Patents

Literature

49results about How to "Assembly is easy to achieve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

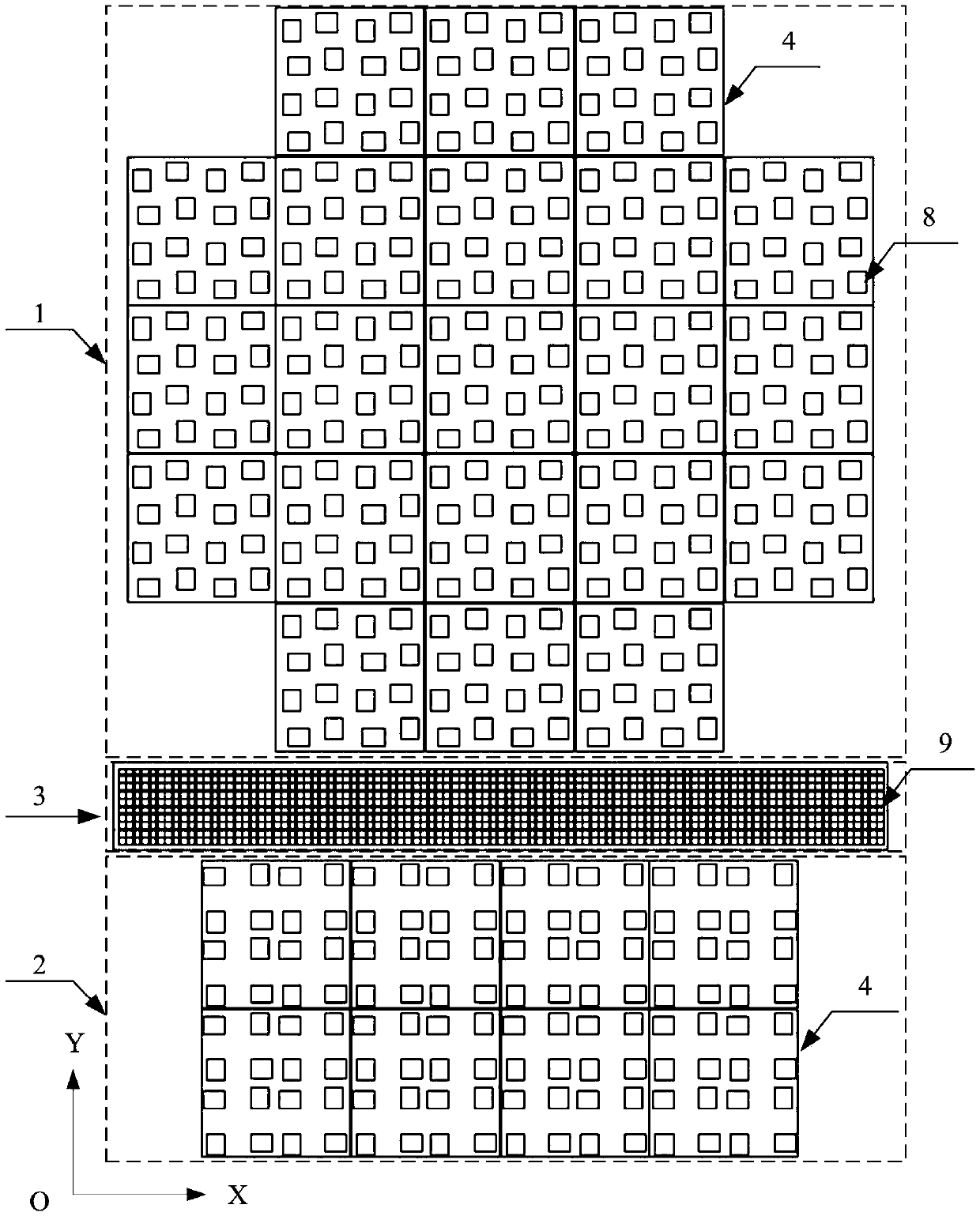

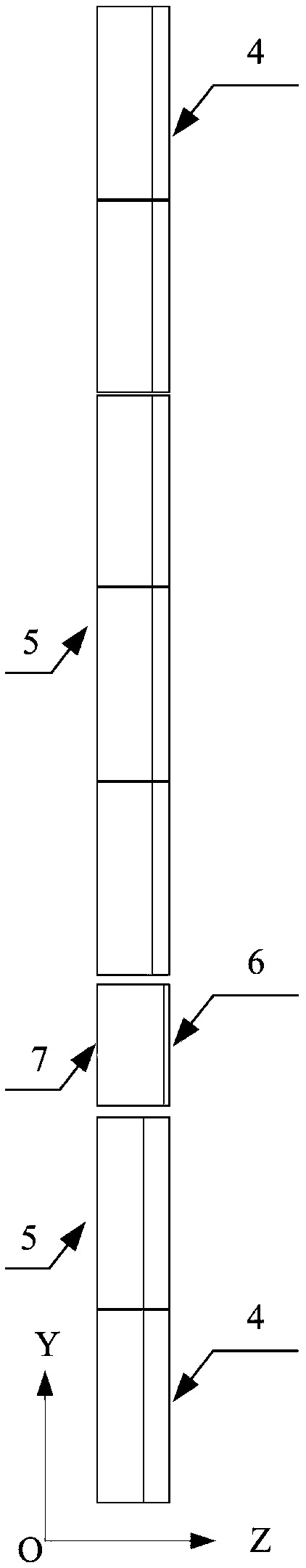

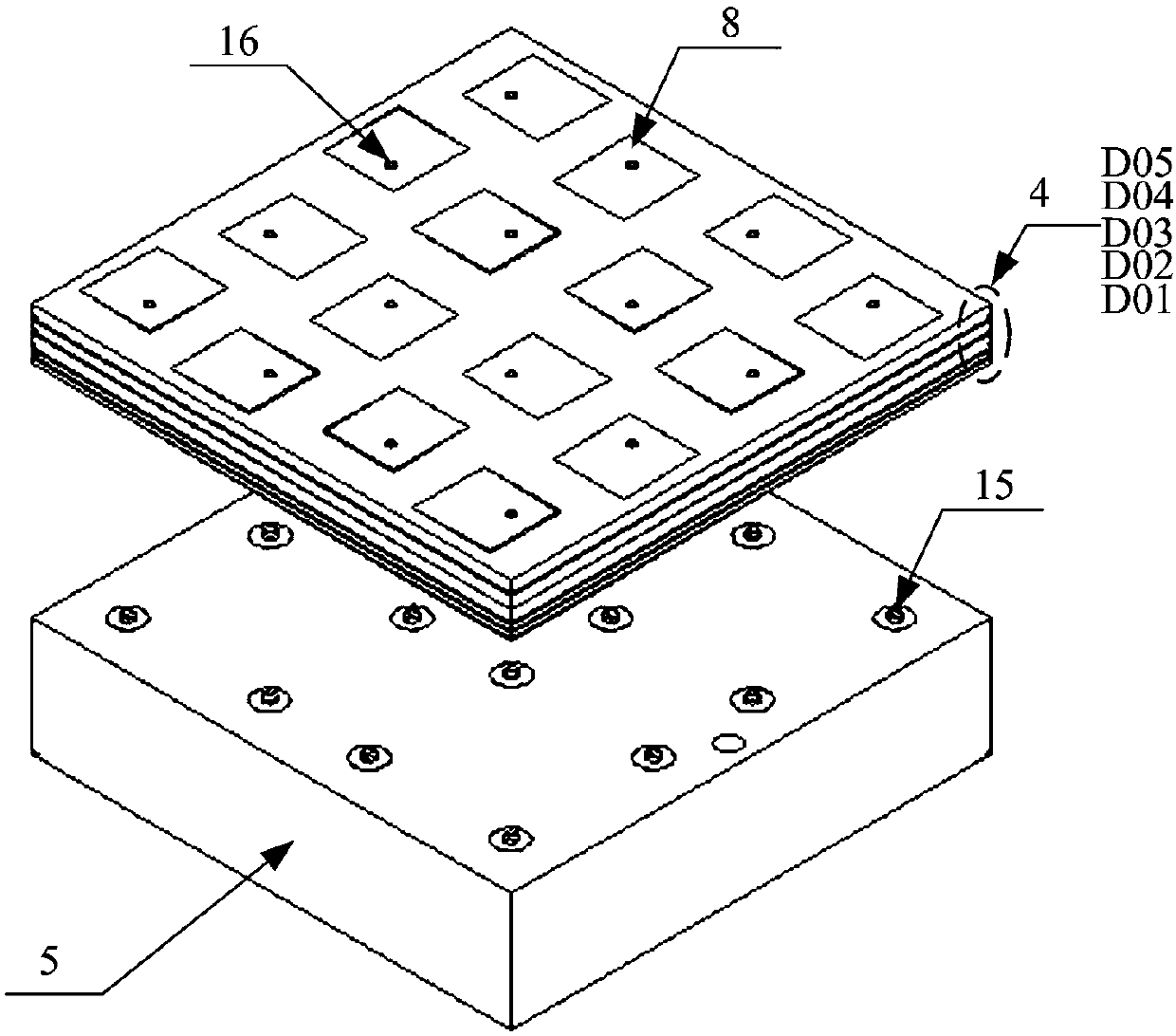

Full-duplex active phased filter antenna array surface

ActiveCN109616759ALow costReduce power consumptionAntenna arraysRadiating elements structural formsRadio frequencyActive phase

The invention discloses a full-duplex active phased filter antenna array surface, and aims at providing an antenna array surface with high-isolation array transmitting and receiving and good filter characteristic. A transmitting antenna array surface of a transmitting array antenna and a receiving antenna array surface of a receiving array antenna consist of a plurality of arrayed radiation units;a multi-layer printed board integrally integrating a radiation circuit, a feed switching circuit and a filter circuit achieves connection between different circuits by vertical interconnection structures of metallized via holes; a metal upper cavity body of a transmitting-receiving component serves as a metal ground; a metal upper cavity body base of a metal floor is consubstantially connected byradio-frequency fuzz button connectors; and then a radiation unit and transmitting-receiving component integrated box-type submatrix module filter antenna unit is formed. With the adoption of the full-duplex active phased filter antenna array surface, high-isolation array transmitting and receiving can be achieved; insertion losses of array transmitting and receiving can be reduced; and high-precision amplitude and phase control can be achieved.

Owner:10TH RES INST OF CETC

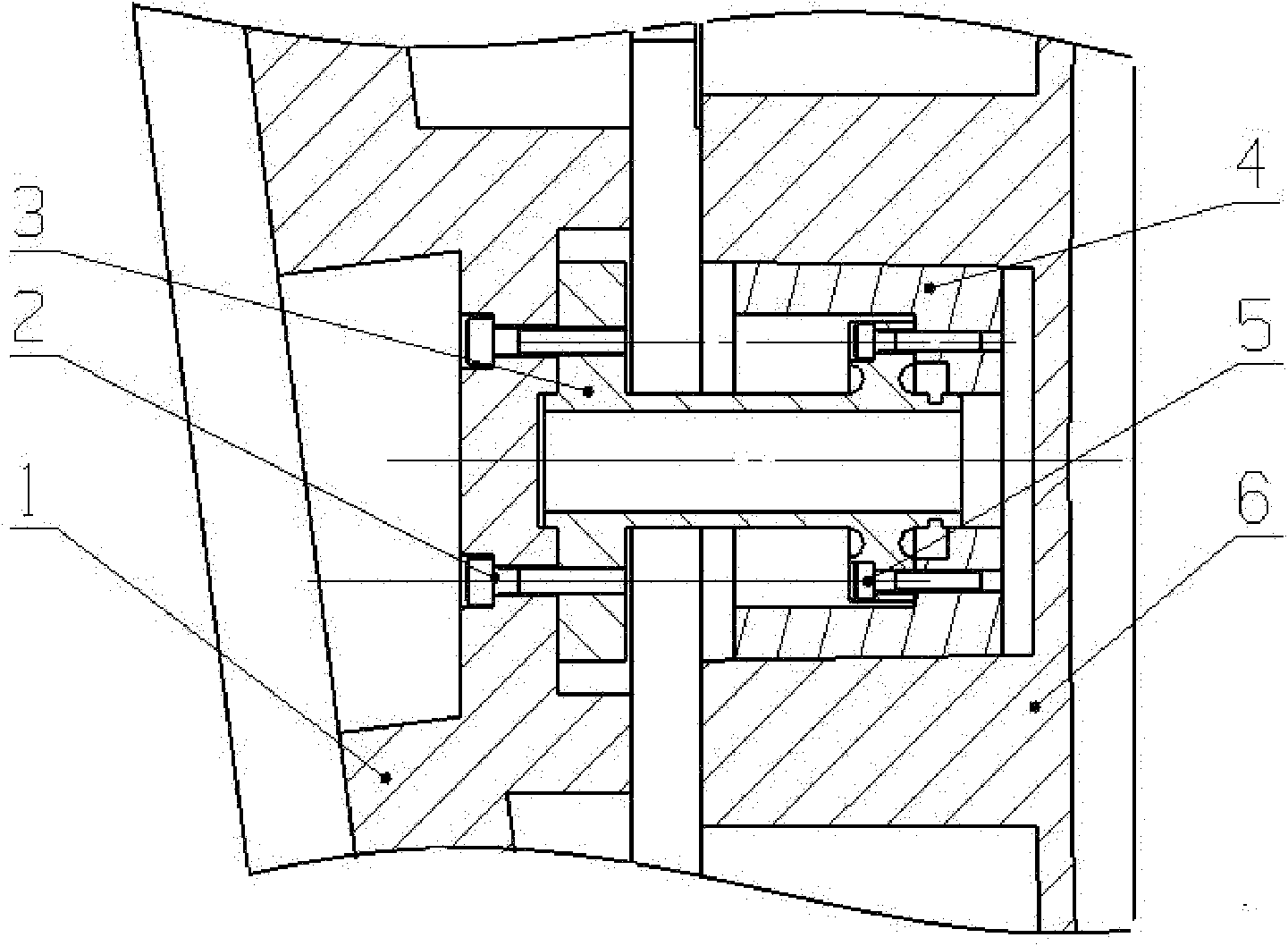

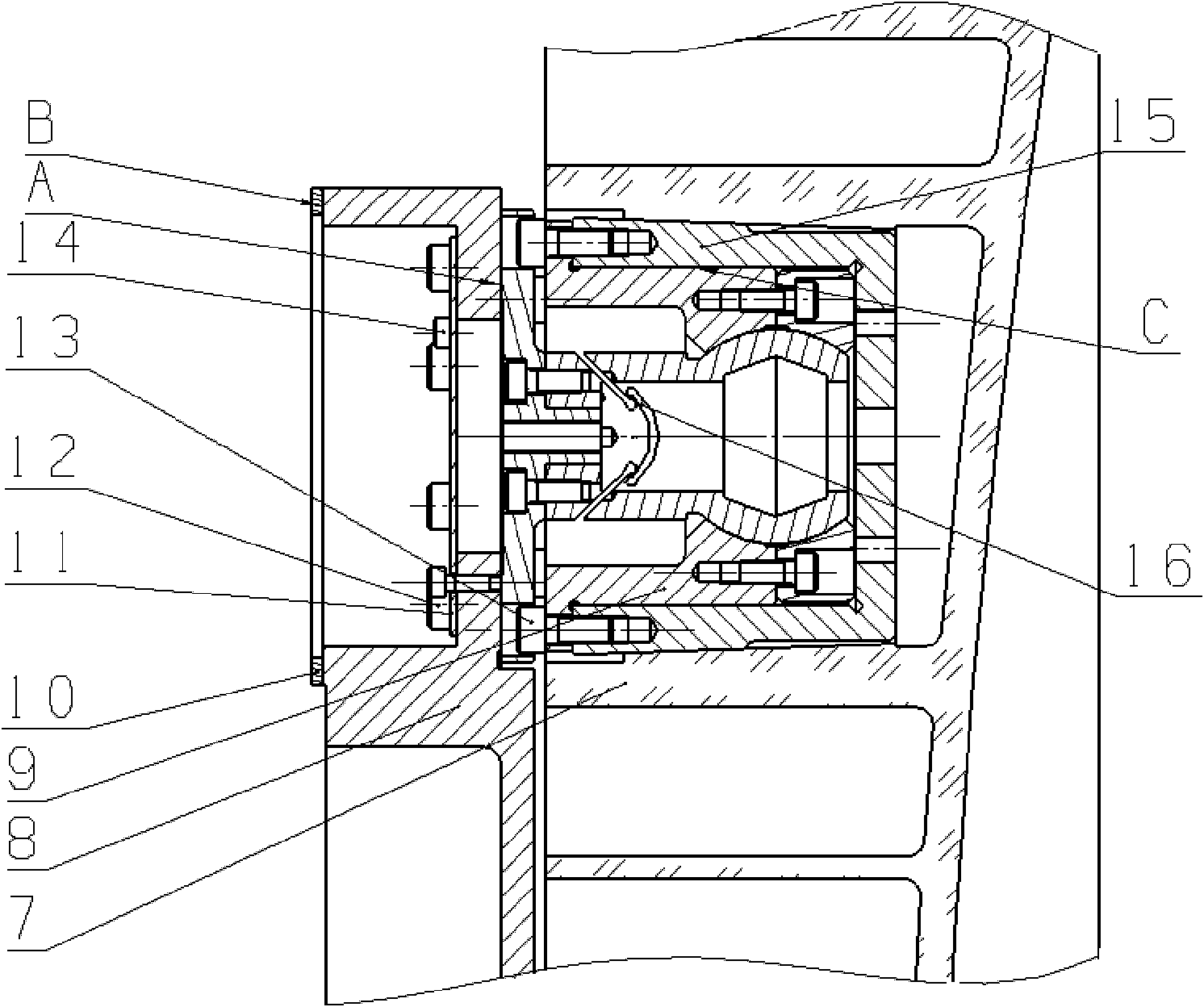

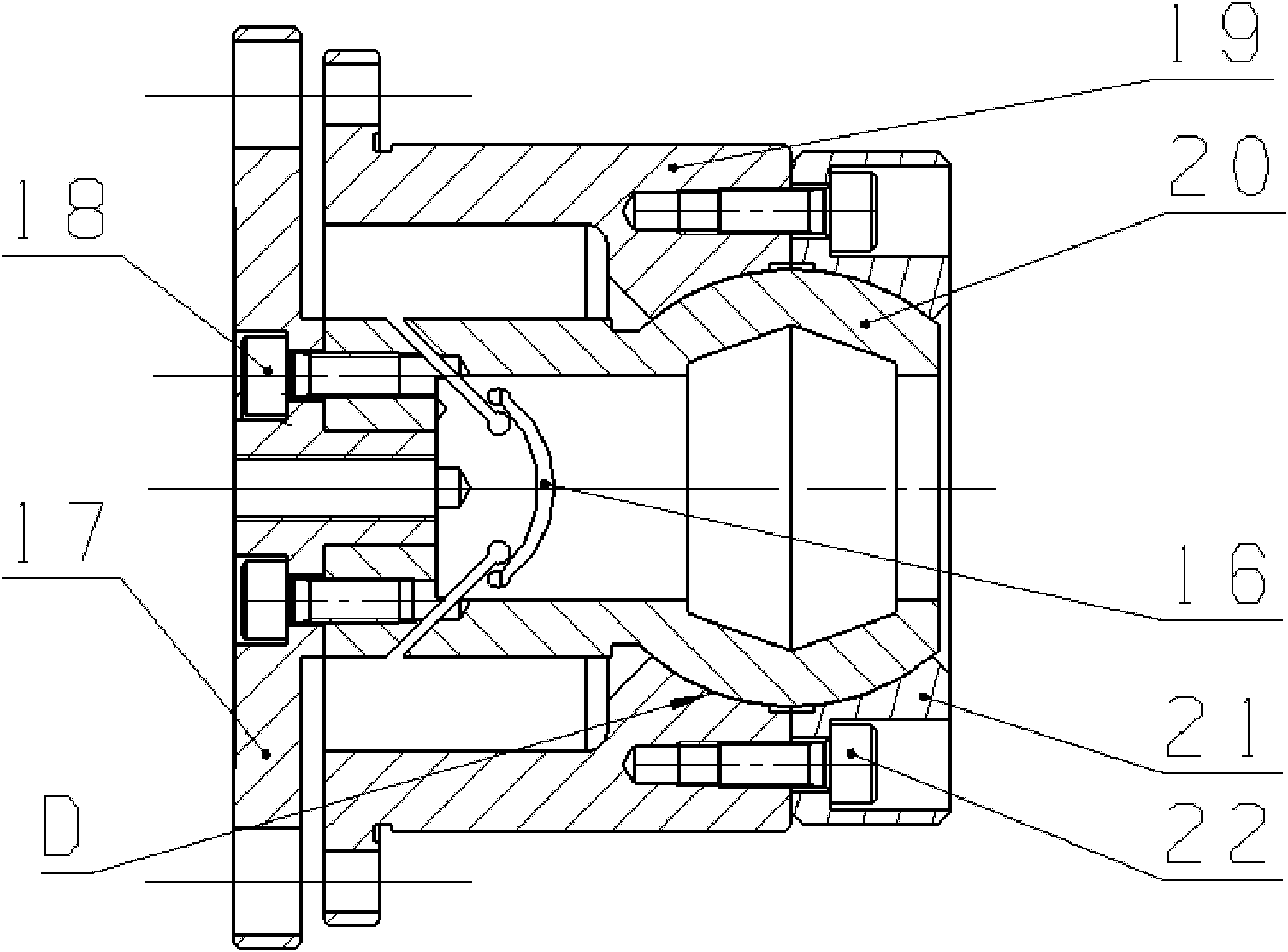

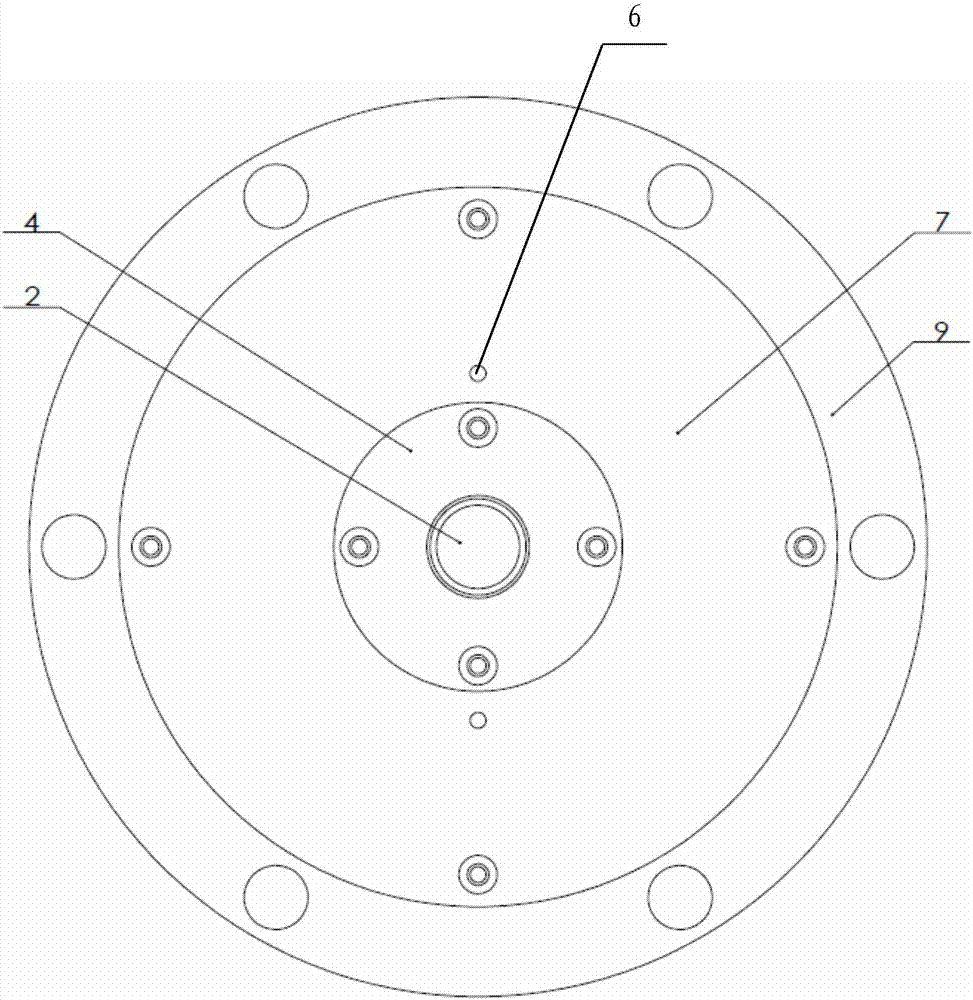

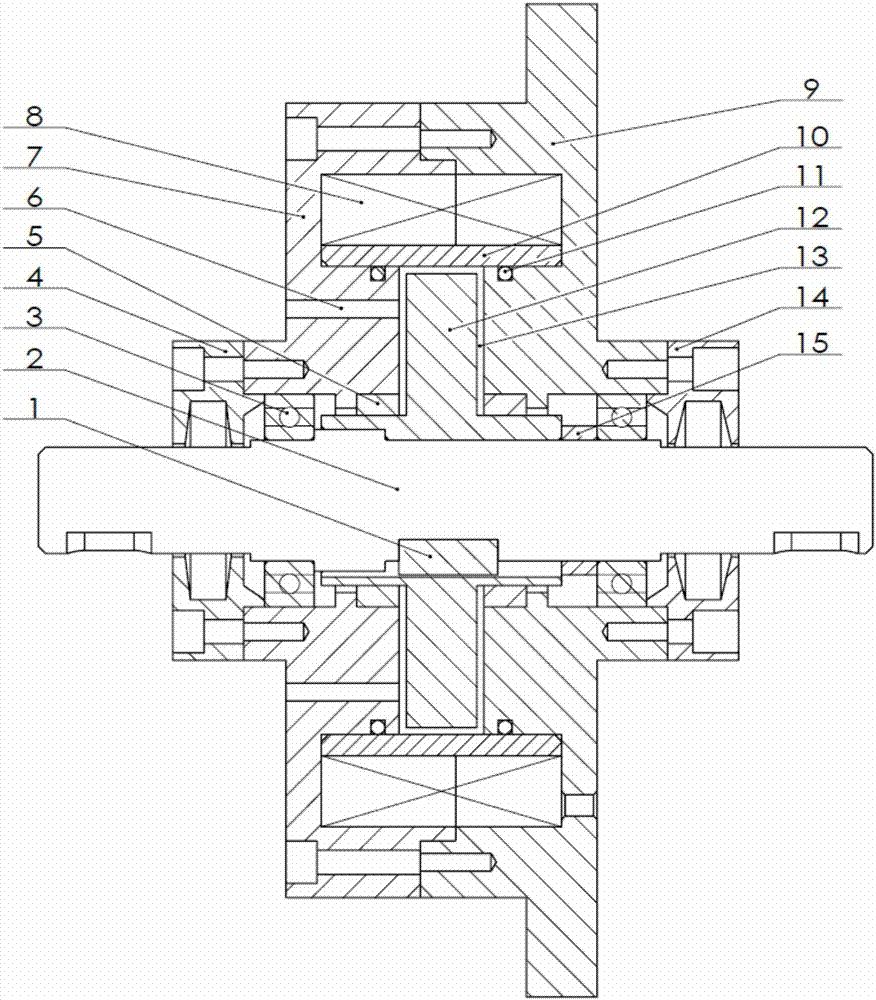

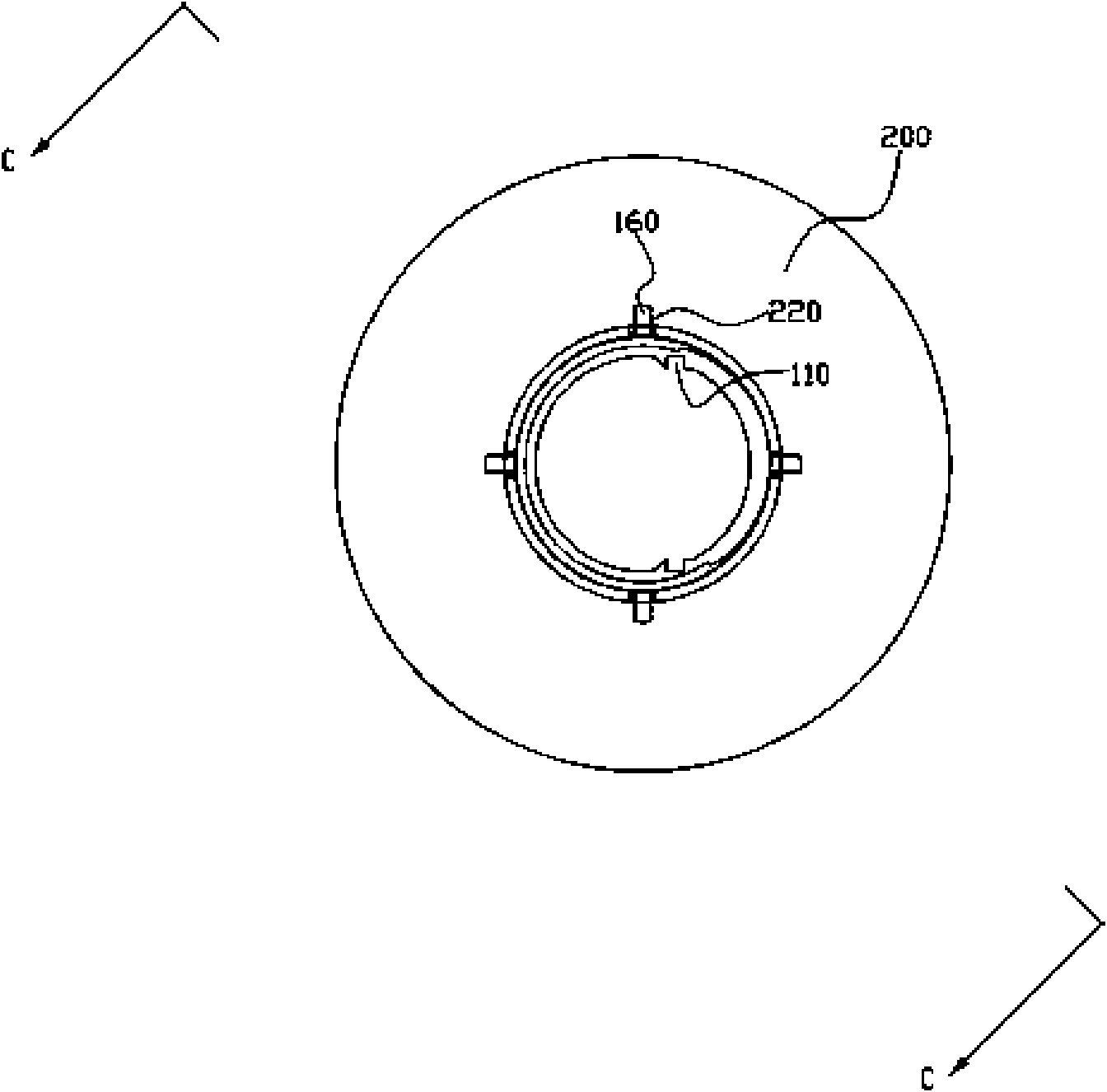

Ball hinge support structure of large caliber reflector of space remote sensor

InactiveCN102109657AAvoid assembly stressAssembly is easy to achieveWave based measurement systemsMountingsBackplaneCaliber

