ActiveUS20160031594A1Improvement in metal reduction metalImprovement in metal metal utilizationCapsClosure capsEngineeringDouble seam

A beverage can for carbonated soft drinks, beer, and other pressurized uses includes a drawn and ironed can body, a highly necked portion, and an relatively small end that is attached to the can body by a double seam.

Owner:CROWN PACKAGING TECH

Can shell and double-seamed can end

InactiveUS8313004B2Reduce the overall diameterRaise the ratioRigid containersHollow articlesAluminum canEngineering

A drawn aluminum can shell has a peripheral crown which is double-seamed with an end portion of an aluminum can body to provide a can end having a generally flat center panel connected by an inclined curved or straight panel wall to an inclined inner wall of an annular U-shaped countersink. The countersink has an outer wall which connects with an inclined lower wall portion of a chuckwall at a junction below the center panel, and the chuckwall has a curved or inclined upper wall portion which connects with an inner wall of the crown. The chuckwall also has an intermediate wall portion forming a break, and the inner bottom width of the countersink is less than the radial width of the panel wall. The inclined upper wall portion of the chuckwall extends at an angle greater than the angle of the inclined lower wall portion of the chuckwall.

Owner:BALL CORP +1

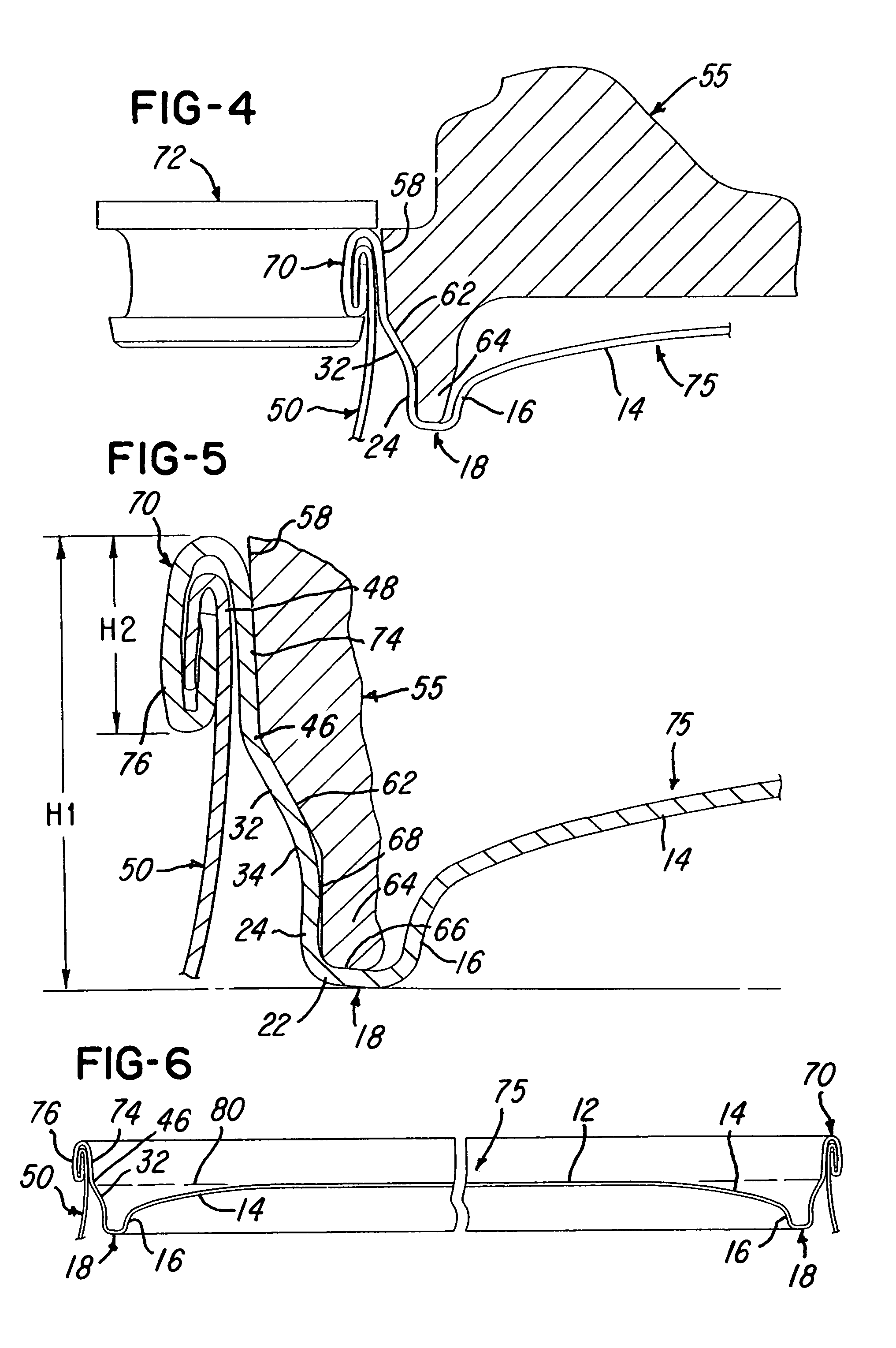

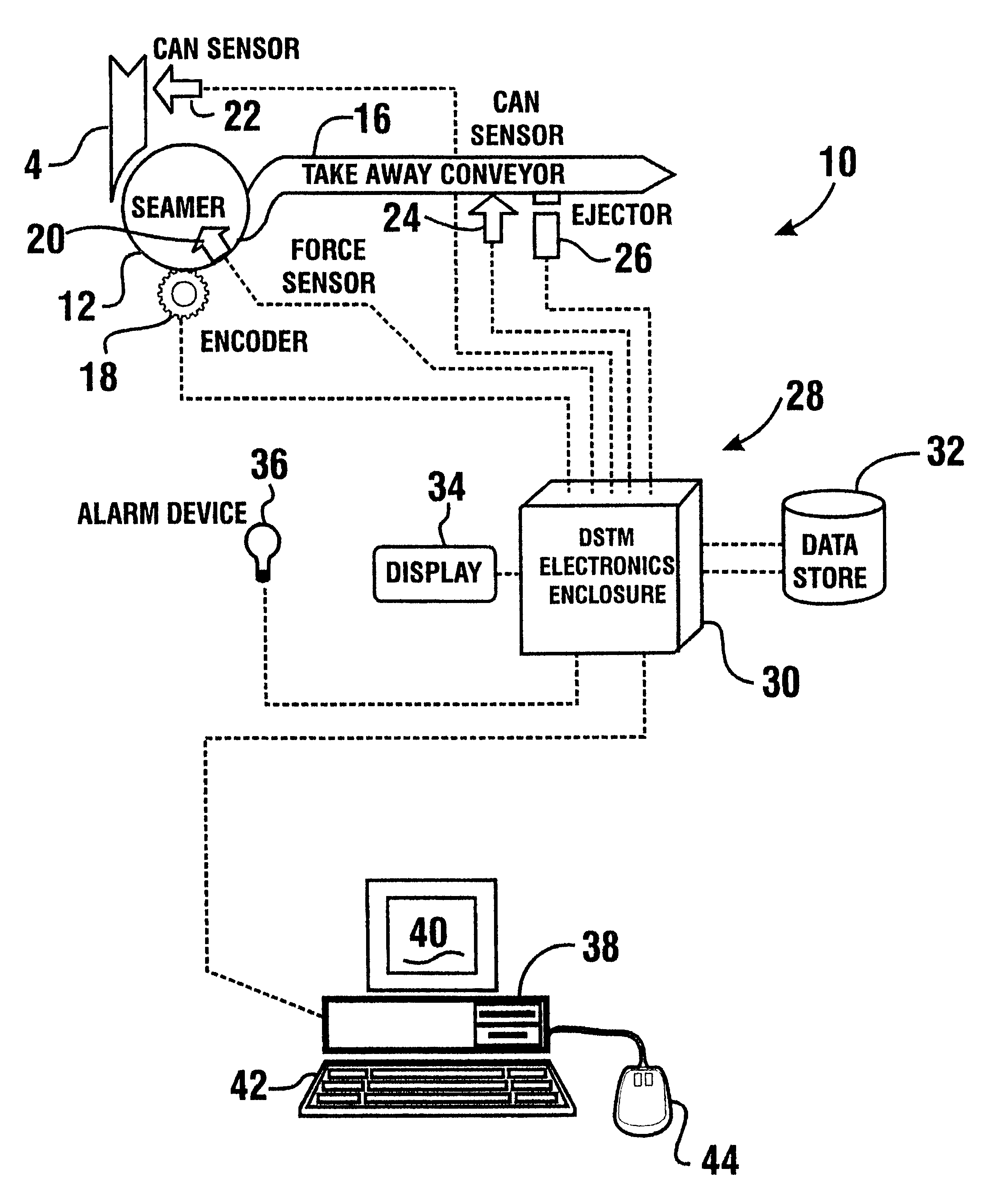

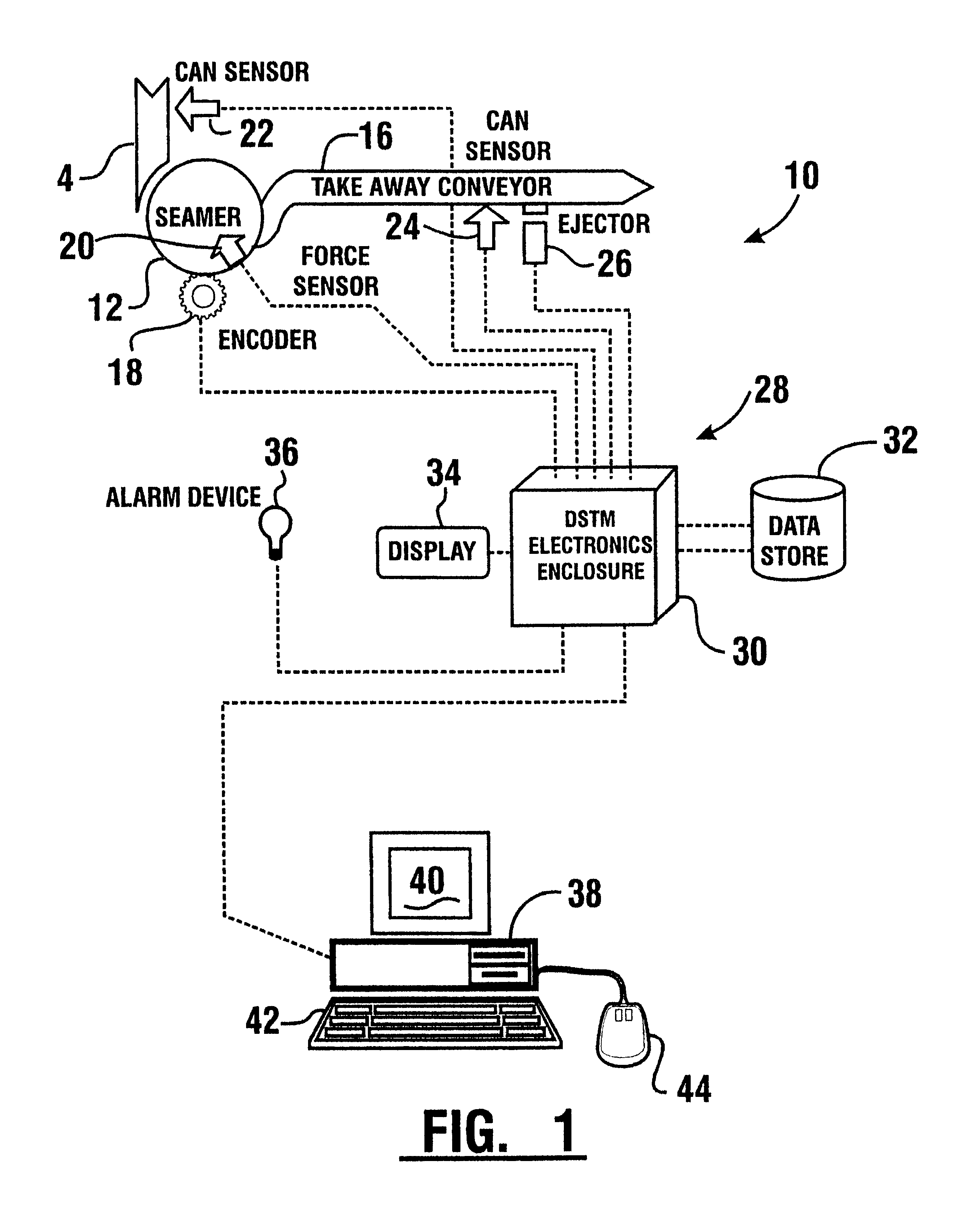

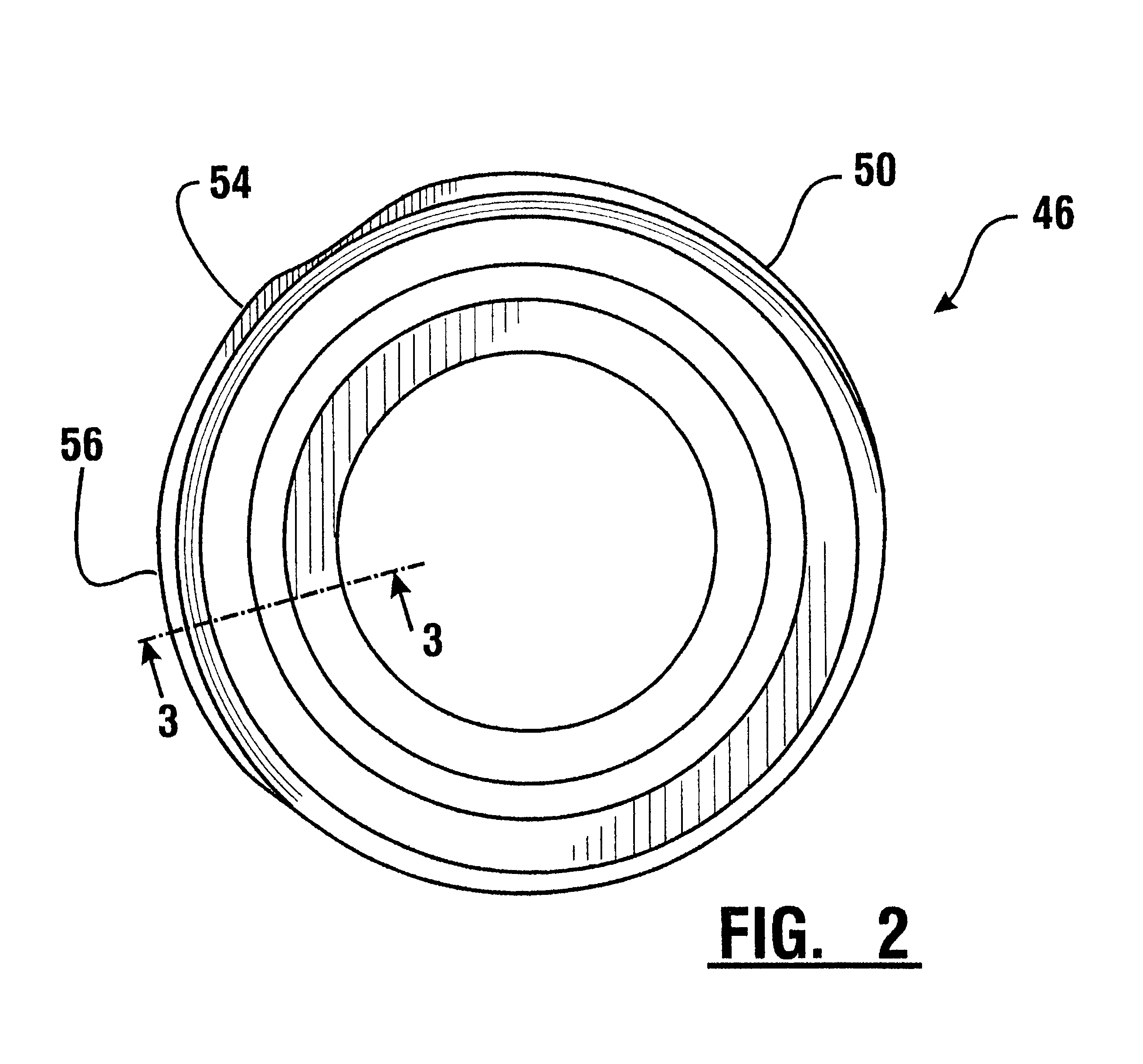

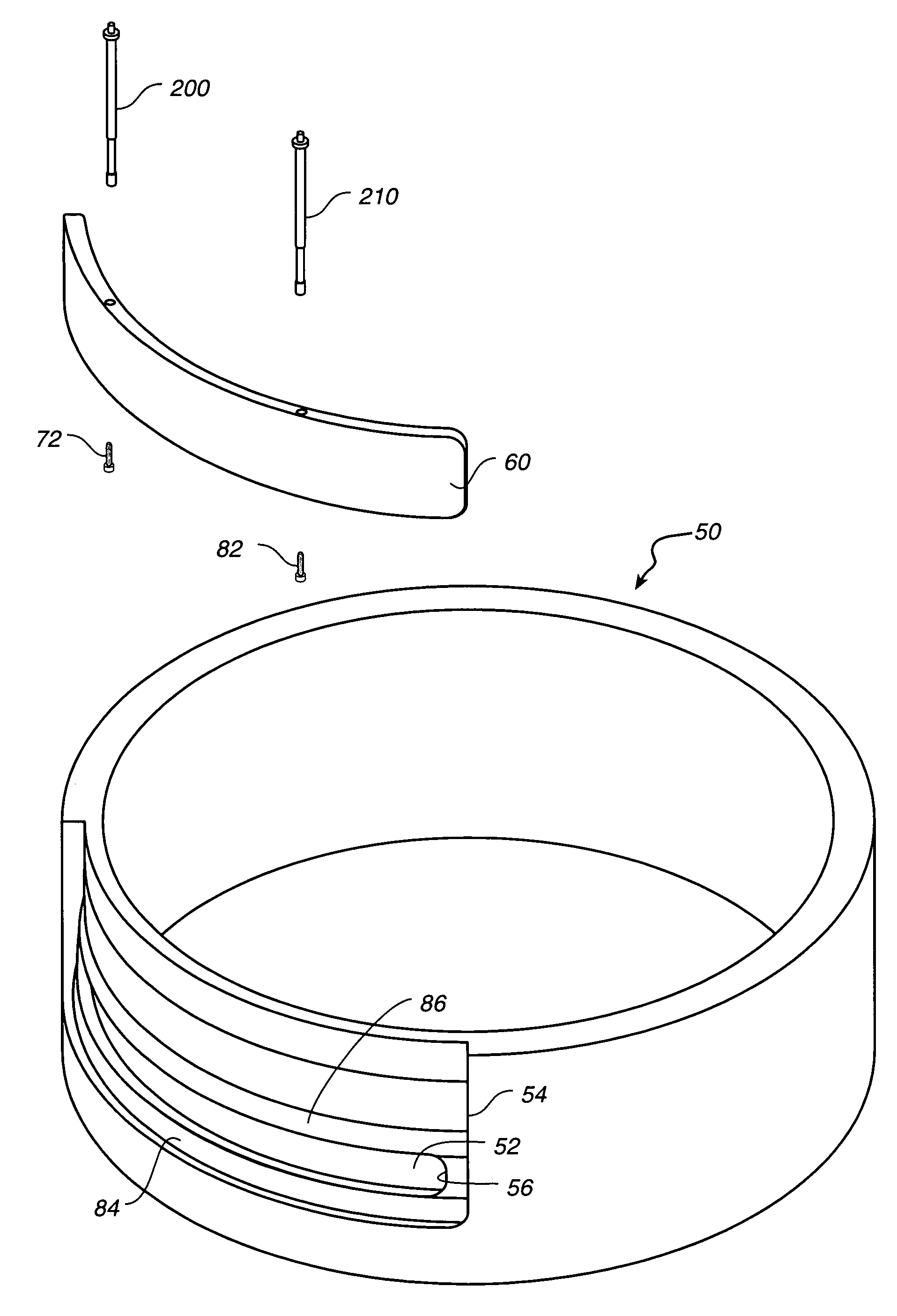

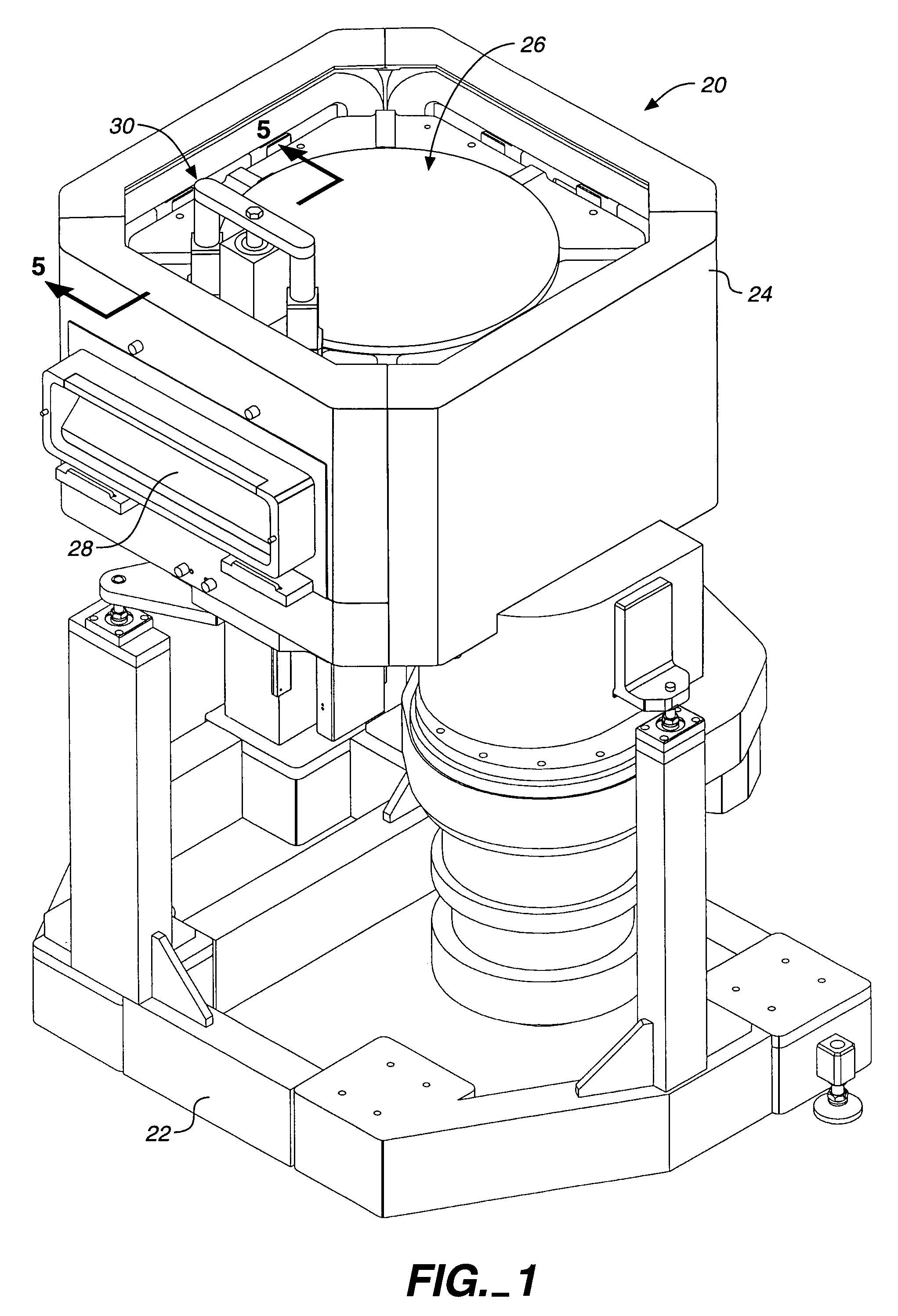

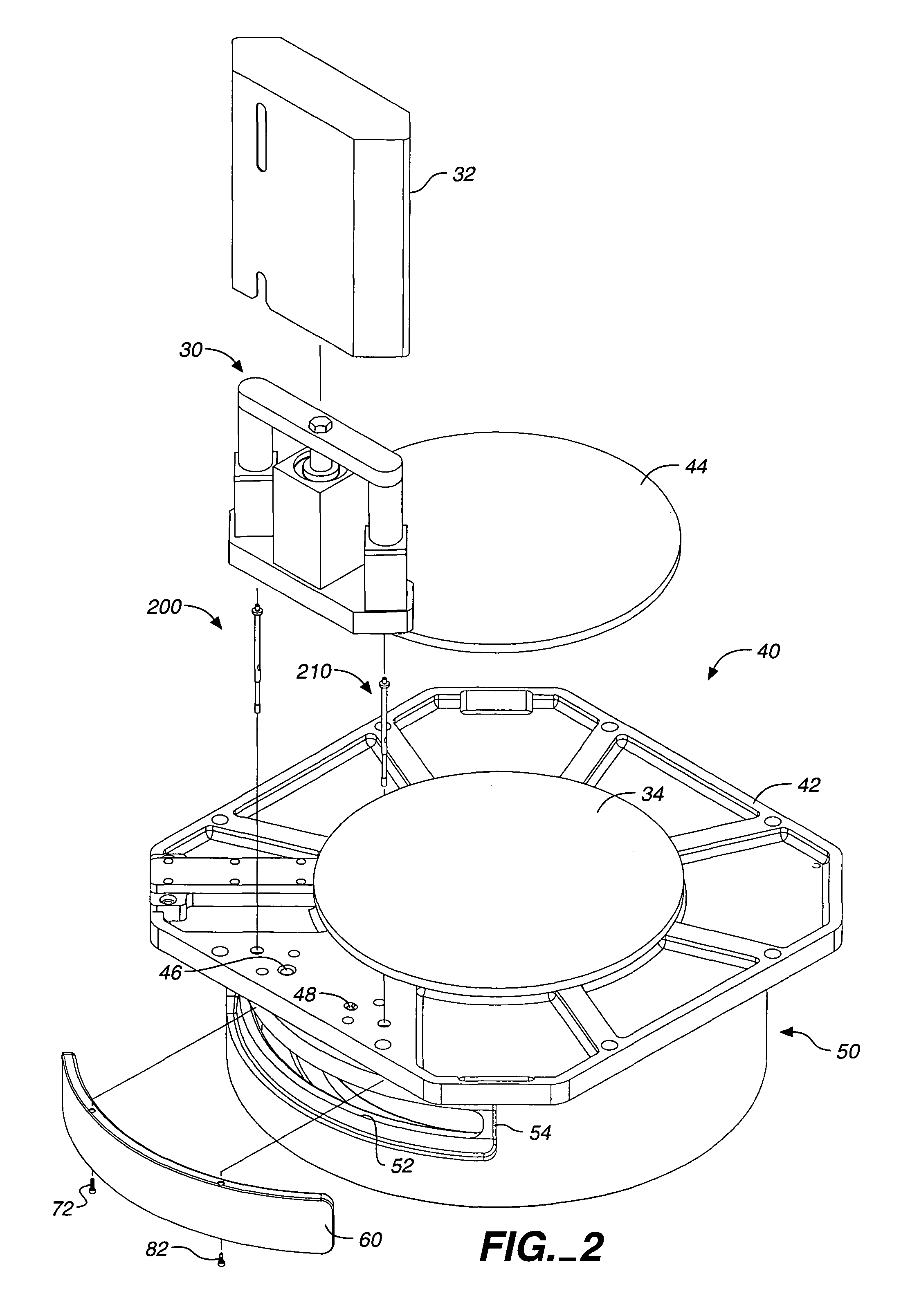

Can seam forming apparatus

InactiveUS6623230B1Reduce setup timeReduce riskApparatus for force/torque/work measurementHollow articlesEngineeringData memory

A double seam forming apparatus for applying end units to can bodies includes a can seamer (12) with a seaming cam (46). Seaming cam (46) includes a high dwell portion (56) which deforms responsive to force encounterred by tooling during forming of a can seam. A reinforcing pin (72) limits deformation of the high dwell portion to prevent damage. The high dwell portion of the cam includes a force sensor (20) which generates a signal responsive to strain of the high dwell portion due to applied force. The apparatus further includes a monitor apparatus (28). The monitor apparatus includes a controller (30) which includes a processor and a data store (32), and a host station (38). The monitor apparatus is operative to identify seam fault conditions and to store data concerning seamer conditions. The monitor apparatus also operates a can ejector (26) to divert cans identified as having defective seams.

Owner:PNEUMATIC SCALE CORP

Double slit-valve doors for plasma processing

InactiveUS7147719B2Uniform processingAvoid depositionValve arrangementsDecorative surface effectsEngineeringParticle generation

In a substrate vacuum processing chamber, a second inner slit passage door apparatus and method to supplement the normal slit valve and its door at the outside of the chamber. The inner slit passage door, blocks the slit passage at or adjacent the substrate processing location in a vacuum processing chamber to prevent process byproducts from depositing on the inner surfaces of the slit passage beyond the slit passage door and improves the uniformity of plasma in the processing chamber by eliminating a large cavity adjacent to the substrate processing location into which the plasma would otherwise expand. The inner slit passage door is configured and positioned in such a way as to avoid generating particles from the opening and closing motion of the second slit valve door, as it does not rub against any element of the chamber during its motion and the inner slit passage door is positioned with a predetermined gap from adjacent pieces and the door configuration includes beveled surfaces to further reduce the chance for particle generation, even when there is deposition of process byproducts on the door and its adjacent surfaces.

