Patents

Literature

197results about How to "Guaranteed assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

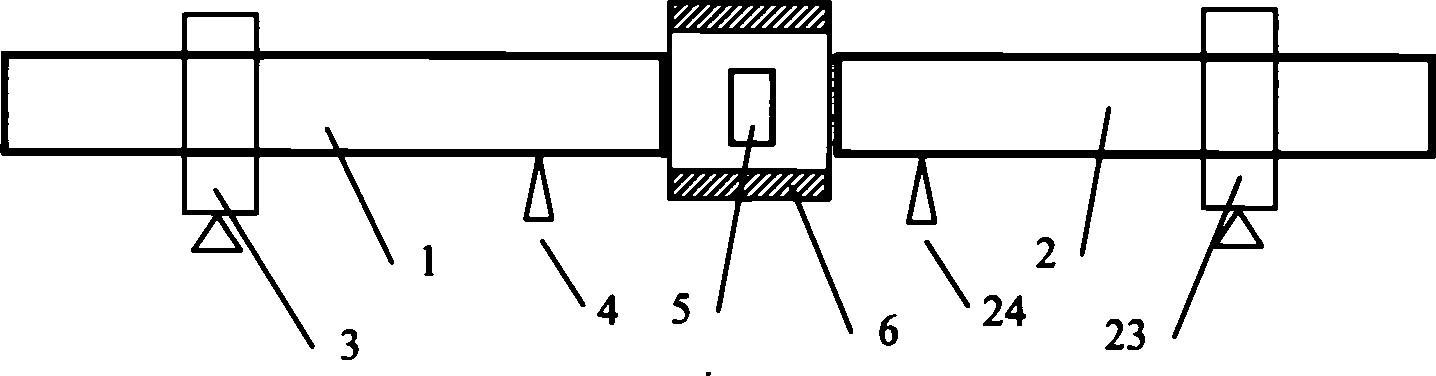

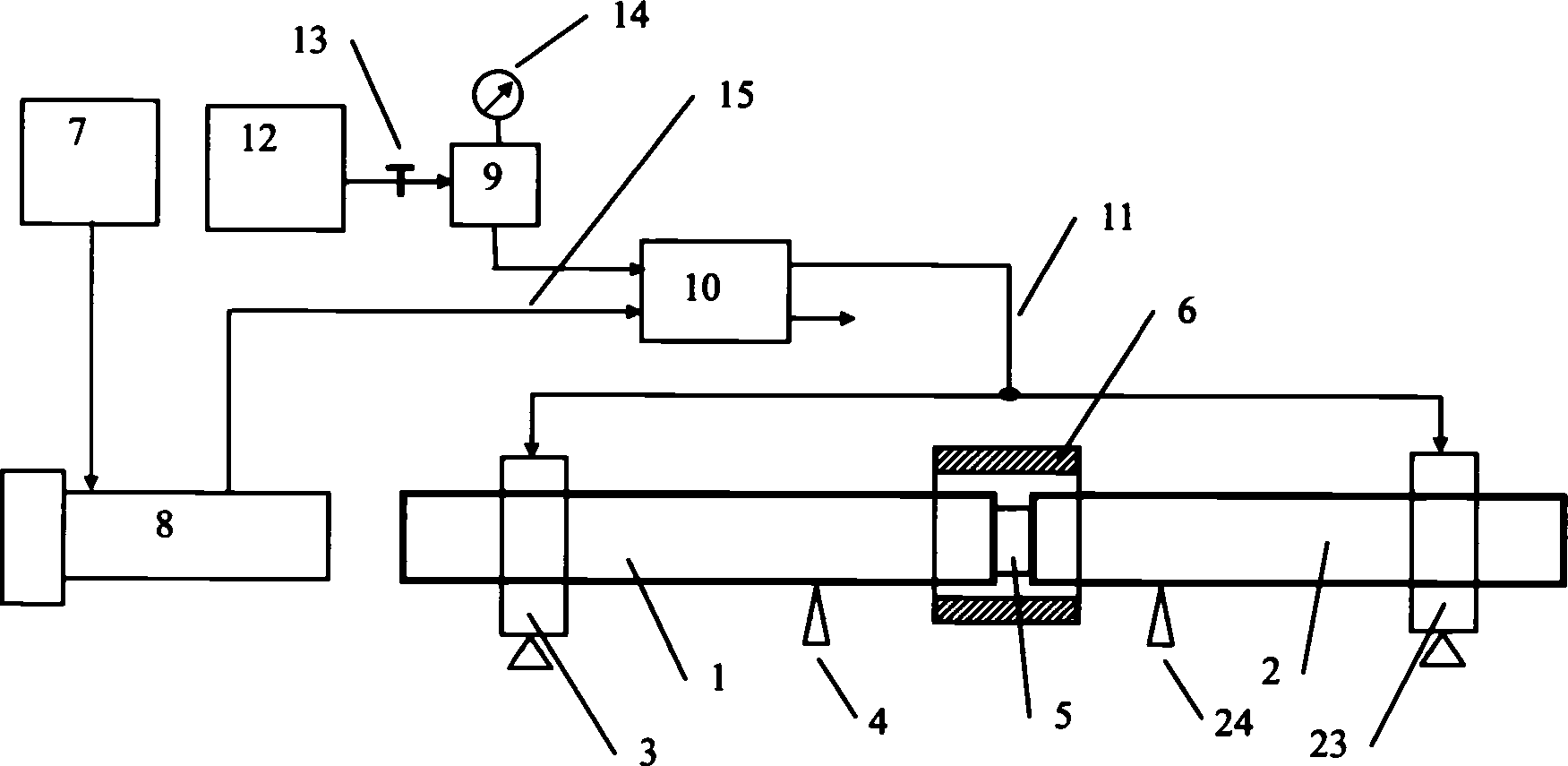

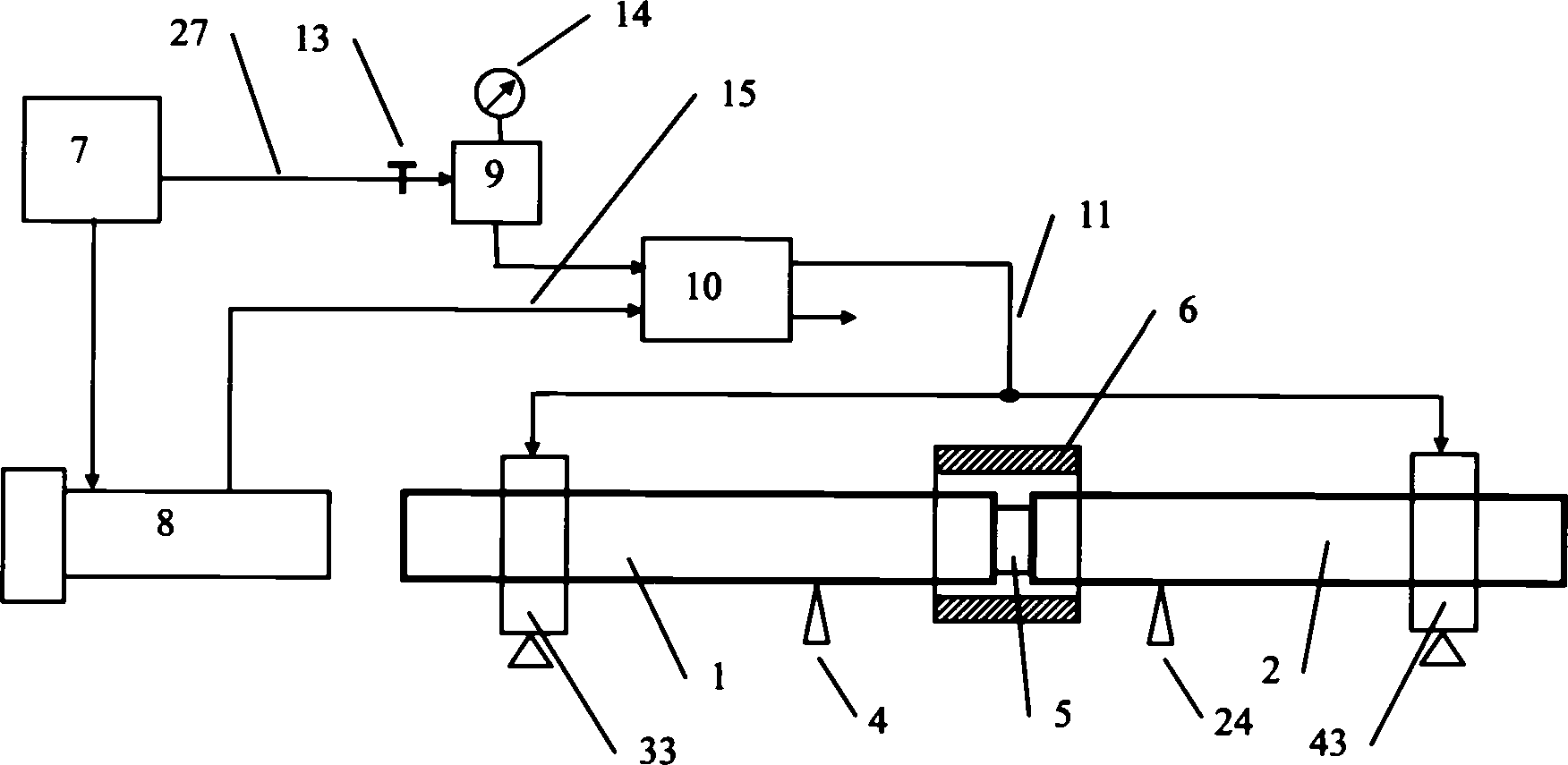

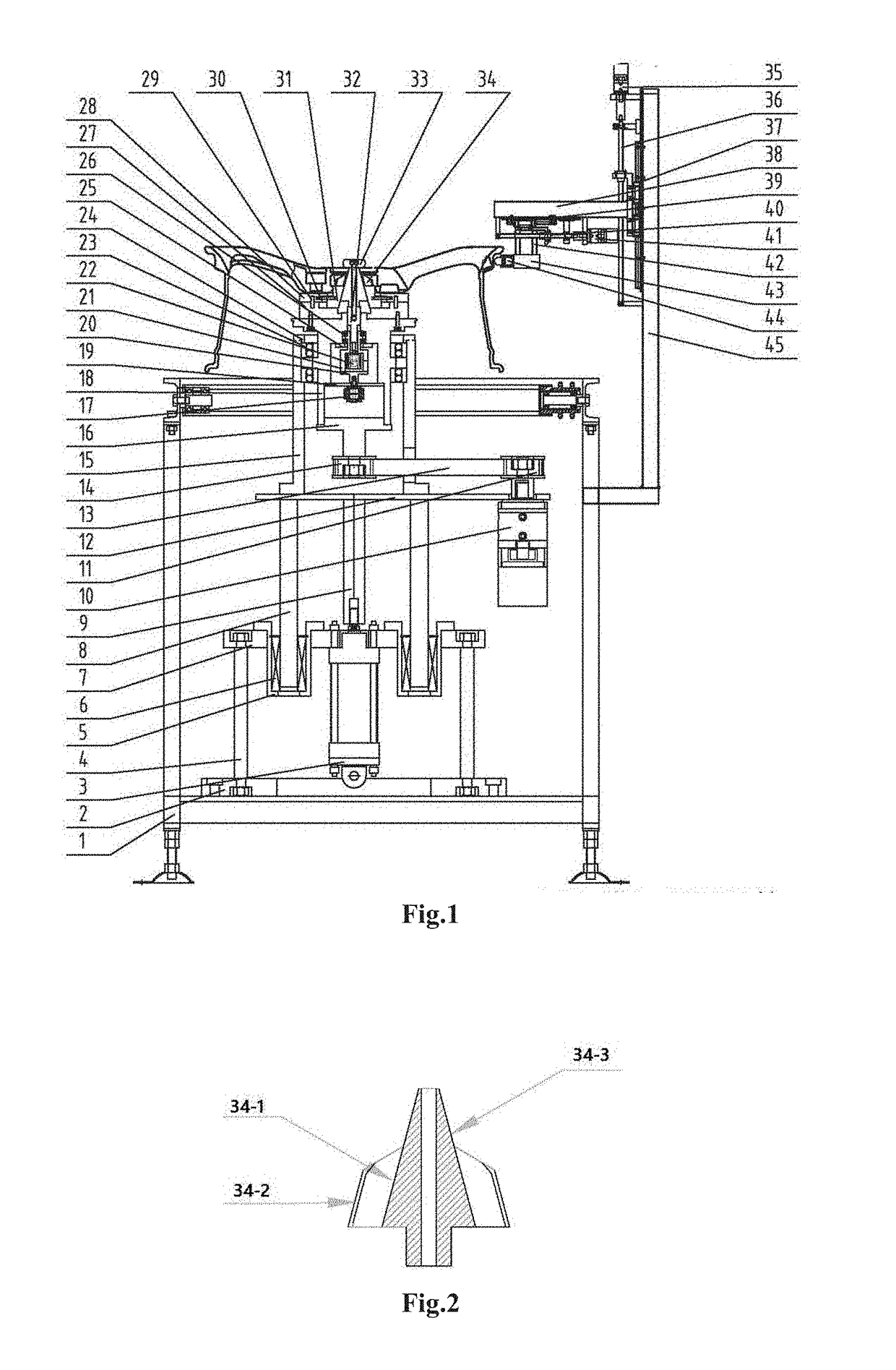

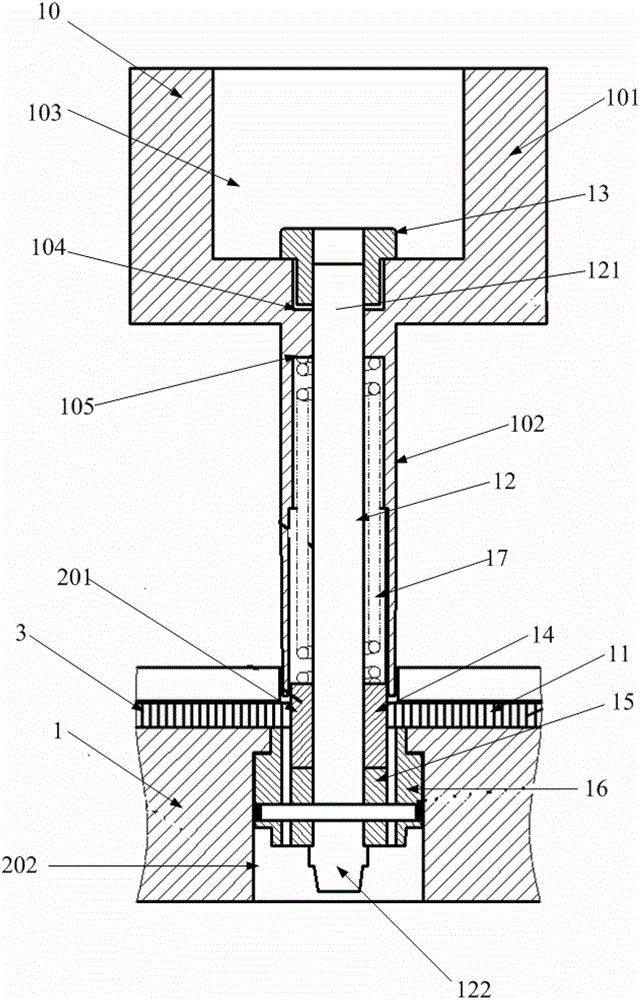

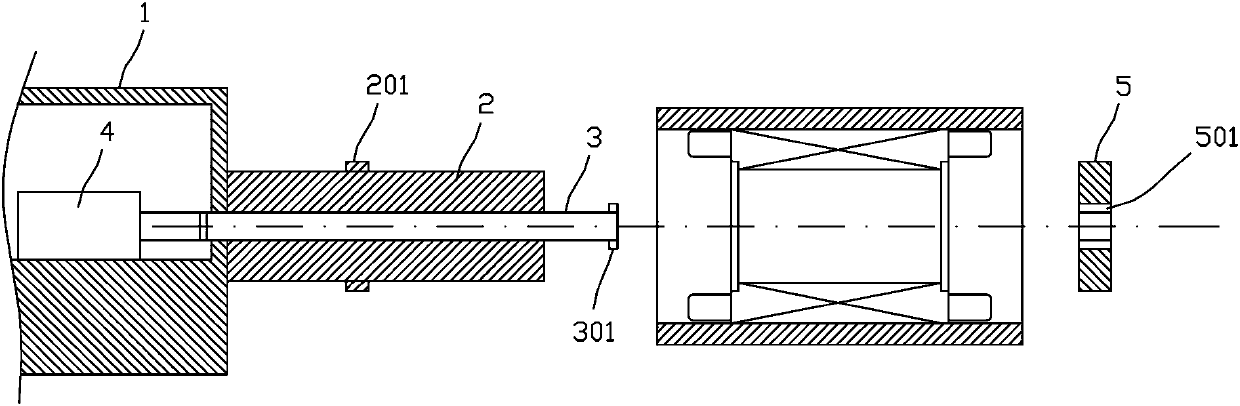

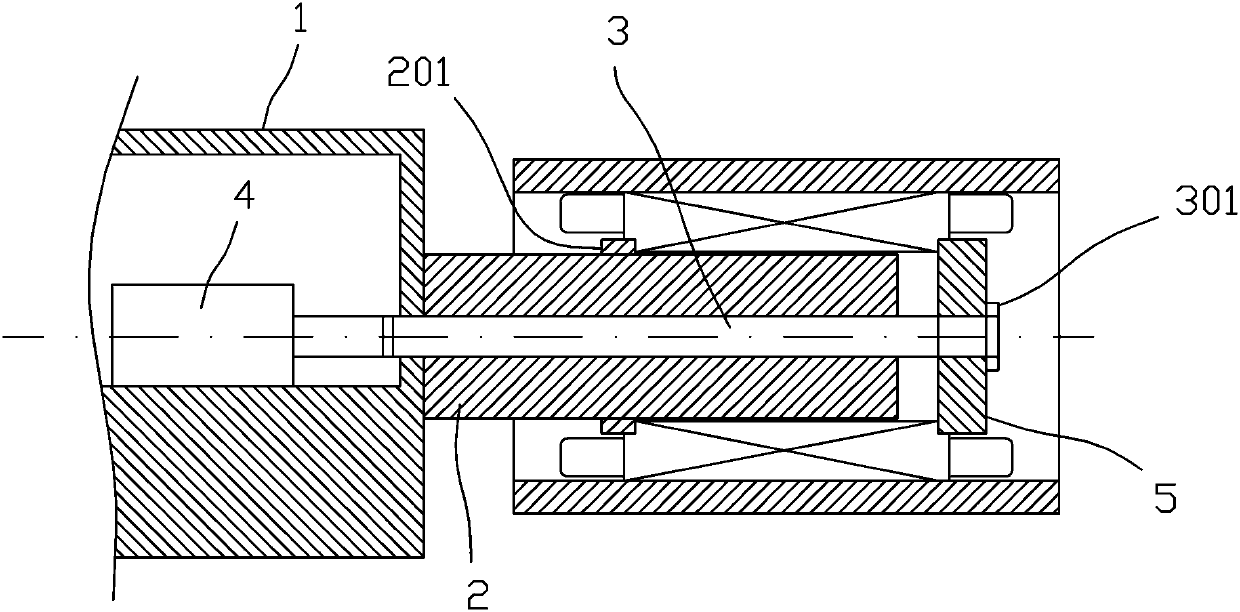

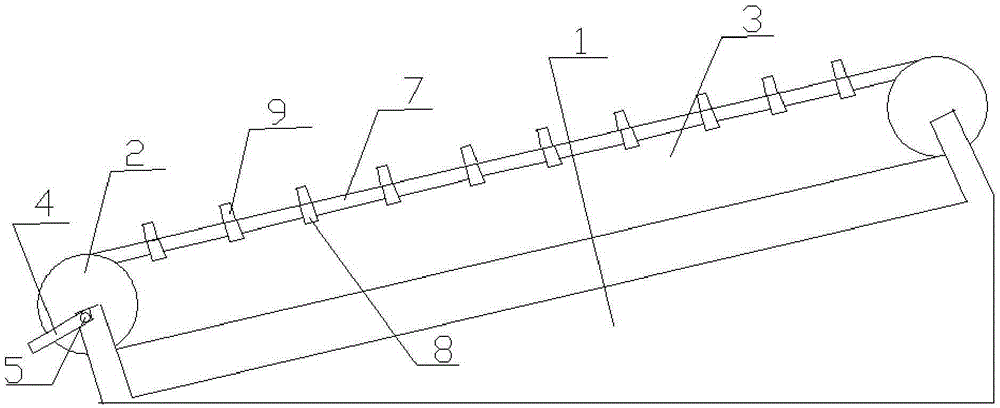

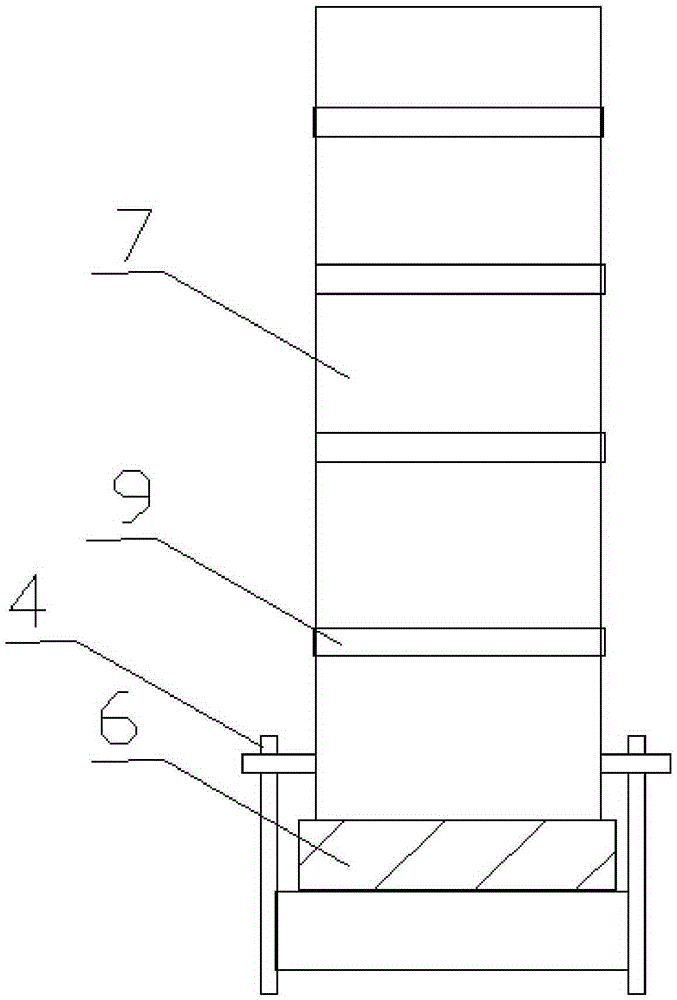

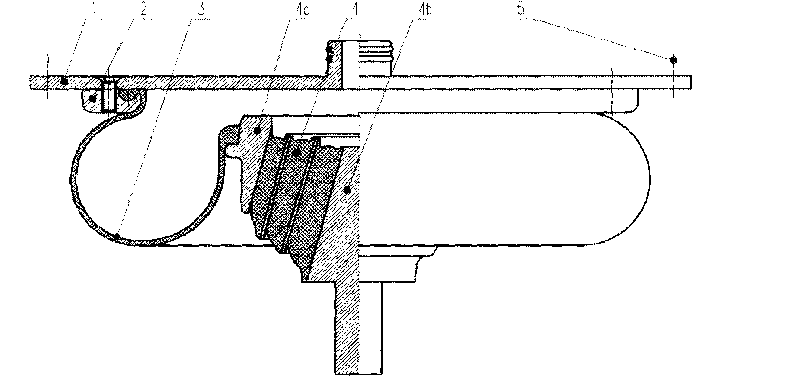

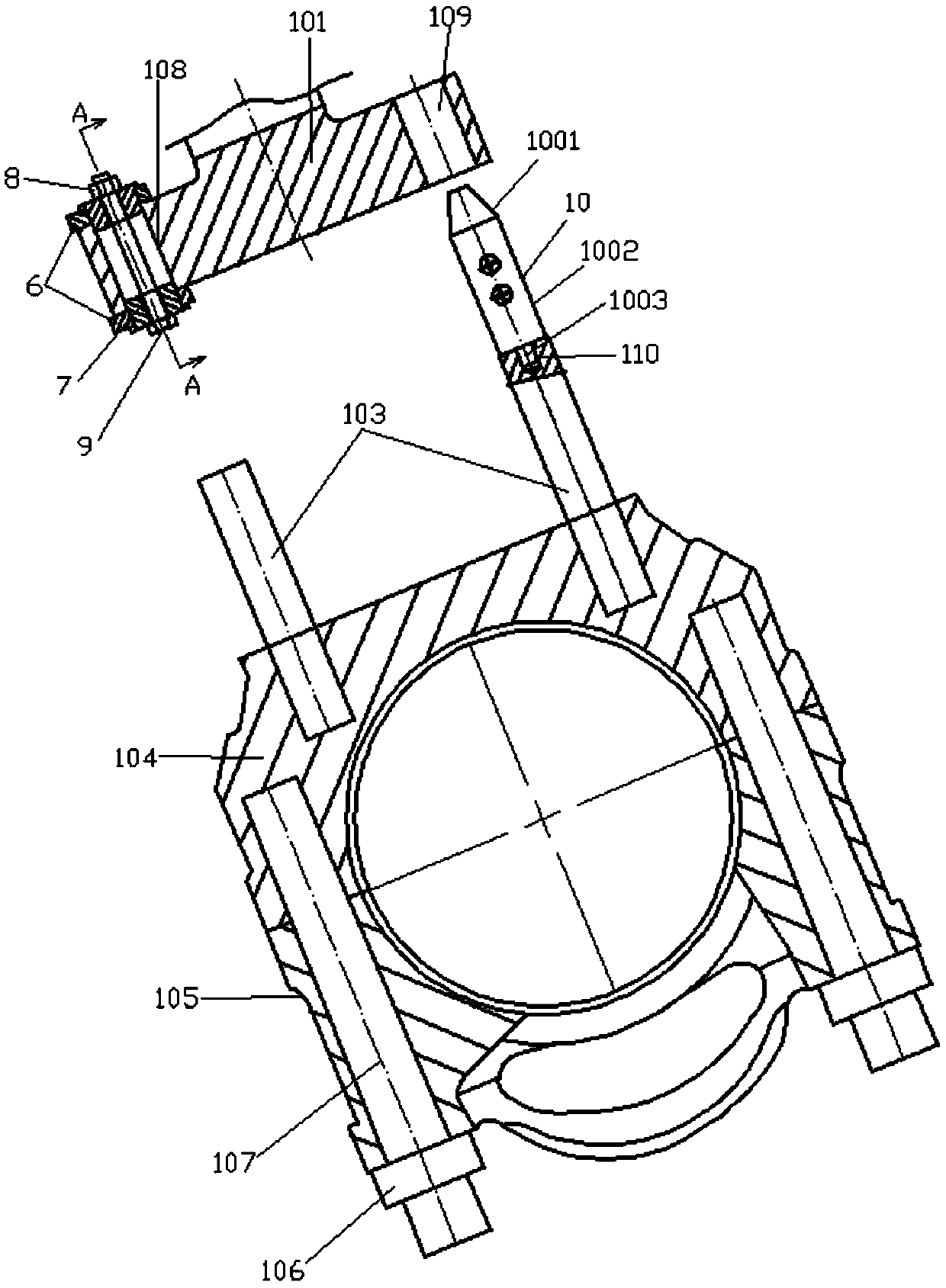

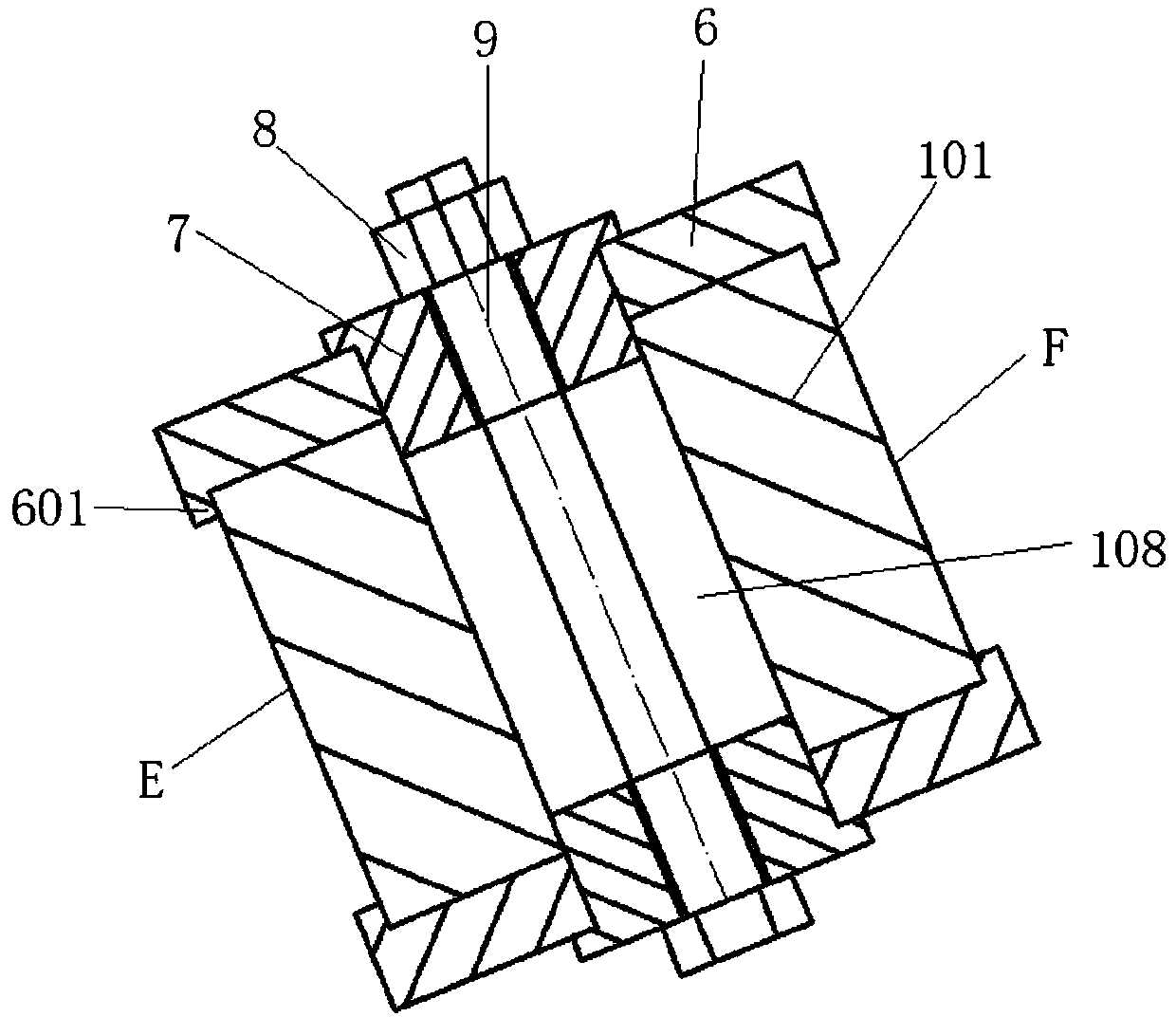

Double-air path bidirectional automatic assembling device for high-temperature Hopkinson pressure bar experiment

