Energy-saving lamp

An energy-saving lamp, a technology that is applied to discharge lamps, loss prevention measures for lighting devices, lighting devices, etc., can solve the problems of low production efficiency, inconvenient assembly, repair and disassembly, and complicated processes, so as to improve production efficiency and meet market demands. Demand and customer preference, the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

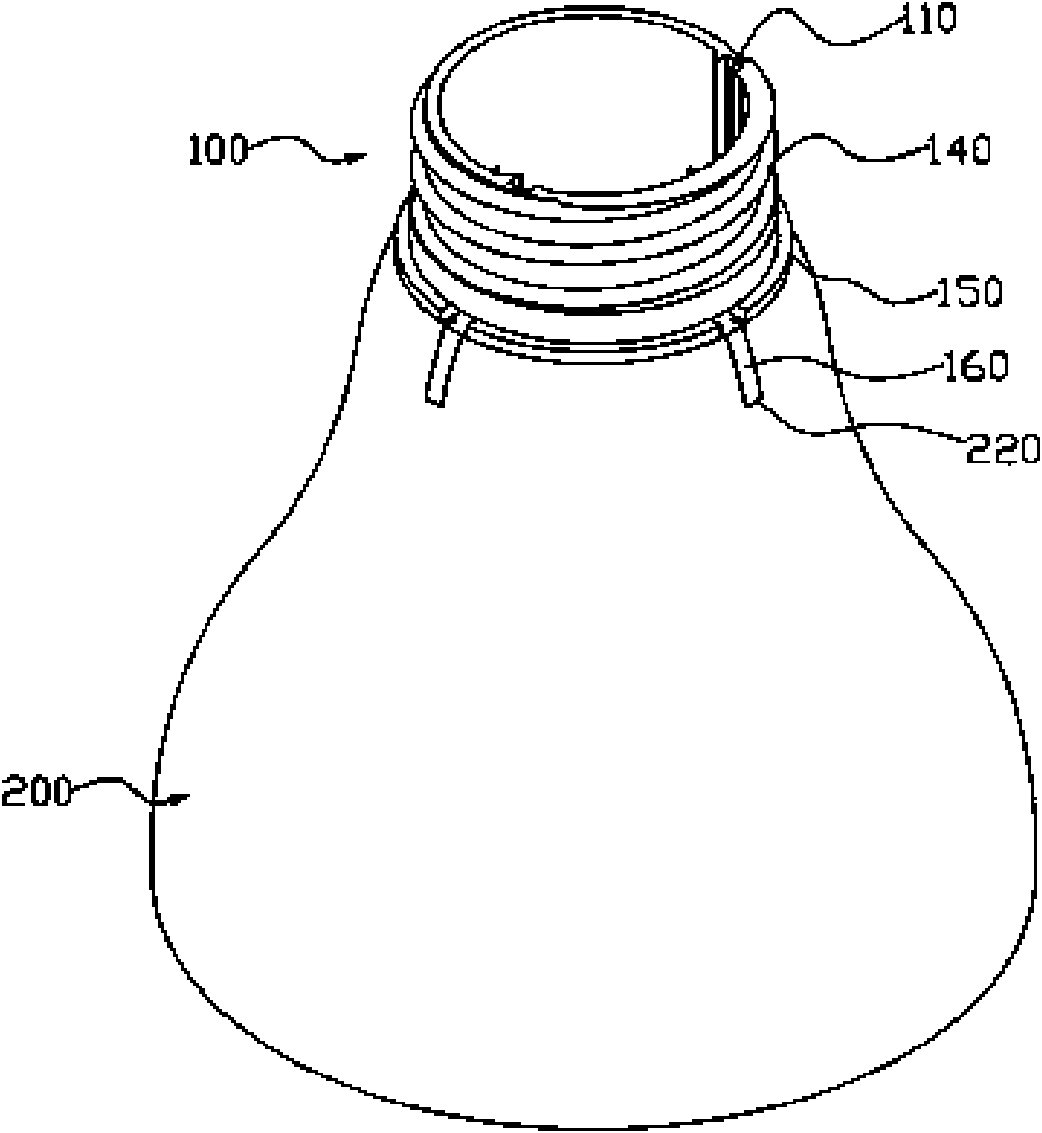

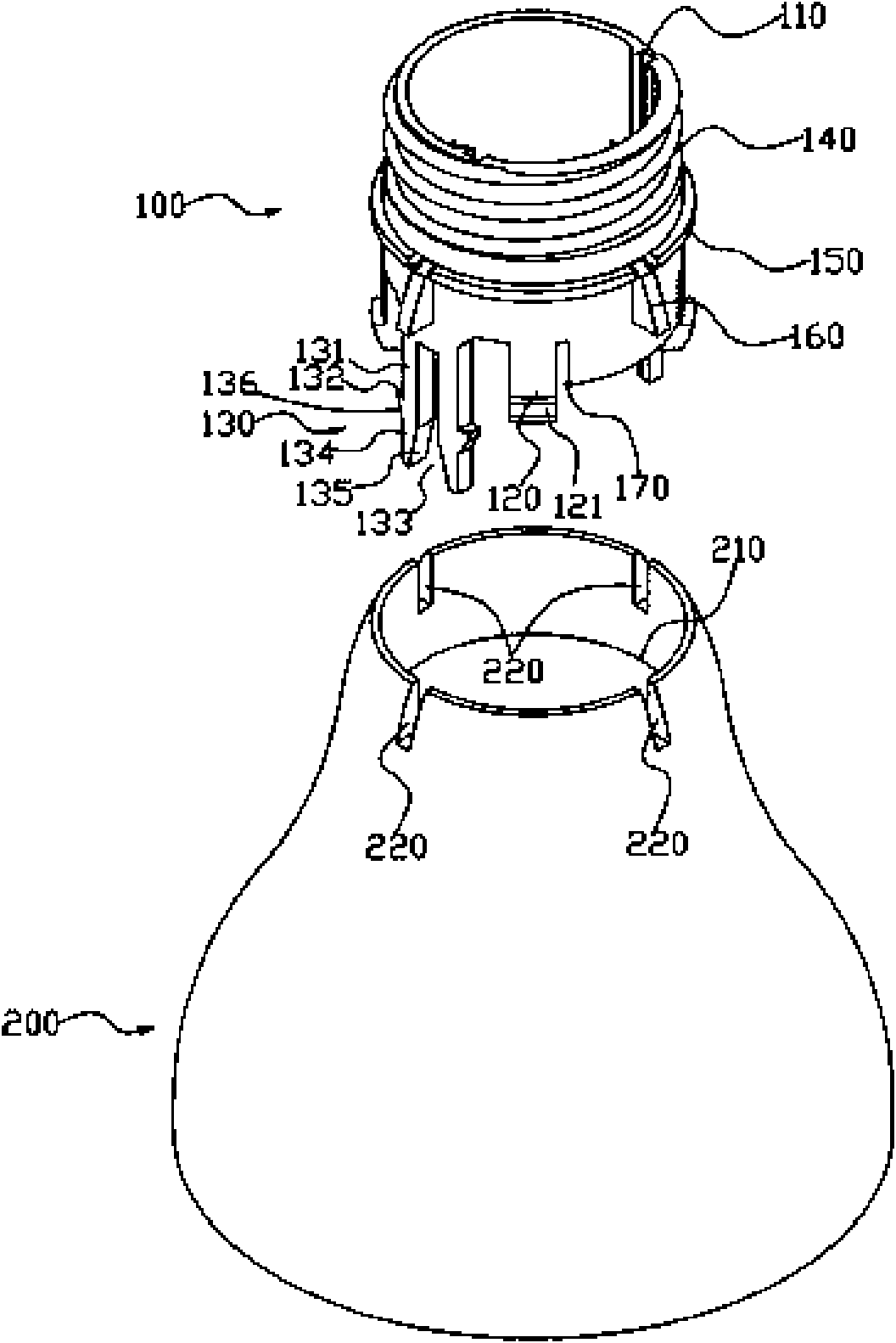