Owner:APPLIED MATERIALS INC

Double-seam submerged-arc welding pipe with petroleum and natural-gas transfer and its production

ActiveCN101074749AReduce widthReduce manufacturing difficultyRigid pipesMetallurgyOil and natural gas

Oil and natural gas are delivered by the double-slit sew pipe and method of production. Characteristic is: Adopt two pieces of steel plate whose width as steel pipe the girth 1 / 2 , make use of two-sided arc weld to put together two pieces of steel plate following lengthways, then take common used method to product steel pipe . Another method is to make two pieces of steel plates carry on C's model respectively. The two C-shaped are weld to a group of O-pipe, after expanding, nondestructive testing, the product is completed. Effect: Reduce the steel pipe's manufacturing difficulty; make use of existing LSAW pipe equipment, use of existing LSAW pipe equipment, produce outside path at 1016 mms above, wall thickness at 21 mm above the high-quality steel pipe.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

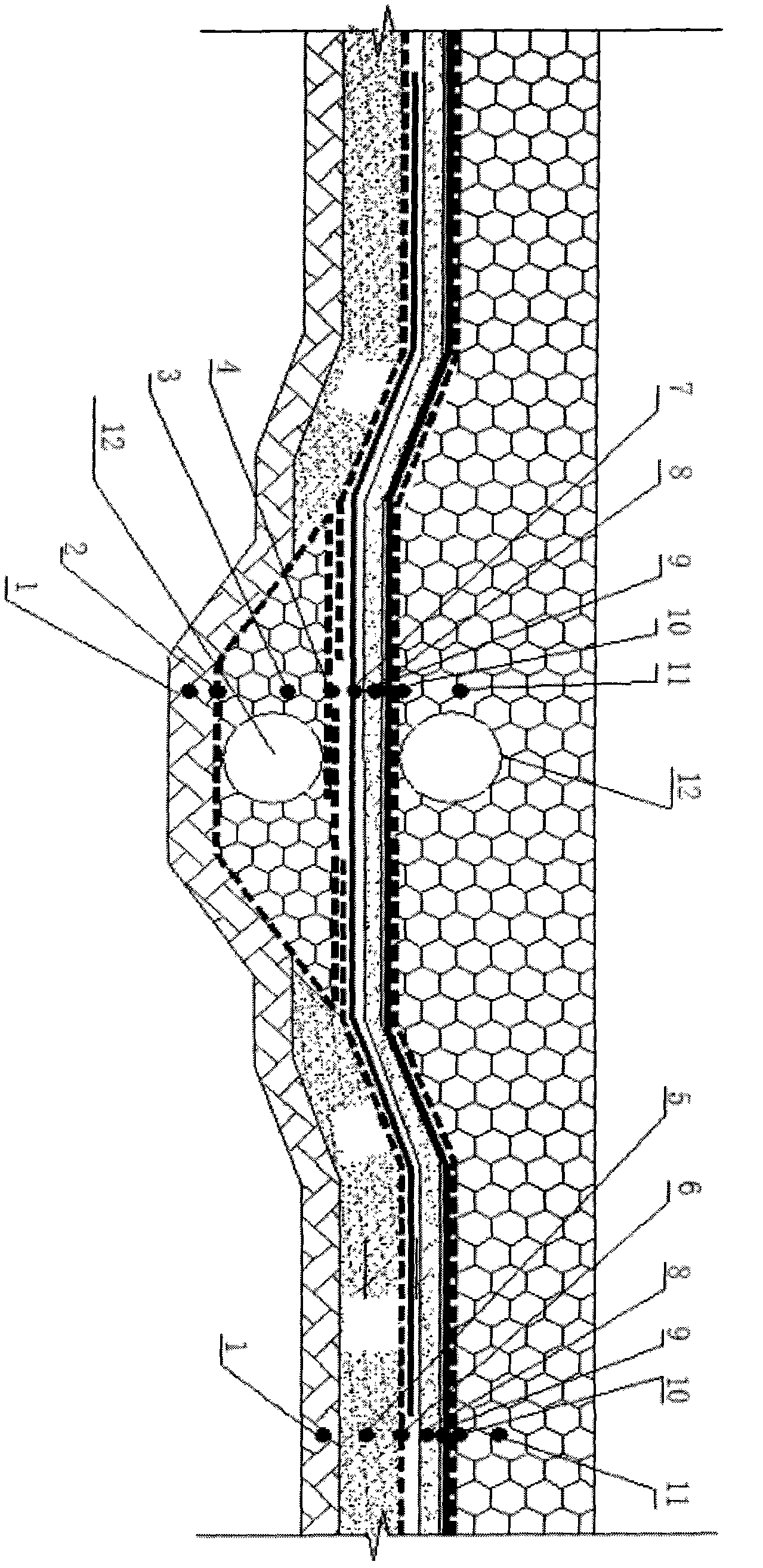

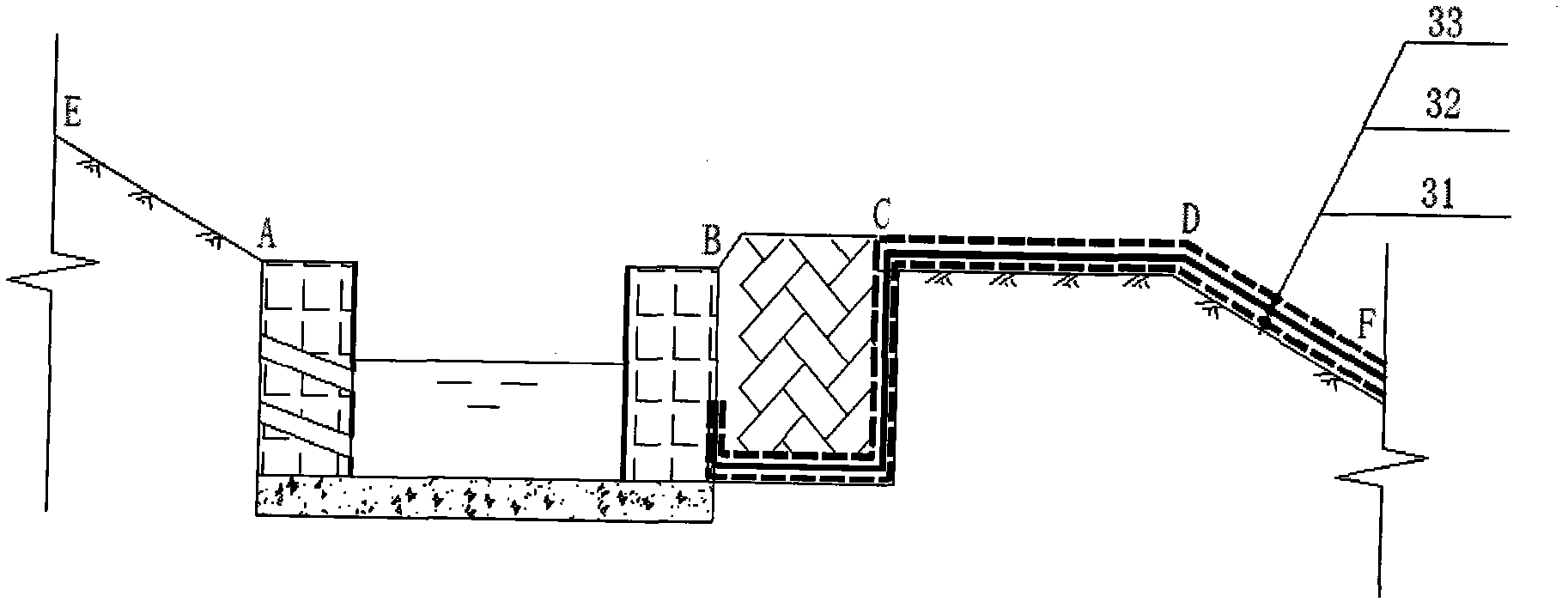

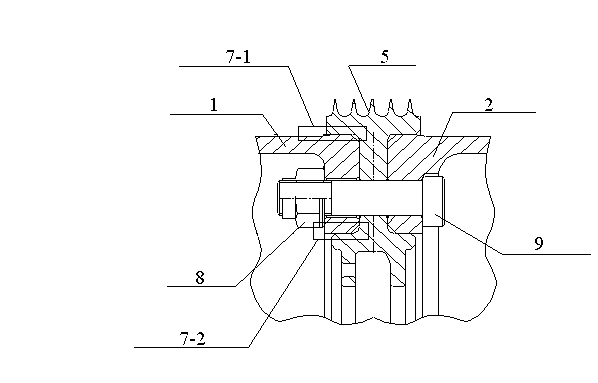

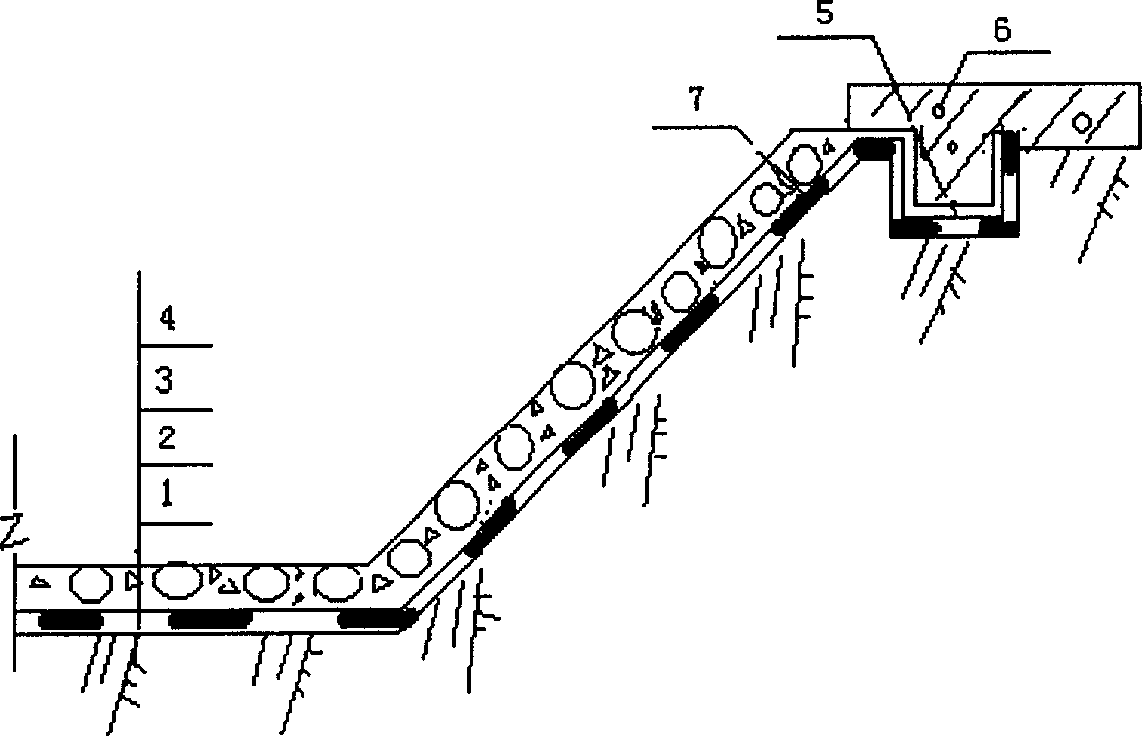

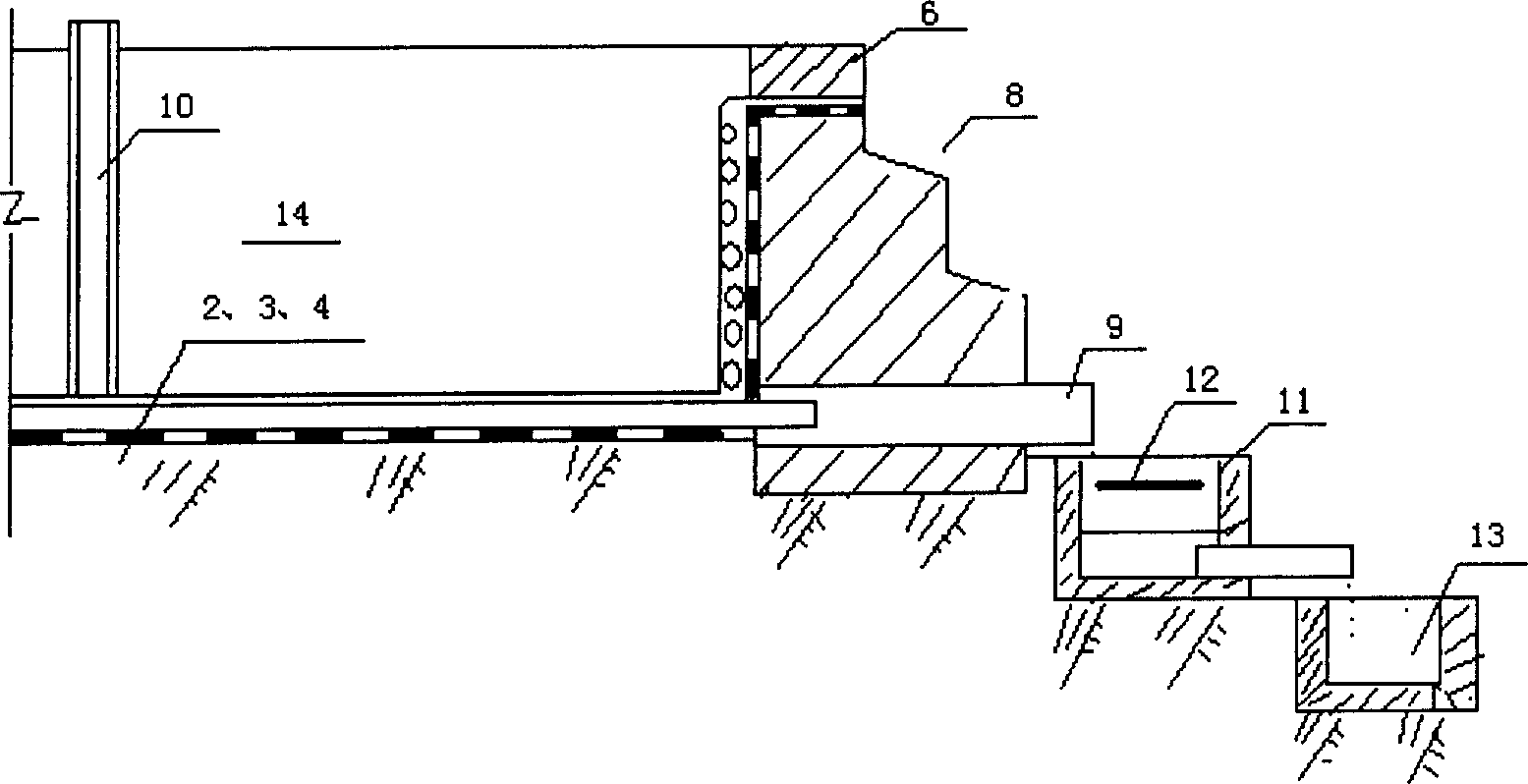

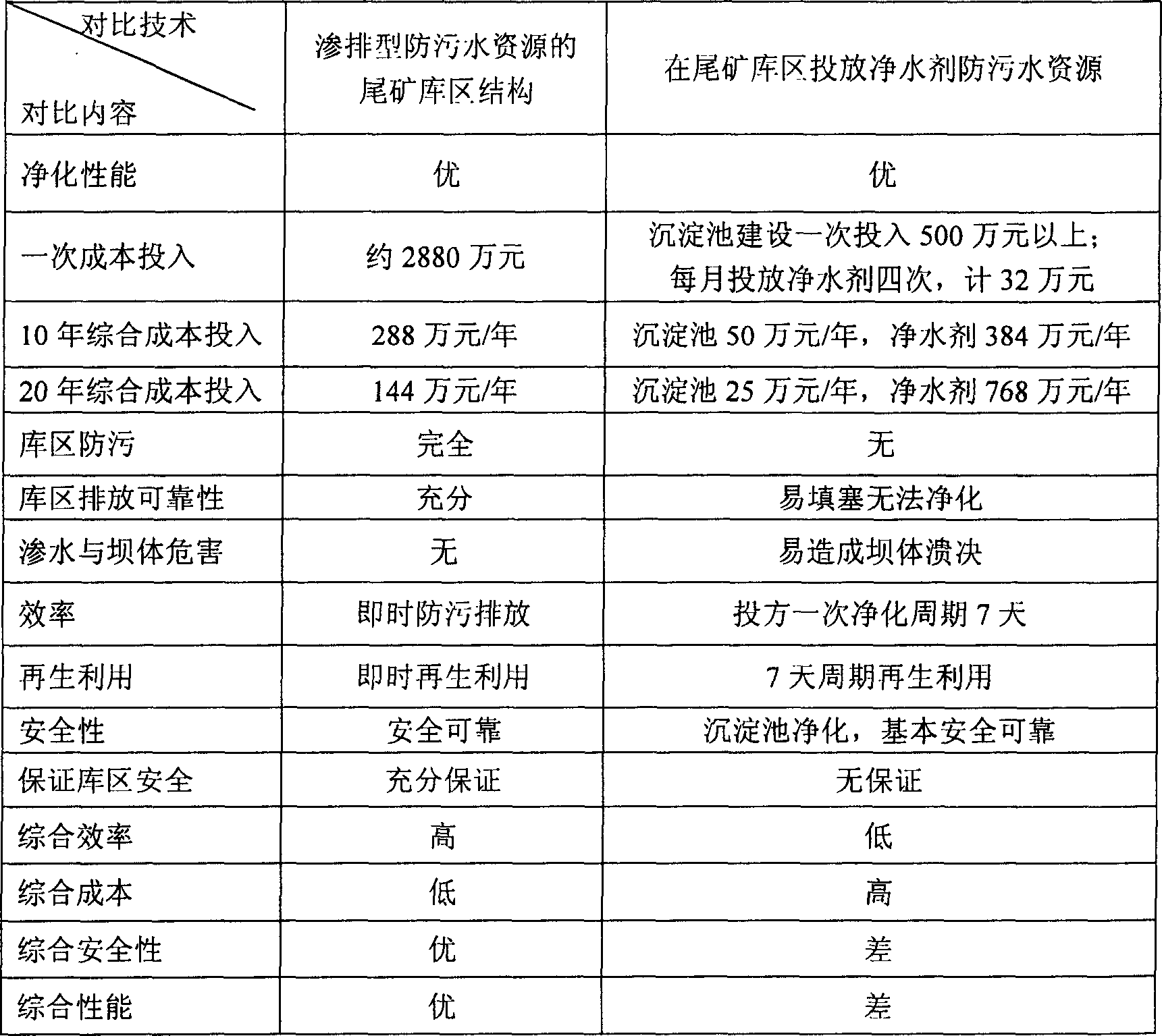

Refuse landfill seepage-proofing guide drainage system structure and laying method thereof

InactiveCN103835317AHigh mechanical strengthImprove tear resistanceProtective foundationSewage drainingCrushed stoneLap joint

The invention discloses a refuse landfill seepage-proofing guide drainage system structure and a laying method thereof. An independent closed flexible reservoir-shaped seepage-proofing layer is composed of an HDPE geomembrane, a GCL (geosynthetic clay liner), a non-woven geotechnical cloth and the like, the seepage-proofing layer is provided with macadam, coarse sand and an HDPE floral tube to form a guide drainage structure for conducting guide drainage of landfill leachate and underground water, and a landfill reservoir base layer and the seepage-proofing guide drainage system structure are made stable, wherein anchoring measures are used for the guide drainage process. A double-slit sweat soldering process is mainly used for the HDPE geomembrane, and a single-slit extrusion soldering process is supplemented. A holt melting butt joint mode is used for the HDPE floral tube, a lap joint mode is used for the GCL, and a heat bonding lap joint mode is used for the non-woven geotechnical cloth. The refuse landfill seepage-proofing guide drainage system structure and the laying method thereof can solve the problems that secondary pollution happens due to the fact that refuse landfill leachate permeates into a subterranean layer, and a basement is damaged due to accumulation of the underground water. The refuse landfill seepage-proofing guide drainage system structure has very high seepage-proofing capacity, the permeability coefficient reaches 1.0*10<-11> cm / s, long-term stability is achieved, erosion can not happen, and the natural aging life is more than 50 years.

Owner:HANGZHOU QIANXI ENVIRONMENTAL PROTECTION SCI & TECH

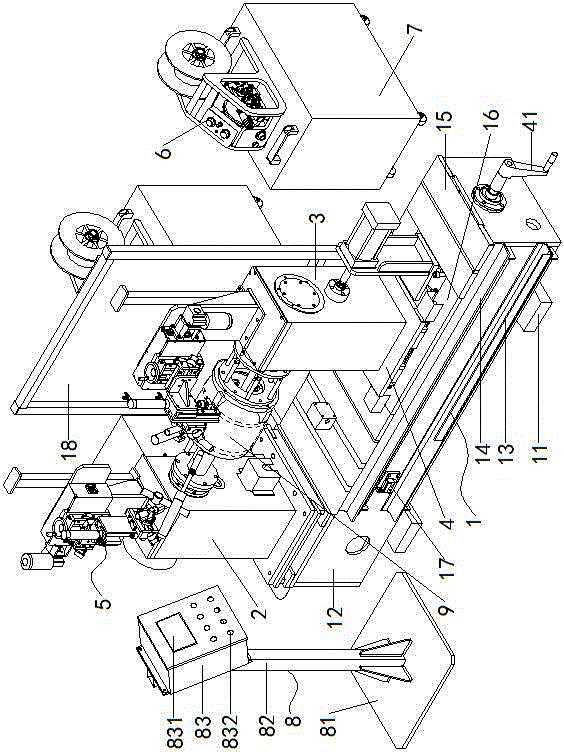

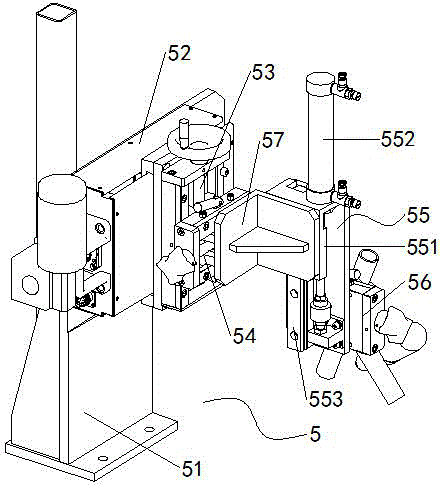

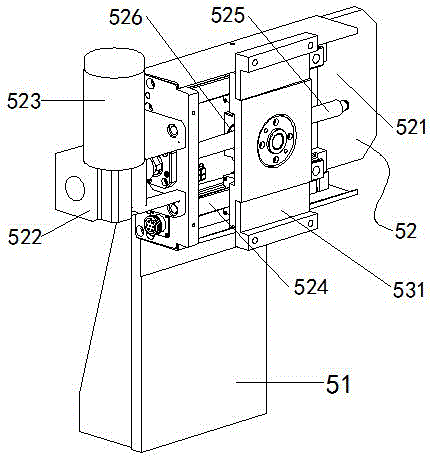

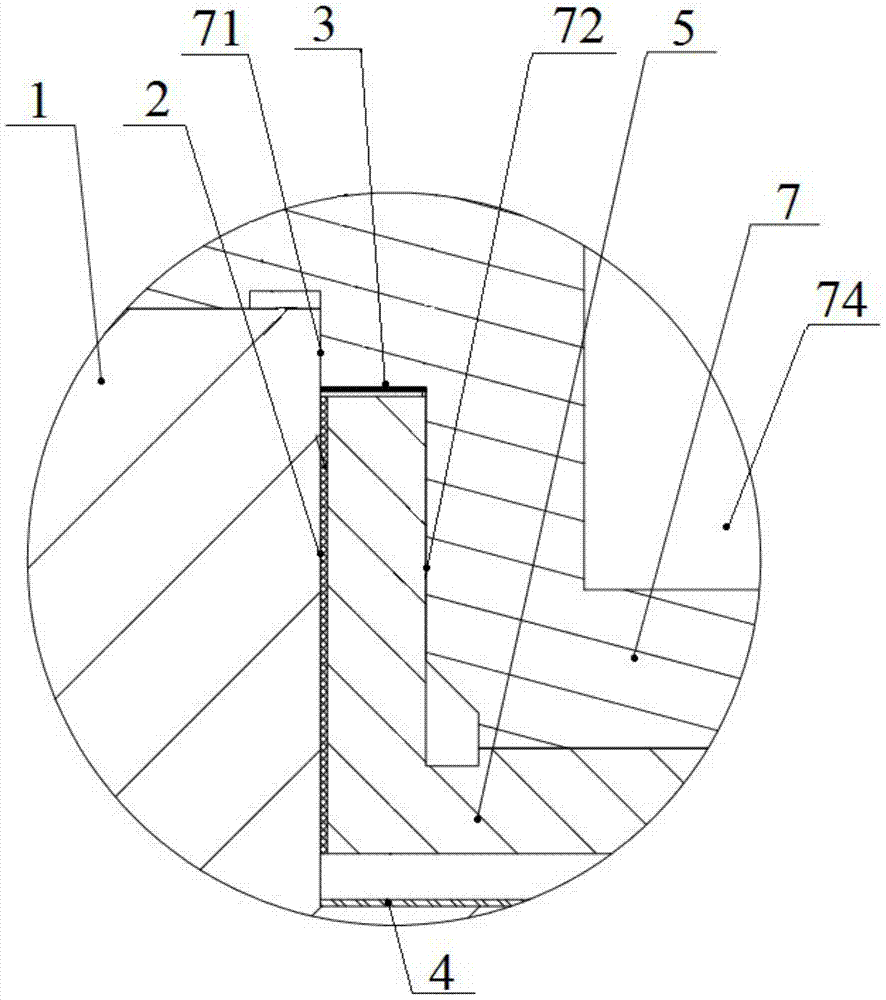

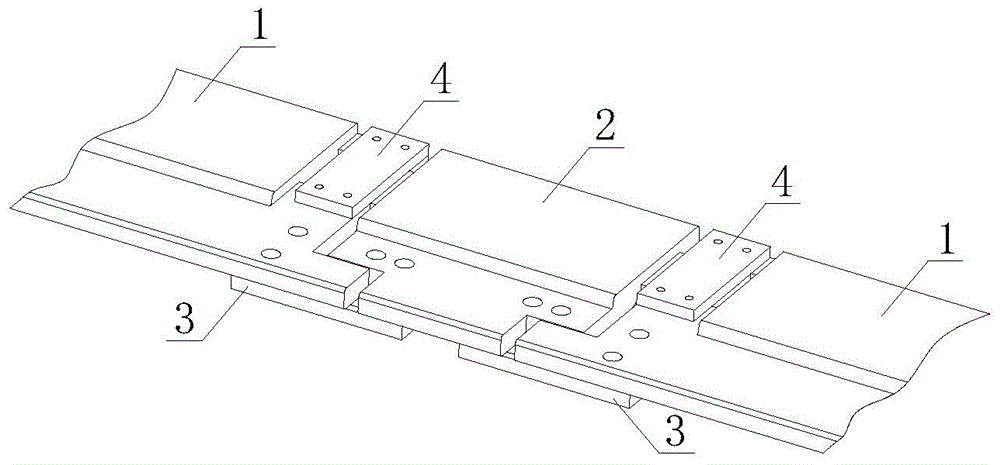

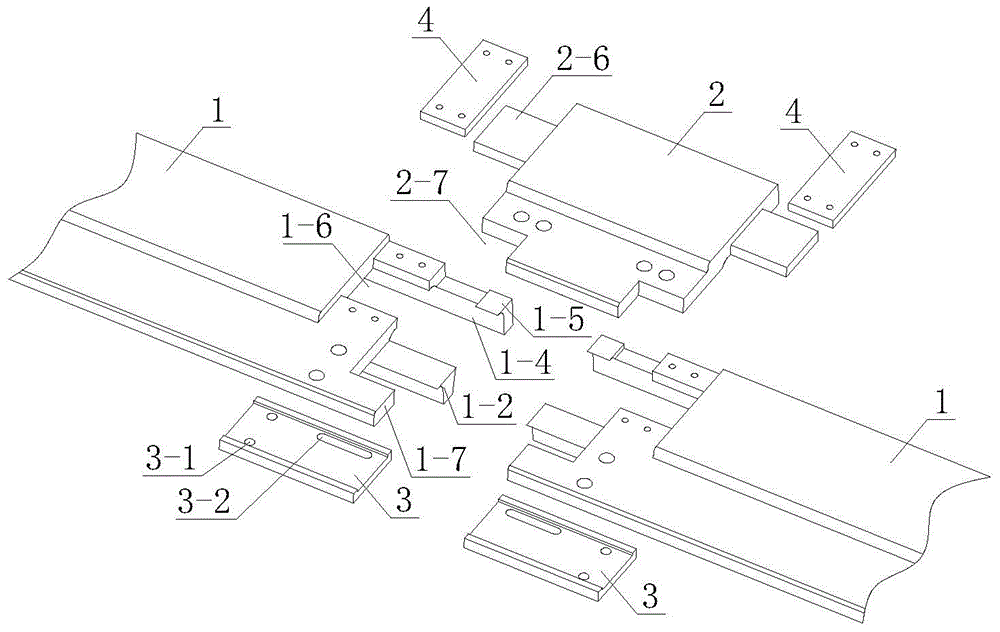

Double-seam automatic welder

ActiveCN104625523AGuarantee welding qualityReasonable structural designWelding/cutting auxillary devicesElectrode holder supportersEngineeringWeld seam

The invention provides a double-seam automatic welder and relates to the technical field of welding devices. The double-seam automatic welder comprises a lathe bed, a left clamp, a right clamp and welding gun mechanisms, the left clamp and the right clamp are arranged on the lathe bed and used for clamping a workpiece, the welding gun mechanisms are arranged on the left clamp and the right clamp respectively, and each welding gun mechanism comprises a transverse rough adjustment device, a vertical adjustment device, a transverse fine adjustment device, a vertical linkage device and an angle adjustment device which are connected with one another in sequence. By means of the double-seam automatic welder, the whole structure design is reasonable, double-seam welding works can be synchronously finished, only one welding gun mechanism can be started according to work demands, positions of the right clamp and welding guns can be adjusted according to size of the workpiece, and welding requirements of various workpieces can be met. Besides, the welding gun mechanisms can accurately adjust positions of the welding guns according to workpiece size and welding seam positions so that the welding requirements can be met, and welding qualities can be guaranteed.