InactiveCN1888851AGuaranteed synchronicityReduce temperature unevennessStrength propertiesEngineeringAtmospheric pressure

Two-way double steam paths self-motion assembled equipment for high temperature Hopkinson pressure-bar experiment belongs to material high temperature dynamic mechanics capability research field. Each gas driving rack set on incidence perch and transmission perch and push them towards specimen in assembling to form two-way assemble in order to keep specimen in the availability heating range. Push the driving gas path of rack and separate setting of air cannon startup gas path and set gas chief valve control the switch of driving gas path and air cannon startup gas path. It makes the driving rack and air cannon startup linkage without influence. Set small gas storage tin as driving gas source and control its air pressure to control the driving speed of the driving rack. It can keep the assembled stability of the equipment and enhance assembled success probability. It assures the synchronism of assembled equipment when the stress wave arrives to specimen to avoid the temperature of specimen rapidly drop for leaving heat fountain.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

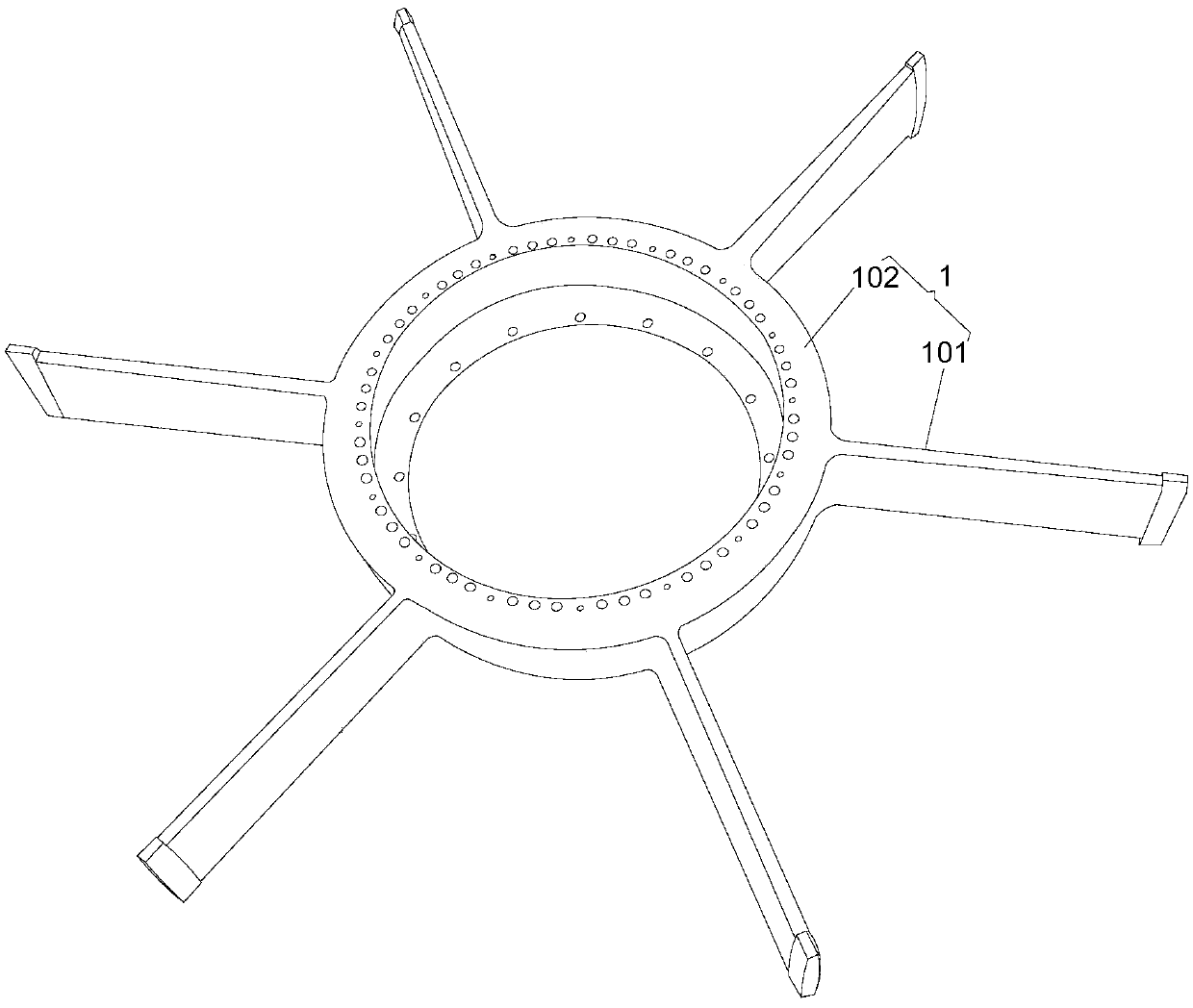

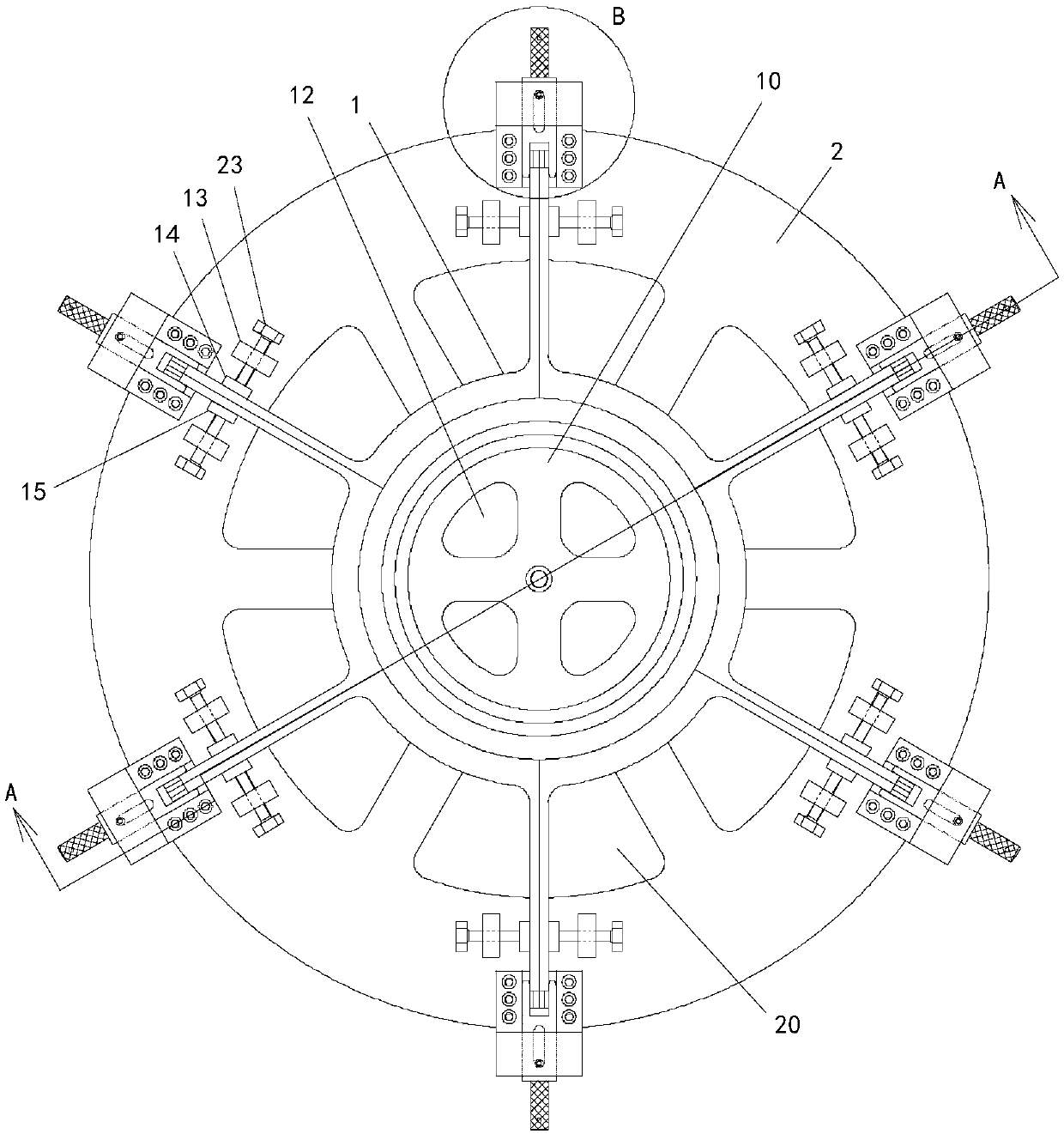

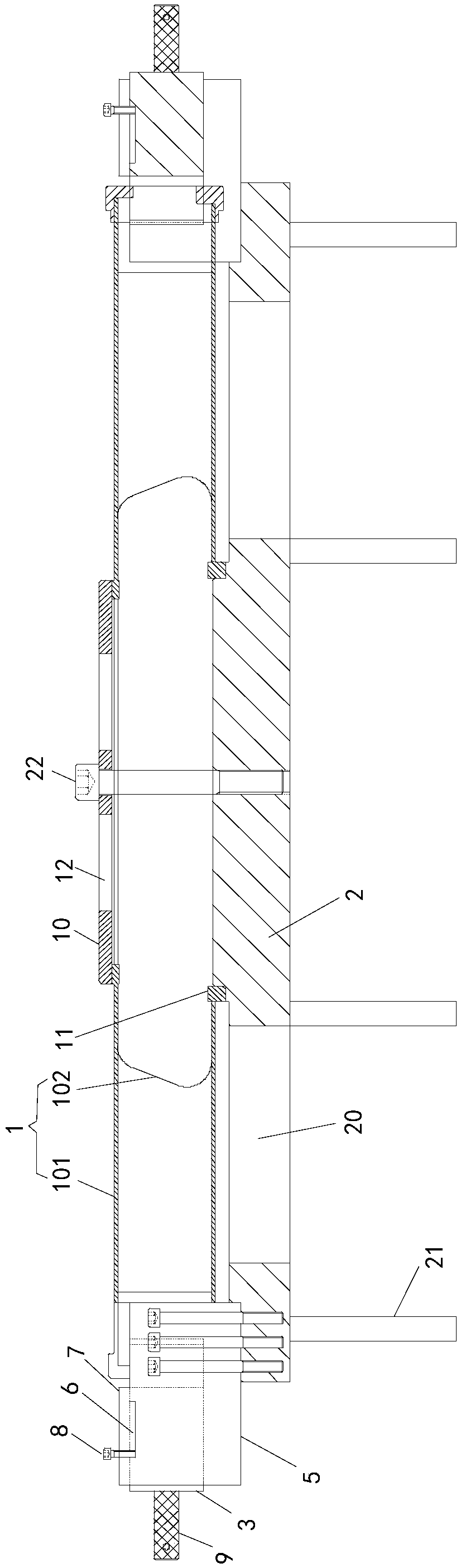

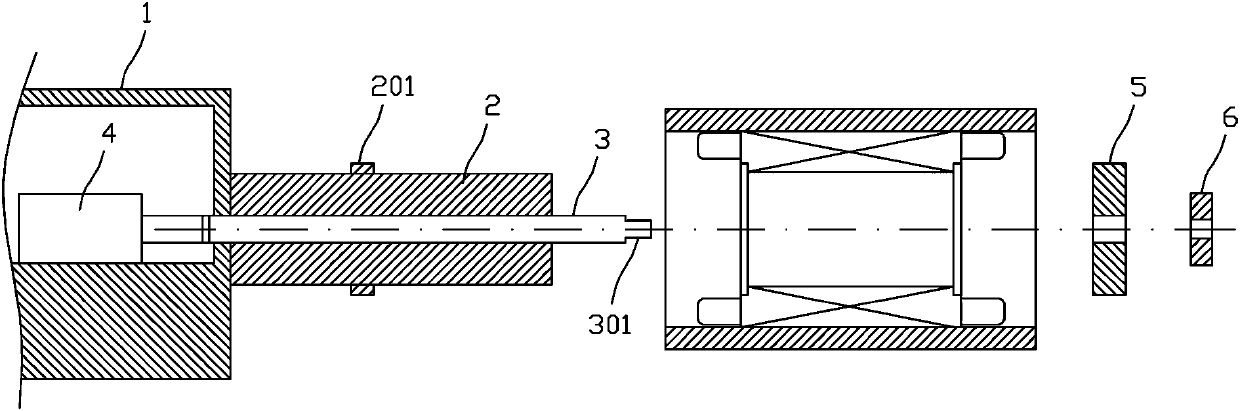

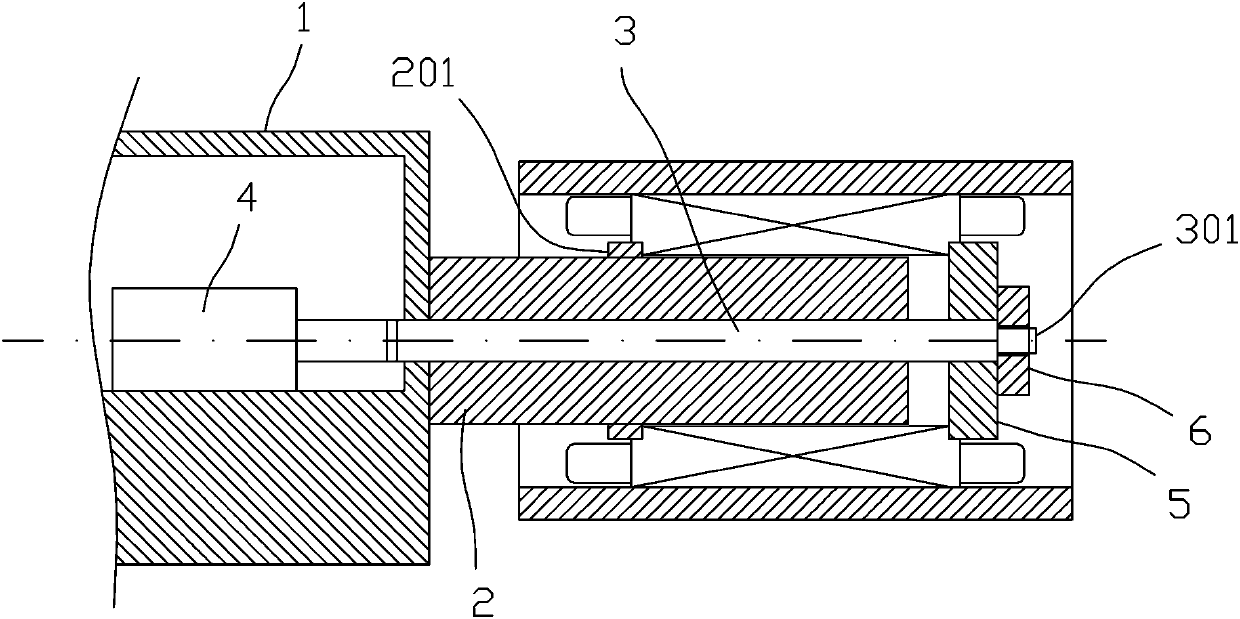

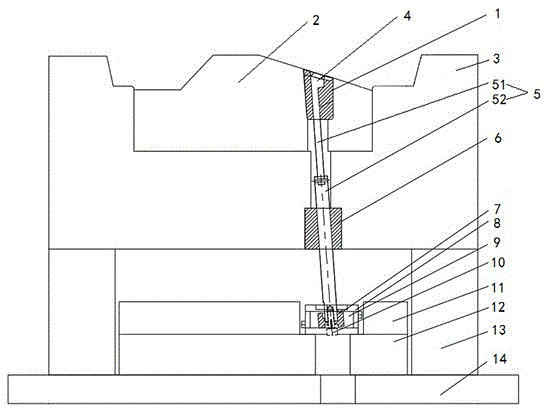

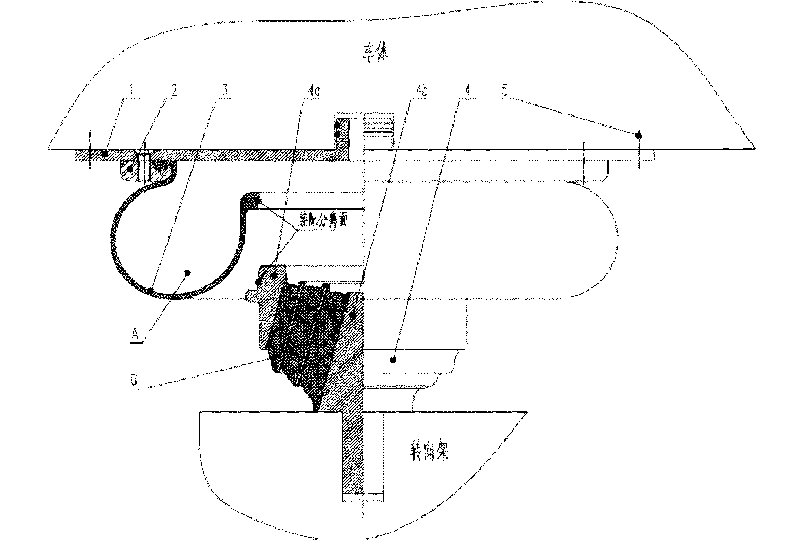

Online wheel run-out detecting device

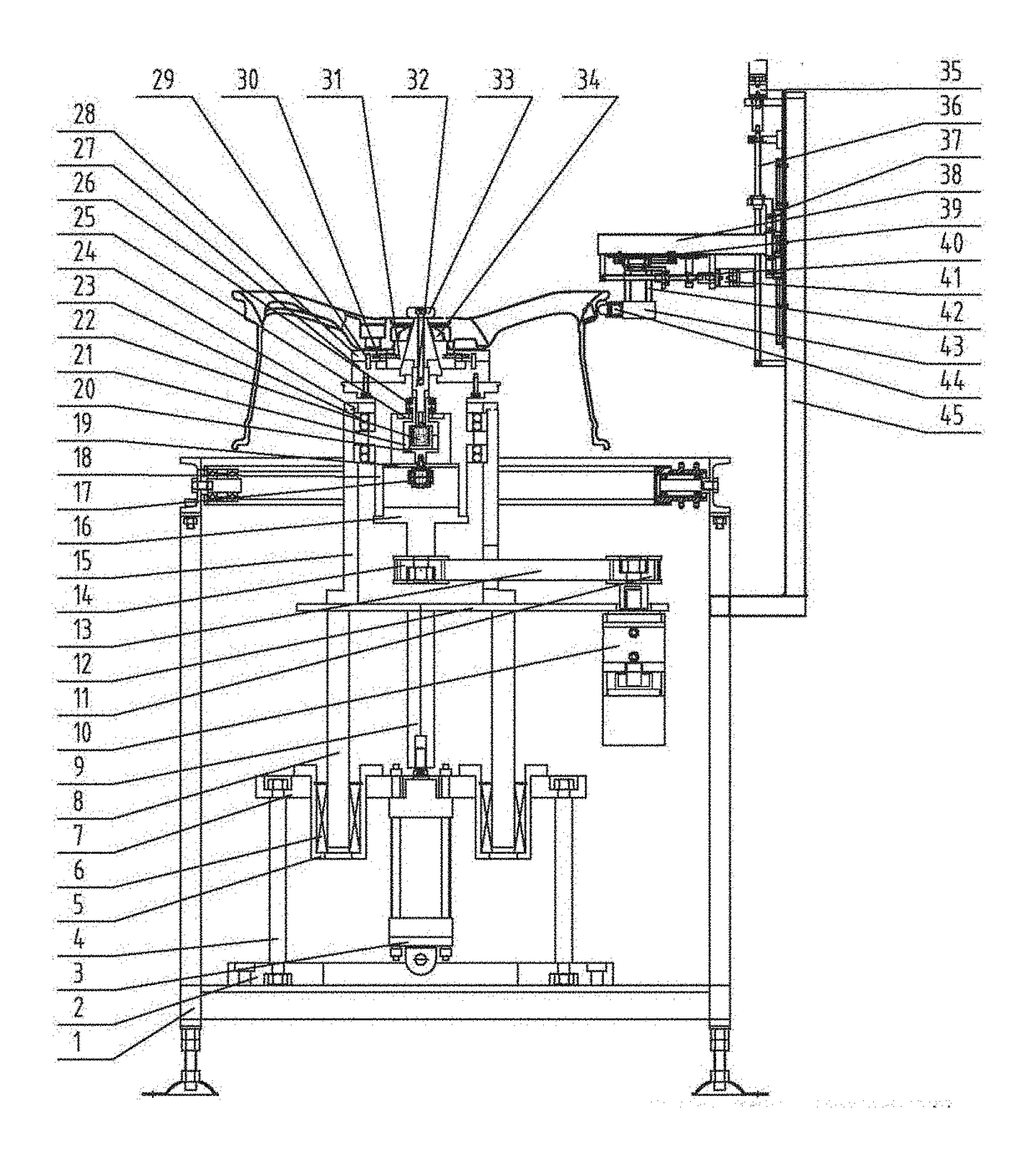

ActiveUS20180003592A1Process is finishedSimple structureStatic/dynamic balance measurementVehicle wheel testingEngineeringPulley

The invention relates to an online wheel run-out detecting device. The online wheel run-out detecting device includes a frame, a chassis, a lifting cylinder, supports, bearing bases, linear bearings, mounting plates, guide shafts, a lifting shaft, a servo motor, a synchronous pulley, a connecting plate, a synchronous belt, a synchronous pulley, a base, a connecting shaft, a servo motor, a shaft sleeve, a lower end cap, a connecting shaft, a shaft sleeve, and an oil cylinder. The online wheel run-out detecting device can meet requirements of online wheel run-out detection, meanwhile it has the characteristics of simple structure, convenience in manufacturing, stable performance and capability of meeting machining requirements on precision, and can meet requirements of automatic production.