A ball hinge support structure of a large caliber reflector of a space remote sensor belongs to the technical field of space remote sensors, relates to a ball hinge support structure, and aims to provide the ball hinge support structure of the large caliber reflector of the space remote sensor. The invention adopts the technical scheme that the ball hinge support structure comprises a connecting flange, an upper bearing support, a lower bearing support, a ball rod, a ball rod grooves, cylindrical pins, a taper sleeve, a reflecting mirror, a back panel, and the like, wherein an end of the ball hinge adjacent to the flange is a cylinder-shaped structure; four grooves are formed on the ball rod at intervals; a ball head at the other end of the ball rod is a spherical cavity; the rod end of the ball rod is connected with the flange through a screw and the cylindrical pin; the flange is connected with the back panel through a screw; the upper bearing support, the ball head of the ball rod and the lower bearing support are assembled together through a screw and the cylindrical pin; the upper bearing support is connected with the taper sleeve through a screw; and glue is used for gluing the taper sleeve and the reflecting mirror. By the adoption of the ball hinge support structure, the temperature stress and the assembly stress caused by different linear expansion coefficients of materials are unloaded, the vibration is reduced, and the reflecting mirror shape accuracy and the imaging quality are ensured.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

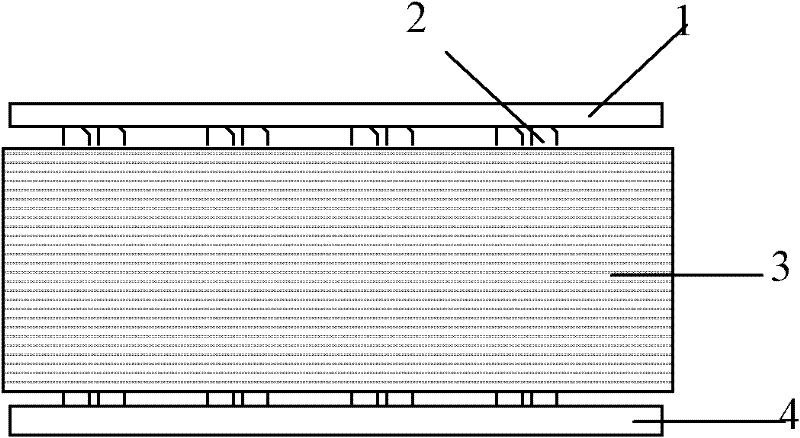

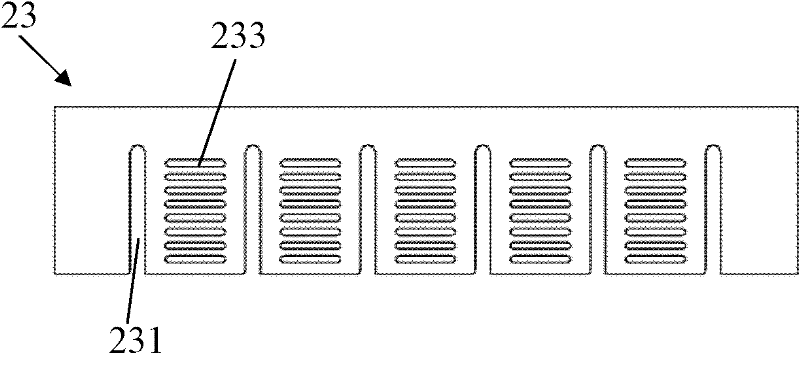

Flat pipe heat exchanger and assembly method thereof

InactiveCN102192674ASimple structureEasy to processAssembly machinesTubular elementsEngineeringFlanging

The invention discloses a flat pipe heat exchanger. The flat pipe heat exchanger comprises fins provided with pipe channel slots, and flat pipes which are fixedly connected with the fins; each pipe channel slot is U-shaped; the pipe channel slots are provided with flangings; and the side wall of the flat pipe is provided with fixed inclined sides corresponding to the flangings. The invention also discloses an assembly method of the flat pipe heat exchanger. The method comprises the following steps of: 1) fixing the flat pipes at intervals corresponding to the pipe channel slots; 2) horizontally pushing the fins into the flat pipes; 3) clamping the fixed inclined sides by using a clamping device to ensure that the fixed inclined sides are tightly connected with the flangings; 4) continuously inserting the next fin; and 5) connecting two ends of the flat pipes and an inlet collecting pipe and an outlet collecting pipe respectively to finish assembly. The flat pipes are inserted in the horizontal direction, the travel of the flat pipes are shortened, one fixed inclined side is formed on the surface of each flat pipe aiming at each fin, the fixed inclined sides can clamp the flangings of the fins by using the clamp device to ensure the contact areas between the fixed inclined sides and the flangings, high and uniform heat radiation effect is achieved, and product performance is improved.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

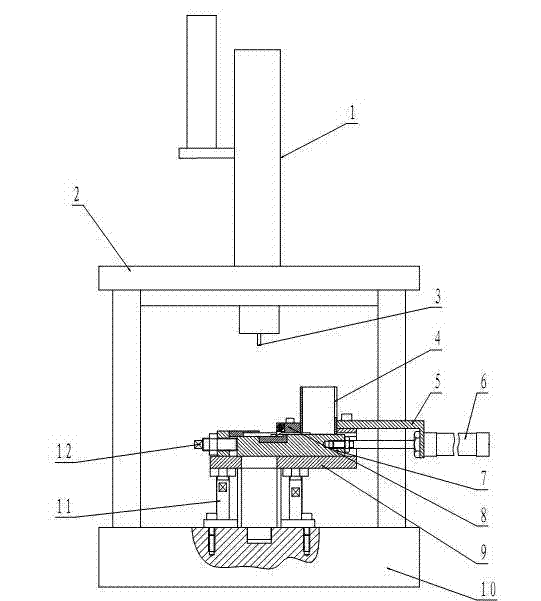

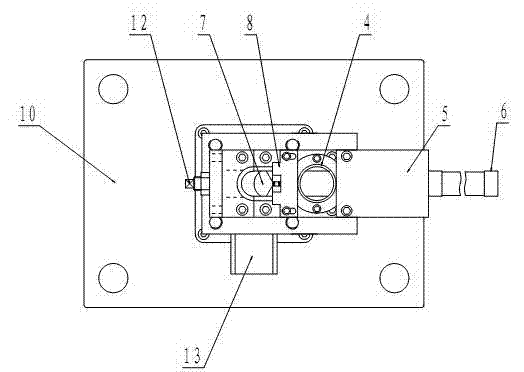

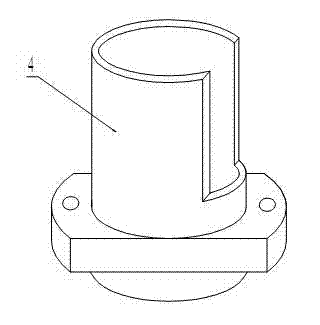

Automatic mark punching machine

InactiveCN103240317AReduce equipment cost investmentImprove space utilizationMetal-working feeding devicesPositioning devicesSlide plateAutomation

An automatic mark punching machine is used for solving problems of poor safety performance and low work efficiency in a product mark punching procedure. The automatic mark punching machine comprises a fixing mounting seat, a mark punching actuating mechanism, a loading and unloading mechanism and a PLC (programmable logic control) system. The fixing mounting seat comprises a base, height adjusting upright columns, a working platform, a charging slide plate and a gantry, the loading and unloading mechanism is assembled with the working platform, the charging slide plate is arranged obliquely, the upper end of the charging slide plate is fixedly assembled with the working platform, and the mark punching actuating mechanism is mounted on the gantry. The automatic mark punching machine has the advantages of high automation degree, small occupied space and low manufacturing cost, the labor intensity and personal injury risks of operators can be reduced, and the work efficiency is obviously improved.

Owner:BAODING GREAT MACHINERY CO LTD

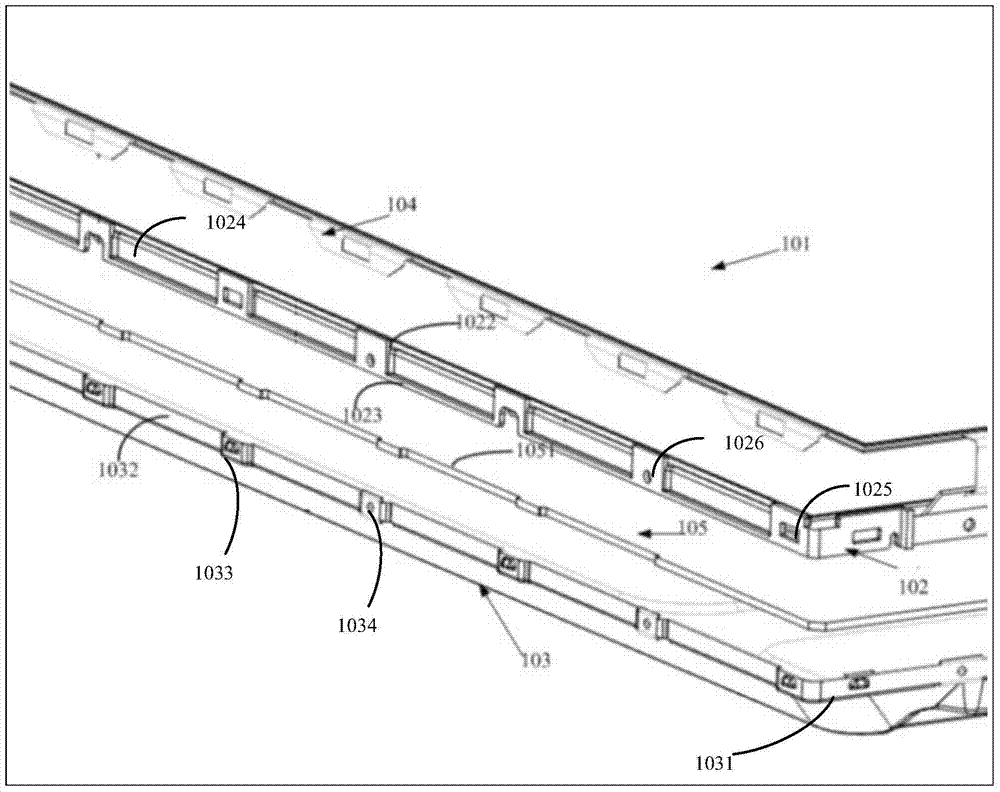

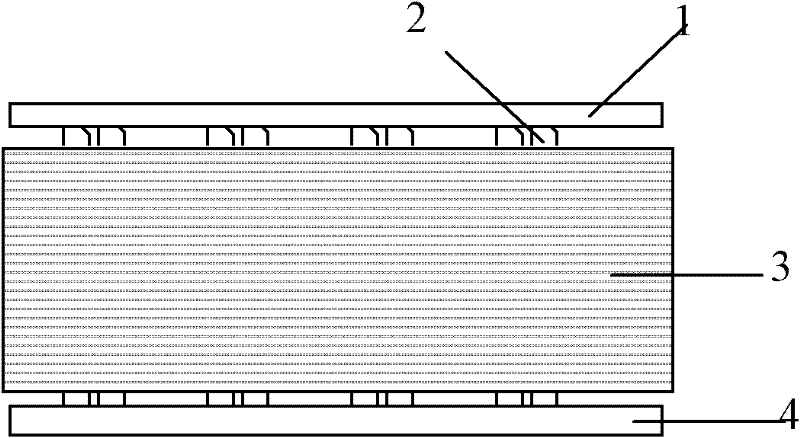

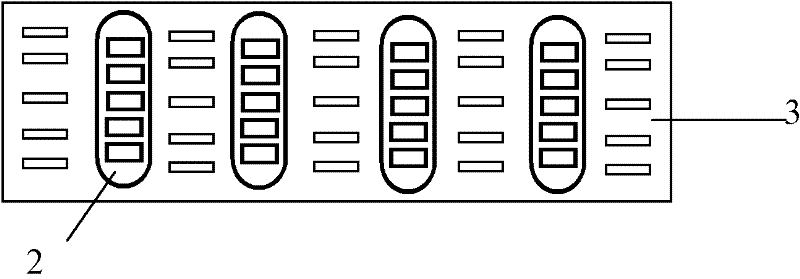

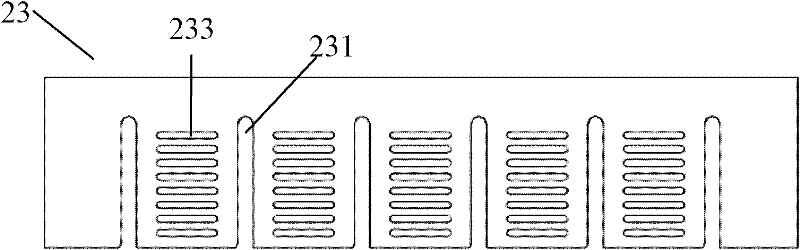

Liquid crystal display module and display device

ActiveCN104503109AImprove stabilityAssembly is easy to achieveStatic indicating devicesNon-linear opticsLiquid-crystal displayFlexible circuits

The invention discloses a liquid crystal display module and a display device. A notch is formed in the position, corresponding to the place where a flexible circuit board is formed in a liquid crystal display panel, of a limiting part, wherein the flexible printed circuit board stretches out through the notch and is bended towards a connecting part; meanwhile, a first concave part for accommodating the flexible printed circuit board is arranged at the position, corresponding to the notch, of the connecting part; a second concave part sunken inwards is arranged at the position, corresponding to the first concave part, of a folded side, so that the first concave part is matched with the second concave part. With adoption of the series of matched structures, the flexible printed circuit board can be accommodated well, the matching among the structural parts is realized through the first concave part and the second concave part, and the stability of the liquid crystal display module is improved.

Owner:HISENSE VISUAL TECH CO LTD

Rotary magnetorheological damper

InactiveCN107035807AAchieving semi-active controlGood vibration reduction effectSpringsNon-rotating vibration suppressionSemi activeDamping torque

The invention relates to a damper, in particular to a rotary magnetorheological damper. The left and right sides of a shell are tightly connected with left and right end covers; a rotating shaft penetrates through the left and right end covers and the shell in sequence, and is rotationally connected with the shell; a damping disc piece is accommodated in the shell, and rotates along with the rotating shaft; a damping gap is formed between the damping disc piece and the inner surface of the shell; the shell is provided with an injection hole for communicating with the damping gap and injecting magnetorheological fluid in the damping gap; the magnetorheological fluid in the damping gap is sealed through an oil seal arranged between the rotating shaft and the shell; a copper ring positioned at the outer periphery of the damping disc piece is arranged in the shell, and is tightly contacted with the shell; a magnet exciting coil is wound on the outer surface of the copper ring; and the control of a damping torque generated to the damper can be realized through the magnet exciting coil. The rotary magnetorheological damper can realize semi-active control of the damping torque, is wide in torque control range, is low in electric energy consumption, and is high in reliability and stability in long-time system working.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

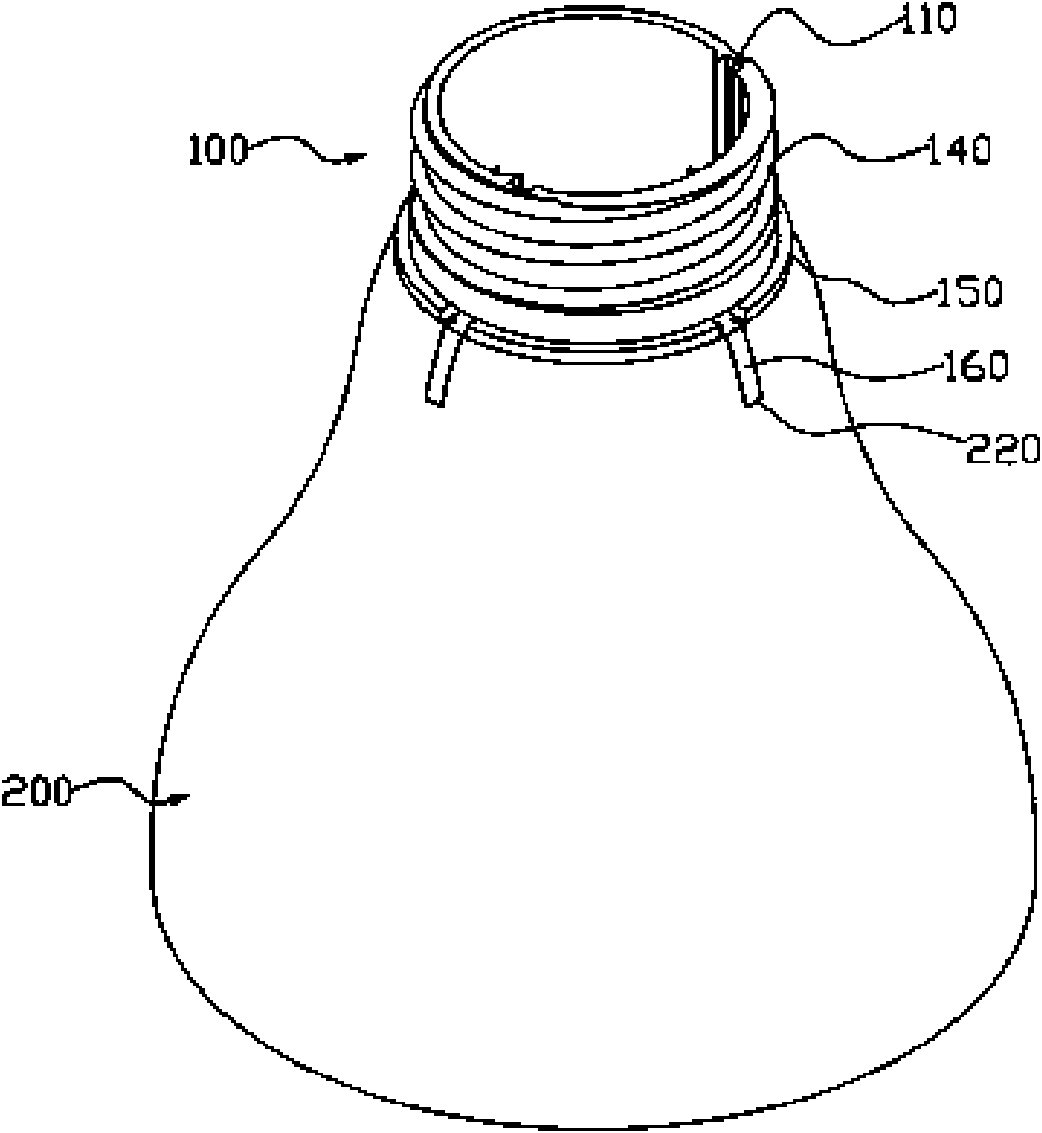

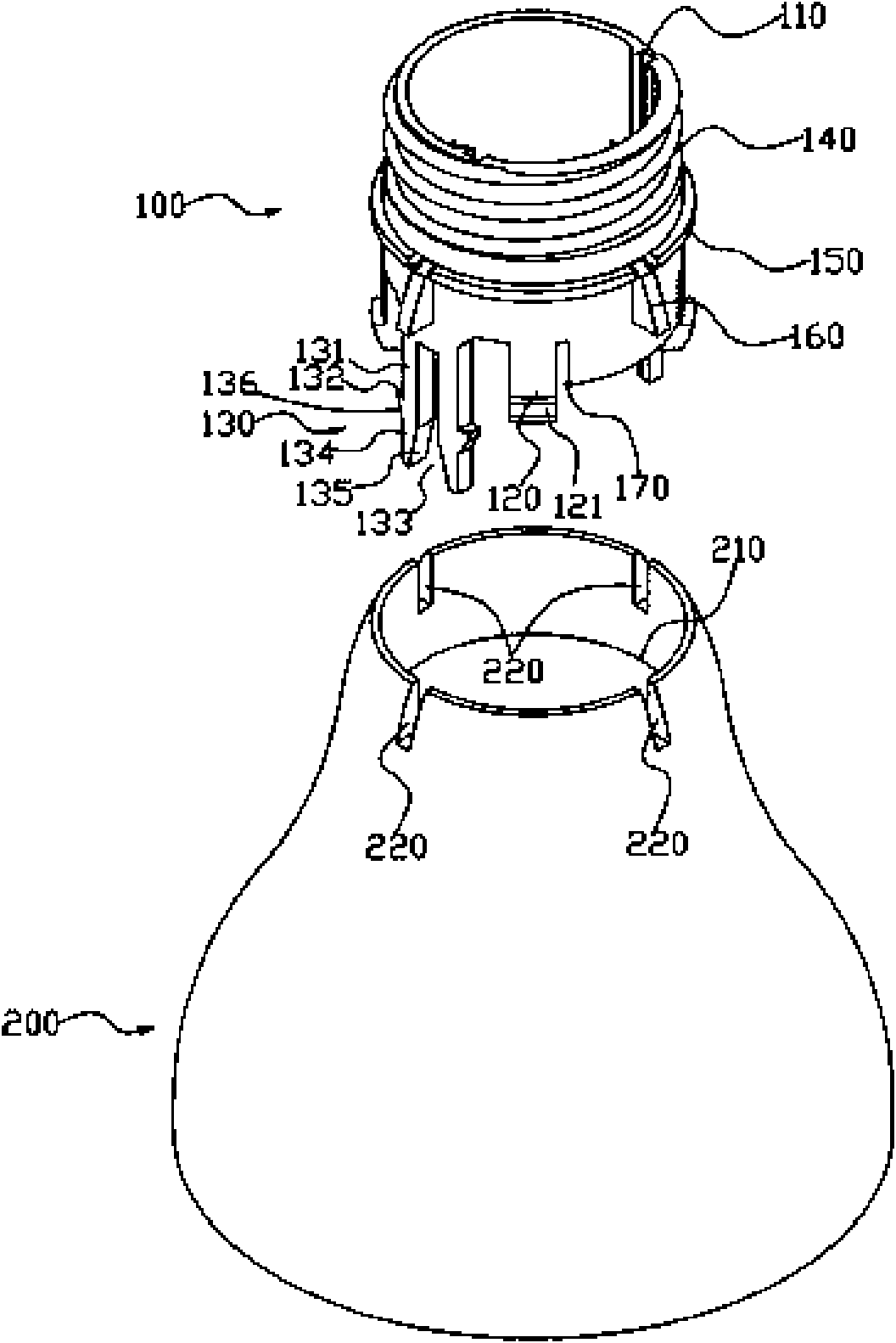

Energy-saving lamp

InactiveCN101988690AReduce defective rateSimple structureElectric discharge tubesProtective devices for lightingEngineeringFlange

The invention discloses an energy-saving lamp. The energy-saving lamp comprises an upper molded case, an upper bulb, a lower molded case, a rectifier and a lamp tube, wherein the lower molded case is positioned in the upper bulb; the rectifier is connected with the upper molded case; the lamp tube is connected with the lower molded case; the upper molded case is provided with a main body and at least two first suspending arms which are arranged on the bottom surface of the main body; the tail ends of the first suspending arms protrude outwards to form clamping flanges; the upper bulb is made of plastic; the upper section of the inner revolution surface of the upper bulb is provided with a positioning step of which the stepped surface faces downwards; and the clamping flanges of the first suspending arms of the upper molded case are clamped on the stepped surface of the positioning step of the upper bulb, so that the upper molded case is fixedly connected with the upper bulb.

