Integrated double-seam double-arc TIG (Tungsten Inert Gas) welding system and Double-seam double-arc TIG welding method for T-shaped joints

An integrated system and welding tooling technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as incomplete penetration, welding bumps, burn-through, etc., and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

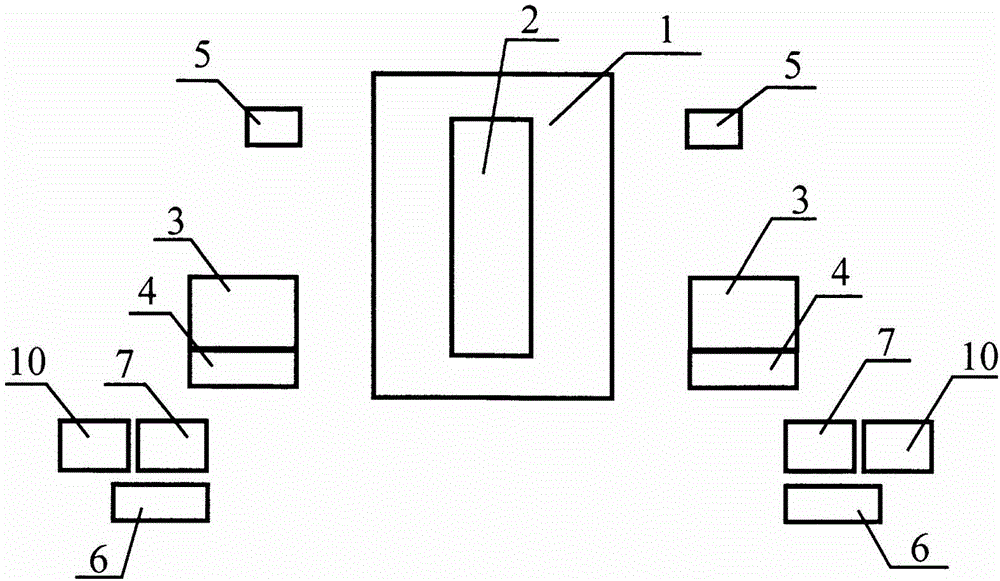

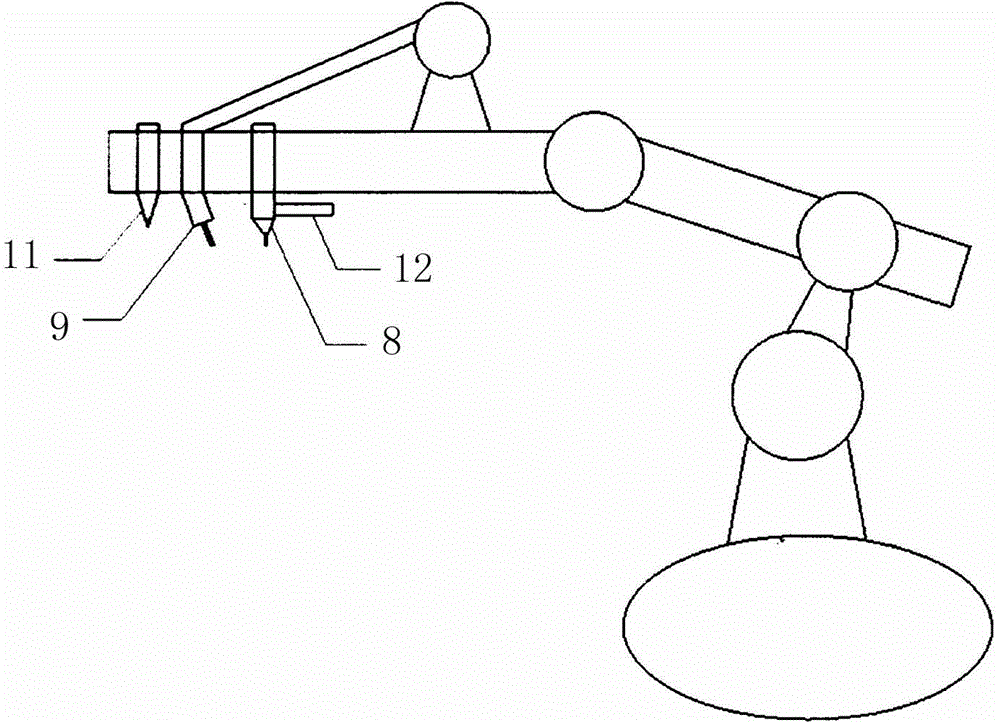

[0019] Such as figure 1 and figure 2 As shown, a T-joint double-slit double-arc TIG welding integrated system, the welding tool 2 is installed on the workbench 1, the T-joint parts to be welded are installed on the welding tool 2, and the movement of the robot is controlled by the electric operation box 5 The trajectory is programmed and set, the robot 3 is placed above the robot guide rail 4, the control hardware of the robot 3 is optimized and integrated in the robot control cabinet 6, the robot guide rail 4 is symmetrically arranged on both sides of the workbench 1, and the front end of the robot 3 is equipped with a welding torch 8 , automatic wire feeding device 9, laser tracking system 11 and welding torch drag cover 12, robot 3 is equipped with pressure sensor and anti-collision software, cooling water tank 10 is connected with welding power supply 7, in the working process of robot 3, cooling water tank 10 pairs of argon arc welding The power supply 7 is cooled.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com