Splicing paving method of waterproof plates in tunnel and splicing paving structure of waterproof plates in tunnel

A technology of tunnel waterproof board and laying method, which is applied in tunnels, tunnel lining, mining equipment and other directions to achieve the effect of eliminating hidden dangers of waterproofing, reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

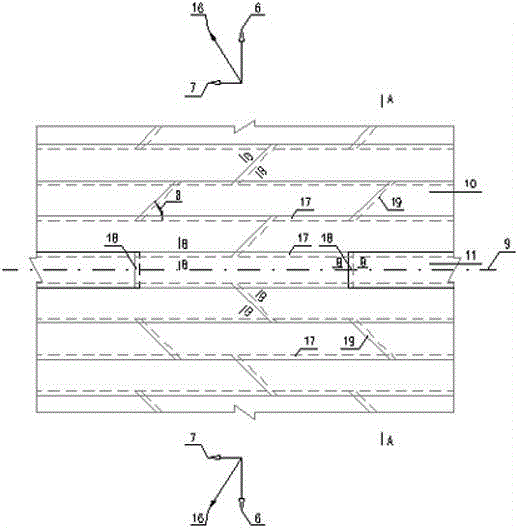

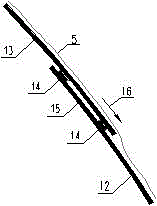

[0027] refer to Figure 1 to Figure 4 , the invention relates to a splicing and laying method of a tunnel waterproof board, comprising the following steps:

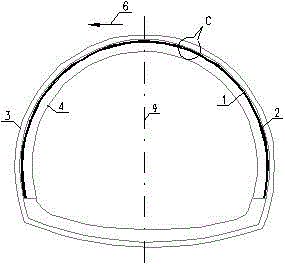

[0028] (1) After the special trolley for laying the waterproof board 1 is in place and the base surface of the tunnel initial support 3 is leveled, lay the non-woven geotextile 2 on the base surface of the initial support 3 . Use nails to fix the thermoplastic gasket and non-woven geotextile 2 on the base surface smoothly and closely, with a distance of 50 cm between the fixing points, and the lap width of the non-woven geotextile 2 is not less than 5 cm.

[0029] (2) Before laying the tunnel vault waterproof membrane, carry out accurate lofting of the tunnel vault waterproof membrane. Mark the longitudinal tunnel centerline 9 at the tunnel vault position, and mark the laying and lofting lines of the two long sides of the waterproof membrane according to the width and length of the waterproof membrane.

[0030] (3) Use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com