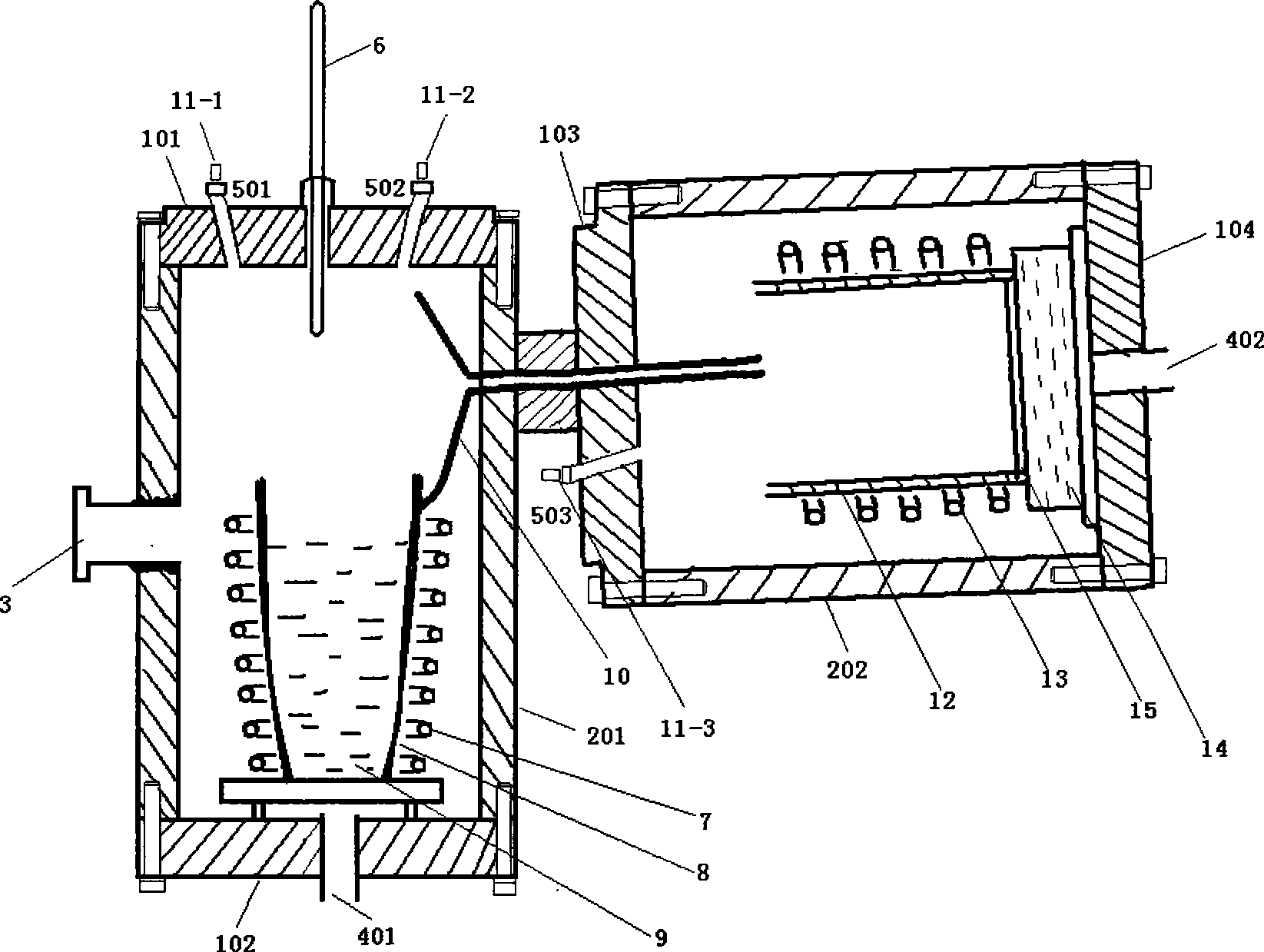

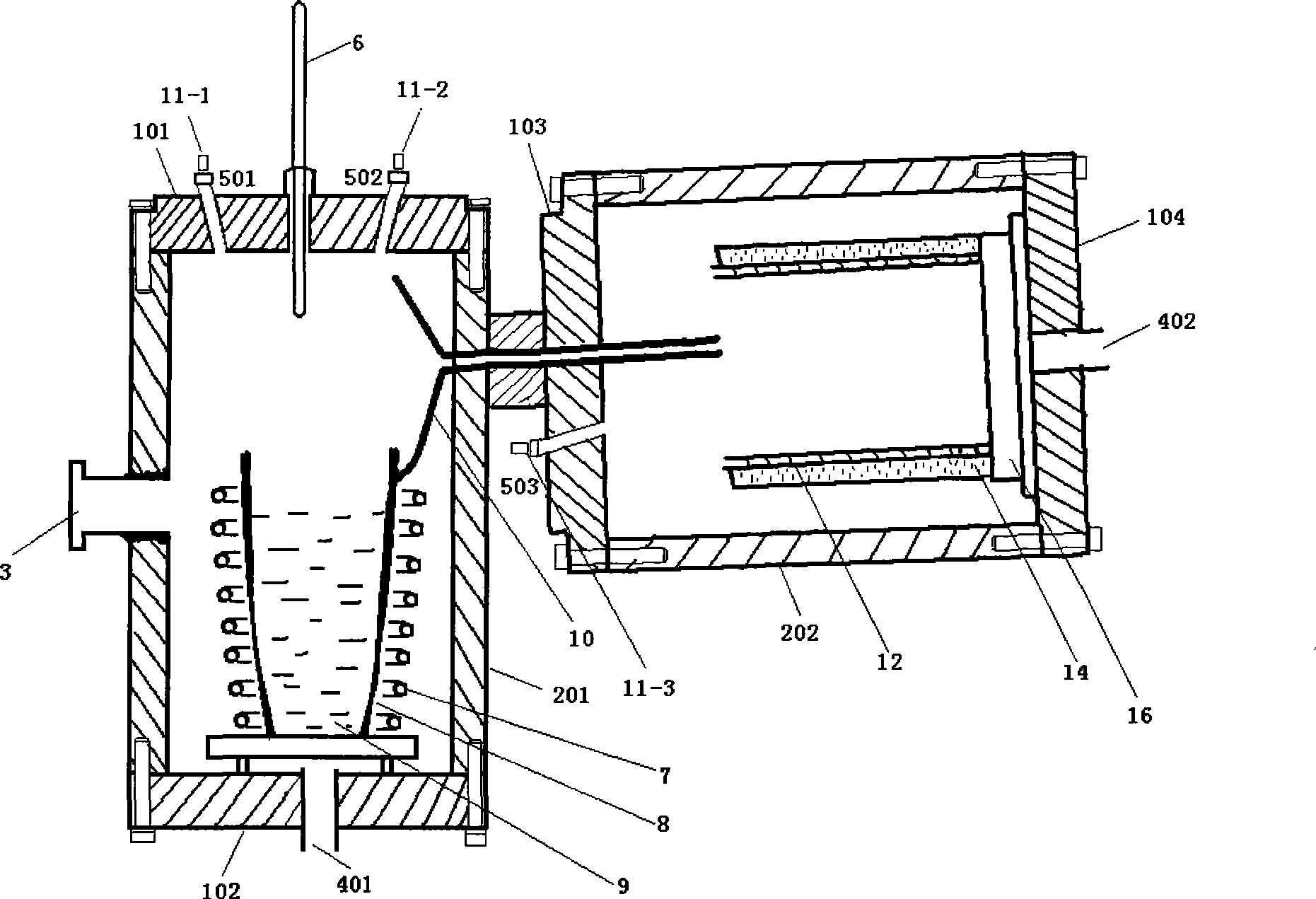

Multifunctional vacuum-positive pressure smelting solidification equipment

A multi-functional and equipment technology, applied in the direction of lighting and heating equipment, crucible furnace, furnace, etc., can solve the problems such as difficult to obtain porous materials, unable to ensure heat insulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Preparation of High Strength Oriented Porous Copper

[0035] The device is in the vertical state of the melting furnace, open the lower cover sealing flange I 102, put metal copper into the melting crucible 8, close and tighten the melting furnace lower cover sealing flange I 102, and make sure that all flanges are fixed to the melting furnace shell 201 ,seal. Turn on the water cooling system of the device, turn on the vacuum system to evacuate the whole device through interface 3, when the pressure in the furnace reaches 10 -2 Turn on the power supply of the induction heating coil 7 of the smelting furnace at Pa, start heating the crucible 8 of the smelting furnace, after the charge is completely melted, measure the temperature of the melt 9 with the temperature measuring device 6, set the current of the heating coil 7 to make the melt 9 reach the preset temperature 1250°C and maintain. Close the vacuum pumping system and open the inflation control valve, p...

Embodiment 2

[0036] Example 2 Preparation of high nitrogen austenitic stainless steel

