Vibration Generating Device

A technology of vibration generating device and transmission device, which is applied in the direction of fluid using vibration, transportation and packaging, chemical/physical process, etc., which can solve the problems of uneven vibration, increase cleaning, and affect the effect of vibration, so as to avoid vibration Effect of uneven or unidirectional vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

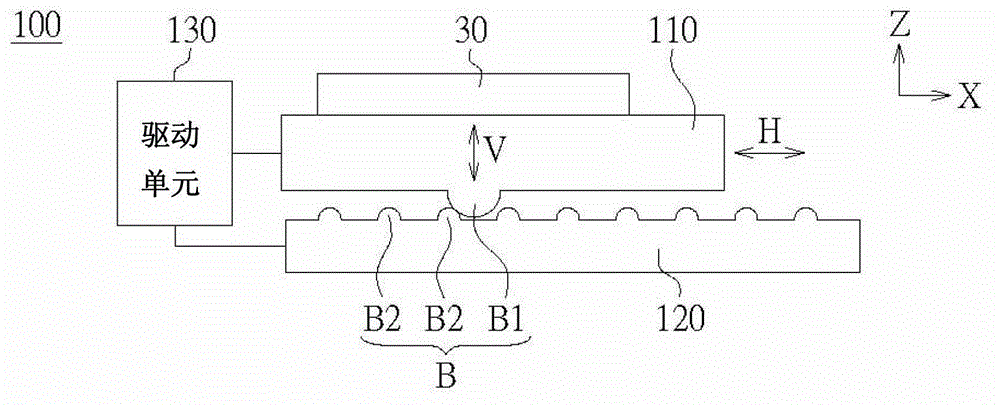

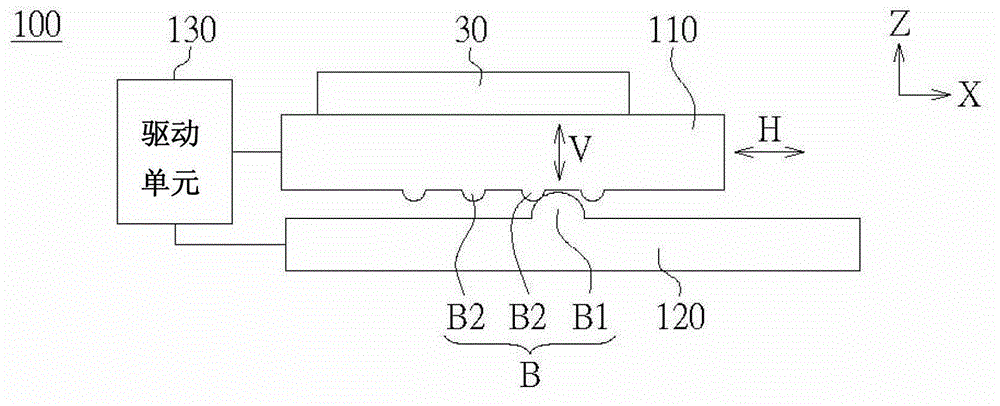

[0046] Please refer to Figure 2A and 2B , respectively depicting a schematic view of the vibration generating device 100 according to an embodiment of the present invention. The vibration generating device 100 includes a working platform 110 , a counter platform 120 and a driving unit 130 . The working platform 110 is used for carrying a workpiece 30 , and the workpiece 30 is disposed on one side of the working platform 110 . The opposite platform 120 is adjacent to the other side of the working platform 110 . The working platform 110 and the opposite platform 120 are in contact with each other with at least two bumps B1 and B2 projecting oppositely between the working platform 110 and the opposite platform 120 .

[0047] For example, in Figure 2A Among them, the working platform 110 is disposed above the opposite platform 120 and fixed by clamps (not shown), so as to keep the working platform 110 to move horizontally on the opposite platform 120 smoothly. At least one ...

no. 2 example

[0054] Please refer to Figure 5 , which is a schematic diagram of a vibration generating device 200 according to an embodiment of the present invention. The vibration generating device 200 includes a working platform 210 , a counter platform 220 and a driving unit 230 . Regarding the working platform 210, the relative platform 220, and a plurality of projections (not shown) that are arranged between the working platform 210 and the relative platform 220 and contact each other, the arrangement thereof is similar to that of the first embodiment, please refer to Figure 2A-2B , 3A-3C and 4A-4C and their descriptions will not be repeated here.

[0055] The difference between this embodiment and the first embodiment is that the driving unit 230 is coupled to the working platform 210 and the relative platform 220 to drive the working platform 210 and the relative platform 220 to move relative to each other on a two-dimensional plane. For example, see Figure 6C The vibration gen...

no. 3 example

[0058] Furthermore, please refer to Figure 6D and 6E In the second embodiment, the drive unit is in addition to Figure 6A In addition to the linear transmission device 142 to drive the working platform 110 or the relative platform 120, a non-linear transmission device (such as a suspension transmission device or a ground-shaking transmission device) can also be used to drive the working platform 110 or the relative platform 120, so as to Make the working platform 110 or the relative platform 120 generate a horizontal movement.

[0059] For example, see Figure 6D The vibration generating device 104, the drive unit 134 includes a controller 141 and a suspension transmission 145, the suspension transmission 145 is used to support the work platform 110, so that the work platform 110 can be placed on the opposite platform 120 smoothly, And drive the working platform 110, so that the working platform 110 has a horizontal movement relative to the relative platform 120. The hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com