Owner:XIAMEN TOPSTAR LIGHTING

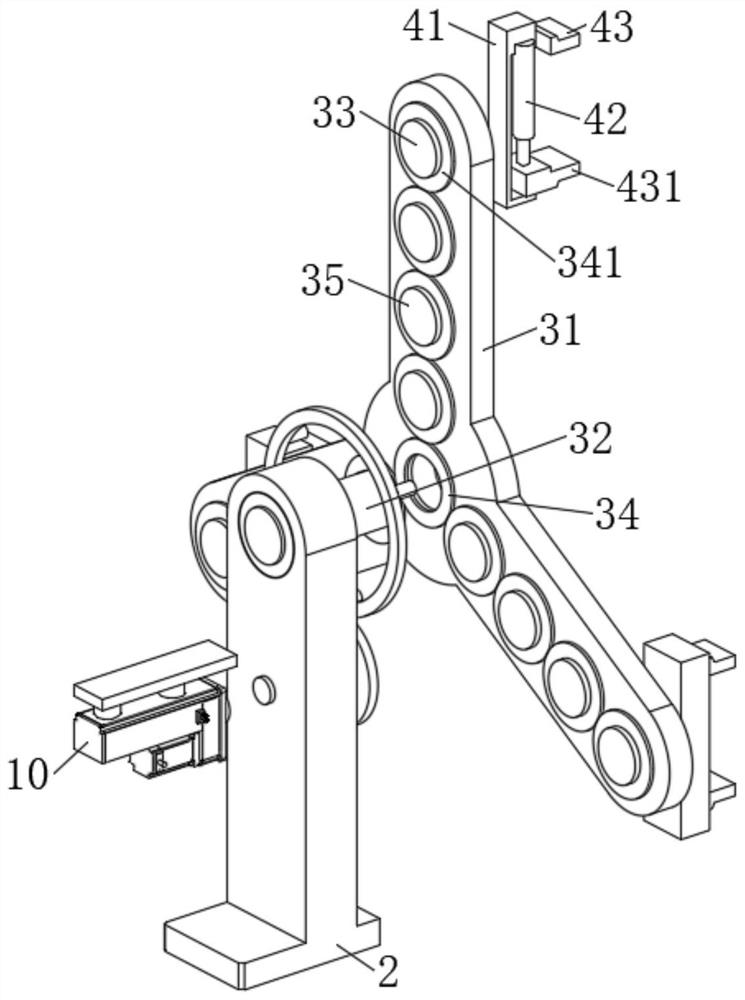

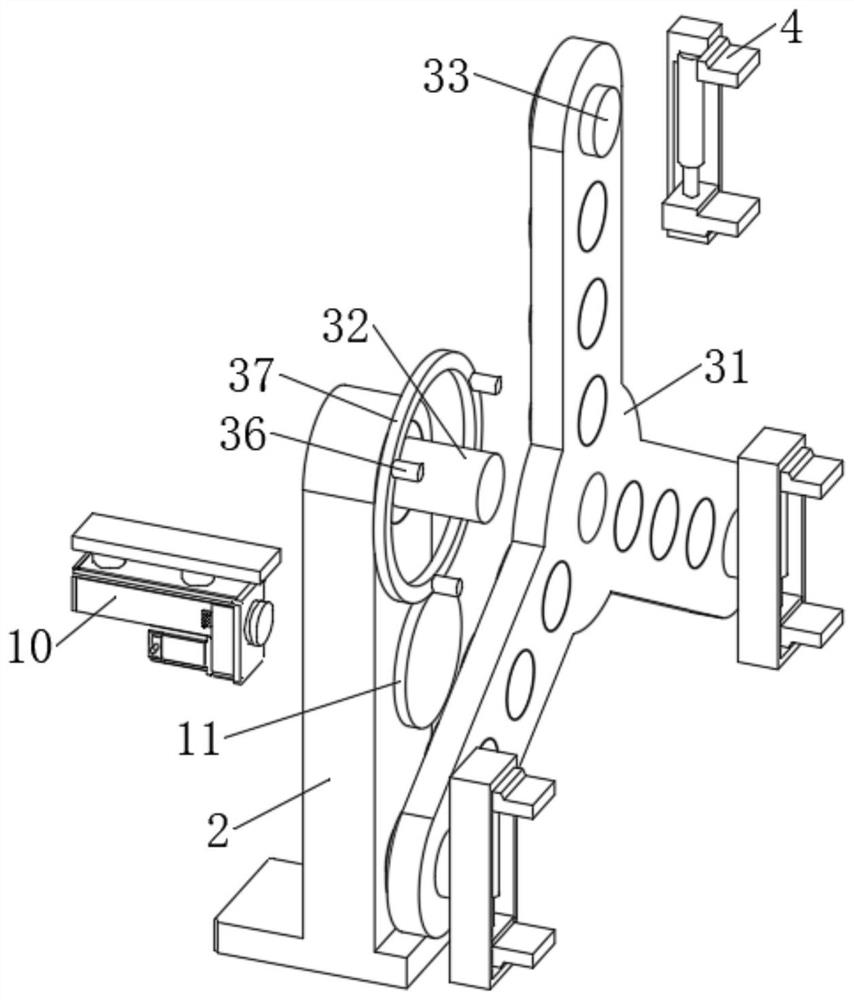

Simple movement mechanism with movement direction capable of changing and working method of simple movement mechanism

PendingCN109434824AEasy to change direction of movementAchieving a change in direction of movementProgramme-controlled manipulatorReciprocating motionEngineering

Owner:FUZHOU UNIV

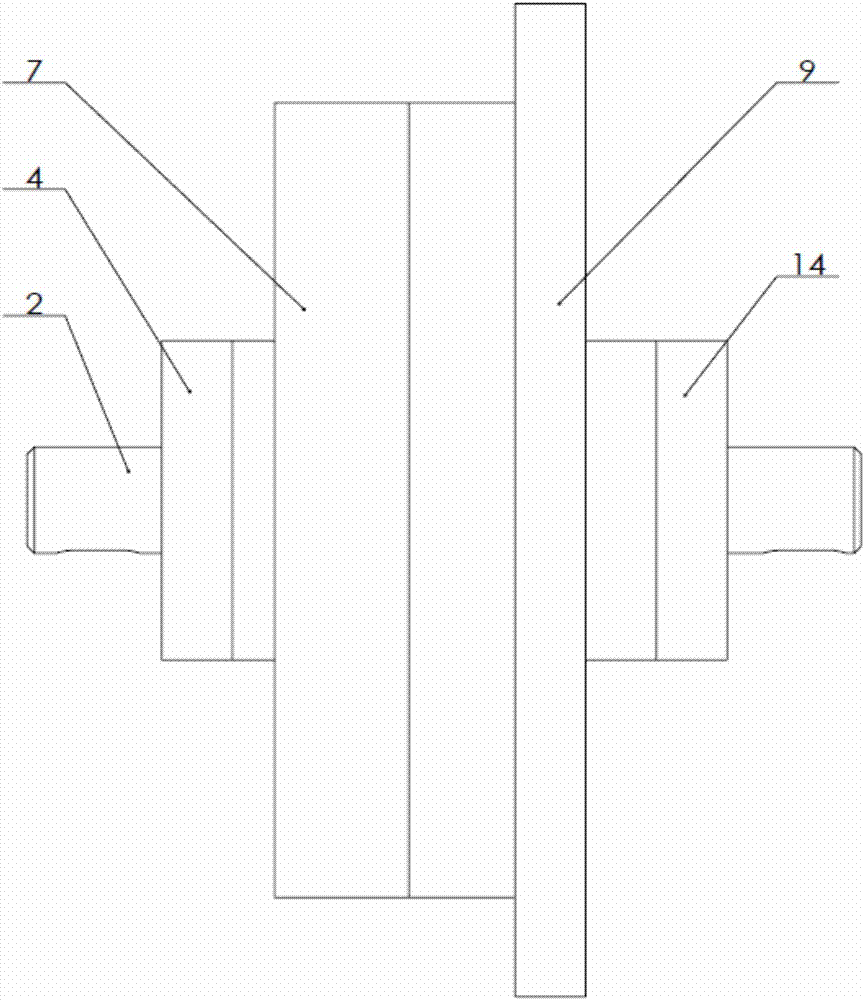

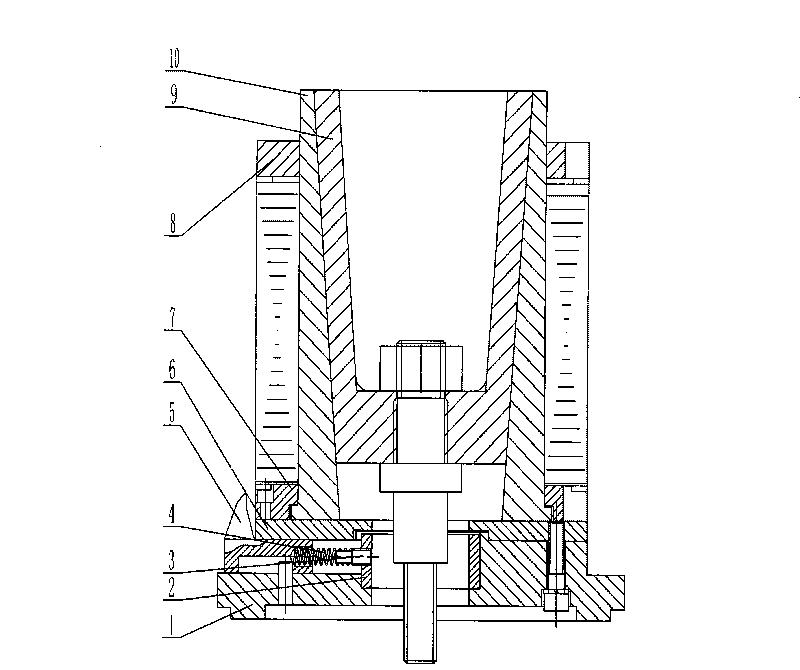

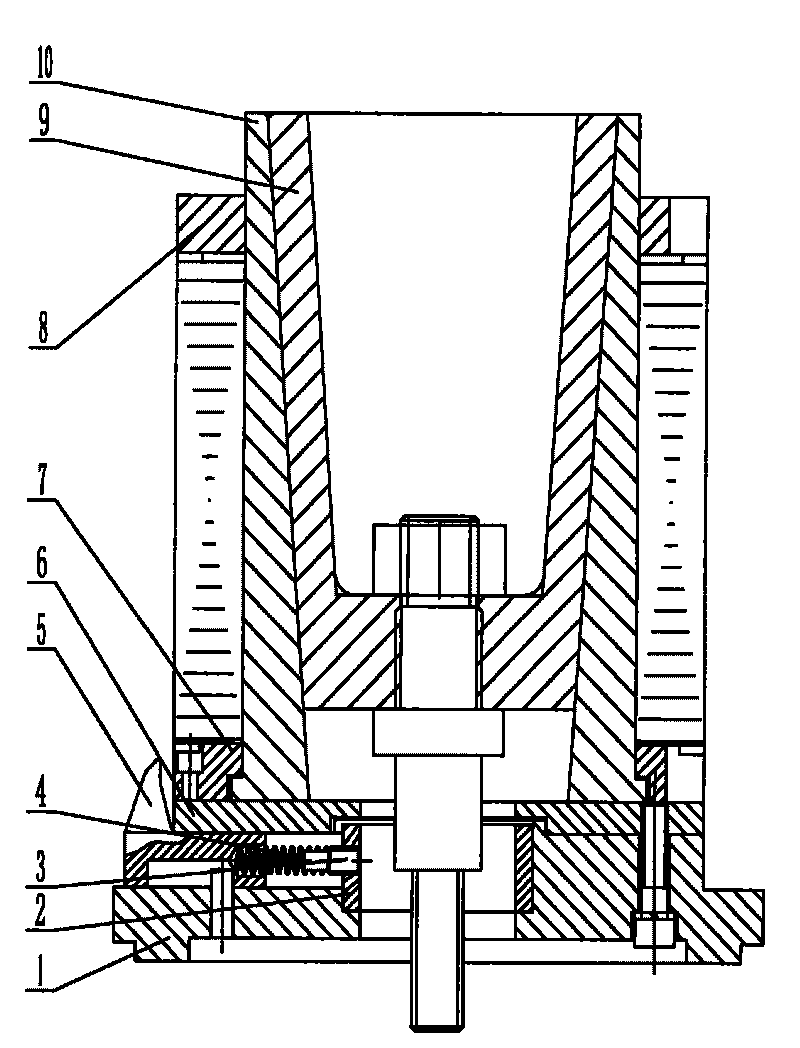

Structure for press mounting stator and rotor

InactiveCN101697441AAssembly is easy to achieveManufacturing stator/rotor bodiesEngineeringConical surface

The invention discloses a structure for press mounting a stator and a rotor, which comprises an inner expansion cylinder and a positioning cylinder, wherein the inner expansion cylinder is assembled in the positioning cylinder and is in conical surface fit with the positioning cylinder; the positioning cylinder is assembled in an upper pressure plate and a lower pressure plate and is fixed on a cover plate through screws on the lower pressure plate; the cover plate is fixed on a base through the screws at a lower part; a mandrel is mounted in the centre of the inner expansion cylinder and runs through the cover plate; a positioning sleeve is mounted outside the mandrel and is positioned between the cover plate and the base; and positioning screws are mounted on the lateral surfaces of the positioning sleeve and are pressed tightly against a slider through a spring. Stress between the inner expansion cylinder and the positioning cylinder is changed into the stress of a whole conical surface due to the conical surface fit; and compared with point stress, the stress of the conical surface is easier to realize assembly and ensure an assembly tolerance, personally is not easy deformed or abraded, can be easily and automatically adjusted and balanced even if the stress of the conical surface is deformed or abraded, and can automatically correct the tolerance.

Owner:WUXI NEW GREAT POWER ELECTRICAL MACHINE

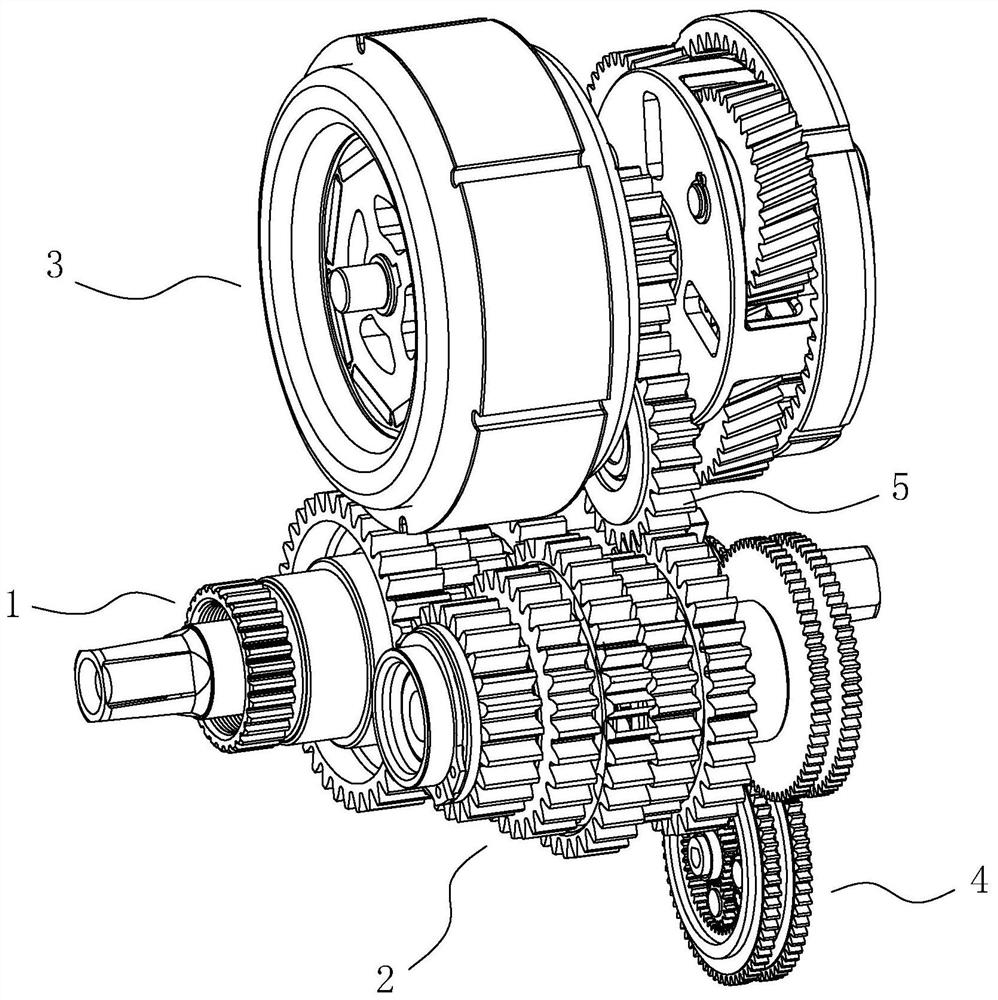

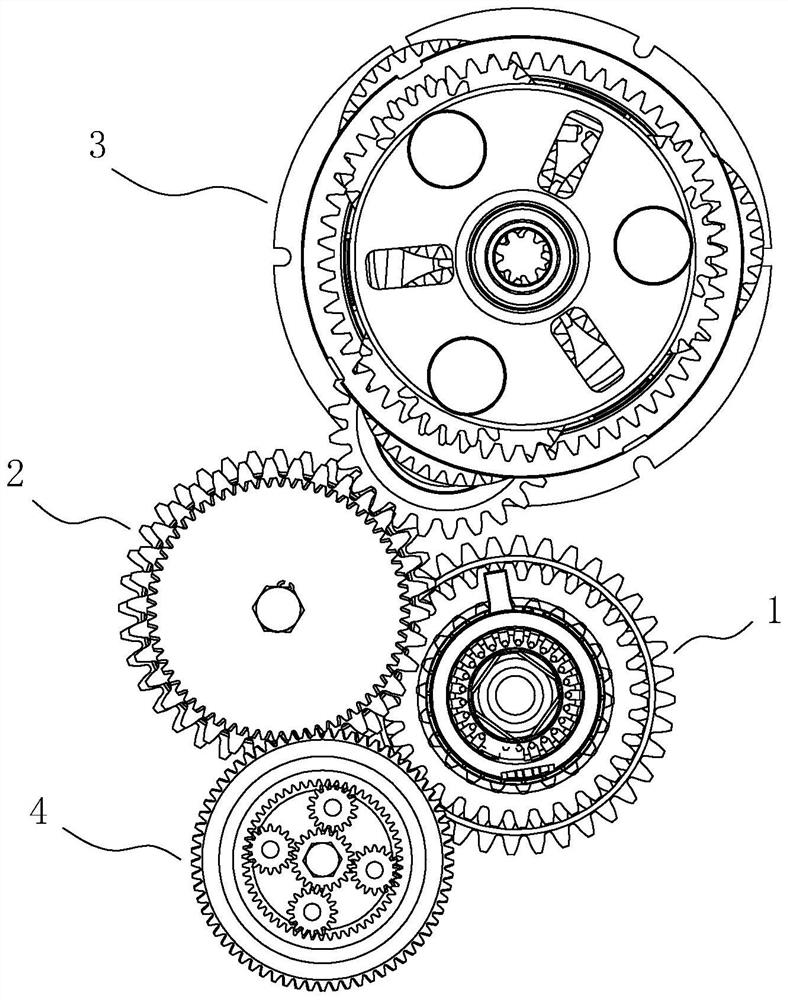

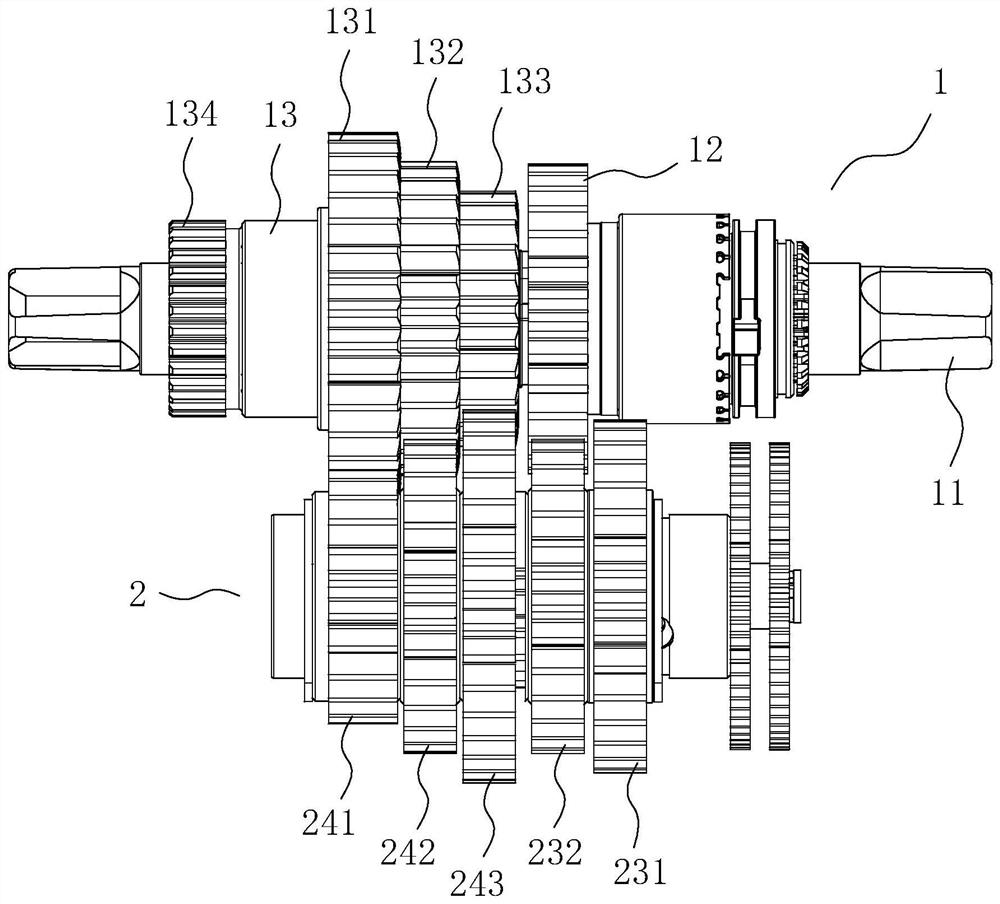

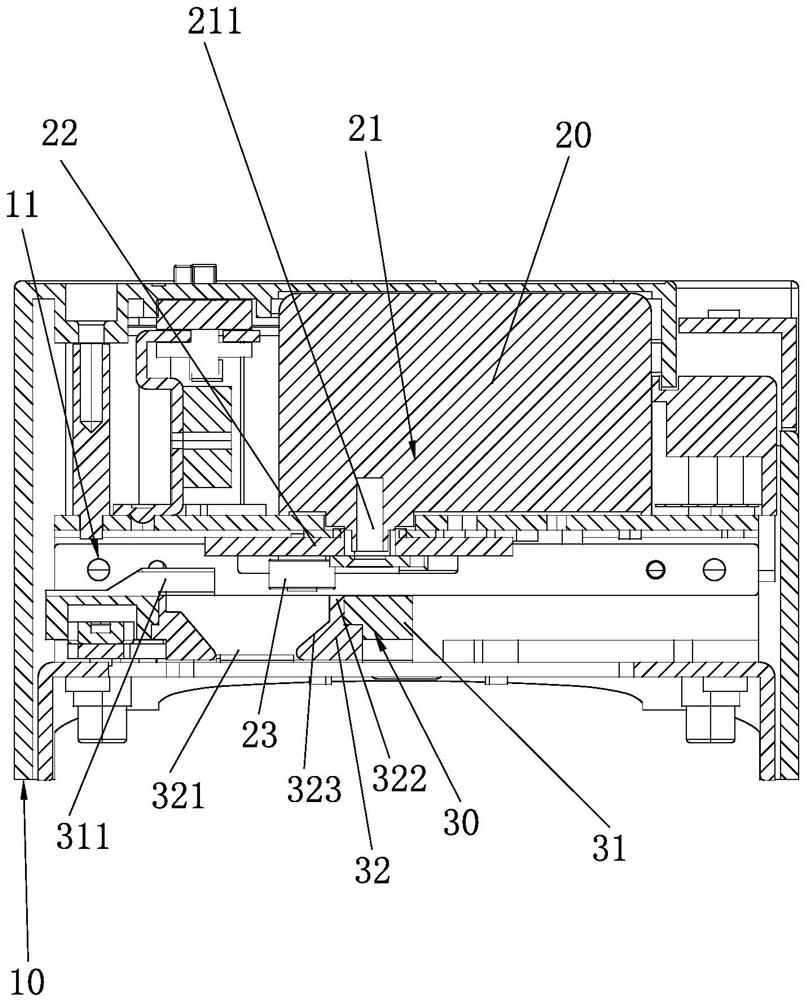

Centrally-mounted variable-speed motor

PendingCN113184106AAssembly is easy to achieveEase of processabilityWheel based transmissionRider propulsionAuto regulationAutomatic control

The invention discloses a centrally-mounted variable-speed motor, and relates to the field of centrally-mounted motors. According to the key points of the technical scheme, the motor comprises a center shaft mechanism, a power-assisted driving mechanism and a speed change mechanism, and further comprises a gear-shifting driving mechanism, and the gear-shifting driving mechanism comprises a rotating speed superposition execution assembly and a gear-shifting motor used for controlling the rotating speed superposition execution assembly. The gear-shifting driving mechanism and the speed change mechanism are separated and then connected in a transmission mode, meanwhile, the gear shifting driving mechanism adopts the gear-shifting motor to achieve automatic adjustment of gears and can be matched with automatic control of the motor, centralized control is achieved, operation of a rider is facilitated, and therefore the riding experience is improved.

Owner:BAFANG ELECTRIC (SUZHOU) CO LTD

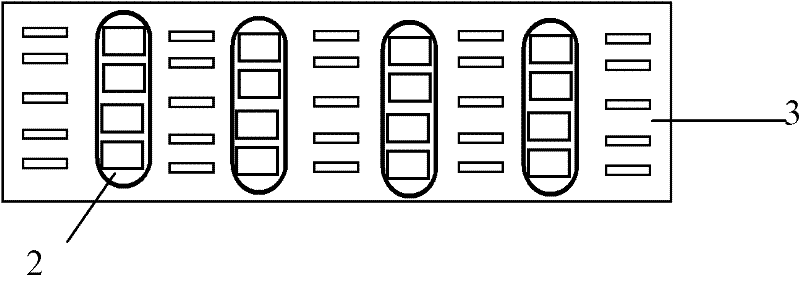

Flat tube heat exchanger and assembling method thereof

InactiveCN102192671ASimple structureEasy to processTubular elementsPlate heat exchangerStructural engineering

The invention discloses a flat tube heat exchanger which comprises fins and flat tubes, wherein the fins are provided with pipeline slots; the flat tubes are connected with the fins; and the pipeline slots are U-shaped, and the opening ends of the pipeline slots are arranged at the same side of the fins. The invention also discloses an assembling method of the flat tube heat exchanger. The method comprises the following steps: 1) inserting and fixing the fins sequentially in the fixing slots of a first fixing table and a second fixing table; 2) inserting the flat tubes sequentially and horizontally into the pipeline slots of fin sets of the first fixing table; 3) enabling the second fixing table to be close to the first fixing table, and enabling the fins fixed on the second fixing table to be inserted between two adjacent fins fixed on the first fixing table respectively; 4) inserting and fixing the flat tubes completely in the pipeline slots of the fin sets of the second fixing table; and 5) fixing the fins and the flat tubes in an interference or welding mode. According to the invention, the flat tubes are inserted along a transverse direction, the stroke of the flat tubes is shortened, the assembling method is easy to combine with other methods so as to realize connection, and the fins have simple structures, and are easy to manufacture.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

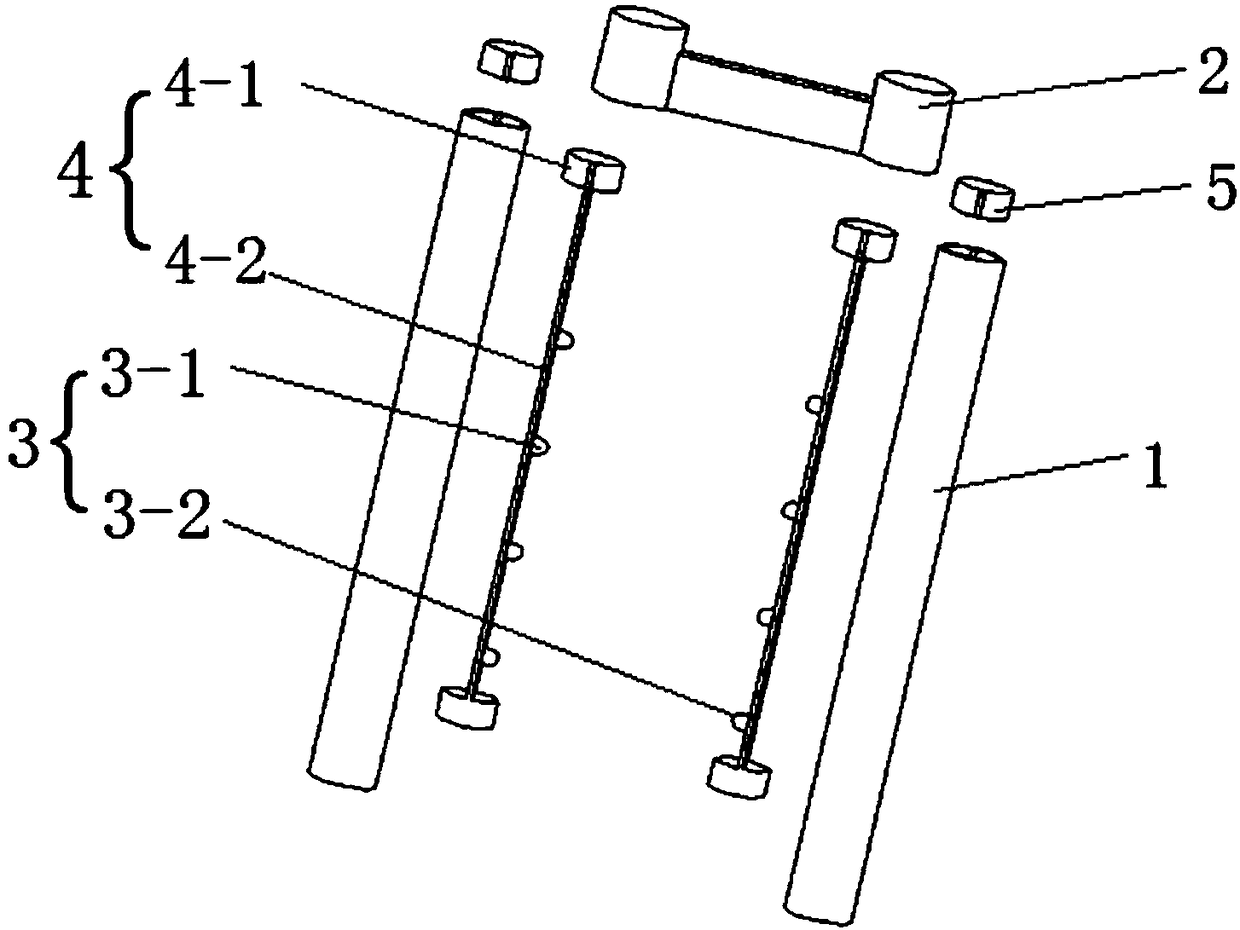

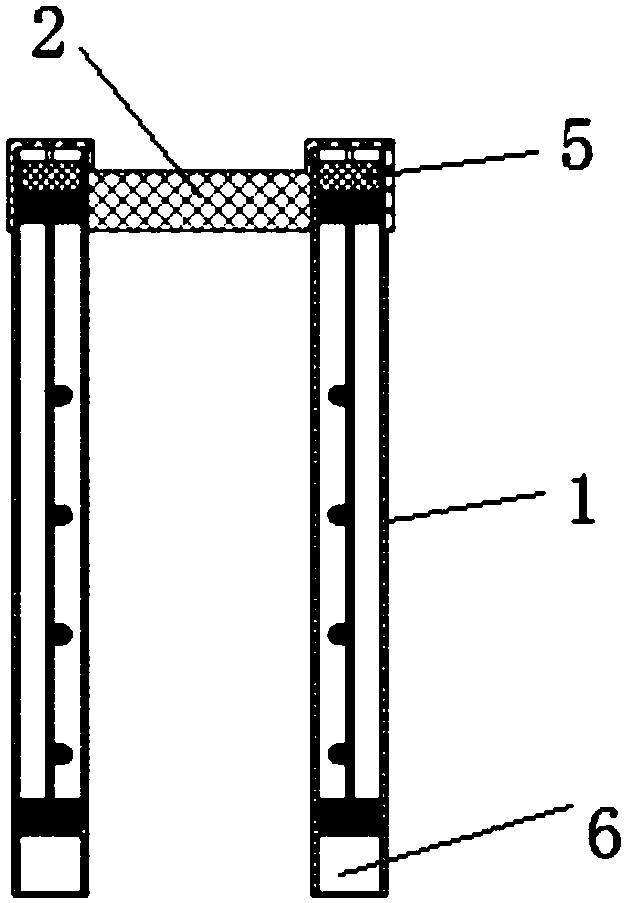

Device for monitoring water softener resin regeneration salt consuming state

PendingCN108483575AImprove experienceThere will be no frequent alarms indicating salt shortageWater/sewage treatment by ion-exchangeEngineeringAcousto-optics

The invention discloses a device for monitoring a water softener resin regeneration salt consuming state. The device is characterized by comprising a plurality of groups of infrared sensors, a controller and a display alarm device, wherein each infrared sensor comprises an infrared emitter and an infrared receiver which are mutually paired, all the groups of the infrared sensors are distributed from top to bottom, and the controller is connected with all the groups of the infrared sensors and can control the display alarm device to work according to the signals fed back by all the groups of the infrared sensors. In actual work, the infrared emitters can emit infrared signals in real time; when the corresponding infrared receivers receive the infrared signals, the controller can display thesalt consuming state on a display screen in real time by treating the infrared signals; when the receiver of the lowest group of the infrared sensor receives the infrared signals, the controller candisplay salt deficiency on the display screen by treating the infrared signals and give out sound-light alarm.