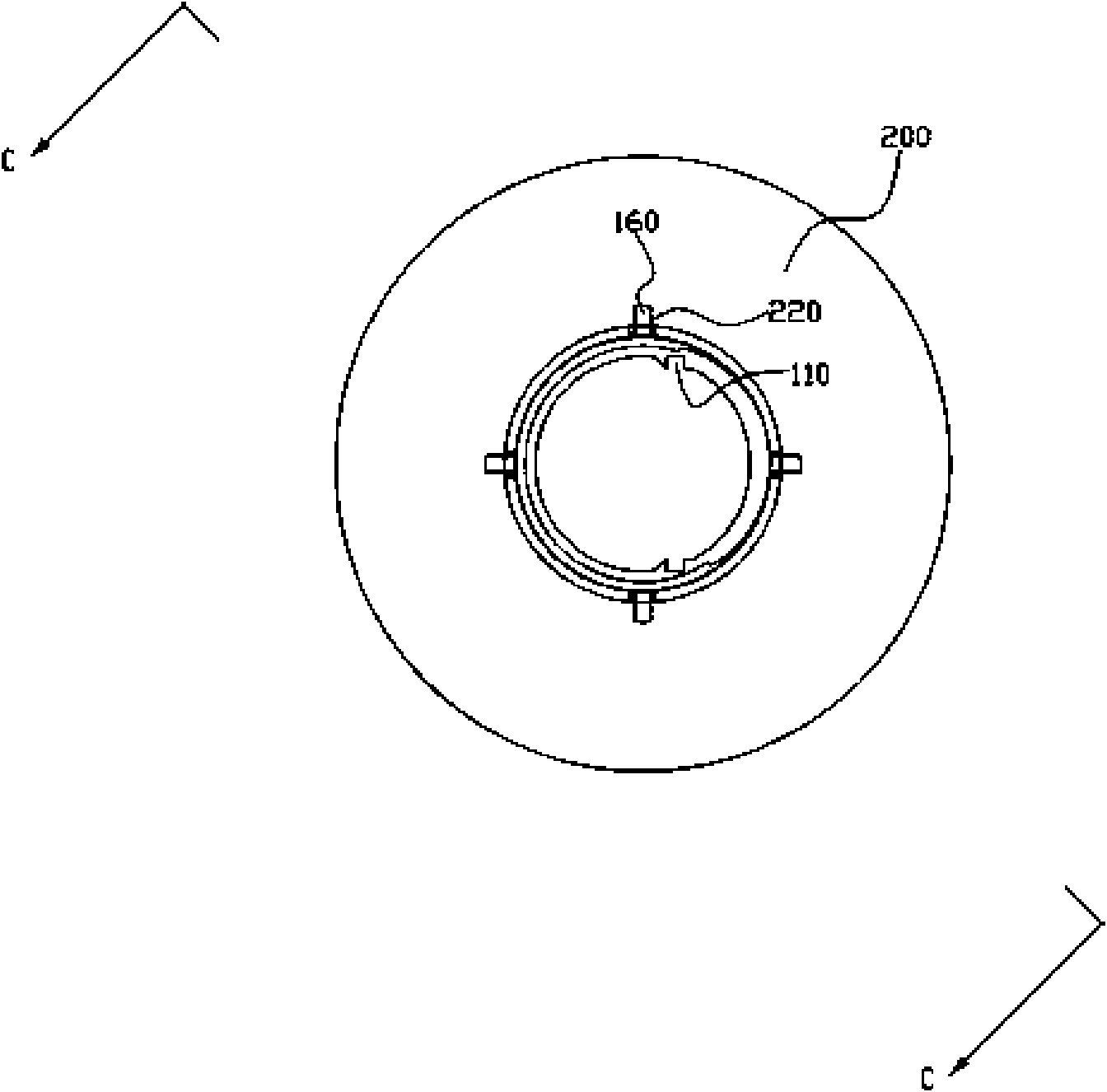

[0043] Please check figure 1 , figure 2 , Figure 8 , Figure 9 , Figure 10 , an energy-saving lamp, which includes an upper plastic shell 100, an upper bulb shell 200, a lower plastic shell 300, a ballast circuit board 400, a lamp tube 500, a lamp holder 600, a lower bulb shell 700, and two conductive Wire. Both the upper plastic case 100 and the lower plastic case 300 are made of plastic material through injection molding or blow molding, and the upper bulb 200 is made of transparent or translucent plastic through injection molding or blow molding. The transparent or translucent plastic is, for example, PC , PMMA, etc.

[0044] Please check figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11, the upper molded case 100 is hollow, and the U-shaped axial groove 110 facing the matching ballast circuit board 400 is opened on the inner turning surface of the hollow hole, so that the bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com