Owner:杭州焊林科技有限公司

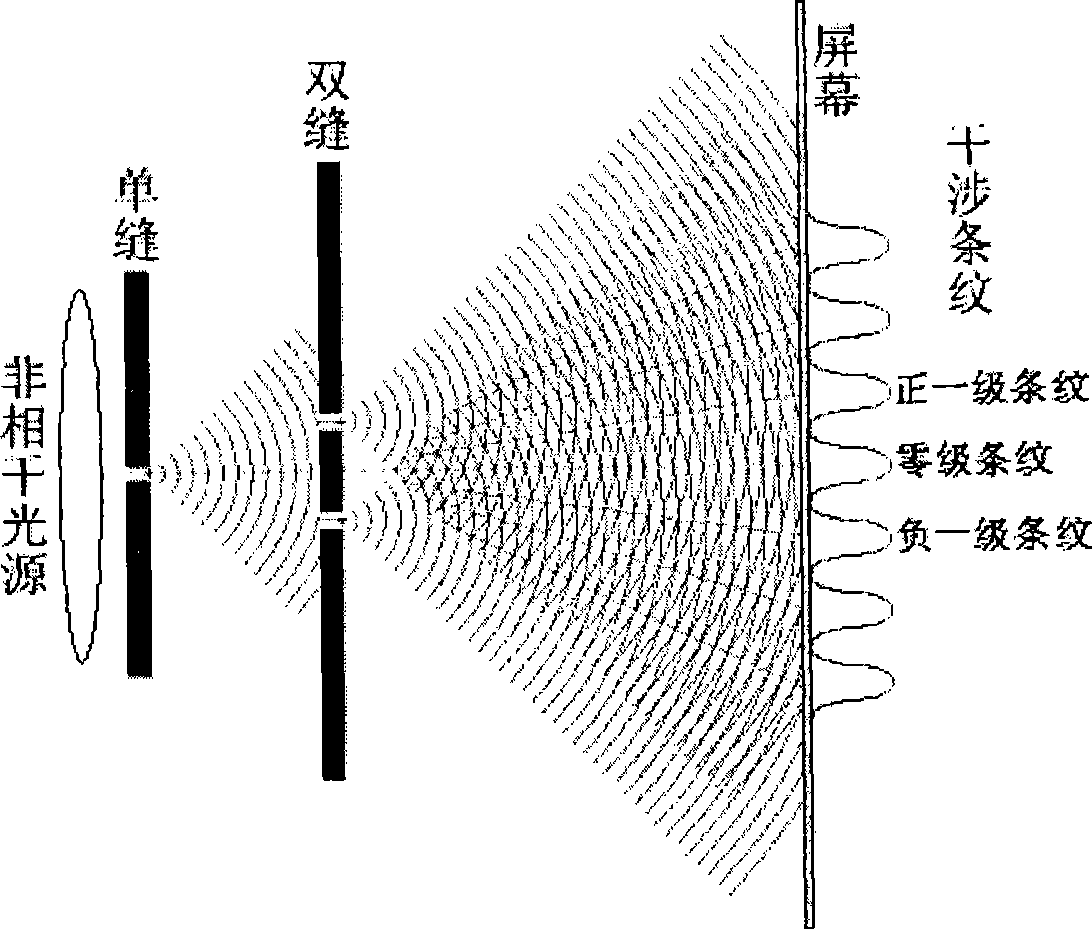

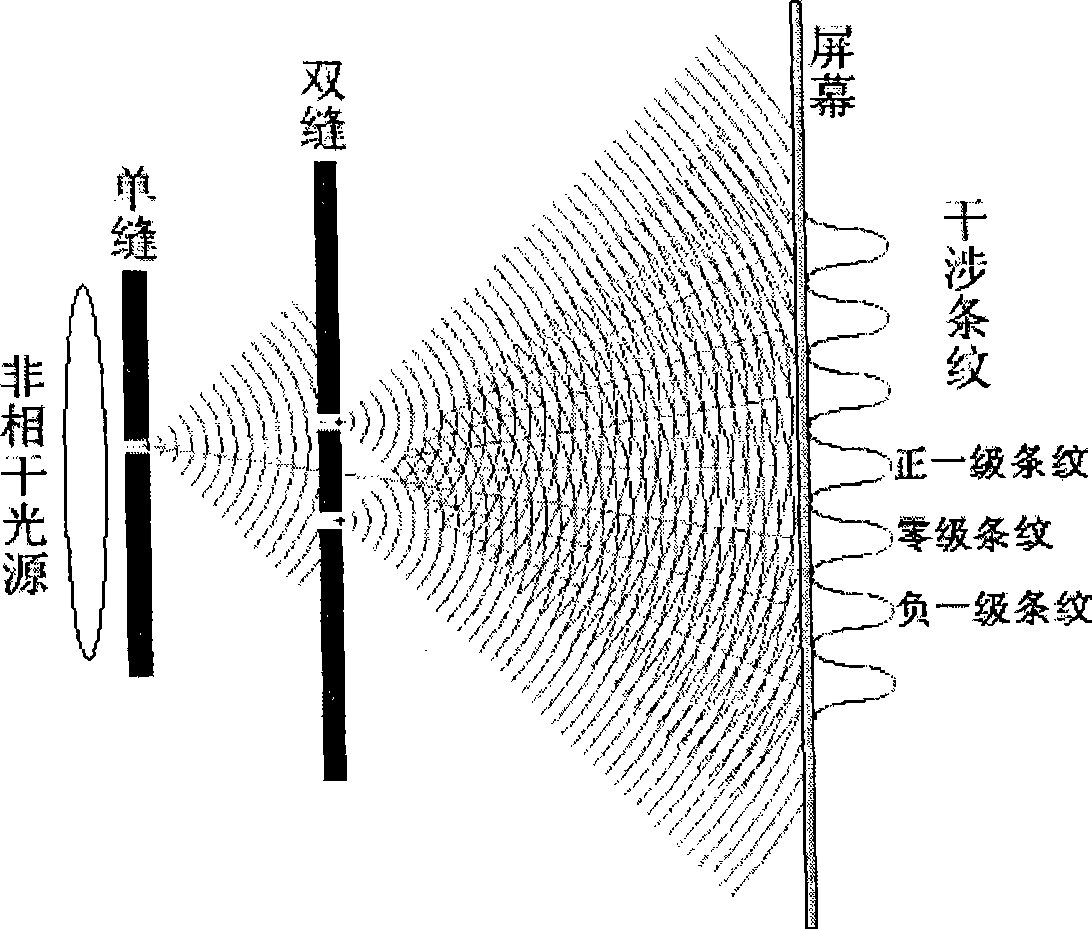

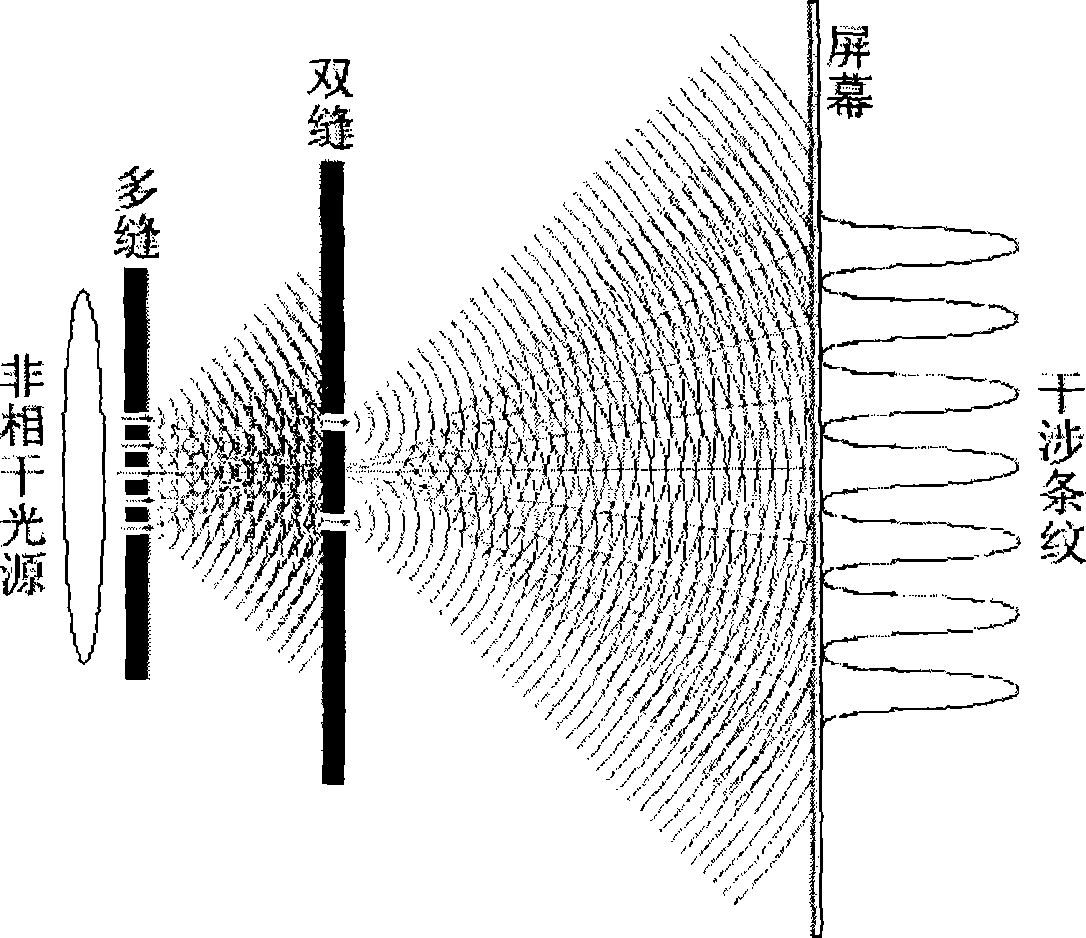

Multi-slilt filtering double slit interferometer

InactiveCN101458211AHigh strengthReduce difficultyInterferometric spectrometryPhase-affecting property measurementsRefractive indexNon coherent

The invention relates to a two-slit interferometer with a multi-slit filter, and is an improvement based on the Young's two-slit interferometer. A single-slit filter in the Young's two-slit interferometer is changed into a multi-slit filter, the multiple slits are employed to divide an incoherent light source into a plurality of independent coherent slit light sources, wherein, each slit can be employed to perform a two-slit interference experiment independently; when the positions of the multiple slits, the two slits and interference fringes satisfy a certain geometrical relation, the positions of the two-slit interference fringes generated by various slit light sources can be superposed, and the obtained two-slit interference fringe contrast is much higher than the Young's two-slit interference fringe contrast. The two-slit interferometer with the multi-slit filter can simply and facilitate the two-slit interference experiment by using a common visible light source, thus reducing the cost of the two-slit interference experiment and measuring the refractive index of materials.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACAD OF SCI

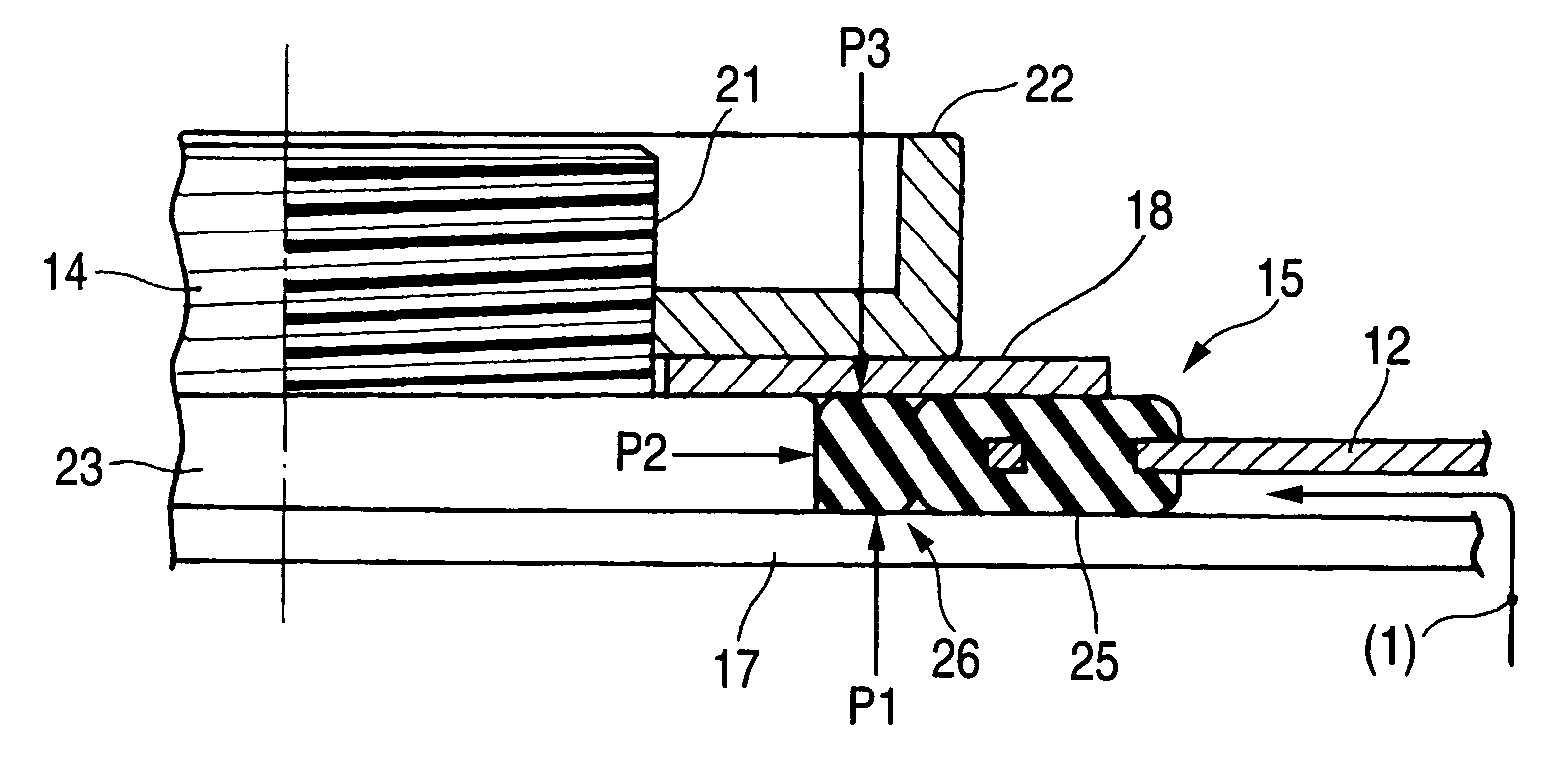

Storage battery and insulating material and battery container using the same

InactiveUS20090104521A1Extended service lifeRich in elasticityCell lids/coversElectric connector introductionAdhesiveEngineering

A storage battery which can further intensify the sealing properties of the electrode rod piercing portion thereof, a technique capable of increasing the area of the sealing surface at the sealed portion of the storage battery, a technique capable of certainly preventing the missing of mounting of a rubber-based sealing material corresponding to O-ring at the sealed portion of the storage battery, and an insulating material having an excellent corrosion resistance to highly corrosive battery content and a battery container including same are provided.An electrode rod 14 is allowed to extend upward through an annular member 15, a pressing member 18 is placed on the annular member 15, and a nut 22 is then threaded on a thread portion 21. This threading job is effected until the pressing member 18 is placed on and stopped by a collar portion 23. At the time when threading ends, a neck portion 25 is somewhat compressed to exhibit sealing properties. At the same time, a head portion 26 is drastically compressed and thus forms a first sealing portion at Point P1, a second sealing portion at Point P2 and a third sealing portion at Point P3. Further, while a disc sealing member 23 being properly compressed by the annular member 15 made of a resin and a current collecting plate 17, they are put in a vacuum heating furnace where they are then subjected to heat treatment at 160° C. in vacuo for 72 hours. This heat treatment allows PET film 25 to be heat-fused to the annular member 15 made of a resin and PET film 26 to be heat-fused to the current collecting plate 17. Moreover, a lid body 12 is formed integrally with an annular member 15 of rubber having a spindle-shaped section. And, this annular member 15 of rubber is bonded to PET film 32, 32 by the action of adhesive layer 33, 33. Since this bonding is firm, the annular member 15 of rubber cannot be detached from the lid body 12 during use.Further, an insulating material for electrode mounting to be used in a battery container which is made of a polyethylene terephthalate resin and a container having a lid member obtained by forming a polyester resin-coated aluminum sheet double-seamed attached to the opening of the body of a can are provided, and a polyethylene terephthalate resin insulating material for electrode mounting is attached to a through-hole provided piercing the central part of the lid member with an adhesive including (B) a hardener made of at least one of phenolic resin, amino resin and polyisocyanate resin incorporated in (A) a polyester resin including a dicarboxylic acid component mainly including terephthalic acid and a glycol component and having a glass transition temperature of from 30° C. to 110° C., whereby the battery content has an excellent corrosion resistance to the electrolyte including a highly corrosive propylene carbonate salt as a main component, etc. and an enhanced leakage resistance.