Owner:GUANGDONG MACRO GAS APPLIANCE

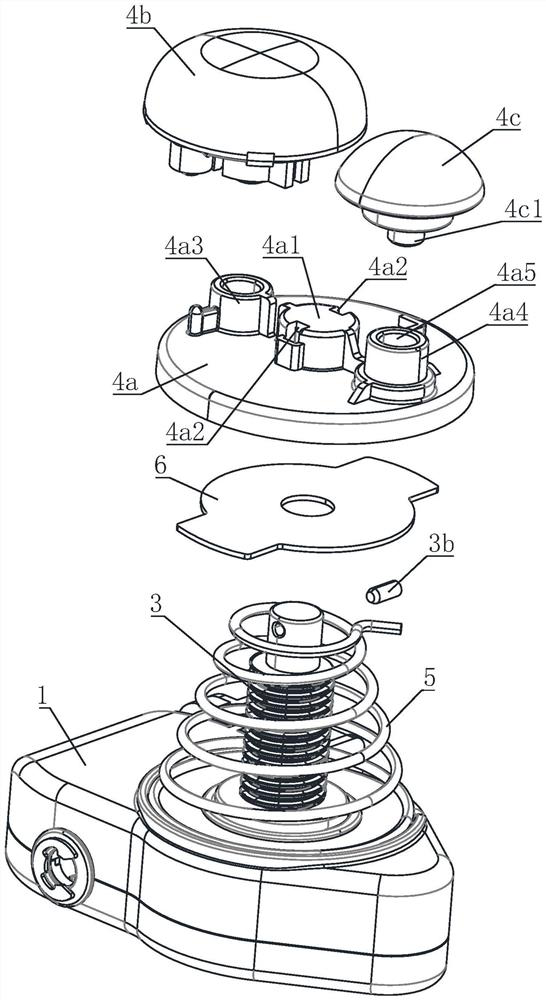

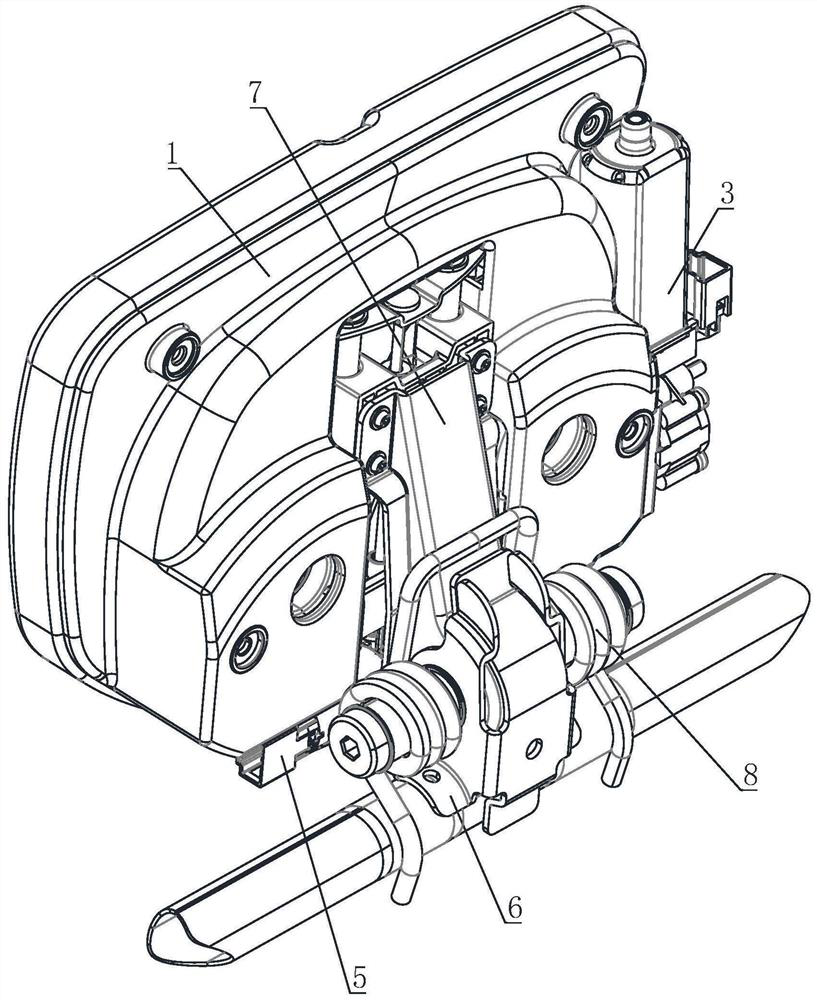

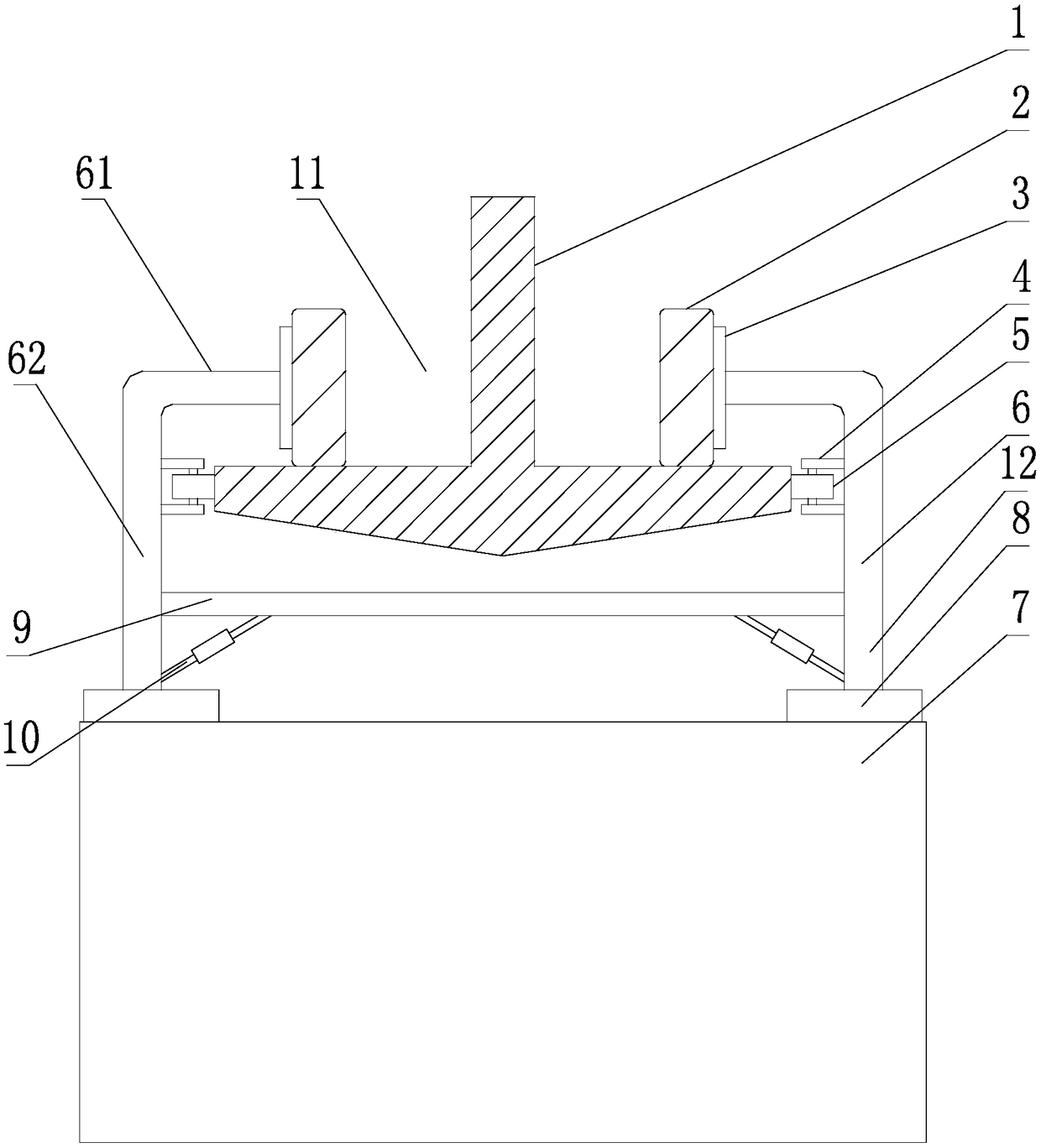

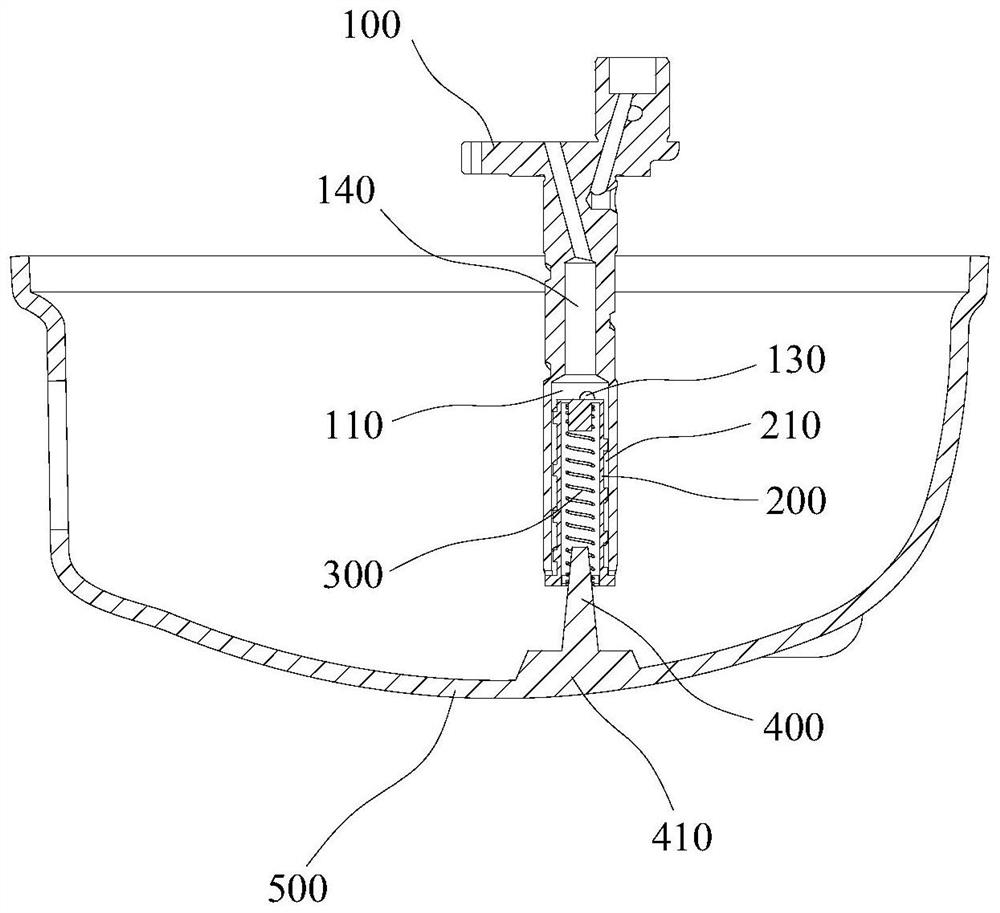

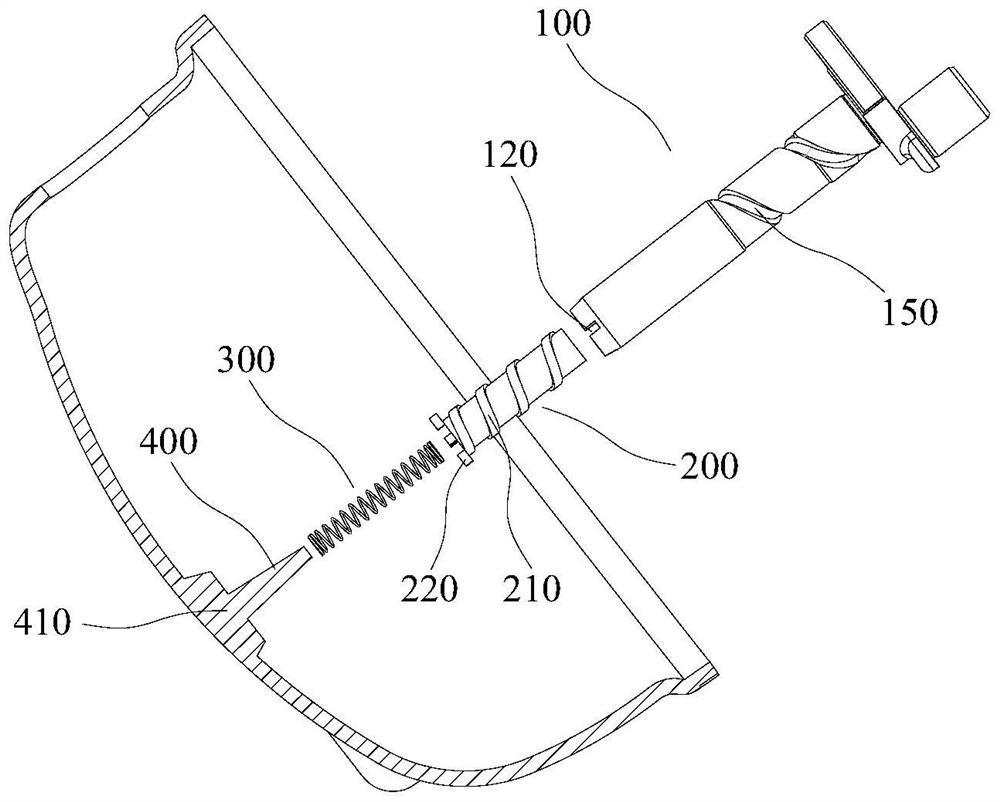

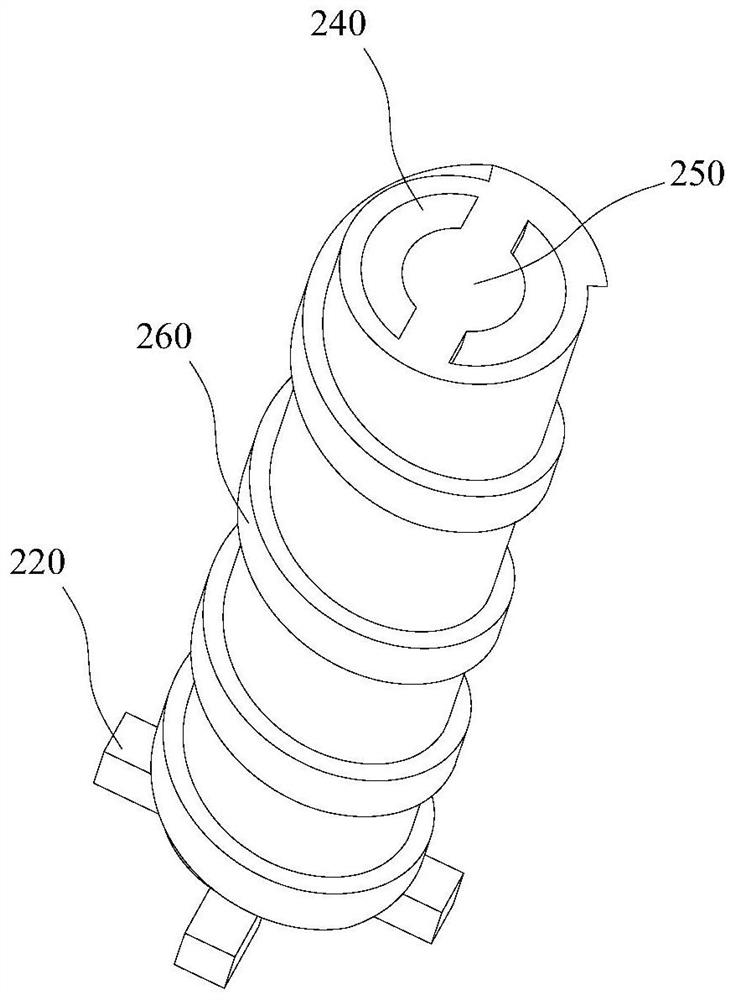

Lifting type massage head and waist massage device with massage head

PendingCN112315760AEnsure ride safetyAvoid contactVehicle seatsSuction-kneading massagePhysical medicine and rehabilitationElectric machinery

The invention discloses a lifting type massage head, a waist massage device with the massage head. A rotating wheel is rotatably mounted in a mounting seat of the lifting type massage head, the middleof the rotating wheel sleeves a screw in threaded connection in the axial direction of the rotating wheel, the upper end of the screw penetrates out of the mounting seat, and massage assemblies are mounted at the upper end of the screw. A spring is arranged between the massage assemblies and the mounting seat, one end of the spring is fixedly connected with the mounting seat, and the other end frictionally abuts against the massage assemblies; and each massage mechanism comprises a supporting assembly, wherein a driving assembly and two sets of lifting type massage heads are mounted on the corresponding supporting assembly, the driving assembly comprises a motor and a rotating shaft driven by the motor to rotate, and the rotating shaft is rotationally mounted on the mounting seat of two sets of lifting type massage heads and used for driving the rotating wheel to rotate. The lifting type massage head and the waist massage device have the beneficial effects that the structural design is ingenious, the technical obstacle that a massager is integrally designed on a backrest is broken through, the condition that the massage head is always in contact with the waist of a driver, can beavoided, and the safety of the seat can be guaranteed.

Owner:CHONGQING YANFENG ADIENT AUTOMOTIVE COMPONENTS CO LTD

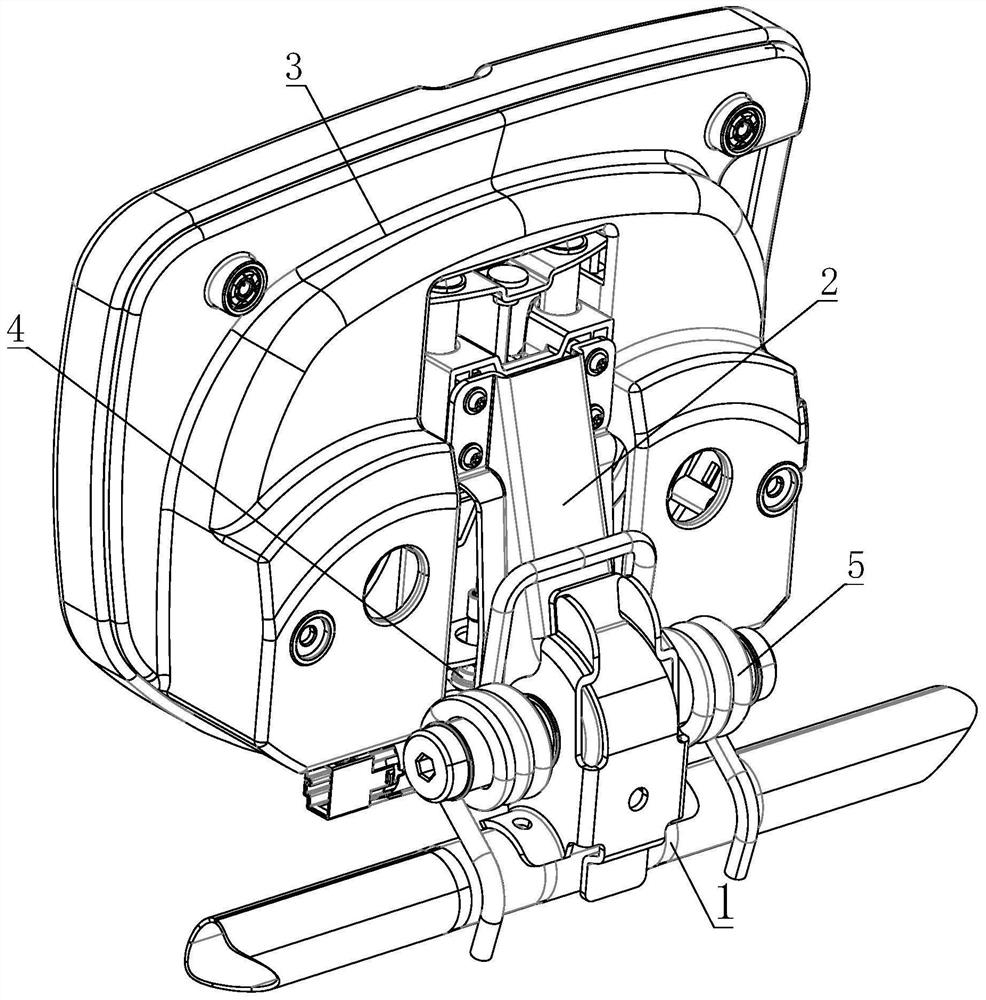

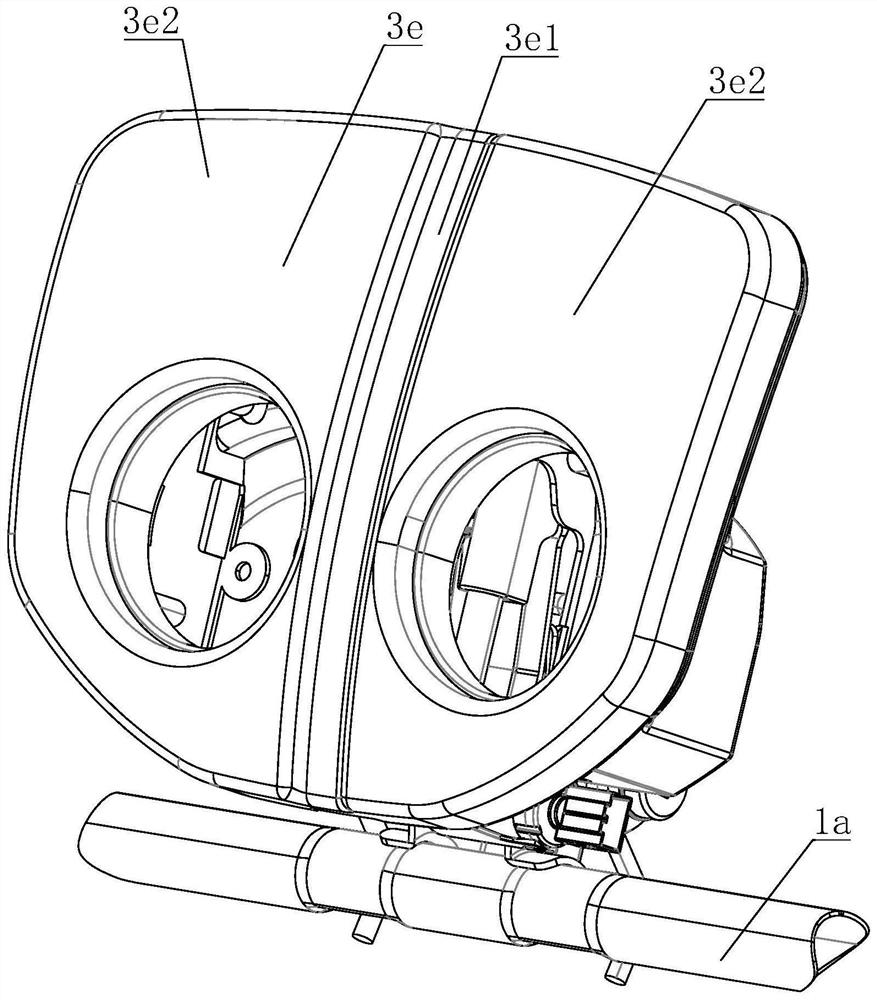

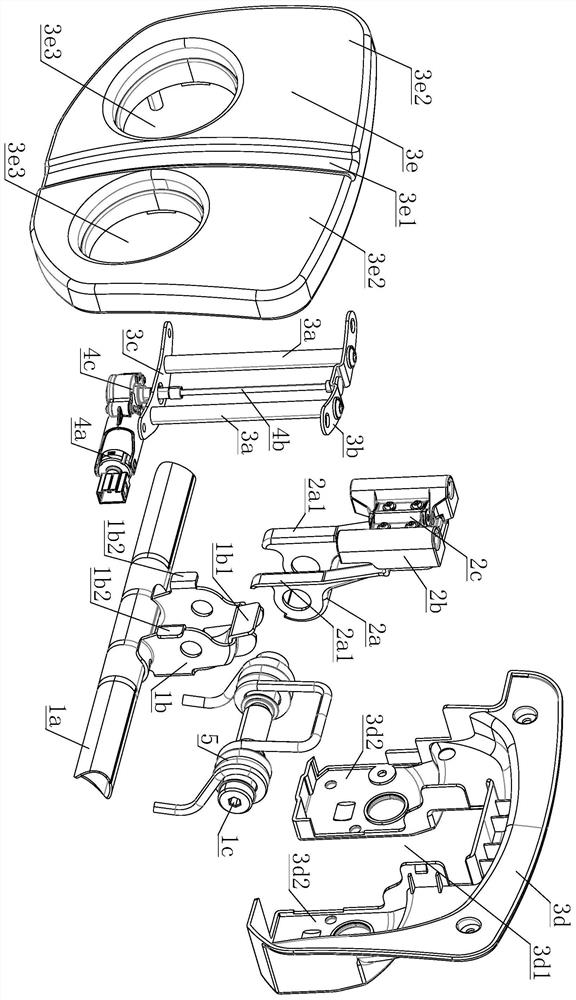

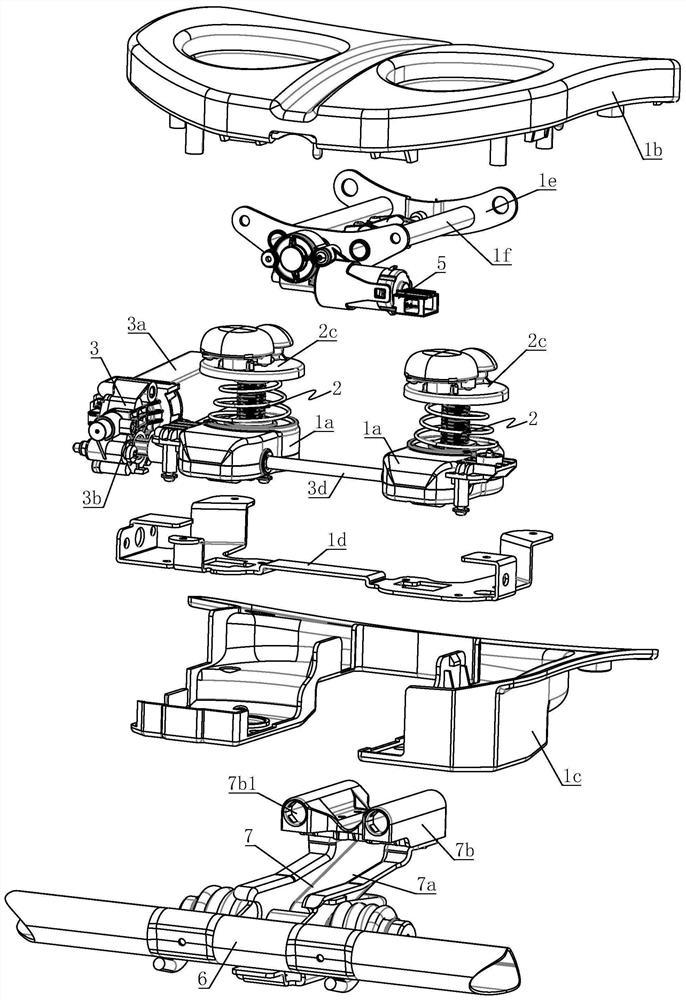

Seat waist support and automobile seat with same

The invention discloses a seat waist support and an automobile seat with the same. The seat waist support comprises a connecting assembly fixedly connected to a seat backrest; a seat body assembly, which is rotationally assembled on the connecting assembly; a waist supporting assembly, which can be mounted on the seat body assembly in an up-and-down moving and sliding manner; a driving mechanism,which is arranged between the waist supporting assembly and the seat body assembly and used for driving the waist supporting assembly to move up and down; and an elastic element, which is arranged between the seat body assembly and the connecting assembly. The waist supporting assembly is elastically supported on the seat backrest under the action of the elastic element. The seat waist support hasthe advantages that the seat is provided with the waist support with the adjustable supporting height, the waist support can provide certain elastic auxiliary supporting force for the waist of a user, and good comfort is provided.