Owner:CITIC DICASTAL

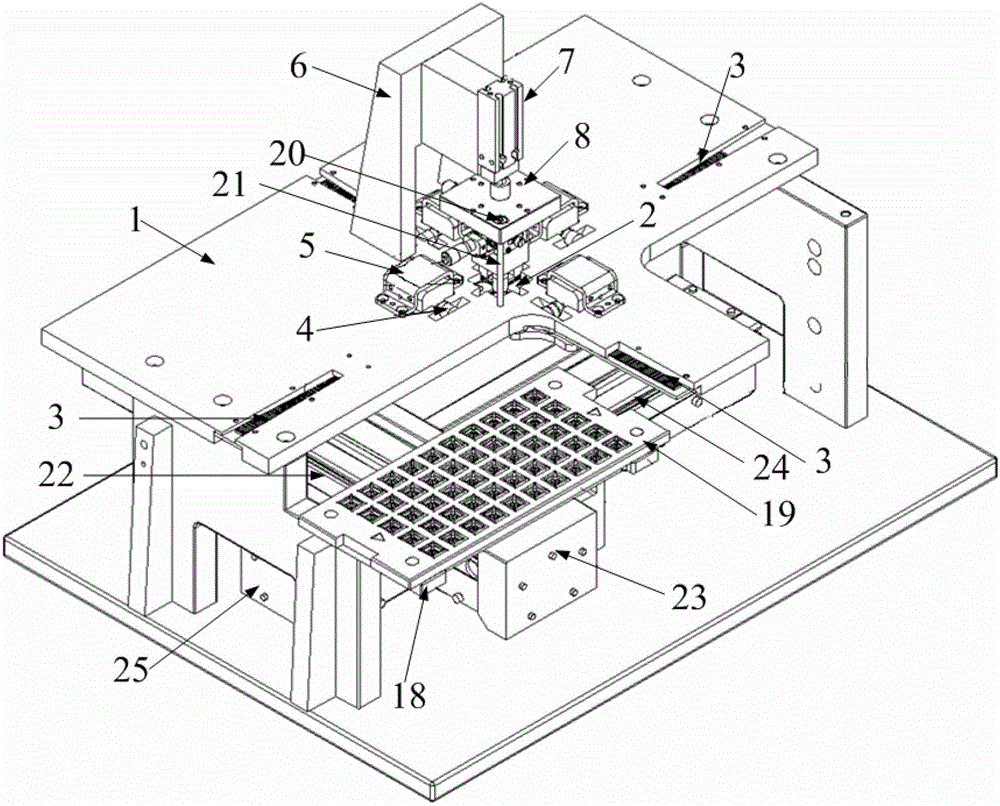

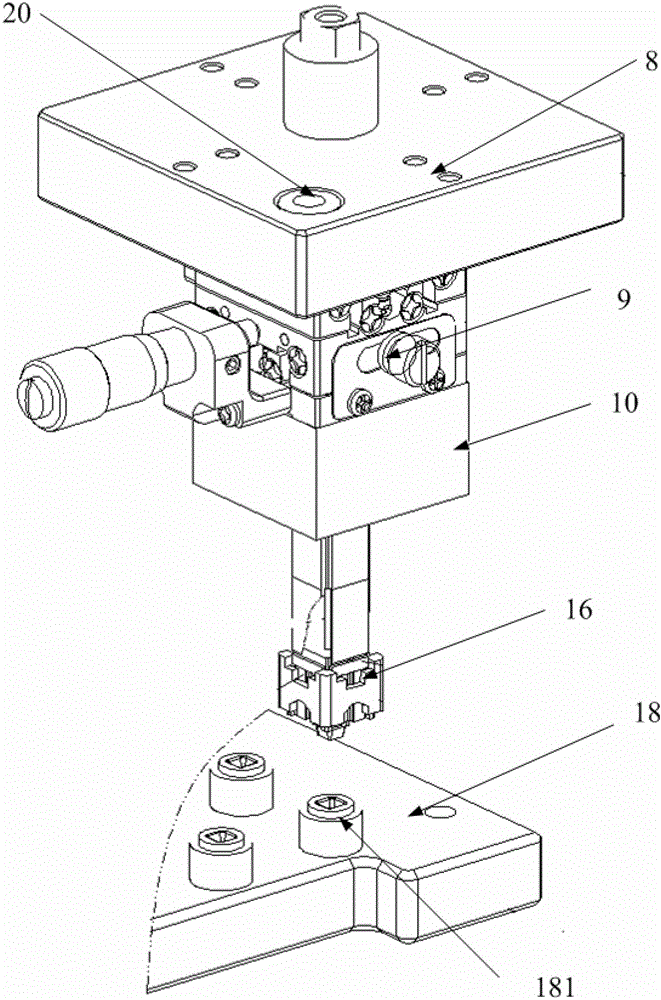

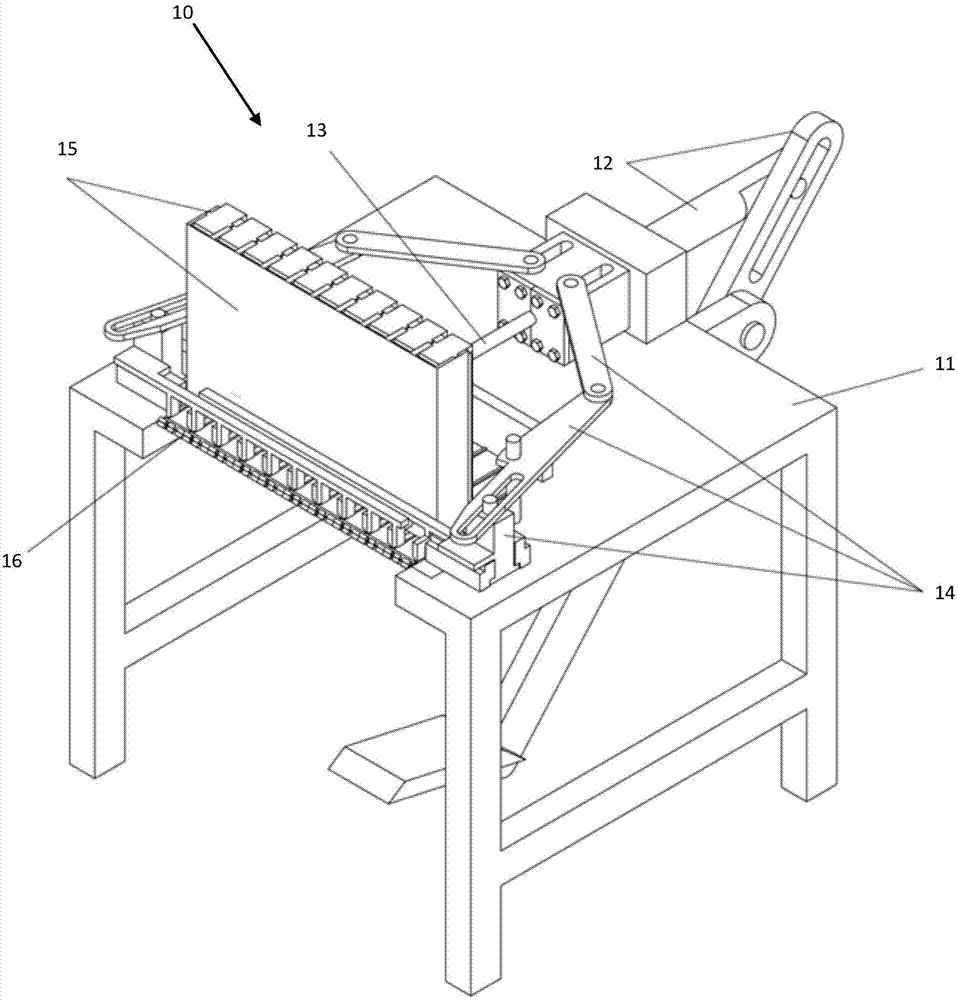

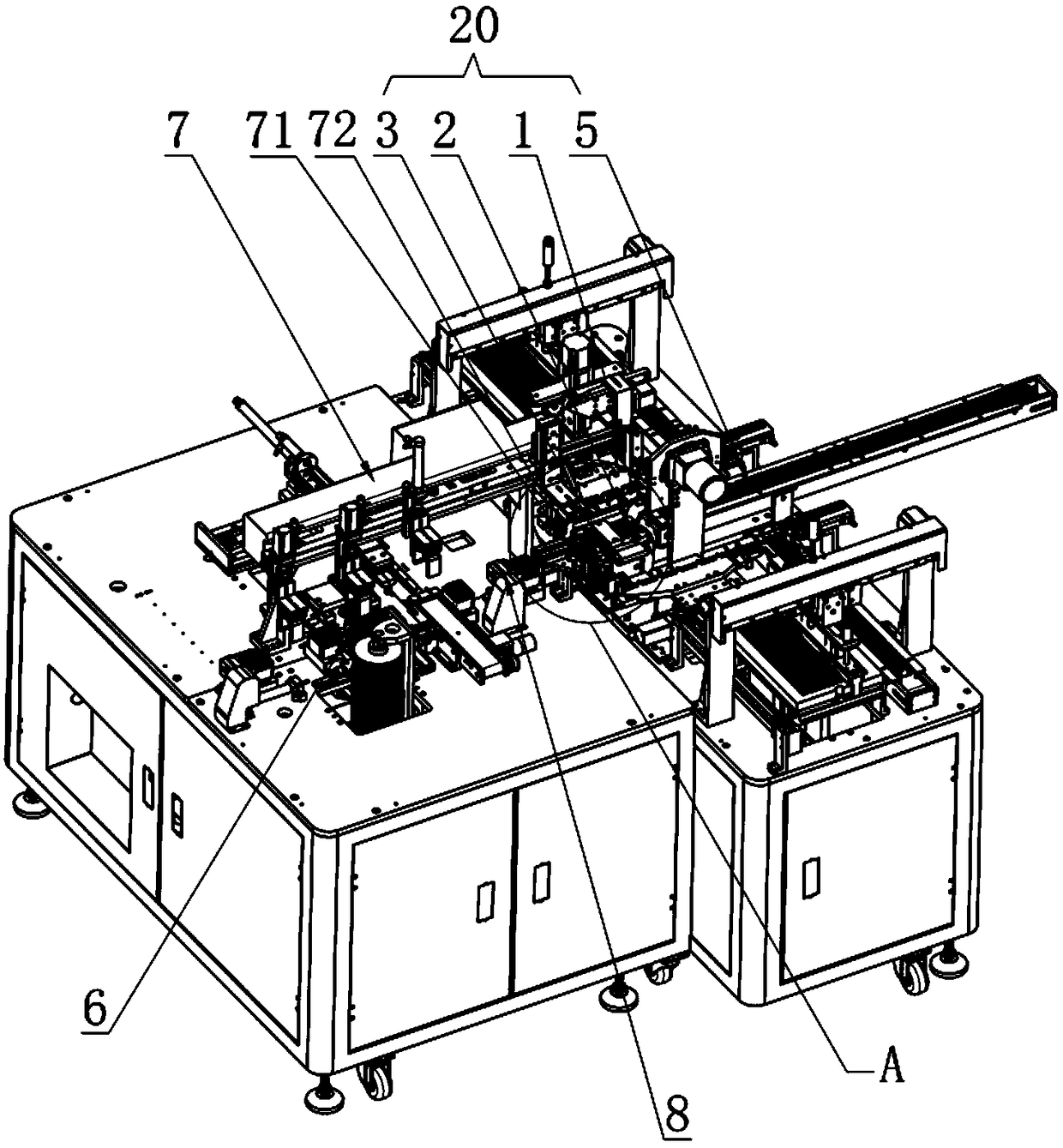

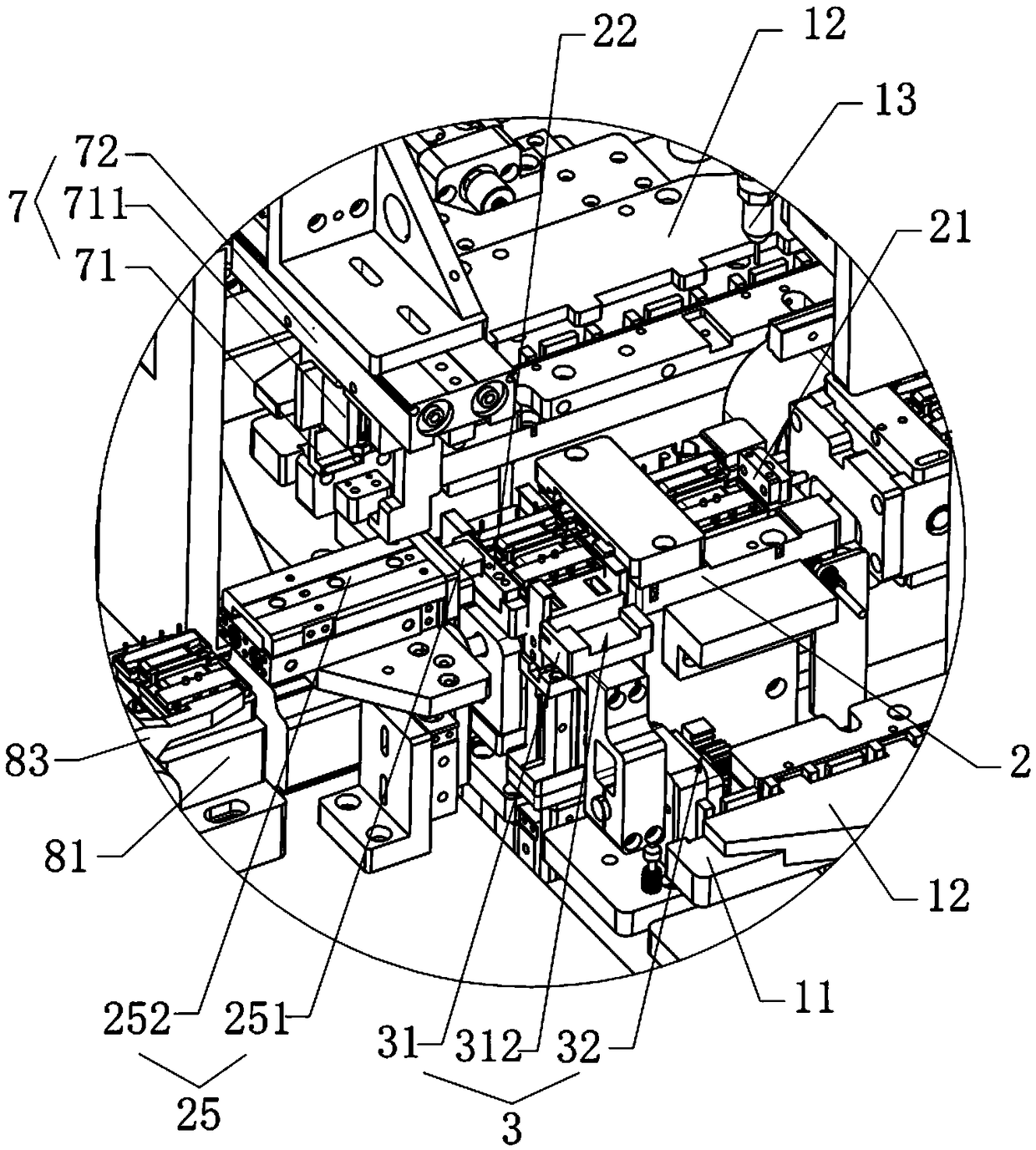

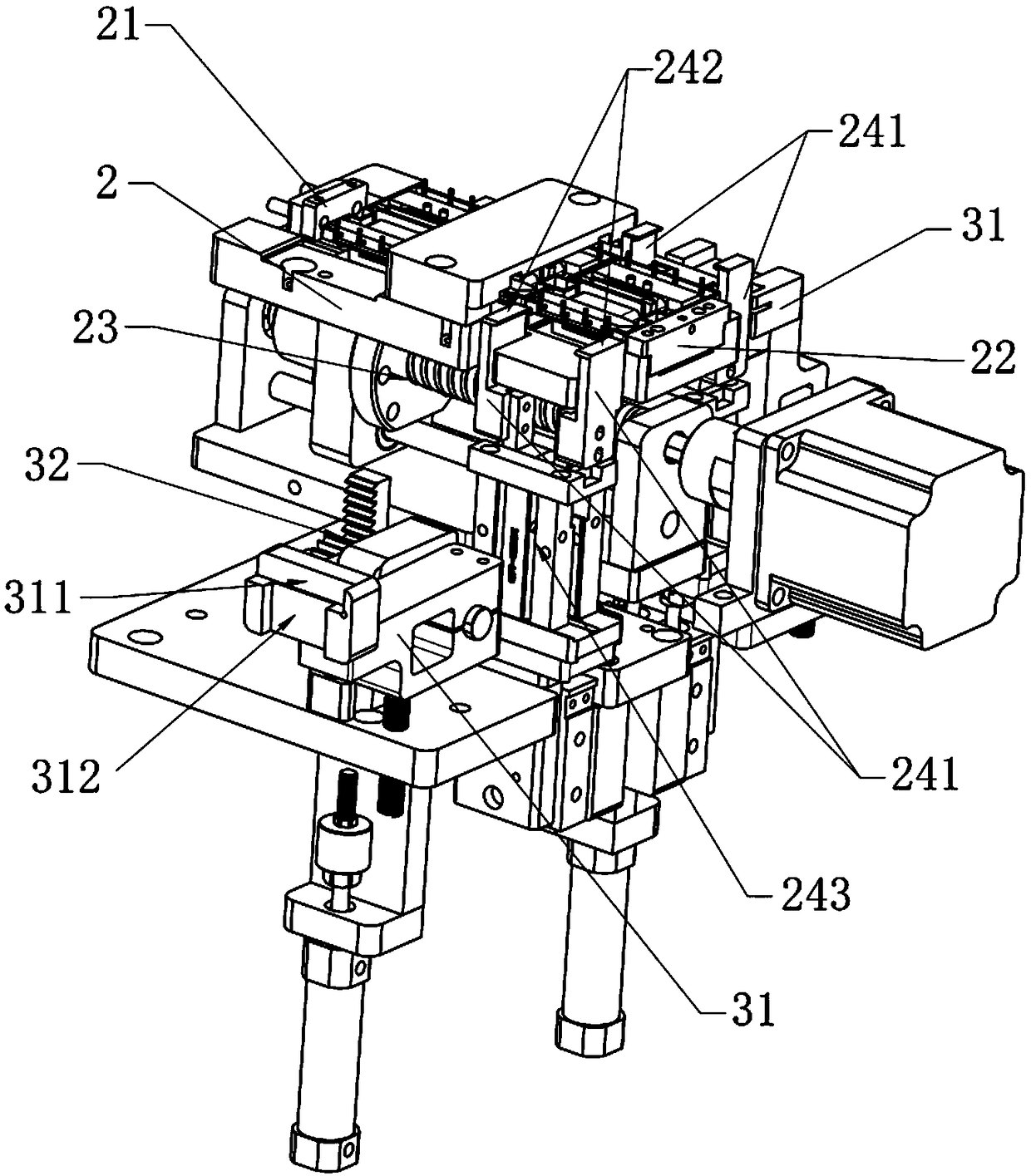

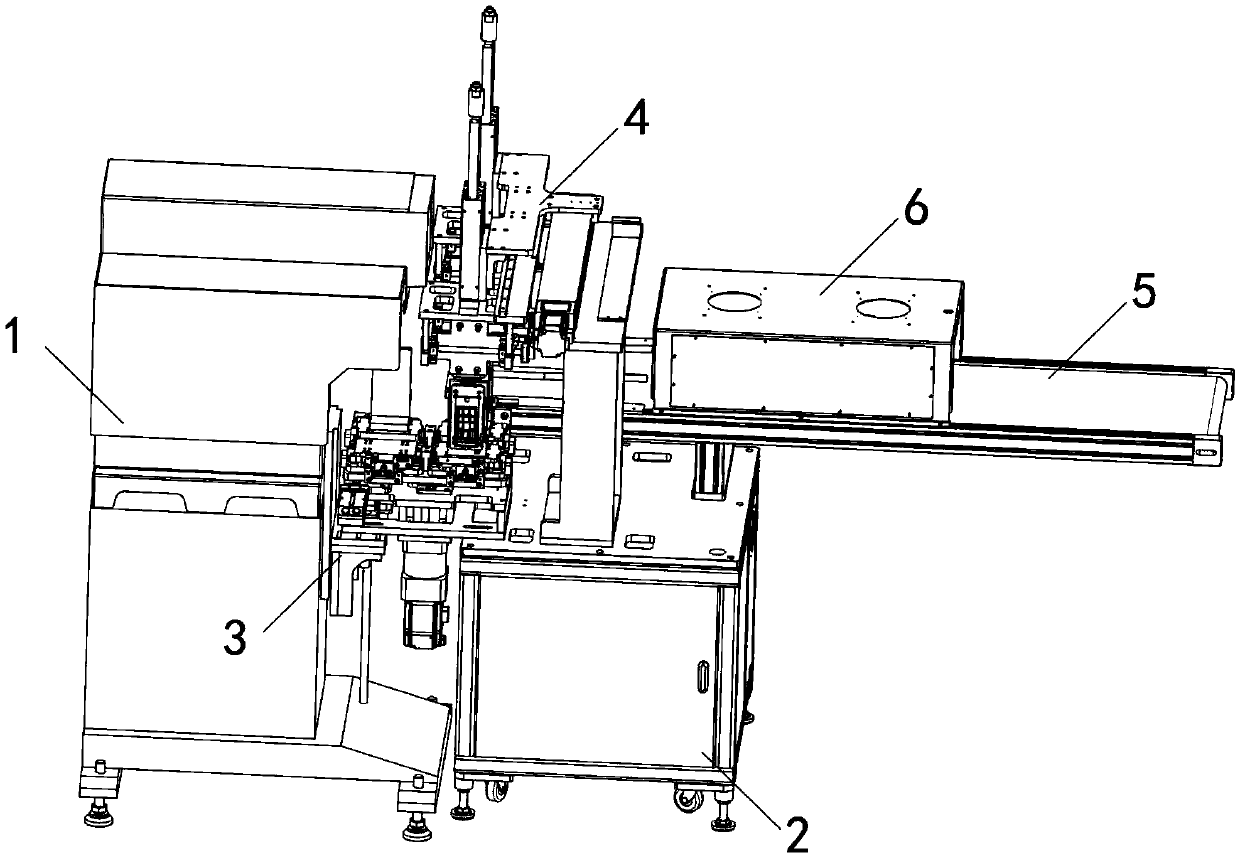

Voice Coil Motor (VCM) magnetic sheet assembly device

ActiveCN102946169AAvoid surface scratchesAvoid breakingManufacturing dynamo-electric machinesControl systemEngineering

The invention discloses a Voice Coil Motor (VCM) magnetic sheet assembly device. The device comprises a bench, a feed system, a feeding system, a carrying system and a control system, wherein a feeding hole is arranged on the bench, the feed system which is used for feeding a magnetic sheet to the feeding hole is arranged at the position of the inside of the bench, which corresponds to the magnetic sheet installation position, the feeding system which is used for automatically assembling the magnetic sheet fed by the feed system to motors to be assembled is arranged at the position of the upper portion of the bench, which corresponds to the feeding hole, the carrying system which is used for fixing the motors to be assembled is arranged at the position of the lower portion of the bench, which corresponds to the feeding device, and the control system is used for controlling the working of the feed system, the feeding system and the carrying system. The feeding system which moves vertically is matched with a magnetic sheet feed system, magnets sheets which are required to be assembled are assembled to the carrying system for fixing the motors to be assembled one time, the carrying system is set to move along an X axis and a Y axis, a plurality of motor fixing groove for fixing motors to be assembled are fixedly arranged on a fixture carrier, a plurality of motors can be assembled continuously, and the production efficiency and the pass percentage are improved.

Owner:辽宁中蓝光电科技有限公司

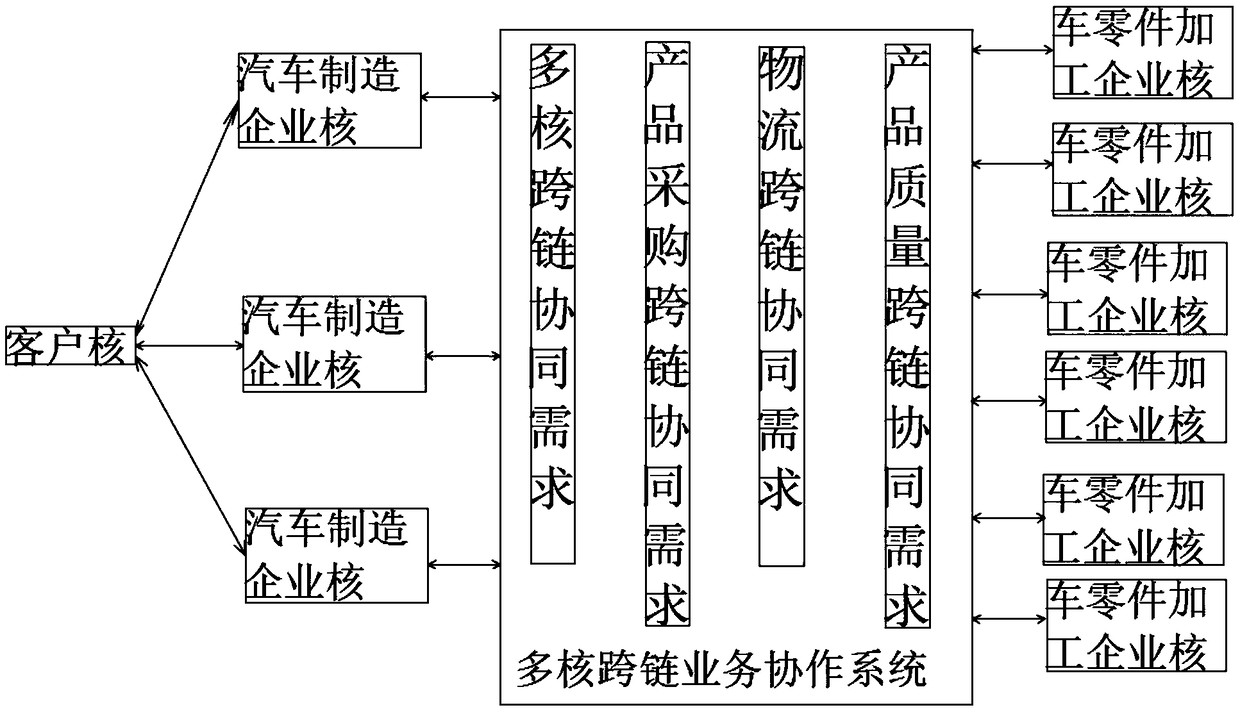

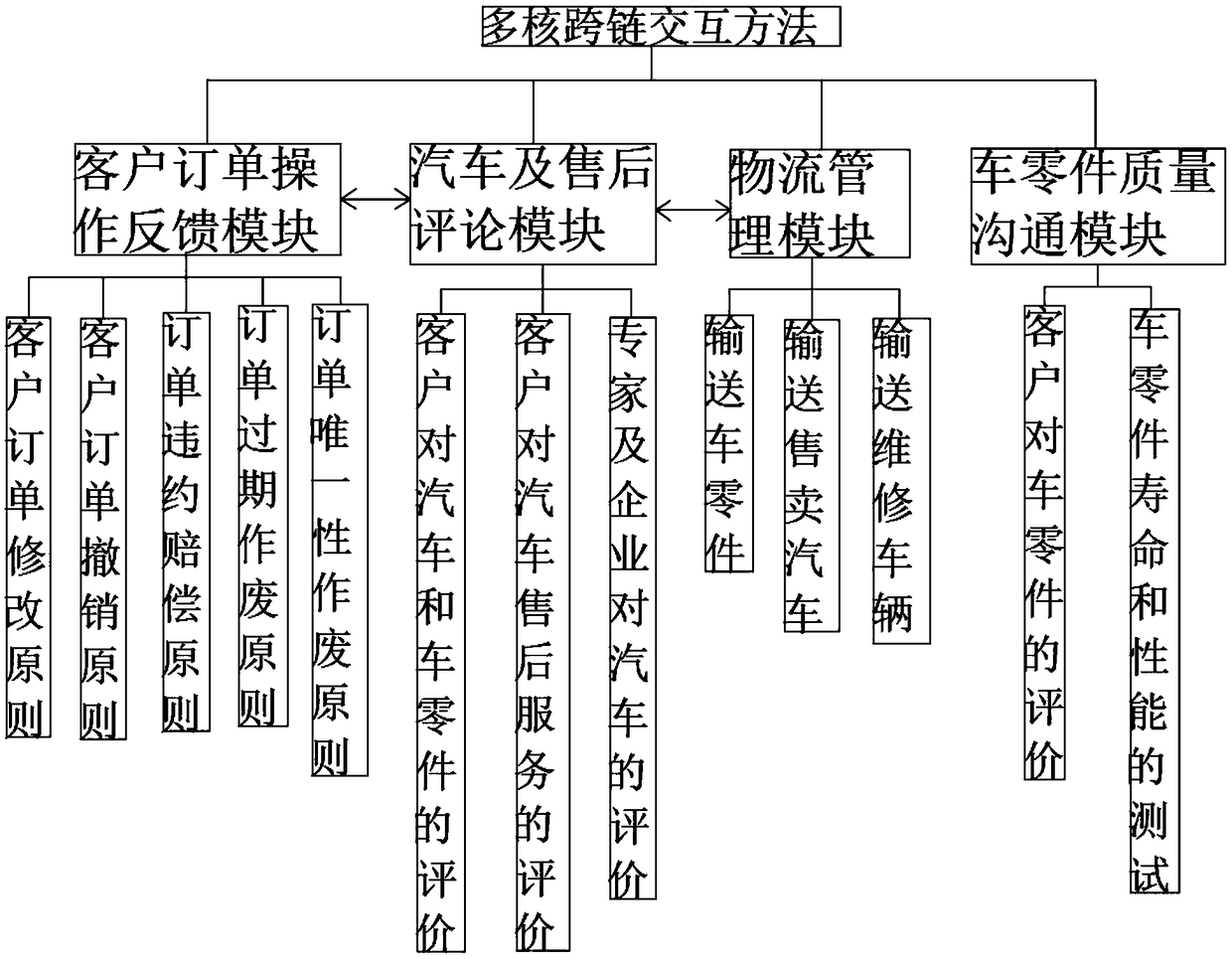

A multi-core cross-chain service cooperation system and an interactive method based on a cloud platform

InactiveCN109389370AGuaranteed to be manufactured at all timesGuaranteed assemblyOffice automationManufacturing computing systemsLogistics managementLogistic management

The invention discloses a multi-core cross-chain service cooperation system and an interactive method based on a cloud platform, including cloud platforms. cross-chain business collaboration includesthe collaboration between the customer core and the automotive manufacturing enterprise core, the multi-core and cross-chain business cooperation system between the automobile manufacturing enterprises and the automobile parts processing enterprises. The interaction method includes: setting up the interaction between between an automobile and after-sale comment module, a customer order operation feedback module, a logistics management module, and a vehicle part quality communication module on the cloud platform; service cooperation among automobile manufacturing enterprise nuclear, machiningenterprise of automobile parts, and customer cores reflects the diversity of choices and collaboration, the customer order operation feedback module safeguards the interests and rights of customers and automobile enterprises. Customer or expert evaluation can provide the improvement direction for automobile manufacturing enterprises and parts processing enterprises, and promote the automobile industry to advance, innovate and develop continuously.