Owner:HONDA MOTOR CO LTD +1

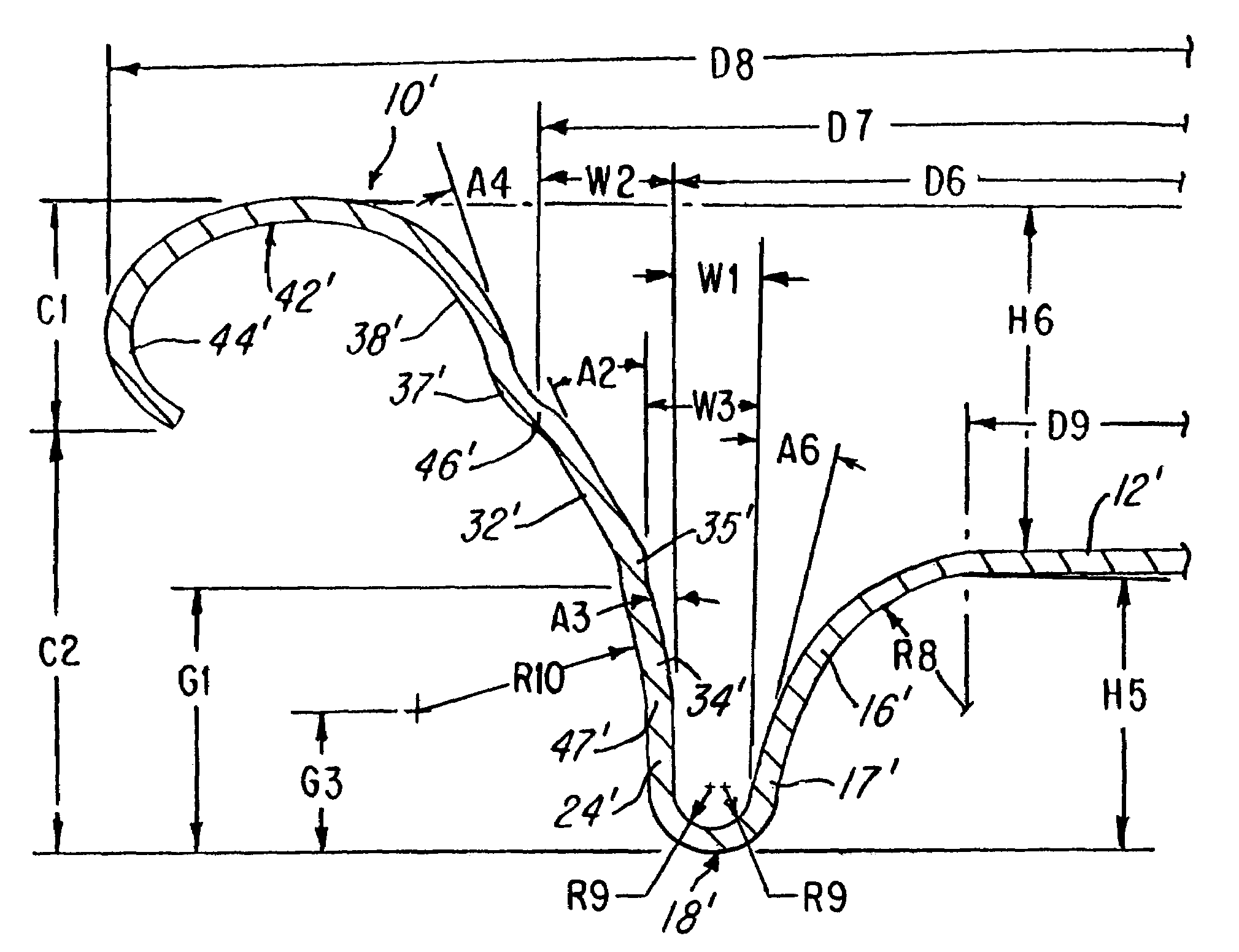

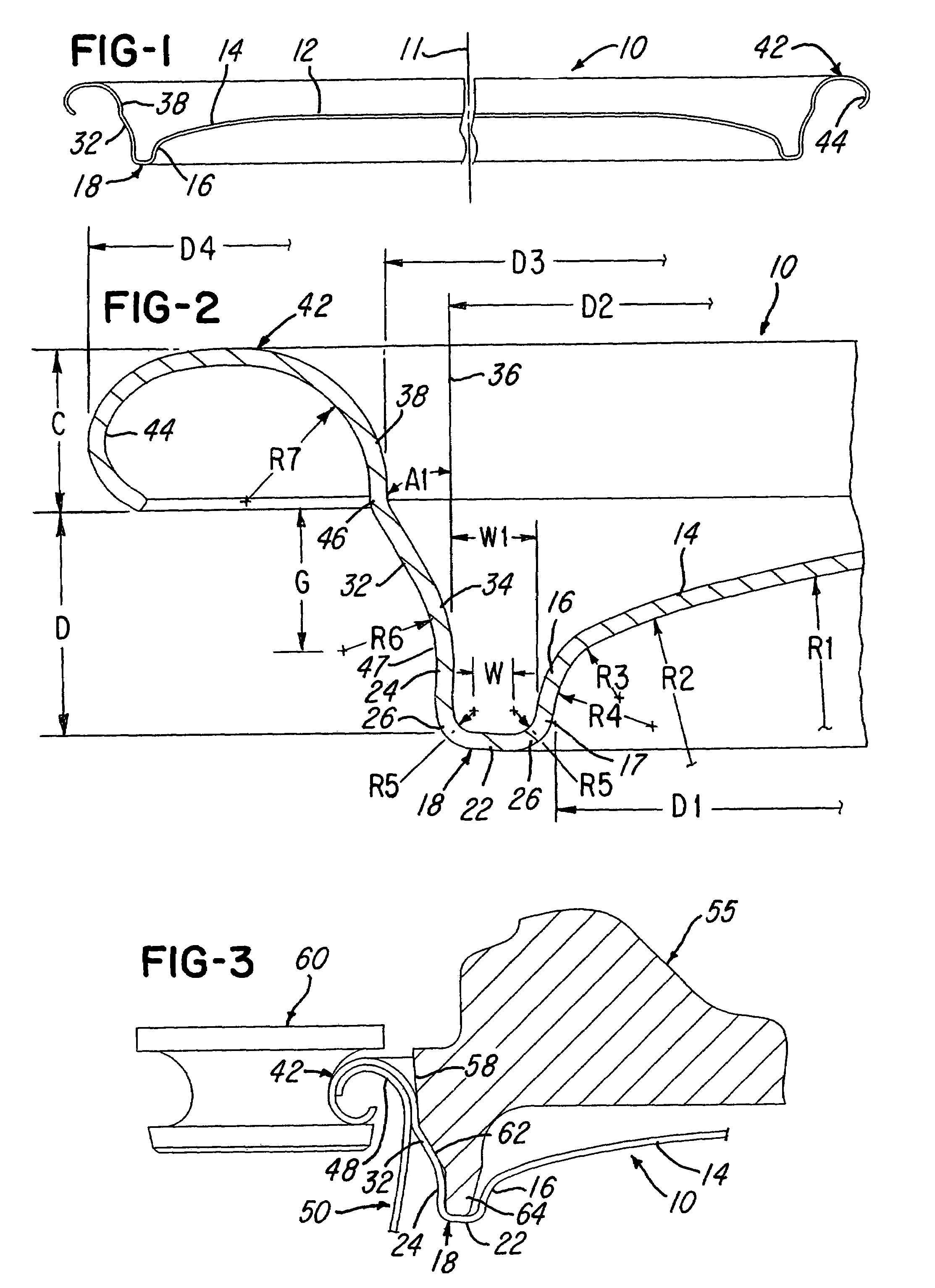

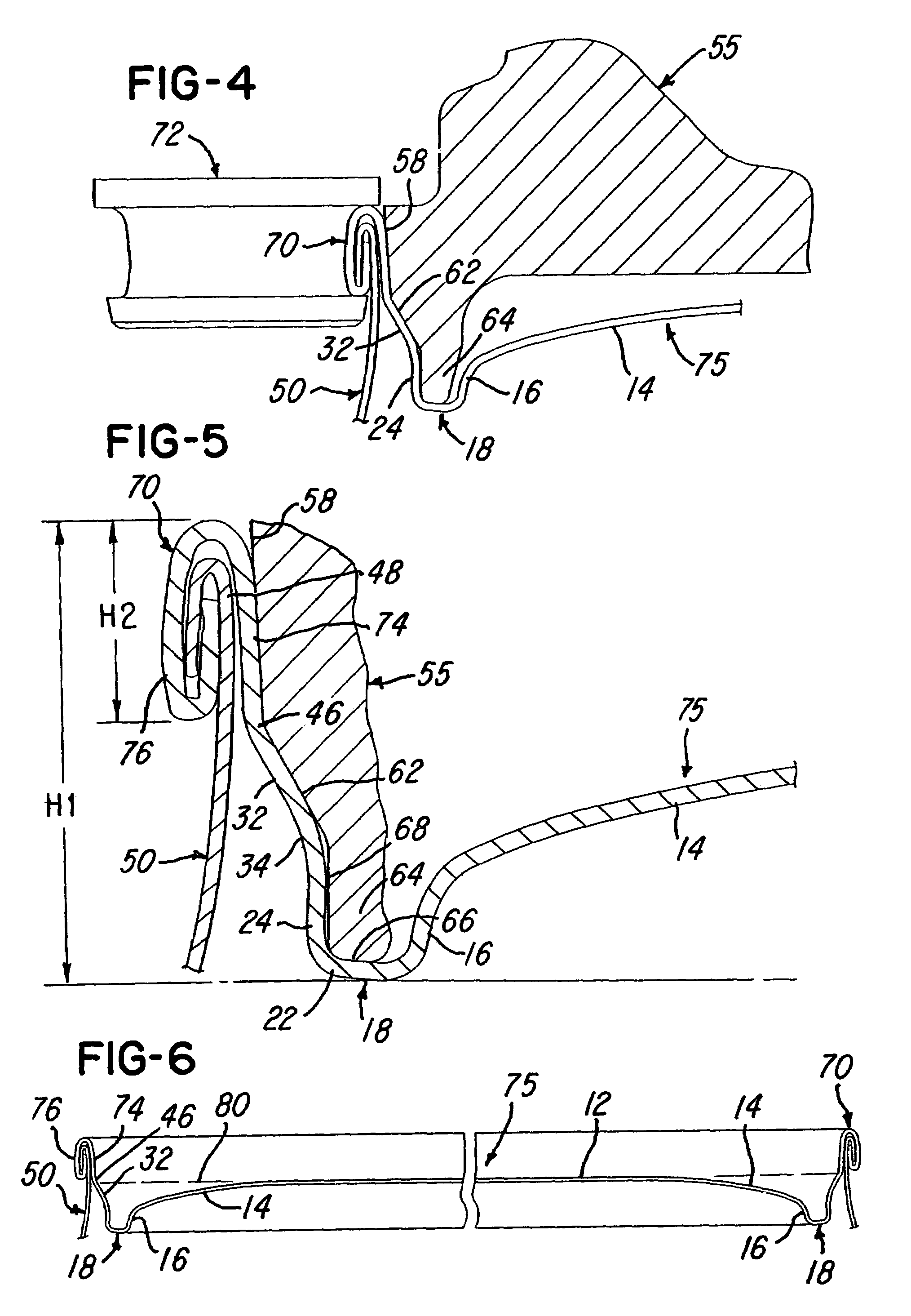

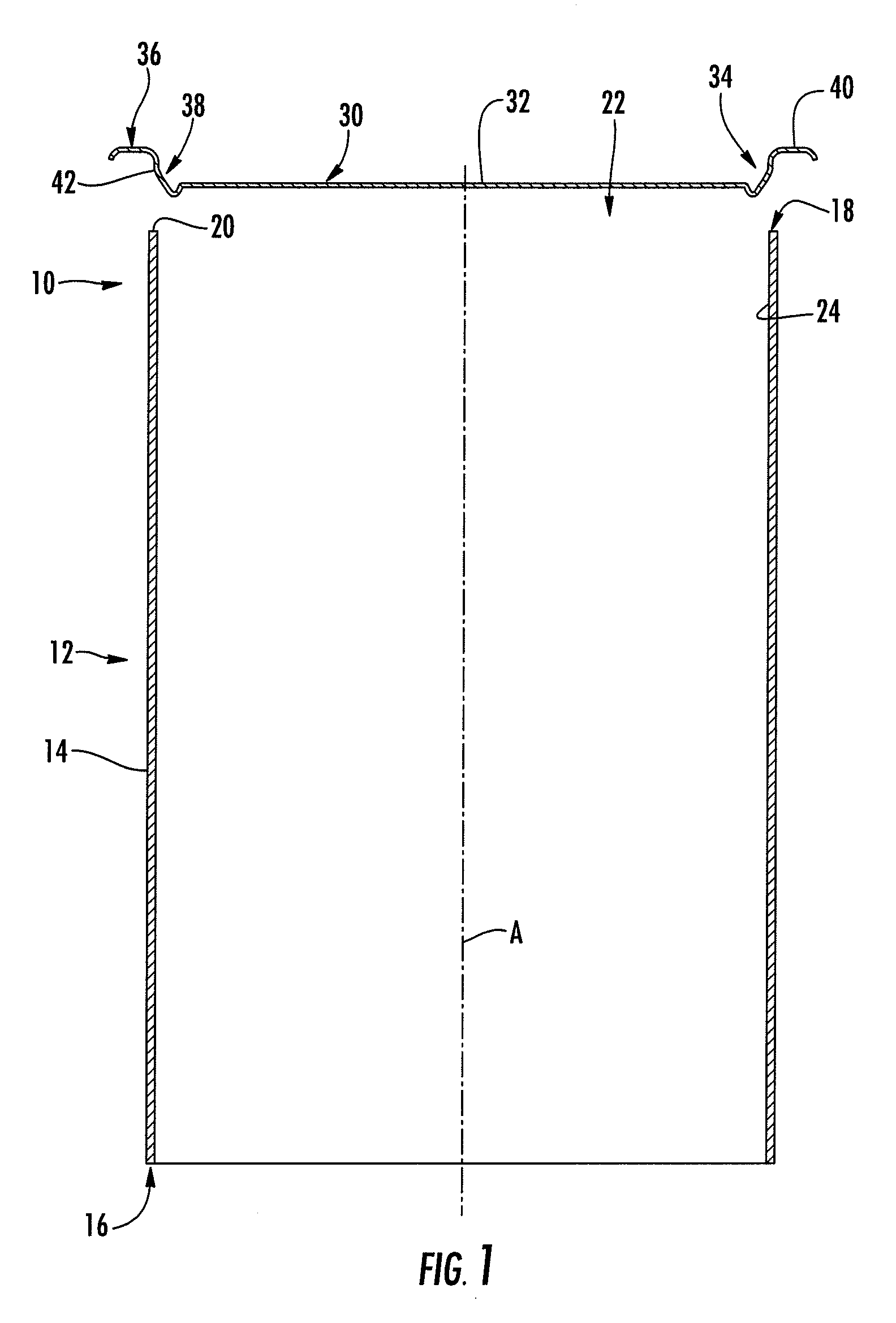

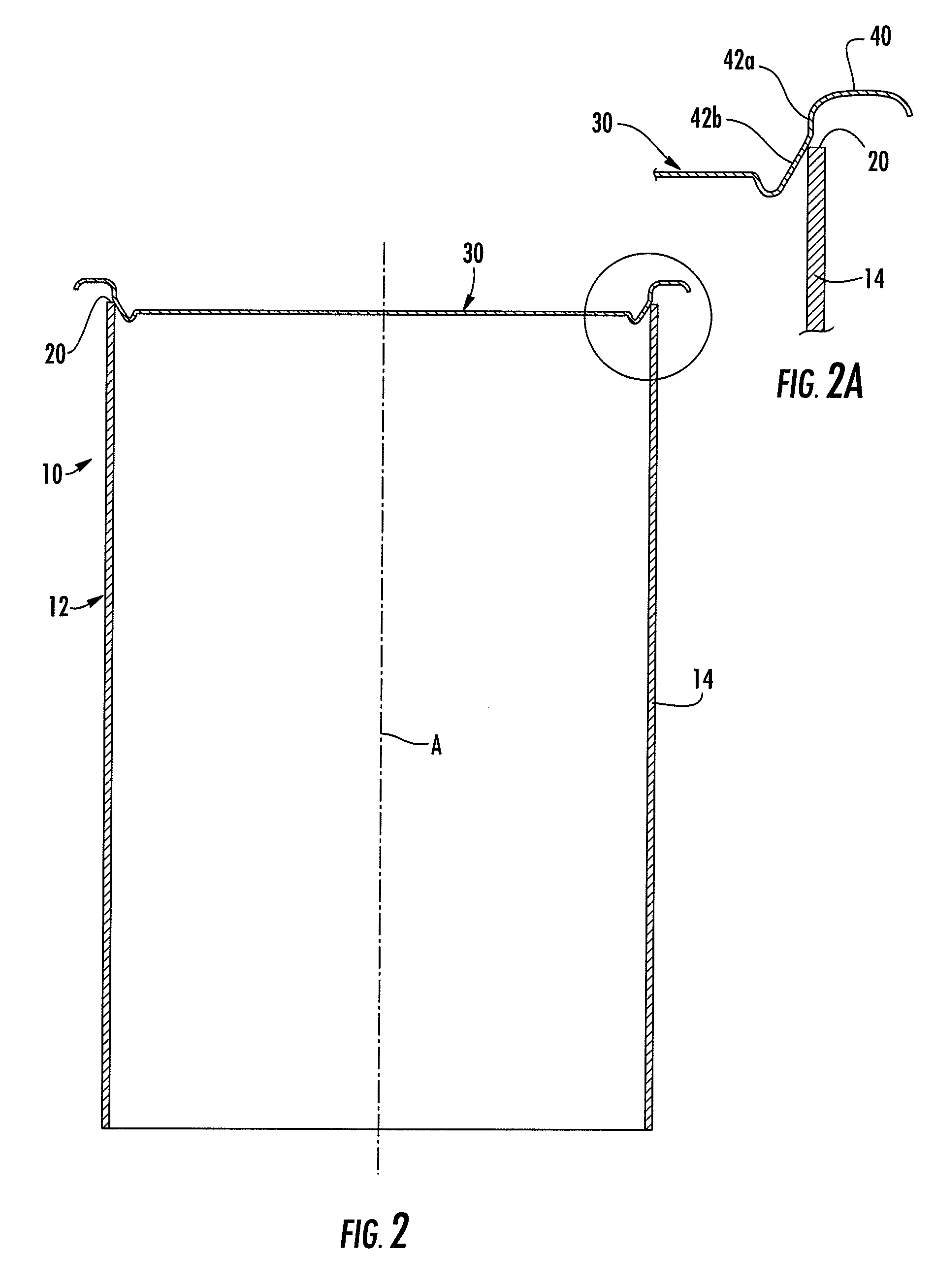

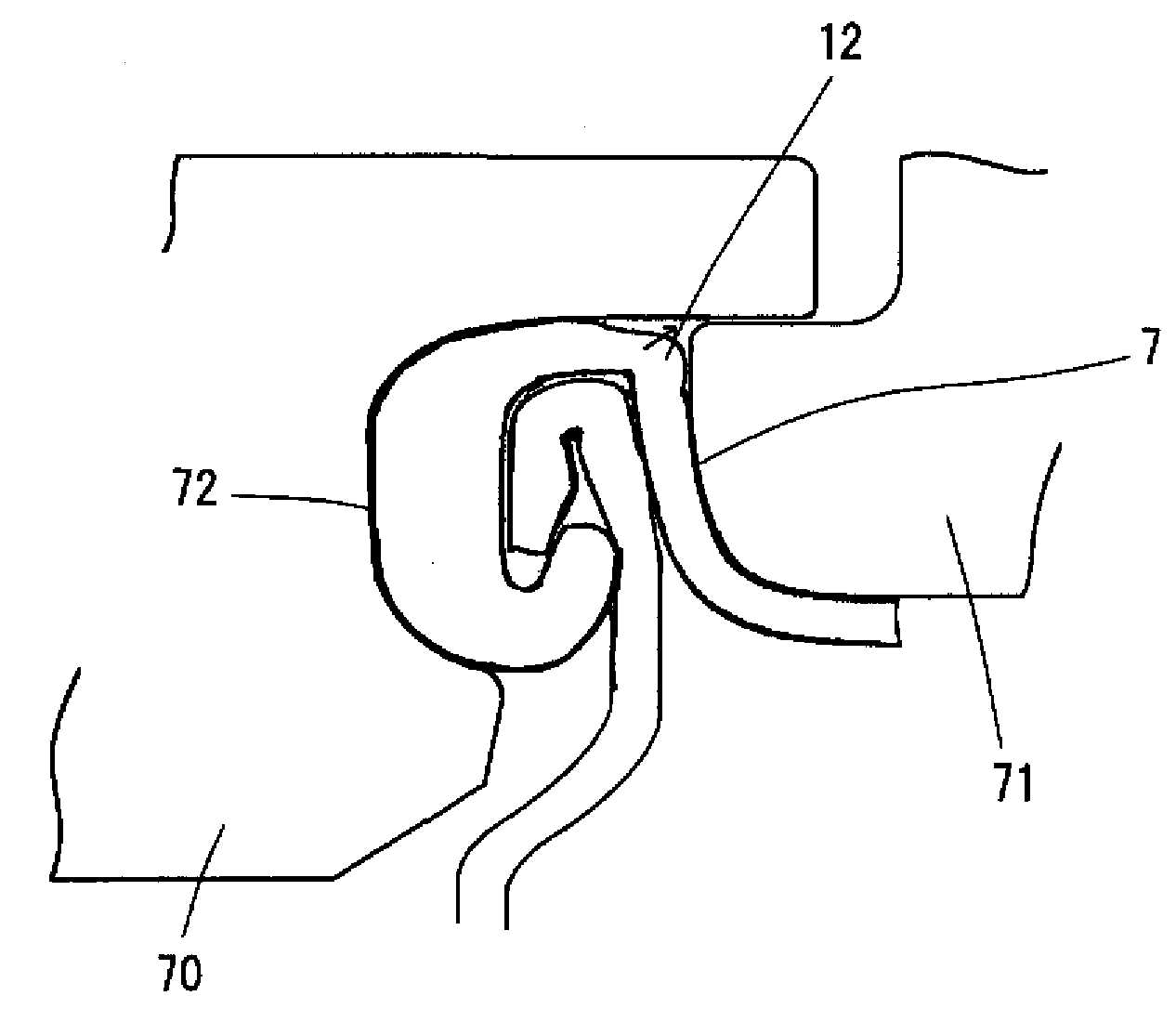

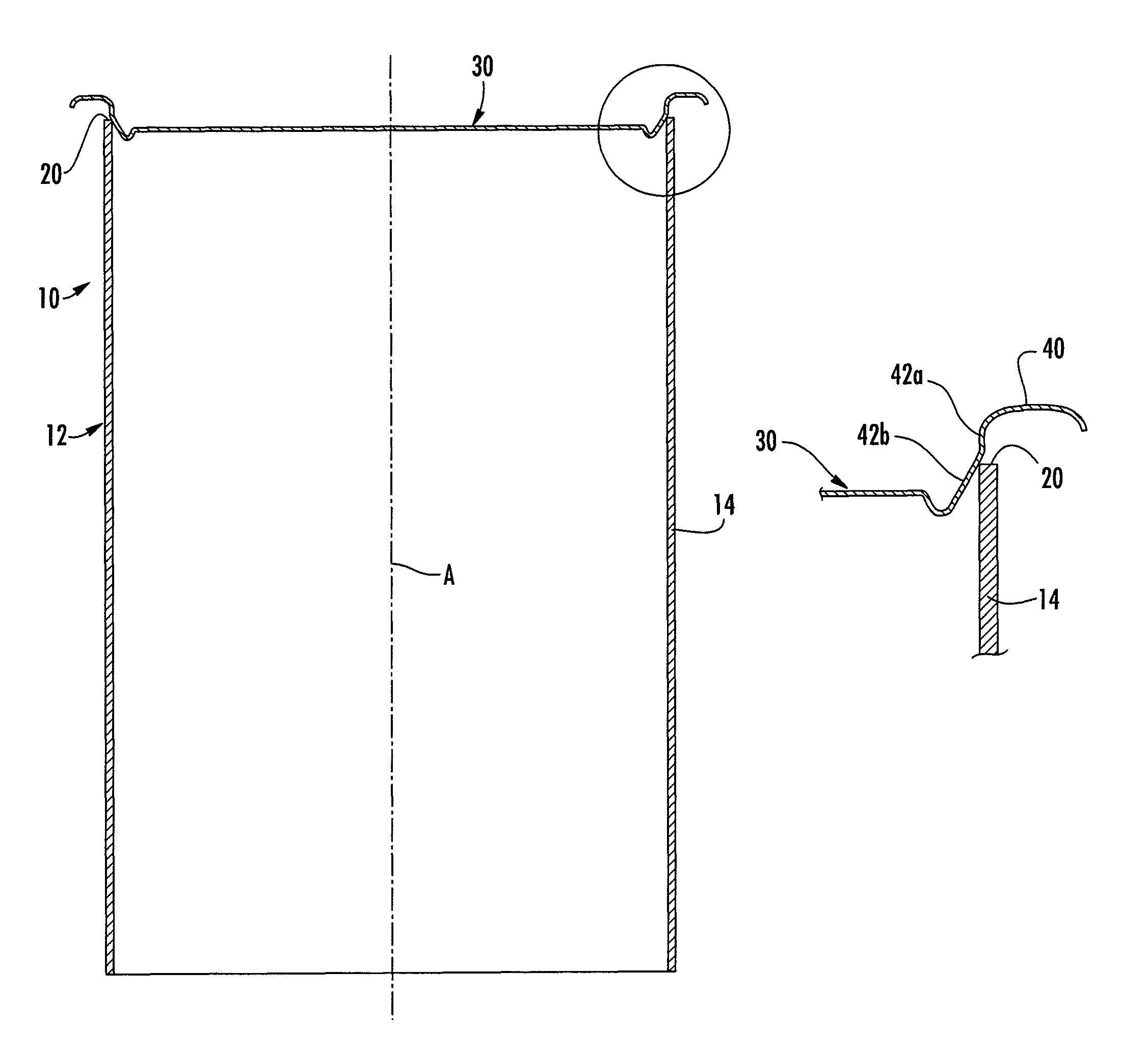

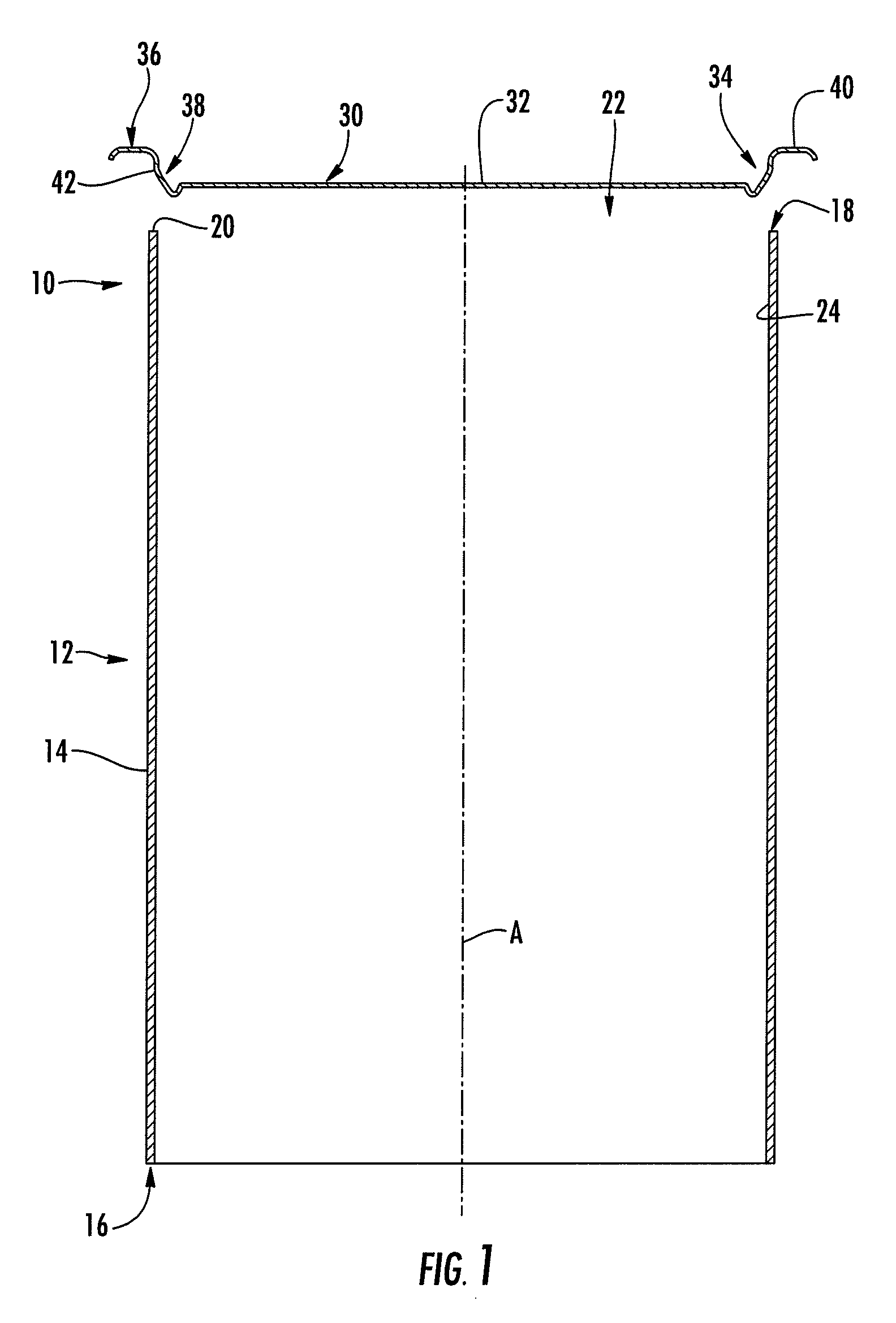

Method for Applying a Metal End to a Container Body

InactiveUS20120321415A1Reduce chanceBroaden applicationCapsFlanged caps applicationInterference fitEngineering

A metal end is applied and sealed to a plastic or paper / plastic composite container body by a crimp-seaming or double-seaming operation. The metal end has an outer curl joined to a compound-angle chuck wall that extends down from the curl. The chuck wall has an upper part that is substantially linear and at an angle α1 with respect to an axis of the end, and a lower part that is substantially linear and at a larger angle α2 with respect to the axis. The compound-angle chuck wall allows a substantial diametral clearance between a lower end of the lower part of the chuck wall and the inner surface of the container body, while there is substantially zero clearance, or preferably an interference fit, between the upper part of the chuck wall and the inner surface of the container body. Accordingly, the chuck wall guides the end into concentric alignment with the container body during application.

Owner:SONOCO DEV INC

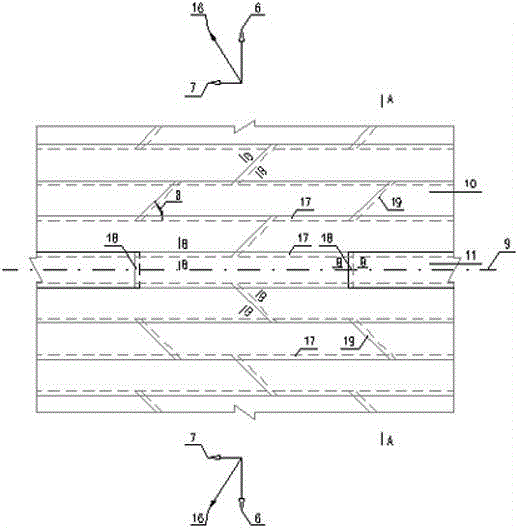

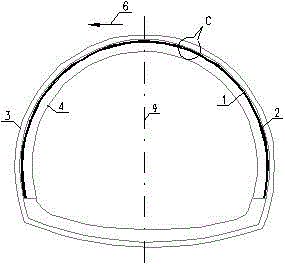

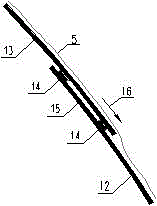

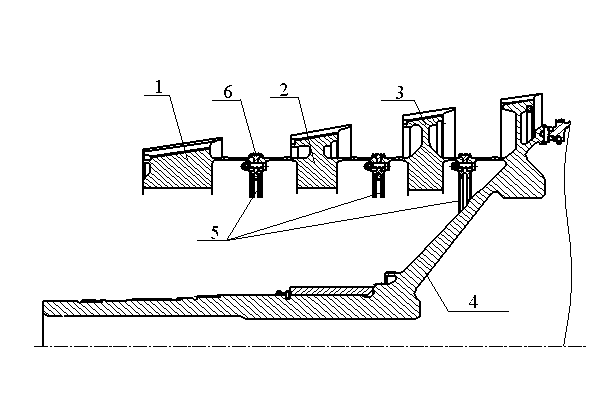

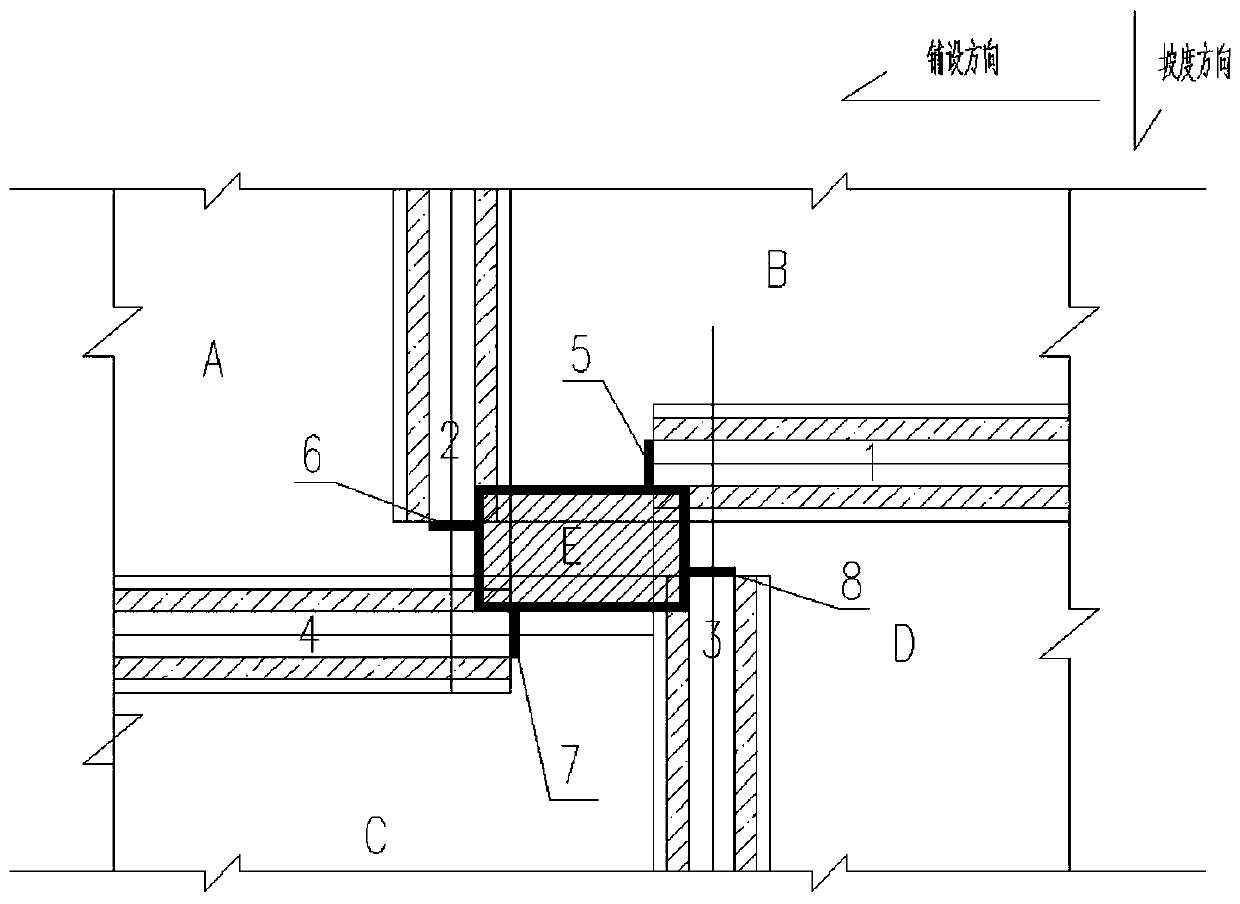

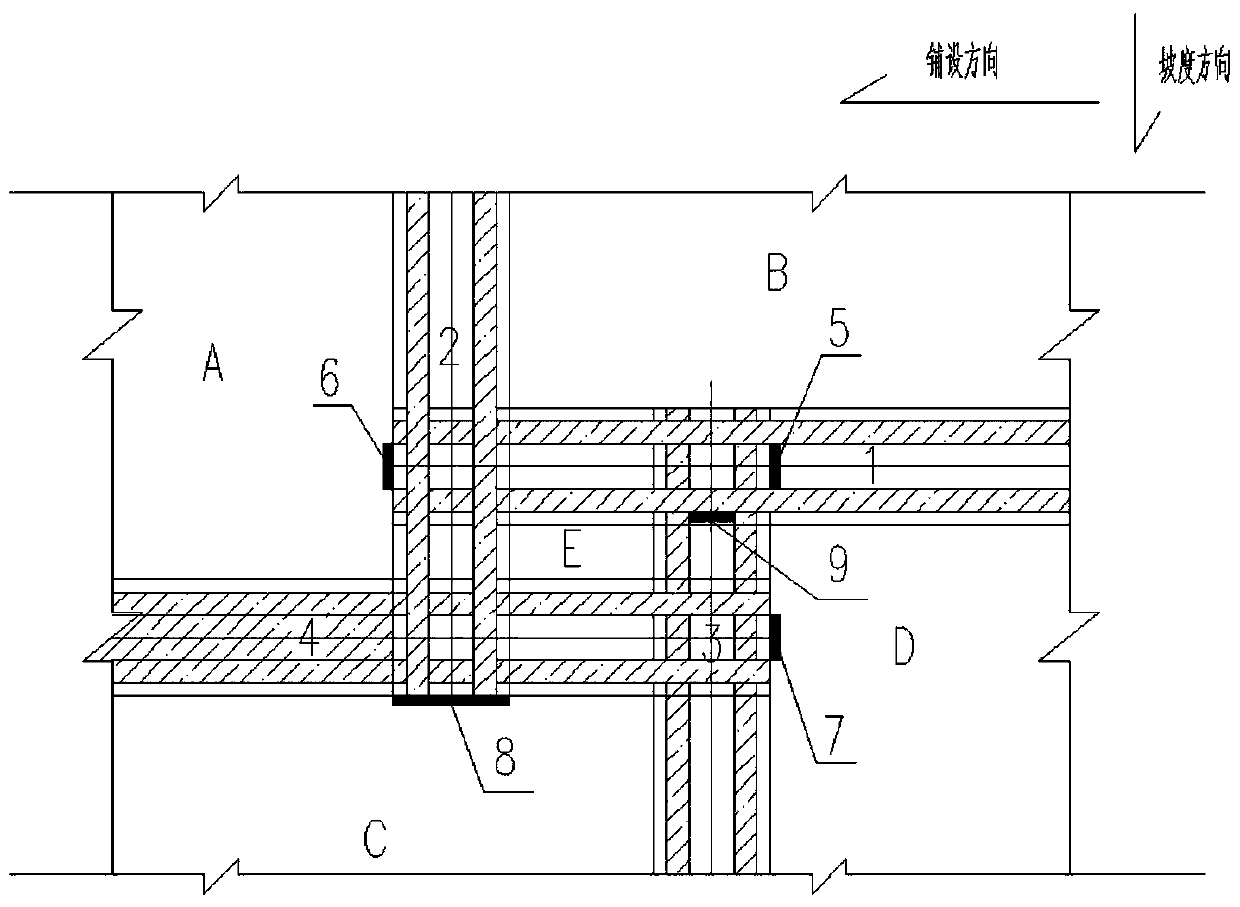

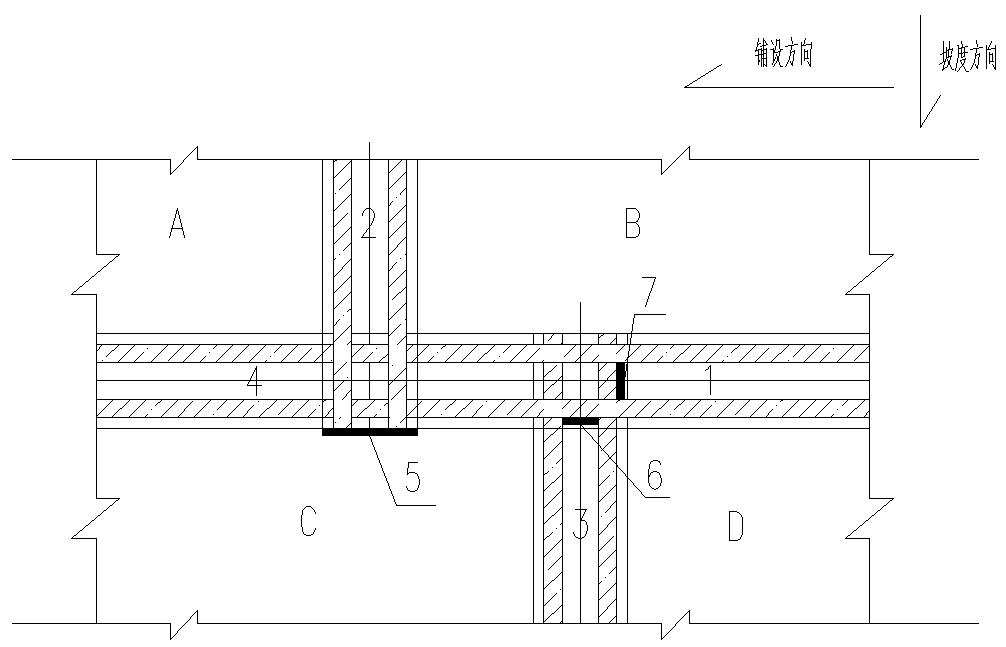

Splicing paving method of waterproof plates in tunnel and splicing paving structure of waterproof plates in tunnel

ActiveCN104018857AGuaranteed waterproof performanceRealize the principle of multi-channel defenseUnderground chambersTunnel liningWater dischargeWater flow

The invention relates to waterproof engineering in a tunnel, in particular to a splicing paving method of waterproof plates in the tunnel and a splicing paving structure of the waterproof plates in the tunnel. The method is characterized in that the splicing paving method of the waterproof plates in the tunnel belongs to a method applicable to the combination of waterproofing and water discharge. A traditional roof tile lap joint waterproof mechanism is utilized; a splicing paving method of the waterproof plates is improved; lap joint seams parallel to the water flow direction are adopted; on the basis of twice waterproofing measures of double-seam welding of the existing waterproof plates, one waterproof measure of adopting a joint seam which is parallel to the water flow direction and is not directly correlated to the welding quality of the waterproof plates is added; a multiple-protection-measure principle of the waterproofing in the tunnel is perfectly realized; the waterproof hidden danger can be effectively eliminated; and the waterproof effect of the joint seams is ensured. The paving technology of waterproof rolls in the longitudinal direction of the tunnel is adopted; an operation platform for a special trolley for waterproof plate pavement and a track walking technology are utilized; the horizontal operation in the same elevation platform and the continuous paving operation of the whole roll of the waterproof rolls can be realized; the work intensity of workers can be reduced; and the work efficiency for paving the waterproof plates is improved.