Owner:CHONGQING YANFENG ADIENT AUTOMOTIVE COMPONENTS CO LTD

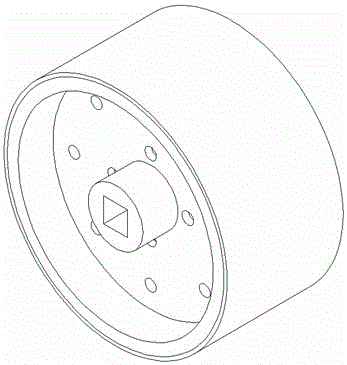

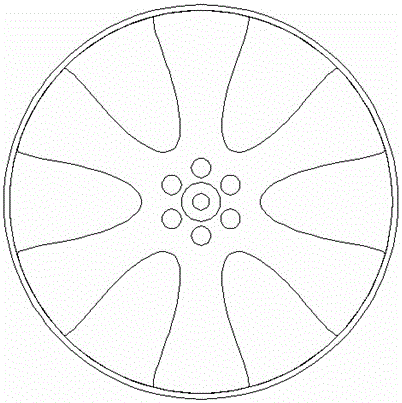

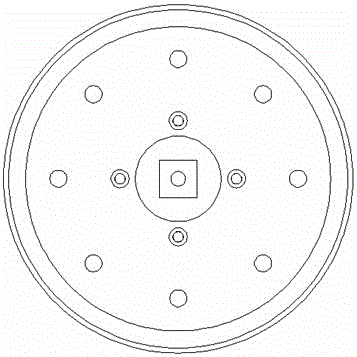

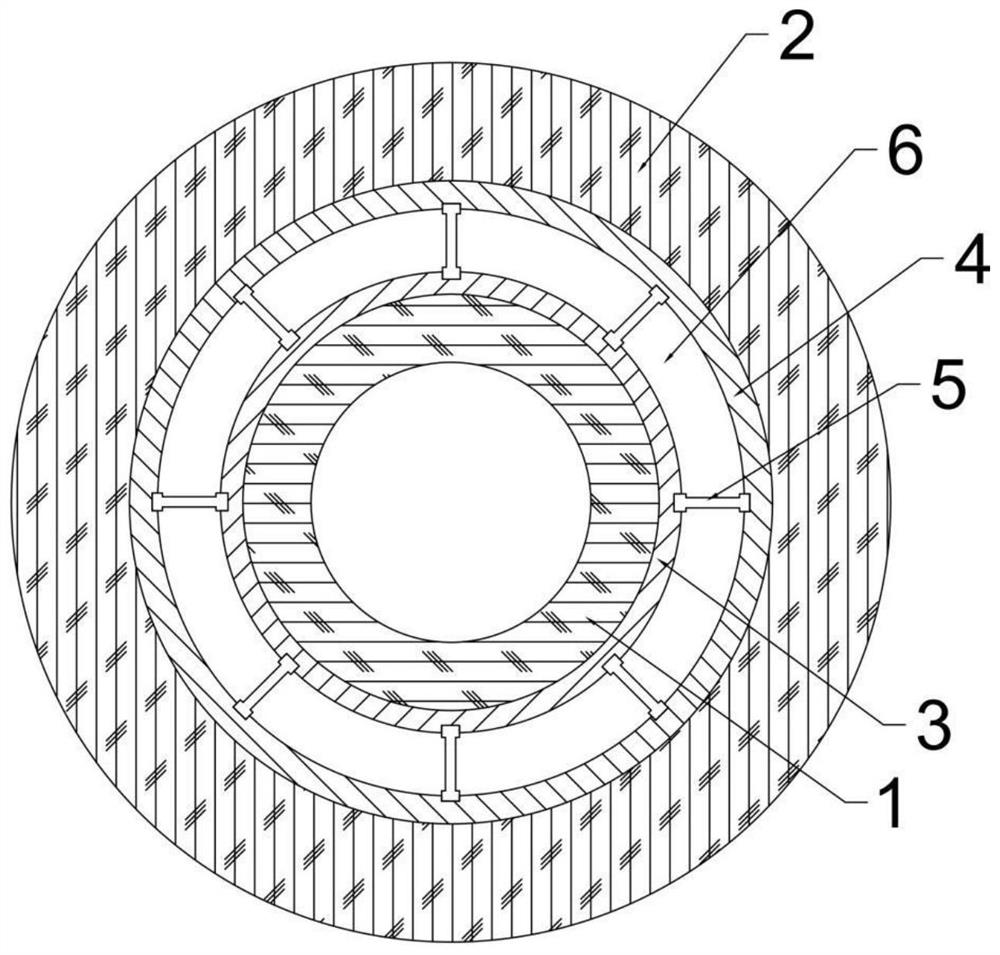

Wheel type permanent magnetic adsorption device

ActiveCN106697100AImprove the utilization rate of magnetic energyReduce volumeVehiclesMagnetic tension forceDrive shaft

The invention relates to the technical field of industrial robots, and discloses a wheel type permanent magnetic adsorption device. The device comprises an annular neodymium iron boron permanent magnet, an outer silicon steel magnetic conductive yoke, an inner silicon steel magnetic conductive yoke and a positioning sleeve, wherein one end of the positioning sleeve sleeves the outer circle of the center of the outer silicon steel magnetic conductive yoke, and the other end of the positioning sleeve sleeves the outer circle of the center position of the inner silicon steel magnetic conductive yoke; the annular neodymium iron boron permanent magnet is embedded in the groove between the outer silicon steel magnetic conductive yoke and the inner silicon steel magnetic conductive yoke; the outer silicon steel magnetic conductive yoke and a magnetic wheel driving shaft are fixed together through a bolt at the tail end of a driving shaft; and the outer silicon steel magnetic conductive yoke and the inner silicon steel magnetic conductive yoke are fixed and screwed respectively by threaded holes in side faces of the outer and inner silicon steel magnetic conductive yoke to form a sandwich structure. The wheel type permanent magnetic adsorption device adopts the sandwich structure, has relatively small size and light weight, and is convenient to assemble and disassemble, permanent magnets with different magnetisms can be replaced easily, and the magnetic wheel can be prevented from sliding in the rotating process, so that the coaxiality is ensured, the dislocation phenomenon cannot happen, and the assembly can be easily implemented.

Owner:LUOYANG SHENGRUI INTELLIGENT ROBOT

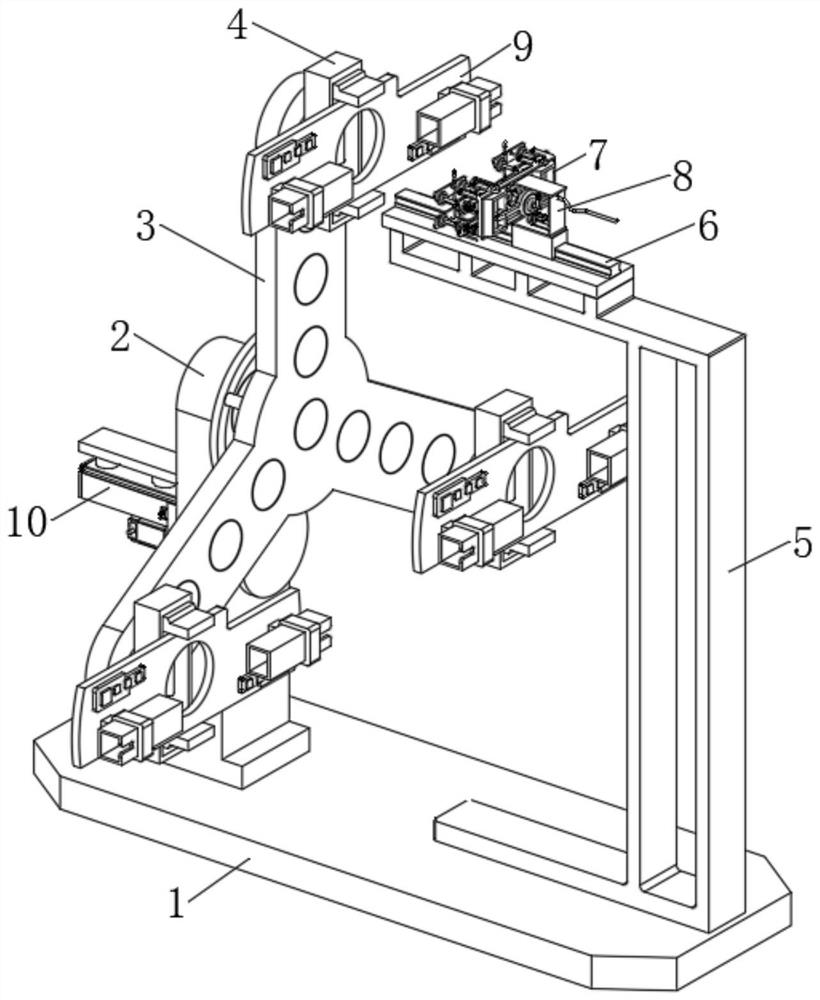

Processing device applied to carbon brush structure on brush motor

InactiveCN114583526AChange stationFlexible change of positionGrinding drivesDynamoelectric machine connectorsElectric machineryEngineering

The invention discloses a machining device applied to a carbon brush structure on a brush motor, and particularly relates to the technical field of motor part machining, the machining device comprises a bottom plate, a support is fixedly installed on one side of the top end of the bottom plate, an indexing mechanism is arranged on the top of the support, and a positioning assembly is arranged on the side, away from the support, of the indexing mechanism; according to the invention, the transposition mechanism and the positioning assembly are arranged, and the first motor is used in cooperation, so that the position of the positioning assembly can be driven to change without autorotation, the station of the positioning assembly can be flexibly changed, and the positioning assembly is convenient to use. Orderly and automatic polishing, assembling and detecting of a plurality of carbon brushes can be conveniently realized, so that the use effect of the whole carbon brush structure is improved; and by arranging the clamping and driving assembly, roller type positioning can be conveniently conducted on the carbon brushes of different sizes, the stability of the subsequent carbon brush polishing machining is improved, and the carbon brushes can be conveniently driven to horizontally move to be automatically assembled in the subsequent process.

Owner:江苏众联祥博新能源科技有限公司

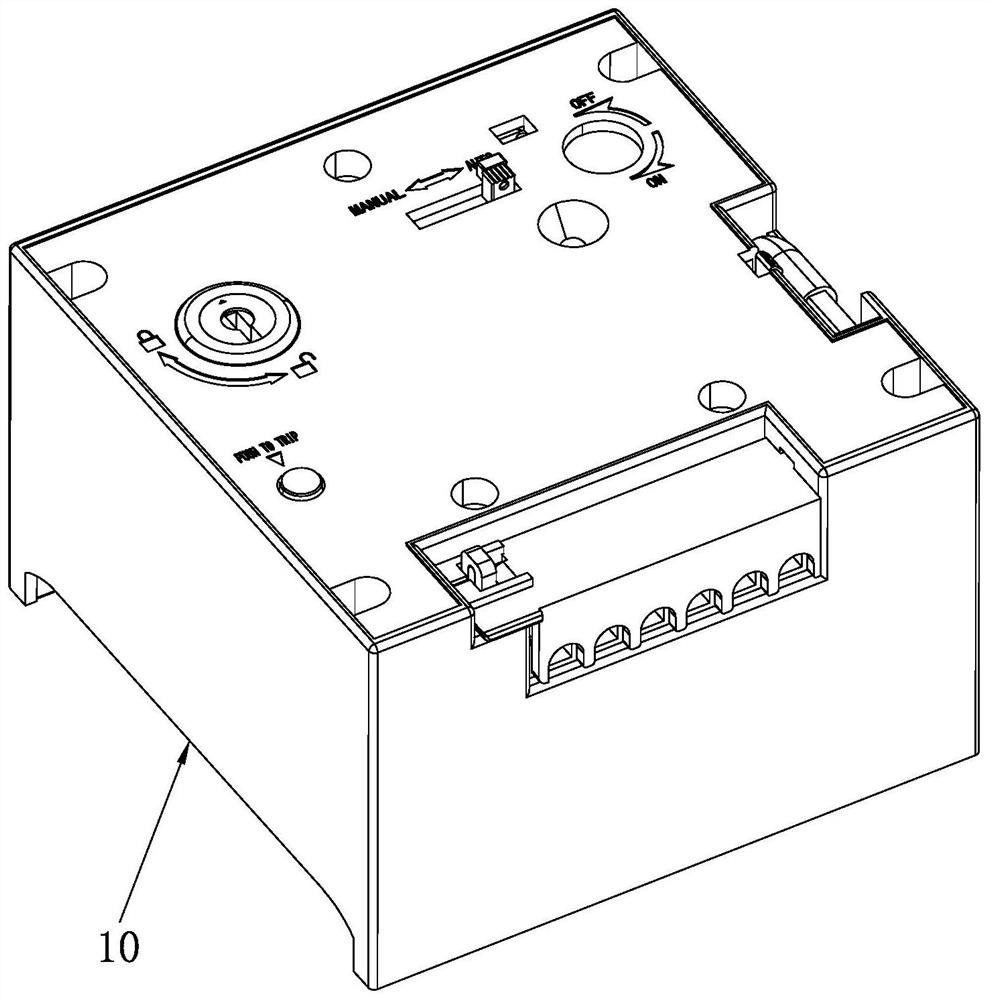

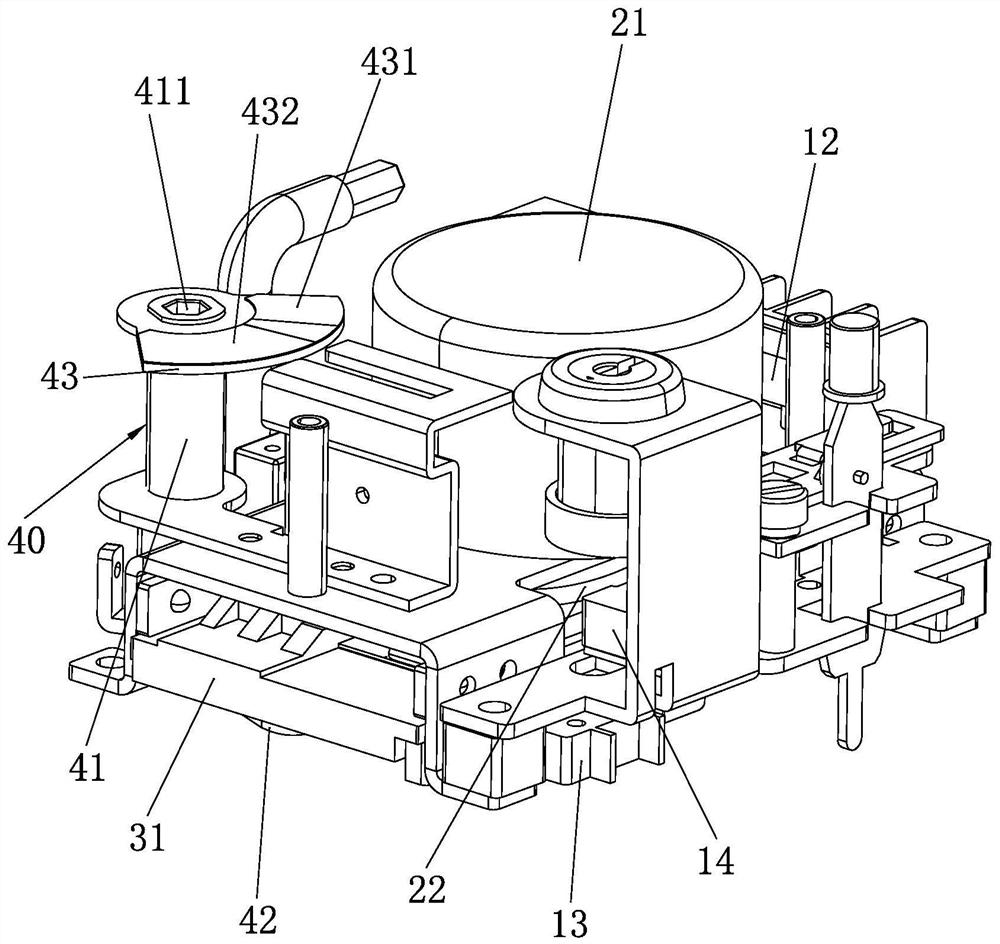

Electric operating mechanism

PendingCN111900055AReliable driveIncrease contact areaSwitching device condition indicationProtective switch operating/release mechanismsElectric machineryElectric drive

The invention relates to an electric operating mechanism. The electric operating mechanism comprises a shell, a mechanism frame, an intelligent control circuit board, an electric driving assembly, a sliding block assembly and a manual driving assembly. The electric drive assembly comprises a motor arranged on the mechanism frame and a cam in linkage with the motor. The sliding block assembly comprises a sliding block which is arranged on the mechanism frame in a sliding mode and is in linkage fit with the cam, and a sleeve piece which is arranged on the molded case circuit breaker handle in asleeving mode and is in linkage fit with the sliding block. A poking wheel matched with the sliding block in a linkage mode is arranged on the cam in a rotating mode, two protruding blocks matched with the poking wheel are arranged on the sliding block, the poking wheel acts along with the cam and can push the two protruding blocks, and the sliding block can slide on the mechanism frame in a reciprocating mode. The electric operating mechanism has the advantages of simple structure, stable and reliable performance, safety, reliability, small volume and convenience in assembly.