Owner:CHENGDU UNIV OF INFORMATION TECH

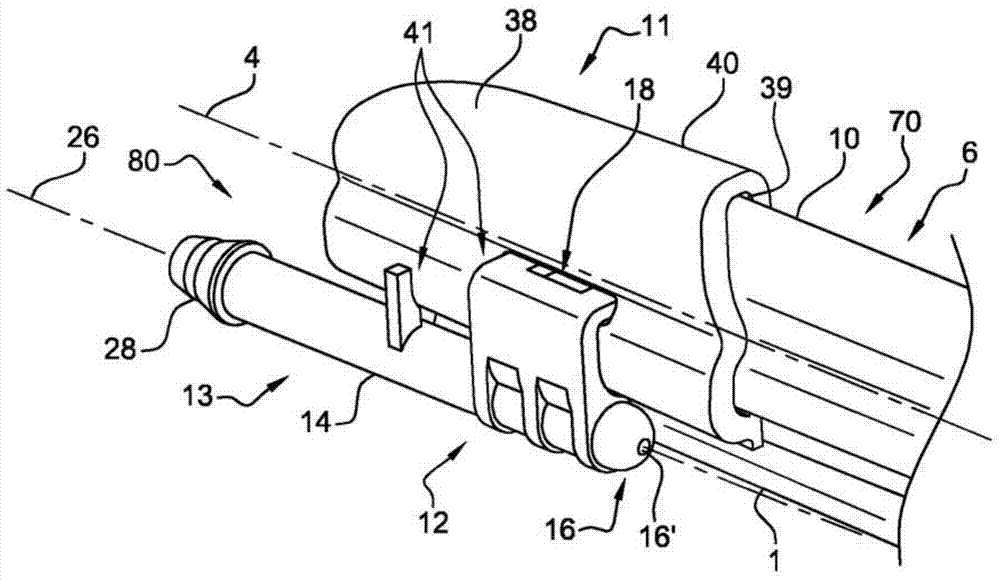

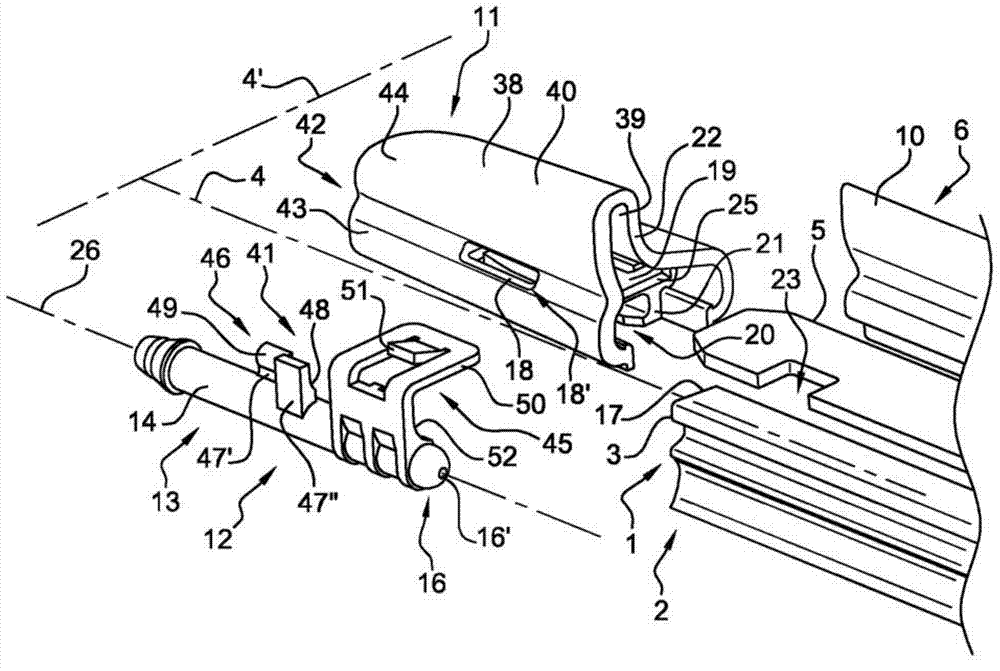

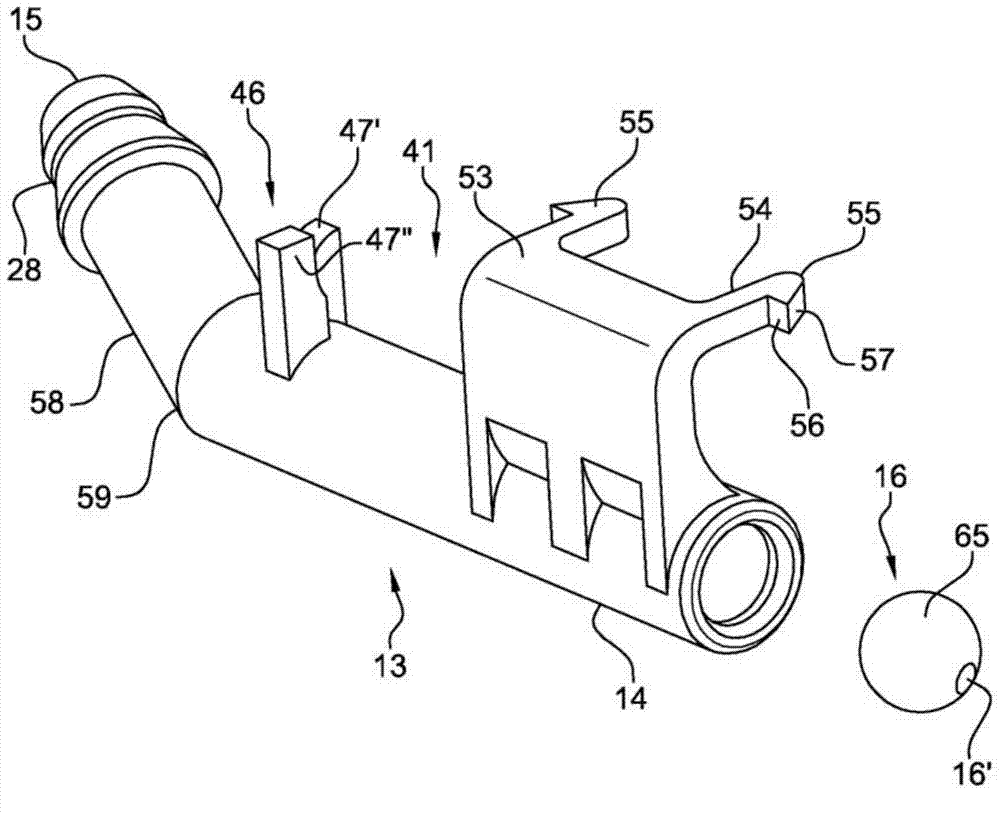

Assembly comprising a ferrule and a device for spraying a liquid, wiper blade comprising such an assembly, method for fitting a device for spraying a liquid to a ferrule

ActiveCN103596818AGuaranteed assemblyReliable and meets economic constraintsVehicle cleaningEngineeringMechanical engineering

The invention relates to an assembly (80) comprising, on the one hand, a ferrule (11) able to be fitted to a longitudinal end of a wiper blade (70) and, on the other hand, a device (12) for spraying a liquid, said ferrule (11) and said spraying device (12) being two separate, mechanically connected parts. According to the invention, said ferrule (11) comprises a cavity (18) that receives a means (41) for fastening the spraying device (12) to the ferrule (11). The invention also relates to a wiper blade (70) comprising an assembly (80) according to the invention and a method for fitting such an assembly (80).

Owner:VALEO SYST DESSUYAGE

Clamping tool for machining motor case

ActiveCN105515309AAffect mobileNo deformationManufacturing dynamo-electric machinesMechanical engineering

The invention discloses a clamping tool for machining a motor cause, and the clamping tool carries out the end face clamping of a motor rotor in the motor case, so as to fix a motor and machining the end face of the motor case. The clamping tool can prevent the motor stator from being expanded, and prevents the motor case from deforming.

Owner:上海雷祥压铸有限公司

Intelligent product assembling method based on machine vision recognition

PendingCN111191546AGuaranteed assemblyGuaranteed assembly speedImage enhancementImage analysisPattern recognitionImaging processing

According to the invention, a method of combining deep learning and traditional digital image processing is adopted; according to the method, the detection precision and the detection speed are comprehensively considered, rough position information of an object can be detected in a complex environment by adopting a deep learning target detection algorithm, then the detected position is used as a region of interest, and image processing is performed to detect more accurate target contour information. According to the invention, a target detection method based on deep learning is improved, so that the detection speed and the detection precision are improved, requirements on workshop hardware are greatly reduced, and the production cost is reduced. In conclusion, the assembly efficiency and the assembly precision of parts are greatly improved, and the situation that assembly fails due to deviation of the positions of the parts is reduced.

Owner:广西柳州联耕科技有限公司

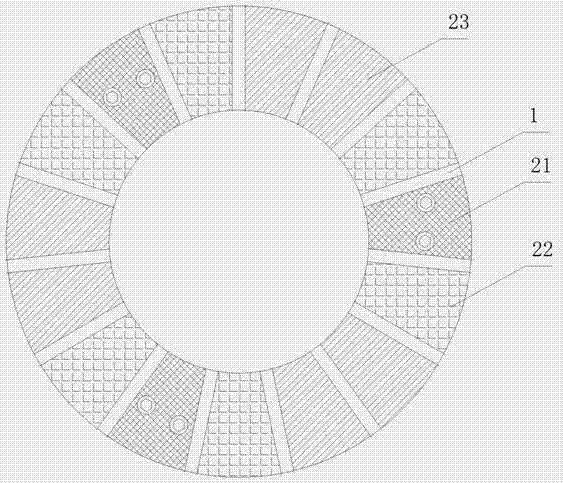

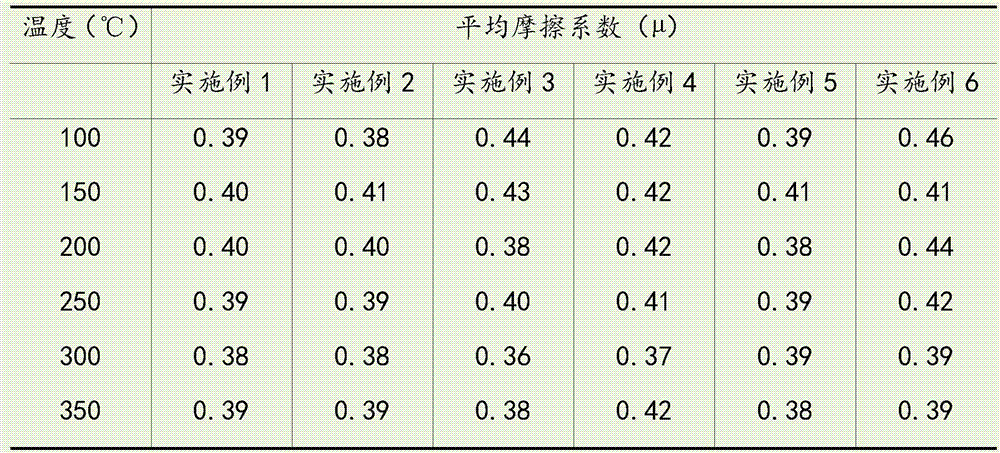

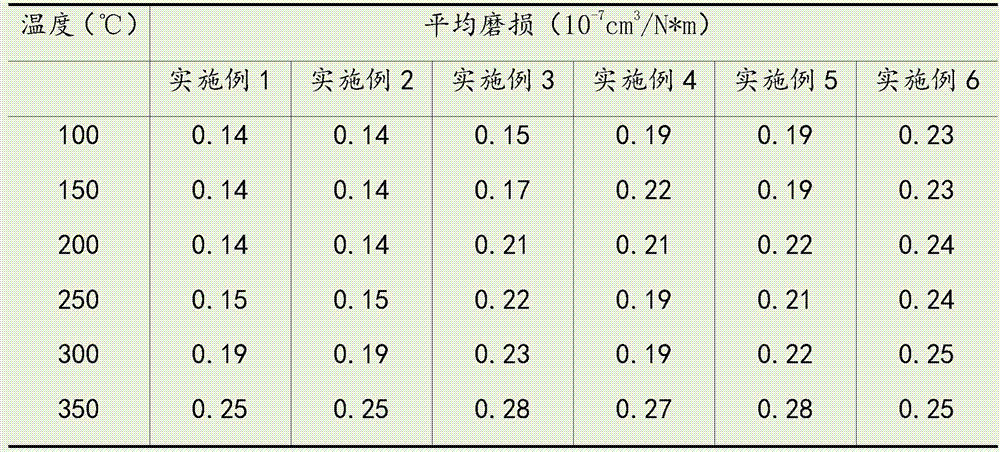

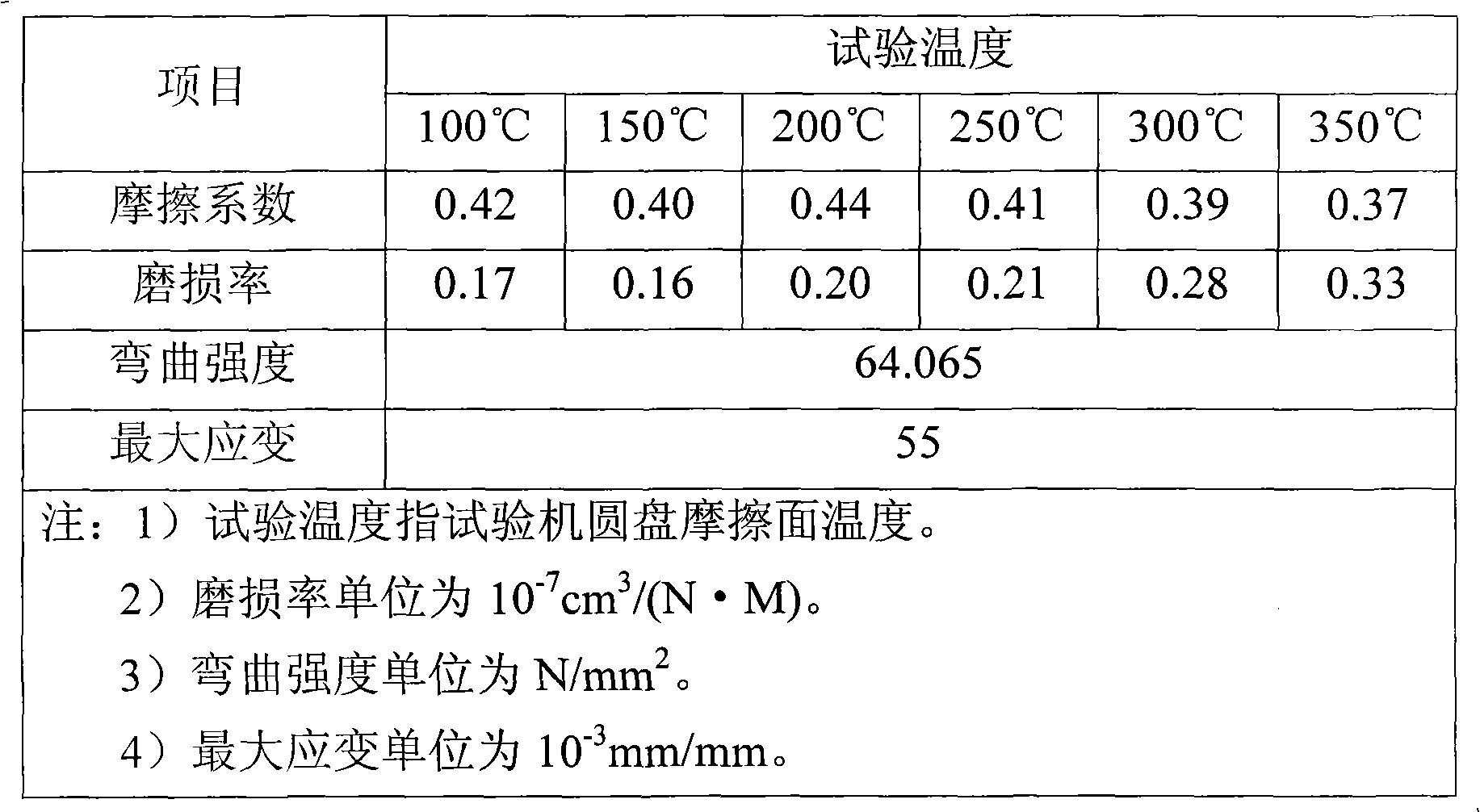

High-performance clutch plate for heavy truck

The invention provides a high-performance clutch plate for a heavy truck. The high-performance clutch plate for the heavy truck achieves the technical purposes of being novel in structure, reasonable in material formula and balanced and excellent in performance index, cost and application effect. The high-performance clutch plate for the heavy truck is divided into a friction working layer and a structural layer. The friction working layer comprises at least three friction linings made of different materials. The three friction linings made of the different materials comprise the rubber-based friction linings, the substitute rubber FA friction linings and the ceramic fiber friction linings, all of which are of the same thickness. The high-performance clutch plate has the following beneficial effects that due to the fact that the rubber-based friction linings, the ceramic fiber friction linings and the substitute rubber FA friction linings are arranged on the surface of the structural layer in a mixed manner, in clutch operation of the clutch plate, the characteristics of the three different materials can be brought into play, when the clutch plate is applied to a clutch mechanism of the heavy truck, friction force resistant to attenuation and stable at high temperature is effectively reduced, and the high-performance clutch plate is particularly suitable for being applied to the heavy truck.

Owner:浙江科马摩擦材料股份有限公司

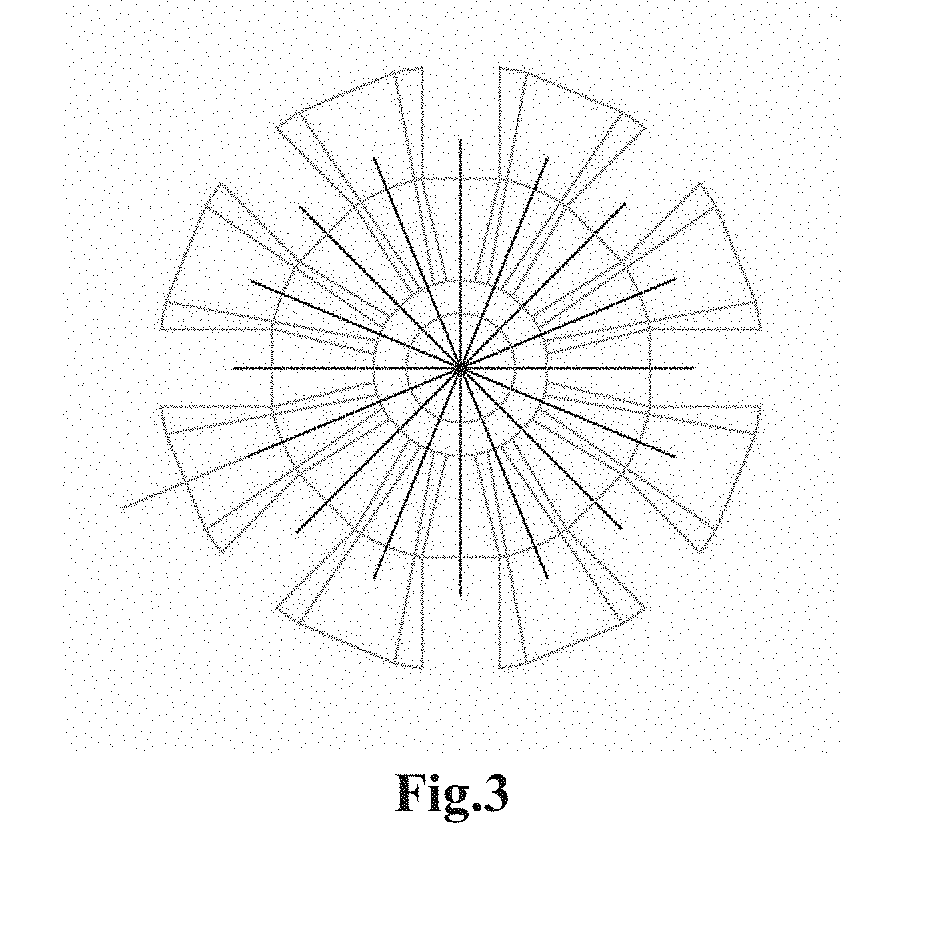

Integrated device for angular alignment and detection of turbine supporting casing support plates

ActiveCN109520400AImprove stabilityImprove pass rateMechanical solid deformation measurementsManufacturing technologyEngineering

The invention provides an integrated device for angular alignment and detection of turbine supporting casing support plates, and relates to the technical field of manufacturing of aeroengine turbine supporting casing assemblies. The technical problems of difficult angular size control, size tolerance, unstable part processing and low qualification rate of six support plates of a turbine supportingcasing rear housing support in the prior art are solved. The problem that product delivery is seriously restricted is solved. The problem that the progress of model development is affected is solved.The device comprises a base, support plate correction devices, support plate detection devices, and a fixing device which is used for fixing the turbine supporting casing rear housing support on thebase. The support plate correction devices and the support plate detection devices are arranged on the base. A set of support plate correction device and support plate detection device are correspondingly arranged on each end, which is corresponding to the turbine supporting casing rear housing support, of six support plates. The device provided by the invention is used for angular alignment and detection of the turbine supporting casing support plates.

Owner:AECC AERO SCI & TECH CO LTD

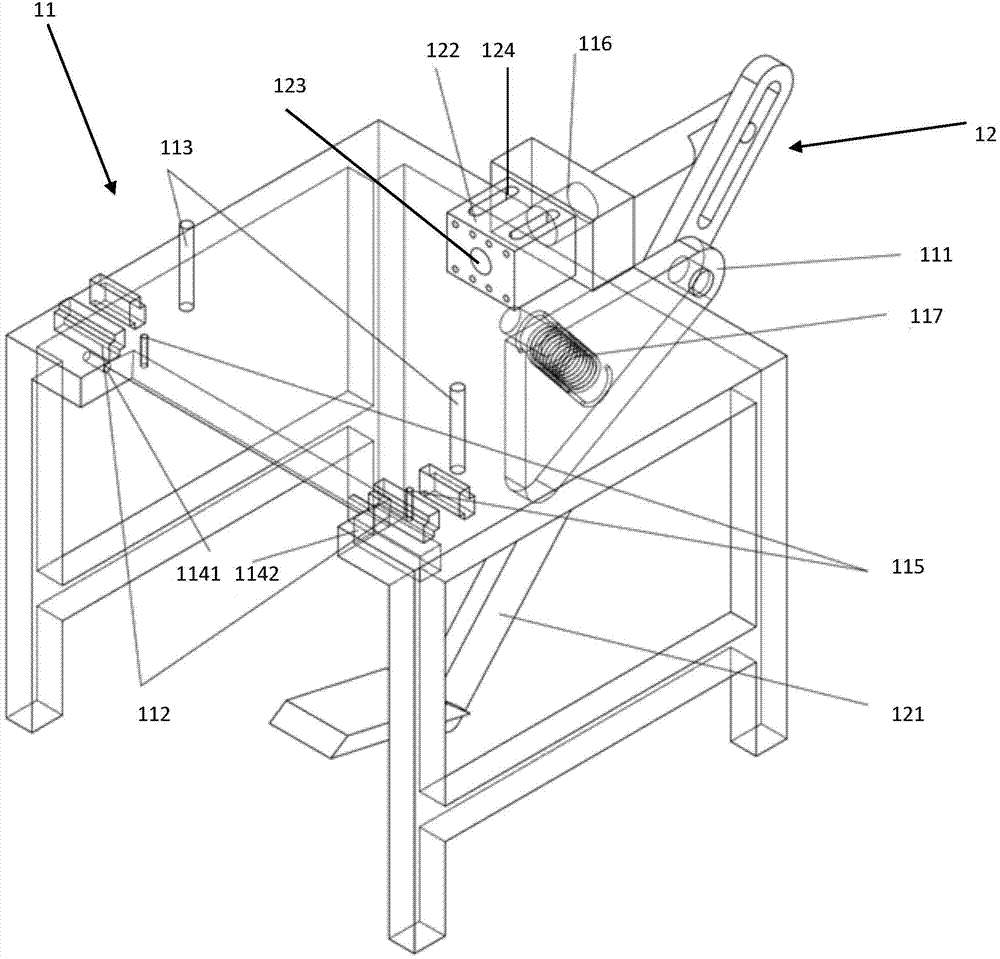

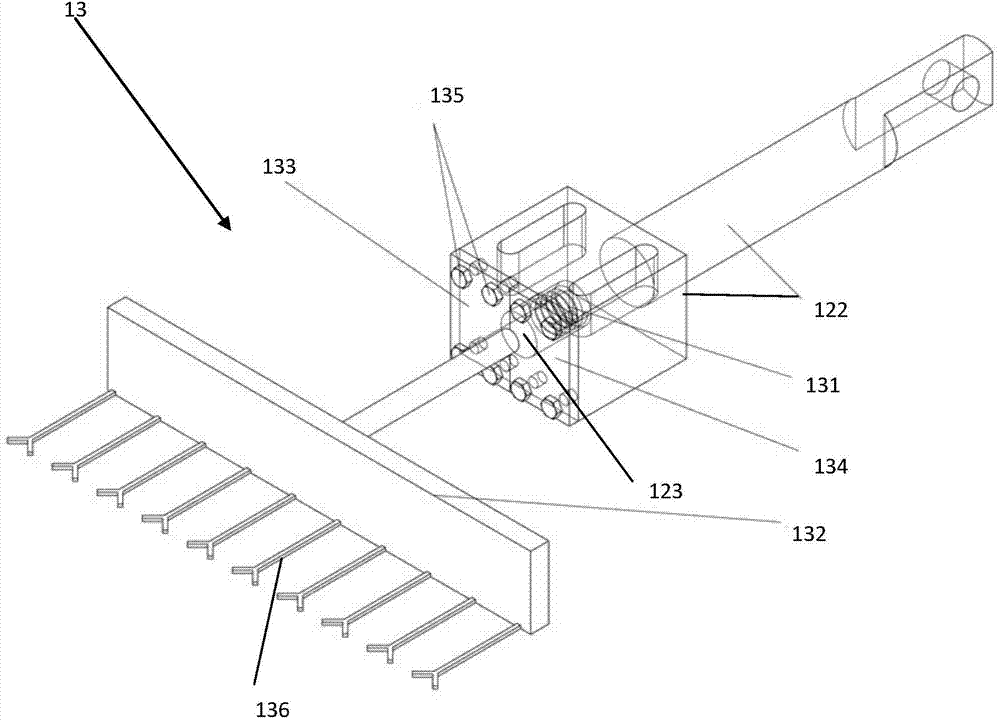

Binder clip assembly device

InactiveCN103753174AImprove work efficiencyReduce labor intensityWork holdersMetal working apparatusBody positionsEngineering

The invention provides a binder clip assembly device used for assembling a body and handles for a binder clip. The binder clip assembly is characterized by comprising a bench, a power mechanism, a handle push mechanism, a handle compressing mechanism, a handle feed mechanism and a clip body positioning mechanism; the power mechanism is disposed on the bench, the handle push mechanism is connected with the power mechanism, the handle compressing mechanism is fixed on the bench, and the handle feed mechanism and the clip body positioning mechanism are fixed on the bench. The handle feed mechanism is disposed between the handle push mechanism and the handle compressing mechanism; the handle compressing mechanism is disposed between the handle feed mechanism and the clip body positioning mechanism. Compared to the prior art, the binder clip assembly device is simple in structure, high in assembly efficiency, low in production and maintenance costs and has great social application value; labor intensity is low.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