Owner:FUZHOU PLANNING DESIGN & RES INST

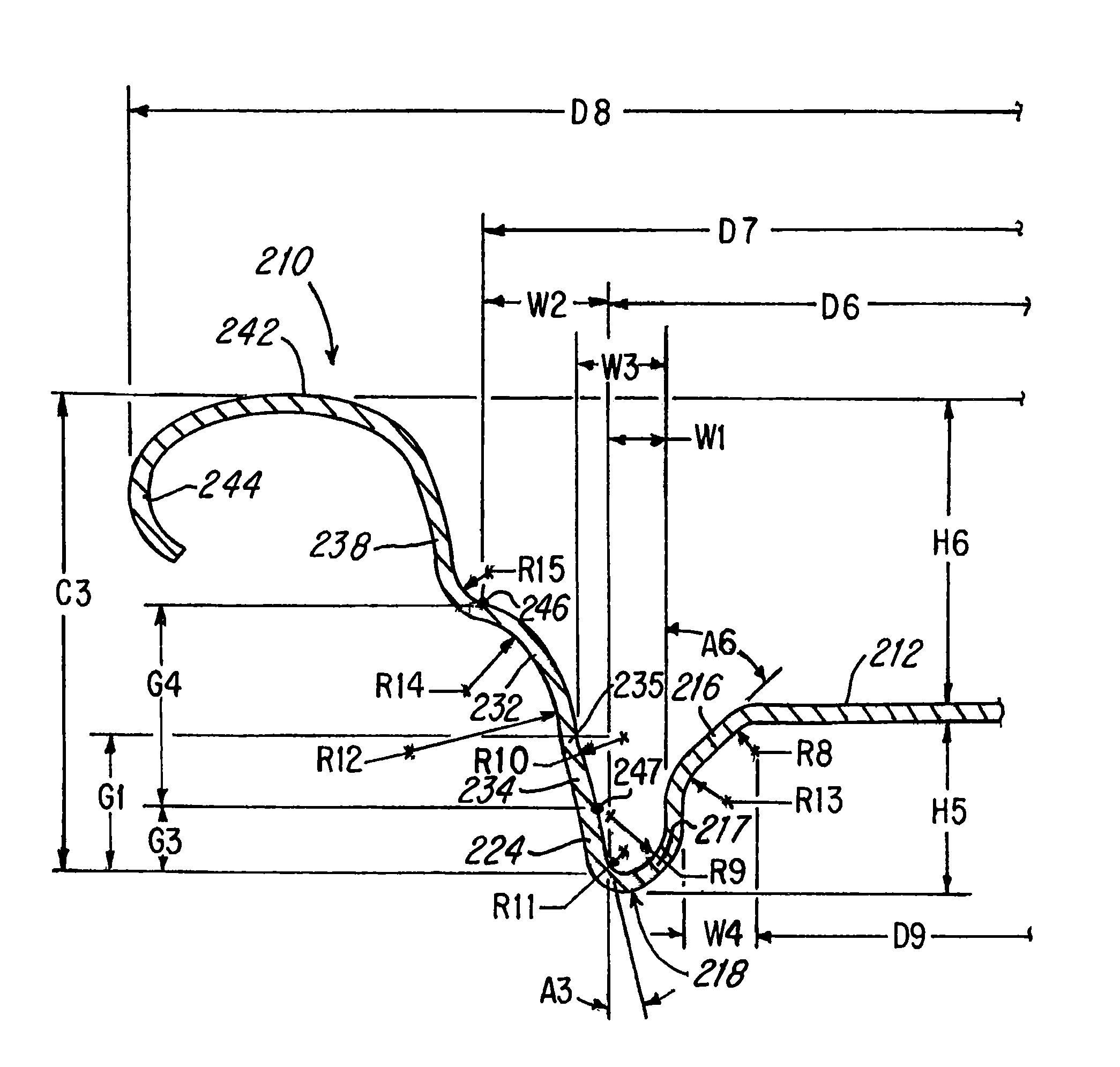

Can Shell and Double-Seamed Can End

InactiveUS20110031256A1Reduction in blank diameterIncrease strength/weight ratioRigid containersHollow articlesEngineeringDouble seam

A drawn aluminum can shell has a peripheral crown which is double-seamed with an end portion of an aluminum can body to provide a can end having a generally flat center panel connected by an inclined curved or straight panel wall to an inclined inner wall of an annular U-shaped countersink. The countersink has an outer wall which connects with an inclined lower wall portion of a chuckwall at a junction below the center panel, and the chuckwall has a curved or inclined upper wall portion which connects with an inner wall of the crown. The chuckwall also has an intermediate wall portion forming a break, and the inner bottom width of the countersink is less than the radial width of the panel wall. The inclined upper wall portion of the chuckwall extends at an angle greater than the angle of the inclined lower wall portion of the chuckwall.