Owner:乐清市建波电气有限公司

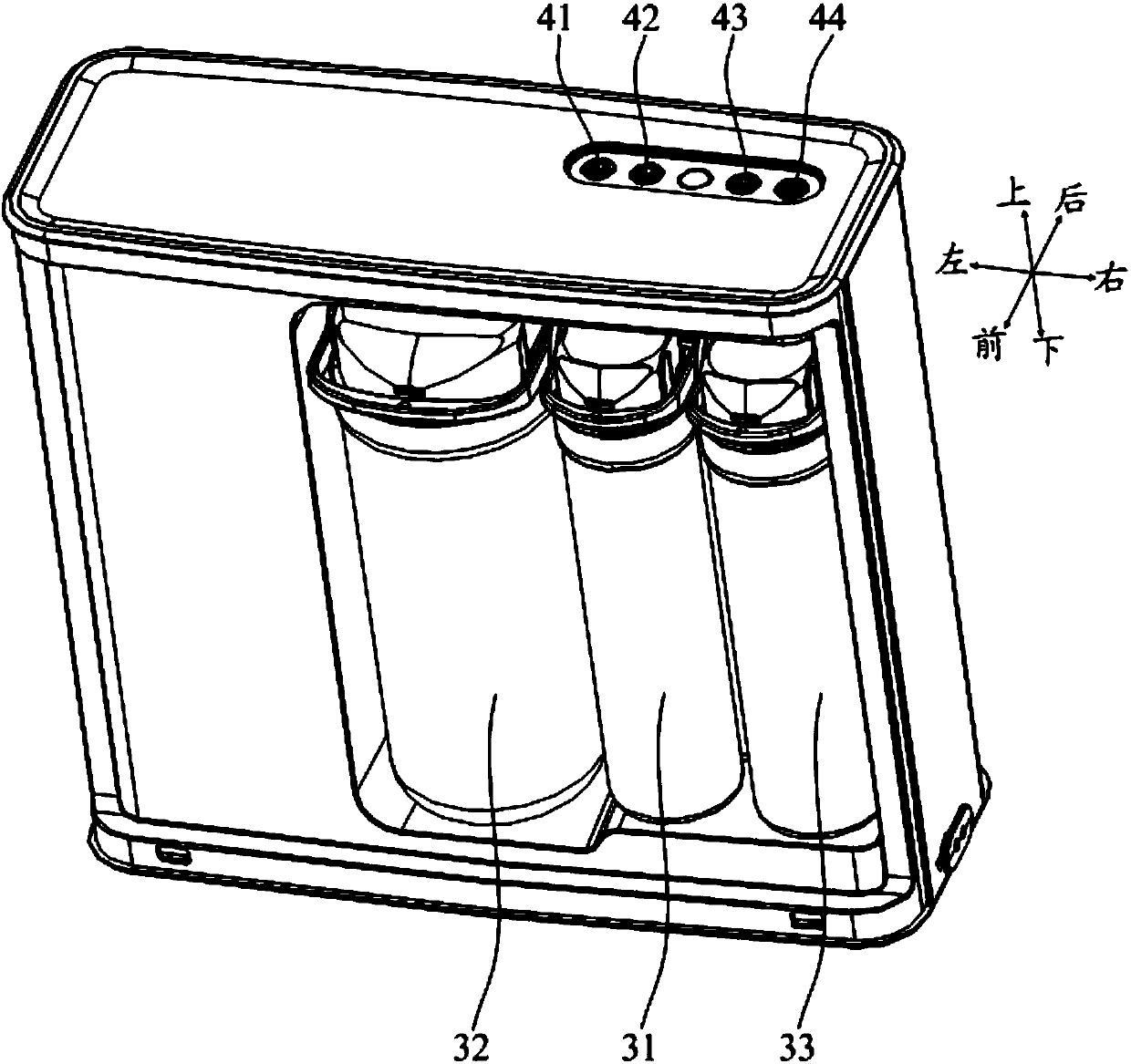

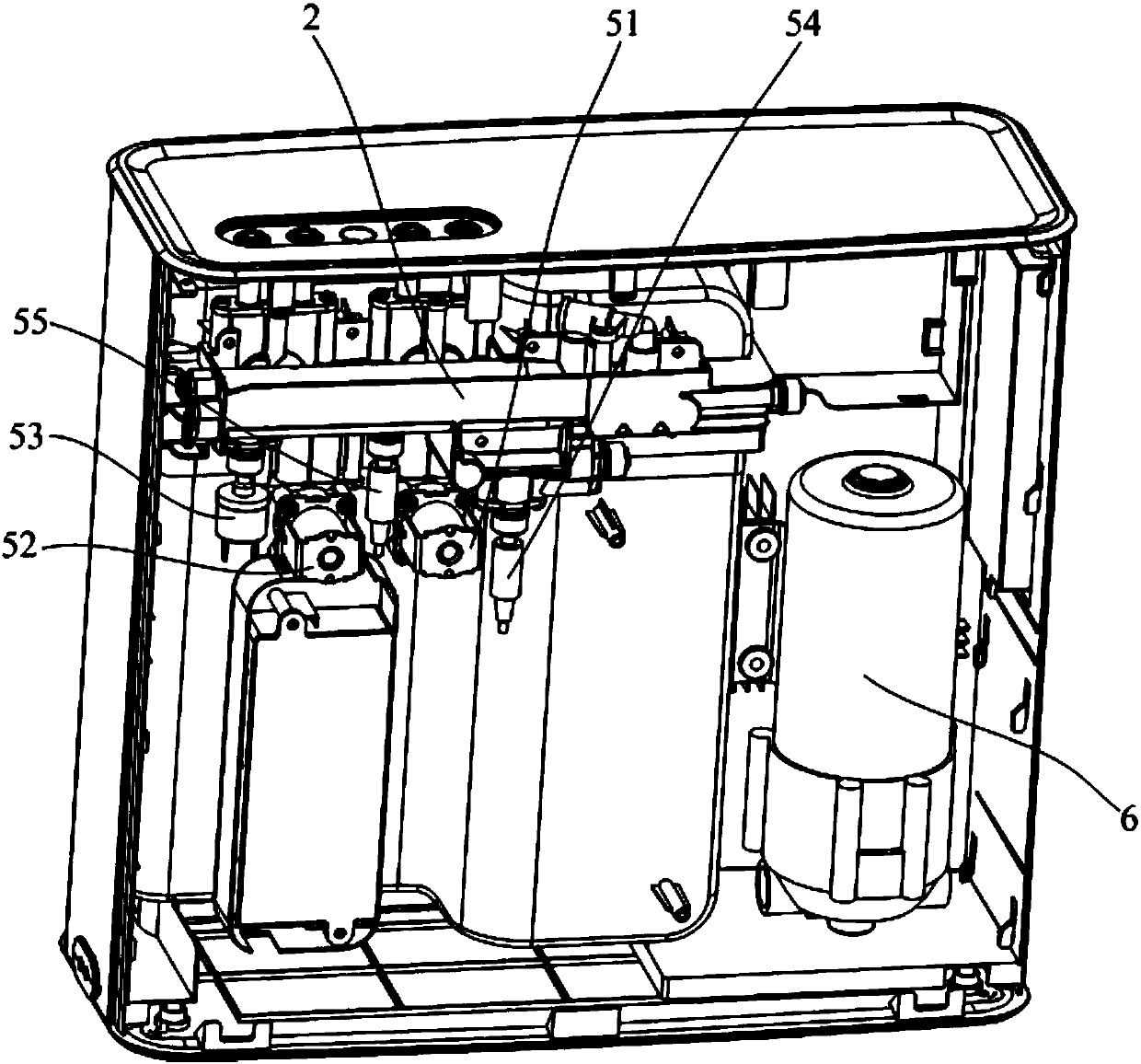

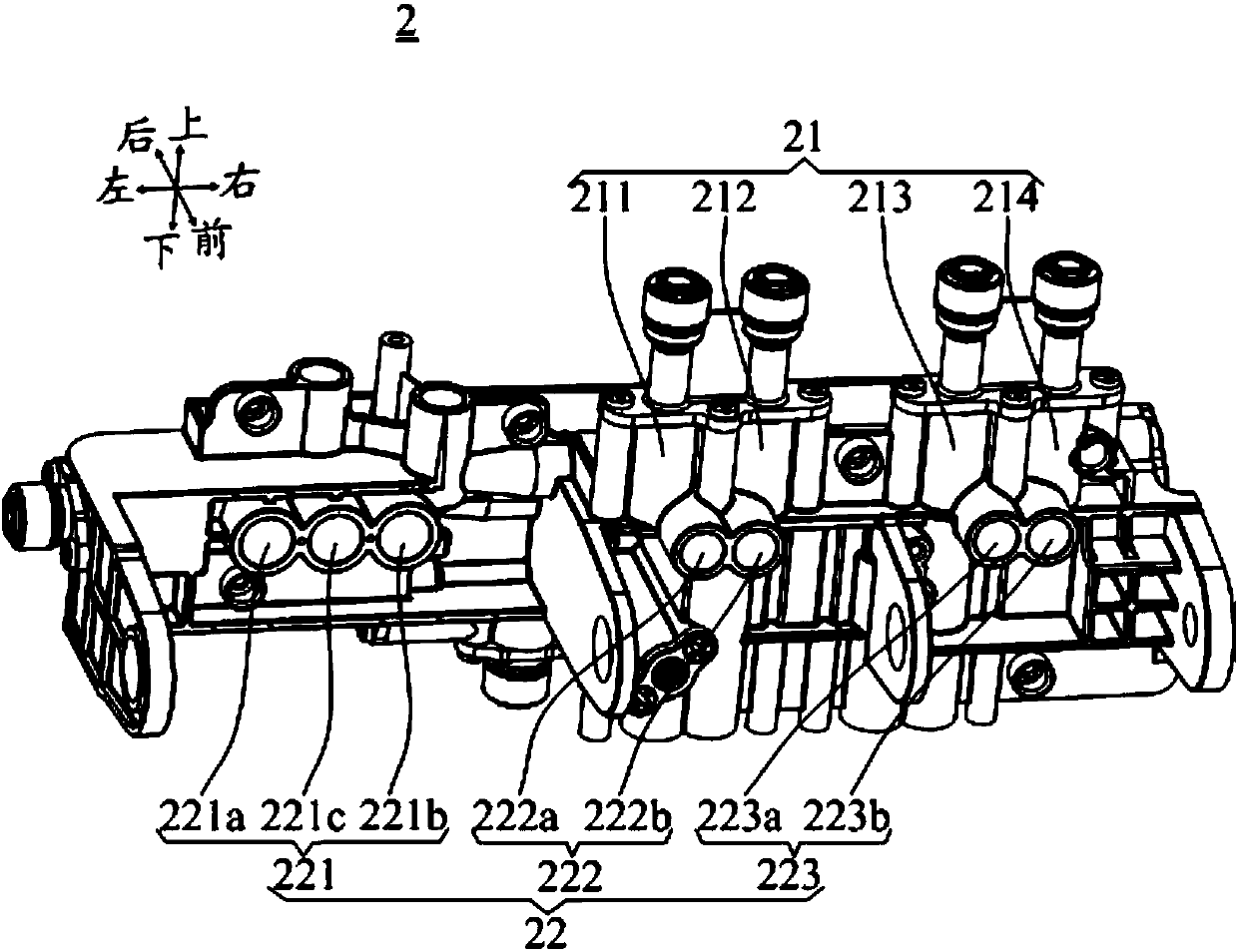

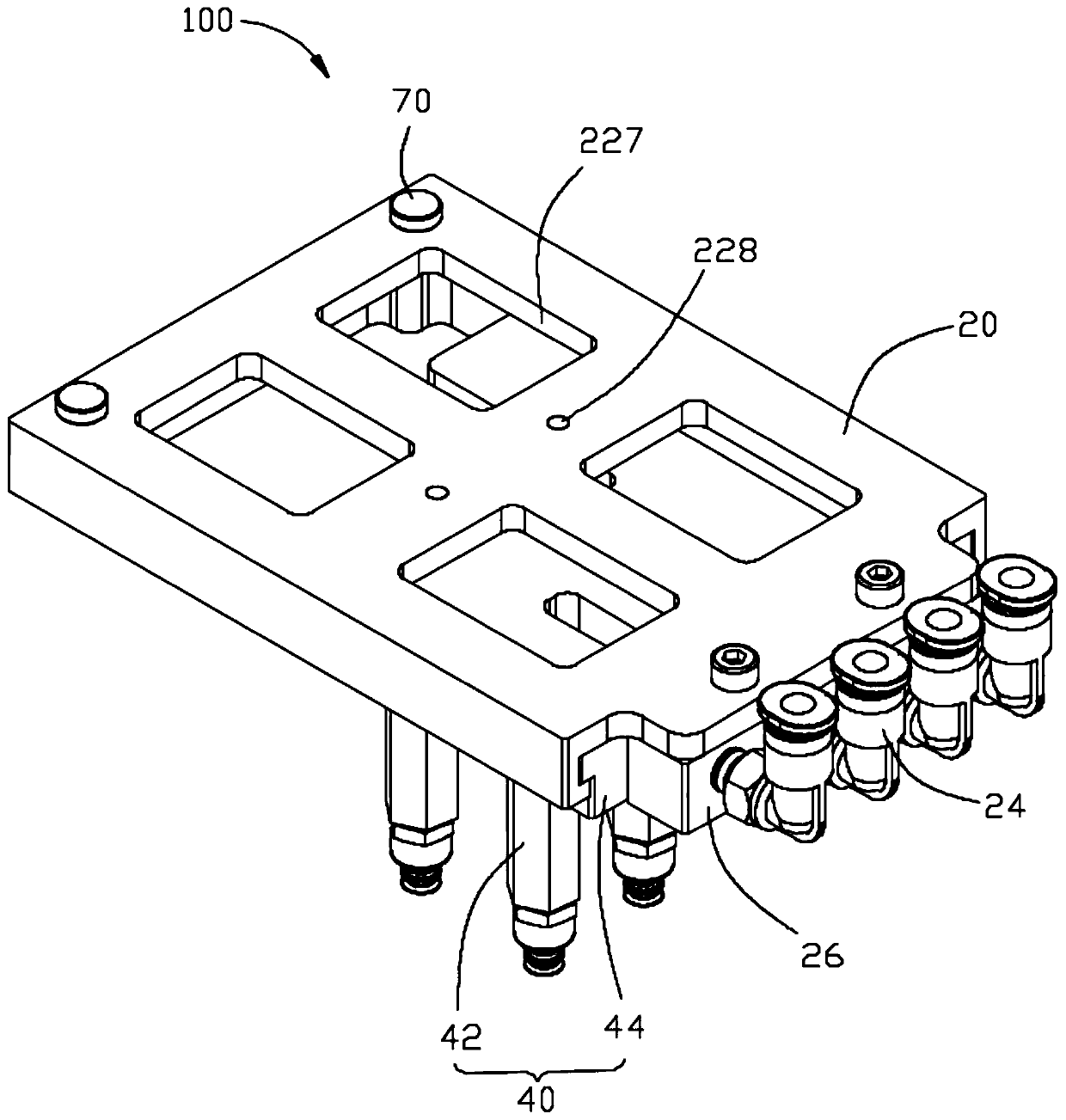

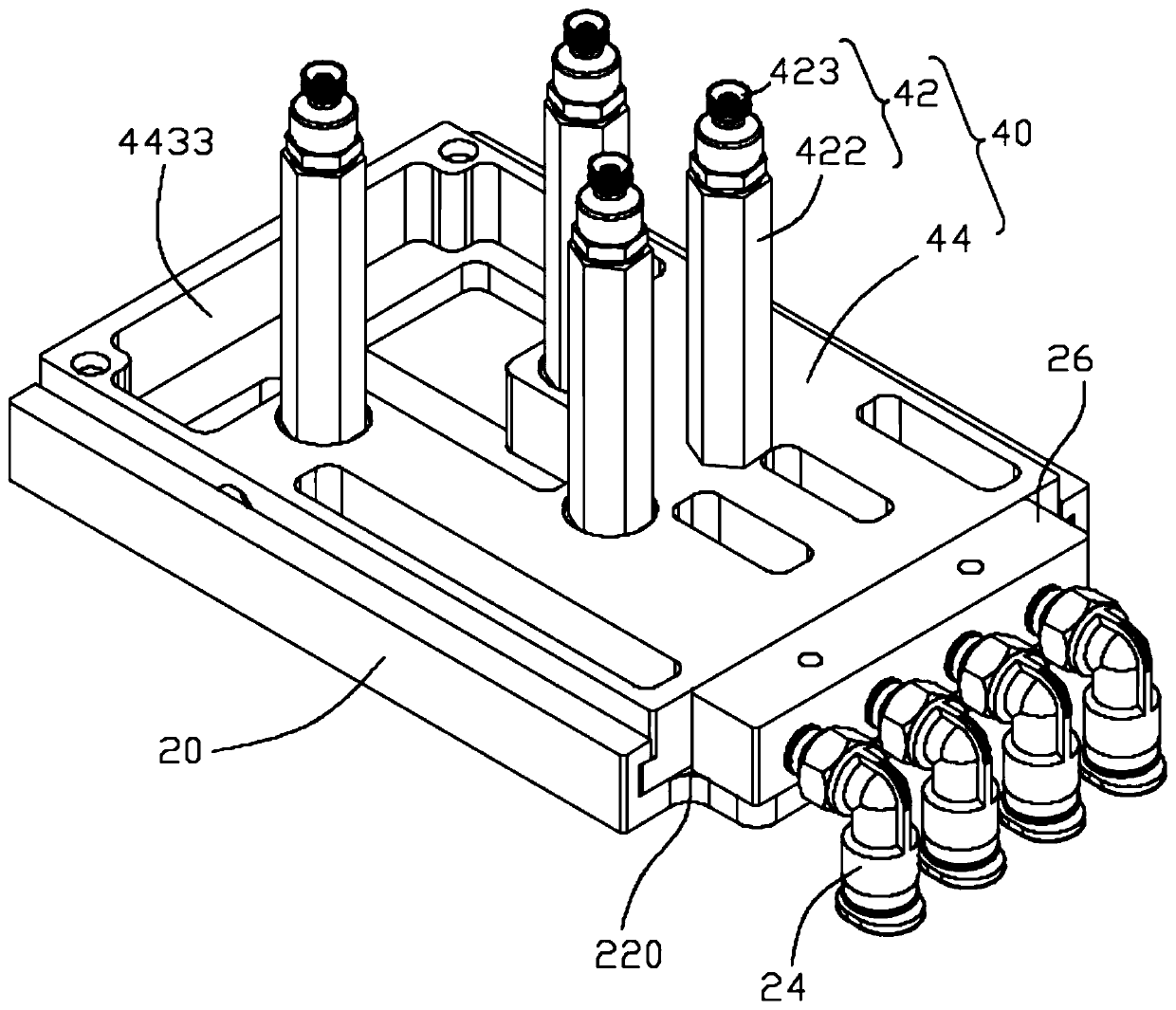

Integrated water path member and water purifier

ActiveCN107902773ALow mass production costRealize the assemblyGeneral water supply conservationTreatment involving filtrationEnvironmental engineeringControl valves

The invention discloses an integrated water path member and a water purifier. The integrated water path member comprises a member body, wherein a plurality of filtration core straight flow channels capable of extending forward and a plurality of control valve straight flow channels capable of extending downward are formed in the member body, the filtration core straight flow channels are used forconnecting the filtration core of a water purifier, and the control valve straight flow channels are used for connecting the control valve of the water purifier. With the technical scheme of the present invention, the assembly efficiency of the water purifier can be improved.

Owner:FOSHAN SHUNDE MIDEA WATER DISPENSER MFG +1

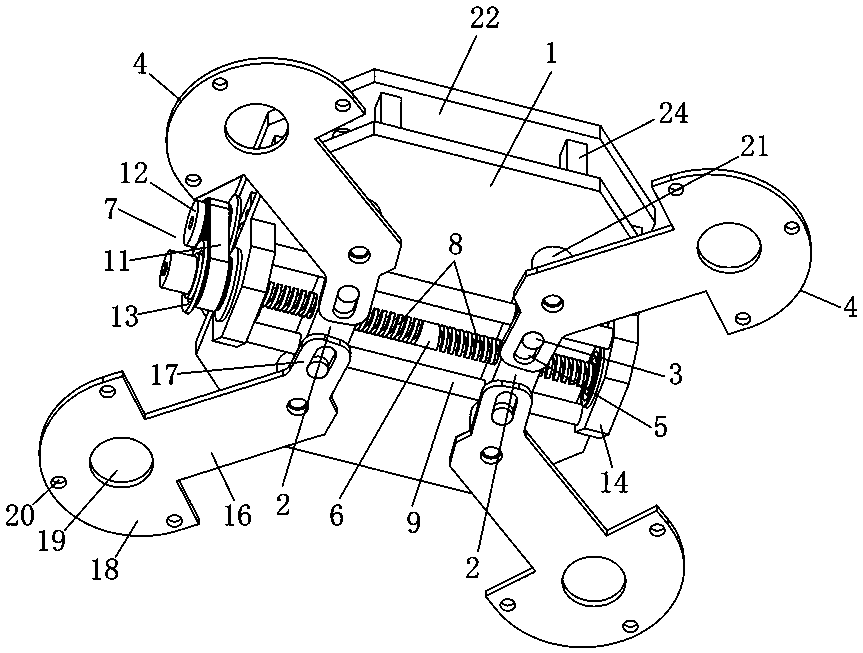

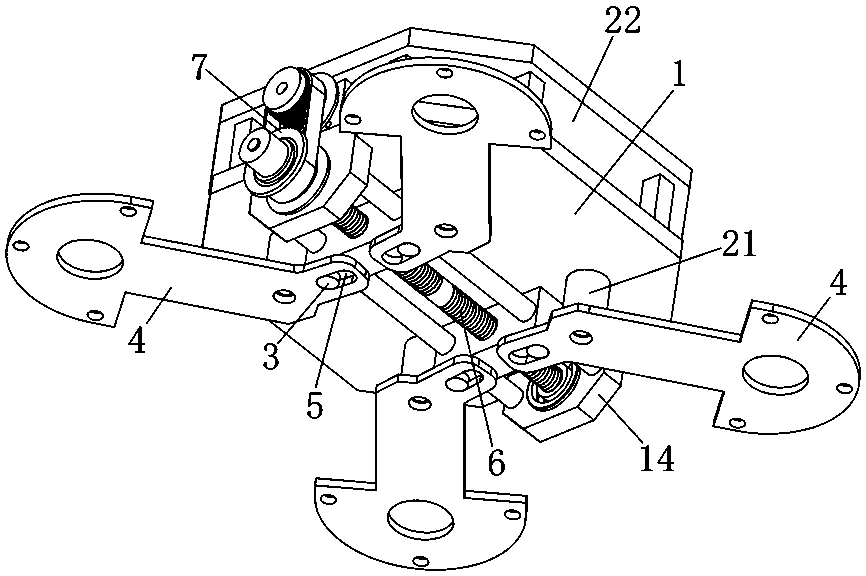

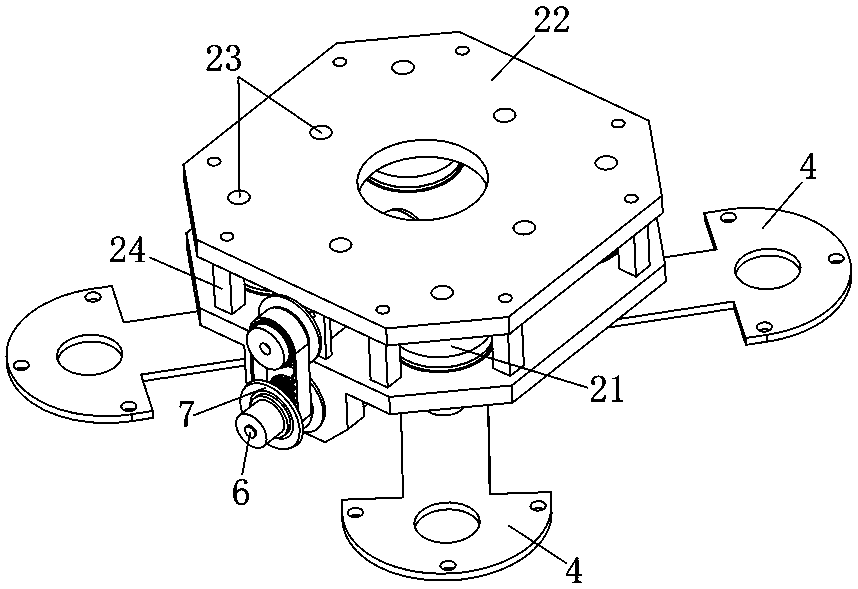

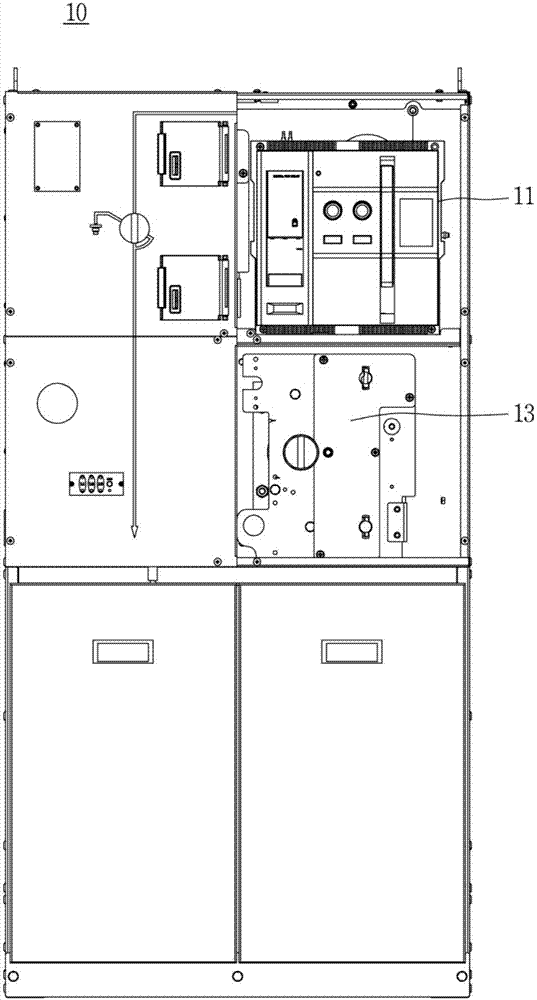

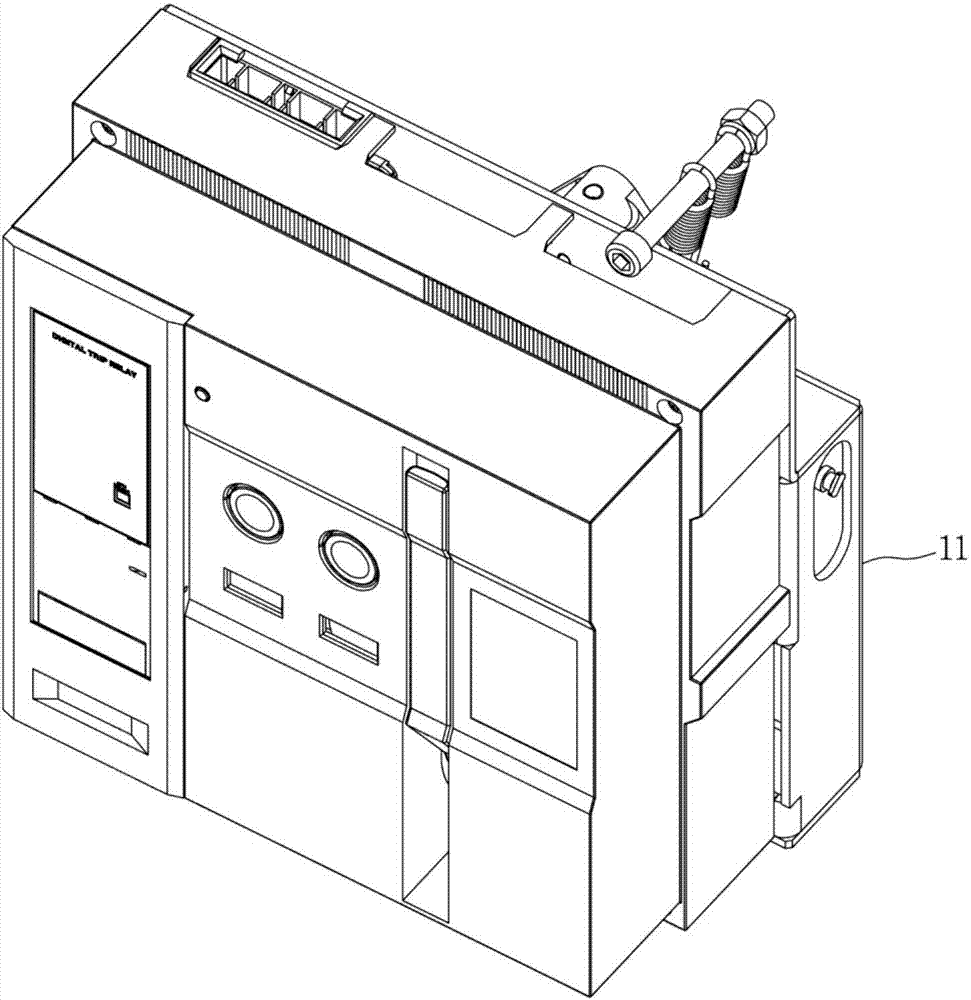

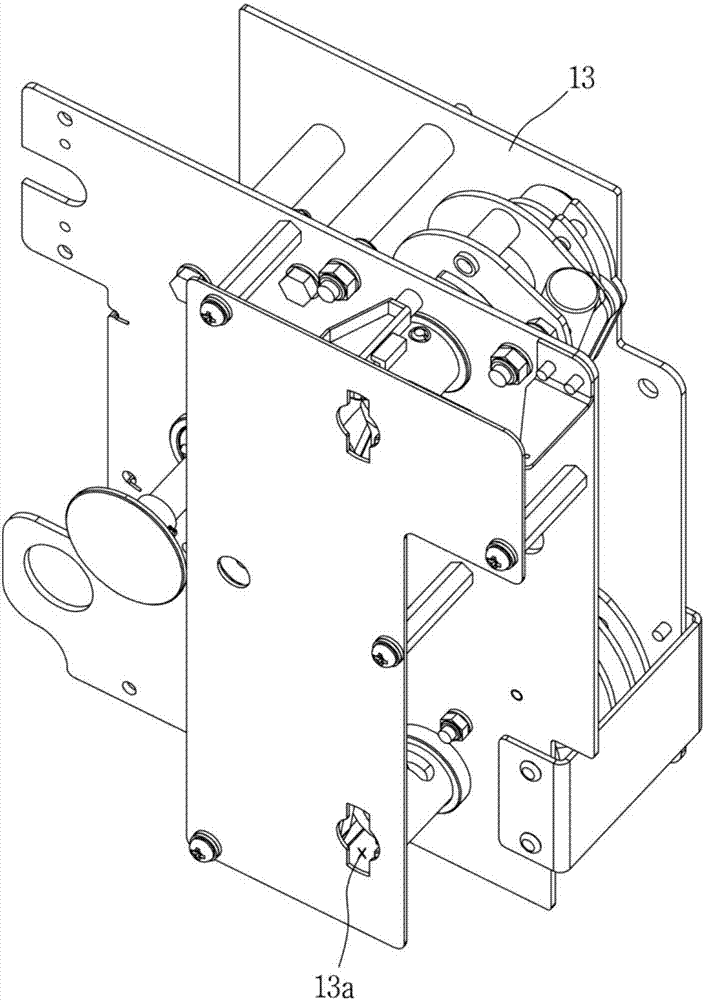

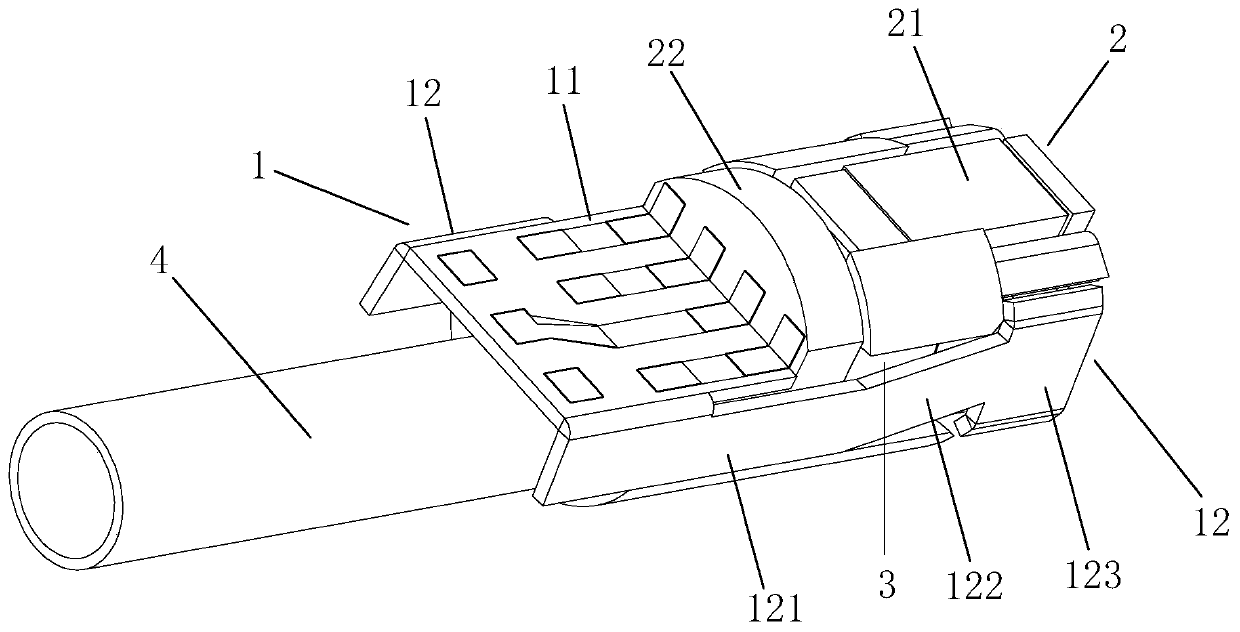

Interlock apparatus of ring main unit

ActiveCN106935448AAvoid damageAvoid controlHigh-tension/heavy-dress switchesProtective switch operating/release mechanismsEngineeringClosed state

An interlock apparatus of a ring main unit is provided. The interlock apparatus of the ring main unit may change a rotational motion of the shaft included in the circuit breaker to a rectilinear motion, and thus, the insertion hole may be opened or closed according to a closed or cutoff state of the circuit breaker. Accordingly, in the closed state of the circuit breaker, the control of a state of the disconnector is prevented.