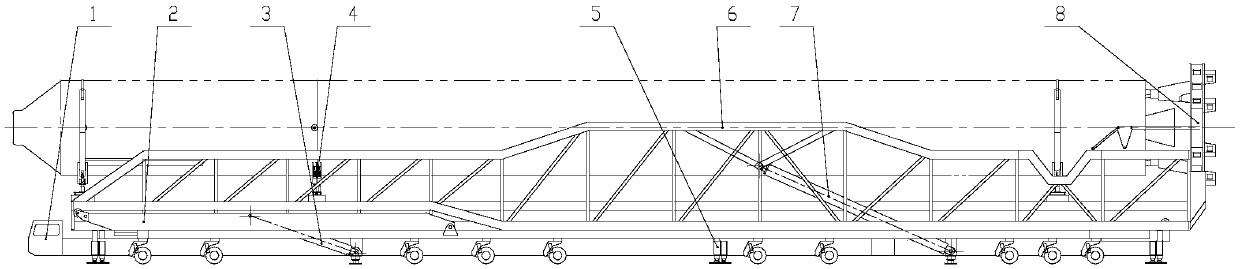

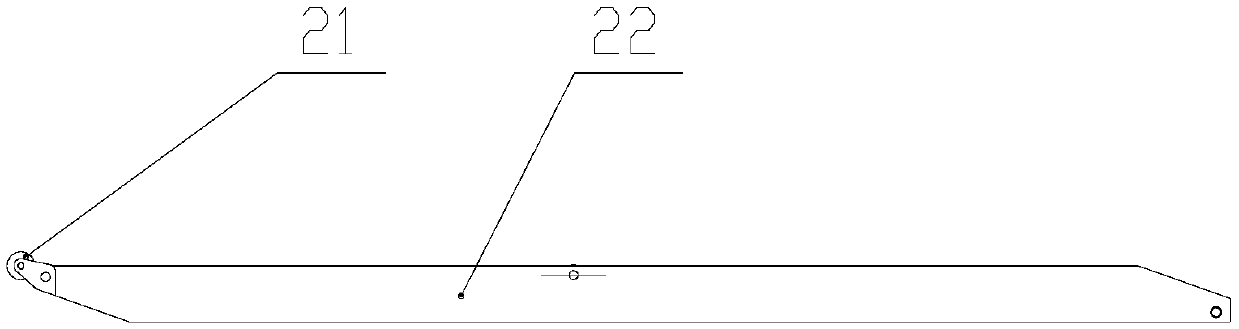

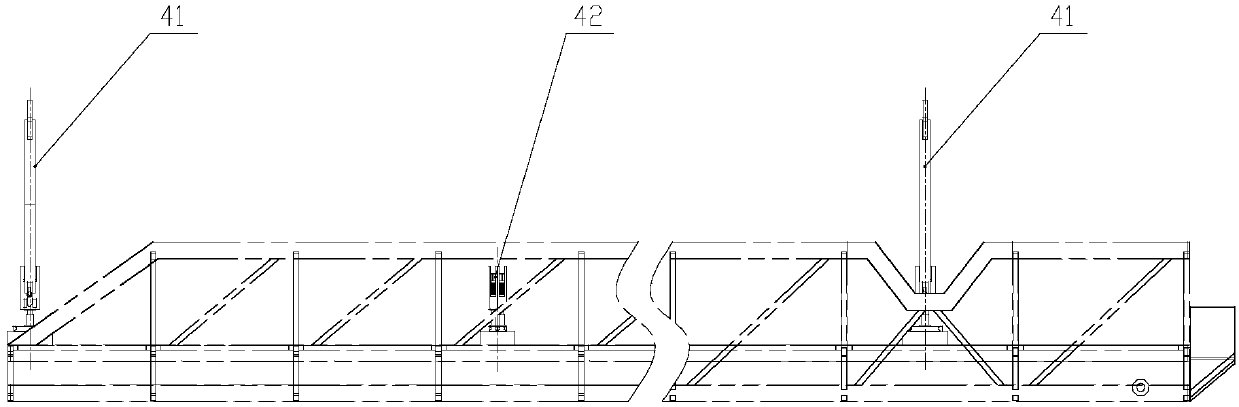

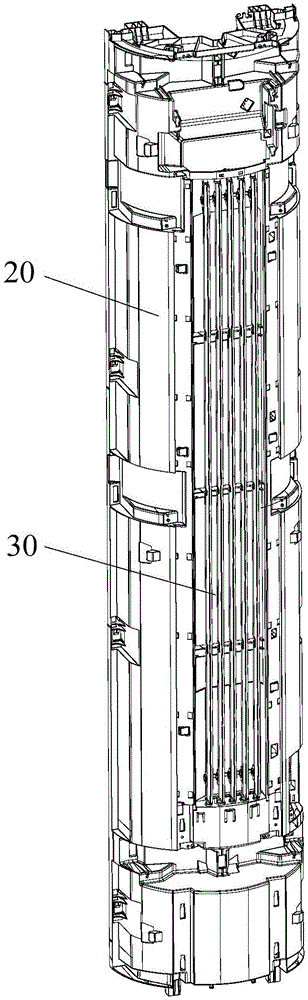

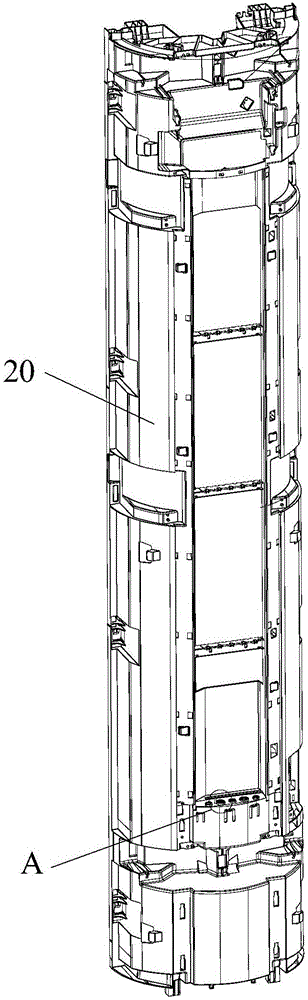

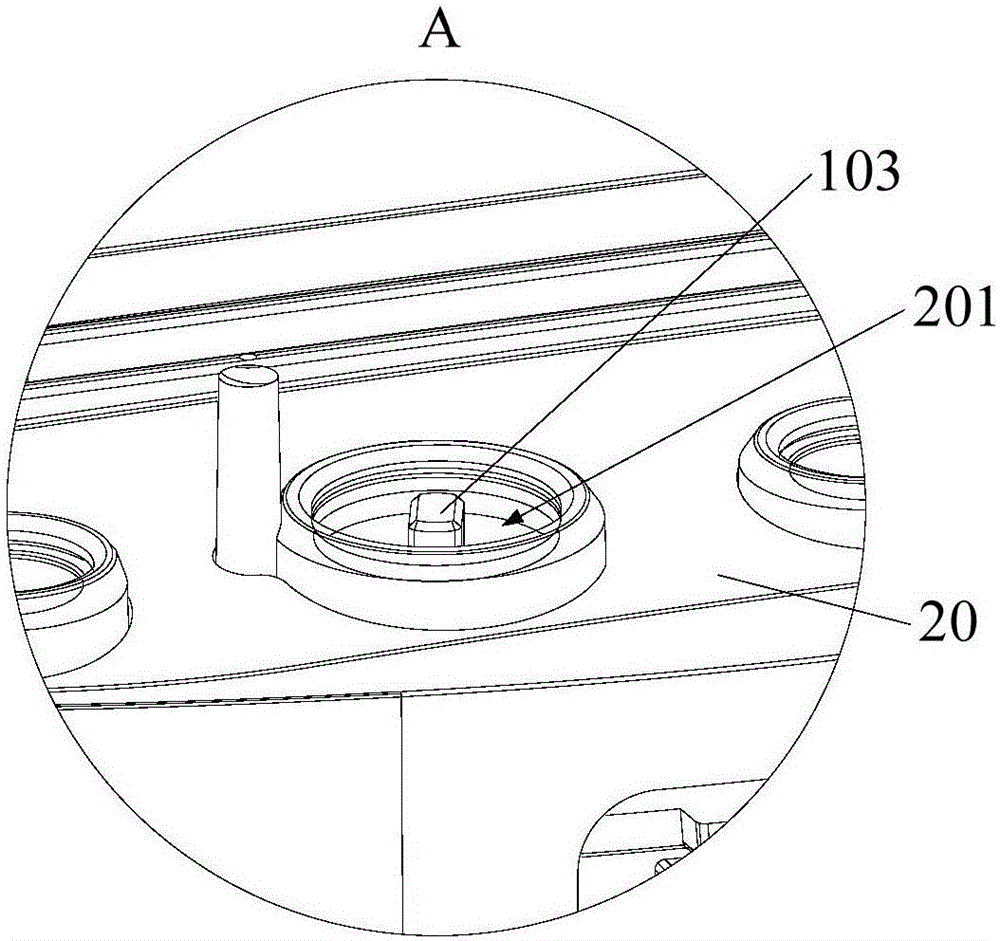

Multistage rocket transportation erecting vehicle

ActiveCN110949228AGuaranteed assemblyAutomate operationVehicle fittings for liftingItem transportation vehiclesSpaceflightMechanical engineering

The invention discloses a multi-stage rocket transportation erecting vehicle, and belongs to the technical field of spaceflight ground support equipment. The support vehicle comprises a transport vehicle, a support adjusting system, an erecting arm assembly, a main erecting oil cylinder, a support seat and a lifting system, one end of the erecting arm assembly is hinged to the tail of the transport vehicle, and an auxiliary supporting arm is arranged at the bottom of the other end of the erecting arm. The main erecting oil cylinder is arranged on the inner side of the erecting arm assembly; the supporting and adjusting system is installed on the erecting arm assembly and has the functions of supporting, locking and four-degree-of-freedom adjusting of the multiple stages of rocket bodies, and butt joint between the multiple stages of rocket bodies and between the rocket bodies and the supporting base is achieved. The supporting seat is connected to the tail part of the erecting arm assembly, so that the perpendicularity of the erected rocket body can be adjusted, and support can be provided; the lifting system is installed on the erecting arm and can send an operator to the front binding point and the rear binding point of the rocket to achieve rocket connection. The erecting vehicle can achieve transportation and transfer of rockets, the rockets are erected as a whole after arriving at a launching area, and erecting work before launching is completed rapidly.

Owner:NO 63921 UNIT OF PLA +1

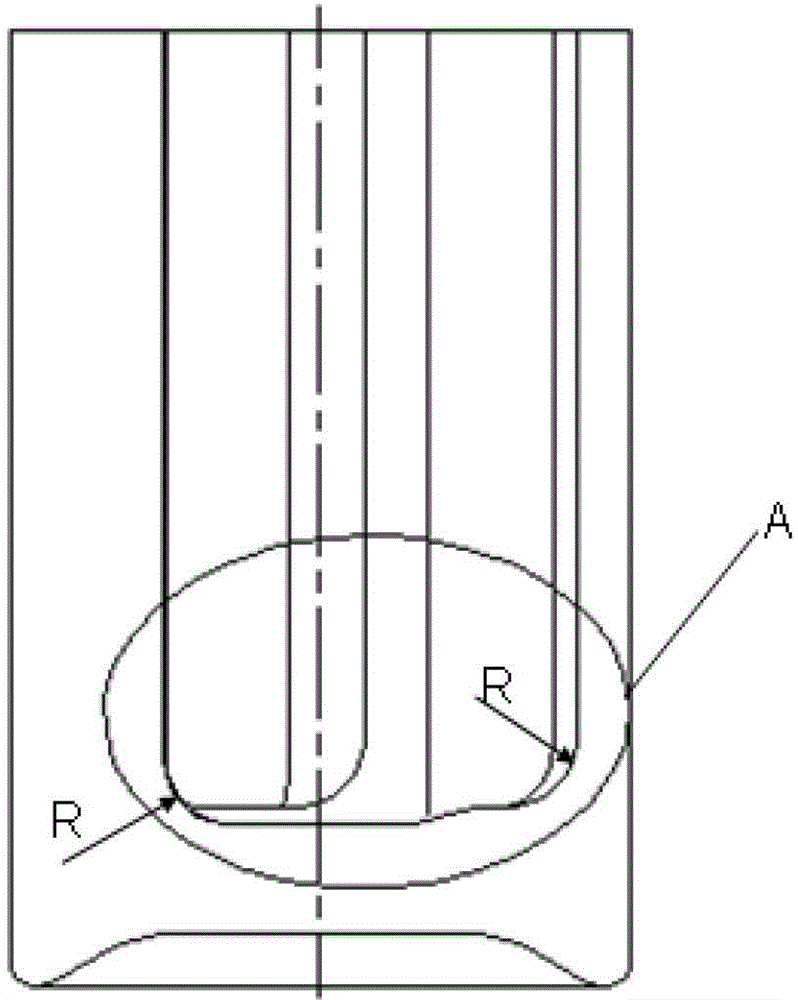

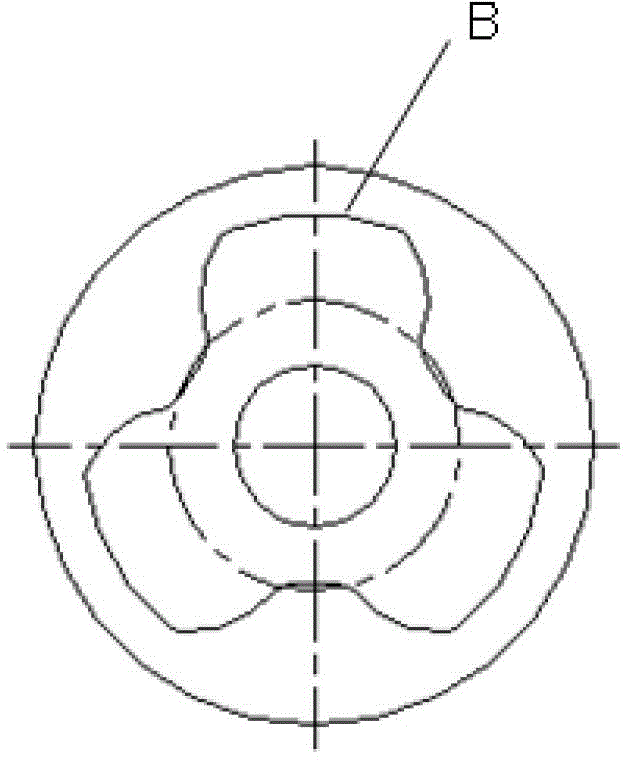

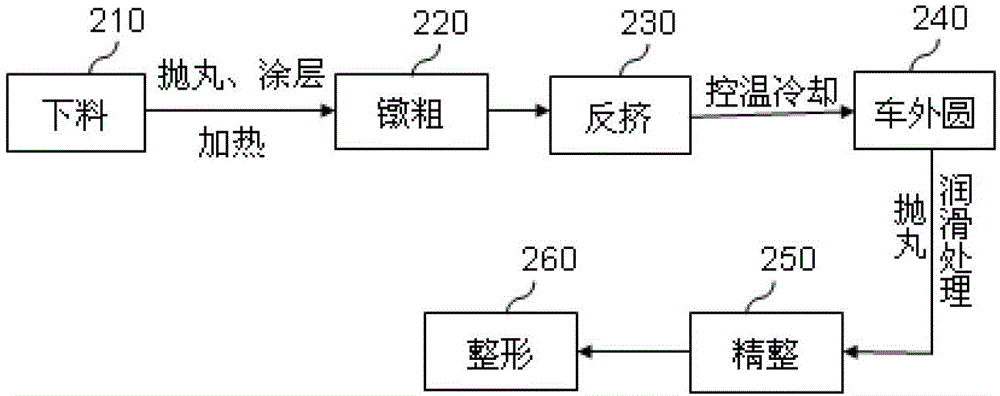

Universal joint forging method and shaping mould

ActiveCN102909309ASolve the inconsistency of the R angle at the bottom of the cavityGuaranteed processing and assemblyShaping toolsRailway componentsMachine pressEngineering

The invention provides a universal joint forging method. The universal joint forging method comprises the steps of upsetting, reverse extruding, truning and finishing. The reverse extruding is to perform reverse extrusion on an upset blank to form a cylindrical blank with an inner cavity at one end and a groove at the other end; the finishing is to perform finish forging of the shape sizes of the inner cavity and the cylindrical blank on the cylindrical blank with the inner cavity at one end and the groove at the other end by adopting a shaping mould and a press machine; the shaping procedure of shaping rounded corners (for short, R corners) at the bottom of the inner cavity of the cylindrical forging blank to enable the R corners at the bottom of the inner cavity of the cylindrical forging blank to be consistent is added after the finishing procedure. Compared with the prior art, as the shaping process for the R corners at the bottom of the inner cavity of the forging blank is added on the basis of the traditional process, and the simple shaping mould structure is adopted to perform shaping on the R corners at the bottom of the inner cavity is adopted, the universal joint forging method, disclosed by the invention, has the advantages of solving the problem of inconsistence of the R corners at the bottom of the inner cavity of the forging blank in a common process and guaranteeing subsequent processing and assembling of the forging member.

Owner:江苏理研科技股份有限公司

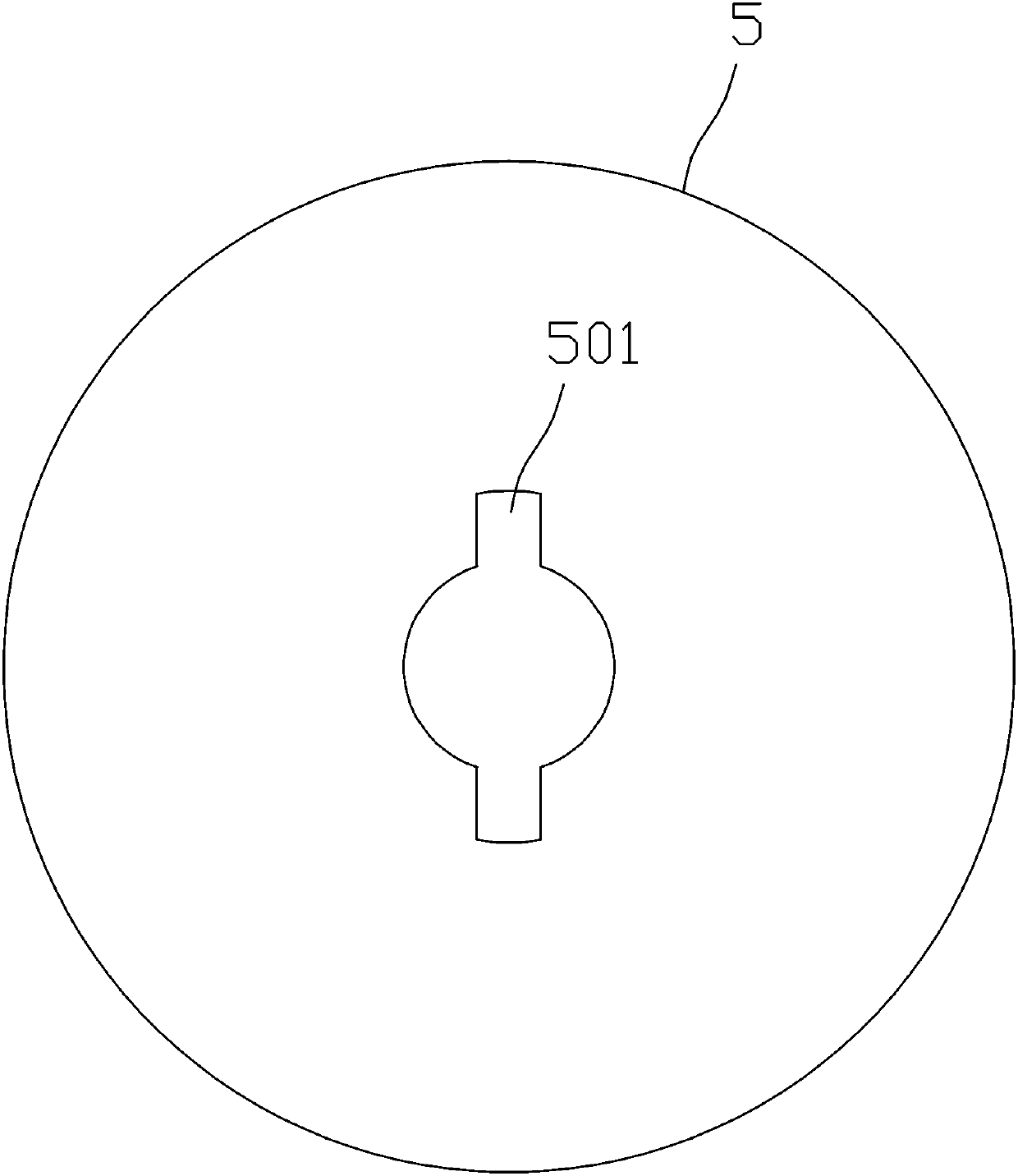

Driving motor and air conditioner indoor unit

ActiveCN106100194ASimple structureAvoid security issuesLighting and heating apparatusSpace heating and ventilation detailsDrive motorControl theory

The invention provides a driving motor and an air conditioner indoor unit. The driving motor comprises a motor body and a motor shaft cap. The motor body is provided with a motor shaft, which is cooperated with a shaft hole. The motor shaft cap is disposed on the end part of the motor shaft in a sleeved manner, and can be inserted in the shaft hole. The driving motor provided by the invention is advantageous in that by arranging the motor shaft cap on the end part of the motor shaft, when an air deflector is detached, a finger can only touch the motor shaft cap through an air deflector installation hole, and cannot touch the metal motor shaft, and therefore safety hidden troubles caused by the exposed metal motor shaft are effectively solved; the structure of the motor shaft cap is simple, the size of the motor shaft is small, and the production cost of the motor shaft is low, and when the driving motor is assembled with the air deflector, the motor shaft cap and the motor shaft are together inserted in the air deflector shaft hole, and therefore by using an original assembly structure, the normal assembly of the driving motor and the air deflector is guaranteed, and the safety problem of the driving motor is solved in a cost effective way, and a good market popularization prospect is provided.

Owner:WUHU MATY AIR CONDITIONING EQUIP CO LTD +1

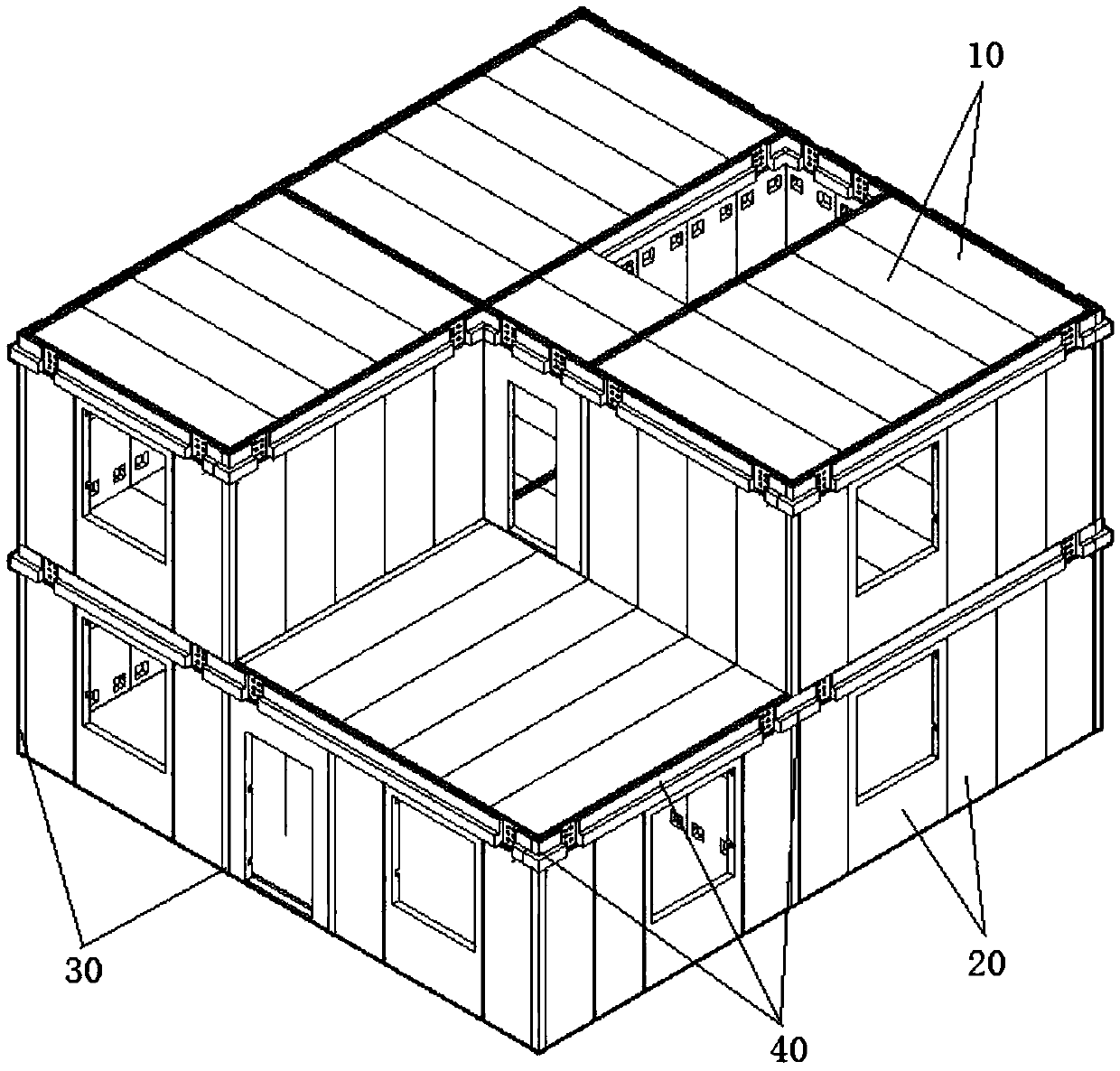

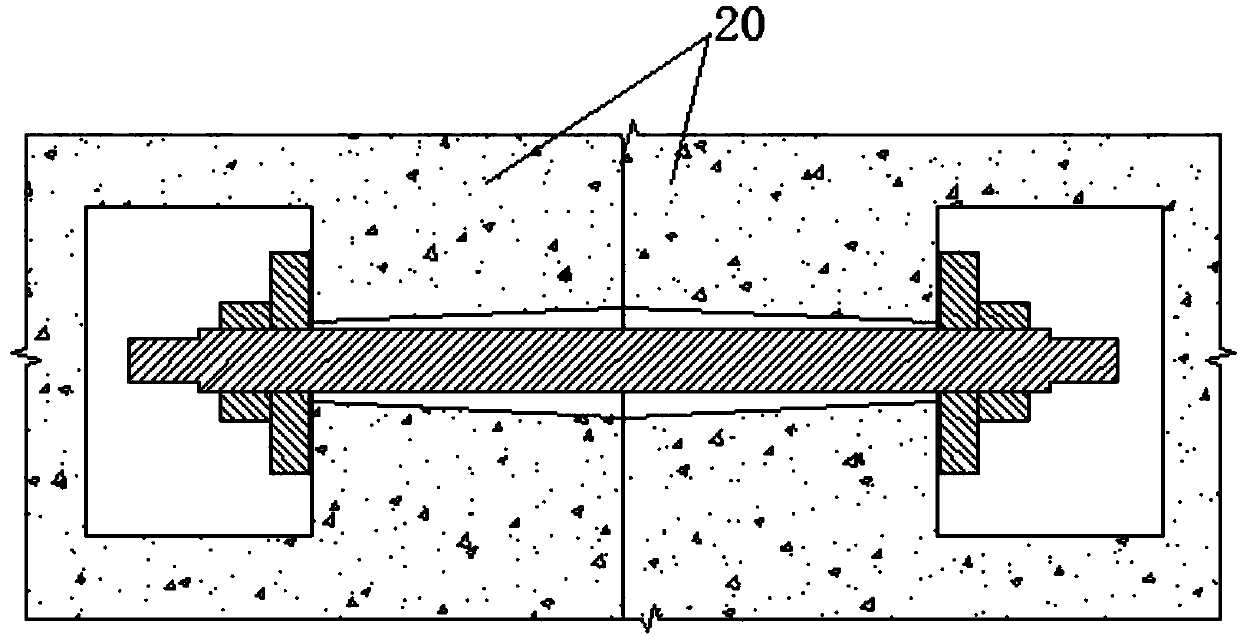

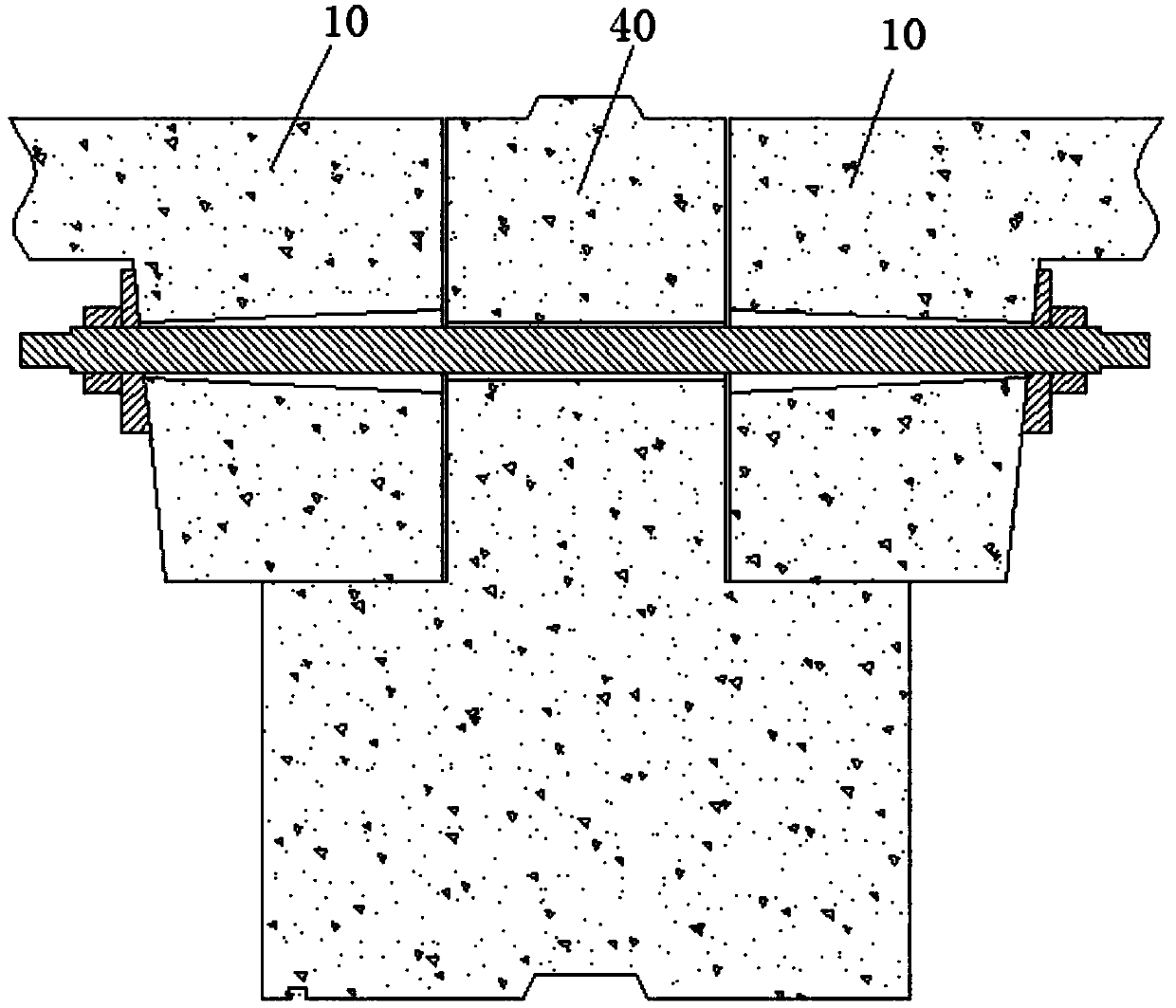

Full-fabricated-type house system

PendingCN107687211AImprove assembly rateFast assembly rateFloorsSpecial buildingEnvironmental resistanceArchitectural engineering

The invention provides a full-fabricated-type house system and belongs to the technical field of fabricated-type buildings. According to the full-fabricated-type house system, through a bearing wall system capable of bearing an upper layer structure, a continuous beam system and a floor slab system, and combination of a connecting mode of an extrusion opposite-pull-type connecting structure, fullfabricating of house buildings can be ensured, the fabricating rate reaches 100%, the cost can be greatly saved, and the working period is shortened. Construction is dry operation, and no wet construction exists, the construction working face is neat and clean, all materials are customized, waste is avoided, building waste is not generated, environmental friendliness is achieved, pollution to theenvironment and waste discharge are greatly reduced in the house building process; and meanwhile, forming and maturing of materials such as concrete do not need to be waited, mounting of very layer achieves the effect that force is stressed the moment mounting is conducted, construction of the previous layer can be conducted when mounting is completed, construction is easy and rapid, the speed ishigh, and the overall construction period is basically about 20% the construction period of a common concrete building.

