Sewing method for fabric joints in cold dyeing process

A process and fabric technology, which is applied in the sewing field of fabric joints in the cold dyeing process, can solve the problems of dye waste and affect the quality of fabric dyeing, and achieve the effect of reducing the length and avoiding uneven dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0018] A sewing method for cloth joints in cold dyeing process, including sewing process:

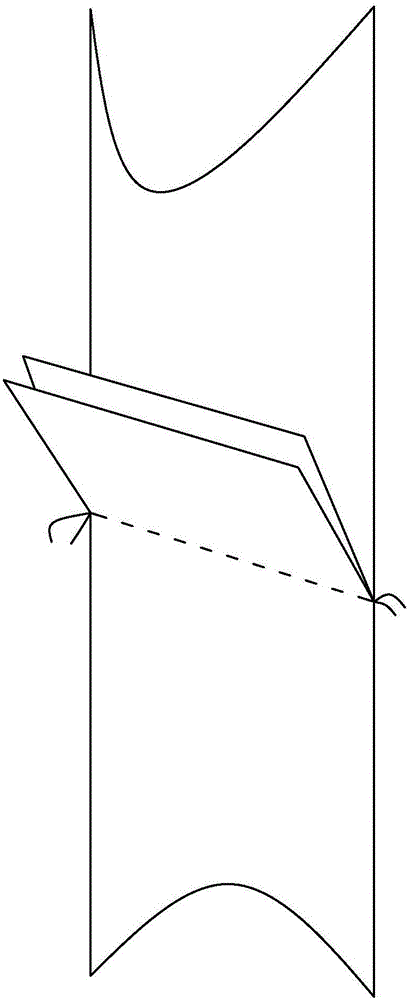

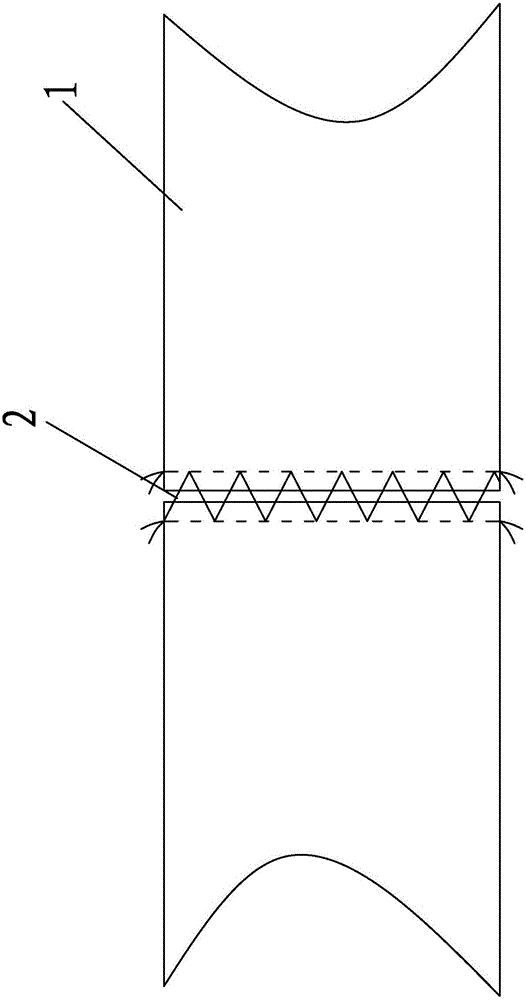

[0019] Such as figure 2 As shown, the seam ends of the two sections of gray cloth 1 are tiled and aligned, and an interval of 2mm is reserved between the seam ends of the two sections of gray cloth 1;

[0020] Take the way of double-thread double-seam butt seam, use 32 s / 2 strands of thread as seam 2 to sew the seam ends of the two pieces of gray fabric together.

[0021] The joints of the gray cloth sewn by a sewing method for fabric joints in the cold dyeing process of the present invention are smooth, and the thickness of the joints is the same as that of the whole piece of cloth, thereby avoiding uneven dyeing at the joints, which is different from that of the whole piece of fabric. For the problem of inconsiste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com