Owner:BALL CORP +1

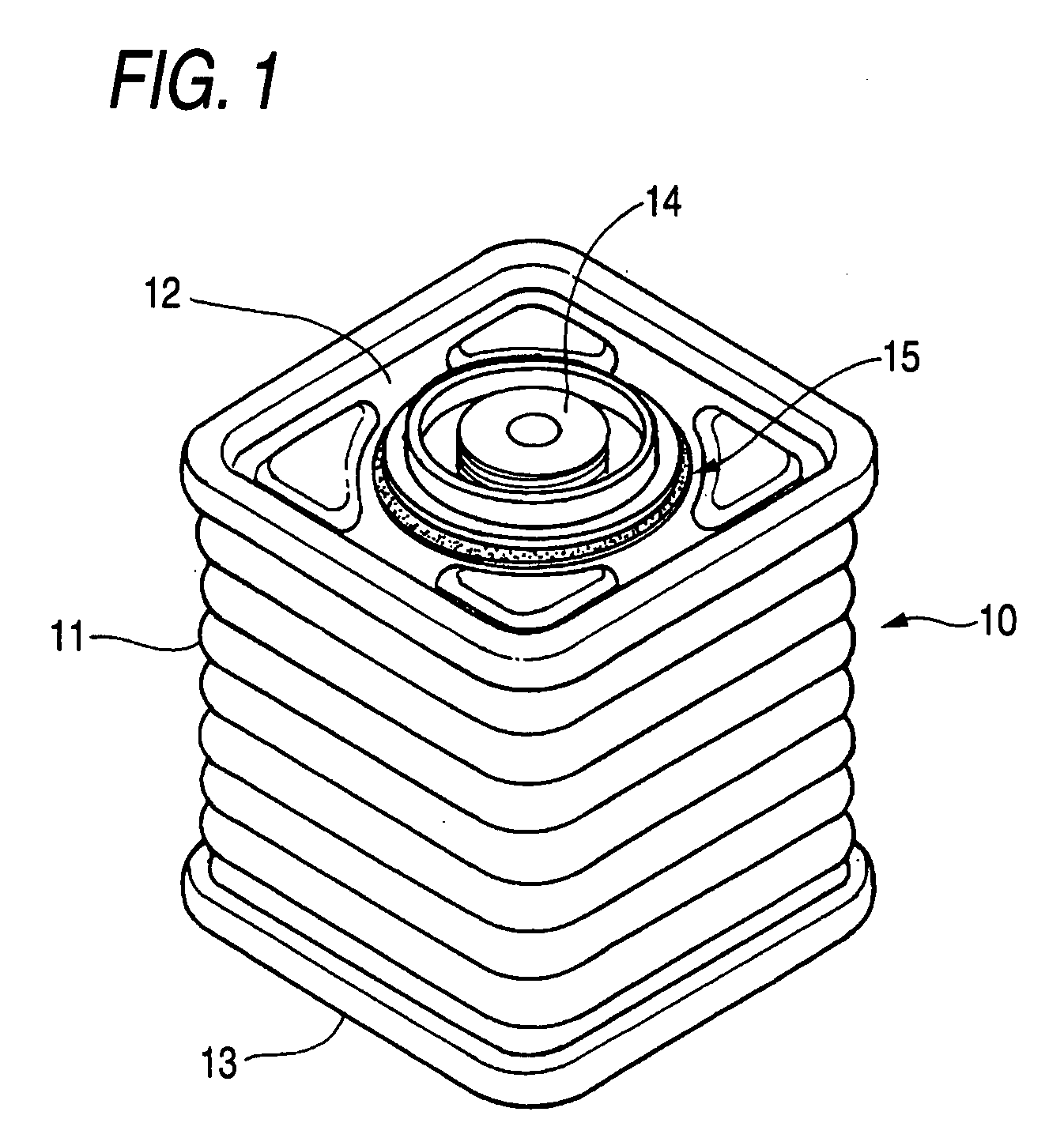

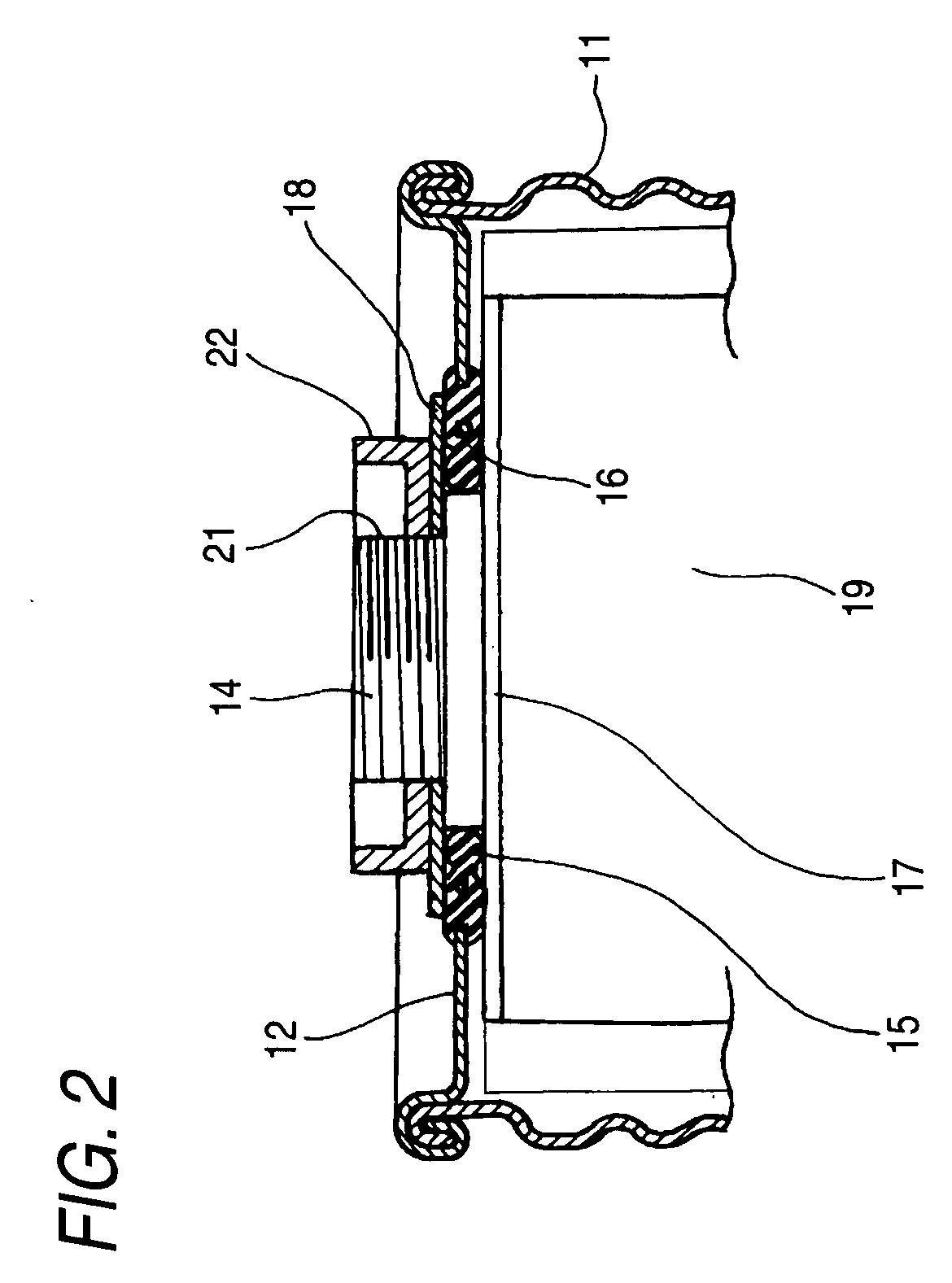

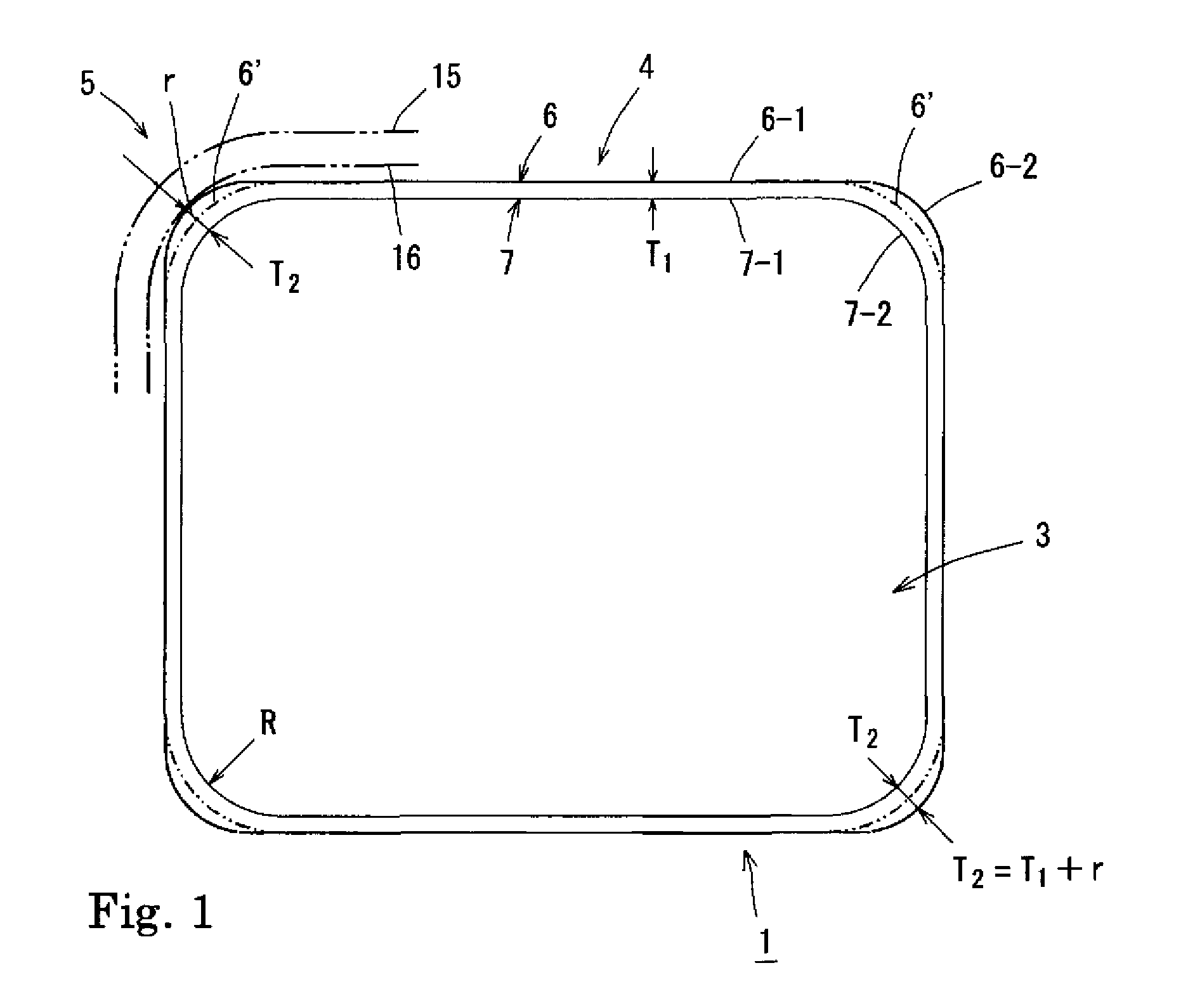

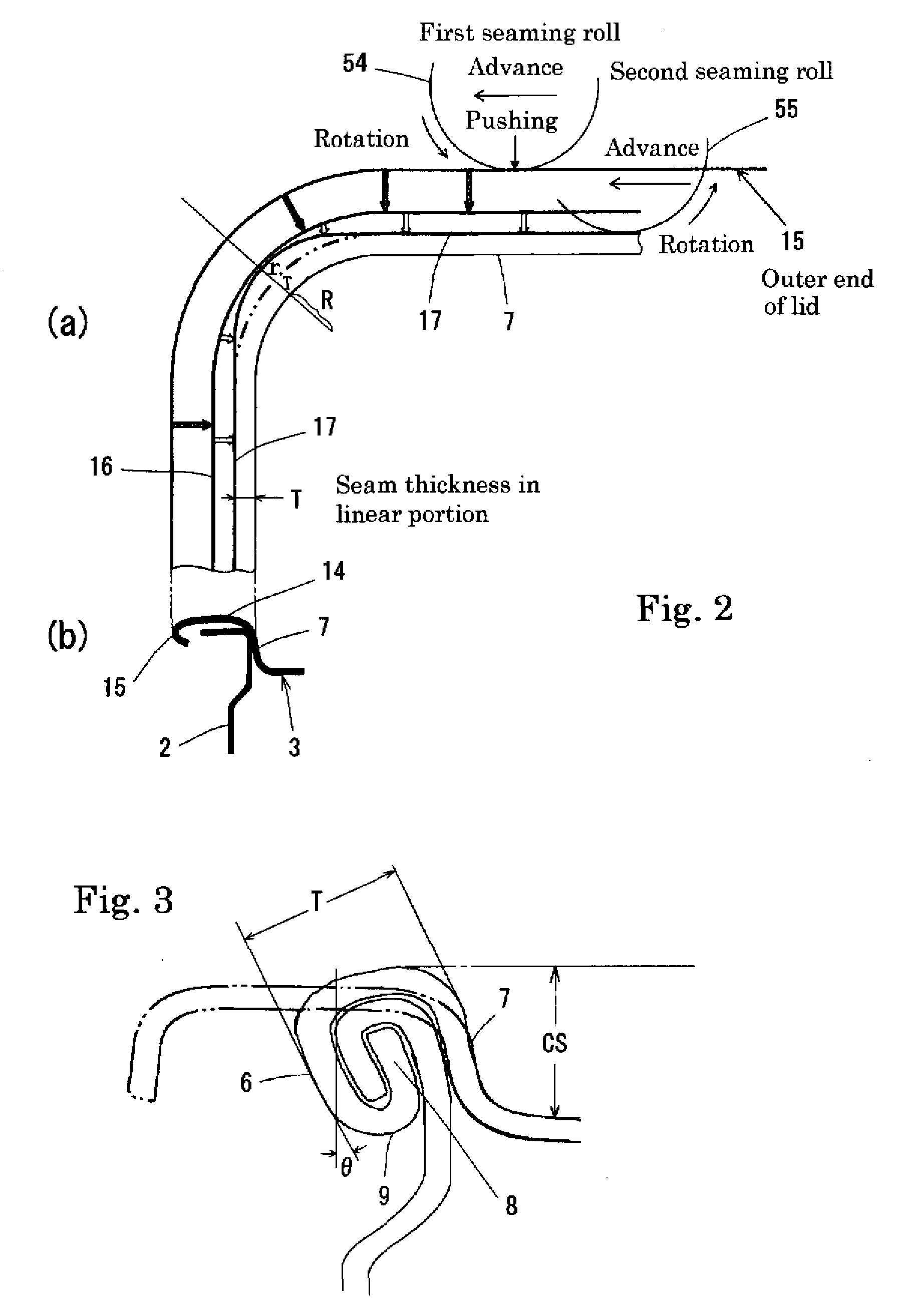

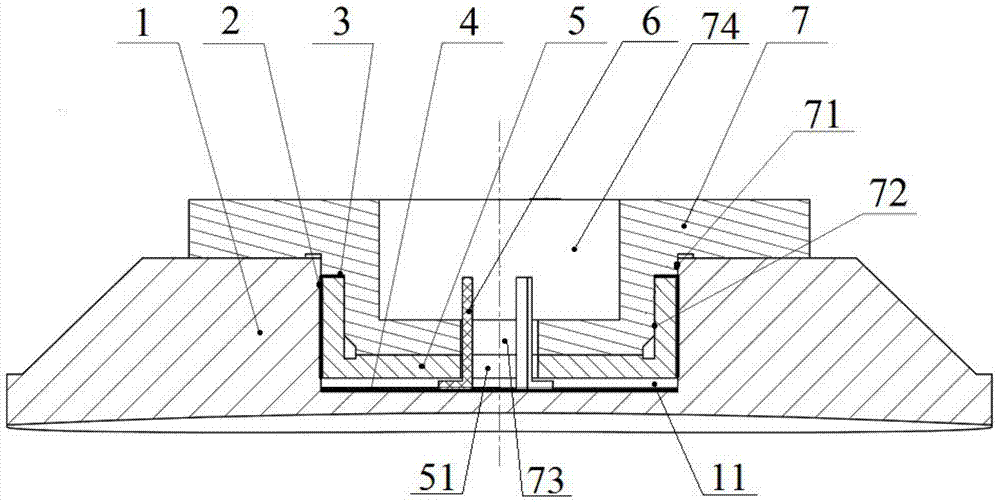

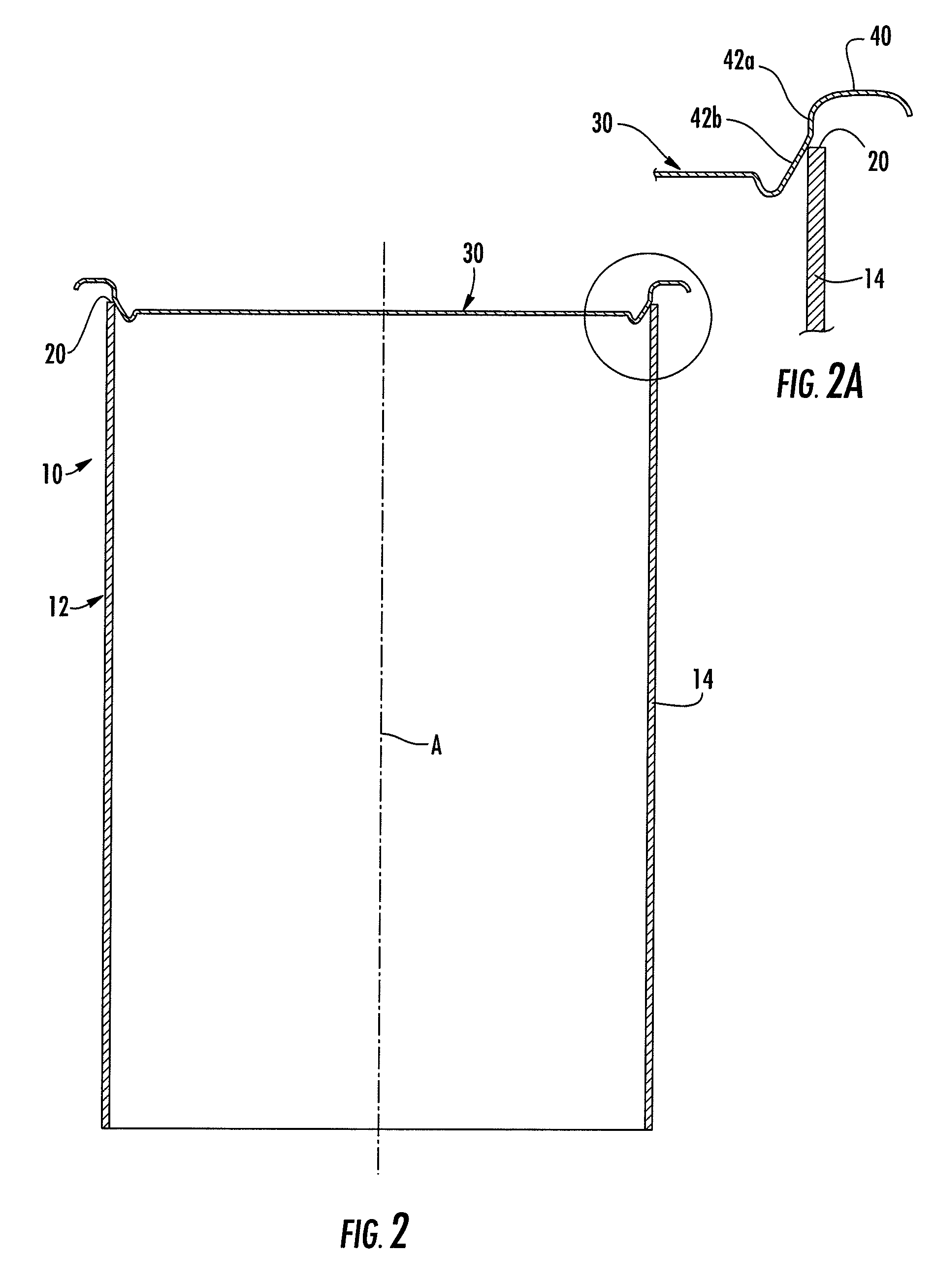

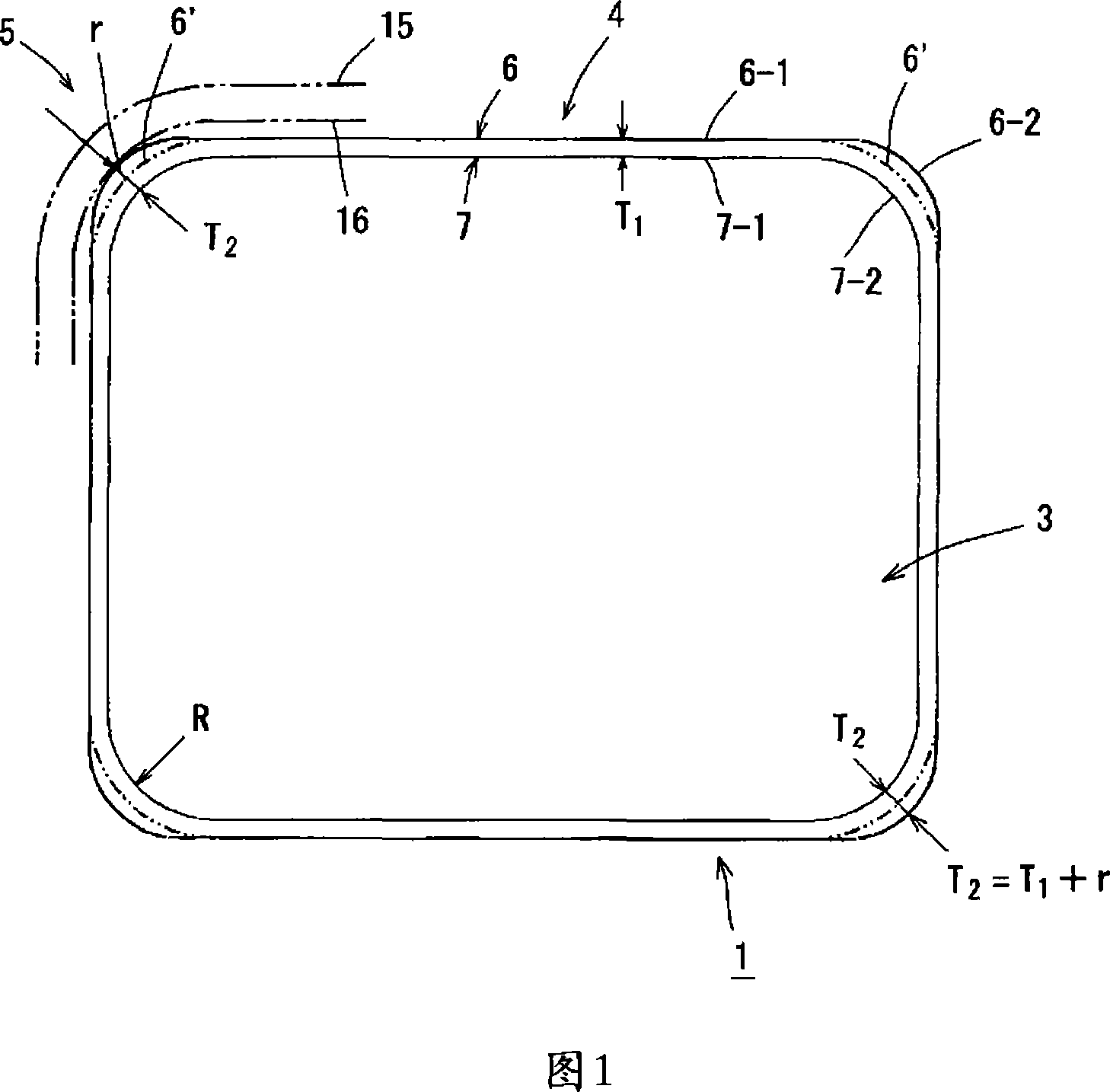

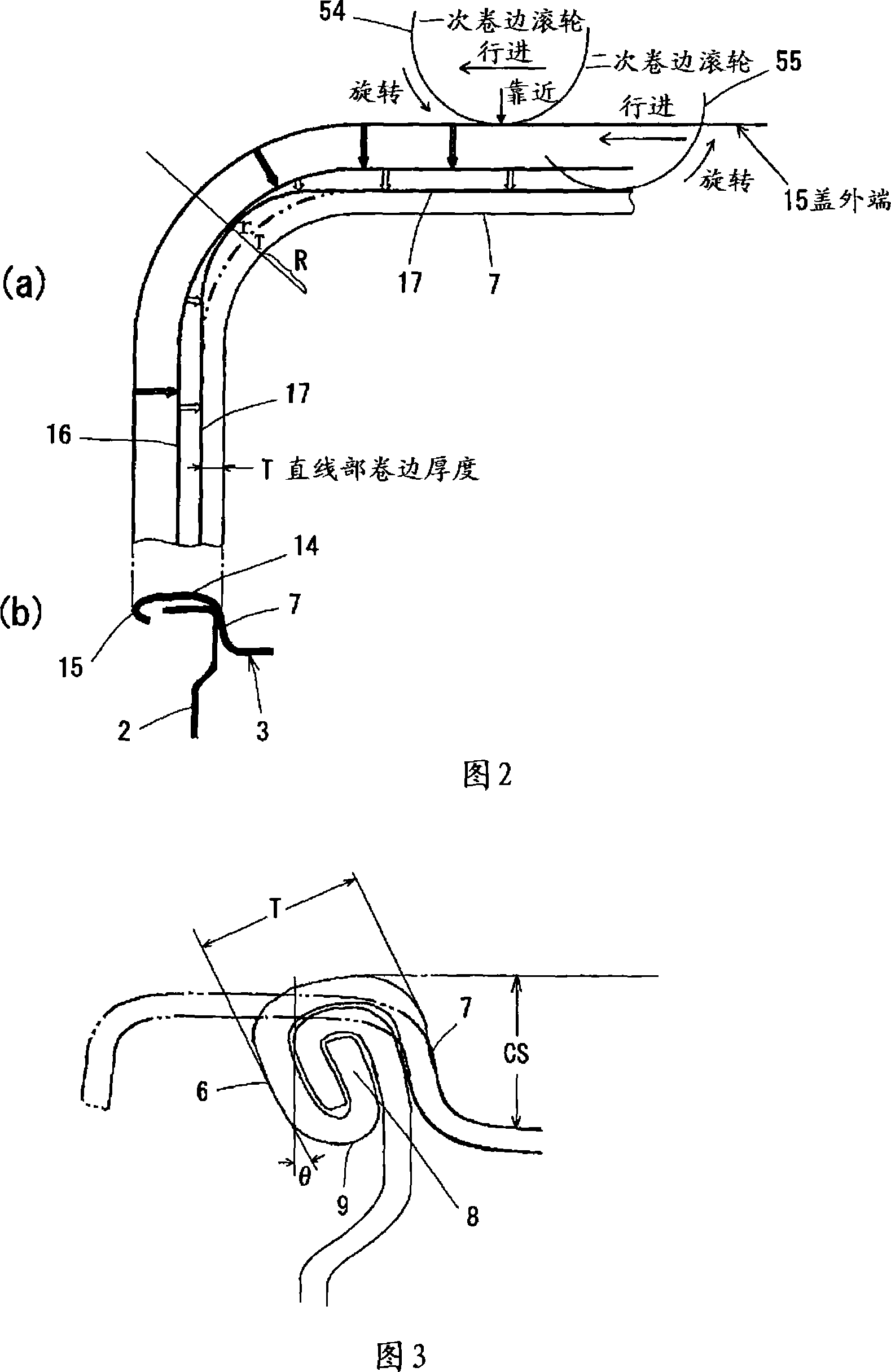

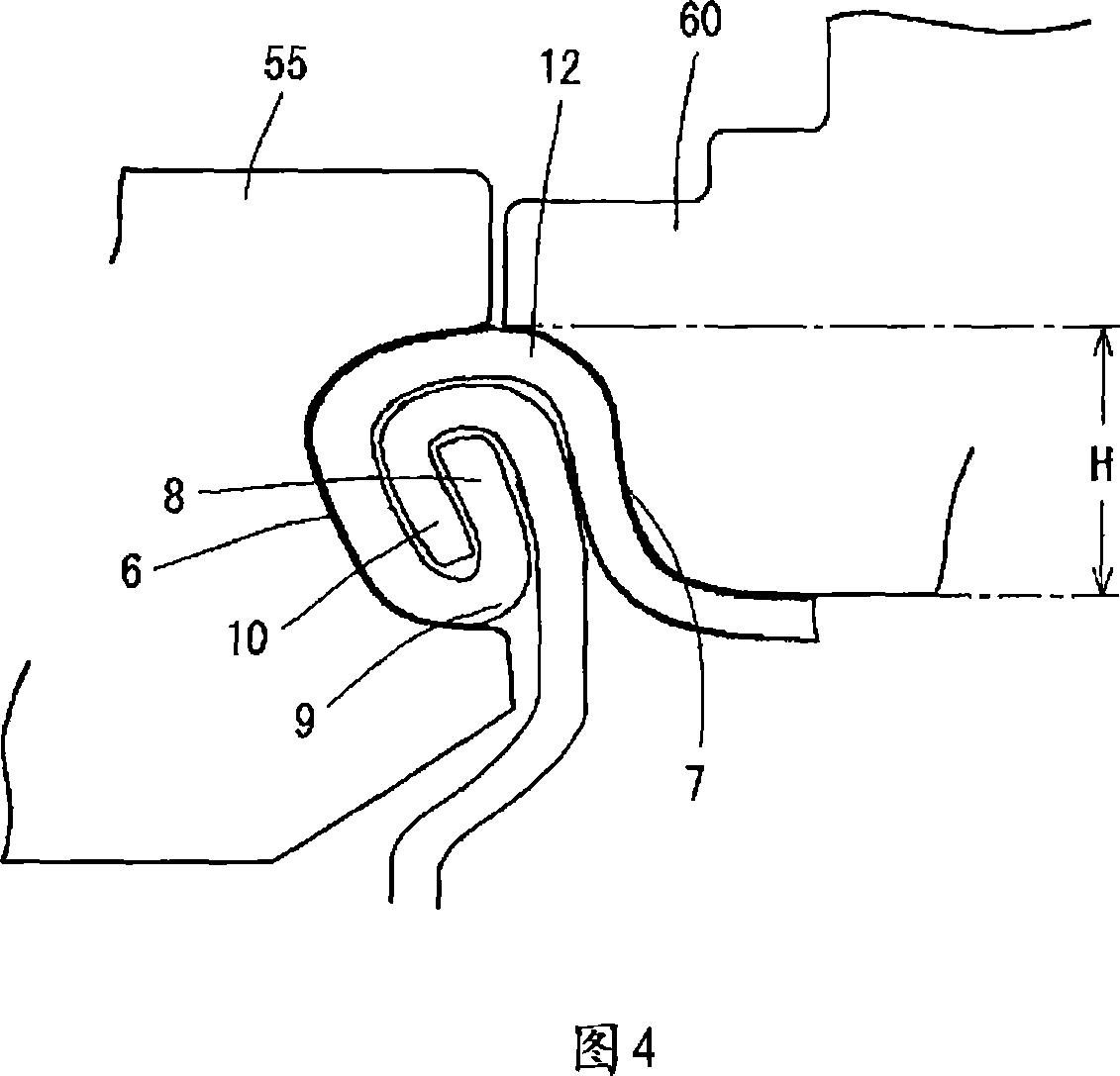

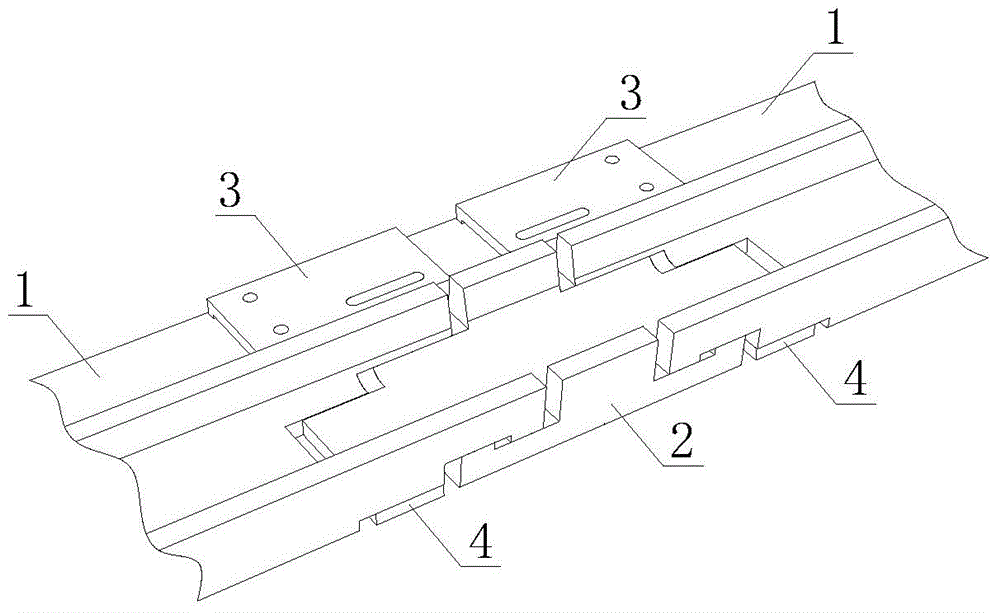

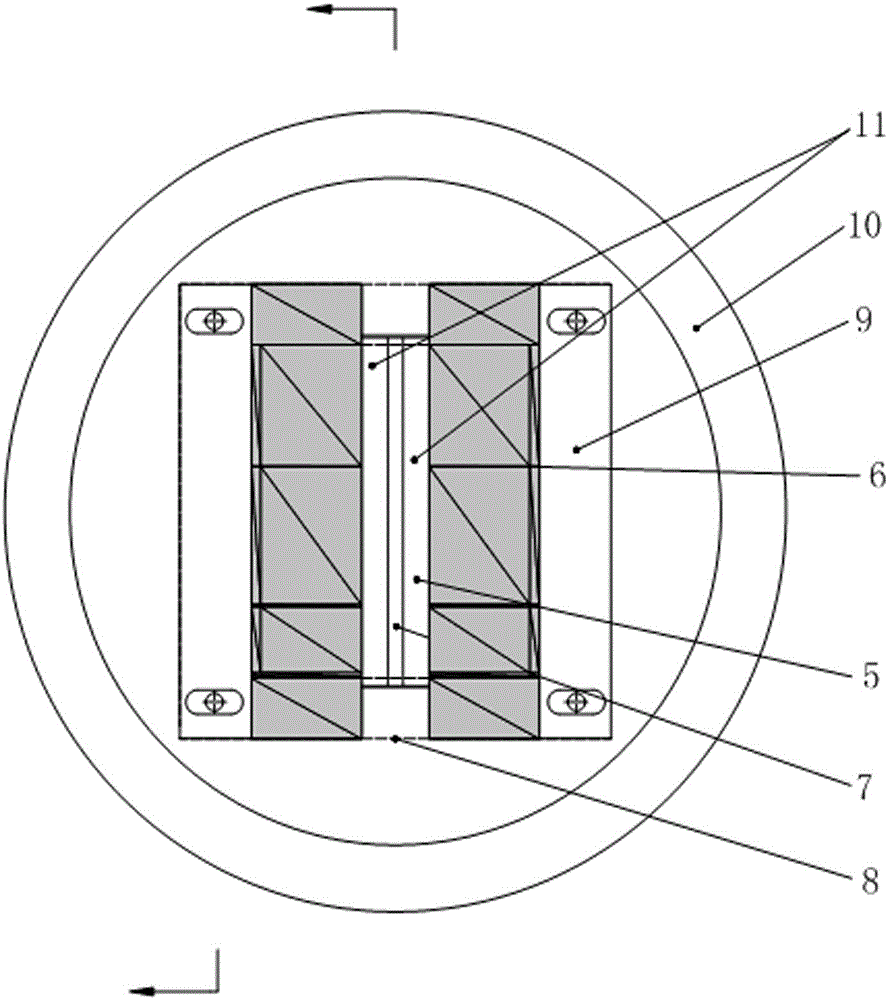

Square can and method and apparatus for double seaming the same

InactiveUS20090200321A1Reduced sealing abilityImprove sealingRigid containersHollow articlesEngineeringCam

ABSTRACT A square can capable of securing high sealing performance even if a curvature radius of a seamed portion at a seamed corner portion is reduced, enabling a reduction in a countersink depth, reduced in size, having excellent sealing ability and storage efficiency and a method and an apparatus for double seaming the square can. A second seaming roll (55) is guided by a model cam for second seaming having a model cam surface for second seaming formed in such a shape that it is swelled from a model cam surface for first seaming outwards at a corner seamed portion (5). Accordingly, the seaming shape of the corner seamed portion (5) is formed in such a shape that the seaming width thereof at the center of the corner seamed portion is larger than the seaming width of a linear sealed portion (4) and is swelled outwards to absorb an increase in sheet thickness at the corner seamed portion. Also, a seaming wall (6) is formed in an obliquely inclined seamed shape so that the overlap of a cover hook (8) with a body hook (10) of a prescribed amount can be secured without allowing the cover hook (8) to fall from the body hook (10) so as to maintain excellent sealing ability.

Owner:TOYO SEIKAN KAISHA LTD

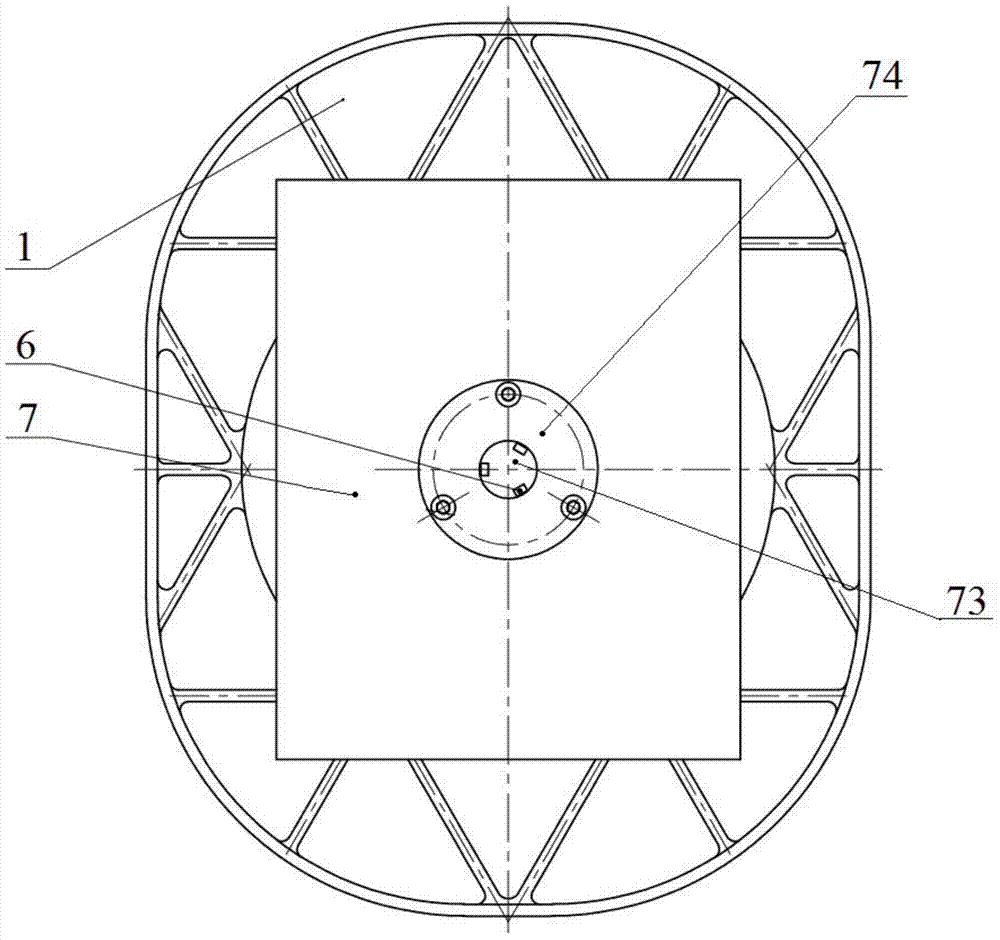

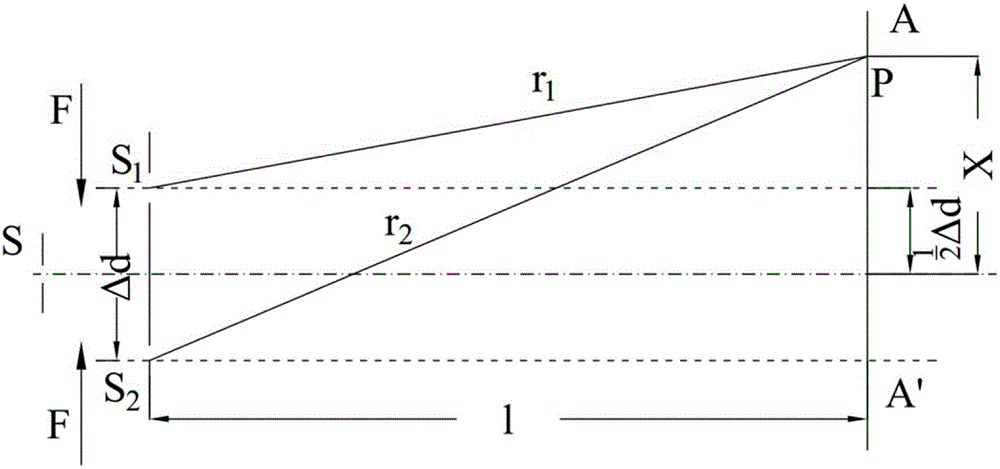

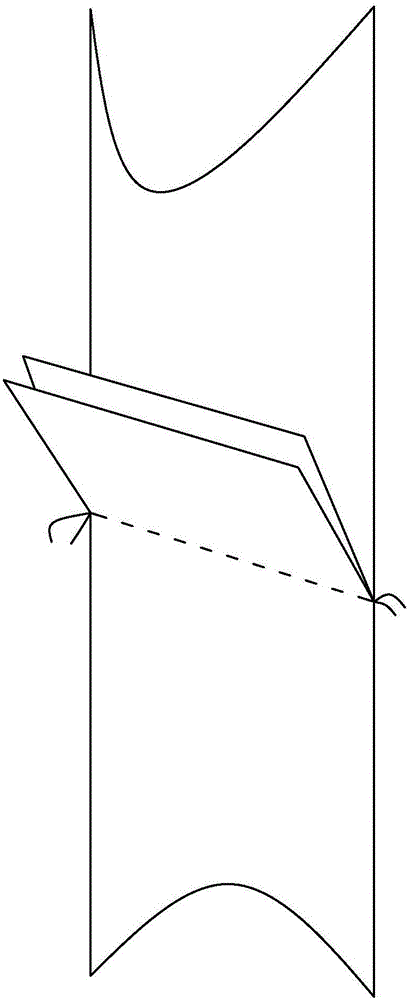

Method for gluing two seams of spatial reflector

InactiveCN104749741AGuaranteed coaxialityImprove uniformityMountingsStress distributionLayer thickness

The invention provides a method for gluing two seams of a spatial reflector, relates to the technical field of spatial optical remote sensing, and aims at solving the problems of small positioning precision, non-uniform glue layer thickness, reduction of surface figure accuracy of the spatial reflector caused by residual stress after solidifying of a glue layer, and unstable stress distribution in the existing method of gluing the spatial reflector and an embedded part through three jackscrew. The method is that glue coats the lower side of the inner hole wall of the spatial reflector; the upper side of the inner hole wall of the spatial reflector is in match with a large seam of a double-seam adhering tool; meanwhile, the glue coats the outer wall of the embedded part; the inner wall of the embedded part is in match with a small seam of the double-seam adhering tool to finish the adhering of the spatial reflector and the embedded part; the large seam and the small seam of the double-seam adhering tool are processed based on the same reference, so that the coaxiality of the two seams can be ensured, and the uniformity of the glue layer thickness can be greatly improved; the glue layer is uniform in thickness; the residual stress is small after the solidifying of the glue layer; therefore, the surface figure accuracy of the spatial reflector can be fully ensured. The method is simple and reliable to operate.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

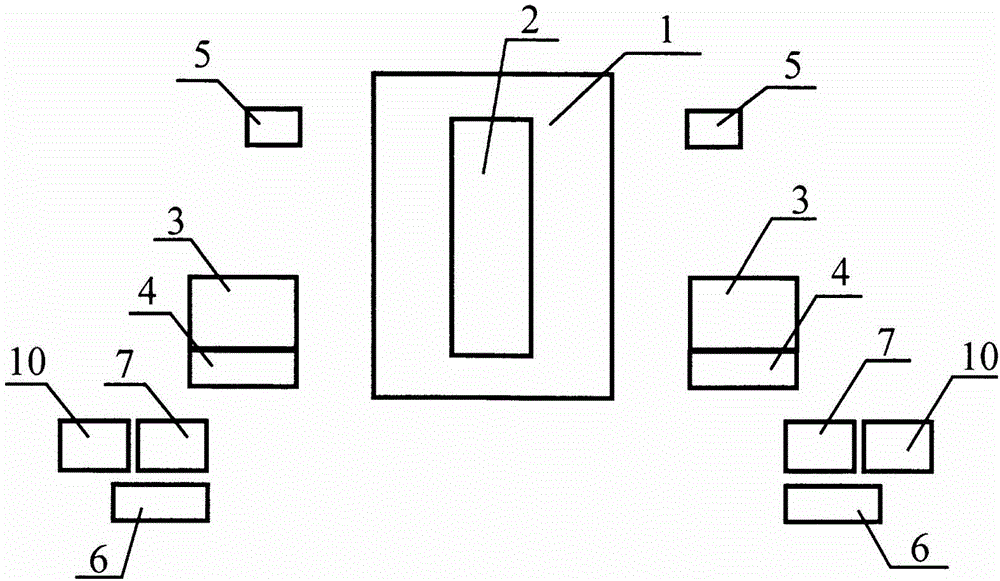

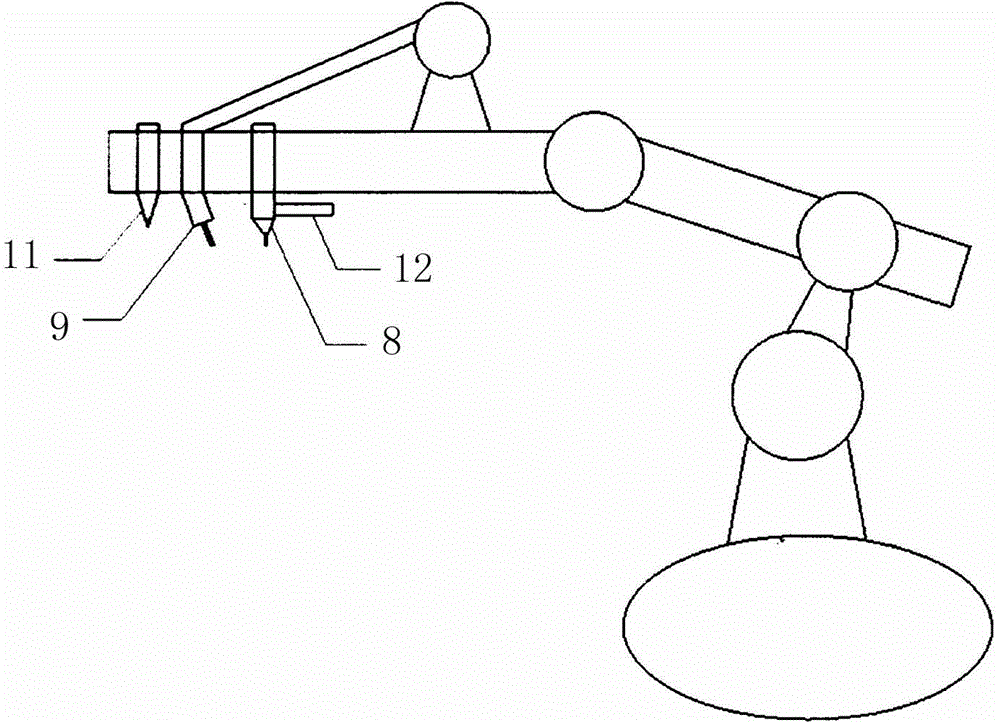

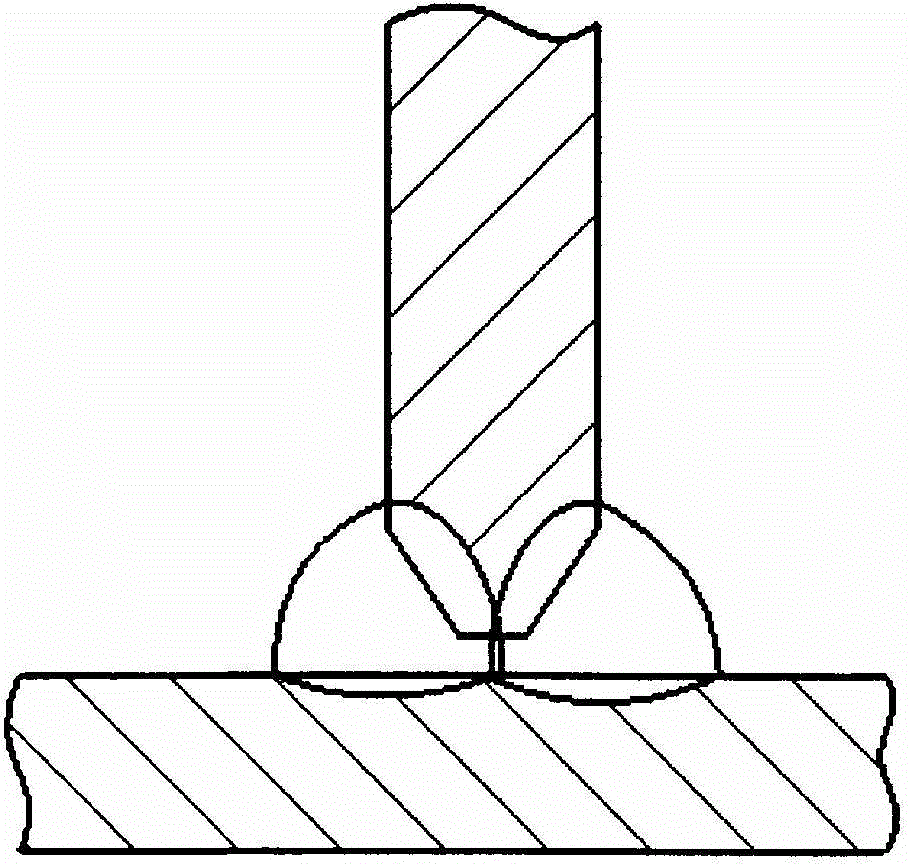

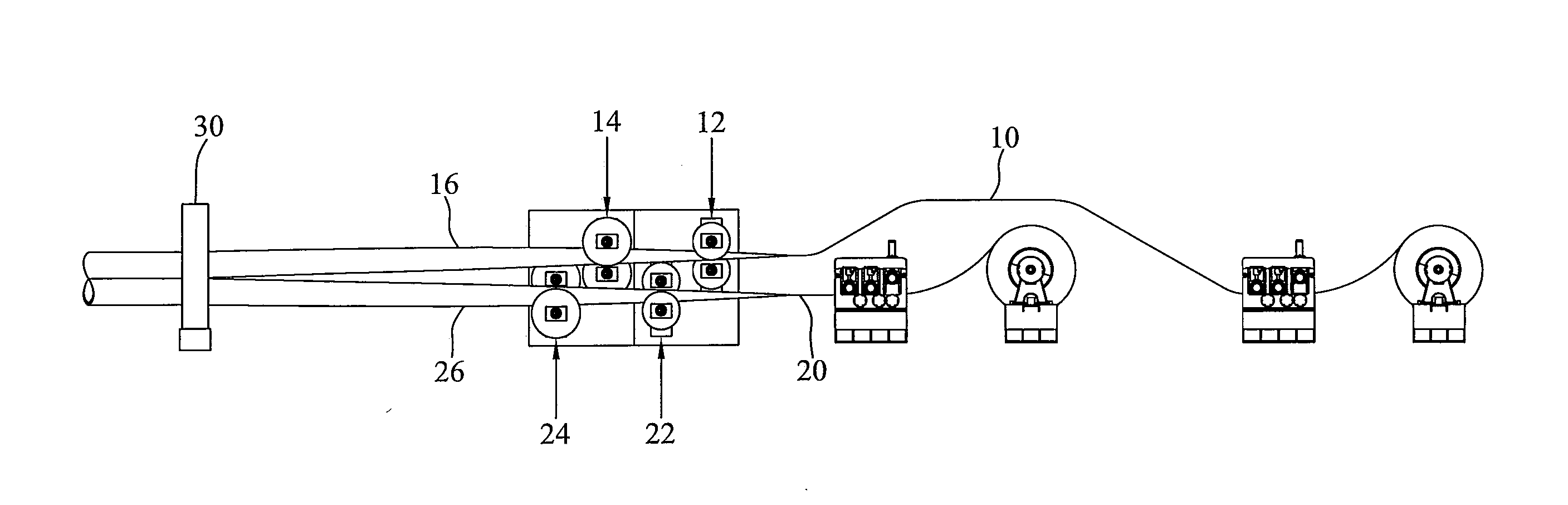

Integrated double-seam double-arc TIG (Tungsten Inert Gas) welding system and Double-seam double-arc TIG welding method for T-shaped joints