Owner:河北丽建丽筑集成房屋有限公司

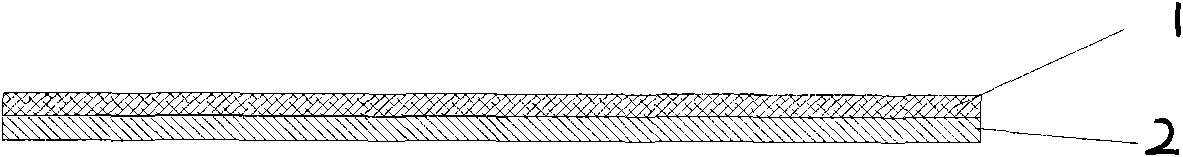

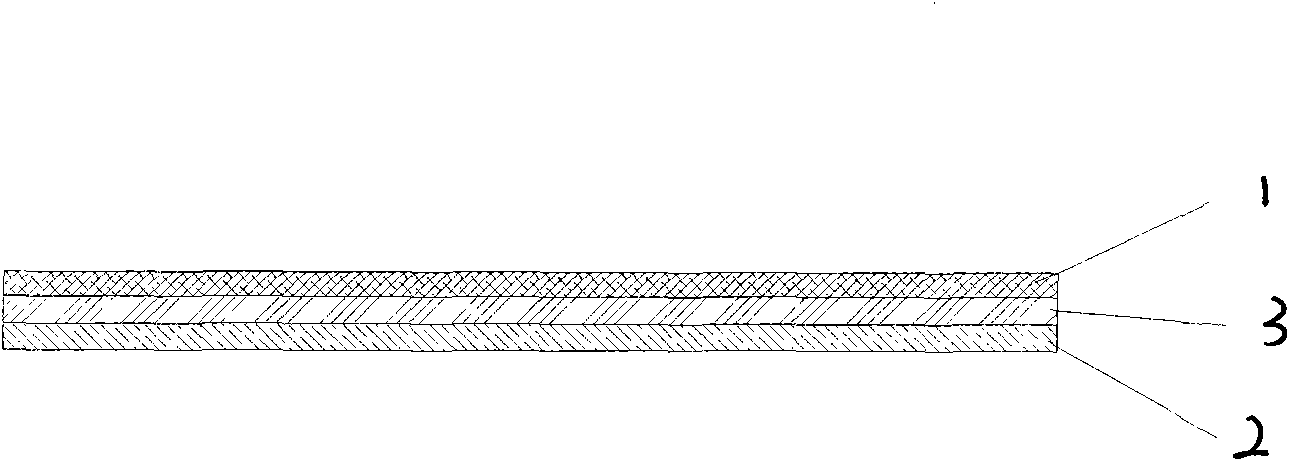

Clutch facing

InactiveCN101876353ABest friction and wear resistanceFast heat conductionFibre treatmentFriction clutchesEngineeringMultiple layer

The invention discloses a clutch facing, which consists of a frictional working layer and a structural layer, wherein the frictional working layer is a working face; the back of the frictional working layer is provided with the structural layer; the number of the structural layer can be one or more, and the structural layers can be divided into a heat transfer layer and a support layer according to the action, wherein the heat transfer layer can be used as required; the frictional working layer participates in the friction operation and provides friction and abrasion properties required during using; the structural layer does not participate in the friction operation and provides other auxiliary properties for a clutch facing product; and the whole clutch facing product consists of two or more layers according to the property requirement. The frictional working layer and the structural layer are combined and thermally pressed to form the clutch facing so as to improve the comprehensive performance thereof and reduce the comprehensive cost.

Owner:十堰法雷诺动力科技有限公司

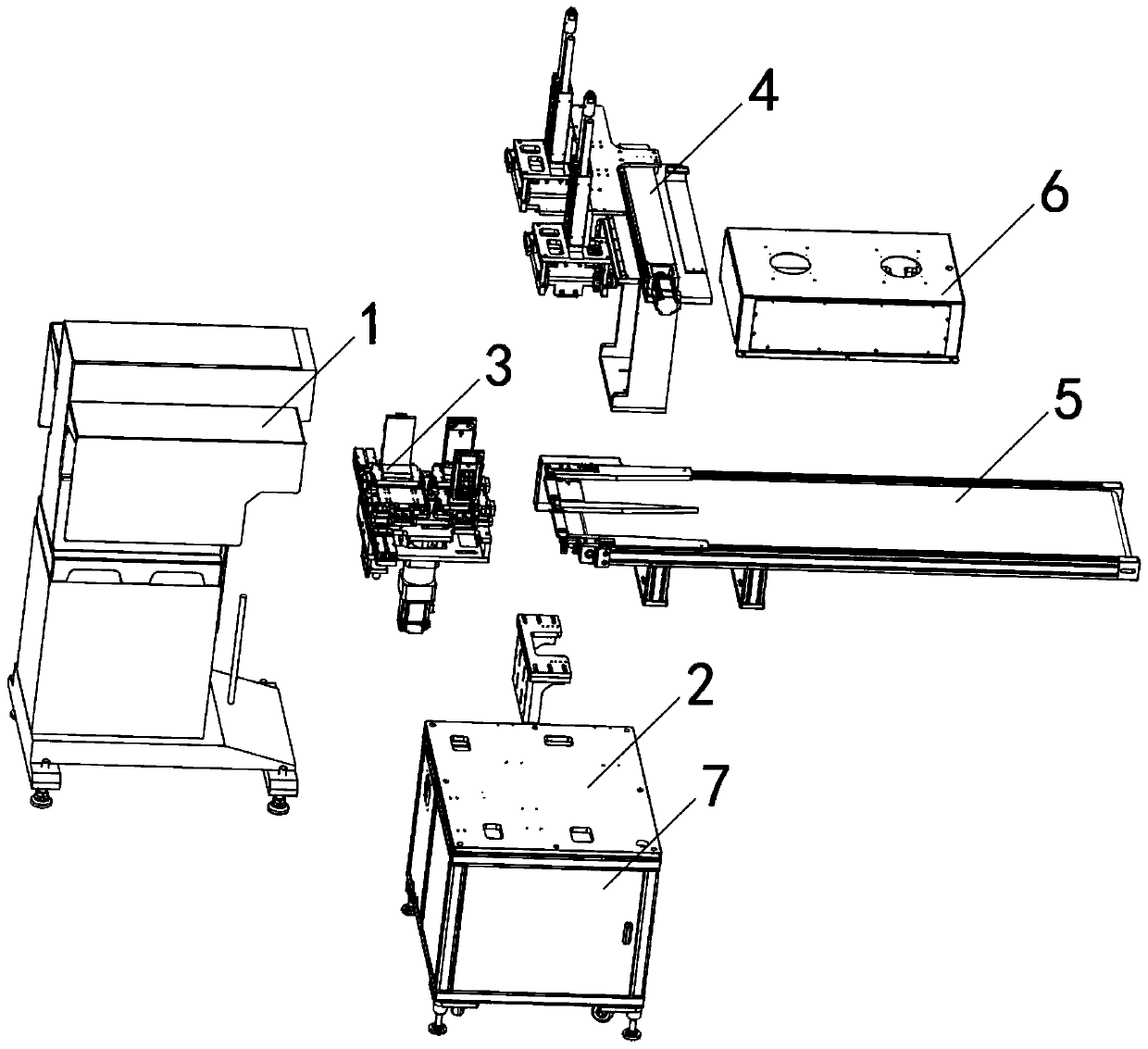

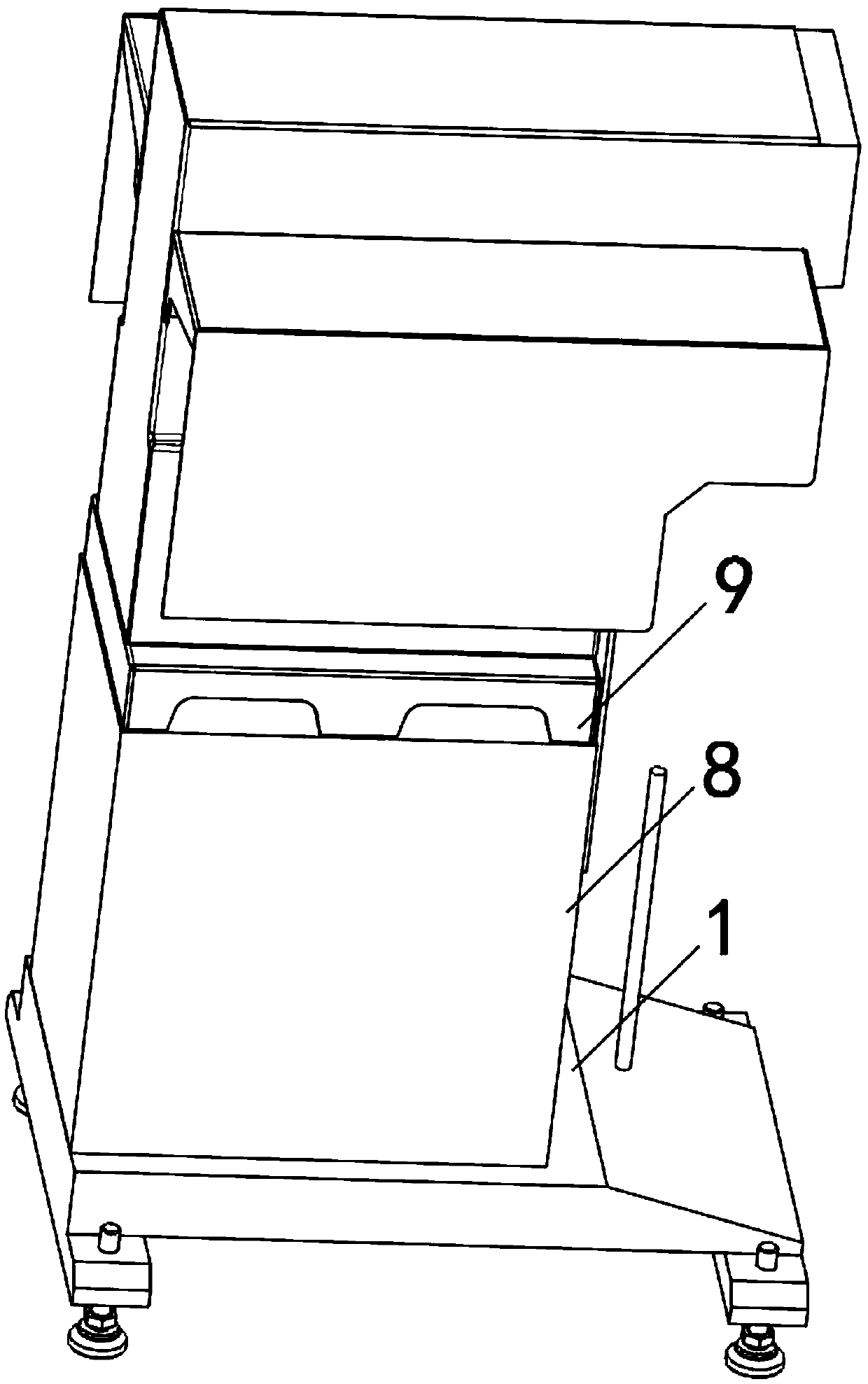

Transformer assembly and glue-coated integration machine

PendingCN108766745AGuaranteed assemblyQuality assuranceInductances/transformers/magnets manufactureTransformerUltimate tensile strength

The invention relates to the field of automation equipment, in particular to a transformer assembly and glue-coated integration machine, including a transformer assembly device, glue-wrapping device for the transformer, transfer manipulator, wherein, the transformer assembly device comprises a transformer assembly base, a skeleton feed device for loading a skeleton of a transformer assembly base,two iron core dispensing devices respectively arranged on both sides of the transformer assembly base and two iron core transferring devices respectively arranged on both sides of the transformer assembly base, the iron core transferring devices are used for transferring the iron core output from the iron core dispensing device to the transformer assembly base. The invention realizes the automaticcompletion of the whole assembly process and the manual assembly, greatly improves the high production efficiency, saves the manual cost, avoids the problem that the assembly quality is not uniform due to the labor intensity of the workers, and thus ensures the assembly quality of the transformer.

Owner:东莞市键环自动化设备科技有限公司

Refractory brick conveying belt

The invention discloses a refractory brick conveying belt. The refractory brick conveying belt comprises a bottom frame, rolling shafts are arranged at the two ends of the bottom plate, and the rolling shafts at the two ends are connected through a belt; connecting columns are arranged on the two sides of one end of the bottom frame, and are sleeved with connecting rods; and a brush plate is connected between the connecting rods at the two ends and is in contact with the belt, the upper surface of the belt is connected with buffer layers, inserting holes are connected to the belt, and a rubber partition board is connected to the inserting holes. The conveying belt has the beneficial effects that the structure is simple, the conveying belt has the beneficial effects that damage to products is reduced, and normal assembling is ensured; the buffer layers are connected to the conveying belt face at intervals, the advantages of convenient fixing and easy replacement are achieved; and the brush plate is utilized for scraping particular impurities on the belt, cleaning is convenient, and the conveying belt is cleaned to be neat.

Owner:怀宁县凉亭建材有限责任公司

Integral molding process for fuselage of helicopter

The invention discloses an integral molding process for a fuselage of a helicopter, and belongs to the field of helicopter preparation. The integral molding process comprises the following steps of S1: tailoring a carbon fiber prepreg; S2, laying an isolating membrane; S3, laminating the tailored carbon fiber prepreg; S4, mounting a gas guiding system on the outer surface of the carbon fiber prepreg; S5, performing heating treatment by an autoclave; and S6: taking. The carbon fiber prepreg is used as a raw material, the fuselage of the helicopter in all angles has high strength through lay-updesign, a split module set and a vacuum bag enables the strength of the interior of the fuselage of the helicopter to reach the requirements through an autoclave molding technology, the assembly of the interior is ensured, the fuselage of the helicopter is high, the process is simple and easy to operate, the molding time is short, the product size is accurate and controllable, and the production efficiency is improved.

Owner:湖南欧亚碳纤维复合材料有限公司

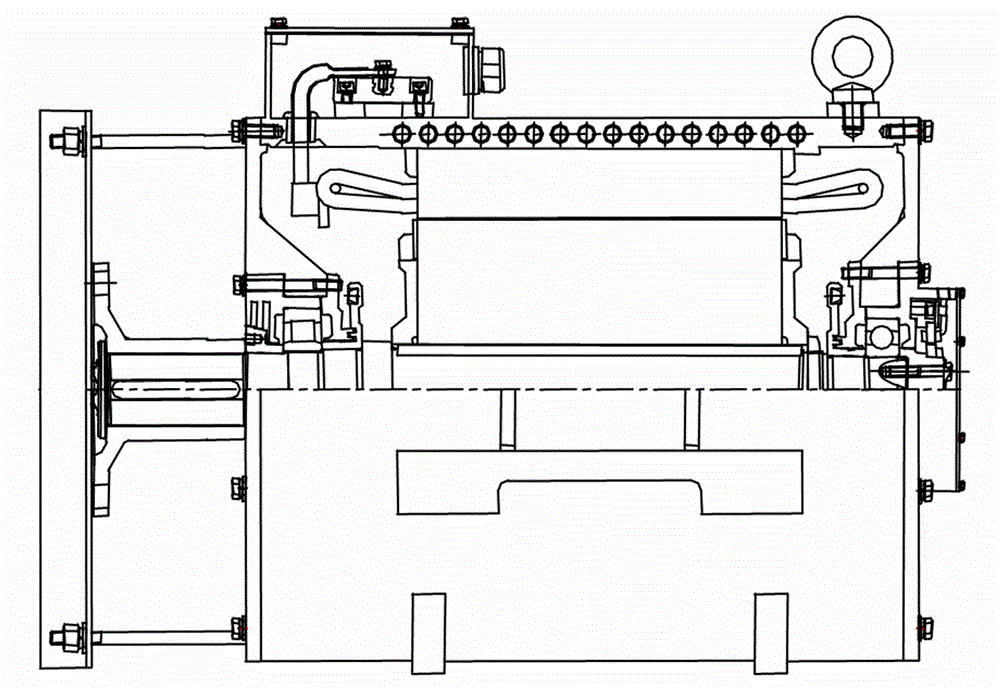

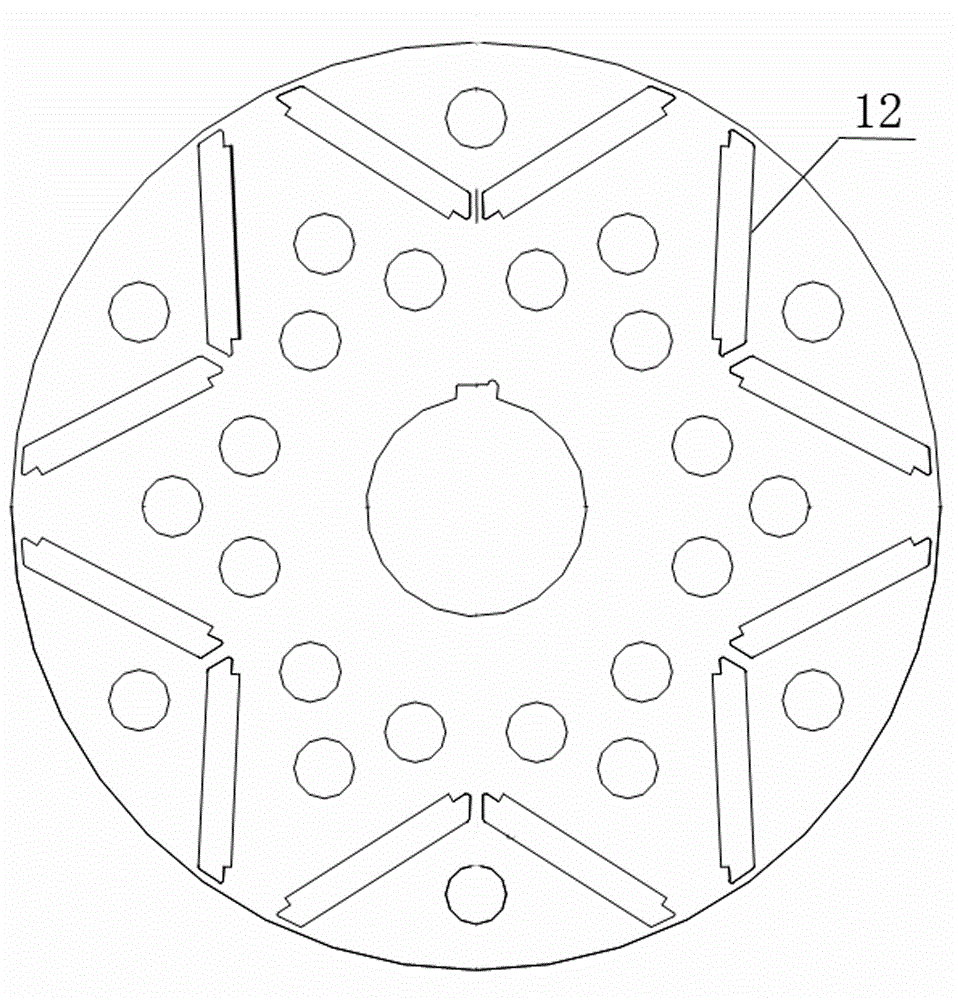

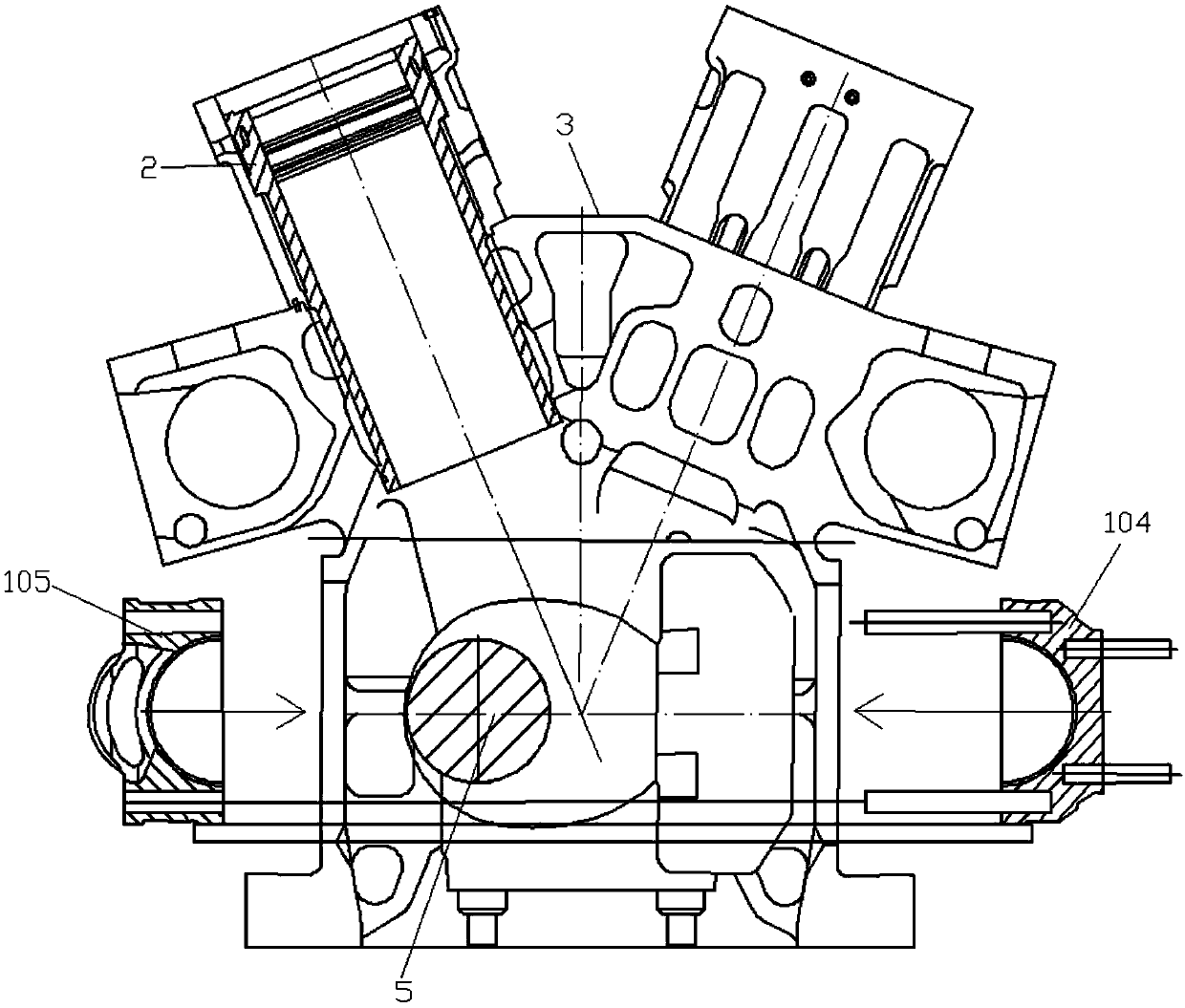

Permanent magnet generator for hybrid power motor train unit

InactiveCN104702017AGuaranteed assemblyReduce your weightMagnetic circuit rotating partsSupports/enclosures/casingsStator coilEngineering

The invention relates to a traction motor for a hybrid power motor train unit, in particular to a permanent magnet generator for a hybrid power motor train unit. The permanent magnet generator for the hybrid power motor train unit comprises a machine base and an end cover, wherein a stator assembly and a rotor assembly are arranged in the machine base, the stator assembly is provided with a stator coil, the rotor assembly is provided with a rotary shaft, a rotor iron core, a permanent magnet baffle, a permanent magnet baffle pressing ring and a permanent magnet, a front inner sealing ring and a rear inner sealing ring are arranged at the two ends of the rotary shaft respectively, a punched piece of the rotor iron core is a permanent magnet structure which is provided with a thick magnetic steel tank and is of a V-shaped radial magnetic structure, the machine base is a cast-aluminum machine base and is of a structure formed by casting two rows of spiral copper pipes in parallel, the permanent magnet baffle pressing ring is of a cast-aluminum structure, and magnetic steel assembling and disassembling holes are evenly formed in the pressing ring. According to the motor, under the same size condition, the sectional area of the permanent magnet is increased, the power density and demagnetization resistance of the motor are improved, fluctuation of output voltage is reduced, the weight of the motor can be effectively reduced, and the margin of temperature rise of the motor is increased; meanwhile, the self weight can be reduced through the cast-aluminum pressing ring, assembly of the motor can be guaranteed, design cost is reduced, operation reliability is improved, and the service life is prolonged.