Owner:LSIS CO LTD

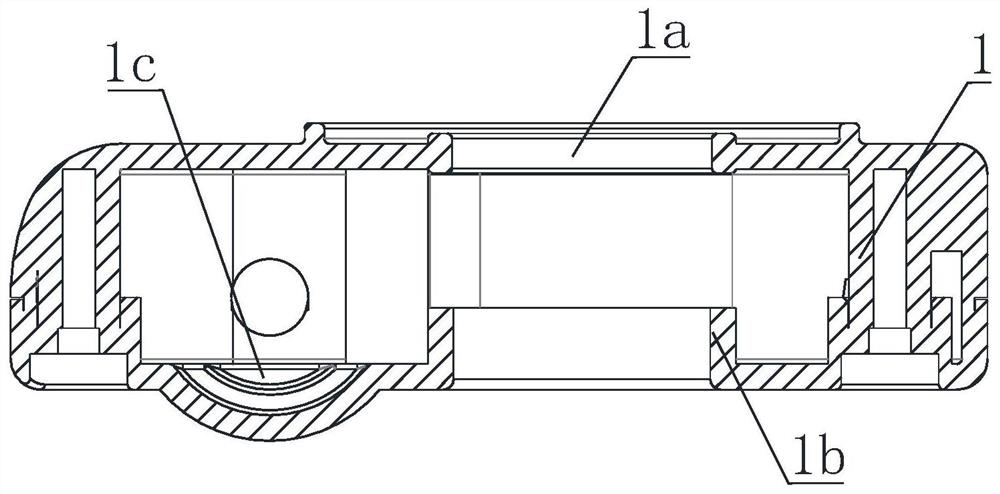

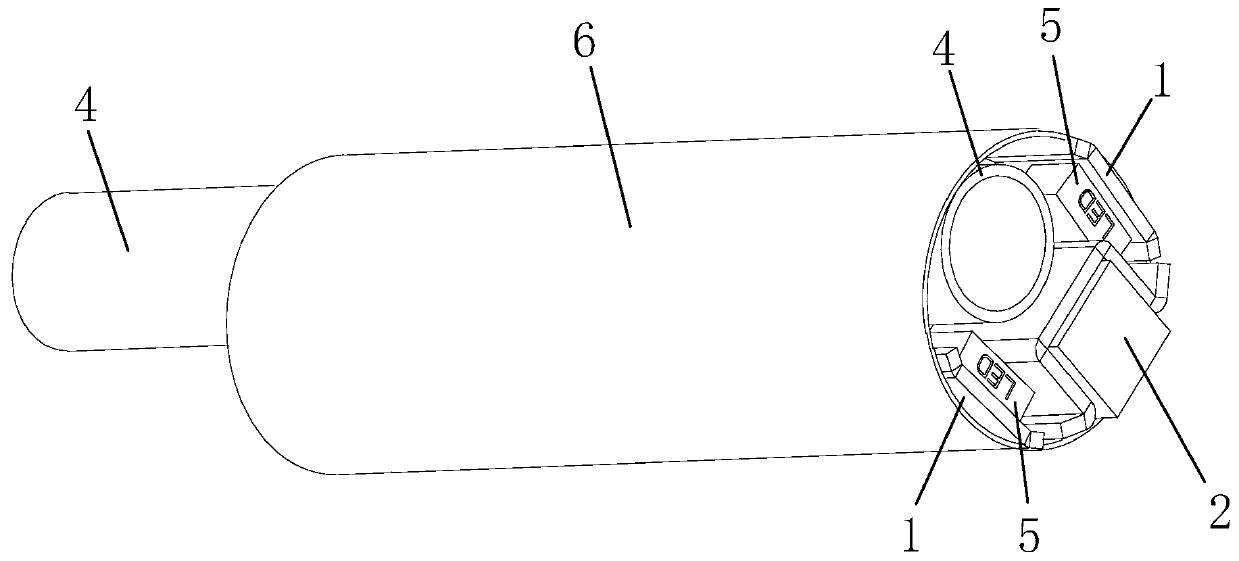

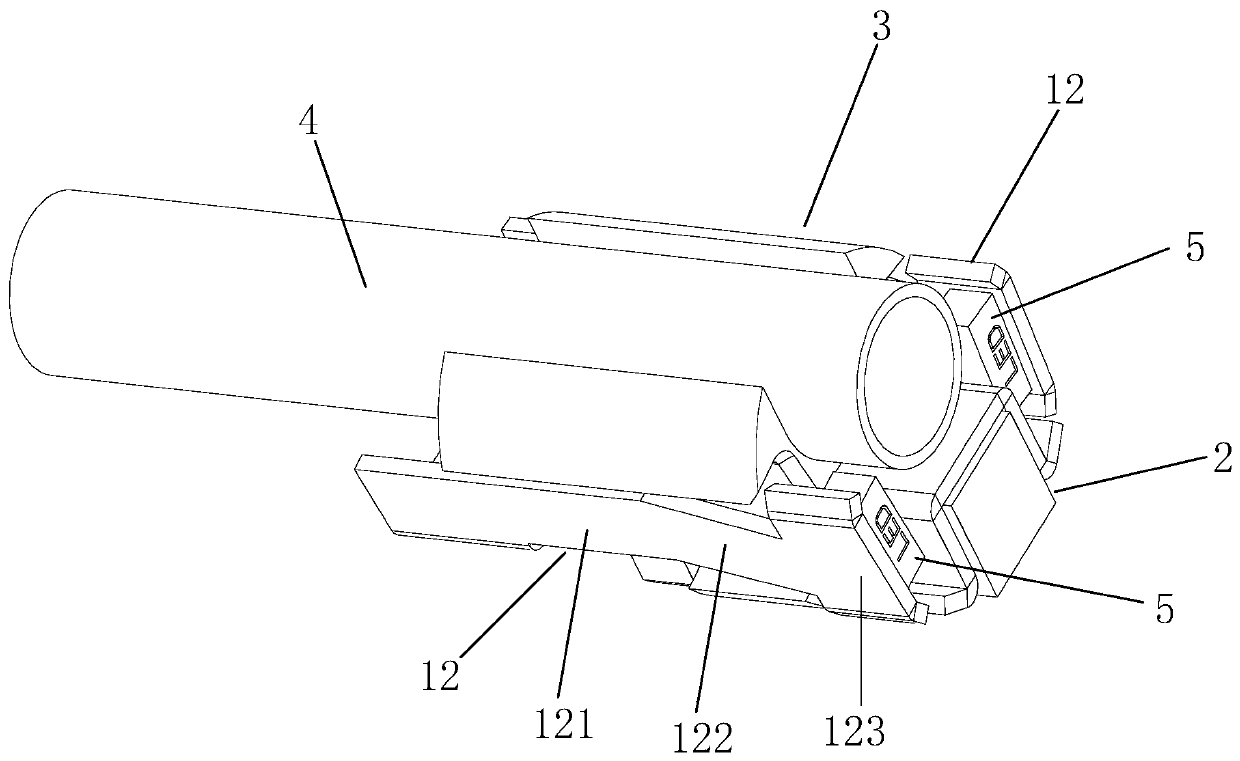

Detection package structure and inside detection device

PendingCN109730654AAvoid direct solderingEasy to zoom inPrinted circuit assemblingPrinted circuit aspectsFlexible circuitsConductive materials

The invention provides a detection package structure and an inside detection device. The detection package structure includes a detection component arranged inside an outer sleeve pipe, a flexible circuit board, a module base and a lighting component. The flexible circuit board includes a main flexible board body and a secondary flexible board body, direct welding of a cable and the detection component is avoided, a detection conductive material and a detection wiring part on the main flexible board body are used, a welding point is amplified, thus the difficulty of welding operation is reduced, the strength and reliability of welding are improved, and the stability of conduction welding under various motion conditions are met. Meanwhile, the flexible circuit board is adopted, conduction connection is guaranteed, assembly is easily achieved, due to the flexibility of the flexible circuit board, the flexible circuit board is not easily affect by size errors or external force, and the stability of conduction welding is thus improved. Through bending of the flexible circuit board, the radial size of a packaging structure is easily reduced.

Owner:SHANGHAI ANQING MEDICAL INSTR

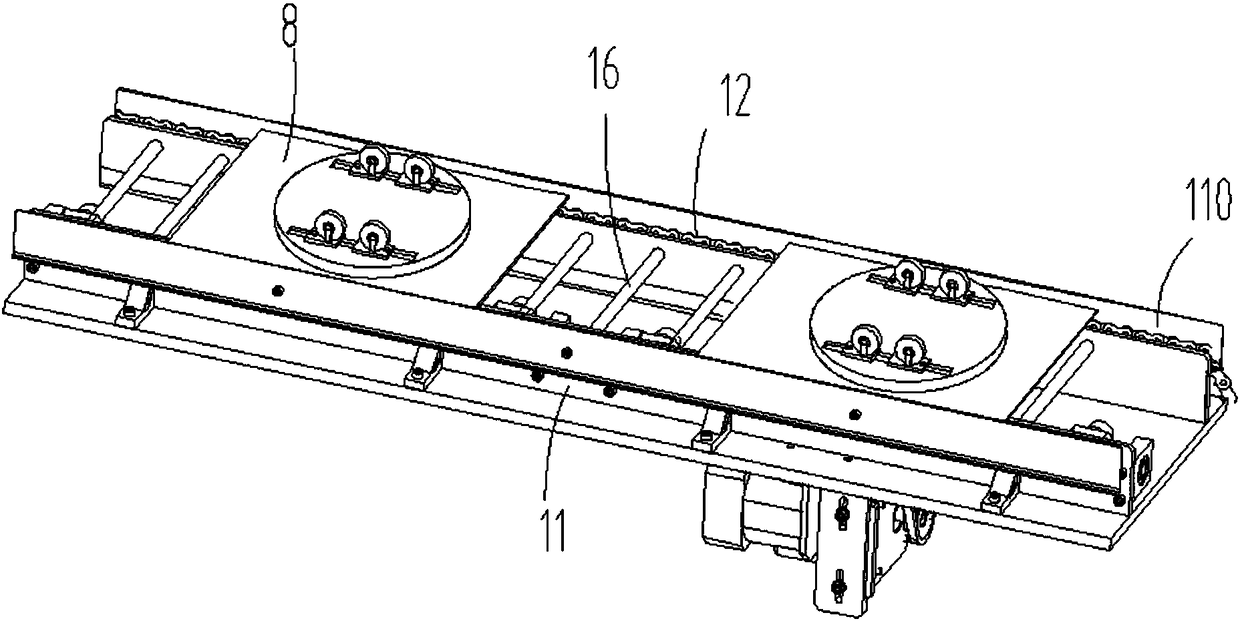

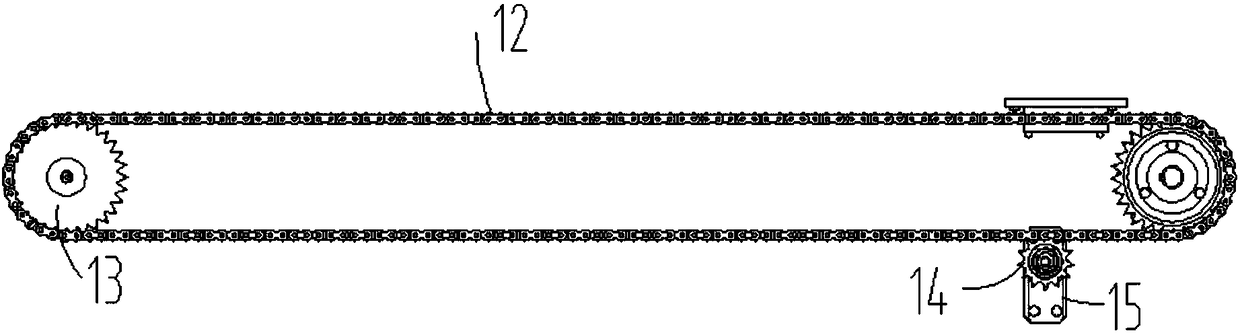

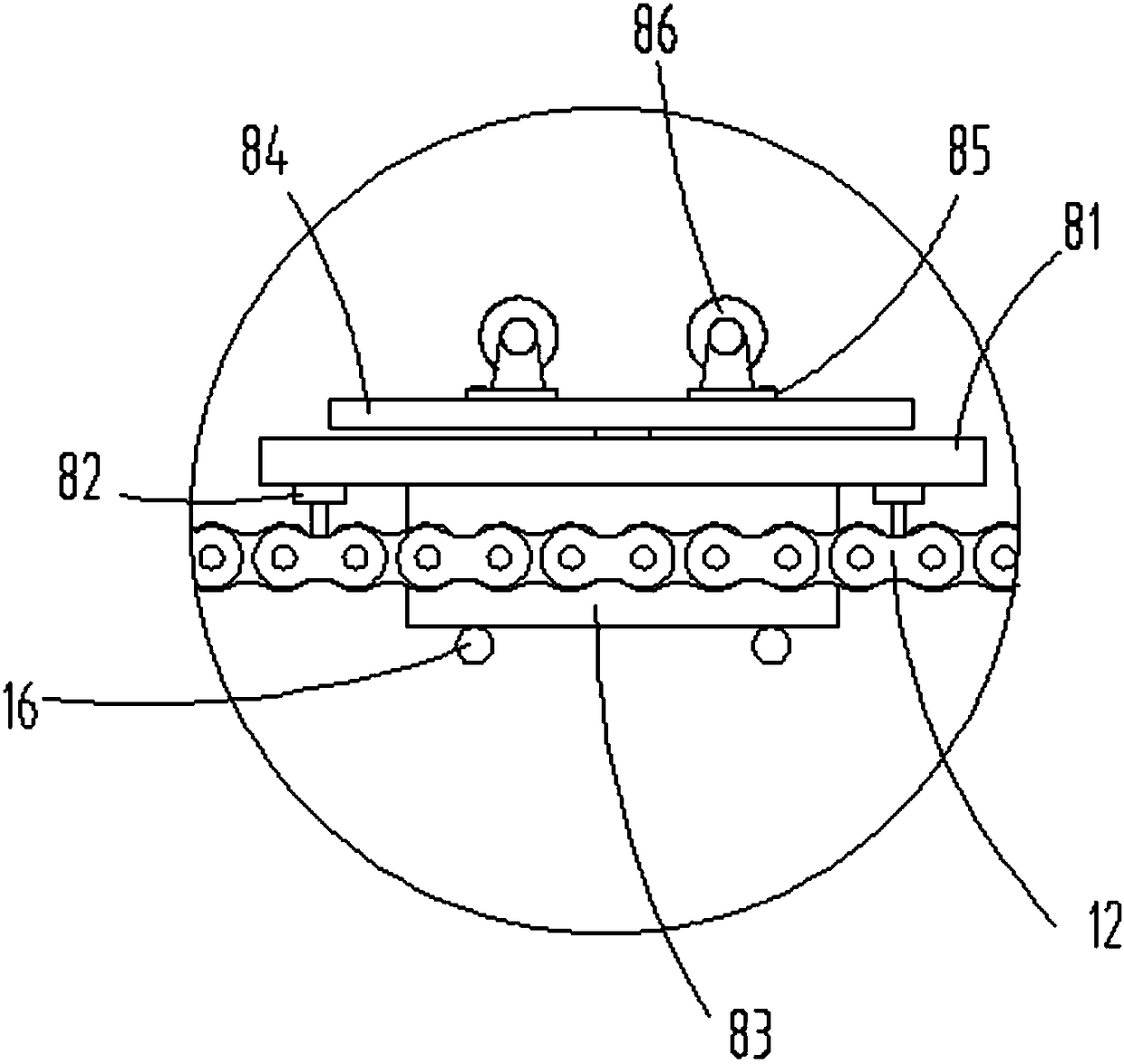

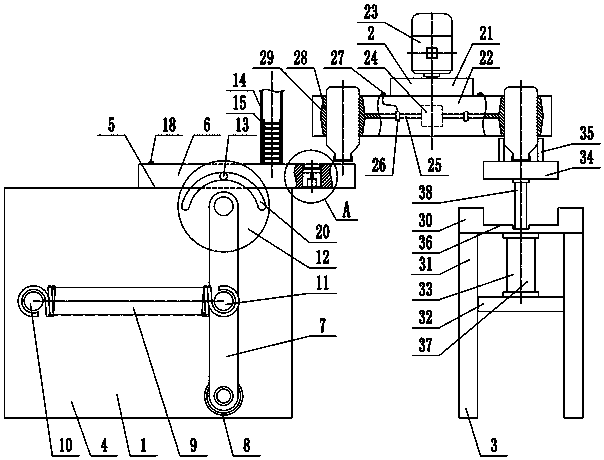

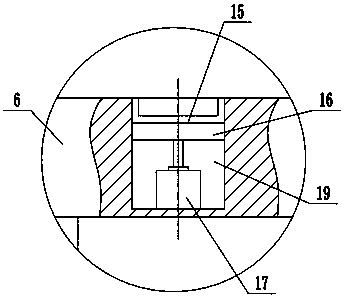

Processing production line for motor rotor of electric automobile

InactiveCN108551244AEasy to processEasy to assembleElectric machinesManufacturing stator/rotor bodiesElectric machineSprocket

The invention discloses a processing production line for a motor rotor of an electric automobile. Four driven sprocket wheels in pairs are rotatably connected onto a machine frame in parallel mutually; furthermore, the two driven sprocket wheels in each pair are linked through a chain; a connecting shaft is rotatably connected onto the machine frame; two driving sprocket wheels are fixedly connected onto the connecting shaft; furthermore, the two driving sprocket wheels are correspondingly meshed with two chains; a motor is connected with the connecting shaft through a decelerator; a pluralityof support rollers are rotatably connected onto the machine frame at a certain interval; furthermore, the support rollers are parallel to the axis of the driven sprocket wheels; a plurality of support tooling are inserted into the chain at a certain interval; and furthermore, the lower end of the support tooling is supported on the support roller. The processing production line disclosed by the invention is simple in structure and convenient to use; line production can be conveniently realized; the processing production line is convenient to use; in the process of processing or assembling themotor rotor of the electric automobile, rotation of the rotor is conveniently realized; and thus, processing or assembly is conveniently carried out.

Owner:南京高传电机制造有限公司

Bottle cap feeding and assembling device

InactiveCN108946605APrecise angle of rotationPrevent accidentsFlanged caps applicationEngineeringAir compressor

The invention provides a bottle cap feeding and assembling device and belongs to the technical field of bottle and can processing. The bottle cap feeding and assembling device comprises a feeding mechanism, a rotating assembling mechanism and a discharging mechanism; a feeding slider of the feeding mechanism is arranged on a feeding guide rail in a left and right sliding manner; a feeding notch isformed in the right side of a feeding material way; an electromagnet is connected with a top plate; the lower end of a swinging rod is connected with a swinging cylinder; a movable groove wheel is rotationally arranged at the upper end of the swinging rod; a pin shaft installed on the feeding slider is inserted into an arc-shaped groove of the movable groove wheel; the two ends of a spring are connected with a spring left pulling rod and a spring right pulling rod correspondingly; bottle and can clamping grooves are uniformly arranged on a rotating disk of the rotating assembling mechanism; aclamping gas bag is installed in the bottle and can clamping grooves of the rotating disk; the two ends of a gas sucking pipeline are connected with the clamping gas bag and an air compressor correspondingly; the gas sucking pipeline is provided with a gas valve; and the upper end of a discharging piston rod of the discharging mechanism is connected with a discharging bearing frame. The bottle cap feeding and assembling device can achieve feeding and assembling of bottle caps, tensile force of the spring is small in changing, and the service life of the spring is greatly prolonged.

Owner:徐晓伟

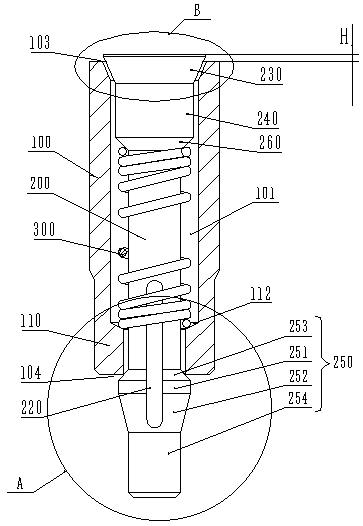

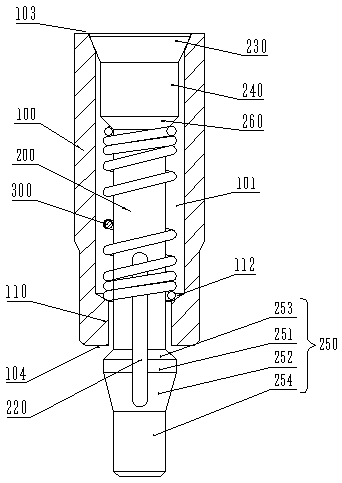

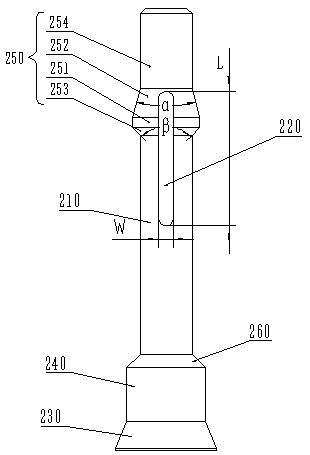

Exhaust device and tire mold

ActiveCN110027138BAssembly is easy to achieveNot easy to eccentricTyresVulcanizationAgricultural engineering

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

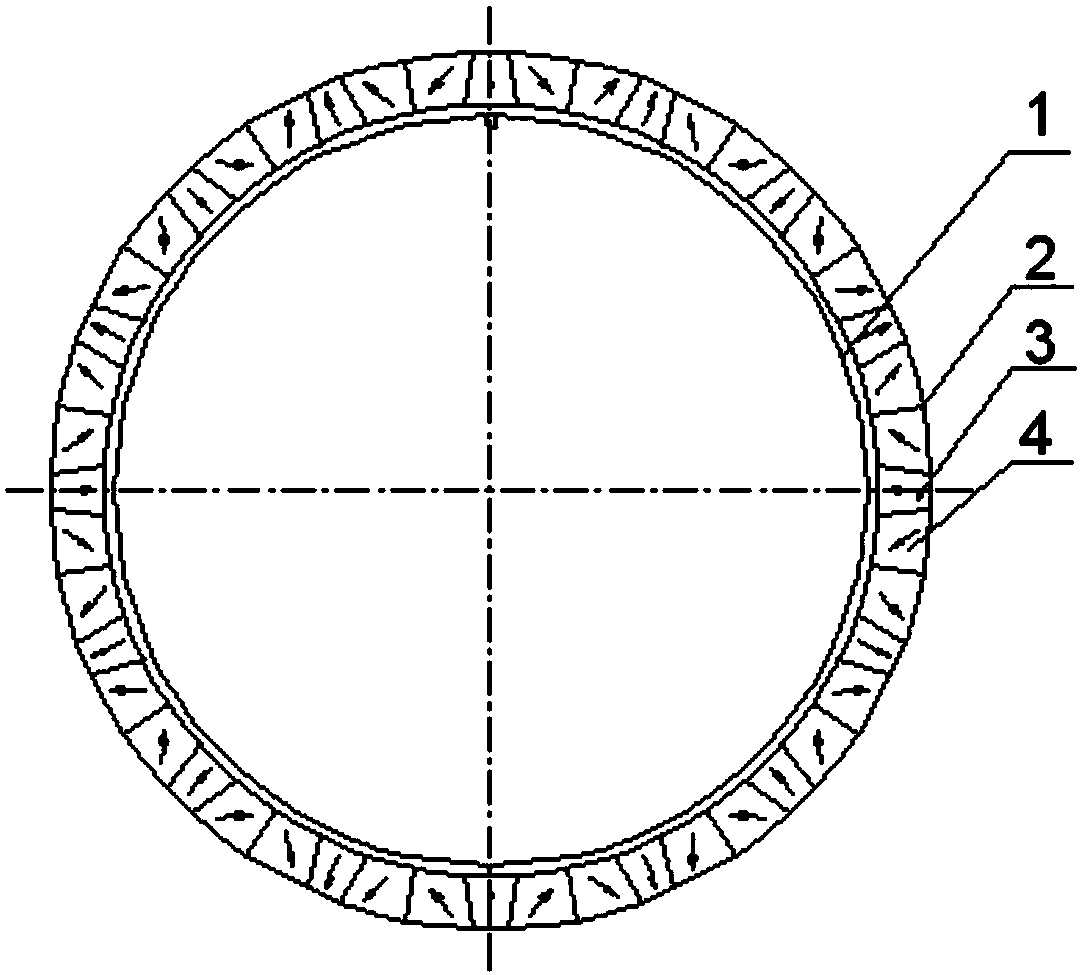

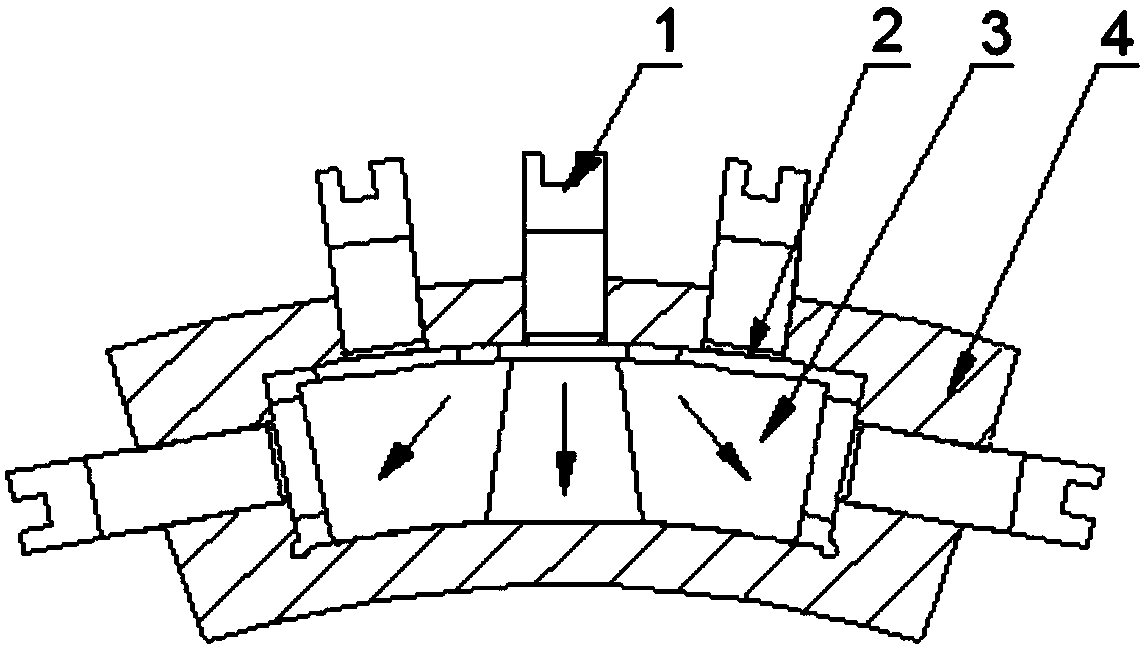

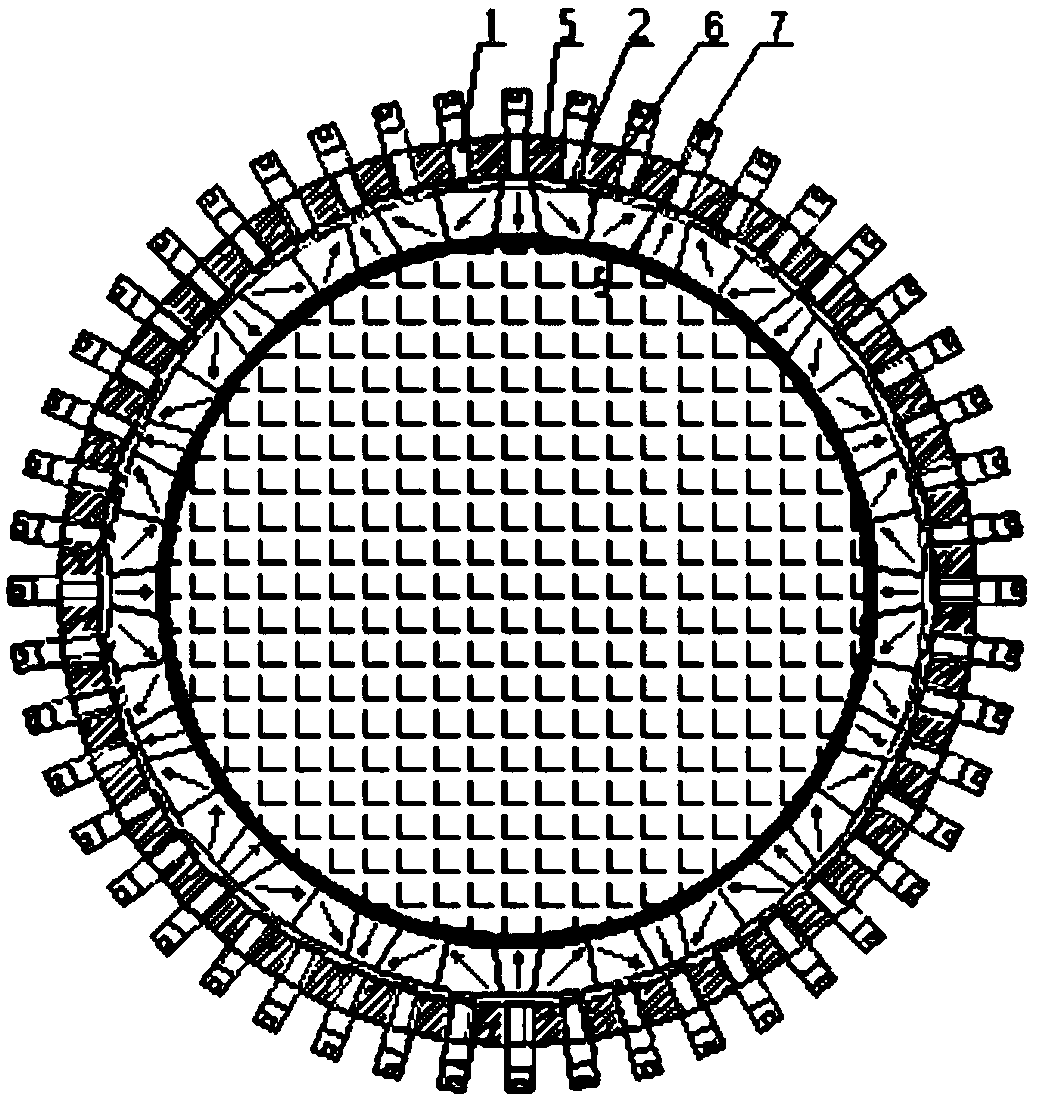

A kind of halbach magnetic steel structure permanent magnet synchronous motor and assembly method

ActiveCN105429411BImprove engineering efficiencySimple structureMagnetic circuit rotating partsManufacturing stator/rotor bodiesPermanent magnet synchronous motorMagnetic poles

The invention discloses a Halbach magnetic steel structure permanent magnet synchronous motor and an assembly method. The Halbach magnetic steel structure permanent magnet synchronous motor comprises: a lock screw, a magnetic-isolating anti-collision pad, a magnetic steel analog block, a synthetic die case, a rigid support frame, magnetic poles, a rotor yoke and a concentric apparatus, wherein the Halbach magnetic steel is mounted on the synthetic mold case via the lock screw; an end surface constraint of the Halbach magnetic steel can actively control bonding accuracy; the magnetic isolating anti-collision is used to prevent wear of the Halbach magnetic steel and the lock screw; and the magnetic steel analog block is used to keep intervals between the magnetic poles t to be uniform. Through mechanical finishing, it is ensured that mating surface position accuracy of an inner hole of the synthetic mold case to be consistent with mating surface accuracy of a yoke of the permanent magnet synchronous motor rotor; a thickness of an outer wall of the hole is appropriately increased, so as to improve material rigidity and ensure geometric tolerance of a mounting surface. According to the Halbach magnetic steel structure permanent magnet synchronous motor and the assembly method provided by the invention, a problem of high-accuracy assembly of the Halbach magnetic steel is solved; rapid assembly of the Halbach magnetic steel is realized; and mass production of the product is realized.