ActiveCN104551351AGuaranteed accuracyProtection from damageArc welding apparatusWelding power supplyTracking system

The invention relates to an integrated double-seam double-arc TIG (Tungsten Inert Gas) welding system and a double-seam double-arc TIG welding method for T-shaped joints. The structure of the Integrated double-seam double-arc TIG welding system for T-shaped joints is as follows: a welding tooling is mounted on a worktable, to-be-welded T-shaped joint parts are mounted on the welding tooling, the motion tracks of robots are programmed and set by electrical operation boxes, the robots are arranged upon robot guideways, the control hardware of each robot is completely optimized and integrated in a robot control cabinet, the robot guideways are symmetrically arranged on both sides of the worktable, a welding gun, an automatic welding stick feeder, a laser tracking system and a welding gun shield are assembled at the front end of each robot, each robot is provided with a pressure sensor and anticollision software, cooling water tanks are connected with welding sources, and in the working process of the robots, the argon arc welding sources are cooled by the cooling water tanks. The system not only decreases the labor intensity of workers, improves the working environment and increases working efficiency, but also remarkably improves the welding quality of joints.

Owner:SHENYANG AIRCRAFT CORP

Assembly and disassembly method for double-seam allowance matched super large size drum in heavy type gas turbine

InactiveCN102837157AGuaranteed assemblySatisfy the cooperative relationshipMetal working apparatusElectricityMallet

The invention belongs to the field of machining and particularly relates to and an assembly and disassembly method for a double-seam allowance matched super large size drum in a heavy type gas turbine. According to the assembly and disassembly method for the double-seam allowance matched super large size drum in the heavy type gas turbine, the outer diameter of a tightly sealed ring is fully accommodated by a heating belt, a heat preservation belt is wrapped outside the heating belt, when the electricity is turned on, a wooden mallet is used to axially press different positions on the periphery of the drum, so that the assembly of the double-seam allowance matched super large size drum is achieved; the disassembly method of the double-seam allowance matched super large size drum in the heavy type gas turbine is characterized in that ten, twelve or fourteen lifting jacks are evenly disposed along circumferential direction on a bottom plane of a end face groove of the drum, the height of the lifting jacks is adjusted, according to a principle that counter points form a pair of points, and by means of a force limited spanner, the tightly sealed ring can be disassembled from the drum. The assembly and disassembly method achieves the assembly and disassembly of the double-seam allowance matched super large size drum in heavy type gas turbine, wherein the double-seam allowance matched super large size drum in the heavy type gas turbine is super big in size, complex in structure, precise and compact, and has the advantages of being practical, low in cost, easy to popularize, and capable of further improving product machining quality and efficiency and reducing machining period of parts.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

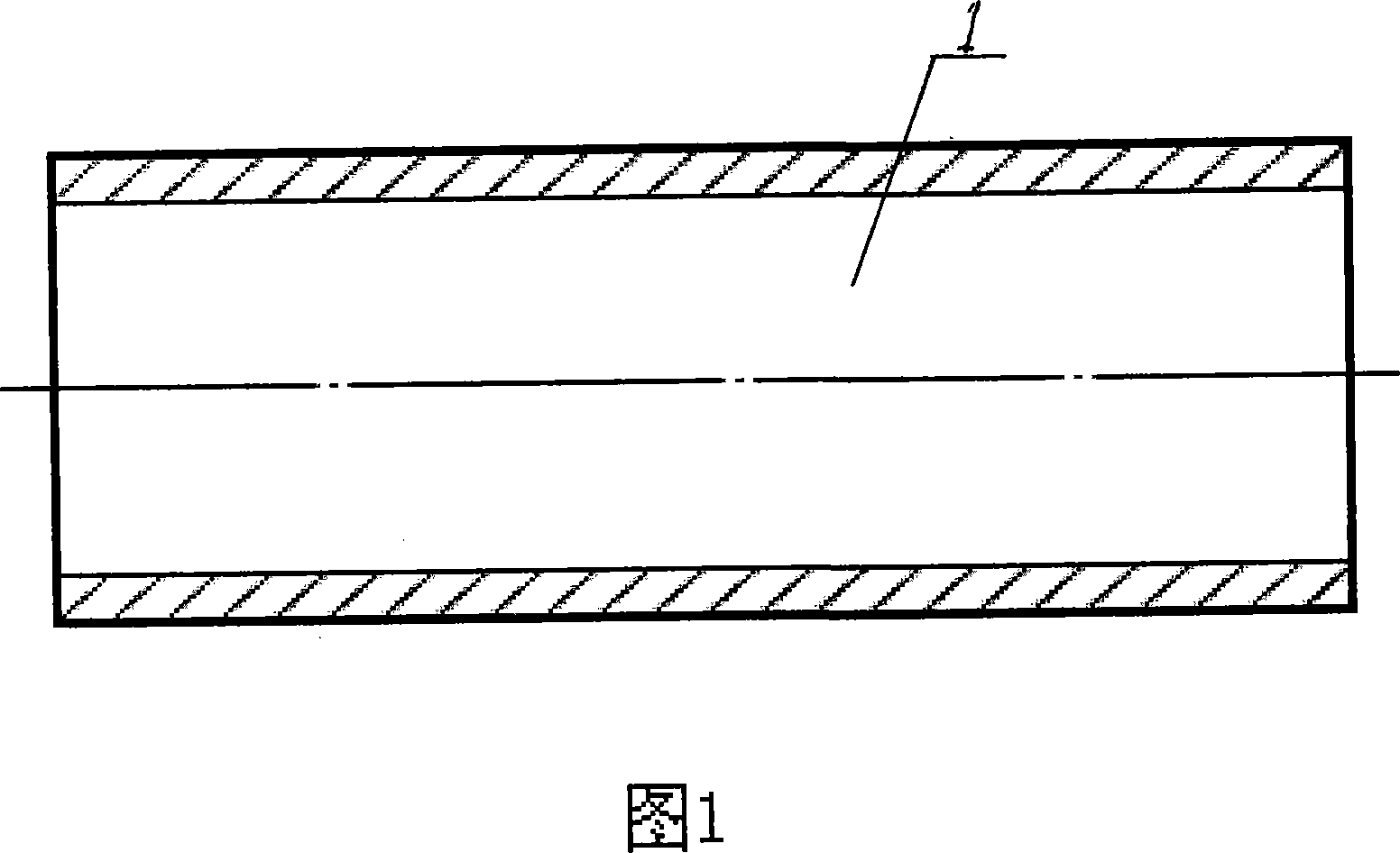

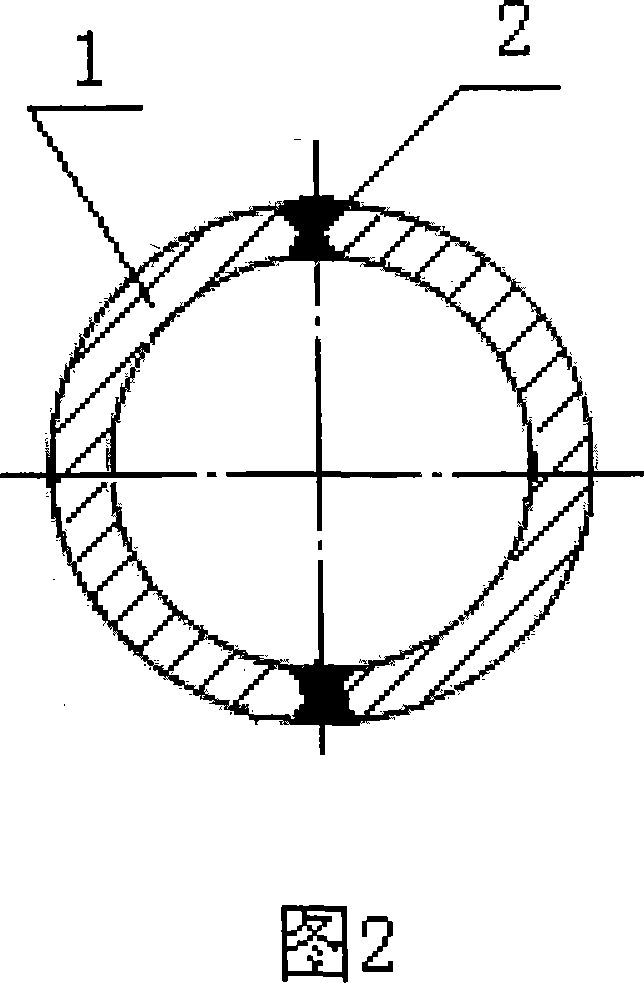

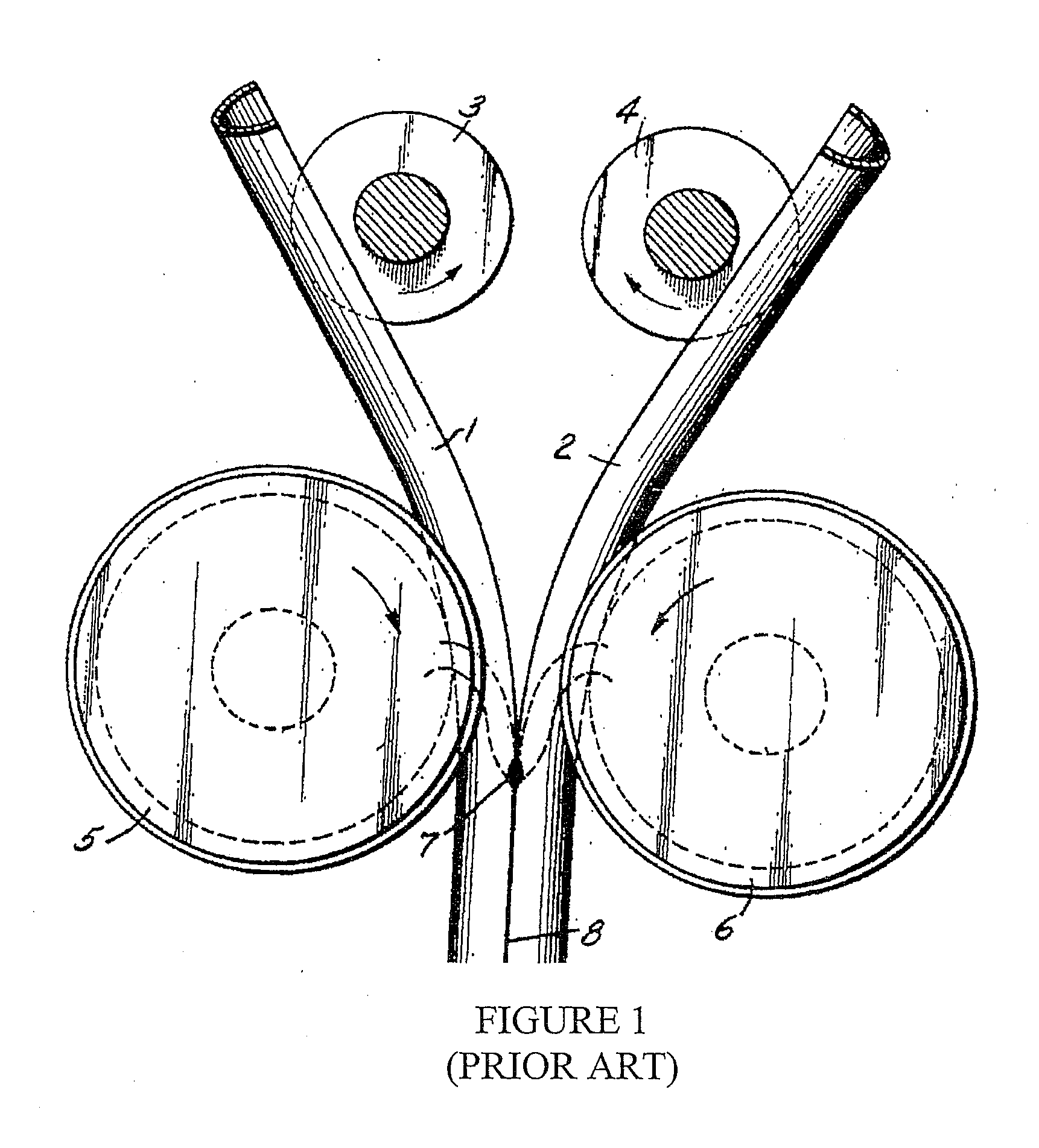

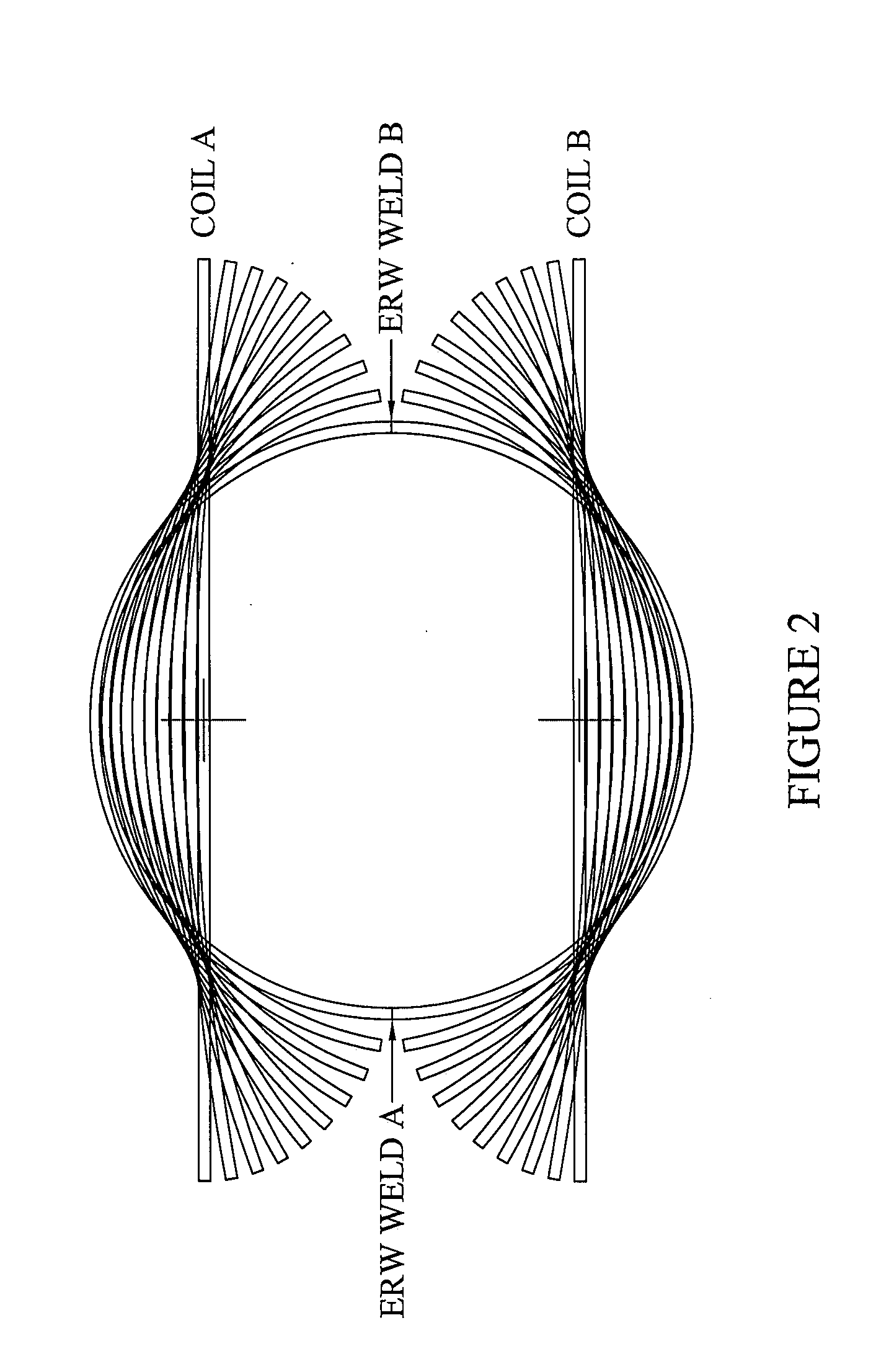

Dual seam electric resistance welded tubes

A method of continuously forming a dual seam welded tubular product includes the steps of providing two coils of sheet metal material, uncoiling the two coils and forming the material into opposing sections, bringing the two opposing sections together at a convergence angle of less than about 4°; and welding the two seams created between the two opposing sections. An apparatus is configured to bring the sections together at a convergence angle less than about 4° to produce the tubular product. The tubular product may have a diameter greater than 26 inches.

Owner:DFI

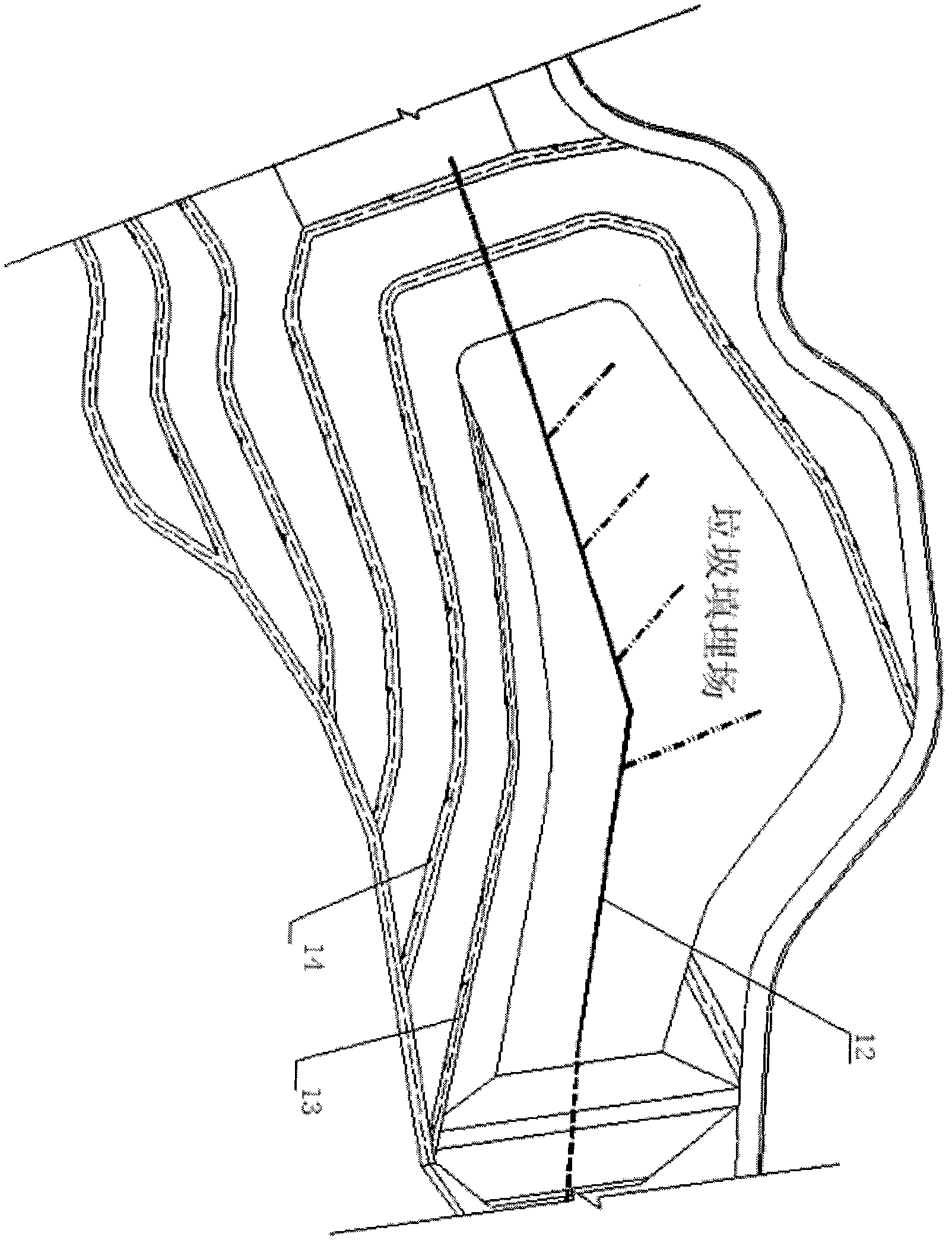

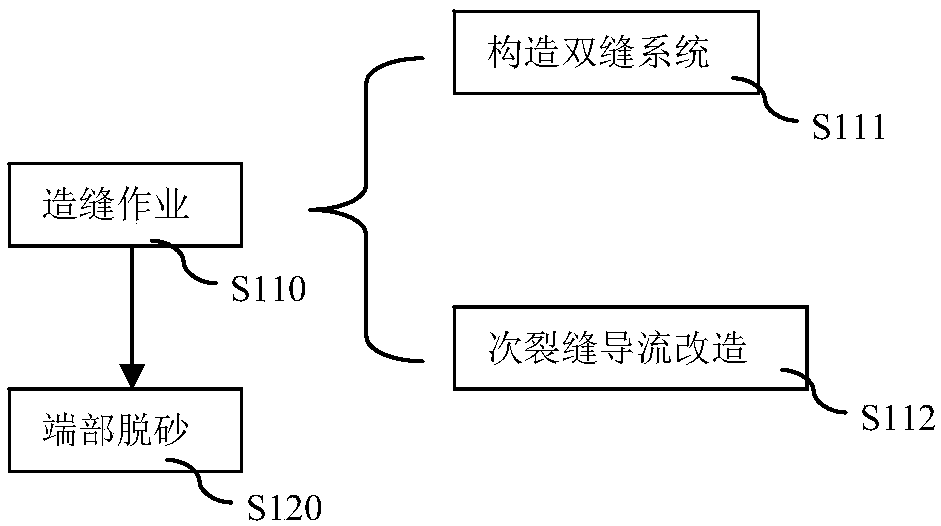

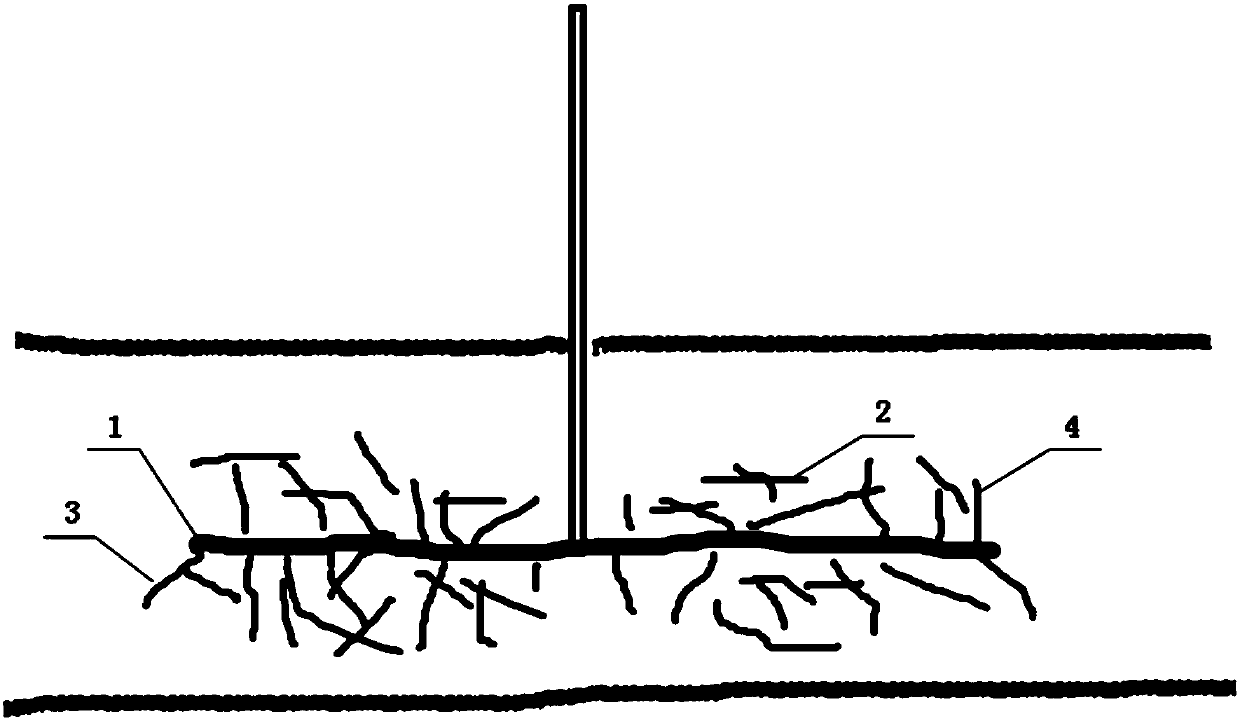

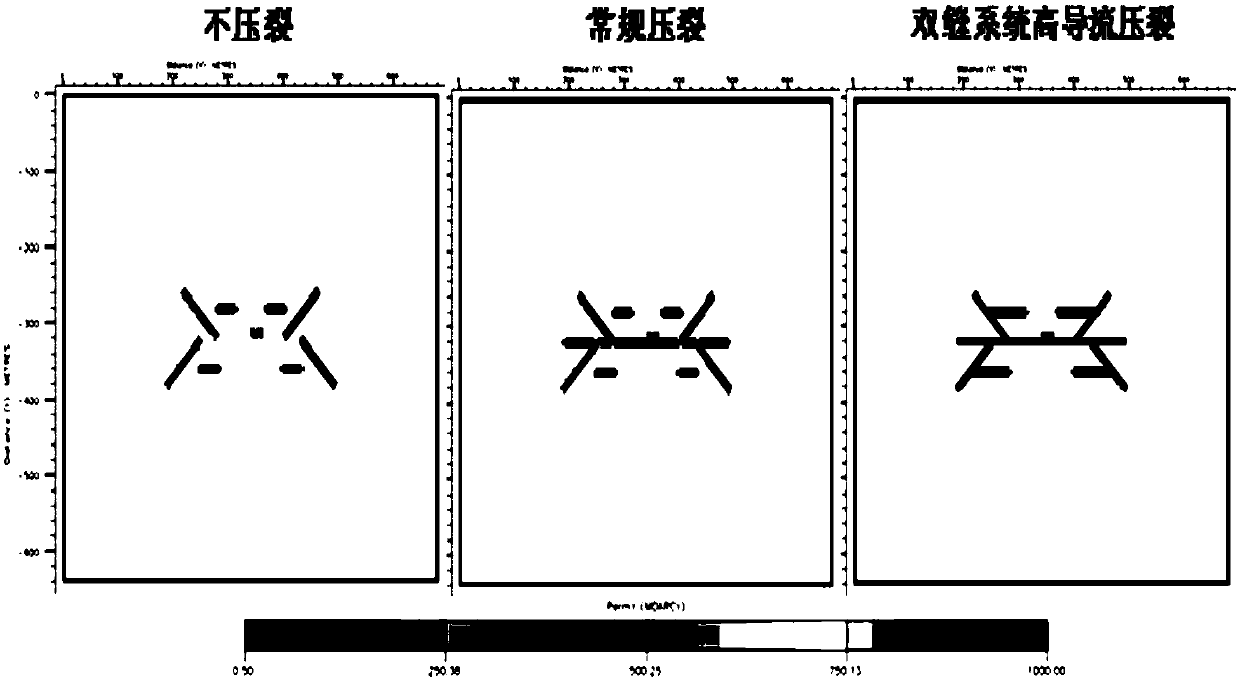

Fracturing method for compact sandstone reservoir

ActiveCN109751033AImprove diversion capacityMovable oil range increasedFluid removalOil wellMaterials science

The invention discloses a fracturing method for a compact sandstone reservoir. The method comprises the steps that a double-crack system comprising a main crack and a secondary crack is constructed, diversion modification is conducted on the secondary crack in the double-crack system in the crack forming process, the secondary crack comprises a branch crack composed of natural cracks and a micro crack, the branch crack communicates with the main crack, and the micro crack communicates with the branch crack; and end desanding is realized in the double-crack system. According to the method, theflow conductivity of a crack system required by fracturing exploitation can be effectively improved, so that the movable oil range around the whole oil well is increased, and the effects of increasingthe yield and stabilizing the yield are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for applying a metal end to a container body

InactiveUS8939695B2Reduce chanceImprove sealingCapsFlanged caps applicationInterference fitEngineering

A metal end is applied and sealed to a plastic or paper / plastic composite container body by a crimp-seaming or double-seaming operation. The metal end has an outer curl joined to a compound-angle chuck wall that extends down from the curl. The chuck wall has an upper part that is substantially linear and at an angle α1 with respect to an axis of the end, and a lower part that is substantially linear and at a larger angle α2 with respect to the axis. The compound-angle chuck wall allows a substantial diametral clearance between a lower end of the lower part of the chuck wall and the inner surface of the container body, while there is substantially zero clearance, or preferably an interference fit, between the upper part of the chuck wall and the inner surface of the container body. Accordingly, the chuck wall guides the end into concentric alignment with the container body during application.