Owner:CRRC YONGJI ELECTRIC CO LTD

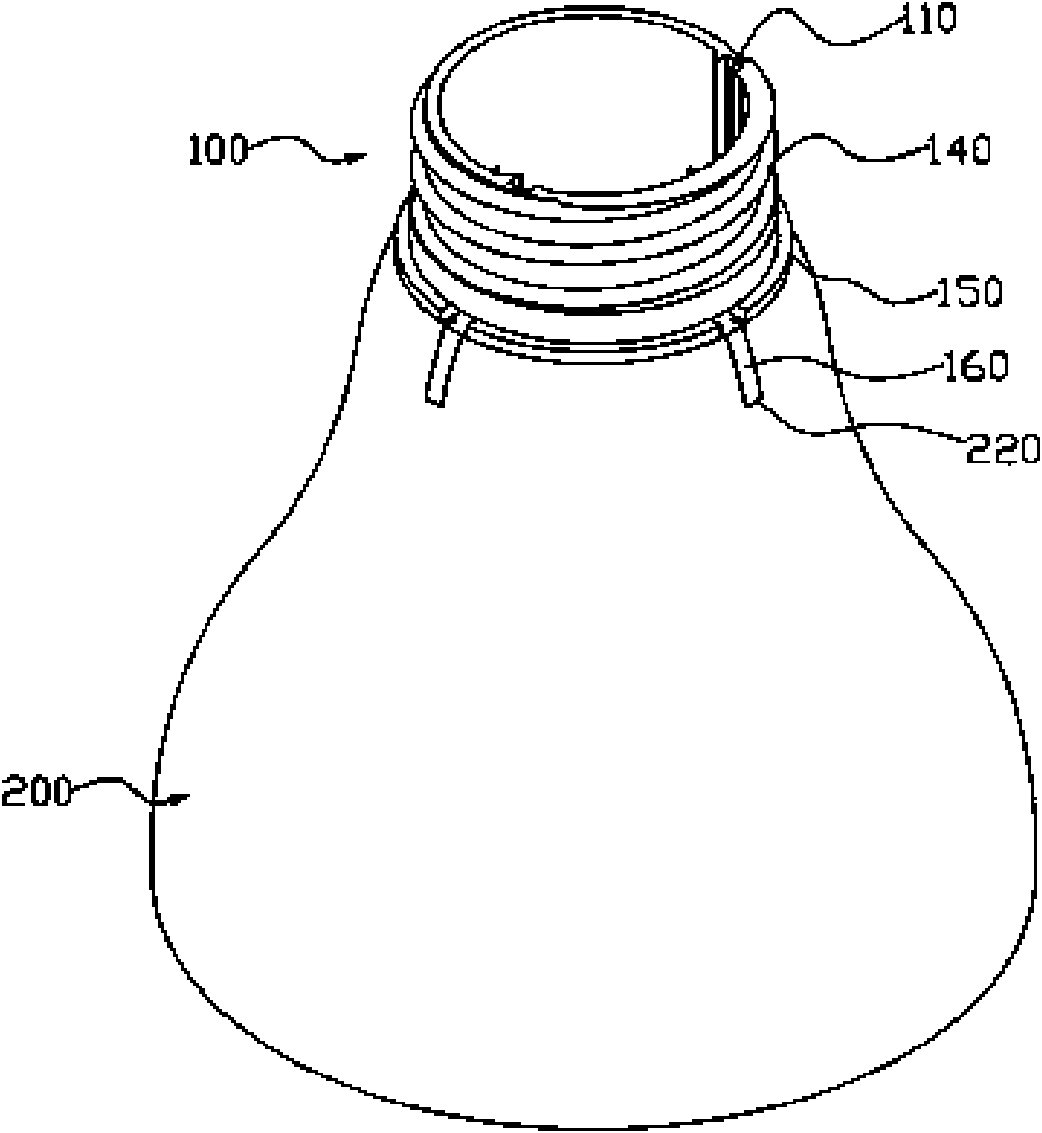

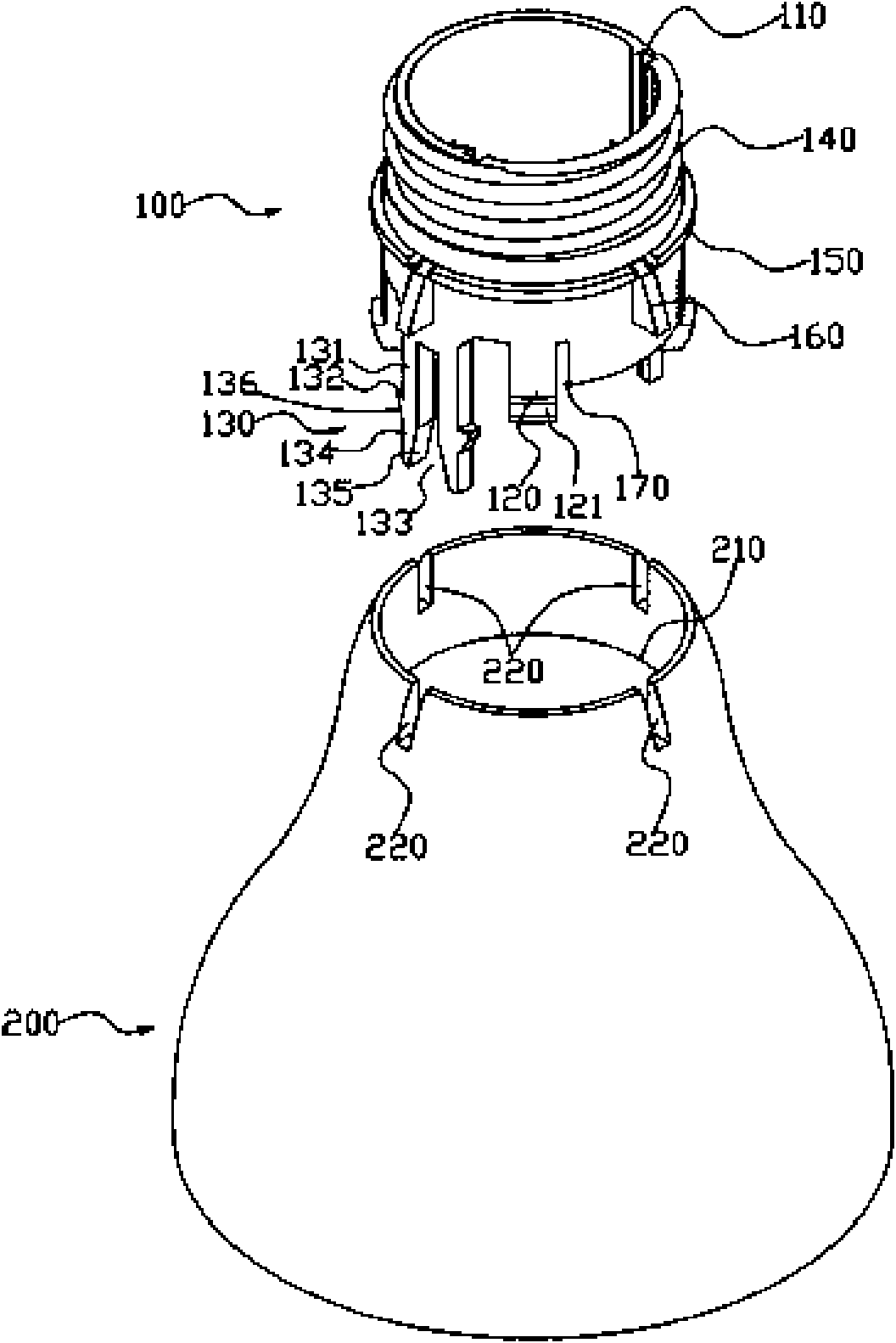

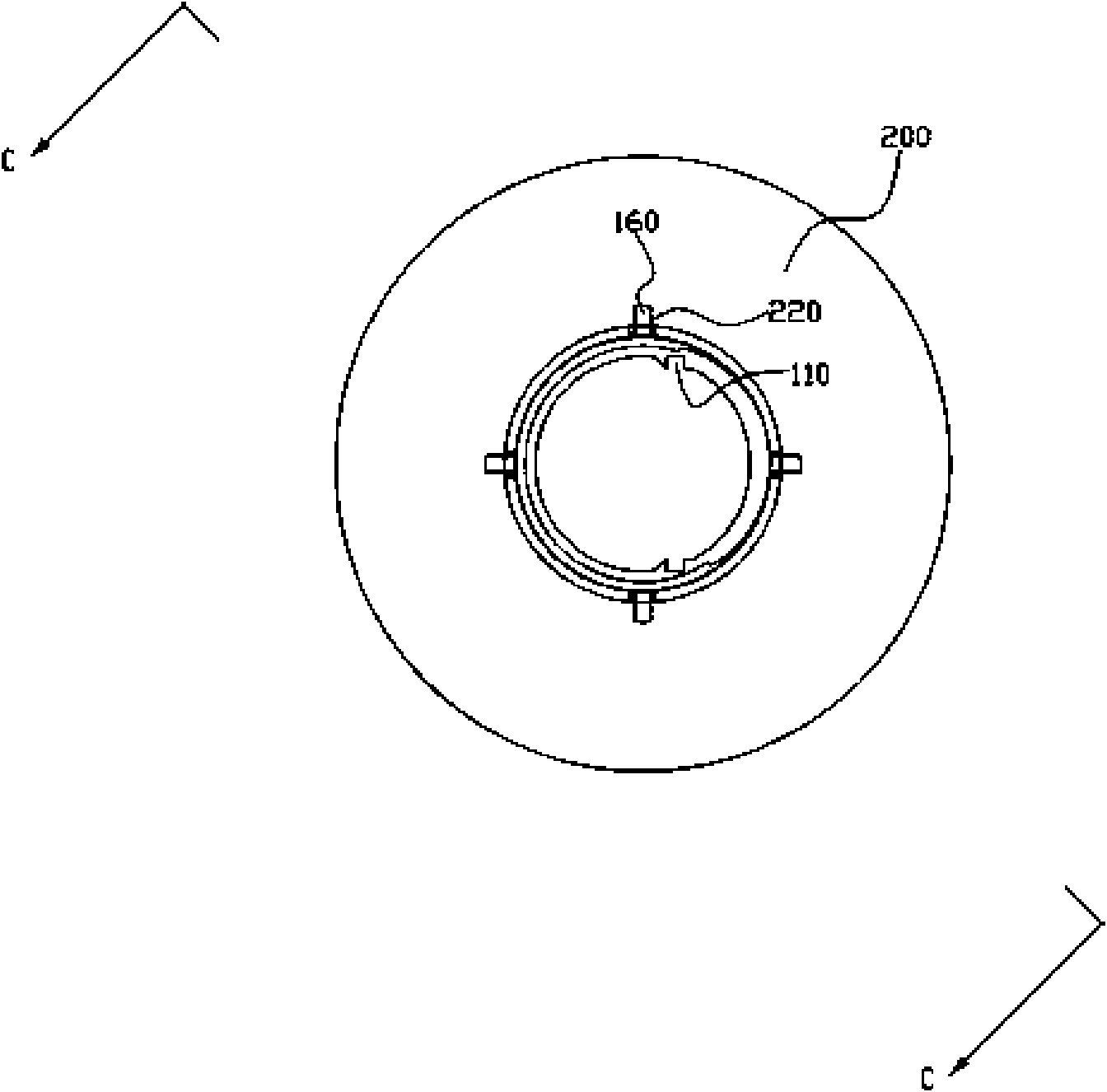

Energy-saving lamp

InactiveCN101988690AReduce defective rateSimple structureElectric discharge tubesProtective devices for lightingEngineeringFlange

The invention discloses an energy-saving lamp. The energy-saving lamp comprises an upper molded case, an upper bulb, a lower molded case, a rectifier and a lamp tube, wherein the lower molded case is positioned in the upper bulb; the rectifier is connected with the upper molded case; the lamp tube is connected with the lower molded case; the upper molded case is provided with a main body and at least two first suspending arms which are arranged on the bottom surface of the main body; the tail ends of the first suspending arms protrude outwards to form clamping flanges; the upper bulb is made of plastic; the upper section of the inner revolution surface of the upper bulb is provided with a positioning step of which the stepped surface faces downwards; and the clamping flanges of the first suspending arms of the upper molded case are clamped on the stepped surface of the positioning step of the upper bulb, so that the upper molded case is fixedly connected with the upper bulb.

Owner:XIAMEN TOPSTAR LIGHTING

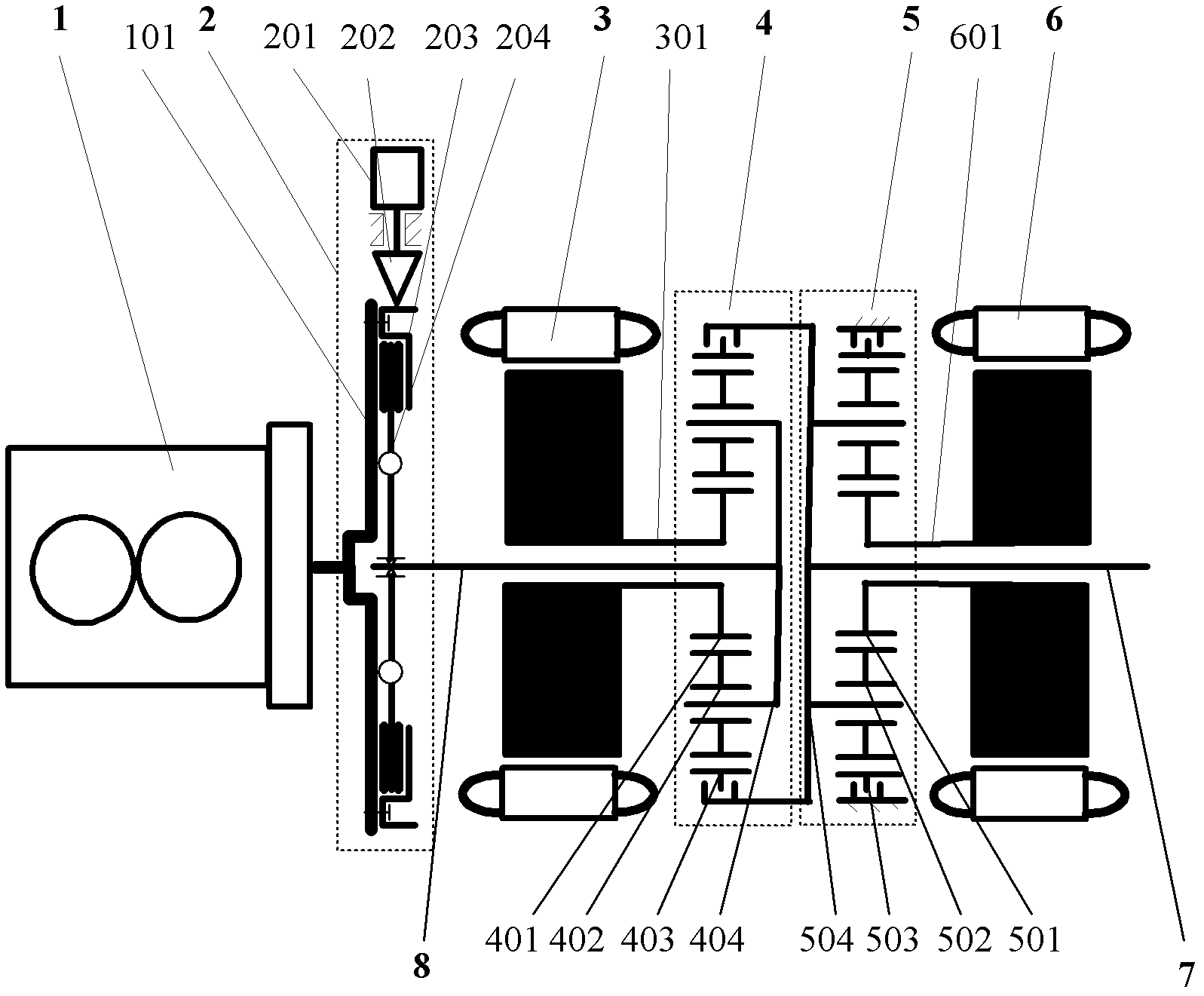

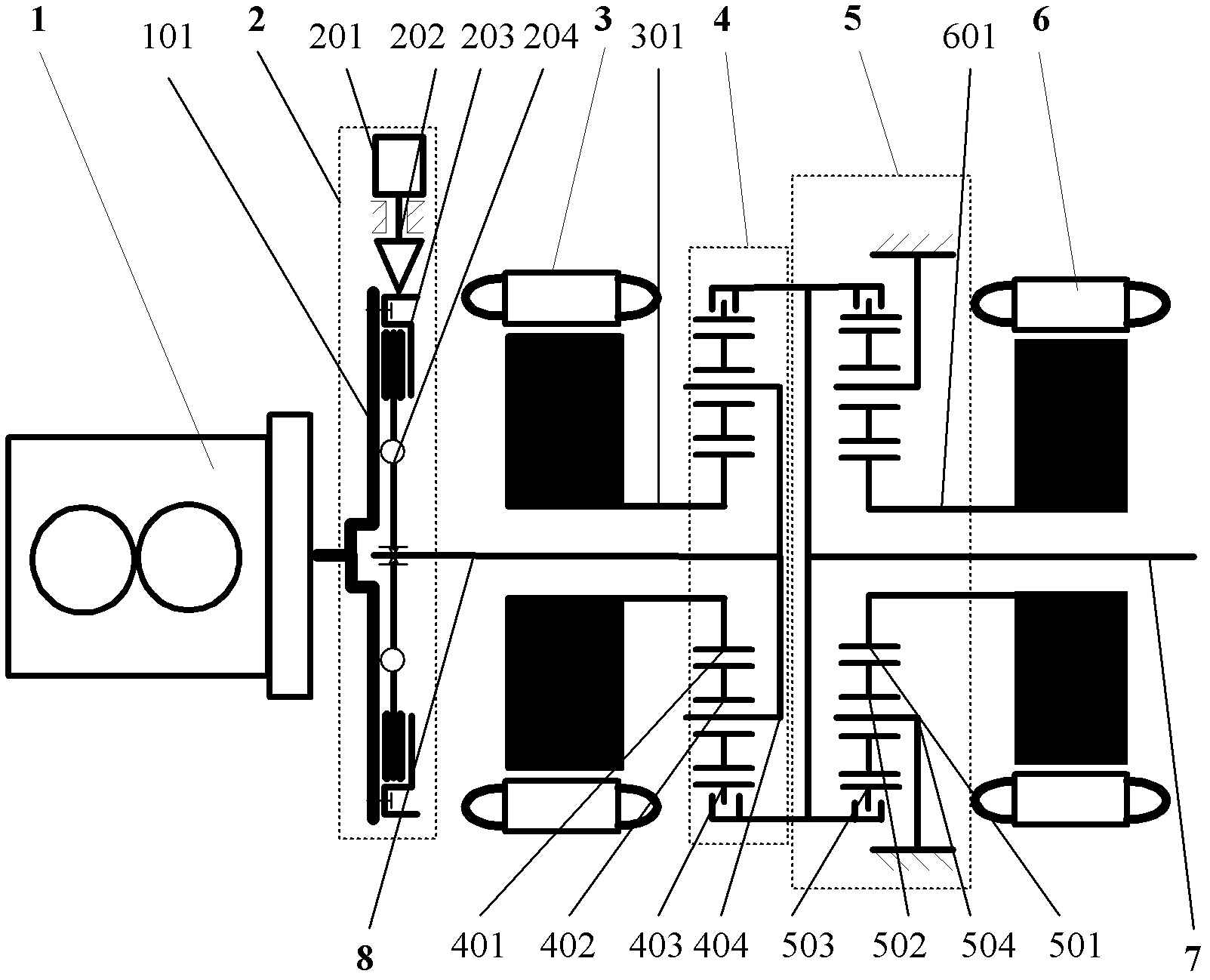

Hybrid power device provided with engine lock mechanism and drive method thereof

InactiveCN102320238BReduced concentricity requirementsGuaranteed assemblyGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingMotor driveLocking mechanism

The invention discloses a hybrid power device provided with an engine buffer lock mechanism. The hybrid power device comprises an engine, a buffer and lock combination mechanism, a first generator / motor, a first row of planetary gear mechanism, a second row of planetary gear mechanism, a second generator / motor, a first shaft and a second shaft; the buffer and lock combination mechanism is used for locking and buffering the engine; an engine flywheel is connected with the first shaft via the buffer and lock combination mechanism; the first shaft is connected with a planetary carrier of the first row of planetary gear mechanism; and a rotor of the second generator / motor is connected with the second first row of planetary gear mechanism. According to the invention, the engine is locked via the lock mechanism and two generators / motors are used for a dual-motor drive mode when a car is in a pure electric mode, so that the dynamic property of the car is improved. In the invention, two motors are respectively located in two separate shells and then integrally assembled; and meanwhile, the tooth rings of the planetary gear mechanisms are floated so that the planetary gear mechanisms can realize the self-aligning function.

Owner:CHINA AUTOMOTIVE TECH & RES CENT

Clamping tool for machining motor case

ActiveCN105515308AAffect mobileGuaranteed to proceed normallyManufacturing dynamo-electric machinesMechanical engineeringStator

The invention discloses a clamping tool for machining a motor case, and the tool clamps an end face of a motor stator in the motor case, so as to fix a motor and to machine the end face of the motor case. The tool can prevent the motor state from being expanded by supporting, and prevents the motor case from deforming.

Owner:上海雷祥压铸有限公司

Injection mold with high-strength ejection lifter

The invention discloses an injection mold with a high-strength ejection lifter, and belongs to the technical field of injection molds. The injection mold comprises a movable mold kernel, a movable mold plate, a lifter head, a lifter rod, support blocks and a lower fixing plate, wherein the lifter rod comprises an end ejector rod and a tail ejector rod connected with the end ejector rod; the lifter head is sleeved with an insert; a lifter guiding block is arranged at the bottom of the movable mold plate, the lifter rod is located on the movable mold plate and only fixed and guided by the lifter guiding block, and clearances are reserved between other portions of the lifter rod and the movable mold plate. According to the injection mold, the lifter rod is divided into the end ejector rod and the tail ejector rod, and the diameter of the tail ejector rod is larger than that of the end ejector rod, so that a reasonable movement mechanism of a small part in the large mold is realized, the ejection strength of a lifter ejection mechanism is guaranteed, and the phenomenon that the lifter rod is broken is avoided; material cost is reduced, and the injection mold is simple in structure and convenient to assembly, reduces labor cost and has high market competitiveness.

Owner:TAICANG QIUJING PLASTIC MOLD

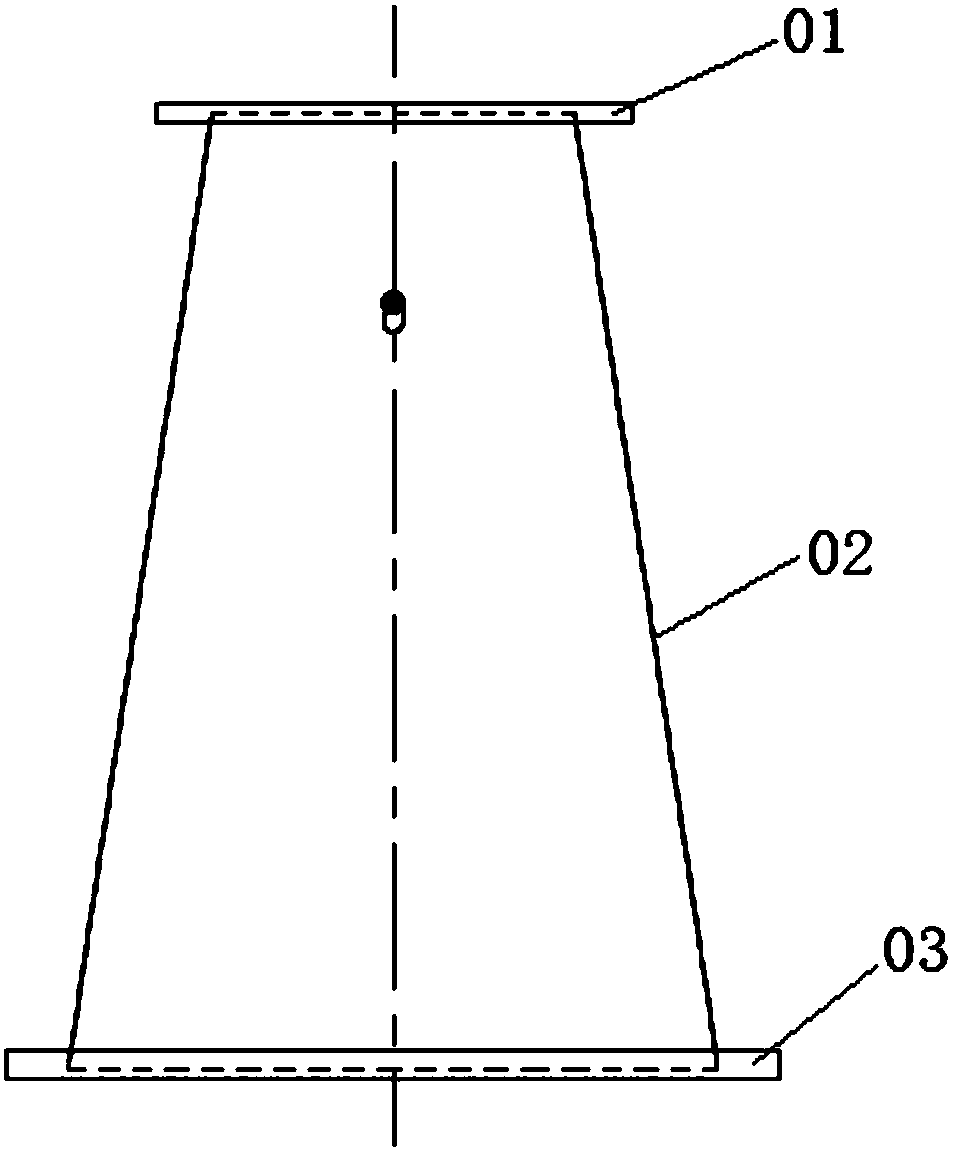

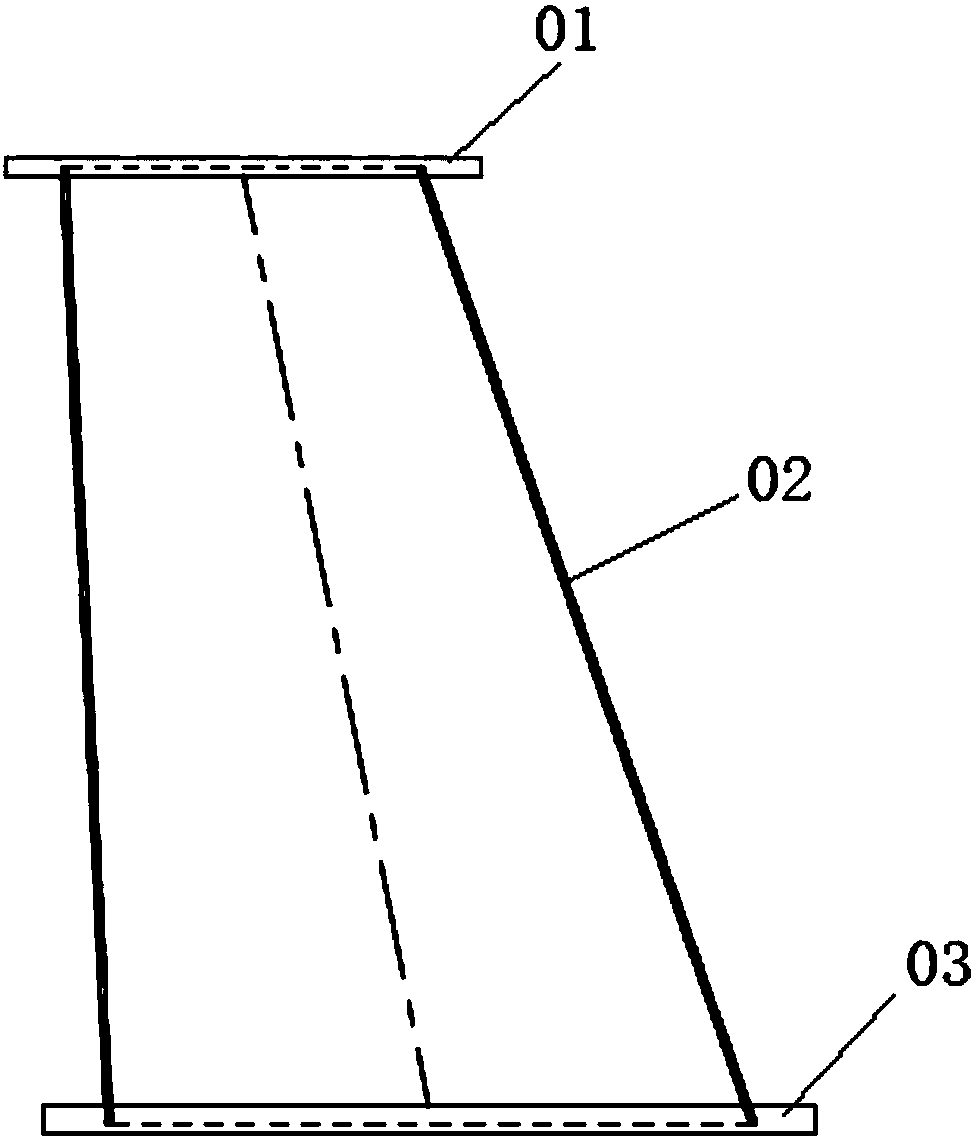

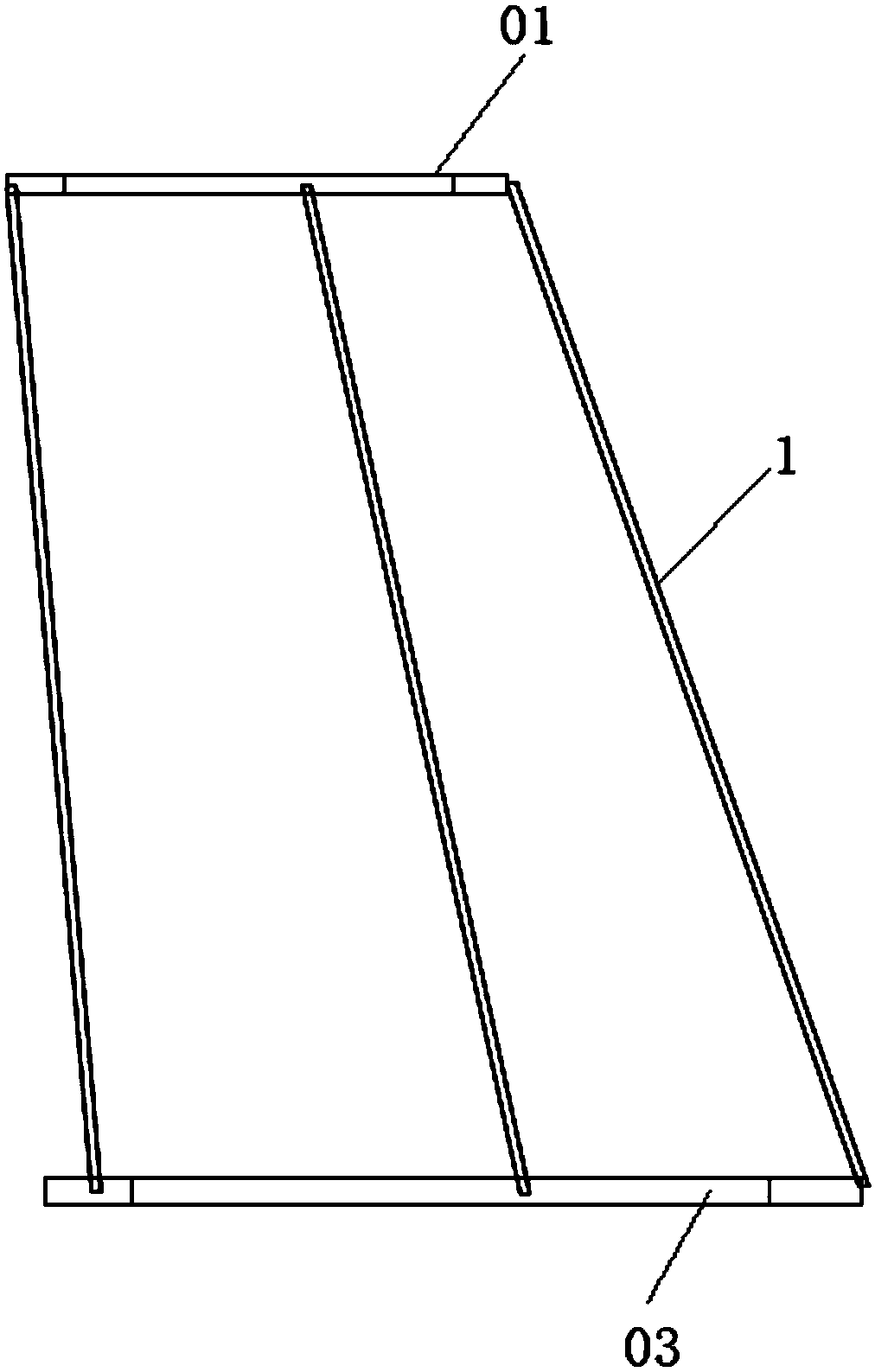

Technological method for assembly and welding of diffuser tube in marine diesel engine