Owner:北京兴华机械厂有限公司

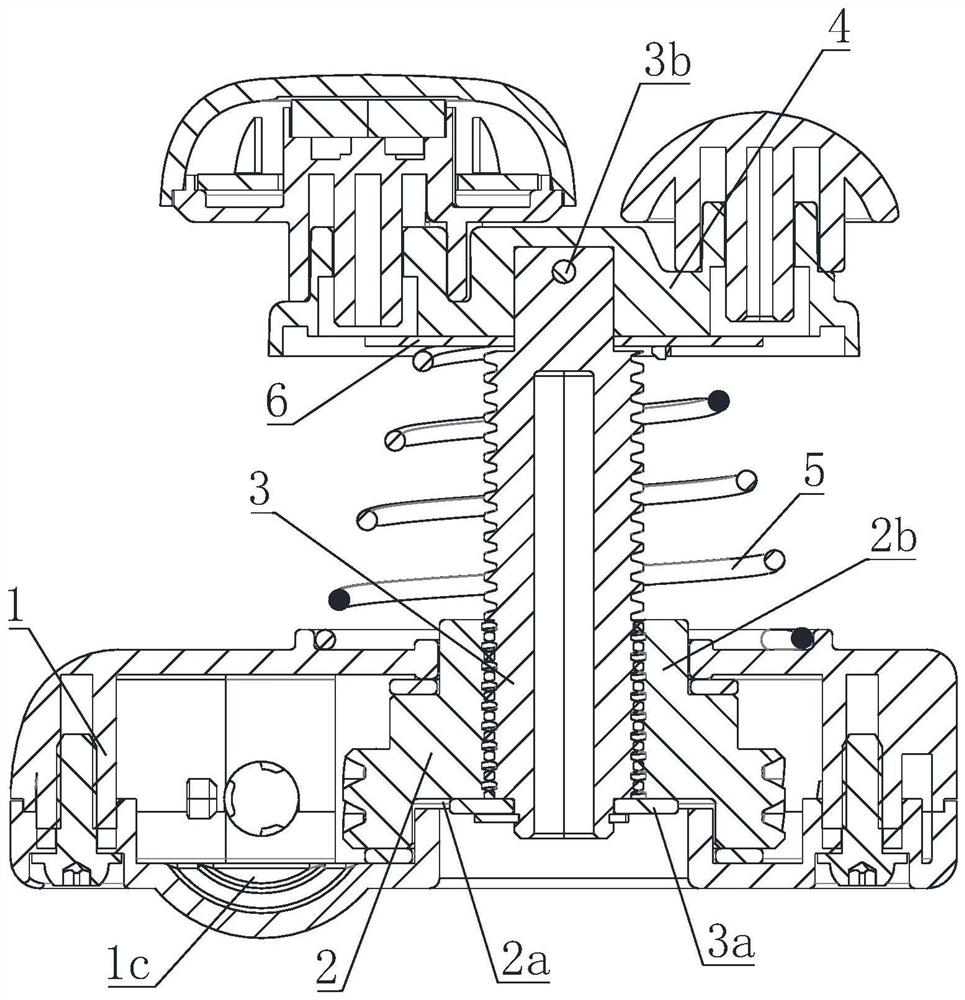

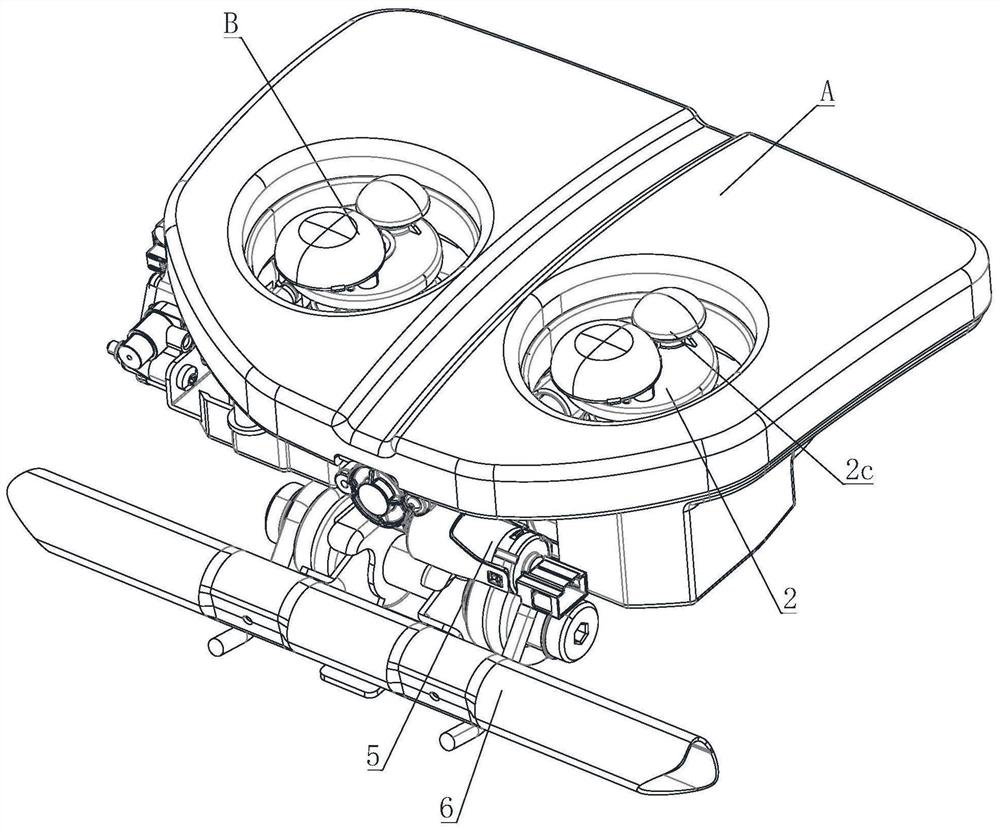

Automobile seat waist support assembly with massage function

ActiveCN112277747AImprove comfortAdjust the use heightBack restsSuction-kneading massageCar seatPhysical medicine and rehabilitation

The invention discloses an automobile seat waist support assembly with a massage function. The automobile seat waist support assembly comprises a waist support system and a waist massage system, the waist support system comprises a shell assembly, a seat body assembly and a connecting assembly, a lifting driving mechanism is arranged between the shell assembly and the seat body assembly, and an elastic element is arranged between the seat body assembly and the connecting assembly; the waist massage system comprises two groups of massage mechanisms installed in the shell assembly and a massagedriving mechanism used for driving the two groups of massage mechanisms to act, and massage assemblies are arranged on the massage mechanisms; when the waist massage system is not started, the massageassembly is located in the shell assembly, and after the waist massage system is started, the massage assembly can extend outwards in the thickness direction of the seat backrest under the driving effect of the massage driving mechanism. The waist support structure has the beneficial effects that the technical obstacle that the design space of the backrest is limited can be broken through, the waist support structure is endowed with a massage function, and the comfort of waist support can be remarkably improved.

Owner:CHONGQING YANFENG ADIENT AUTOMOTIVE COMPONENTS CO LTD

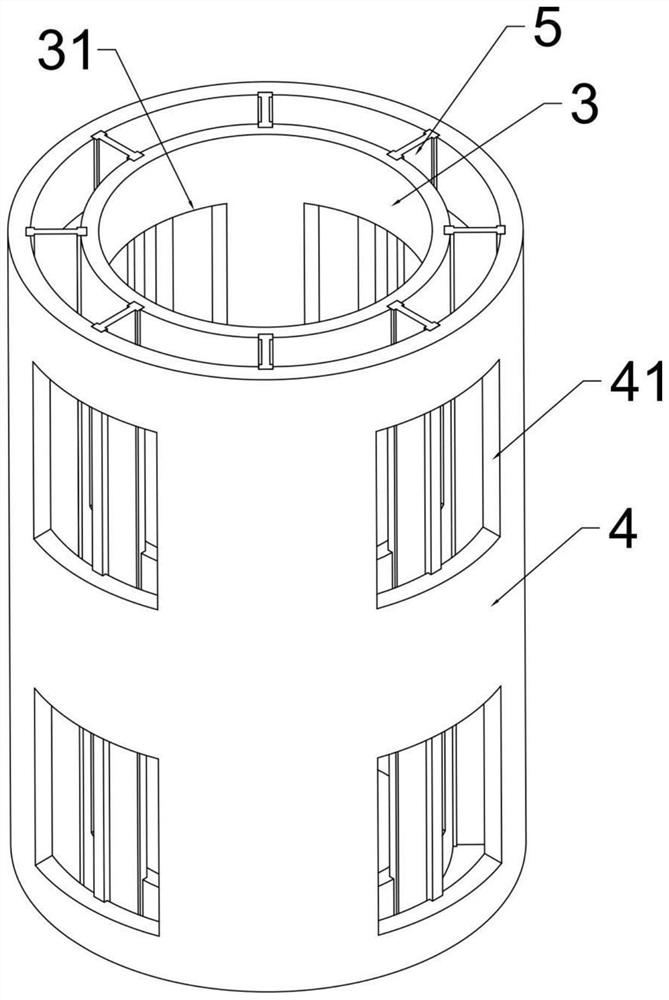

Coil structure suitable for dry-type transformer

PendingCN113903572AEfficient assemblyGuaranteed cooling effectTransformers/inductances coolingTransformers/inductances coils/windings/connectionsCoil structureStructural engineering

The invention belongs to the technical field of transformer coils, and relates to a coil structure suitable for a dry-type transformer. The coil structure comprises a low-voltage coil, a high-voltage coil, a support inner sleeve and a support outer sleeve; the periphery of the low-voltage coil is coated with the high-voltage coil; the support inner sleeve and the support outer sleeve are arranged between the outer peripheral wall of the low-voltage coil and the inner peripheral wall of the high-voltage coil; the support inner sleeve is arranged on the peripheral wall of the low-voltage coil in a sleeving mode; the support outer sleeve is attached to the inner circumferential wall of the high-voltage coil; a gap channel is formed between the support inner sleeve and the support outer sleeve; and the outer peripheral wall of the support inner sleeve is connected with the inner peripheral wall of the support outer sleeve through a plurality of supporting bridges. According to the coil structure suitable for the dry-type transformer, the support inner sleeve and the support outer sleeve are used for carrying out auxiliary supporting on the low-voltage coil and the high-voltage coil respectively, and the supporting bridges are adopted, so that winding and assembling of the low-voltage coil and the high-voltage coil are conveniently achieved; and a heat dissipation channel is formed through the gap channel between the support inner sleeve and the support outer sleeve, so that the heat dissipation effect is guaranteed.

Owner:GUANGDONG POWER GRID CO LTD +1

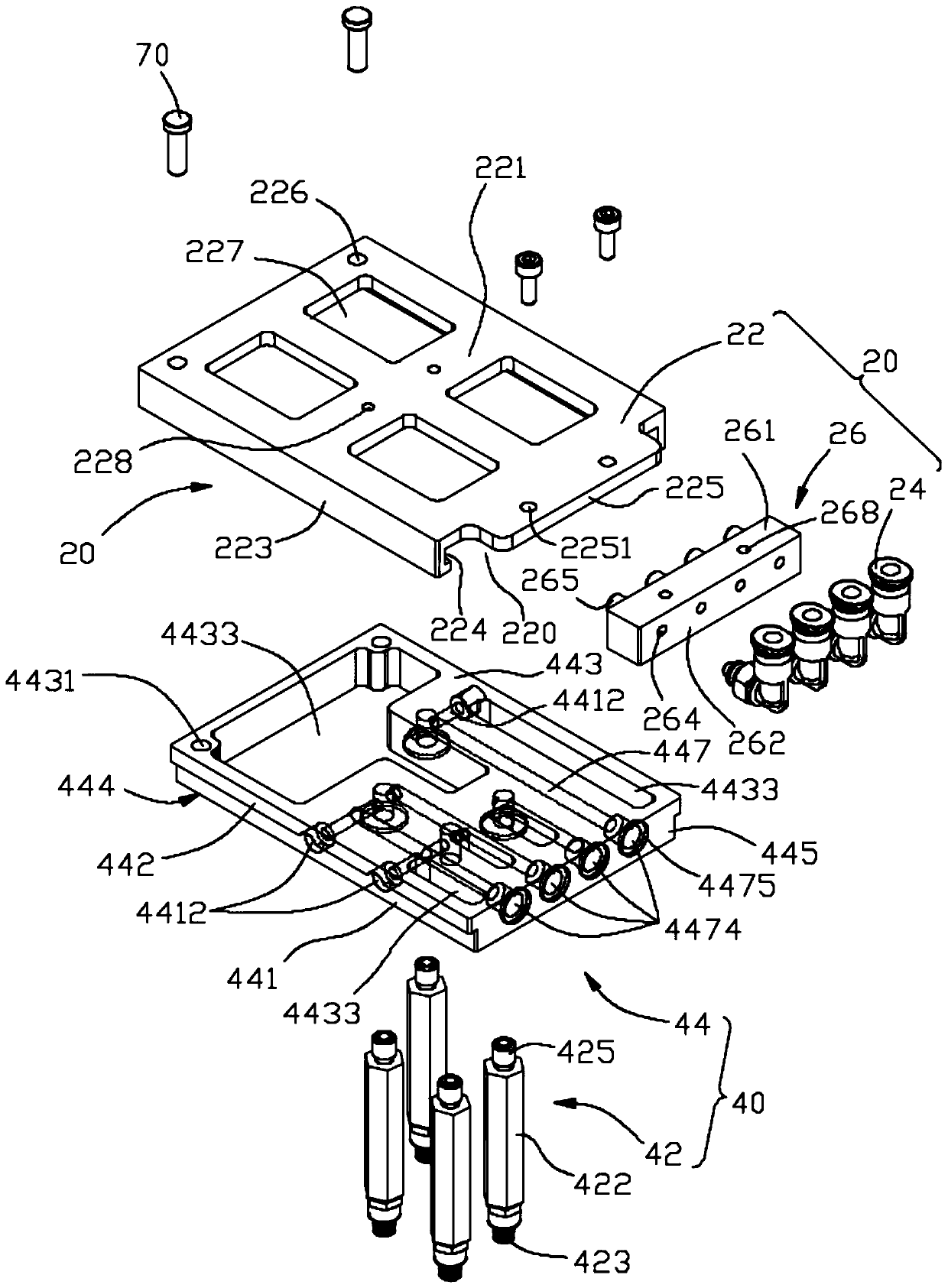

Material sucking mechanism and material conveying device

The invention provides a material conveying device. The material conveying device comprises a material sucking mechanism and a mechanical hand or a motion module connected to the material sucking mechanism, wherein the material sucking mechanism comprises a mounting base and a plurality of suction nozzle modules; each suction nozzle module can be detachably connected to the mounting base; each suction nozzle module comprises a plurality of suction nozzle parts; and number of the suction nozzle parts on each suction nozzle module is different and / or the position distribution of the suction nozzle parts on each suction nozzle module is different; and the mechanical hand or the motion module drives the material sucking mechanism to move. While the material sucking mechanism needs to suck different products, corresponding suction nozzle modules can be quickly replaced, i.e, a sucking disc can be quickly replaced, so that different products can be quickly produced and converted by a production line, and therefore, production efficiency is improved. The invention further provides the material sucking mechanism.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

Power hanging component with vibration damping performance

PendingCN108313071AReduce stressReduce the severity of the driftRope railwaysRail derailment preventionElastic componentEngineering

The invention discloses a power hanging component with a vibration damping performance. The power hanging component with the vibration damping performance comprises a hanging component body and multiple walking wheels installed on the hanging component body. The hanging component body is a rectangular frame of which the middle of the upper end is provided with an opening. Two sides of the openingare provided with the walking wheels. The lower end of the hanging component body is further provided with a cross rod with two fixed ends. The lower part of each of the two ends of the cross rod is provided with a hanging component body extending section extended downwards. An elastic component is installed between each hanging component body extending section and the cross rod. One end of each elastic component is connected with the corresponding hanging component body extending section, and the other end of each elastic component is connected with the cross rod. The power hanging componentis simple in structure, and has the vibration damping capacity in a transverse direction.

Owner:ZHONGTANG SKY RAILWAY GRP CO CO LTD

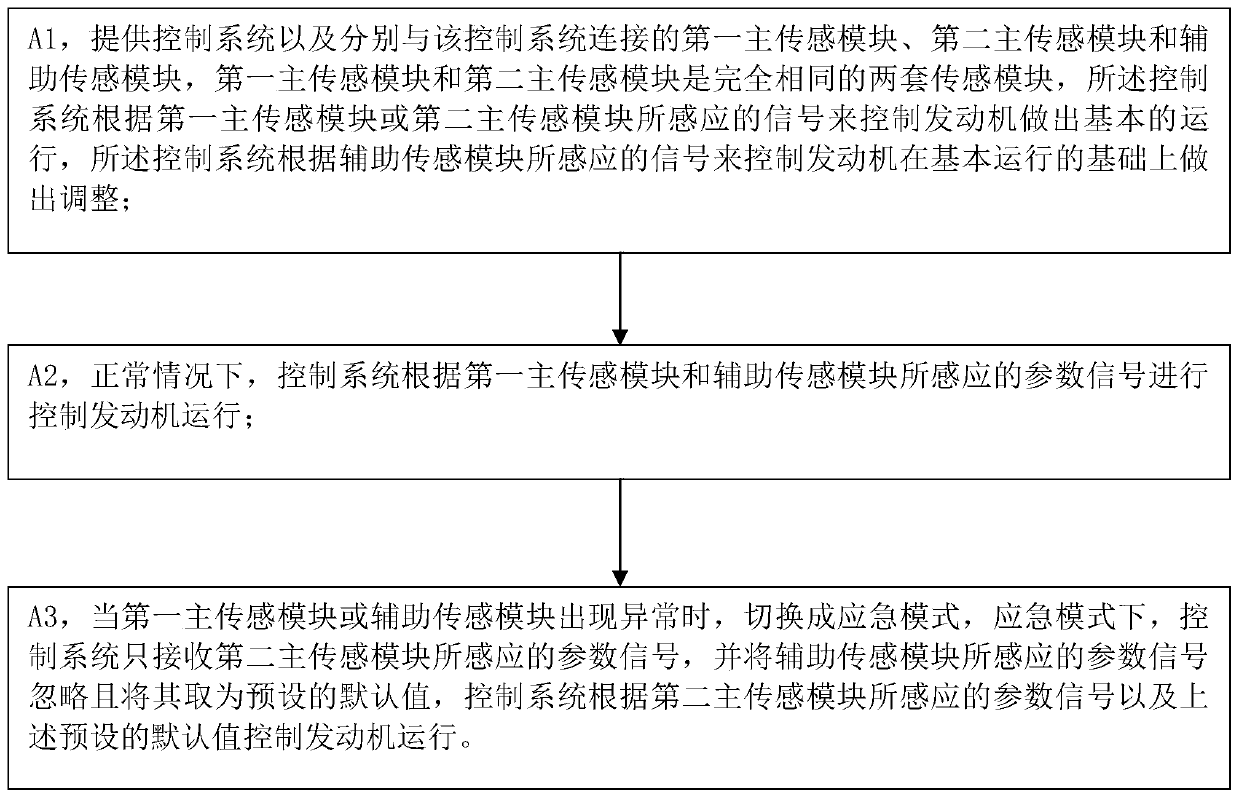

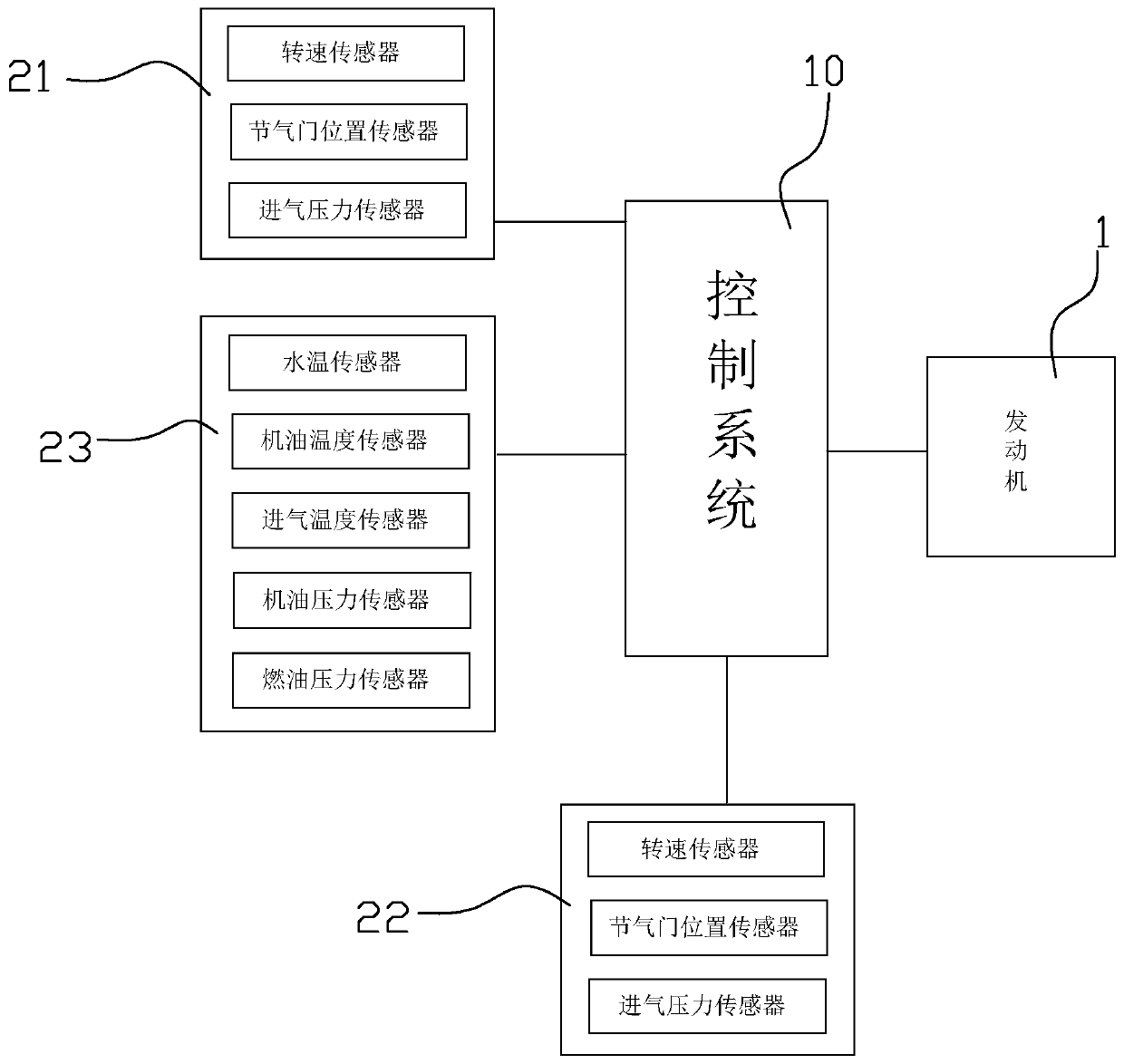

Control method of piston-type aero-engine

The invention provides a control method of an aero-engine. A sensing system is divided into a main sensing module and an auxiliary sensing module, wherein the main sensing module influences basic operation of the engine, and the auxiliary sensing module only plays a role in adjustment. Two sets of main sensing modules are arranged to be used as main / backup modules for switching, and signals sensedby the auxiliary sensing modules in an emergency state are directly ignored and a preset default value is adopted, so that the engine can be ensured to run in a normal range, and the aircraft is ensured to fly in a safe state. From the aspects of structure and assembly, a second set of the auxiliary sensing module is omitted, the structure is simpler, and assembly is easy to achieve; and the riskthat in the prior art, the main sensor and the standby sensor at the same position are damaged at the same time and cannot be used is reduced to a great extent.

Owner:厦门林巴赫航空发动机有限公司

Oil pumping device, compressor and electric appliance

ActiveCN113202729AAvoid Rotating Mechanical FrictionGuaranteed service lifeCrankshaftsPositive displacement pump componentsFriction lossCrankshaft

The invention relates to an oil pumping device, a compressor and an electric appliance. The oil pumping device comprises a crankshaft, an oil pump and an elastic piece. An inner cavity is provided in the crankshaft, and the end, facing an oil pool, of the crankshaft is provided with a positioning groove. The oil pump is arranged in the inner cavity, forms a spiral oil groove with the inner cavity and is provided with a positioning part in clearance fit with the positioning groove. One end of the elastic piece is connected into the oil pump. The crankshaft rotates, and oil enters the spiral oil groove from the oil pool to drive the oil pump and the elastic piece to spirally ascend relative to the crankshaft until the positioning part abuts against the positioning groove. No matter the compressor is in a shutdown period or an operation period, the loss between the oil pump and the oil pool can be reduced, the friction loss after operation is lower, the rotating mechanical friction of the oil pump in the compressor is avoided, the rotating noise of the crankshaft is reduced, and the service life of the oil pump and even the compressor is ensured; it is guaranteed that the compressor has the excellent oil pumping effect at low frequency, and the energy efficiency ratio of the compressor is increased; and the oil pump and the elastic piece are simple in structure, automatic production and assembly are easy, and the assembly precision can be guaranteed.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com