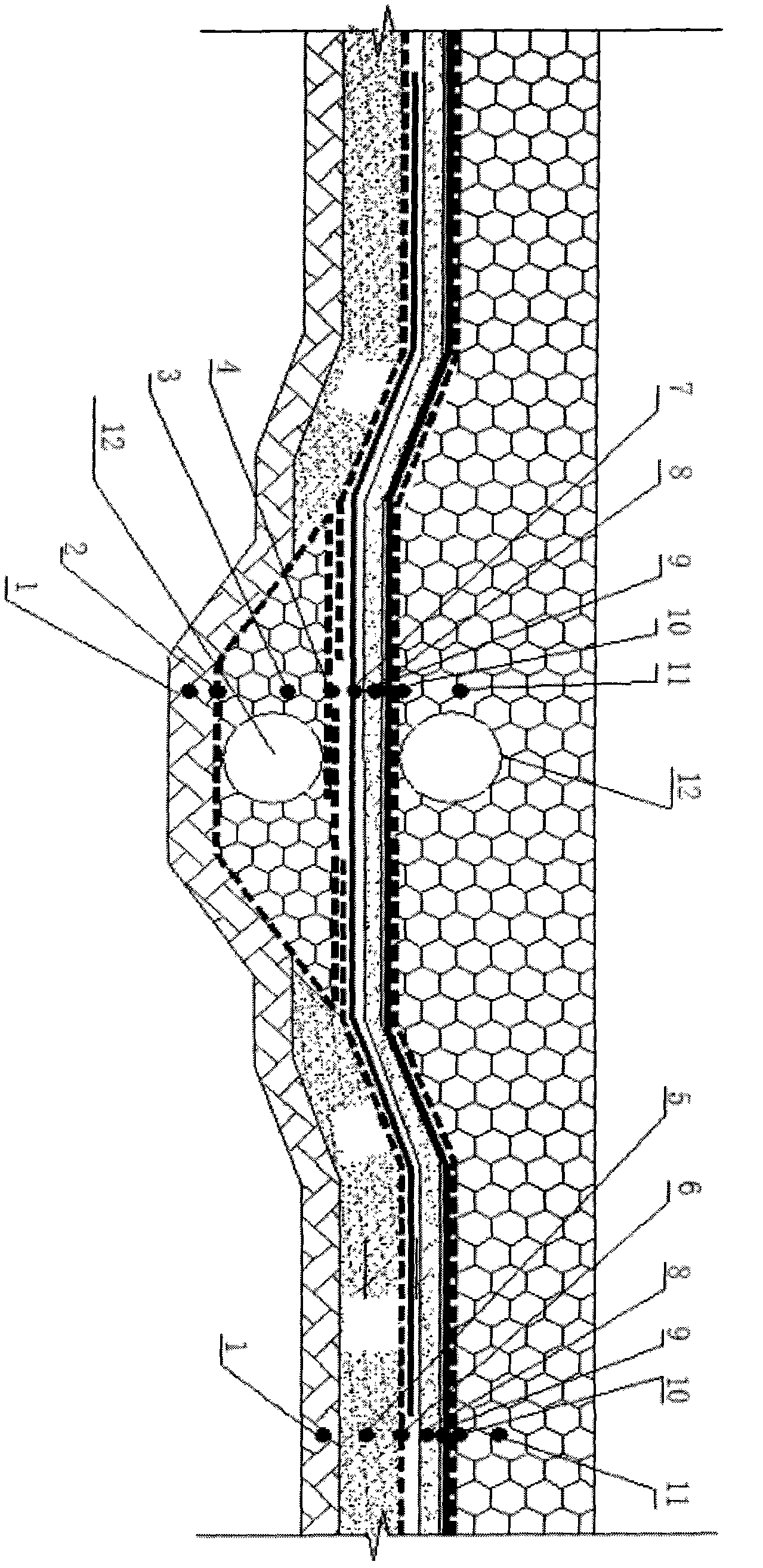

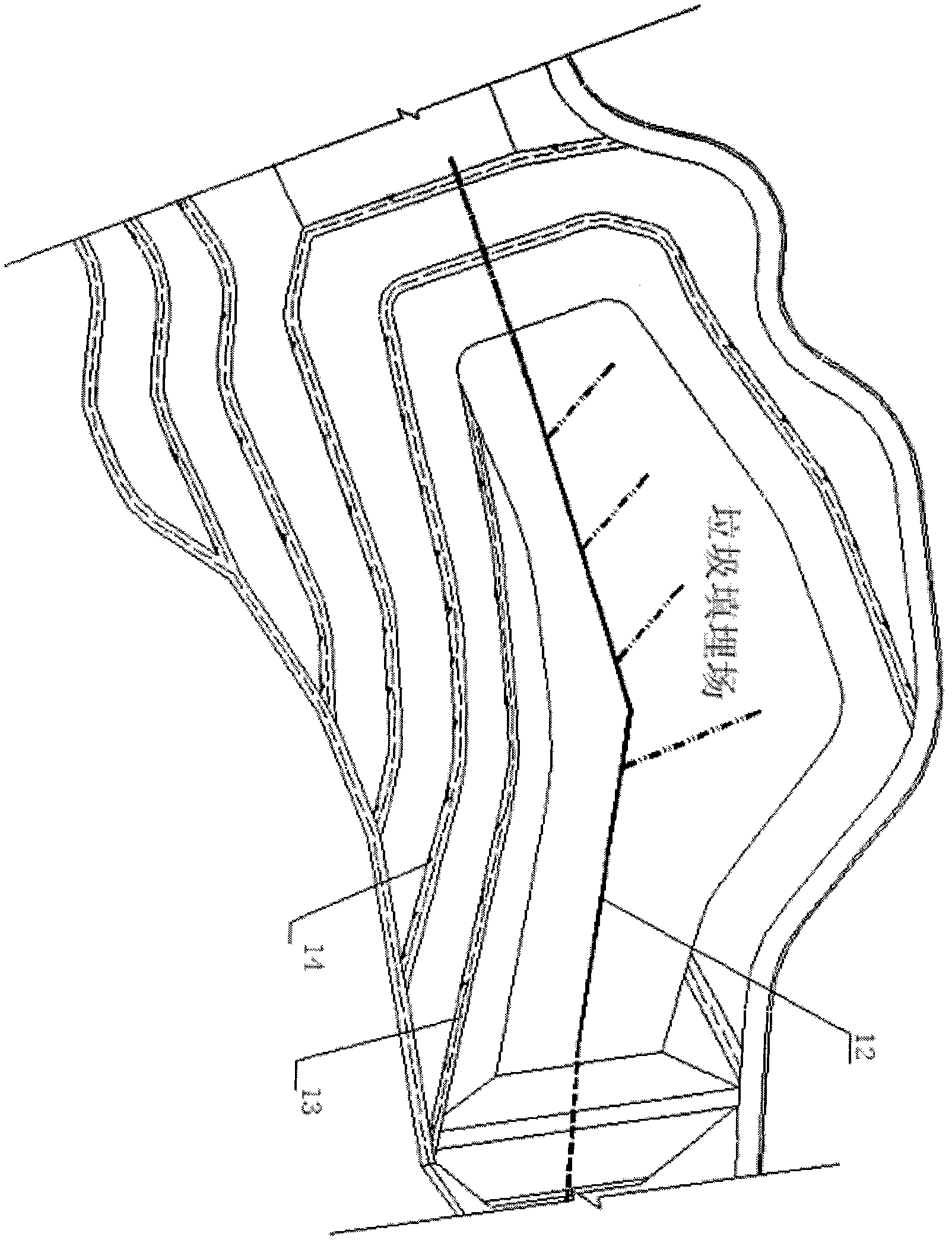

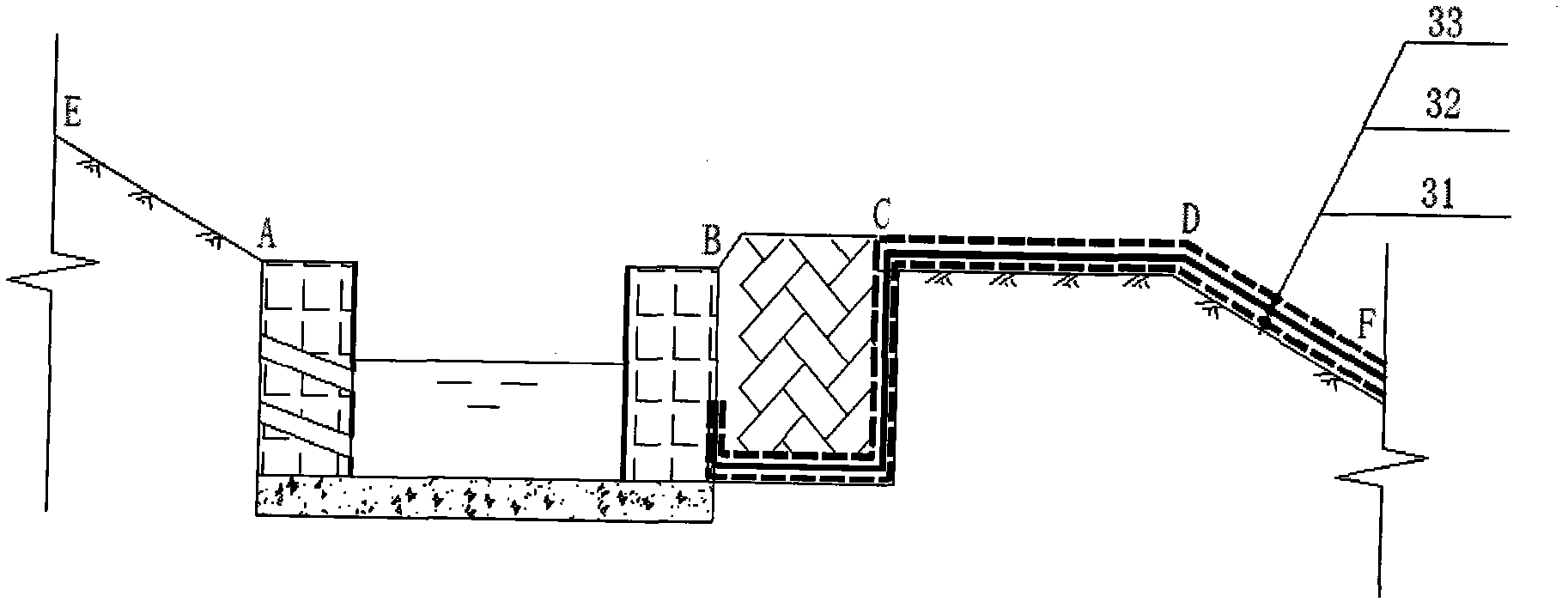

Refuse landfill seepage-proofing guide drainage system structure and laying method thereof

A landfill and system structure technology, applied in the field of landfill anti-seepage and drainage system structure, to achieve good chemical stability, strong tear and puncture resistance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A landfill project, the project is an expansion project, the existing storage capacity is 1.3 million m 3 , the new storage capacity is 3 million m 3 , and the designed service life is fifteen years. The total area of HDPE geomembrane, HDPE flower tube, GCL bentonite pad and non-woven geotextile anti-seepage and drainage system in the landfill area is 72664m 2 , the height of the slope in the landfill area is 20-64m, and the construction time of the anti-seepage system is two months. During the construction of this construction method, an operation group of 5-8 people can lay 1500-2000m per day 2 , the construction speed is fast and the quality is reliable, effectively solving the problems of secondary environmental pollution caused by leachate leakage caused by unreasonable anti-seepage and drainage treatment during the long-term use of the landfill, ensuring the quality of production and living water for the surrounding people , which saves the cost of environmen...

Embodiment 2

[0060] A domestic waste landfill project. The area of the anti-seepage and drainage system in the landfill area is 160,000m 2 , the slope height of the waste landfill reservoir area is 25-60m, and the construction time of the anti-seepage and drainage system is six months. An operation group with 5-8 people can lay 1500m per day 2 It is safe and convenient to operate and reliable in quality. It effectively solves the secondary pollution of drinking water and cultivated land for surrounding people caused by leachate leakage, and ensures the physical and mental health of the people. It has significant social and economic benefits.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com