The invention discloses a technological method for assembly and welding of a diffuser tube in a marine diesel engine. According to the technological method, the adaptation to the relative position between a top flange and a bottom flange can be achieved by replacing a tapered tube in the diffuser tube with a plurality of positioning ribs; on the one hand, the problem that the tapered tube is slowly delivered during the pre-assembly process can be solved and the normal assembly of a main machine can be guaranteed; on the other hand, the onsite assembly and welding of the diffuser tube can be changed into welding in a steel structure workshop through the use of the positioning ribs, the restrictions to the operation space and the operation position during the welding of the diffuser tube canbe changed, and the problem about large assembly and welding deformation can be solved; meanwhile, the process of flatness detection after welding is added in the technological method and the millingprocessing is achieved, so that the problem about assembly flatness errors can be solved; and an expansion joint is arranged on a turbocharger as well as the expansion and contraction quantity of theexpansion joint reaches 3 mm, so that the proper milling operation can be prevented from influencing the assembly.

Owner:中船发动机有限公司

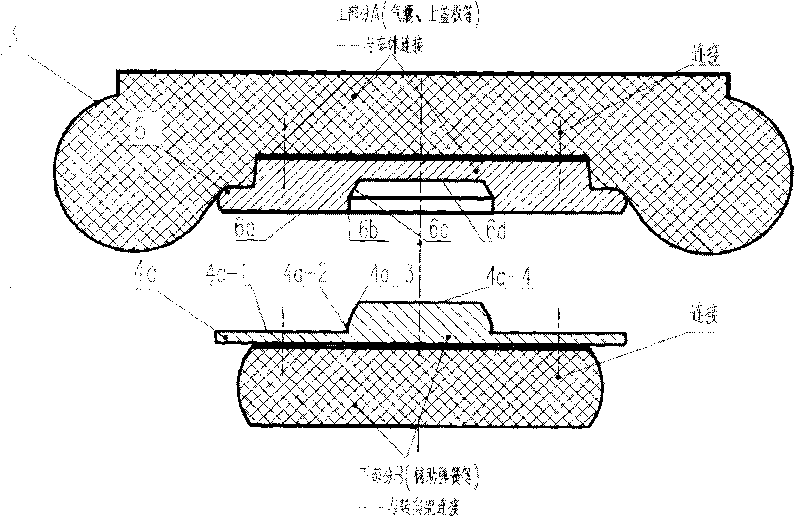

Installing mode and separating mode and device of air spring system

ActiveCN101733629AEasy to operateSimple assembly and separation processSpringsMetal working apparatusAir springAirbag deployment

The invention relates to an installing mode and separating mode and device of an air spring system, wherein an air spring and an auxiliary spring are freely connected, the air spring is the upper part of a secondary air spring system assembly, the auxiliary spring is the lower part of the secondary air spring system assembly, the upper part A is firstly connected with a car body, the lower part B is firstly connected with a bogie; an upper end plate of an auxiliary rubber spring is generally a metal part, after an air spring gasbag is connected with upper and lower metal parts, and a non-rubber concave groove with conical surfaces which is arranged between the lower metal parts and the upper plate of the auxiliary rubber spring is connected with a convex mesa and a horizontal plane. In the invention, the original airbag lower sub-opening surface of the separating interface is changed to a metal interface of the air spring system auxiliary spring upper end plate and the airbag lower connection metal parts, thus the three defects of the original mode are overcome, the operation is convenient and safe, and the system is reliable.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

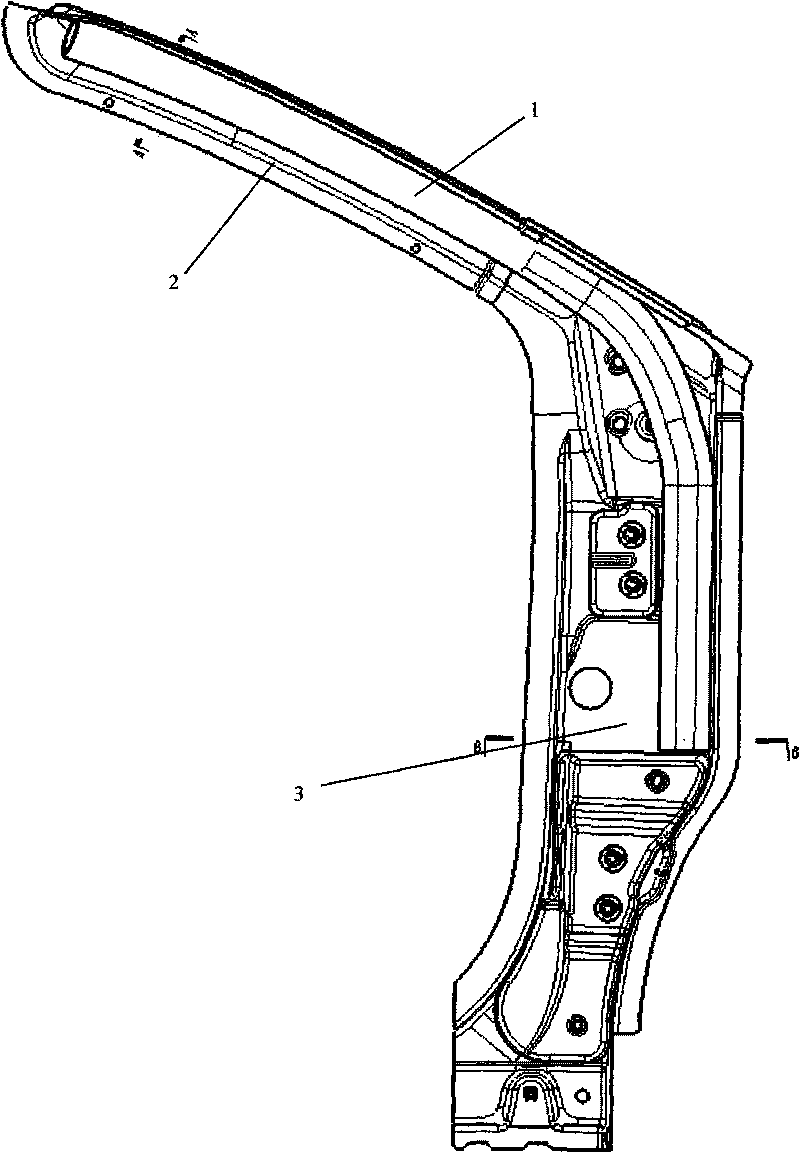

Method for welding automotive anti-rolling steel tube and A column reinforcement plate

ActiveCN101758318AGuaranteed manufacturing tolerancesGuaranteed clamping errorArc welding apparatusWorkpiece edge portionsArchitectural engineeringEngineering

The invention discloses a method for welding an automotive anti-rolling steel tube and an A column reinforcement plate. The A column reinforcement plate comprises an upper reinforcement plate and a lower reinforcement plate. The A column reinforcement plate and the steel tube are positioned by molding surfaces. A certain welding manufacture gap is formed between the steel tube and two sides of the upper reinforcement plate. One side of the lower reinforcement plate contacts the steel tube, and the steel tube is welded on the A column reinforcement plate under the condition that the other side of the lower reinforcement plate is not contacted with the steel tube. The welding method has the following advantages: a tolerance design is adopted for the welding between the A column reinforcement plate and the steel tube, so that a design gap is formed between the A column reinforcement plate and the steel tube, and a manufacturing error and a clamping error of the steel tube (with a curvature) are guaranteed; the A column steel tube and the A column reinforcement plate are positioned by the molding surfaces, the welding is more firm and the requirement on complete automobile performance is met due to a plug welding mode; the welding method can guarantee welding precision and assembly, realizes the welding technology, also can improve the welding strength of the steel tube and has more firm welding.

Owner:CHERY AUTOMOBILE CO LTD

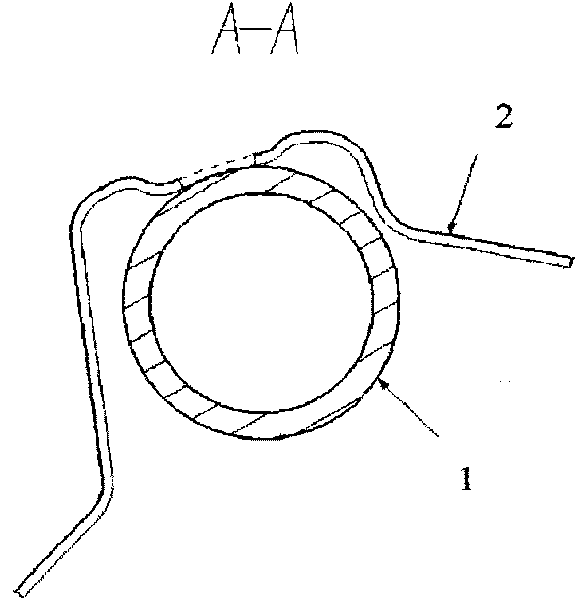

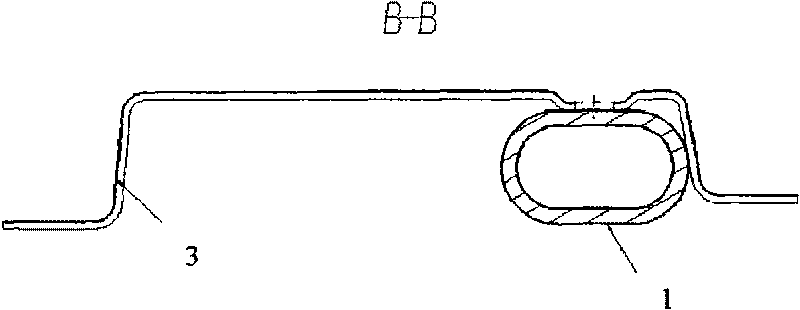

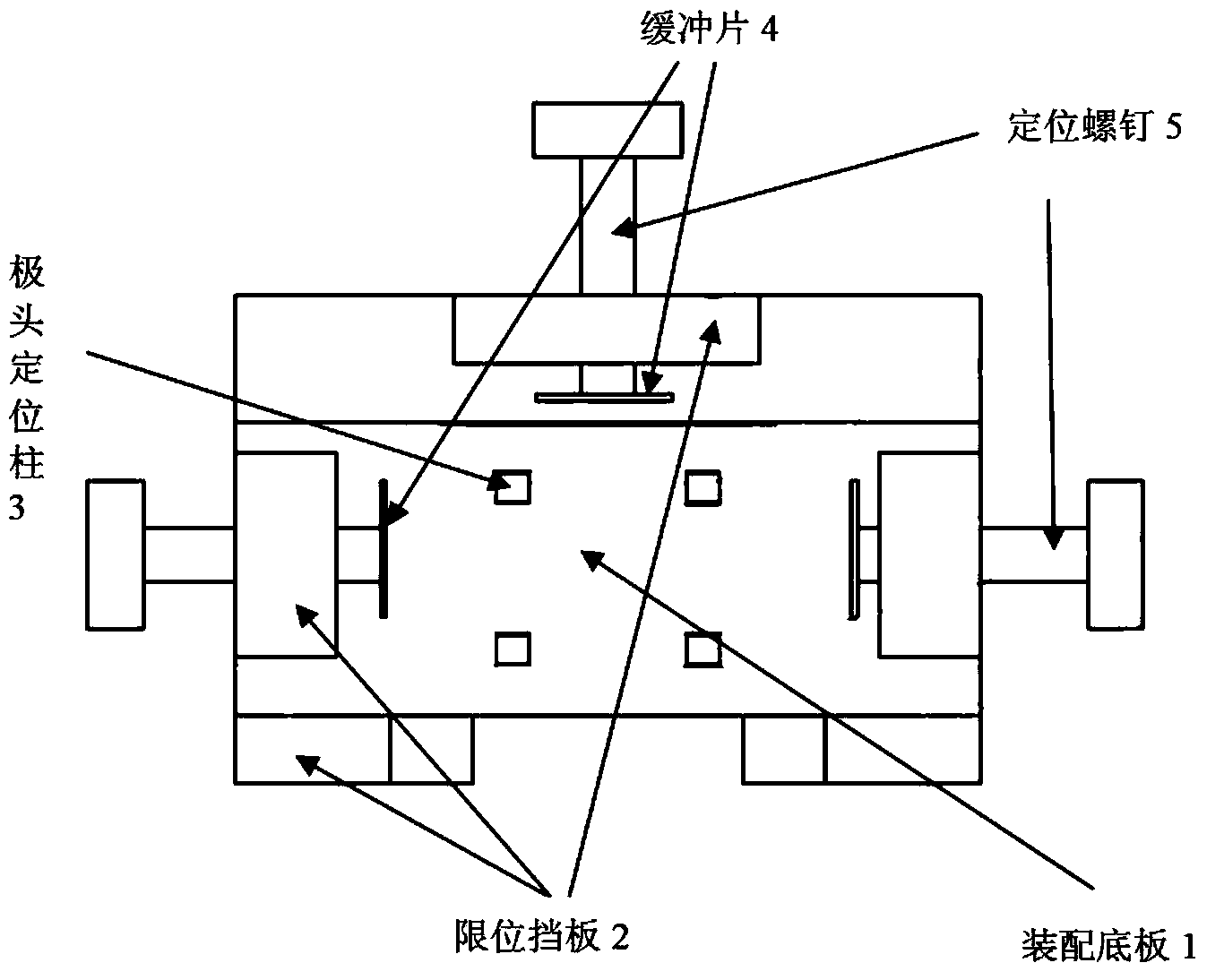

Magnetic separation-state cesium-beam tube state-selection magnet component assembly system and assembly detection method

The invention discloses a magnetic separation-state cesium-beam tube state-selection magnet component assembly system. The magnetic separation-state cesium-beam tube state-selection magnet component assembly system is used for assembling magnetic separation-state cesium-beam tube state-selection magnet components and integrating the assembly and detection, and is simple in structure and reliable and high efficient in assembling. The assembly system comprises an assembly soleplate, a limiting baffle plate, a pole end positioning column, a buffer plate, a positioning screw and a supporting leg, wherein the position and size of each part of the assembly system are determined according to the size and matching requirement of the state-selection magnet components, the structure is simple, the cost is low, the assembly operation flow is simplified in the assembling process, the probability that the magnet steel is damaged in the assembly process can be reduced, the distribution consistency of a magnetic field in a pole end can be improved, and the assembly quality of the cesium-beam tube product in the research process can be guaranteed. By adopting the assembly scheme of the assembly system, the detection on the appearance size of the A / B magnet can be simplified and integrated in the assembly process, and the assembly efficiency of the cesium-beam tube can be improved.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Protecting device and method for preventing cylinder sleeve from being pull-damaged when piston and connecting rod assembly of diesel engine is assembled and disassembled

The invention provides a protecting device and method for preventing a cylinder sleeve from being pull-damaged when a piston and connecting rod assembly of a diesel engine is assembled and disassembled. Aiming at the piston and connecting rod assembly of the diesel engine, guide blocks are mounted on a connecting rod body, a guide rod is arranged at the upper end of one rod body large end upper cover stud, in the assembling process of the piston and connecting rod assembly, one-side protection is adopted, the guide rod on the rod body large end upper cover stud on the opposite side is used forguiding and centering, in the disassembling process of the piston and connecting rod assembly, the guide blocks are mounted on the two sides of the connecting rod body, and two-side protection is adopted. In the assembling downwards-moving process and the disassembling upwards-moving process of the piston and connecting rod assembly, the guide blocks with low hardness make contact with the cylinder sleeve, the connecting rod body is prevented from making contact with the inner wall of the cylinder sleeve, and pull-damage of the connecting rod body to an inner hole of the cylinder sleeve in the whole machine assembling and disassembling processes of the piston and connecting rod assembly of the diesel engine is avoided. In the second half route of piston and connecting rod assembling, theguide rod on the rod body large end upper cover stud is used for rapid centering, radial displacement of the connecting rod body cannot be generated, the connecting rod body is prevented from directlymaking contact with the inner hole of the cylinder sleeve, the mounting efficiency is improved, and the mounting quality is guaranteed.

Owner:SHANNXI DIESEL ENGINE HEAVY IND

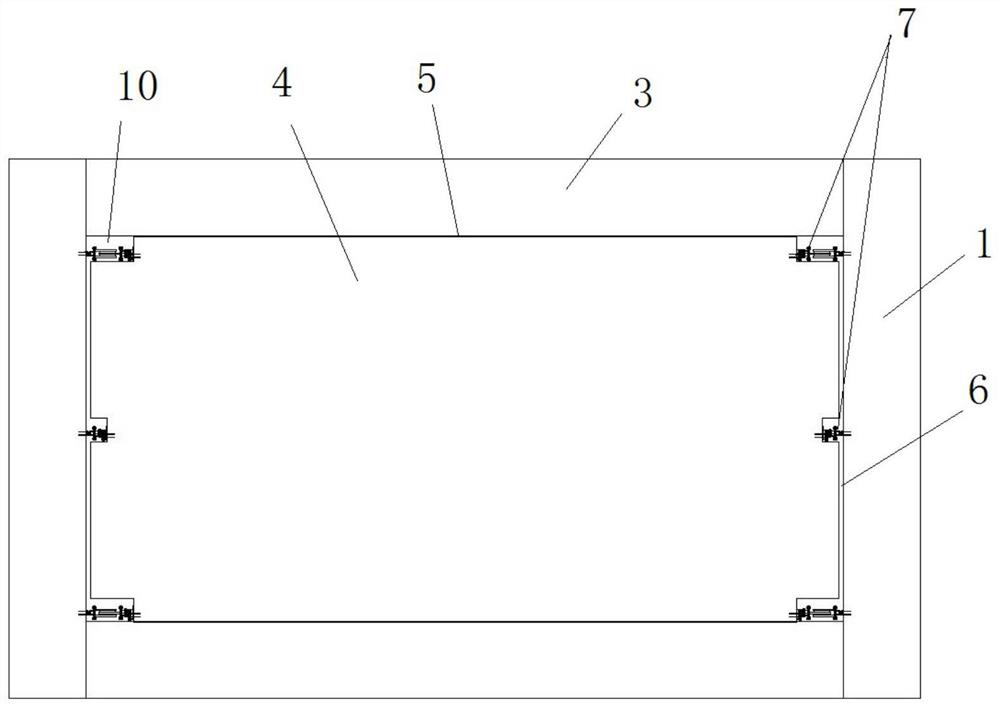

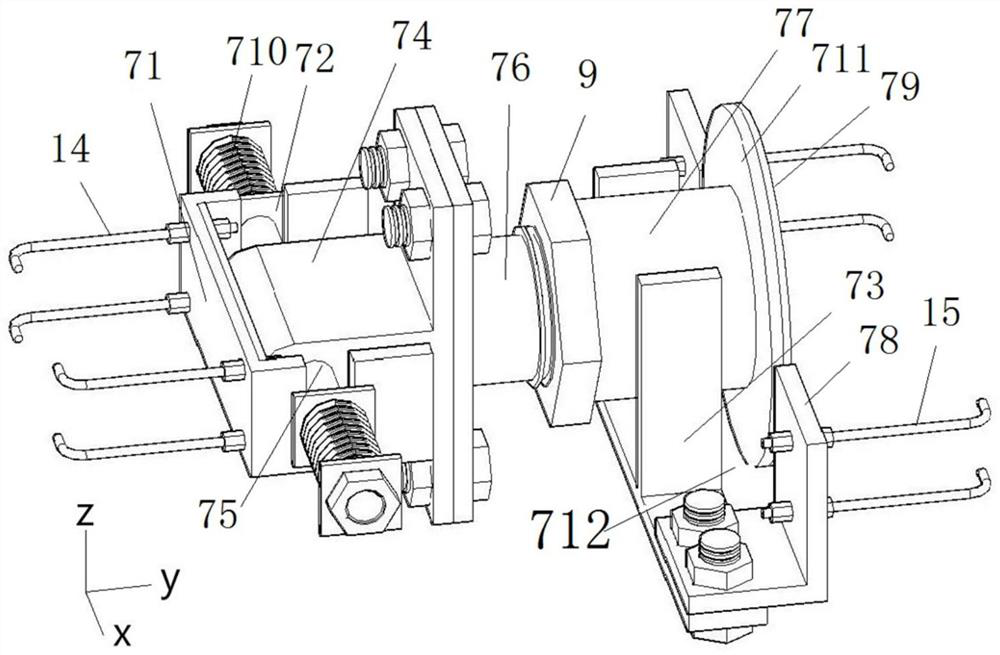

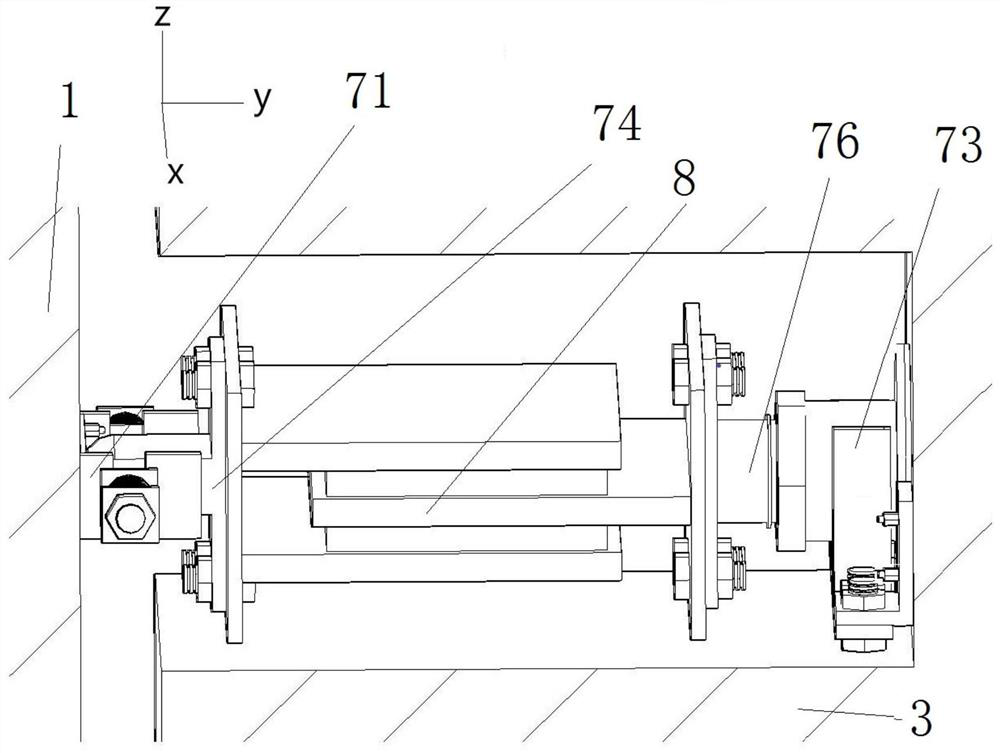

Fabricated energy dissipation and vibration reduction wall slab structure and construction method thereof

PendingCN111749370AAvoid damageReduce out-of-plane stiffnessWallsProtective buildings/sheltersClassical mechanicsMechanical engineering

The invention discloses a fabricated energy dissipation and vibration reduction wall slab structure and a construction method thereof. The wall slab structure comprises frame columns on the left sideand the right side, and the upper parts and the lower parts of the two frame columns are connected through frame beams respectively; an enclosed space for installing a wall slab is formed by the framecolumns and the frame beams in an enclosing manner; a damping layer is mounted between the wall slab and the frame beams; the portion between the wall slab and the frame columns is filled with a flexible filler; and the left and right ends of the wall slab are rotatably connected with the frame columns through connecting structures 7. According to the fabricated energy dissipation and vibration reduction wall slab structure, the frame columns are rotatably connected with the wall slab, so that in the case of an earthquake, the wall slab can be twisted when the frame columns are twisted or deformed, and damage to the wall slab caused by twisting of the frame columns during vibration is avoided; and moreover, fixing parts and the connecting parts are pre-embedded to realize the quick connection and installation of the frame columns and the wall slab, and the wall slab structure can adapt to the installation error of each angle.

Owner:HUNAN UNIV

Accessory connection and assembly device for electronic toy processing and working method of accessory connection and assembly device

The invention discloses an accessory connection and assembly device for electronic toy processing. The device comprises a mounting cabinet, a support cabinet, a lower mounting seat, an upper mountingseat and a conveying tray, wherein the mounting cabinet and the support cabinet are arranged longitudinally in parallel; and the lower mounting seat is arranged above a position between the mounting cabinet and the support cabinet in an embedded manner. The device has the benefits that the conveying tray flexibly increases conveying height to allow toy accessories to fall in two assembly bins of the upper mounting seat for toy assembly; the efficiency of toy accessory connection and assembly of the device is improved; the working flexibility of the device is higher at the same time; a space utilization ratio of the device is increased; a fourth motor drives second rolling wheels on sleeve clamp plates to roll through toothed belts, so as to drive bolt screwing sleeves on first hydraulic pumps at the two ends of a connecting plate to movably adjust bolt screwing positions of bolts on the toy accessories; the assembly and fixing efficiency of the device for screwing the bolts of the toyaccessories is improved; and the device is convenient to operate, has good social benefits and is suitable for popularization and use.

Owner:广州市携创文化传媒科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com