Magnetic separation-state cesium-beam tube state-selection magnet component assembly system and assembly detection method

A magnet assembly and assembly system technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as insufficient adaptability, high operation requirements, complex structure, etc., to reduce damage, simplify operation procedures, and improve consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

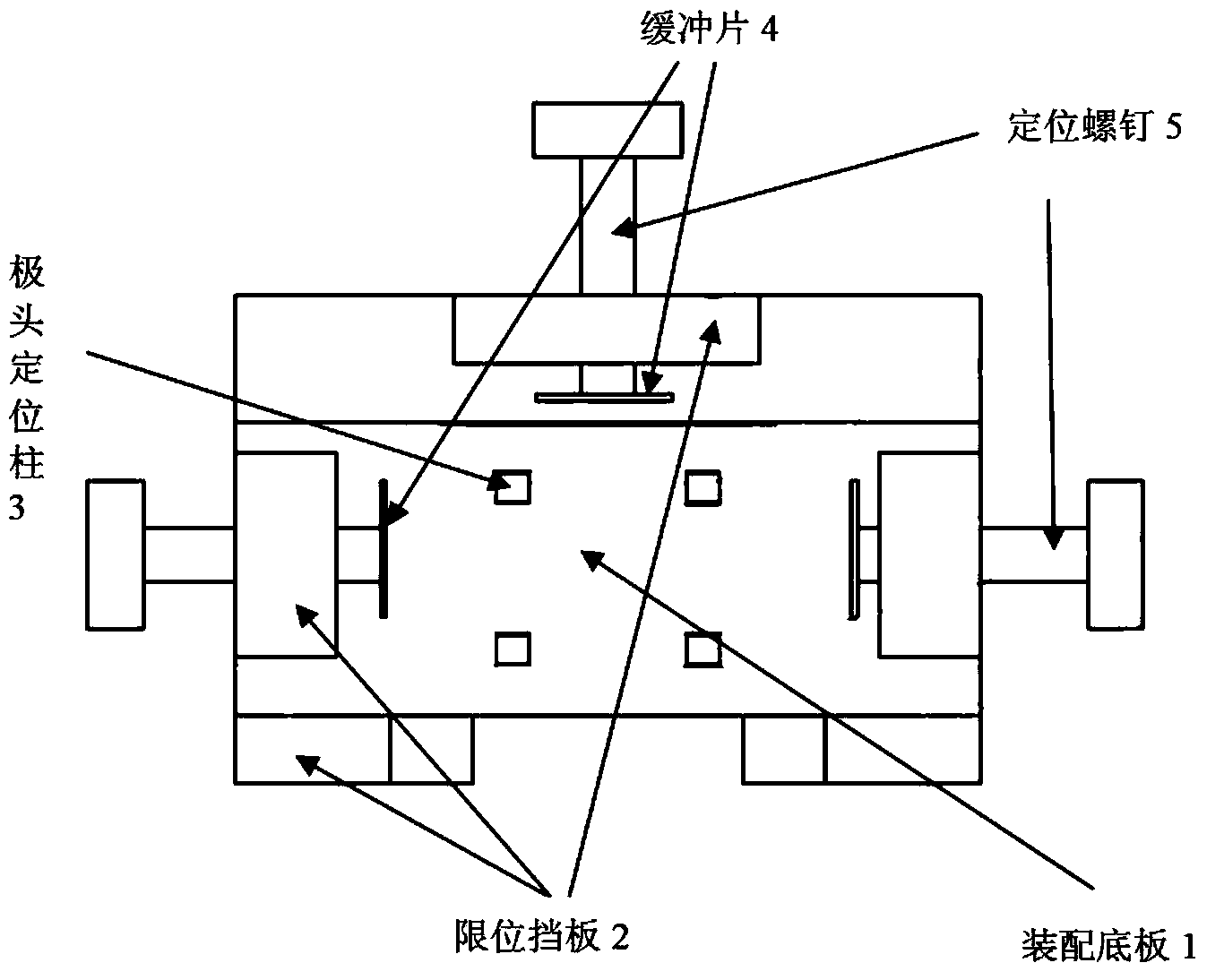

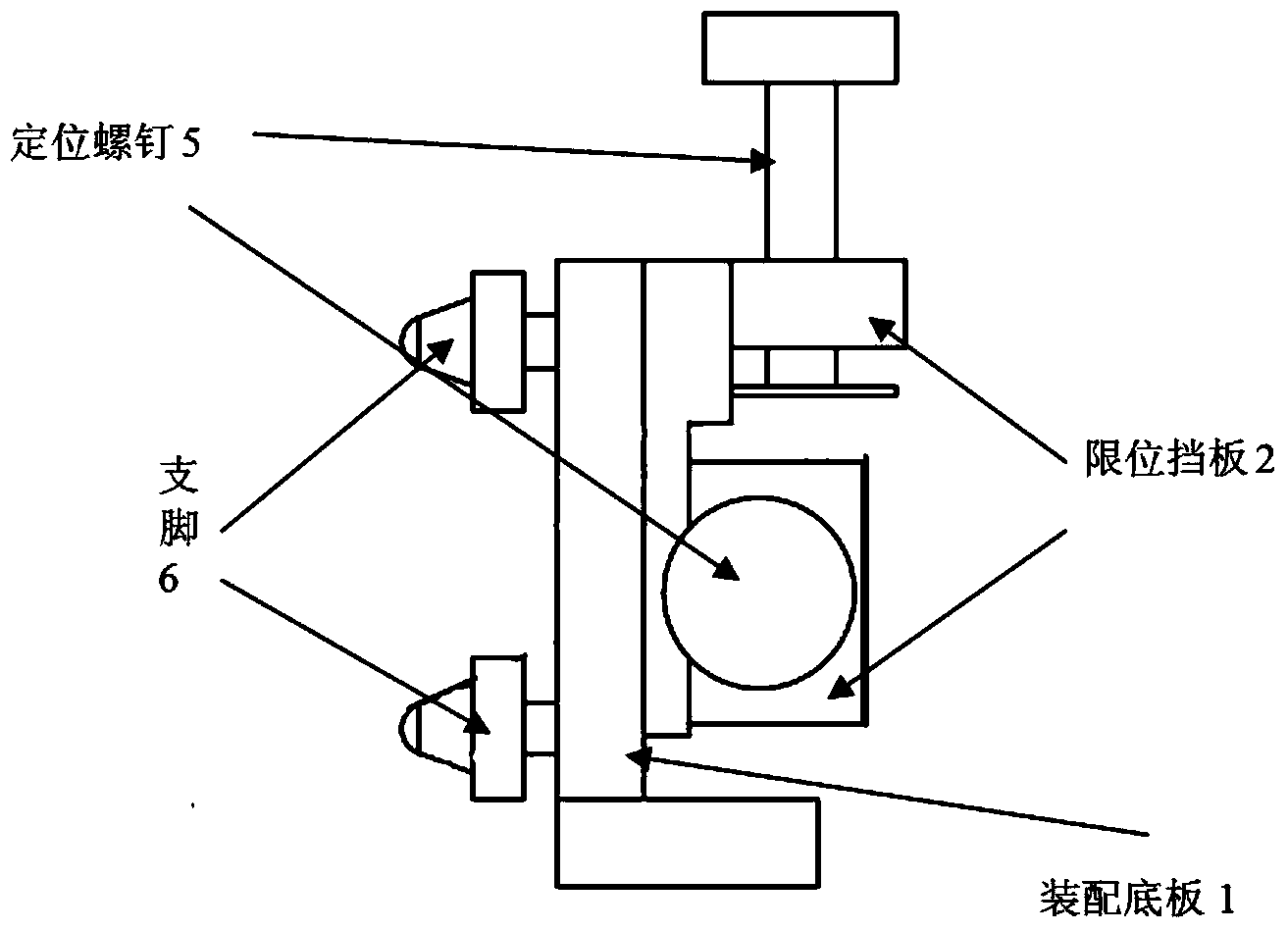

[0028] The invention provides an assembly system for a magnetically selected cesium beam tube selected state magnet assembly, such as Figure 1 ~ Figure 3As shown, it includes an assembly base plate 1, a limit baffle plate 2, a pole head positioning column 3, a buffer sheet 4, a positioning screw 5 and a support foot 6. Wherein, the feet 6 are installed on the lower surface of the assembly base 1 for adjusting and ensuring that the assembly base 1 is in a horizontal position. The flatness of the upper surface of the assembly base plate 1 is better than 0.1mm, and the upper surface of the assembly base plate 1 is vertically installed with pole head positioning columns 3 and limit baffles 2, wherein four pole head positioning columns 3 are located on the upper surface of the assembly base plate In the center of the center, the inner lateral distance between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com