Installing mode and separating mode and device of air spring system

An air spring, system installation technology, applied in the direction of spring, spring/shock absorber, shock absorber-spring combination, etc., can solve the problems of unavoidable foreign matter, affecting life, poor sealing performance of the lower port of the air bag, etc., to achieve assembly With the effect of simple separation process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the utility model is further described.

[0015] The present invention will be further described below in conjunction with schematic diagrams of the implementation principle and examples.

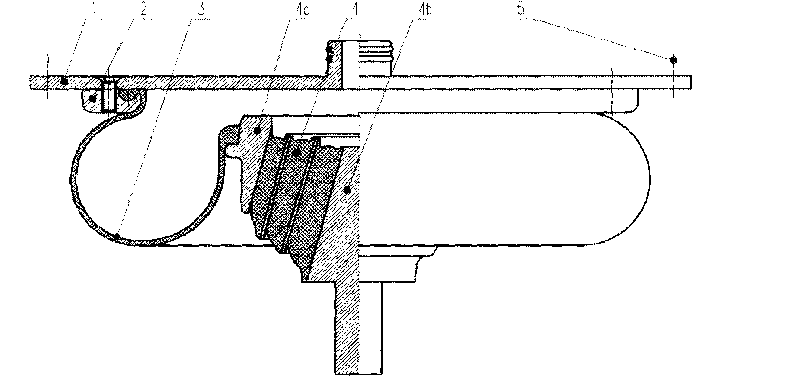

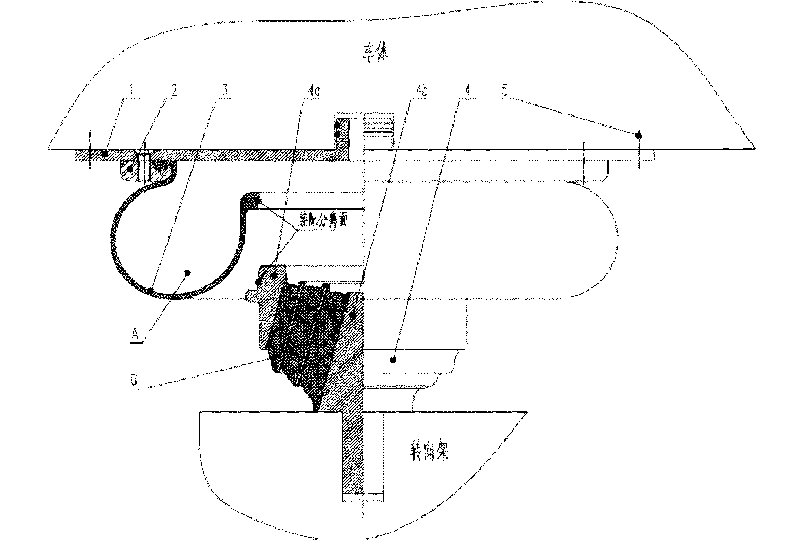

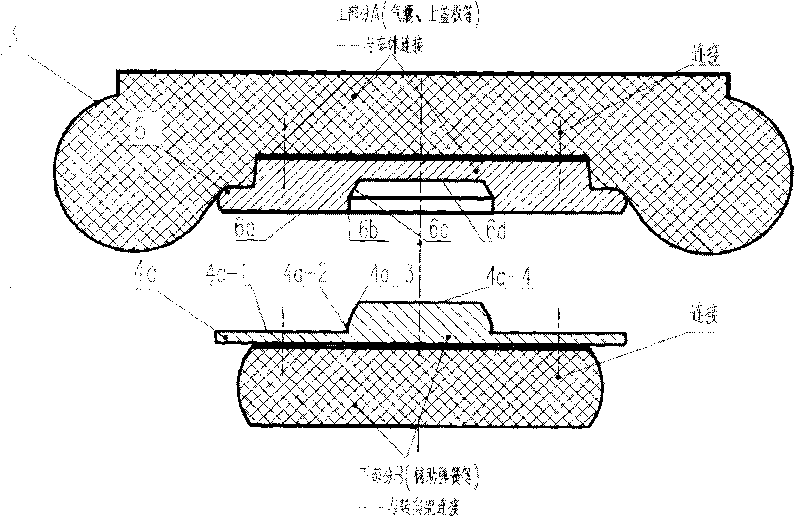

[0016] attached image 3 A schematic diagram of the implementation principle of the present invention is given. It can be seen from the accompanying drawings that the present invention is an air spring system installation and separation method, which adopts a free connection method between the air spring and the auxiliary spring, and the air spring is a secondary air spring system. The upper part of the assembly, the auxiliary spring is the lower part of the secondary air spring system assembly, the upper part A is connected with the car body first, and the lower part B is connected with the bogie first; the upper end plate of the auxiliary rubber spring is usually After the metal parts, the air spring airbag and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com