[0037] When the device is in the vertical state of the melting furnace, open the sealing flange I 102 of the lower cover of the melting furnace, put 25Cr16Ni7Mn steel into the melting crucible, close and tighten the sealing flange I 102 of the lower cover of the melting furnace, and confirm that all flanges are in contact with the melting furnace shell Fixed and sealed. Open the vacuum system to evacuate the whole device through the interface 3, and the system pressure reaches 7×10 -2 After Pa, turn off the vacuum unit, switch port 3 to the inflation port, open the inflation valve, and let in nitrogen or nitrogen-argon mixture until the system pressure is 2MPa. Among them, when the mixed gas was used at that time, the partial pressure of nitrogen was 1.5MPa. Turn on the water-cooling system of the device, connect the power supply of the heating coil 7 around the melting crucible, wait for the charge t...

Embodiment 3

[0038] Example 3 Preparation of isotropic high-porosity foamed aluminum

[0039] Vacuum-pressurized infiltration process is adopted, the device is in the vertical state of the smelting furnace, the lower cover sealing flange I 102 of the smelting furnace and the lower cover sealing flange II 104 of the directional solidification furnace are opened, and the aluminum block and the spherical CaCO 3 Particles are packed into the smelting crucible 8 and the directional solidification mold 12, close and tighten the lower cover sealing flange I 102 of the smelting furnace and the lower cover sealing flange II 104 of the directional solidification furnace respectively, and determine that all flanges are compatible with the smelting furnace and the directional solidification furnace. The solidification furnace shell is fixed and sealed. Open the vacuum system to evacuate the whole device through the interface 3, and the system pressure reaches 10 -2 After Pa, turn off the vacuum unit ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com