Owner:SONOCO DEV INC

Square can and method and device for double-seaming the same

According to the present invention, a square can capable of securing high sealing performance even if the radius of curvature of the seamed part at its seamed corner part is reduced, enabling a reduction in the depth of its counter sink, reduced in size, and having excellent sealability and storage efficiency and a method and a device for double-seaming the square can. A secondary seaming roll (55) is guided by a model cam for secondary seaming having a model cam surface for secondary seaming formed in such a shape that it is swelled from a model cam surface for primary seaming outwards at the corner seamed part (5). Accordingly, the seamed part of the corner caulking part (5) is formed in such a shape that the seamed width thereof at the center of the corner seamed part is larger than the seamed width of the linear sealed part (4) of the can and is swelled outwards to absorb an increase in plate thickness at the corner seamed part. Also, a seaming wall part (6) is formed in a tilted seamed shape so that the overlap of a cover hook (8) with a body hook (10) of a prescribed amount can be secured without allowing the cover hook (8) to fall from the body hook (10) so as to maintain excellent sealability.

Owner:TOYO SEIKAN KAISHA LTD

F-type steel double-slit joint of low- and medium-speed maglev system

The invention discloses an F-type steel double-slit joint of a low- and medium-speed maglev system. The F-type steel double-slit joint comprises two main F-type steel sections, an auxiliary F-type steel section and two press plates and more, wherein each main F-type steel section is provided with a first inner leg and a first outer leg, and the auxiliary F-type steel section is provided with a second inner leg and a second outer leg. The F-type steel double-slit joint of the low- and medium-speed maglev system is simple in structure, convenient to mount and easy to maintain.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

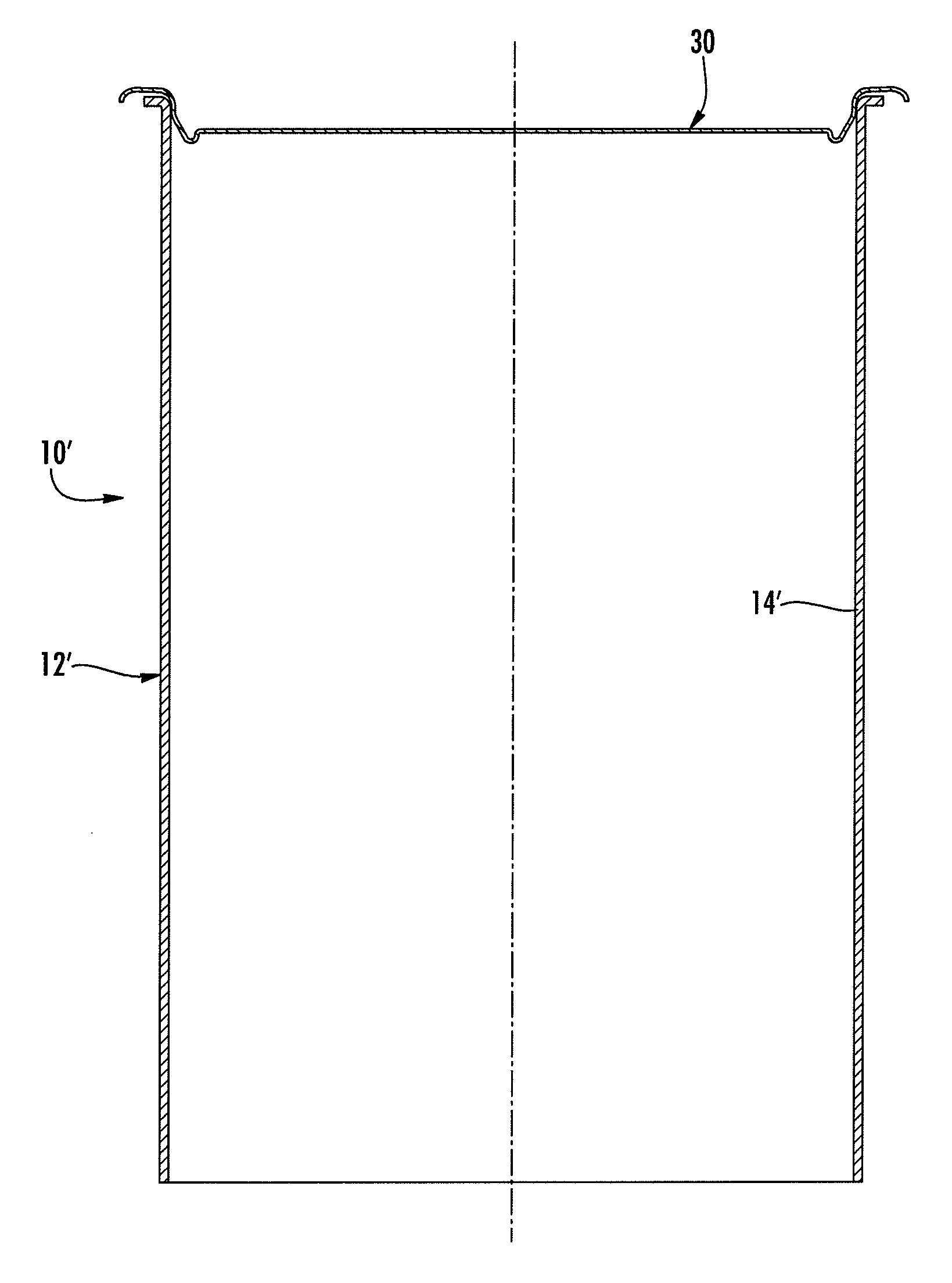

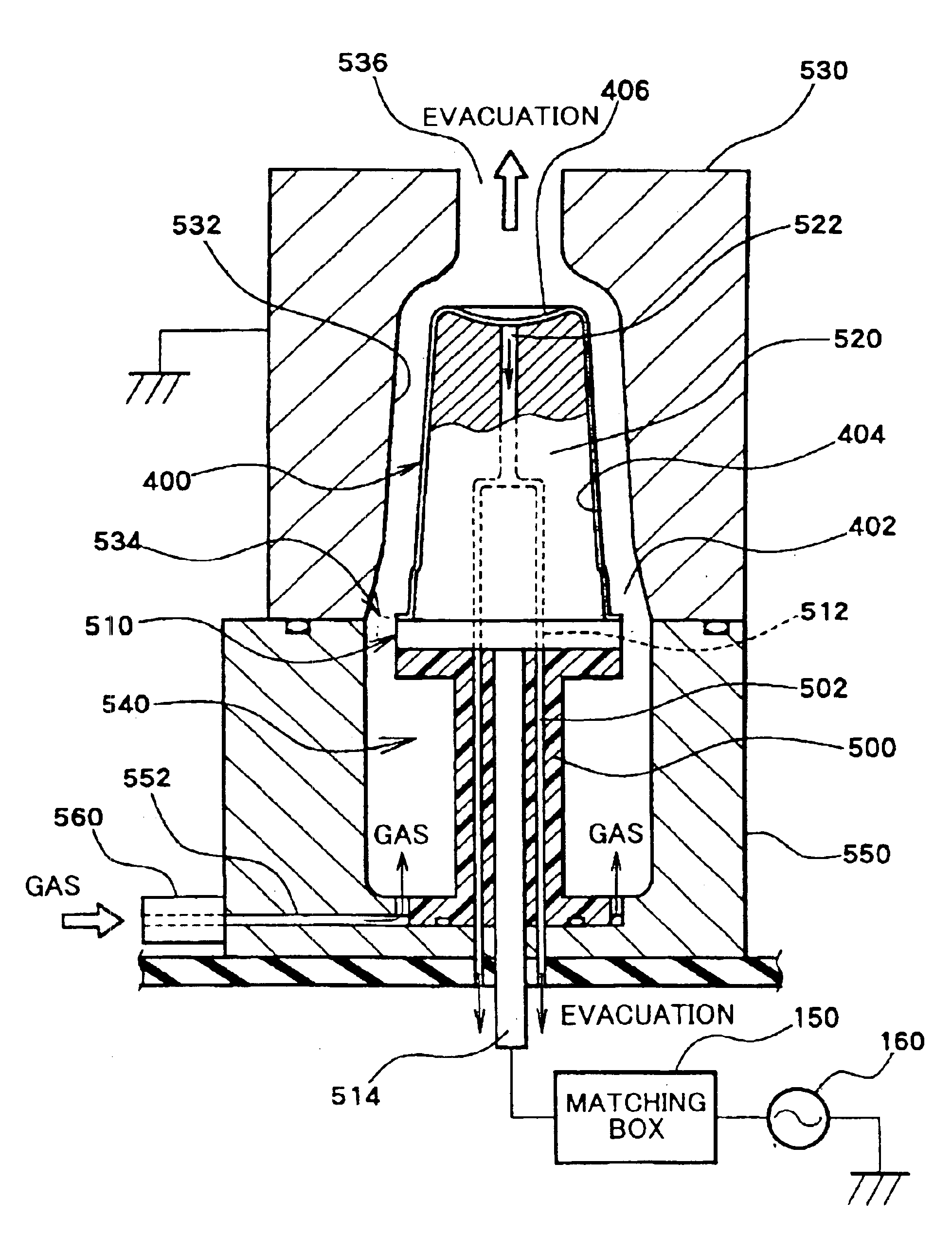

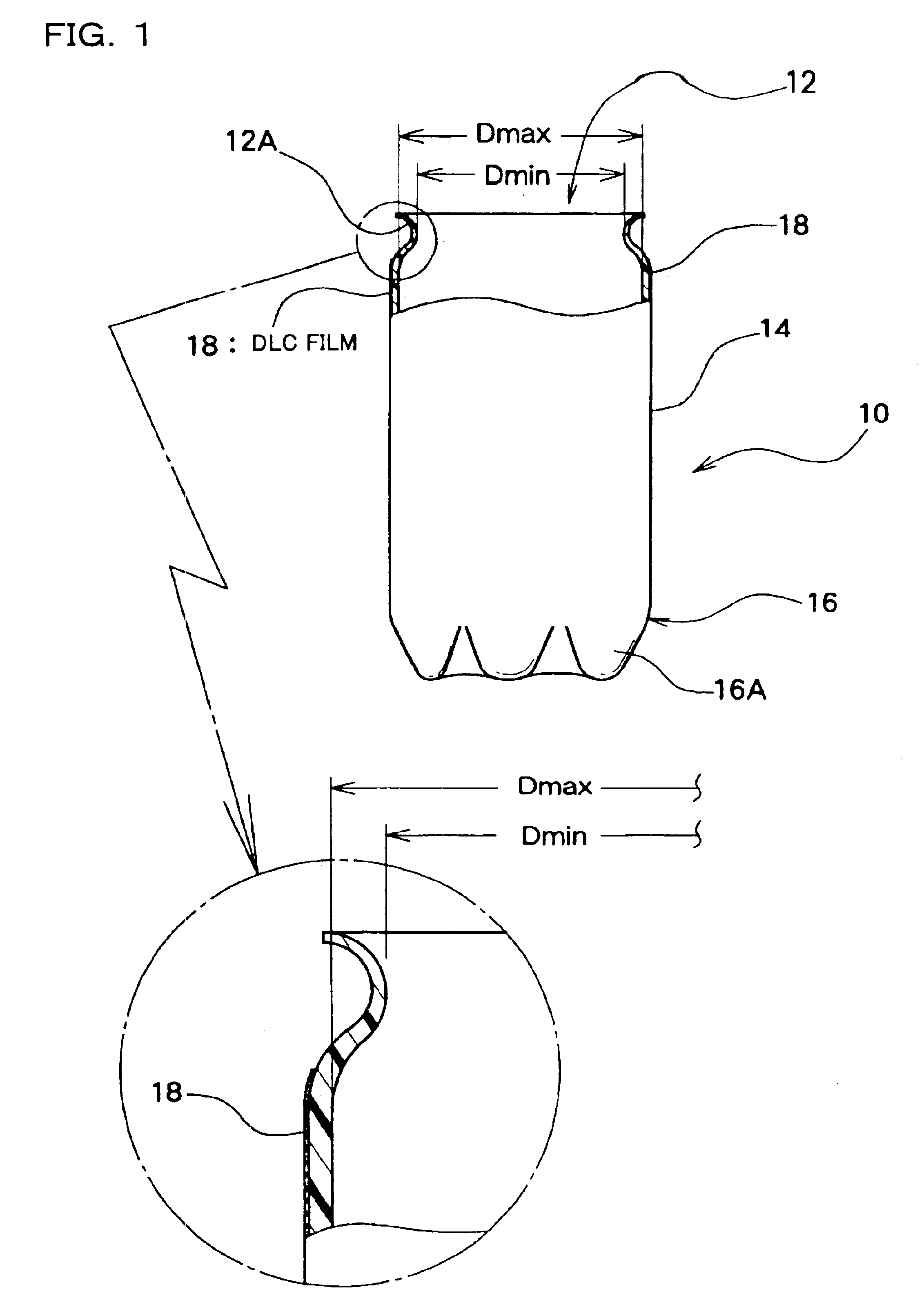

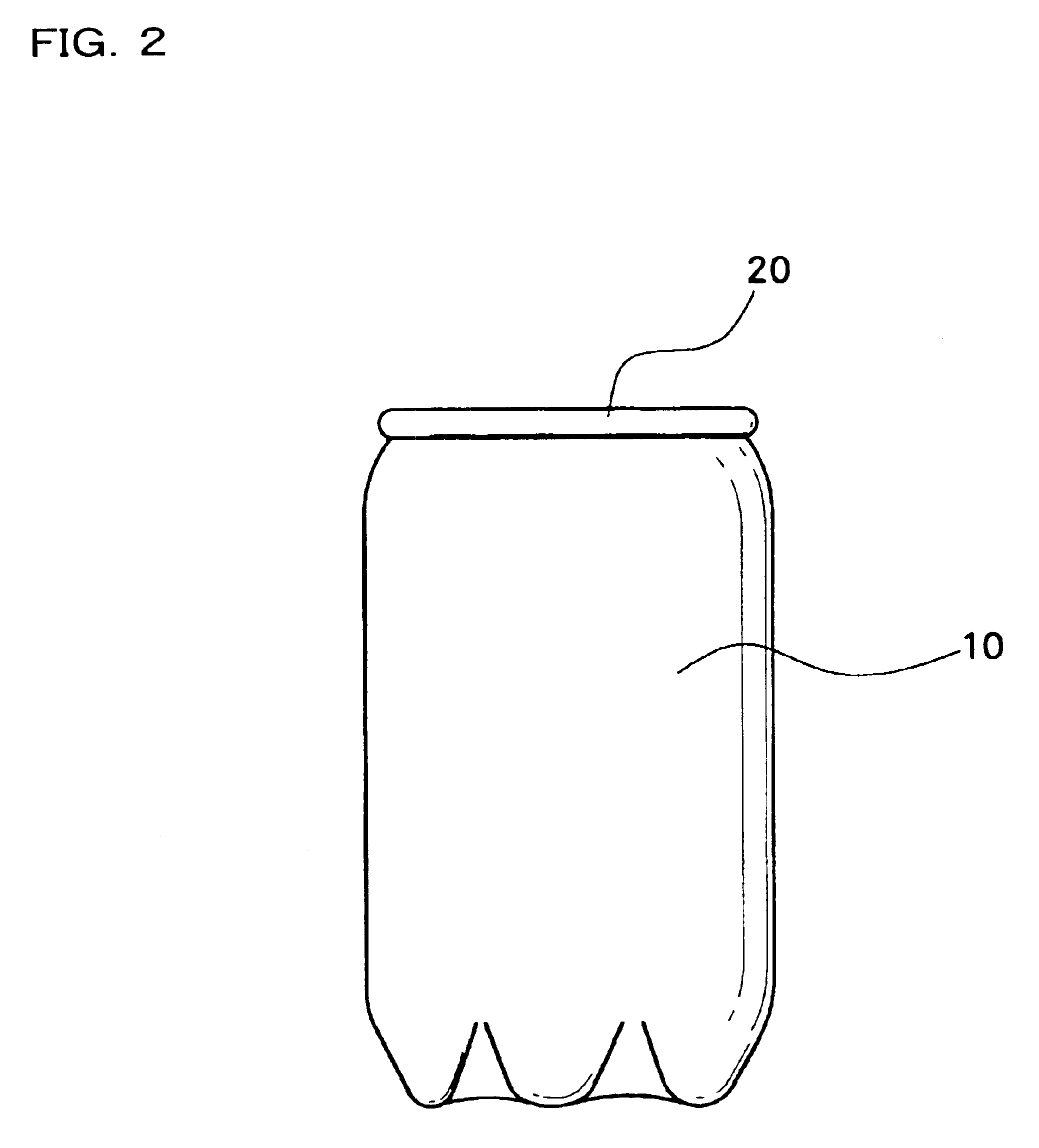

Gas-barrier synthetic resin vessel, device for producing the same, and article-received gas-barrier synthetic resin vessel

InactiveUS6854309B2Smooth movementPromote formationLiquid surface applicatorsClosuresCarbon filmWide mouth

A gas barrier synthetic resin container 10 has an opening portion 12 defined by a flange 12A, a body portion 14 having the opening portion 12, and a bottom portion 16 for closing the end of the body portion 14. The container 10 is a wide mouth container having the minimum inside diameter Dmin of the opening portion 12 larger than the maximum inside diameter Dmax of the body portion. Alternatively, the container 10 may be a wide mouth container having the minimum inside diameter Dmin of the opening portion 12 smaller than the maximum inside diameter Dmax of the body portion, the difference between the diameters being equal to or less than 20 mm. A diamond-like carbon film 18 is formed on an outer wall of the body portion 14 and bottom portion 16 of the container 10. After the container 10 has been filled with contents, a metal cover 20 and the flange 12A are double-seamed onto the container to provide improved gas barrier properties to the entire container.

Owner:NISSEI ASB MASCH CO LTD

Tail ore stock area structure with sewage percolation and resource regeneration

InactiveCN1847616APrevent regenerationPrevent intrusionDamsUnderground miningCrushed stoneWater resources

The present invention is structure for preventing tail ore from polluting water resource. The structure includes base layer, waterproof board layer, water permeating and draining pipe layer and earth work fabric layer set from bottom to up. The base layer rolling grooves and concrete layer; the waterproof board layer is made of high density polyethylene plate; the water permeating and draining pipe layer has antirust spring water permeating and draining pipe, crushed stone stuffing, surface cement mortar layer, and extruded plastic board in the vertical surface; and the earth work fabric layer has overlapped earth work fabric. The present invention can prevent harmful chemical matter, heavy elements and water from tail ore to pollute underground water, river and soil in the peripheral area.

Owner:杜剑

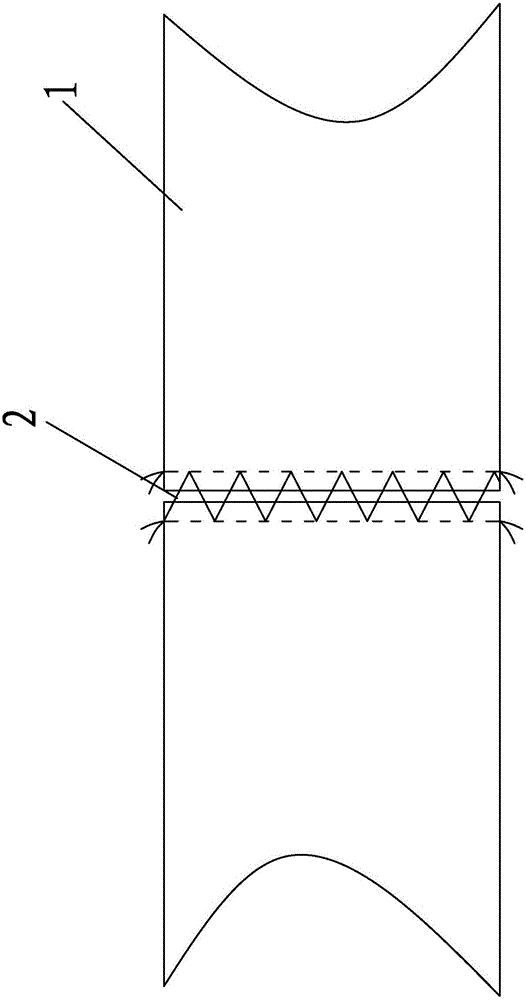

Welding and detection process used for HDPE geomembrane of refuse landfill

The invention discloses a welding and detection process used for an HDPE geomembrane of a refuse landfill. Welding equipment in the welding process comprises a double-seam welding machine, an extrusion welding machine and a hot air blower, double-seam welding is mainly adopted, for pressing sealing and seam lapping or local repairing, the extrusion welding machine is adopted for welding seam extrusion, the hot air blower is used for blowing and melting the lower portion of a lap joint part; and the detection process is mainly based on air pressure detection, vacuum detection is adopted for cooperation, the detection process is suitable for the situation of local width-based propulsion or a welding seam full detection requirement, and air pressure detection and vacuum detection are both based on the CJJ113-2007 standard. The welding and detection process comprises welding construction and detection construction processes, under the condition that full-inspection construction is needed for local welding seams or width-based propulsion is required, the effect of the welding machine can be fully achieved, extrusion welding repairing work is reduced, the welding seam detection process is simplified, the construction efficiency is improved, and the requirements for seepage prevention and long-term operation of the refuse landfill can be met.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

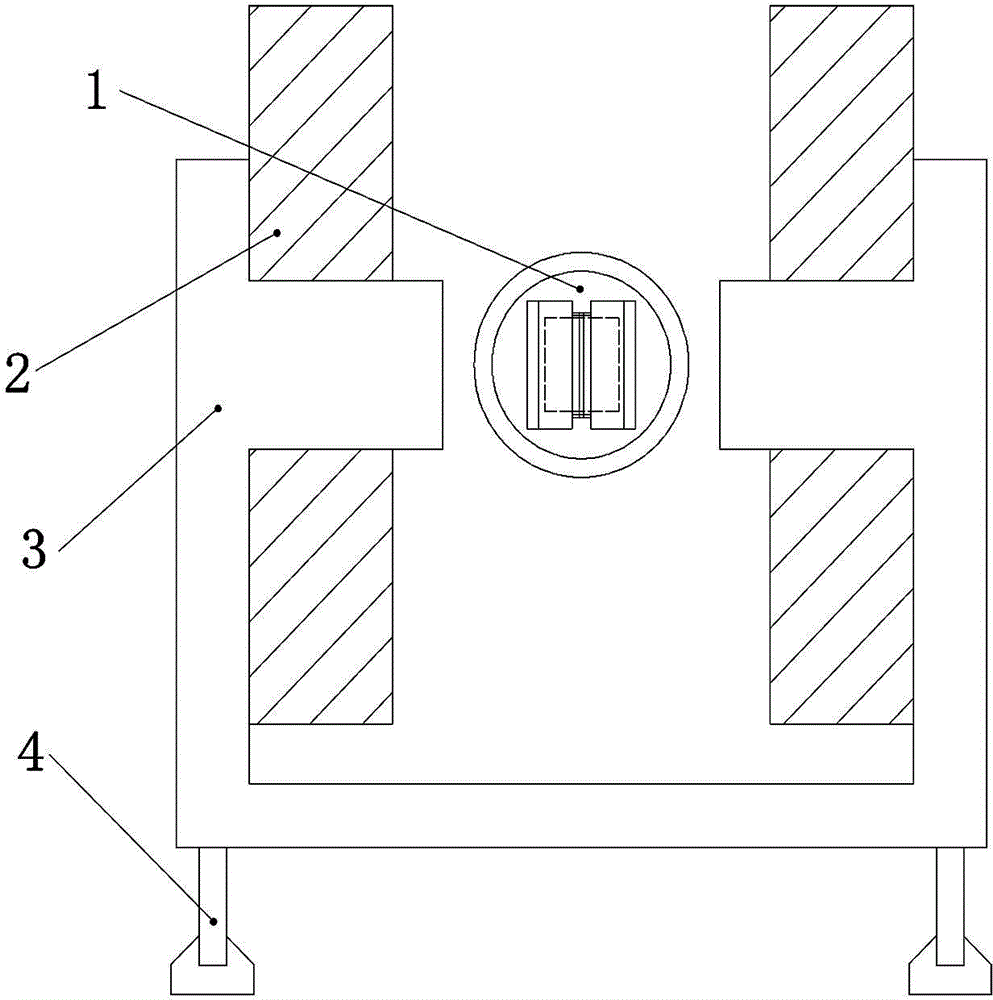

Double-slit device capable of being regulated

The invention discloses a double-slit device capable of being regulated. The double-slit device capable of being regulated comprises an electromagnetic structure which is arranged in a symmetrical mode and can form a magnetic field loop and a double-slit structure arranged in the center of the electromagnetic structure. By means of the double-slit device capable of being regulated, the defects that in the prior art, the horizontal positions of a lighting system, a double-slit system and an observation system need to be assembled and disassembled and adjusted again when multiple experiments are conducted, the difficulty in assembly and disassembly is large, and time is wasted can be overcome, and the double-slit device capable of being regulated has the advantages of being simple in structure, low in assembly and disassembly difficulty and capable of saving time.

Owner:LANZHOU UNIVERSITY

Sewing method for fabric joints in cold dyeing process

InactiveCN105926177AAvoid uniformityAvoid consistencySewing apparatusCotton materialPetroleum engineering

The invention discloses a sewing method for fabric joints in a cold dyeing process. The sewing method comprises steps as follows: a sewing process is performed: joint ends of two sections of gray fabric are horizontally tiled and aligned, and an interval ranging from 0.5 mm to 3 mm is reserved between the joint ends of the two sections of gray fabric; the joint ends of the two sections of gray fabric are sewn together with sutures in a dual-suture dual-sewing flush joint sewing manner. With the adoption of the sewing method for the fabric joints in the cold dyeing process, the joints of the sewn gray fabric are flat, the thickness of the joints is identical to that of the whole piece of fabric, accordingly, the problems of uneven dyeing at the joints and inconsistent colors with the color of the whole piece of fabric are solved, fabric with defectively printed joints in each piece of cloth is reduced to 3-8 m / piece from 18-30 m / piece, and the length of the fabric with defectively printed joints is greatly reduced.

Owner:LILANG CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com