Tail ore stock area structure with sewage percolation and resource regeneration

A technology for resource regeneration and seepage and drainage pipes, which is used in dikes, dams, ground mining and other directions to achieve the effects of high comprehensive efficiency, small thermal deformation and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

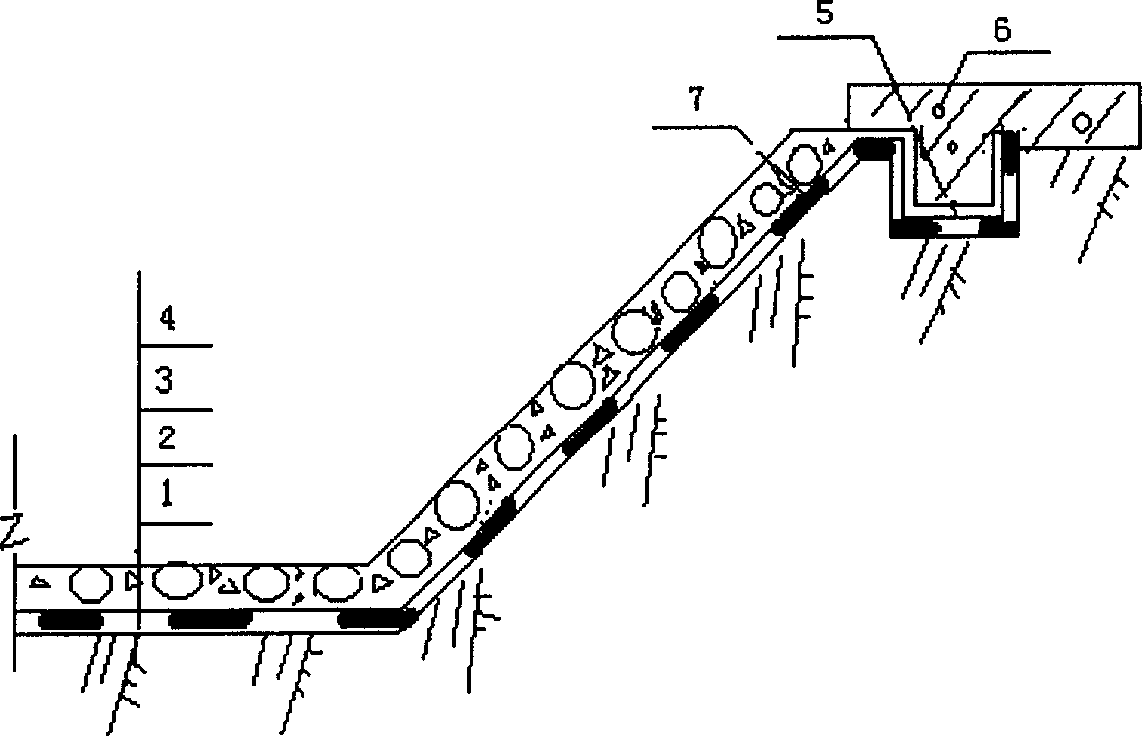

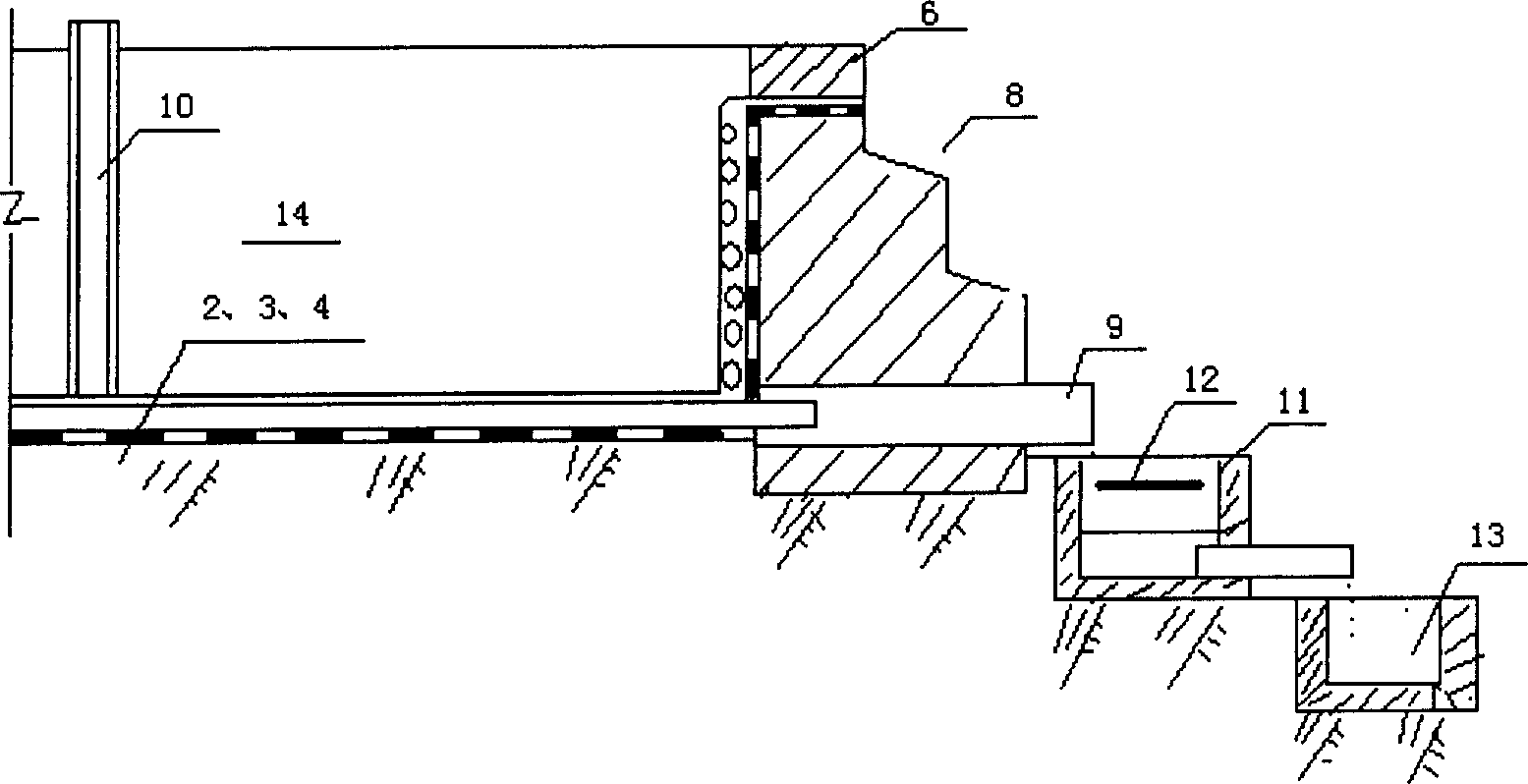

[0031] A large-scale tailings reservoir structure with seepage and drainage type anti-sewage resource regeneration

[0032] Such as figure 1 The structural layer of the slope and the bottom of the large tailings reservoir area shown is provided with a base layer 1, a waterproof board layer 2, a seepage drainage pipe layer 3 and a geotextile layer 4 from bottom to top;

[0033] The base layer 1 is a flat and compacted base layer, and the edge is provided with a pressure groove 5 for trimming the top section of the slope, and a plain concrete pressure roof 6 is arranged above the pressure groove 5 .

[0034] The waterproof board layer 2 is a waterproof high-density polyethylene board with a thickness of 2.0mm arranged on the slope of the reservoir area and the base layer 1 at the bottom. , The overlap between the waterproof board and the board is at least 5cm in width, and the inflation test is adopted, and the quality is qualified if there is no air leakage.

[0035] The seep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com