Welding and detection process used for HDPE geomembrane of refuse landfill

A landfill and geomembrane technology, applied in infrastructure engineering, protective devices, buildings, etc., can solve the problems of heavy inspection workload and difficulty in guaranteeing welding quality, so as to ensure construction quality, reduce weld seam and inspection quantity , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

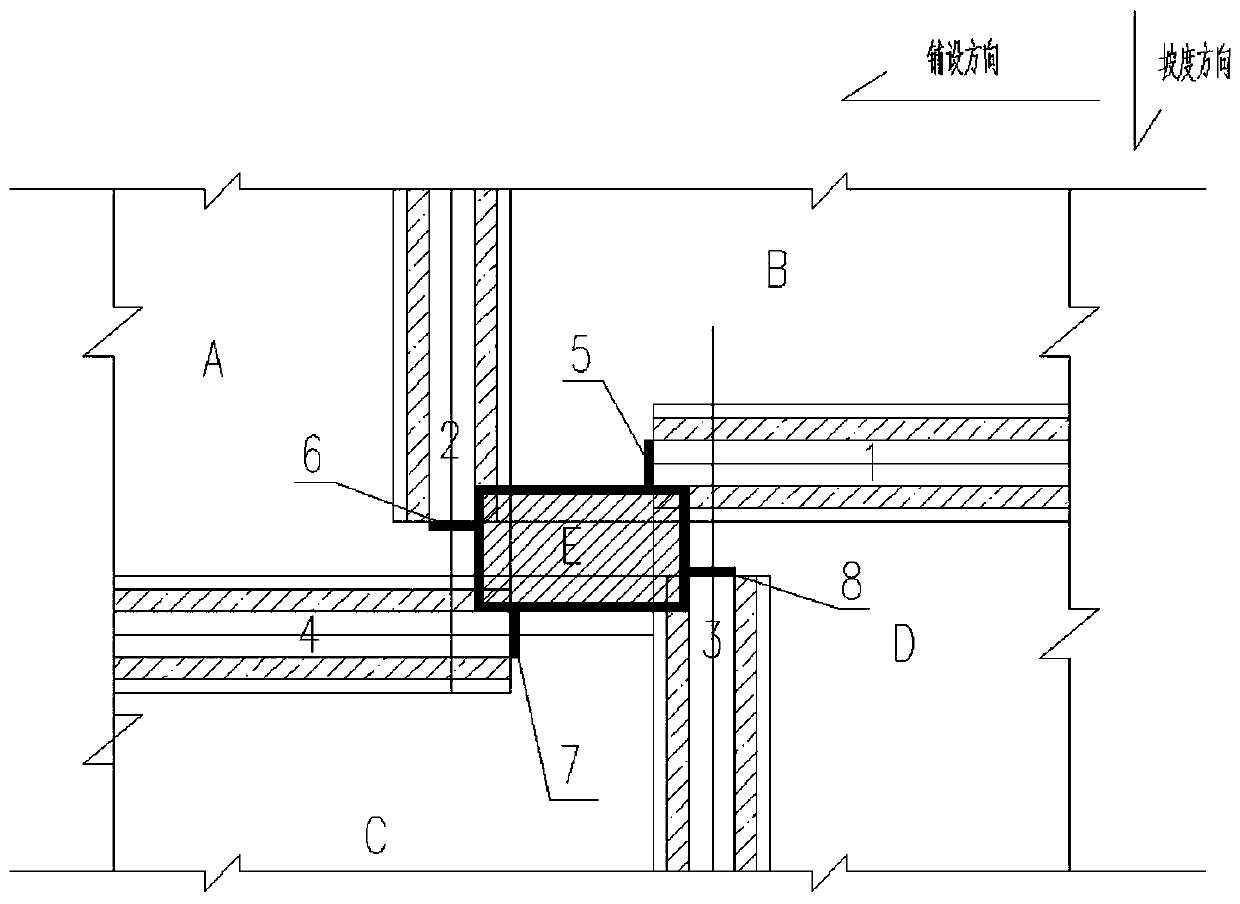

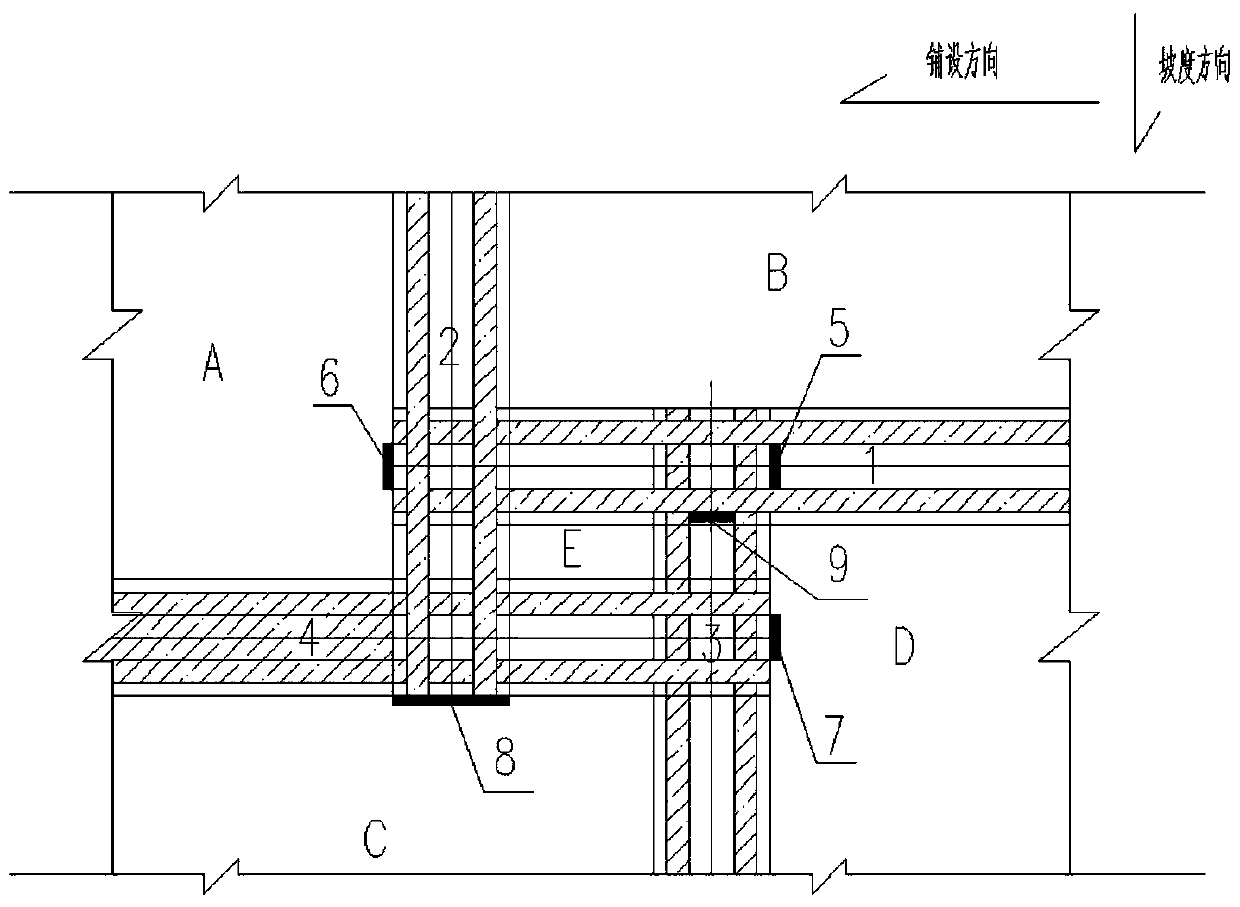

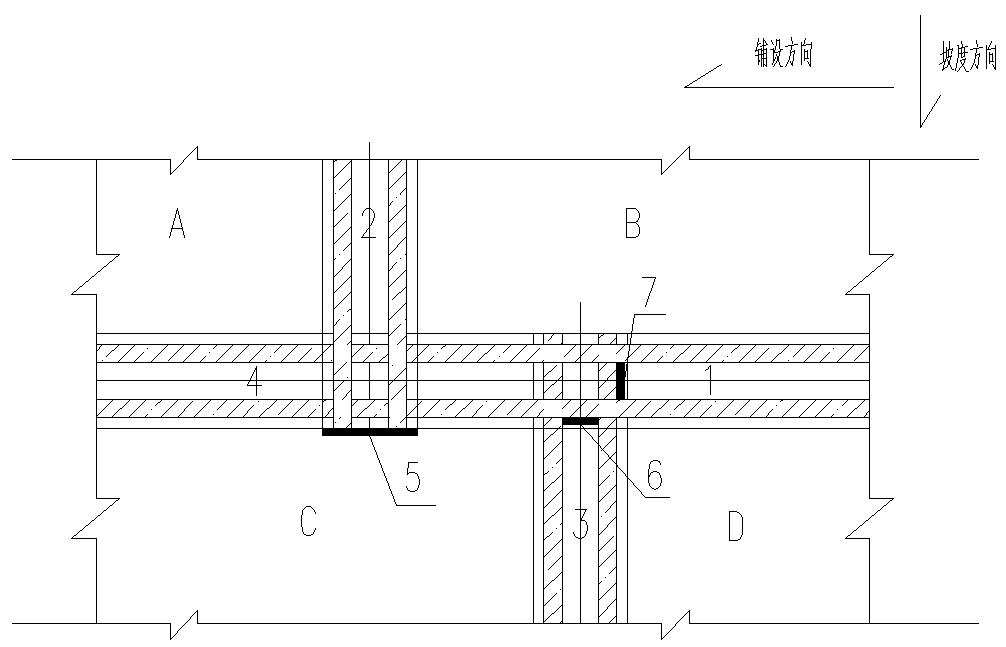

[0017] Such as image 3 As shown, it is a schematic diagram of a welding and detection process for HDPE geomembranes in landfills of the present invention. Taking the common joints of 4 HDPE geomembrane welding as an example, it is divided into four HDPE geomembrane joints of ABCD, and the total construction There are four double seams in 1, 2, 3, and 4, correspondingly forming four pressurized air passages, and three sealing and extrusion welds in 5, 6, and 7. The laying direction is from right to left, and the grading direction is from top to bottom. , the construction is advanced according to each piece, that is, when the node is constructed, the two HDPE geomembranes of BD have been laid and overlapped. When arranging, the upper and lower order of HDPE geomembrane overlap requires the upper layer to cover the lower layer in the slope direction, and the last layer to cover the previous layer in the laying direction. The order of HDPE geomembrane from top to bottom in the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com