Deep-hole and shallow-hole combined bench blasting method capable of reducing blasting boulder rate

A technology of step blasting and large block rate, which is applied in blasting and other directions, can solve the problems of increasing secondary blasting workload, increasing blasting cost, and accelerating equipment wear, so as to improve blasting effect, reduce project cost and accelerate project progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

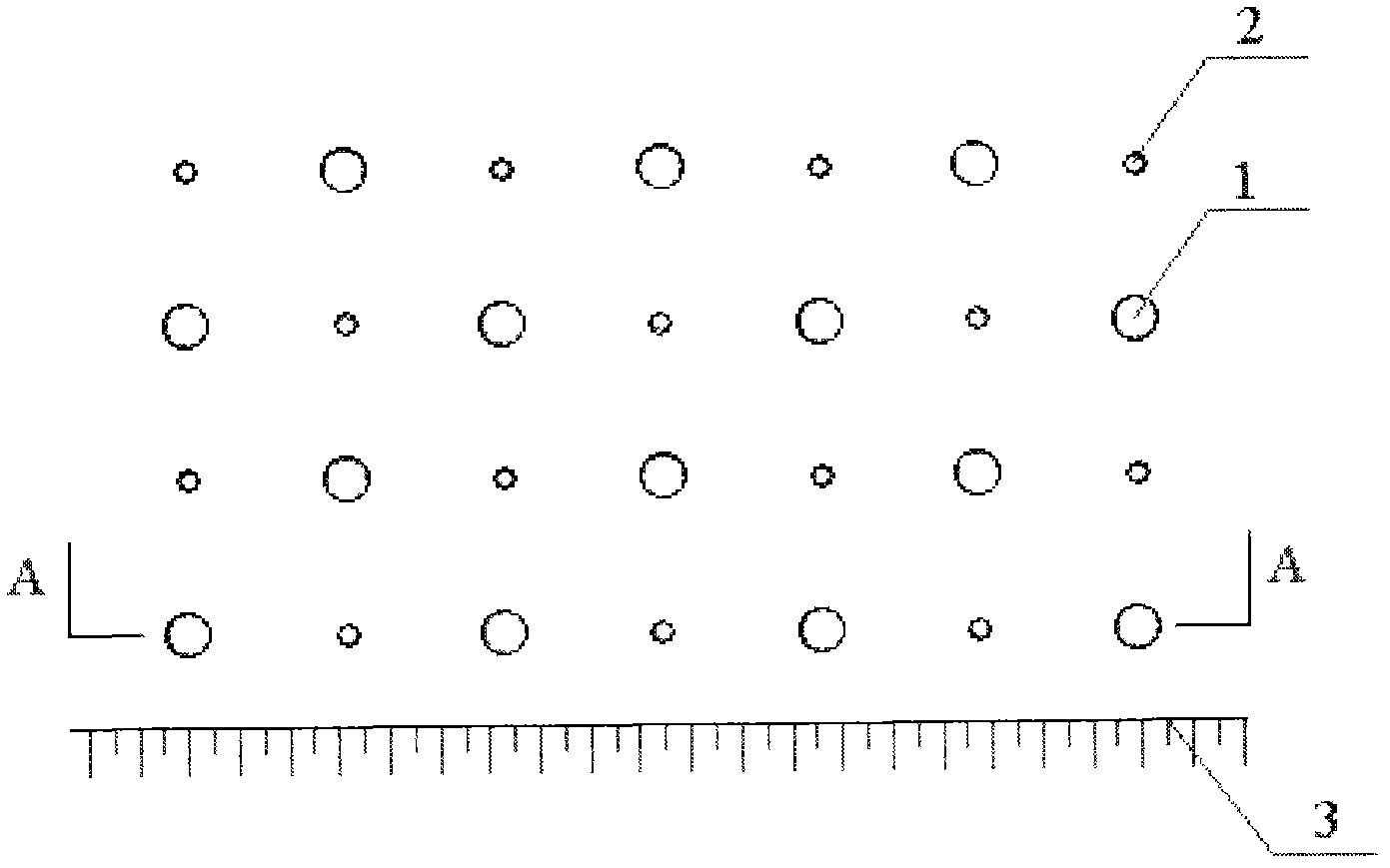

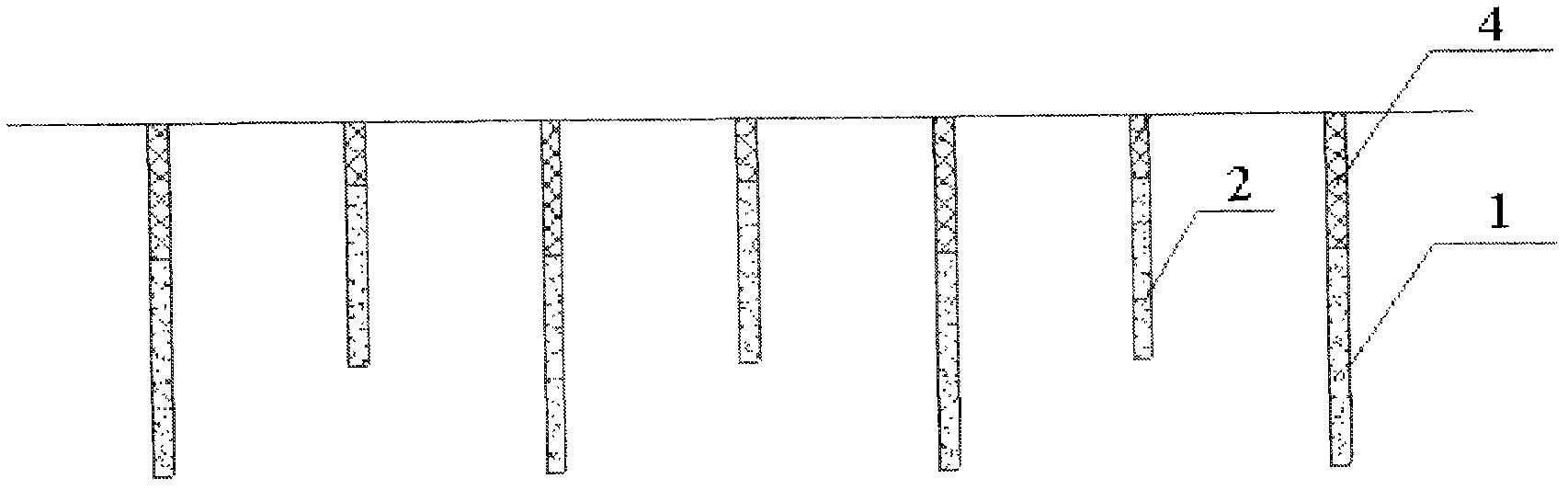

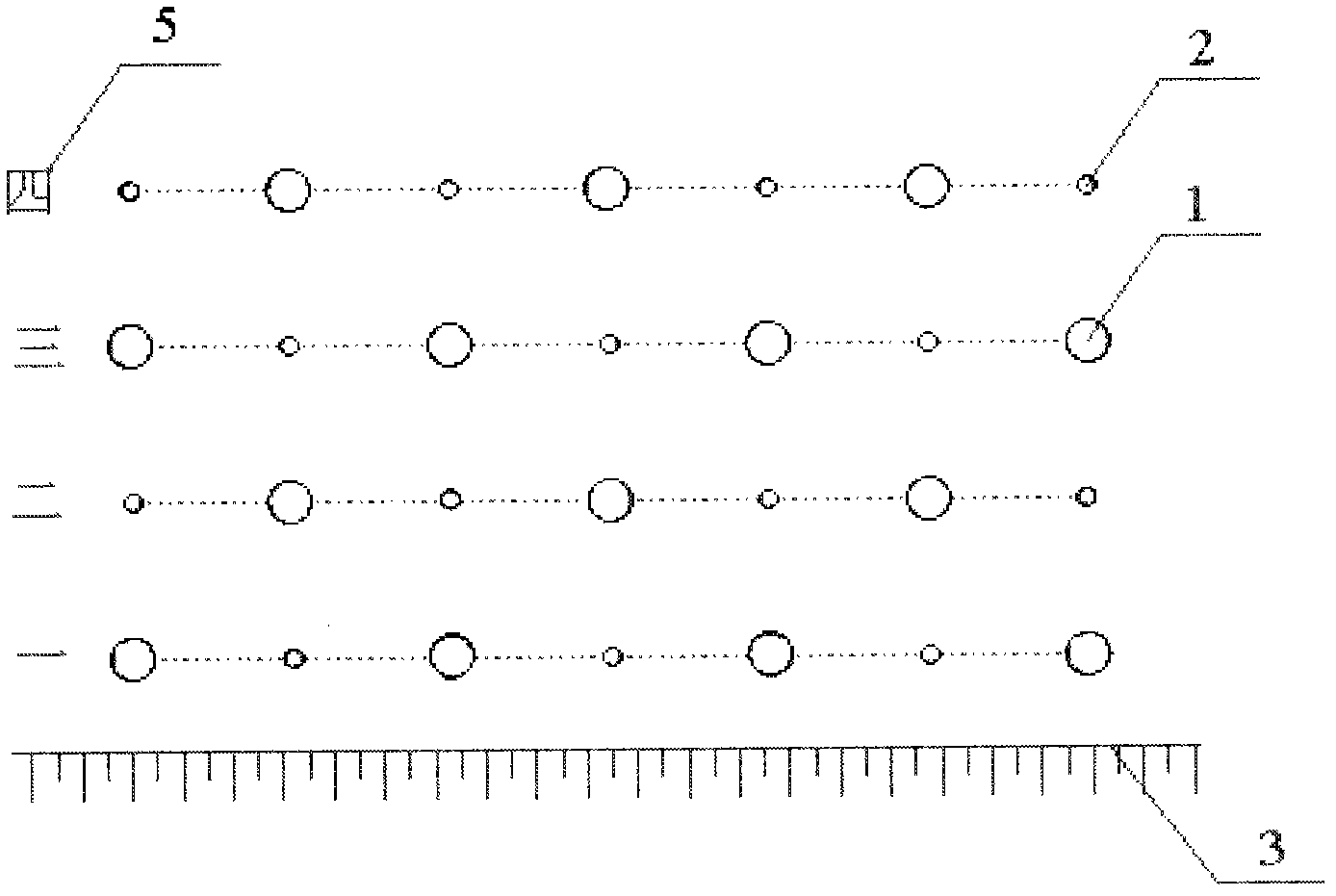

[0017] Such as Figure 1~3 As shown, the deep and shallow holes combined with the stepped blasting method to reduce the blasting large block rate include the following steps:

[0018] (1) According to the triangular (or quincunx) arrangement of holes on the step 3 of the blasting area, and according to the design and requirements of open-air deep hole step blasting, deep blast holes are drilled to obtain the deep hole 1.

[0019] (2) Drill a shallow blast hole with a diameter Φ≤50mm at the center position between every two deep holes 1 in the same row to obtain shallow holes 2.

[0020] (3) Charge the deep hole 1 and the shallow hole 2 respectively, and arrange the priming charges to block the openings of the deep hole 1 and the shallow hole 2 .

[0021] (4) According to the detonation sequence 5 in the design requirements, the sequential detonation between rows is performed with a slight difference, and one blasting is enough.

[0022] The depth of the shallow hole 2 is gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com