LED packaging structure

一种LED封装、LED芯片的技术,应用在电气元件、电固体器件、电路等方向,能够解决荧光粉激发效果降低、演色性不佳、出光颜色不均匀等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

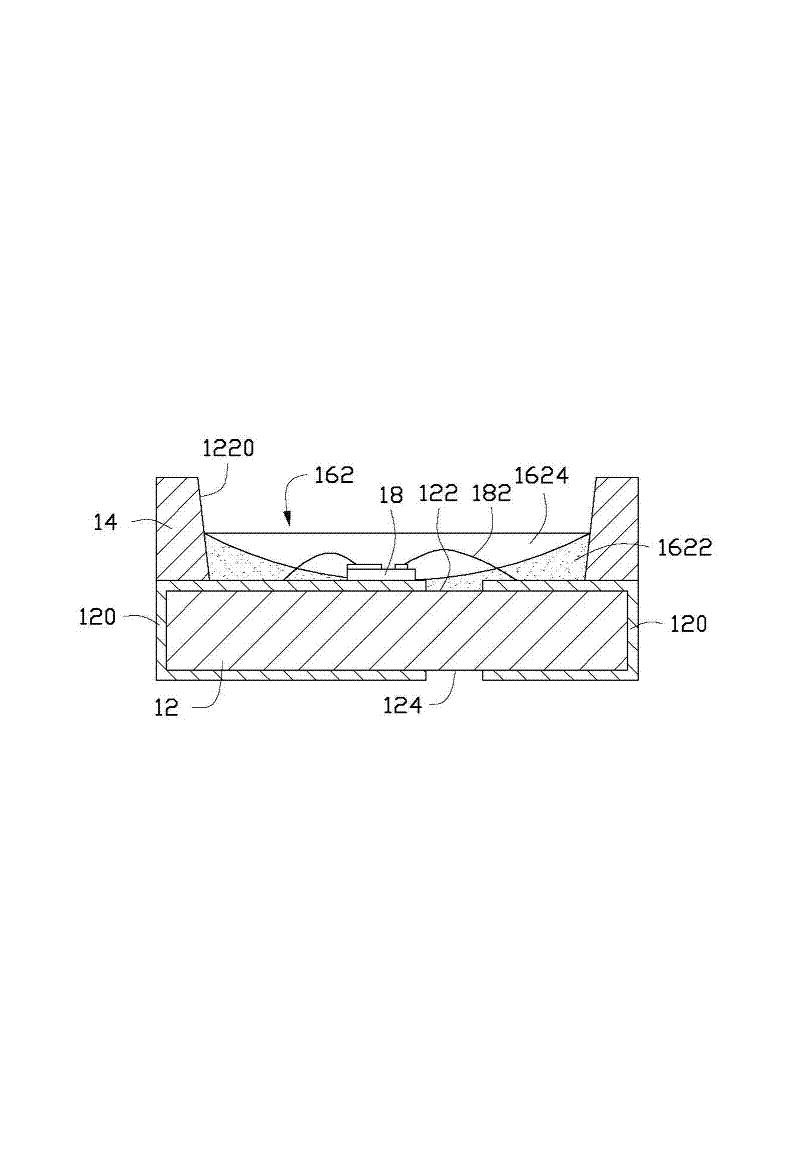

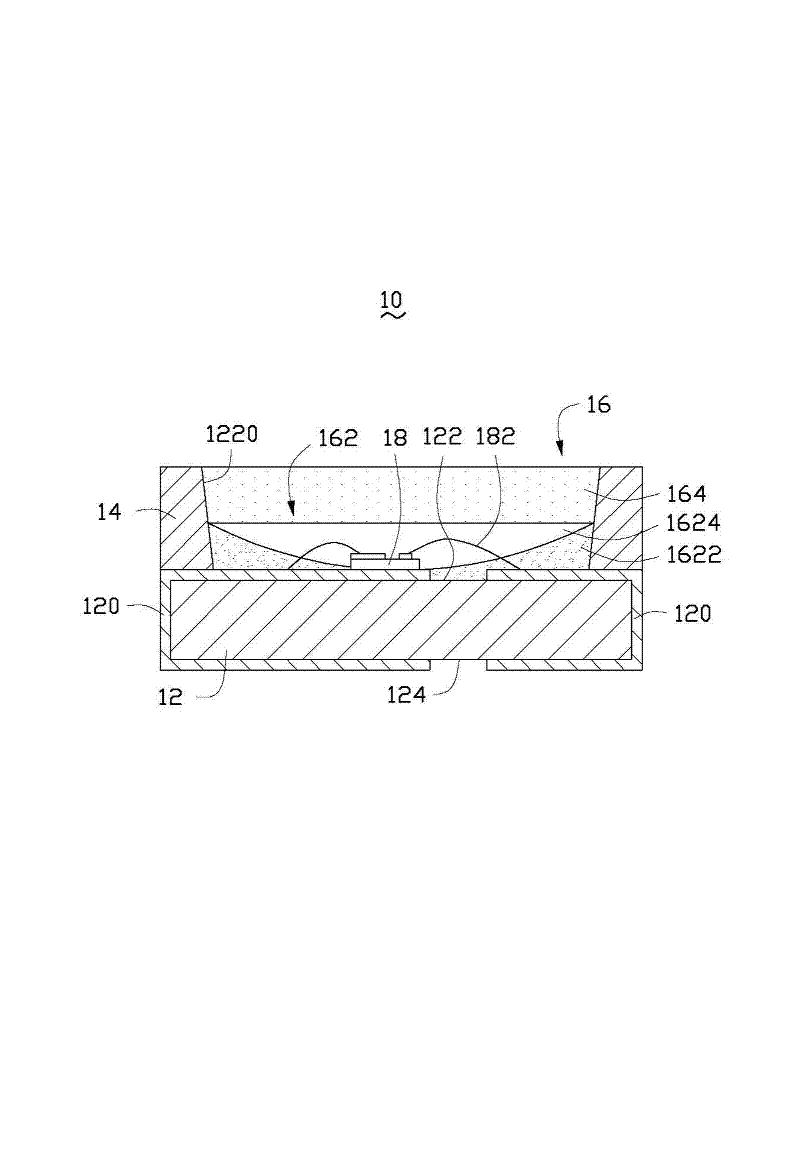

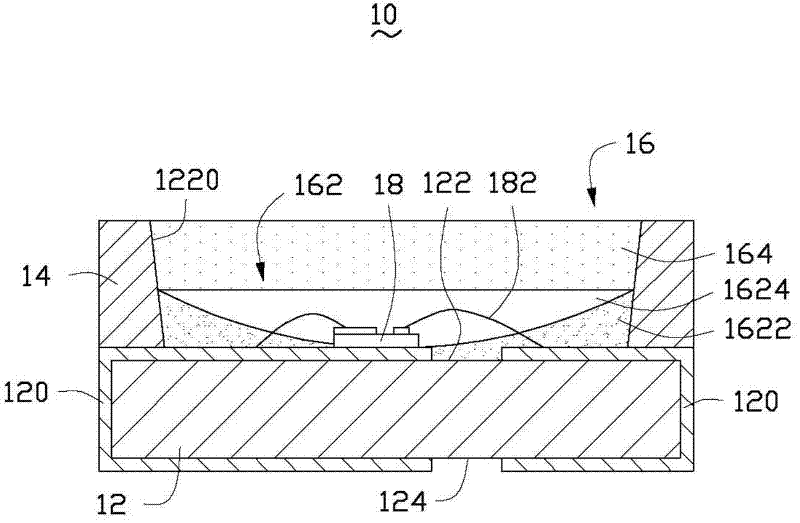

[0012] see figure 1 as well as figure 2 , shows the LED packaging structure 10 of the present invention, which includes a substrate 12 , a reflective cup 14 , an encapsulant 16 and an LED chip 18 .

[0013] The substrate 12 has a top surface 122 with two electrodes 120 on the top surface 122 . The two electrodes 120 extend from the top surface 122 to the bottom surface 124 opposite to the top surface 122 . One of the two electrodes 120 is a positive electrode and the other is a negative electrode. The reflecting cup 14 is disposed on the top surface 122 and surrounds the periphery of the substrate 12 , and a groove 1220 is formed on the top surface 122 . The LED chip 18 is disposed at the bottom of the groove 1220 and is electrically connected to the two electrodes 120 through conductive wires 182 . After the LED chip 18 is electrically connected, the light emi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com